Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduce reciprocating inertia force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

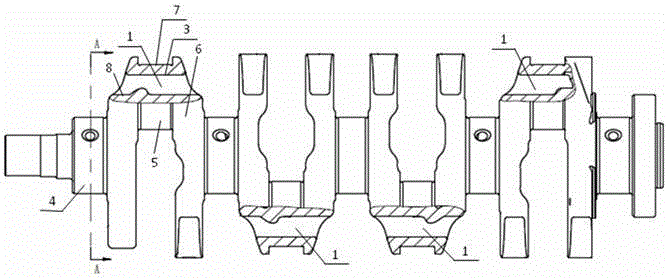

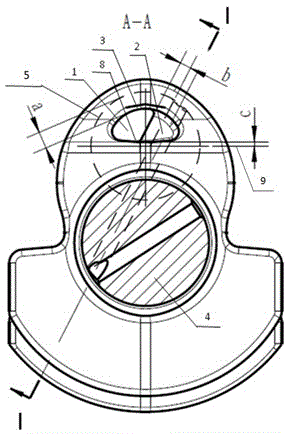

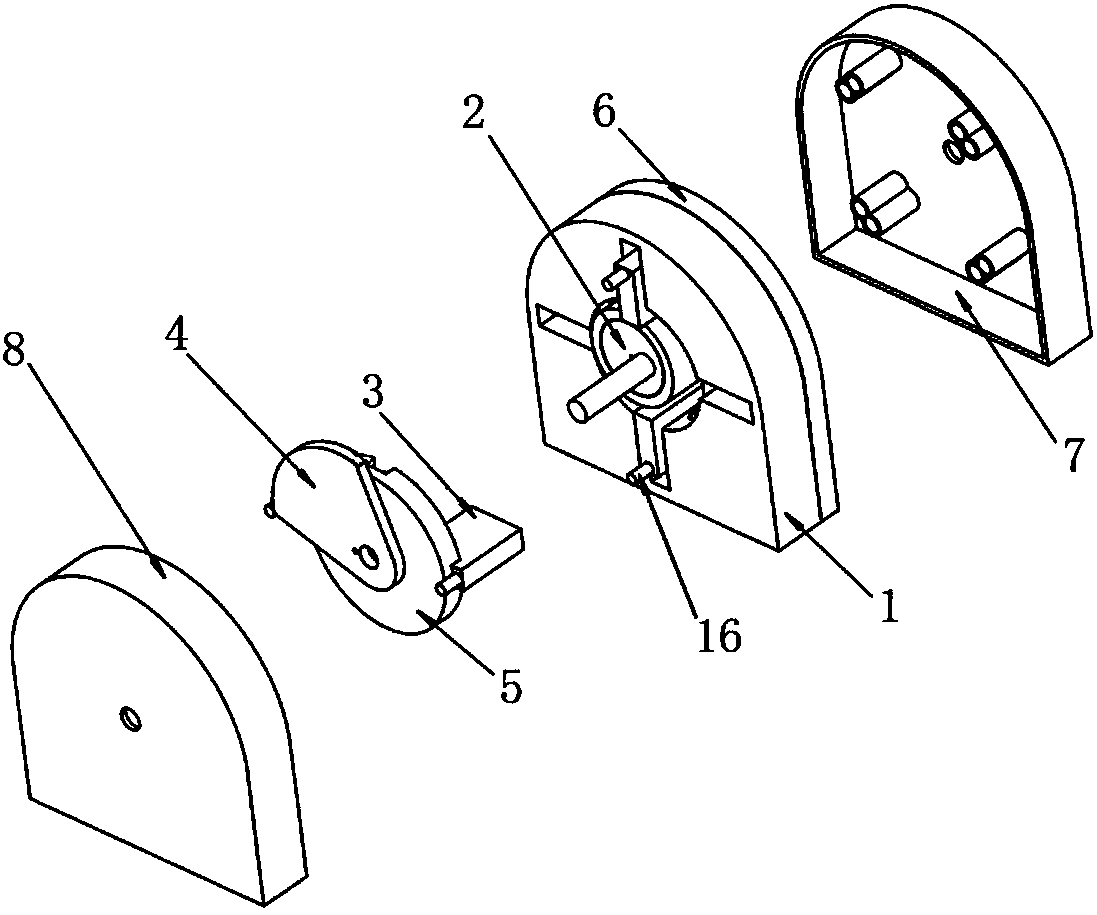

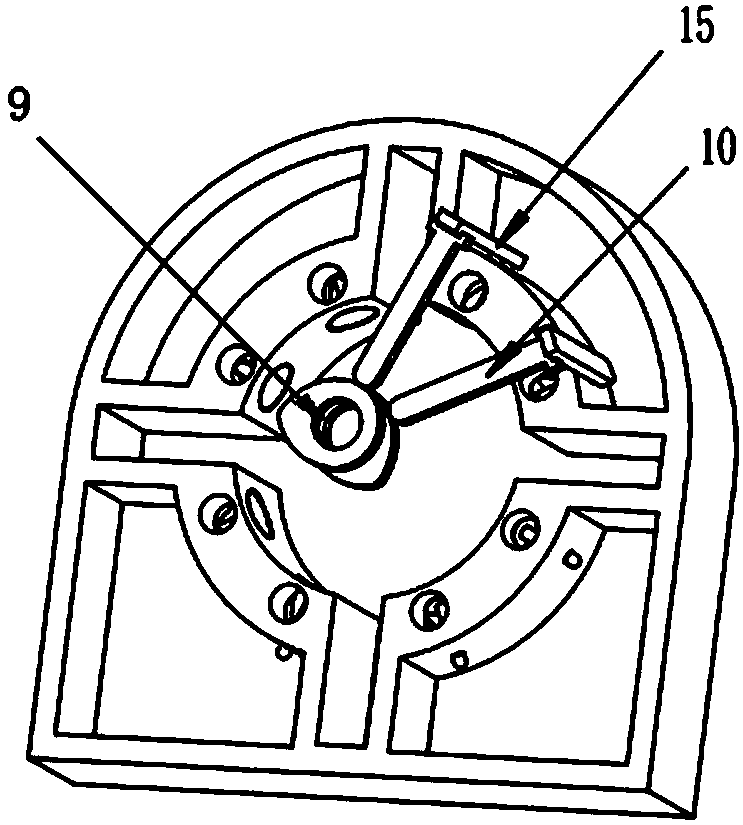

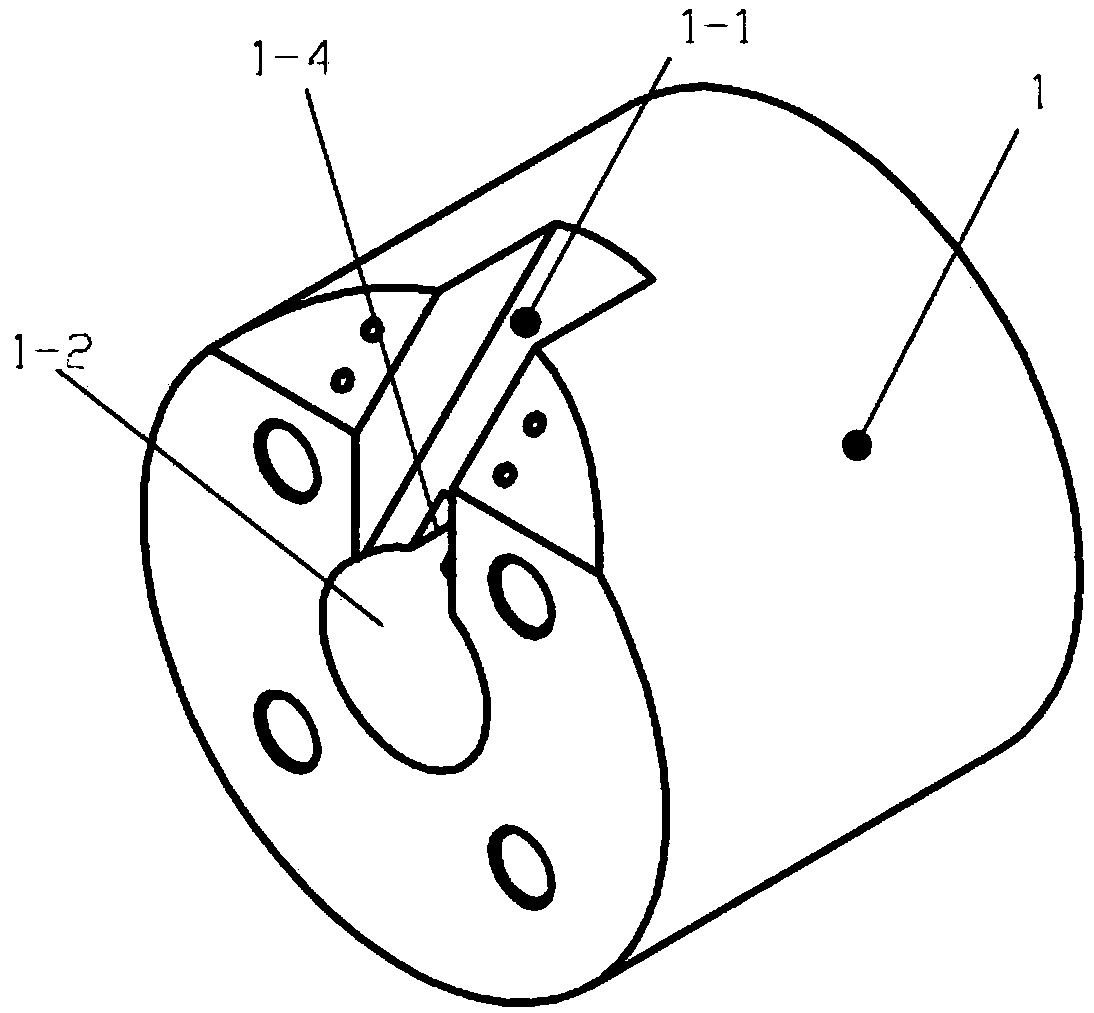

Motorcycle engine vibration damping device

InactiveCN101105206ALow costReduce weightInertia force compensationMachines/enginesCrankcaseEngineering

A vibration damping structure for motorcycle engine is provided. A piston is connected with a small end of a connecting rod through a piston pin, the big end of the connecting rod is arranged between a left crank and a right crank through a crack pin, a left crack shaft bearing is arranged on the left crank, a right crank shaft bearing and a balancing driving gear are sequentially arranged on the right crank, the balancing driving gear is engaged with an balancing driven gear disposed at the right end of a balancing shaft, a second balancing block is equipped in the middle (deviation to the right) position of a first balancing block, the opposite faces of the shank portion of the left and right crank are symmetrically opened with two notches, and when the balancing shaft rotates, the second balancing block can pass through between the two notches of the shank portion of the left and right crank. The invention can effectively balance the reciprocating inertial force generated when the large-discharge amount motorcycle engine running, so as to essentially improve the engine vibration, improve the usage comfort, service life and reliability of the motorcycle. The invention can be arranged with no need to change the structure of crank shaft case, so as to effectively reduce the manufacturing cost of the entire motorcycle.

