Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Secure sealing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

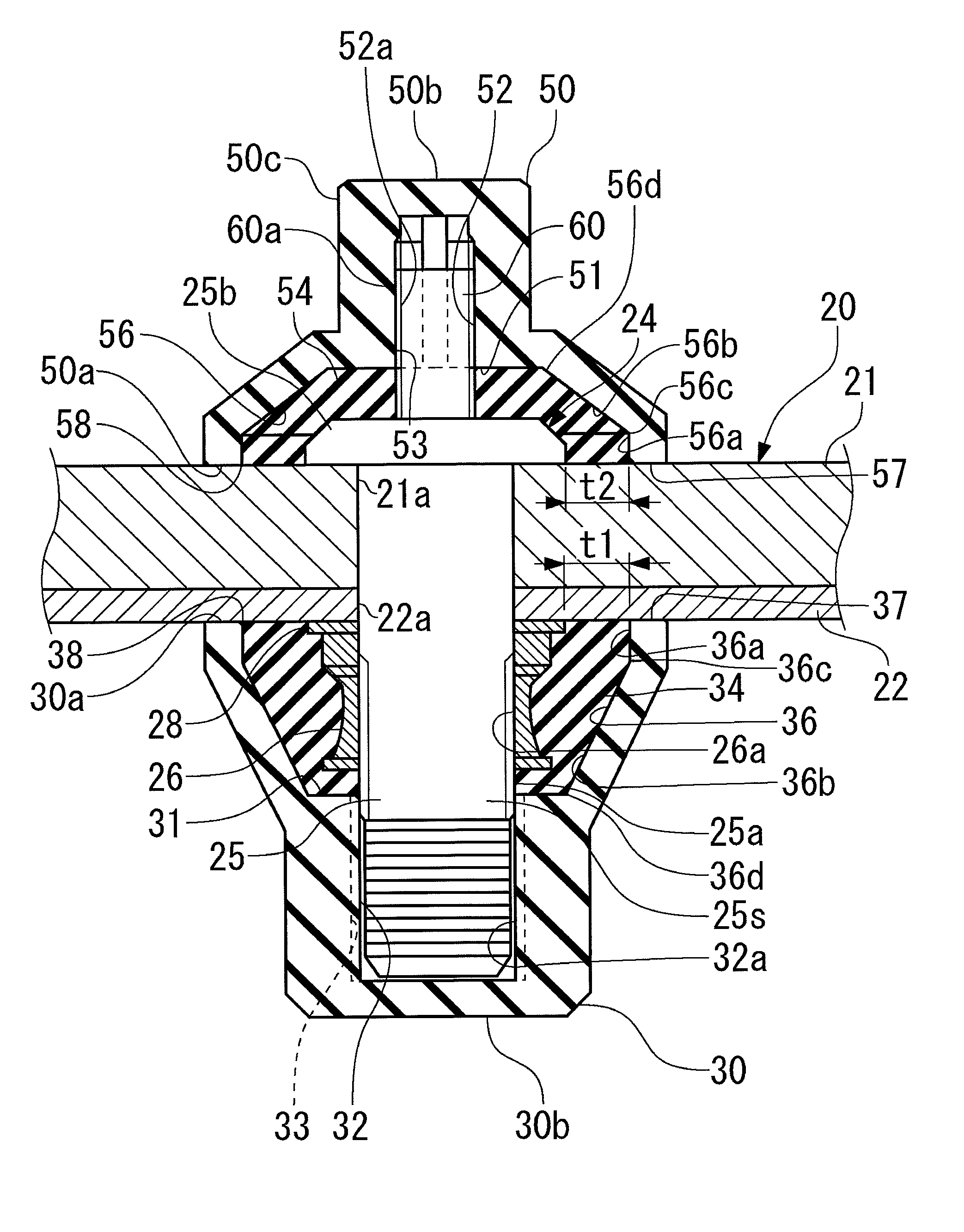

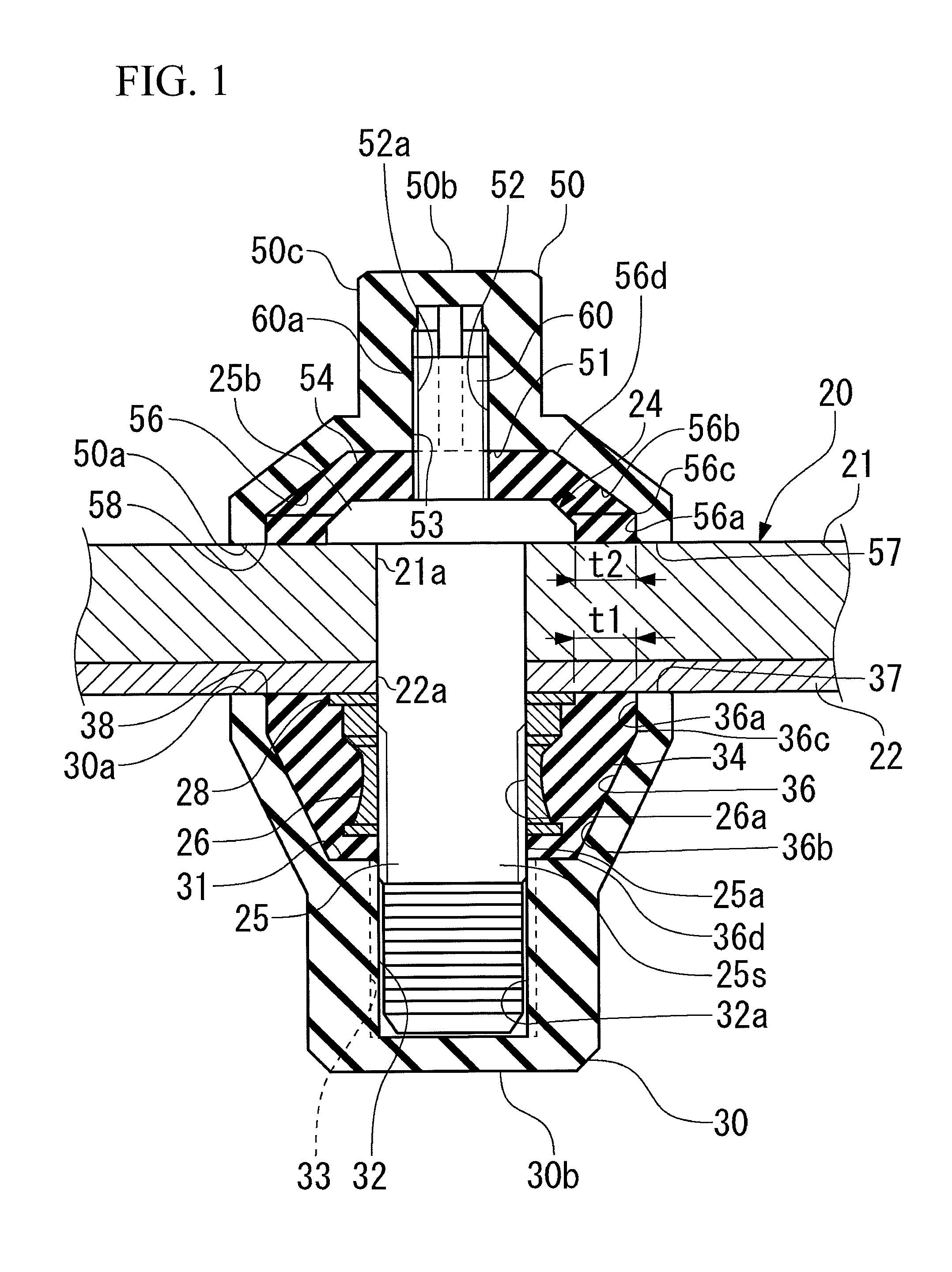

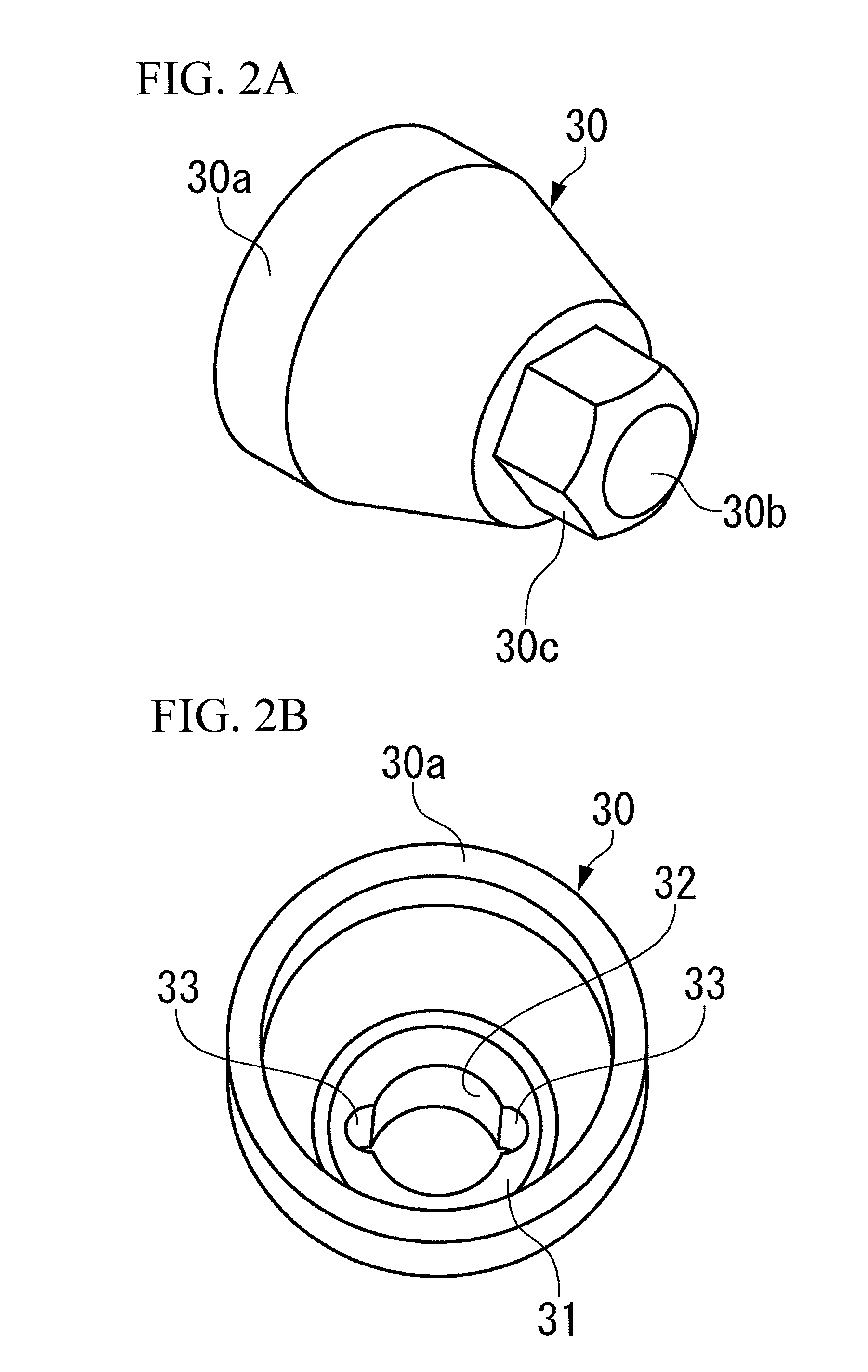

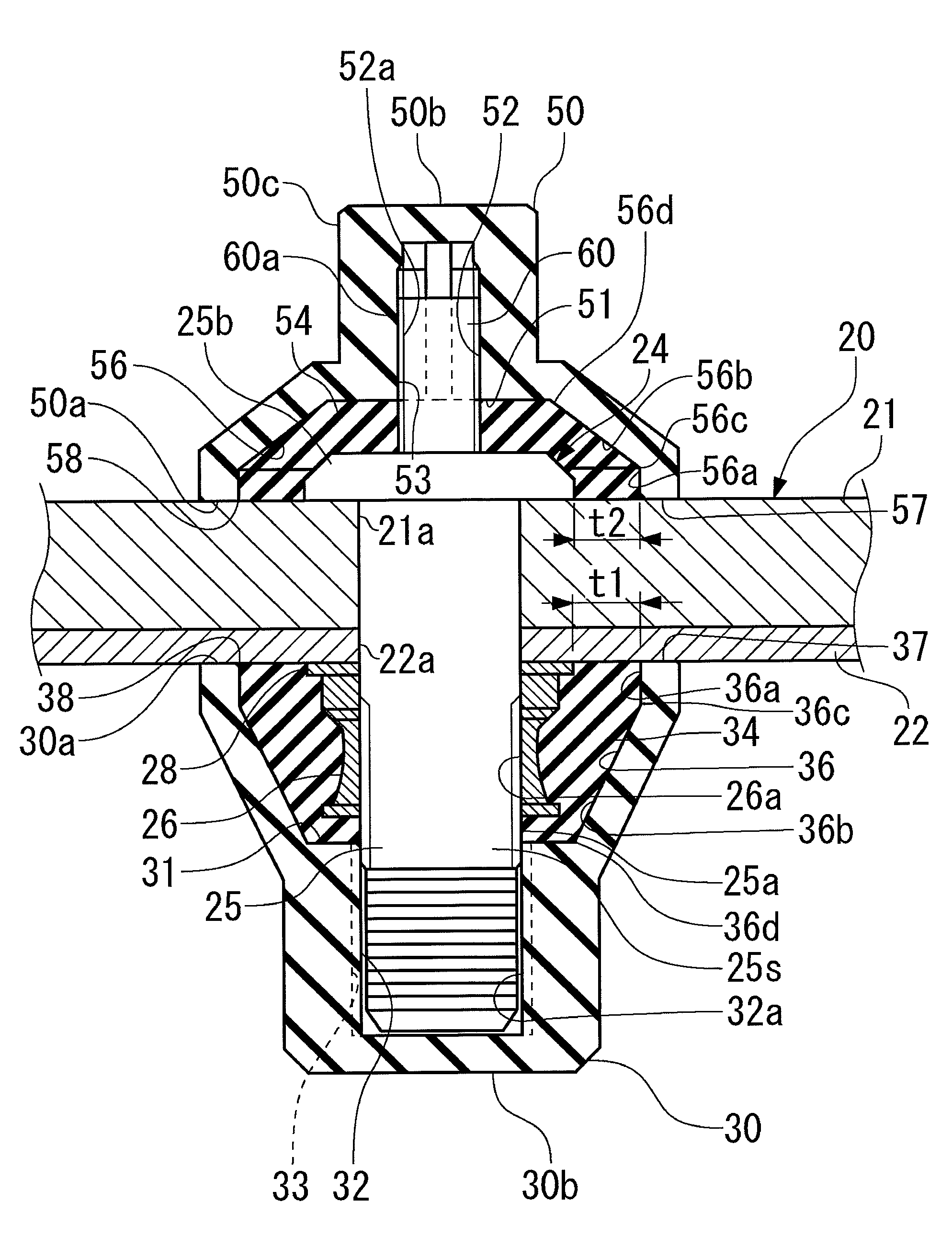

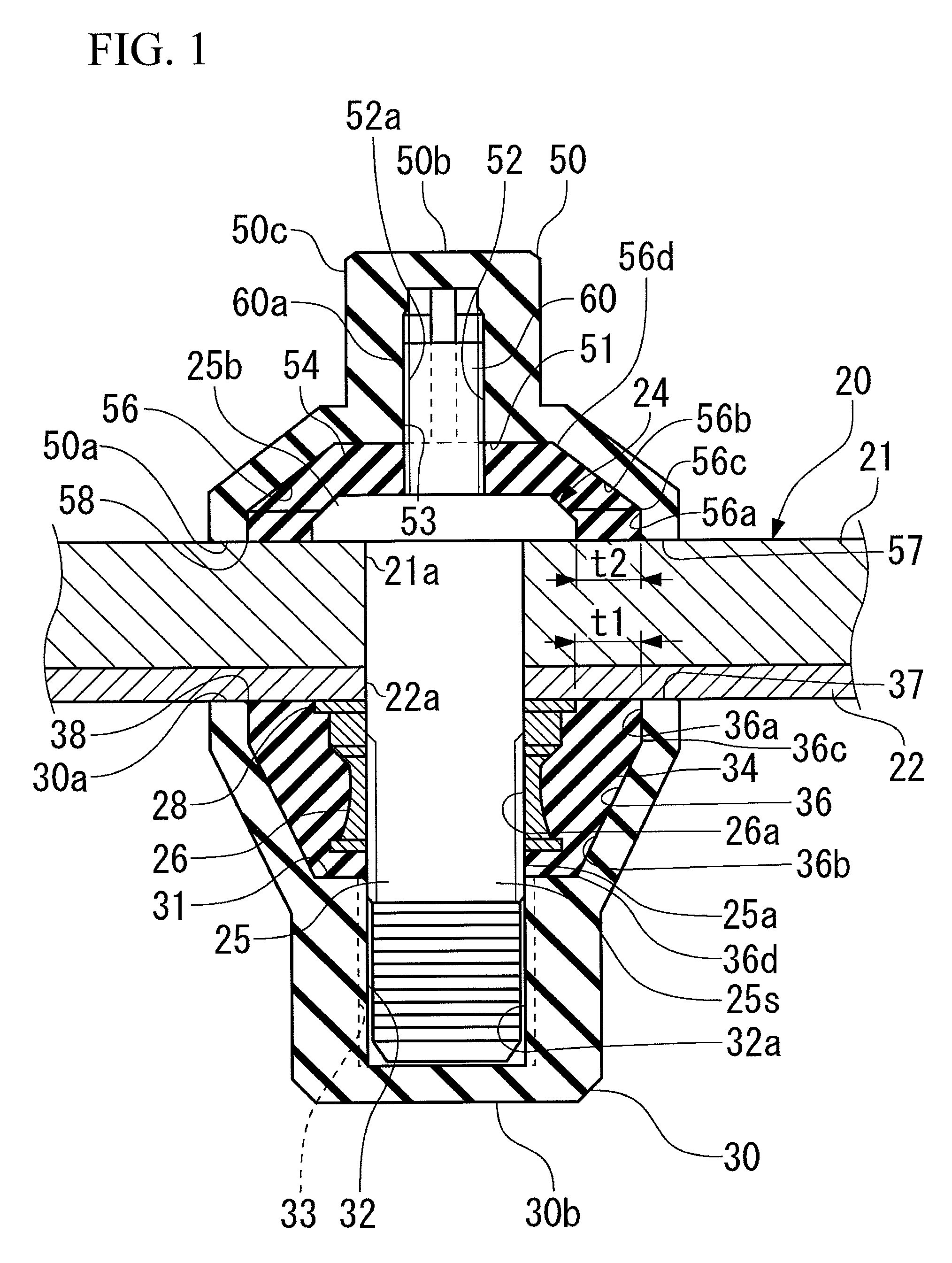

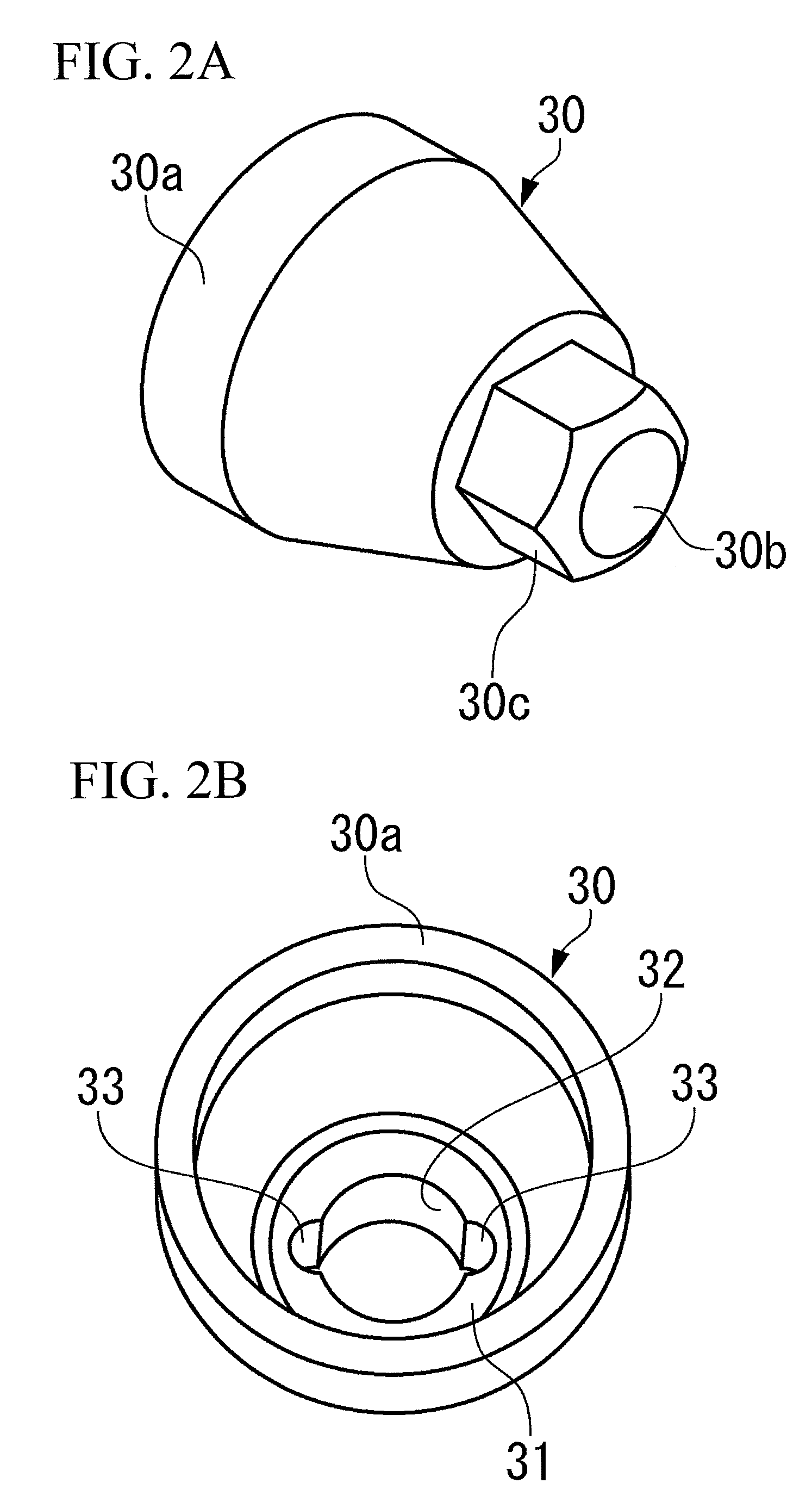

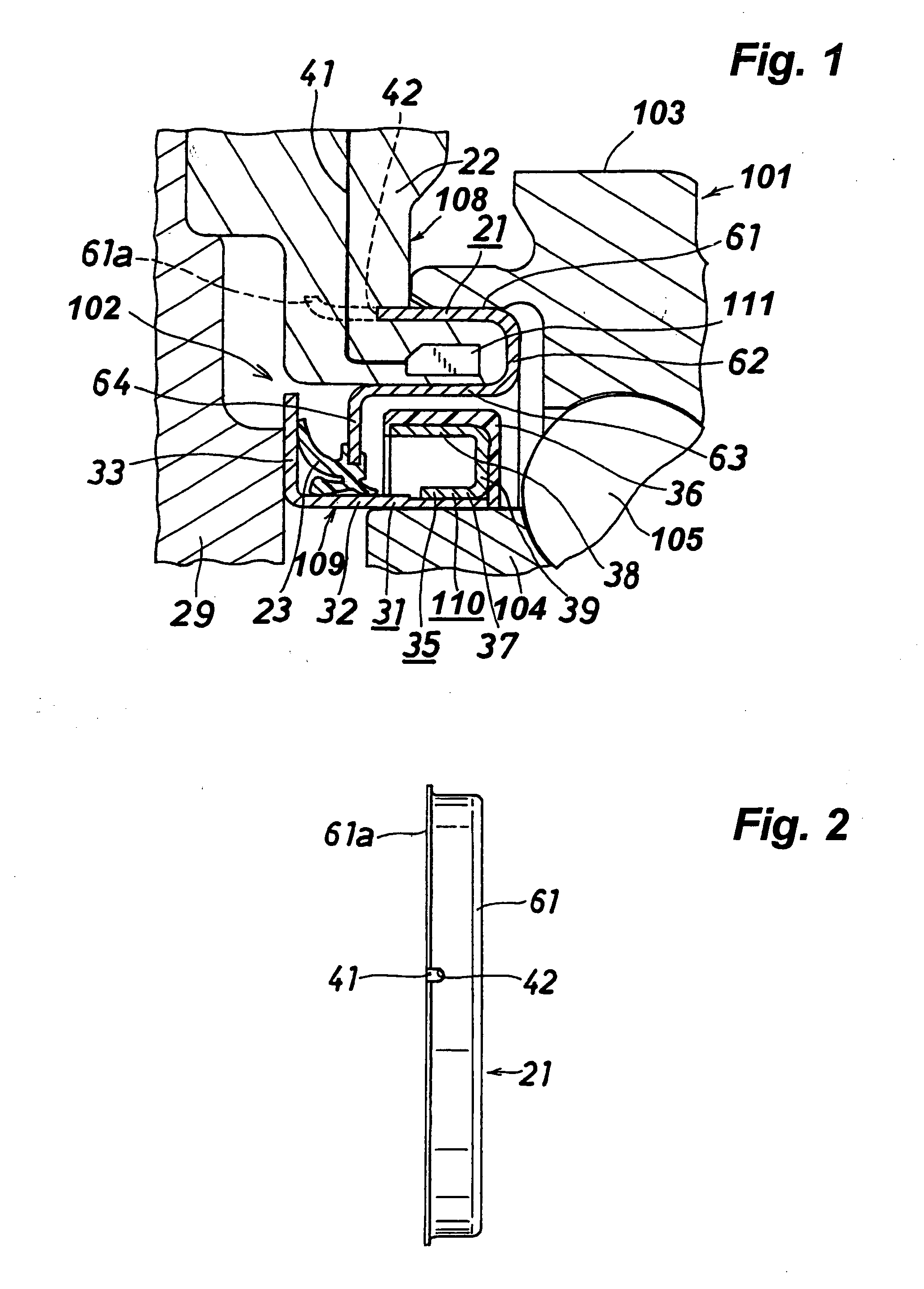

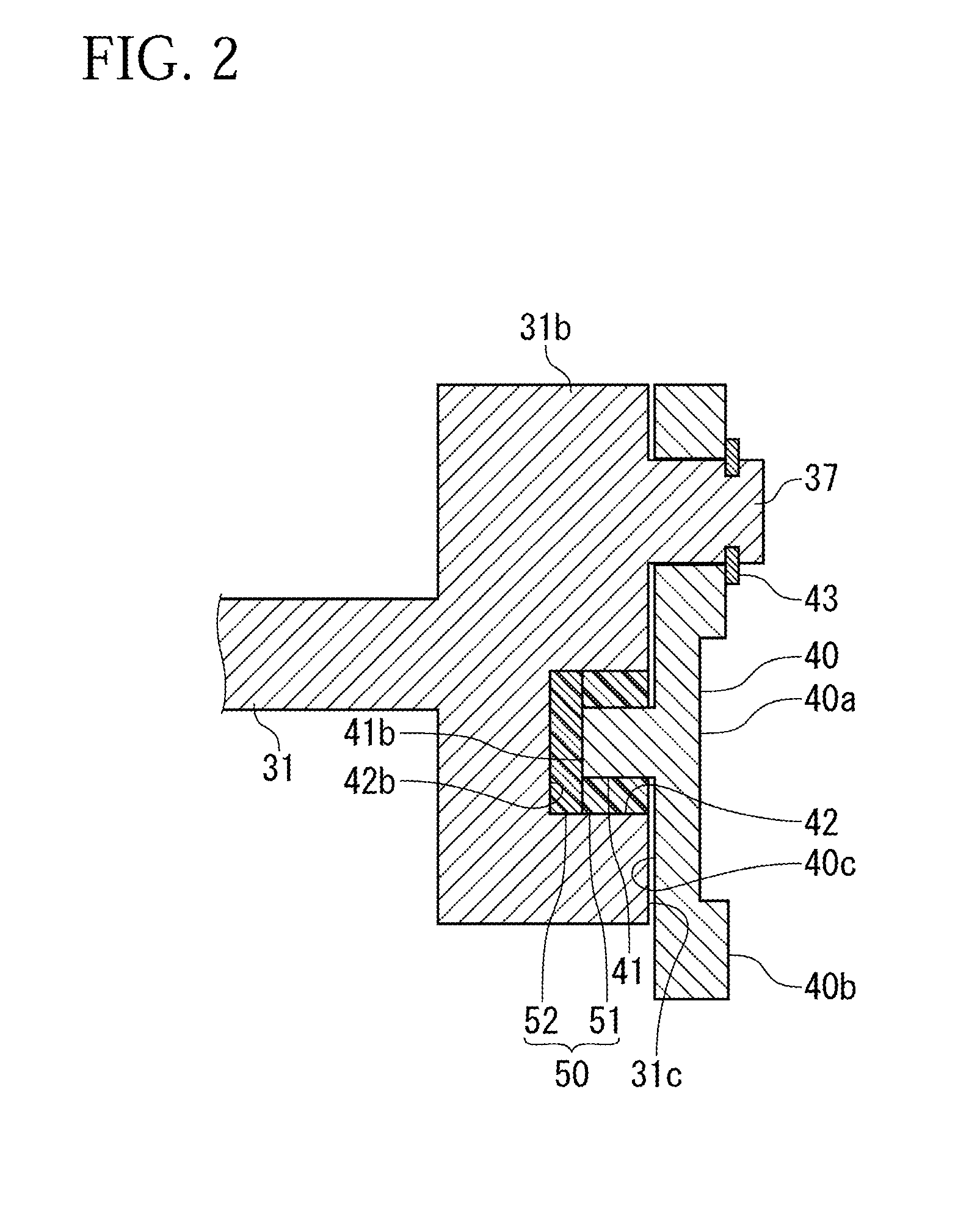

Lightning-resistant fastener, cap, fastener member, and method for attaching lightning-resistant fastener

ActiveUS20110226896A1Quality improvementReliably securing lightning resistanceFuselage framesNutsManufacturing cost reductionLightning strike

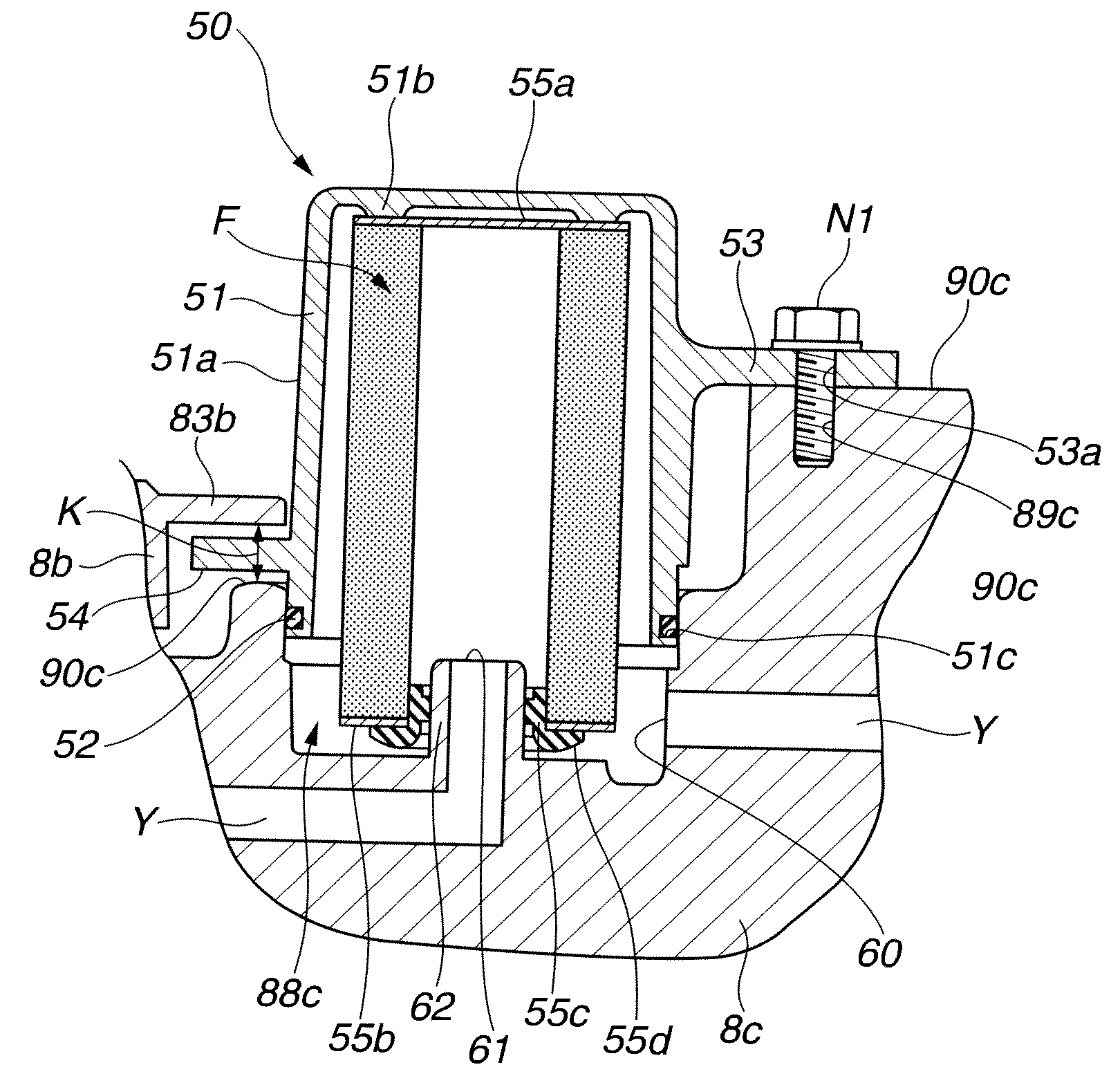

A lightning-resistant fastener, a cap, a fastener member, and a method for attaching the lightning-resistant fastener are provided, which enhance workability and quality stability besides reliably securing an insulating property, and can lead to enhancement in safety of an airframe and reduction in manufacturing cost. A head portion 25b of a fastener main body 25 includes a head cap 50, and a shaft portion 25s of the fastener main body 25 includes a shaft cap 30, whereby a direct strike of lightning to a fastener member 24, and occurrence of an arc discharge from the fastener member 24 in the case of a lightning strike can be suppressed. A hole 52 is formed in the head cap 50, and a thread groove 52a is formed in the hole 52, whereby the head cap 50 can be reliably and easily positioned and attached to the fastener member 24.

Owner:MITSUBISHI AIRCRAFT

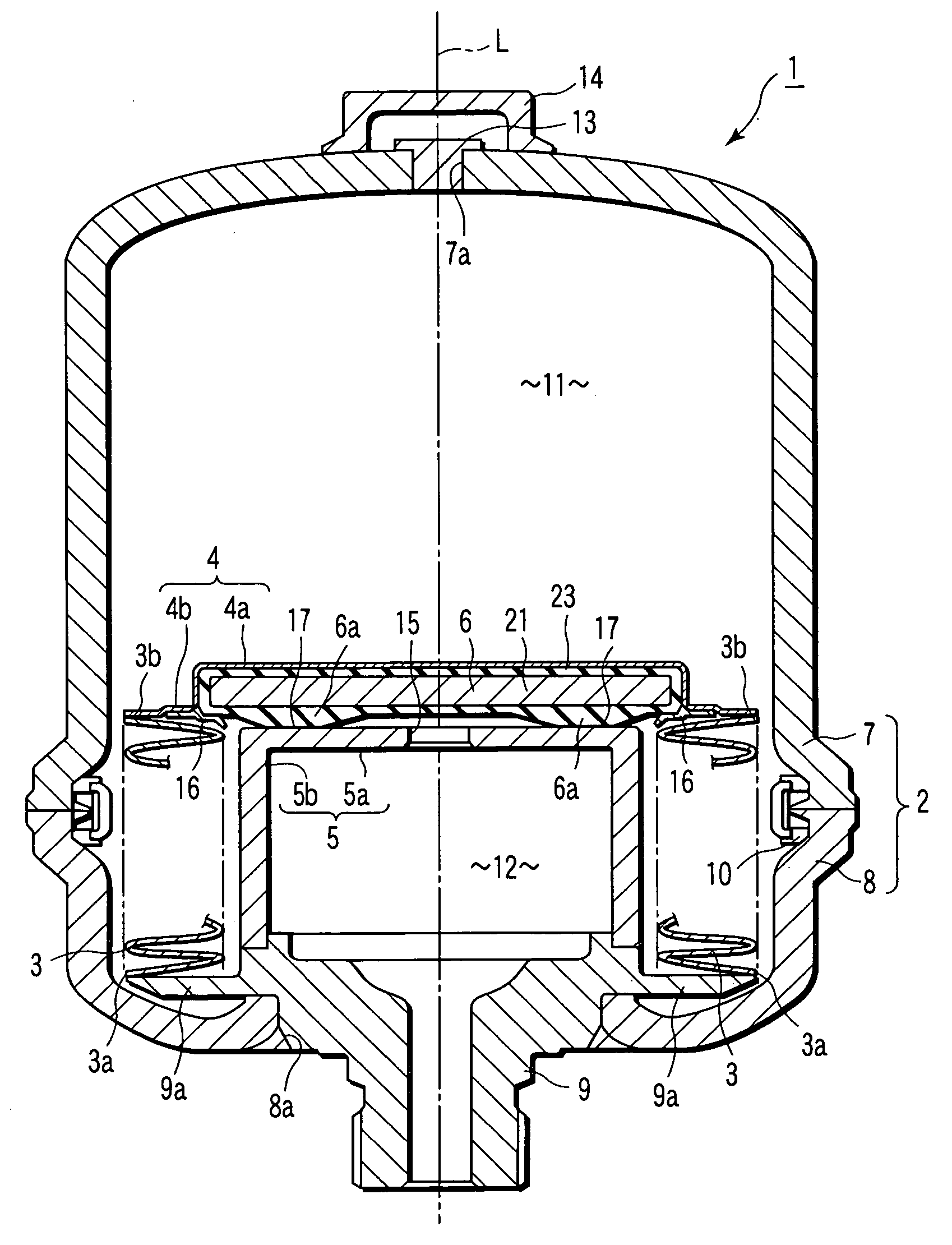

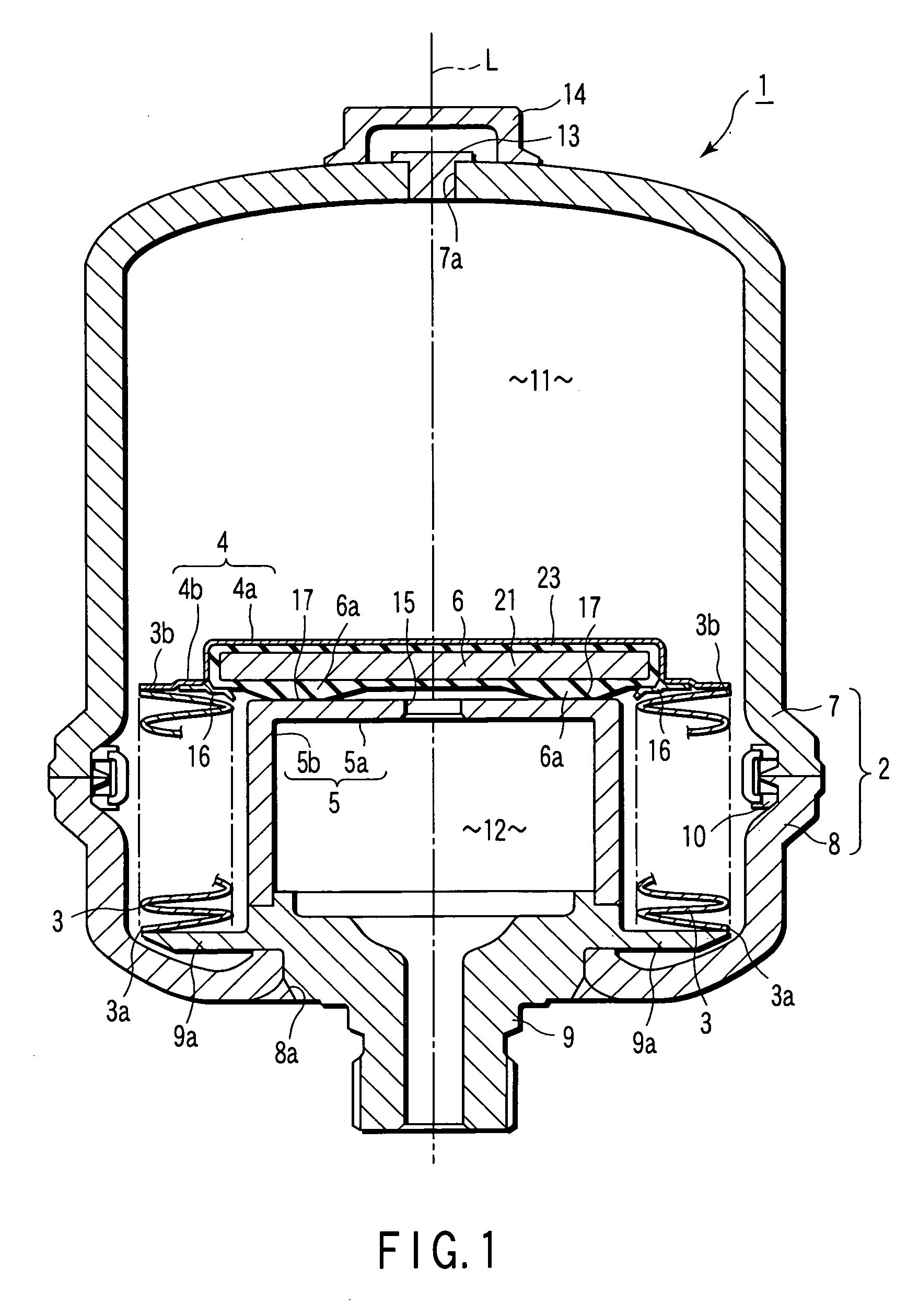

Vehicular brake system component

ActiveUS20050061379A1Peel strengthHigh peel strengthAccumulator installationsPipe elementsBrake fluidBraking system

