Cup overturning device

A technology for turning cups and packages, which is applied in packaging, transportation and packaging, climate sustainability, etc. It can solve the problems of low production efficiency and easily damaged packages, and achieve the effect of improving the efficiency of cup turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

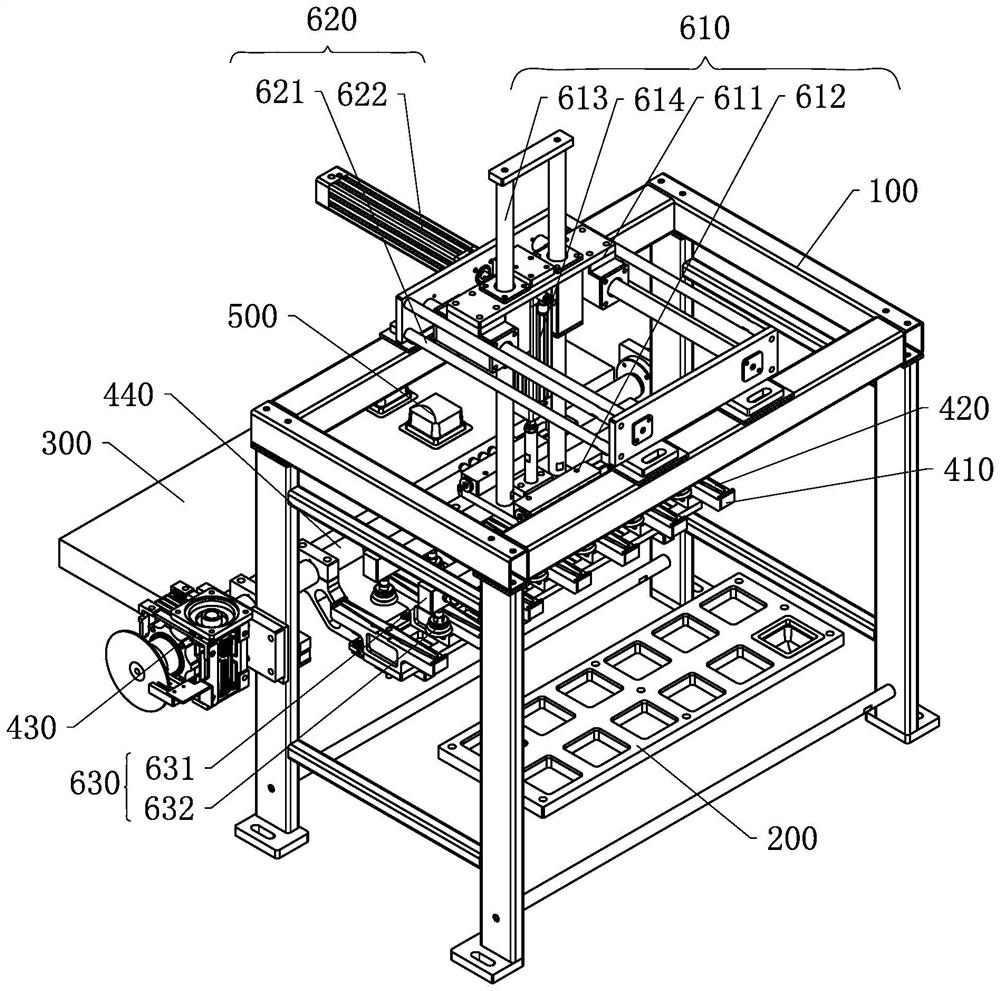

[0045] A cup turning device, such as Figure 1 to Figure 4 As shown, it includes a mounting bracket 100, an input conveying assembly 200, a handling assembly, a turning assembly, and an output conveying assembly 300. The handling assembly and the turning assembly are arranged on the mounting bracket 100, and the input conveying assembly 200 and the output conveying assembly 300 are respectively located on the opposite sides of the turning assembly. On both sides, the carrying assembly is located above the input conveying assembly 200 and the turning assembly, and the bottom of the carrying assembly is provided with a suction cup assembly 630 .

