Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Stable and reliable turning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

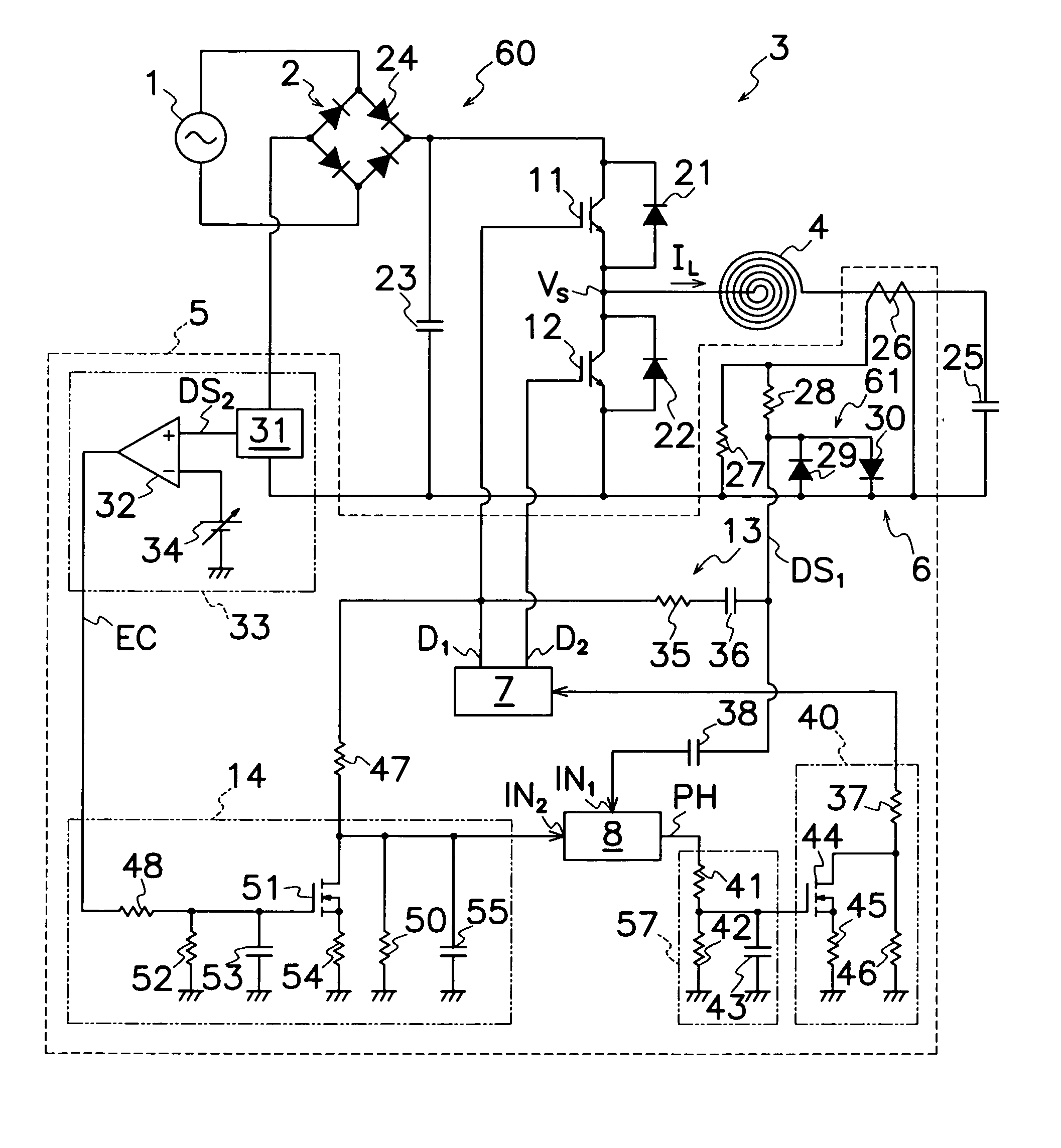

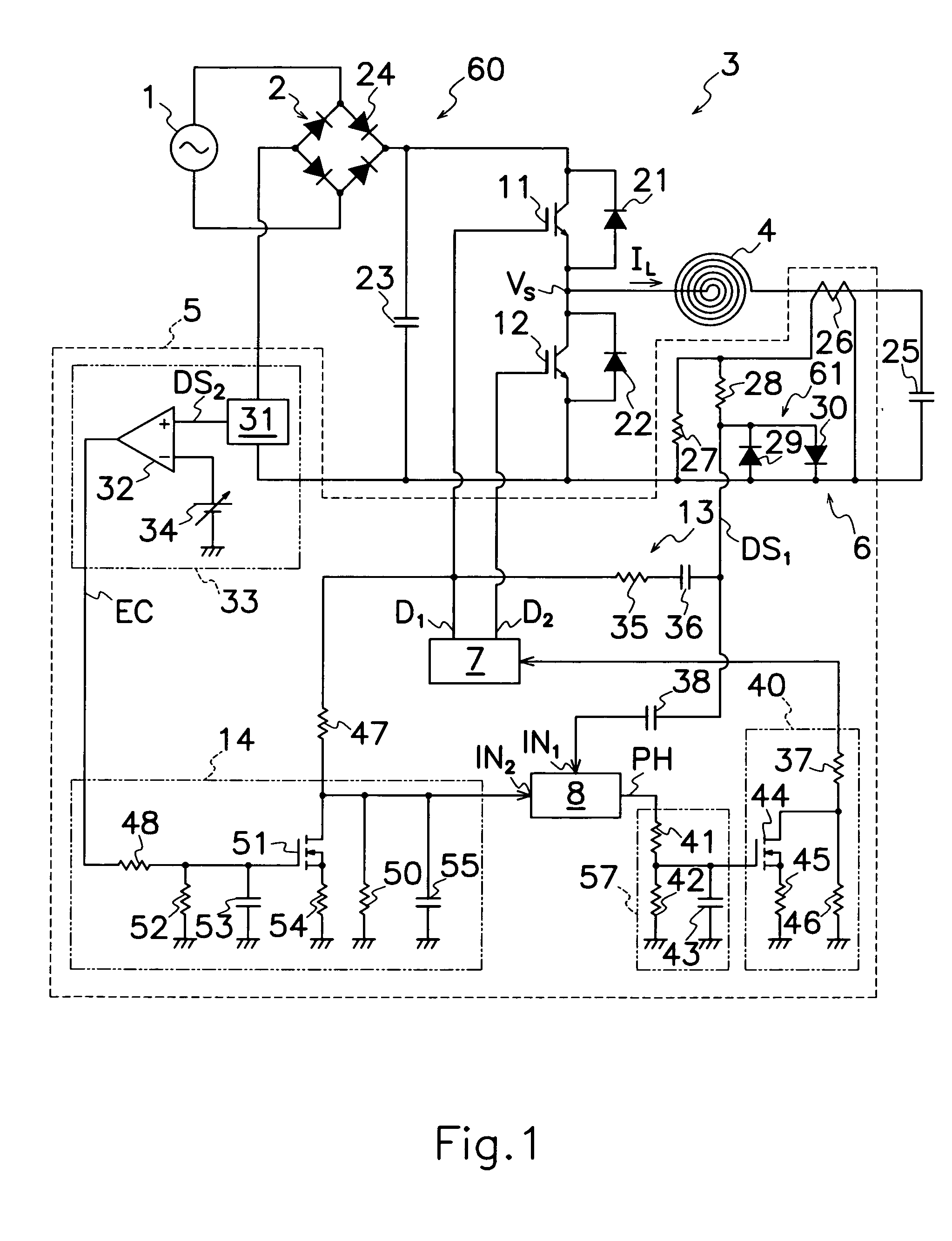

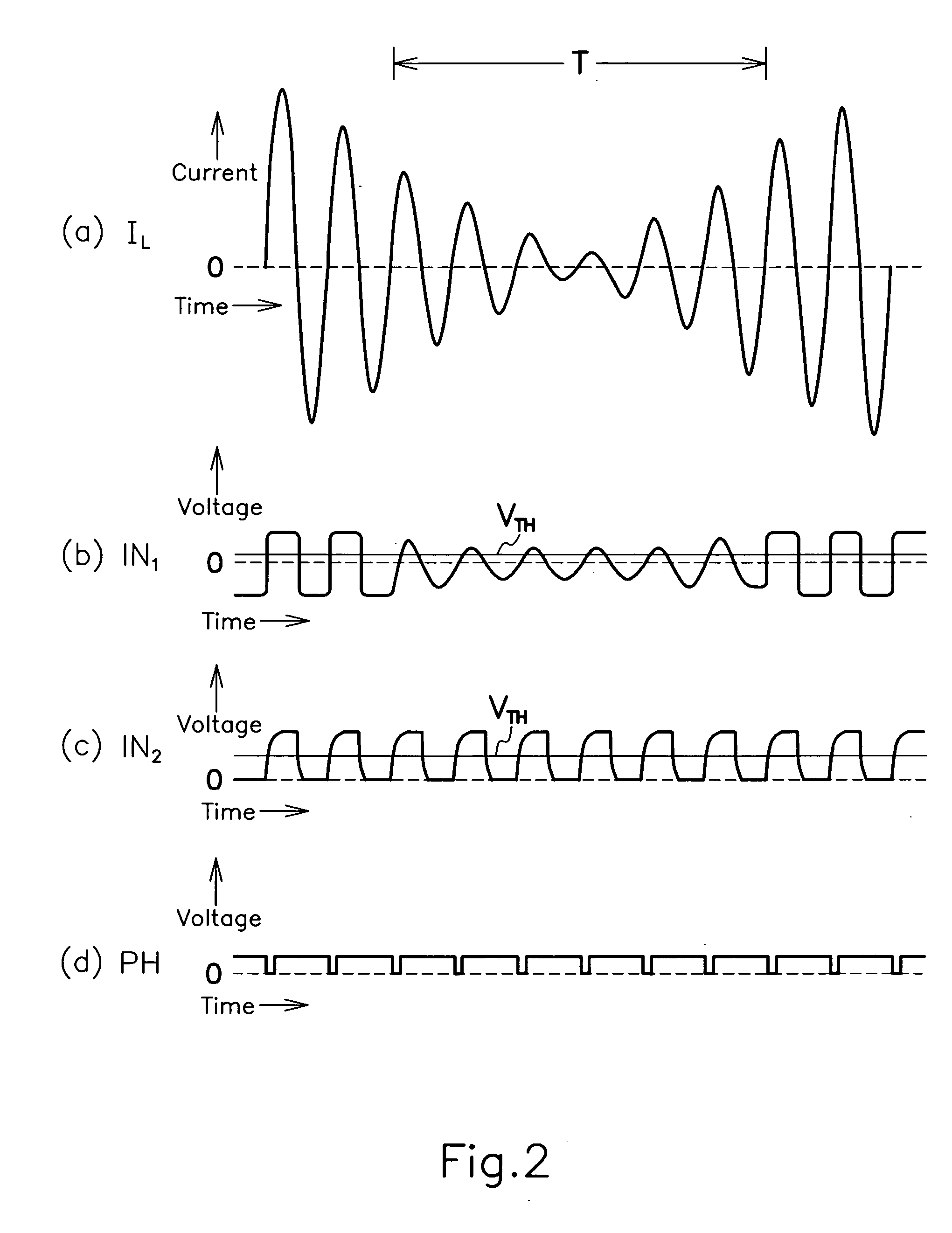

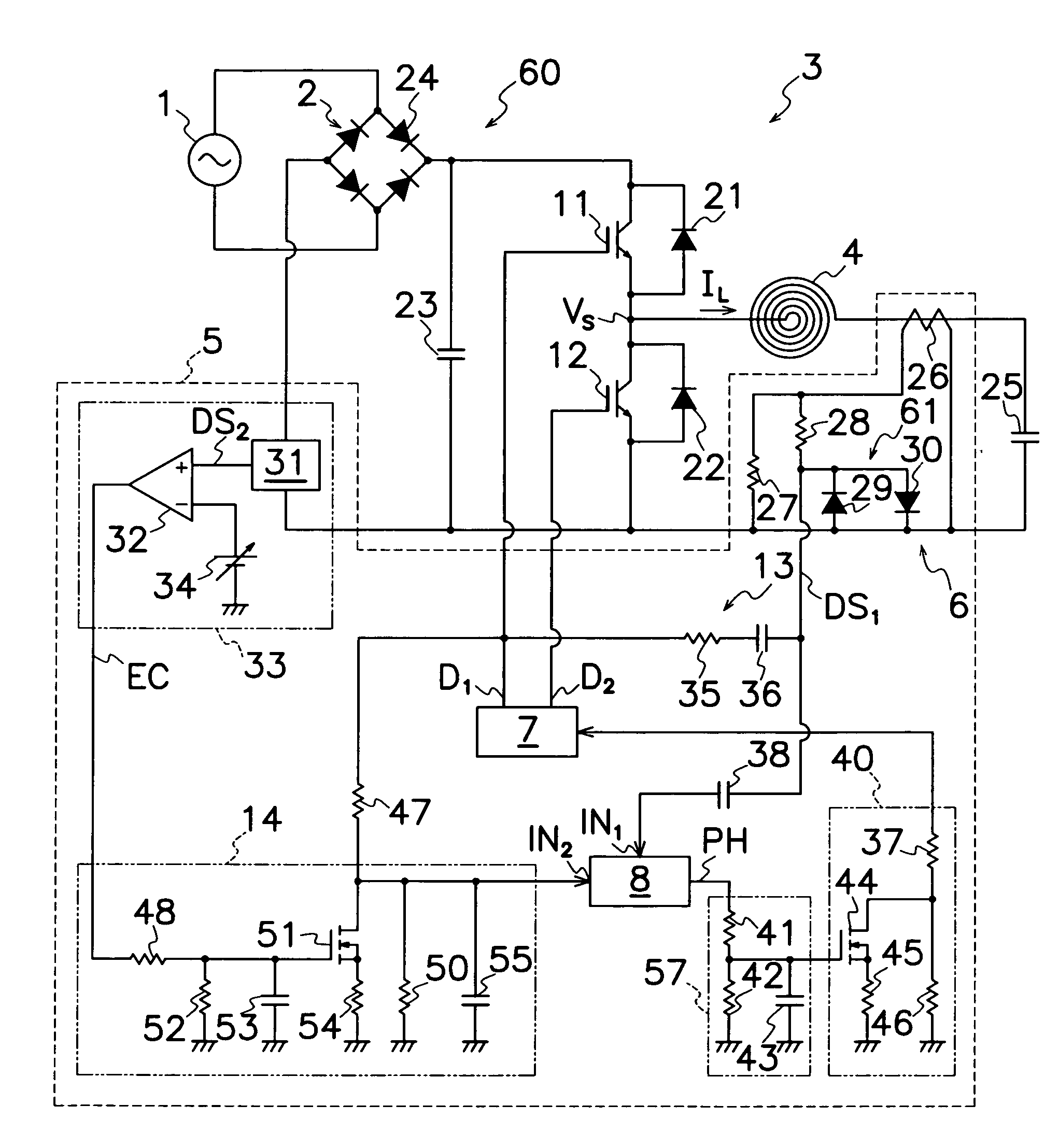

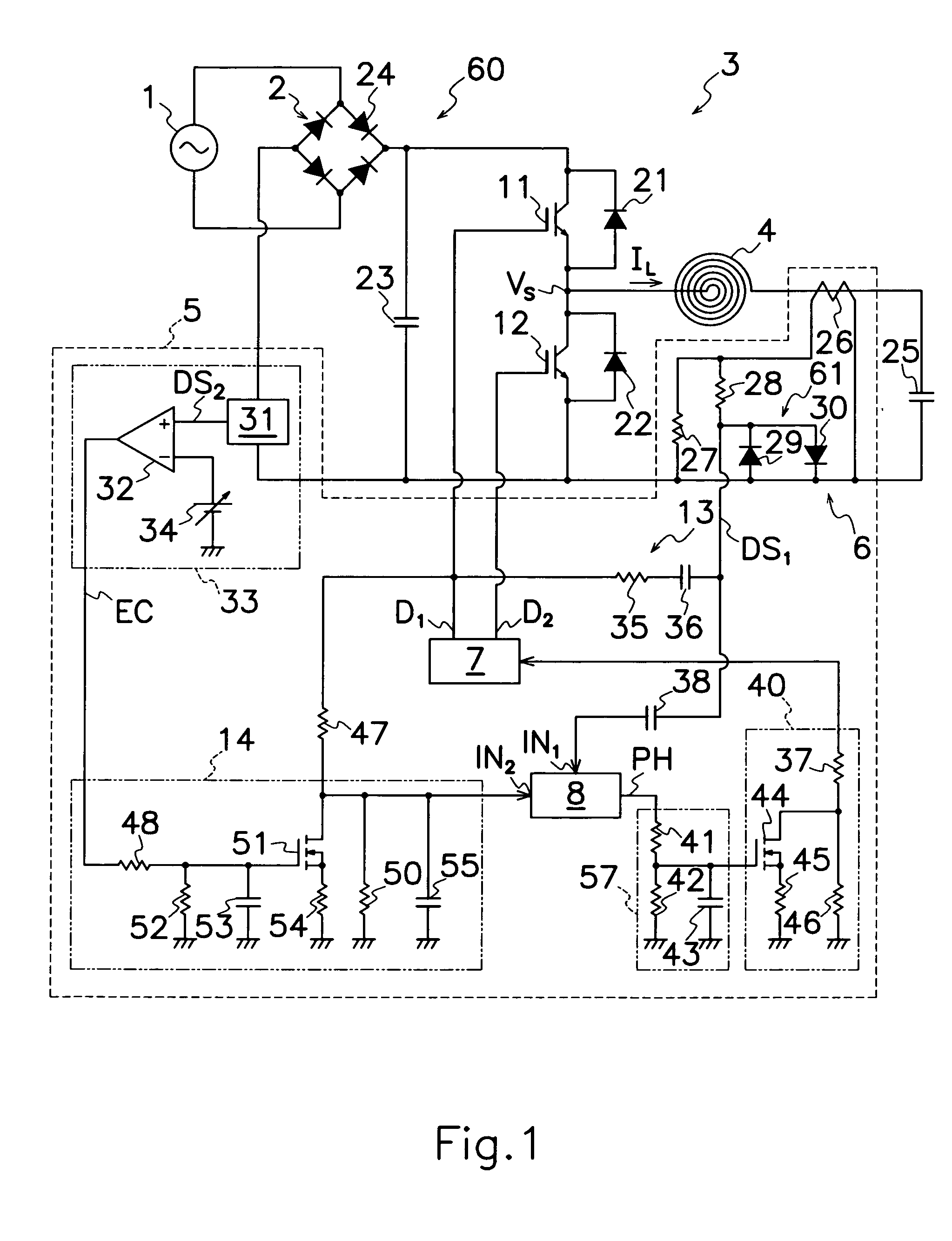

Induction heating apparatus

InactiveUS20070084857A1Change in oscillation frequencyImprove reliabilityConversion with intermediate conversion to dcEmergency protective circuit arrangementsPhase differenceResonance

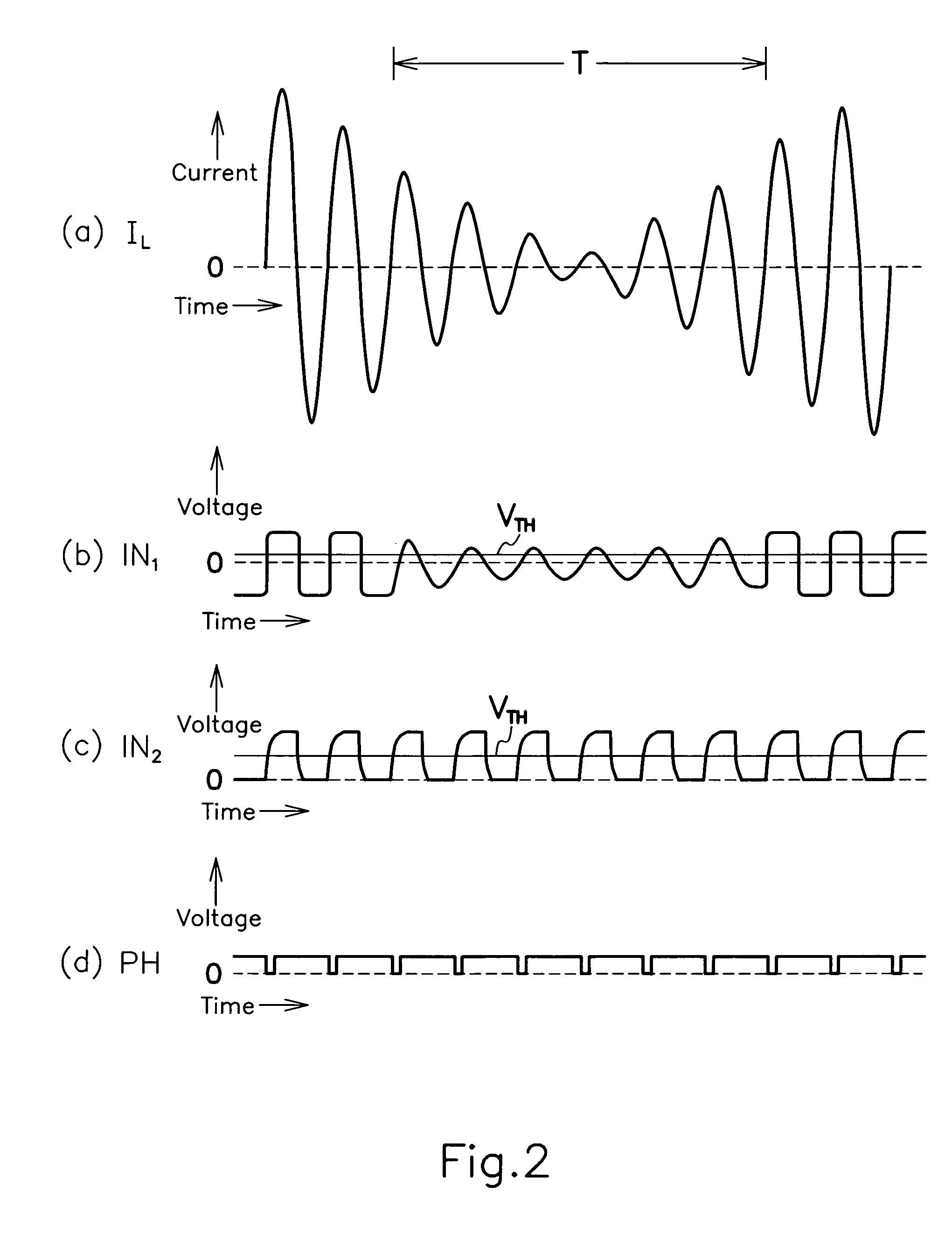

An induction heating apparatus is provided with a control circuit 5 which comprises a resonance waveform detector 6 for detecting a high frequency AC waveform supplied from an inverter circuit 3 to a heating coil 4 to produce a detection signal DS1 corresponding to high frequency AC power waveform; a phase comparator 8 for producing an adjusting signal PH corresponding to a phase difference between detection signal DS1 from resonance waveform detector 6 and drive signal D1 from drive circuit 7; and an addition circuit 13 for superimposing the drive signal D1 from drive circuit 7 on detection signal DS1 from resonance waveform detector 6 to supply the superimposed signal to phase comparator 8. Even though power source 60 generates the output of lowered voltage level, at least a part of the superimposed signal of detection signal DS1 and drive signal D1 can be maintained on a level same as or over operation threshold value VTH for phase comparator 8, while keeping normal operation of phase comparator 8. Thus, in detecting resonance current flowing through inverter circuit 3 in the apparatus to control oscillation frequency of drive signals to IGBTs 11 and 12, the induction heating apparatus can always stably turn IGBTs 11 and 12 of inverter circuit 3 on and off even with lowered resonance current through inverter circuit 3.