Owner:NHK SPRING CO LTD +2

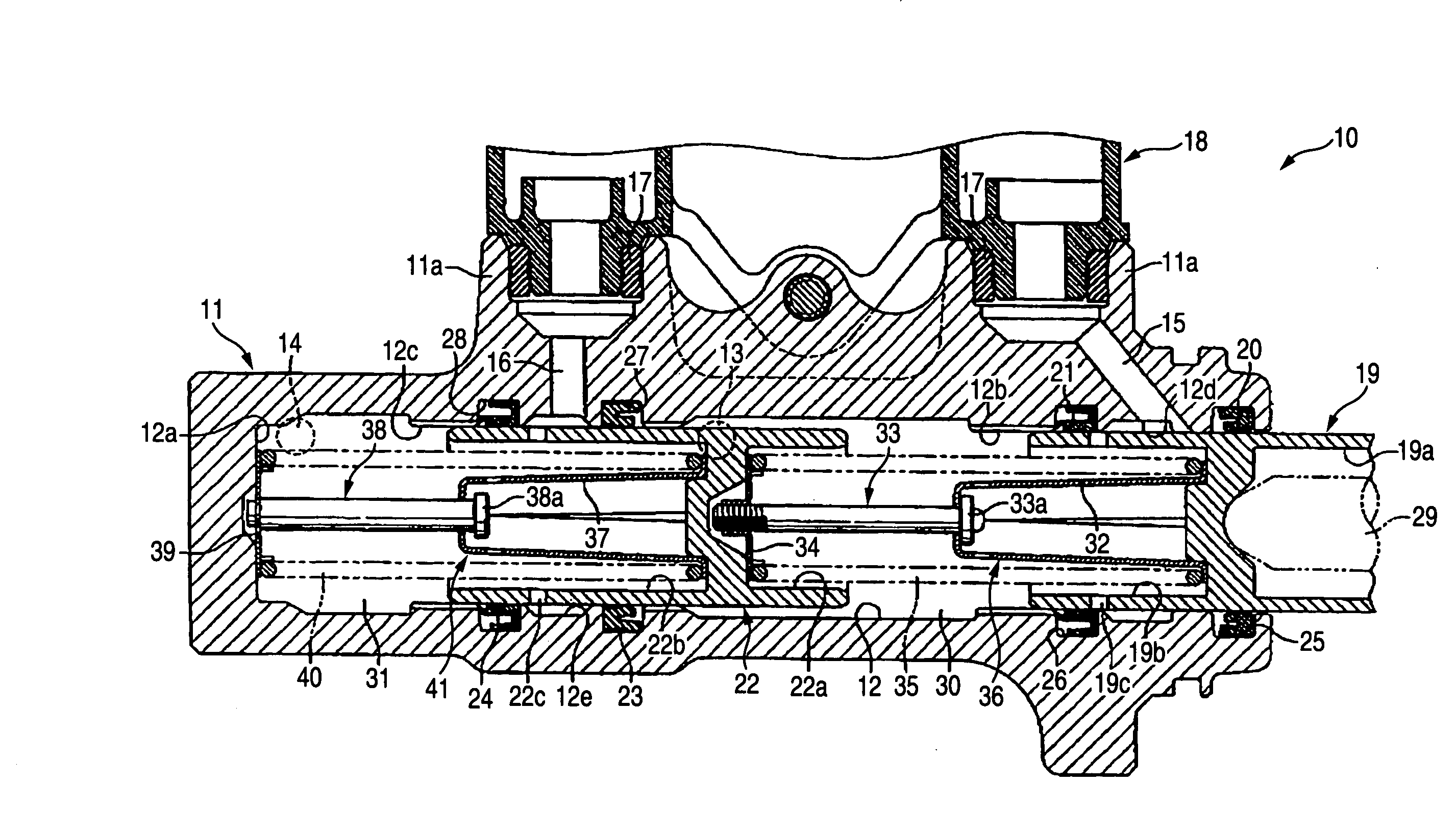

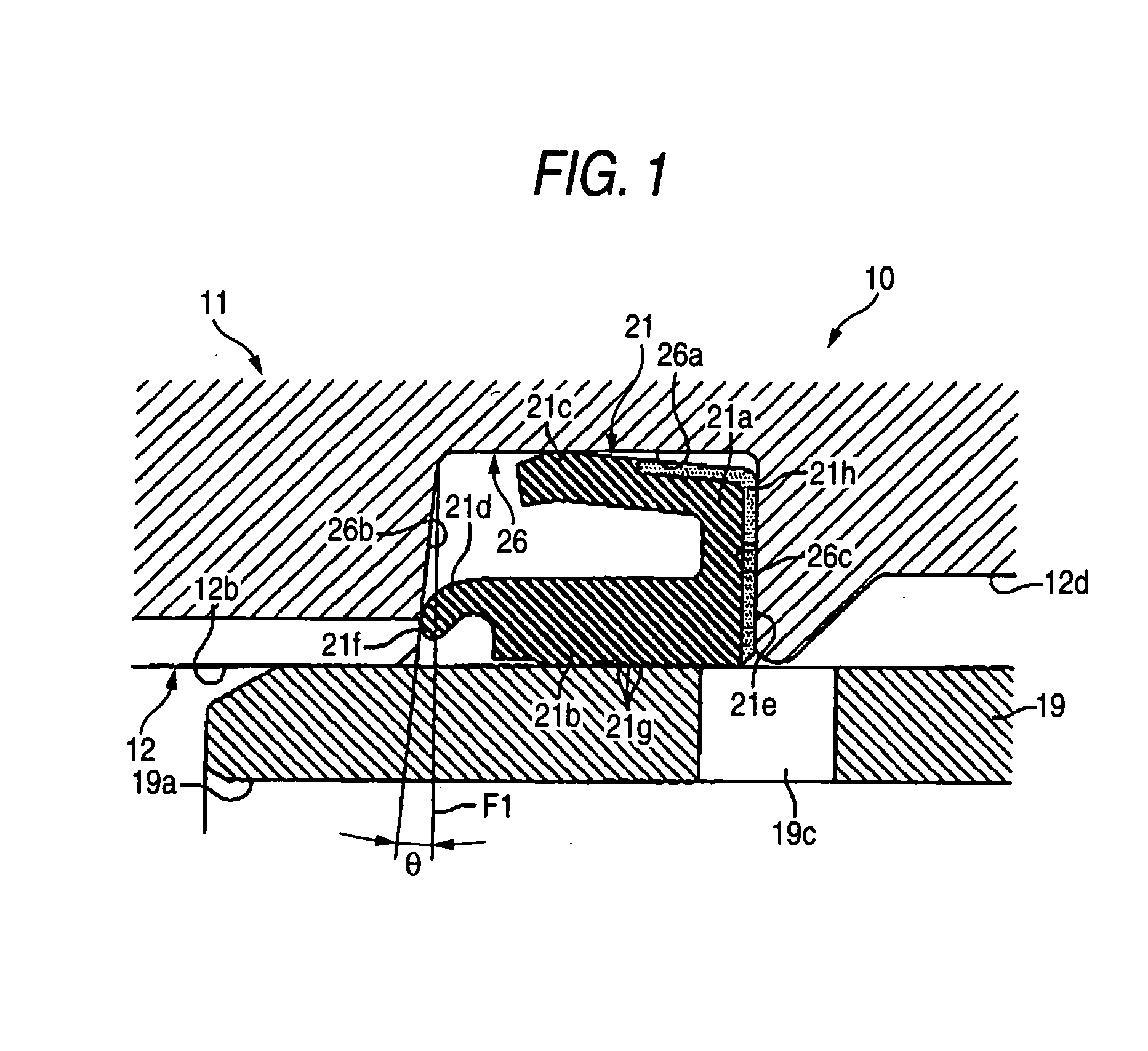

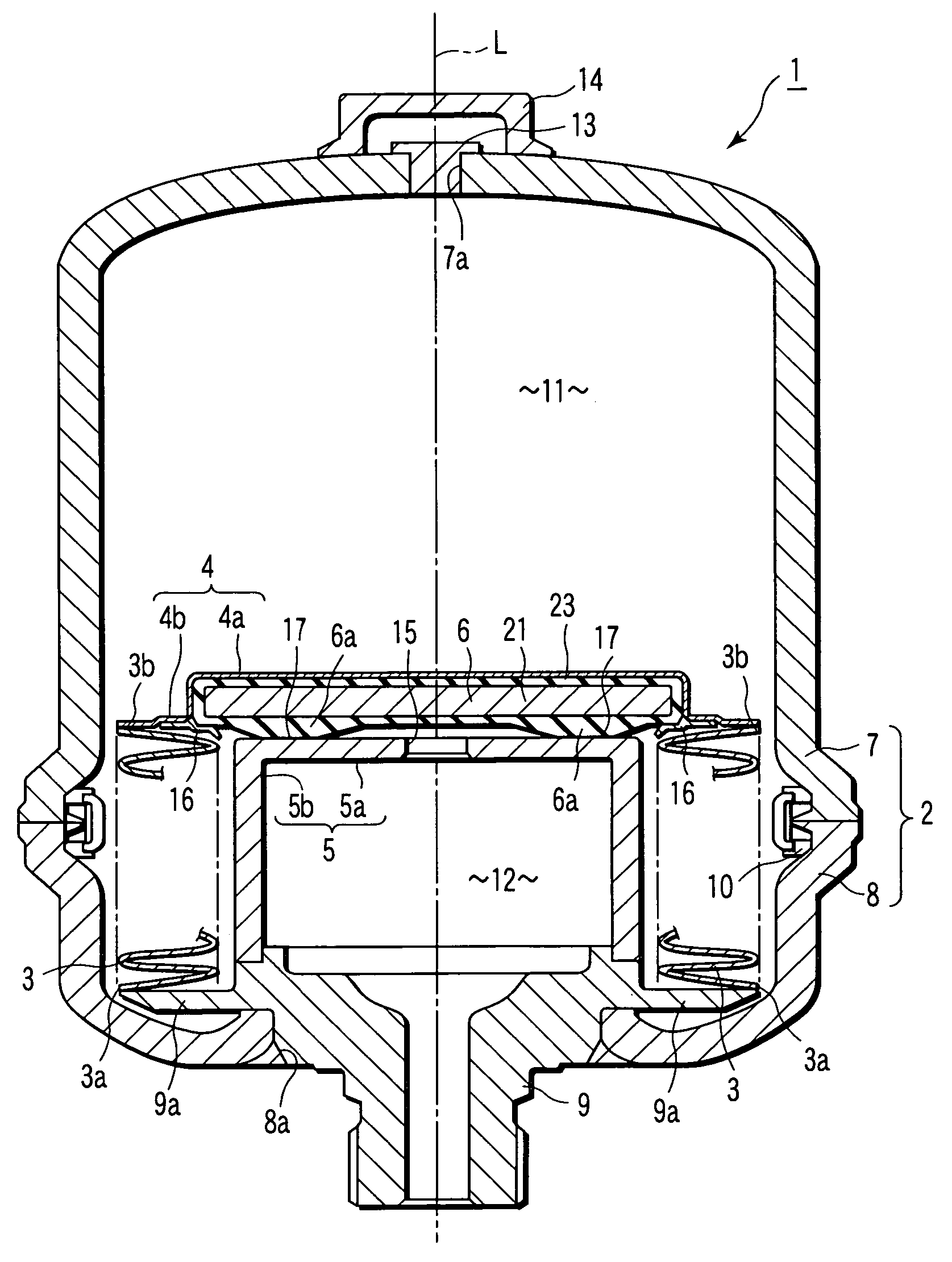

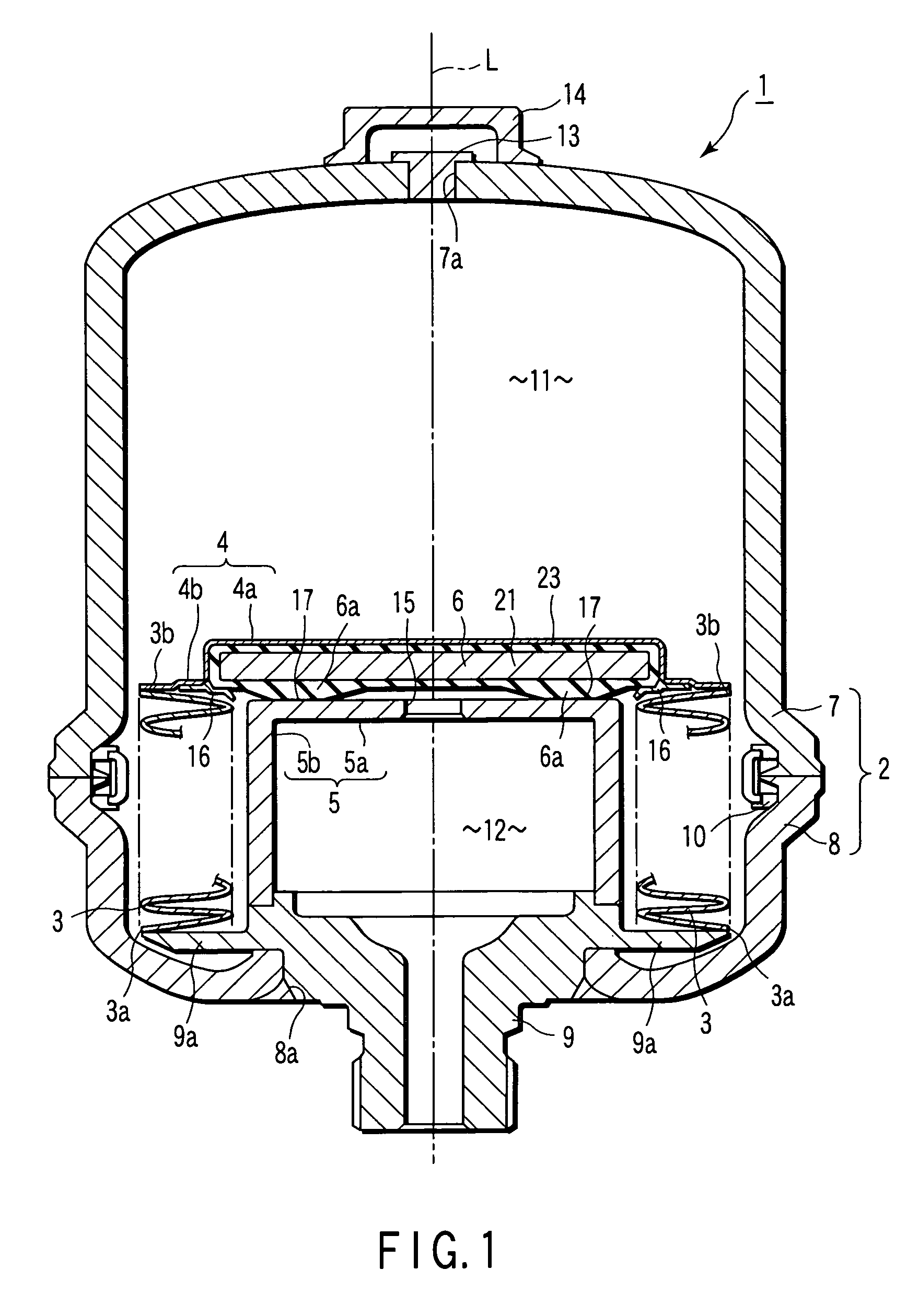

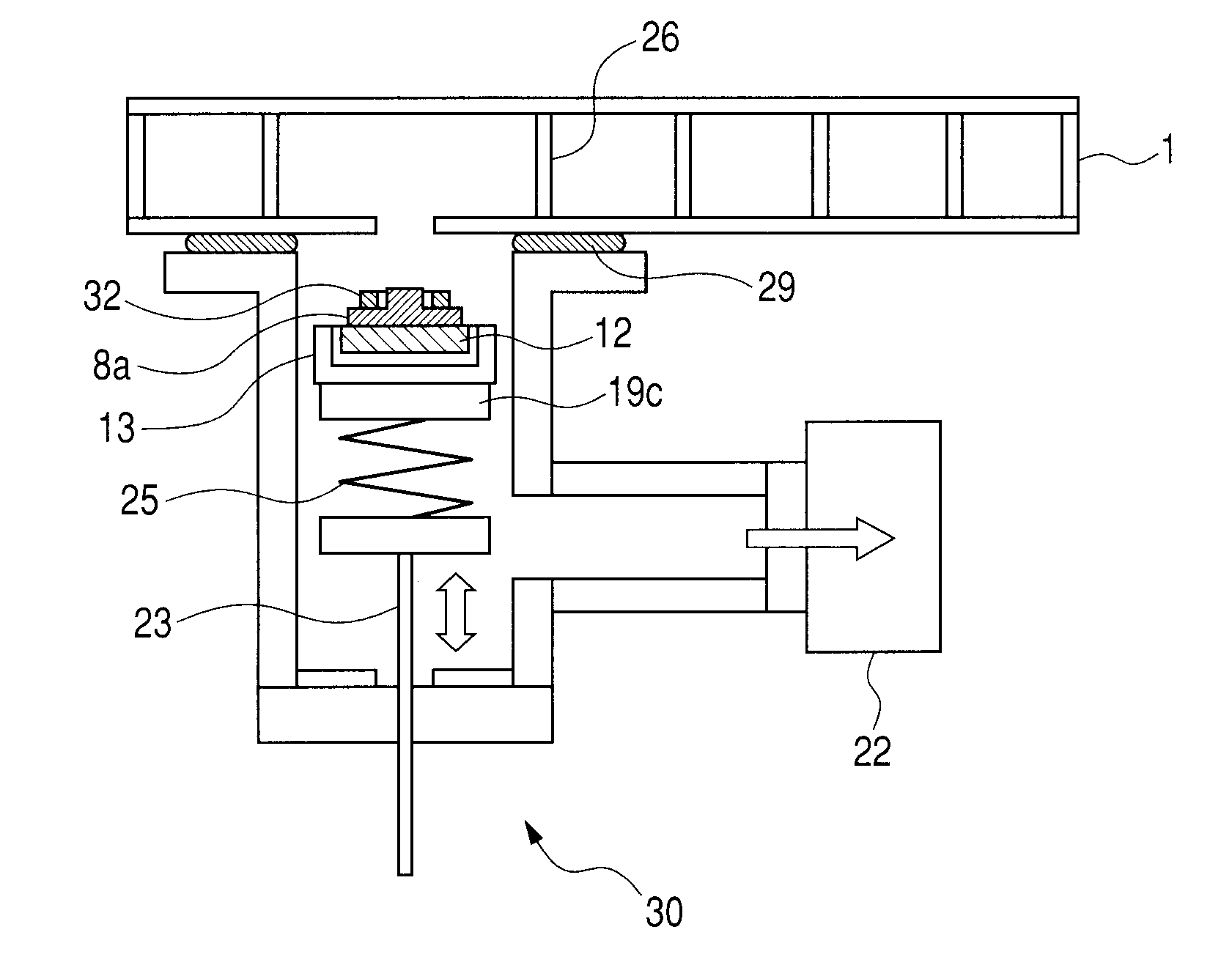

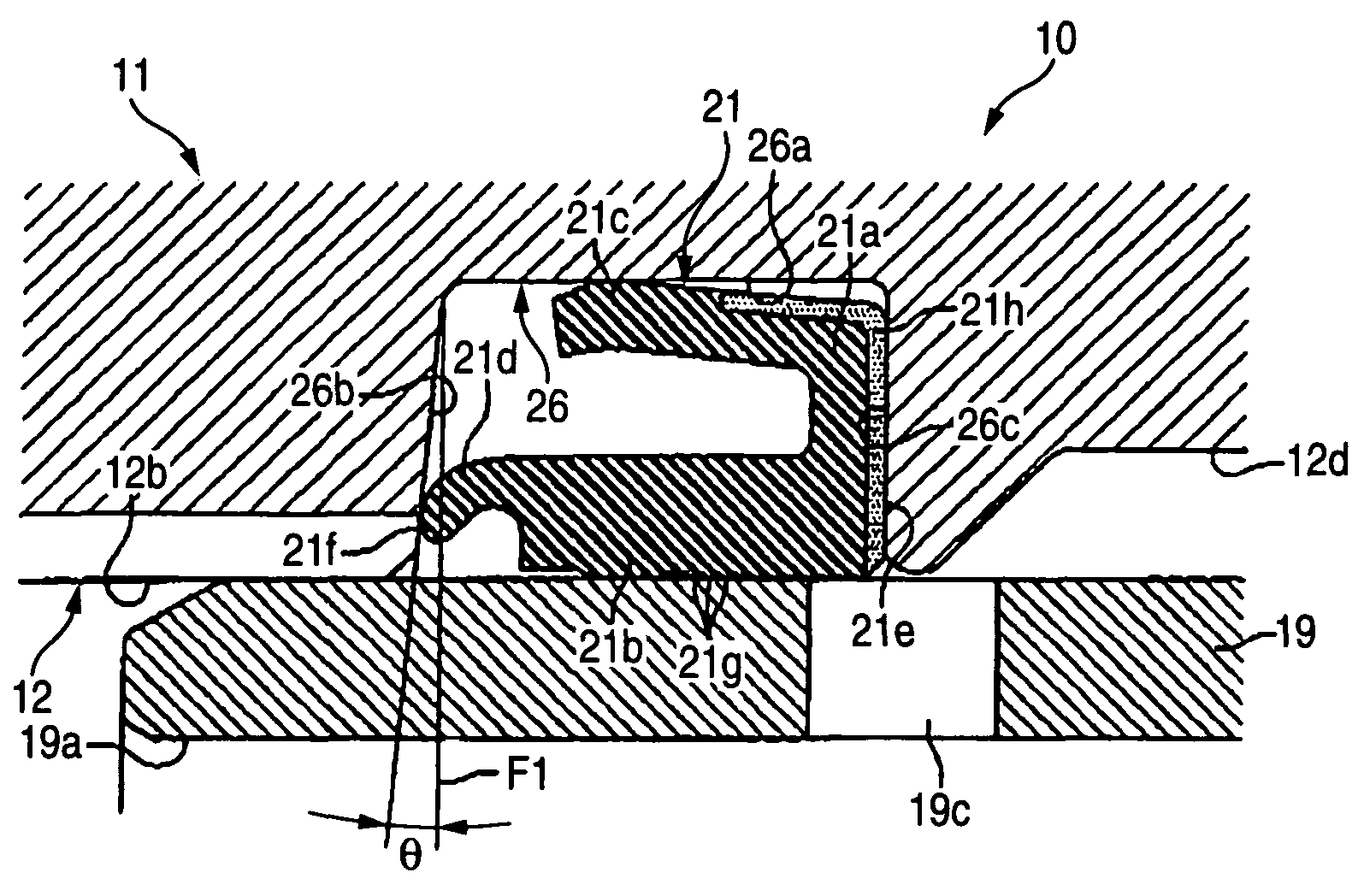

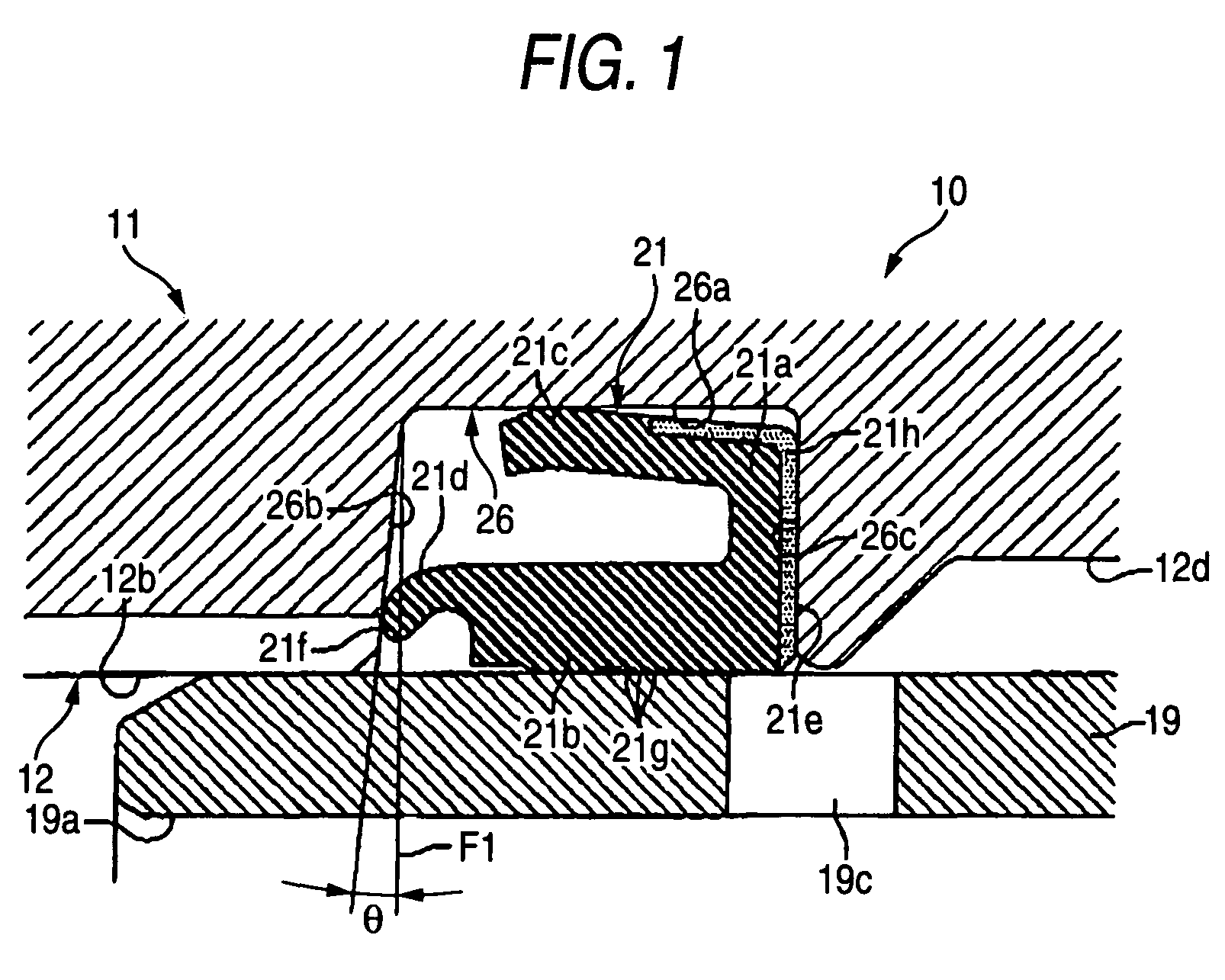

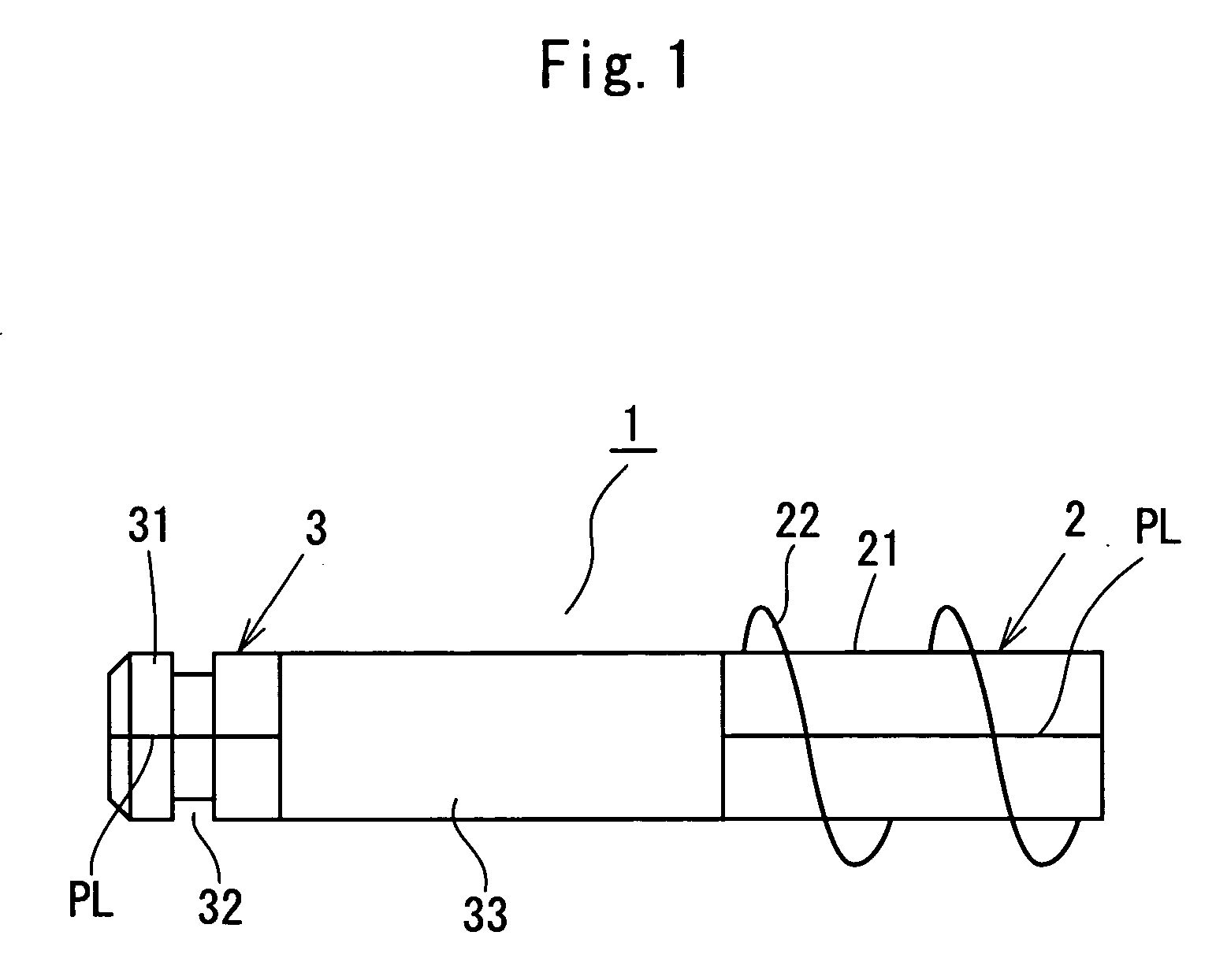

Cylinder device

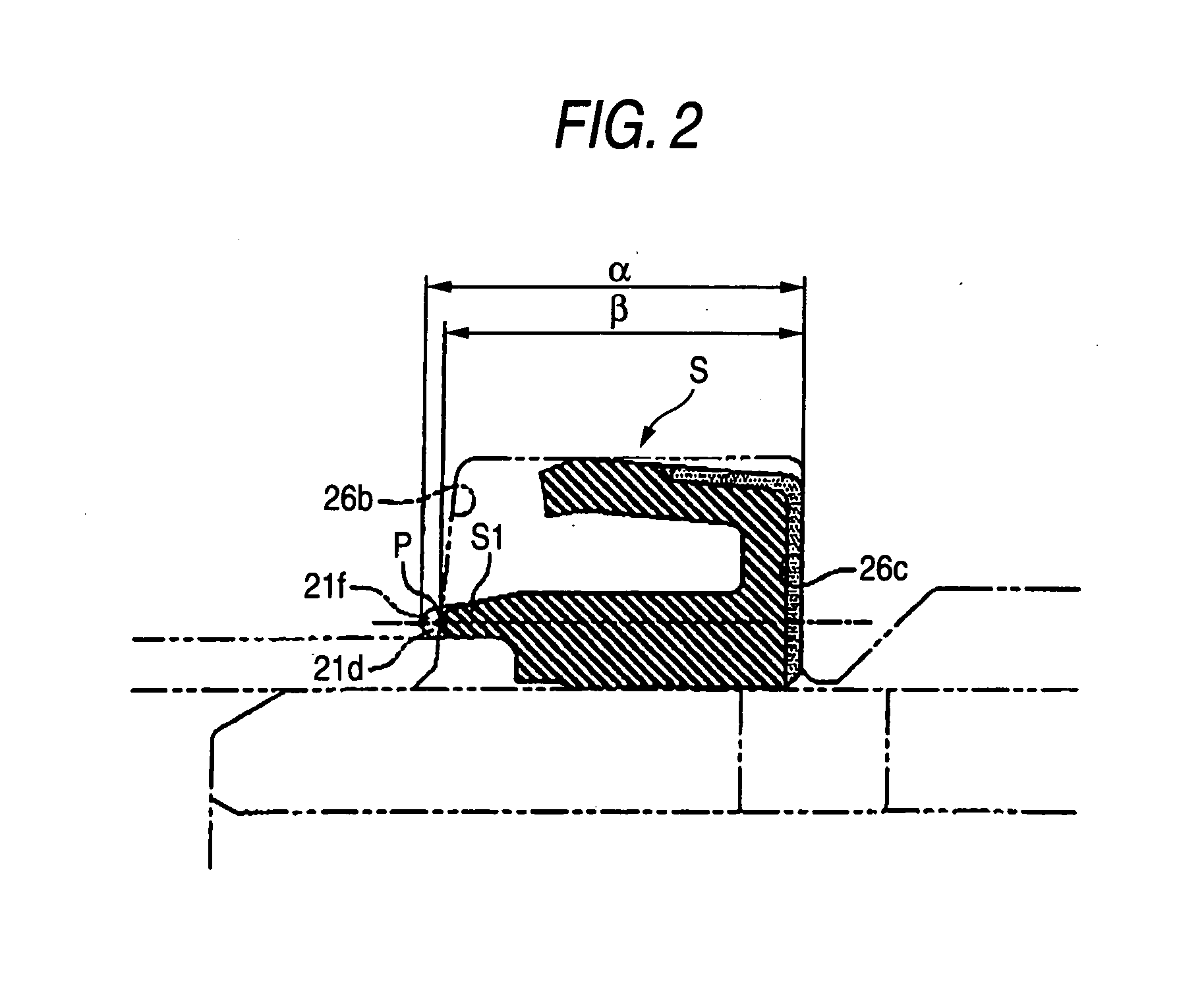

ActiveUS20090071325A1Secure proper seal performanceSimple structureEngine sealsPiston ringsMechanical engineeringPiston

A cup seal 21 includes a base portion 21a, an inner circumferential lip 21b slidingly contactable with a plunger 19 and an outer circumferential lip 21c contactable with the bottom surface 26a of the seal groove 26. Further, on the cup seal 21, there are provided elastic projections 21d projecting from the outer circumferential side leading end of the inner circumferential lip 21b toward the cylinder hole bottom portion. The length of the cup seal 21 from the base end face 21e to the leading end portions 21f is set longer than axial length of the seal groove 26. When the cup seal 21 is fitted into the seal groove 26, force is imparted on the inner circumferential lip 21b toward the cylinder hole inner circumferential direction to energize the inner circumferential lip 21b toward the piston all the time.