Owner:力帆科技(集团)股份有限公司

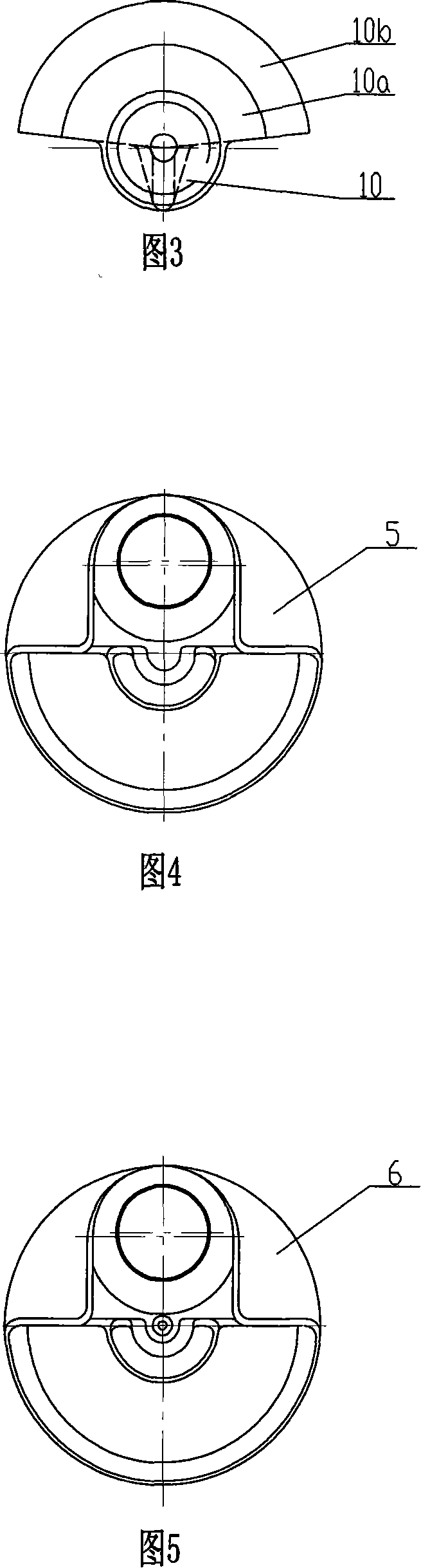