Owner:SANKEN ELECTRIC CO LTD

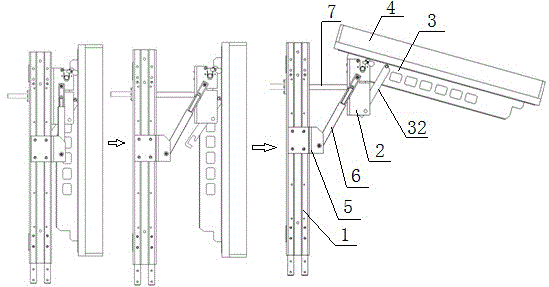

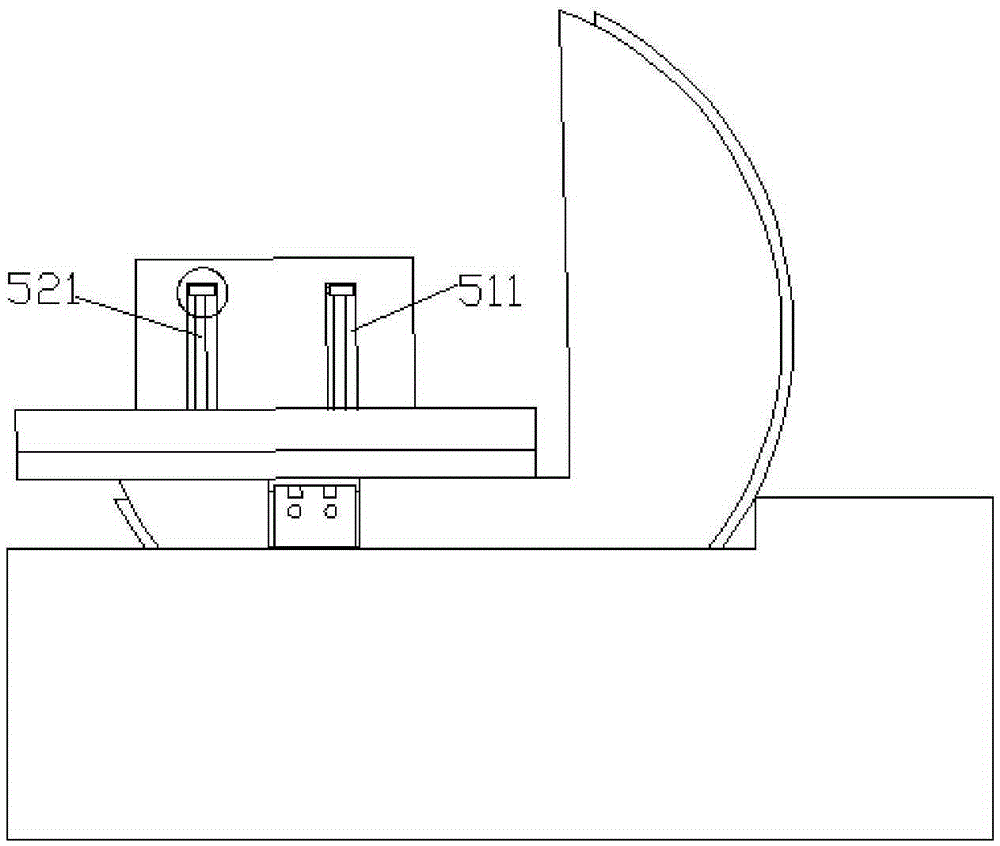

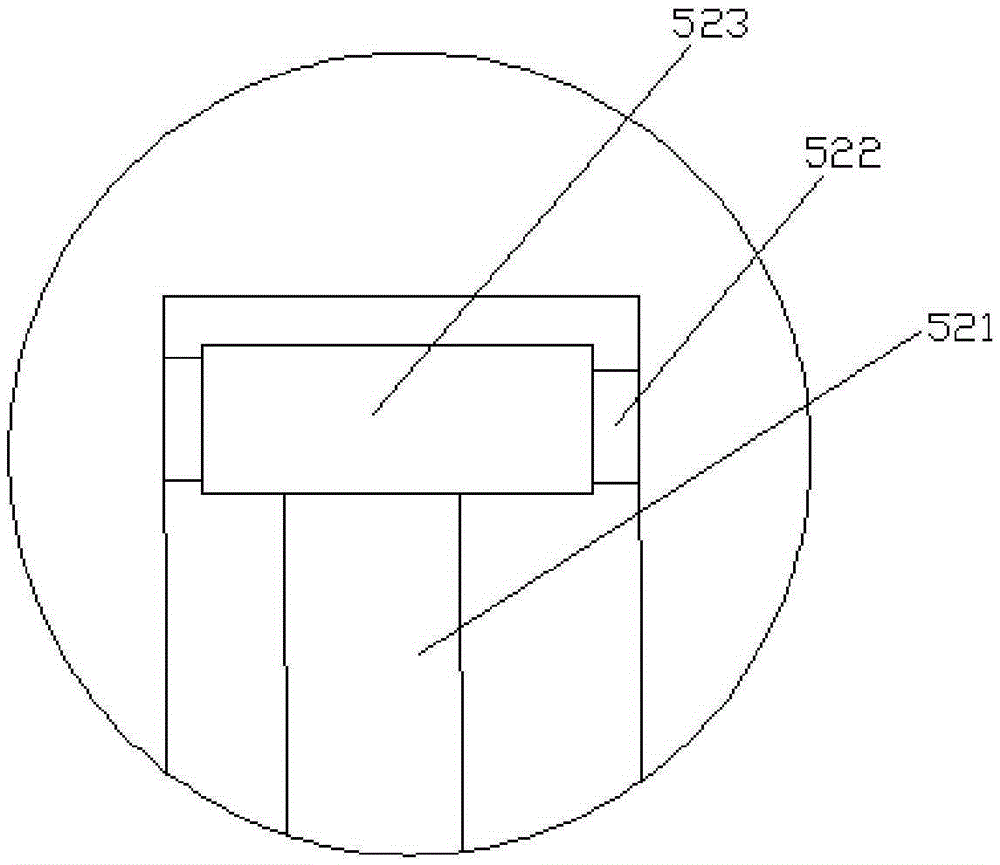

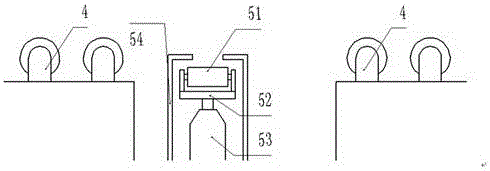

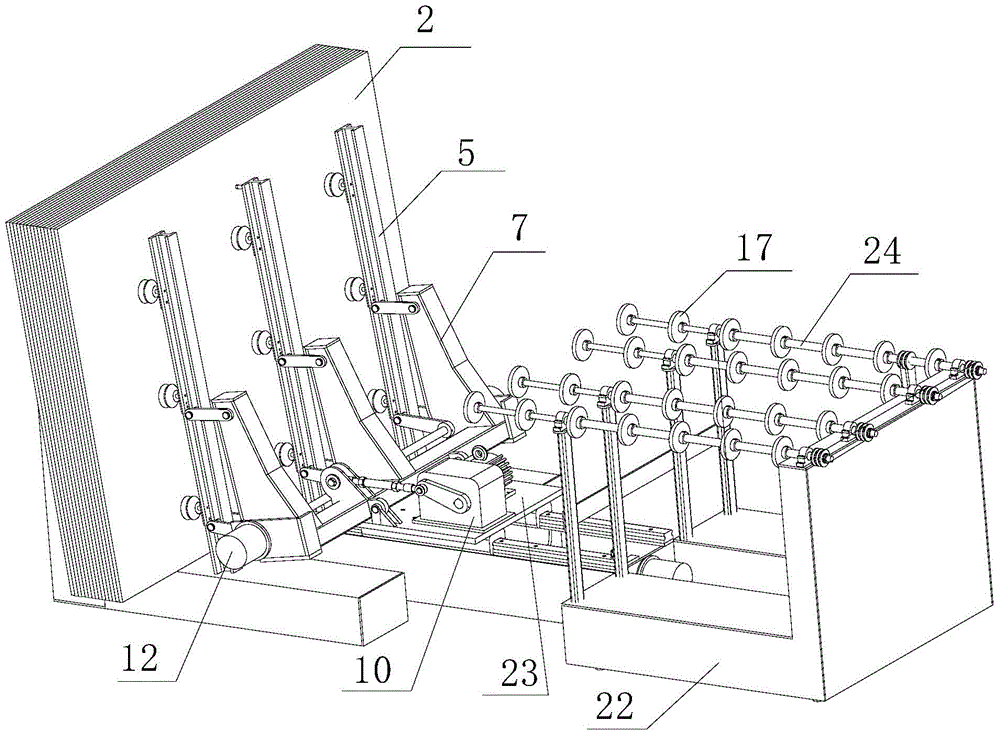

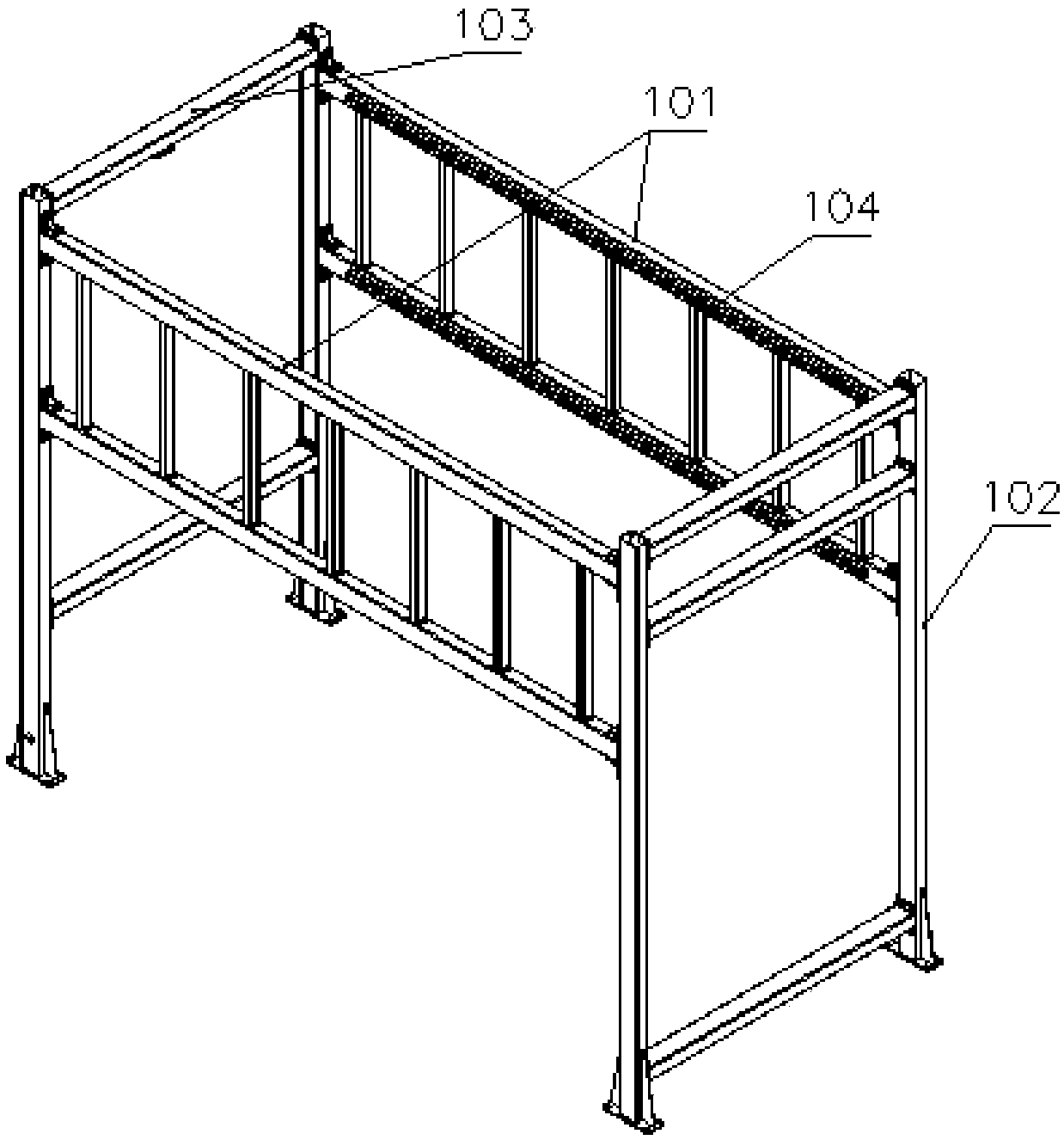

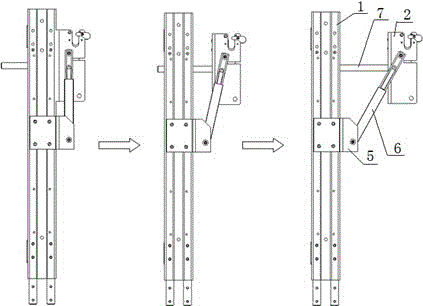

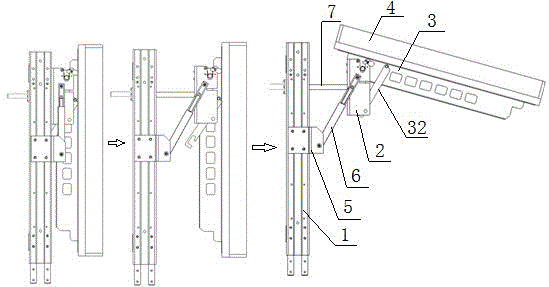

Screen pull-out overturning structure

ActiveCN103335194ASimple and reliable cooperationStable and reliable pull and flipStands/trestlesEngineering