Owner:HITACHI ASTEMO LTD

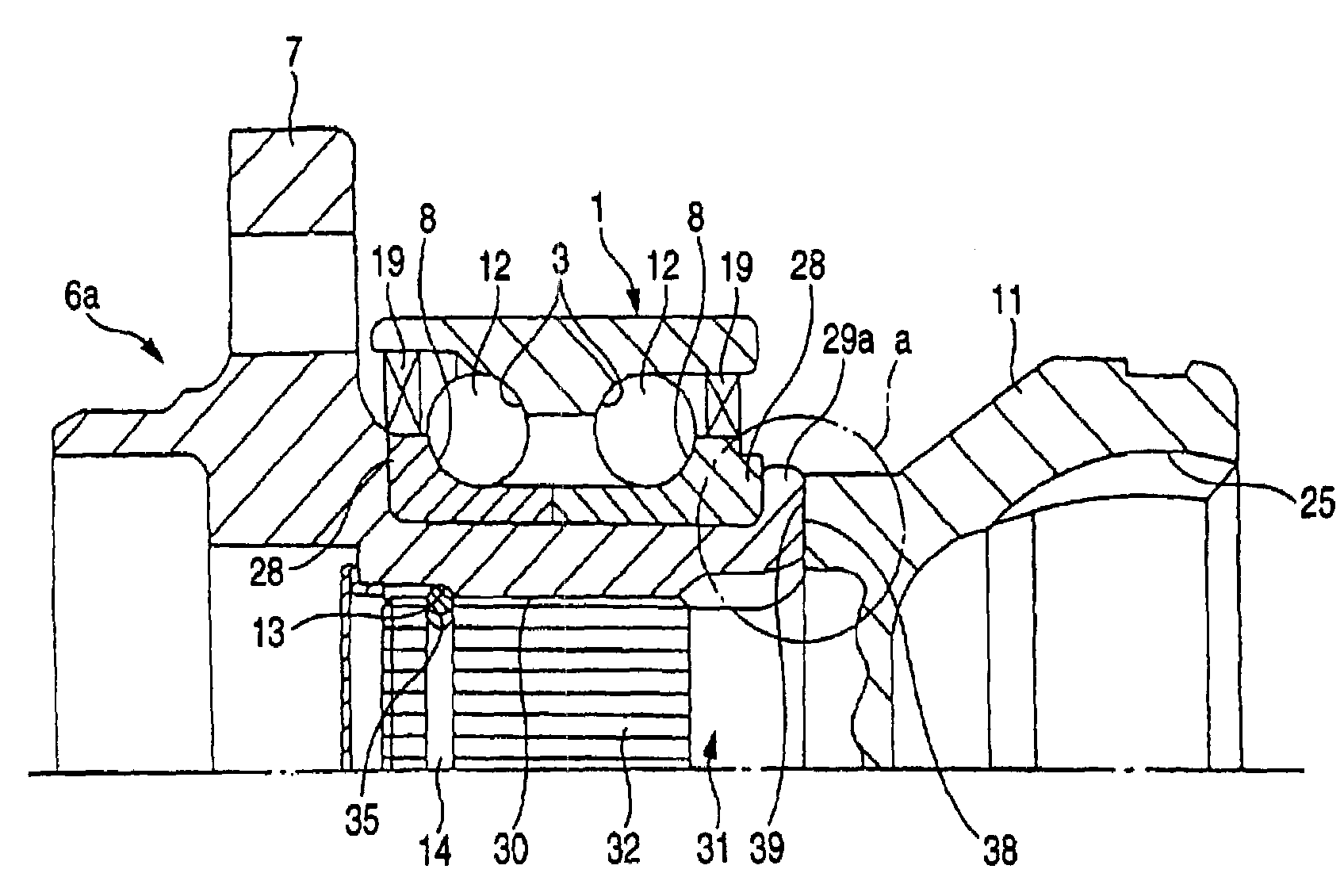

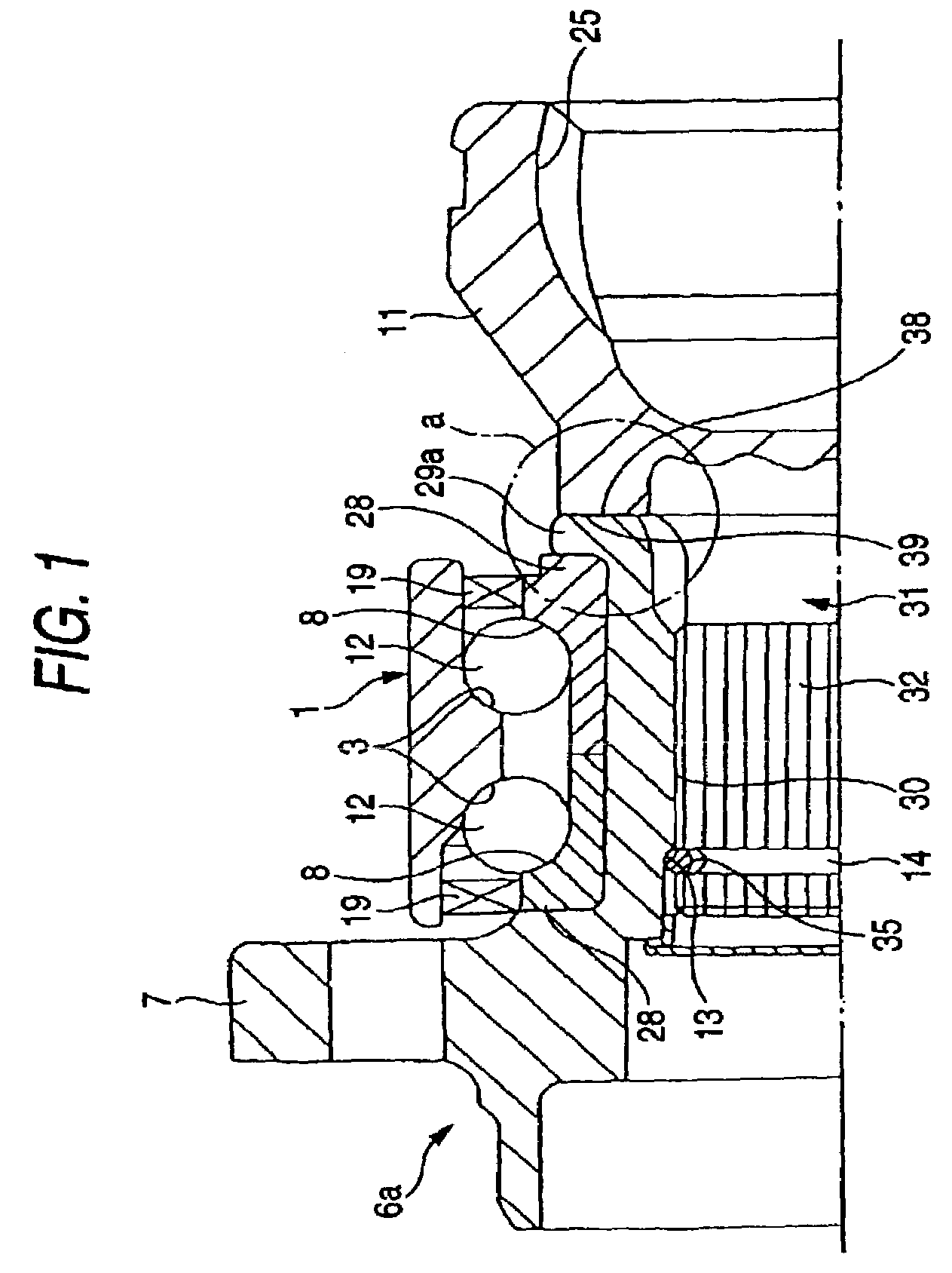

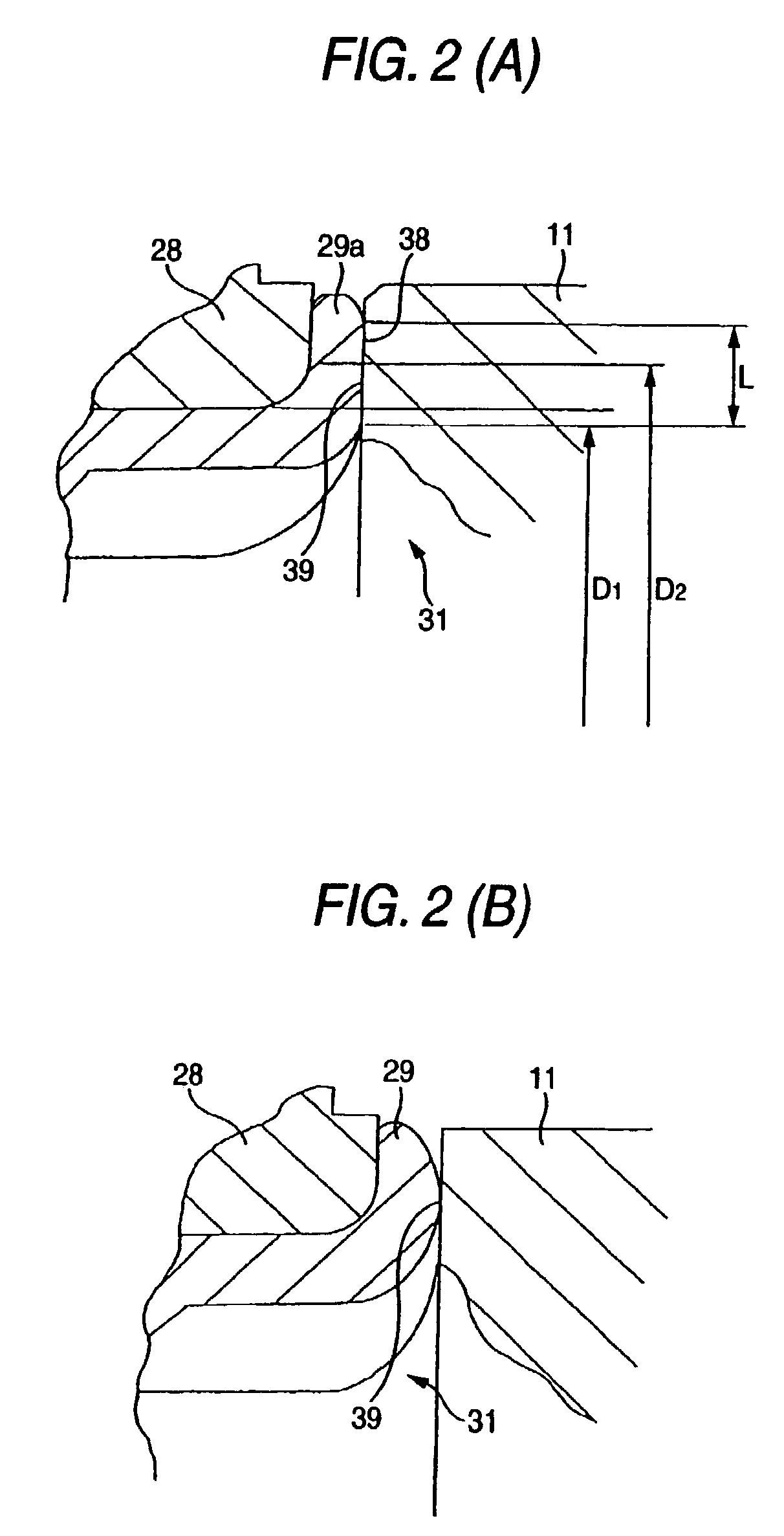

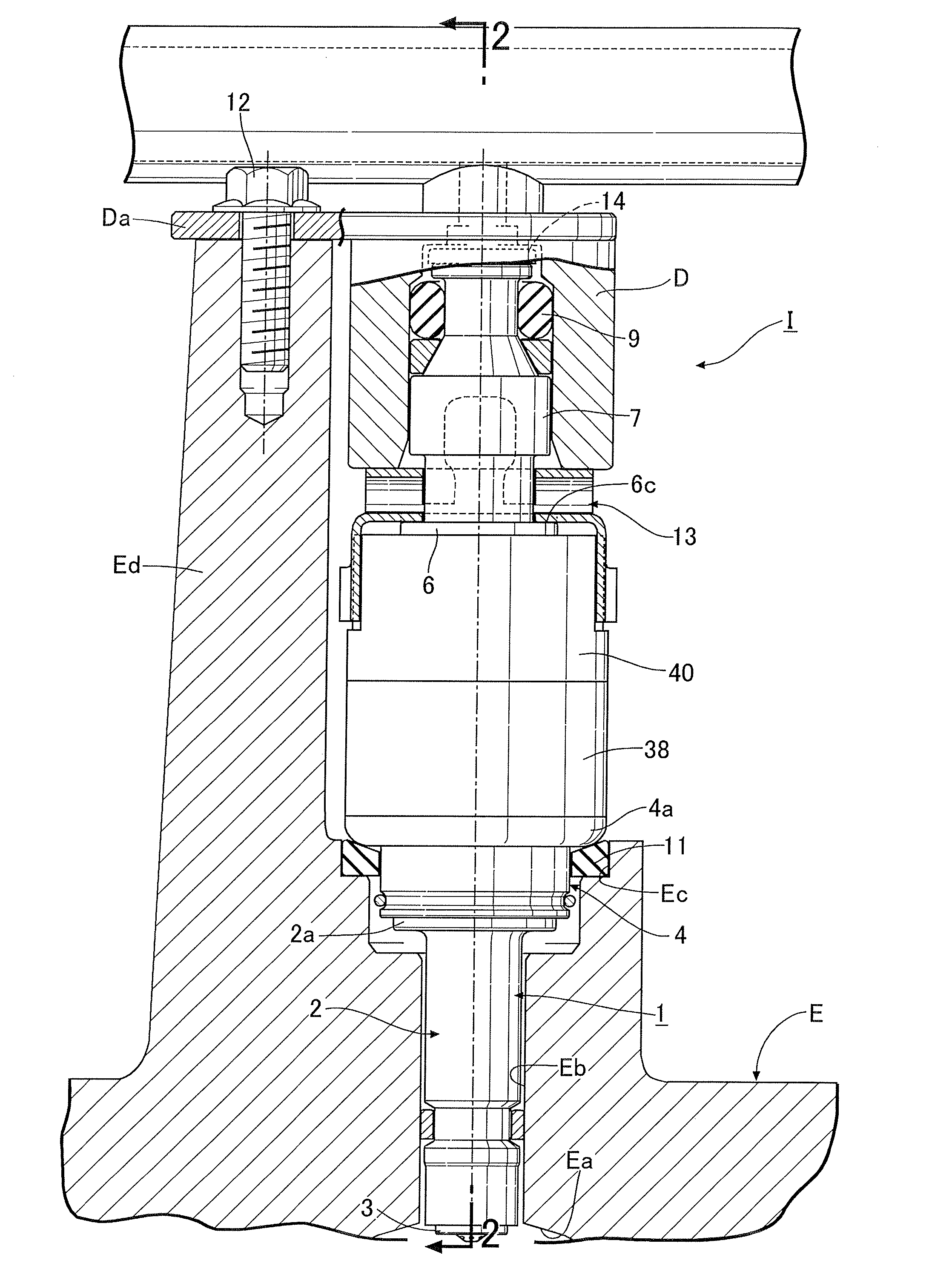

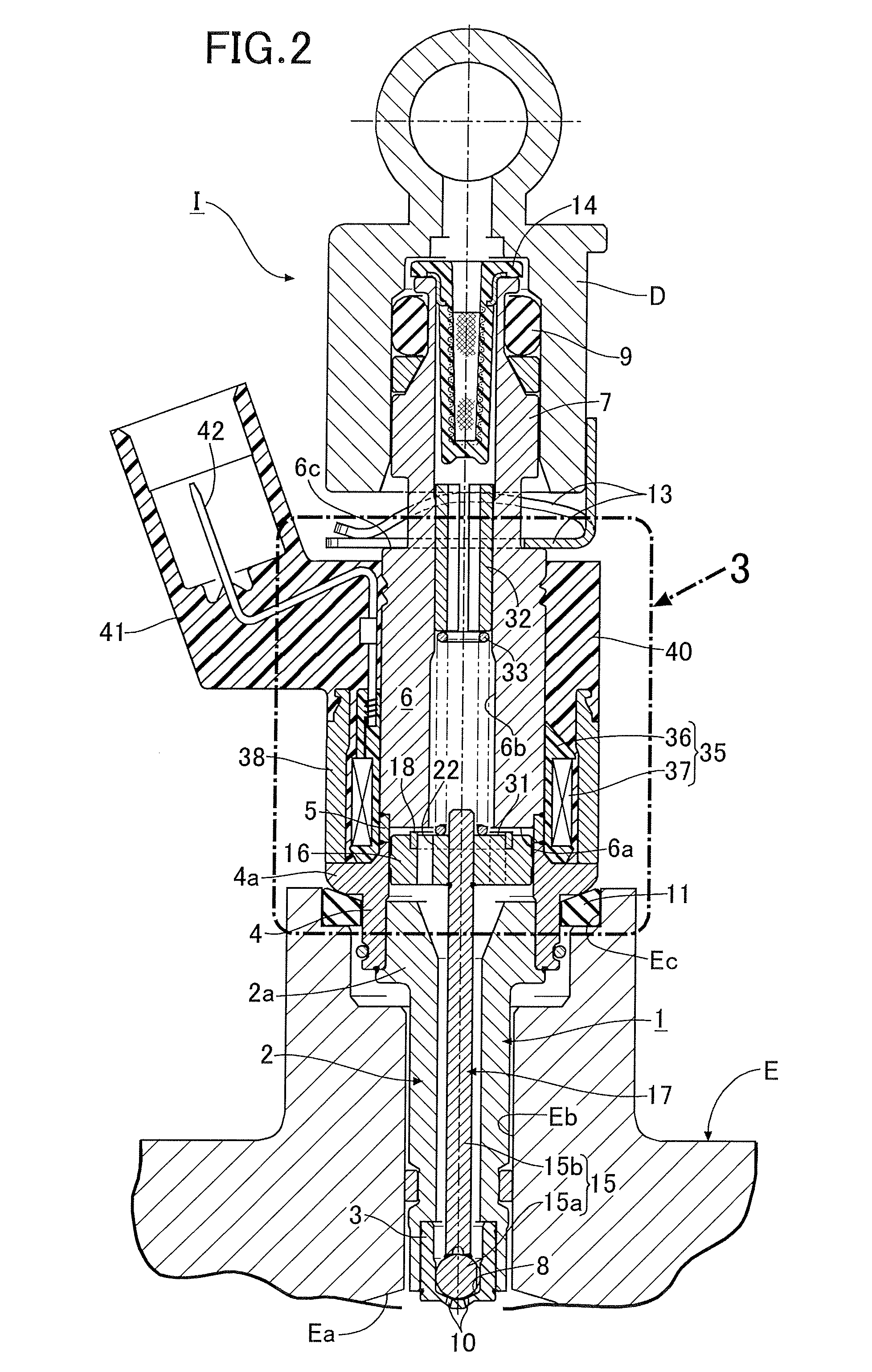

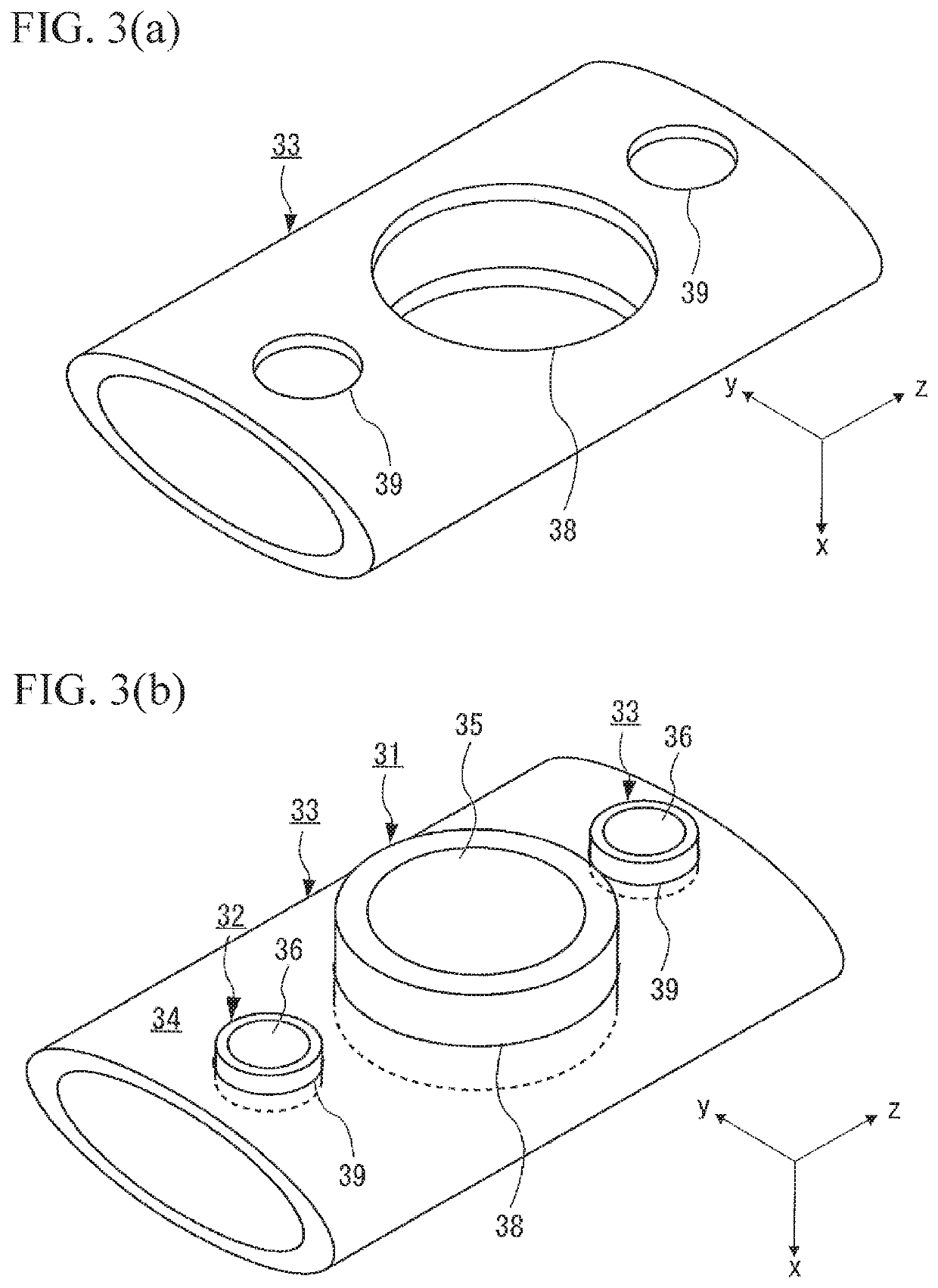

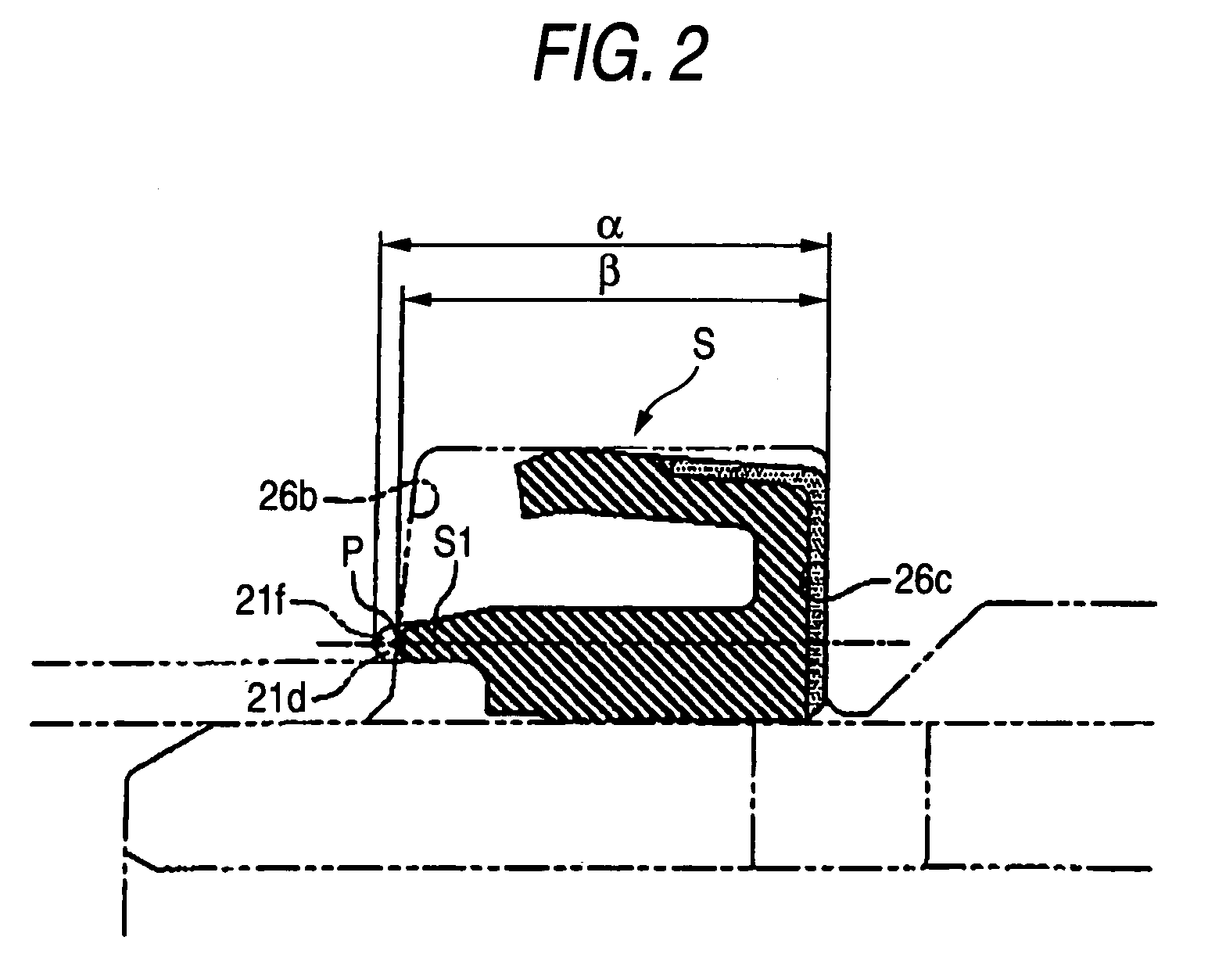

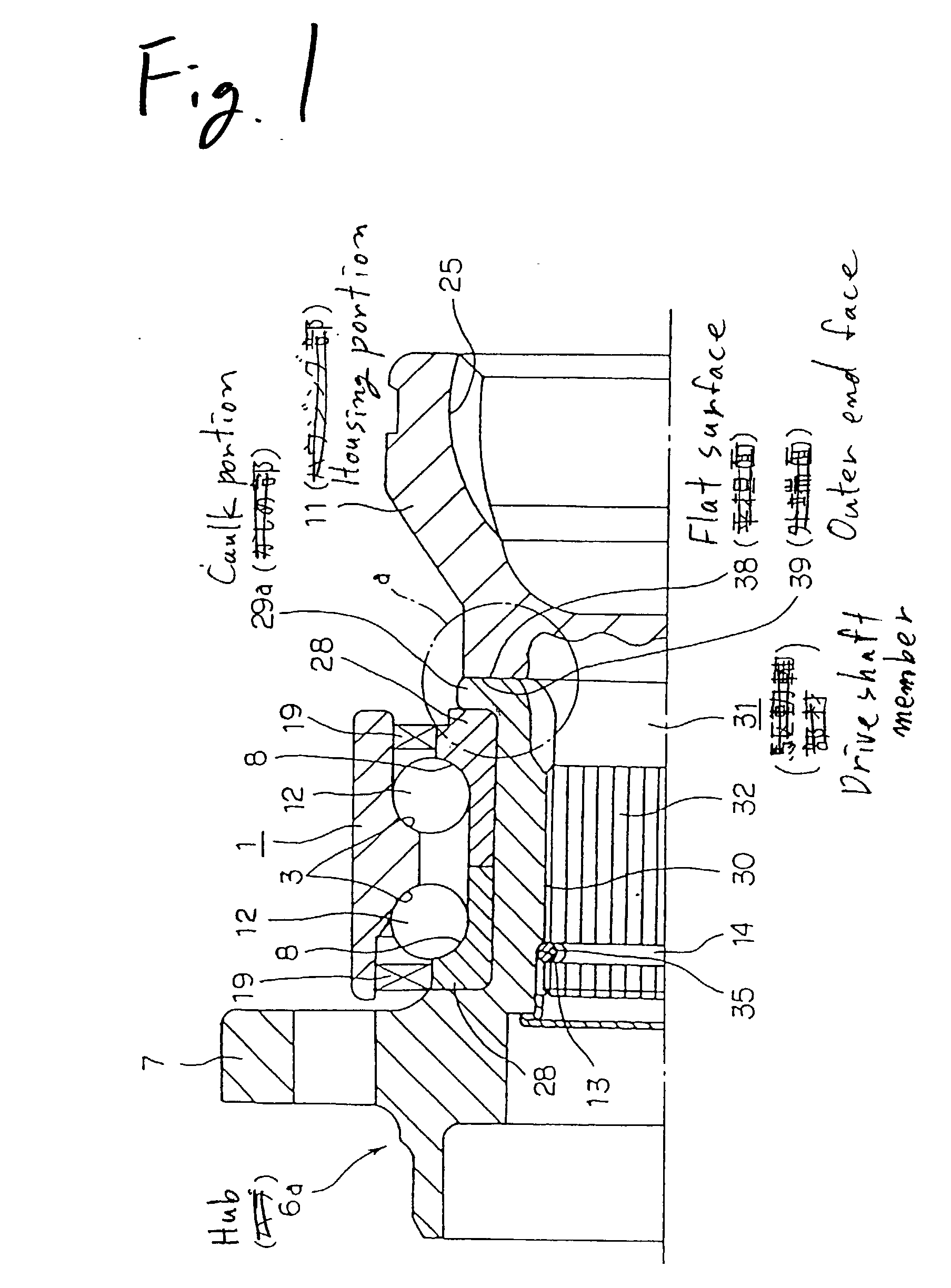

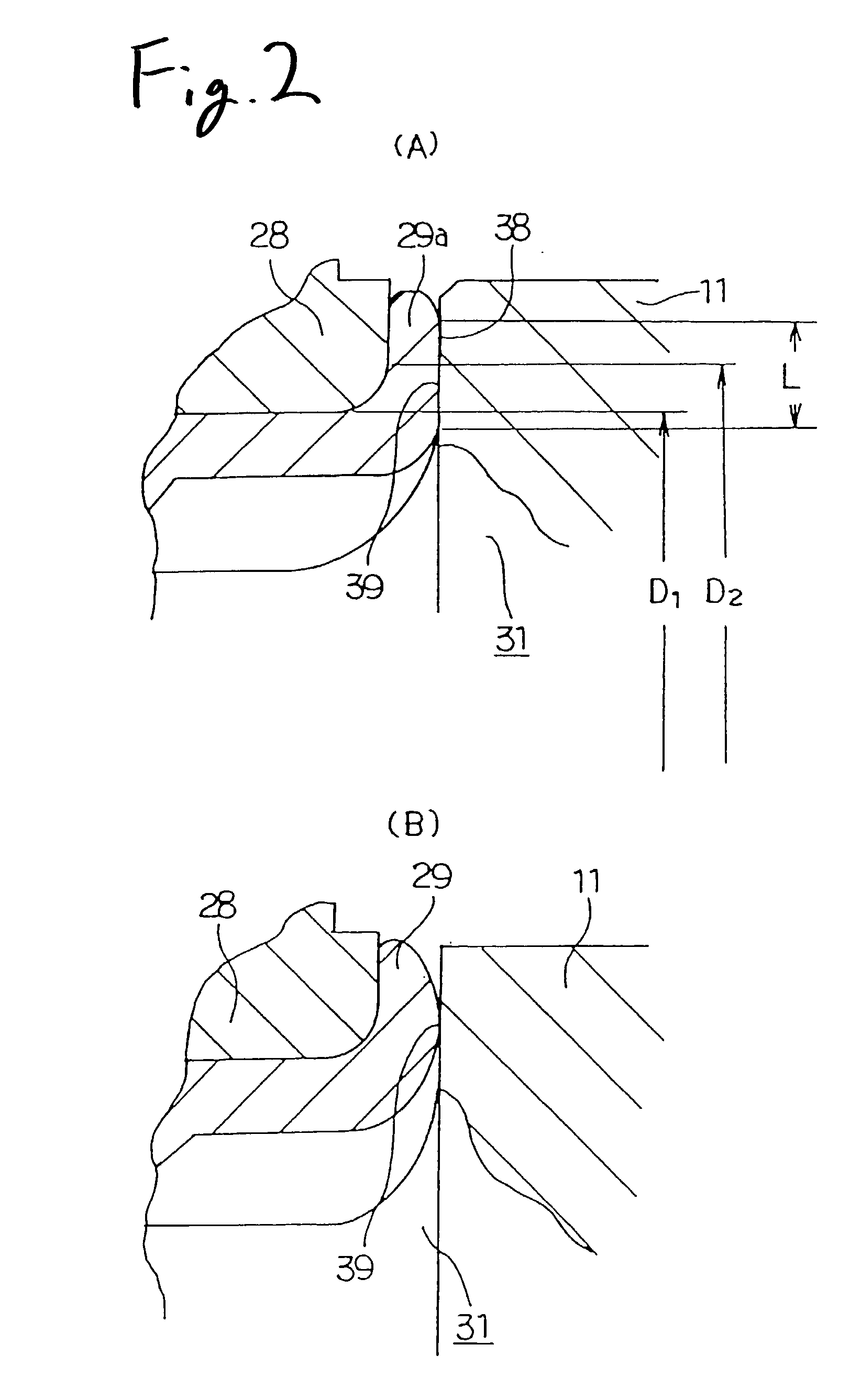

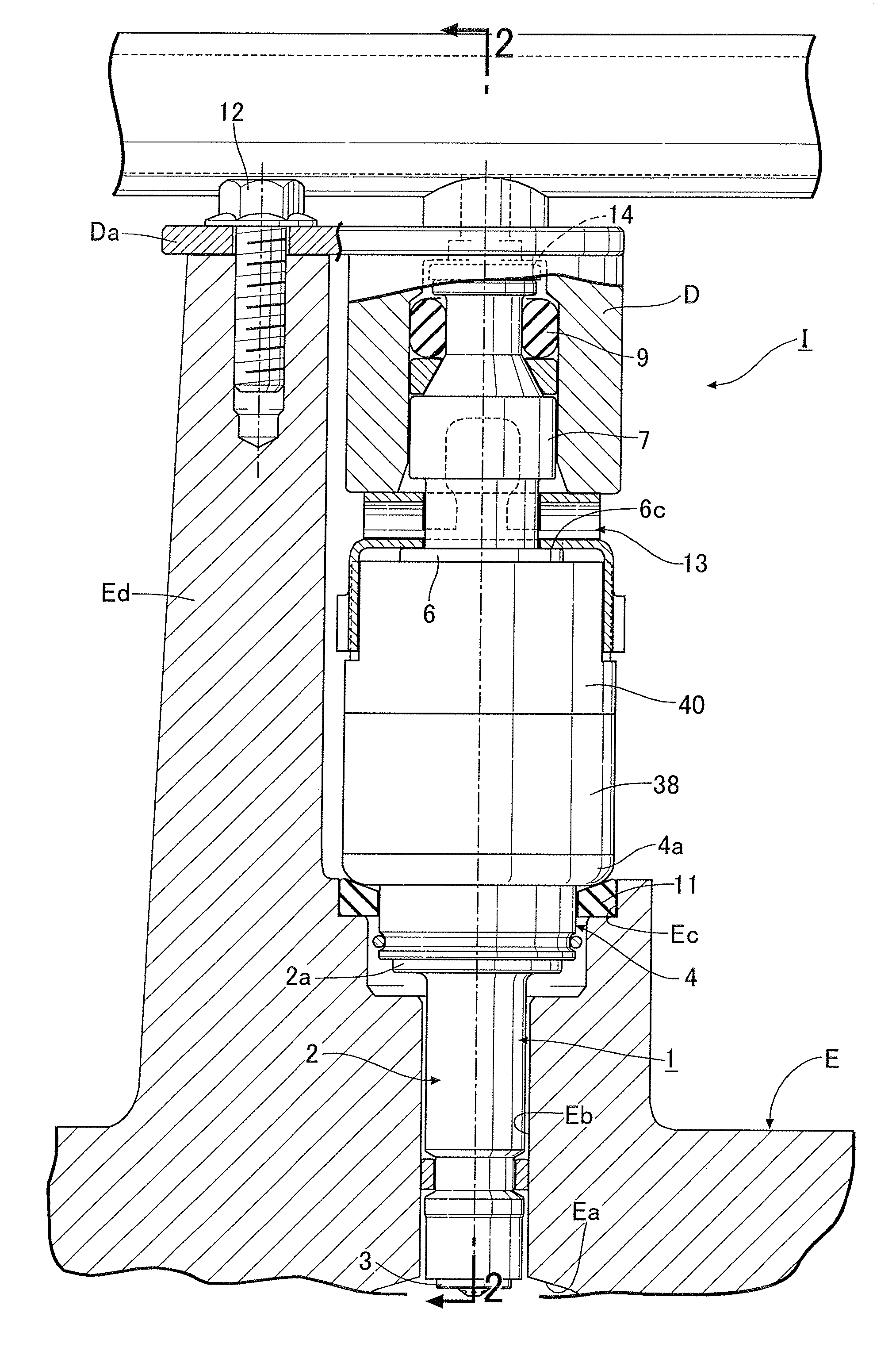

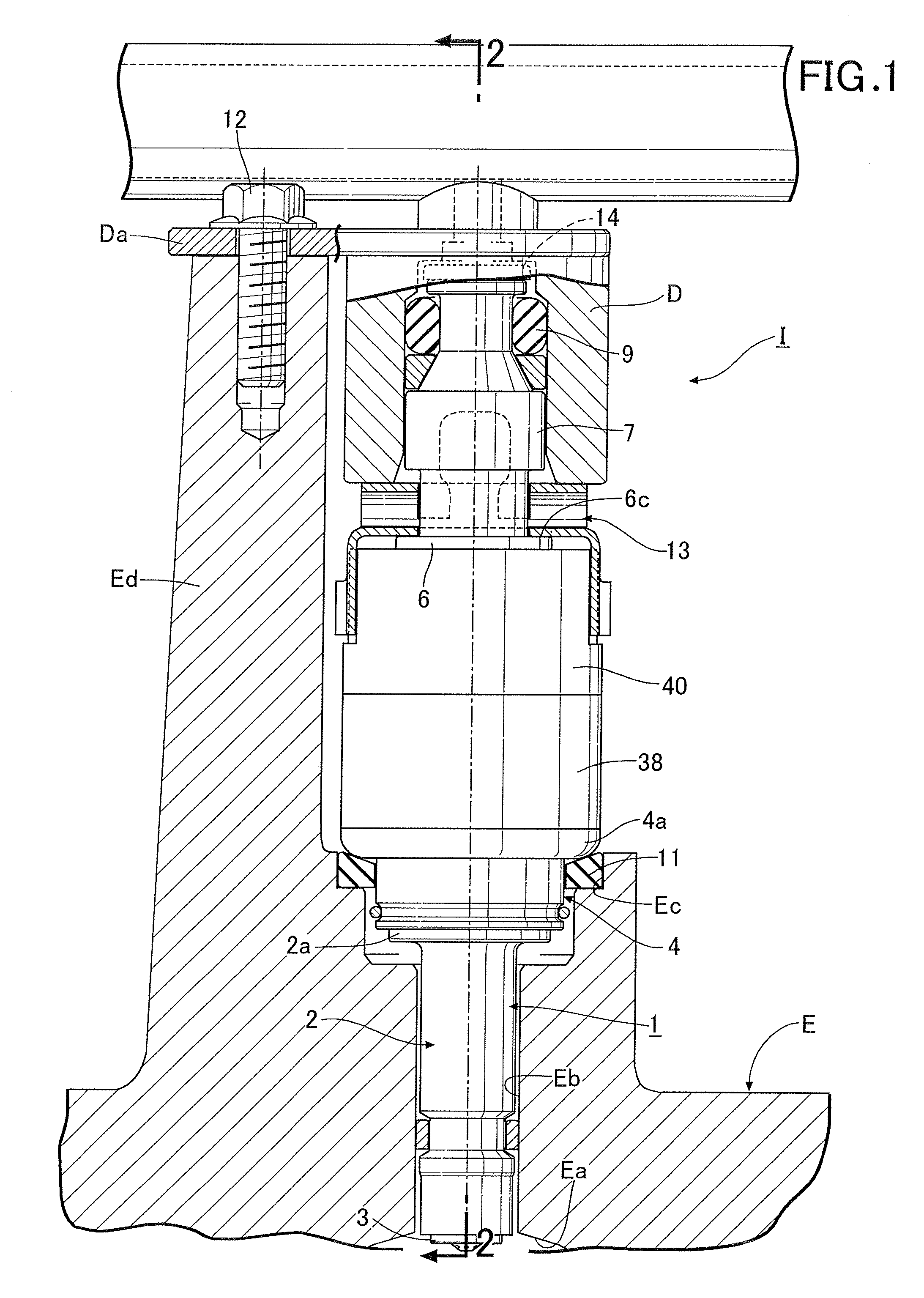

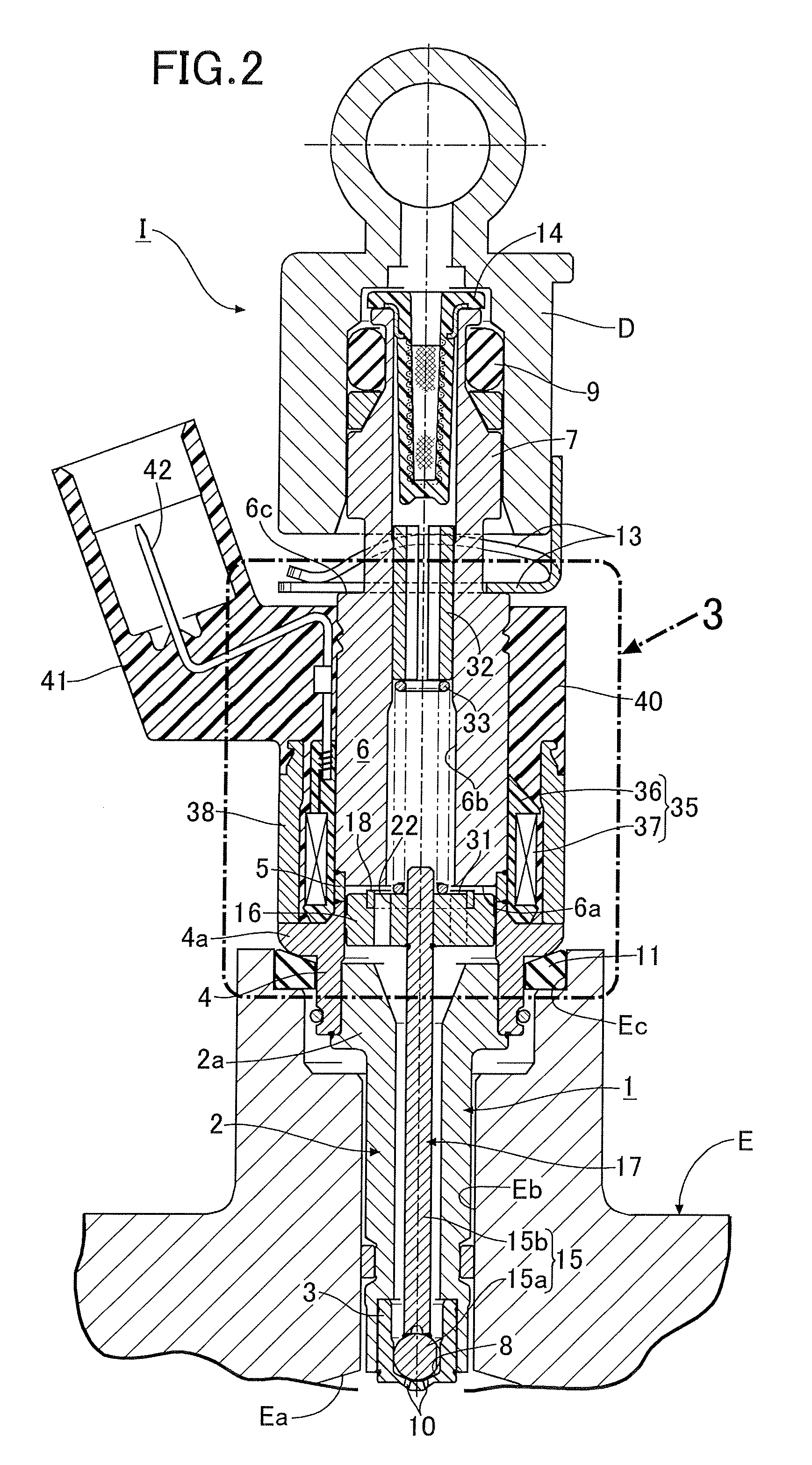

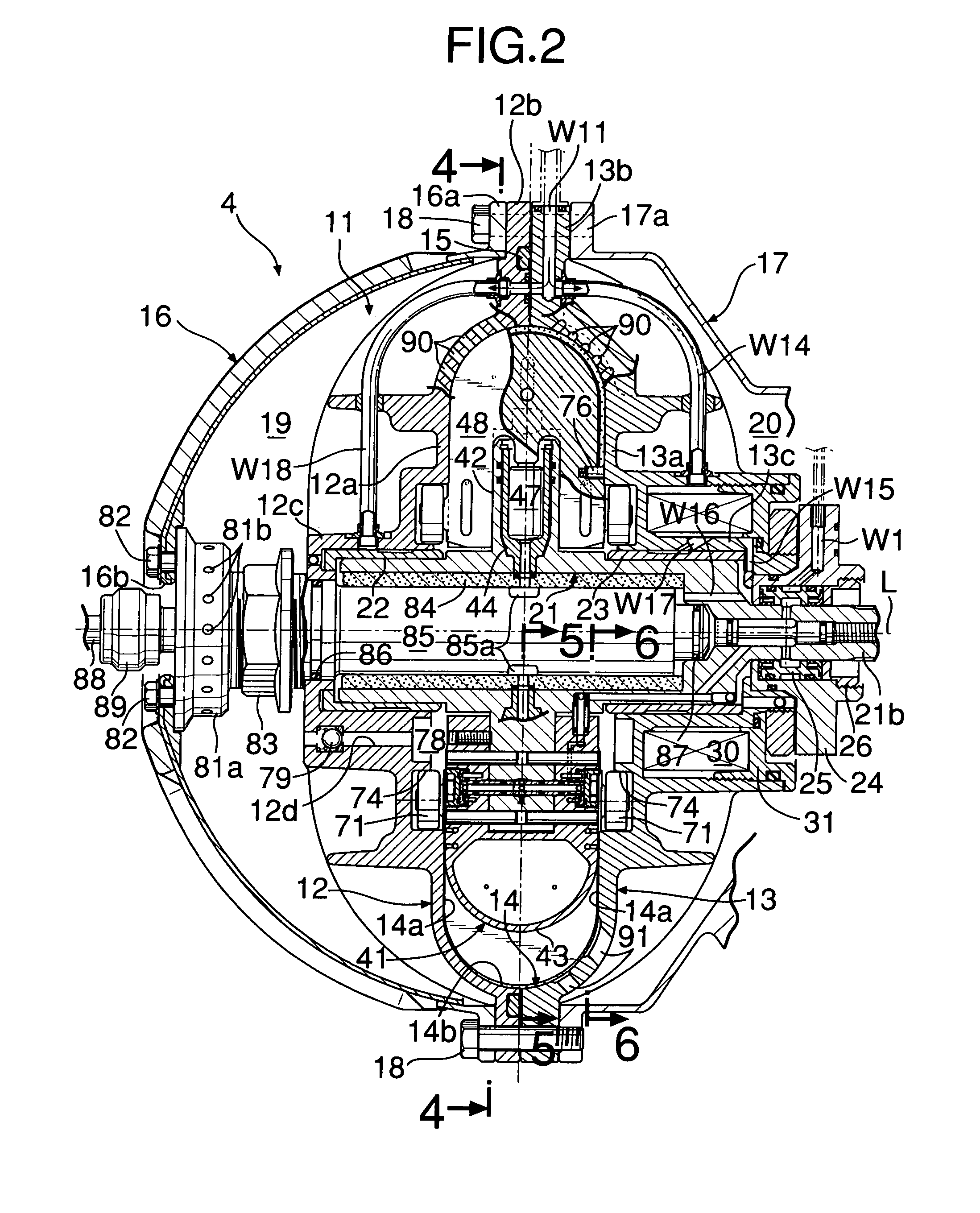

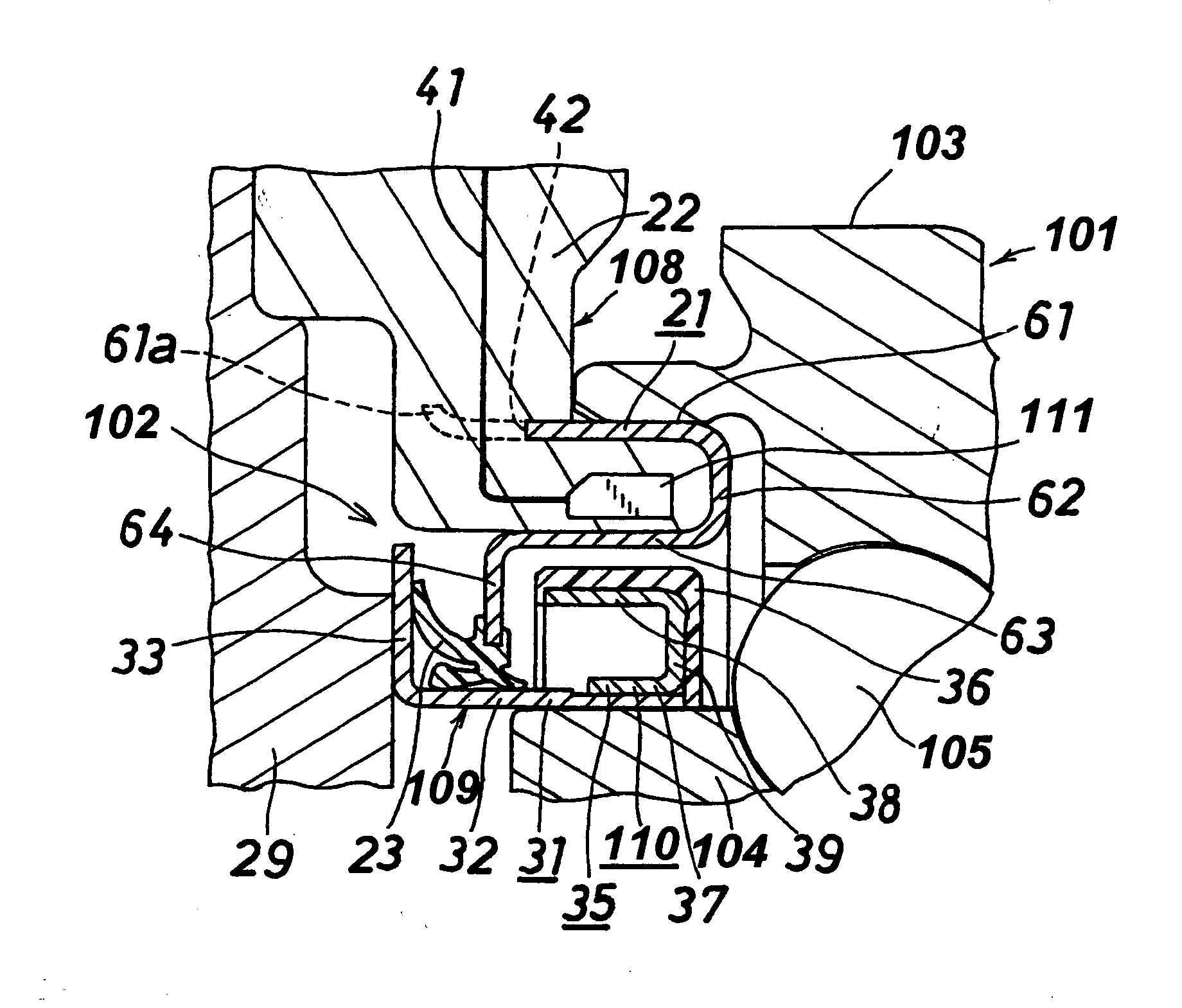

Axle unit for driving wheel

InactiveUS7118182B2Prevent leakagePrevent occurrenceYielding couplingRolling contact bearingsDrive wheelDrive shaft

A drive-wheel axle unit which prevents the mutual contact portion between a caulk portion (29a) of a hub (6a) and an outer-end face (39) of a housing portion (11) of a drive shaft member (31) from being exhausted, thereby preventing the occurrence of shaky motion, strange sounds and vibrations for a long period of time. A flat surface (38) is formed in the end face of the caulk portion (29a), and is contacted over a large area with the outer end face (39), which makes it possible to reduce the contact surface pressure in the mutual contact portion between the flat surface (38) and outer end face (39).

