Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Save transfer time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Non-Volatile Memory with Background Data Latch Caching During Read Operations

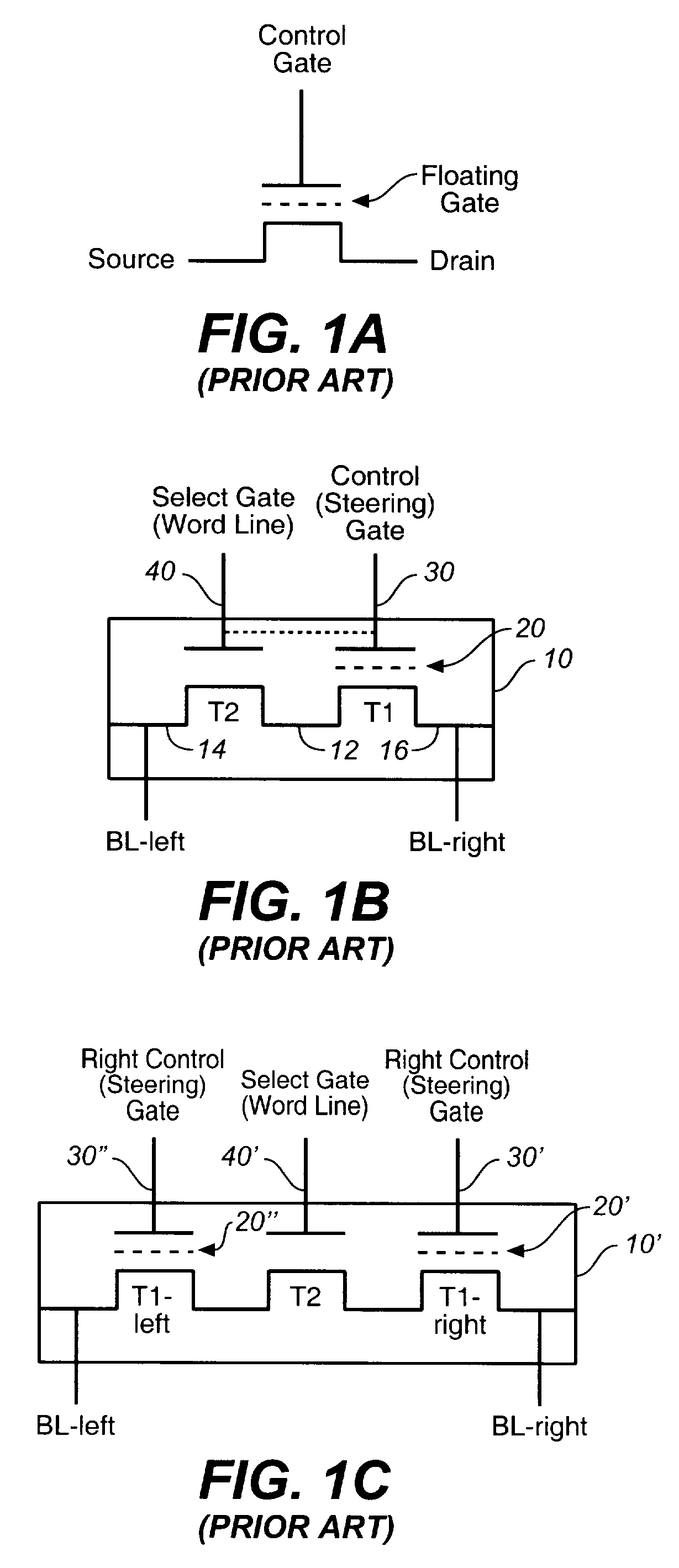

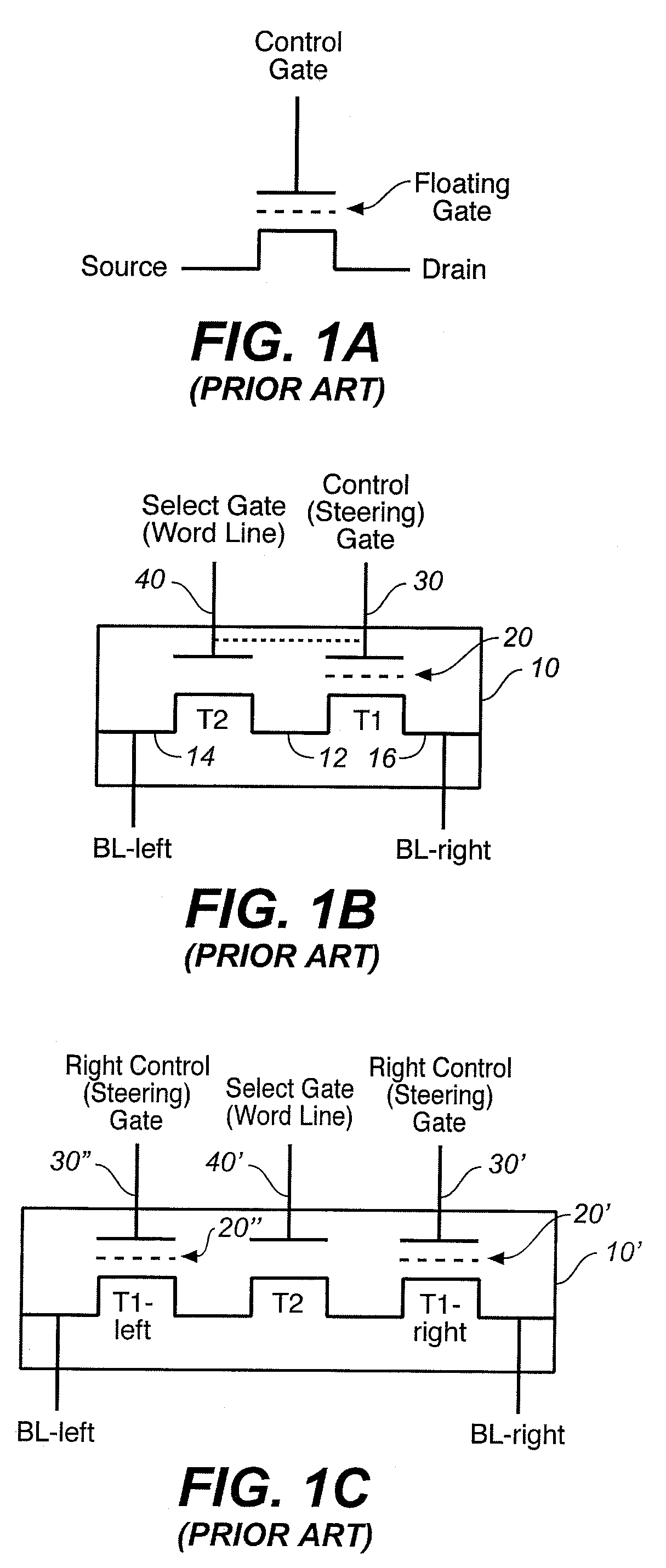

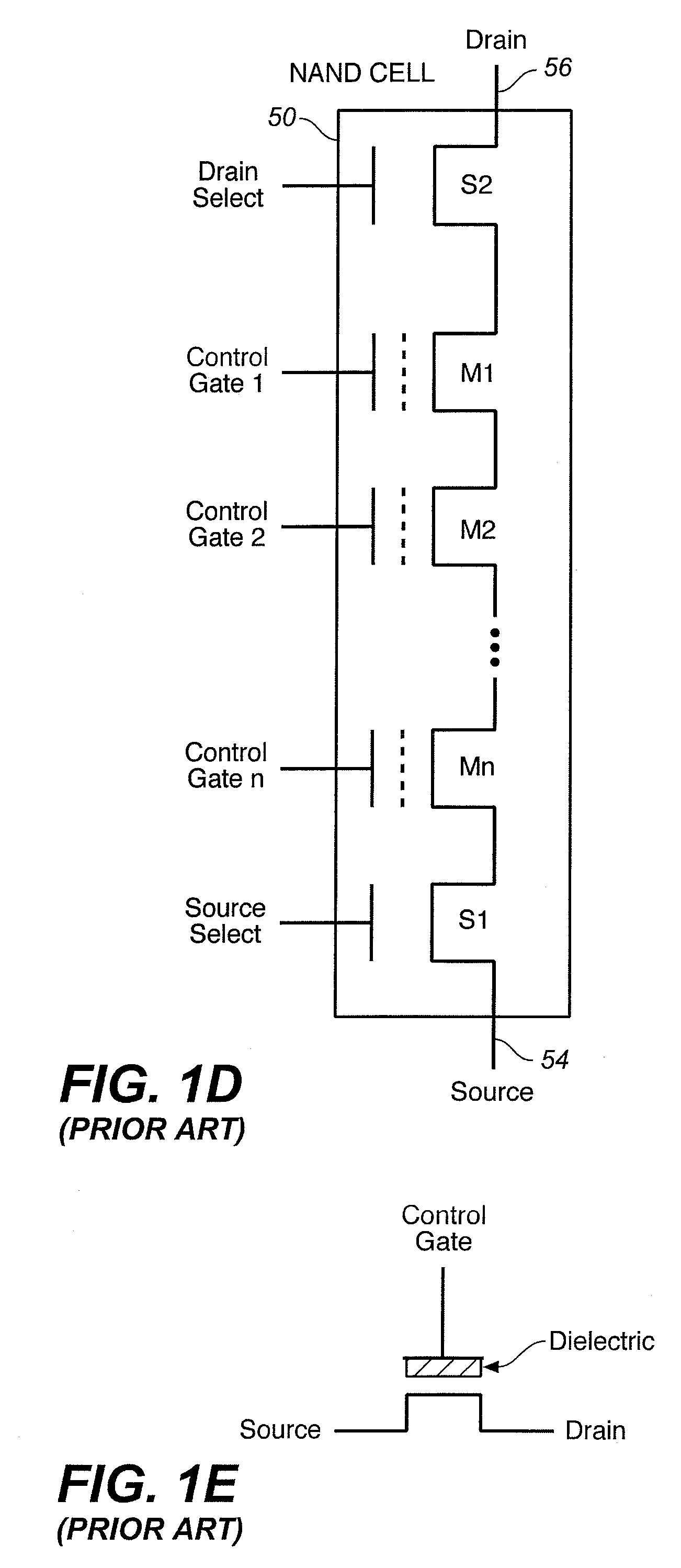

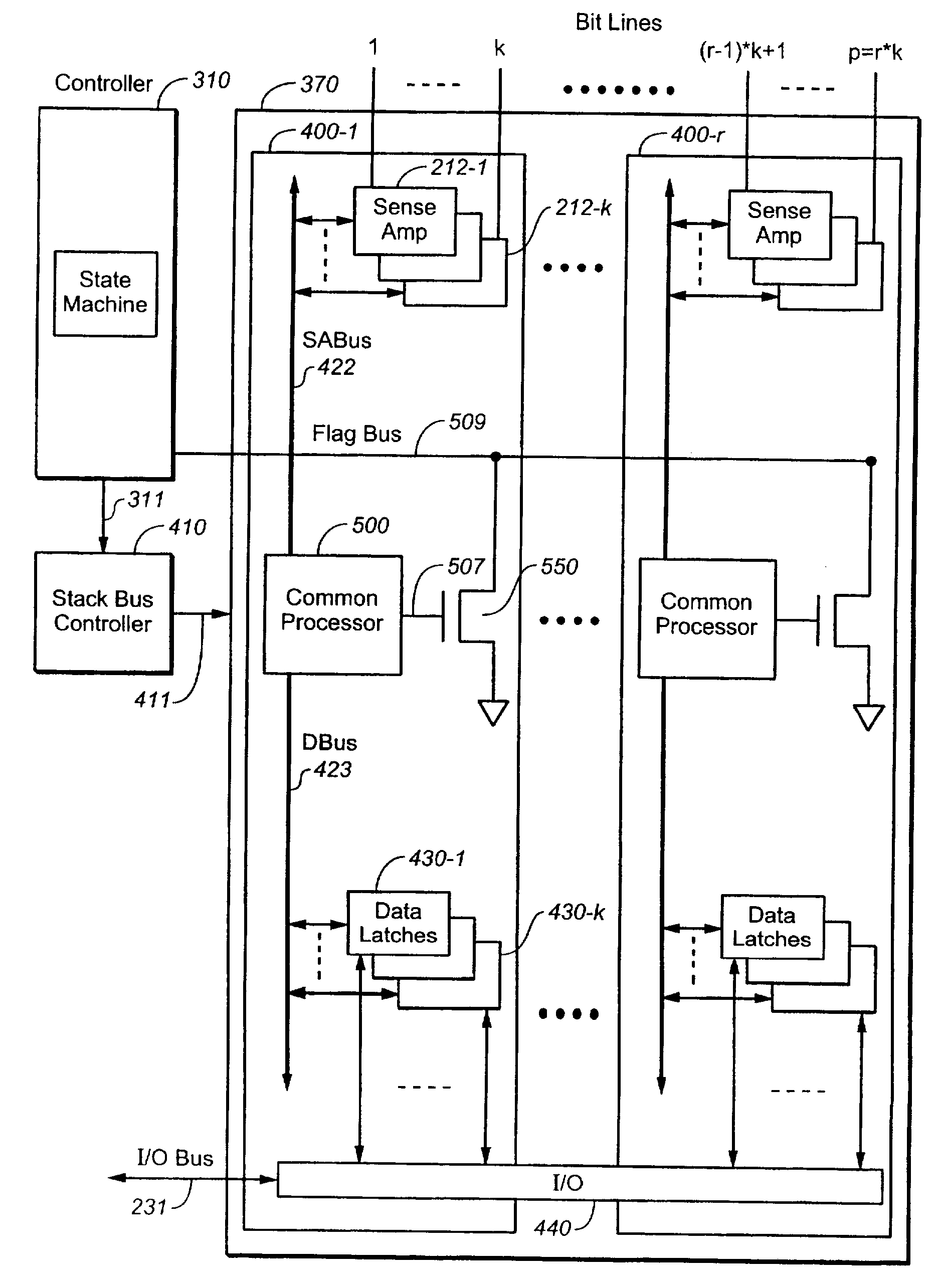

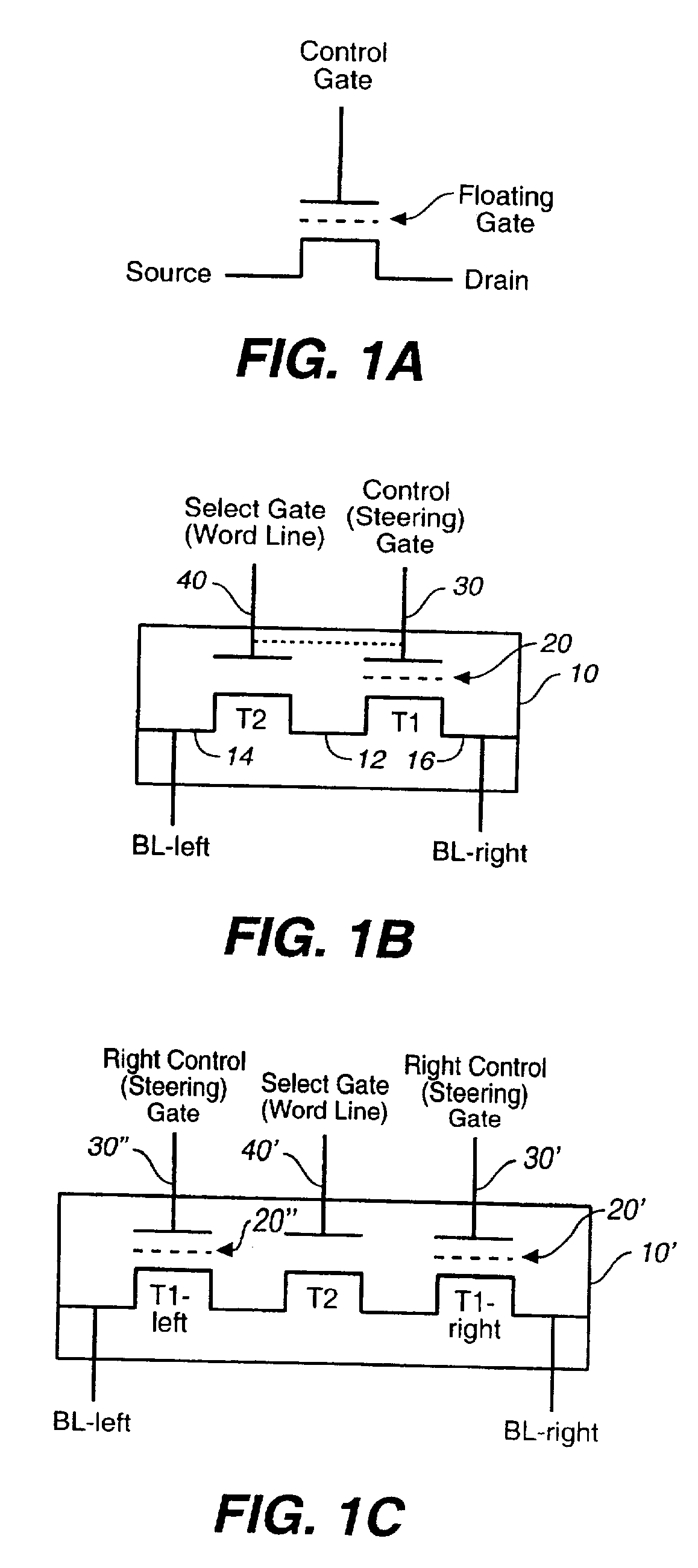

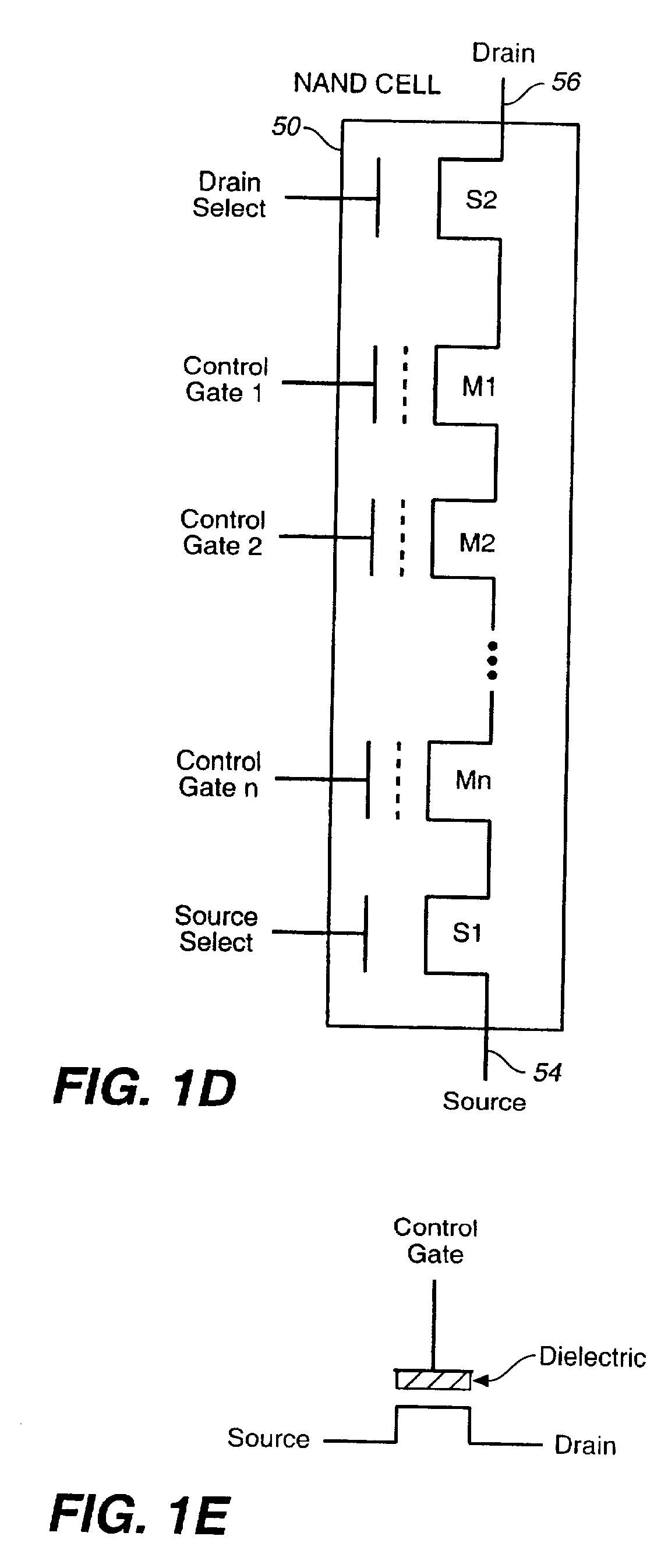

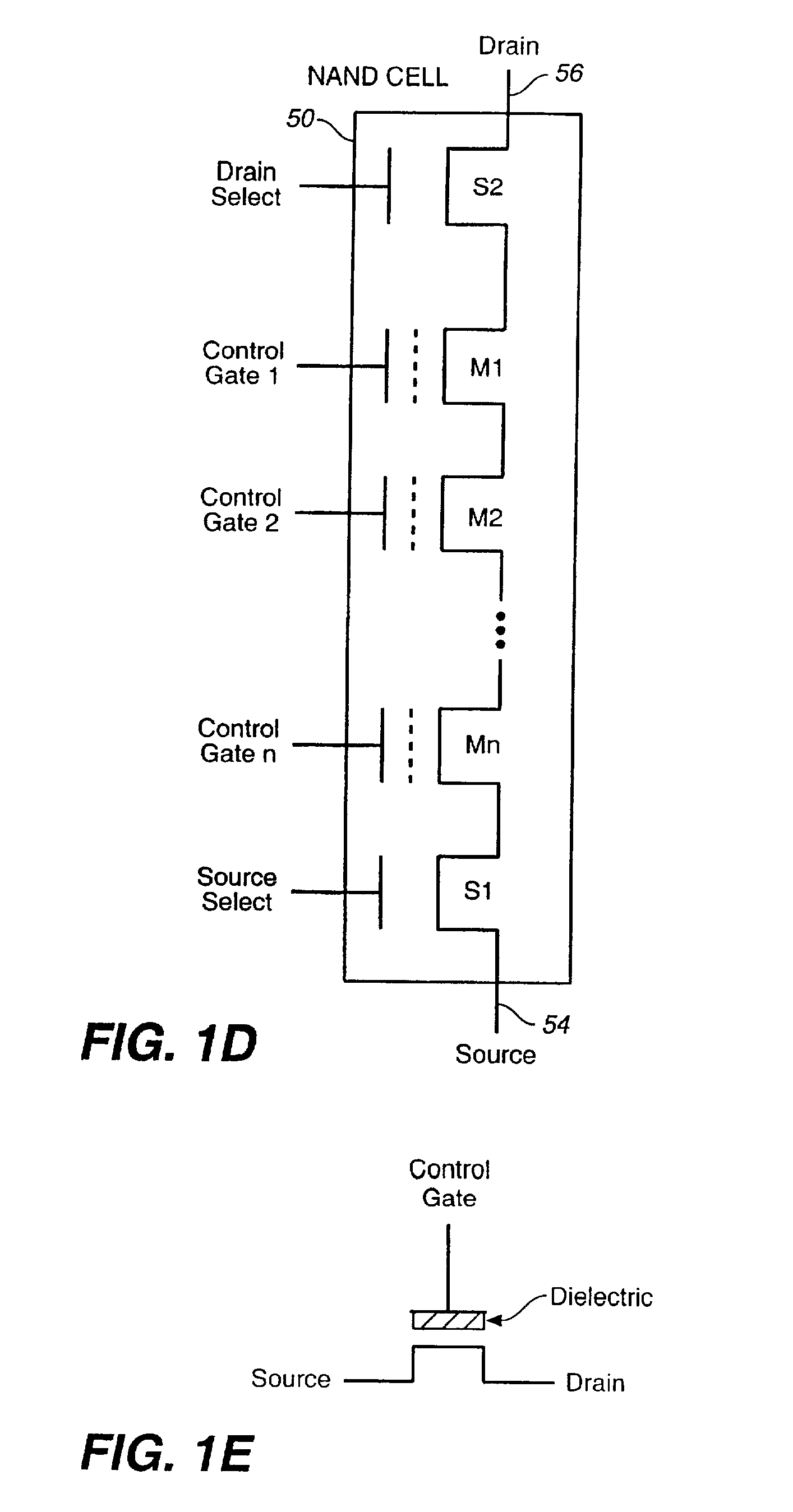

ActiveUS20060221696A1Minimize perturbationSave transfer timeMemory architecture accessing/allocationRead-only memoriesTransfer operationNon-volatile memory