Owner:GUANGDONG VTRON TECH CO LTD

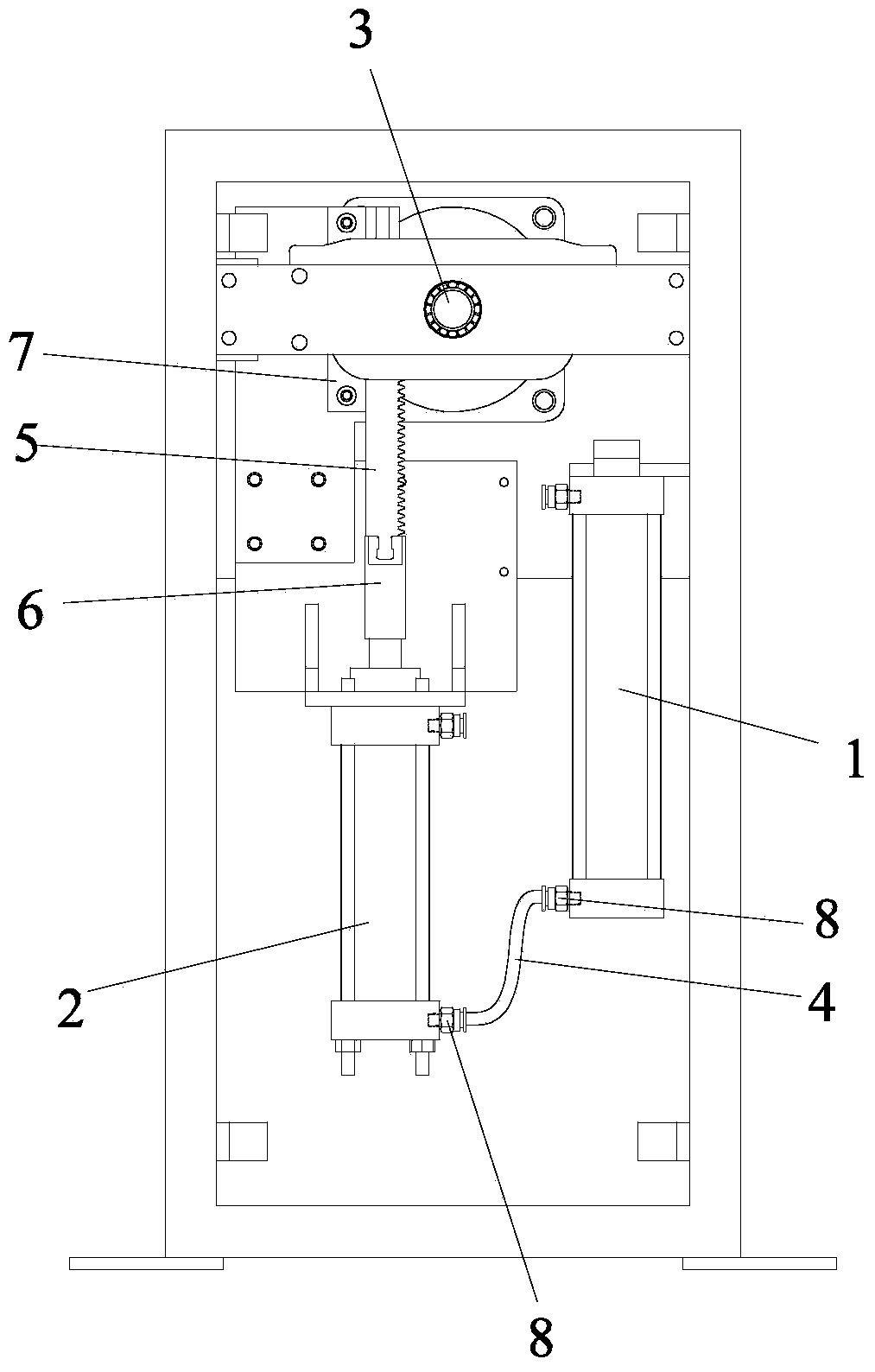

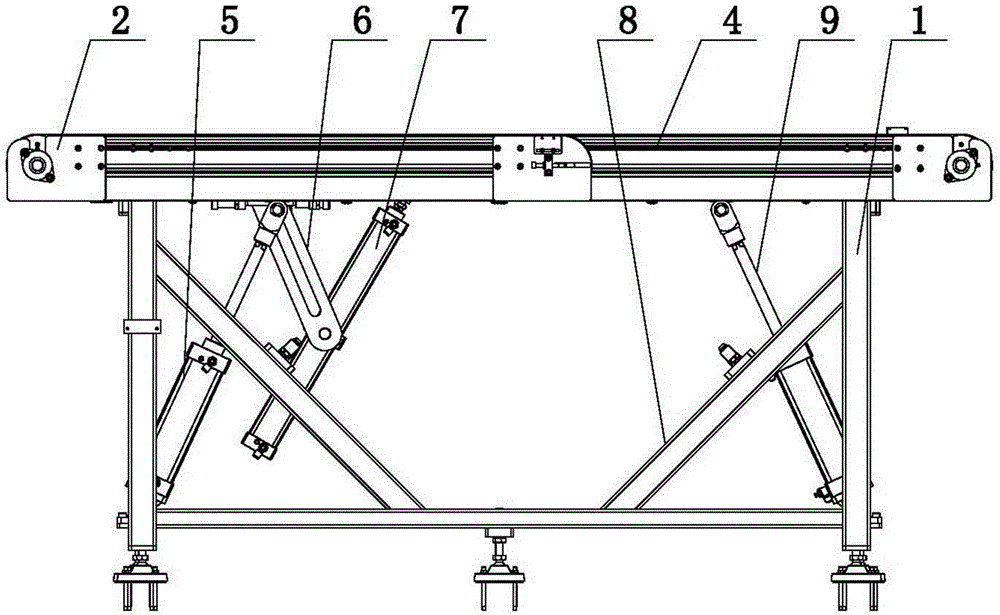

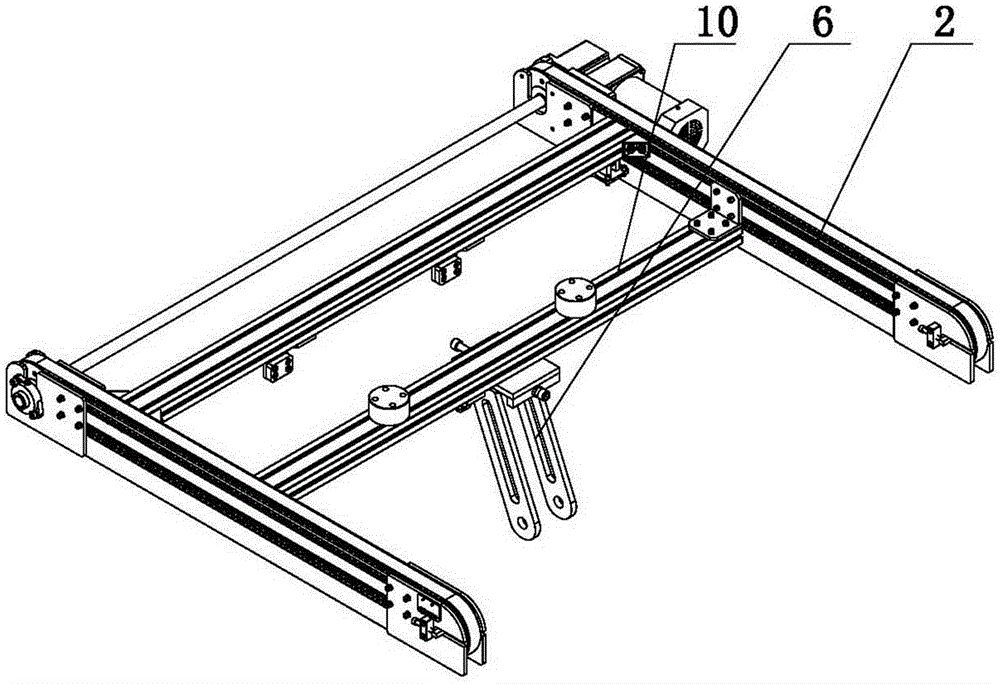

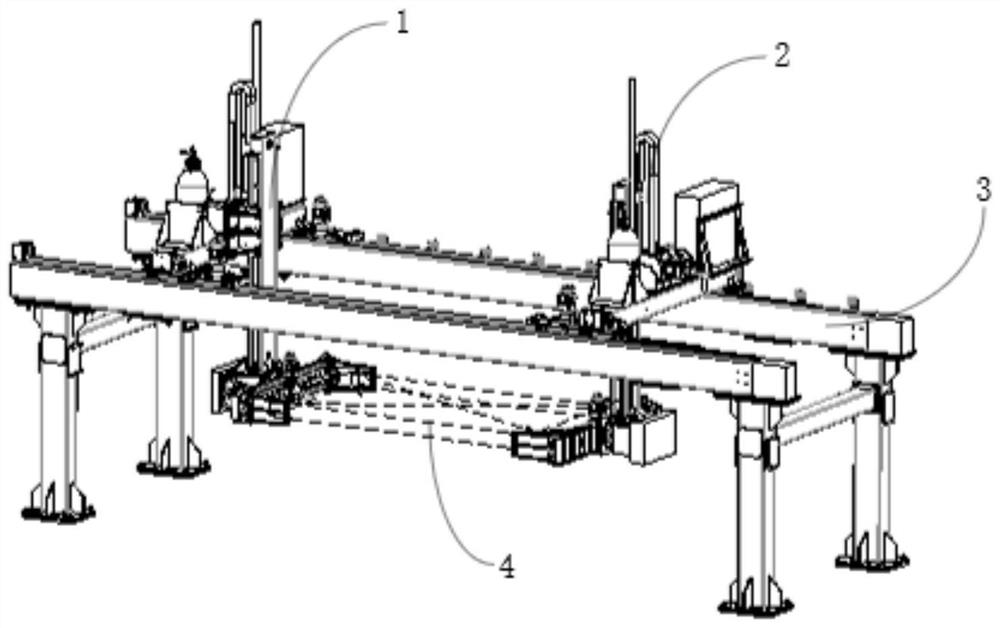

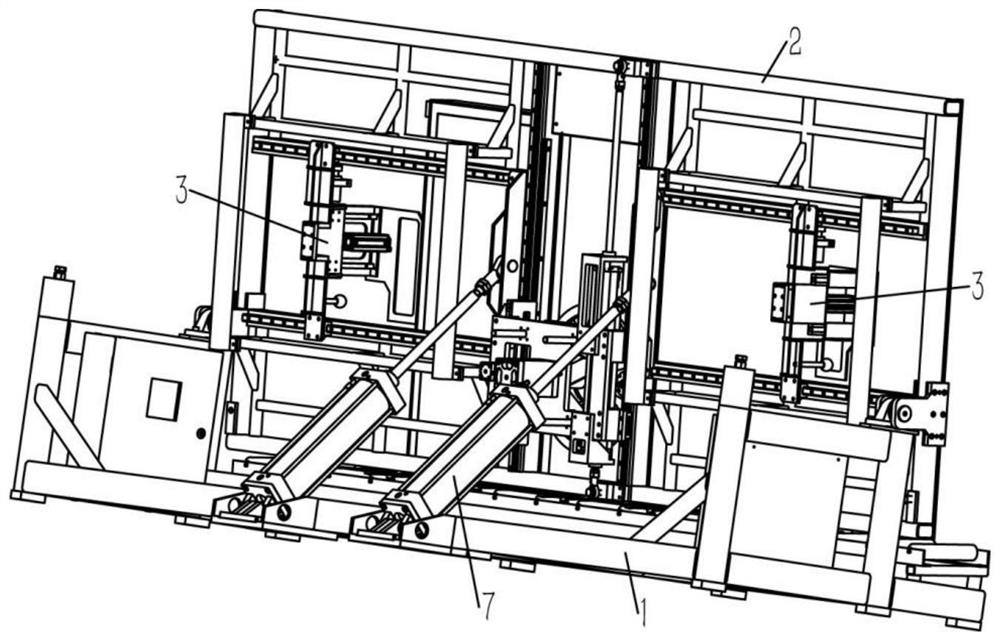

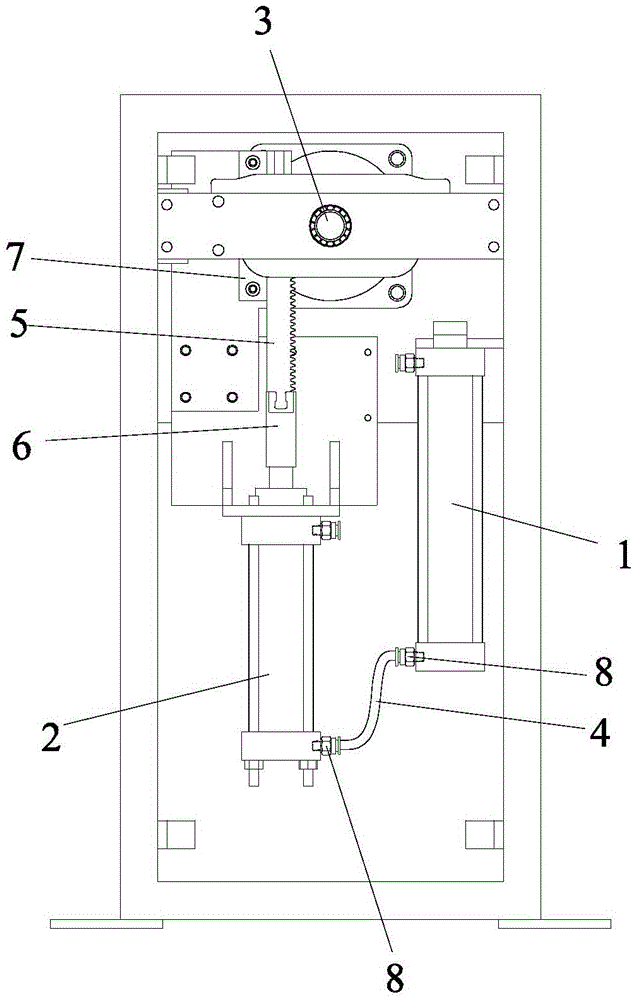

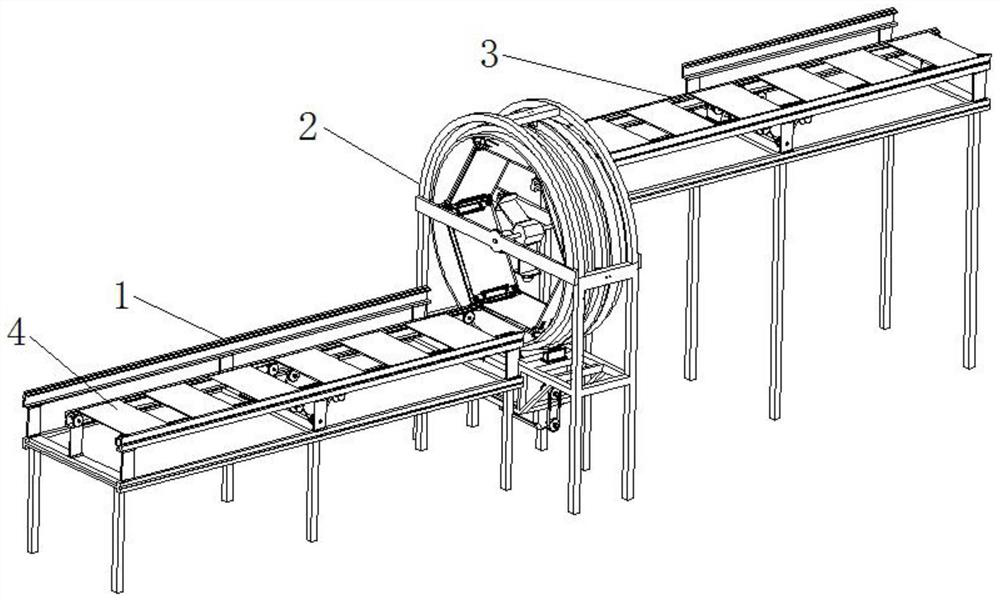

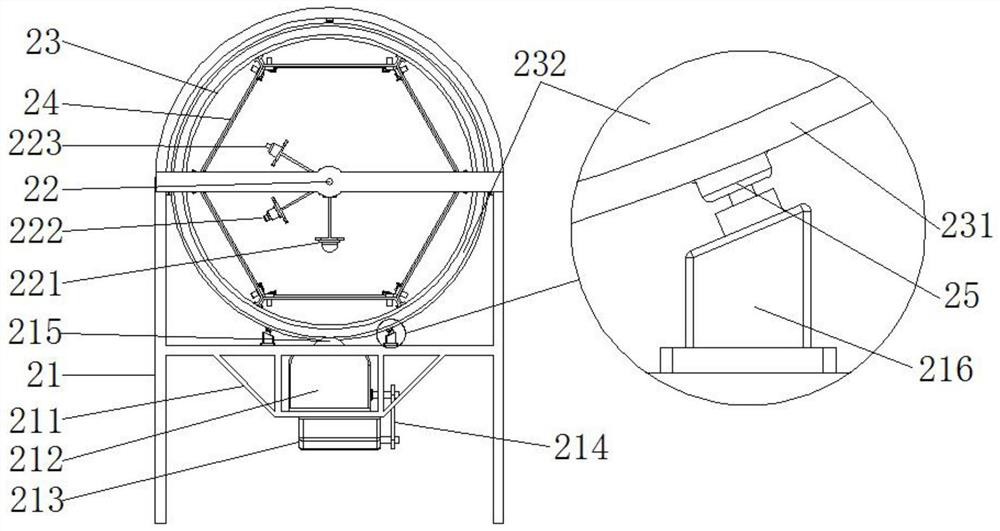

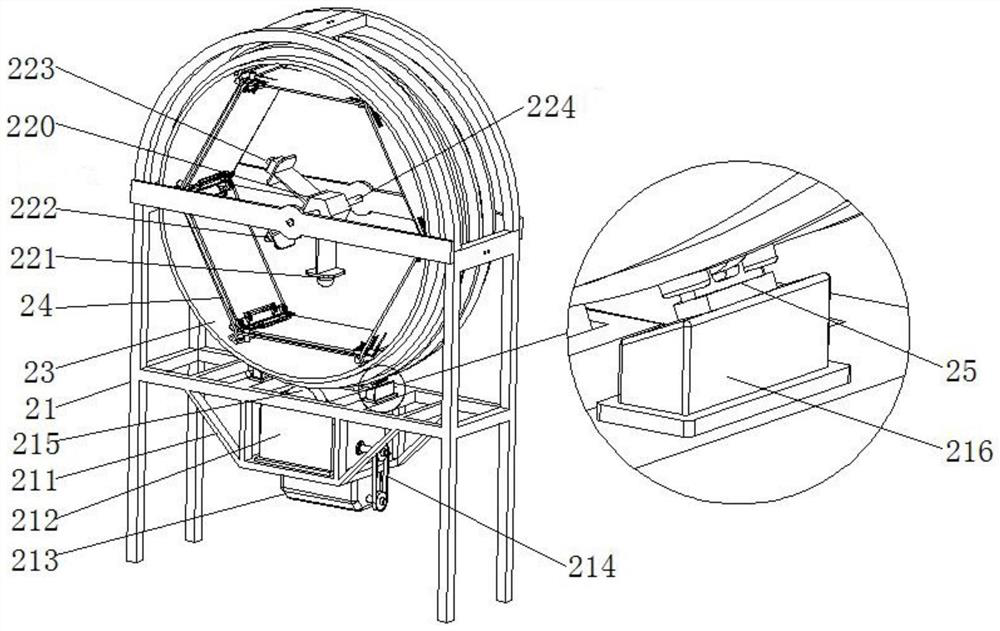

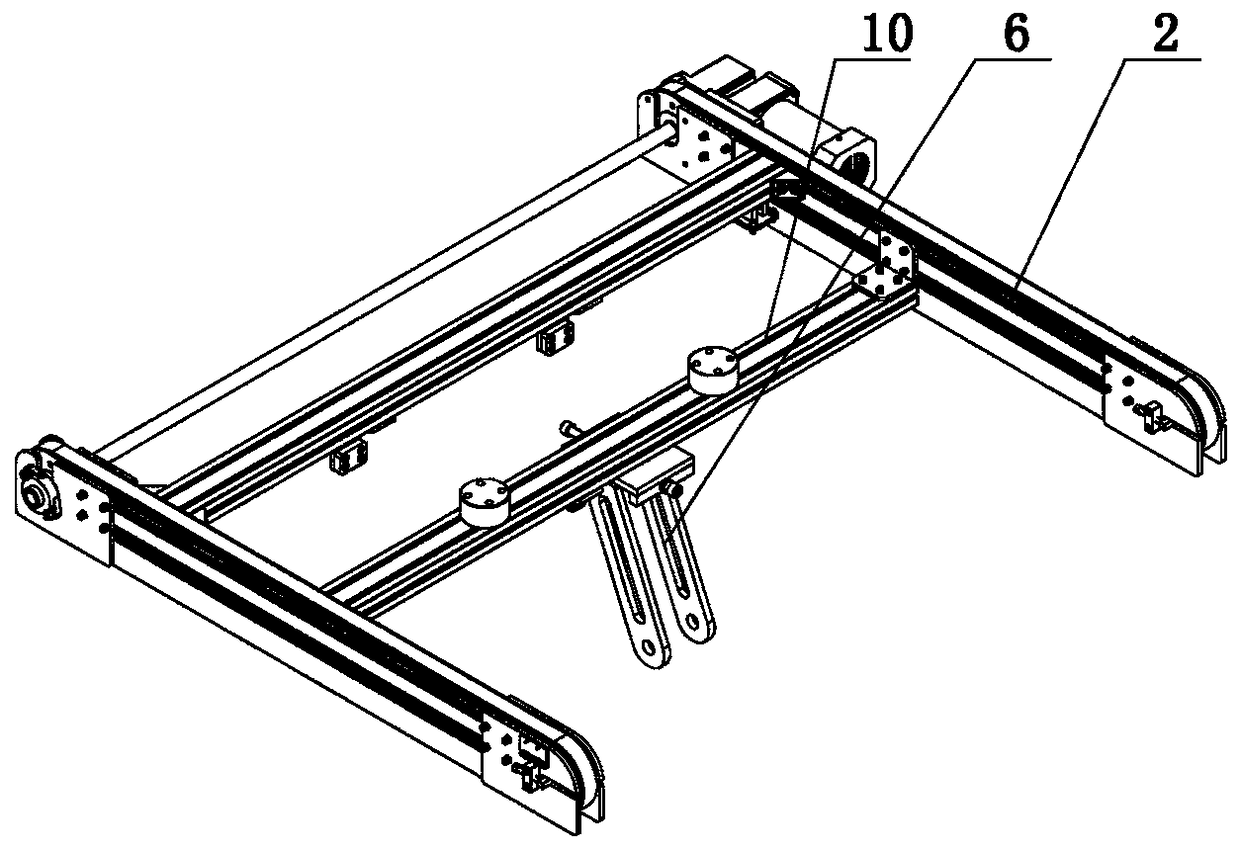

Welding jig overturning method and device

ActiveCN103862217AReduced buffer periodSmooth flipWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

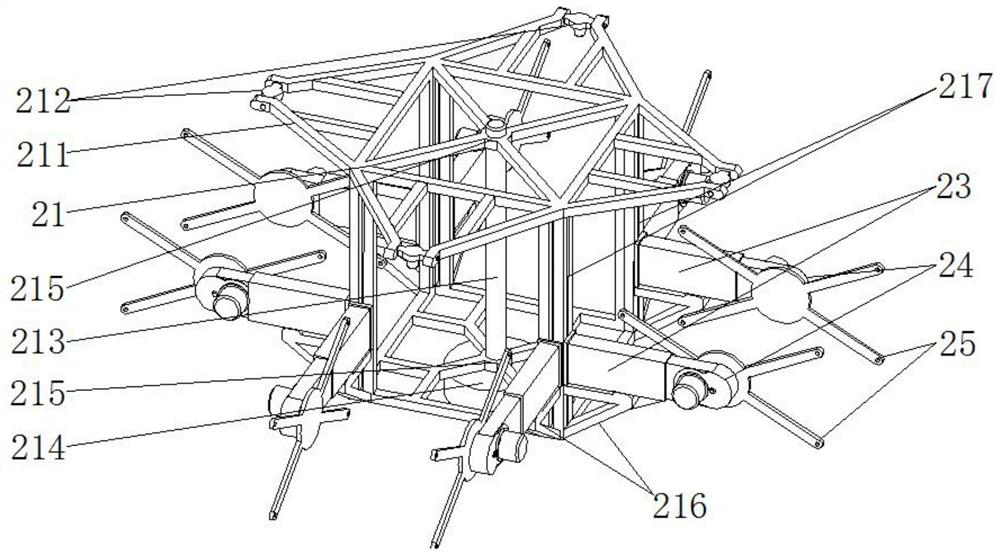

The invention provides an economical and practical welding jig overturning method. The welding jig overturning method includes the step of conducting staging control over the rotating speed of a jig main shaft for driving a jig to be overturned to achieve overturning of the welding jig, wherein the staging control over the rotating speed of the jig main shaft for driving the jig to be overturned is characterized in that a combination of a pneumatic system and a hydraulic system is adopted to achieve the staging control over the rotating speed of the jig main shaft for driving the jig to be overturned. By means of the welding jig overturning method, the using cost of robot automation welding can be effectively reduced, the welding quality can be improved, and the welding jig overturning method is of great significance on popularizing robot automation welding. The invention further provides a welding jig overturning device, and the welding jig overturning device comprises a connecting mechanism and a driving mechanism for driving the connecting mechanism to further drive the jig to be overturned; the driving mechanism is composed of the hydraulic system and the pneumatic system in a connected mode. By means of the welding jig overturning device, the jig overturning accuracy is improved; meanwhile, the welding jig overturning device has the advantages of being simple in structure, convenient to operate and the like; the welding effectiveness and the welding accuracy of the jig can be guaranteed.

