Horizontal and super combined beehive

A technology for nest boxes and bees, which is applied in the field of plastic nest base sheets and waxes, can solve problems such as laborious grasping, high labor intensity, poor safety performance, etc., and achieve the effects of increasing output and quality, improving work efficiency, and facilitating production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

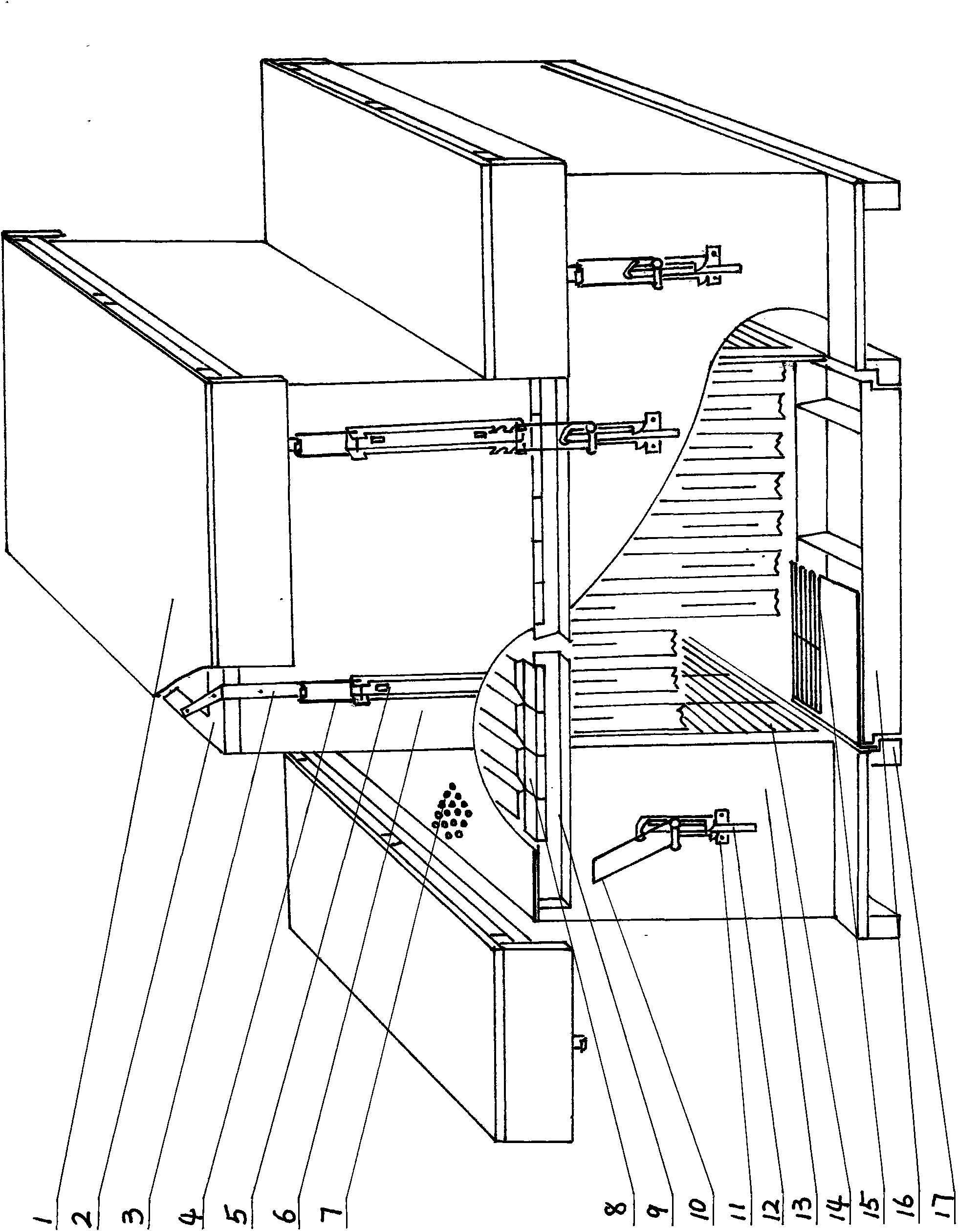

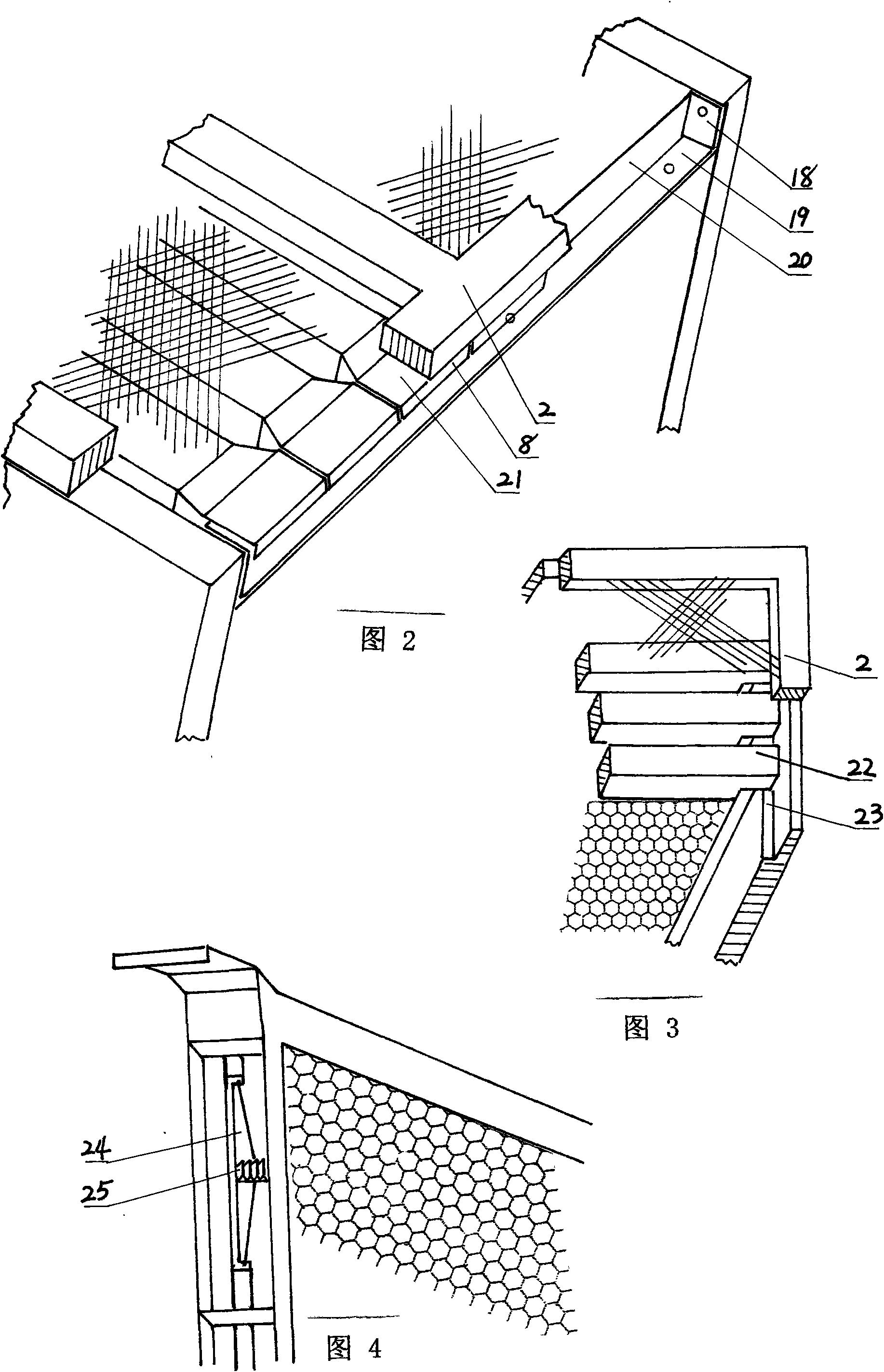

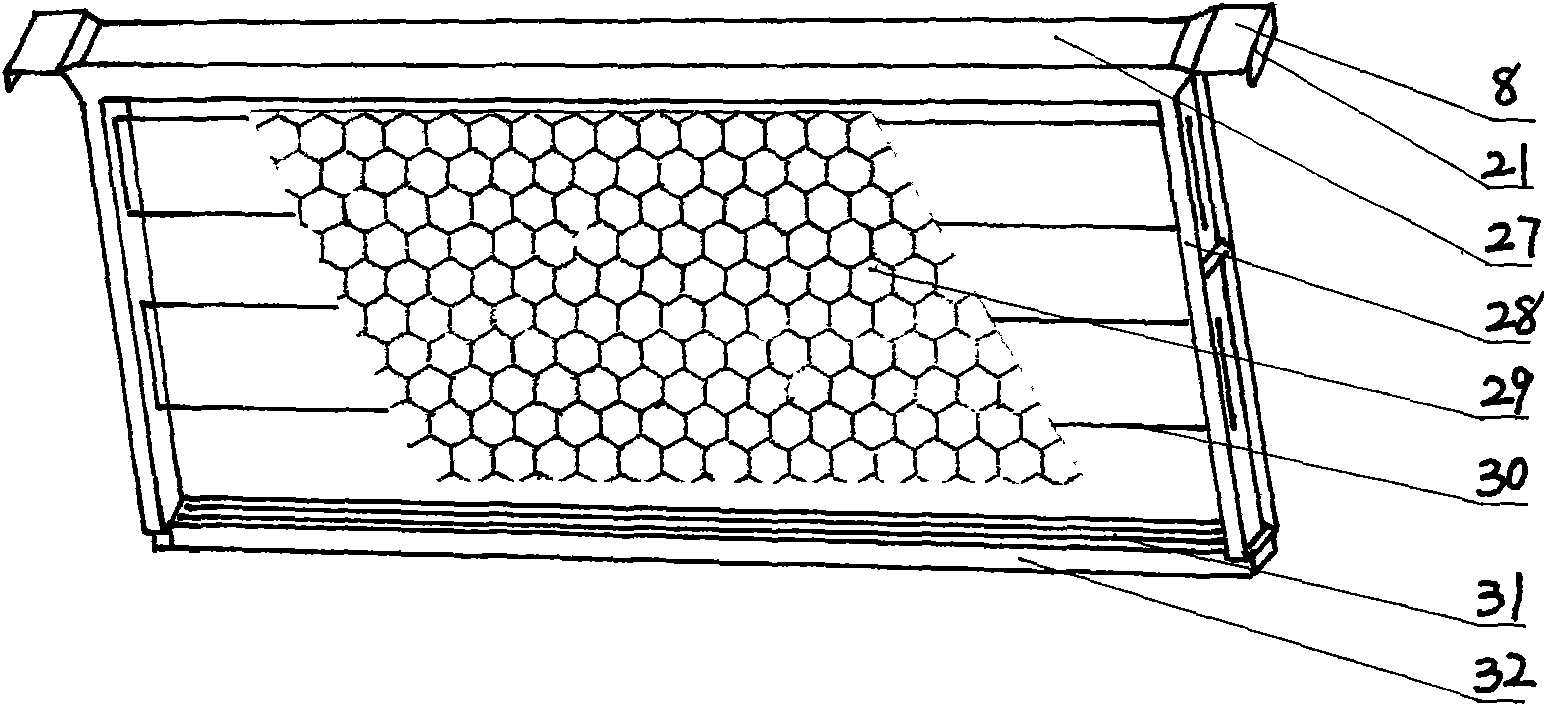

[0033] Example 1. Split box lid, 2. Box lid inner frame, 3. Angle iron hook, 4. Upper pull ring, 5. Pull multi-tooth hook, 6. Following box, 7. Degumming cloth covering, 8. Nest frame head, 9. Nest frame bracket, 10. Drop ring, 11. Connector base, 12. Spiral crowbar, 13. Wide nest box, 14. Frame partition, 15. Front bottom plate of production area, 16 .Pollen box, 17. Box feet, 18. Connection surface, 19. Base, 20. Elevation, 21. Handle, 22. Nest frame wooden head, 23. Beehive wooden slot, 24. Wide hook, 25. Adjusting buckle group, 26. Side bar nest base groove, 27. Upper beam, 28. Side bar, 29. Nest base piece, 30. Nest base hanging ring, 31. Lower beam nest base groove, 32. Lower beam, 33. Upper Slot, 34. Lower slot, 35. Top hole, 36. Double shaft nut, 37. Spring, 38. Lock bolt, 39. Lock card.

[0034] figure 1 : The two ends of the nest box (13) are breeding areas for two groups of bees, and the middle of the box is divided into two groups of bees with a frame partition (14) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com