Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Reduce scattered light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

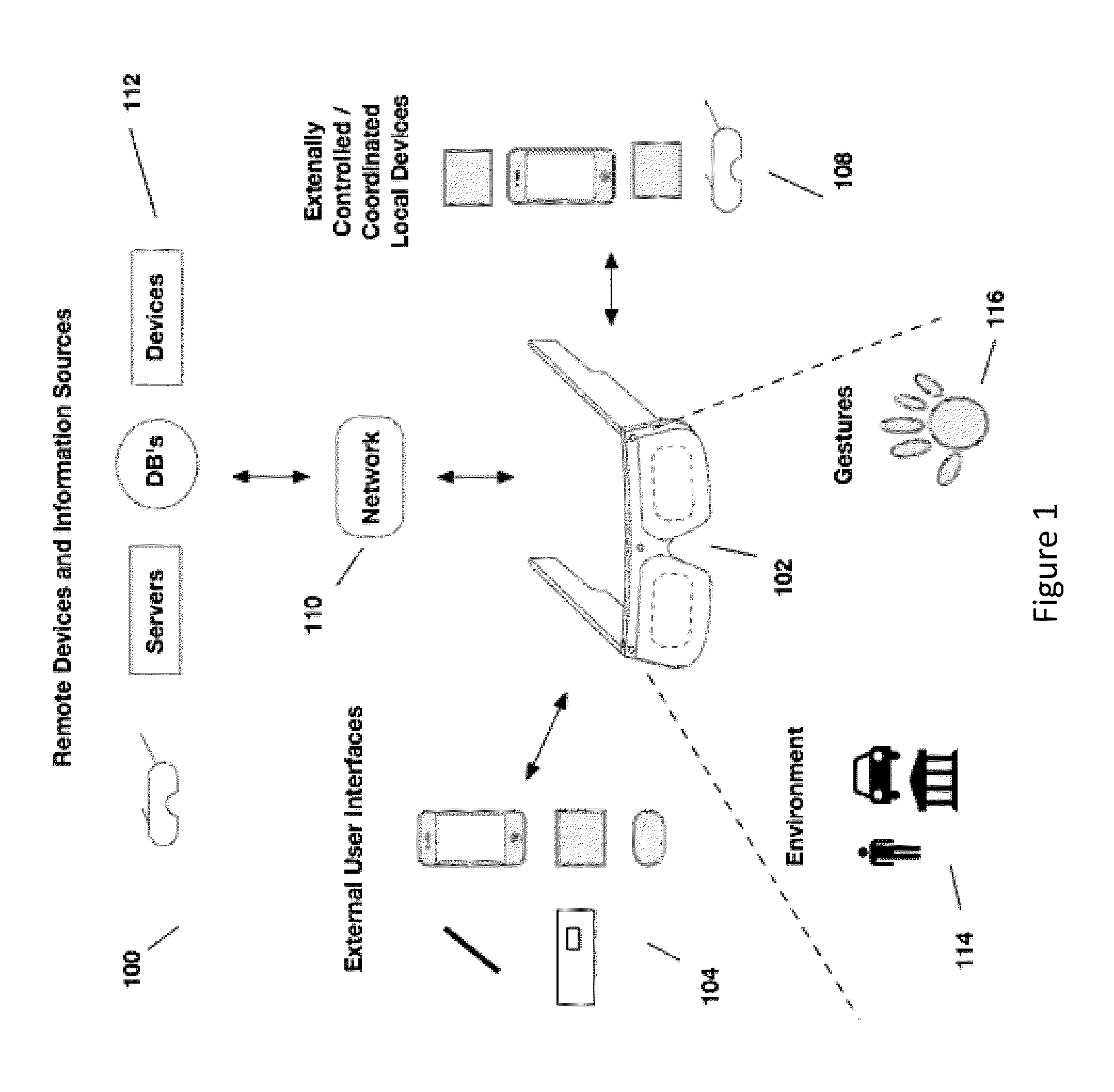

Optical systems for see-through displays

ActiveUS9366867B2Reduce weightComfortable to wearPolarising elementsCathode-ray tube indicatorsSee-through displayComputer science

Aspects of the present invention relate to methods and systems for providing a high quality display images in see-through head-worn optics.

Owner:OSTERHOUT GROUP INC

Optical configurations for head-worn see-through displays

ActiveUS20170023790A1Reduce weightComfortable to wearPolarising elementsSee-through displayDisplay device

Aspects of the present invention relate to methods and systems for providing high quality display images in see-through head-worn optics.

Owner:OSTERHOUT GROUP INC

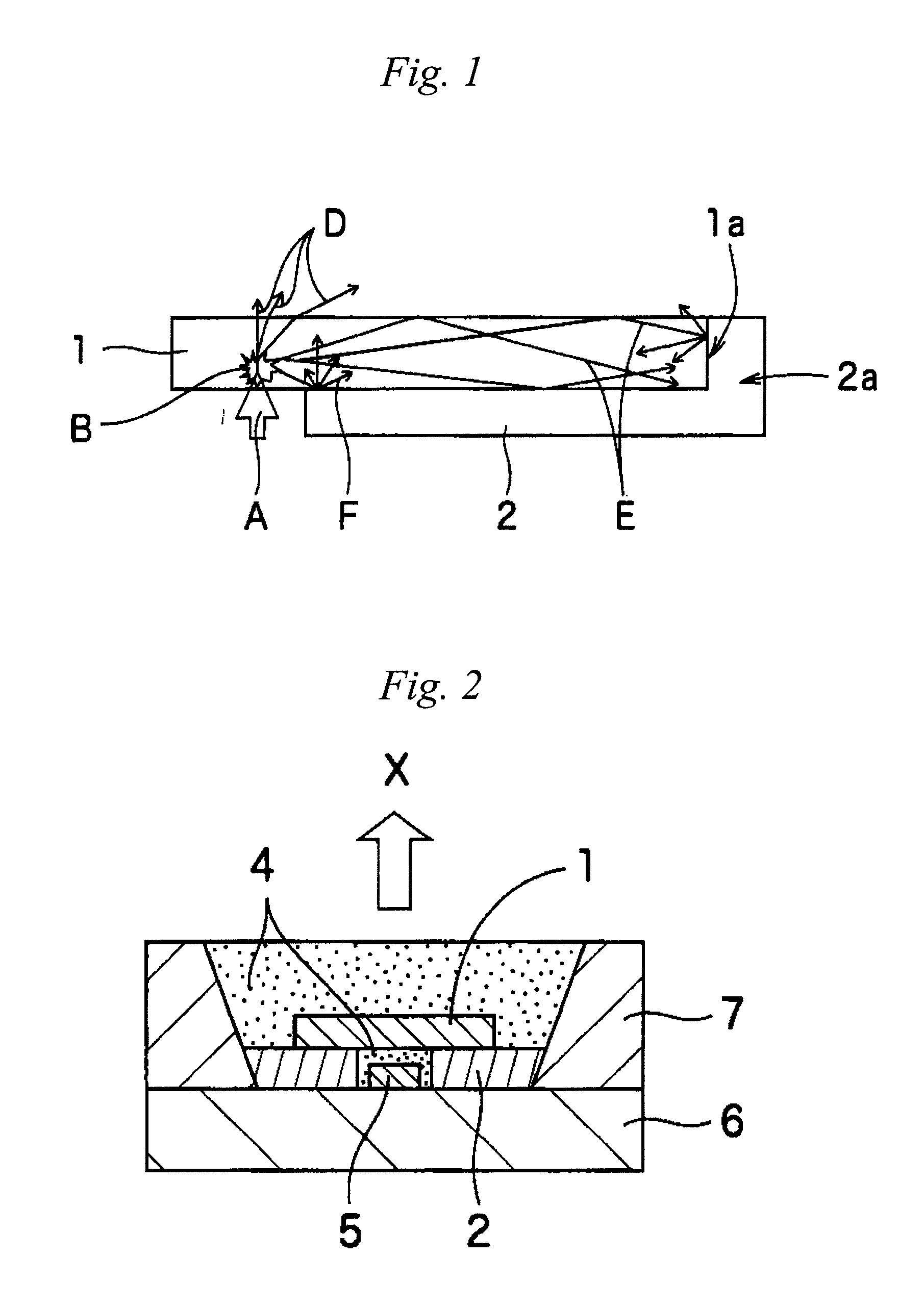

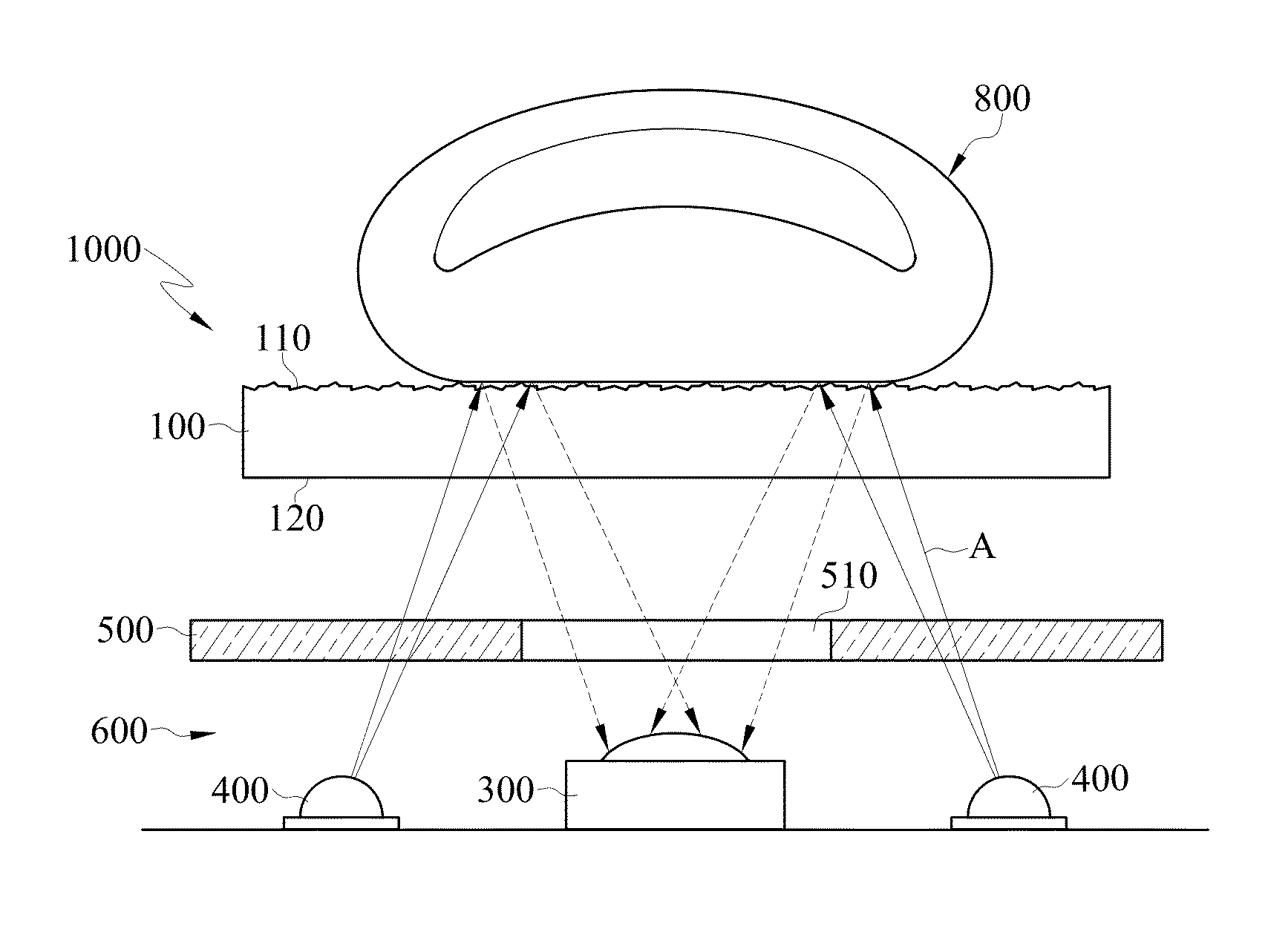

Semiconductor light emitting device

InactiveUS20110309384A1Reduce scatter lightLight extraction efficiency be enhanceSolid-state devicesSemiconductor devicesPhysicsElectricity

The present invention relates to a semiconductor light emitting device including: a substrate for element mounting; a wiring provided on the substrate; an LED element provided on the substrate and electrically connected to the wiring; an encapsulating resin layer for encapsulating the LED element; and a wavelength conversion layer which contains a phosphor material and converts a wavelength of light emitted by the LED element, in which the wavelength conversion layer is provided on an upper side of the LED element, and a diffusive reflection resin layer is provided in a state that side faces of the LED element are surrounded therewith, and an area at the LED element face side of the wavelength conversion layer is at least twice larger by area ratio than an area of light emitting area on an upper surface of the LED element.

