AOI detection equipment and detection method

A technology of testing equipment and testing machines, which is applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve problems such as machines not working normally and damage to machines, and achieve precise and direct driving methods and smooth movement. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

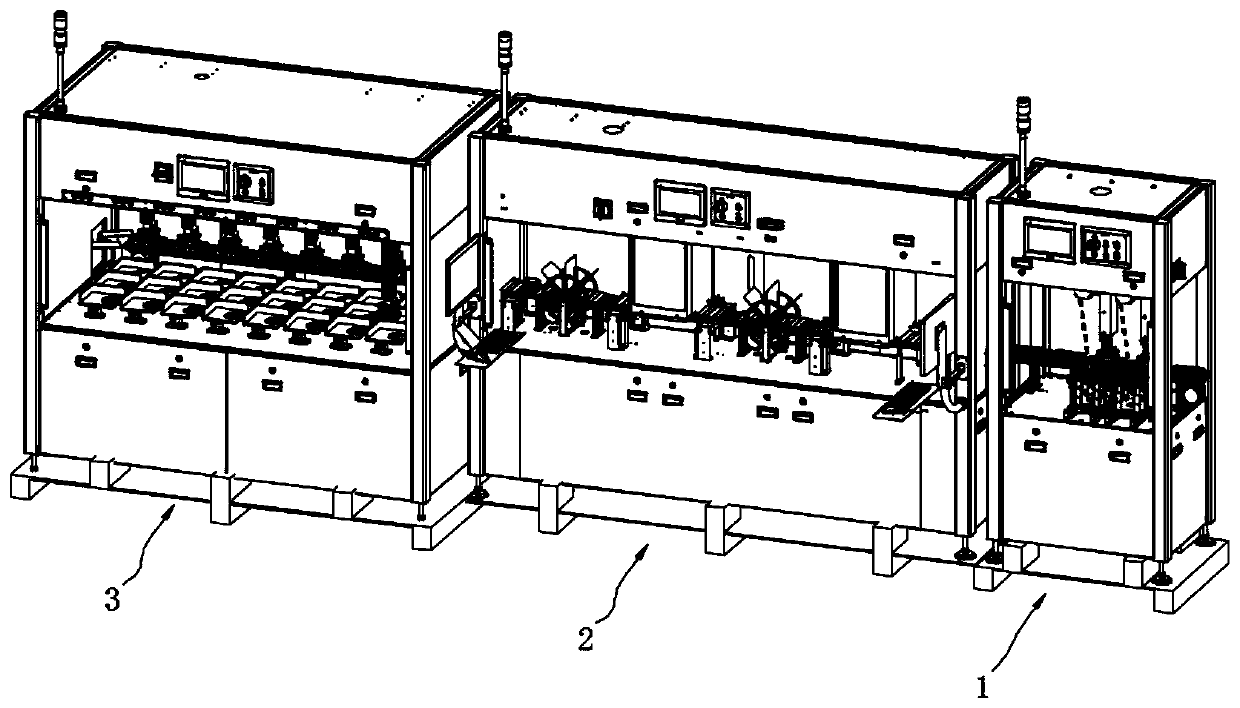

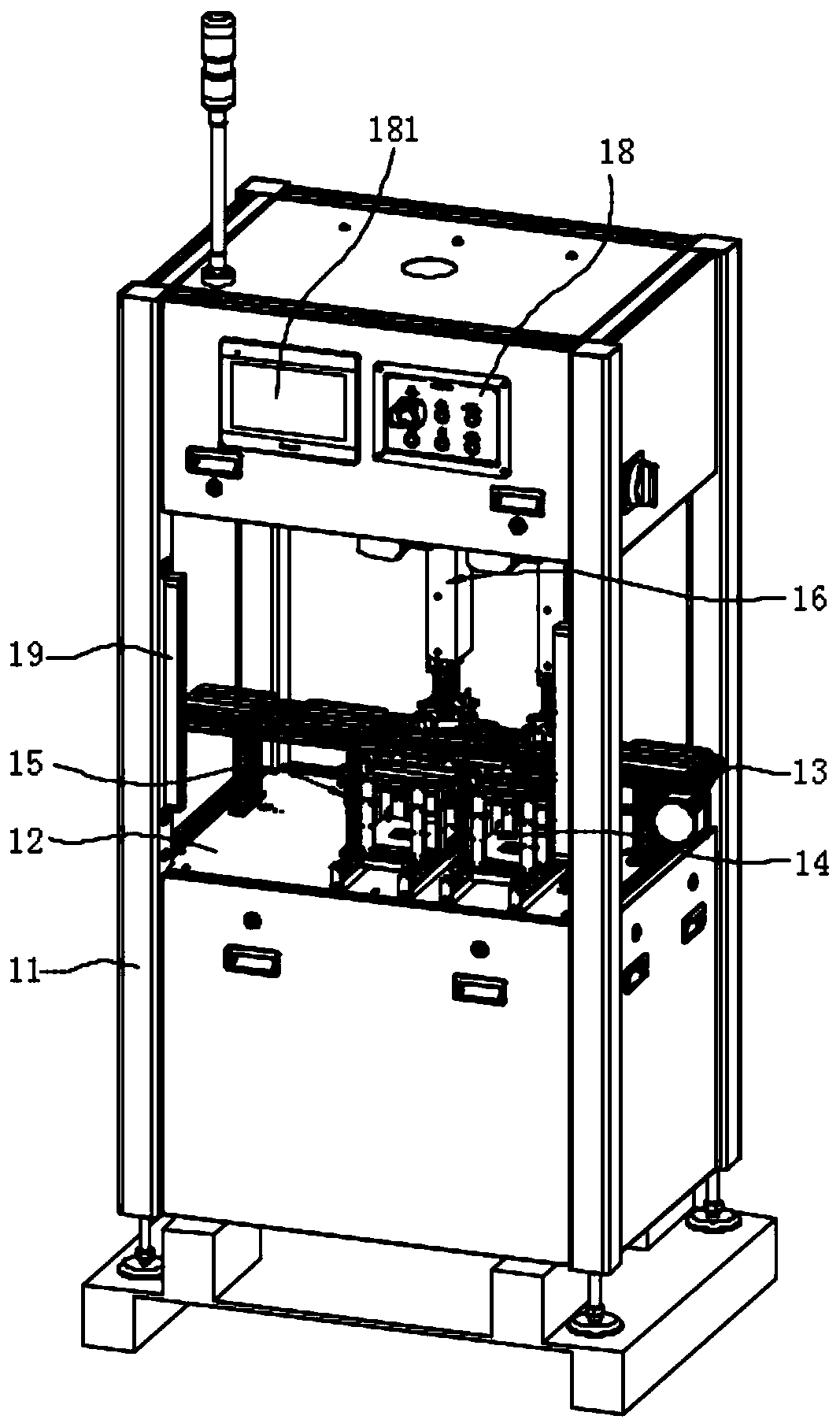

