Regulation type proportional mixer

A proportional mixer and adjustable technology, applied in multi-way valves, fire rescue, engine components, etc., can solve problems such as difficult to find the working state of the working point, cumbersome work to replace the orifice plate, and maintain good linearity. , to achieve the effect of reducing installation and maintenance time and corresponding costs, reducing labor intensity and improving the quality of the mixed solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

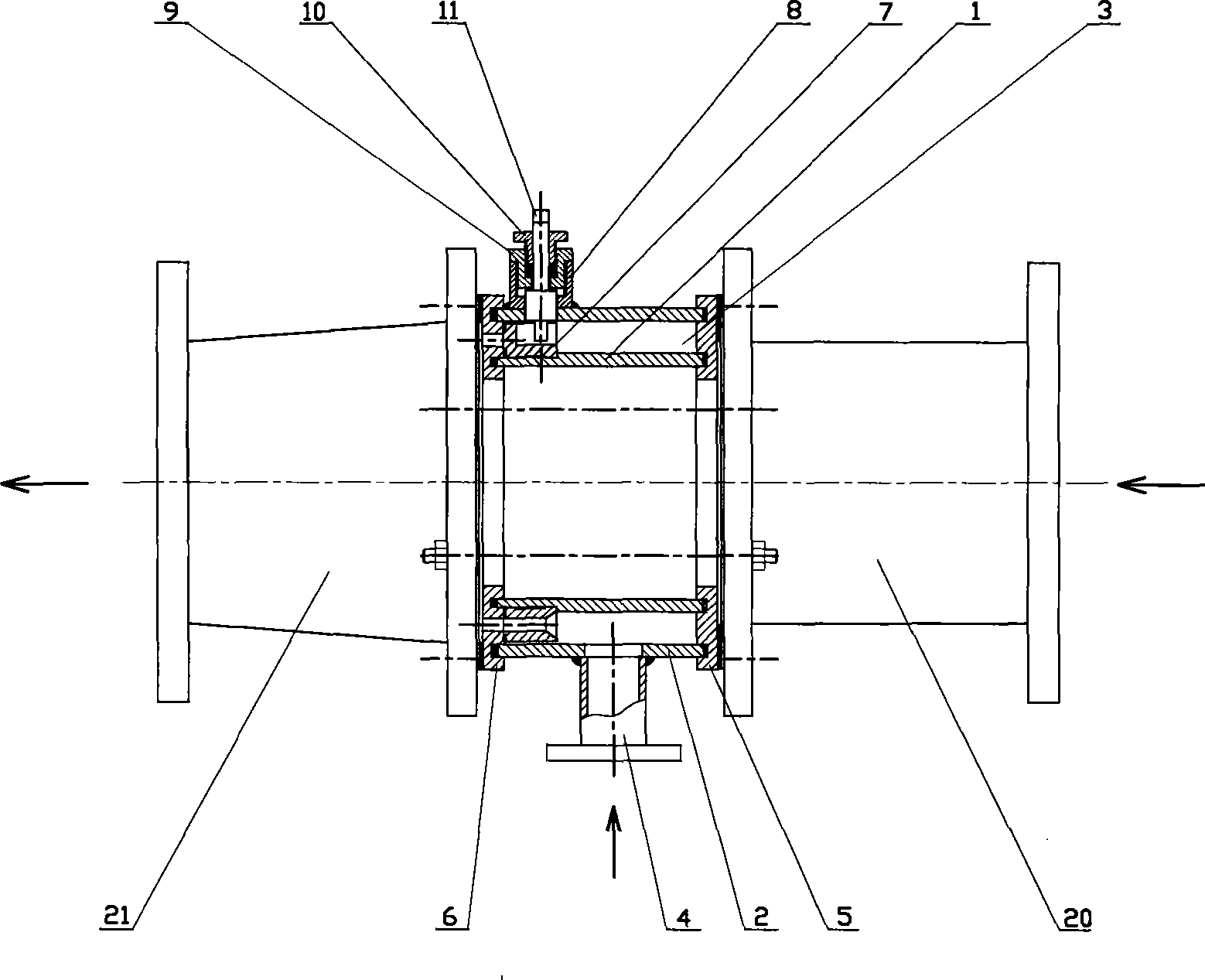

[0014] As shown in the accompanying drawings: the present invention includes a flow pipe 1, the flow pipe 1 is provided with an outer casing 2, a cavity 3 is provided between the flow pipe 1 and the outer casing 2, and a foam liquid pipe 4 is arranged on the outer casing 2, and a foam liquid pipe 4 is arranged on the outer casing 2. The liquid pipe 4 communicates with the cavity 3, and the end of the flow pipe 1 and the outer casing 2 is provided with a sealing plate 5. The sealing plate 5 seals the annular cavity formed by the ends of the flow pipe 1 and the outer casing 2. The flow pipe 1 and the outer casing The other end of the tube 2 is provided with an orifice plate 6, and several holes are arranged on the orifice plate 6. The holes on the orifice plate 6 communicate with the annular cavity formed by the circulation tube 1 and the outer cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com