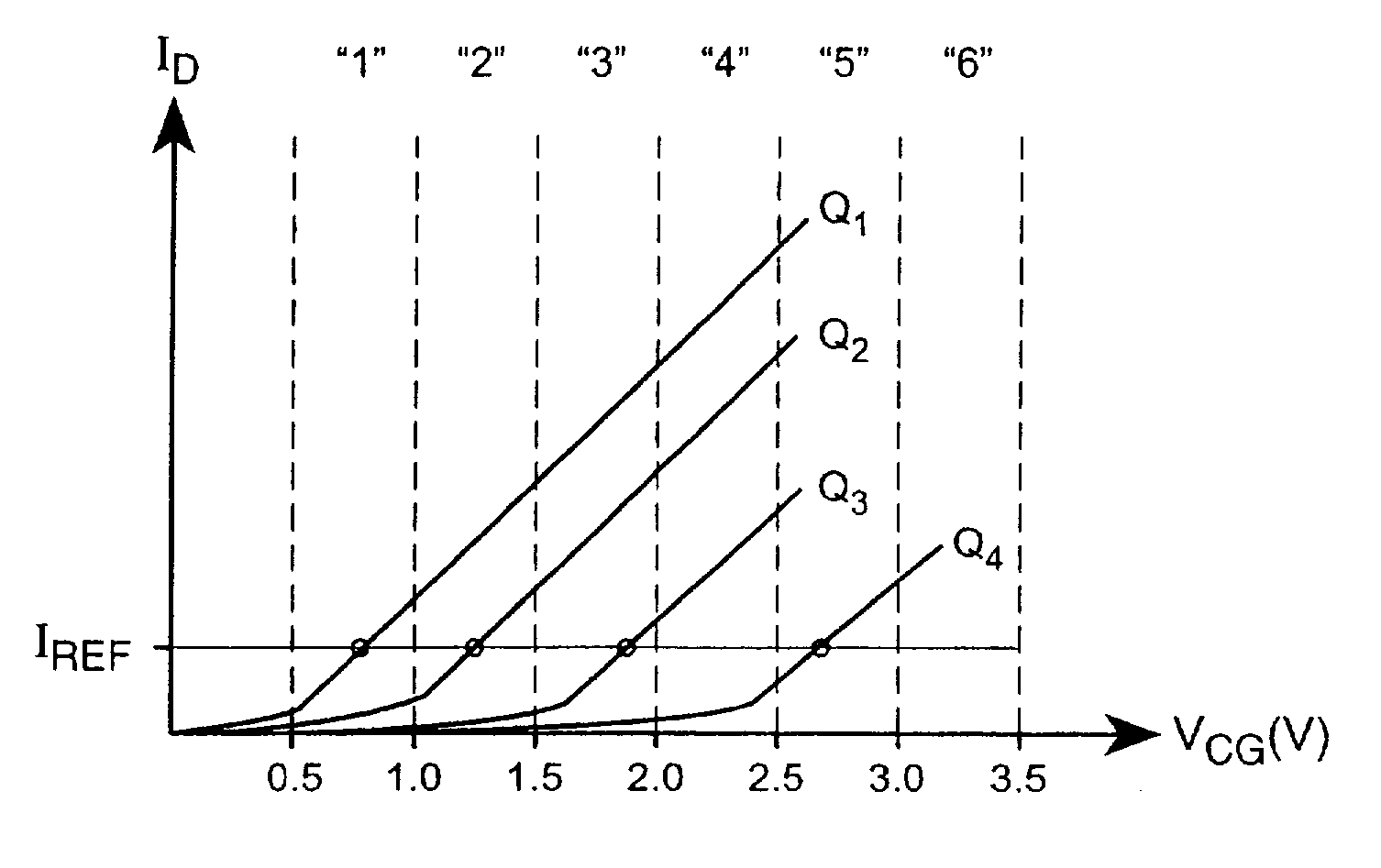

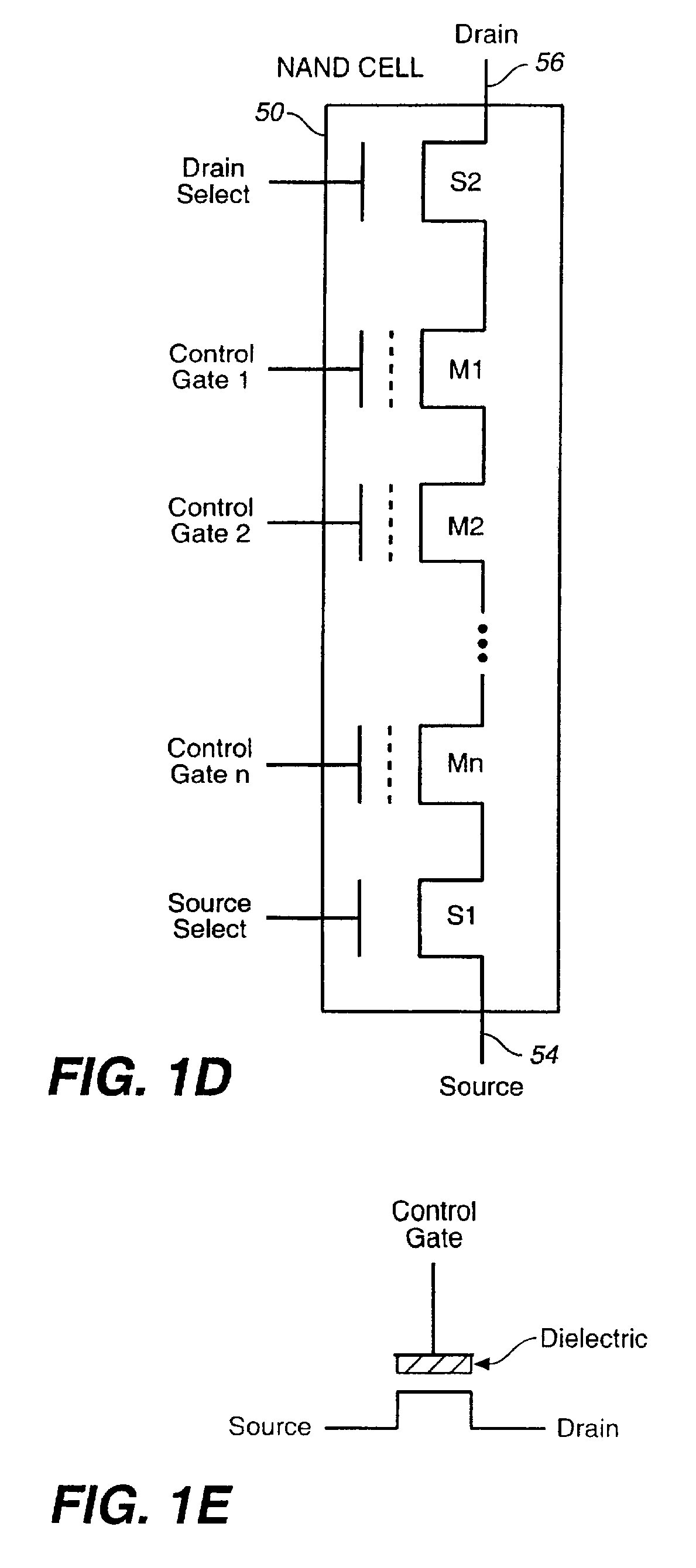

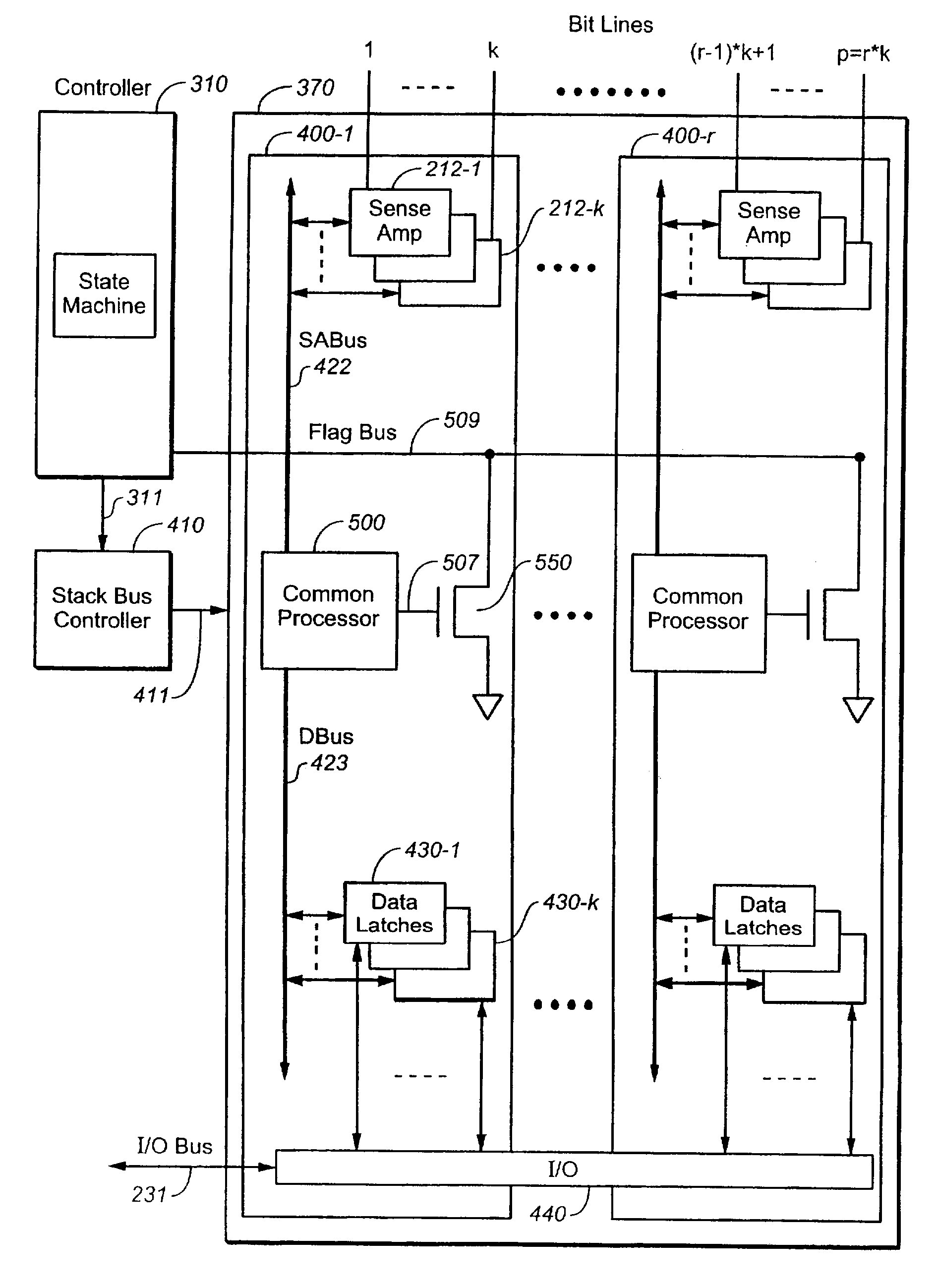

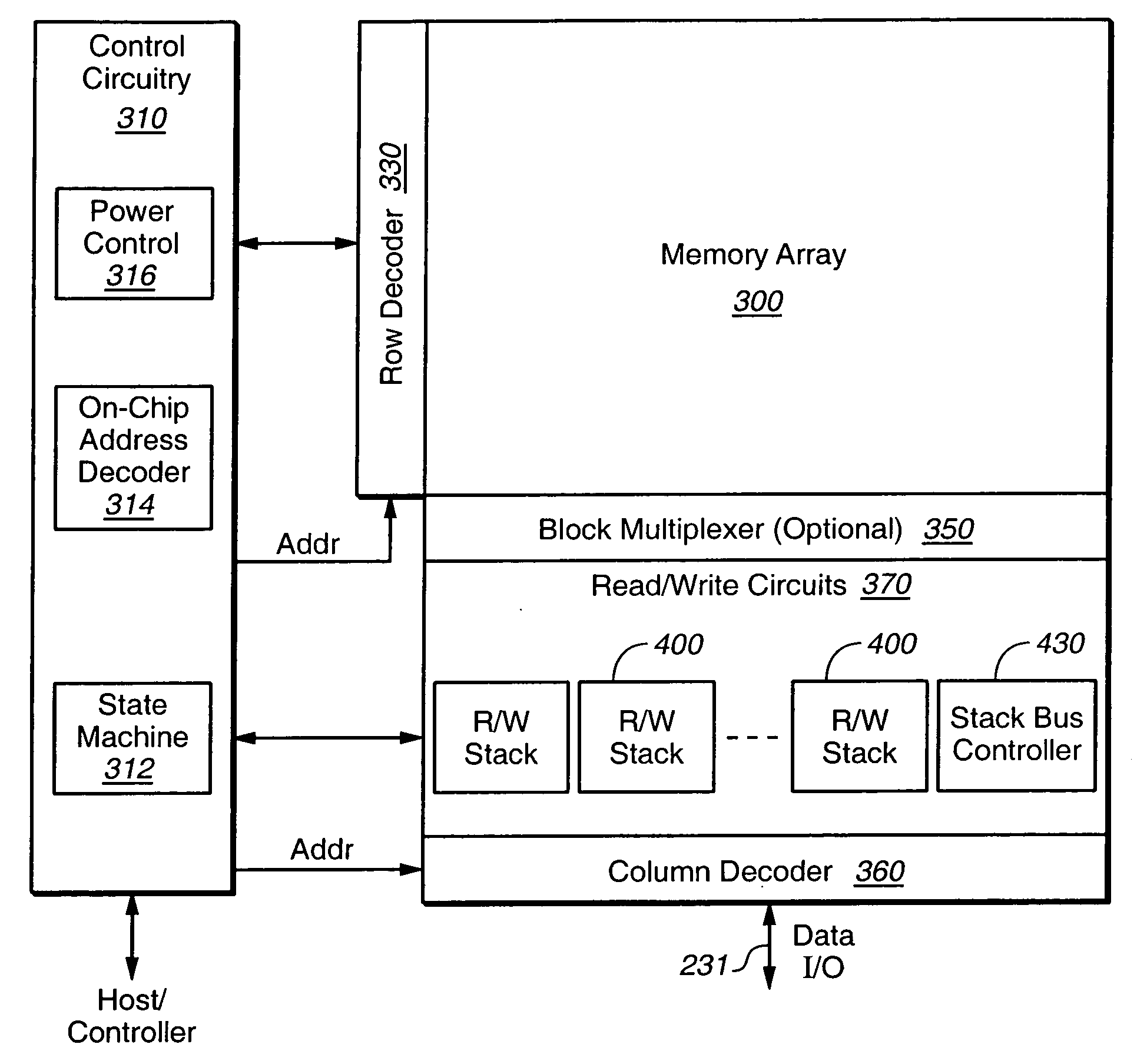

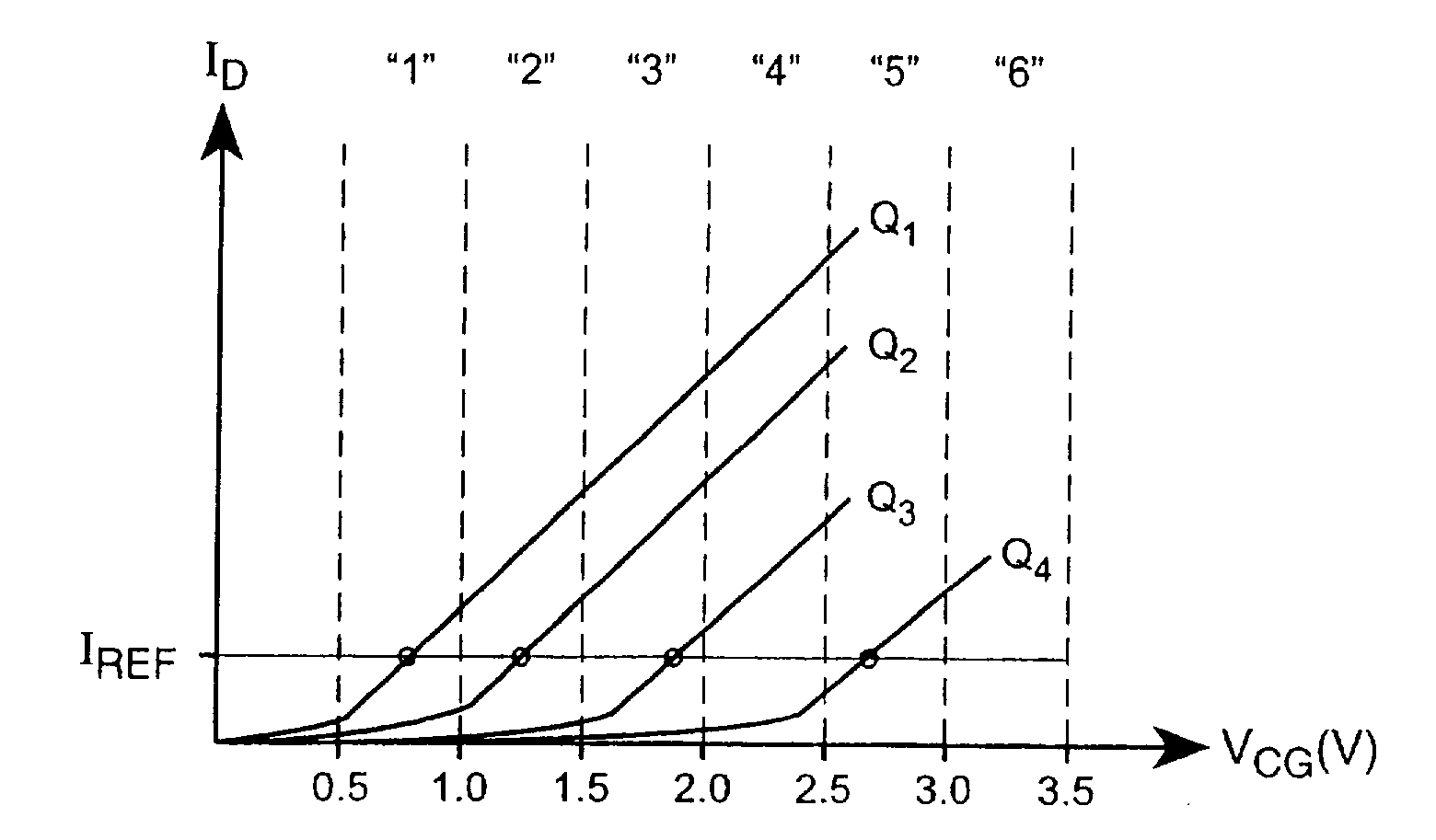

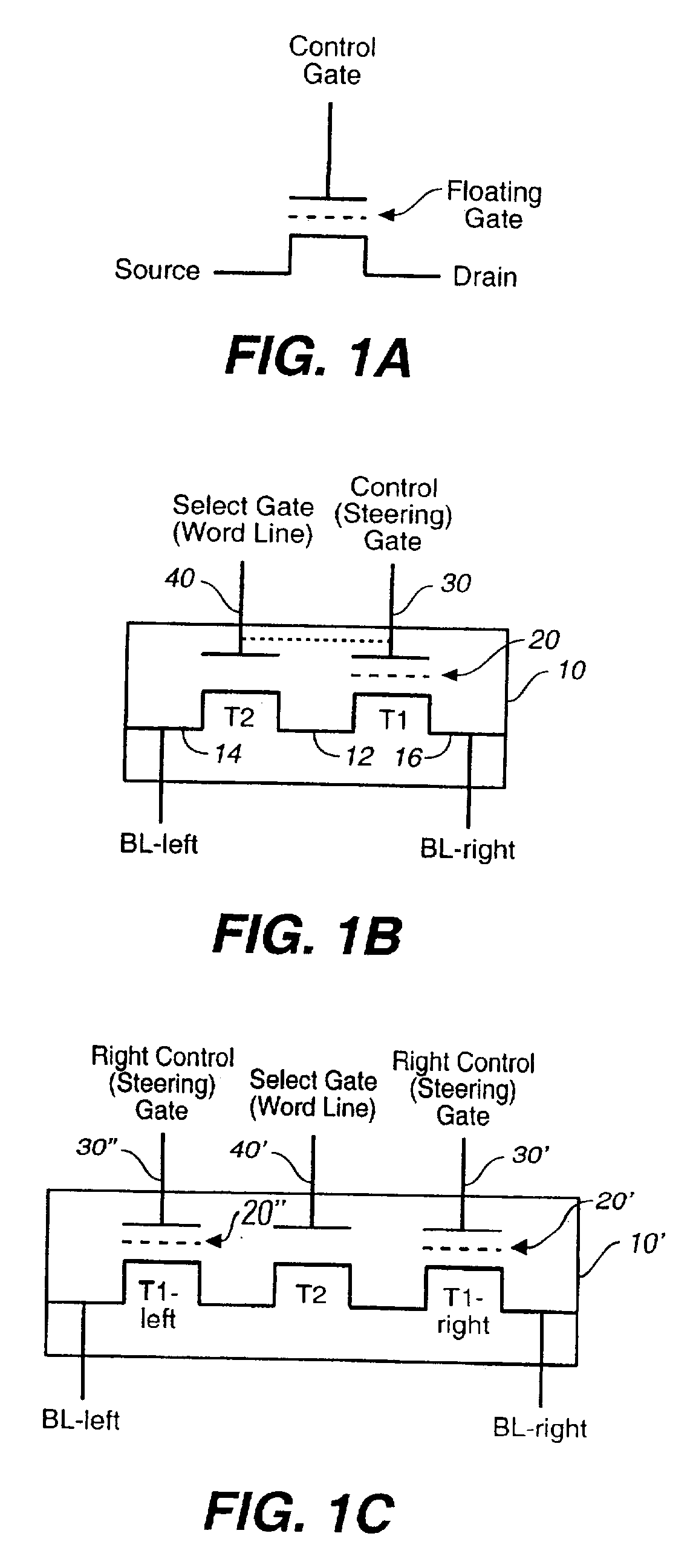

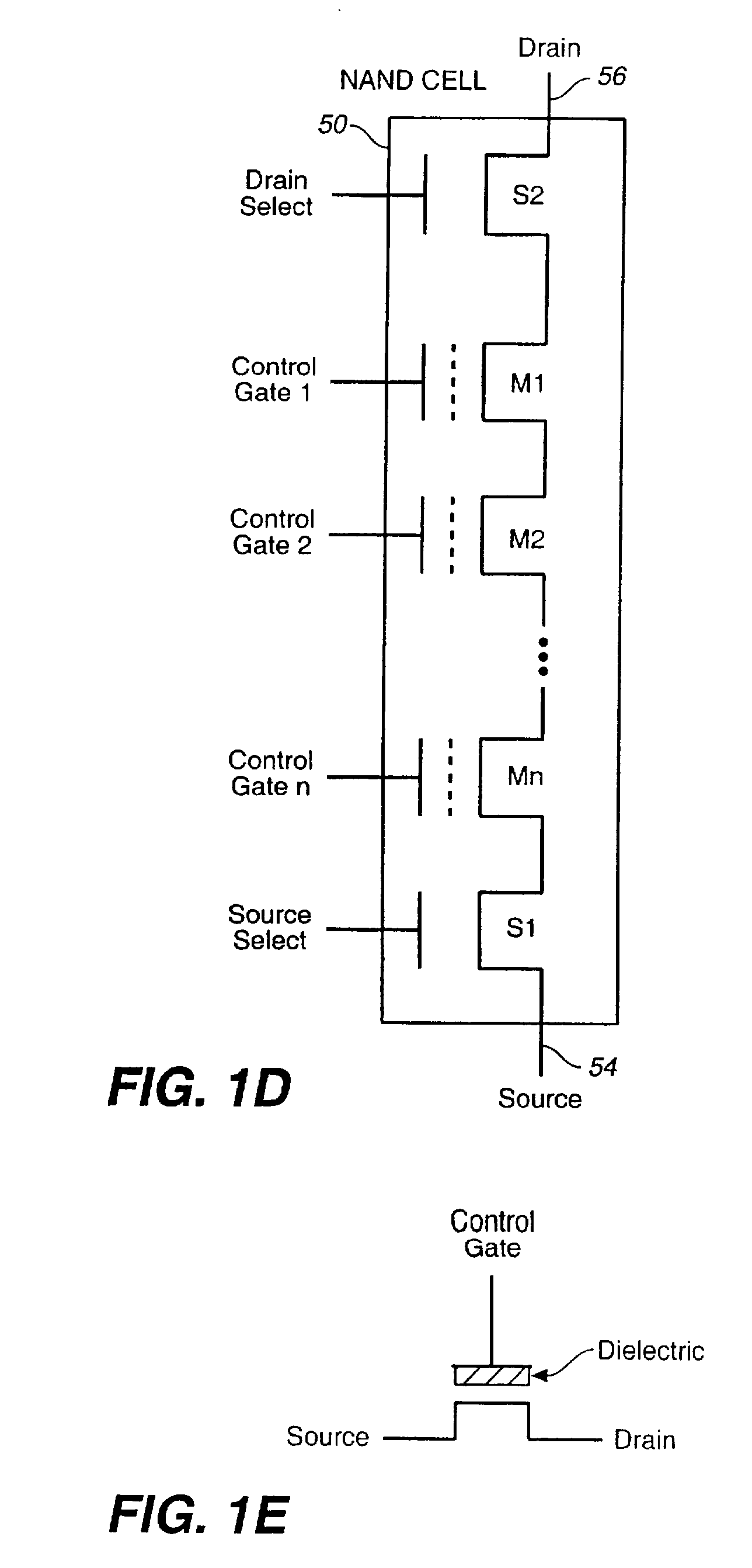

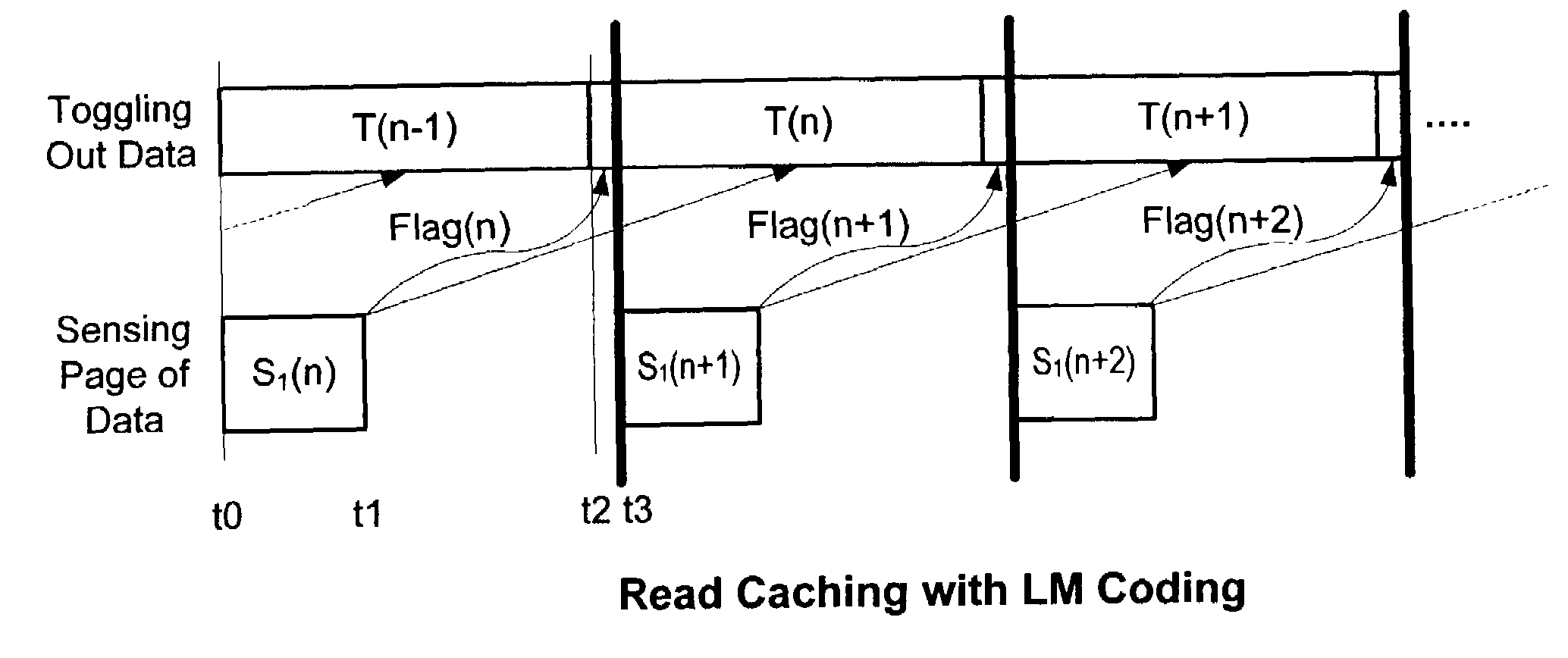

Part of the latency from memory read or write operations is for data to be input to or output from the data latches of the memory via an I / O bus. Methods and circuitry are present for improving performance in non-volatile memory devices by allowing the memory to perform some of these data caching and transfer operations in the background while the memory core is busy with a read operation. A scheme for caching read data is implemented so that even when the read for a current page on a current wordline must be preceded by a prerequisite read of data on an adjacent wordline, the prerequisite read along with any I / O access is preemptively done in the cycle for reading a previous page so that the current read can be performed while the previously read page is busy with the I / O access.

Owner:SANDISK TECH LLC

Method for Non-Volatile Memory with Background Data Latch Caching During Erase Operations

ActiveUS20060233023A1Save transfer timeImprove performanceMemory architecture accessing/allocationEnergy efficient ICTTransfer operationNon-volatile memory

Part of the latency from memory read or write operations is for data to be input to or output from the data latches of the memory via an I / O bus. Methods and circuitry are present for improving performance in non-volatile memory devices by allowing the memory to perform some of these data caching and transfer operations in the background while the memory core is busy with an erase operation. In the exemplary embodiment, a read operation is inserted just prior to the erase operation or one or more read operations are inserted during a soft programming phase of the erase operation. In this way, the read data could be output while the erase operation is taking place, thereby making use of otherwise waiting time.

Owner:SANDISK TECH LLC

Use of data latches in cache operations of non-volatile memories

ActiveUS20060221704A1Save transfer timeImprove performanceMemory architecture accessing/allocationEnergy efficient ICTOperating systemNon-volatile memory

Methods and circuitry are present for improving performance in non-volatile memory devices by allowing the inter-phase pipelining of operations with the same memory, allowing, for example, a read operation to be interleaved between the pulse and verify phases of a write operation. In the exemplary embodiment, the two operations share data latches. In specific examples, at the data latches needed for verification in a multi-level write operation free up, they can be used to store data read from another location during a read performed between steps in the multi-level write. In the exemplary embodiment, the multi-level write need only pause, execute the read, and resume the write at the point where it paused.