Owner:SCHOTT AG

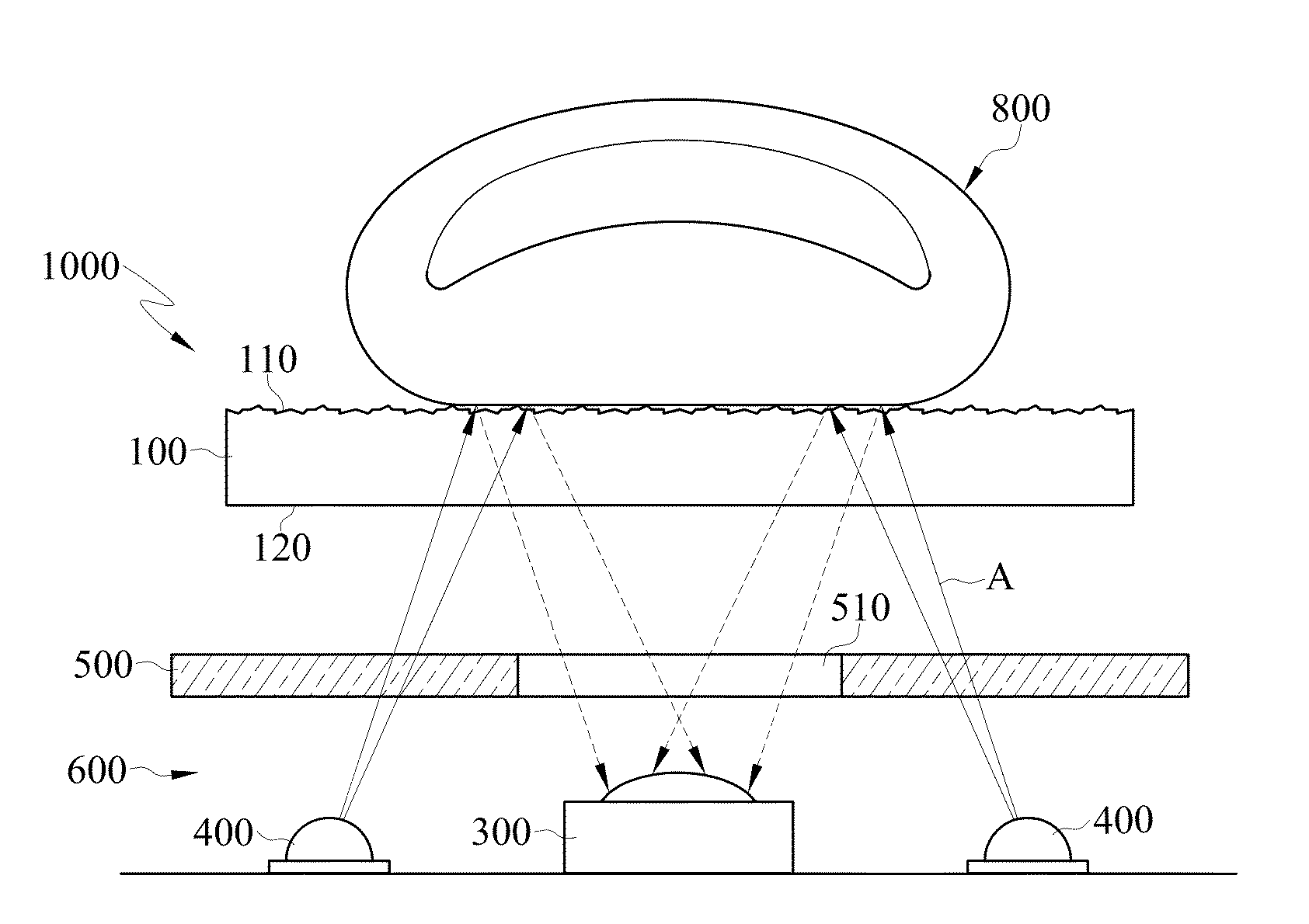

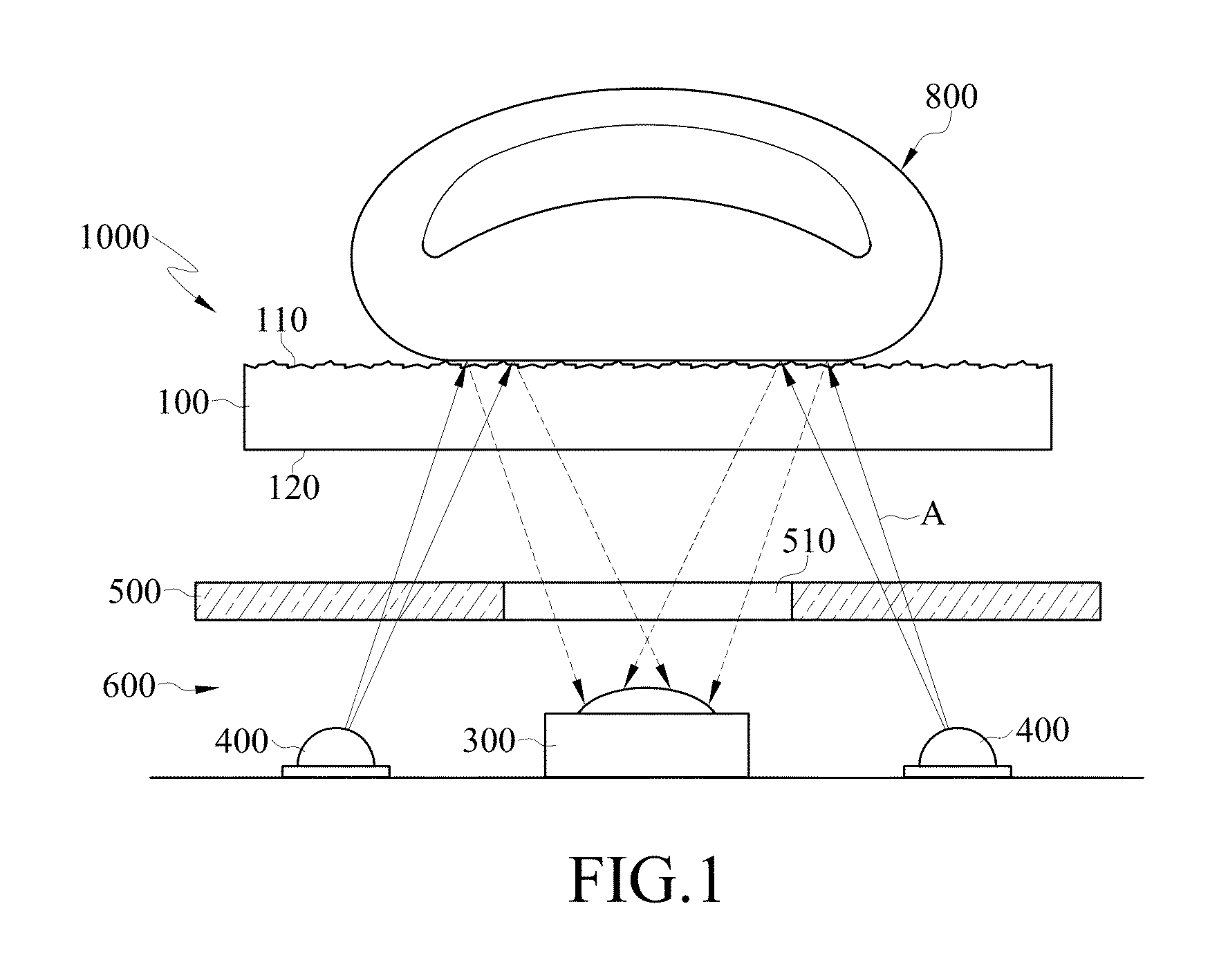

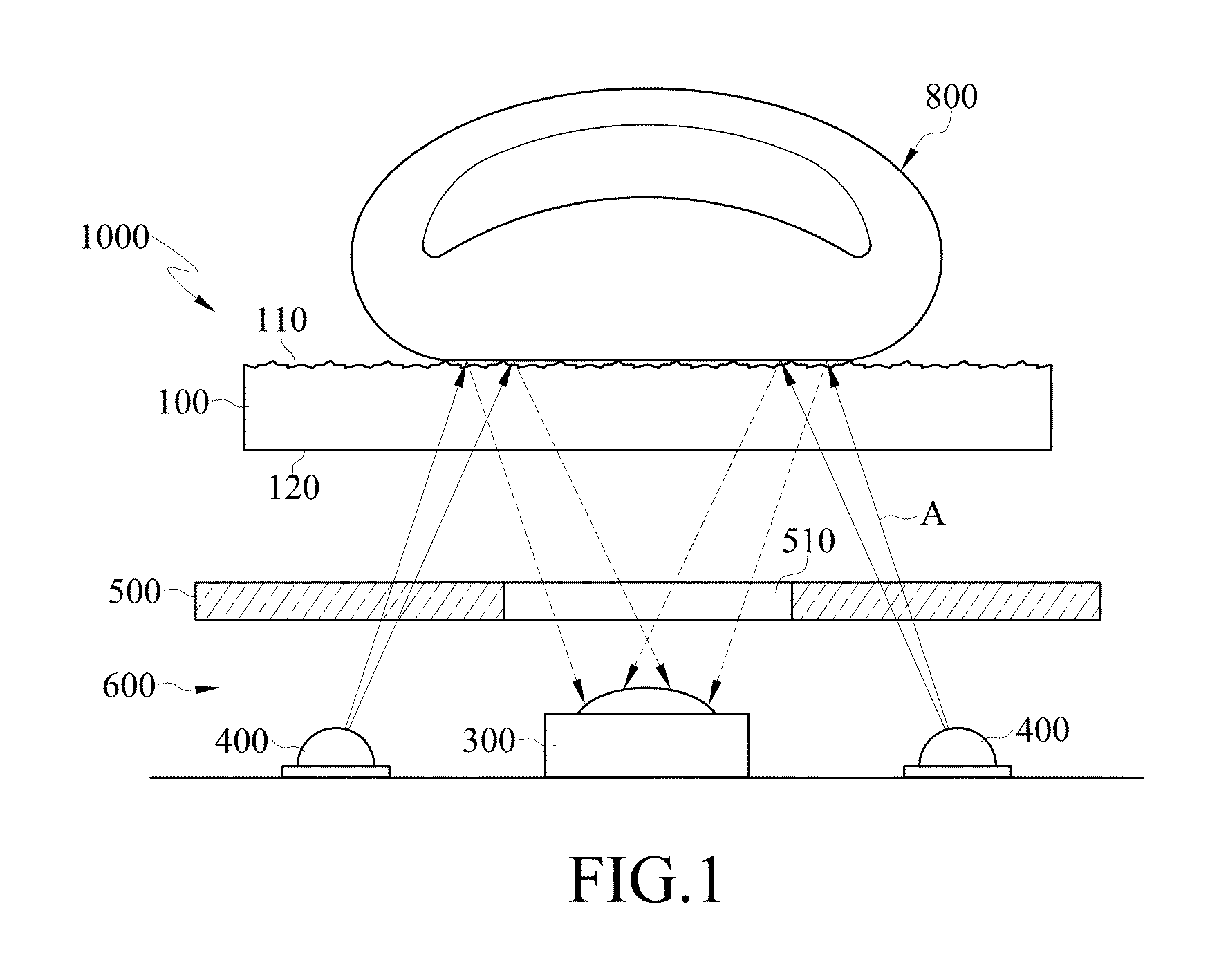

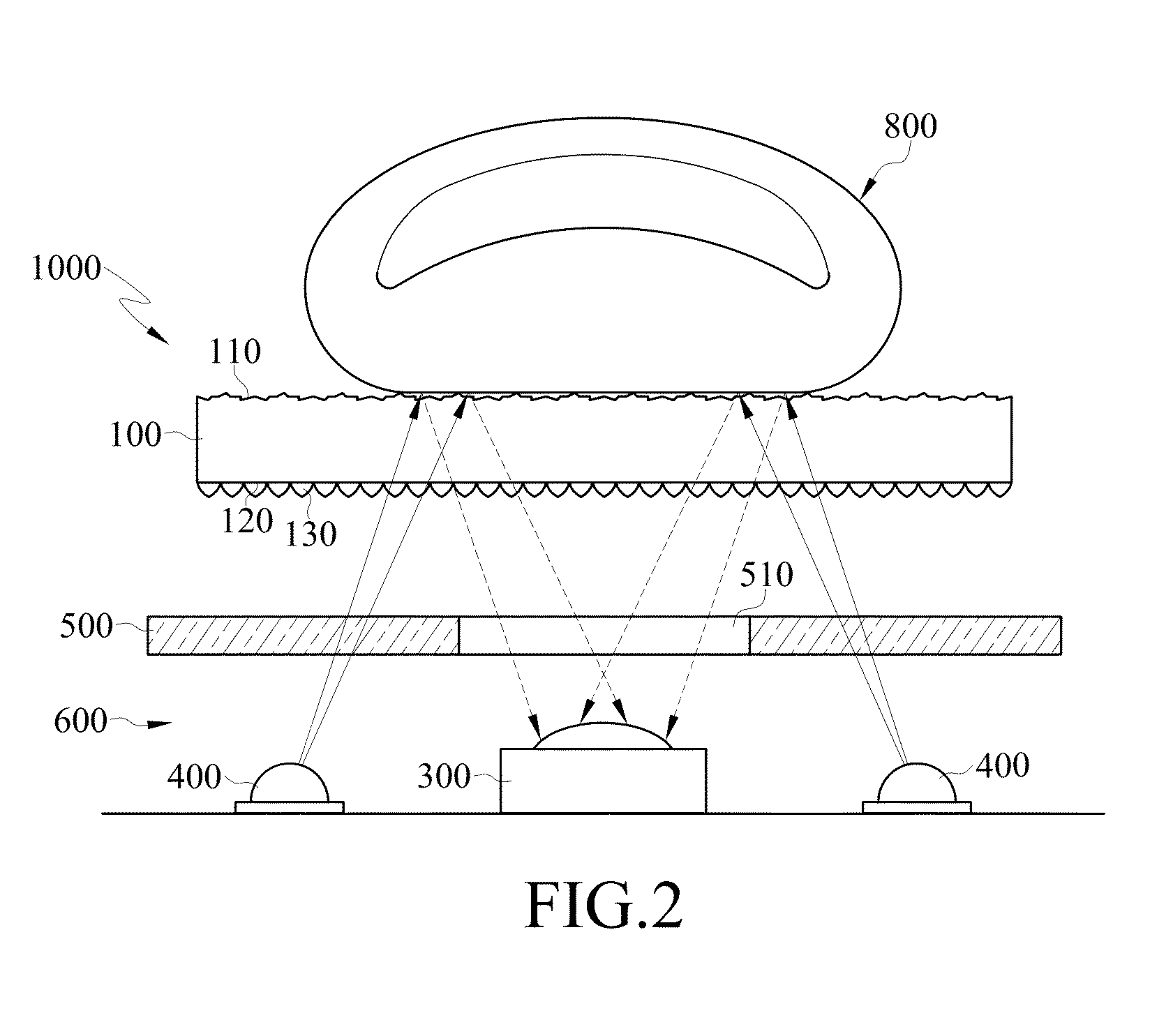

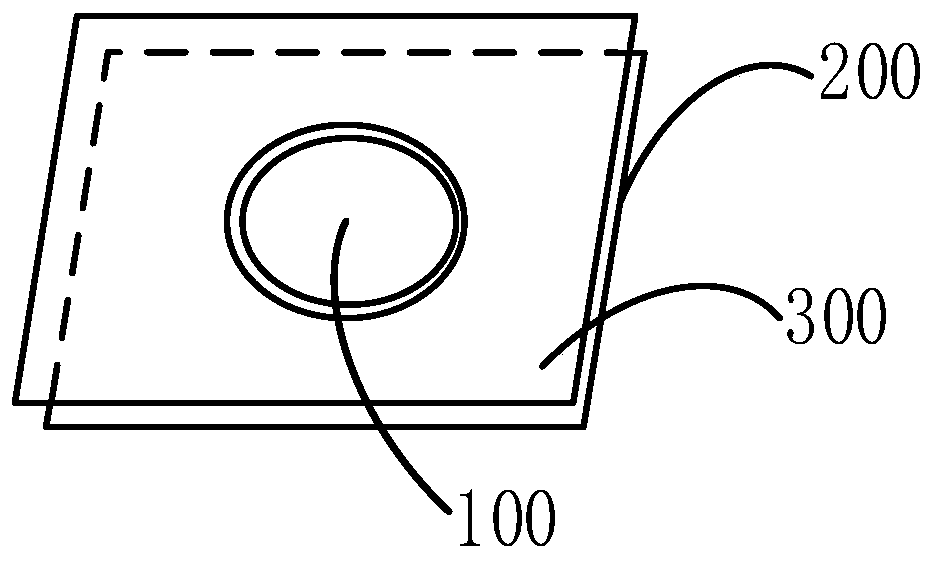

Substrate for fingerprint contact

ActiveUS20130051635A1Increase lighting brightnessWeakening unnecessary scattered lightAcquiring/reconising fingerprints/palmprintsFingerprintScattered light

A substrate for fingerprint contact includes a plate, and the plate includes a first surface and a second surface. The first surface is an optical diffusing surface. The optical diffusing surface is used for being contacted by a finger, and features hazed particles. The second surface faces an optical imaging system. The optical diffusing surface of the plate helps to enhance light to be evenly emitted to the finger and weakens the unnecessary scattered light to the optical imaging system, so as to enhance the recognition rate of a fingerprint when the optical imaging system is used for intercept the light applied on a finger.

Owner:GINGY TECH

Optical filter, solid state image-capturing device using same, and camera module using same

ActiveCN103858028AReduce scattered lightExcellent transmittance characteristicsMethine/polymethine dyesSolid-state devicesFluorescenceTransmittance

The present invention addresses the problem of providing an optical filter having exceptional transmittance characteristics in which the drawbacks of conventional near-infrared-cutting filters and other optical filters are overcome, and light scattering is minimal even during light absorption. This optical filter is characterized by containing a squarylium compound and a compound for absorbing or quenching fluorescence. This optical filter preferably contains a near-infrared absorbing dye that contains a squarylium compound (A), and at least one compound (B) selected from the group consisting of a phthalocyanine compound (B-1), and a cyanine compound (B-2).

Owner:JSR CORPORATIOON

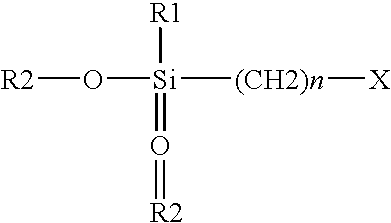

Coating composition and optical mar-resistant tintable coating

ActiveUS20080047468A1Improve clarityHigh transparencyFibre treatmentPretreated surfacesDye absorptionOligomer

A coating composition and coating for ophthalmic lenses and other polymeric substrates having a unique combination of excellent solution stability, rapid cure rate, improved mar resistance, rapid dye absorption, and improved receptivity towards antireflective coatings. The coating comprises an abrasion resistant polymer and a dye-absorption-enhancing oligomer. The coating is tinted after curing with a dye to provide light absorbency in the coating.