Owner:NSK LTD

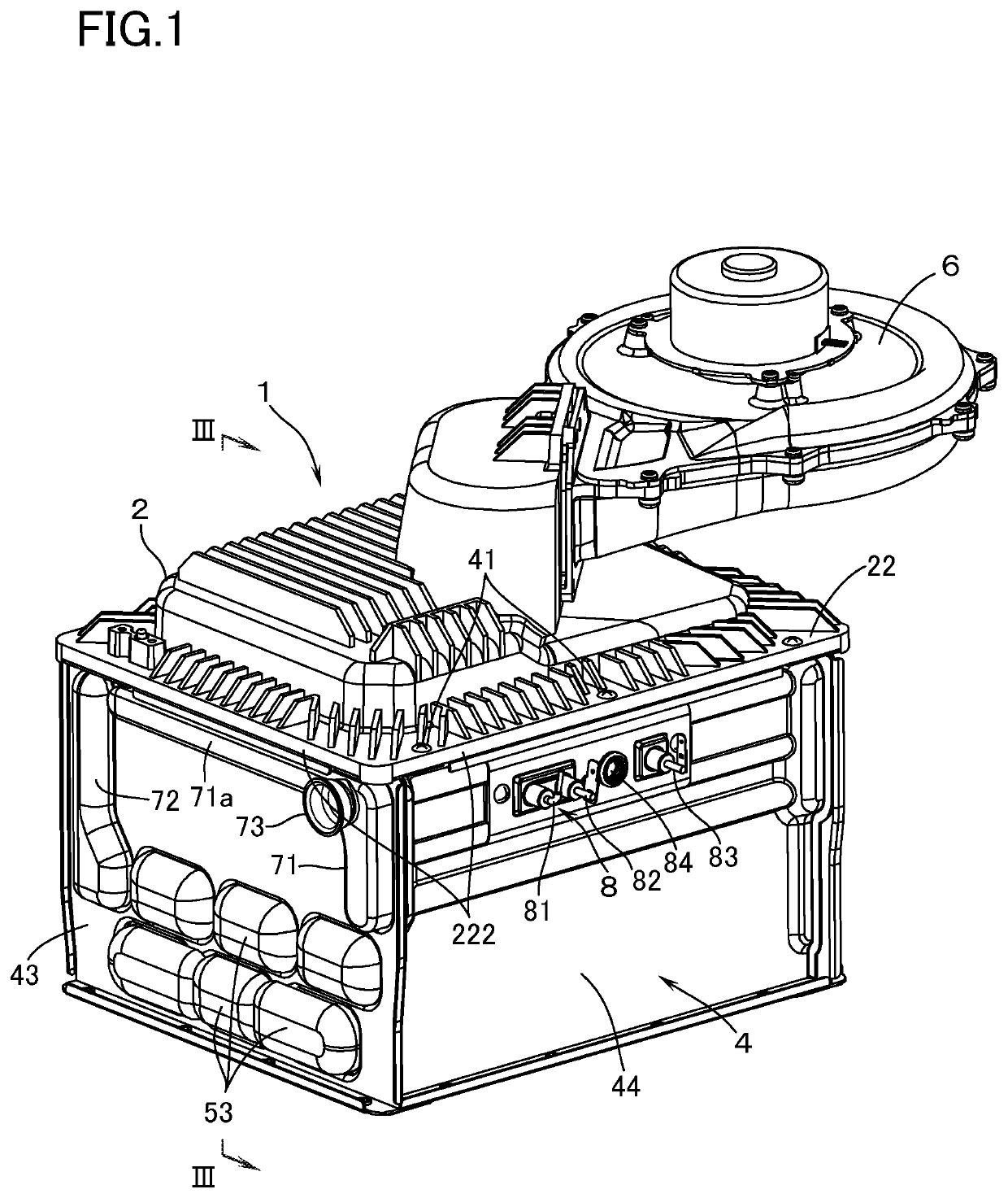

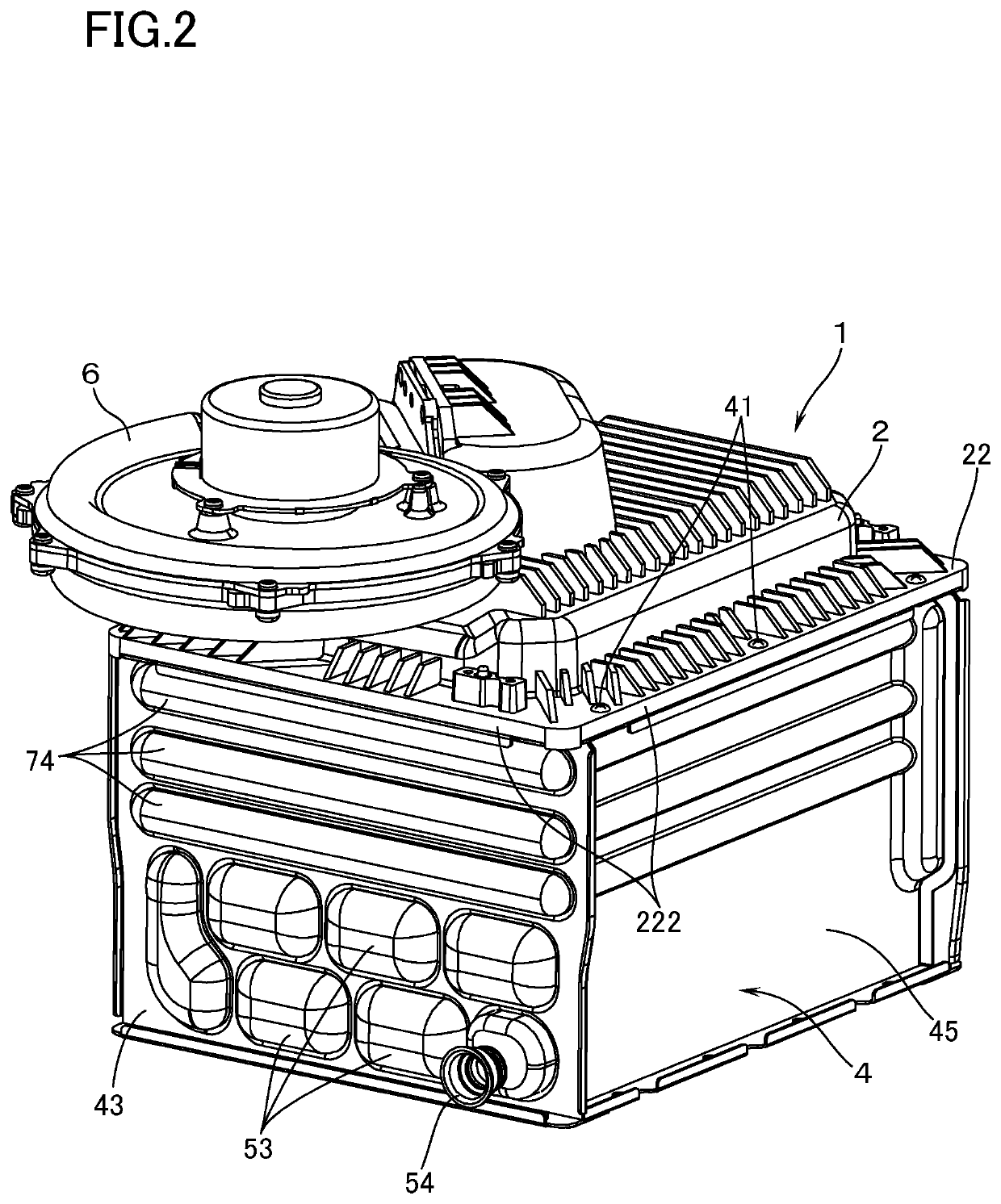

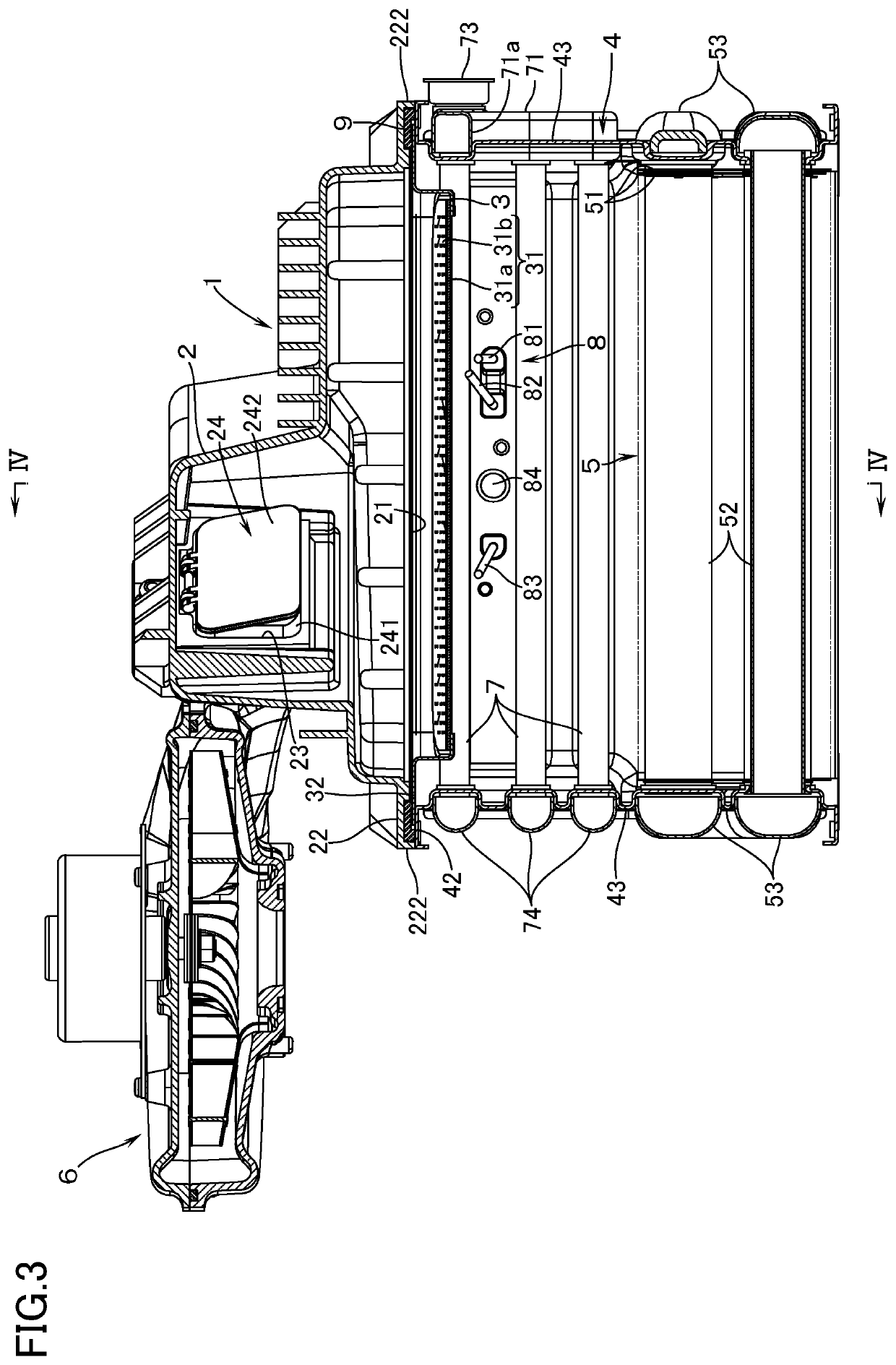

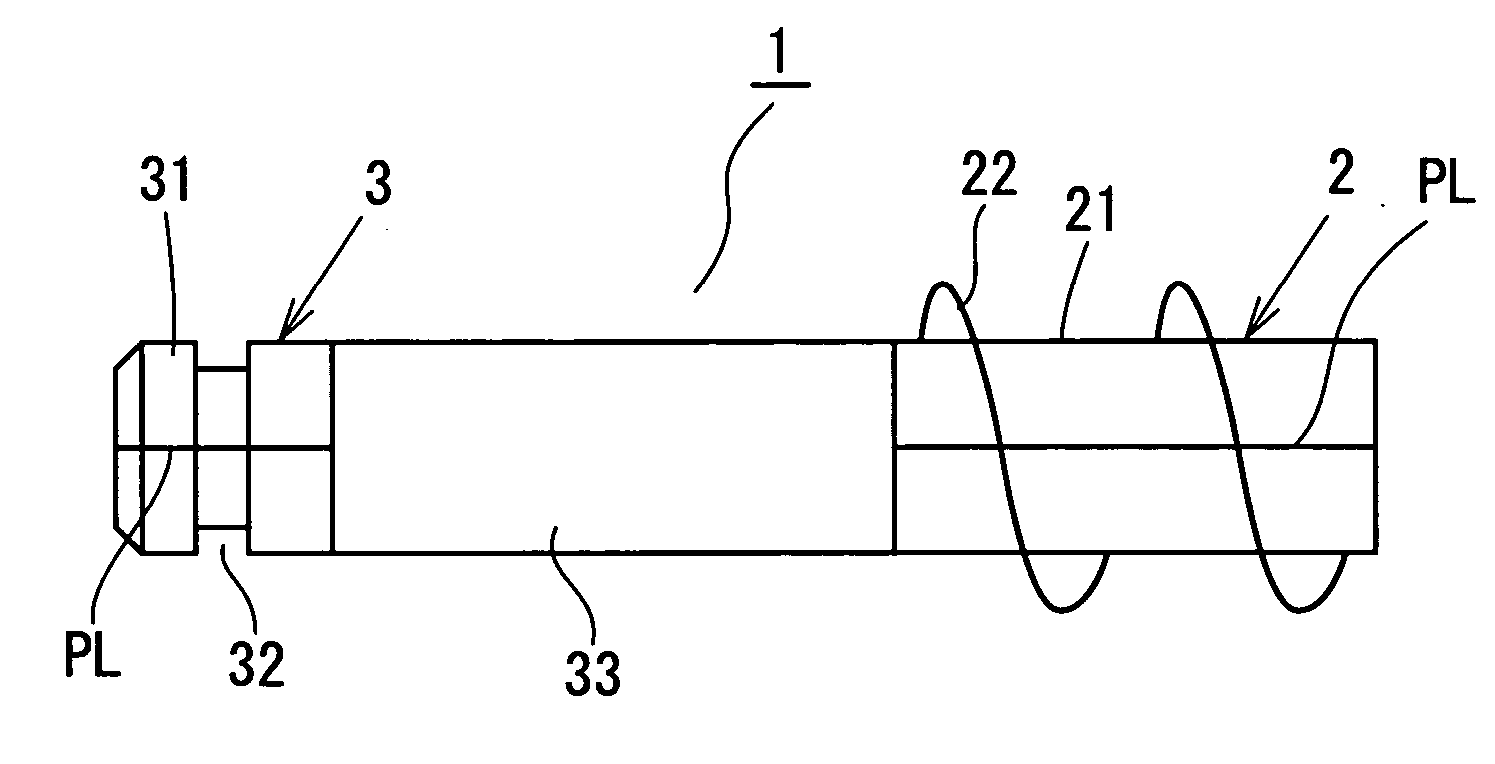

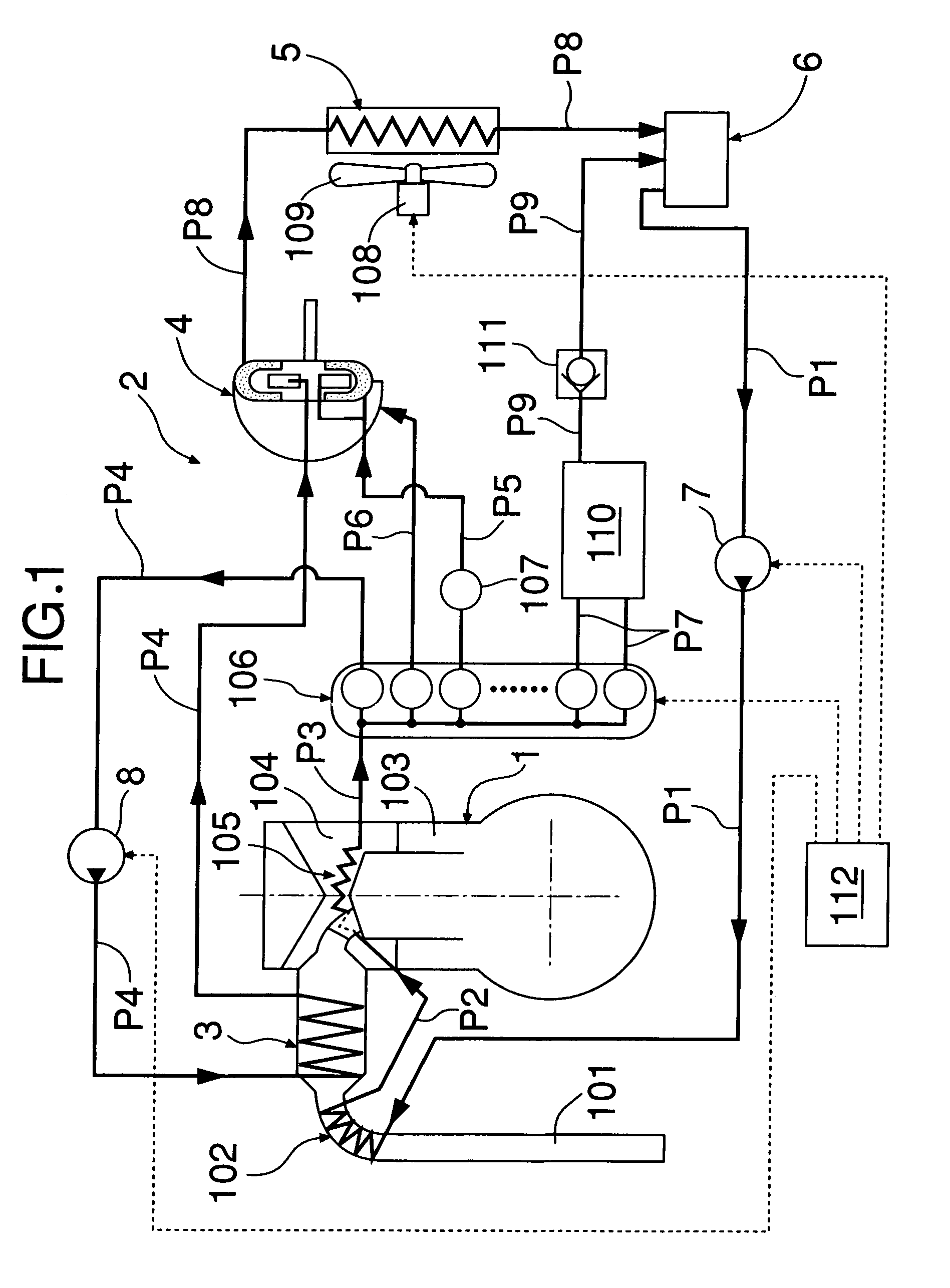

Support structure of direct fuel injection valve

ActiveUS20140123933A1Reducing setting loadReduce loadCombustion enginesSpecial fuel injection apparatusFuel distributionEngineering

In a support structure of a direct fuel injection valve capable of supporting a fuel injection valve stably for a long period of time, a valve housing is made of a metal and is provided with a first load bearing portion which is to be supported by an engine in an axial direction of the valve housing, a rear end portion of the fixed core is provided with a second load bearing portion which is to be supported by a resilient holding member in the axial direction, and the first and second load bearing portions are held between the engine and the resilient holding members with a forward set load applied to the resilient holding member by a fuel distribution pipe fitted to a fuel inlet tube and fixed to the engine.

Owner:HITACHI ASTEMO LTD

Vehicular brake system component

ActiveUS7377292B2Improve sealingSecure sealing performanceAccumulator installationsPipe elementsBrake fluidBraking system

Owner:NHK SPRING CO LTD +2

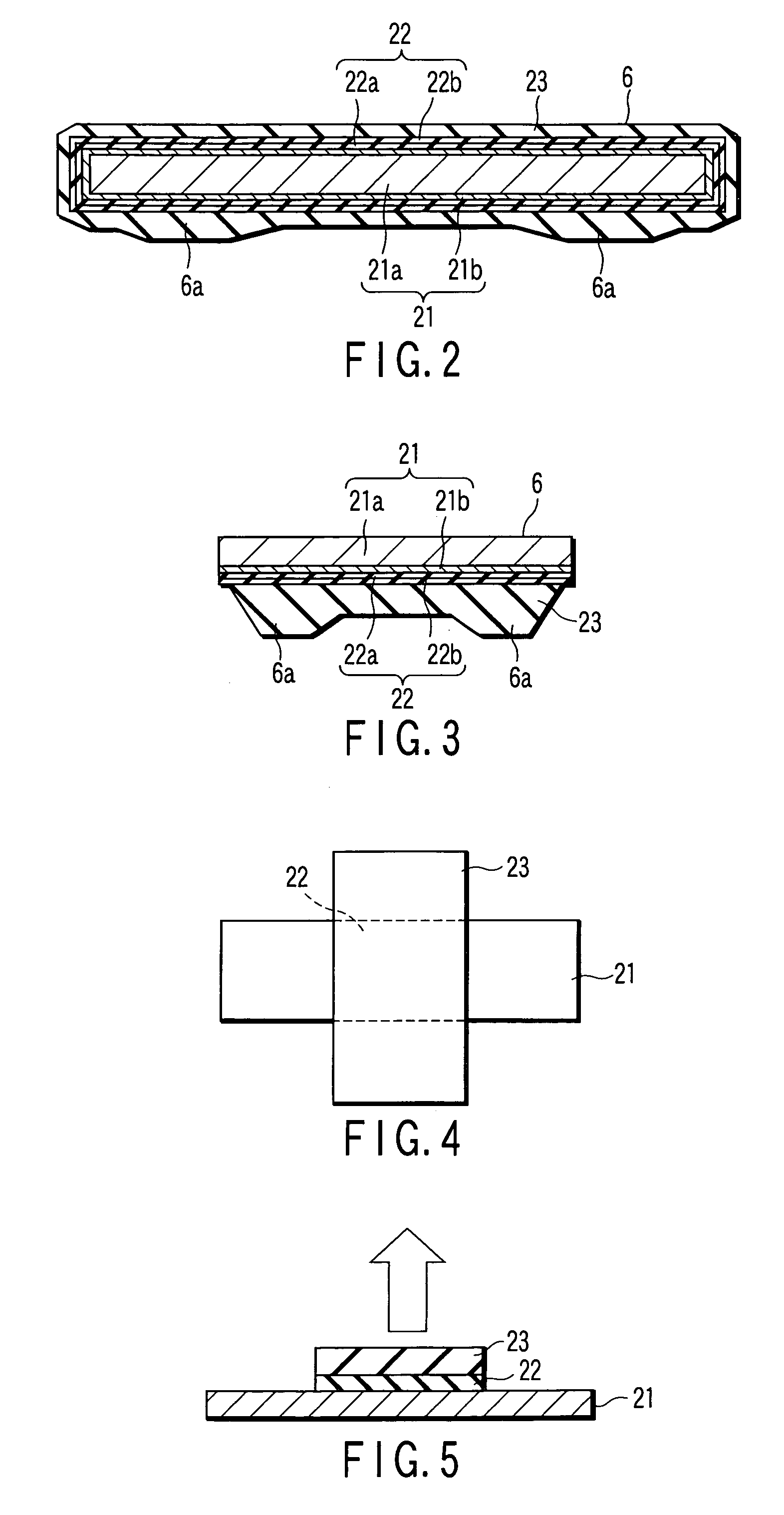

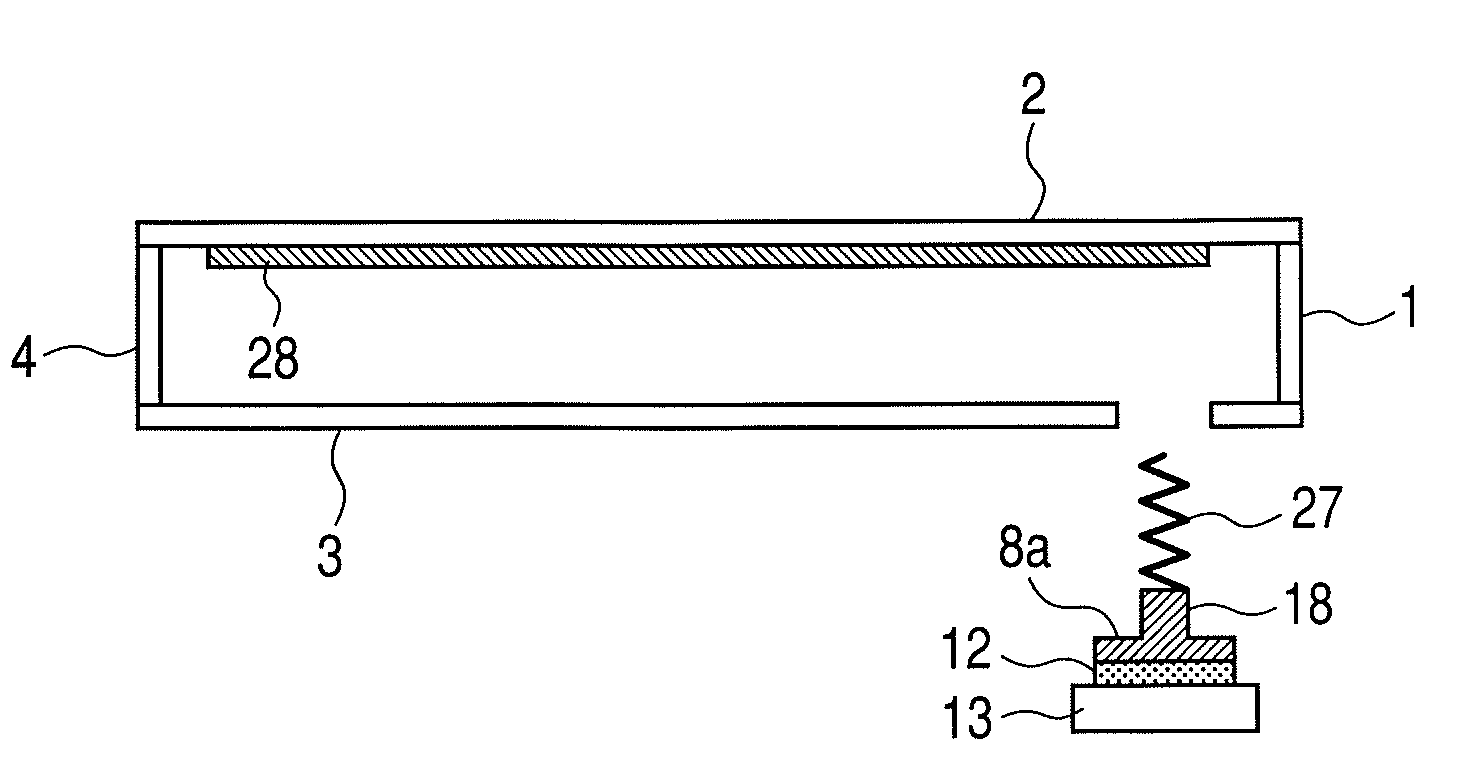

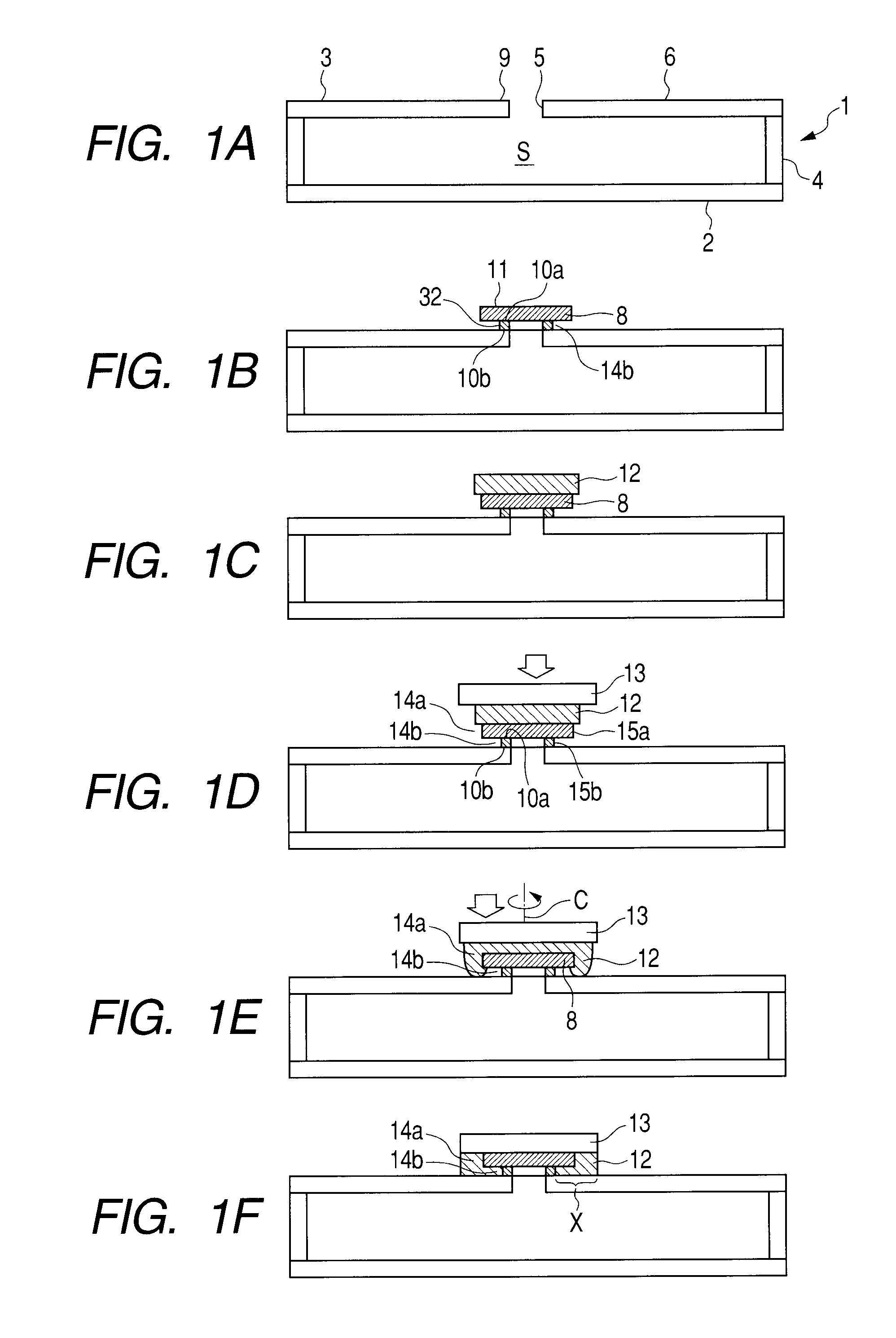

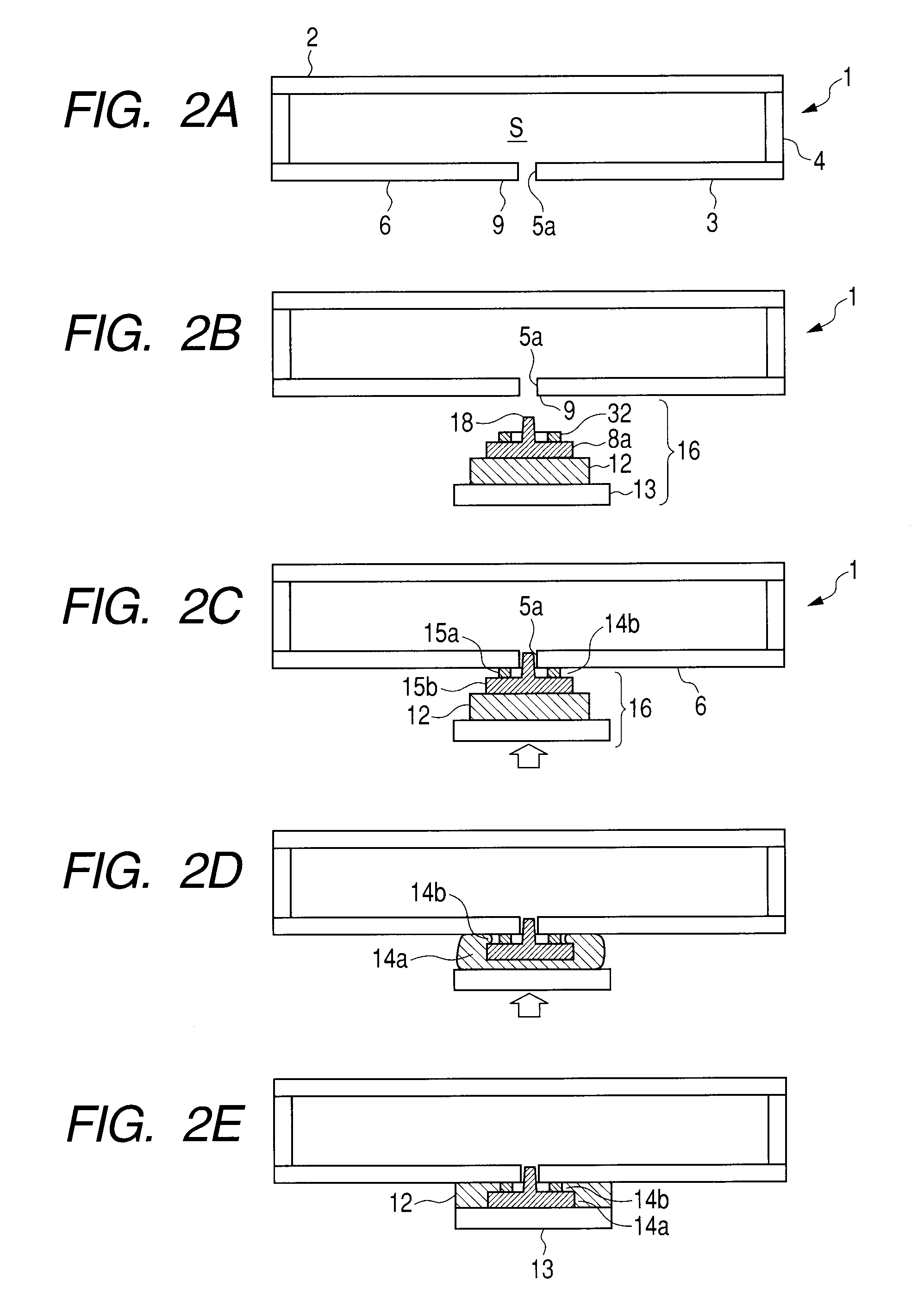

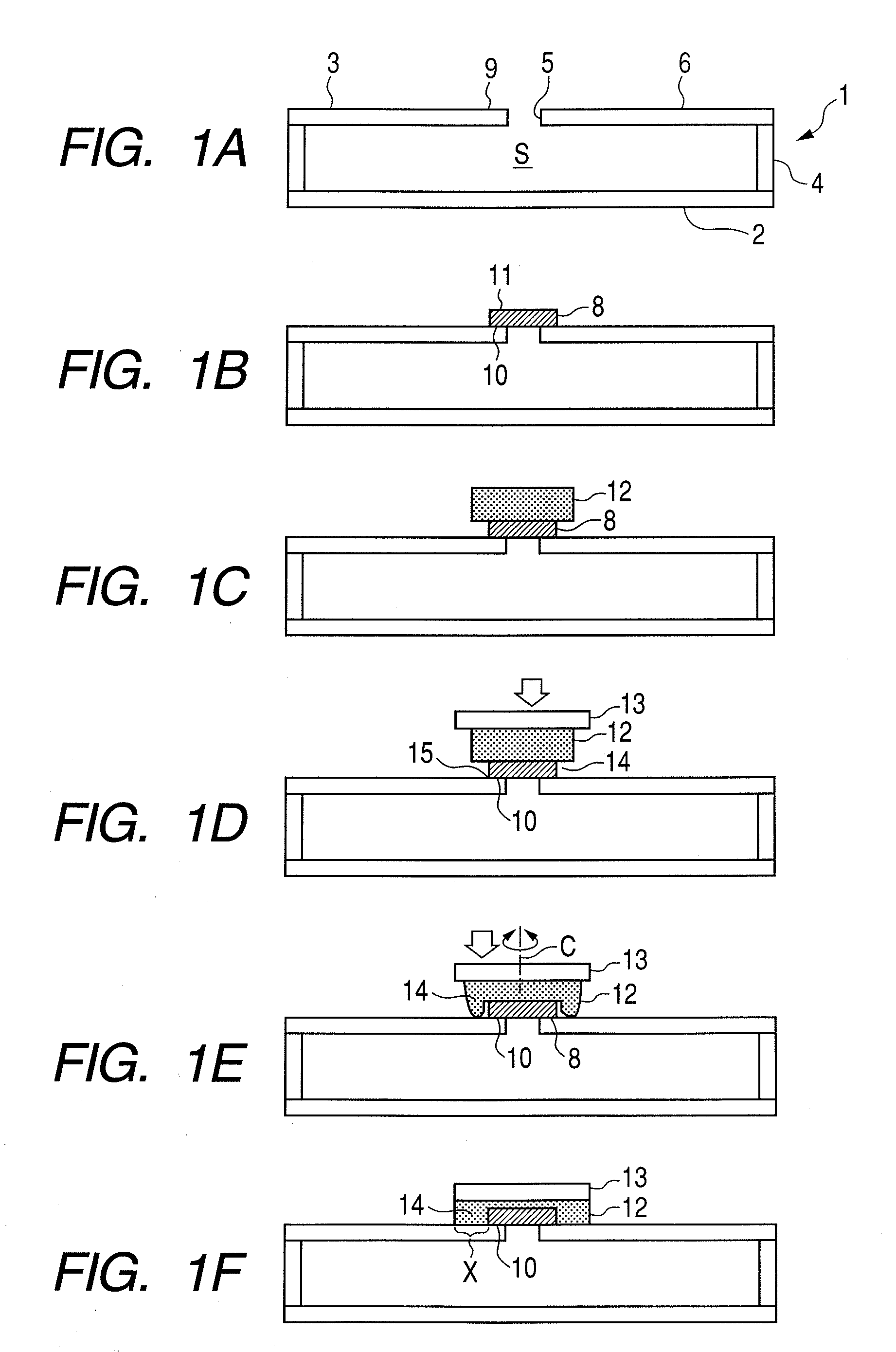

Airtight container and manufacturing method of image displaying apparatus using airtight container

InactiveUS7914357B2Secure sealing performanceAvoid flowVessels or leading-in conductors manufacturePhoto-emissive cathodes manufactureConductive materialsEngineering

A manufacturing method of an image displaying apparatus, having an airtight container with a vacuum interior, includes the steps of exhausting an inside of a container via a through-hole provided in the container, arranging a plate member on an outer surface of the container, the inside of which was exhausted, so as to close the through-hole, and sealing the container by arranging a cover member to cover the plate member and by bonding the arranged cover member and the outer surface of the container to each other via a sealant positioned between the cover member and the outer surface of the container. The sealing includes hardening the sealant after deforming the sealant by pressing the plate member, and the plate member has a terminal portion including a conductive material. Additional steps include providing an anode electrode in the airtight container, and performing the sealing in a state that the terminal portion is in contact with the anode electrode.