Owner:SANDISK TECH LLC

Method for non-volatile memory with managed execution of cached data

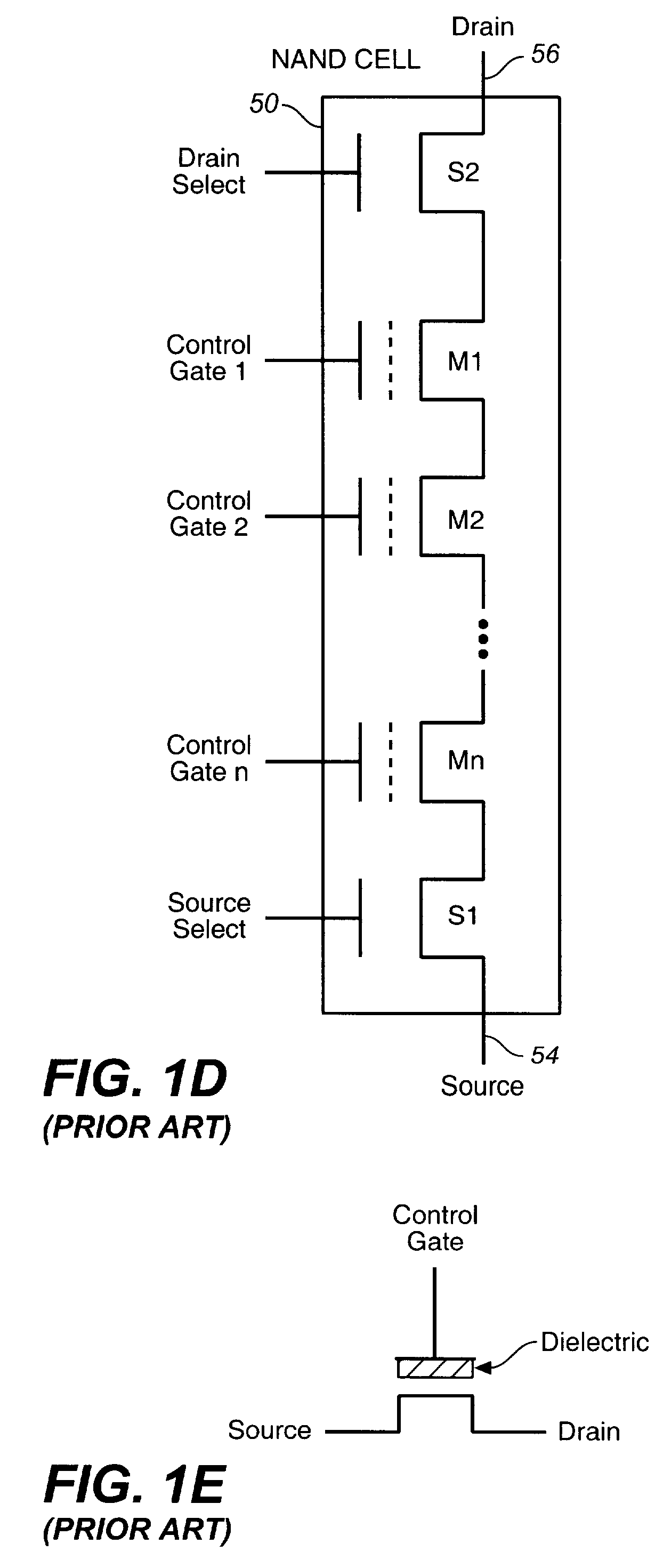

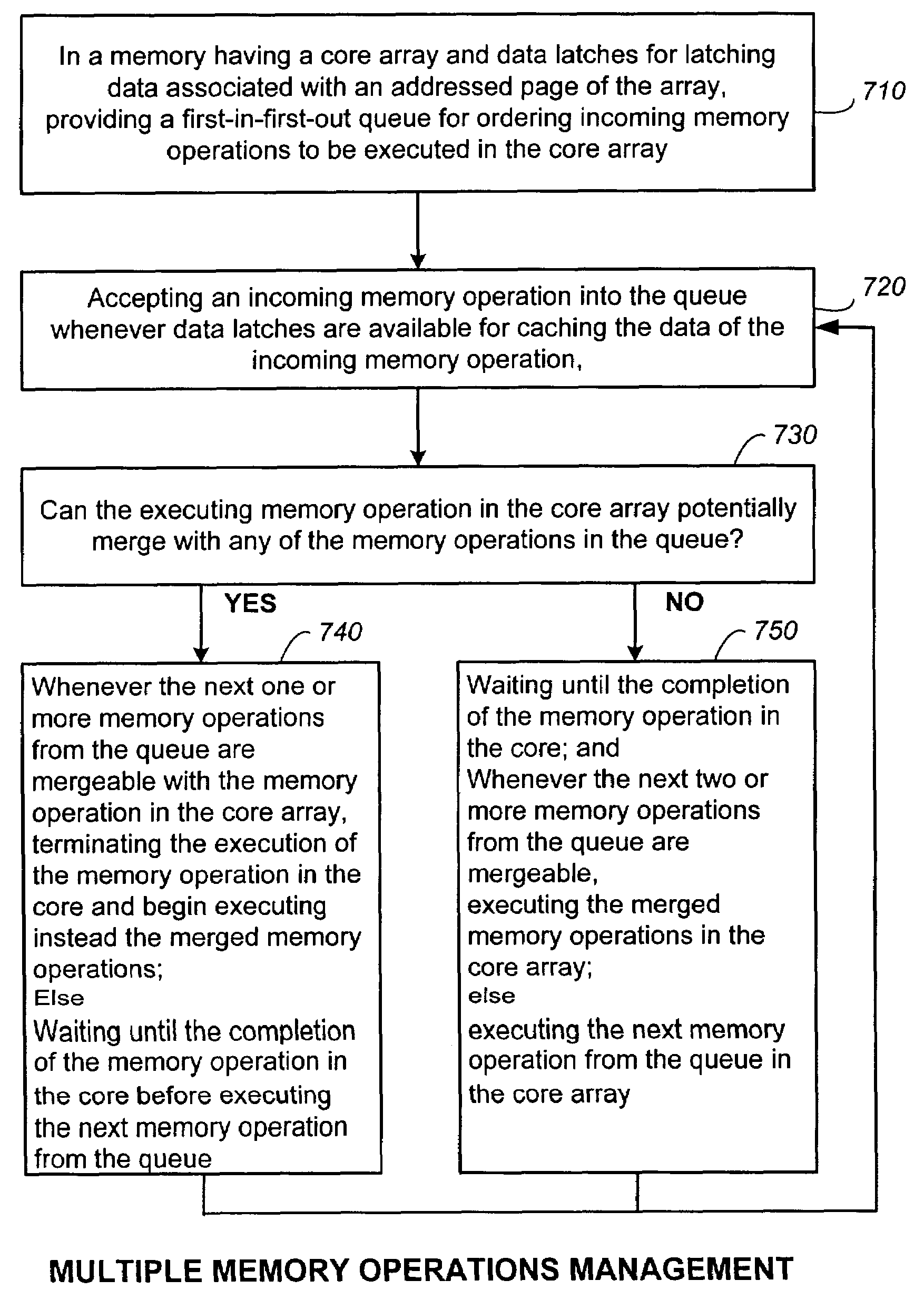

ActiveUS7463521B2Save transfer timeImprove performanceMemory architecture accessing/allocationRead-only memoriesParallel computingControl memory

Methods and circuitry are present for executing current memory operation while other multiple pending memory operations are queued. Furthermore, when certain conditions are satisfied, some of these memory operations are combinable or mergeable for improved efficiency and other benefits. The management of the multiple memory operations is accomplished by the provision of a memory operation queue controlled by a memory operation queue manager. The memory operation queue manager is preferably implemented as a module in the state machine that controls the execution of a memory operation in the memory array.

Owner:SANDISK TECH LLC

Method for Non-Volatile Memory with Background Data Latch Caching During Program Operations

ActiveUS20060233026A1Save transfer timeImprove performanceMemory architecture accessing/allocationEnergy efficient ICTParallel computingTransfer operation

Part of the latency from memory read or write operations is for data to be input to or output from the data latches of the memory via an I / O bus. Methods and circuitry are present for improving performance in non-volatile memory devices by allowing the memory to perform some of these data caching and transfer operations in the background while the memory core is busy with a write operation. In the exemplary embodiment, when the multiple phases of a write operation vary as to the number of states to track, a phase-dependent coding enables efficient utilization of the available data latches, thereby allowing a maximum of surplus latches for background cache operations.

Owner:SANDISK TECH LLC

Non-Volatile Memory with Background Data Latch Caching During Read Operations

ActiveUS20060233010A1Save transfer timeImprove performanceMemory architecture accessing/allocationEnergy efficient ICTTransfer operationNon-volatile memory

Part of the latency from memory read or write operations is for data to be input to or output from the data latches of the memory via an I / O bus. Methods and circuitry are present for improving performance in non-volatile memory devices by allowing the memory to perform some of these data caching and transfer operations in the background while the memory core is busy with a read operation. A scheme for caching read data is implemented so that even when the read for a current page on a current wordline must be preceded by a prerequisite read of data on an adjacent wordline, the prerequisite read along with any I / O access is preemptively done in the cycle for reading a previous page so that the current read can be performed while the previously read page is busy with the I / O access.

Owner:SANDISK TECH LLC

Method for Non-Volatile Memory with Managed Execution of Cached Data

ActiveUS20060239080A1Improve programming performanceMore program dataMemory architecture accessing/allocationRead-only memoriesControl memoryOperating system

Methods and circuitry are present for executing current memory operation while other multiple pending memory operations are queued. Furthermore, when certain conditions are satisfied, some of these memory operations are combinable or mergeable for improved efficiency and other benefits. The management of the multiple memory operations is accomplished by the provision of a memory operation queue controlled by a memory operation queue manager. The memory operation queue manager is preferably implemented as a module in the state machine that controls the execution of a memory operation in the memory array.

Owner:SANDISK TECH LLC

Non-Volatile Memory with Background Data Latch Caching During Erase Operations

ActiveUS20060233021A1Save transfer timeImprove performanceMemory architecture accessing/allocationEnergy efficient ICTTransfer operationNon-volatile memory

Part of the latency from memory read or write operations is for data to be input to or output from the data latches of the memory via an I / O bus. Methods and circuitry are present for improving performance in non-volatile memory devices by allowing the memory to perform some of these data caching and transfer operations in the background while the memory core is busy with an erase operation. In the exemplary embodiment, a read operation is inserted just prior to the erase operation or one or more read operations are inserted during a soft programming phase of the erase operation. In this way, the read data could be output while the erase operation is taking place, thereby making use of otherwise waiting time.

Owner:SANDISK TECH LLC

Method for non-volatile memory with background data latch caching during read operations

ActiveUS7447078B2Save transfer timeImprove performanceMemory architecture accessing/allocationRead-only memoriesTransfer operationComputer science

Part of the latency from memory read or write operations is for data to be input to or output from the data latches of the memory via an I / O bus. Methods and circuitry are present for improving performance in non-volatile memory devices by allowing the memory to perform some of these data caching and transfer operations in the background while the memory core is busy with a read operation. A scheme for caching read data is implemented so that even when the read for a current page on a current wordline must be preceded by a prerequisite read of data on an adjacent wordline, the prerequisite read along with any I / O access is preemptively done in the cycle for reading a previous page so that the current read can be performed while the previously read page is busy with the I / O access.

Owner:SANDISK TECH LLC

Non-Volatile Memory with Background Data Latch Caching During Program Operations

ActiveUS20060233022A1Save transfer timeImprove performanceMemory architecture accessing/allocationEnergy efficient ICTParallel computingTransfer operation

Part of the latency from memory read or write operations is for data to be input to or output from the data latches of the memory via an I / O bus. Methods and circuitry are present for improving performance in non-volatile memory devices by allowing the memory to perform some of these data caching and transfer operations in the background while the memory core is busy with a write operation. In the exemplary embodiment, when the multiple phases of a write operation vary as to the number of states to track, a phase-dependent coding enables efficient utilization of the available data latches, thereby allowing a maximum of surplus latches for background cache operations.

Owner:SANDISK TECH LLC

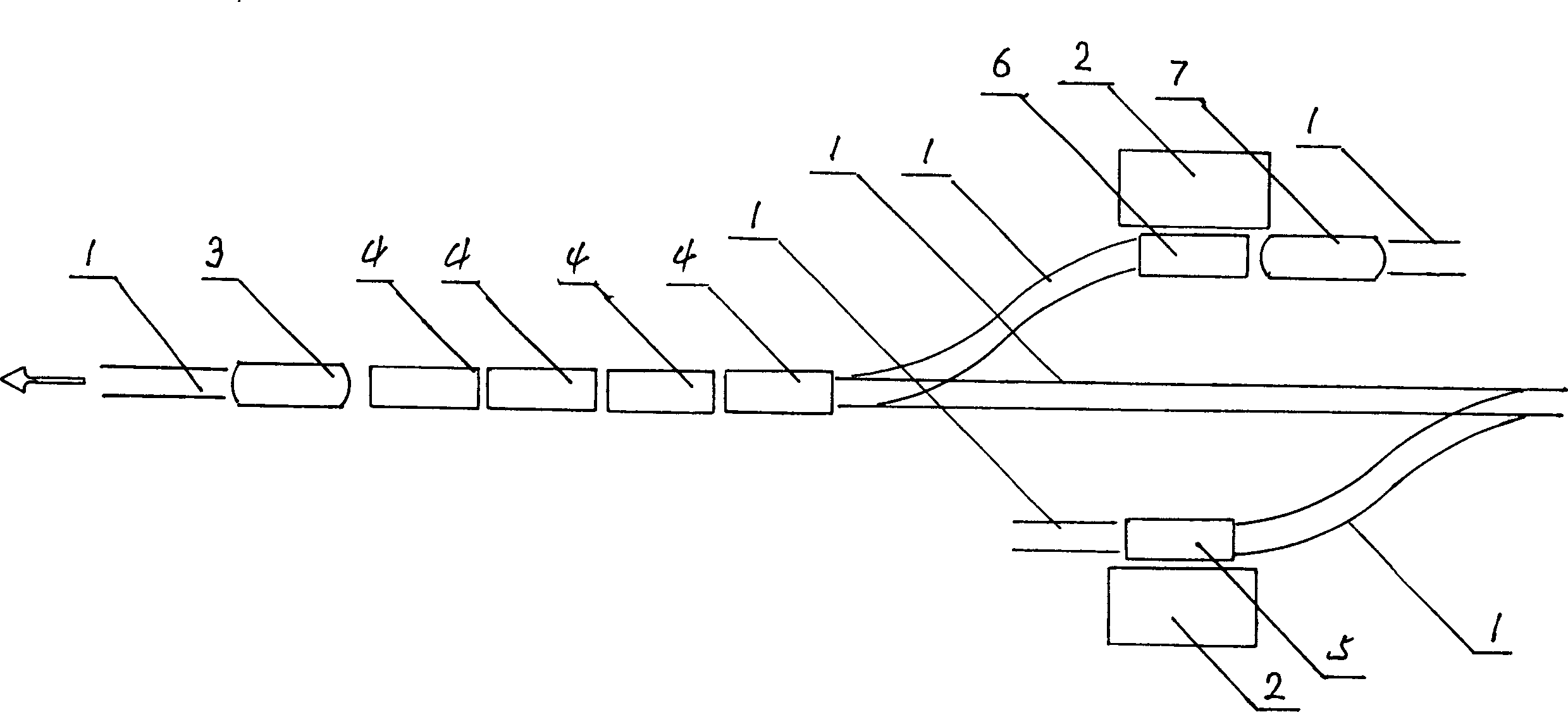

No-stop vehicle transfer method for passenger train

InactiveCN1781791AMake up for empty drivingMake up for the shortage of passengers waiting for buses along the wayRailway componentsRailway stationStop timePassenger train

The no-stop vehicle transfer method for passenger train includes arranging the passengers to be going to get off in some station in the tail carriage, or pulling-in carriage, in advance, separating the pulling-in carriage while the train body goes forwards, arranging boarding passengers in the outgoing carriage in advance, pushing the outgoing carriage with one assisting locomotive to connect with the train body, and transferring the boarding passengers to the main carriages. The present invention has separated pulling-in carriage and outgoing carriage, makes the getting on and getting off convenient, and results in saving in stop time and raised train transportation efficiency.

Owner:赵云祥

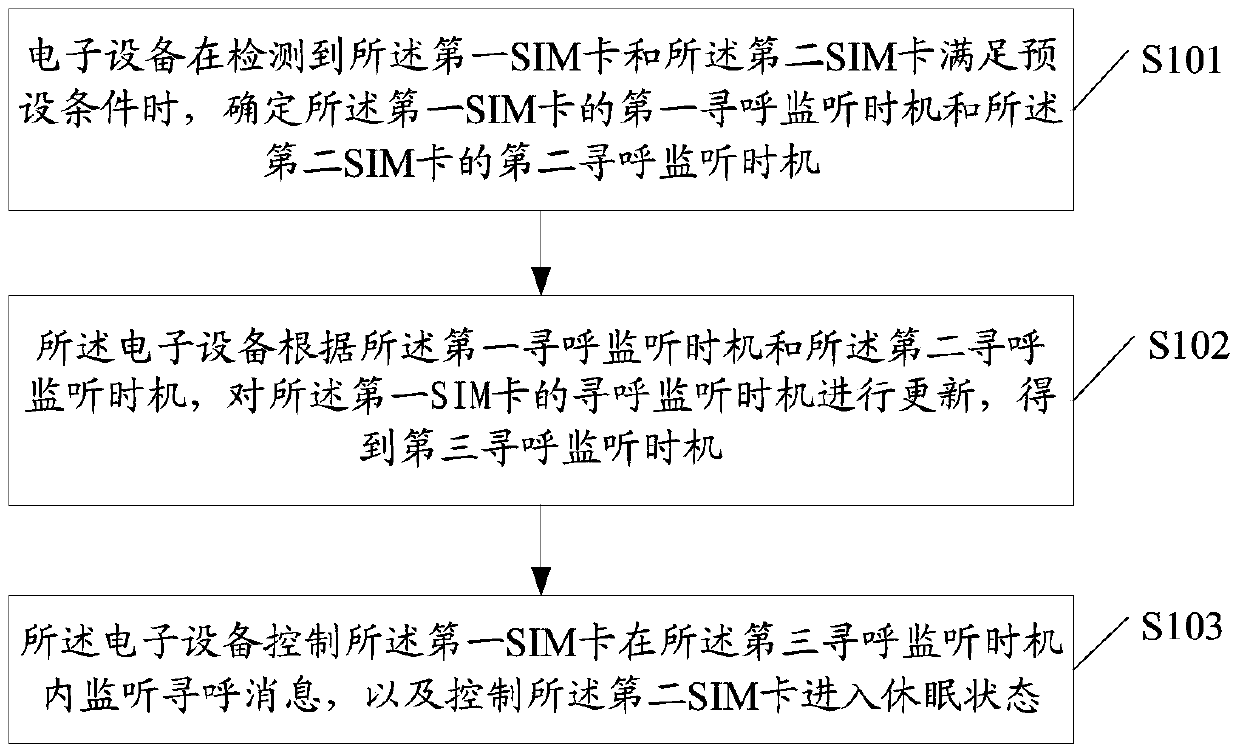

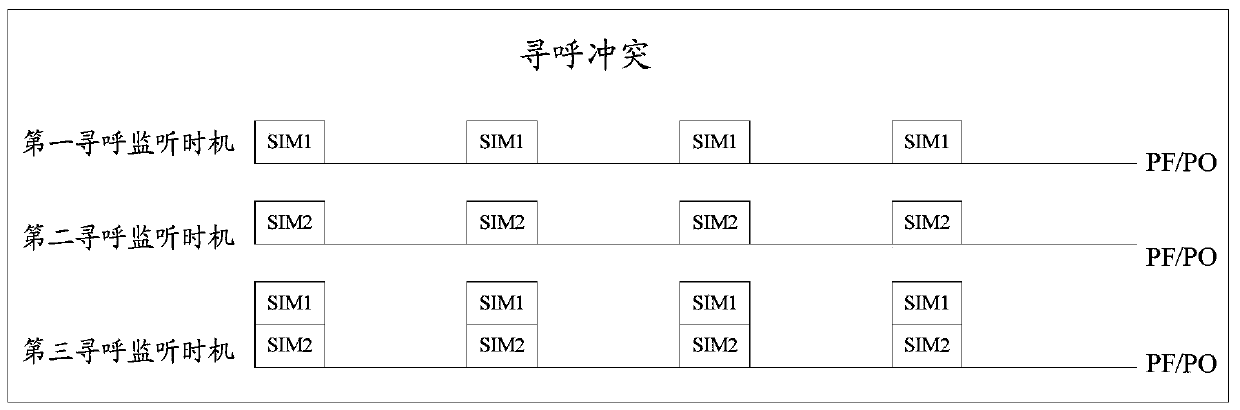

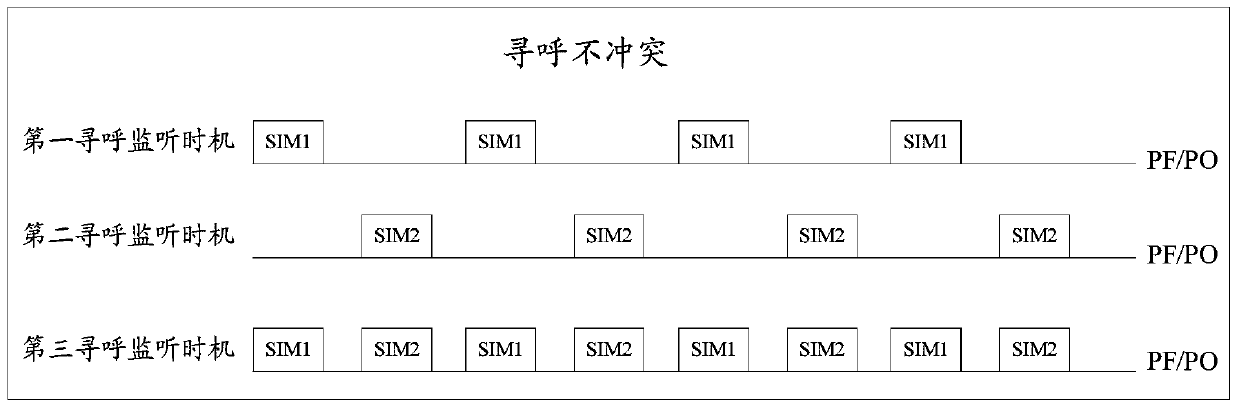

Paging processing method and related device

ActiveCN110677900AShorten the timeReduce power consumptionPower managementHigh level techniquesRadio frequencyLow power dissipation

The embodiment of the invention discloses a paging processing method and a related device, which are applied to electronic equipment, and the method comprise the steps of determining a first paging monitoring opportunity of a first SIM card and a second paging monitoring opportunity of a second SIM card when it is detected that the first SIM card and the second SIM card meet a preset condition; updating the paging monitoring opportunity of the first SIM card according to the first paging monitoring opportunity and the second paging monitoring opportunity to obtain a third paging monitoring opportunity; and controlling the first SIM card to monitor a paging message in the third paging monitoring opportunity, and controlling the second SIM card to enter a dormant state. According to the embodiment of the invention, the method facilitates the saving of the tune-off time of the radio frequency between double cards in each period, and reduces the power consumption.

Owner:REALME CHONGQING MOBILE TELECOMM CORP LTD

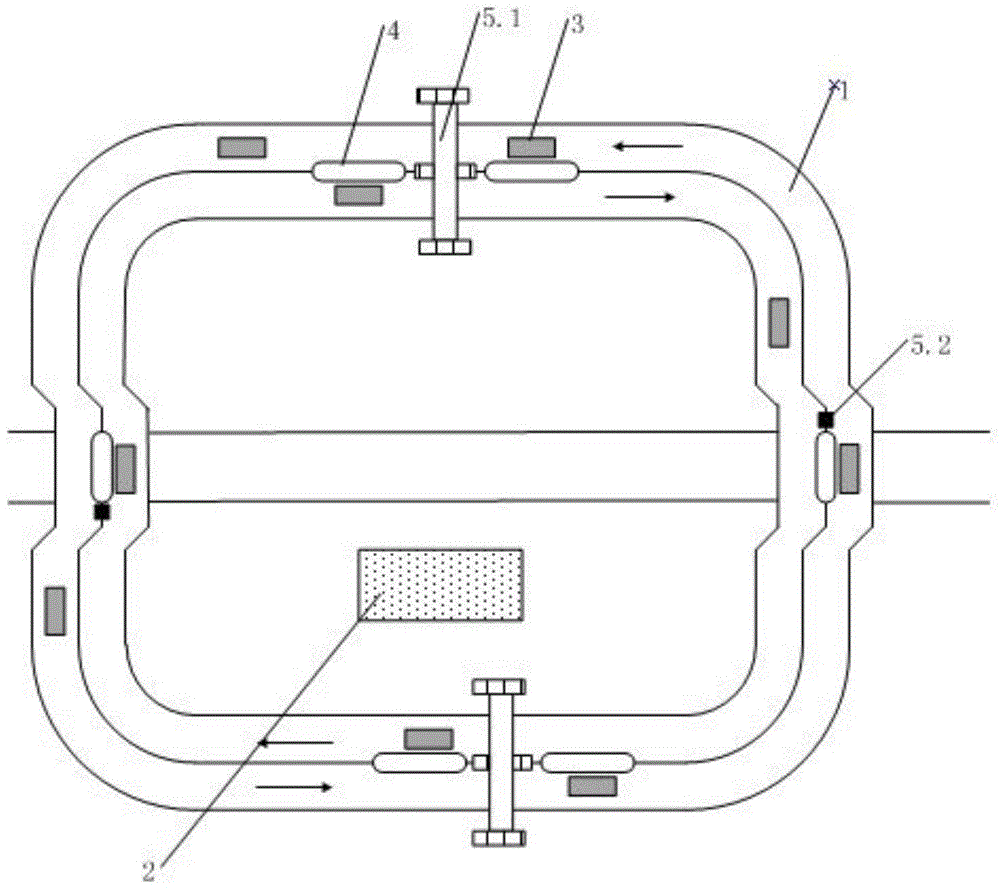

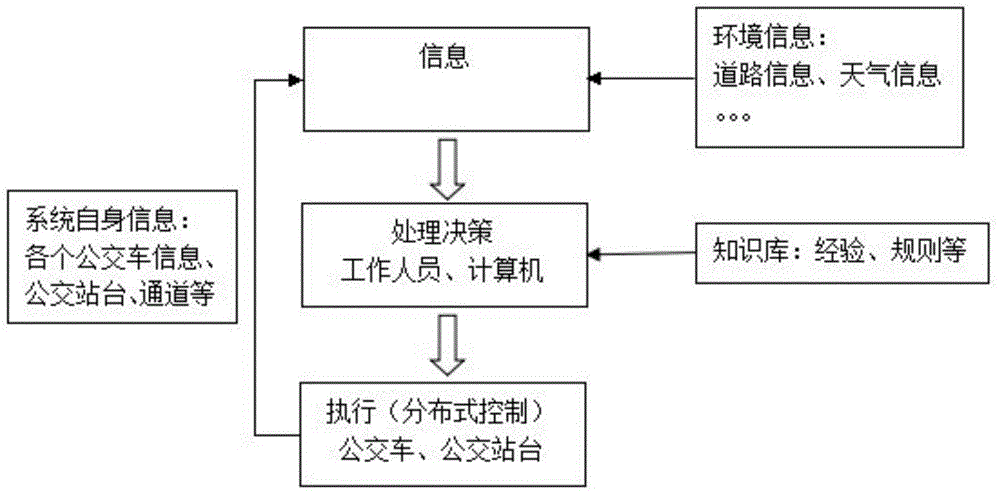

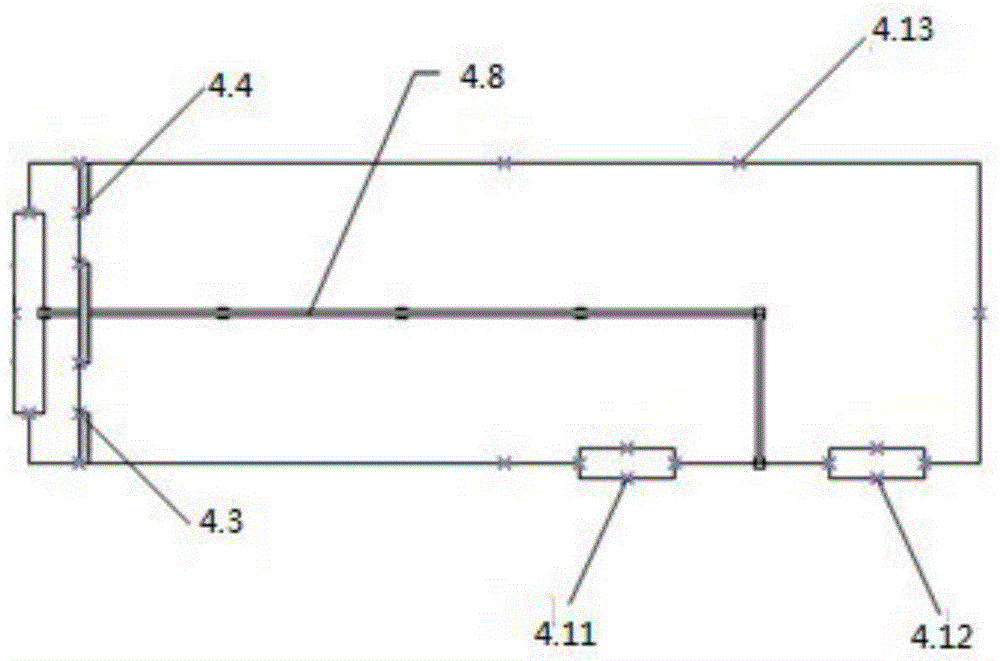

Novel bus rapid transit system for annular express road net

InactiveCN104594147AAvoid interferencePrevent fall hazardsRefuge islandsRoadwaysBus laneBus rapid transit

The invention discloses a novel bus rapid transit system for an annular express road net. The annular express road is divided into an inner annular express road and an outer annular express road, wherein bus stops are arranged on a road separation zone between the inner annular express road and the outer annular express road of the annular express road according to the bus stop distance; according to the bus stops, two bus stops of the same specification are arranged in the same bus stop area and respectively correspond to the inner annular express road and the outer annular express road; rapid buses respectively and independently run along express lanes on the leftmost side of the inner annular express road and the outer annular express road on the annular express road, and the lane on the leftmost side of the inner and outer rings serves as an exclusive bus lane; the bus stops are respectively connected with the sidewalk by virtue of a ground connecting channel and an elevated road channel; and the system control center mutually interacts with the rapid buses and bus stops by virtue of a wireless network. According to the corresponding control algorithm and scheduling algorithm in the system control center, safe and stable operation of the rapid buses can be guaranteed.