Owner:COBURN TECH INT

Substrate for fingerprint contact

ActiveUS8649001B2Difficult to recognizeEnhanced light scatteringAcquiring/reconising fingerprints/palmprintsFingerprintScattered light

Owner:GINGY TECH

Grid for radiography, radiation image detector, radiation imaging system, and method for manufacturing grid

InactiveCN102590913APrevent proliferationReduce vignettingDiffraction gratingsTomographyEtchingX-ray

Owner:FUJIFILM CORP

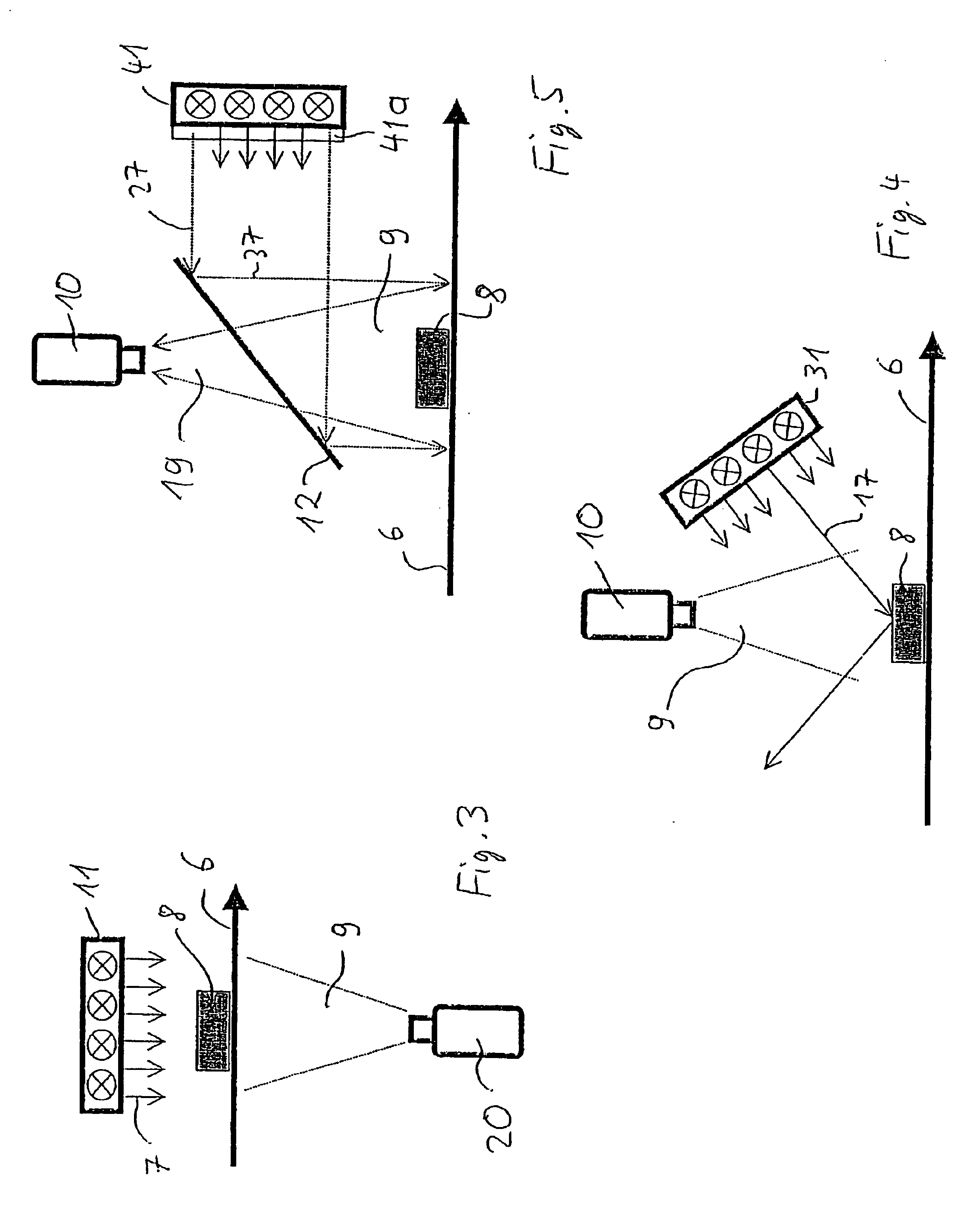

Compact Paramagnetic Oxygen Sensor

ActiveUS20110304322A1High sensitivityShorten arm lengthSusceptibility measurementsMaterial magnetic variablesMagnetic susceptibilityPhotovoltaic detectors

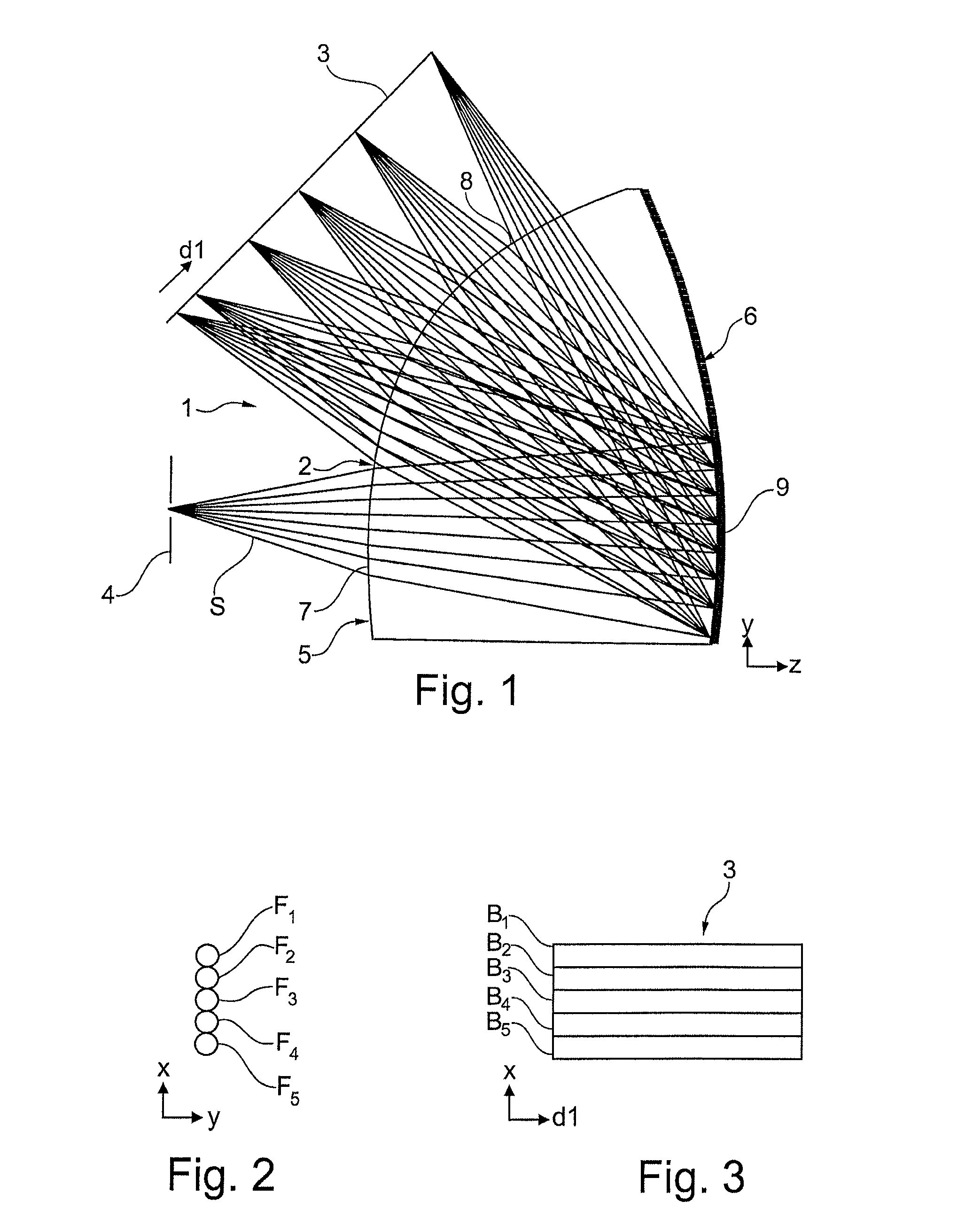

An apparatus for the measurement of the magnetic susceptibility of a gas mixture comprises: a gas sample chamber (8) adapted to receive the gas mixture, and a test body (1) rotatably suspended within the gas sample chamber; means (10) for creating an inhomogeneous magnetic field within the gas sample chamber; means for detecting rotational motion of the test (body 1), comprising a compact optical system including a light source (12) and photodetectors (13) arranged to detect a light signal indicative of the rotational motion; and an actuation system (4) arranged to keep the test body (1) substantially at a null position determined by said optical system, wherein the optical system comprises at least one photodetector (13) positioned on either side of the plane which is normal to the mirror and parallel with the rotation axis of the test body, having the light source (12) positioned in the plane. For enhanced performance, an optical element (16) is placed in front of the light source or photodetectors to modify properties of the light emitted by the light source or received by the photodetectors.