Owner:CANON KK

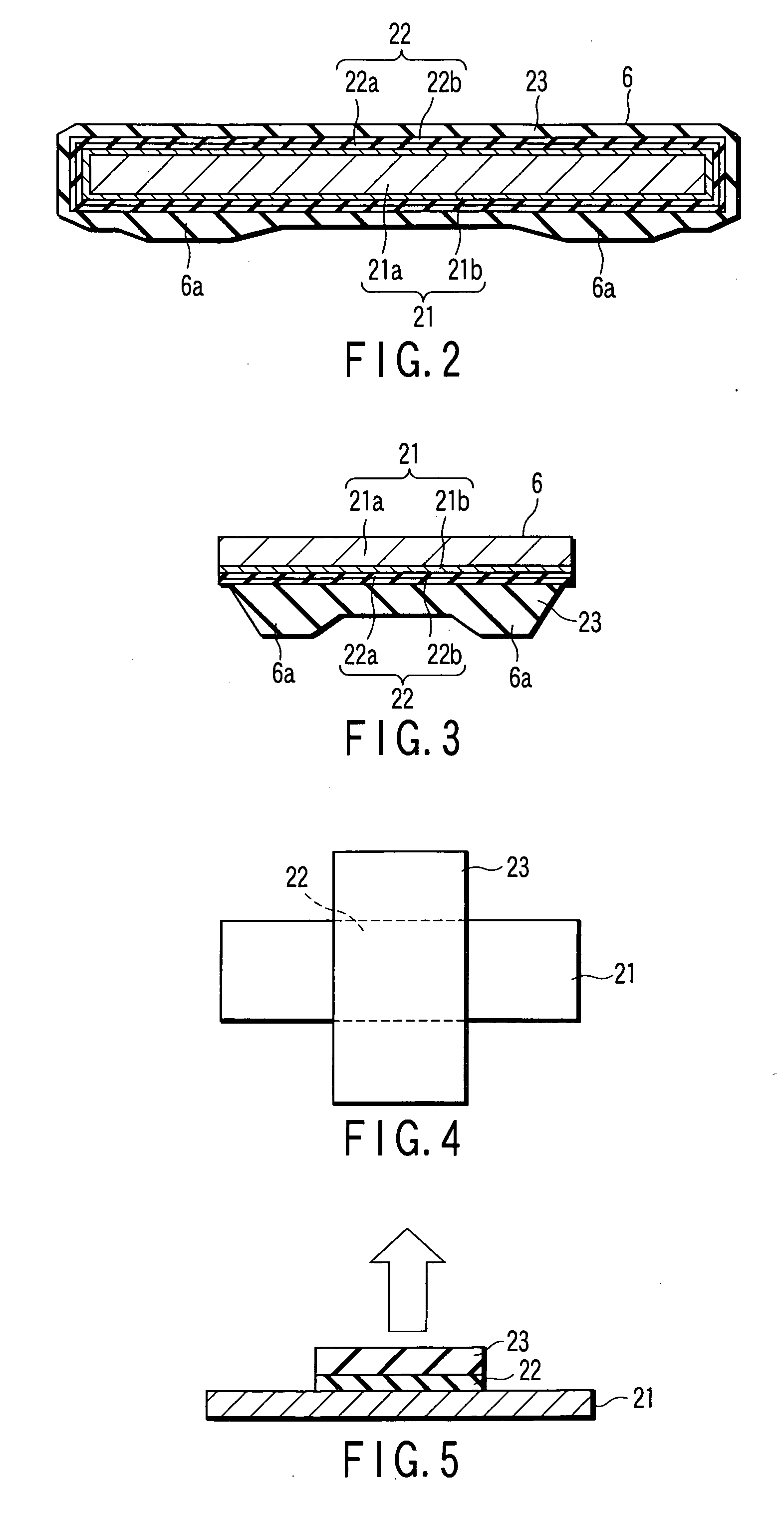

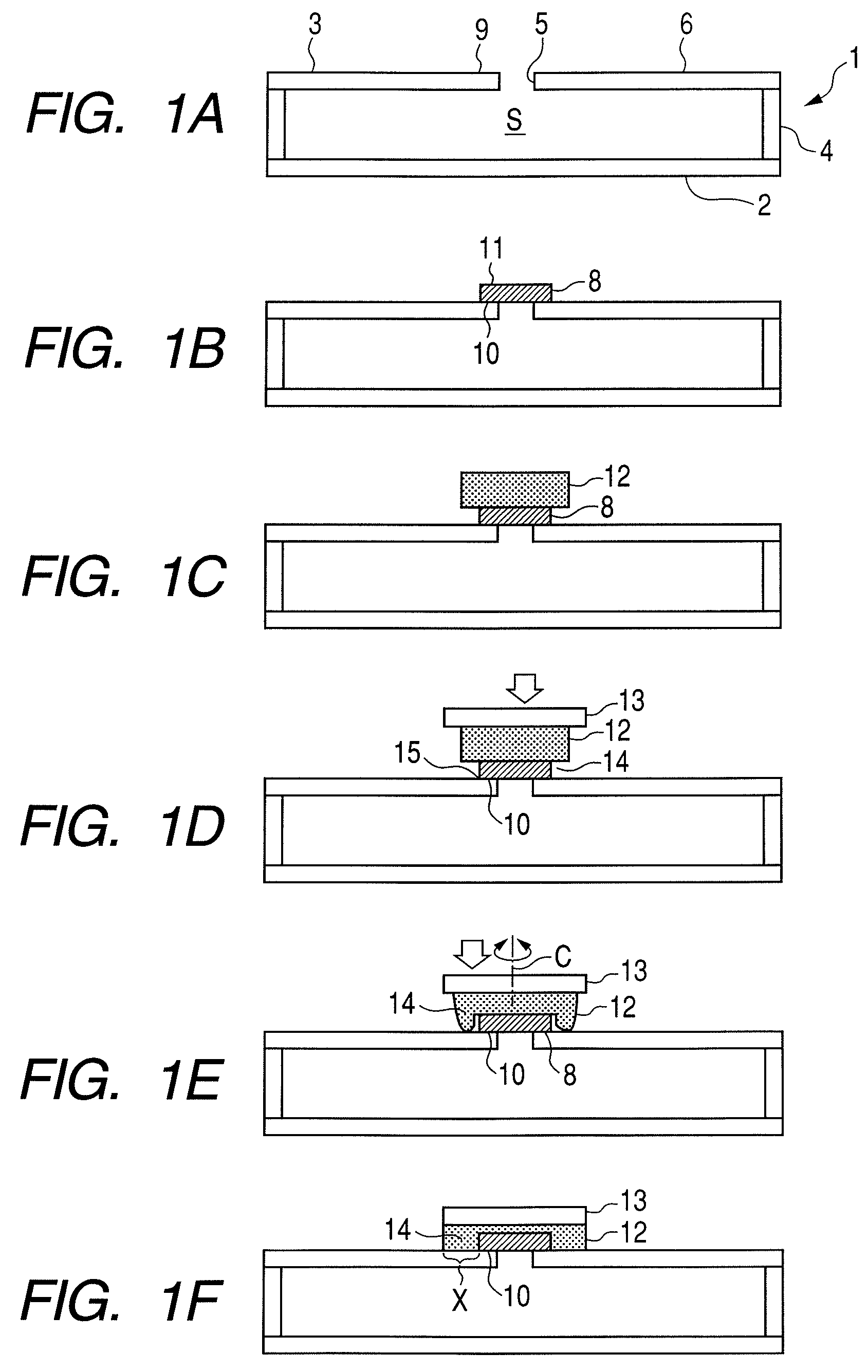

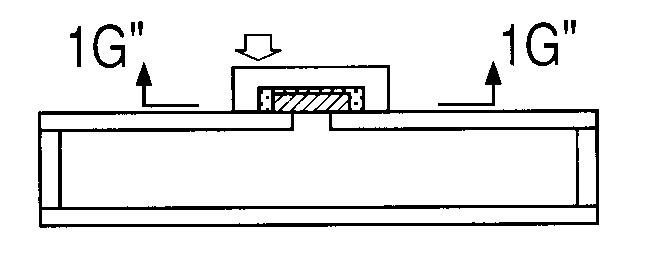

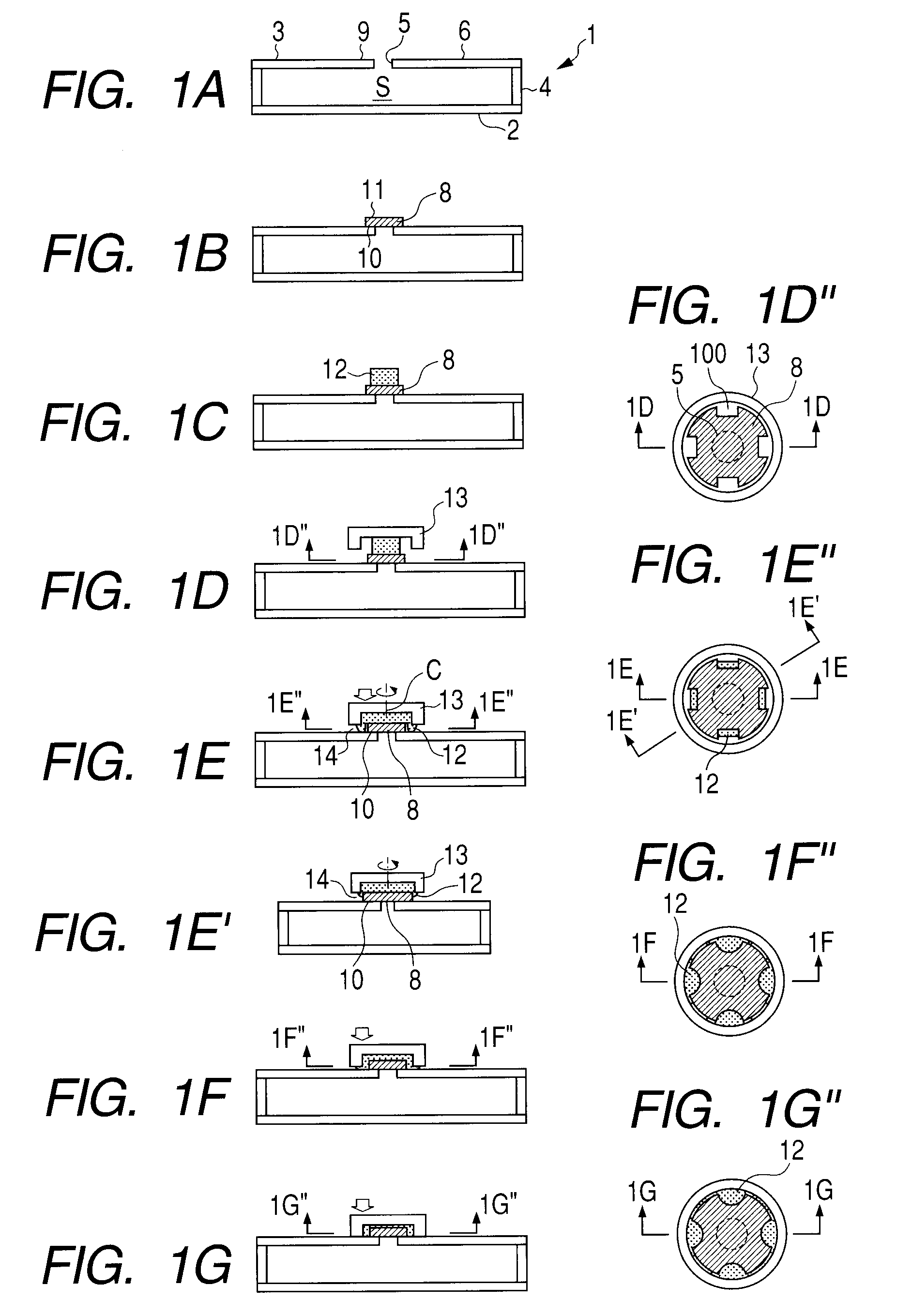

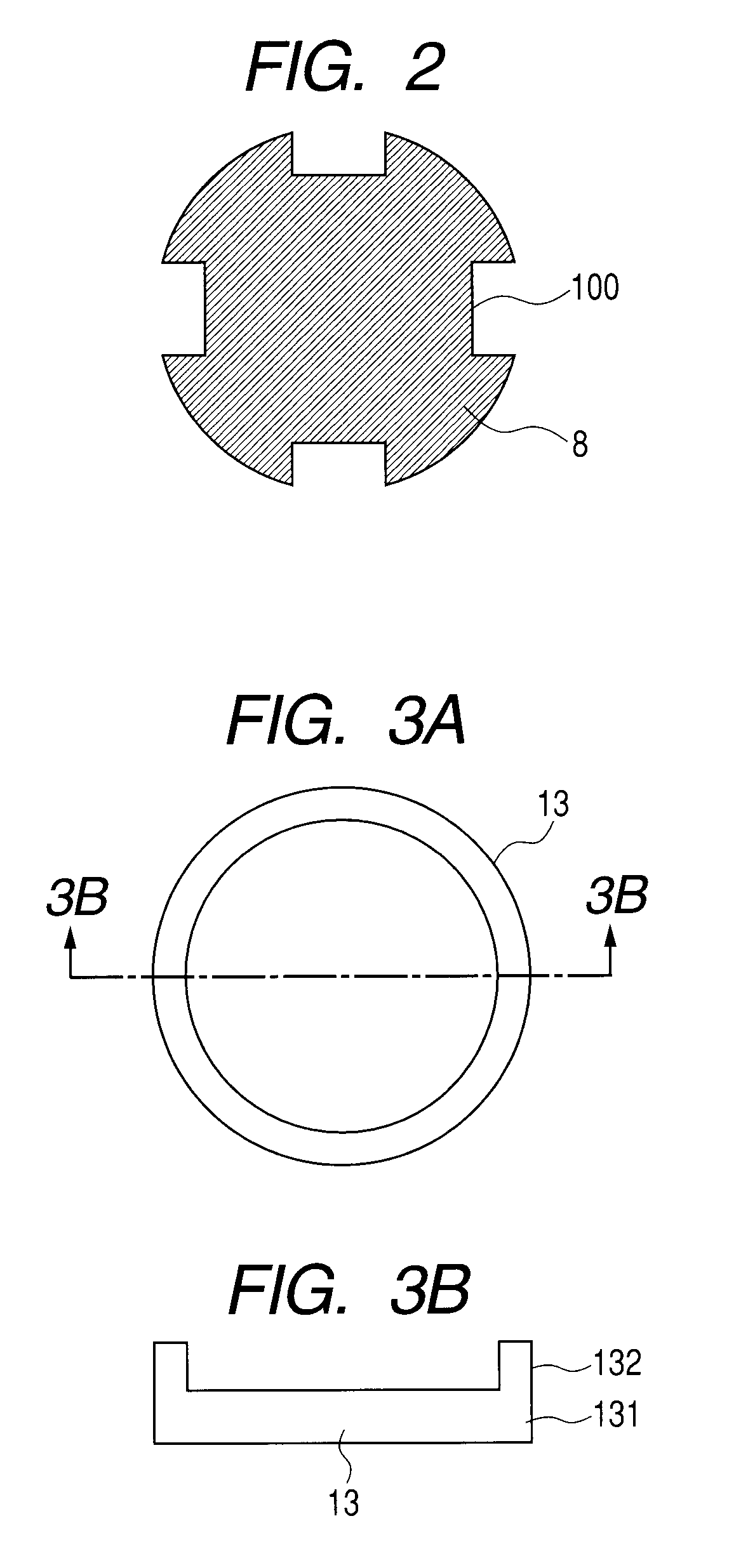

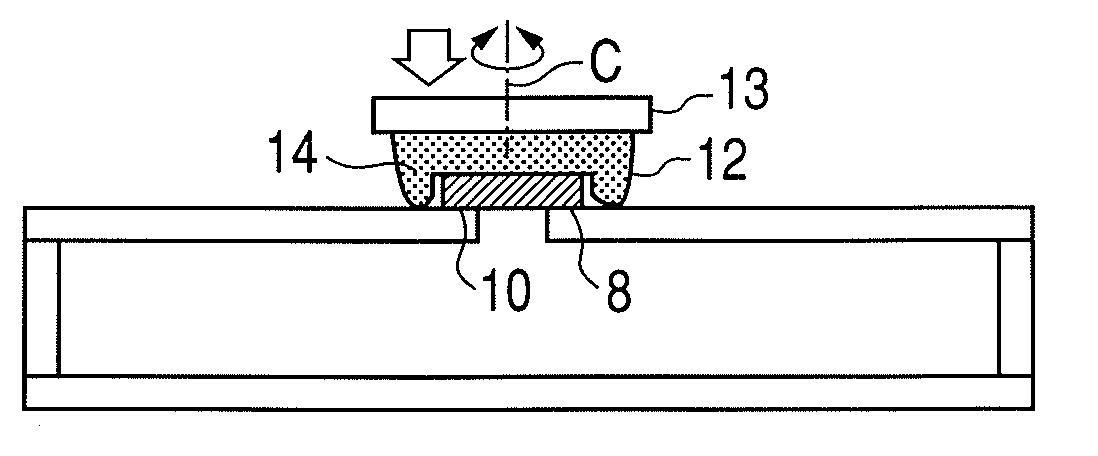

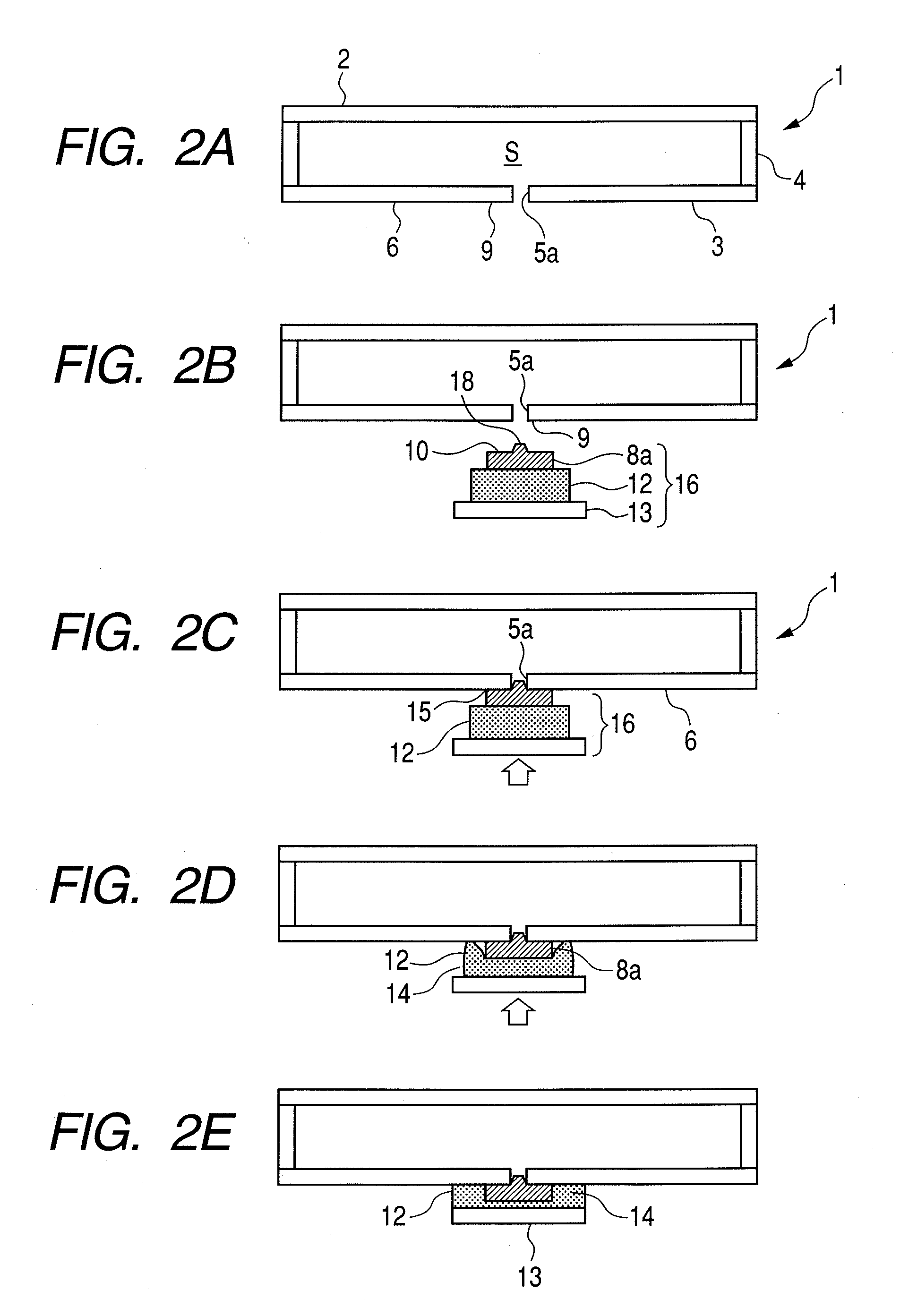

Manufacturing method of airtight container and image displaying apparatus

InactiveUS20100190409A1Sealing is reliablePreventing sealantCathode-ray/electron-beam tube vessels/containersTube vessels vacuum closureEngineeringSealant

In an airtight container manufacturing method including sealing a through-hole by a cover, it secures sealing performance and restrains a sealant from flowing into the through-hole. The method comprises: (a) exhausting the inside of a container through the through-hole provided on the container; (b) arranging a plate member having, at its periphery, grooves penetrating the plate member in its plate thickness direction on the outer surface of the container the inside of which has been exhausted, so as to close up the through-hole; and (c) arranging the cover so as to cover the plate member via the sealant and bonding the cover and the outer surface of the container via the sealant, wherein the sealing includes hardening the sealant after deforming the sealant as pressing the plate member by the cover so that the sealant is positioned between the cover and the outer surface of the container via the grooves.

Owner:CANON KK

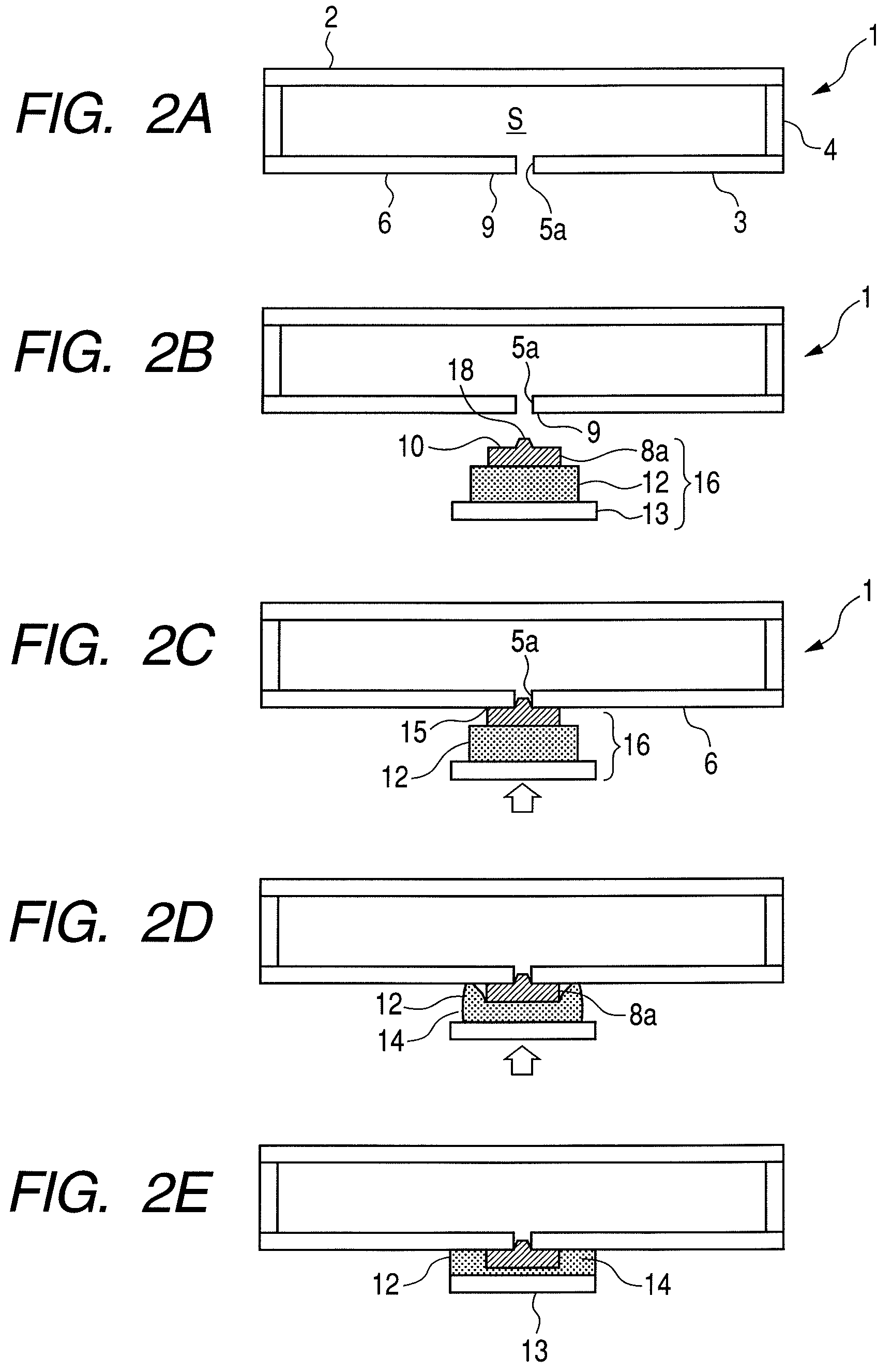

Manufacturing method of airtight container and image displaying apparatus

InactiveUS20100186350A1Sealing is reliablePreventing sealantPrinted circuit assemblingElectrically conductive connectionsEngineeringSealant

In airtight container manufacturing method including sealing a through-hole by a cover, it secures sealing performance and restrains sealant from flowing into the through-hole. The method comprises: (a) exhausting inside of a container through the through-hole; (b) arranging a spacer along periphery of the through-hole on an outer surface of the container the inside of which has been exhausted; (c) arranging a plate so that the spacer and the through-hole are covered by the plate and gap is formed along a side surface of the spacer between the plate and the container outer surface; and (d) arranging the cover to cover the plate and bonding the cover and the container outer surface via sealant positioned between the cover and the container outer surface, wherein the sealing includes hardening the sealant after deforming the sealant as pressing the plate by the cover so that the gap is infilled with the sealant.