Owner:BEIJING UNIV OF TECH

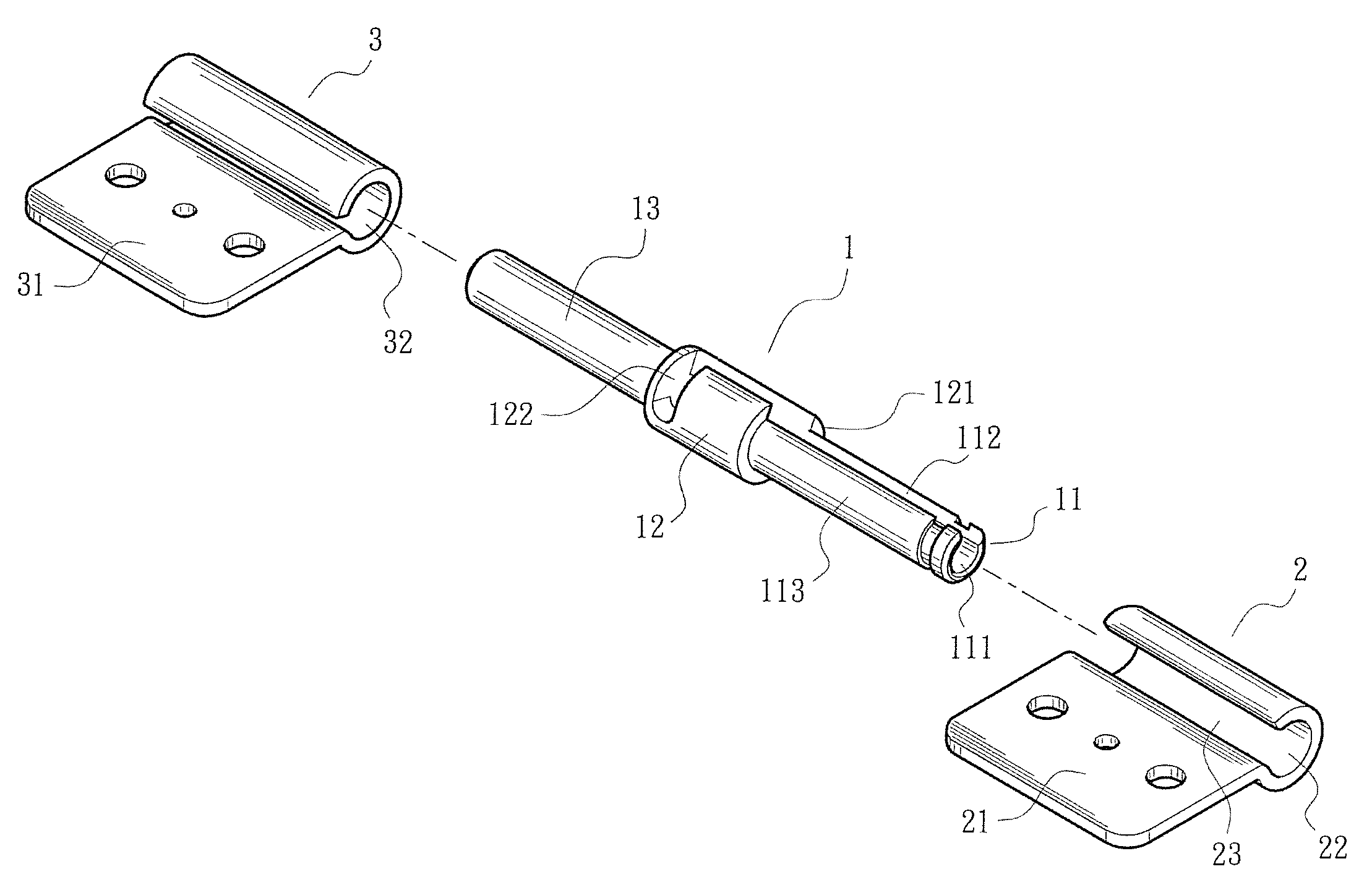

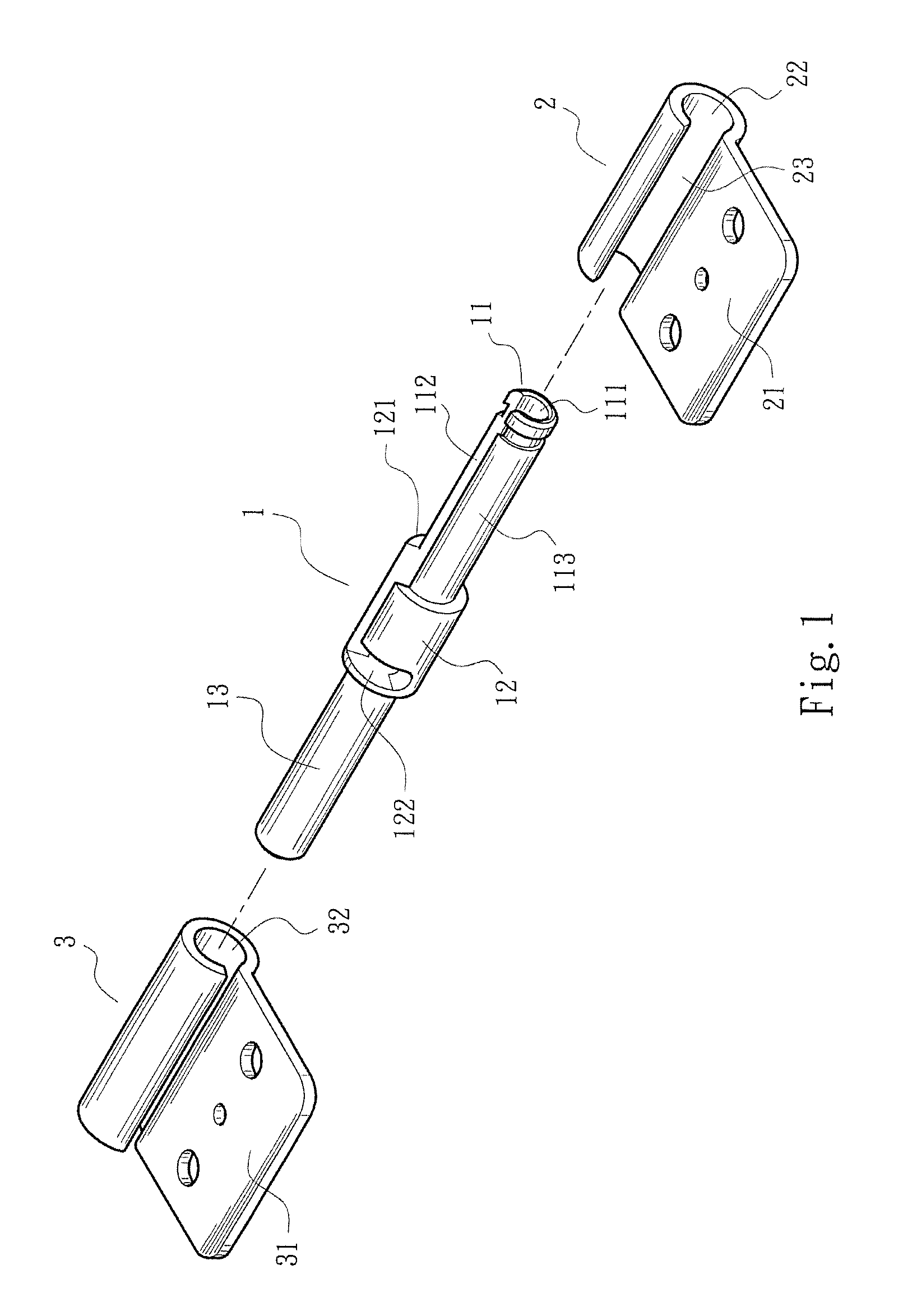

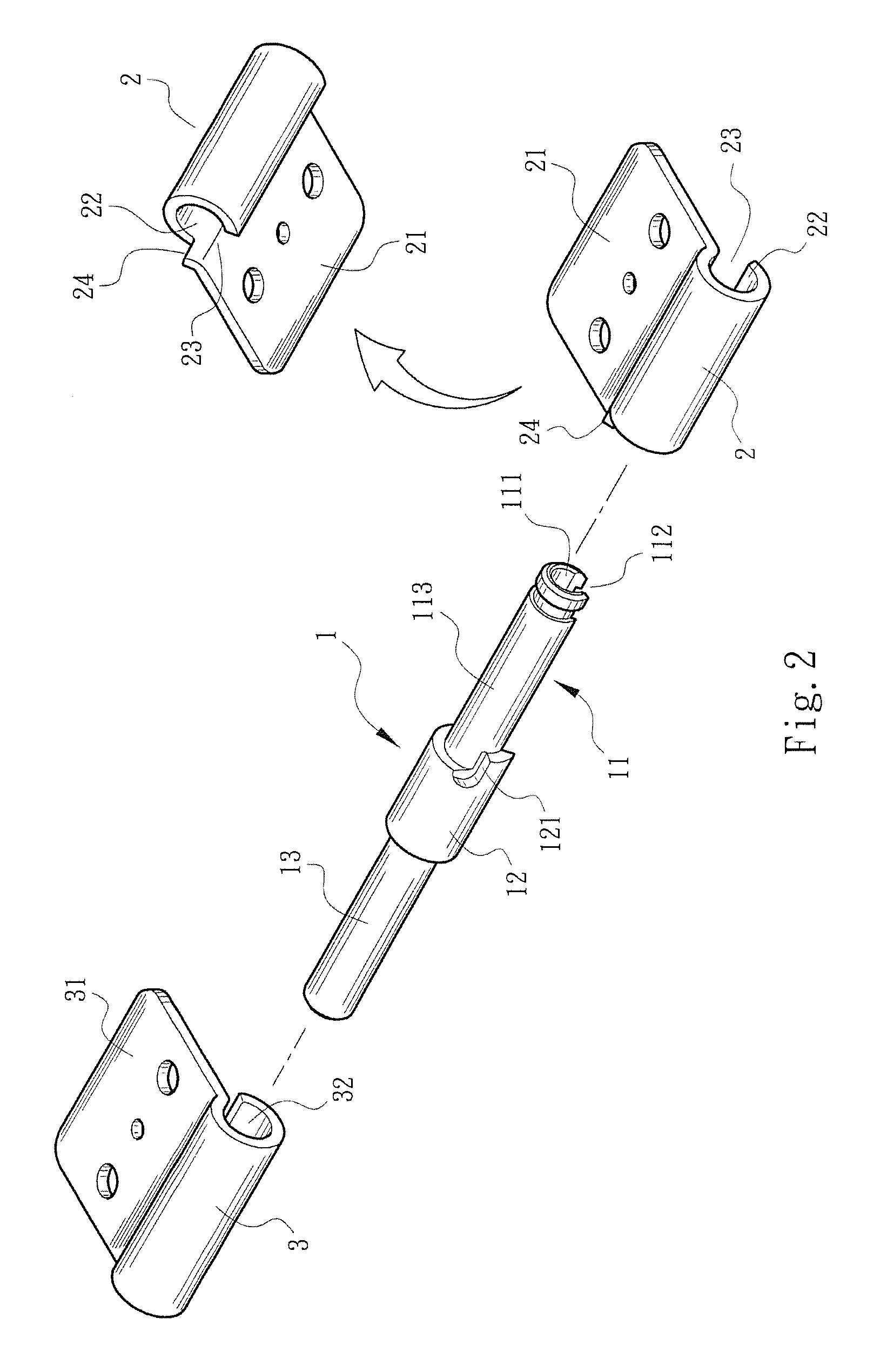

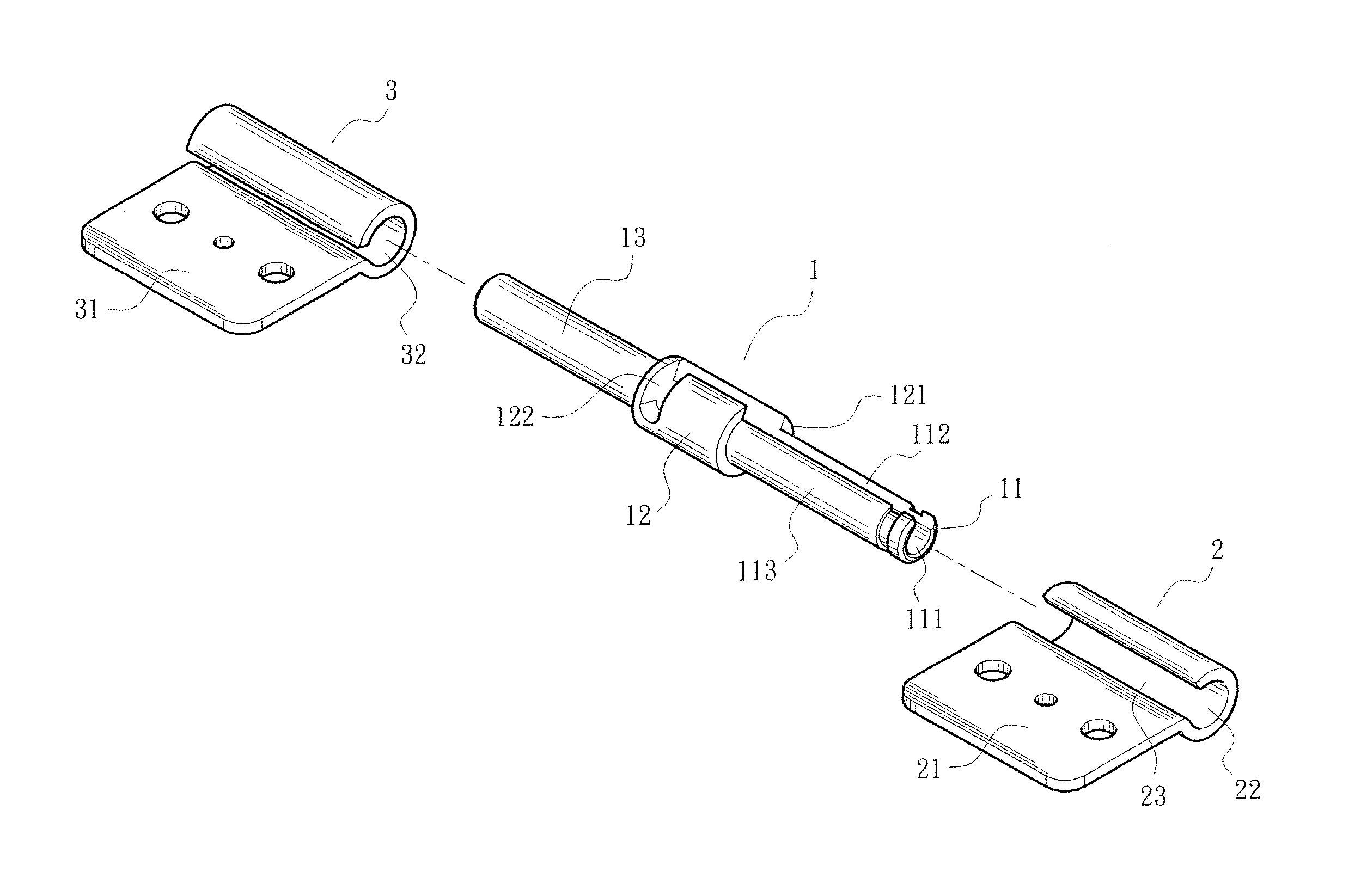

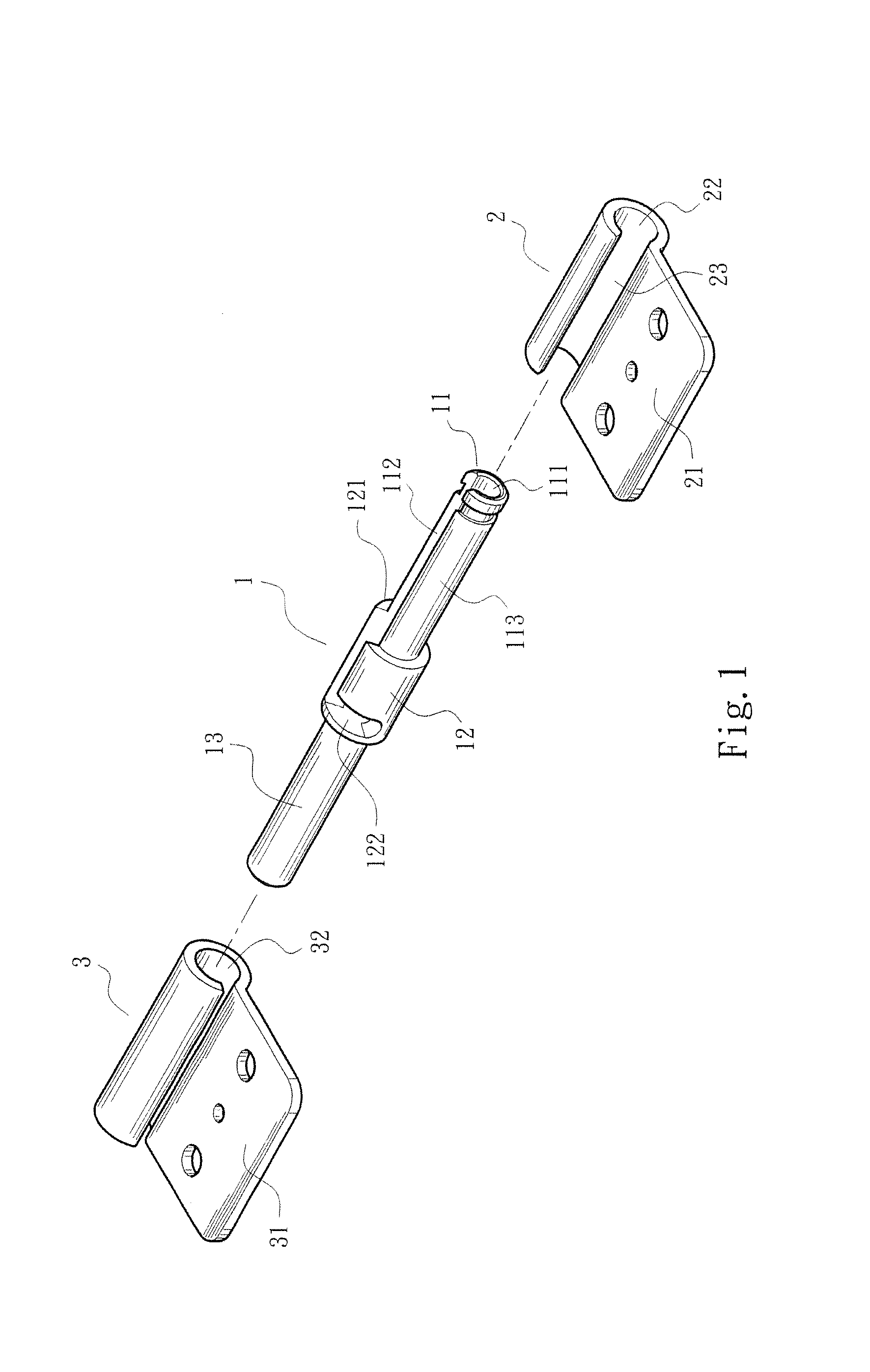

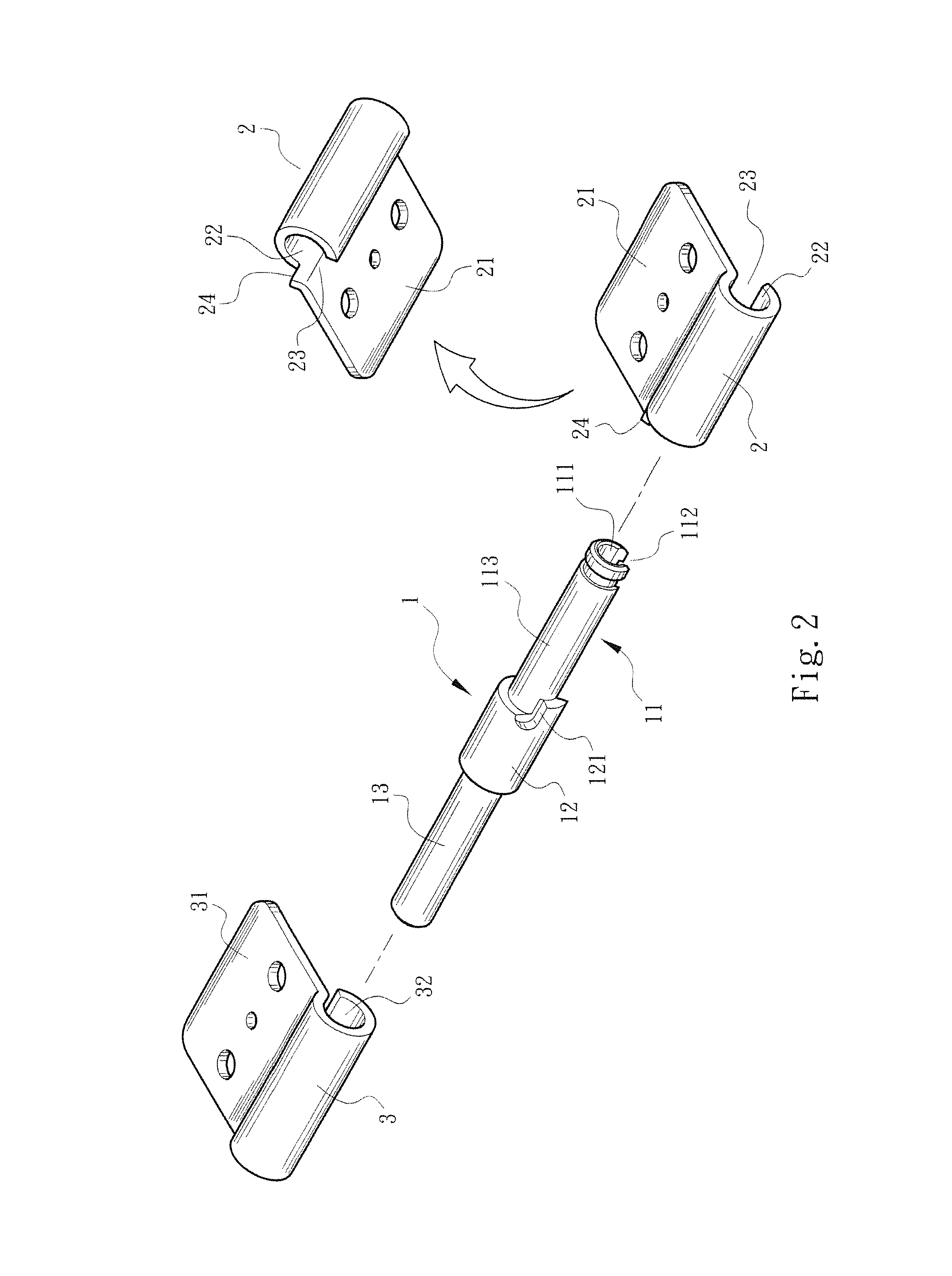

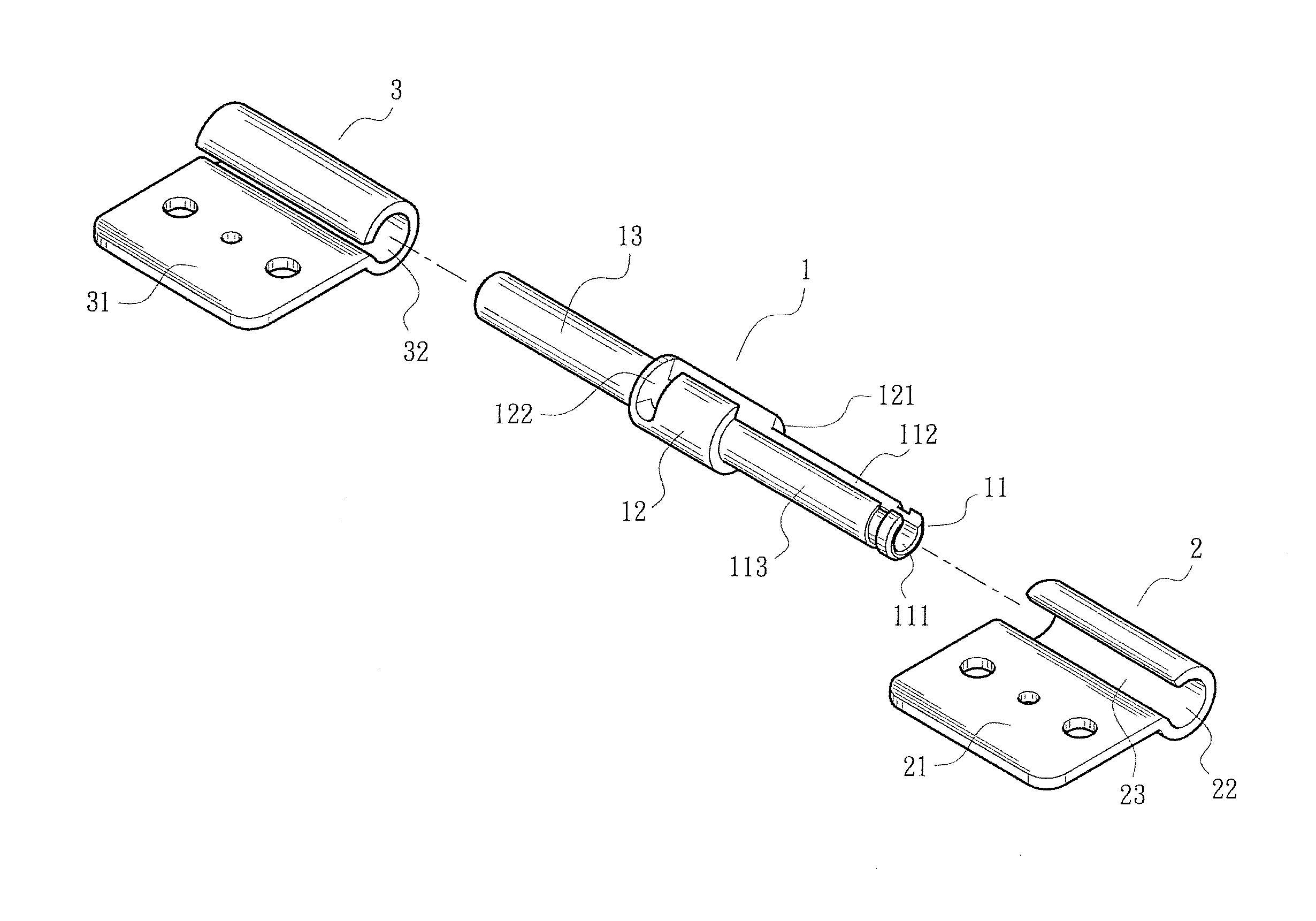

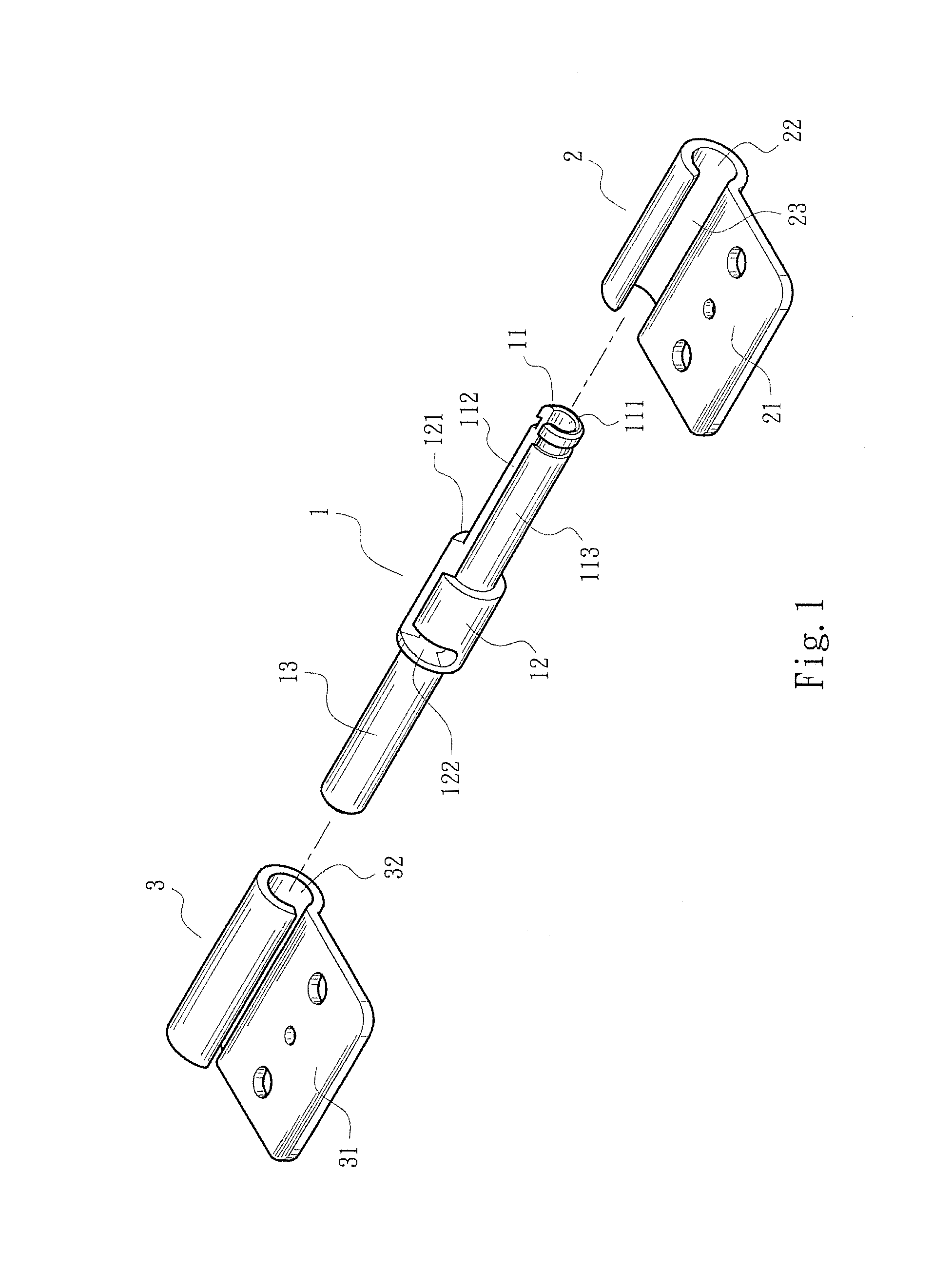

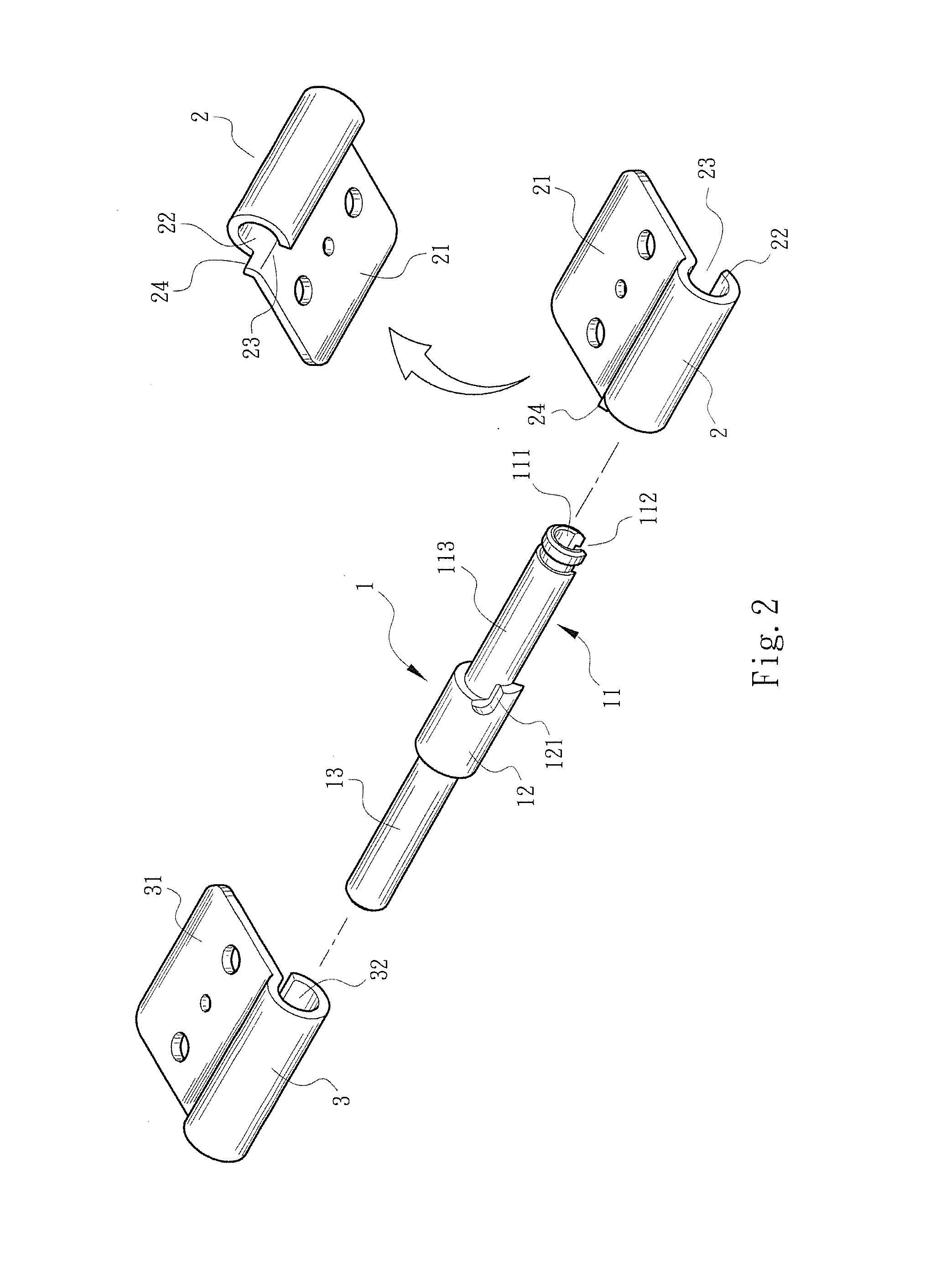

Rotary shaft wire passage structure

InactiveUS8769771B2Easy to assembleRaise the ratioDigital data processing detailsWing fastenersMechanical engineering

A rotary shaft wire passage structure includes a pivot pin and a pivot seat respectively fixedly connected with a pivotal rotary member and a relative pivotal rotary member. The pivot pin has a pivoted section and an annular raised section disposed at one end thereof. The pivoted section is formed with an axial through hole in full communication with outer side via a split. The pivot seat has a shaft hole in which the pivoted section is fitted. One side of the shaft hole is formed with a fissure in communication with the outer side. The fissure is adjustable to a position where the fissure is aligned with the split for placing a wire into the through hole. When the relative pivotal rotary member is pivotally rotated to a working position by a certain angle, the fissure is misaligned from the split to prevent the wire from slipping out.

Owner:FIRST DOME

Transfer printing machine

ActiveCN109367217AImprove transfer efficiencyReduce labor burdenTransfer printingTime scheduleEngineering

The invention discloses a transfer printing machine. The transfer printing machine comprises transfer printing rail sets, heating furnace door opening and closing sets, a vacuum cavity opening and closing set and vacuum cavities. Each transfer printing rail set comprises rail portions, roller portions, roller fixing portions and reduction boxes. The transfer printing rail sets are used for transferring the vacuum cavities to a transfer printing box. The roller portions are arranged on the corresponding rail portions in a sliding mode. Each heating furnace door opening and closing set comprisesa time schedule control portion and an opening and closing portion, wherein the opening and closing portion is connected with a heating furnace door. The vacuum cavity opening and closing set comprises an opening portion, a pneumatic portion and a first matching portion, wherein the opening portion is connected with the pneumatic