Owner:SERVOMEX GRP LTD

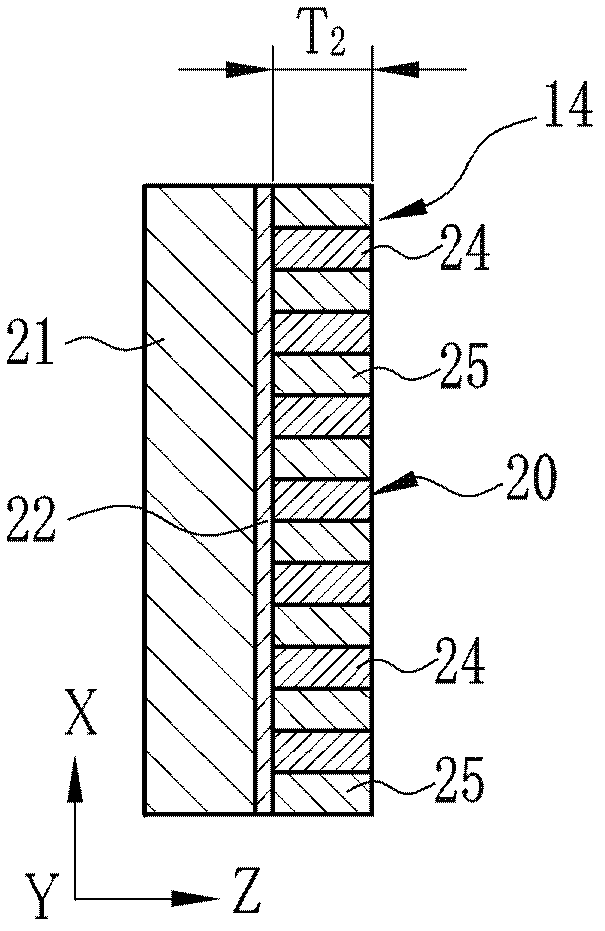

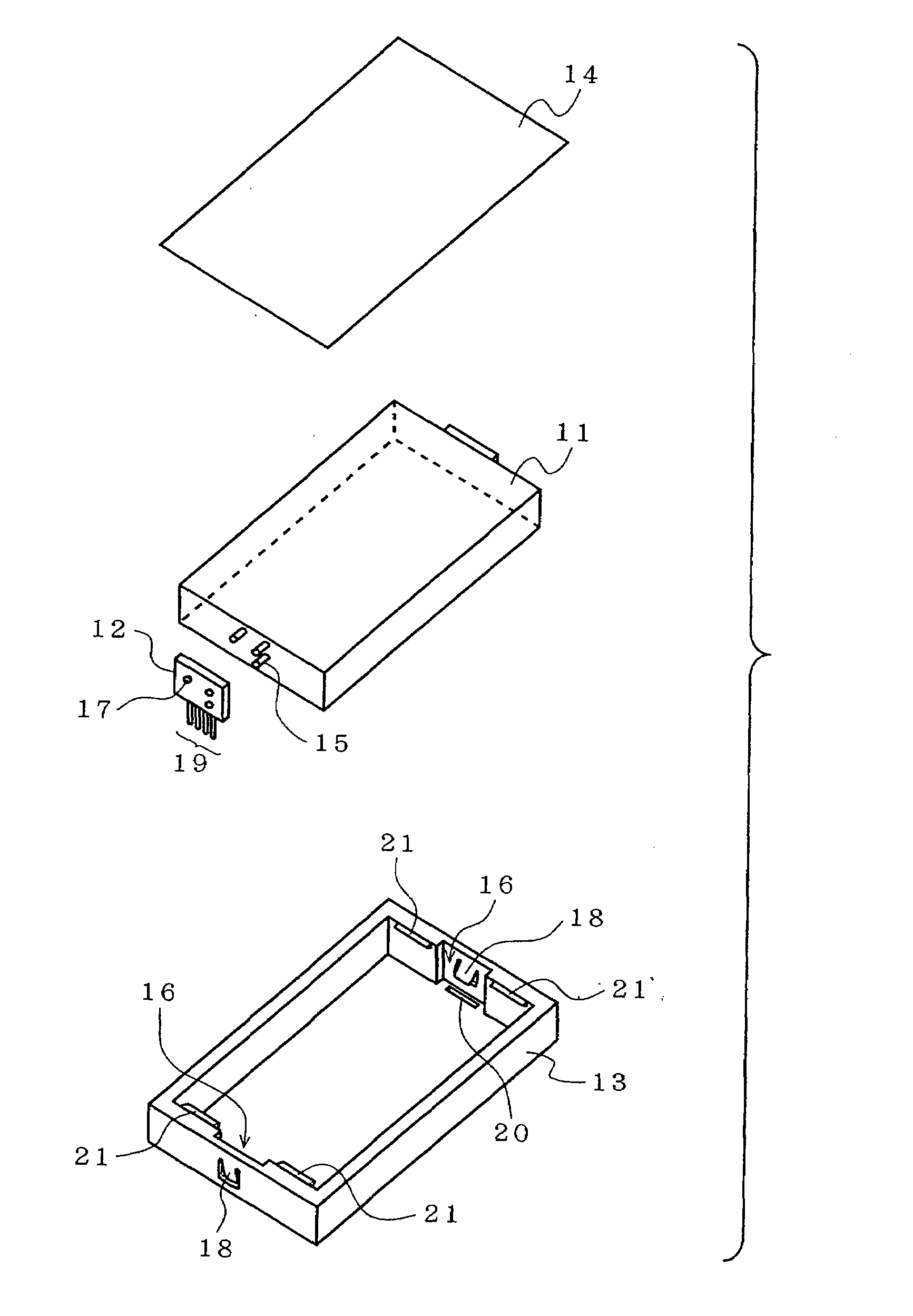

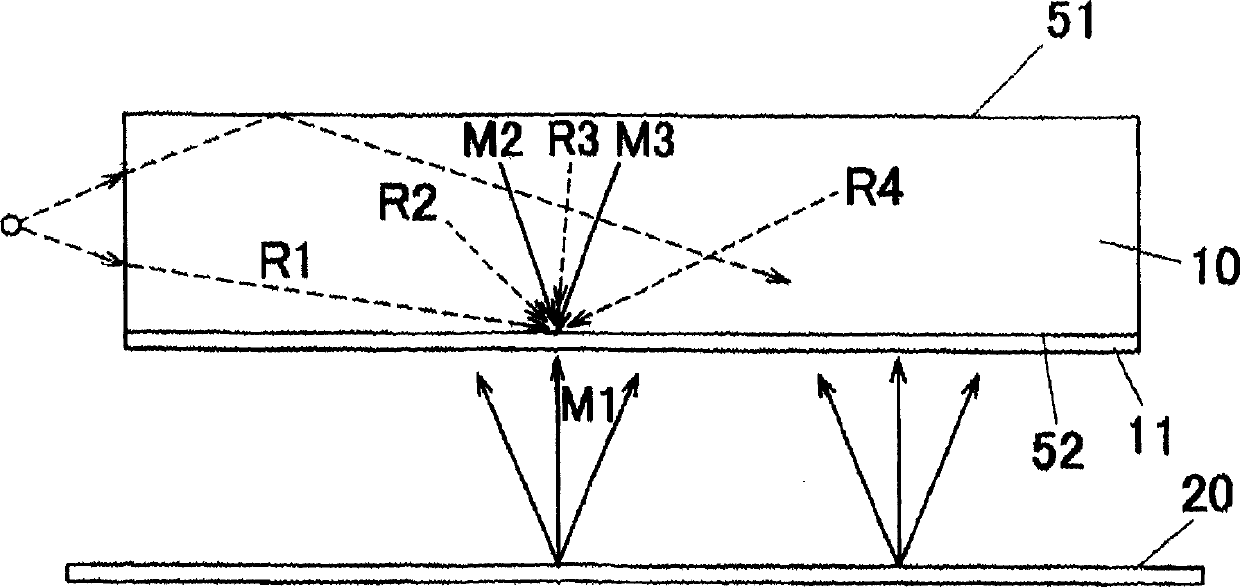

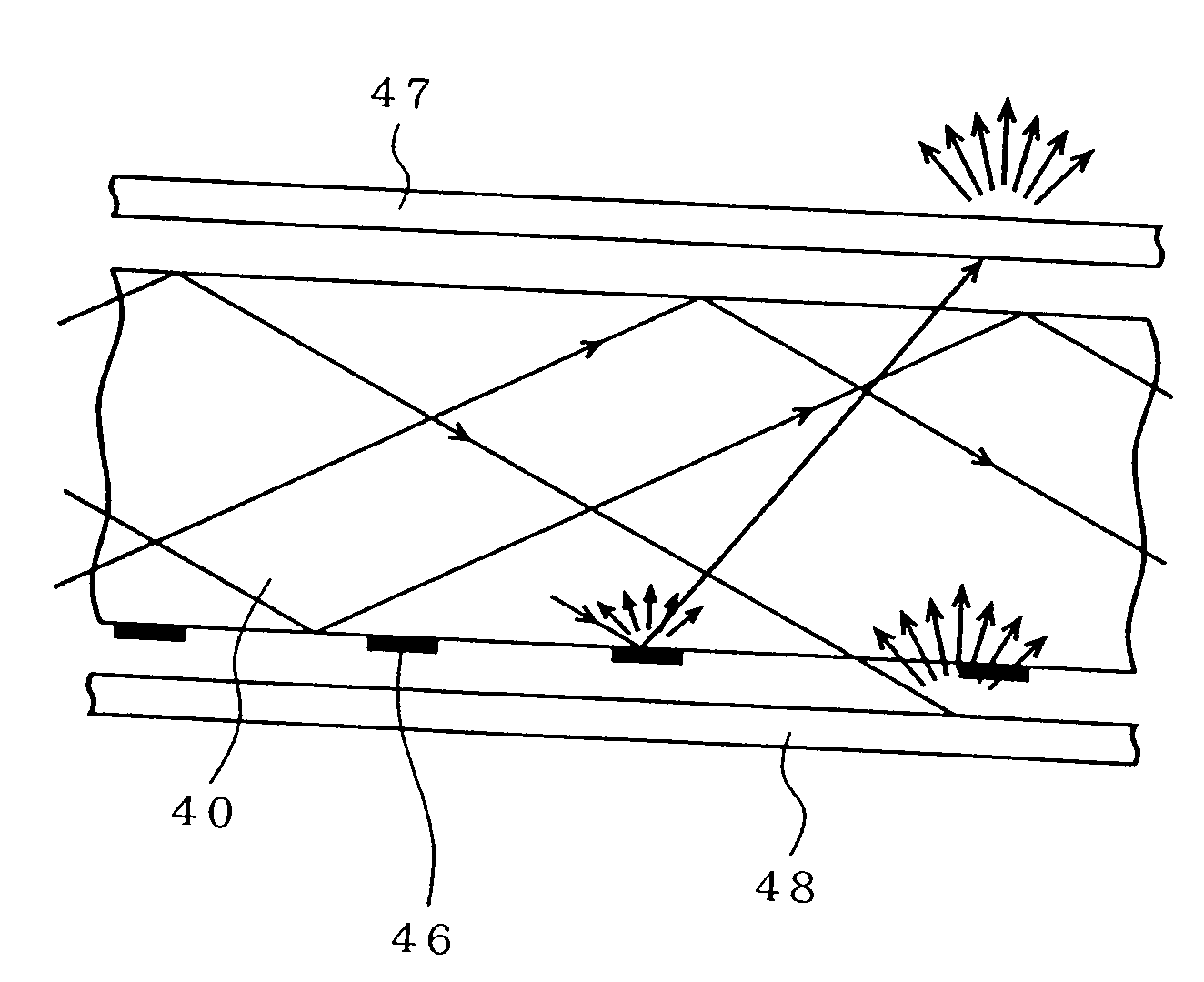

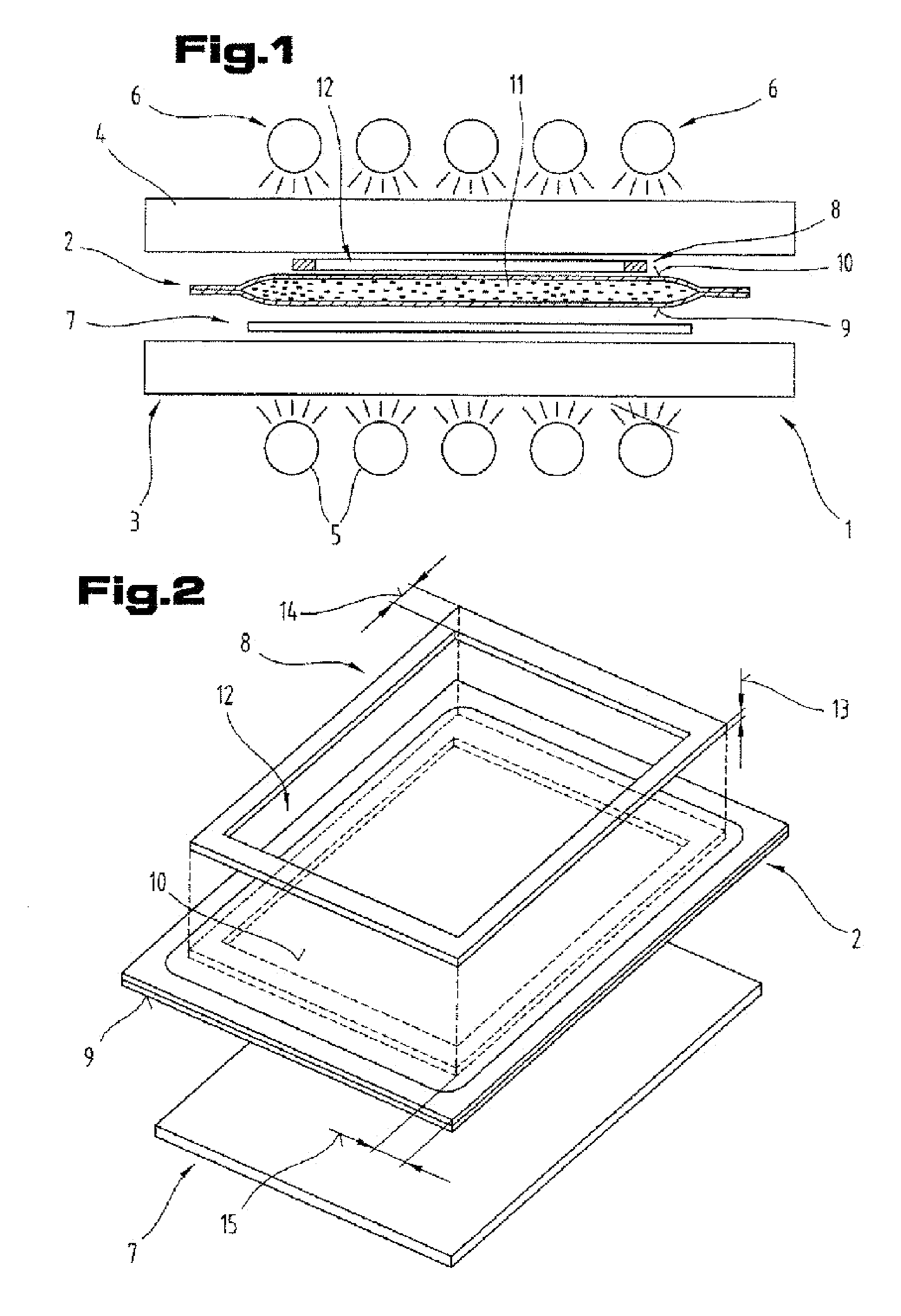

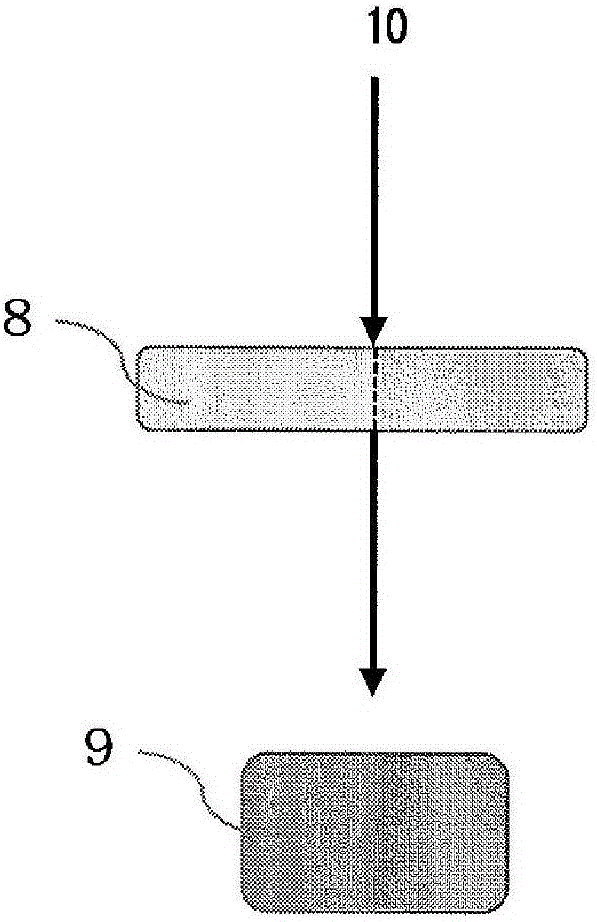

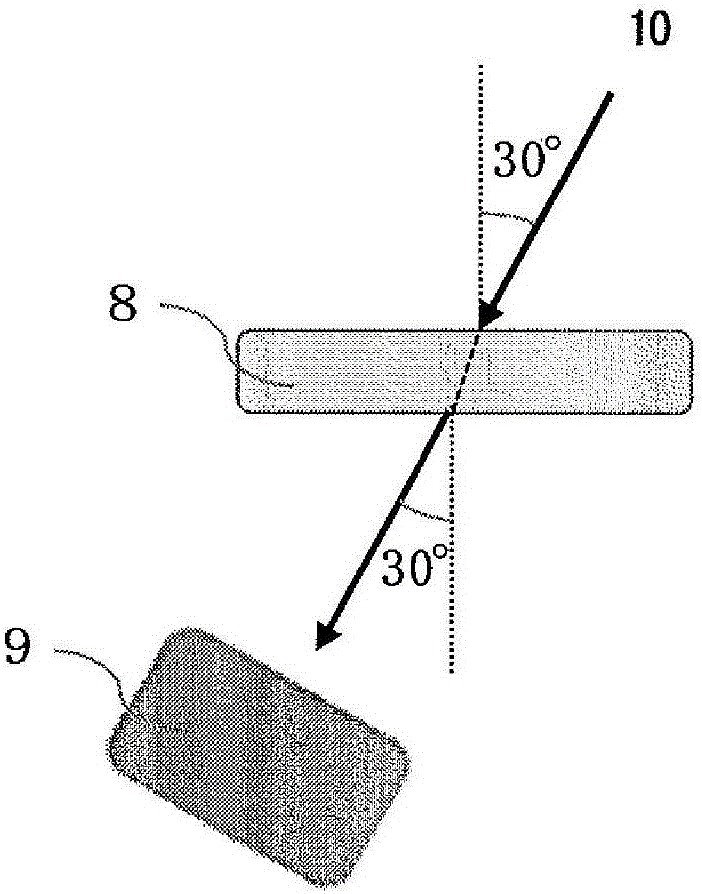

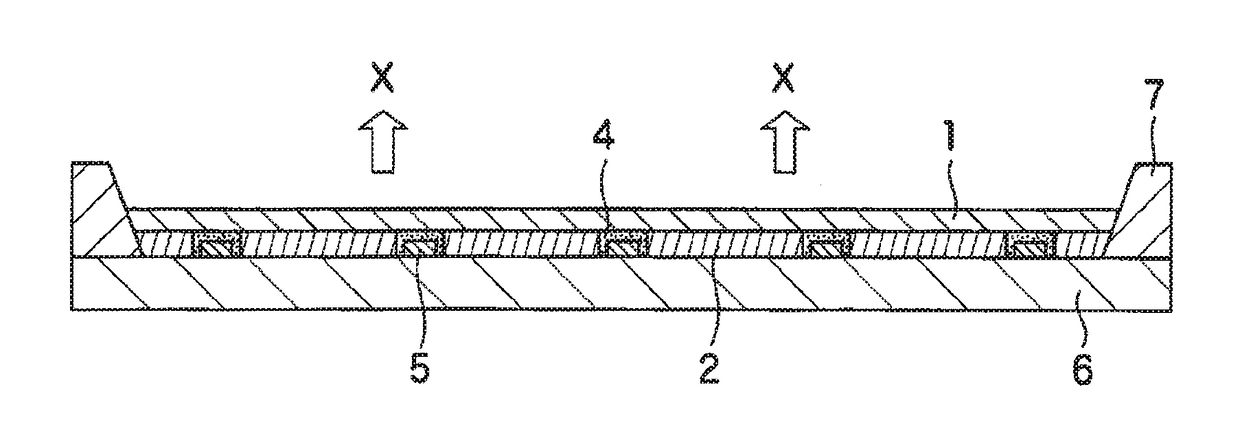

Light-guide plate, area light source apparatus and image reading apparatus

InactiveUS20080285305A1Simple moldingMade thinnerMechanical apparatusLight guides for lighting systemsLight guideWork product

An LED module is mounted on a case frame by fitting three pins formed at a concave portion of the case frame, into holes in the LED module corresponding to the pins. A light-guide plate is fitted into the case frame formed integrally with a bottom cover in a descending direction. The light-guide plate is fixed by a hook provided for the case frame. A space between the light-guide plate and the LED module is prevented by pressing the light-guide plate to the LED module with a pressing spring. Since the light-guide plate is fitted into the case frame in the descending direction and a light scattering sheet is adhered to an outer end surface of the case frame in the descending direction, it is not necessary to reverse the worked product and so the number and time of working processes can be saved.