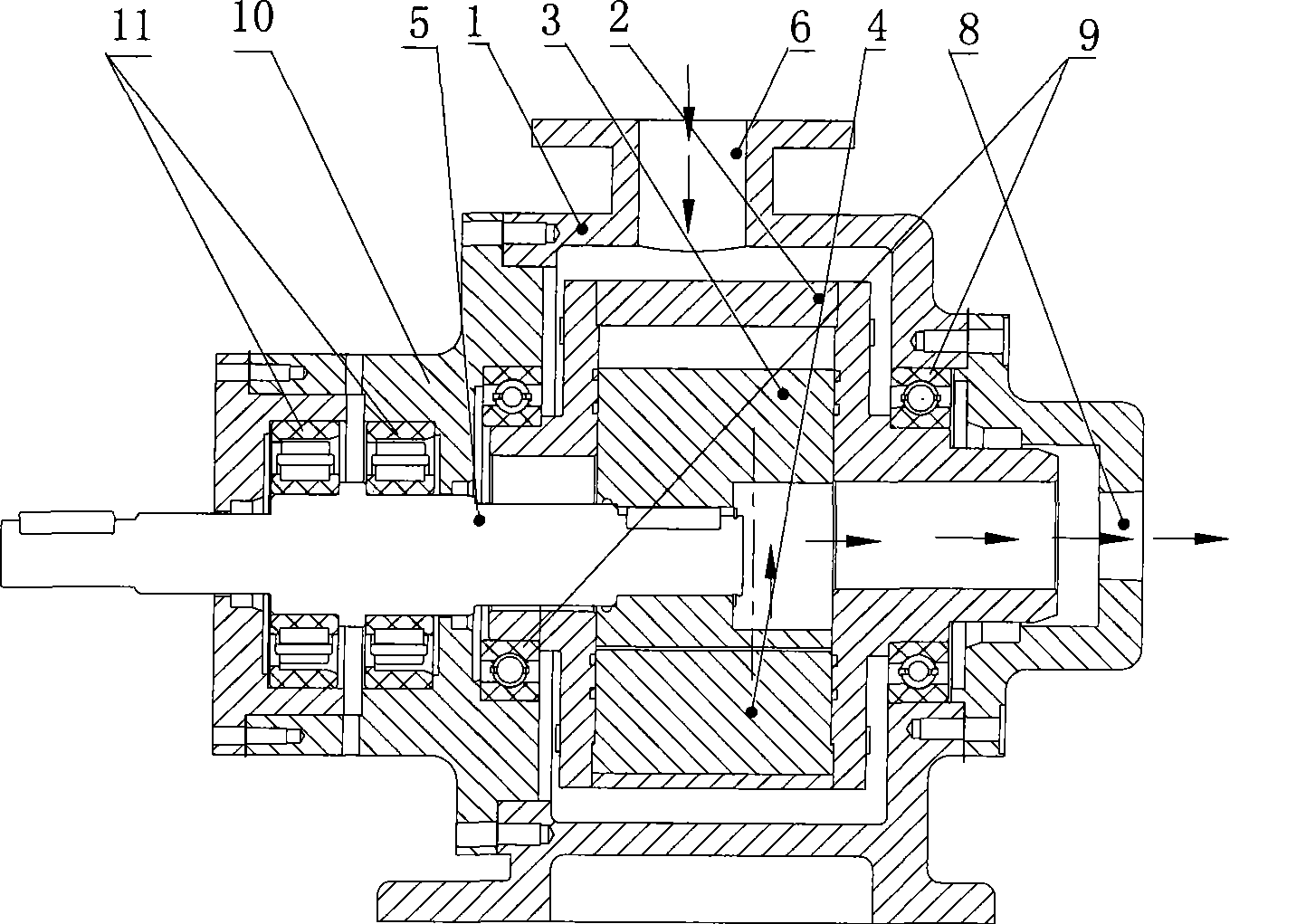

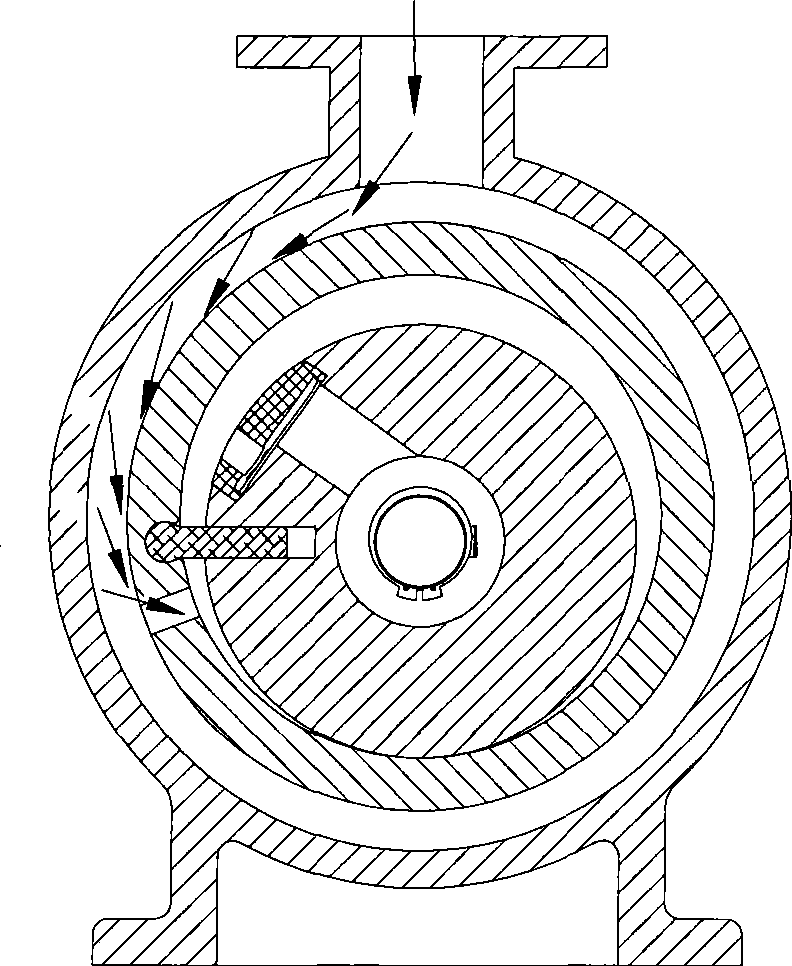