portion, and the pneumatic portion is connected with the first matching portion. The controllability of actions of the rails and the vacuum cavity transfer speed are achieved through the reduction boxes, the time schedule control portions control the heating furnacedoors, the opening and closing portions provide power, artificial burden is reduced, opening and closing of vacuum cavity doors are controlled manually, manual control is convenient and fast, the safety performance is high, pneumatic devices are adopted, saves energy and are efficient, the transfer printing machine can be used for performing transfer printing on profiled plates, and a plurality ofplates can be subjected to transfer printing simultaneously.

Owner:湖北永和安门业有限公司

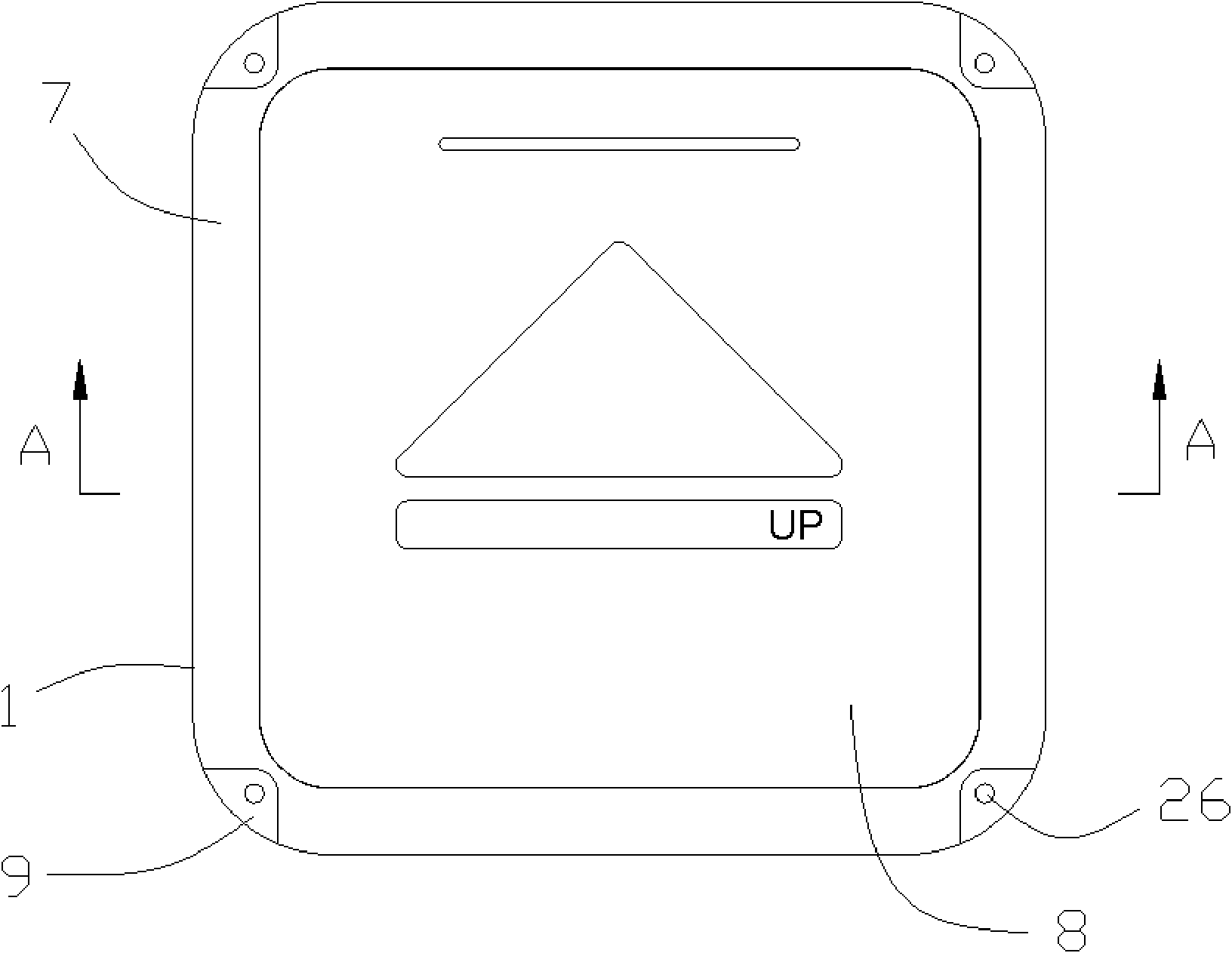

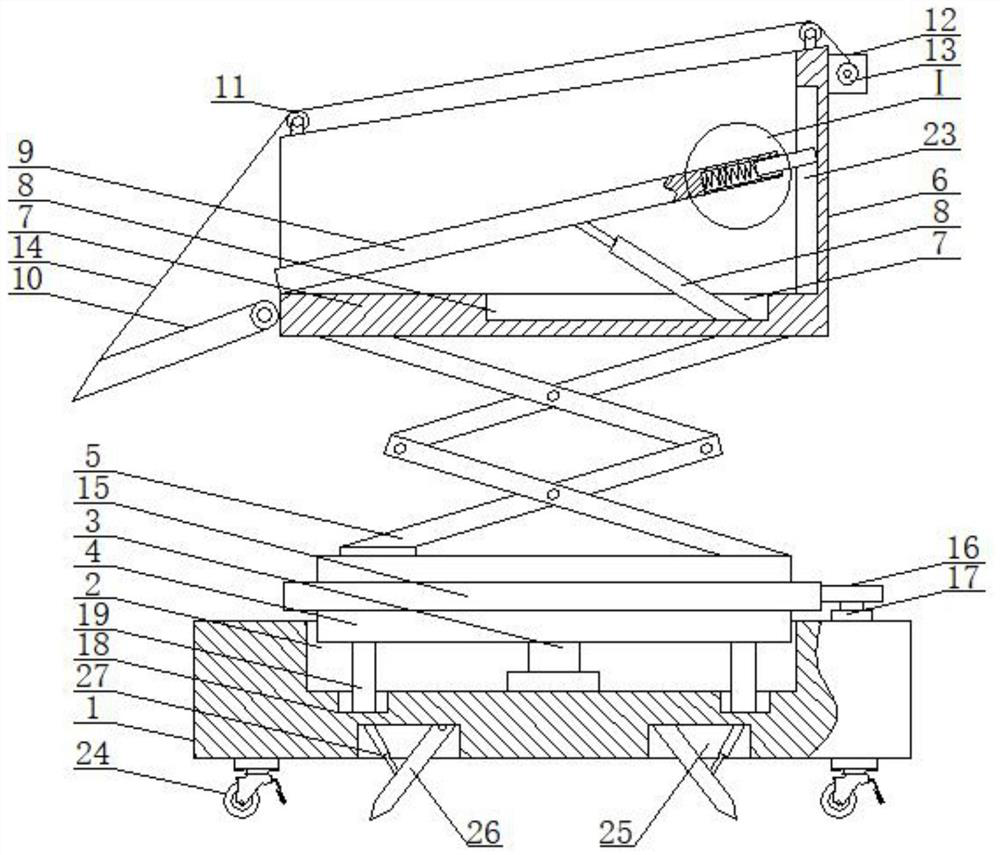

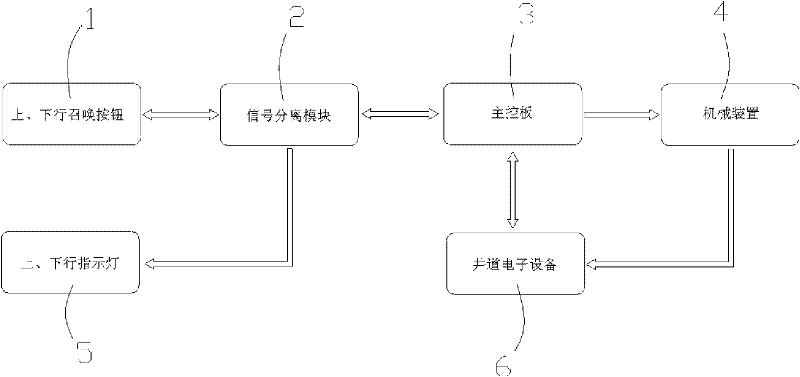

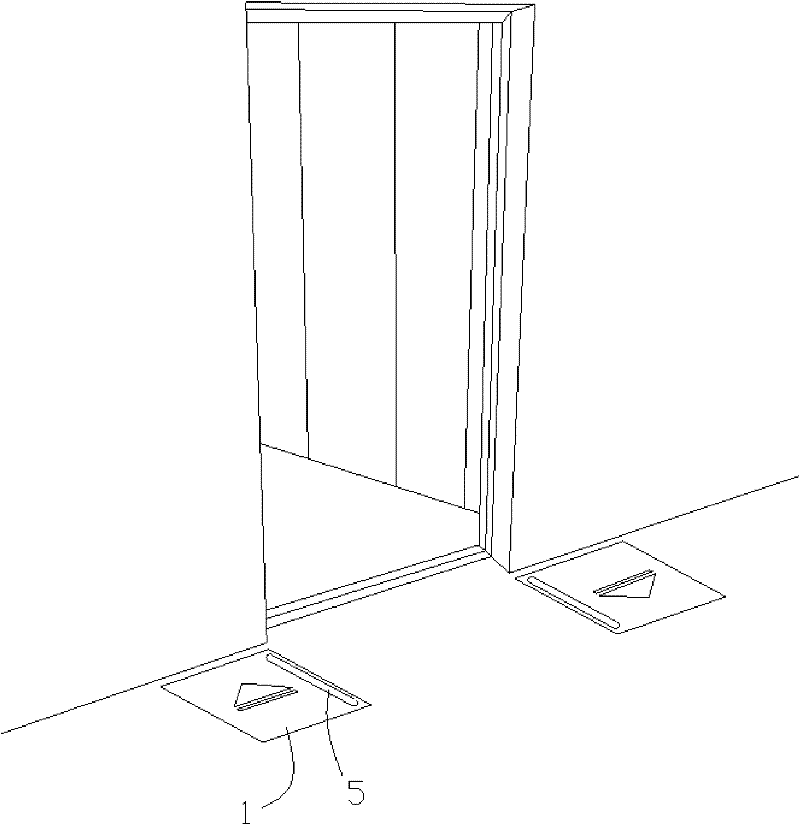

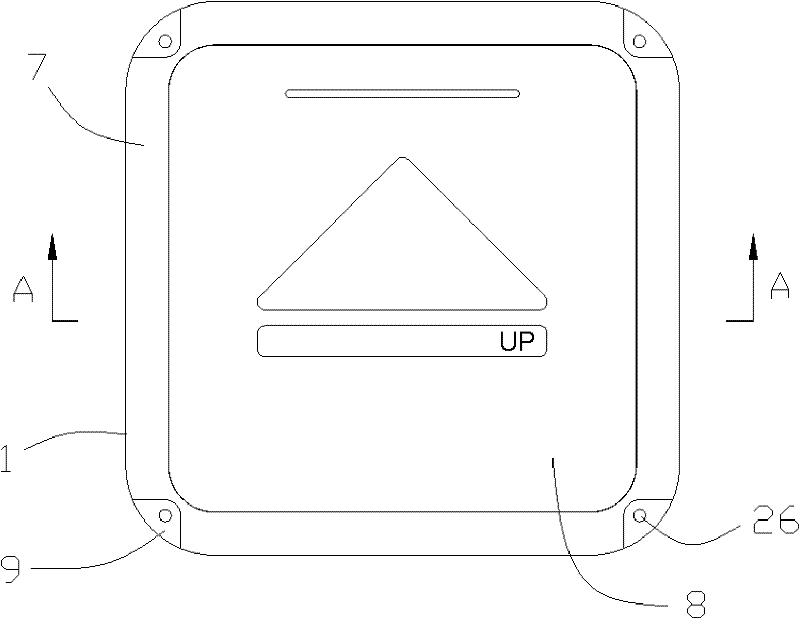

Pedal type elevator calling system

ActiveCN101875456AImprove the elevator environmentOrderly transferElevatorsEmbedded systemElectronic equipment

The invention relates to a pedal type elevator calling system. The system comprises an upgoing calling button and a downgoing calling button, wherein the upgoing and downgoing calling buttons are pedal type buttons and are respectively installed on the ground on the two sides of an elevator door; the upgoing and downgoing calling buttons are connected with an elevator master control board through a signal separation module; the master control board is connected with a mechanical device which drives the elevator to run; a shaft way electronic device, which feeds the motion state information of the elevator back to the master control board, is connected between the master control board and the mechanical device; an upgoing indicator lamp and a downgoing indicator lamp which are corresponding to the upgoing and downgoing calling buttons are respectively arranged on the two sides of the elevator door; and the upgoing and downgoing indicator lamps are connected with the signal separation module. The invention improves the elevator taking environment, realizes ordered transfer and civilized elevator taking, enhances the elevator transfer efficiency, reduces the congestions, saves the transfer time, increases the utilization ratio of the elevator, avoids wasting time, and blocks up the transmission routes of communicable diseases by using the pedal type calling mode.

