Depth-adjustable glass loading mechanism

An adjustable, glass-based technology, used in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve the problems of time-consuming maintenance, low safety and reliability, and unadjustable depth of exploration, and solve the difficulty of depth adjustment. , The structure design is compact and reasonable, and the glass transfer path is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

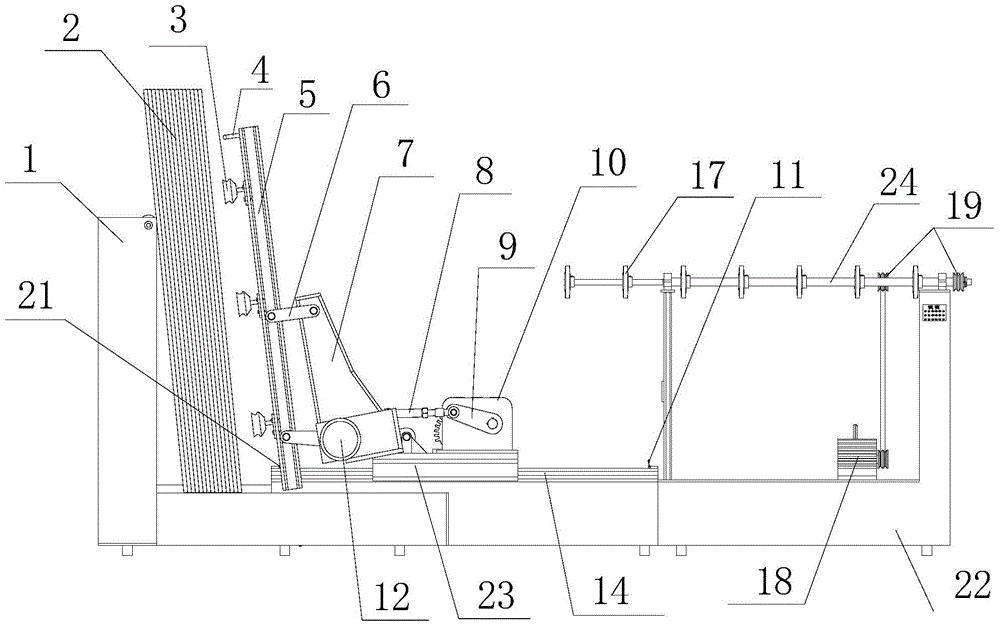

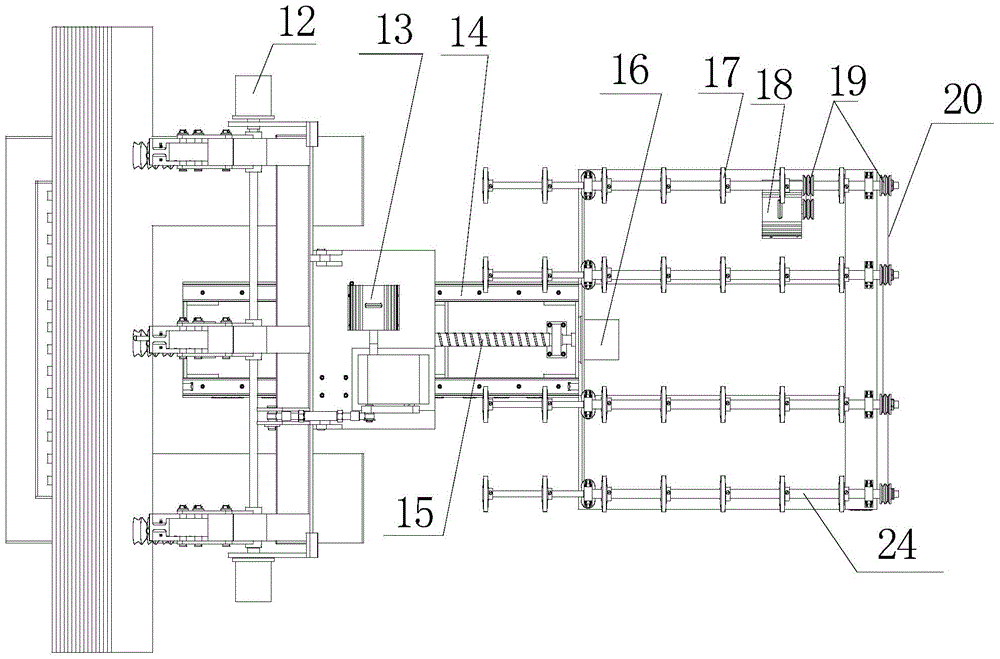

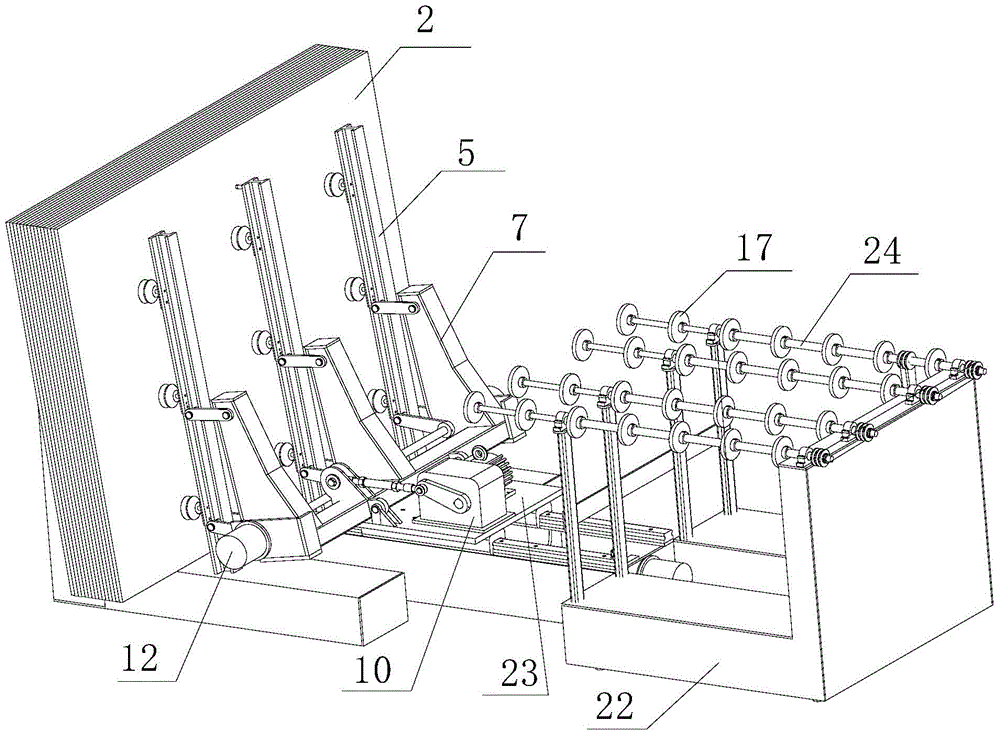

[0022] Such as Figure 1 to Figure 3 The shown adjustable depth-of-depth glass loading mechanism includes a frame 22, a depth-of-depth adjustment device, a glass suction and turning device, and a glass carrying and transporting platform. The depth-of-depth adjustment device includes two The guide rail 14 that is arranged in parallel, the screw mandrel 15 that is parallel to the guide rail 14 and driven by the fourth drive motor 16, is arranged on the guide rail 14 and is driven by the screw mandrel 15 to move along the moving slide 23 of the guide rail 14, the fourth The driving motor 16 is also arranged on the frame 22, and the two ends of the guide rail 14 are respectively provided with the first proximity switch 11 and the second proximity switch 21; Between the two guide rails 14, and the position of the screw rod 15 is lower than that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com