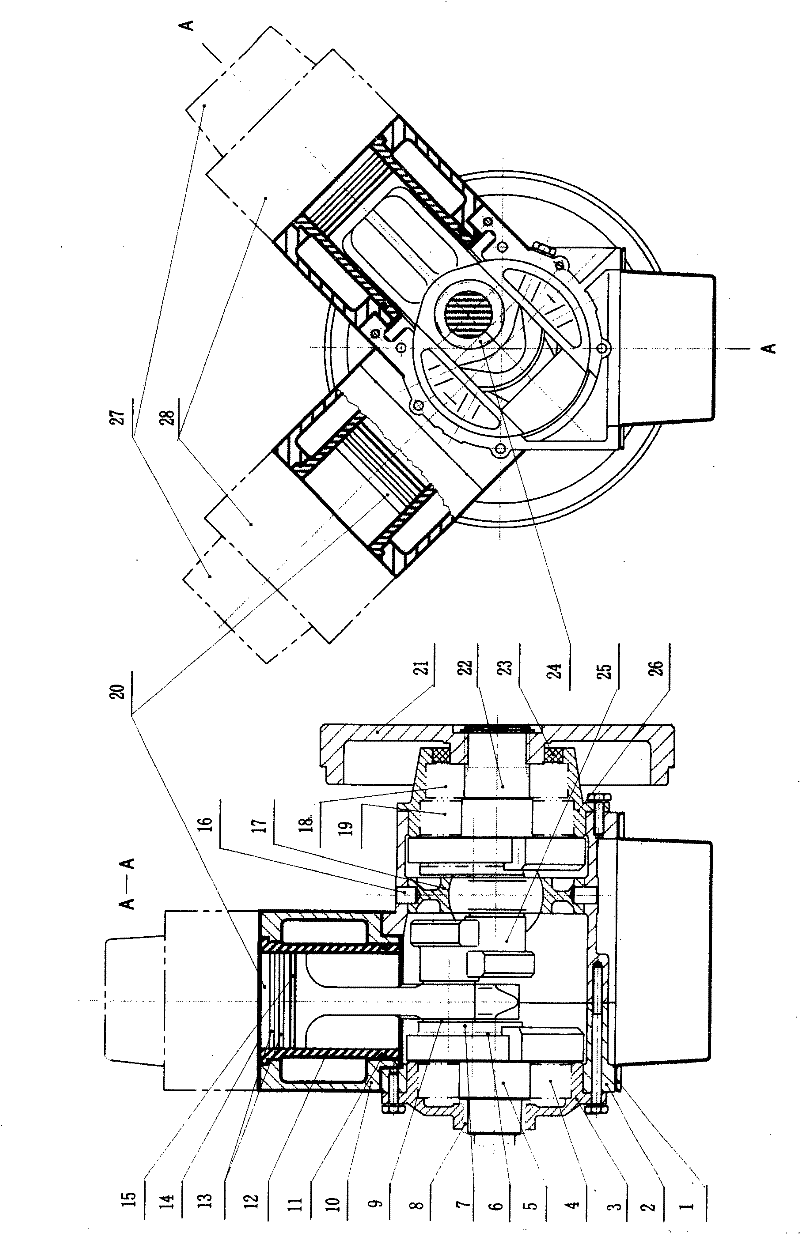