Owner:XIZI OTIS ELEVATOR

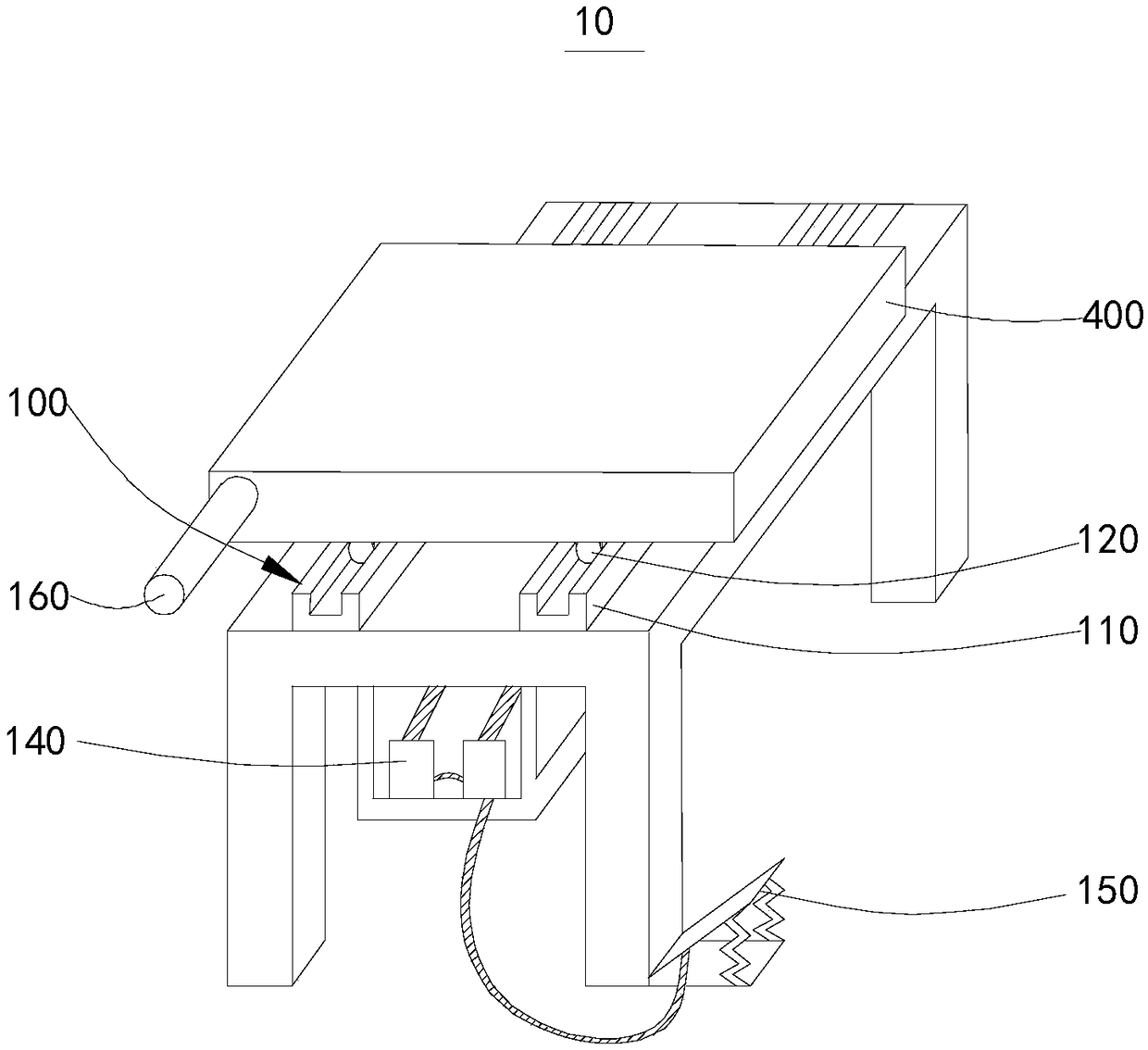

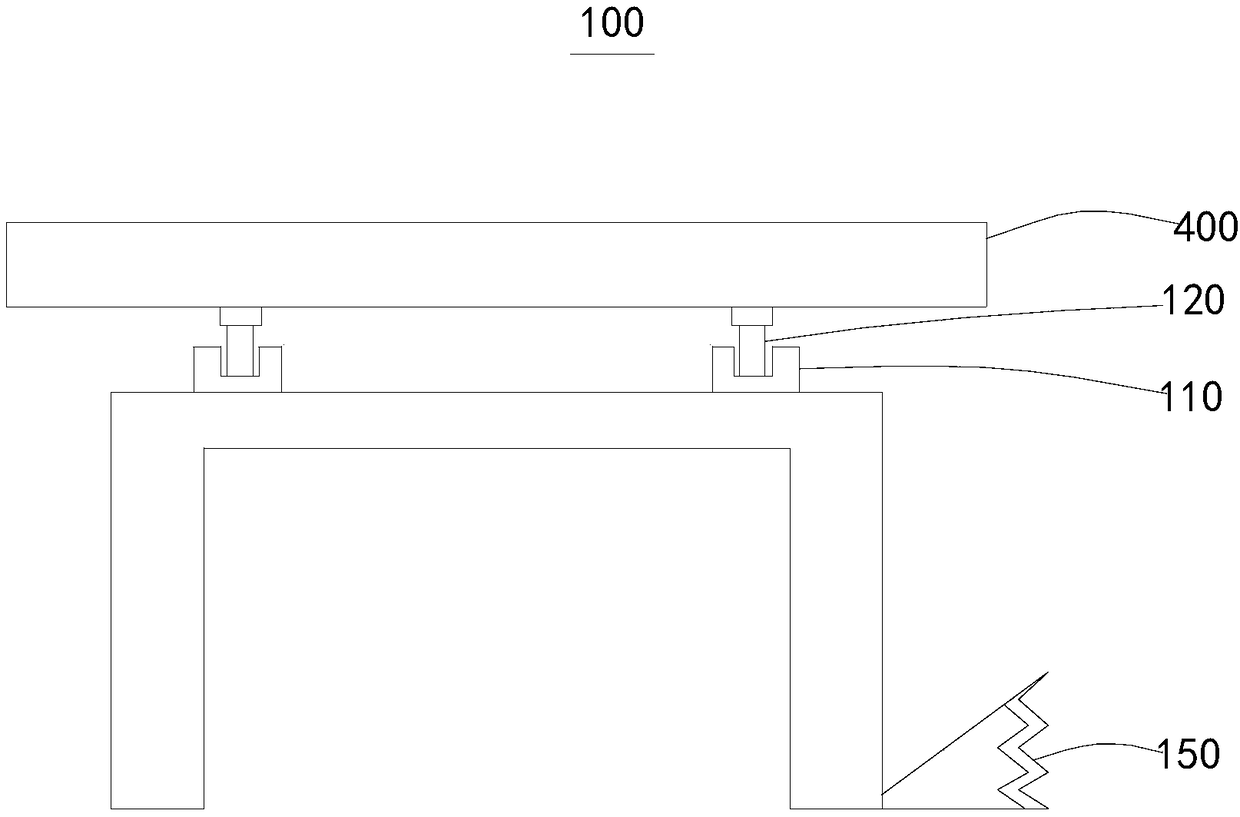

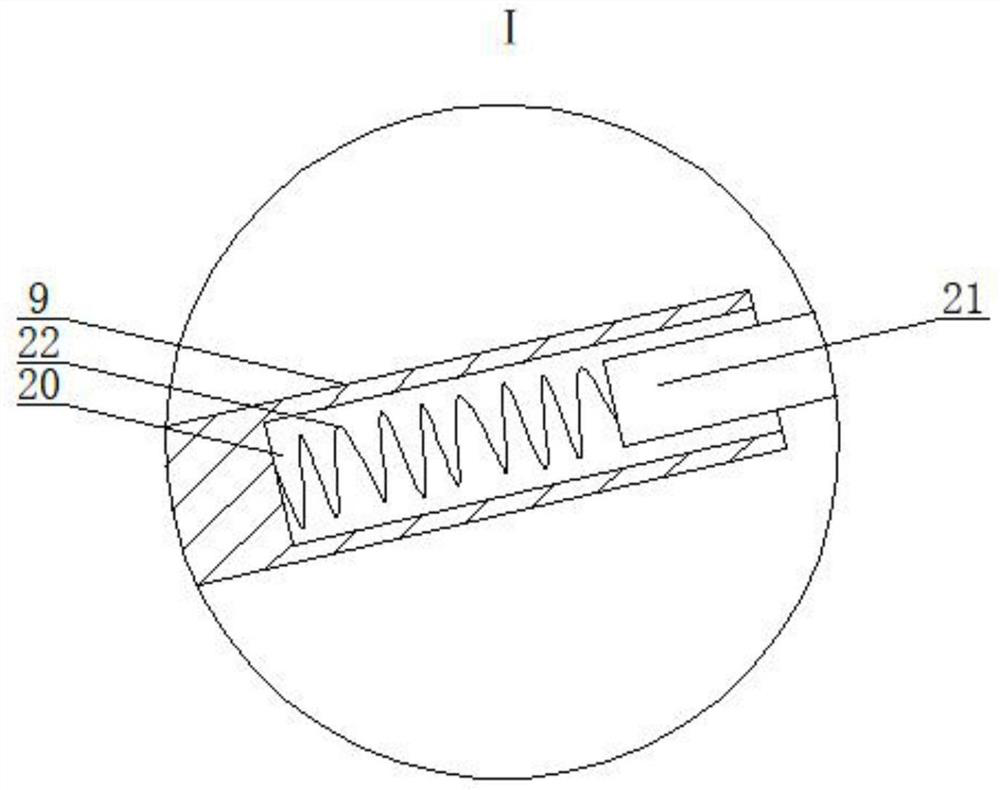

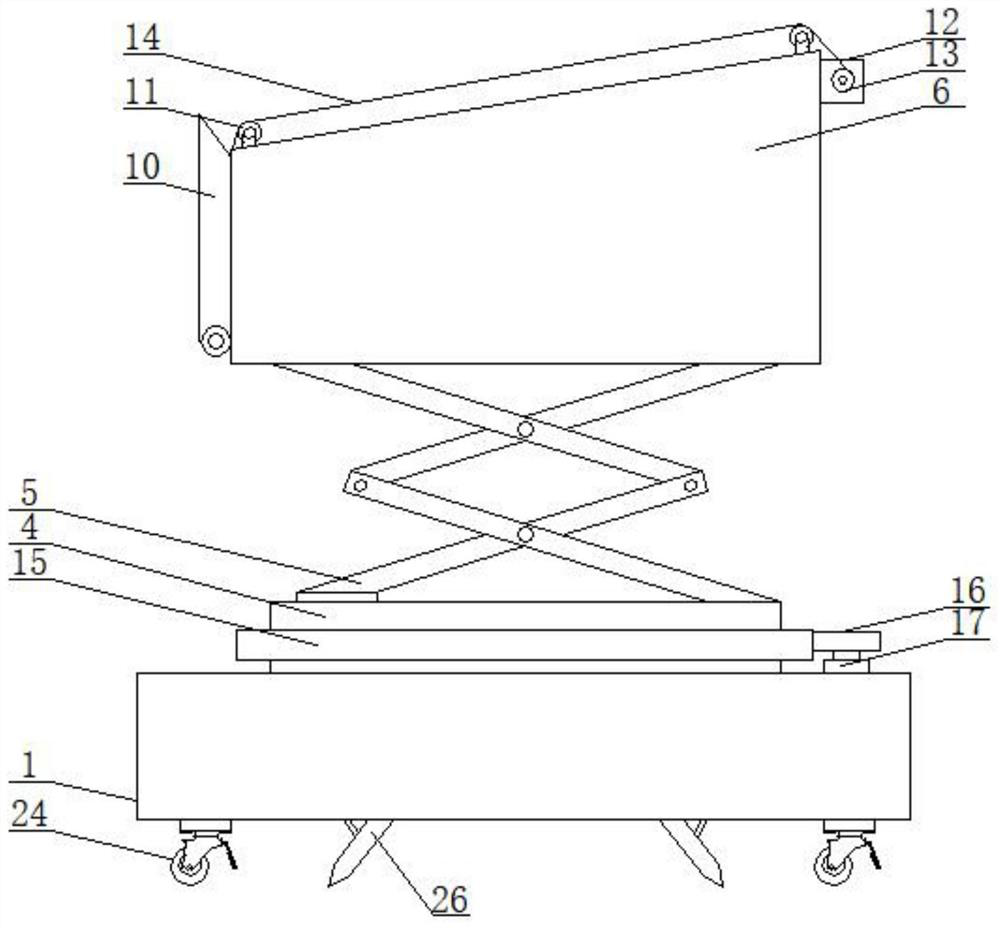

Material transferring device for aluminum alloy production

InactiveCN113277277AEasy to produceReduce physical laborConveyor partsMechanical conveyorsRotational axisEngineering

The invention provides a material transferring device for aluminum alloy production, and mainly relates to the technical field of aluminum alloy production. The material transferring device for aluminum alloy production comprises a bottom plate, a rectangular groove is formed in the top face of the bottom plate, a rotating shaft is rotationally installed in the rectangular groove through a bearing, a rotating disc is installed at the top end of the rotating shaft, a shear fork lifting mechanism with a power device is installed on the top face of the rotating disc, and a containing box is installed at the top end of the shear fork lifting mechanism. The top face and the left side face of the containing box are open, and a first groove is formed in the bottom face of the containing box. The material transferring device has the beneficial effects that the structure is simple, operation is convenient, automatic material transferring can be achieved, the physical labor of operators is reduced, the safety guarantee of the operators is improved, and the labor cost is reduced; and meanwhile, the material transferring time is shortened, the material transferring efficiency is improved, material transferring can be conducted at different heights and in different directions, the material transferring requirements at different positions and in different directions can be met, and convenience is brought to aluminum alloy production.

Owner:山东呗特科技发展有限公司

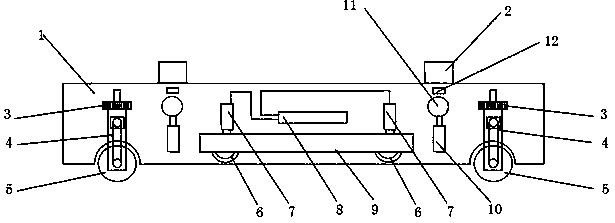

Transportation cart suitable for recycling and disassembling scraped car

ActiveCN103802916ACompact transportNot limited to one-way straight line transportationVehicle dissasembly recoverySolid waste disposalControl theoryReliability engineering

The invention discloses a transportation cart suitable for recycling and disassembling a scraped car. The transportation cart comprises a plane type cart body provided with a ground track type running system and a ground table running system, the ground table running system is provided with a steering mechanism, and the ground track type running system is connected with the plane type cart body through a lifting device. The transportation cart can meet transportation requirements in a recycling and disassembling process, greatly reduce required equipment or manpower cost, and improve disassembling efficiency of the scraped car.

Owner:HUNAN BRUNP SCRAP CARS RECYCLING +2

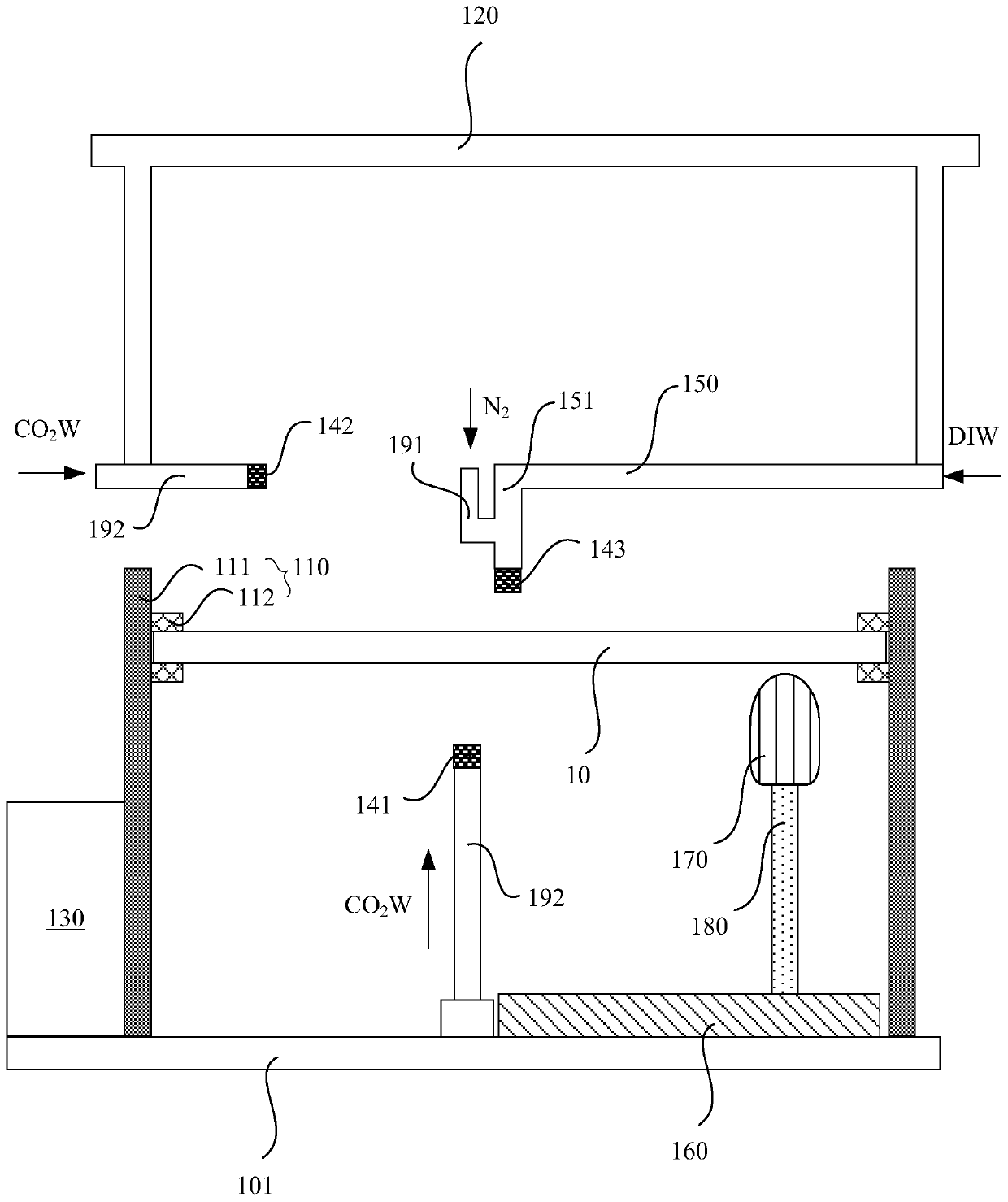

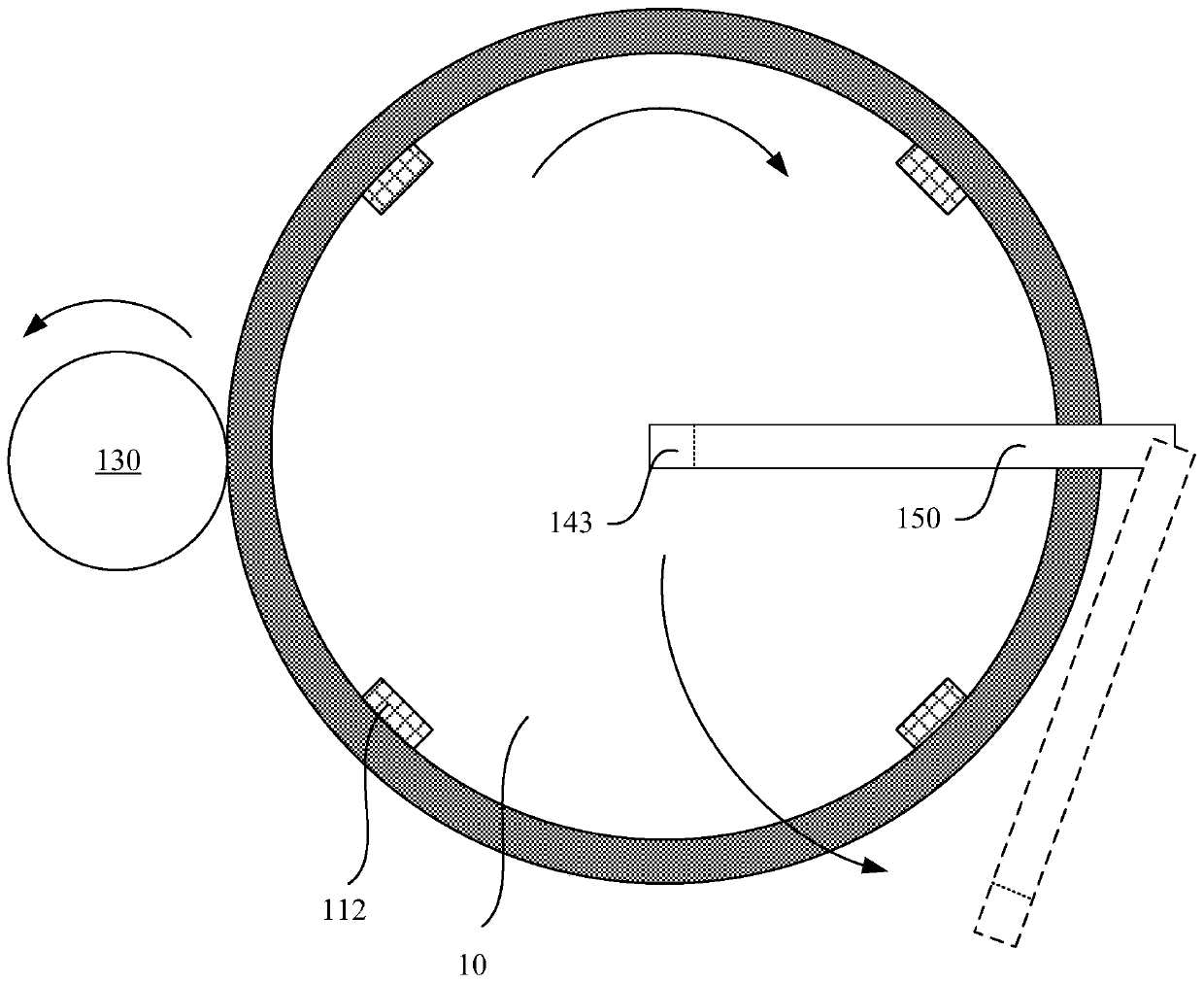

Wafer cleaning device

ActiveCN110707022AEasy to removeEasy to cleanSemiconductor/solid-state device manufacturingWaferEngineering

The invention discloses a wafer cleaning device, and the device comprises a wafer placing mechanism which is used for clamping the edge of a wafer and driving the wafer to rotate; a first spray head which is positioned on one side of the wafer placing mechanism and is used for upwards spraying a cleaning agent to the back surface of the wafer; and a cleaning brush and a guide rail which are located on one side of the wafer placing mechanism, wherein the cleaning brush is movably connected with the guide rail, and the cleaning brush can move relative to the guide rail and is used for cleaning the back of the wafer. When the wafer cleaning device is used for cleaning the back surface of the wafer, pollutants on the back surface of the wafer can be influenced by the shearing force of the cleaning brush and the gravity of the cleaning brush at the same time, so that the pollutants can be moved out of the back surface of the wafer more easily, and the cleaning effect is enhanced.

Owner:YANGTZE MEMORY TECH CO LTD

Rotary shaft wire passage structure

InactiveUS20140020209A1Easy to assembleRaise the ratioDigital data processing detailsHingesEngineeringMechanical engineering

A rotary shaft wire passage structure includes a pivot pin and a pivot seat respectively fixedly connected with a pivotal rotary member and a relative pivotal rotary member. The pivot pin has a pivoted section and an annular raised section disposed at one end thereof. The pivoted section is formed with an axial through hole in full communication with outer side via a split. The pivot seat has a shaft hole in which the pivoted section is fitted. One side of the shaft hole is formed with a fissure in communication with the outer side. The fissure is adjustable to a position where the fissure is aligned with the split for placing a wire into the through hole. When the relative pivotal rotary member is pivotally rotated to a working position by a certain angle, the fissure is misaligned from the split to prevent the wire from slipping out.

Owner:FIRST DOME

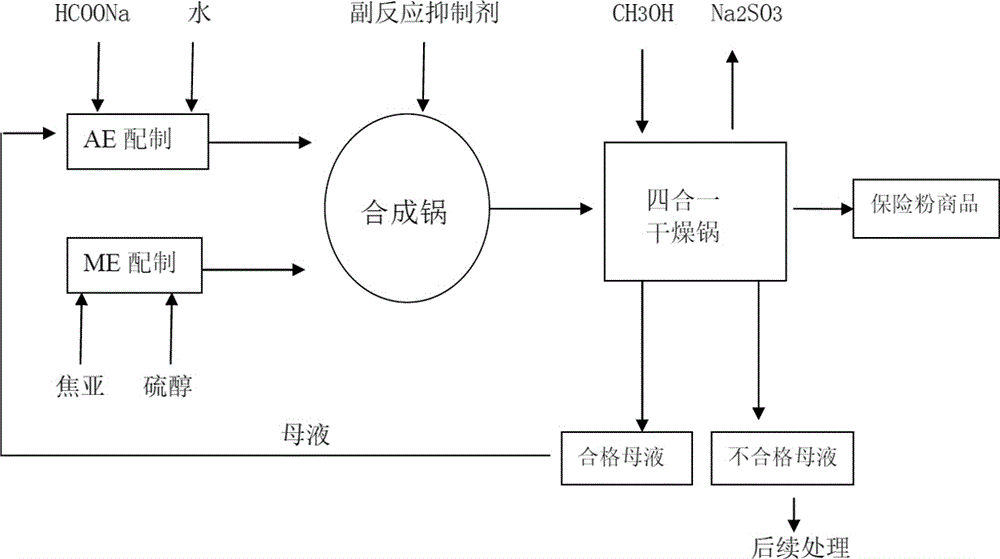

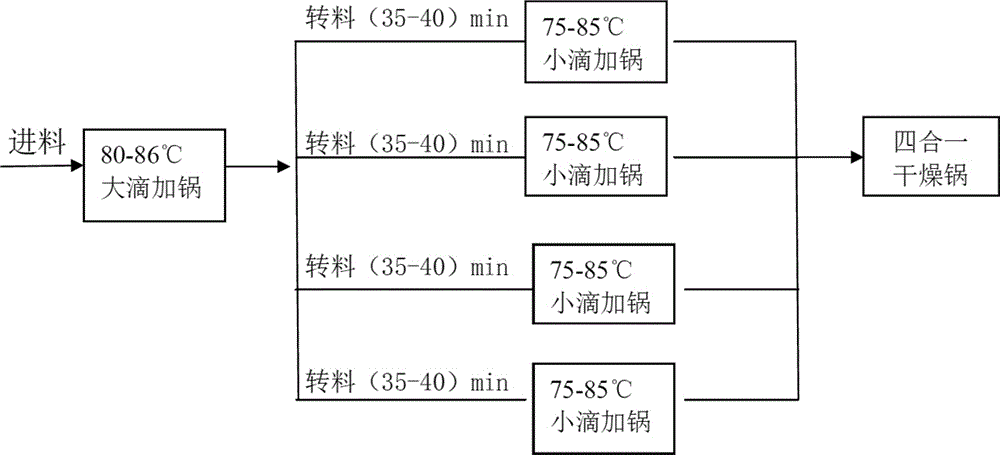

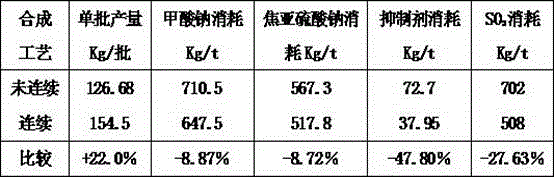

Sodium hydrosulfite synthesizing and continuous producing method

ActiveCN106517103ALess investmentSave overall synthesis timeThiosulfates/dithionites/polythionitesRipeningMaterial transfer

The invention discloses a sodium hydrosulfite synthesizing and continuous producing method. The sodium hydrosulfite synthesizing and continuous producing method comprises the following steps: taking a synthesizing pot as a tubular reactor; after preparing raw materials AE and ME, transferring the raw materials AE and ME into AE and ME storage tanks via inert gas; adding the raw materials AE and ME in a large synthesis dropwise adding pot; opening the pot and inserting a bottom tube into the large synthesis dropwise adding pot to transfer the materials into a small synthesis dropwise adding pot; keeping the liquid level of the materials in the large dropwise adding pot to be stable relatively in a material transferring process; continuing adding the raw materials AE and ME into the large synthesis dropwise adding pot continuously and uniformly; after the small synthesis dropwise adding pot receives a first batch of materials, enabling a second small dropwise adding pot to begin to receive the material from the large synthesis dropwise adding pot, and enabling the rest dropwise adding pot to begin to receive the material from the large synthesis dropwise adding pot in the same way; continuously adding a SO2-CH3OH solution as a raw material at a suitable speed to an end point by the small dropwise adding pots from the time when the small dropwise adding pots begin to receive the material to the time when reaction reaches the end point; and after insulating and ripening are completed, placing the material in a drying process for subsequent use. A repeated operation process of a reaction process is omitted, so that a synthesis process is continuous, and while the efficiency of the device is improved, consumption of sodium formate and sodium pyrosulfite is reduced.

Owner:CHIFENG RUIYANG CHEM

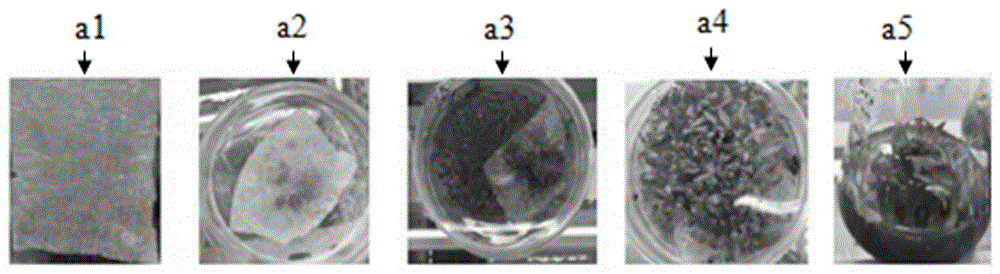

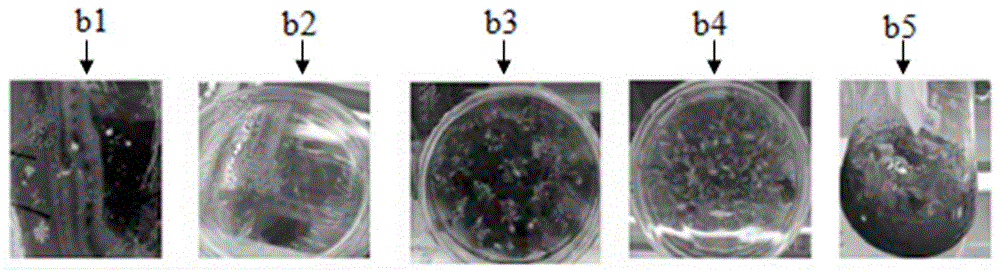

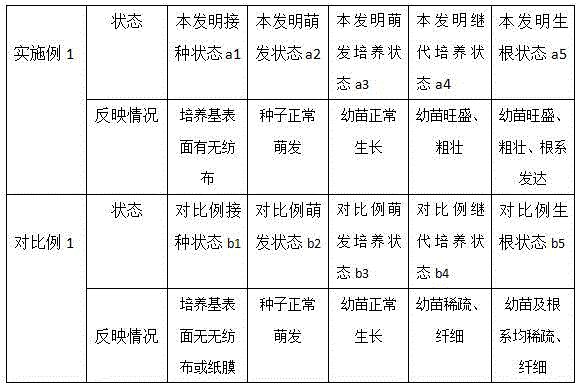

Tissue culture method for bletillastriata (thunb.) reichb.f. seedlings

InactiveCN105660422APromote growthImprove efficiencyHorticulture methodsPlant tissue cultureForcepsMicrobiology

The invention discloses a tissue culture method for bletillastriata (thunb.) reichb.f. seedlings in the technical field of medicinal plant tissue culture. The method comprises the steps of preparing a germination medium, a subculture medium and a rooting medium; preparing a paper membrane or nonwoven cloth: shearing the paper membrane or the nonwoven cloth into round sheets or square blocks; transferring the germination medium into a culture dish I and tiling the paper membrane or the nonwoven cloth on the surface of the germination medium; transferring the subculture medium into a culture dish II; transferring the rooting medium into a culture dish III; shearing bletillastriata (thunb.) reichb.f. capsules to obtain bletillastriata (thunb.) reichb.f. seeds, uniformly sowing the seeds in the culture dish I, and performing closed culture; clamping the paper membrane or the nonwoven cloth in the culture dish I by using aseptic forceps and directly performing subculture on tissue culture seedlings between the culture dish II and the culture dish III along with the paper membrane or the nonwoven cloth; and hardening and transplanting the seedlings. Compared with the prior art, the method is high in efficiency and small in quantity of work; and the obtained tissue culture seedlings grow well.

Owner:ZUNYI MEDICAL UNIVERSITY

Rotary shaft wire passage structure

InactiveUS20140020207A1Easy to assembleRaise the ratioElectrical apparatusDigital data processing detailsEngineeringMechanical engineering

A rotary shaft wire passage structure includes a pivot pin and a pivot seat respectively fixedly connected with a pivotal rotary member and a relative pivotal rotary member. The pivot pin has a pivoted section and an annular raised section disposed at one end thereof. The pivoted section is formed with an axial through hole in full communication with outer side via a split. The pivot seat has a shaft hole in which the pivoted section is fitted. One side of the shaft hole is formed with a fissure in communication with the outer side. The fissure is adjustable to a position where the fissure is aligned with the split for placing a wire into the through hole. When the relative pivotal rotary member is pivotally rotated to a working position by a certain angle, the fissure is misaligned from the split to prevent the wire from slipping out.