Owner:广东泰格威机器人科技有限公司

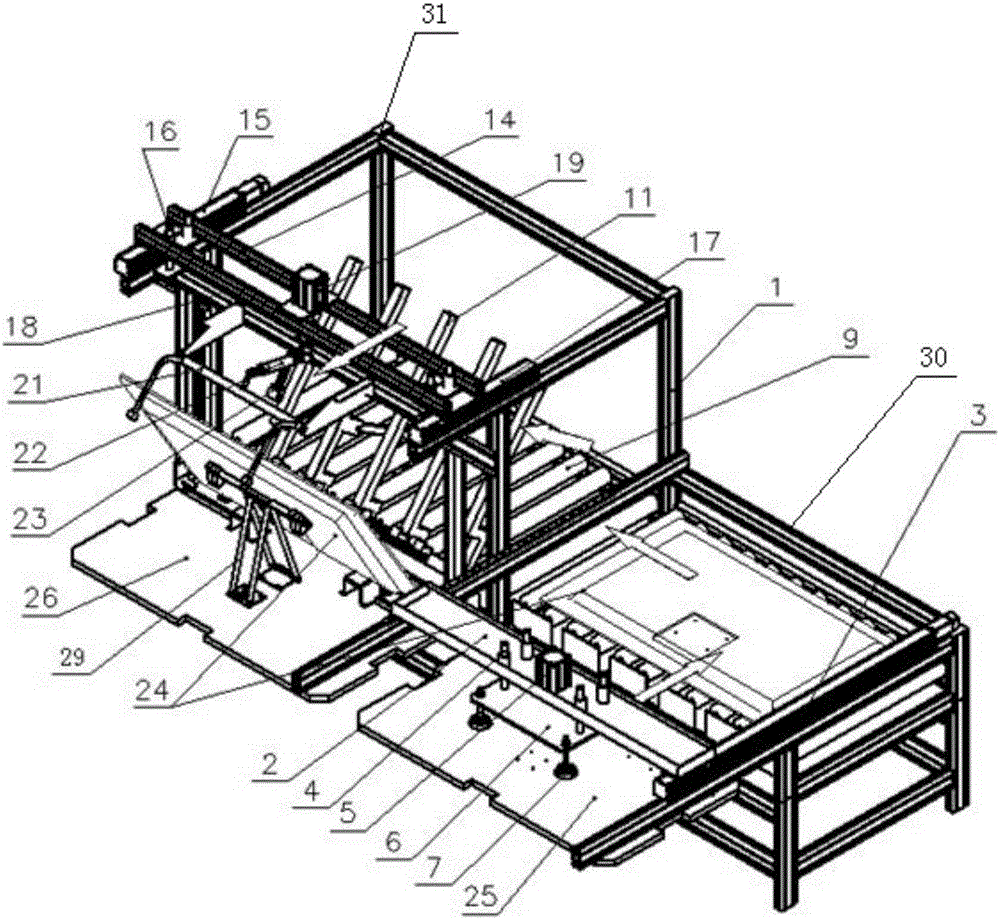

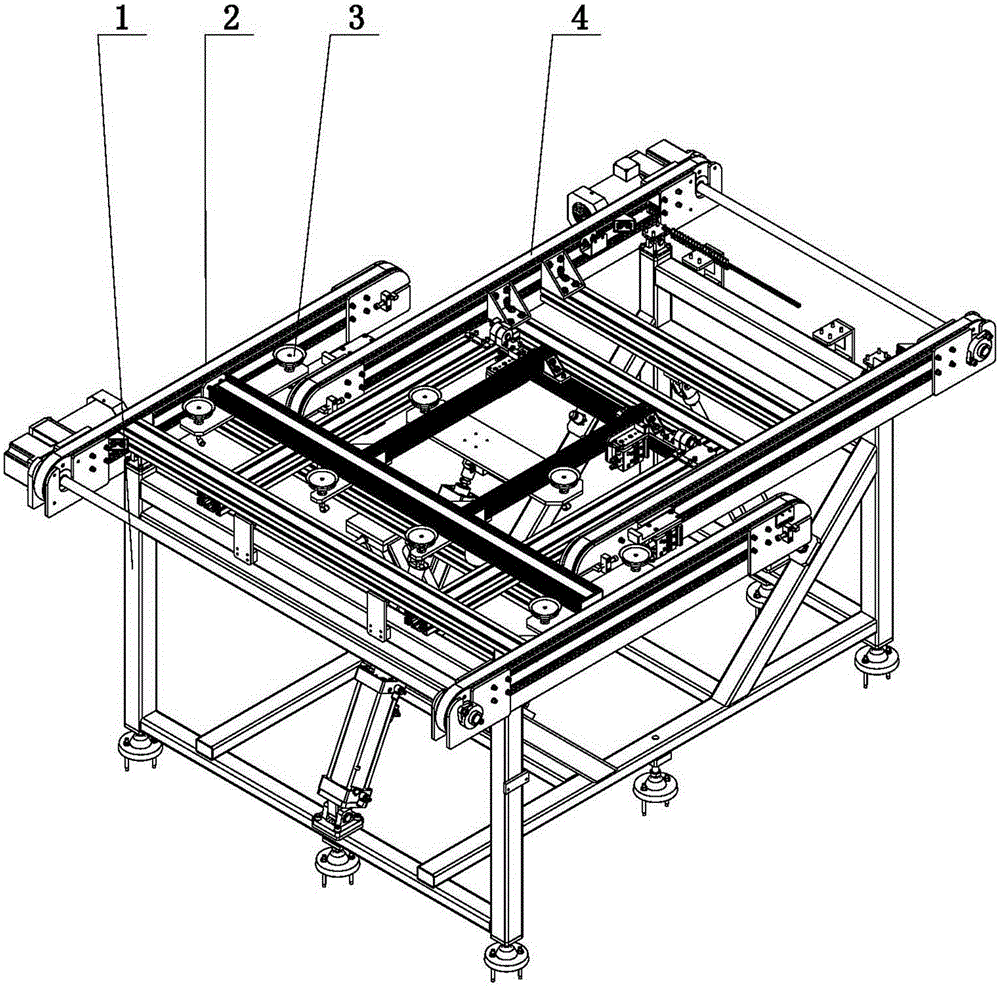

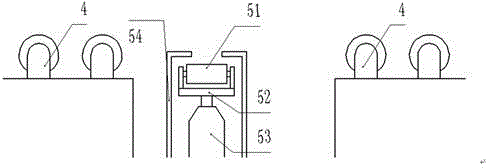

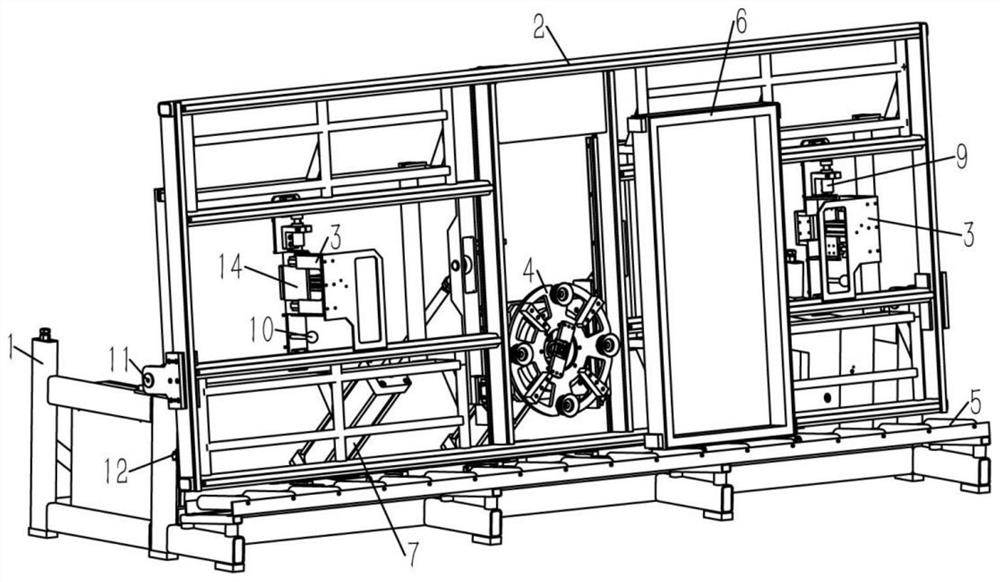

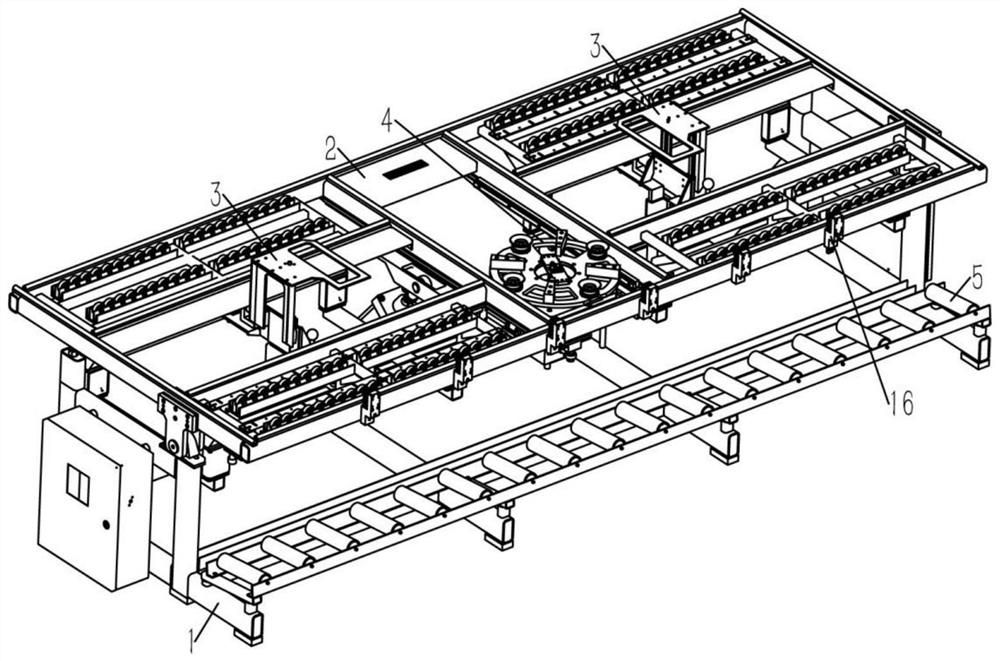

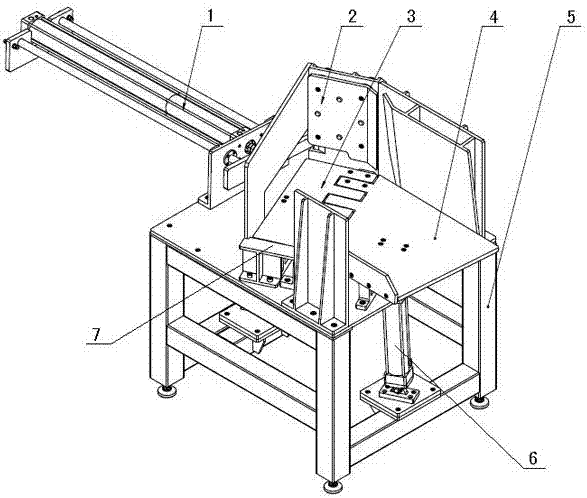

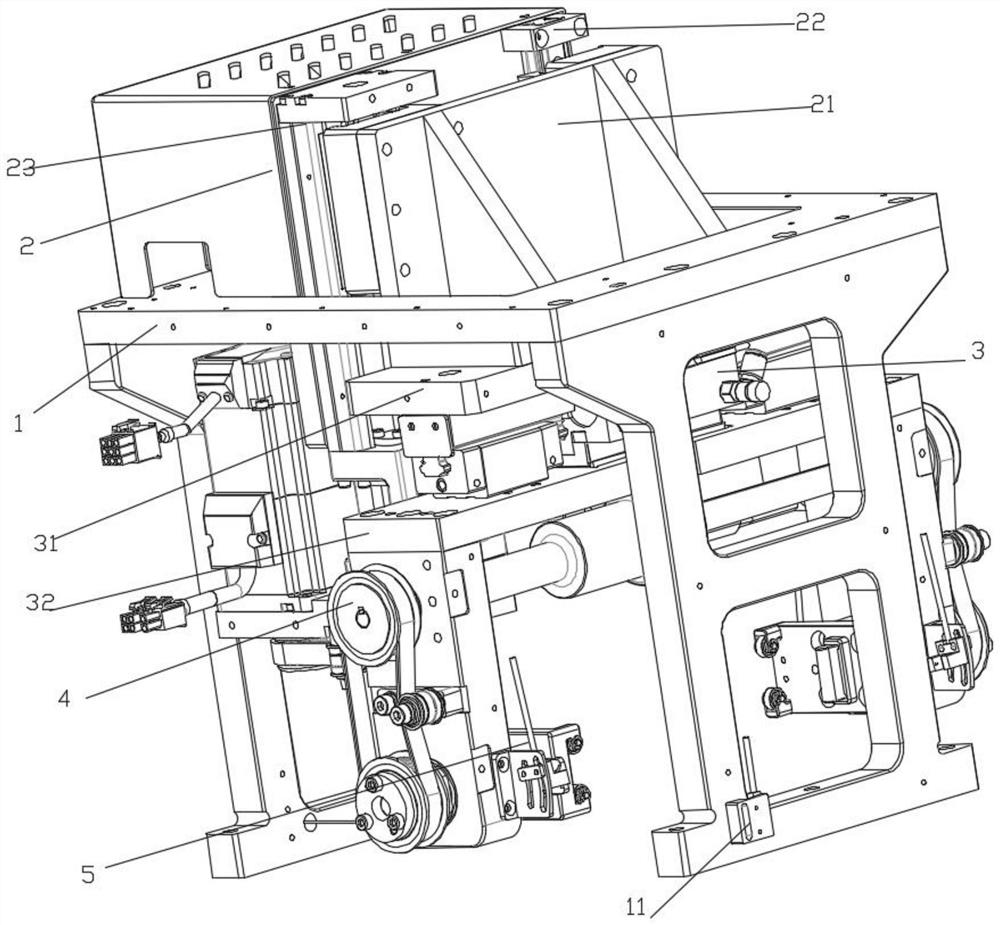

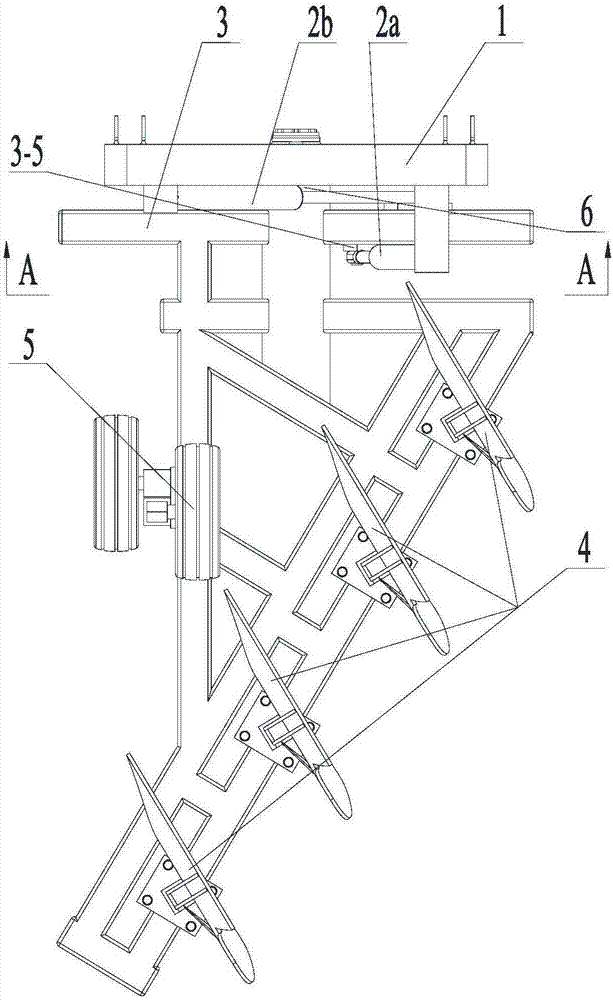

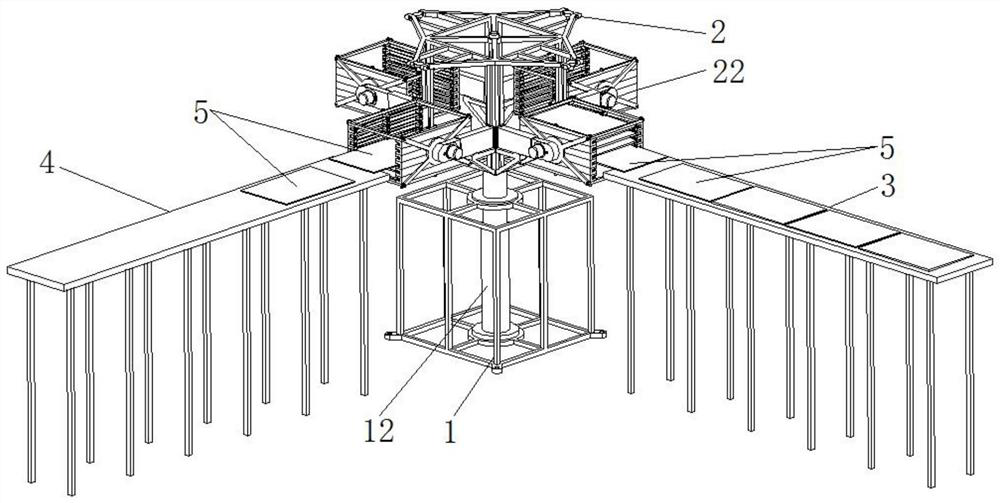

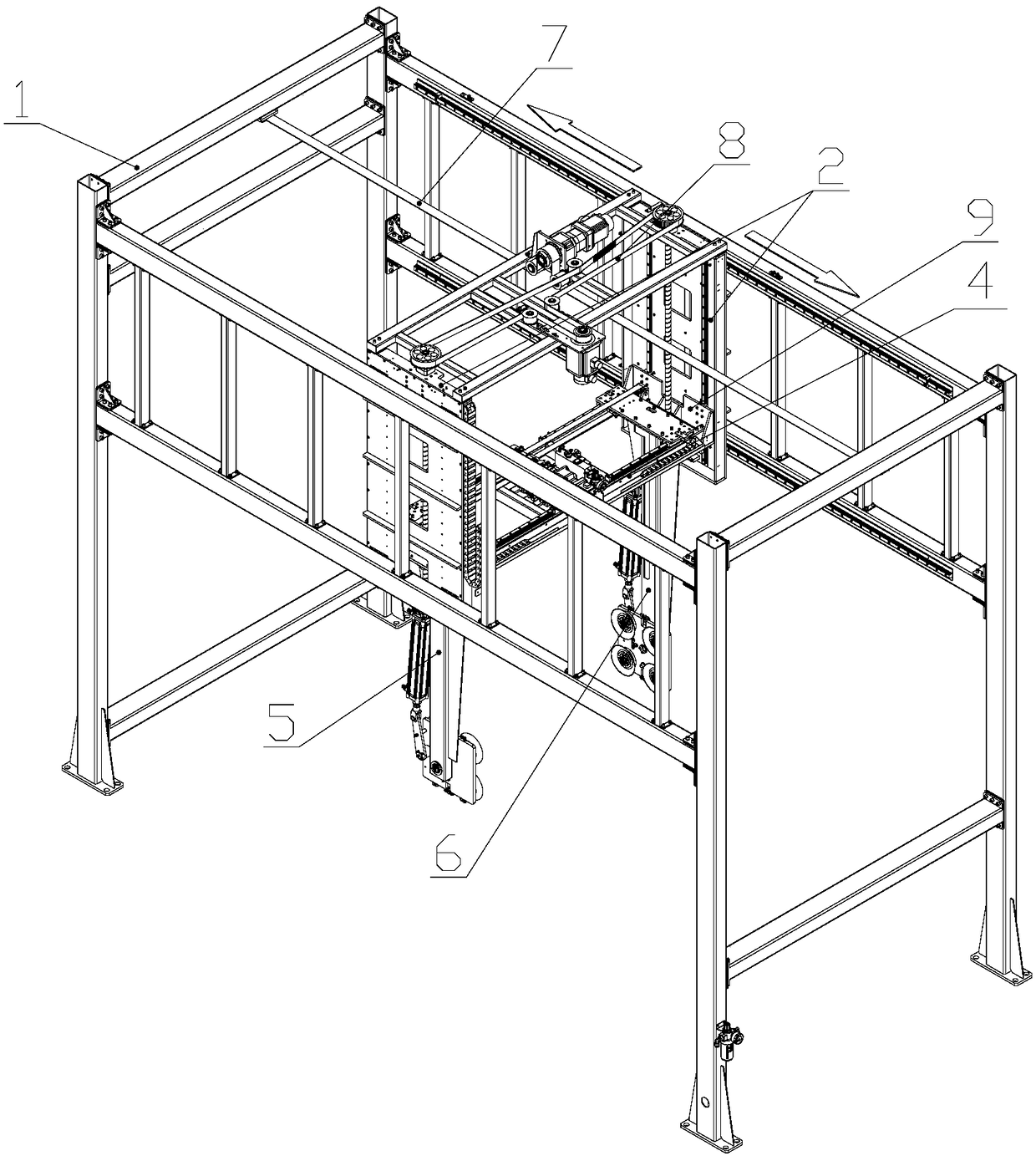

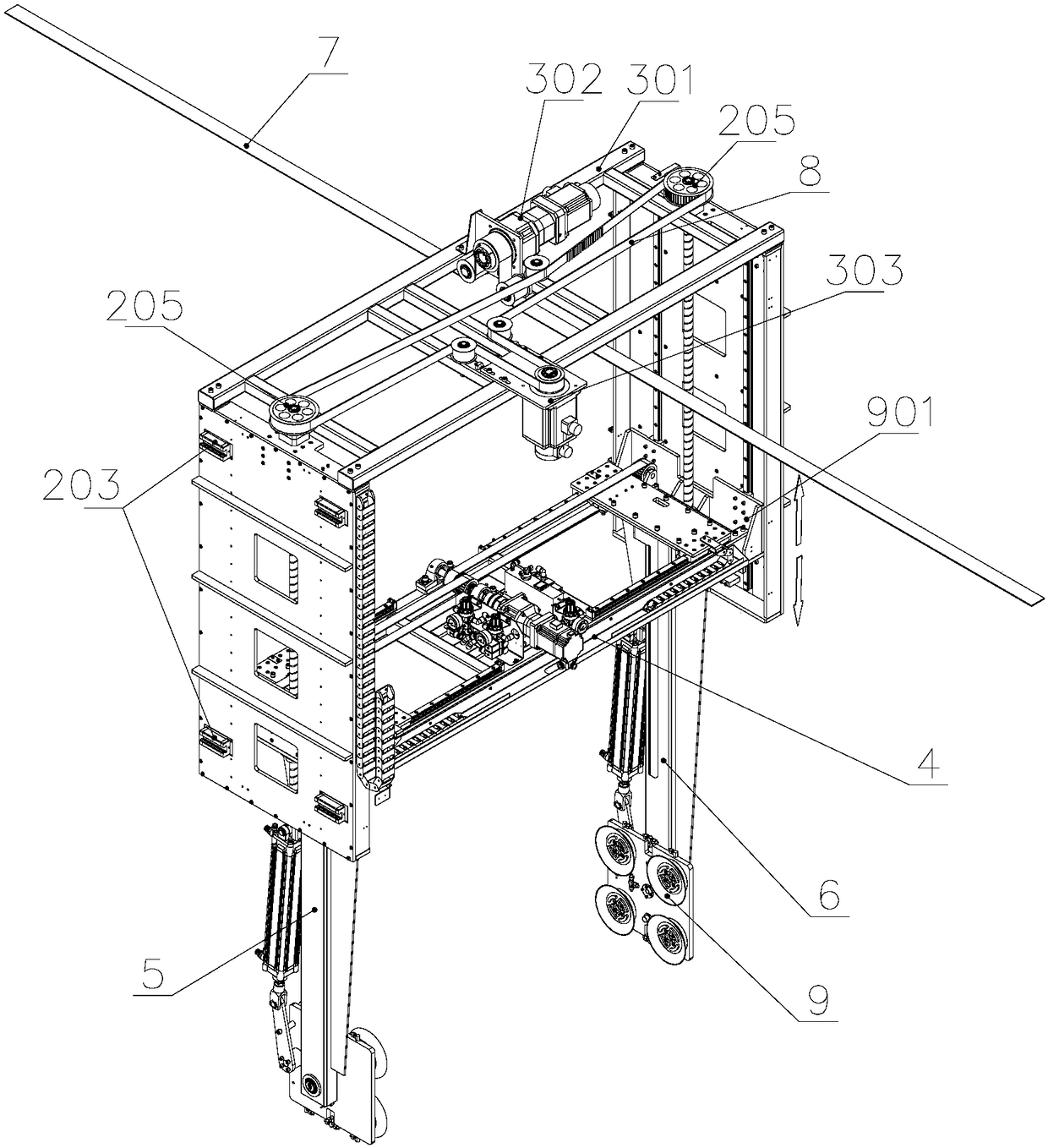

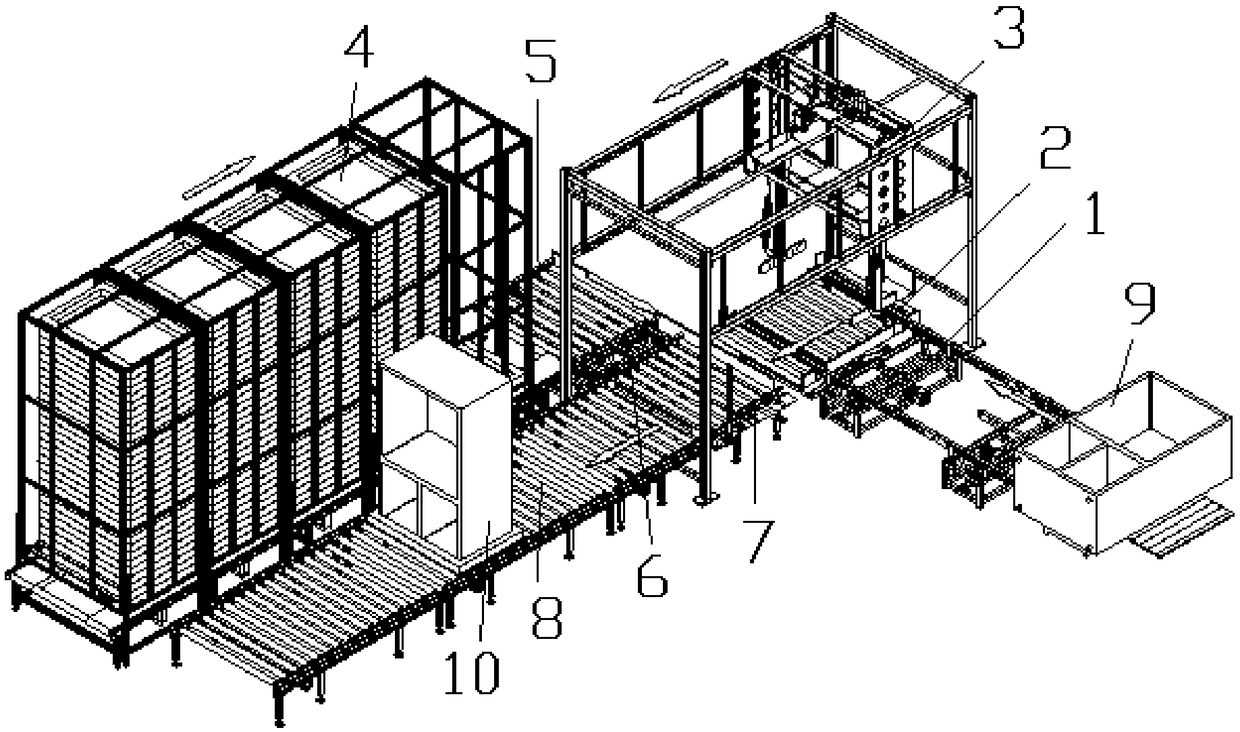

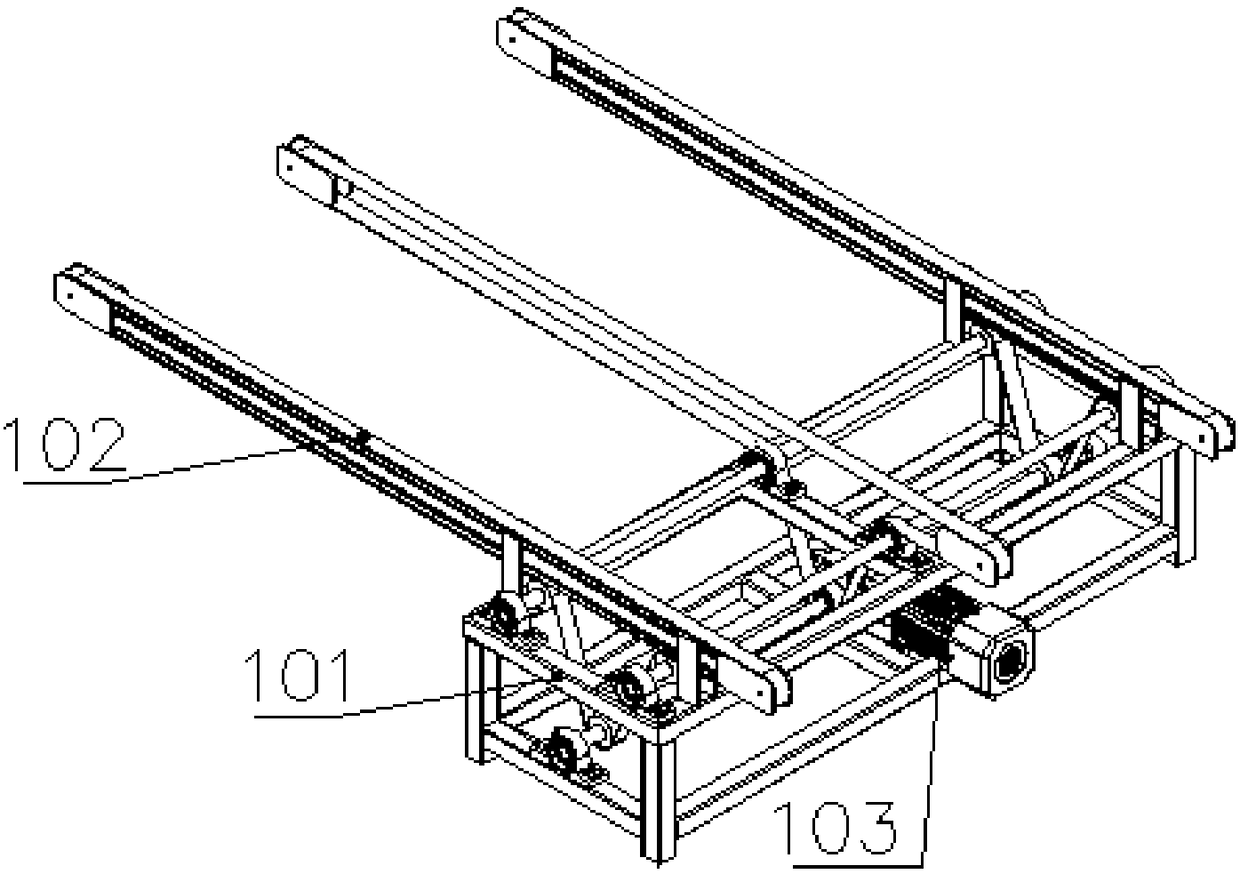

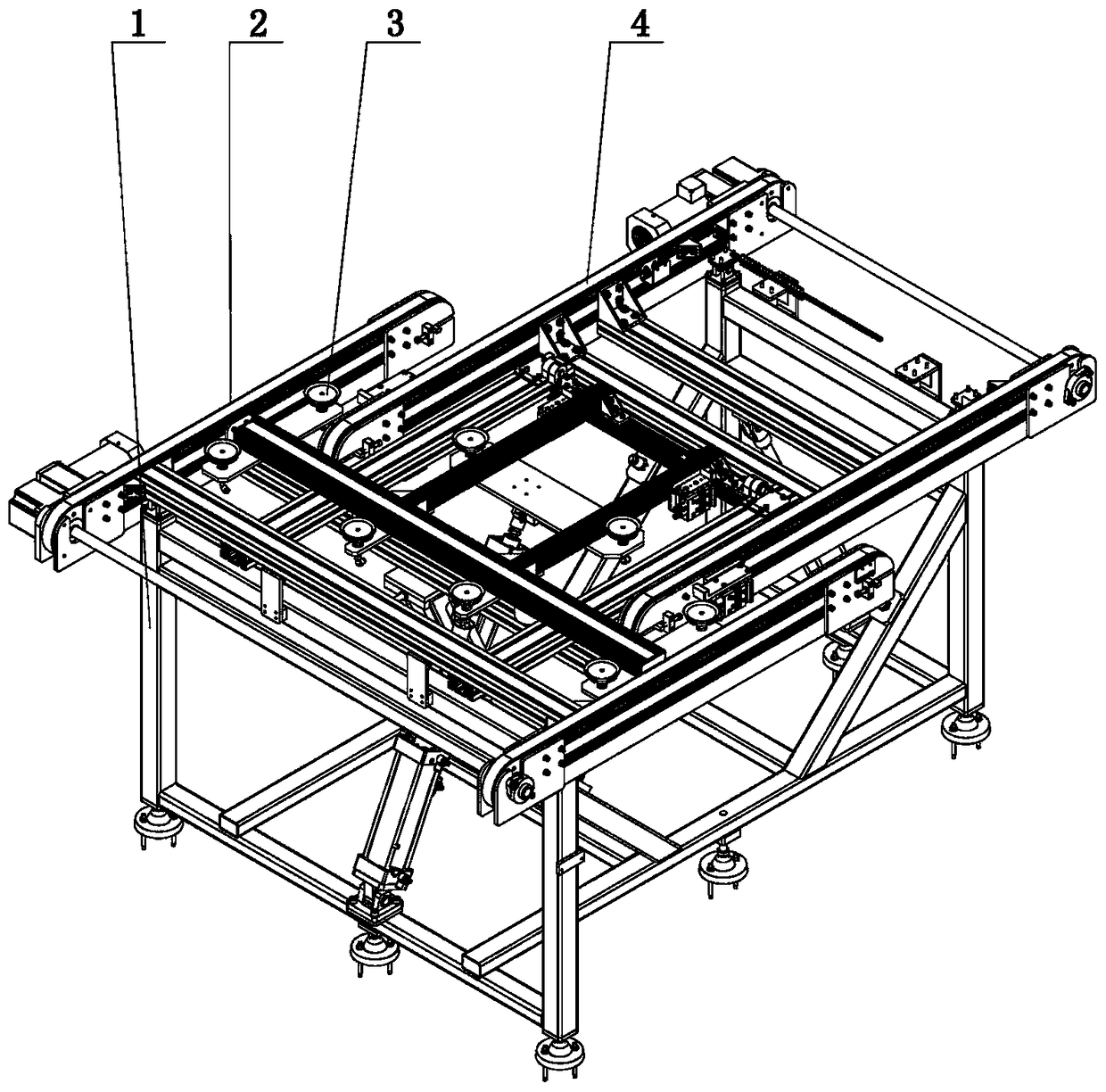

Equipment for transferring, overturning and leaning panel television set

The invention discloses equipment for transferring, overturning and leaning a panel television set. The equipment comprises a rack. The rack is composed of a first rectangular frame and a second rectangular frame. The second rectangular frame is installed on the first rectangular frame. A horizontal tool plate and a leaning tool plate are sequentially arranged on the same side of the first rectangular frame. The leaning tool plate is located below the second rectangular frame. An adsorption transferring mechanism is arranged above the horizontal tool plate. The leaning tool plate is sequentially provided with an overturning mechanism and a leaning transferring mechanism from bottom to top. The leaning transferring mechanism is connected with the upper end of the second rectangular frame. A conveying mechanism is arranged on the surface of the first rectangular frame. The equipment has the beneficial effects that it can be guaranteed that the panel television set can be smoothly transferred, overturned and leaned, manpower can be replaced, the production manner of multiple types, flexibility and easy switching is met, and meanwhile efficiency and product quality are improved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Automatic face changing device

The invention relates to an automatic face changing device for a solar cell assembly or flat glass or other products. The automatic face changing device is simple in structure, safe and reliable, and the function of conveying and the function of overturning are combined, and the technology takt is greatly improved. The automatic face changing device comprises a rack, and is characterized in that a first conveying belt and a second conveying belt are hinged to the two ends of the rack, a first oblique air cylinder is arranged between the first conveying belt and the rack, and a second oblique air cylinder is arranged between the second conveying belt and the rack; and a connecting frame is arranged below the first conveying belt, an overturning air cylinder is hinged to the connecting frame and provided with a suction cup device, and the suction cup device is hinged to a rack body of the first conveying belt.

Owner:南通金诺智能制造有限公司

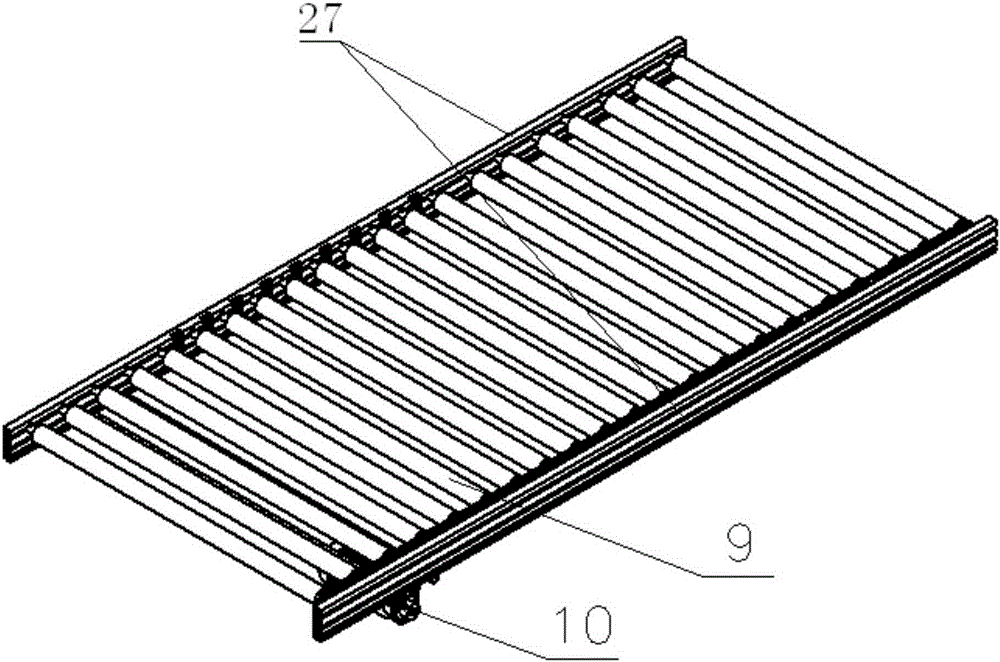

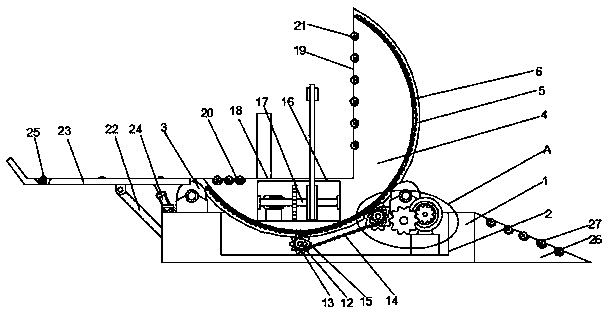

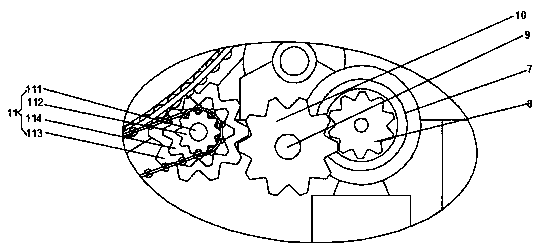

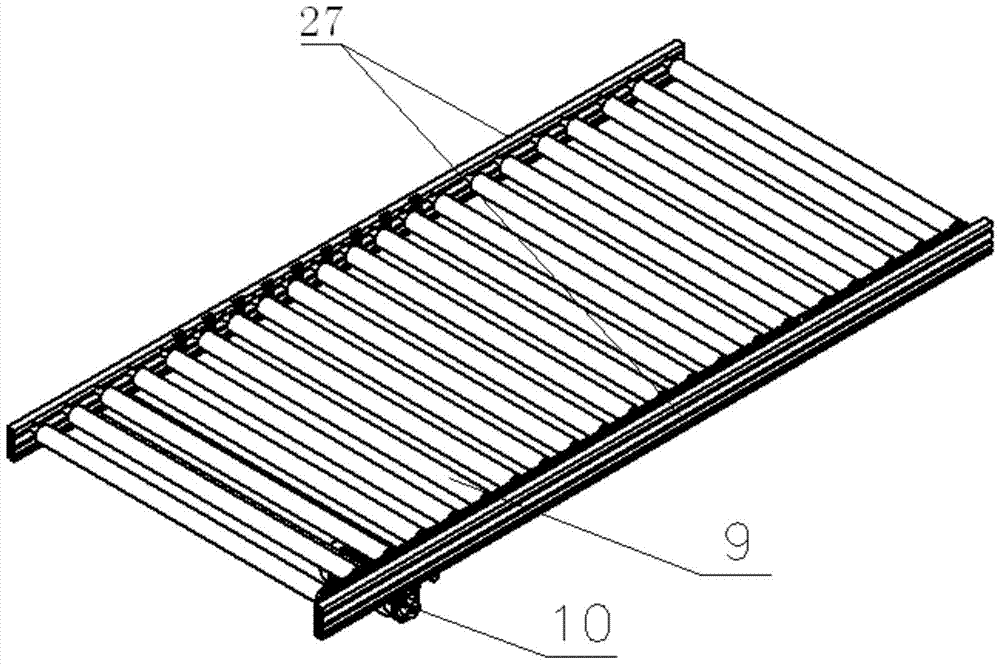

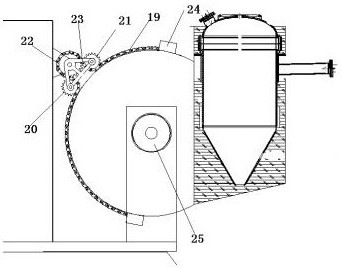

High-stability steel coil turnover device

InactiveCN105398795AImprove stabilityStable and reliable turningConveyor partsRoller-waysSprocketAutomation

The invention provides a high-stability steel coil turnover device. The high-stability steel coil turnover device comprises a worktable and an underframe; the underframe comprises a groove for accommodating the worktable; a chain wheel group and a supporting roller are arranged in the groove; the worktable is located on the supporting roller; the worktable comprises a cambered surface, and a first worktable top and a second worktable top, the two of which are perpendicular to each other; a chain engaged with the chain wheel group is arranged on the cambered surface; a conveying mechanism is arranged on the first worktable top; the conveying mechanism is fixedly connected with the worktable through a fastener; the conveying mechanism comprises a frame and a plurality of rollers located within the frame; a steel coil limiting mechanism is arranged on the frame. The high-stability steel coil turnover device has the positive effects of stable and reliable turnover process, high automation degree, labor cost saving and working efficiency improvement.