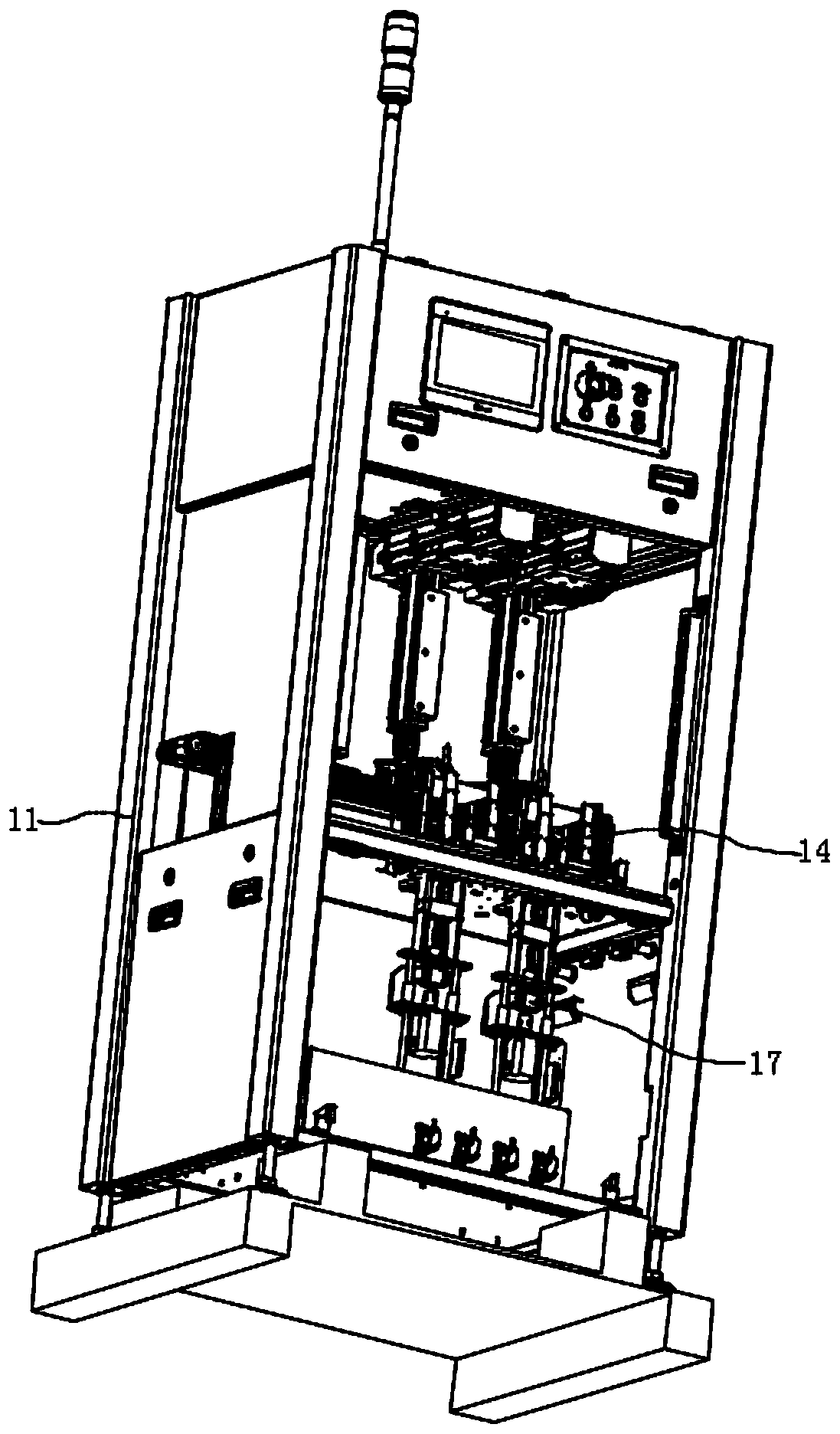

[0047] Such as Figure 1 to Figure 16 Shown: a kind of AOI testing equipment, including feeding machine 1, testing machine 2 and sorting machine 3, testing machine 2 includes feeding side and discharging side, loading machine 1 is set at the feeding side of testing machine 2 , the sorting machine 3 is located at the discharge side of the testing machine 2;

[0048] Feeding machine 1 comprises feeding frame 11, is provided with feeding substrate 12 on feeding frame 11, is provided with feeding transfer device 13 laterally at the rear side of feeding substrate 12, and feeding transfer device 13 includes and is located at The feeding conveying bracket 131 on the feeding substrate 12 is provided with a feeding conveying drive shaft 132 at one end of the feeding conveying support 131, and a feeding conveying driving wheel 133 is respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com