Owner:FIRST DOME

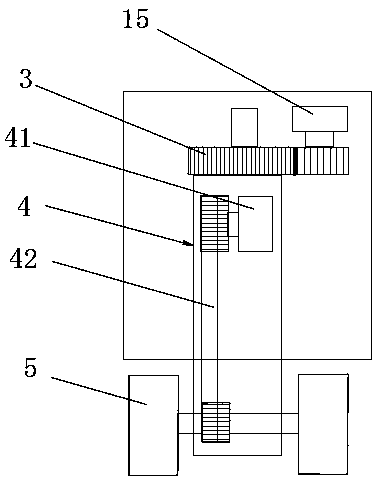

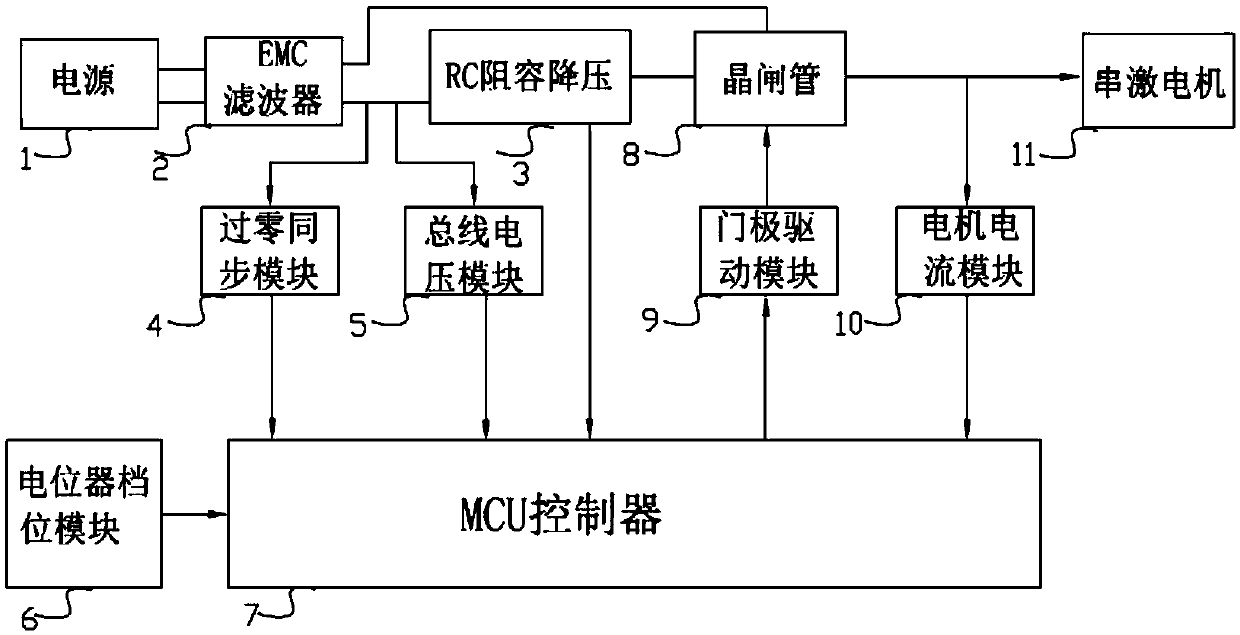

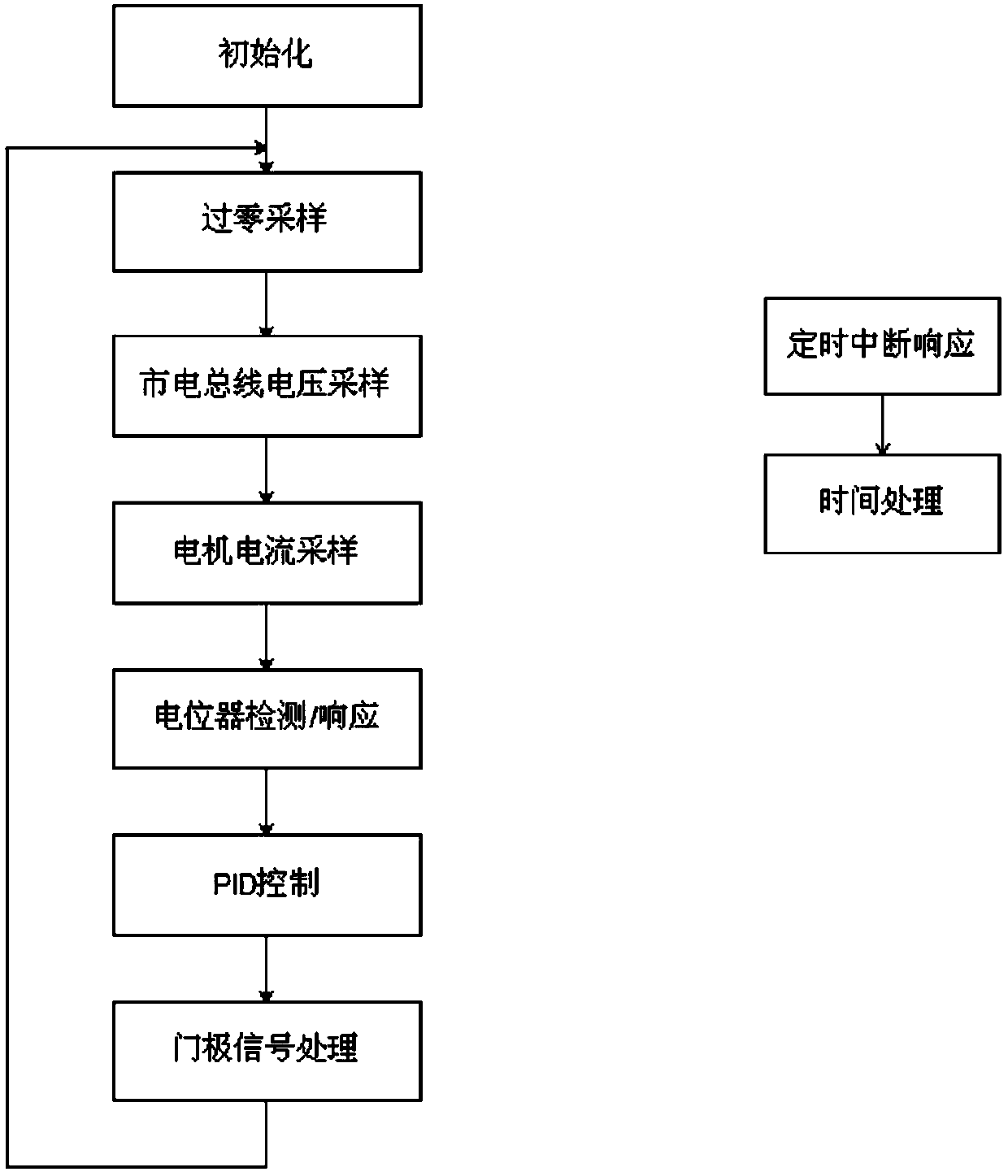

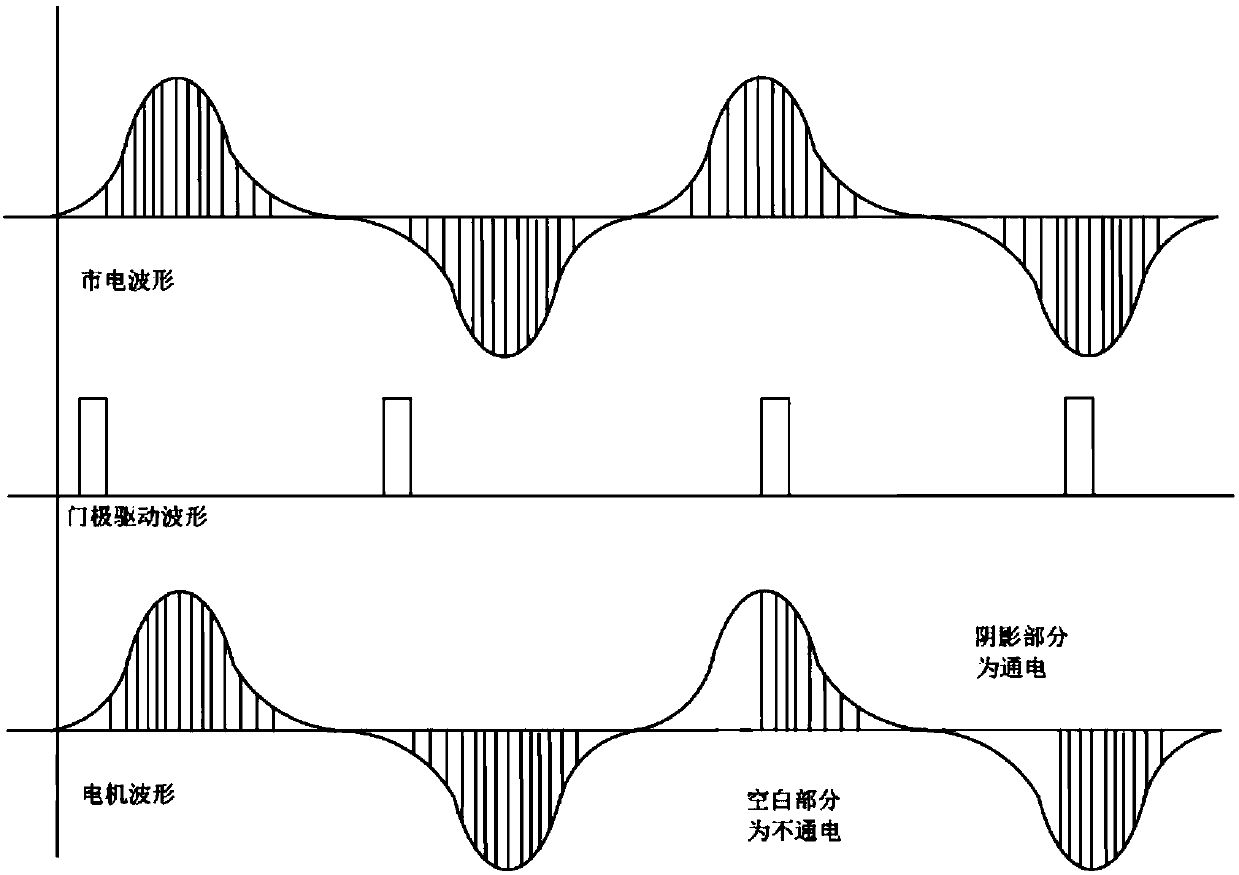

Series motor control system and method

InactiveCN109672391ALow costFunction to achieve constant speed controlAC motor controlResistance capacitanceThyratron

The invention discloses a series motor control system and method. The system mainly comprises an MCU (Microprogrammed Control Unit) (7), a connection power supply (1), an EMC (Electro Magnetic Compatibility) filter (2), a resistance-capacitance voltage reduction module (3), a zero-crossing synchronous module (4), a bus voltage module (5), a potentiometer gear module (6), a thyristor (8), a gate electrode driving module (9), a motor current module (10) and a series motor (11), wherein the EMC filter (2) is connected with the power supply (1); the thyristor (8) is connected with the series motor(11); the MCU (7) is connected with the resistance-capacitance voltage reduction module (3), the zero-crossing synchronous module (4), the bus voltage module (5), the potentiometer gear module (6), the gate electrode driving module (9) and the motor current module (10); the bus voltage module (5) is used for acquiring voltage of the EMC filter (2); the motor current module (10) is used for acquiring current in a rotating process of the series motor (11); the gate electrode driving module (9) is arranged between the MCU (7) and the series motor (11).

Owner:深圳博英特科技有限公司

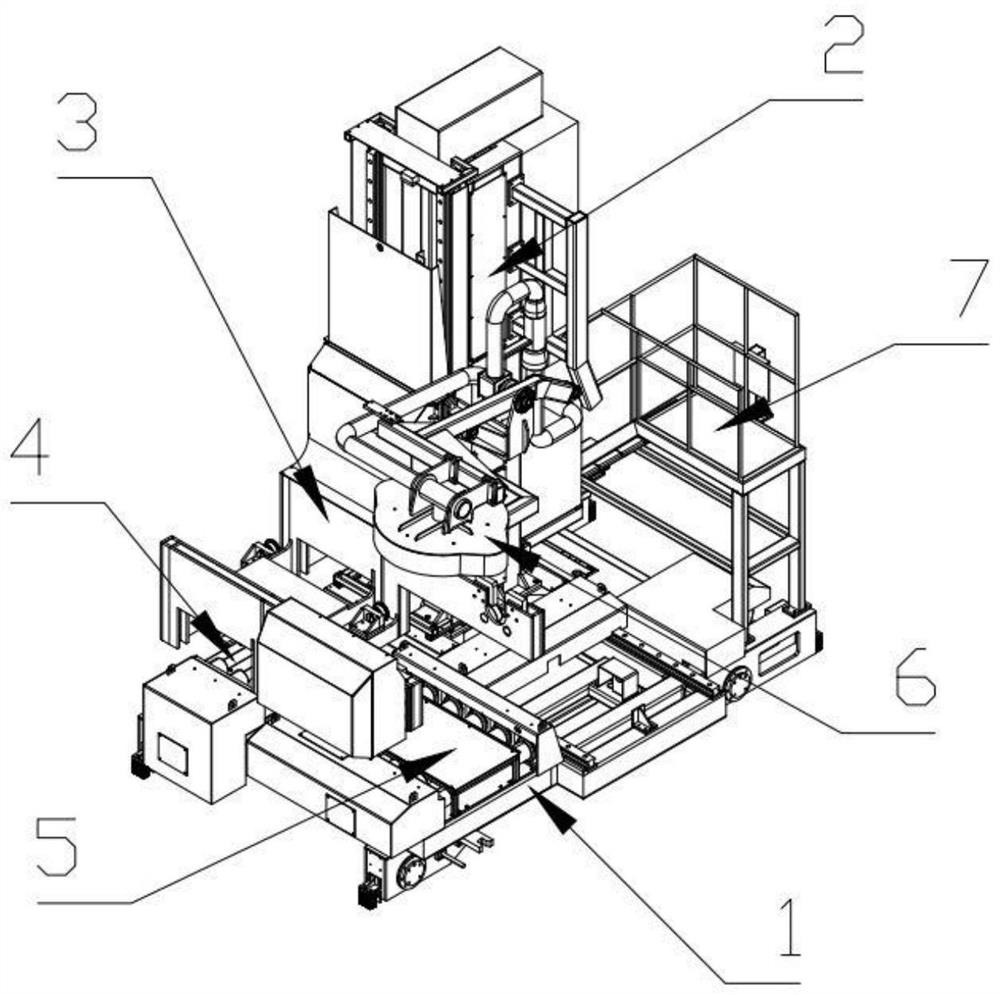

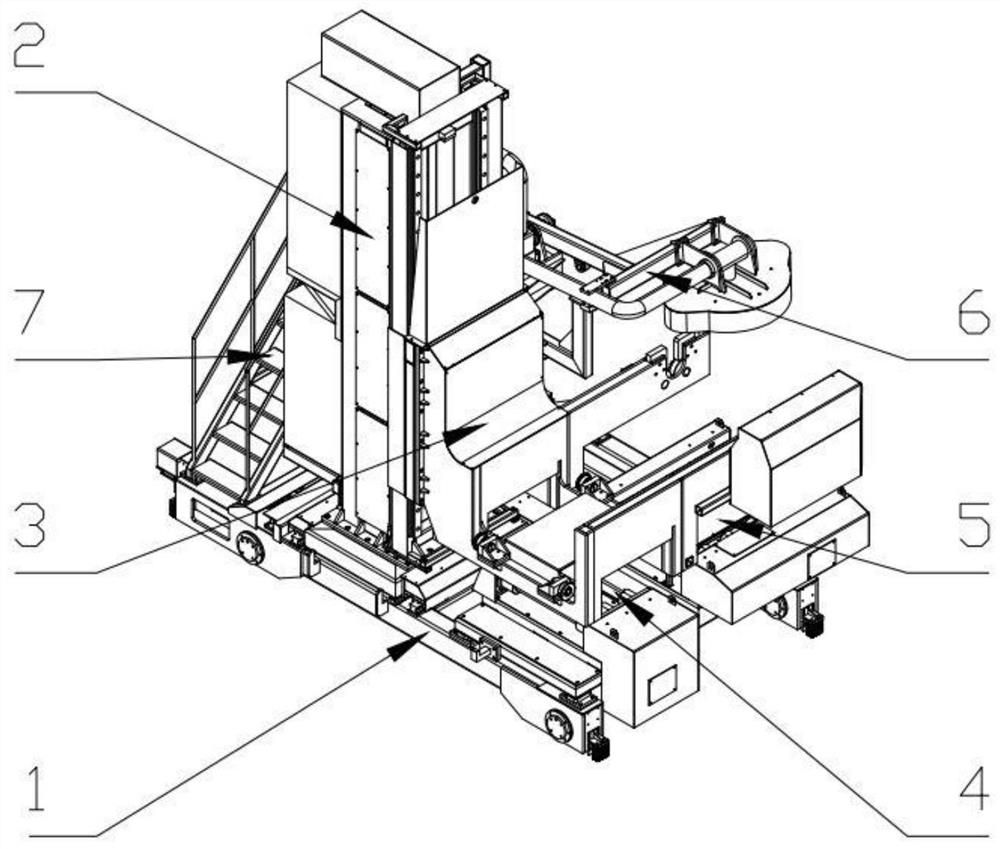

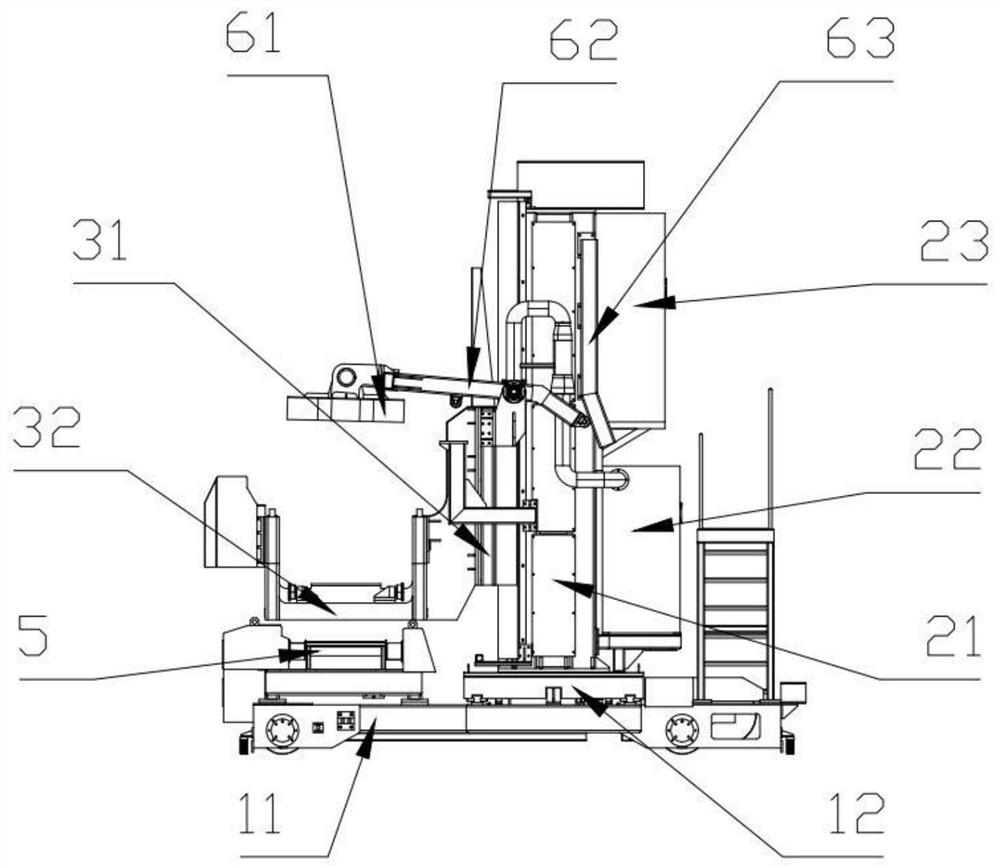

Pass-type lifting and tilting transfer trolley for molten iron transfer

ActiveCN114054735AEasy to installEasy maintenanceMelt-holding vesselsLifting framesMechanical engineeringMelting furnace

The invention provides a pass-type lifting and tilting transfer trolley for molten iron transfer, and the pass-type lifting and tilting transfer trolley comprises a translation part, a stand column, a lifting part and a roller way device, the translation part comprises a horizontally-arranged trolley body, the trolley body moves along a rail through wheels on the lower portion, the stand column is vertically arranged on the trolley body, one side of the stand column is slidably connected with the lifting part, and the lifting part can vertically ascend and descend along the stand column; the roller way device is further fixed above the trolley body and located below the lifting part, a through passing cavity is formed in the lifting part in the direction perpendicular to the movement direction of the trolley body, the height of the passing cavity is larger than that of a molten iron containing container, an opening is formed in the bottom of the lifting part, and the size of the opening is matched with that of the roller way device. By means of the design mode that the through type lifting part is matched with the two-roller way device, even if a melting furnace and a pouring station are not located on the same side of a transfer track, transfer work can be rapidly completed, meanwhile, the device can complete the transfer work without rotating, the arrangement space is effectively saved, and the transfer rhythm is saved.

Owner:山东杰创机械有限公司

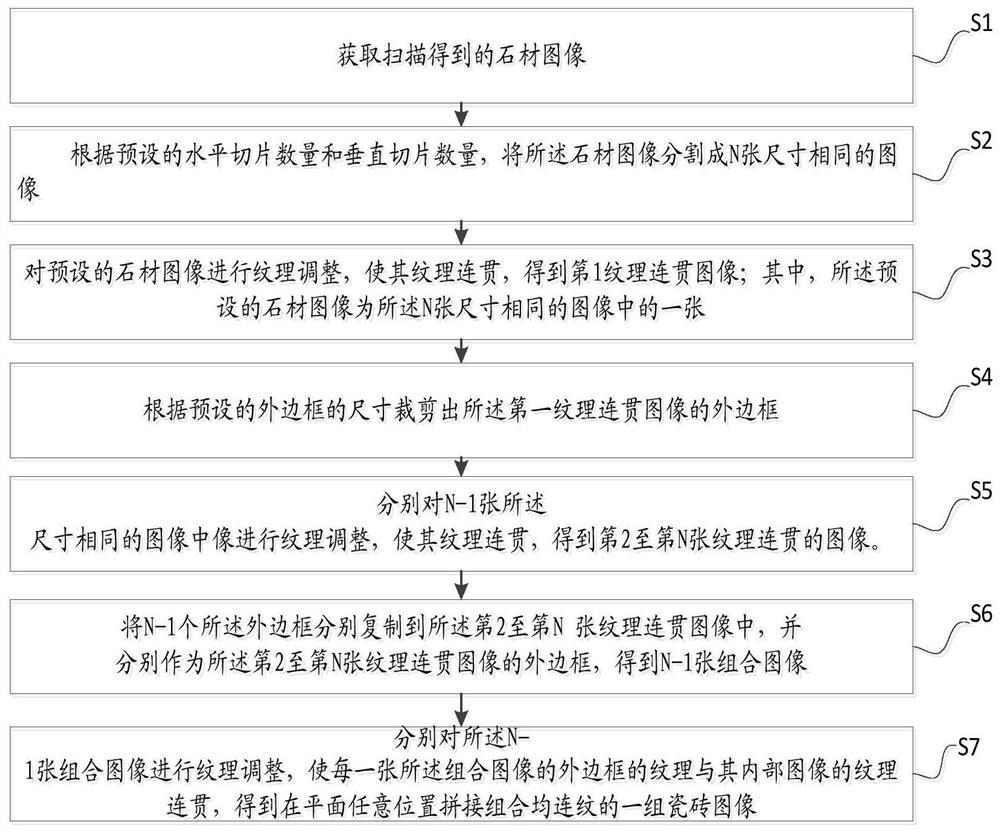

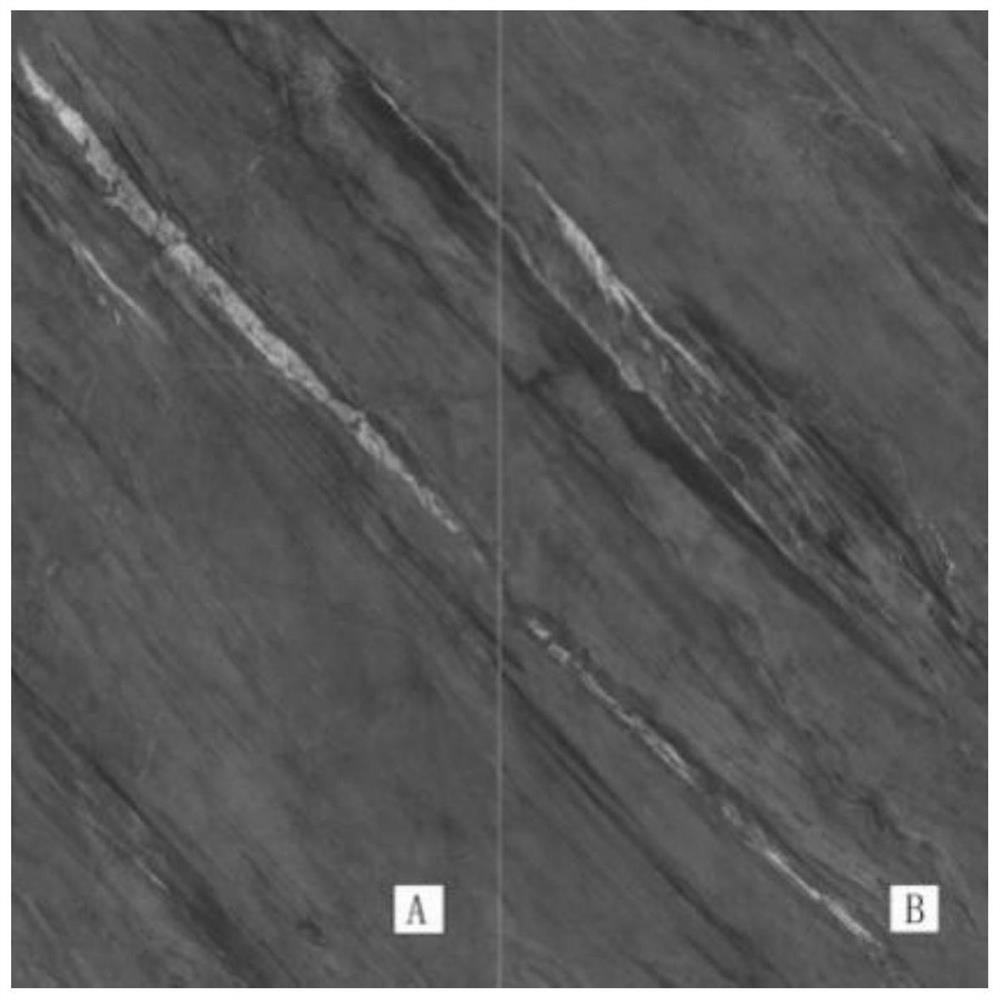

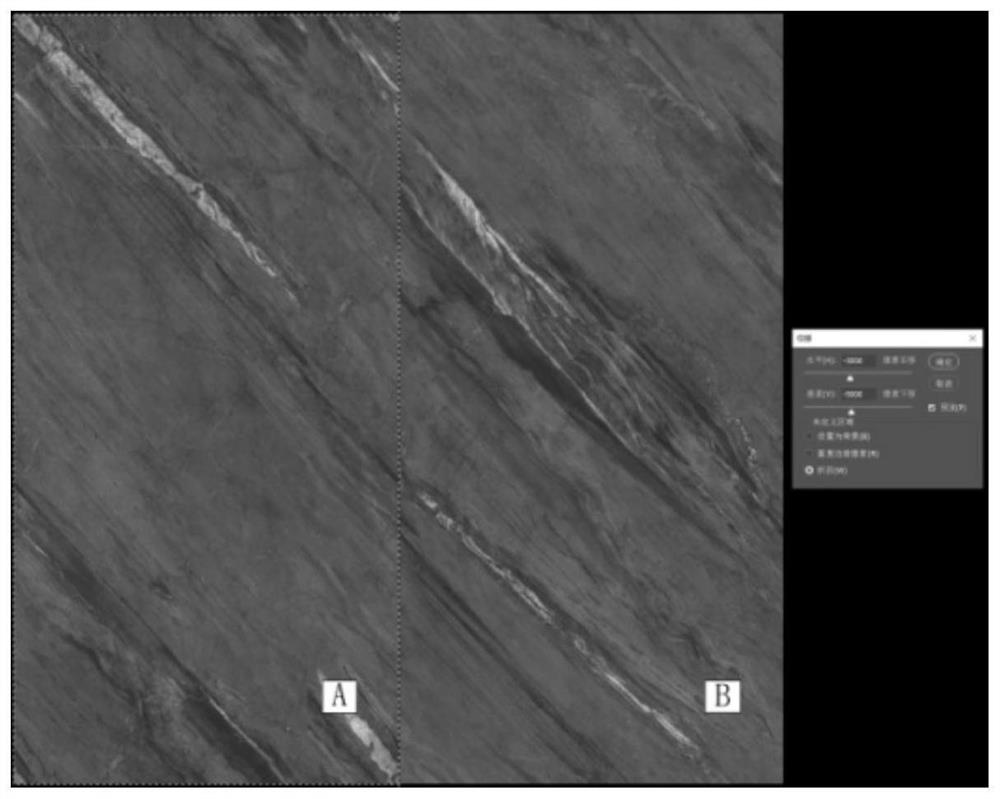

Infinite continuous pattern image processing method for ceramic tile production

PendingCN112085819ASave human resourcesReduce labor costsImage analysisLogisticsPattern recognitionImaging processing

The invention discloses an infinite continuous grain image processing method for ceramic tile production. The method comprises the following steps: acquiring a stone image obtained by scanning; segmenting the stone image into N images with the same size; performing texture adjustment on a preset stone image, so that the texture of the preset stone image is coherent, and a first texture coherent image is obtained; cutting out an outer frame of the first texture coherent image; carrying out texture adjustment on the N1 images with the same size, so that the textures of the N1 images are coherent, and second to Nth images with coherent textures are obtained; respectively copying the N1 outer frames into the second to Nth texture coherent images to obtain N1 combined images; and respectively carrying out texture adjustment on the N1 combined images, so that the texture of the outer frame of each combined image is consistent with the texture of the inner image of the combined image, and a group of tile images which are spliced and combined at any position of a plane and are uniformly connected are obtained. When the ceramic tile with the continuous grains is paved, a construction workercan show the overall continuous grain effect without paving the ceramic tile according to a specific sequence.