Owner:CANON KK

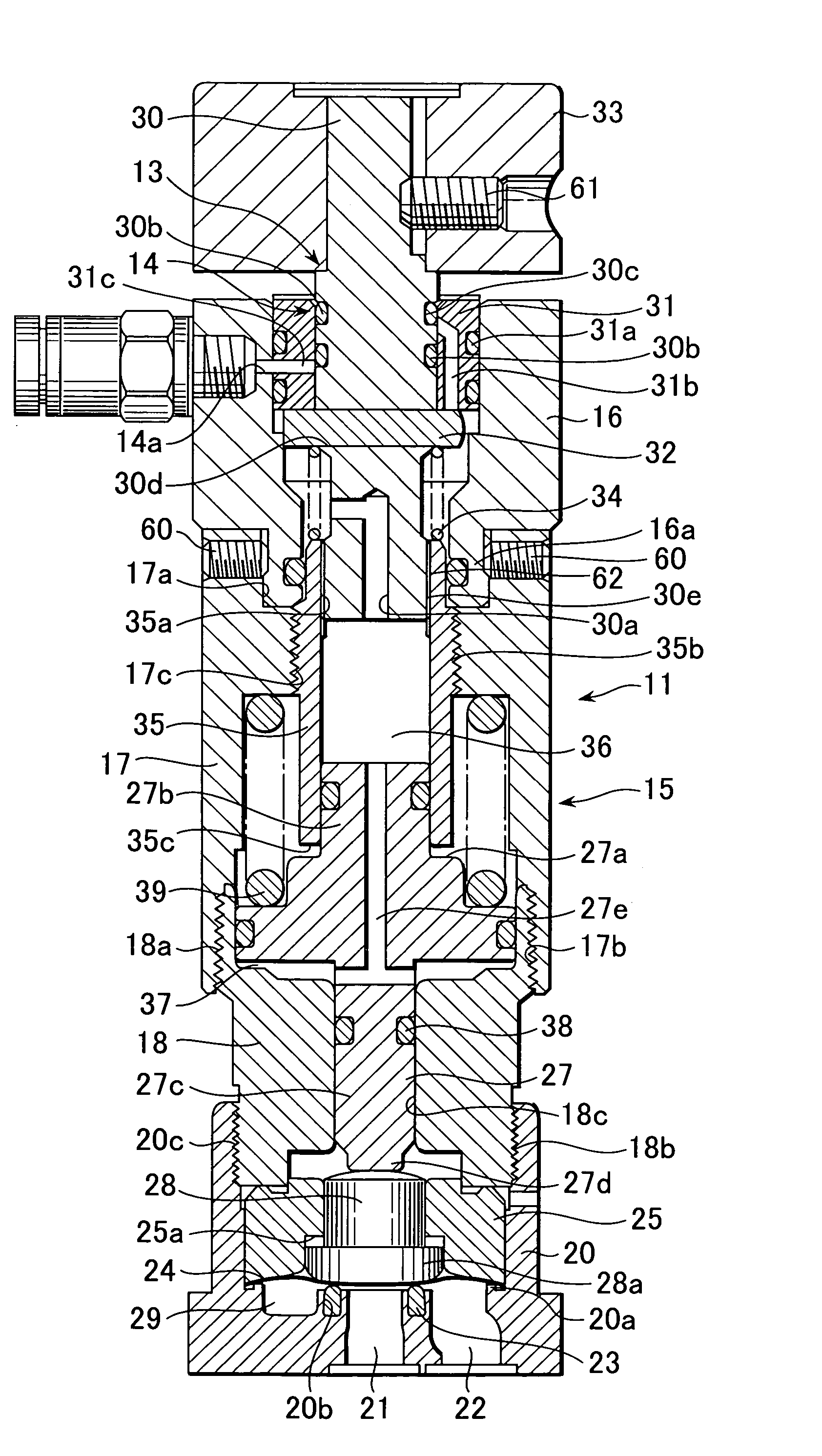

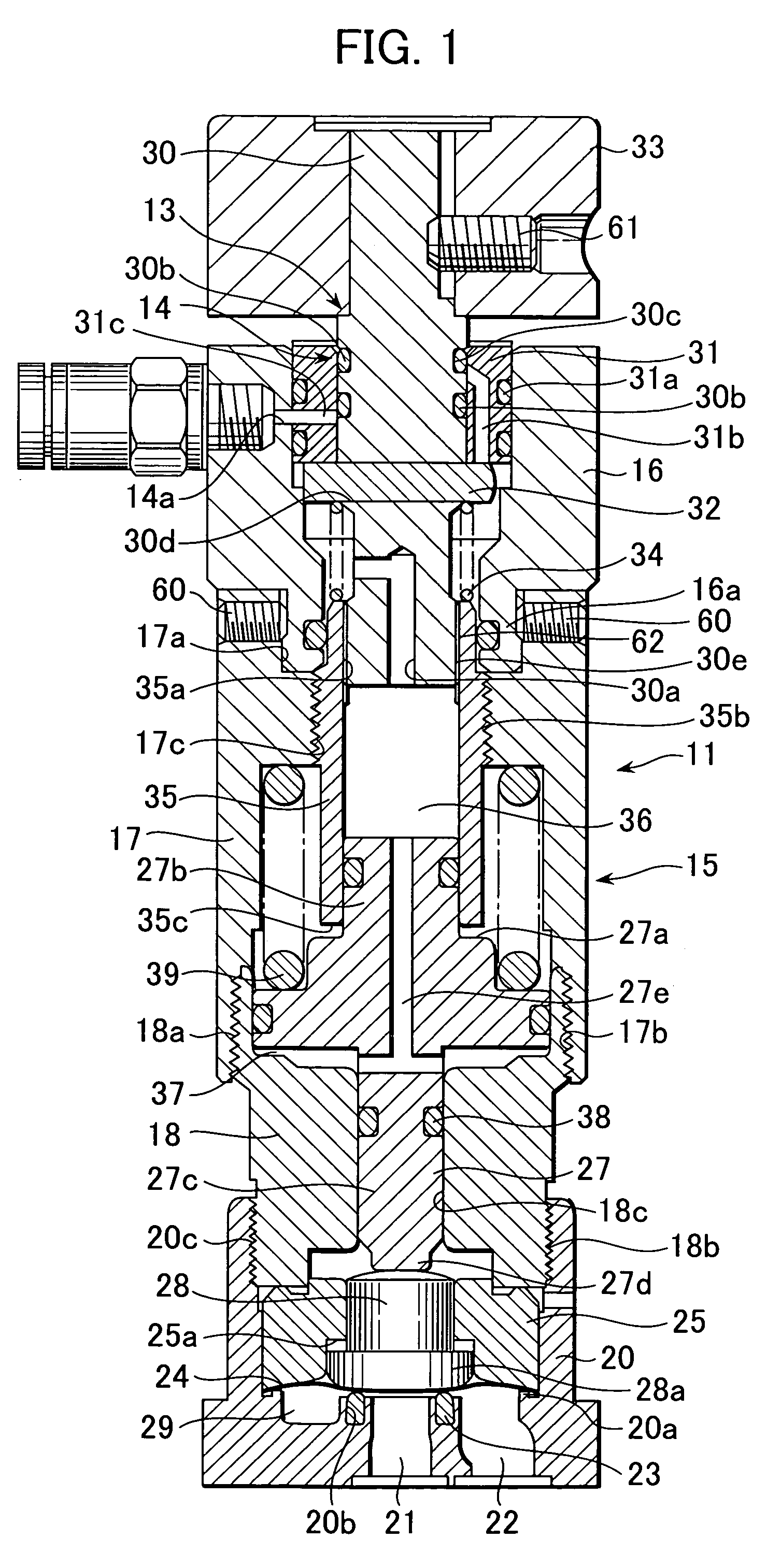

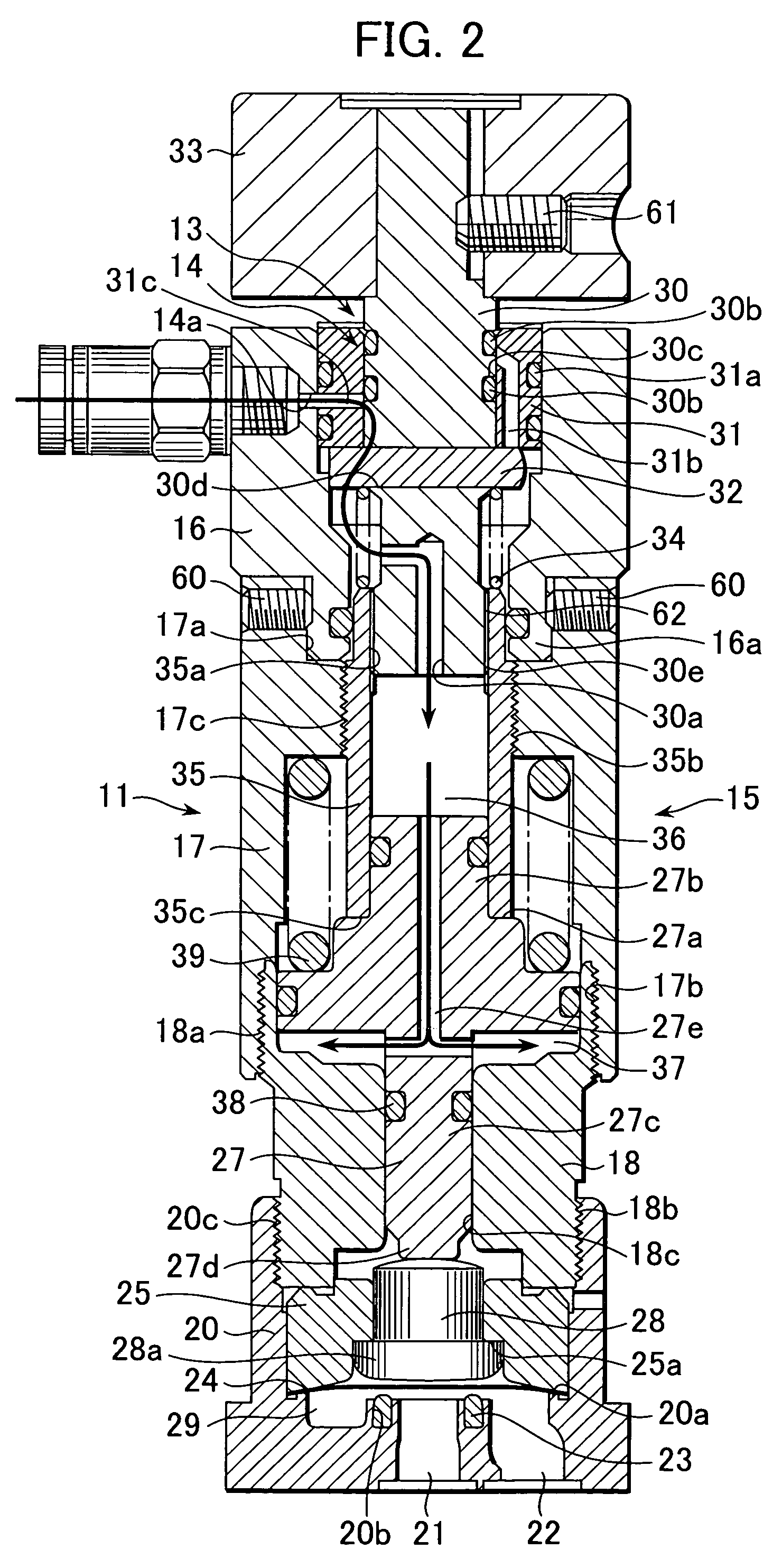

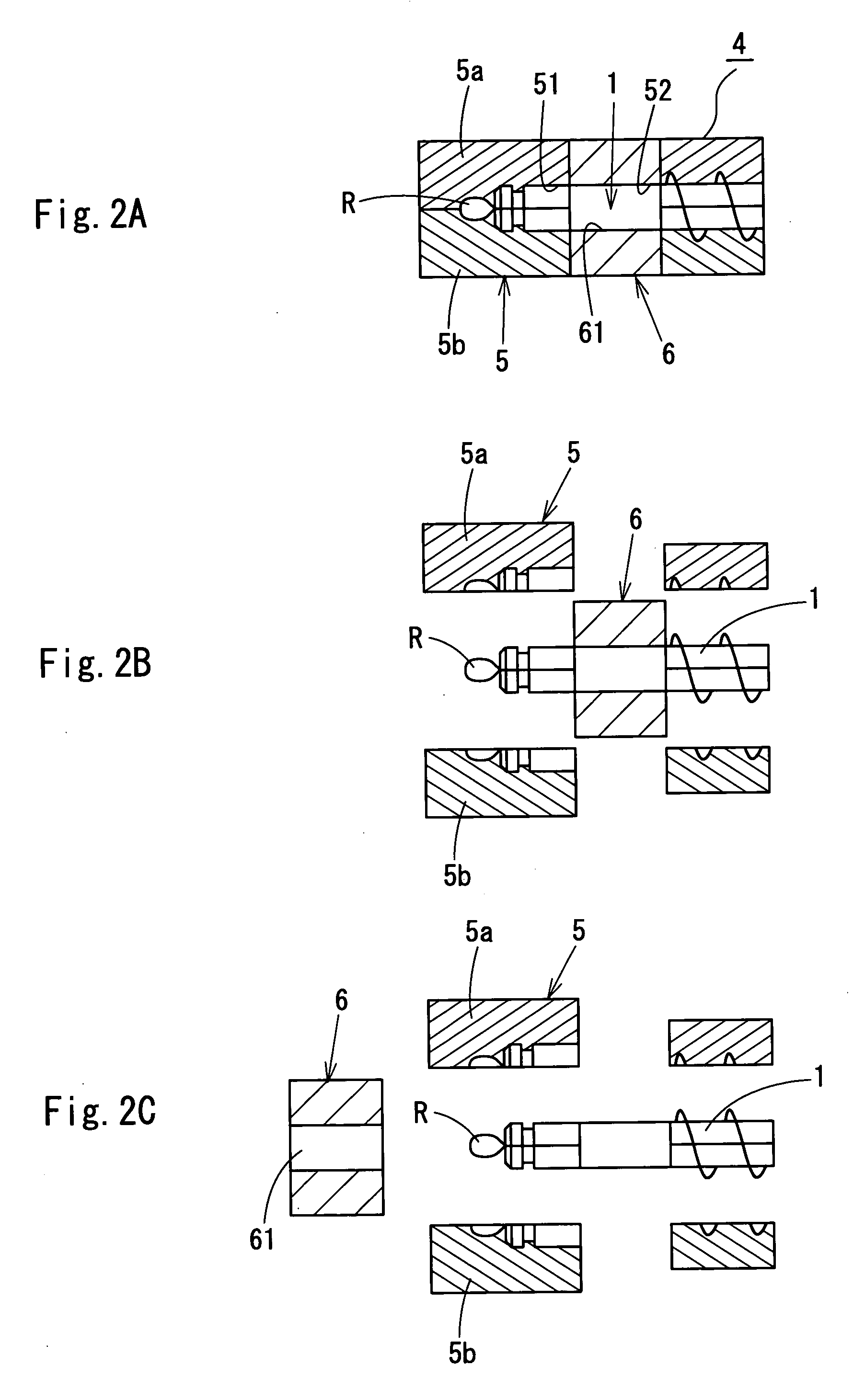

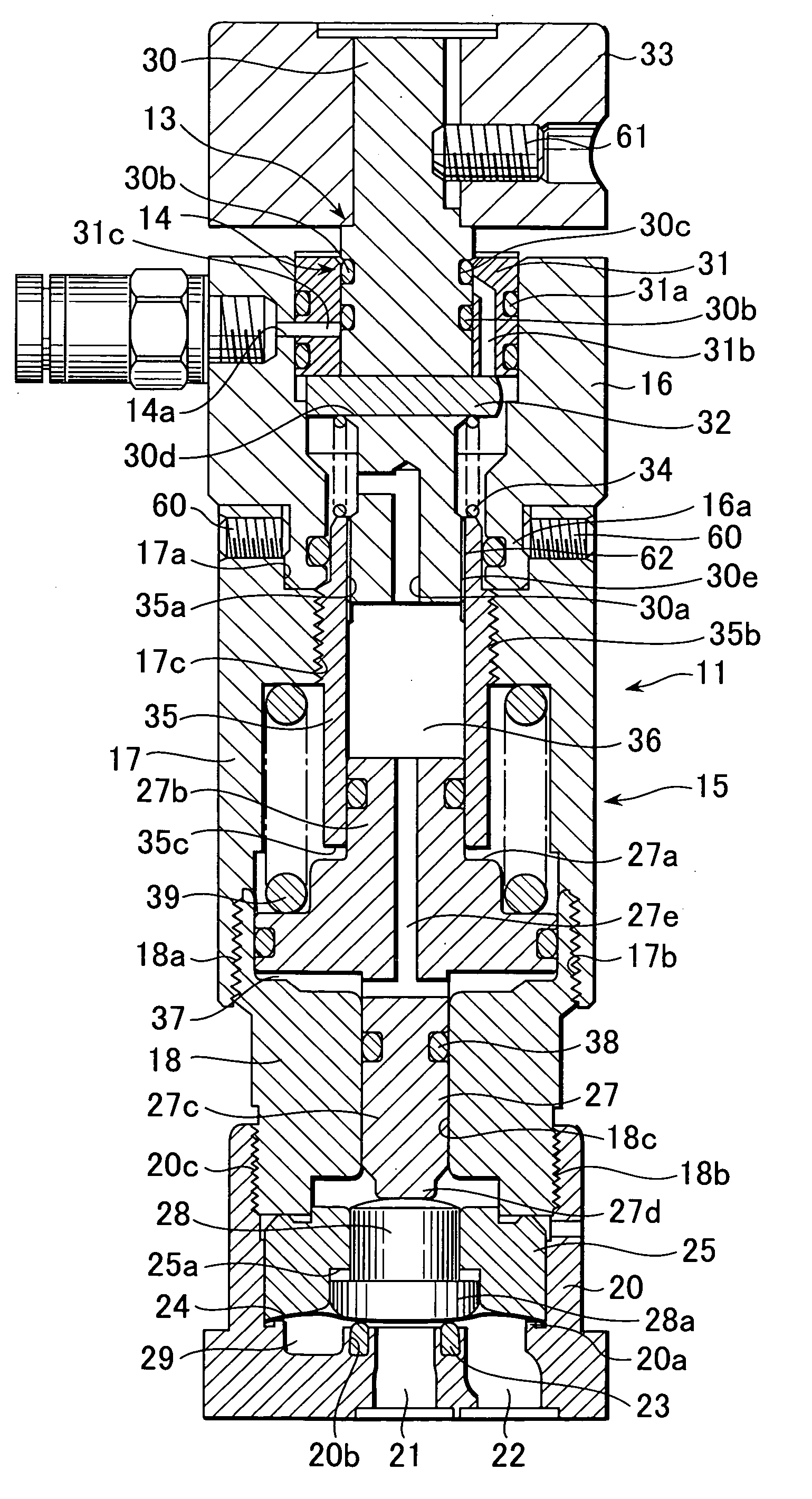

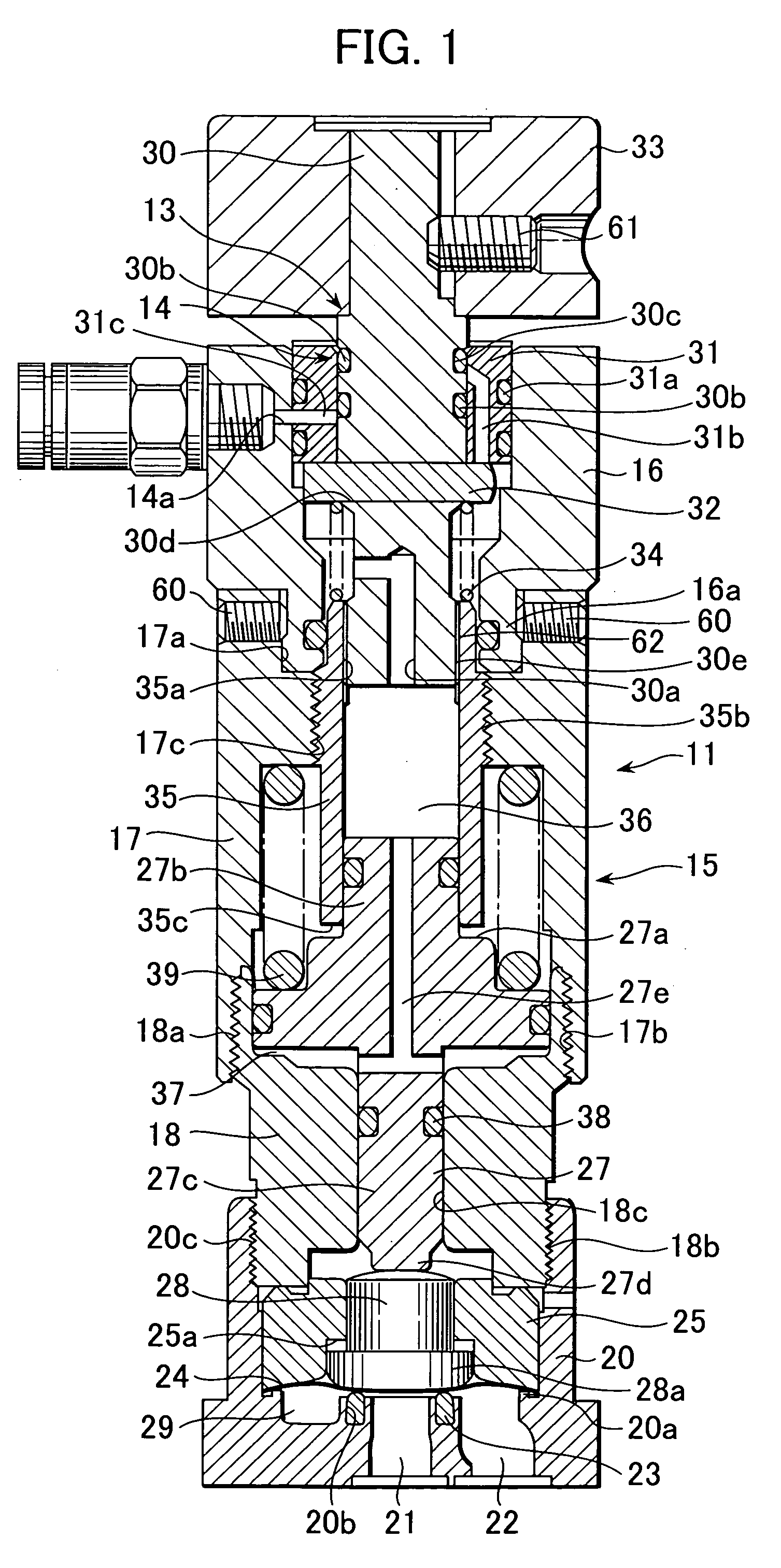

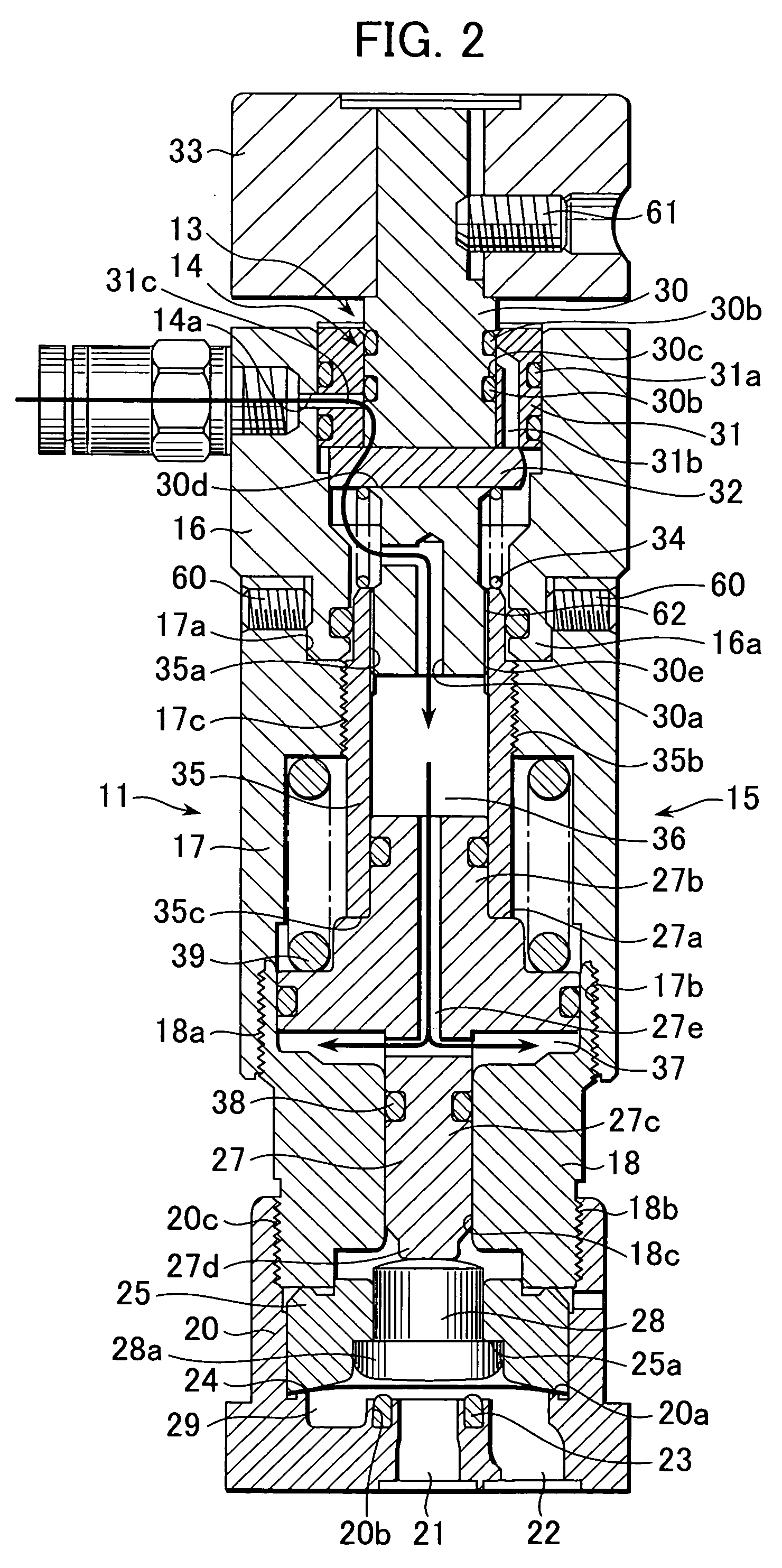

Composite valve for gas supply system

ActiveUS7131629B2Compact structureSecure sealing performanceOperating means/releasing devices for valvesValve housingsEngineeringGas supply

An automatic-and-manual operation composite valve includes a valve main body into which an air is supplied and from which the air is discharged, a piston provided within the valve main body to be vertically movable by means of the air supplied or discharged and a snapping force of a spring attached to the piston, a valve body provided within the valve main body, and opened and closed by the piston, an air switch valve portion provided within the valve main body for switching air supply and air discharge and a manual operation mechanism portion for operating the air switch valve portion.

Owner:KITZ SCT

Lightning-resistant fastener, cap, fastener member, and method for attaching lightning-resistant fastener

ActiveUS8451577B2Improve securityQuality improvementFuselage framesAircraft lighting protectorsManufacturing cost reductionLightning strike

A lightning-resistant fastener, a cap, a fastener member, and a method for attaching the lightning-resistant fastener are provided, which enhance workability and quality stability besides reliably securing an insulating property, and can lead to enhancement in safety of an airframe and reduction in manufacturing cost. A head portion 25b of a fastener main body 25 includes a head cap 50, and a shaft portion 25s of the fastener main body 25 includes a shaft cap 30, whereby a direct strike of lightning to a fastener member 24, and occurrence of an arc discharge from the fastener member 24 in the case of a lightning strike can be suppressed. A hole 52 is formed in the head cap 50, and a thread groove 52a is formed in the hole 52, whereby the head cap 50 can be reliably and easily positioned and attached to the fastener member 24.

Owner:MITSUBISHI AIRCRAFT

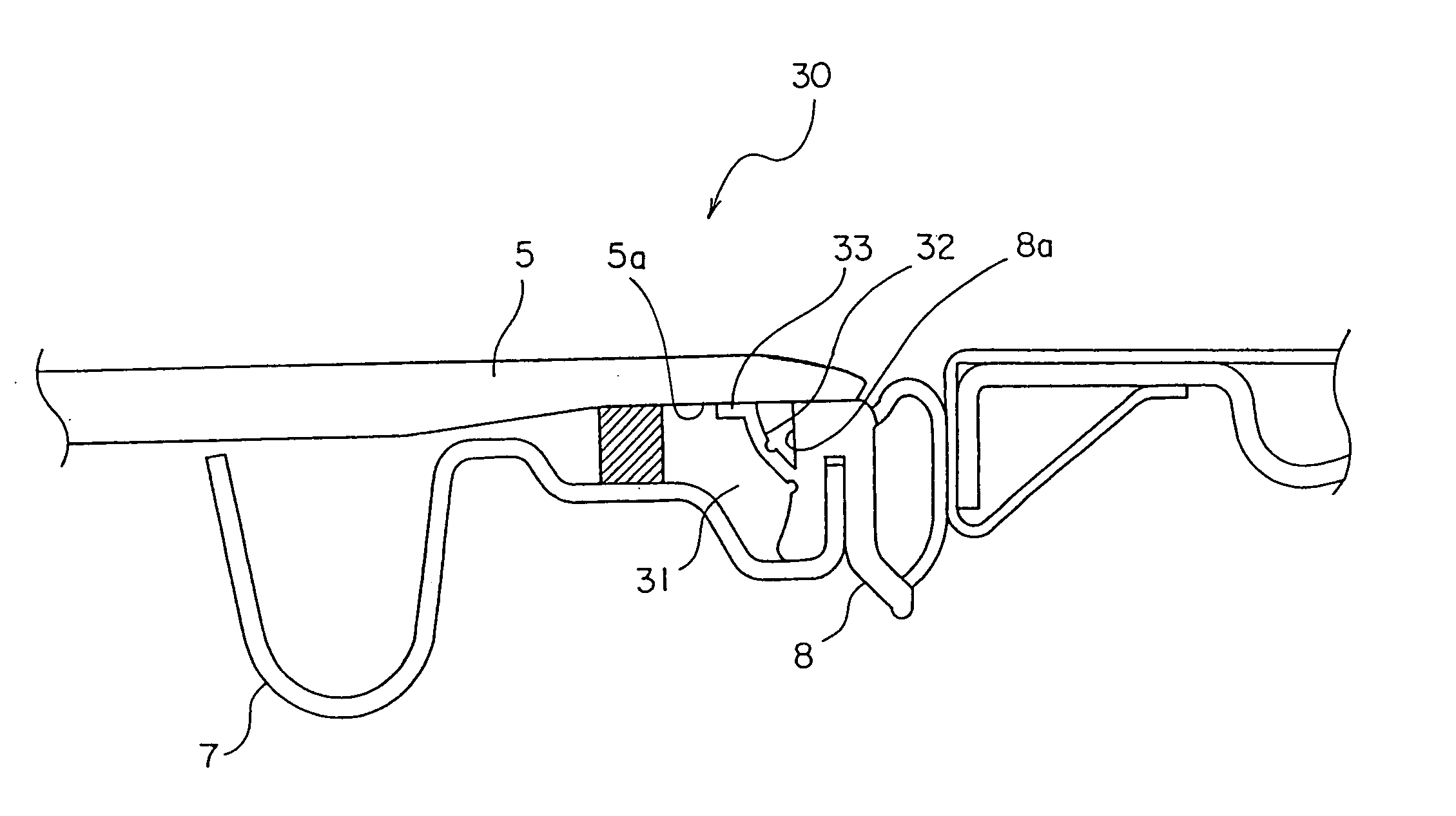

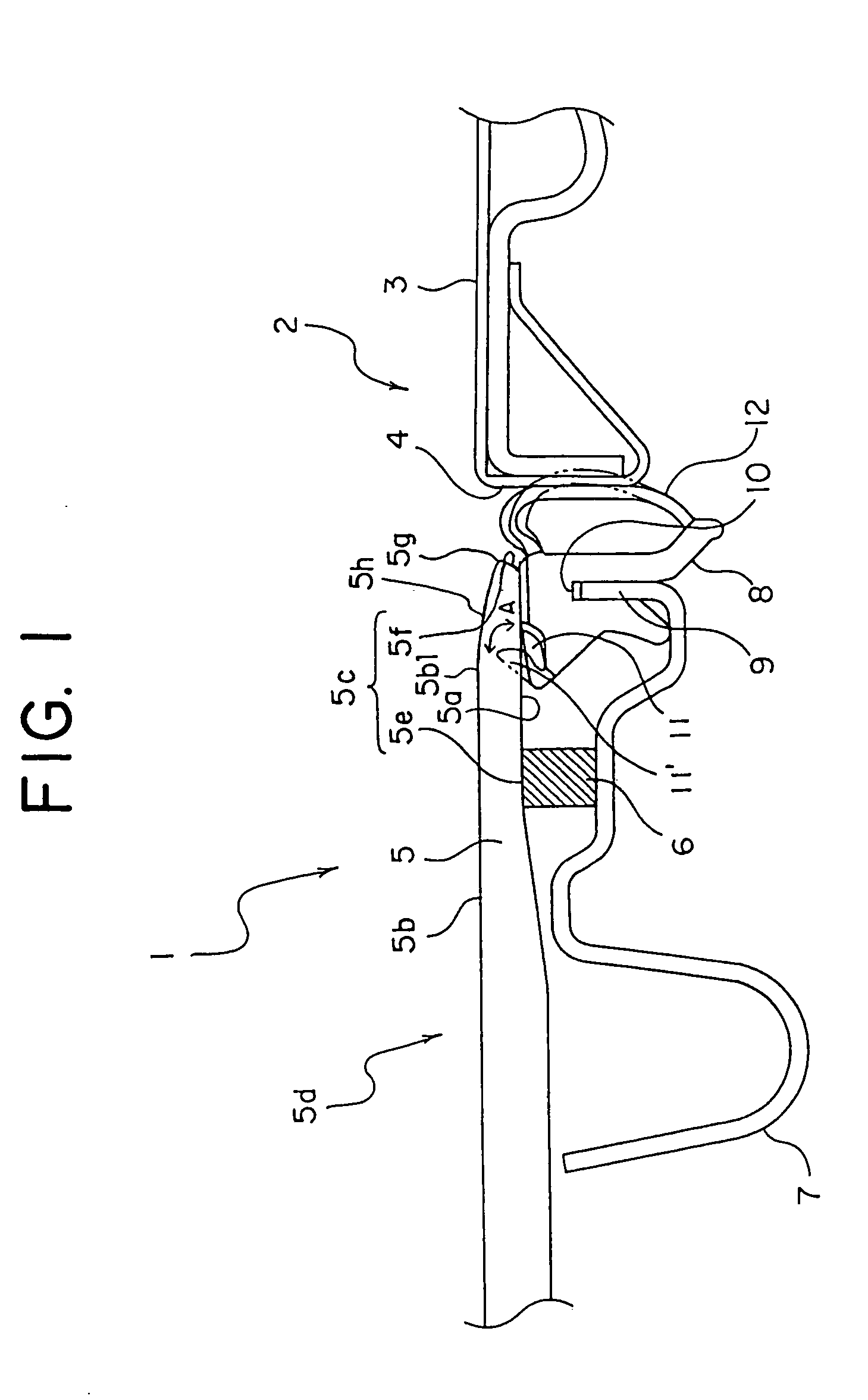

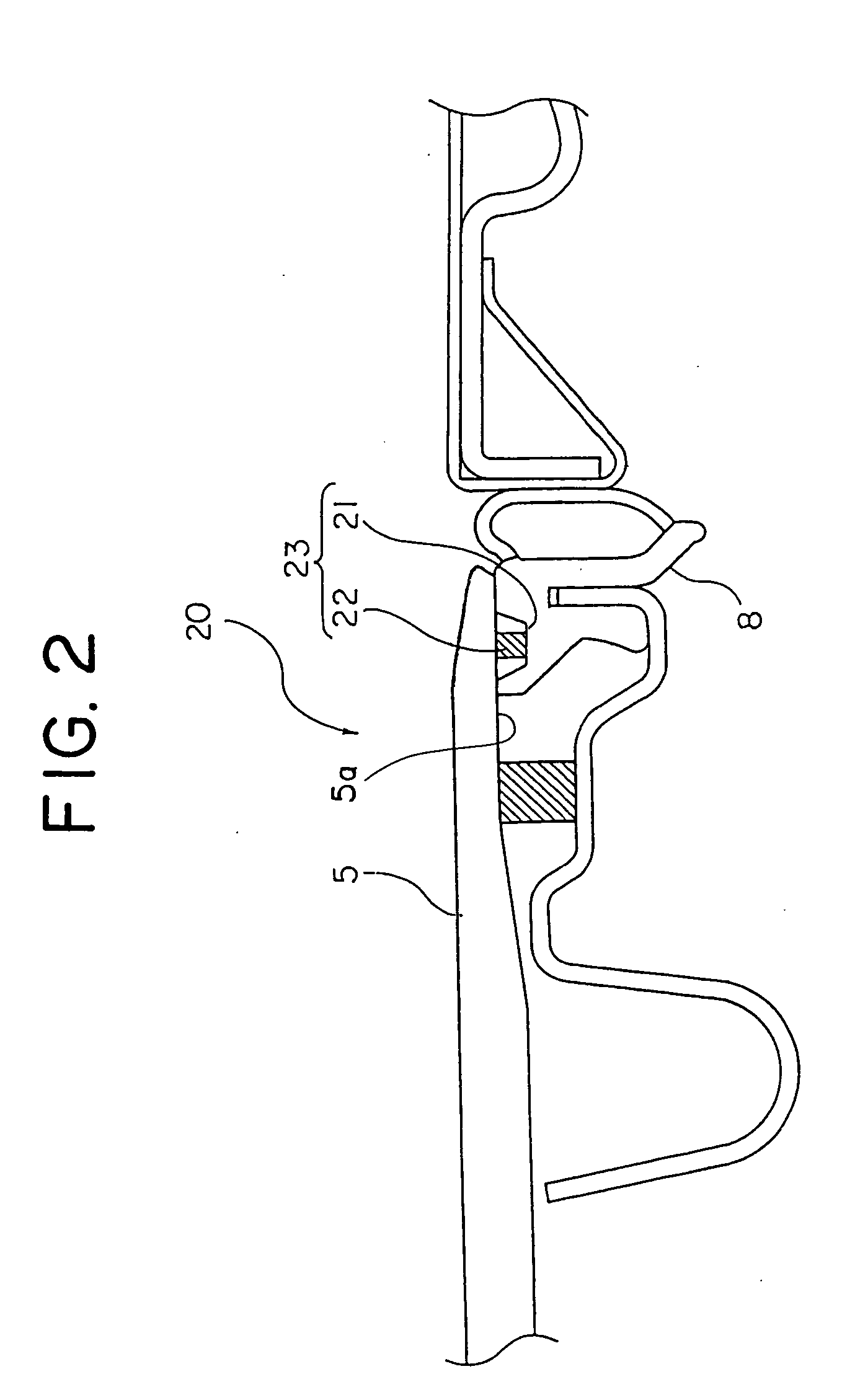

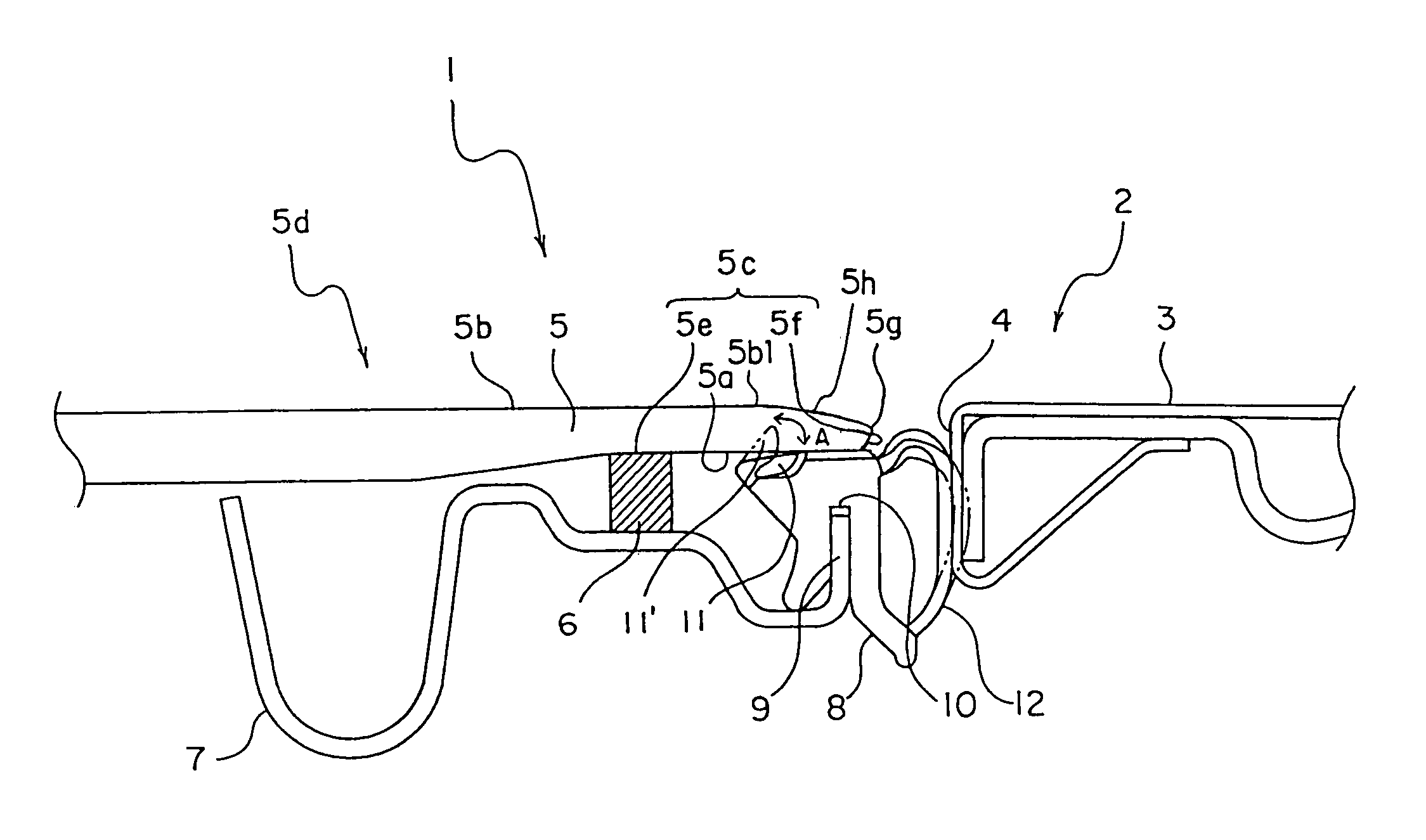

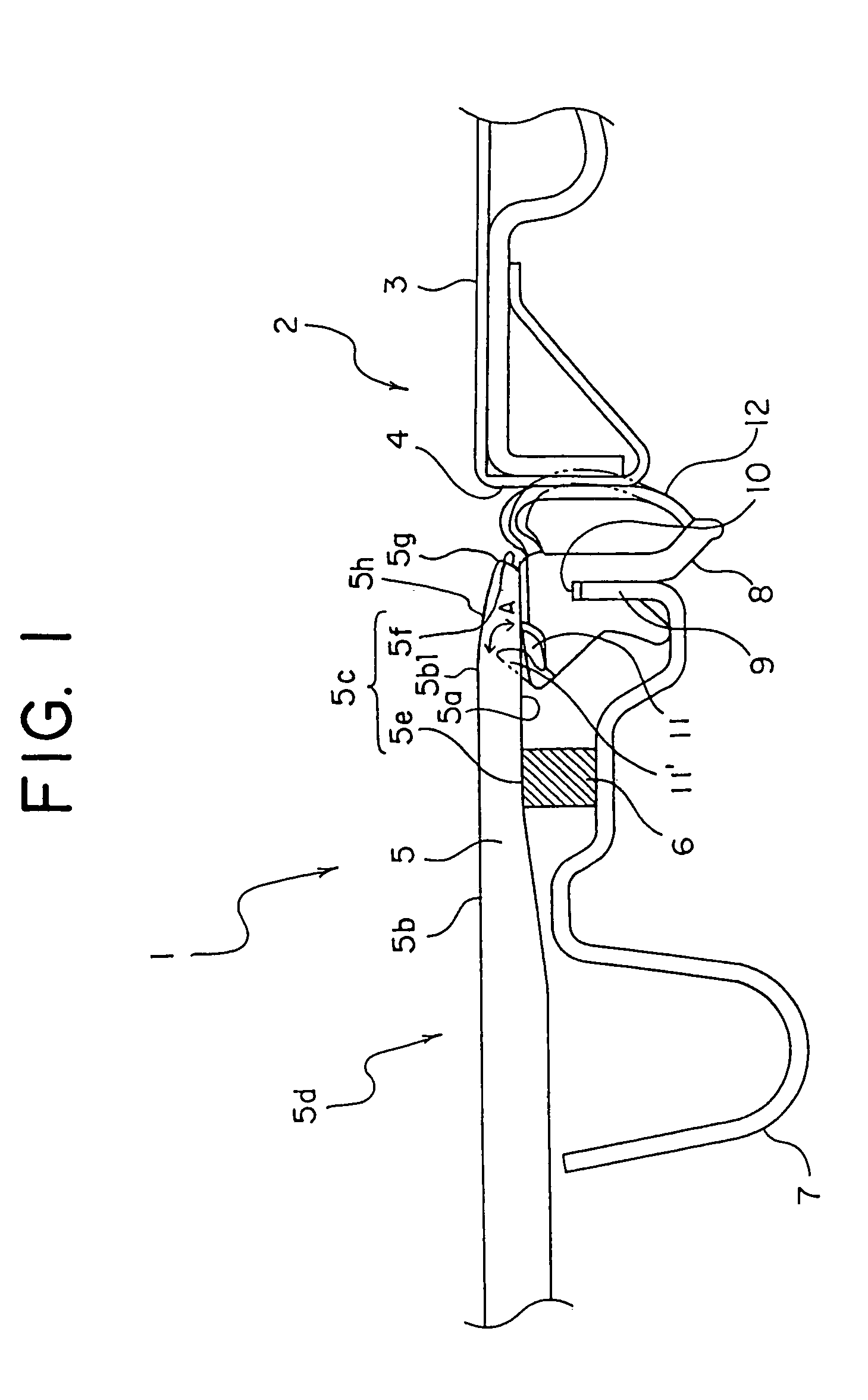

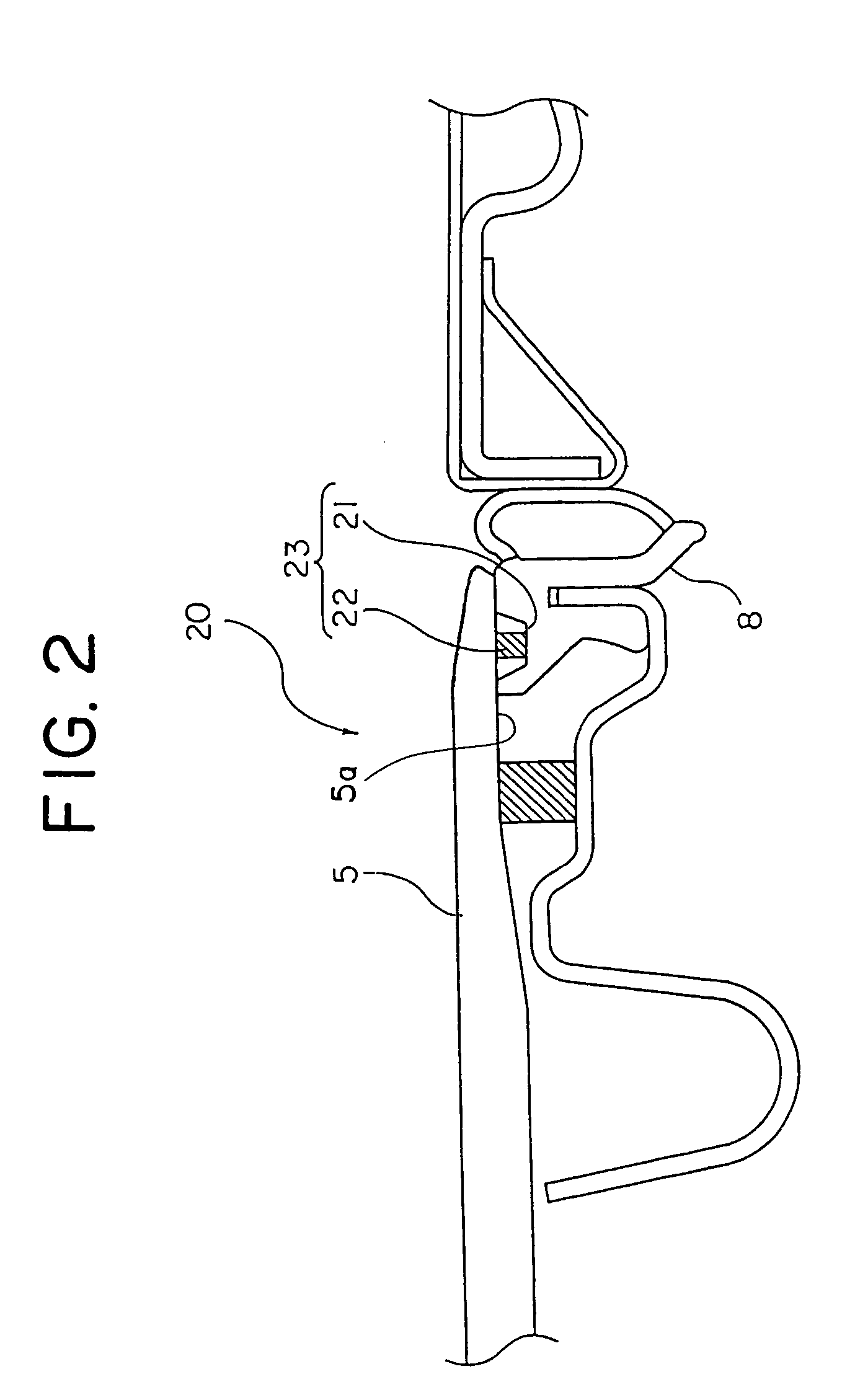

Sunroof panel for a vehicle

ActiveUS20050206201A1Sealing is reliableSecure sealing performanceEngine sealsSuperstructure subunitsAdhesiveEngineering

A sunroof panel is composed of a resin panel and a weather strip. The resin panel is a plate-like resin panel and has a vehicle interior surface and a vehicle exterior surface, which are substantially parallel to each other. The resin panel is attached to a frame by means of a urethane adhesive. The resin panel has a peripheral portion, which extends from a portion sticking to the urethane adhesive to a side face, and a central portion surrounded by the peripheral portion. The peripheral portion is thinner than the central portion. The side face of the resin panel is formed so as to be inclined inwardly toward the vehicle interior surface. An approach-R portion is formed on a peripheral portion of the vehicle exterior surface.

Owner:TOYOTA IND CORP

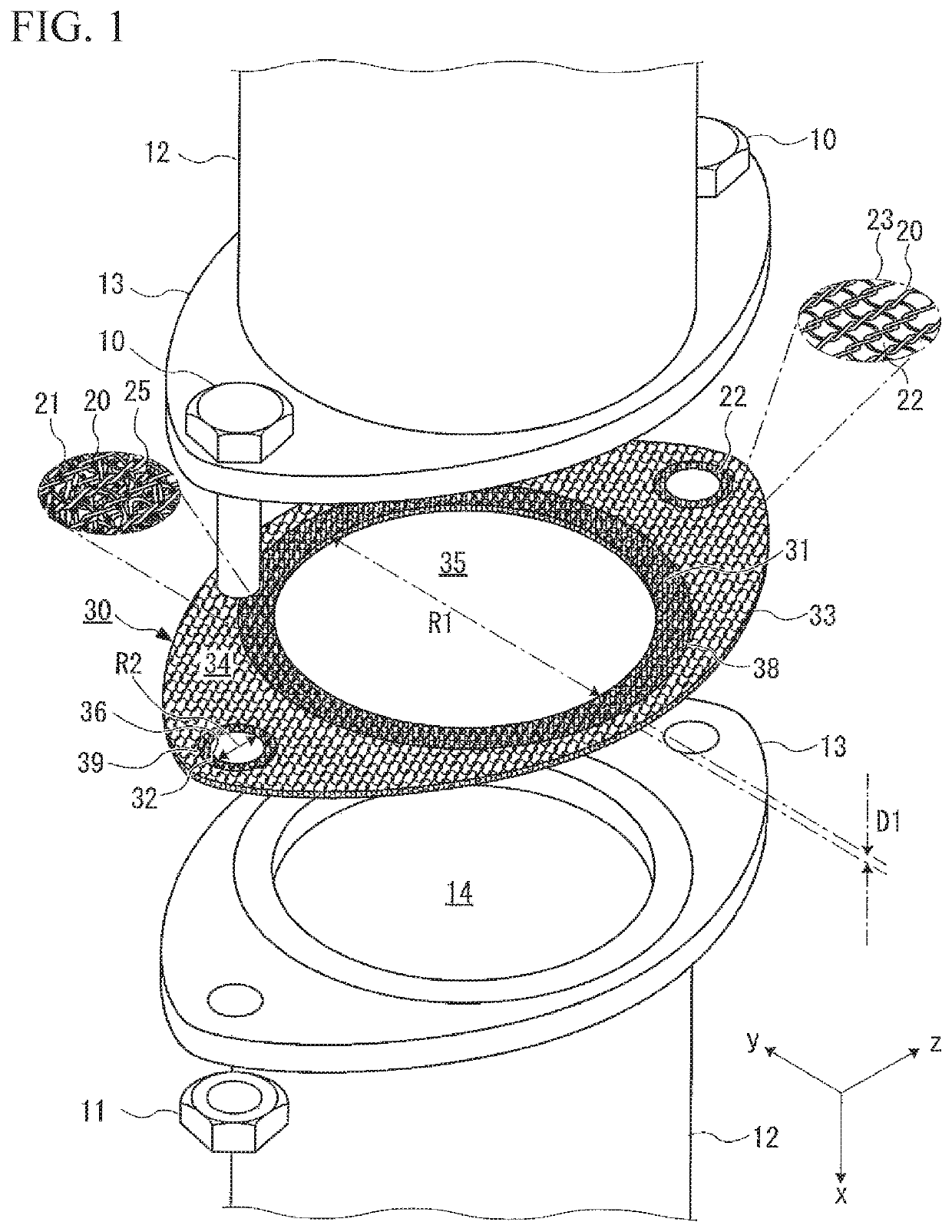

Gasket and manufacturing method thereof

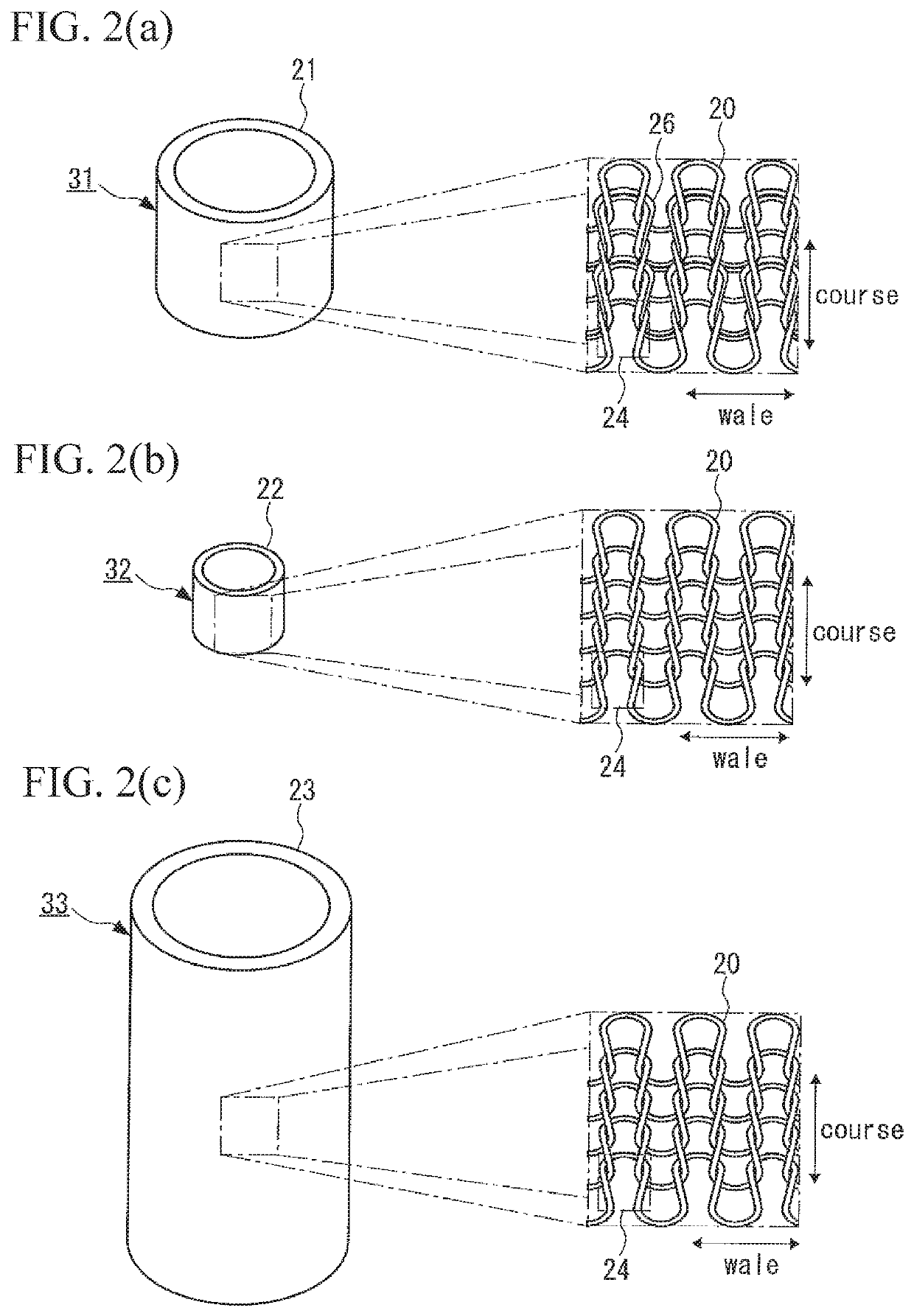

ActiveUS10591062B2Increased durabilitySecure sealing performanceEngine sealsExhaust apparatusBraidManufacturing engineering

An object of the present invention is to provide a gasket capable of maintaining a surface pressure for a long period of time while securing sealing performance and improving durability and a manufacturing method thereof. A gasket includes a first annular portion which is formed by a metal wire woven fabric and has a seal target hole and a main body portion which is formed by a metal wire woven fabric and is in contact with an outer peripheral edge of the first annular portion, in which a metal wire of the metal wire woven fabric and a metal wire of the metal wire woven fabric are entangled so that the first annular portion and the main body portion are joined to each other and a gap between the metal wires forming the first annular portion is sealed by a resin.