Owner:TIANJIN SHENYUAN KAILI GRP CO LTD

Induction heating apparatus capable of stably operating at least one switching element contained therein

InactiveUS7542313B2Stable and reliable turningImprove reliabilityConversion with intermediate conversion to dcEmergency protective circuit arrangementsPhase differenceResonance

Owner:SANKEN ELECTRIC CO LTD

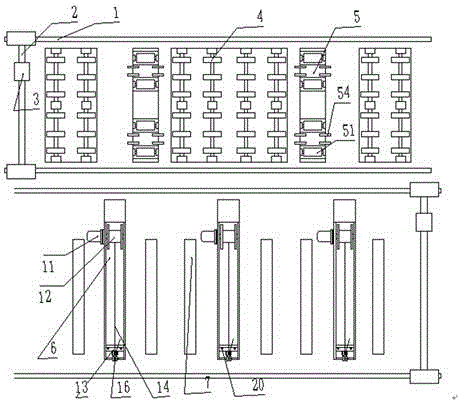

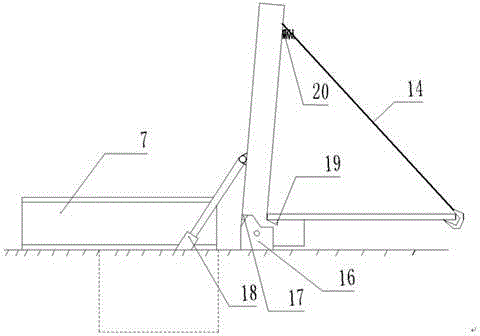

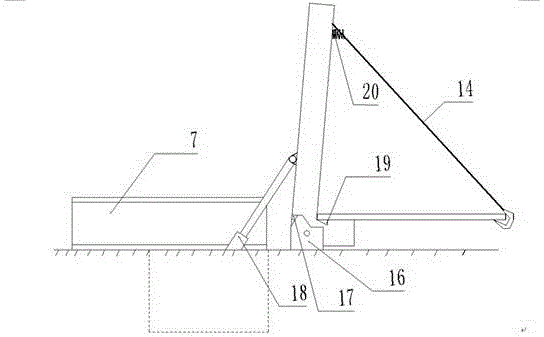

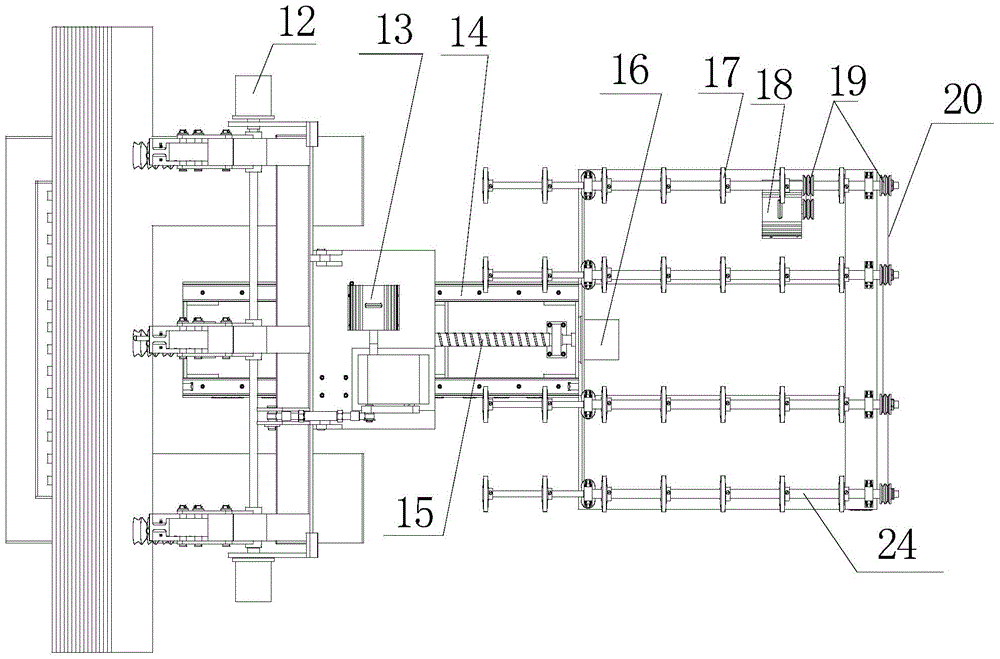

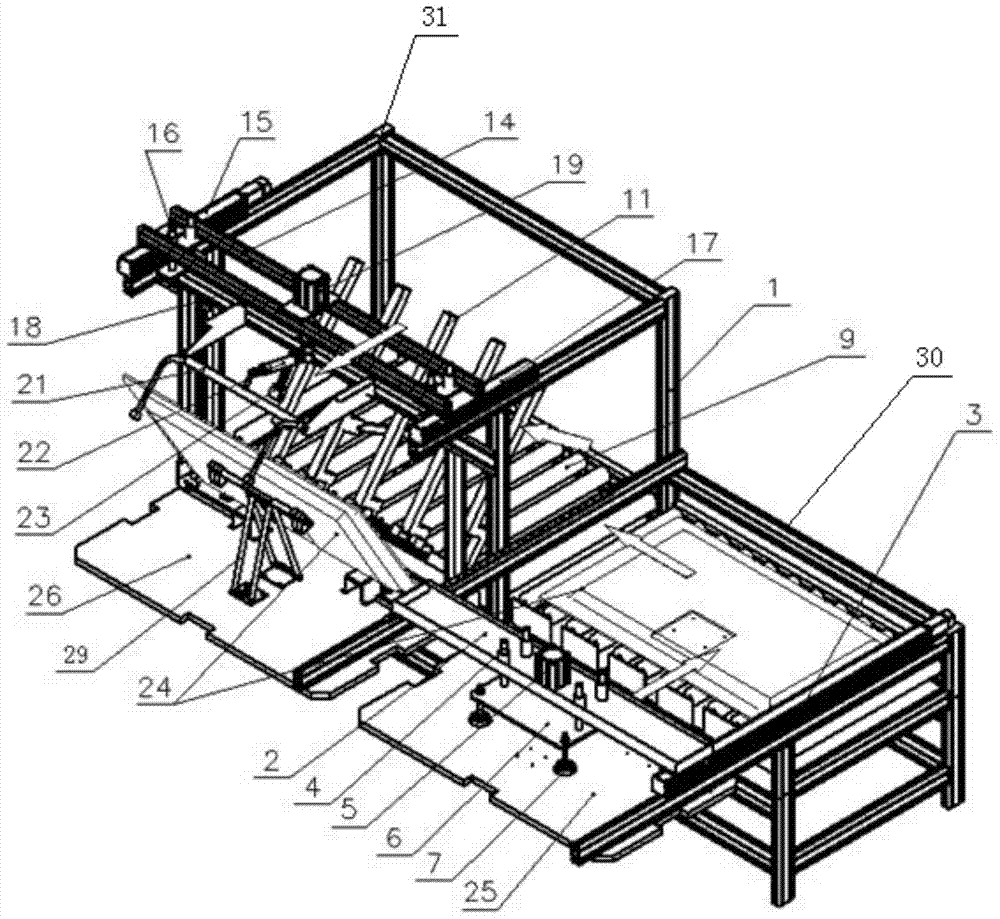

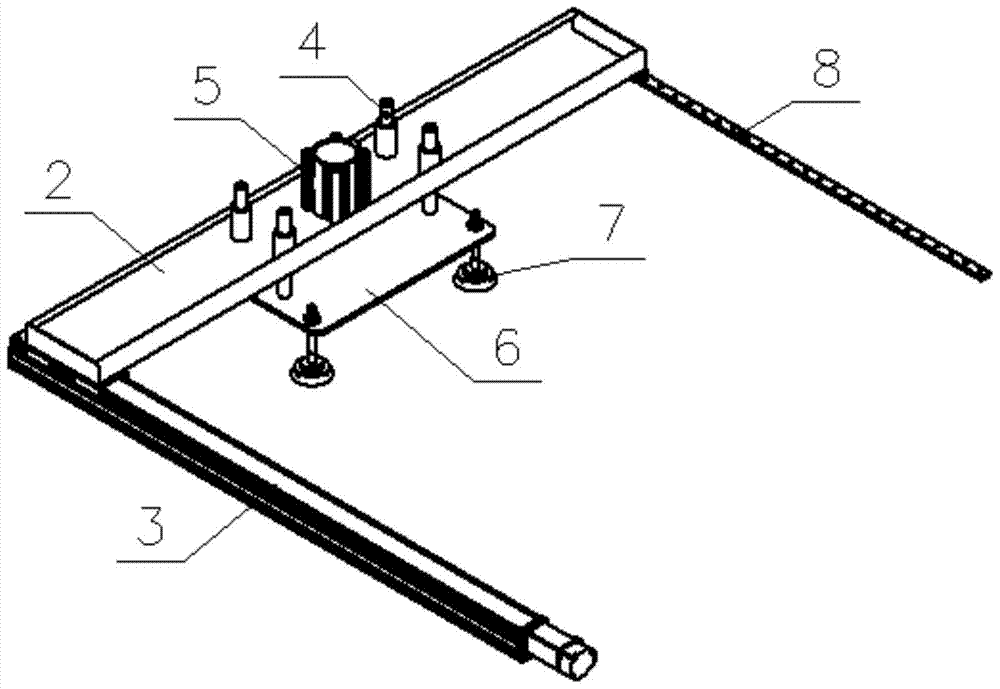

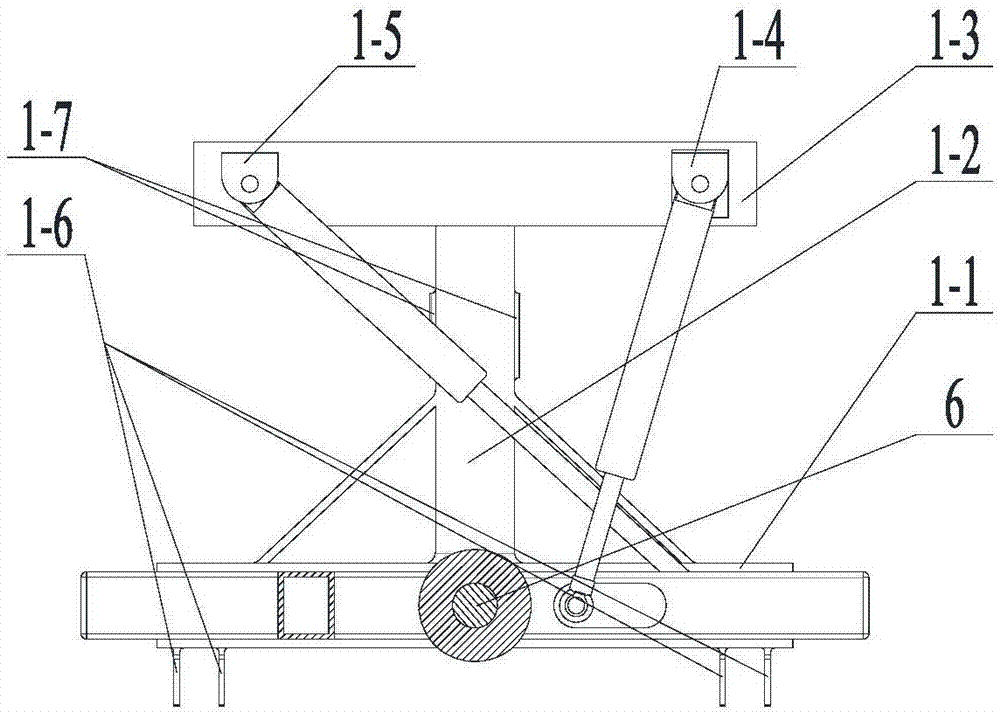

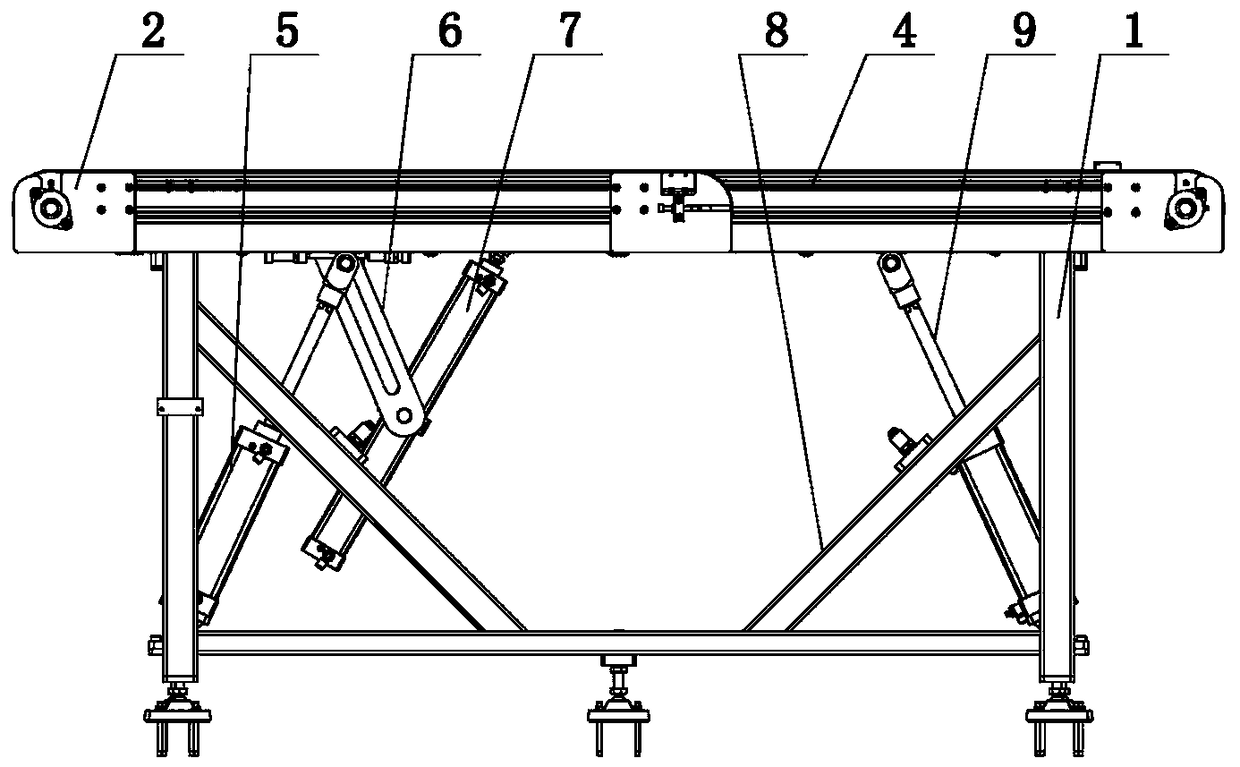

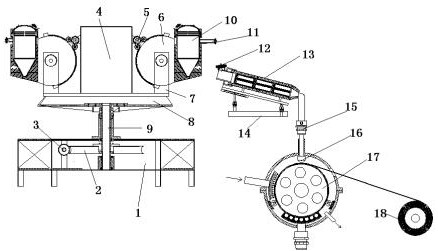

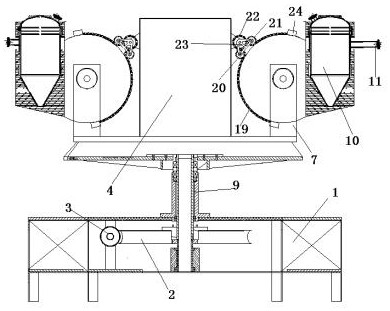

Welding system for large thick-wall steel plate

ActiveCN104476091AEasy dockingEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderButt welding

The invention discloses a welding system for a large thick-wall steel plate. The system comprises a portal type welding mechanism and a steel plate supporting structure. The system is characterized in that the steel plate supporting structure is arranged between two steel rails (1) of the portal type welding mechanism; the steel plate supporting structure is composed of a plurality of groups of carrier rollers (4) and is also equipped with a holding mechanism (5) which is mounted on a lifting hydraulic cylinder (53); an overturning bracket (6) which is hinged to a supporting seat (16) is arranged at one side of the portal type welding mechanism, and the overturning bracket (6) is that the rear surface is connected with a rotating hydraulic cylinder (18), the bottom part is equipped with a steel wire coil (12), and the top part is equipped with a fixed pulley (16); the steel wire coil (12) is connected with a motor (11). With the adoption of the welding system, the abutting, welding, side overturning and other processes in the welding process of a thick steel plate can be done; the stability and reliability in welding and overturning are ensured; workers can operate conveniently; the production efficiency is raised.

Owner:GUIZHOU HUITONG SHENFA STEEL STRUCTURE

Turnover device for electromechanical device installation

InactiveCN108946081AStable and reliable turningFlip Power Source AverageLifting devicesConveyor partsEngineering

Owner:JIUJIANG VOCATIONAL & TECHN COLLEGE

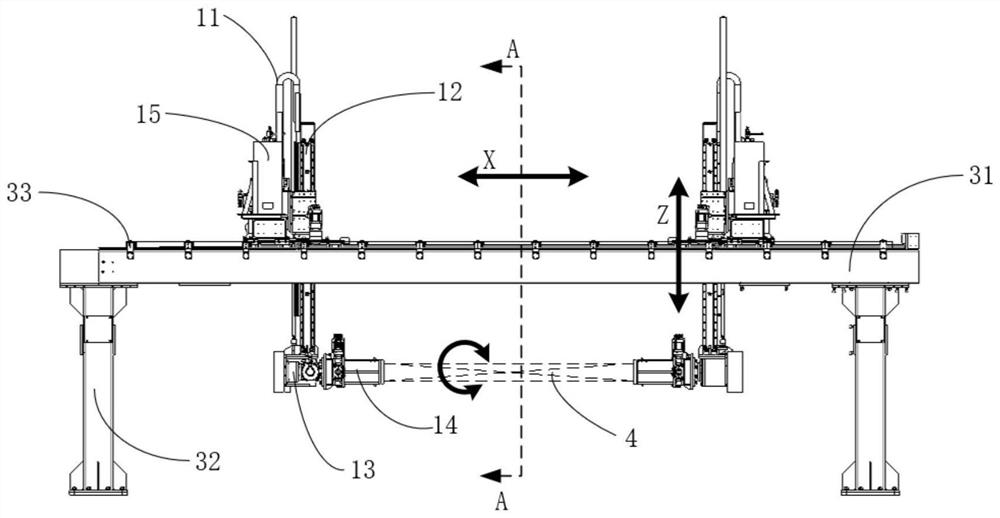

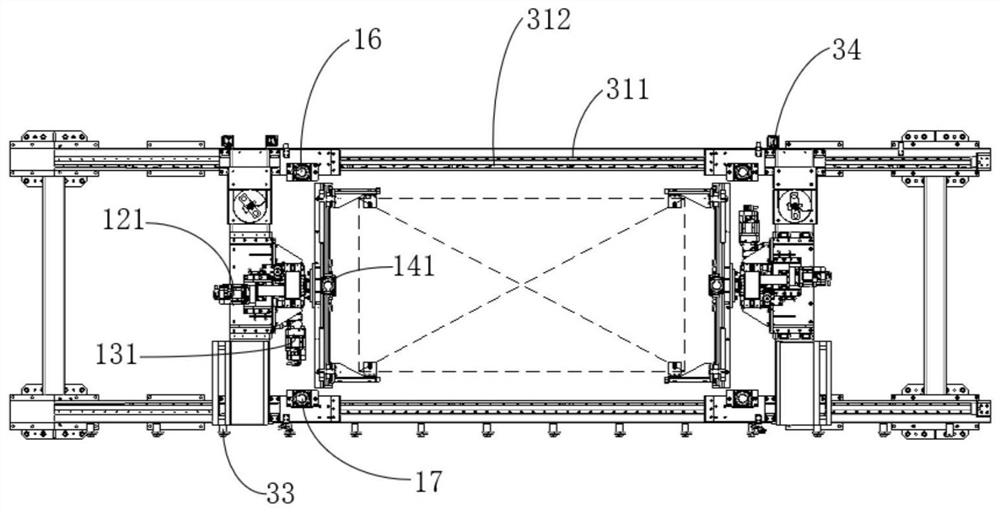

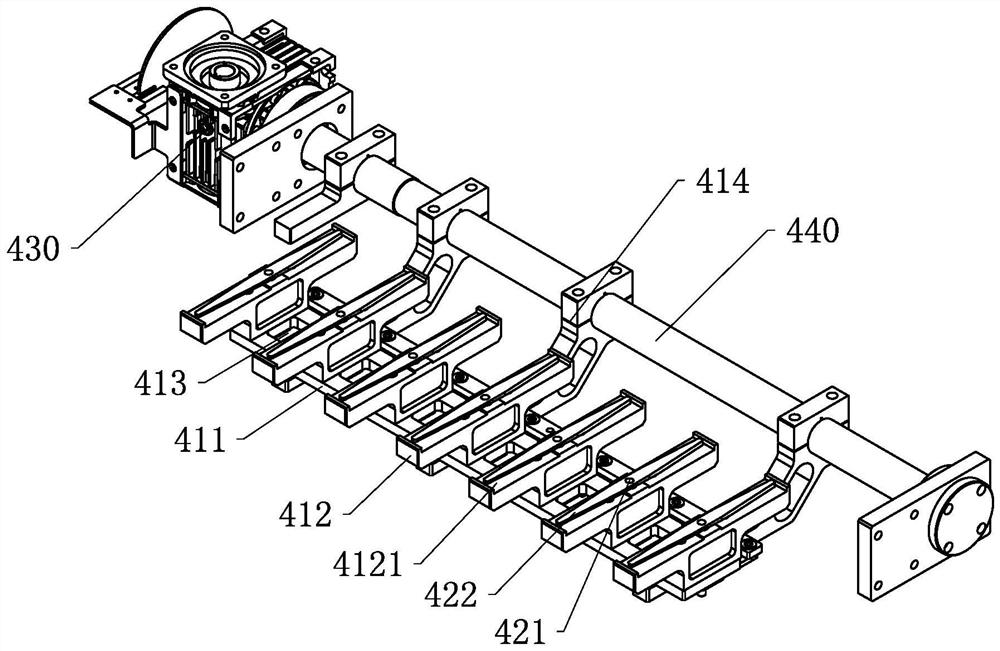

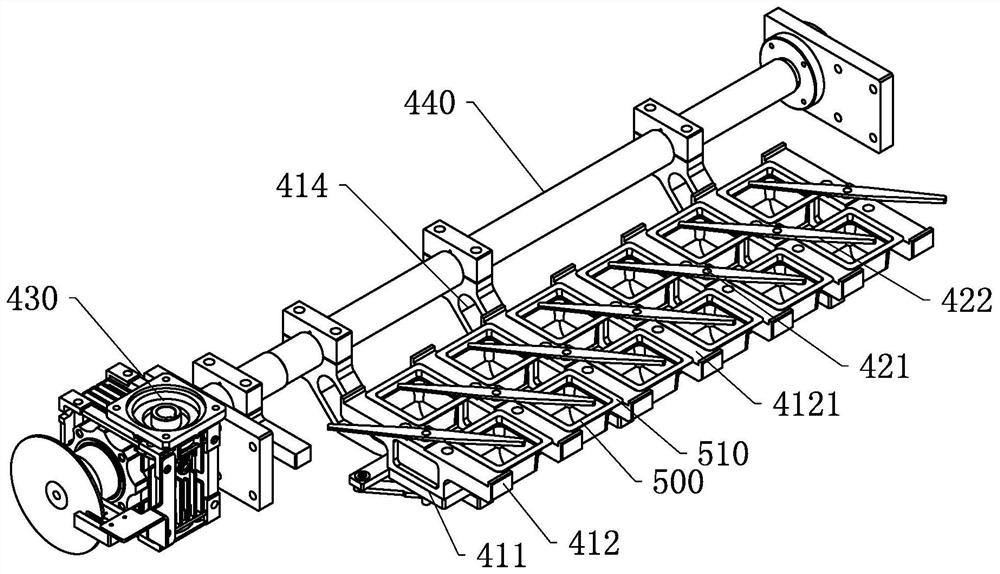

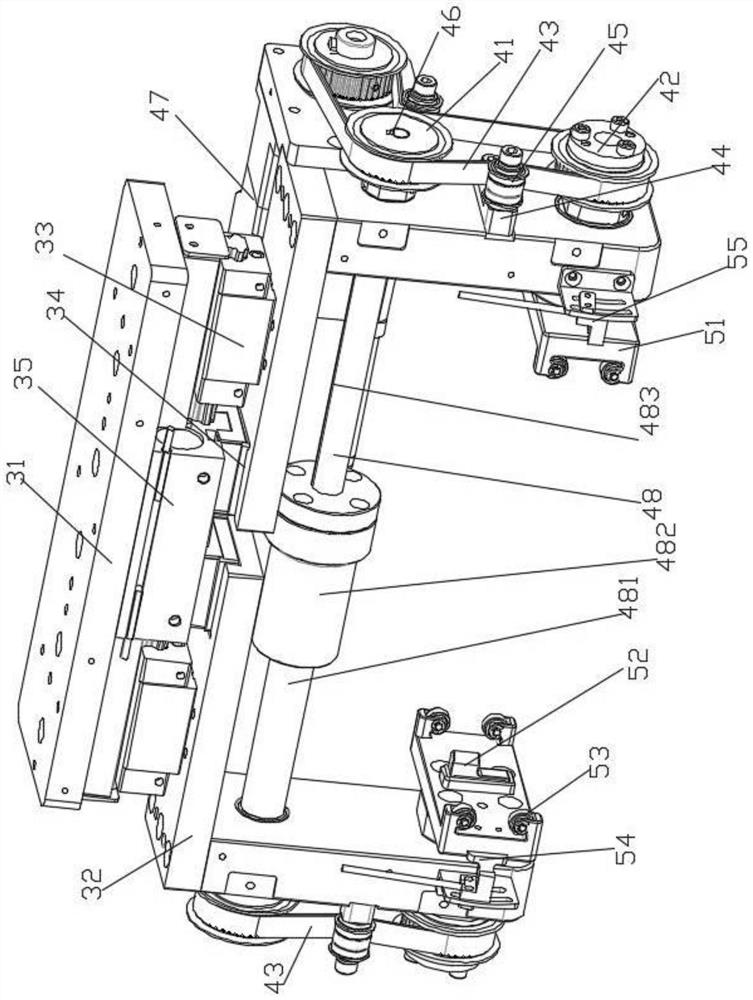

Double-arm clamping and overturning device

PendingCN111805476ARealize fully automatic flipStable and reliable turningWork holdersWork benchesClassical mechanicsManipulator

The invention provides a double-arm clamping and overturning device. The double-arm clamping and overturning device comprises two manipulators and a truss, the two manipulators are arranged on the truss, and the two manipulators are connected with the truss in a sliding mode; each manipulator comprises a cable drag chain, a lifting mechanism, a rotating mechanism and a grabbing mechanism, whereinthe cable drag chain is arranged at the top end of the manipulator, the lifting mechanism is arranged on the manipulator and moves in the Z-axis direction, the rotating mechanism is arranged on the lifting mechanism, the grabbing mechanism is arranged on the rotating mechanism, and the grabbing mechanism rotates through the rotating mechanism; and the two manipulators are oppositely arranged sideby side, and the grabbing mechanisms of the two manipulators are oppositely arranged. The double-arm clamping and overturning device achieves full-automatic overturning, synchronous translation and synchronous lifting of frame type beam frames of multiple varieties and sizes, the overturning process is stable and reliable, the labor intensity of assembling workers in the assembling process of frame type beam frame products is reduced, and the safety and the assembling efficiency in the overturning process are improved.