Owner:NIPPON SHEET GLASS CO LTD

Optical element, light guiding plate, backlight source and LCD device for synthetizing hologram by computer

InactiveCN1680854AAvoid it happening againQuality improvementMechanical apparatusPoint-like light sourceComputer science

Owner:SUMITOMO CHEM CO LTD

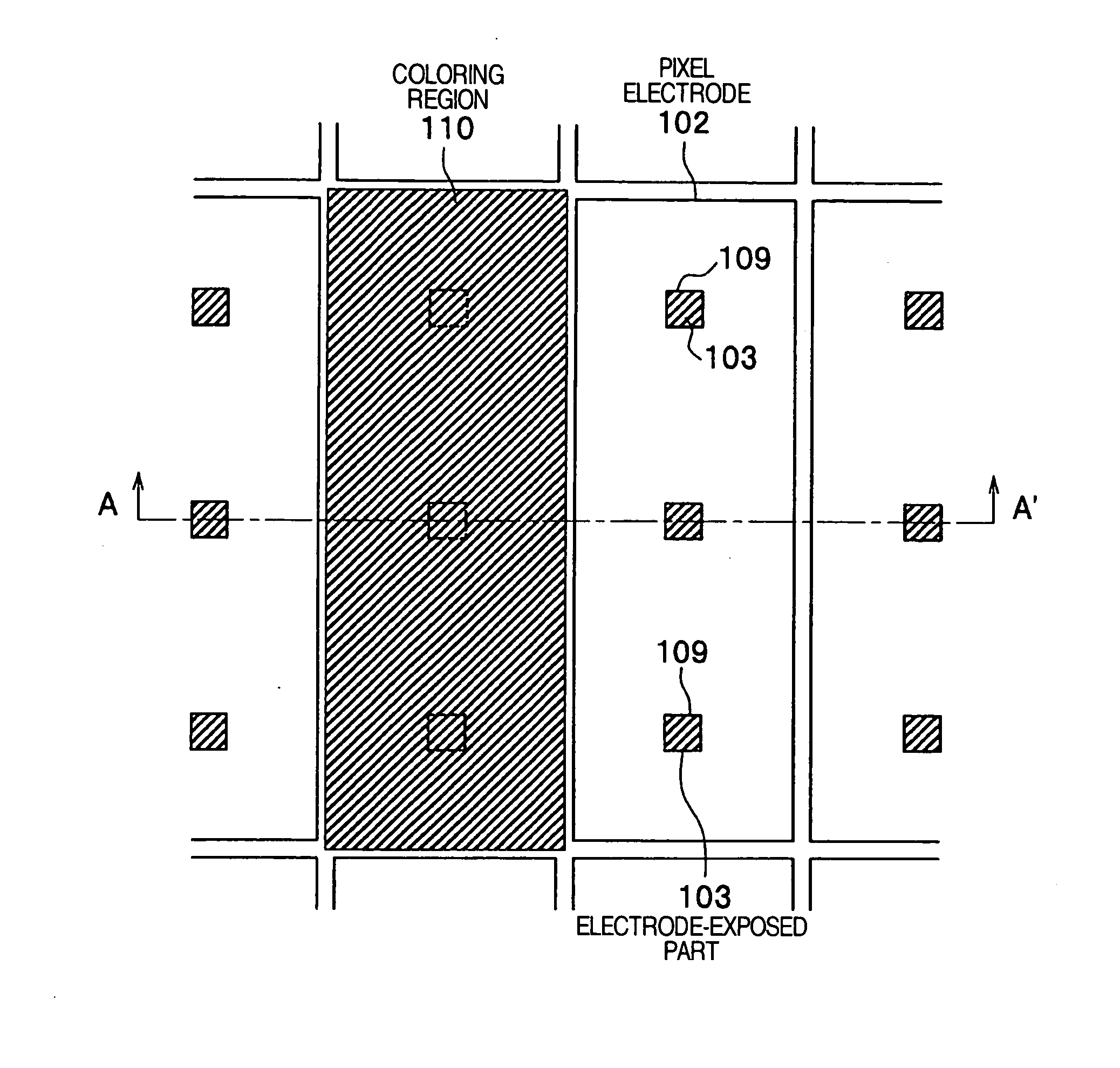

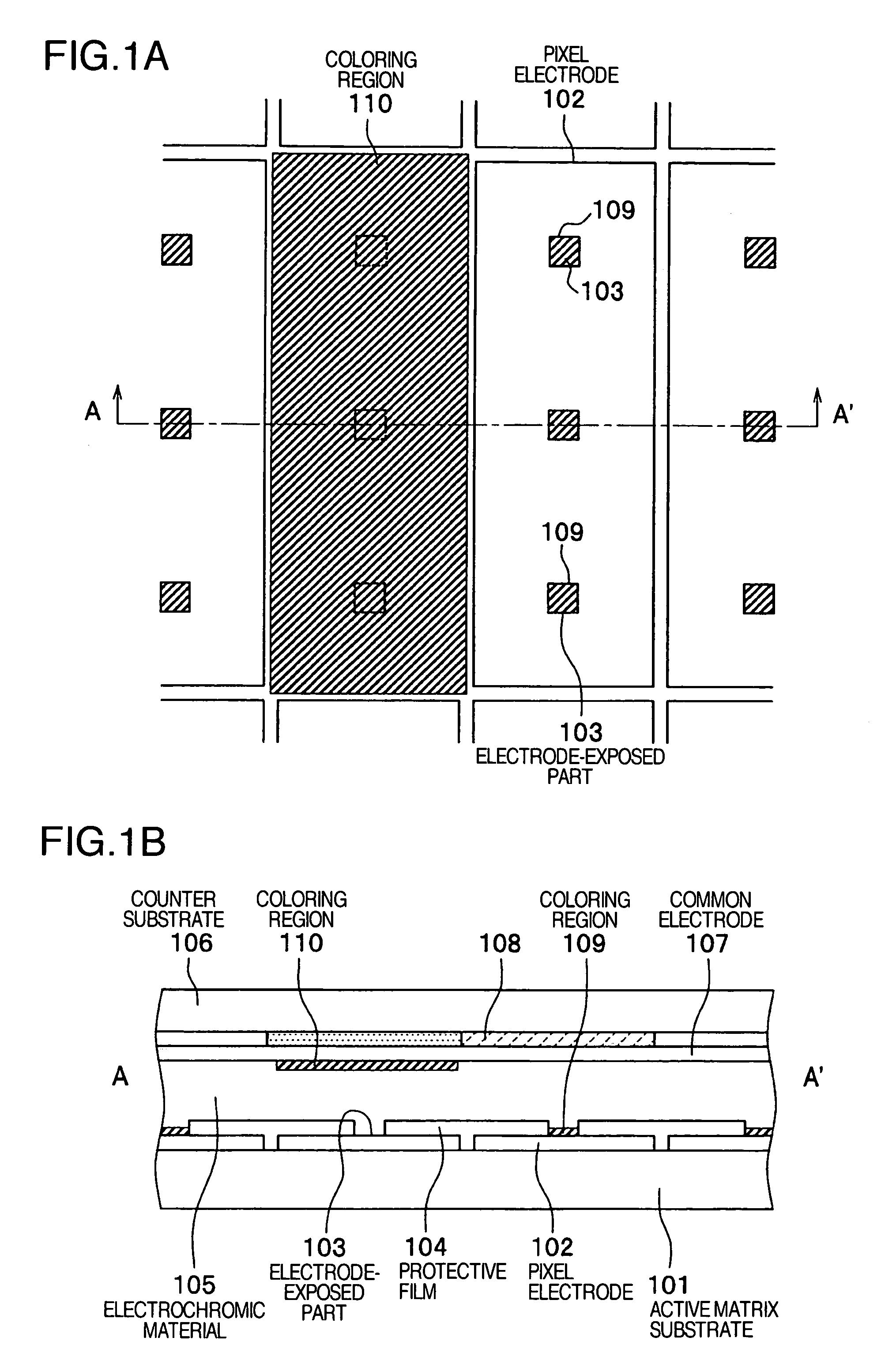

High-definition pixel structure of electrochromic displays and method of producing the same

ActiveUS20070002424A1Reduce scattered lightReduce layer thicknessStatic indicating devicesNon-linear opticsTectorial membraneActive matrix

A display of an electrochromic type, including an active matrix substrate on which a plurality of pixel electrodes corresponding to pixels are arranged in a matrix form; a counter substrate which is provided with a transparent electrode that is common with respect to a plurality of the pixel electrodes; and an electrochromic material which is sandwiched between the active matrix substrate and the counter substrate, and is colored in a boundary either between itself and the pixel electrode or between itself and the transparent electrode; wherein the pixel electrode other than an electrode-exposed part which contacts with the electrochromic material is covered with a transparent protective film; and the electrode-exposed part has a different area from the area of the part onto which a current generated between the transparent electrode and the pixel electrode concentrates, out of the transparent electrode.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

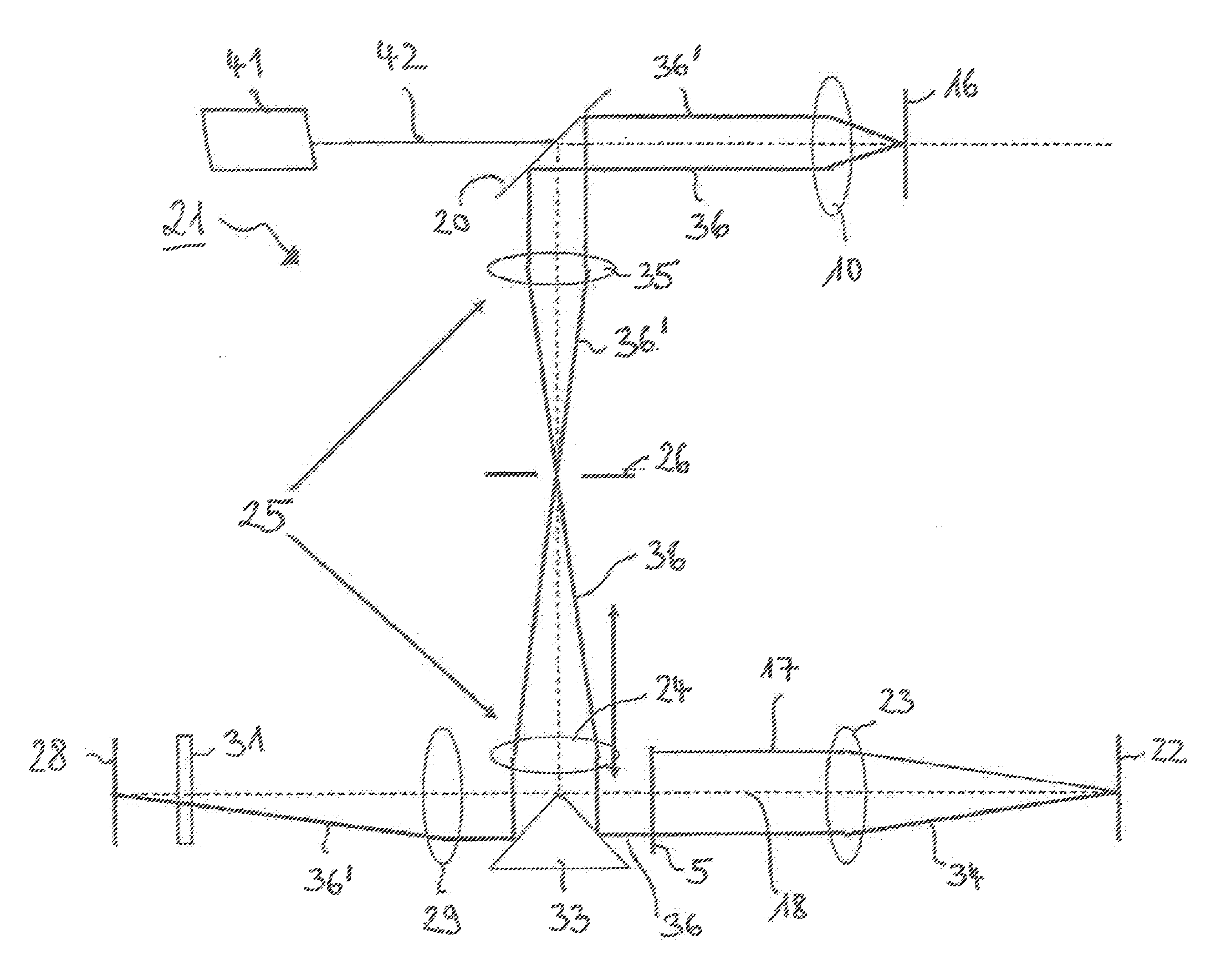

Autofocusing Device for Microscopes and Suitable Autofocus Aperture Stops

ActiveUS20110317260A1Improve signal-to-noise ratioAccurate measurementMicroscopesOptical axisLight beam

The present invention relates to an autofocus aperture stop (5, 6) in a triangulating autofocusing device (21) for a microscope (40), wherein the autofocus aperture stop (5, 6) comprises at least one diaphragm opening (3, 4) with which a measuring beam pencil (34) used for the autofocusing and running in the direction of the optical axis (18) of the autofocusing device (21) can be limited in its cross section, wherein the diaphragm opening (3, 4) of the autofocus aperture stop (5, 6) is arranged in a decentred position at a spacing from the optical axis (18) of the autofocusing device (21), wherein a decentred autofocus measuring beam (36) can be generated by the diaphragm opening (3, 4) in one half of the cross section (17) of the measuring beam pencil (34).

Owner:LEICA MICROSYSTEMS CMS GMBH

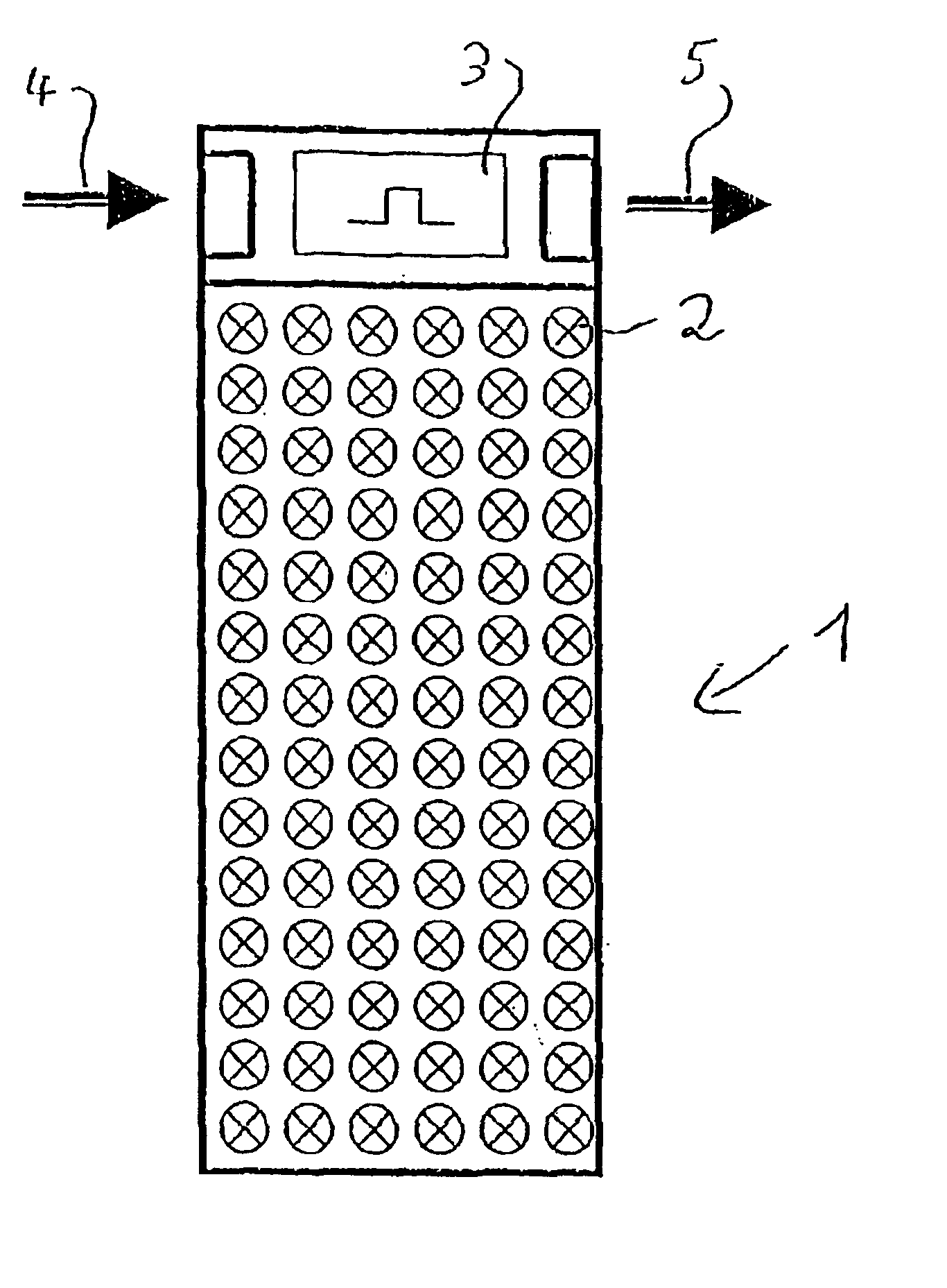

Illuminating unit for an article-sensing camera

InactiveUS6885393B2Accurate image captureImprove lighting qualityControl devices for conveyorsColor television detailsIndividual itemEngineering

A conveying system includes a conveyor for advancing items thereon; and an image-capturing apparatus for detecting individual items on the conveyor and for generating image signals representing an image of the items. The image-capturing apparatus includes an illuminating unit formed of a matrix composed of a plurality of light-emitting diodes; a picture-capturing unit for receiving light rays emitted by the matrix and modified by an item situated in a path of the light rays and for generating the image signals; and a control unit connected to the matrix and the picture-capturing unit for a pulsed illumination of the matrix.