Owner:ISHIKAWA GASKET CO LTD

Sunroof panel for a vehicle

A sunroof panel is composed of a resin panel and a weather strip. The resin panel is a plate-like resin panel and has a vehicle interior surface and a vehicle exterior surface, which are substantially parallel to each other. The resin panel is attached to a frame by means of a urethane adhesive. The resin panel has a peripheral portion, which extends from a portion sticking to the urethane adhesive to a side face, and a central portion surrounded by the peripheral portion. The peripheral portion is thinner than the central portion. The side face of the resin panel is formed so as to be inclined inwardly toward the vehicle interior surface. An approach-R portion is formed on a peripheral portion of the vehicle exterior surface.

Owner:TOYOTA IND CORP

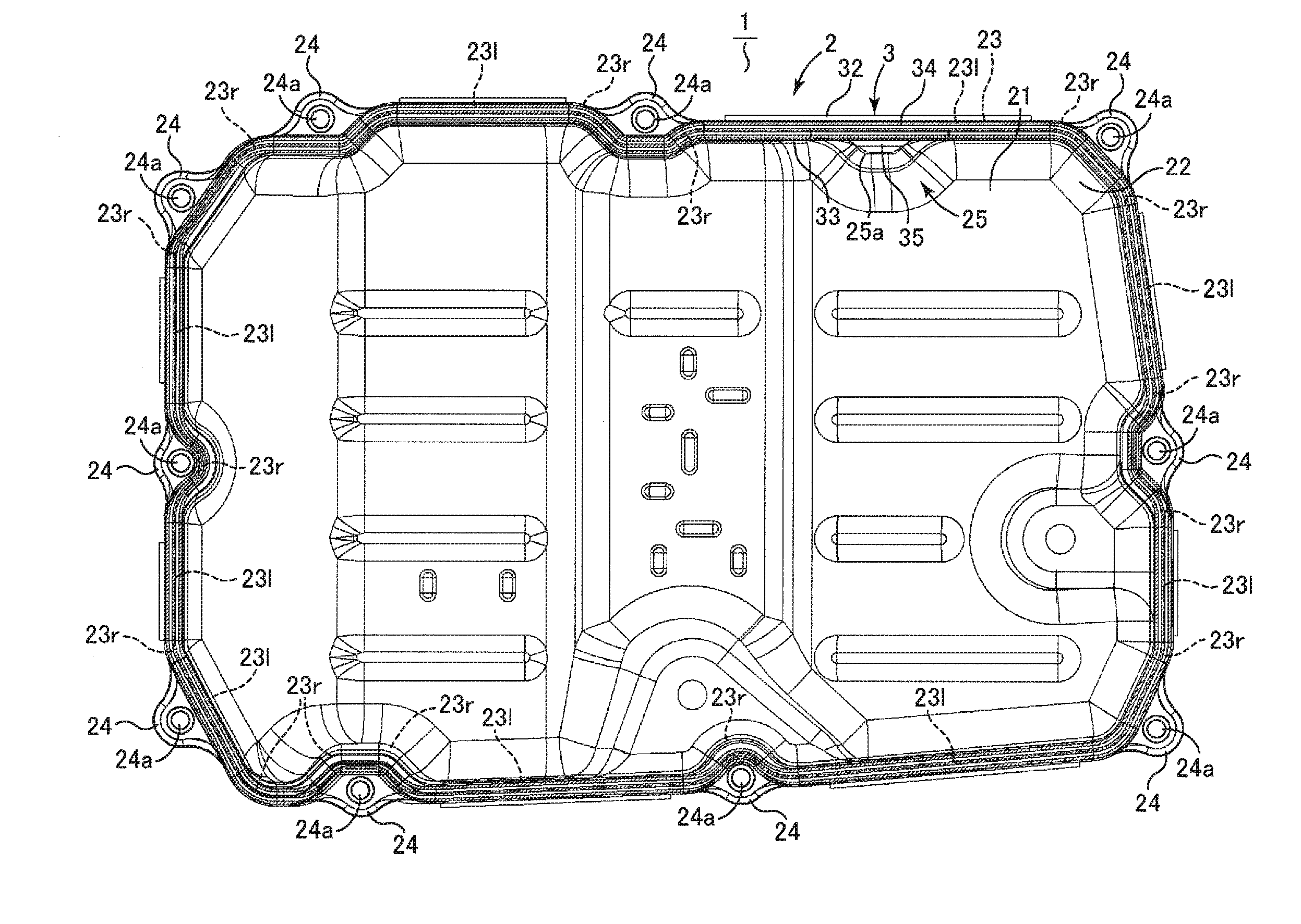

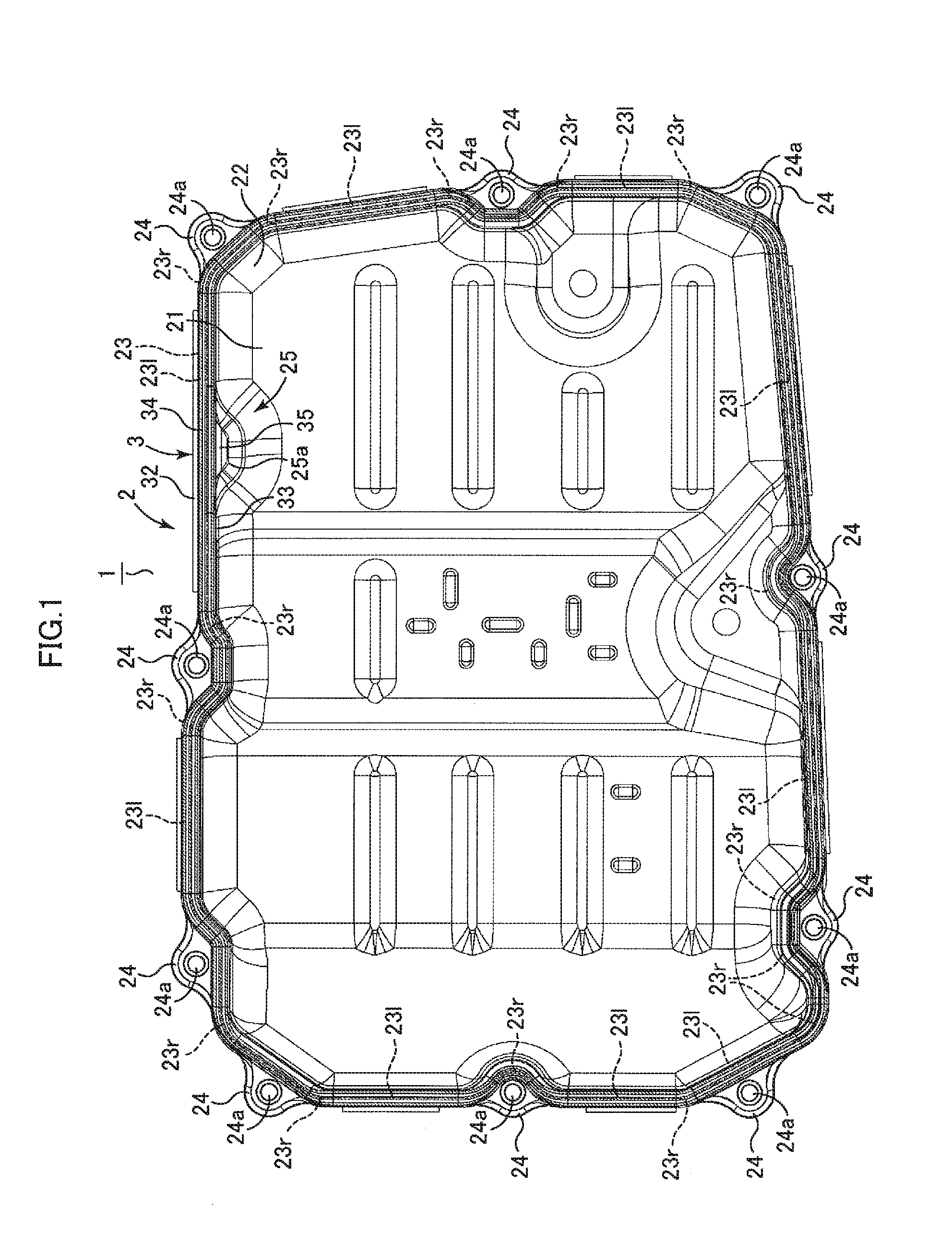

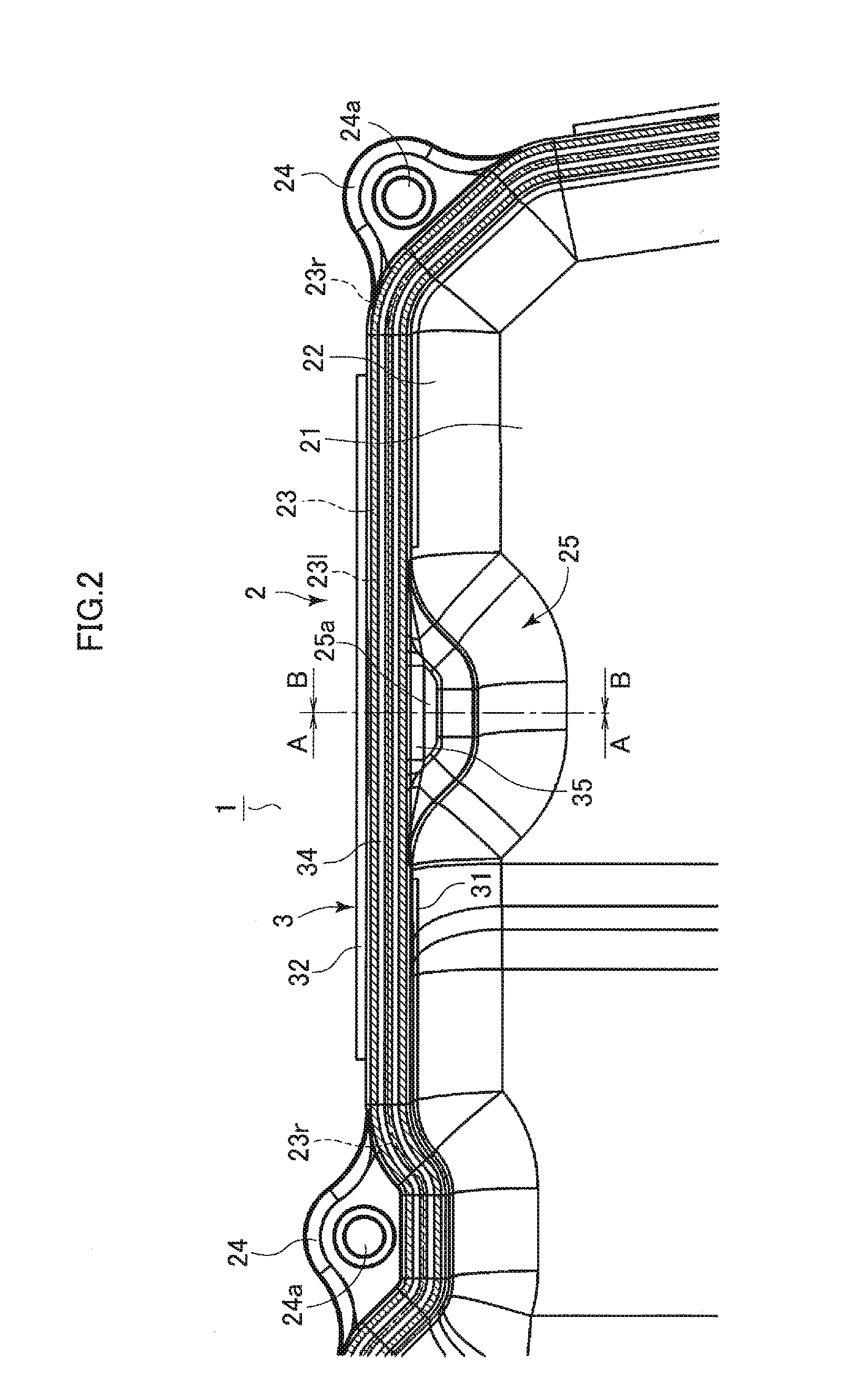

Sealing-equipped oil pan

ActiveUS20160222846A1Secure seal performanceSecure sealing performanceEngine sealsSealing arrangements for enginesEngineeringGasket

A sealing-equipped oil pan includes a gasket and an oil pan having a bottom portion and a peripheral wall for storing oil, and a ring-shaped rim portion located at an end of the peripheral wall and provided with the gasket, and is fastened to a target device with the gasket interposed between the rim portion and the target device. The gasket has a projection projecting from a sealing surface configured to come into contact with the target device for sealing. The peripheral wall of the oil pan has a base portion projecting from the rim portion and supporting the projection of the gasket. The base portion supports the projection of the gasket to prevent the gasket from tilting with respect to the rim portion, thereby preventing protrusion of the gasket.

Owner:AISIN AW CO LTD

Cylinder device

ActiveUS7963113B2Prevent the ineffective stroke of the piston from increasingSecure sealing performanceEngine sealsPiston ringsEngineeringMechanical engineering

A cup seal 21 includes a base portion 21a, an inner circumferential lip 21b slidingly contactable with a plunger 19 and an outer circumferential lip 21c contactable with the bottom surface 26a of the seal groove 26. Further, on the cup seal 21, there are provided elastic projections 21d projecting from the outer circumferential side leading end of the inner circumferential lip 21b toward the cylinder hole bottom portion. The length of the cup seal 21 from the base end face 21e to the leading end portions 21f is set longer than axial length of the seal groove 26. When the cup seal 21 is fitted into the seal groove 26, force is imparted on the inner circumferential lip 21b toward the cylinder hole inner circumferential direction to energize the inner circumferential lip 21b toward the piston all the time.

Owner:HITACHI ASTEMO LTD

Wheel-driving axle unit

InactiveUS20030155803A1Prevent occurrenceAvoid vibrationYielding couplingRolling contact bearingsDrive wheelDrive shaft

It is an object of the invention to provide an axle unit for driving wheel which can keep the mutual contact portion between the caulk portion (29a) of a hub (6a) and the outer end face (39) of the housing portion (11) of a drive shaft member (31) from being exhausted to thereby be able to prevent occurrence of shaky motion, strange sounds and vibrations in the axle unit for driving wheel for a long period of time. In the present axle unit for driving wheel, a flat surface (38) is formed in the end face of the caulk portion (29a), and the flat surface (38) is contacted with the outer end face (39) in a large area, which makes it possible to reduce the contact surface pressure in the mutual contact portion between the flat surface (38) and outer end face (39).

Owner:NSK LTD

Solid-state imaging device, and method of manufacturing solid-state imaging device

ActiveUS20180277604A1Prevent penetrationReduce heatFinal product manufactureSolid-state devicesEngineeringPhotoelectric conversion

A solid-state imaging device includes: a plurality of pixels each including a first electrode, an organic photoelectric conversion film, and a second electrode in this order on a substrate, the organic photoelectric conversion film including a first inclined surface on a side wall; and a first sealing film formed, on the plurality of pixels, to cover the side wall of the organic photoelectric conversion film and the second electrode.

Owner:SONY SEMICON SOLUTIONS CORP

Support structure of direct fuel injection valve

ActiveUS9546627B2Reduce loadFirm supportMachines/enginesSpecial fuel injection apparatusFuel distributionEngineering

In a support structure of a direct fuel injection valve capable of supporting a fuel injection valve stably for a long period of time, a valve housing is made of a metal and is provided with a first load bearing portion which is to be supported by an engine in an axial direction of the valve housing, a rear end portion of the fixed core is provided with a second load bearing portion which is to be supported by a resilient holding member in the axial direction, and the first and second load bearing portions are held between the engine and the resilient holding members with a forward set load applied to the resilient holding member by a fuel distribution pipe fitted to a fuel inlet tube and fixed to the engine.

Owner:HITACHI ASTEMO LTD

Combustion apparatus

ActiveUS10527279B2Secure sealing performanceSolid fuel combustionWater heatersCombustorThermal insulation

A combustion apparatus includes a burner having a sheet-metal combustion plate which covers an open surface of a burner body; and a combustion box having a connection flange part to be coupled to a body flange part enclosing the open surface of the burner body, and is equipped with a cooling means for cooling the combustion box, an arrangement is made that overheating of the burner body due to heat transmission from the combustion plate can be prevented, even without enhancing thermal insulation performance of a packing to be interposed between a combustion plate flange part and the body flange part. The connection flange part is kept in direct contact with the combustion plate flange part and, coupled to the body flange part. The packing is provided with: a combustion plate seal part to be pressed under pressure against the combustion plate flange part; and a combustion box seal.

Owner:RINNAI CORP

Resin molded article and mold for manufacturing the same

InactiveUS20070014954A1Reduce manufacturing costSealing is reliableLayered productsElectrographic process apparatusEngineeringMechanical engineering

Owner:YOKOI CO LTD

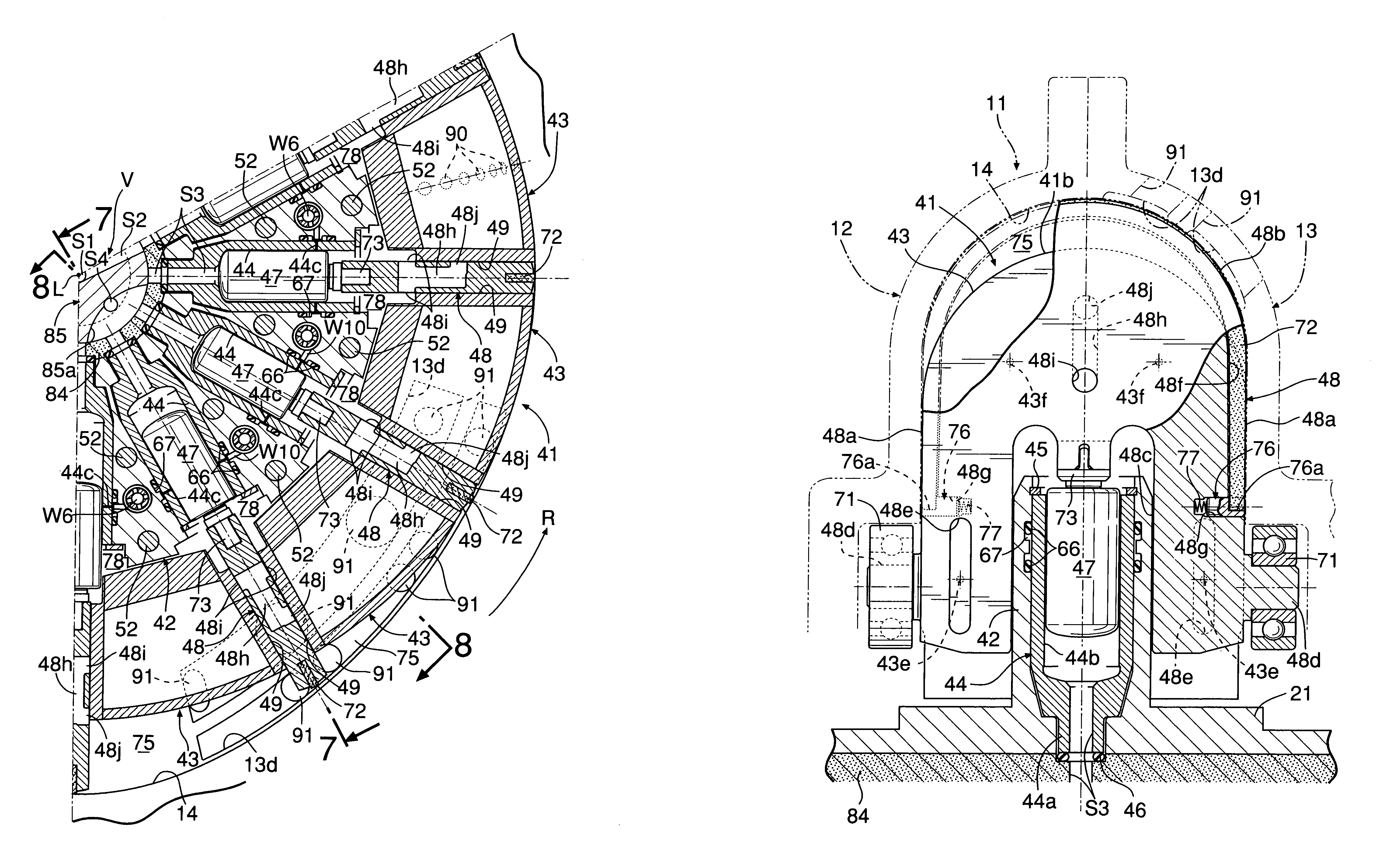

Rotating fluid machine

InactiveUS7083402B2Prevent leakageSecure sealing performanceReciprocating combination enginesOscillating piston enginesGas phaseEngineering

A rotating fluid machine is provided with a rotor chamber, a rotor accommodated in the rotor chamber, and vanes guided by vane grooves formed in the rotor. A U-shaped vane seal is held by a seal holding groove formed in the end face of each of the vanes. The opposite ends of the vane seal are fitted into slits in seal ancillary members which are fitted into engaging holes formed in the end faces of each of the vanes. The seal ancillary members are pressed by springs toward the inner circumferential face of the rotor chamber. The pressure of a gaseous phase working medium introduced into the bottom parts of the seal holding grooves is restrained from leaking out of the ends of the vane seal by the seal ancillary members. Thus, sealing performance can be secured by pressing the vane seal against the inner circumferential face of the rotor chamber.

Owner:HONDA MOTOR CO LTD

Composite valve for gas supply system

ActiveUS20050121634A1Compact structureSecure sealing performanceOperating means/releasing devices for valvesApplication and release valvesEngineeringGas supply

An automatic-and-manual operation composite valve includes a valve main body into which an air is supplied and from which the air is discharged, a piston provided within the valve main body to be vertically movable by means of the air supplied or discharged and a snapping force of a spring attached to the piston, a valve body provided within the valve-main body, and opened and closed by the piston, an air switch valve portion provided within the valve main body for switching air supply and air discharge and a manual operation mechanism portion for operating the air switch valve portion.

Owner:KITZ SCT

Sensor device and sensor-integrated rolling bearing device

InactiveUS20100135605A1Avoid squeezingSealing is reliableEngine sealsPiston ringsRolling-element bearingEngineering

Owner:JTEKT CORP

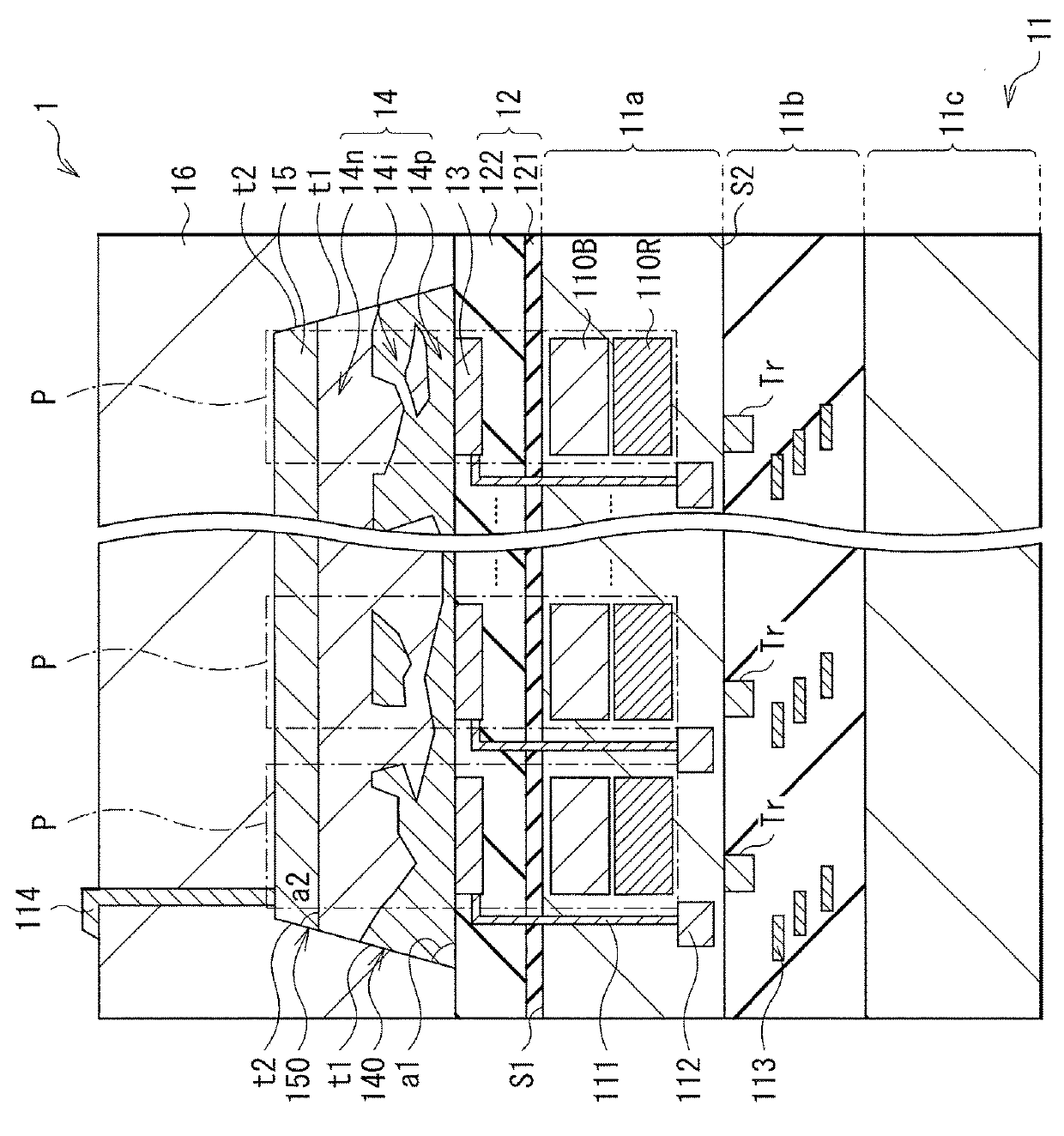

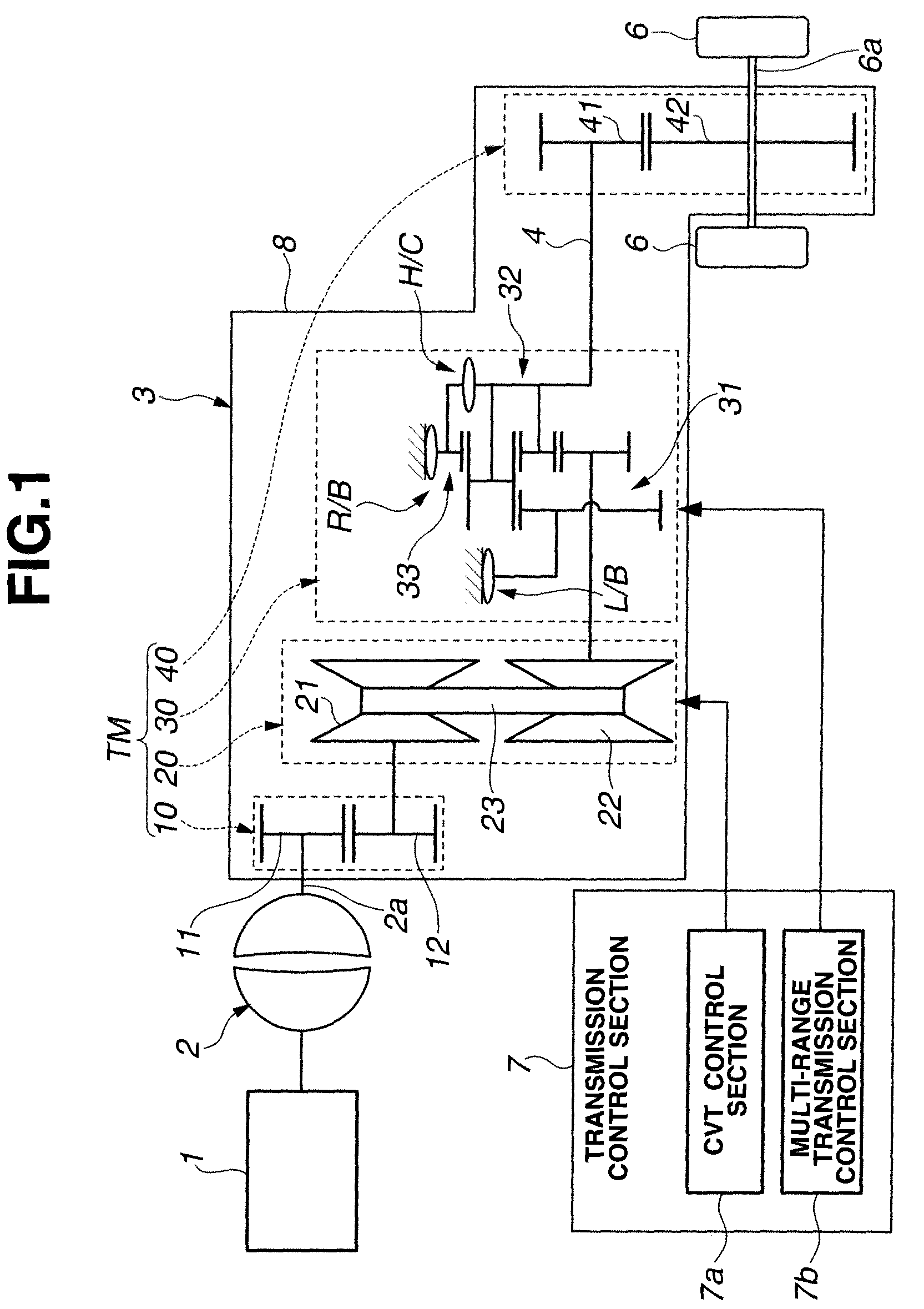

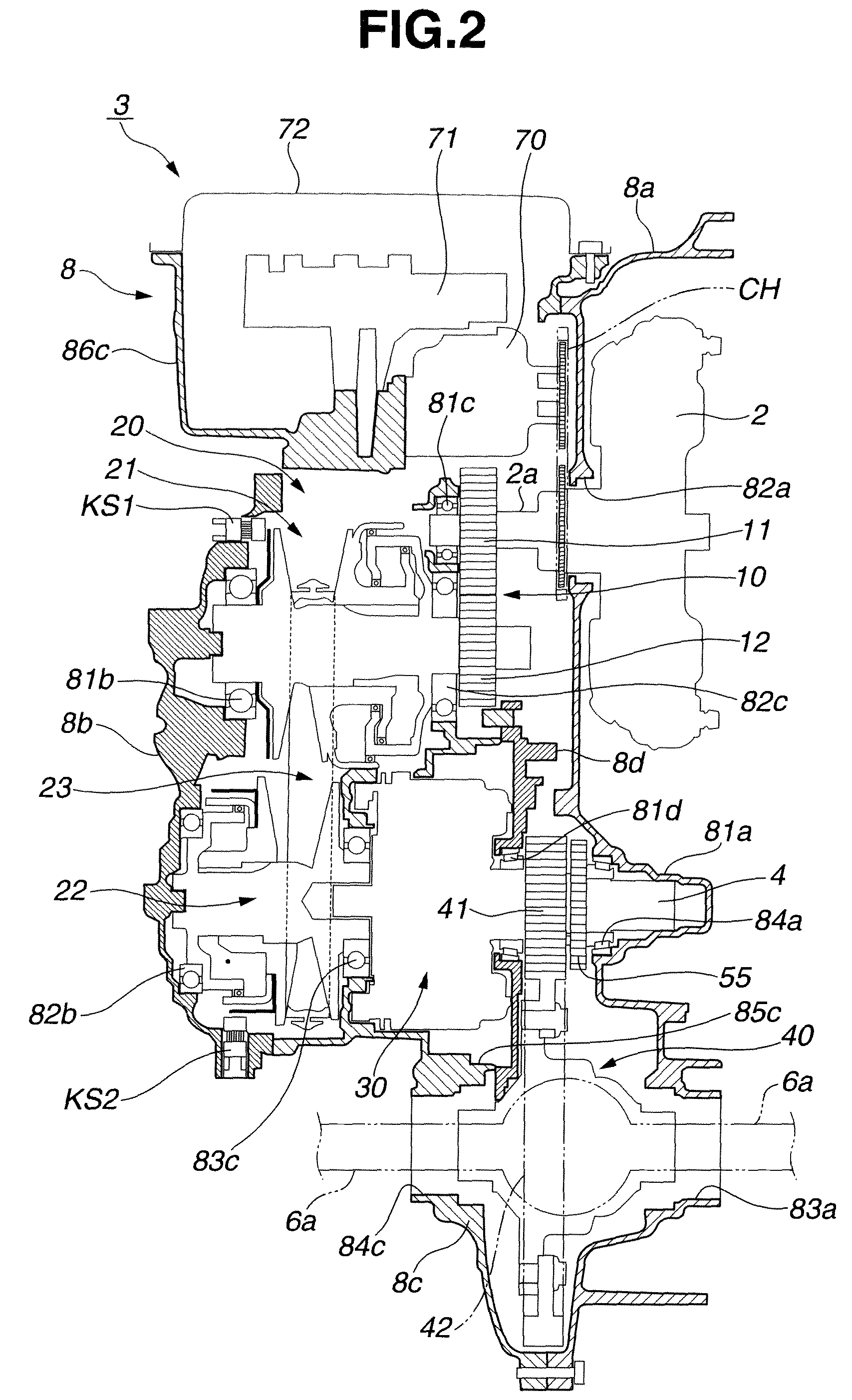

Automatic transmission

ActiveUS8590424B2Reducing fixing pointSecure sealing performanceGearboxesGearingAutomatic transmissionMechanical engineering

An automatic transmission has a transmission casing accommodating a transmission mechanism and a filter case attached to the transmission casing and having an oil filter. The transmission casing has a concave portion with which at least an oil inlet or an oil outlet communicates and an overhanging portion positioned close to the concave portion and extending along a surface of the transmission casing with a clearance provided between the surface and the overhanging portion. The filter case has a case body inserted into the concave portion, a seal member sealing a boundary between an outer circumferential surface of the case body and an inside surface of the concave portion, a first brim portion protruding from the outer circumferential surface and fixed to the surface of the transmission casing, and a second brim portion protruding from the outer circumferential surface and inserted into the clearance.

Owner:JATCO LTD +1

Airtight container and manufacturing method of image displaying apparatus using airtight container

InactiveUS20090029622A1Sealing is reliablePreventing sealantVessels or leading-in conductors manufacturePhoto-emissive cathodes manufactureMethod of imagesEngineering

An airtight container manufacturing method, comprises: exhausting the inside of a container via a through-hole provided on the container; arranging a plate member on the outer surface of the container the inside of which was exhausted, so as to close up the through-hole; and sealing the container by arranging a cover member so as to cover the plate member and by bonding the arranged cover member and the outer surface of the container to each other via a sealant positioned between the cover member and the outer surface of the container, wherein the sealing includes hardening the sealant after deforming the sealant as pressing the plate member.