Owner:XIAN AEROSPACE AUTOMATION

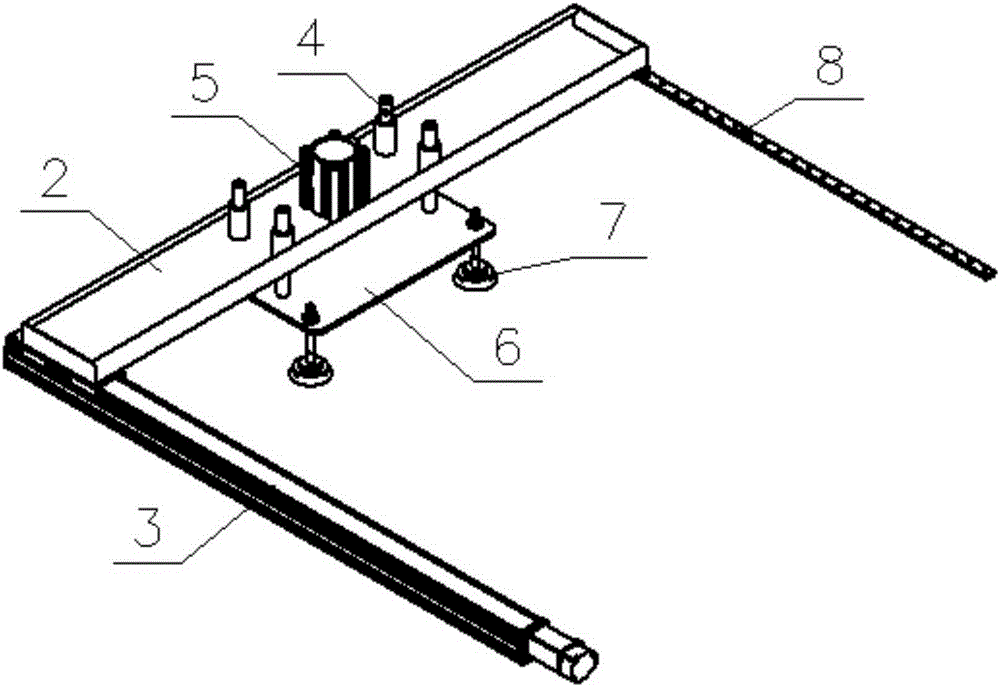

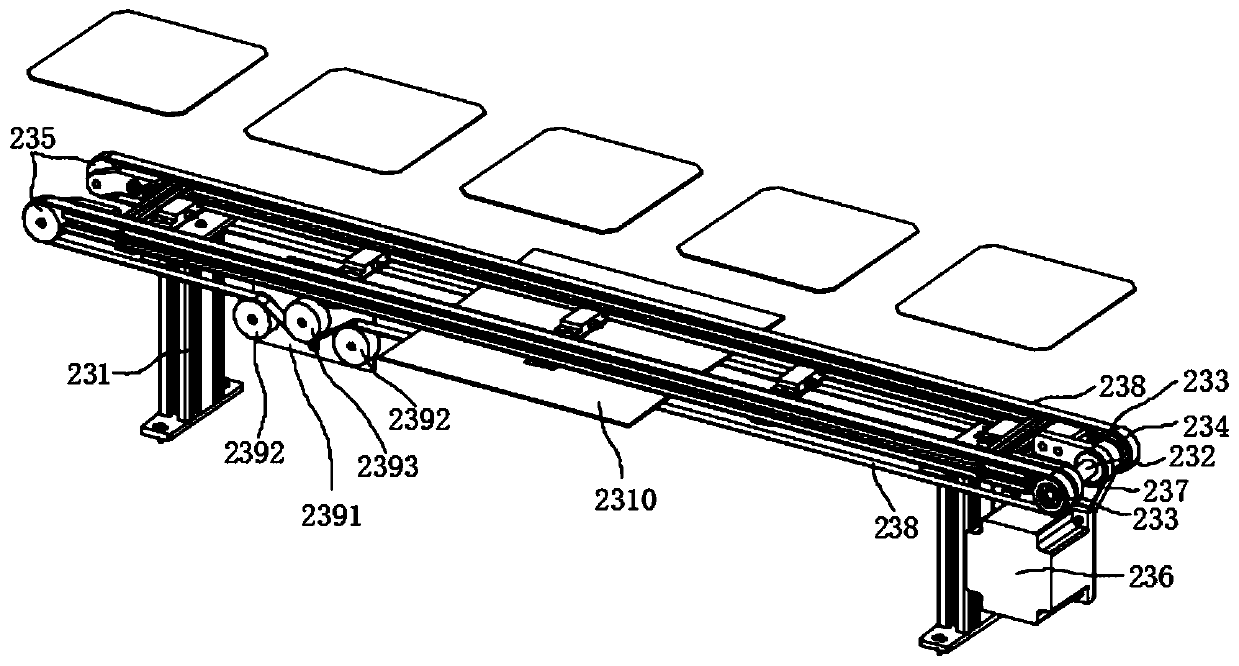

Solar battery assembly turning device

ActiveCN102891205AAvoid the "cracking" problemReduce the possibility of damageFinal product manufactureSemiconductor devicesStructural engineeringSolar battery

The invention discloses a solar battery assembly turning device, belonging to the technical field of turning devices. The invention provides a solar battery assembly turning device of which an assembly is unlikely to be damaged and high in efficiency. The solar battery assembly turning device comprises a rotary bracket, wherein supporting rotary shafts are arranged at two ends of the rotary bracket; the turning device is structurally characterized in that the supporting rotary shafts are connected with a main bracket below the supporting rotary shafts through a bearing base; the supporting rotary shafts are connected with a rotary cylinder; a pipeline frame and a vertically arranged conveyer belt group are arranged on the rotary bracket; the conveyer belt group is composed of an upper conveyer belt and a lower conveyer belt; clamping suckers which correspond to each other are arranged on the upper conveyer belt and the lower conveyer belt; the clamping suckers are connected with sucker cylinders; the conveying direction of the conveyer belt group is perpendicular to the plane of the pipeline frame; and the conveyer belt group penetrates through the pipeline frame.

Owner:YINGKOU JINCHEN MACHINERY

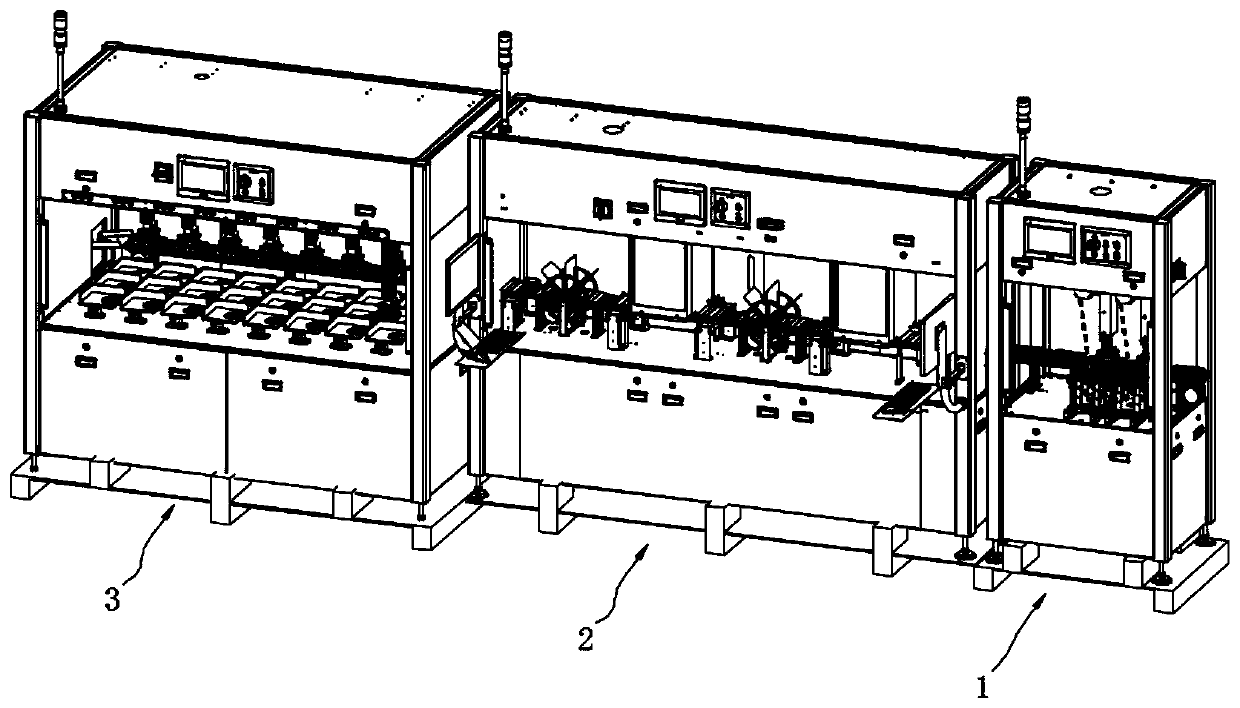

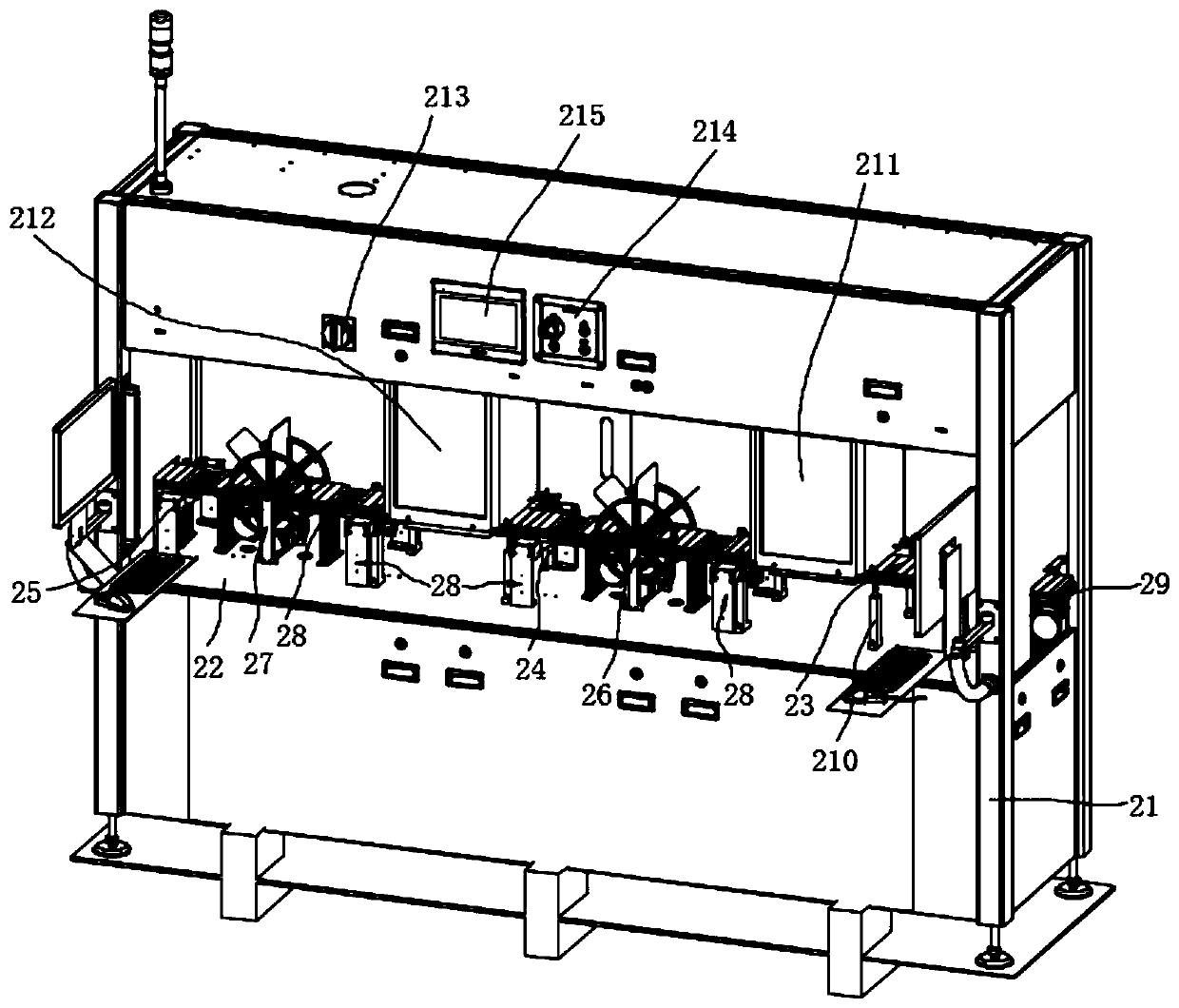

AOI detection equipment and detection method

PendingCN110211892APrecise and direct driveSmooth motionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringAutomation

The invention provides AOI detection equipment and a detection method. The detection equipment comprises a feeding machine, a detection machine and a sorting machine, wherein the detection machine comprises a feeding side and a discharging side, the feeding machine is arranged on the feeding side of the detection machine, the sorting machine is arranged on the discharging side of the detection machine, and the detection machine comprises a detection conveying device, a first overturning device and a second overturning device; the rack of the detection machine is also provided with a first AOIdetection device and a second AOI detection device; and the feeding machine is used for continuously feeding the detection machine, cell slices are overturned twice on the detection machine and are subjected to front and back detection, the transportation and overturning of the cell slices are stable and reliable, and the detection accuracy of the AOI detection device can be effectively ensured. According to the detection machine of the structure, when being detected, the cell slices are on the detection conveying device all the time, and the position of the cell slices is stable, the risk offalling due to the reverse suction does not exist, the accuracy of detection can be effectively guaranteed, and the automation of material loading, detection and sorting can be realized, and the efficiency of detection is high.

Owner:广州蓝海智能装备有限公司

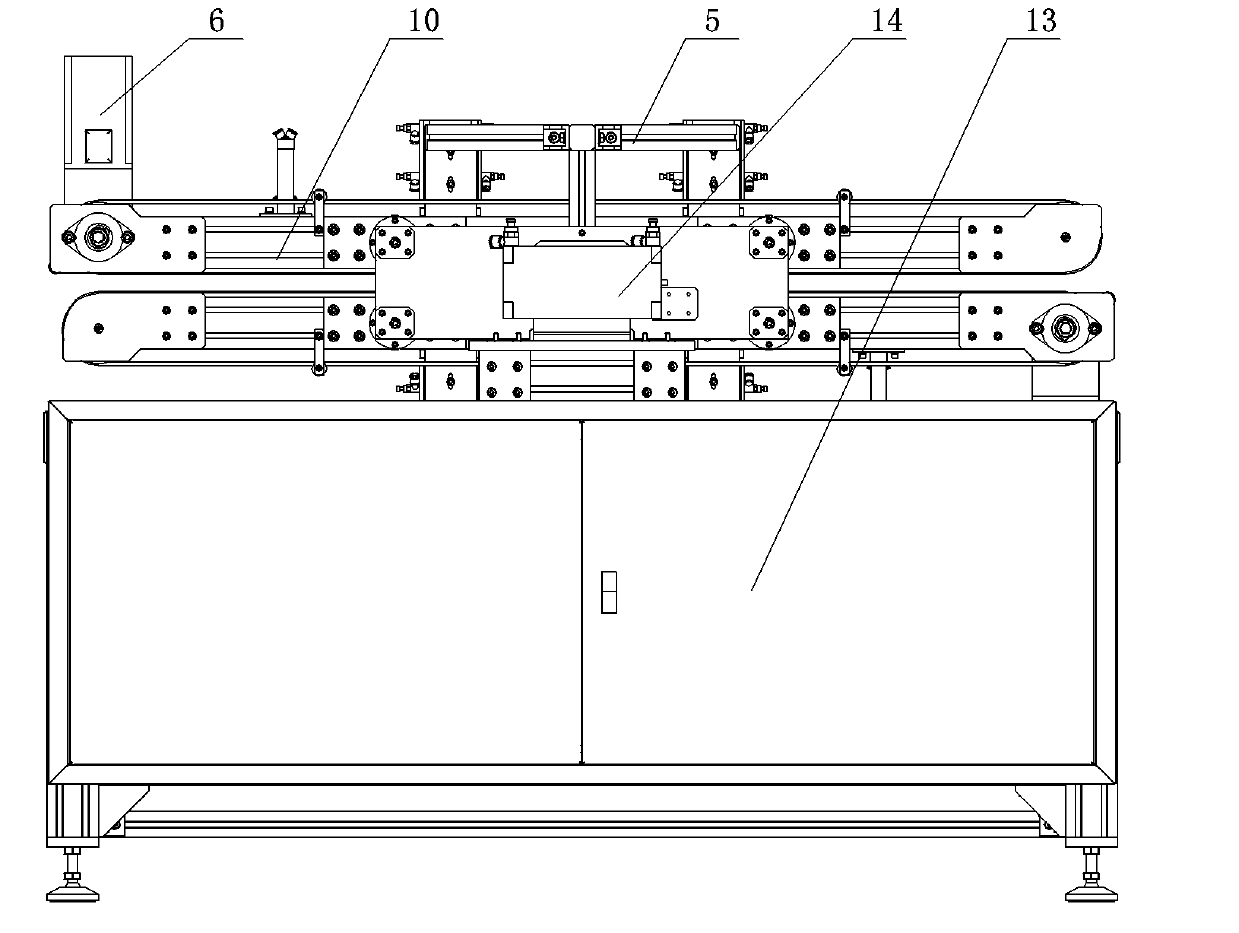

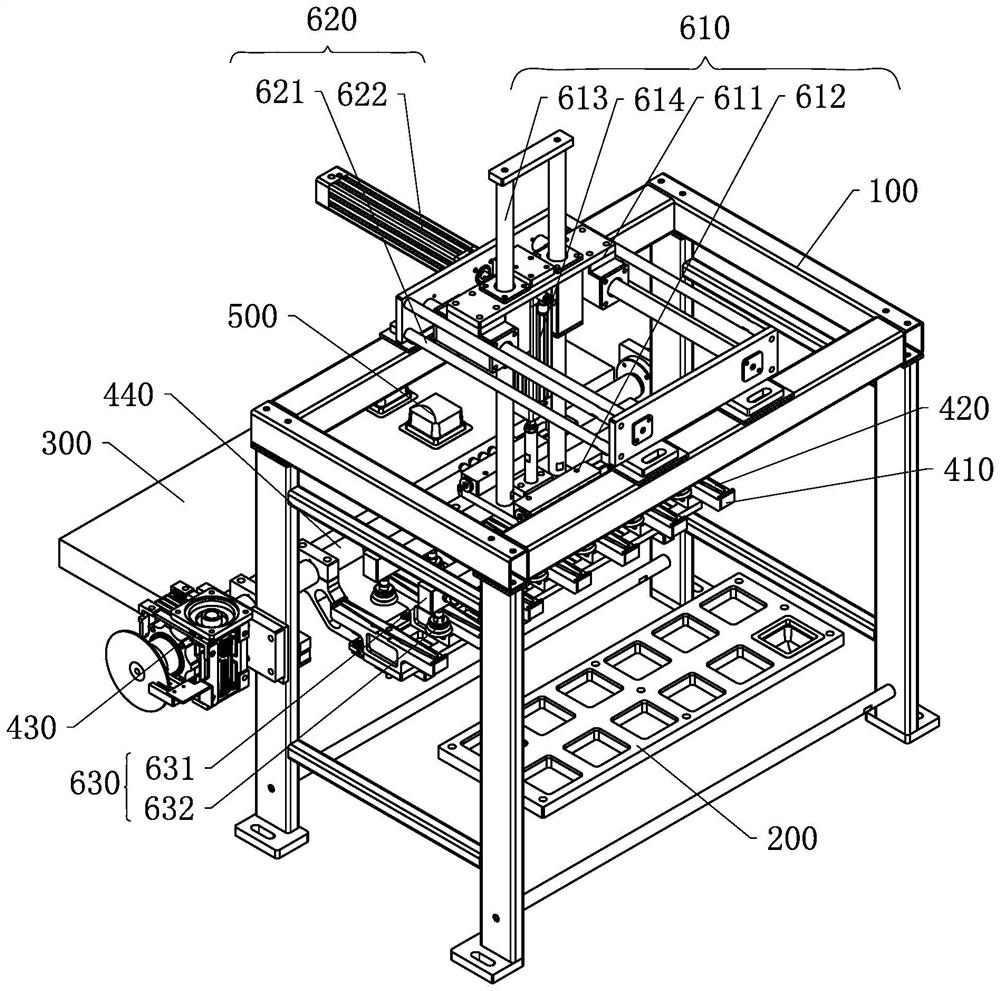

Window frame splicing table

PendingCN112010028AEasy to moveEasy to installConveyor partsStructural engineeringMechanical engineering

The invention discloses a window frame splicing table. The window frame splicing table comprises a base and a table surface hinged to the base. A turnover mechanism is arranged between the table surface and the base to turn over the table surface, the turnover mechanism can turn over the table surface between a horizontal feeding state and an inclined blanking state, a raceway is also arranged onthe base, when the table surface is in a blanking state, the lower edge of the table surface is close to the raceway, an adsorption table is arranged on the table surface, the adsorption table can ascend, descend, slide and rotate relative to the table surface and can adsorb glass. The surface of the adsorption table is higher than the table surface when ascending, and is flush with the table surface when descending. The table surface is further provided with a pressing assembly, the pressing assembly is slidably connected with the table surface and provided with a locking mechanism, the pressing assembly comprises a lifting air cylinder and a pressing plate connected to the lifting air cylinder, the pressing plate is higher than glass adsorbed when the adsorption table descends when the lifting air cylinder ascends, and the pressing plate is not higher than the table surface when the lifting air cylinder descends. The window frame splicing table can assist workers in easily completingassembling of large-size and large-weight finished window frames.