Owner:ROBERT BOSCH GMBH

Microscopic cell observation and inspection system using a plurality of observation methods

InactiveUS7706060B2Quick checkImprove signal-to-noise ratioMaterial analysis by optical meansMicroscopesMicroscope slideTotal internal reflection

Owner:HAMAMATSU UNIV SCHOOL OF MEDICINE +1

Optical scanning device and laser radar

PendingCN110045498AImproved receiver detection capabilitiesReduce scattered lightFluid pressure measurement by electric/magnetic elementsElectromagnetic wave reradiationBlind zoneRadar

The application relates to an optical scanning device and a laser radar. The optical scanning device comprises a mirror, a mirror substrate, and an matte member; the mirror is disposed on the mirror substrate, and the matte member is disposed at the front of the mirror substrate; the mirror is used for reflecting an incident light; and the matte member is used for reducing a scattered light generated by the incident light on the mirror substrate. The optical scanning device can greatly reduce the scattered light inside the laser radar, and reduce the detection blind zone caused by the stray light; therefore, the detection capability of the laser radar is greatly improved.

Owner:SUTENG INNOVATION TECH CO LTD

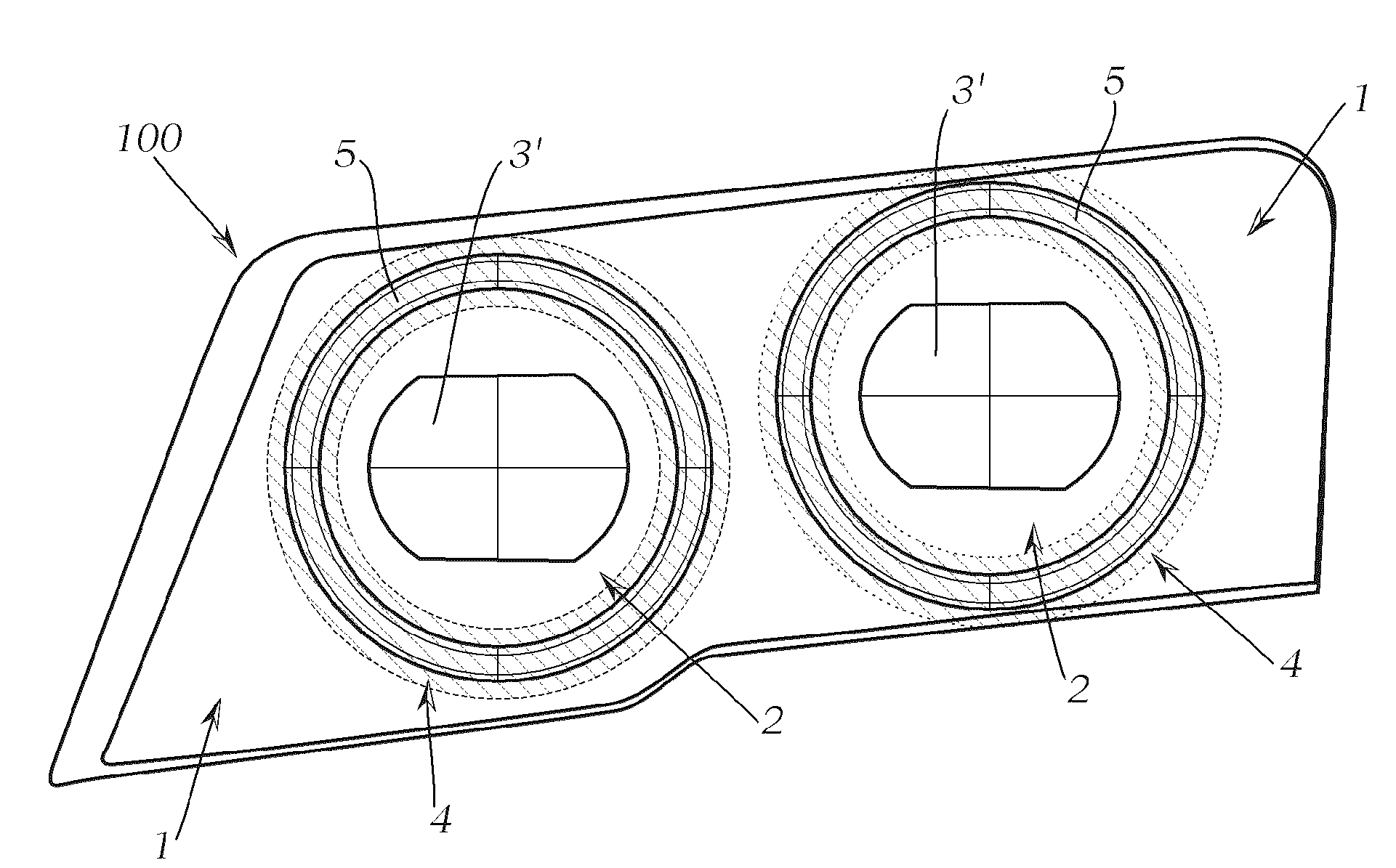

Vehicle headlamp for generating a main light distribution and an additional light distribution

ActiveCN103225780ANo scatteringReduce reflectionVehicle headlampsOptical signallingLight-emitting diodeHeadlamp

The invention relates to a vehicle headlamp. The vehicle headlamp comprises a light emitting unit which produces main light and which comprises a light source and lenses. When the light emitting unit is mounted in a vehicle, the lenses are used as main light distribution so that the light emitted by the light source is projected as main light distribution on the area ahead of vehicle. A supplementary light emitting unit for generating supplementary light distribution is also included. The supplementary light emitting unit is arranged in a manner in which the light or the area of the light of the supplementary light emitting unit is close to the lens of the main light emitting unit. According to the invention, anti-reflection coating is disposed on the at least prost of the light incoming surface of the lens of the main light emitting unit. And / or anti-reflection coating is disposed on the at least prost of the light outgoing surface of the lens of the main light emitting unit. And the supplementary light emitting unit is connected in the operation of the main light.

Owner:ZKW GRP GMBH

Light-guide plate, area light source apparatus, and image reading apparatus

InactiveUS20070159806A1Reduce processing timeReduce the number of productsMechanical apparatusGlobesLight guideEngineering

An LED module is mounted on a case frame by fitting three pins formed at a concave portion of the case frame, into holes in the LED module corresponding to the pins. A light-guide plate is fitted into the case frame formed integrally with a bottom cover in a descending direction. The light-guide plate is fixed by a hook provided for the case frame. A space between the light-guide plate and the LED module is prevented by pressing the light-guide plate to the LED module with a pressing spring. Since the light-guide plate is fitted into the case frame in the descending direction and a light scattering sheet is adhered to an outer end surface of the case frame in the descending direction, it is not necessary to reverse the worked product and so the number and time of working processes can be saved.

Owner:FUJINO KOUZOU +2

Photopolymer assembly

ActiveUS20100035002A1Improve accuracyConvenient lightingLayered productsNanoinformaticsPhotopolymerElectromagnetic radiation

The invention relates to an element, in particular a photopolymer unit, with a rear layer and a top layer which are joined to one another to form a sealed bag in which a precursor of a plastic which can be polymerised with electromagnetic radiation is contained, in particular a photopolymer. The top layer is made from a cast plastic. The invention further relates to the production of a printing plate from this element.

Owner:TRODAT GMBH

Optical filter for solid-state image pickup device, and solid-state image pickup device and camera module using the same

InactiveCN105754367AReduce scattered lightExcellent transmittance characteristicsMethine/polymethine dyesOptical filtersCyanineTransmittance

The object of the present invention is to provide an optical filter for a solid-state image pickup device, and a solid-state image pickup device and a camera module using the same, which overcome drawbacks of conventional optical filters such as near-infrared cut filters and generate little scatted light even during light absorption and has excellent transmittance property. The optical filter of the present invention is characterized by containing a squarylium-based compound and a compound which absorbs or quenches fluorescence of the squarylium-based compound. The optical filter of the present invention preferably contains a near-infrared absorbing dye containing a squarylium compound (A) and at least one compound (B) selected from the group consisting of a phthalocyanine-based compound (B-1) and a cyanine-based compound (B-2).

Owner:JSR CORPORATIOON

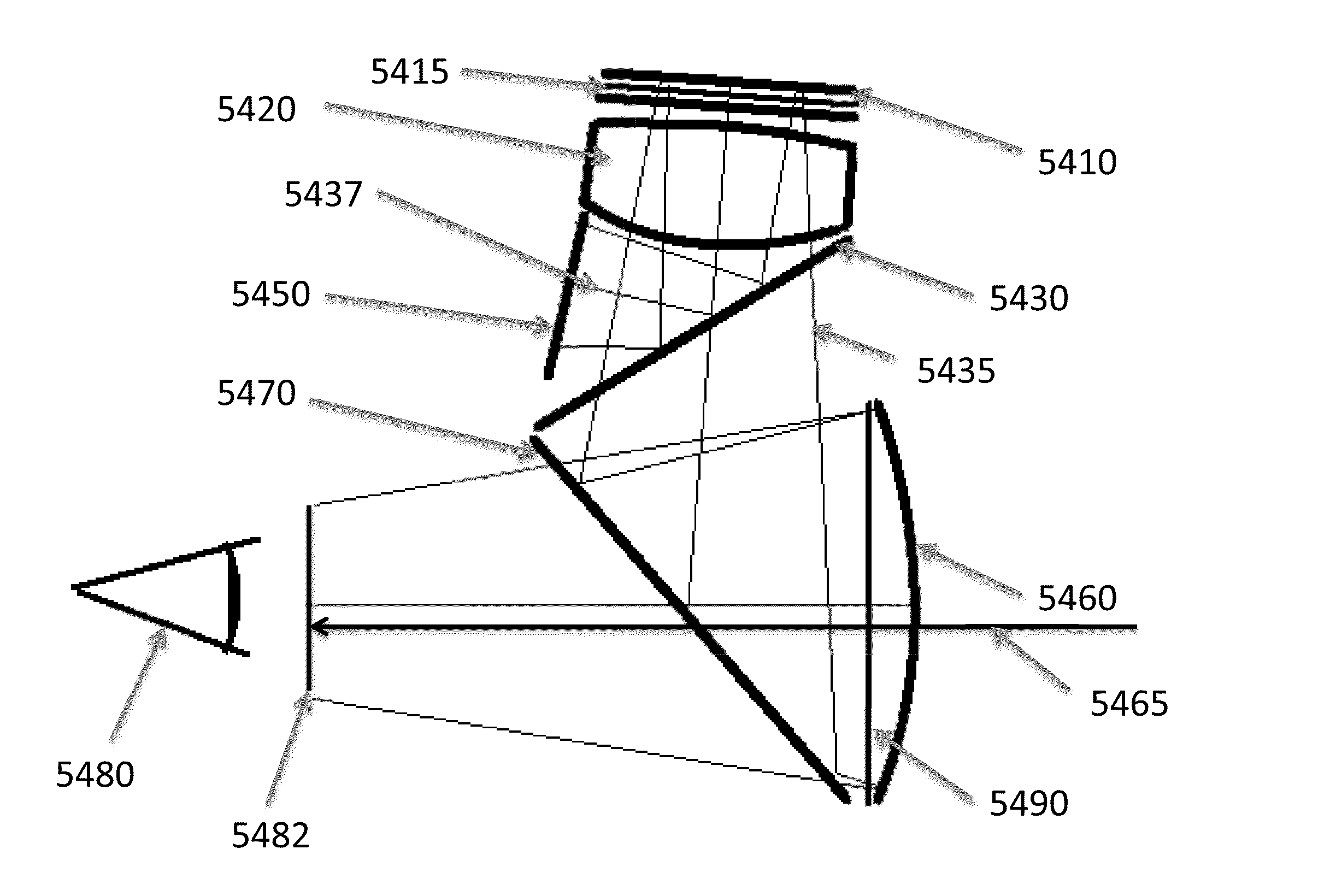

Compact high field of view display

ActiveUS20210033865A1Reduce scattered lightFocal length is lowPolarising elementsLensWide fieldDisplay device

A wide field of view display device employs curved optical components for enhanced performance with a compact arrangement. A wide field of view display includes a curved display device; a first curved lens having a display side and an exit side, wherein the display side is facing the curved display device; a first plurality of Fresnel facets disposed on the display side of the first curved lens; a second curved lens having a display side and an exit side, wherein the display side is facing the exit side of the first curved lens; and a second plurality of Fresnel facets disposed on the display side of the second curved lens, wherein the first plurality of Fresnel facets is configured to focus light from the curved display device on the second plurality of Fresnel facets, and wherein the second plurality of Fresnel facets is configured to focus light from the first plurality of Fresnel facets on a central image point.