Owner:CANON KK

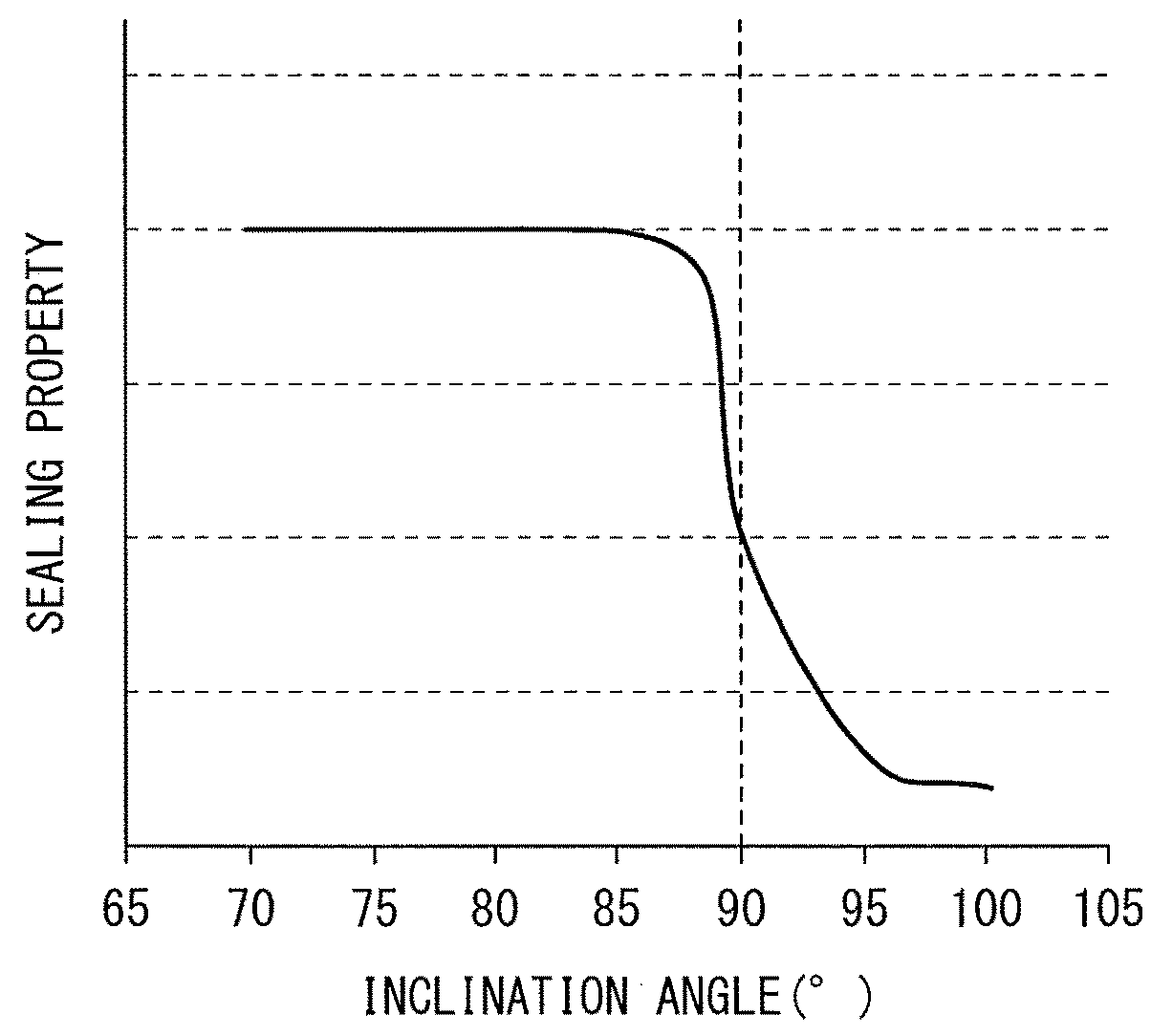

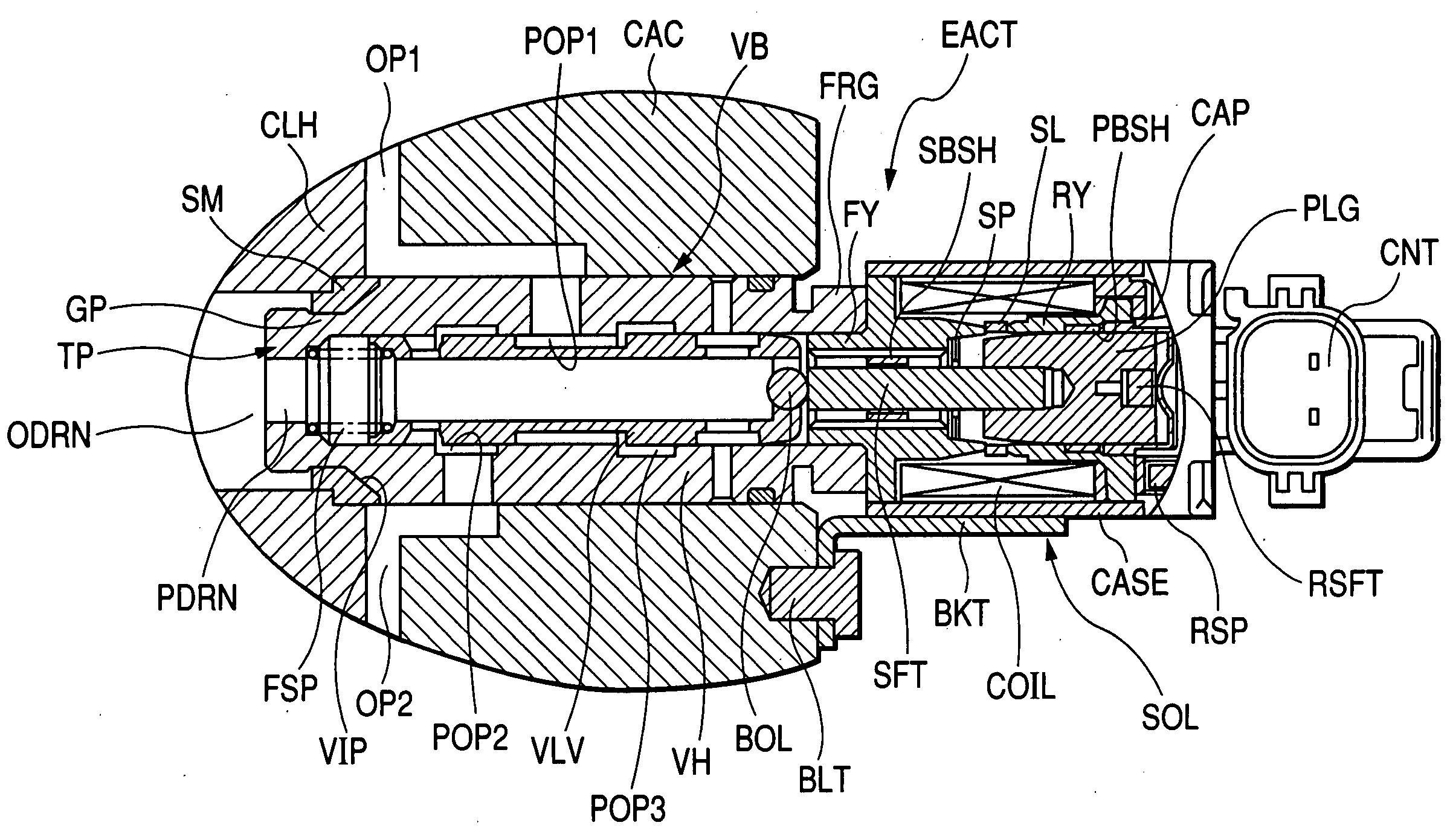

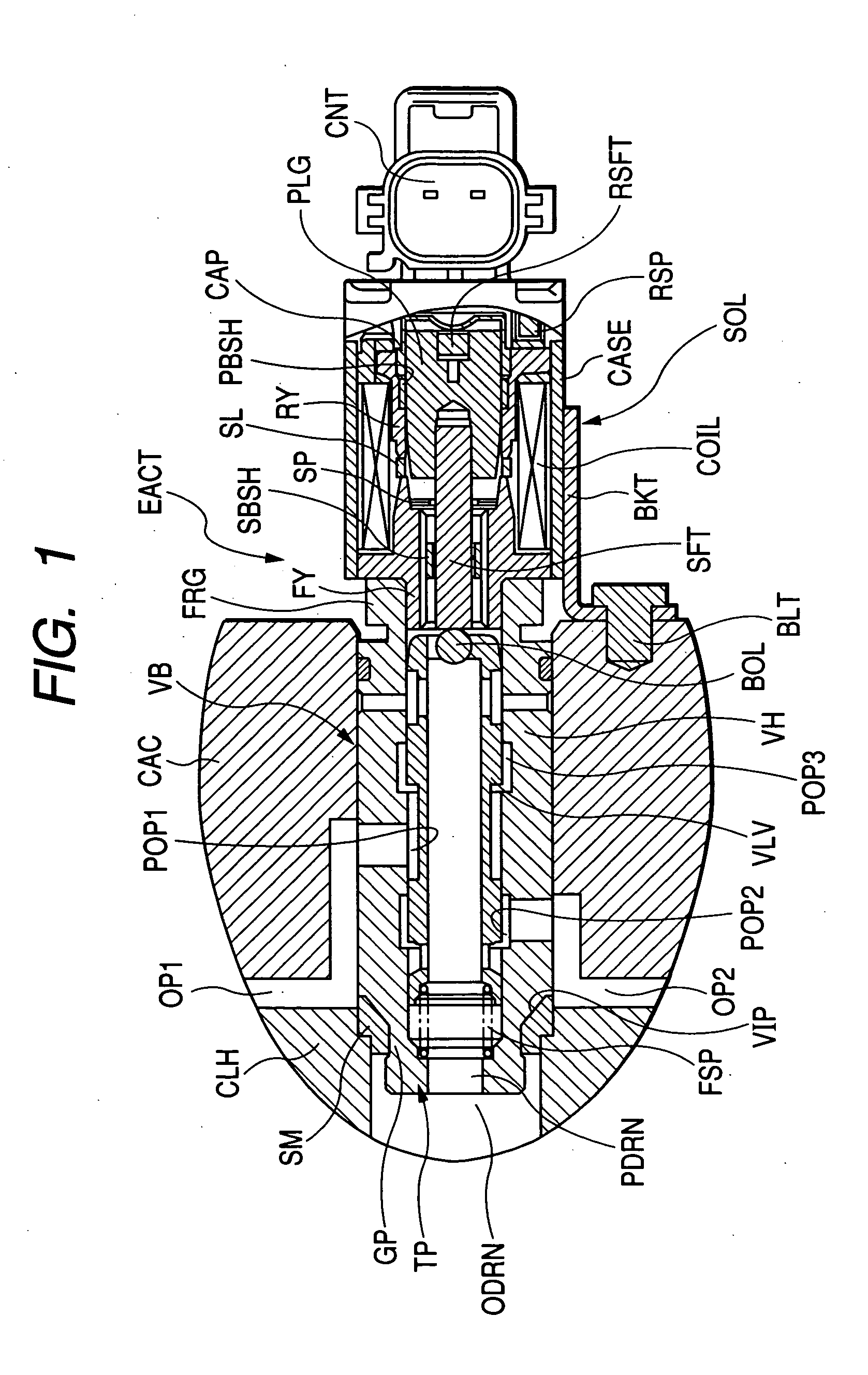

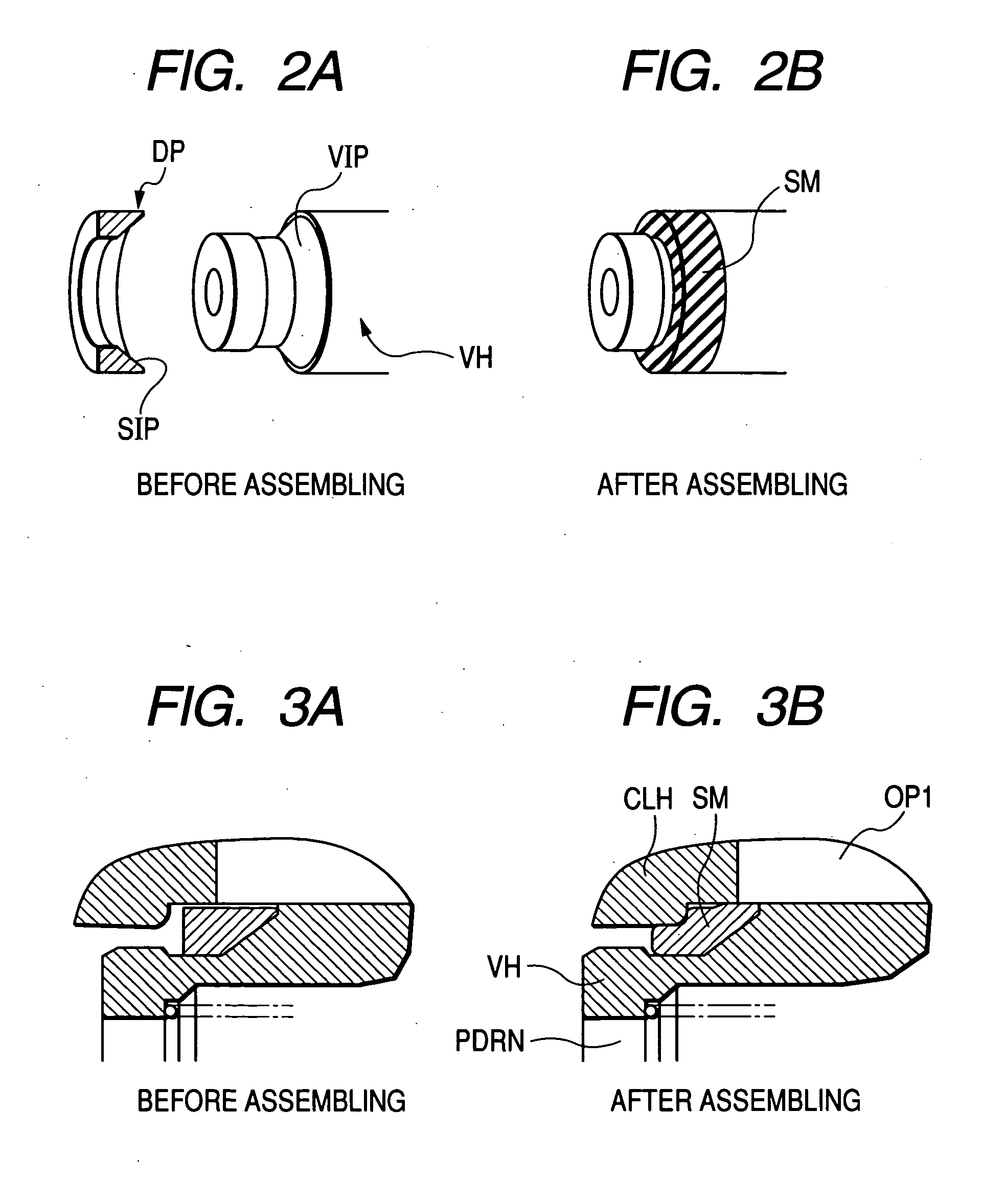

Electromagnetic actuator

InactiveUS20050211935A1Sealing is reliableSecure sealing performanceEngine sealsOperating means/releasing devices for valvesEngineeringSolenoid actuator

An electromagnetic actuator includes: a valve body part formed in a substantially cylindrical shape and provided with: an opening to be connected to an external fluid passage; a valve accommodated in the valve body part; and a groove having an inclined face; a solenoid part that actuates a valve; and a seal member that is fitted on an outer peripheral of the inclined face to be urged in an axial direction of the valve body part.

Owner:AISIN SEIKI KK

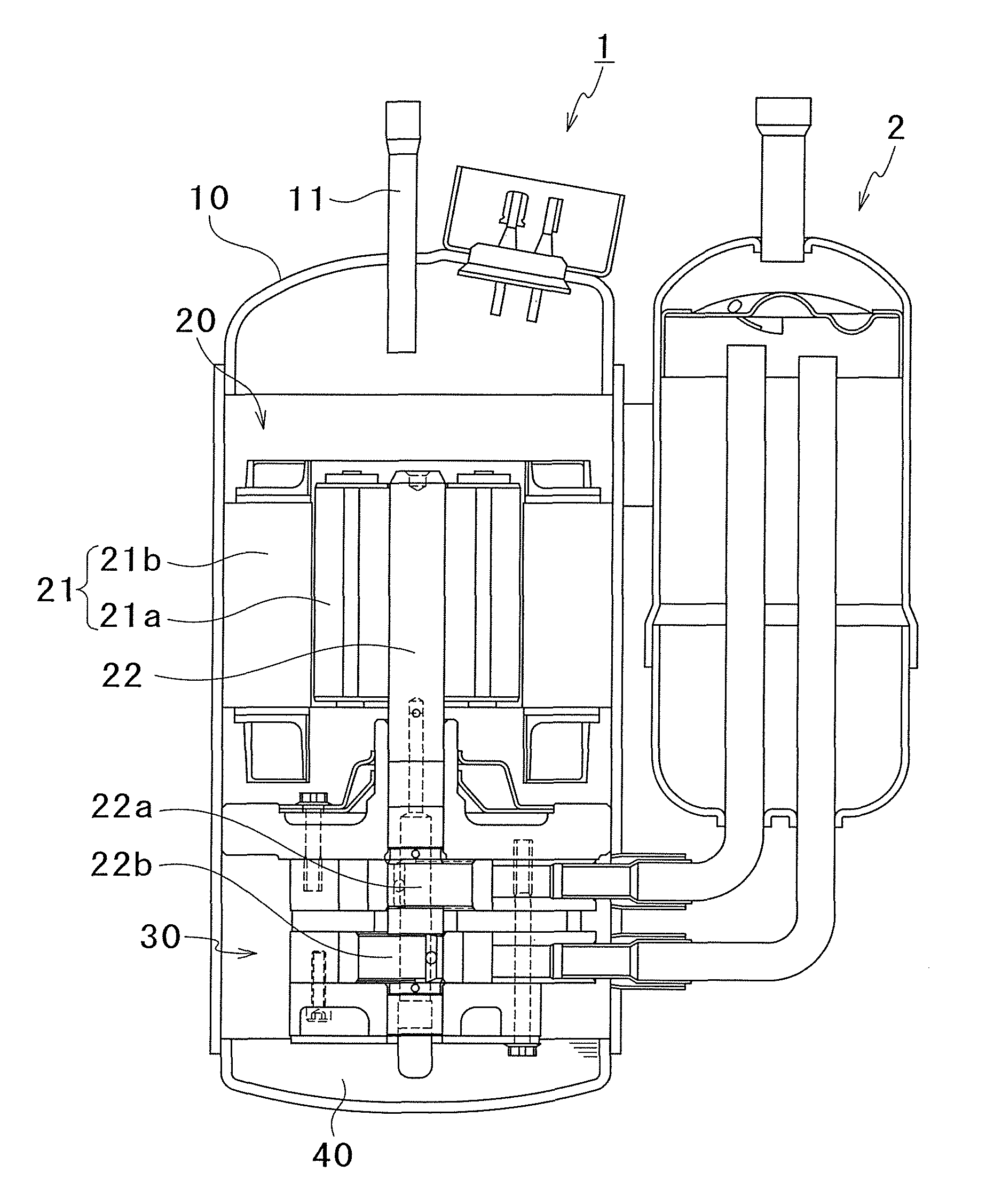

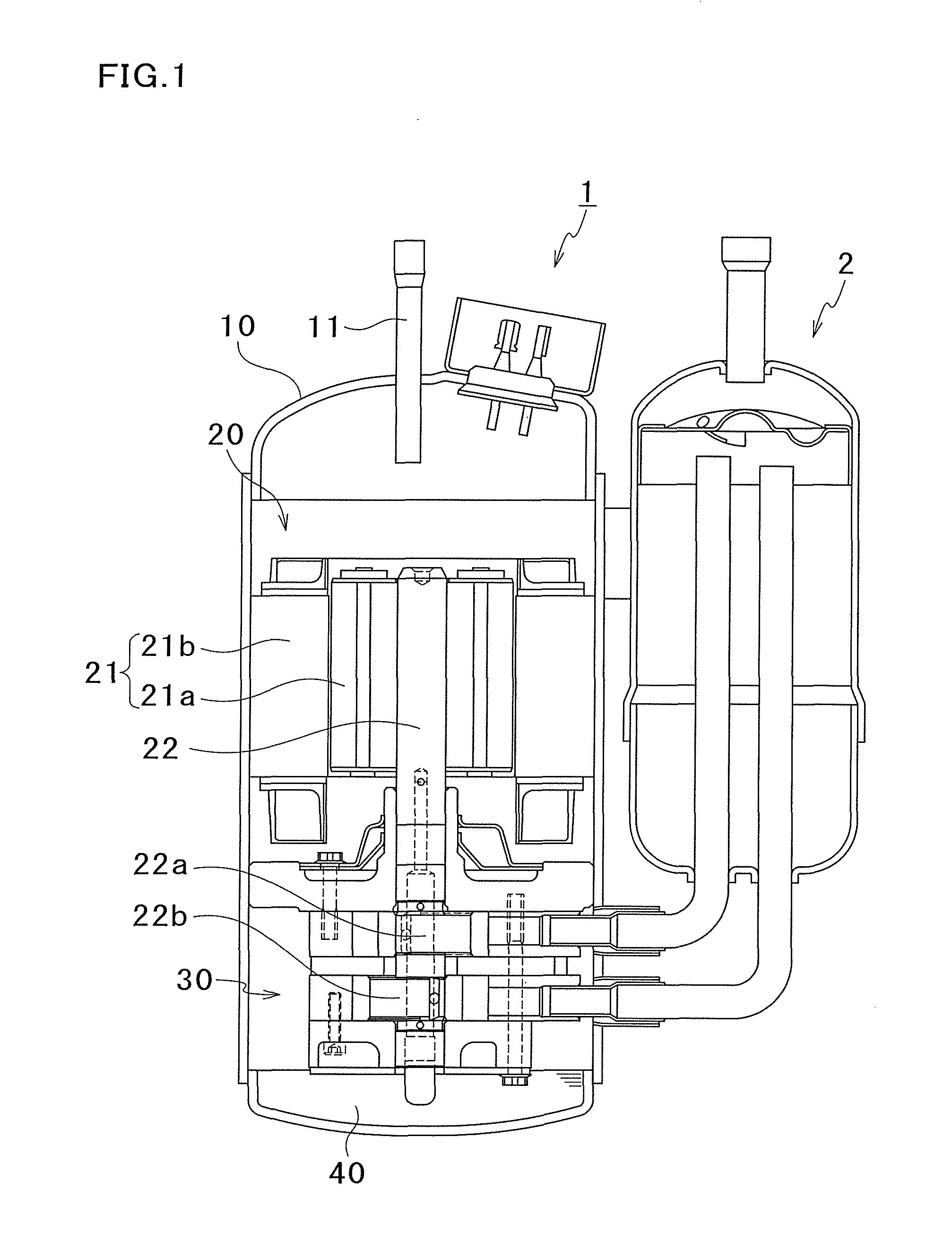

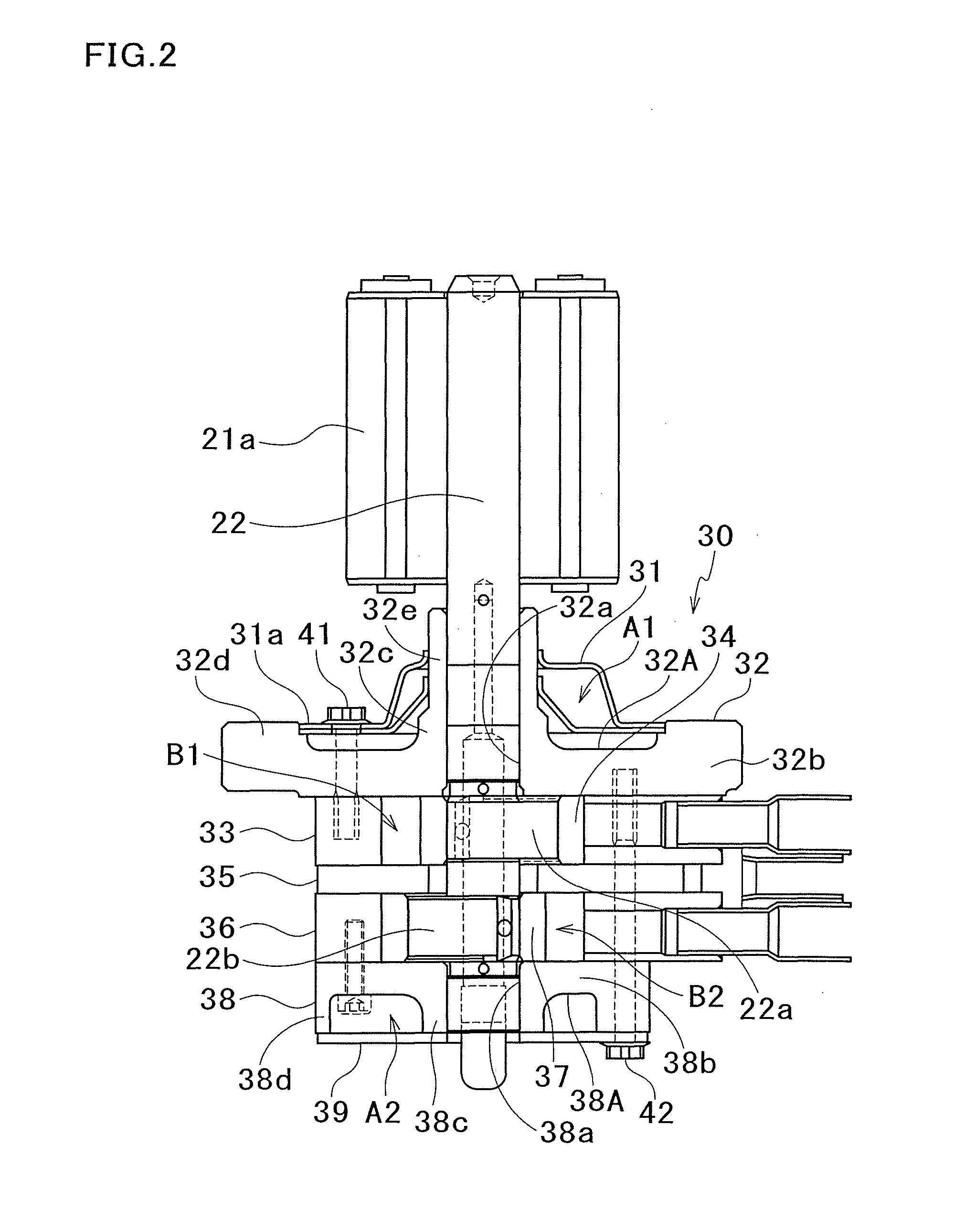

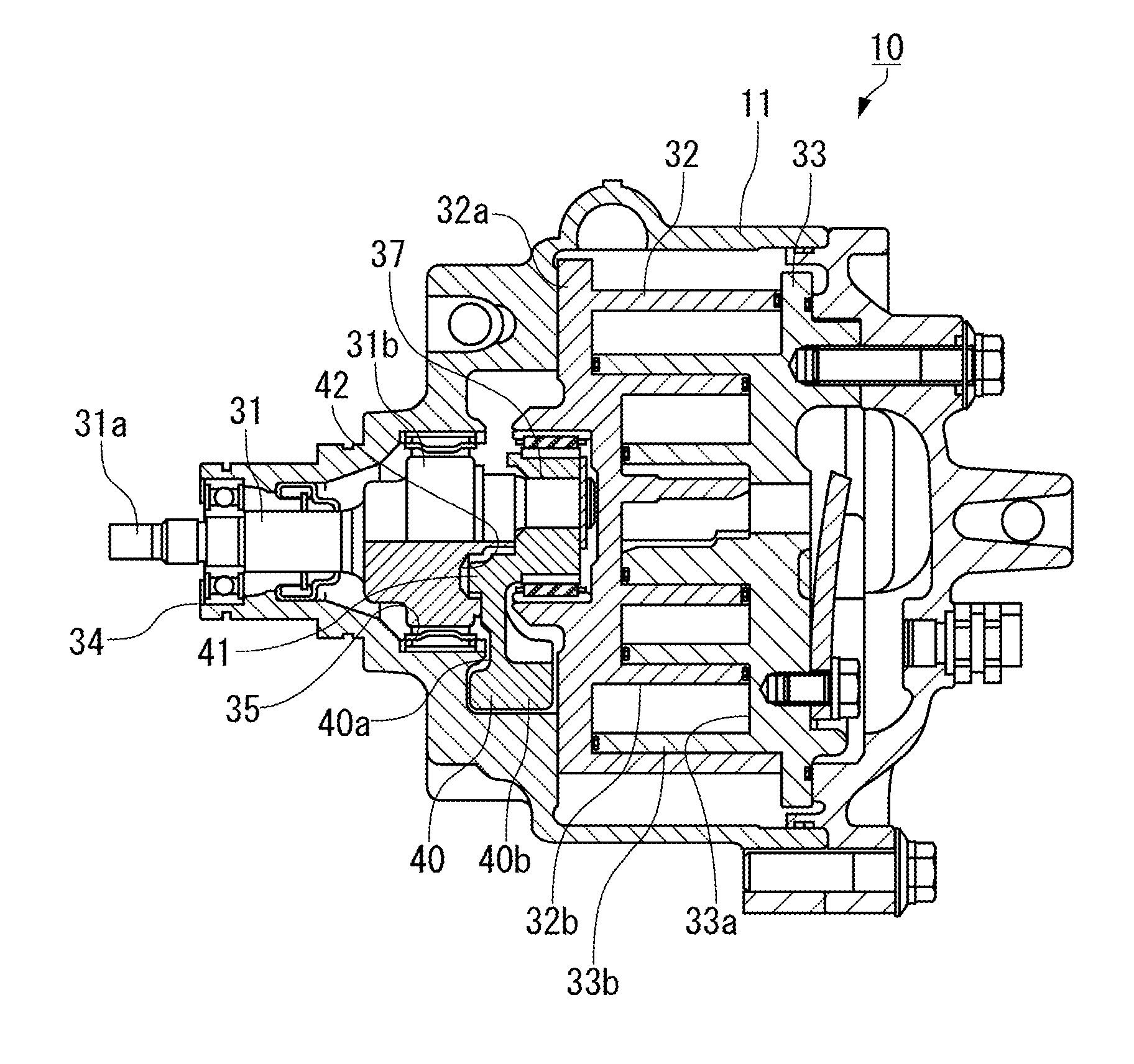

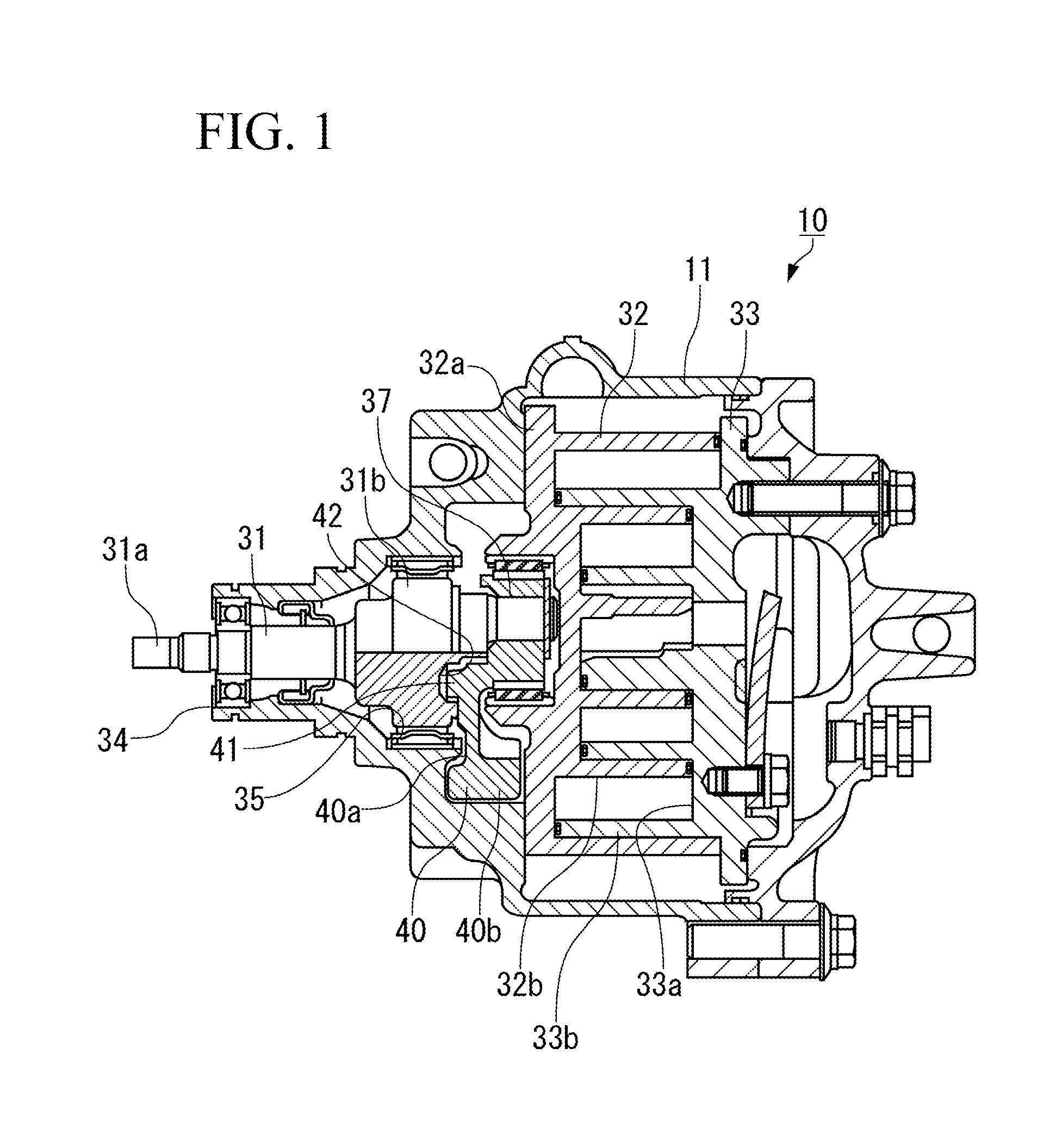

Sealing structure and compressor

ActiveUS8596995B2Improve machining accuracyIncrease the number ofRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringMuffler

A sealing is arranged between a rear head having an ejection port configured and arranged to eject compressed refrigerant and a rear muffler disposed so that a muffler space is formed between the rear muffler and the rear head. The rear head includes a main body having a bearing hole, an annular boss portion protruding from the main body and circumscribing the bearing hole, and an annular side wall protruding from the main body and circumscribing the boss portion. The rear muffler has an opening and is fastened to the end surface of the side wall so that the peripheral portion of the opening contacts the end surface of the boss portion. Preferably, the end surface of the boss portion has a part entirely further from the main body than the end surface of the side wall.

Owner:DAIKIN IND LTD

Scroll type compressor

InactiveUS20110280758A1Increase and decrease loadReduce variationEngine of arcuate-engagement typeOscillating piston enginesEngineeringMechanical engineering

Provided is a scroll type compressor which reduces variations in the pressing load of a rotating scroll on a fixed scroll, reduces the impact at the start of the compressor and suppresses noises, and can provide excellent durability. A peripheral elastic body 51 and a bottom-portion elastic body 52, which is brought into a compressed condition in the axis line direction of the main shaft 31, are interposed between a stopper pin 41 on the rotating scroll side and a concave portion 42 on the main shaft 31 side, whereby working errors of each part are compensated and the rotating scroll is constantly brought into close contact with the fixed scroll to maintain the sealing of the compression chamber.

Owner:MITSUBISHI HEAVY IND LTD

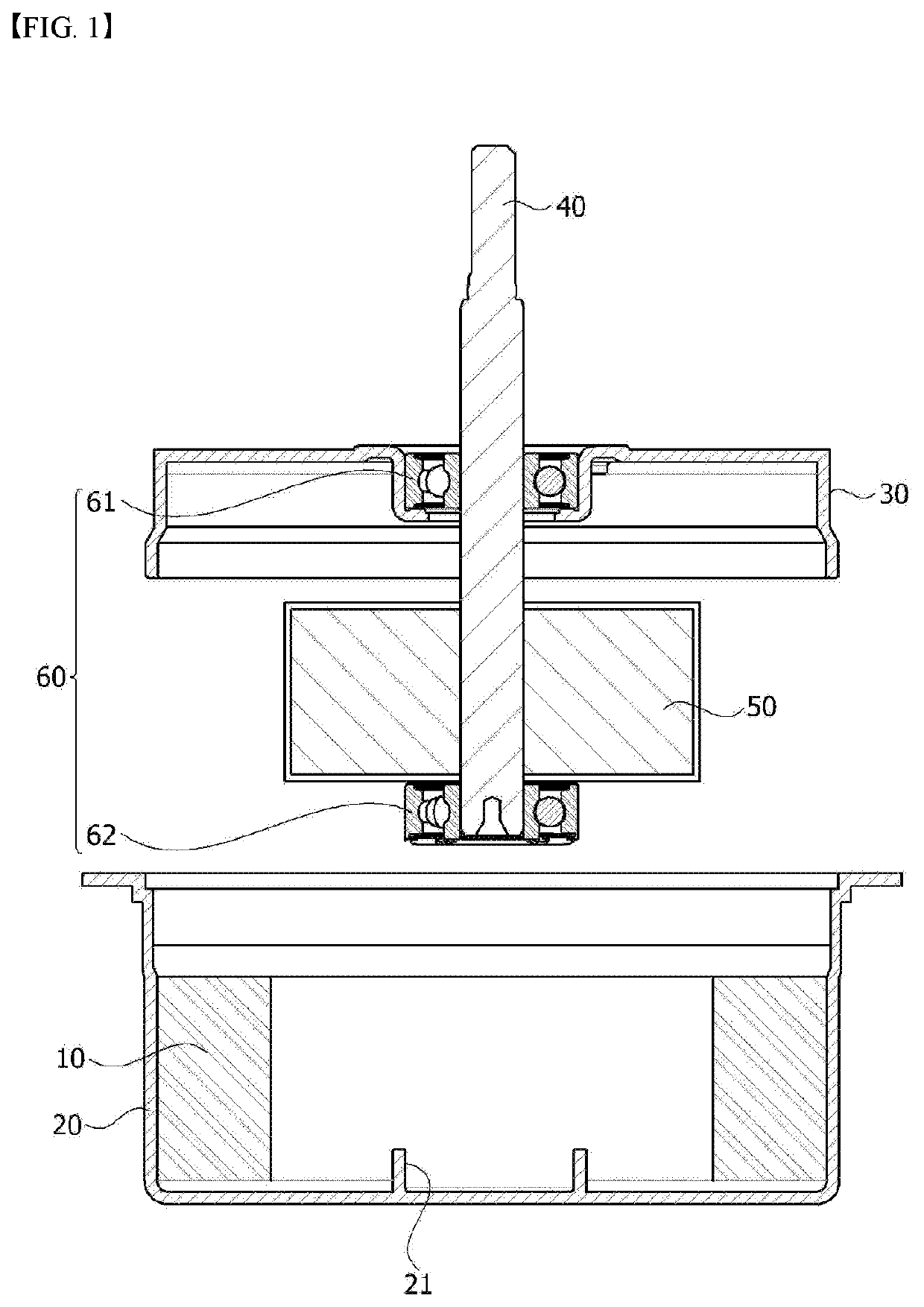

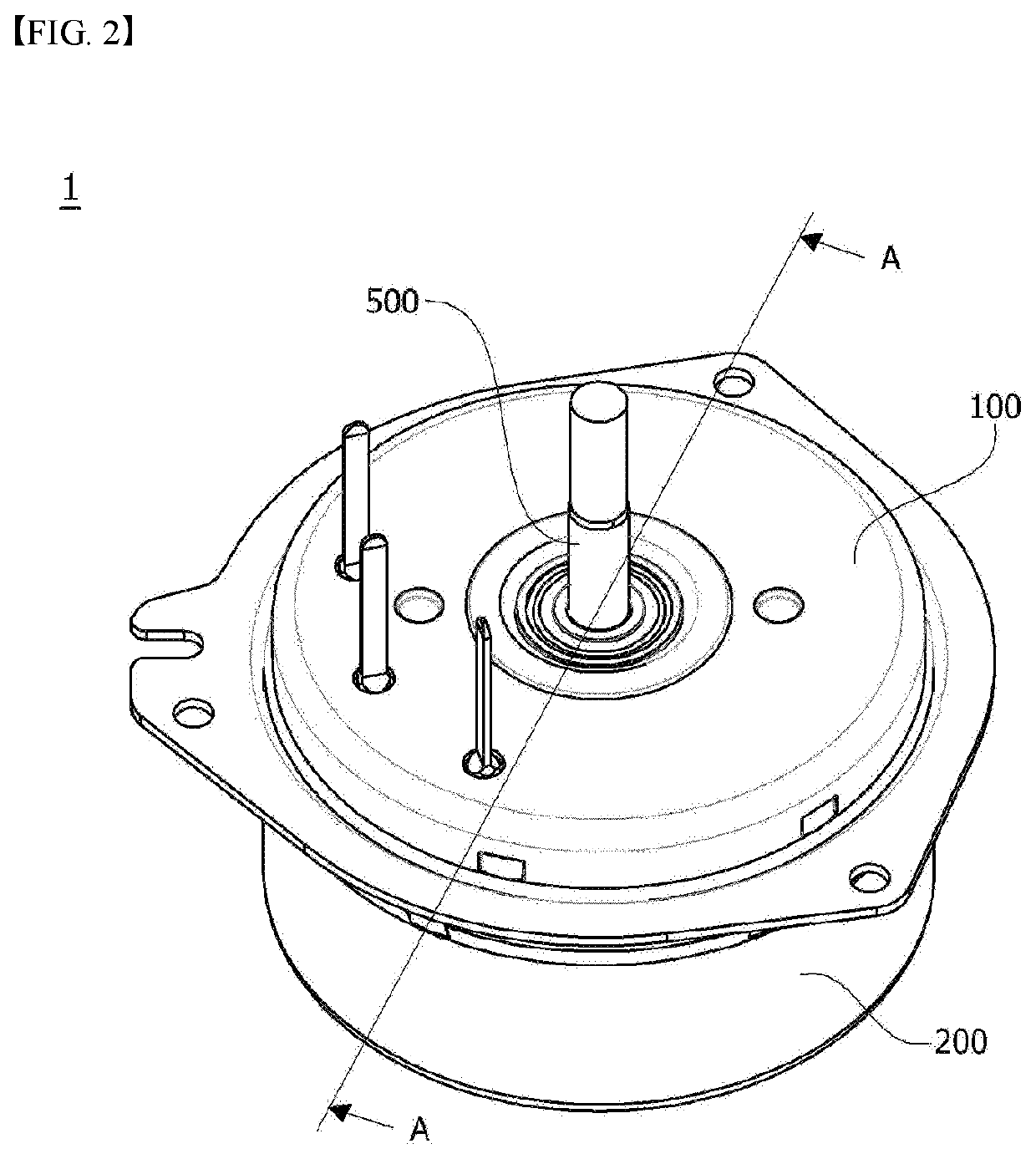

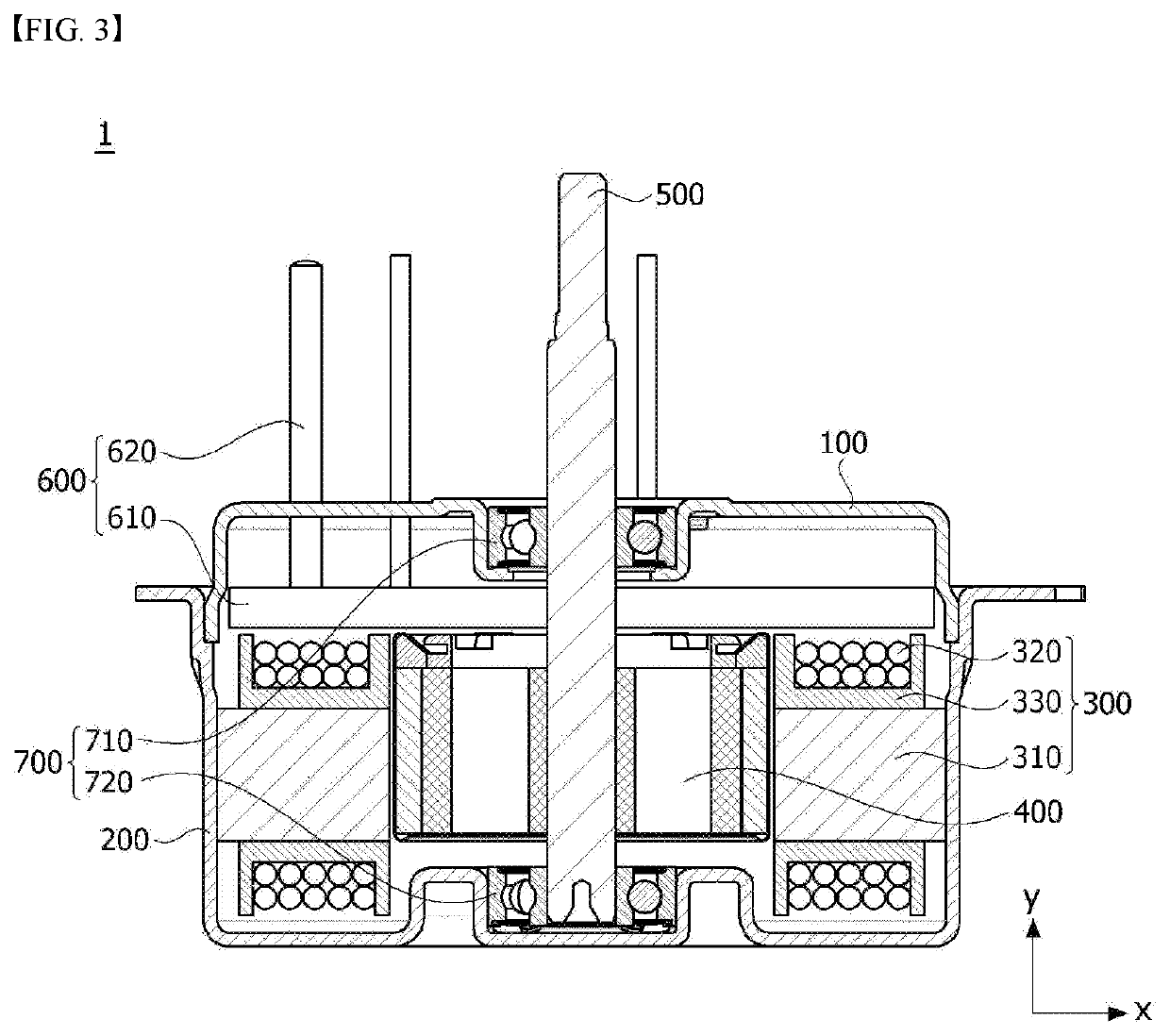

Motor

ActiveUS20200321823A1Secure sealing performanceAvoid damageWindingsCentering/balancing rotorsElectric machineClassical mechanics

An embodiment relates to a motor comprising: a shaft; a rotor which is coupled to the shaft; a stator which is disposed outside the rotor; a housing which accommodates the rotor and the stator and has an opening formed at one side thereof; and a cover which covers the opening, wherein the cover comprises a cover plate portion; and a side wall which extends axially from the cover plate portion, and at least three grooves are formed in the side wall. Accordingly, the motor according to the embodiment can guarantee the sealing performance while preventing the bearing from being damaged when the rotor is assembled on the inside of the stator.

Owner:LG INNOTEK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com