Owner:TAICANG WEGOMA MACHINERY

Cup overturning device

PendingCN114524144AImprove cup turning efficiencySimple structureFinal product manufacturePackagingStructural engineeringMechanical engineering

The invention discloses a cup overturning device which comprises an input conveying assembly, a carrying assembly, an overturning assembly and an output conveying assembly, the carrying assembly is located above the input conveying assembly and the overturning assembly, a suction cup assembly is arranged at the bottom of the carrying assembly, and the carrying assembly moves a packaging piece on the input conveying assembly to the overturning assembly through the suction cup assembly; the input conveying assembly and the output conveying assembly are located on the two sides of the overturning assembly correspondingly, and the overturning assembly rotates to drive packaging pieces on the overturning assembly to be overturned to the output conveying assembly. According to the cup overturning device, the packaging pieces are driven to overturn and move to the output conveying assembly through the overturning assembly, the multiple rows of packaging pieces on the input conveying assembly can be moved to the overturning assembly at the same time through the carrying assembly, the multiple rows of packaging pieces can be overturned at the same time through one-time overturning of the overturning assembly, the packaging pieces do not need to be moved and overturned row by row, and the cup overturning efficiency is improved.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Bearing blank automatic turnover mechanism

InactiveCN107416482AStable and reliable turningImprove continuityConveyor partsEngineeringMachining process

The invention provides a bearing blank automatic turnover mechanism. A turnover push plate and a turnover collection plate are arranged on a base. The turnover push plate and the turnover collection plate are staggered at the intersection. The lower end of the turnover push plate and the lower end of the turnover collection plate are each connected with a turnover air cylinder. A bearing blank inlet is formed in one end of the turnover push plate, and a buffer limiting plate is arranged at the other end of the turnover push plate. The back face of the buffer limiting plate is connected with a buffer. A pushing air cylinder is further arranged on the base. Guide rods are mounted on the two sides of the pushing air cylinder. Hydraulic buffers are mounted on connecting plates at the tail ends of the guide rods. The bearing blank automatic turnover mechanism has the beneficial effects that stable and reliable turnover of a bearing blank is achieved; impacting and bumping are avoided; the continuity and the automation degree in the bearing machining process are improved; and reliability and durability are achieved.

Owner:大连美嘉洛机器人科技有限公司

A welding system for large wall thickness steel plates

ActiveCN104476091BEasy dockingEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderButt welding

The invention discloses a welding system for large-scale thick steel plates, comprising a gantry type welding mechanism and a steel plate support structure, characterized in that: the steel plate support structure is arranged between two rails (1) of the gantry type welding mechanism, and the steel plate The support structure is composed of multiple sets of rollers (4), and is equipped with a lifting mechanism (5), which is installed on the lifting hydraulic cylinder (53); one side of the gantry type welding mechanism is equipped with a flip bracket (6 ), the overturning bracket (6) is hinged on the support (16), the back of the overturning bracket (6) is connected to the rotating hydraulic cylinder (18), the bottom is equipped with a wire plate (12), the top is equipped with a fixed pulley (15), and the steel wire Disc (12) is connected with motor (11). The device can be used to complete the processes of butt jointing, welding and turning over in the thick steel plate welding process. The welding and turning process is stable and reliable, which is convenient for workers to operate and improves the production efficiency.

Owner:GUIZHOU HUITONG SHENFA STEEL STRUCTURE

Carrier overturning and clamping mechanism

PendingCN114873209AReduce labor intensityRealize fully automatic clamping and flippingTotal factory controlConveyor partsEngineeringFully automated

The invention relates to the technical field of automation, in particular to a carrier overturning and clamping mechanism. After the driving component drives the material taking gripper to clamp products, the driver drives the rotating component to drive the products on the material taking gripper to rotate, full-automatic clamping and overturning of various and multi-size carrier products can be achieved, the overturning process is stable and reliable, the labor intensity of assembly workers in the assembly process of the carrier products is reduced, and the production efficiency is improved. The safety and the assembly efficiency in the overturning process are improved, the structure is compact, the occupied space is small, and the stability is good.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

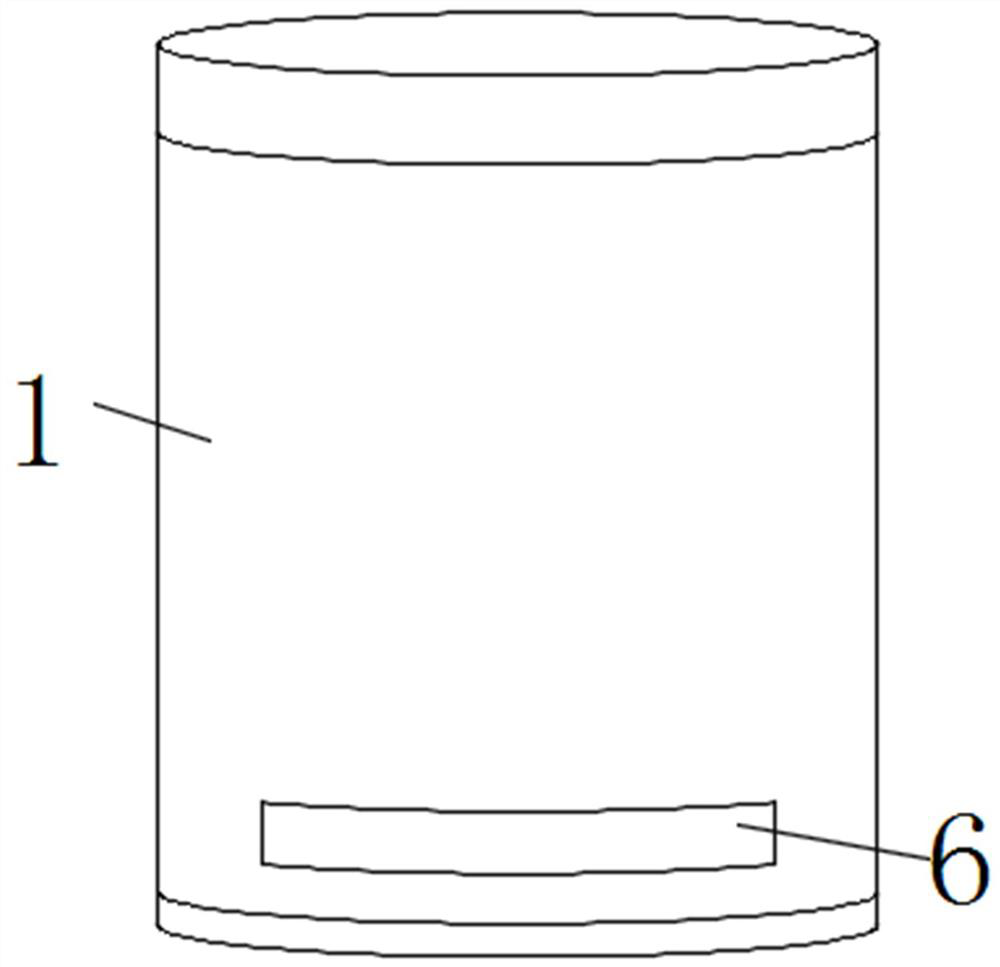

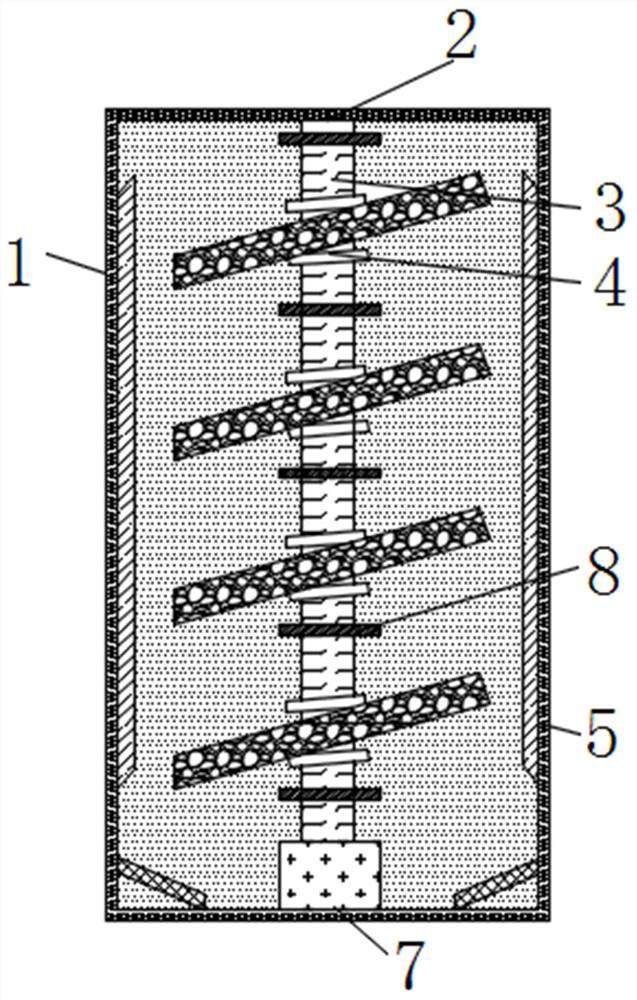

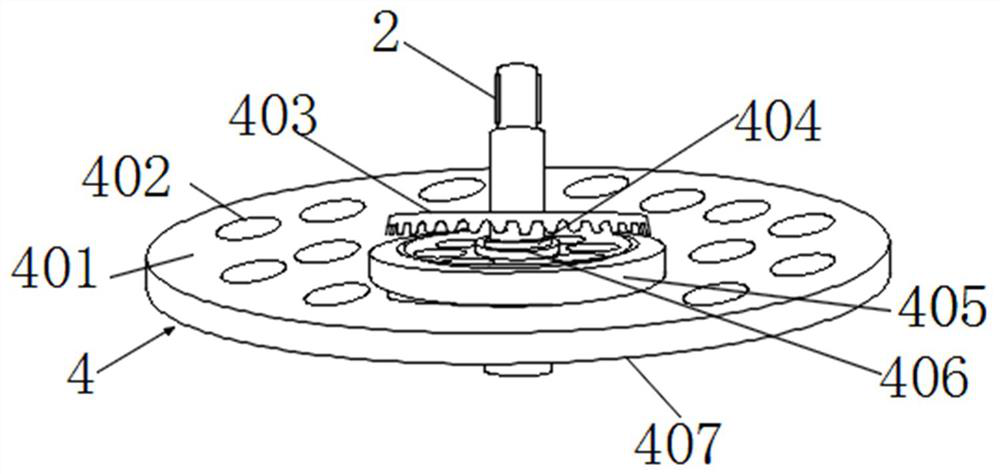

Method for controlling embryo egg hatching speed

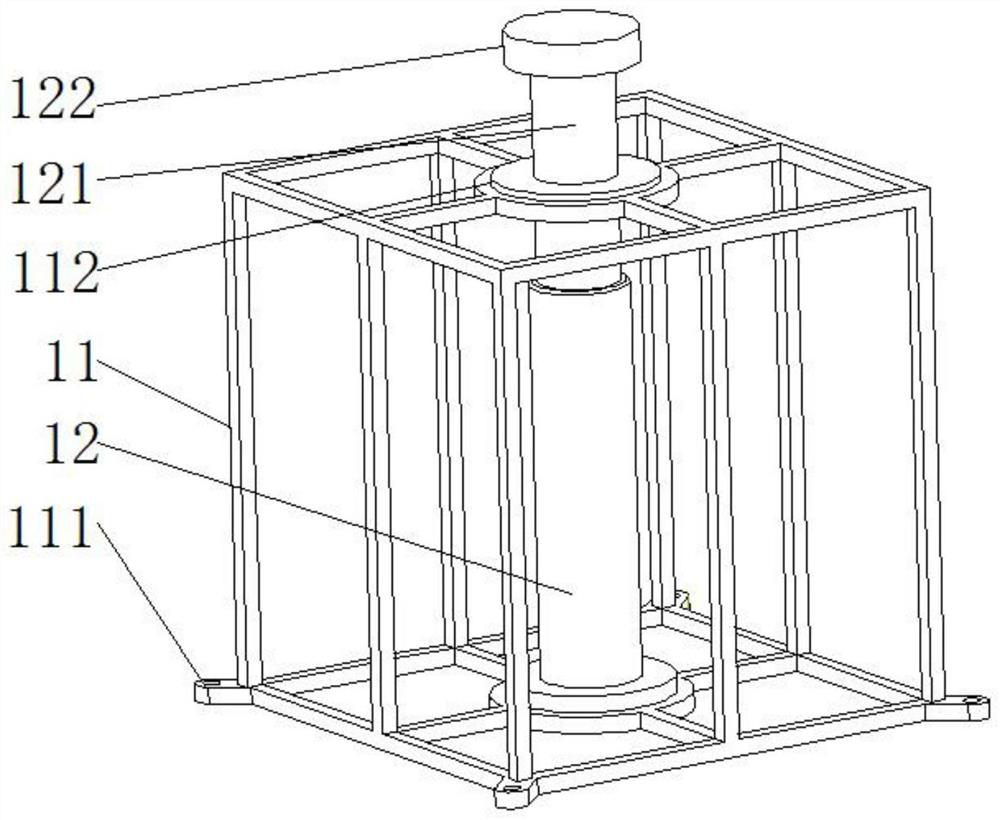

ActiveCN112450128AEvenly heatedGuaranteed hatch rateClimate change adaptationPoultry incubationAnimal scienceElectric machinery

The invention discloses a method for controlling the embryo egg hatching speed. The method involves a box body, wherein a motor is arranged at the bottom end in the box body, a rotating main shaft isarranged at the upper end of the motor, a plurality of uniformly arranged overturning structures are arranged on the rotating main shaft, an oblique caliber is arranged at the upper end of the rotating main shaft, the outer portion of the oblique caliber is connected with an engaging caliber of a center connecting disc arranged on one side, and the rotating main shaft drives the center connectingdisc engaged with the oblique caliber to rotate and enables the center connecting disc to be obliquely arranged. According to the method for controlling the embryo egg hatching speed, the egg overturning function of a small hatching structure can be achieved for the plurality of overturning structures inside, the situation that the working efficiency of manual egg overturning is low is avoided, the hatching rate and hatching speed of fertilized eggs can be guaranteed, a safe and healthy hatching environment is provided for embryo eggs, a proper hatching temperature is provided for embryo eggs,embryo development of the embryo eggs is facilitated, egg overturning time is convenient to adjust, and the overall hatching rate is increased.

Owner:安徽标王农牧股份有限公司

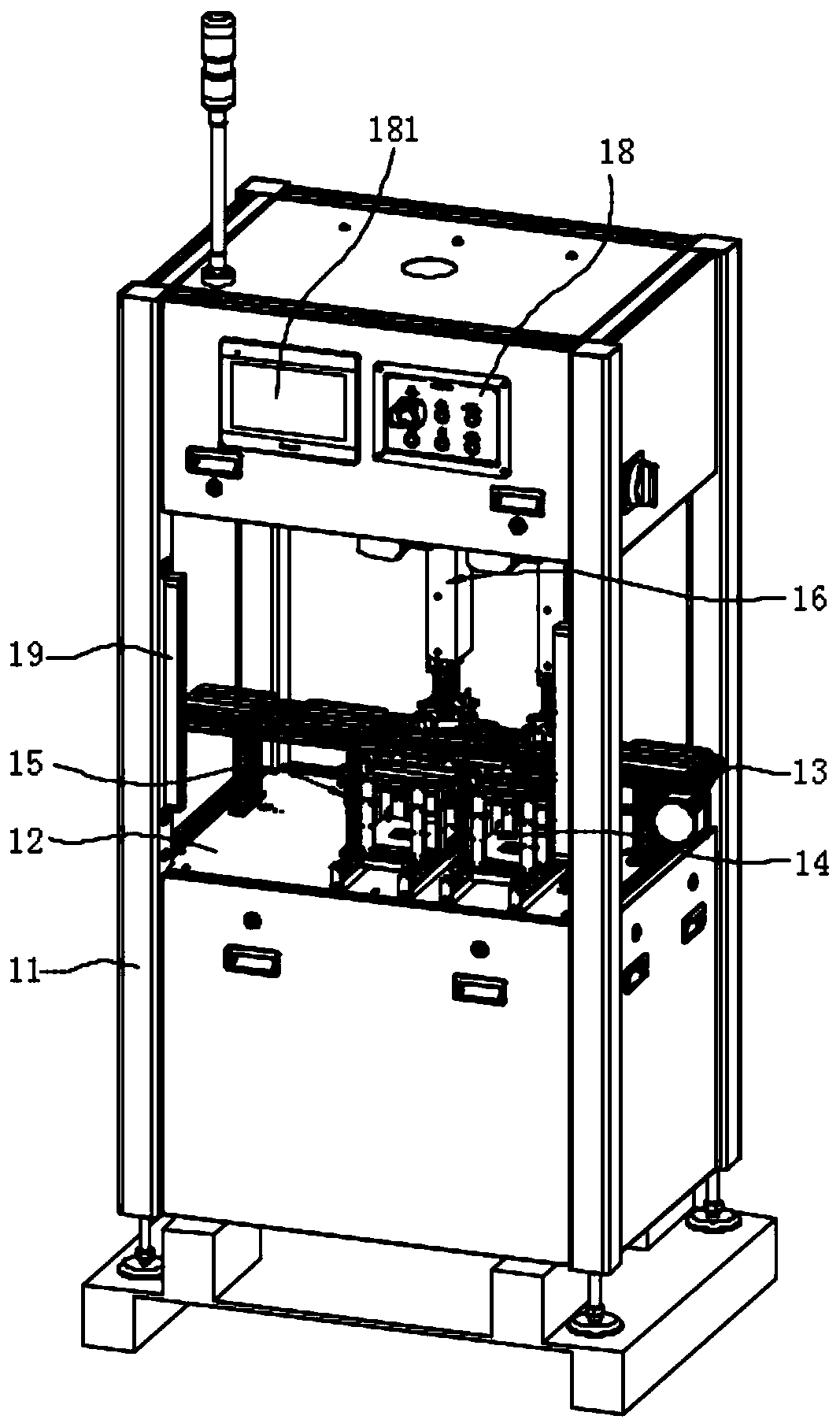

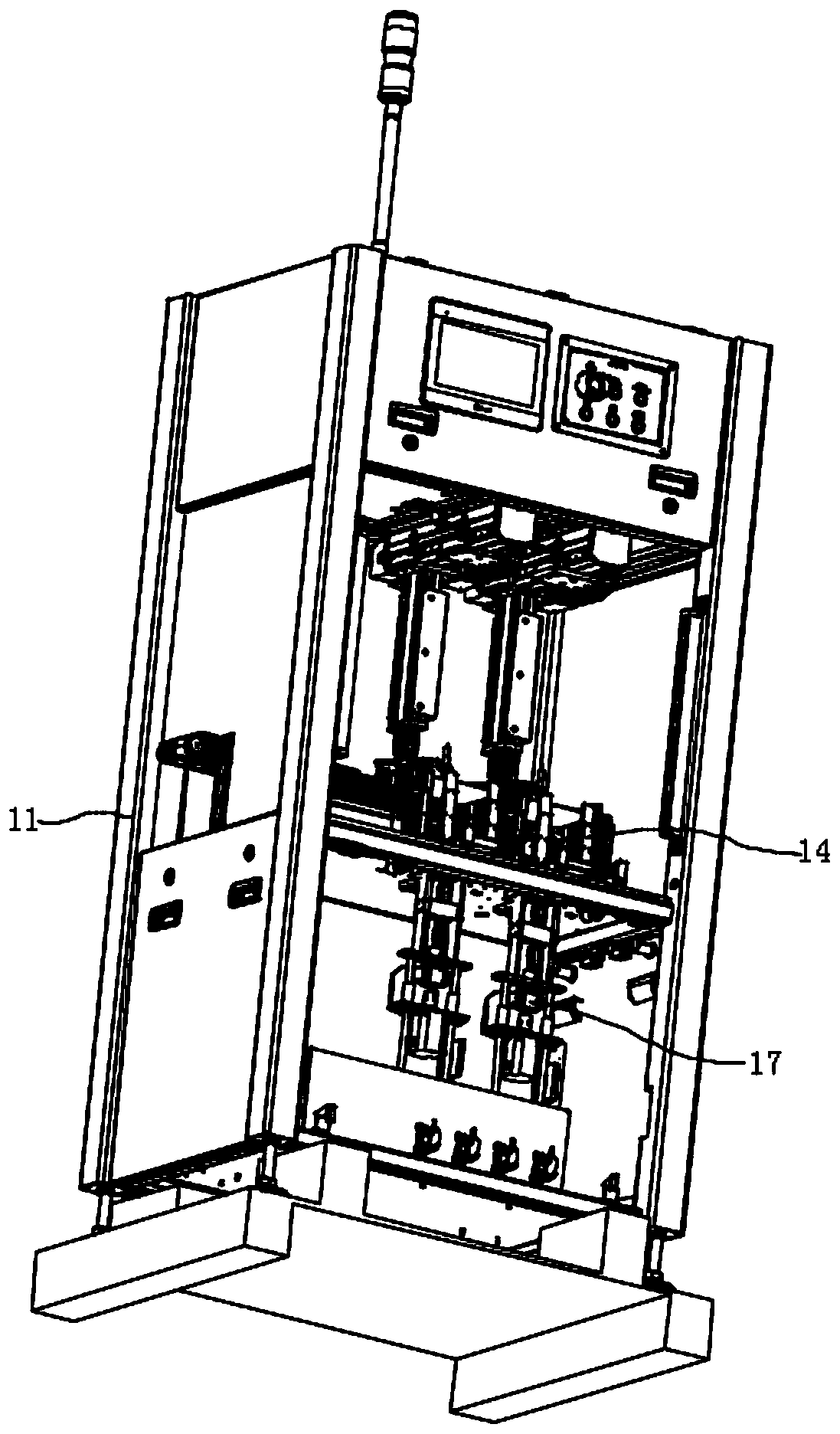

AOI detection machine and detection method

PendingCN110211891AStable and reliable deliveryStable and reliable turningSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringAutomation

The invention provides an AOI detection machine and a detection method. The detection machine comprises a detection conveyer, a first turnover device and a second turnover device; a first AOI detection device and a second AOI detection device are also arranged on a detection rack; a battery piece is turned over twice on the detection machine and is subjected to front and back detection, transportation and turnover of the battery piece are stable and reliable, and detection accuracy of an AOI detection device can be effectively guaranteed. The detection machine of the structure has the advantages that the battery piece is always located on the detection conveyer during detection, a position of the battery piece is stable, a suck-back fall risk can not exist, the detection accuracy can be effectively guaranteed, automation can be realized, and detection efficiency is high.

Owner:广州蓝海智能装备有限公司

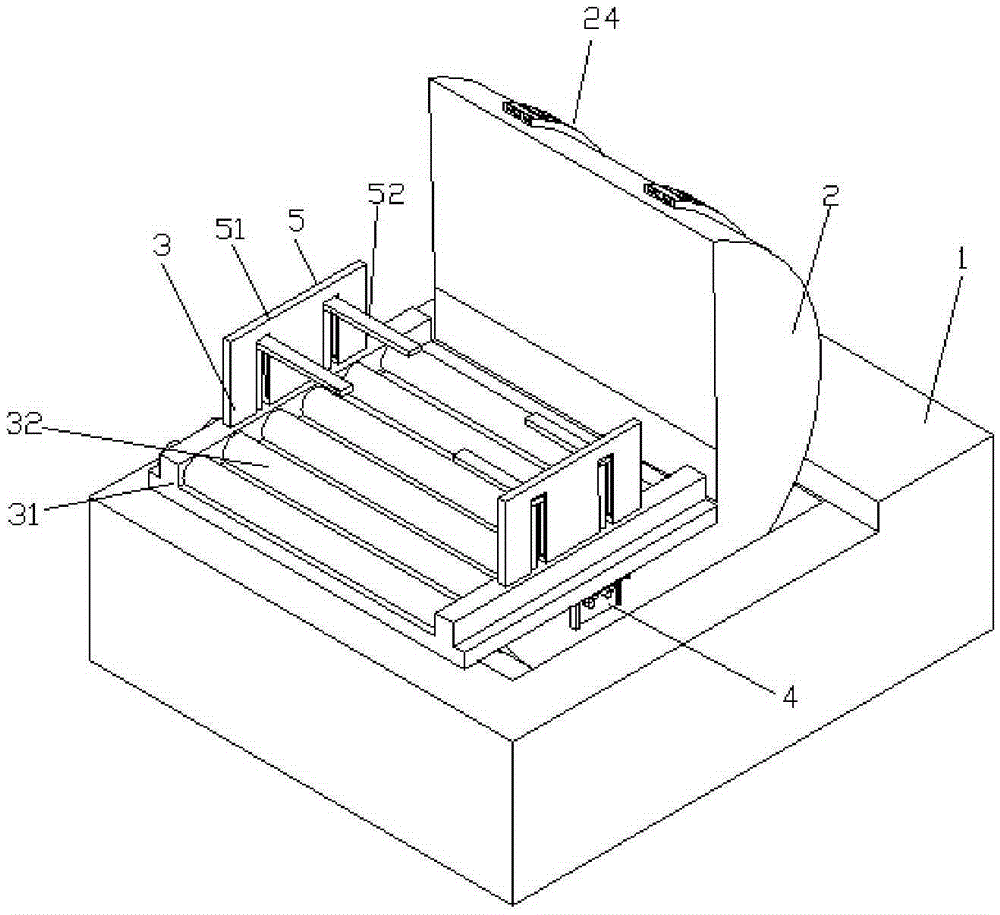

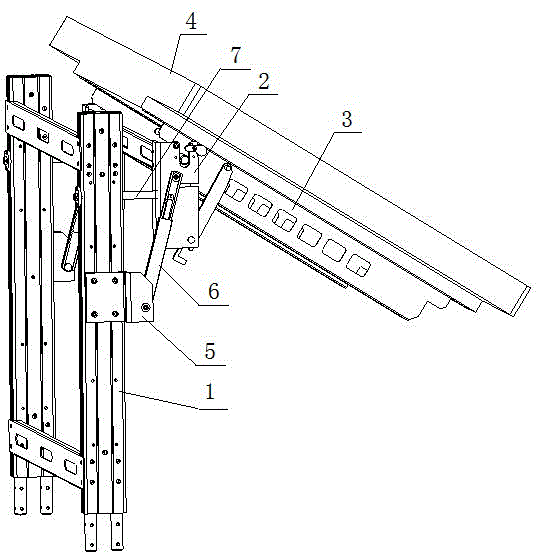

Depth-adjustable glass loading mechanism

InactiveCN103641298BSolve the problem of inconvenient crawlingShort transit pathGlass transportation apparatusVertical planeEngineering

The invention discloses a glass mounting mechanism with an adjustable sounding depth. The glass mounting mechanism is characterized by comprising a stand, a sounding depth adjustment device, a glass sucking and turning device and a glass bearing and transporting table, wherein the glass sucking and turning device and the glass bearing and transporting table are arranged at the two sides of the sounding depth adjustment device; the sounding depth adjustment device is arranged on the stand; the glass sucking and turning device is arranged at one end of the sounding depth adjustment device and can rotate in the vertical plane. The glass mounting mechanism has the beneficial effects that the glass vertically stacked on a material frame is sucked by a sucking disc of the glass sucking and turning device, and the glass is moved and turned to the glass bearing and transporting table; with the reduction of the glass on the material frame, the sounding depth adjustment device drives the glass sucking and turning device to move and the sounding depth is adjusted, so that the glass can be effectively sucked by the glass sucking and turning device; the whole process is automatically controlled by an operation system, and the mechanism is convenient to use and labour-saving.