Owner:SHARP KK

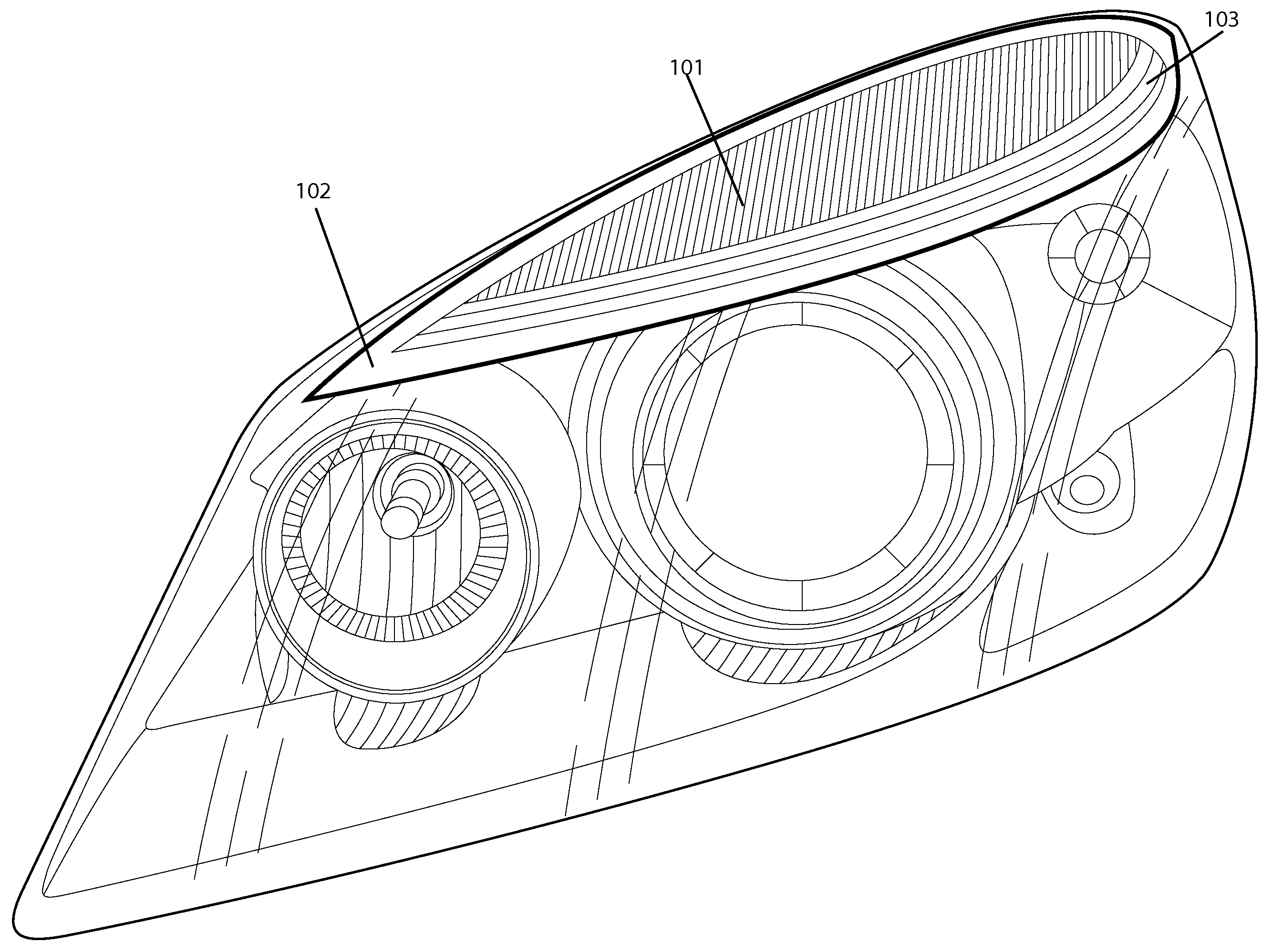

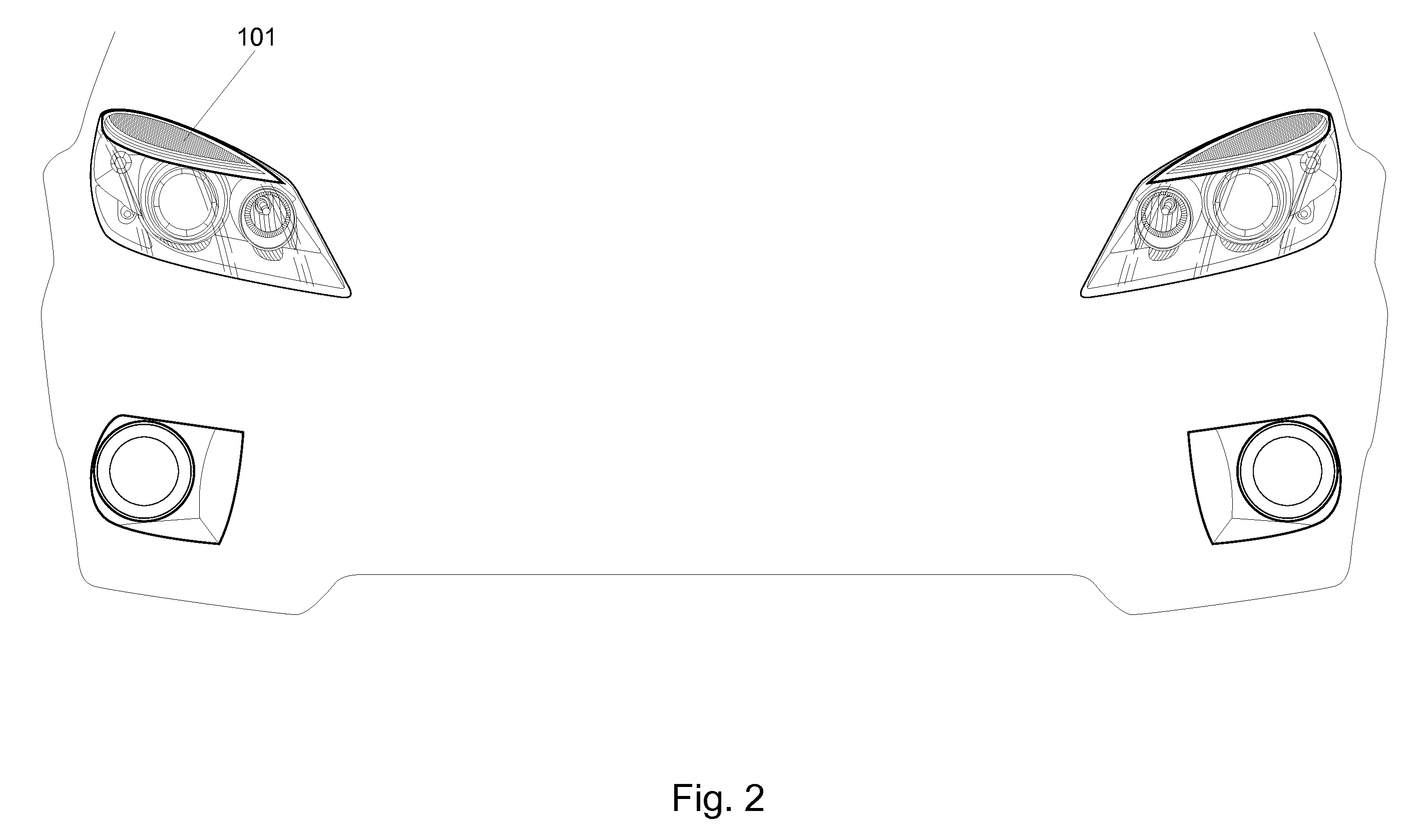

LED Vehicle Eyelid Apparatus

InactiveUS20100177528A1Altering aestheticReducing the vehicle's drag profileLighting support devicesOptical signallingEyelidEngineering

A vehicular LED headlamp eyelid apparatus is disclosed. The vehicular headlamp eyelid apparatus is attached to a vehicle's headlamp and comprises a plurality of LED lights capable of illuminating in patterns signaled by the vehicle. The occlusion resulting from one or more segments of the LED eyelids modifies the overall appearance of the headlamp. The vehicular LED headlamp eyelid is made at least in part of lightweight material such that there results in little impact upon the drag profile of the vehicle.

Owner:LAW CALVIN CHUEN KAM +1

Light-guide plate, area light source apparatus and image reading apparatus

InactiveUS20080123368A1Simple moldingMade thinnerMechanical apparatusLight guides for lighting systemsLight guideWork product

An LED module is mounted on a case frame by fitting three pins formed at a concave portion of the case frame, into holes in the LED module corresponding to the pins. A light-guide plate is fitted into the case frame formed integrally with a bottom cover in a descending direction. The light-guide plate is fixed by a hook provided for the case frame. A space between the light-guide plate and the LED module is prevented by pressing the light-guide plate to the LED module with a pressing spring. Since the light-guide plate is fitted into the case frame in the descending direction and a light scattering sheet is adhered to an outer end surface of the case frame in the descending direction, it is not necessary to reverse the worked product and so the number and time of working processes can be saved.

Owner:NIPPON SHEET GLASS CO LTD

spectrometer

InactiveUS20140233029A1Reduce spendingGood optical performance parameterRadiation pyrometrySpectrum investigationGratingLight beam

A spectrometer with a detector and a transparent body which has an entry area and an exit area on a front side of the body and a reflection grating on a rear side of the body. A beam entering the body via the entry area is reflected at the reflection grating to the exit area and in the process is spectrally split and passes through the exit area and impinges on the detector. The rear side is curved at least in the region of the reflection grating in such a way that the beam is focused in the horizontal and vertical planes when it is reflected at the reflection grating.

Owner:CARL ZEISS MICROSCOPY GMBH

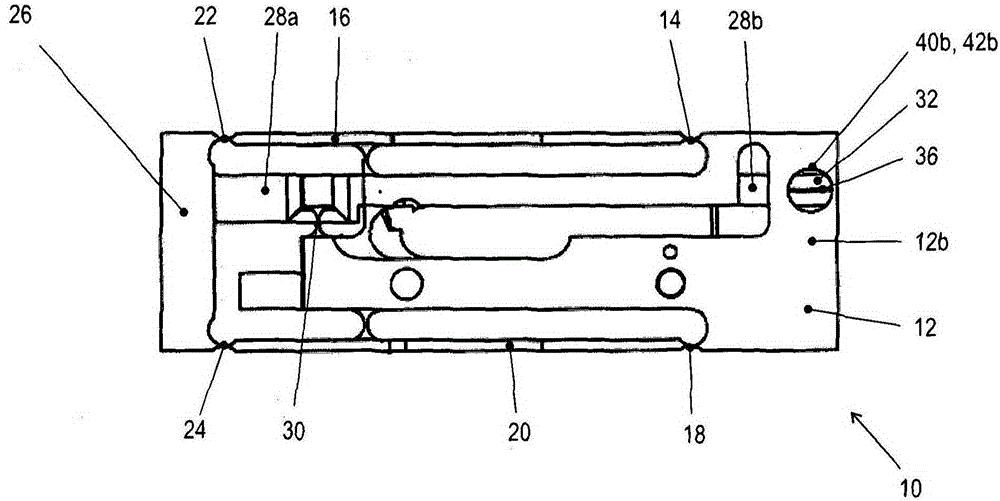

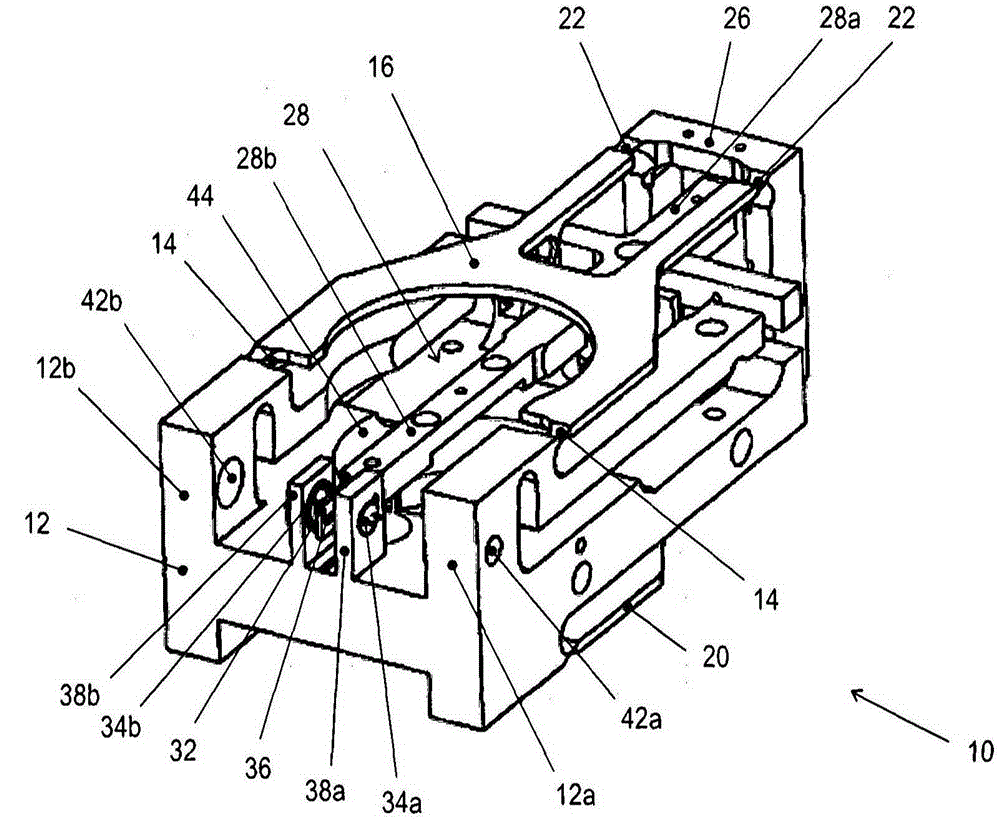

Monolithic weighing system

ActiveCN105143838AGood reproducibilitySolve the problem of excessive stenosisWeighing apparatus using electromagnetic balancingWeighing auxillary devicesInsertion pointMaterial Perforation

The invention relates to a monolithic weighing system (10), comprising a base (12), a load holder (26), which is articulated on the base (12) by means of a parallel link arrangement (16, 20), and a lever (28), which is articulated on the load holder (26) and which has an insertion point for a force-compensating arrangement and a target area (32) for an optical position sensor (34), wherein the target area (32) has a slotted diaphragm (36) in a thin-walled lever section of the lever (28) in the deflection plane thereof. The invention is distinguished in that a pedestal (38a,b) that is integrally connected to the base (12) is arranged adjacent to the target area (32) and is provided with a pedestal perforation (40a,b) oriented at right angles to the deflection plane, wherein the slotted diaphragm (36) of the target area (32) is made through the pedestal perforation (40a,b) by means of laser machining.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