Owner:清远市简一陶瓷有限公司

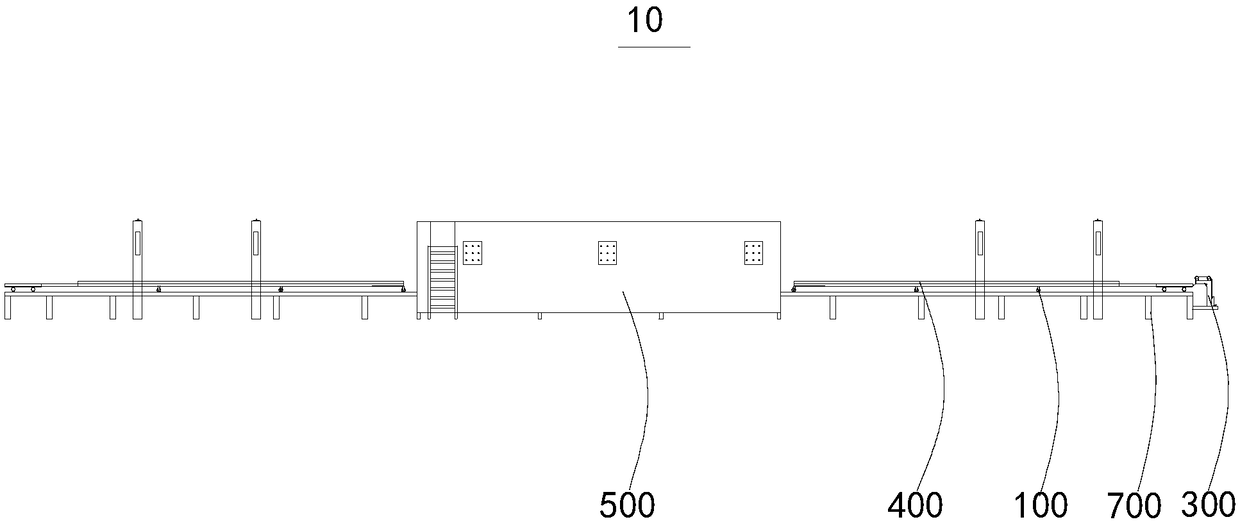

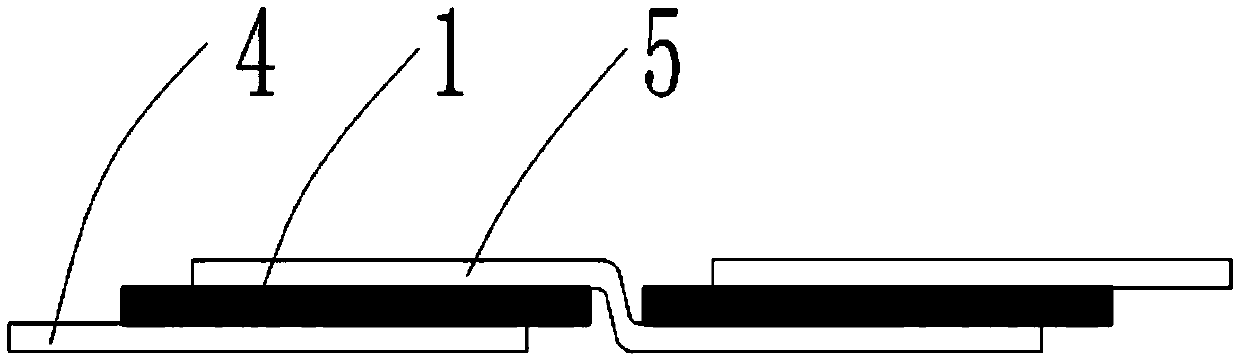

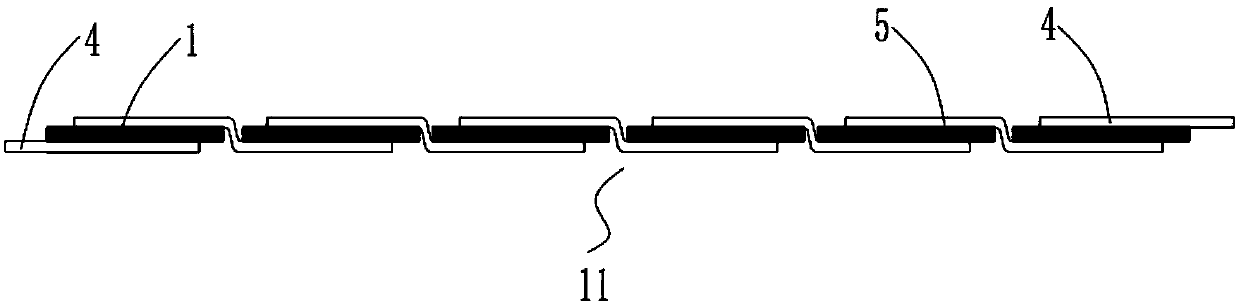

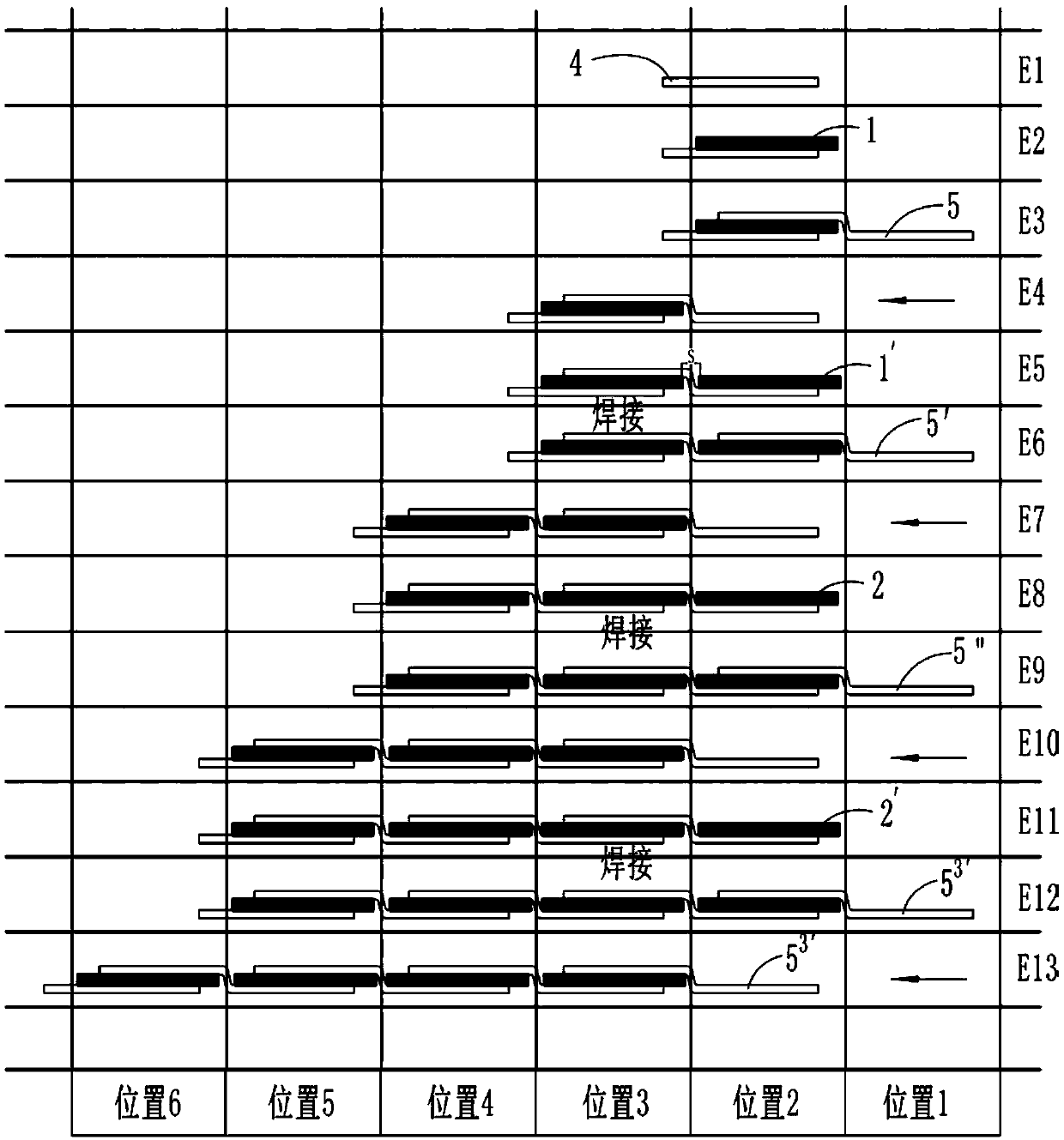

Method and equipment for preparing solar cell string

InactiveCN111463314ASave transfer timeReduce the frequency of movementsFinal product manufacturePhotovoltaic energy generationThermodynamicsElectrical conductor

The invention provides a method for preparing a solar cell string, which mainly overcomes the technical defects of long battery string production time and low production efficiency in the prior art. According to the main technical scheme, when at least two cells and at least one set of second conductor belts are placed each time, the forward movement length of a conveying and moving device for bearing the cells is T, T is equal to the product of n and the sum of S and the length of a single cell, n is greater than or equal to 2, and for the cells and the conductor belts conveyed to the weldingstation, a welding device completes interconnection welding of the at least two cells and the at least one set of second conductor belts. The invention further provides equipment for preparing the solar cell string and implementing the method. The method and the equipment provided by the invention remarkably save the conveying and moving time of the cells, and reduce the action frequency of a driving component, thereby reducing the loss of the driving component, and improving the working efficiency of the string welding equipment.

Owner:NINGXIA XN AUTOMATION EQUIP CO LTD

Pedal type elevator calling system

ActiveCN101875456BImprove the elevator environmentOrderly transferElevatorsComputer moduleEngineering

The invention relates to a pedal type elevator calling system. The system comprises an upgoing calling button and a downgoing calling button, wherein the upgoing and downgoing calling buttons are pedal type buttons and are respectively installed on the ground on the two sides of an elevator door; the upgoing and downgoing calling buttons are connected with an elevator master control board througha signal separation module; the master control board is connected with a mechanical device which drives the elevator to run; a shaft way electronic device, which feeds the motion state information ofthe elevator back to the master control board, is connected between the master control board and the mechanical device; an upgoing indicator lamp and a downgoing indicator lamp which are corresponding to the upgoing and downgoing calling buttons are respectively arranged on the two sides of the elevator door; and the upgoing and downgoing indicator lamps are connected with the signal separation module. The invention improves the elevator taking environment, realizes ordered transfer and civilized elevator taking, enhances the elevator transfer efficiency, reduces the congestions, saves the transfer time, increases the utilization ratio of the elevator, avoids wasting time, and blocks up the transmission routes of communicable diseases by using the pedal type calling mode.

Owner:XIZI OTIS ELEVATOR

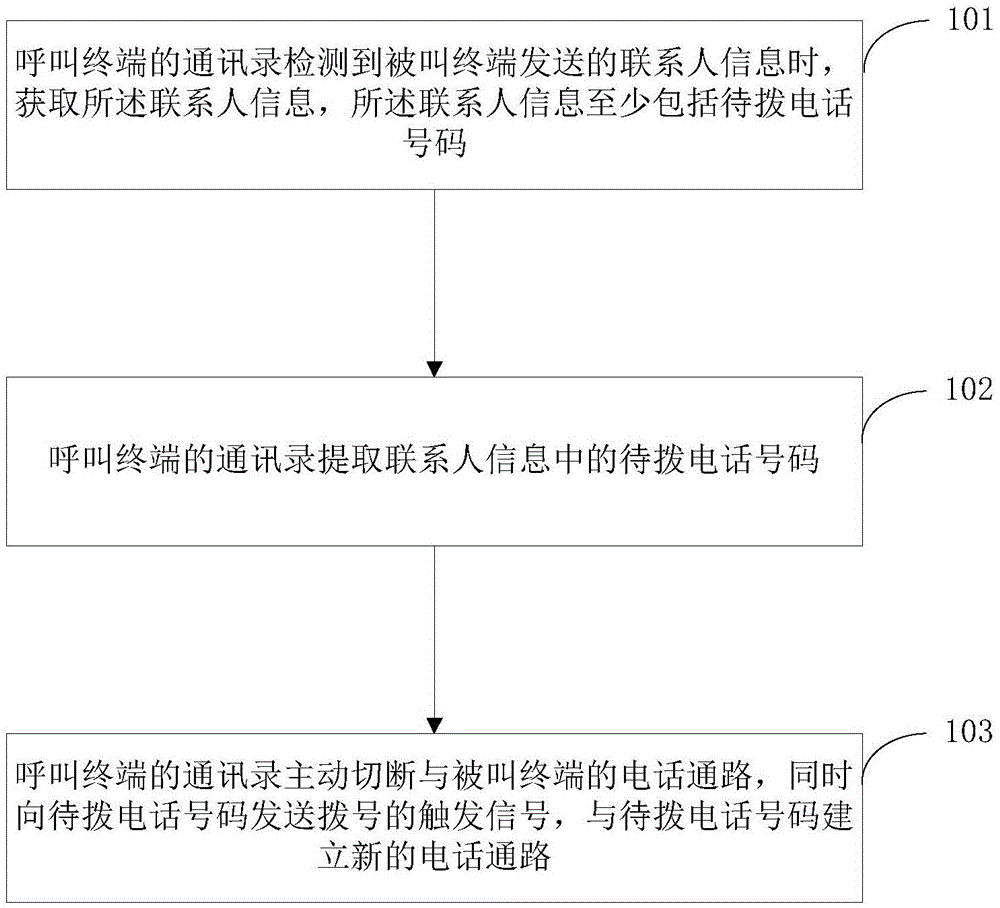

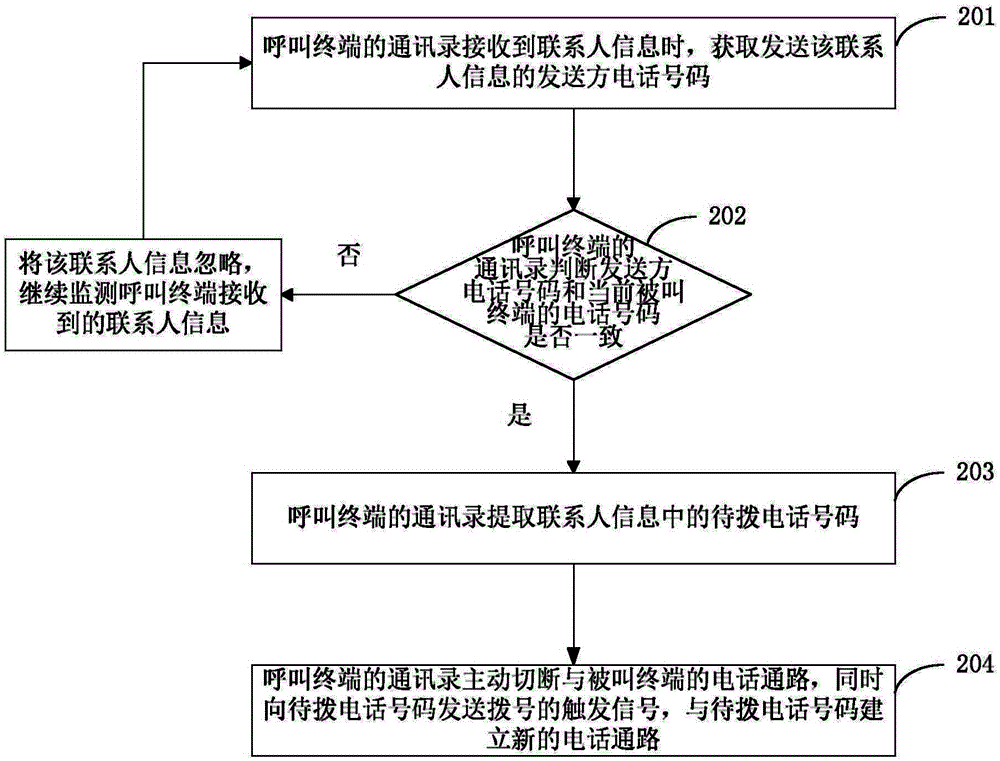

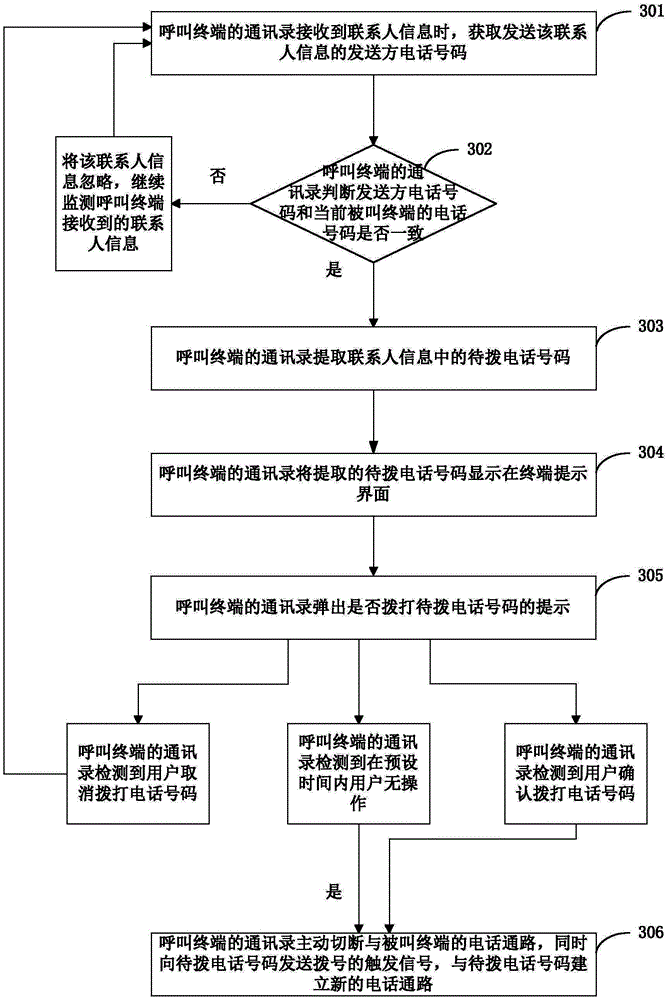

Call transferring method in contact list and contact list

InactiveCN106713683ASimplify call forwarding operationsSave call transfer timeSpecial service for subscribersMobile phoneTelephone call

The invention provides a call transferring method in a contact list and the contact list. The contact list in a calling terminal establishes a call channel with a called terminal. The call transferring method comprises the steps that S1: when the contact list of the calling terminal detects contact person information transmitted by the called terminal, the contact person information is acquired, wherein the contact person information at least includes a phone number to be dialed; S2: the contact list of the calling terminal extracts the phone number to be dialed in the contact person information; and S3: the contact list of the calling terminal actively cuts off the call channel with the called terminal and also transmits a dialing triggering signal to the phone number to be dialed so as to establish a new call channel with the phone number to be dialed. The contact list of the calling terminal detects and extracts the phone number in the contact person information transmitted by the called terminal under the conversation state, and the call channel with the phone number is automatically established so that the call transferring operation in the conversation process of a mobile phone terminal can be simplified through the contact list, the time can be saved and the user experience can be enhanced.

Owner:BEIJING QIHOO TECH CO LTD +1

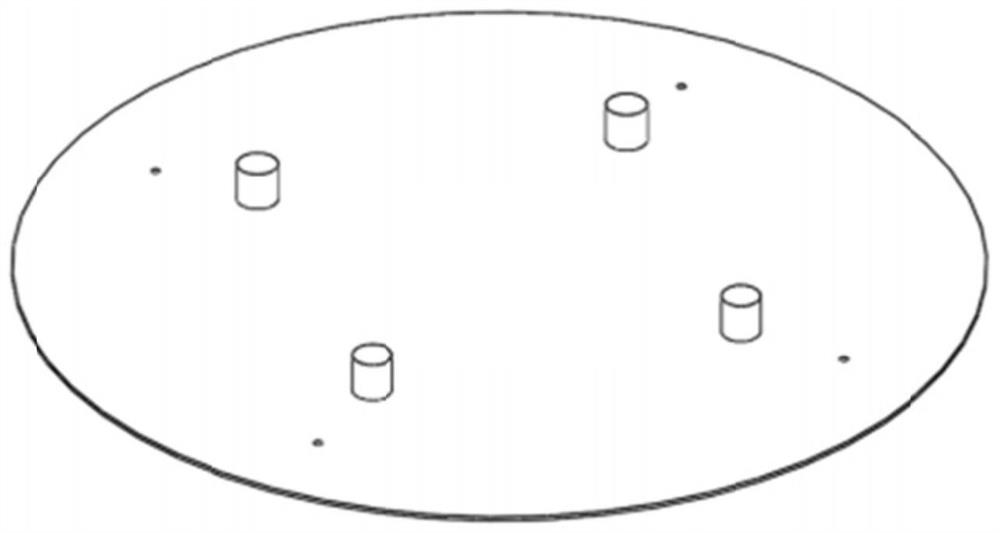

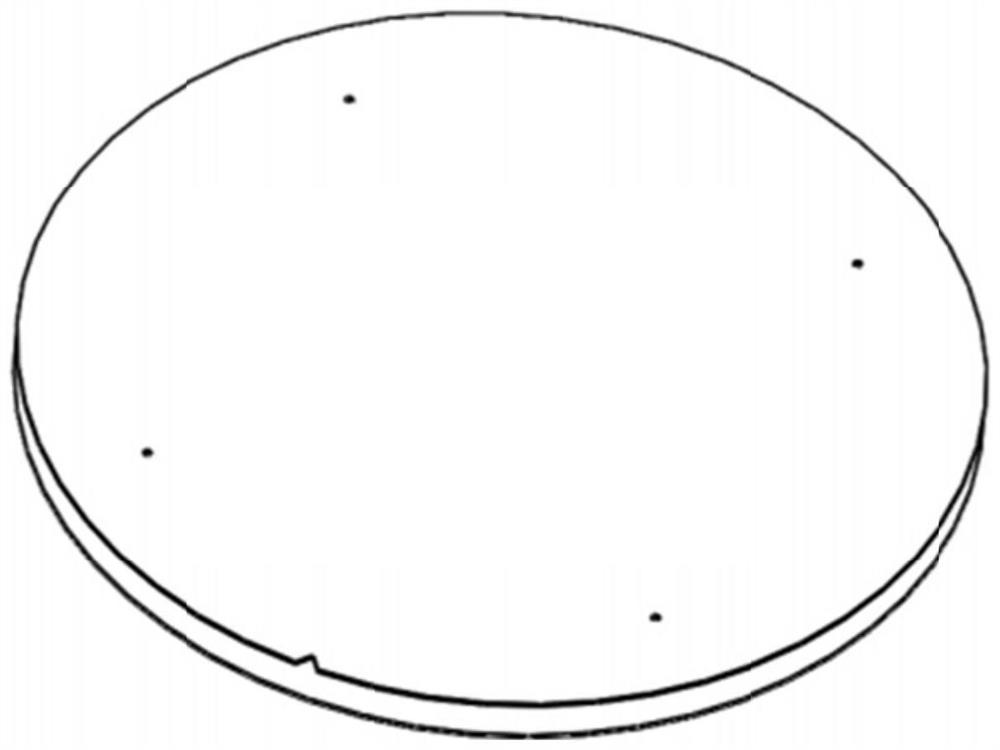

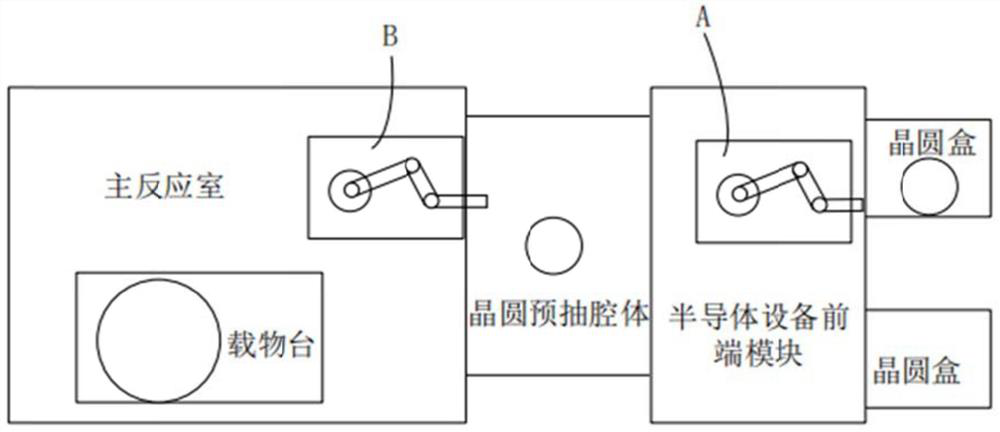

Wafer conveying device, wafer pre-pumping device and rapid wafer conveying system

PendingCN114823445AImprove gripImprove stabilitySemiconductor/solid-state device manufacturingConveyor partsWaferMechanical engineering

The invention provides a wafer conveying device which comprises a base and a wafer supporting component fixed on the base, a plurality of supporting assemblies are formed on the inner side face of the wafer supporting component, clamping grooves are formed between the supporting assemblies, and the supporting assemblies are arranged at intervals in the direction perpendicular to the base; moreover, the inner side surface of the wafer supporting part forms an arc matched with the outer peripheral edge of the wafer, so that the wafer is stably arranged at intervals in the wafer conveying device in the direction perpendicular to the base. The wafer conveying time is shortened, the service life of a sealing ring of the wafer pre-pumping device is prolonged, the amount of particles substituted into the main detection module is reduced, and the service life of a pump for pumping air for the wafer pre-pumping device is prolonged.

Owner:DONGFANG JINGYUAN ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com