Owner:ANHUI SCI & TECH UNIV

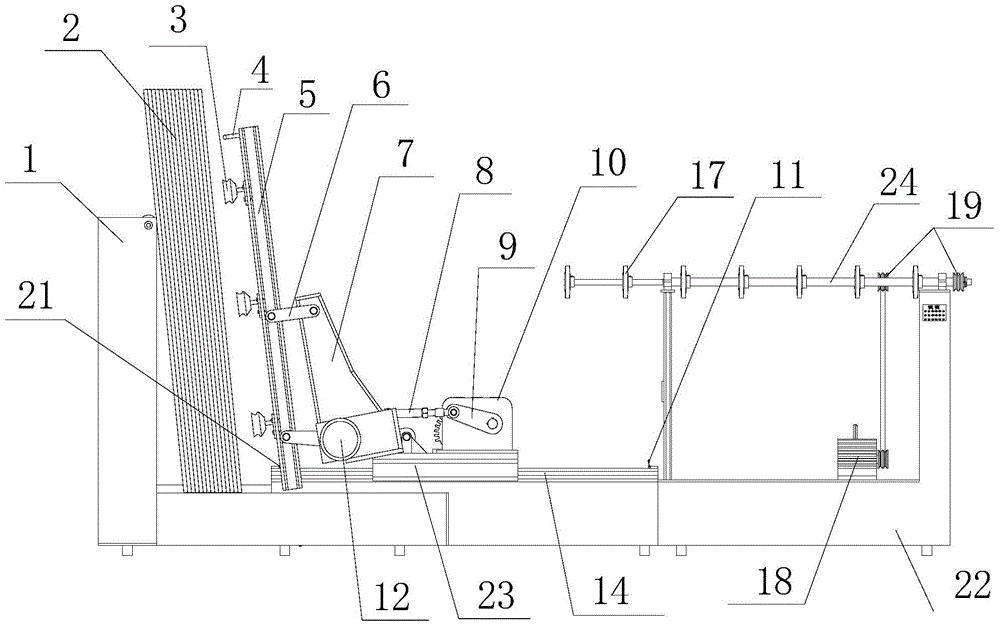

A device for moving, flipping, and leaning flat-panel TVs

ActiveCN105217285BQuality assuranceSimple structureConveyor partsAgricultural engineeringTransfer mechanism

The invention discloses a device for realizing the shifting, turning, and reclining of a flat-panel TV, which includes a frame, the frame is composed of a first rectangular frame and a second rectangular frame, and the second rectangular frame is installed on the first rectangular frame On the same side of the first rectangular frame, a horizontal tooling plate and a leaning tooling plate are sequentially arranged, the leaning tooling plate is located below the second rectangular frame, and an adsorption transfer mechanism is arranged above the horizontal tooling plate. The leaning tooling plate is provided with a turning mechanism and a leaning transfer mechanism sequentially from bottom to top, the leaning transfer mechanism is connected to the upper end of the second rectangular frame, and the surface of the first rectangular frame is provided with a transmission mechanism. Mechanism, the beneficial effects of the present invention are: the present invention can not only ensure the successful completion of the process of transferring, turning and leaning on the flat-panel TV, but also can replace manual work, satisfy multi-variety, flexible and easy-to-switch production methods, and at the same time improve efficiency, Improve product quality.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

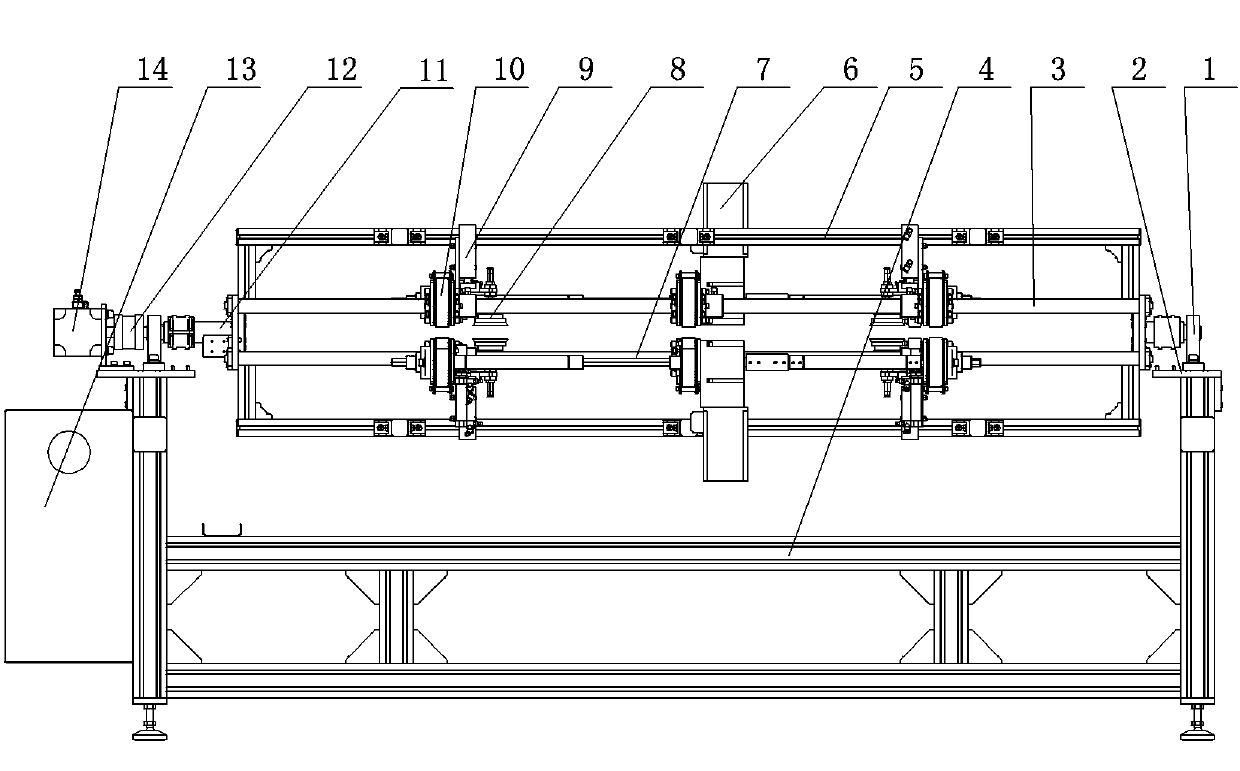

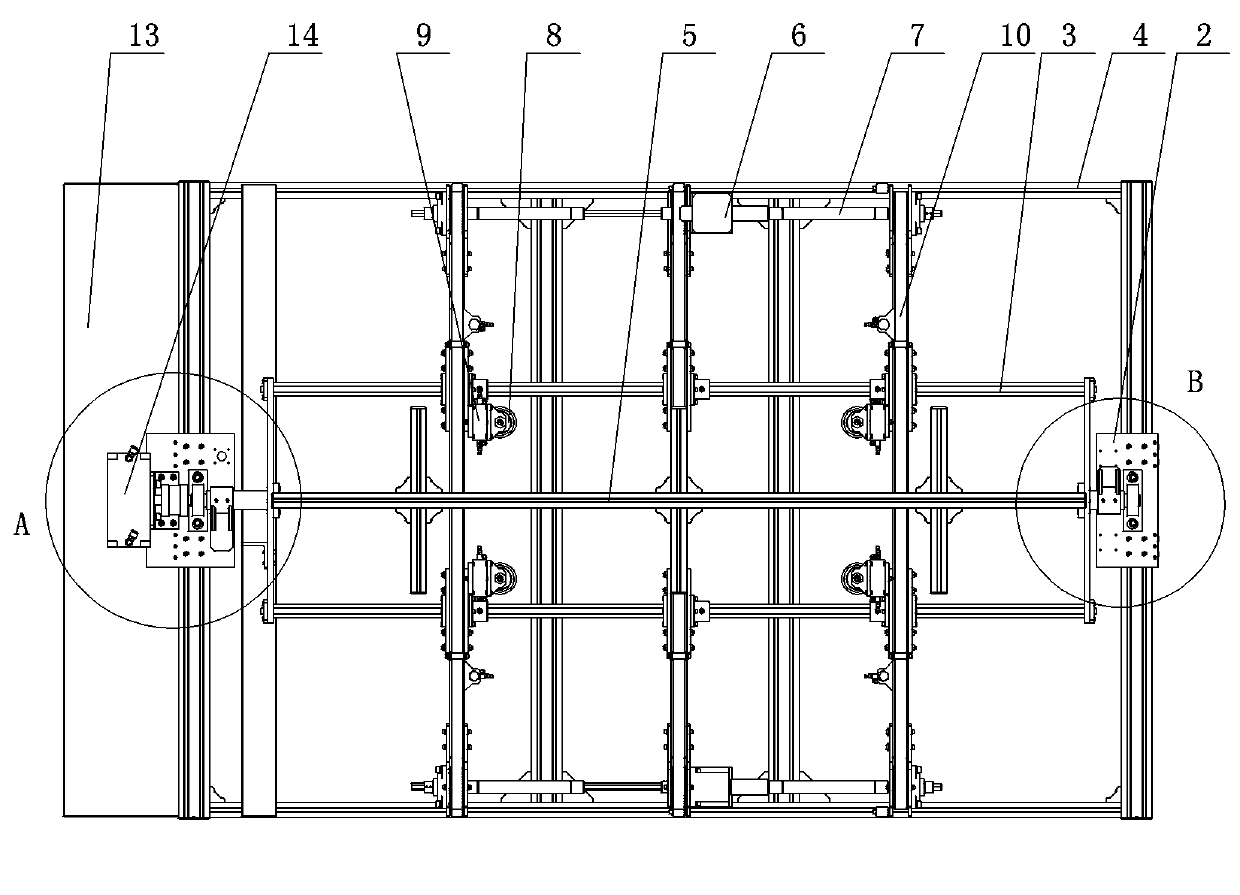

A method for overturning a welding fixture and the device used therefor

ActiveCN103862217BQuick flipStable and reliable turningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention provides an economical and practical welding jig overturning method. The welding jig overturning method includes the step of conducting staging control over the rotating speed of a jig main shaft for driving a jig to be overturned to achieve overturning of the welding jig, wherein the staging control over the rotating speed of the jig main shaft for driving the jig to be overturned is characterized in that a combination of a pneumatic system and a hydraulic system is adopted to achieve the staging control over the rotating speed of the jig main shaft for driving the jig to be overturned. By means of the welding jig overturning method, the using cost of robot automation welding can be effectively reduced, the welding quality can be improved, and the welding jig overturning method is of great significance on popularizing robot automation welding. The invention further provides a welding jig overturning device, and the welding jig overturning device comprises a connecting mechanism and a driving mechanism for driving the connecting mechanism to further drive the jig to be overturned; the driving mechanism is composed of the hydraulic system and the pneumatic system in a connected mode. By means of the welding jig overturning device, the jig overturning accuracy is improved; meanwhile, the welding jig overturning device has the advantages of being simple in structure, convenient to operate and the like; the welding effectiveness and the welding accuracy of the jig can be guaranteed.

Owner:广东泰格威机器人科技有限公司

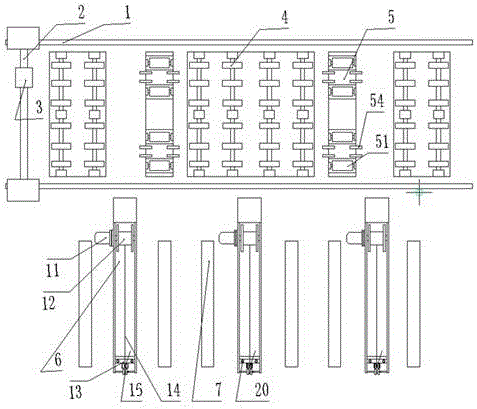

Automatic circuit board flipping device

ActiveCN108689123BStable and reliable turningThree-dimensional flipping processConveyor partsVisual inspectionProcess engineering

Owner:SHANGHAI SUNTECH ELECTRONICS

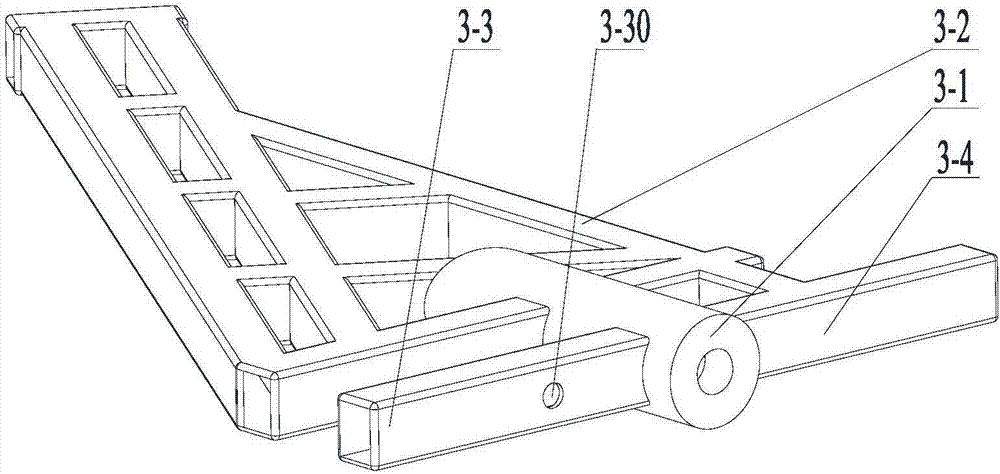

Singularity-free hydraulic bidirectional reversible plow with two oil cylinders

ActiveCN107318276AReduce singularityHigh dexterityPloughsAgriculture gas emission reductionHydraulic cylinderSingularity free

The invention relates to a singularity-free hydraulic bidirectional reversible plow with two oil cylinders. The singularity-free hydraulic bidirectional reversible plow with the two oil cylinders comprises a suspension frame, the two hydraulic oil cylinders, a rotary plow frame, a depth limiting wheel and two plow bodies which are arrayed at an angle of 180 degrees, wherein the rotary plow frame is mounted on the suspension frame; the hydraulic oil cylinders are arranged between the rotary plow frame and the suspension frame; the suspension frame comprises a lower suspension beam and an upper suspension beam; a rotating shaft is arranged at the position of a middle point of the lower suspension beam; two hydraulic oil cylinder mounting seats which are not on the same horizontal plane are symmetrically arranged on the upper suspension frame; the rotary plow frame comprises a rotary shaft sleeve and a rotating shaft; two sides of the rotary shaft sleeve are horizontally welded to an overturning beam and a balancing beam; a coordinated driving assembly is mounted in a mounting hole of the overturning beam; the rotary plow frame and the coordinated driving assembly have the same angular displacement movement rule; the coordinated driving assembly comprises a central shaft and two driving arms; the two driving arms are arrayed at an angle of 180 degrees; and the two hydraulic oil cylinders are separately connected with the hydraulic oil cylinder mounting seats and the two driving arms of the coordinated driving assembly. The problem that singularity exists in an overturning process of the traditional reversible plow is solved fundamentally.

Owner:TIANJIN POLYTECHNIC UNIV

Frame type circuit board turning machine

The invention relates to the technical field of circuit board production equipment, in particular to a frame-type circuit board turning machine that realizes circuit board turning through a turning frame. bracket, and a feeding conveyor frame and an output conveyor frame for transporting circuit boards. The beneficial effect is that the flipping of the circuit board is realized by using the flipping frame provided with the placing bar, so that the flipping process of the circuit board is more stable and reliable, and at the same time, the combined use of the visual detector enables the circuit board to be further detected during the flipping process. The use of the placement bar increases the reliability of the circuit board during the flipping process and prevents the circuit board from slipping; by using the gear transmission of the driving gear and the driven gear, the flipping process of the circuit board is made more stable, and the circuit board is further realized. Automation and intelligence of the flipping process.

Owner:SHANGHAI SUNTECH ELECTRONICS

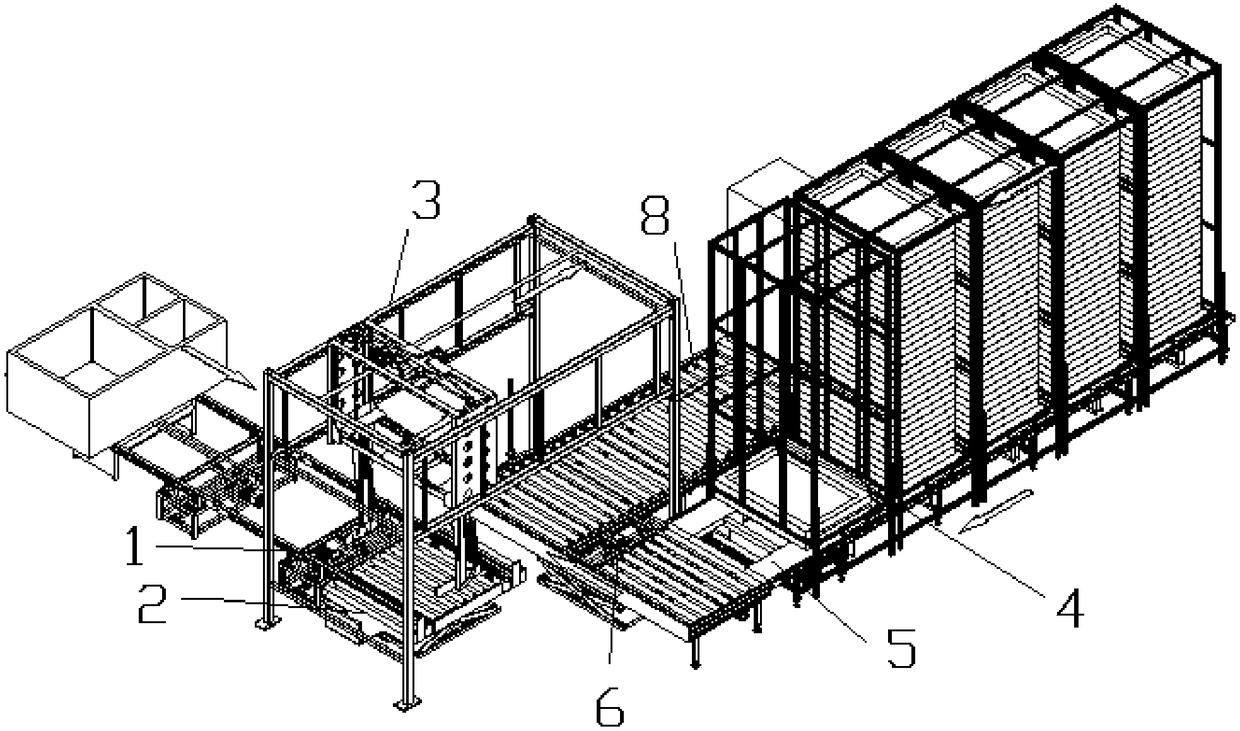

A refrigerator vertical box transfer machine

ActiveCN106743232BQuality assuranceSimple structureConveyor partsMechanical conveyorsEngineeringRefrigeration

The invention relates to a refrigerator erection transfer machine for turning up and erecting a foamed refrigerator body in refrigerator production. Firstly, a lying refrigerator is sucked and grasped by suckers on clamping arms on two sides of the refrigeration erection transfer machine; the refrigerator is lifted to a certain height by using a lifting trolley, and is turned over to be in an upright state of 90 degrees by using the clamping arms; the refrigerator is transferred to an appointed position and placed by using a horizontal moving trolley, so that turning-up erection operation on the refrigerator from a lying state to an upright state can be completed. The refrigerator erection transfer machine mainly consists of a rack, a horizontal moving trolley, a lifting trolley, a clamping centering mechanism and a clamping turning mechanism. The refrigerator erection transfer machine is not only simple in structure, low in cost, small in floor space and capable of meeting multi-model mixed line and flexibility production, but also capable of ensuring product quality and reducing potential production safety hazard, and meanwhile the efficiency and the product quality can be improved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

A device for turning upright and automatically putting on the base of a refrigerator

The invention relates to a refrigerator overturning-to-standing and automatic base assembling device. The device is used for standing a refrigerator body after refrigerator body foaming and automatically assembling a base in refrigerator production. Firstly, the lying refrigerator body is horizontally moved to a refrigerator standing transferring machine through a refrigerator body conveying section to be positioned; then, the refrigerator body is overturned by 90 degrees into a standing state through the refrigerator standing transferring machine; meanwhile, the corresponding base is positioned onto a conveying line of the standing refrigerator body; finally, the standing refrigerator body is transferred onto the base, and thus the overturning-to-standing work of changing the lying state of the refrigerator body into the standing state is completed. The device is mainly composed of the refrigerator body conveying section, a refrigerator body positioning mechanism, the refrigerator standing transferring machine, a base storage device, a base conveying line, a base moving device, a base positioning device and the standing refrigerator conveying line. The device is simple in structure and low in cost, can smoothly complete the process of transferring, overturning and base assembling of a refrigerator, also can replace manual work and meet multi-type flexible production modes easy to switch, and improves efficiency and product quality at the same time.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

An automatic face changing device

An automatic face-changing device relates to an automatic face-changing device for products such as solar battery modules or flat glass. The invention provides an automatic noodle changing device with simple structure, safety and reliability, which combines the functions of transmission and flipping into one, and greatly improves the process beat. The invention includes a frame, which is characterized in that: the two ends of the frame are respectively hingedly provided with a first conveyor belt and a second conveyor belt, a first inclined cylinder is arranged between the first conveyor belt and the frame, and the second conveyor belt and the frame A second tilting cylinder is arranged between the frames; a connecting frame is arranged below the first conveyor belt, and an overturning cylinder is hinged on the connecting frame, and a suction cup device is arranged on the overturning cylinder, and the suction cup device and the frame body of the first conveyor belt hinged between.

Owner:南通金诺智能制造有限公司

Screen pull-out overturning structure

InactiveCN103335194BImplement the flip functionStable and reliable turningStands/trestlesEngineering

Owner:GUANGDONG VTRON TECH CO LTD

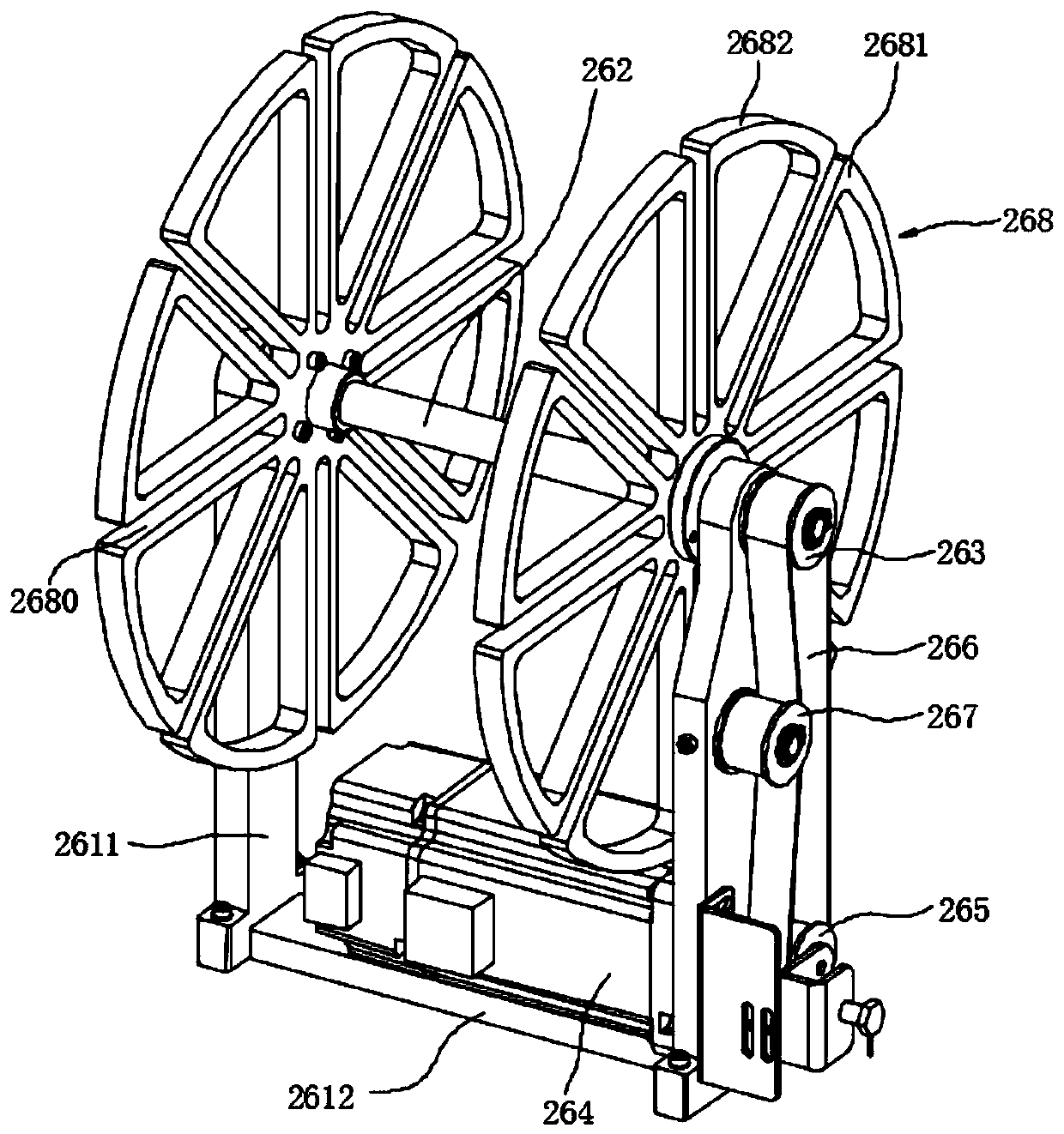

An amorphous strip production system

ActiveCN109290536BIncrease production capacityStable and reliable turningHeater RodProcess engineering

Owner:洛阳中赫非晶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com