Optical element, light guiding plate, backlight source and LCD device for synthetizing hologram by computer

A technology of optical elements and holograms, applied in the field of backlight, liquid crystal display devices, and light guide plates, can solve the problems of low manufacturing efficiency, complex structure, and high manufacturing cost, and achieve the effect of preventing interference fringes and high-quality optical elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

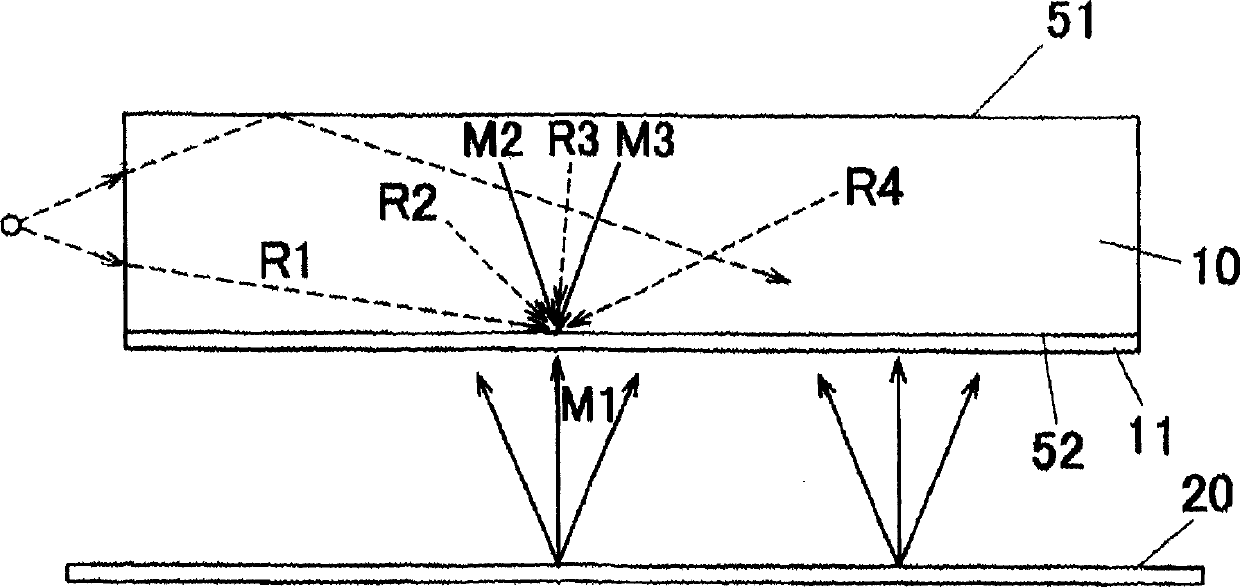

[0068] Fig. 1 shows an optical element-embodiment of the present invention. The optical element is used as a light guide plate, and is integrally formed by laminating a computer-synthesized hologram (11) on the bottom surface (52) of the light guide plate body (10), which is a translucent substrate. In this embodiment, a reflective computer-synthesized hologram (11A) is used as the computer-synthesized hologram. This hologram has a light diffraction function and a polarized light separation function.

[0069] The aforementioned computer-synthesized hologram (11) is to reflect the actual use environment when the interference between the reference light and the object light arriving at each position of the hologram forming surface is calculated by a computer, as shown in Figure 3 As shown, assuming a state in which holograms are stacked on the bottom surface (52) of the aforementioned light guide plate body (10), the interference fringe data is obtained according to the calculat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com