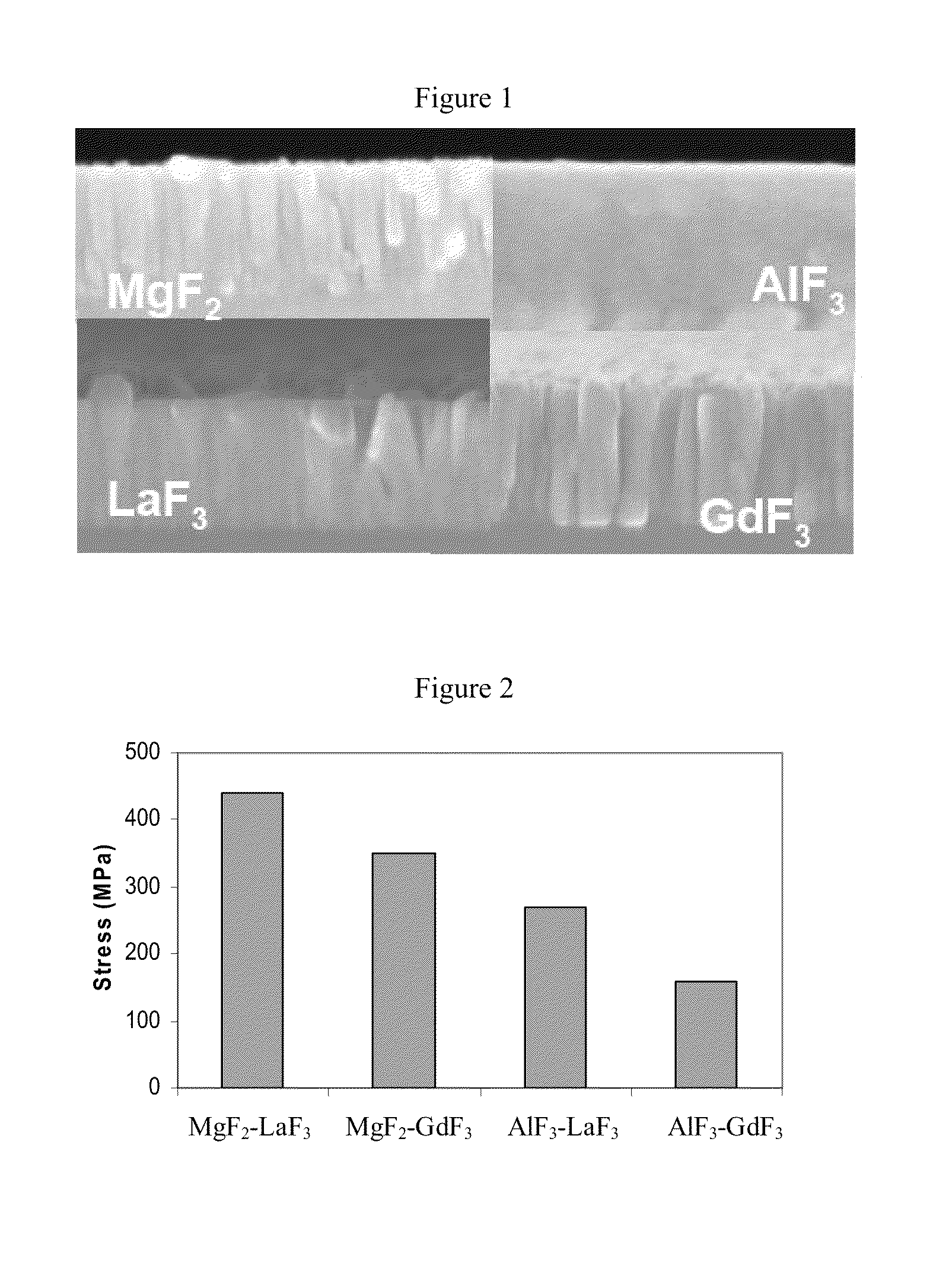

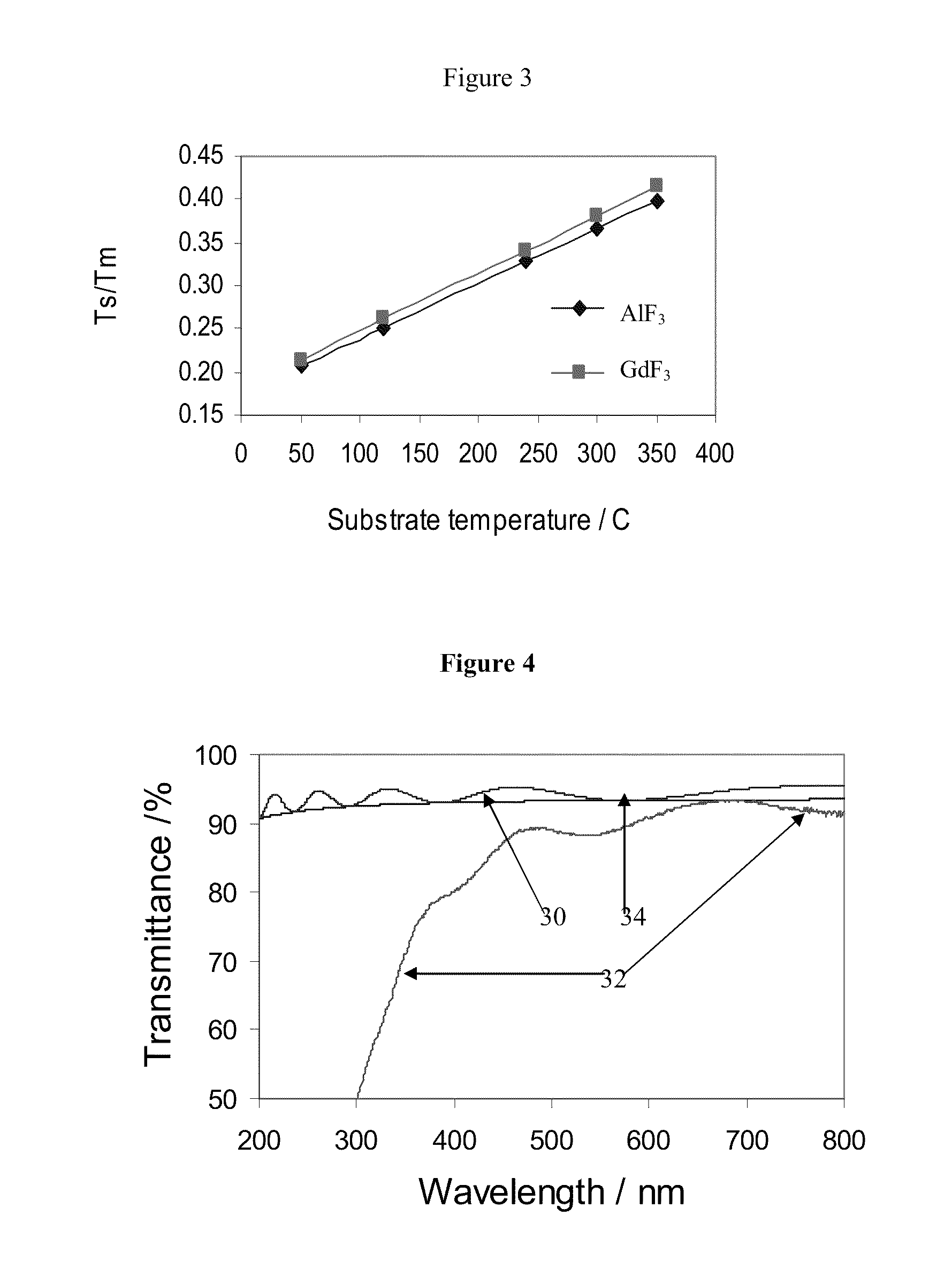

Extending the stability of UV curable adhesives in 193NM laser systems

InactiveUS8335045B2Heating evenlyReduce heating energy consumptionVacuum evaporation coatingSputtering coatingAdhesivePhotochemistry

This disclosure is directed to an optical element and method in which a UV-curable adhesive, used along the edge of the optic to keep it in a holder, has been stabilized against degradation by below 300 nm radiation. The technical solution to the degradation of the adhesive includes both 193 nm scatter light reduction and protective coatings of plasma modified AlF3 films on at least that part of the optical element that is in contact with the adhesive.

Owner:CORNING INC

Semiconductor light emitting device

InactiveUS9608178B2Improve light extraction efficiencyIncrease brightnessSolid-state devicesSemiconductor devicesLength waveLight-emitting diode

Owner:SCHOTT AG

High-definition pixel structure of electrochromic displays and method of producing the same

ActiveUS7336410B2Reduce scattered lightReduce layer thicknessStatic indicating devicesNon-linear opticsTectorial membraneActive matrix

Owner:JAPAN DISPLAY INC +1

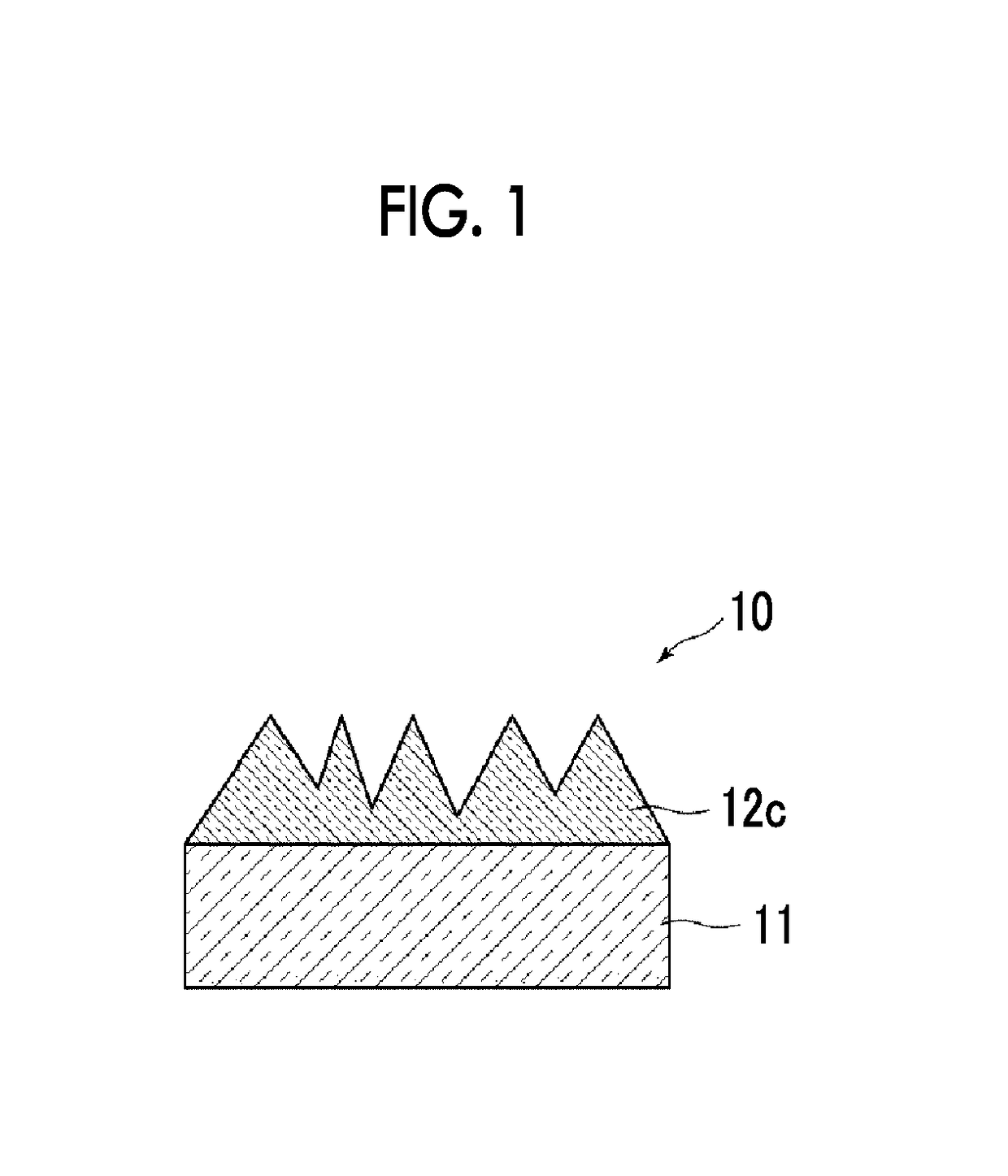

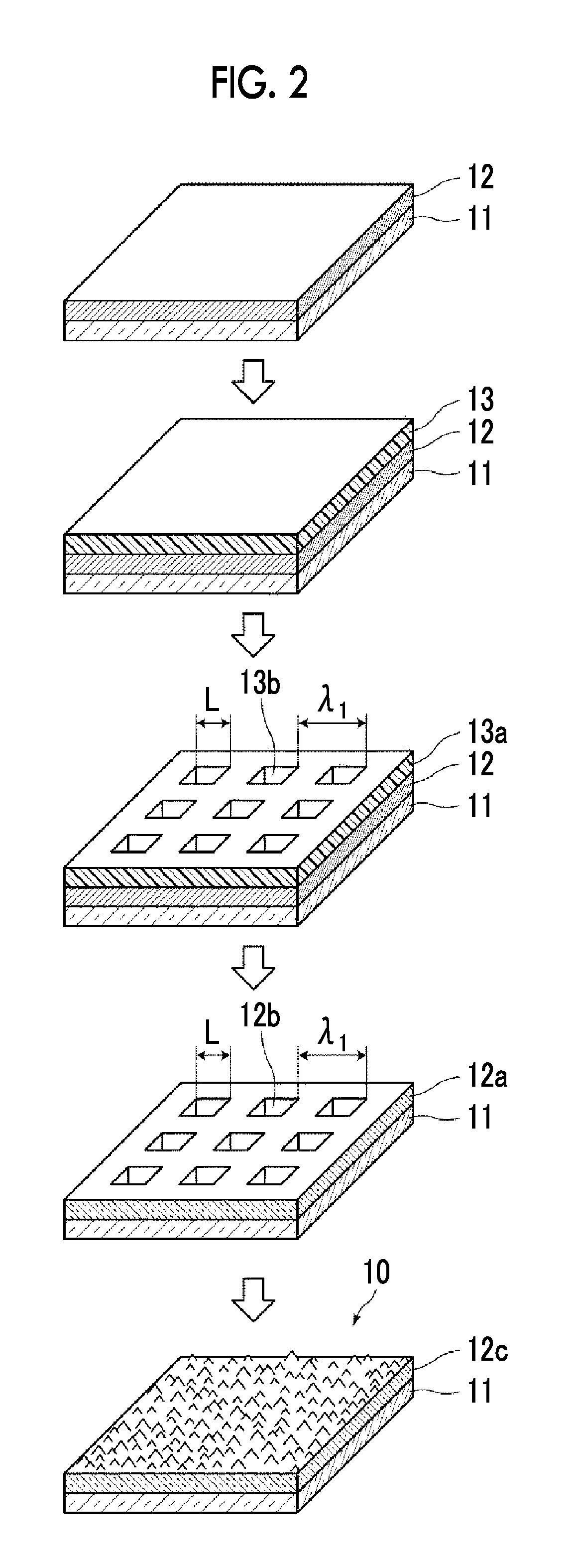

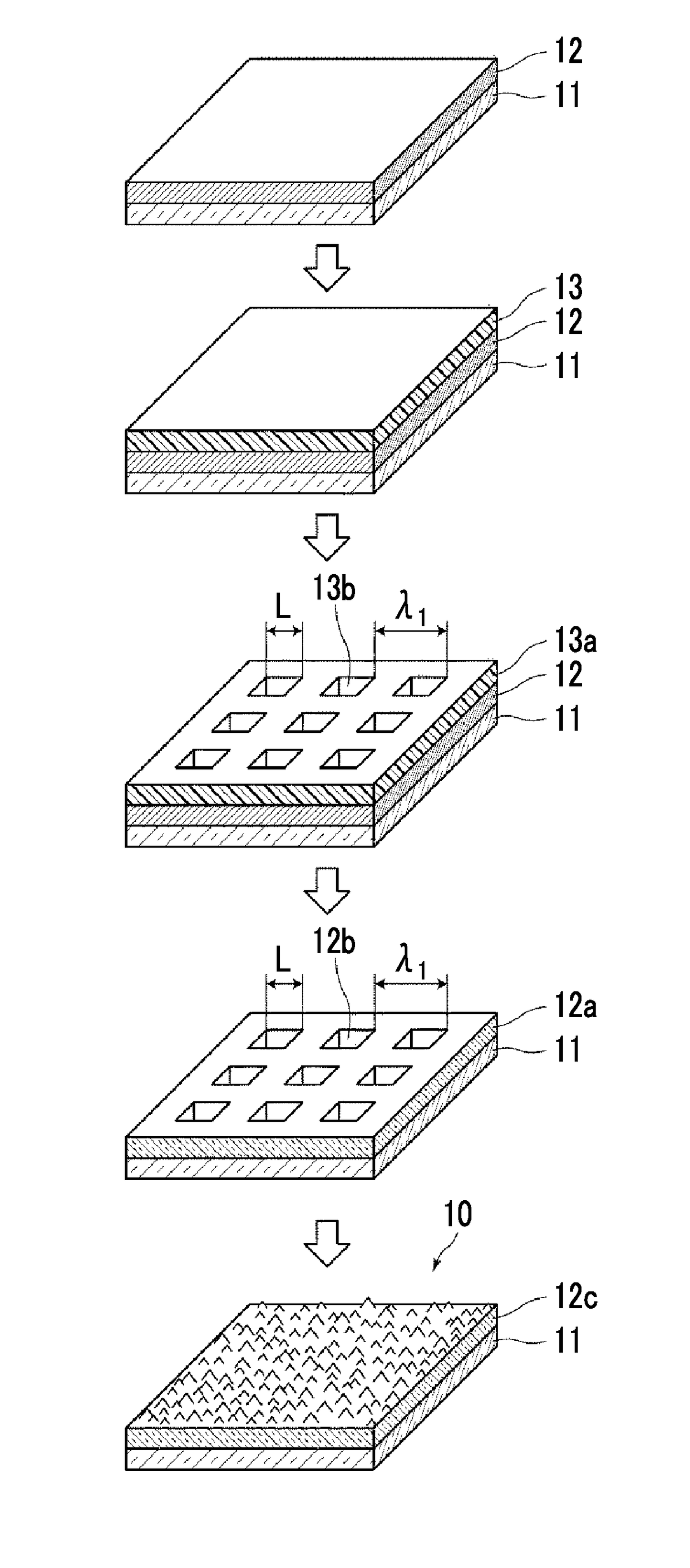

Method of manufacturing structure

InactiveUS10025006B2Satisfactory antireflection performanceGood effectLayered productsCoatingsOptoelectronicsThermal water

Provided is a method of manufacturing a structure having a transparent fine uneven structural body formed by hot water treatment, in which a finer uneven structure is formed. Provided is a method of manufacturing a structure, the method being for manufacturing a structure including a substrate, and a transparent fine uneven structural body which is formed on a surface of the substrate by hot water treatment, including: a first step of forming a precursor film of the transparent fine uneven structural body on the substrate; a second step of forming a fine uneven structure on a surface of the precursor film; and a third step of subjecting, to hot water treatment, the precursor film on which the fine uneven structure is formed to form the transparent fine uneven structural body in which a peak value ν0 of space frequency of the unevenness of the fine uneven structure formed in the second step satisfies ν<ν0 (Expression I). In Expression I, ν0 represents a peak value of space frequency of the fine uneven structure, and ν represents a peak value of space frequency of the transparent fine uneven structural body in a case in which the fine uneven structure is not formed on the surface of the precursor film.

Owner:FUJIFILM CORP

Method of manufacturing structure

InactiveUS20180074230A1Satisfactory antireflection performanceGood effectLayered productsCoatingsOptoelectronicsThermal water

Provided is a method of manufacturing a structure having a transparent fine uneven structural body formed by hot water treatment, in which a finer uneven structure is formed. Provided is a method of manufacturing a structure, the method being for manufacturing a structure including a substrate, and a transparent fine uneven structural body which is formed on a surface of the substrate by hot water treatment, including: a first step of forming a precursor film of the transparent fine uneven structural body on the substrate; a second step of forming a fine uneven structure on a surface of the precursor film; and a third step of subjecting, to hot water treatment, the precursor film on which the fine uneven structure is formed to form the transparent fine uneven structural body in which a peak value v0 of space frequency of the unevenness of the fine uneven structure formed in the second step satisfies v <v0 (Expression I). In Expression I, v0 represents a peak value of space frequency of the fine uneven structure, and v represents a peak value of space frequency of the transparent fine uneven structural body in a case in which the fine uneven structure is not formed on the surface of the precursor film.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com