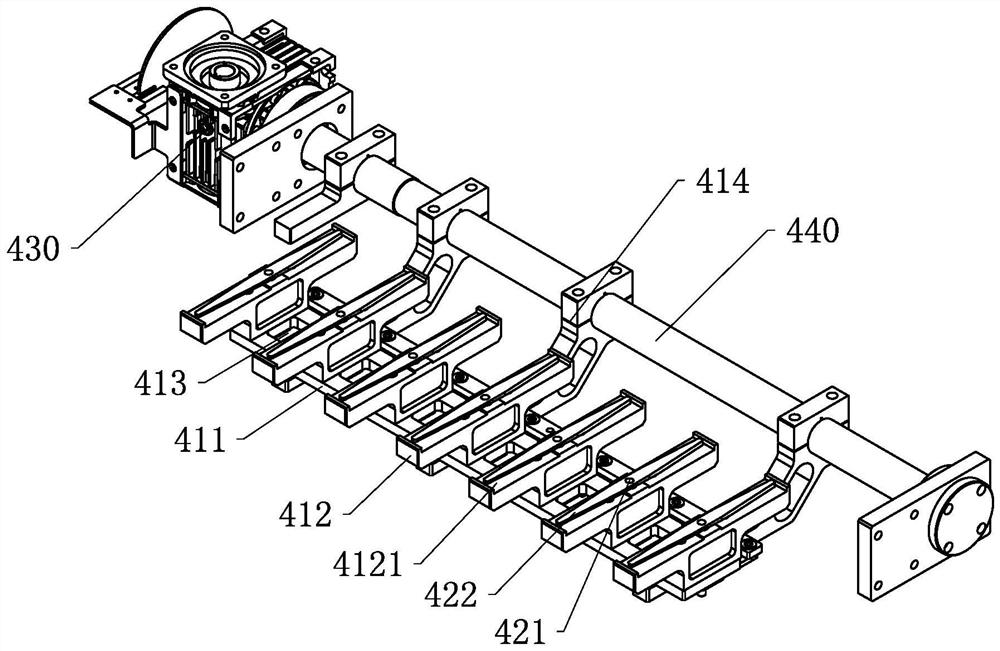

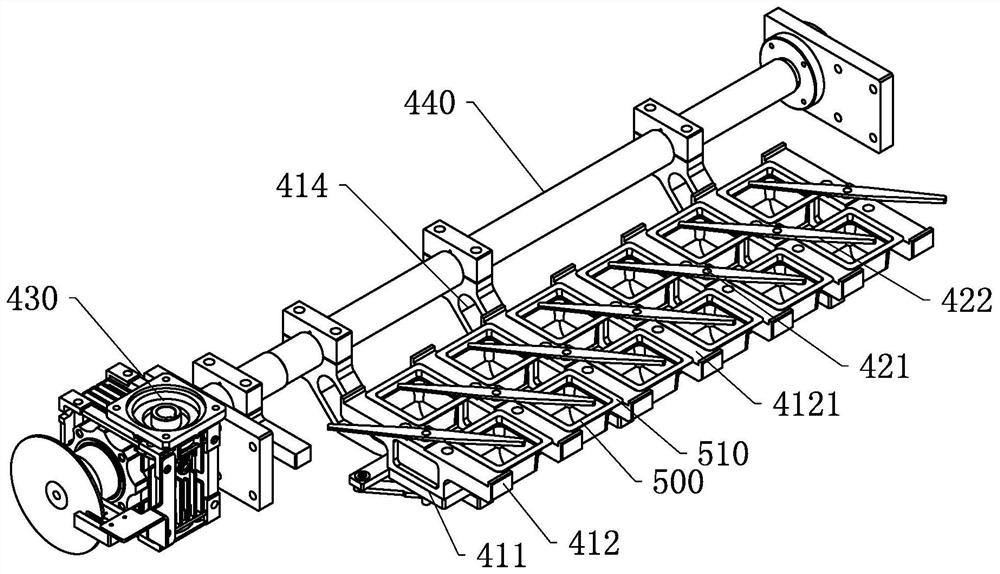

[0046] The flip assembly in this embodiment includes a support mechanism 410, a limit mechanism 420, a first drive mechanism 430 and a rotating shaft 440. The first drive mechanism 430 is fixedly installed on the mounting bracket 100, and the rotating shaft 440 is rotatably connected to the mounting bracket 100. The output shaft of a d...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment is that the transmission shaft in this embodiment is connected to the end of the limit rod, so that when the limit rod rotates, it will swing into the accommodating groove on one side of the support plate as a whole, That is, the limit rods on each support plate shield the accommodating grooves on one side of the support plate respectively, so as to limit the position of the package in the accommodating groove. Prevent collision between limit rods, stable and reliable operation.

Embodiment 3

[0060] The difference between this embodiment and the first embodiment is that the limiting mechanism in this embodiment includes a blocking rod arranged on the top of the supporting mechanism and a linear cylinder set on the side of the supporting mechanism. The shielding rod can be stored in the upper part of the support mechanism to avoid the accommodating groove or move to the top of the accommodating groove to shield the packages in all the installation grooves at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com