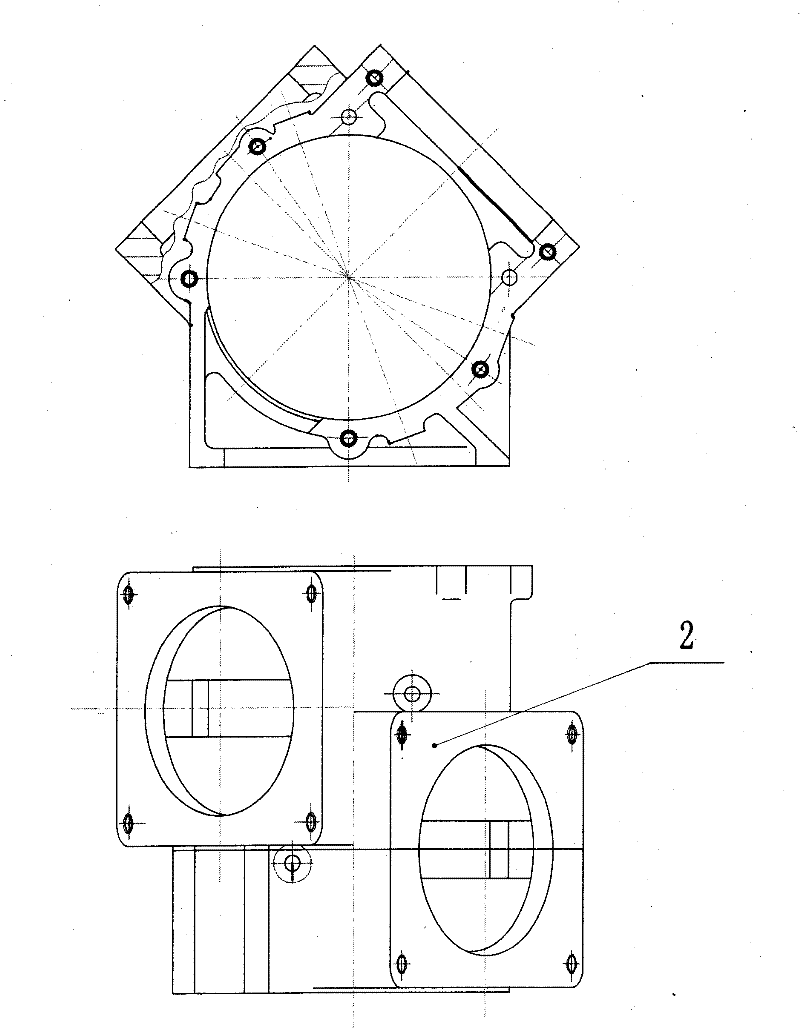

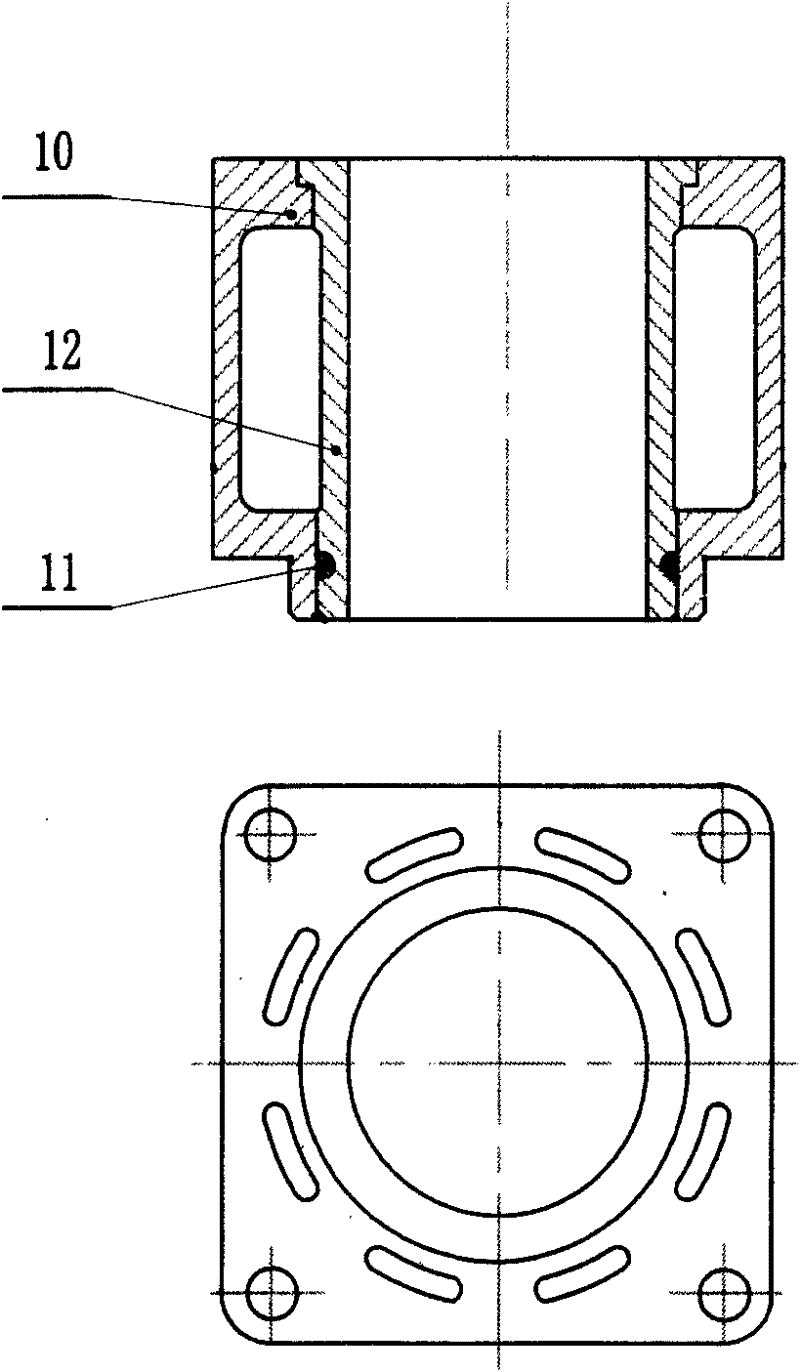

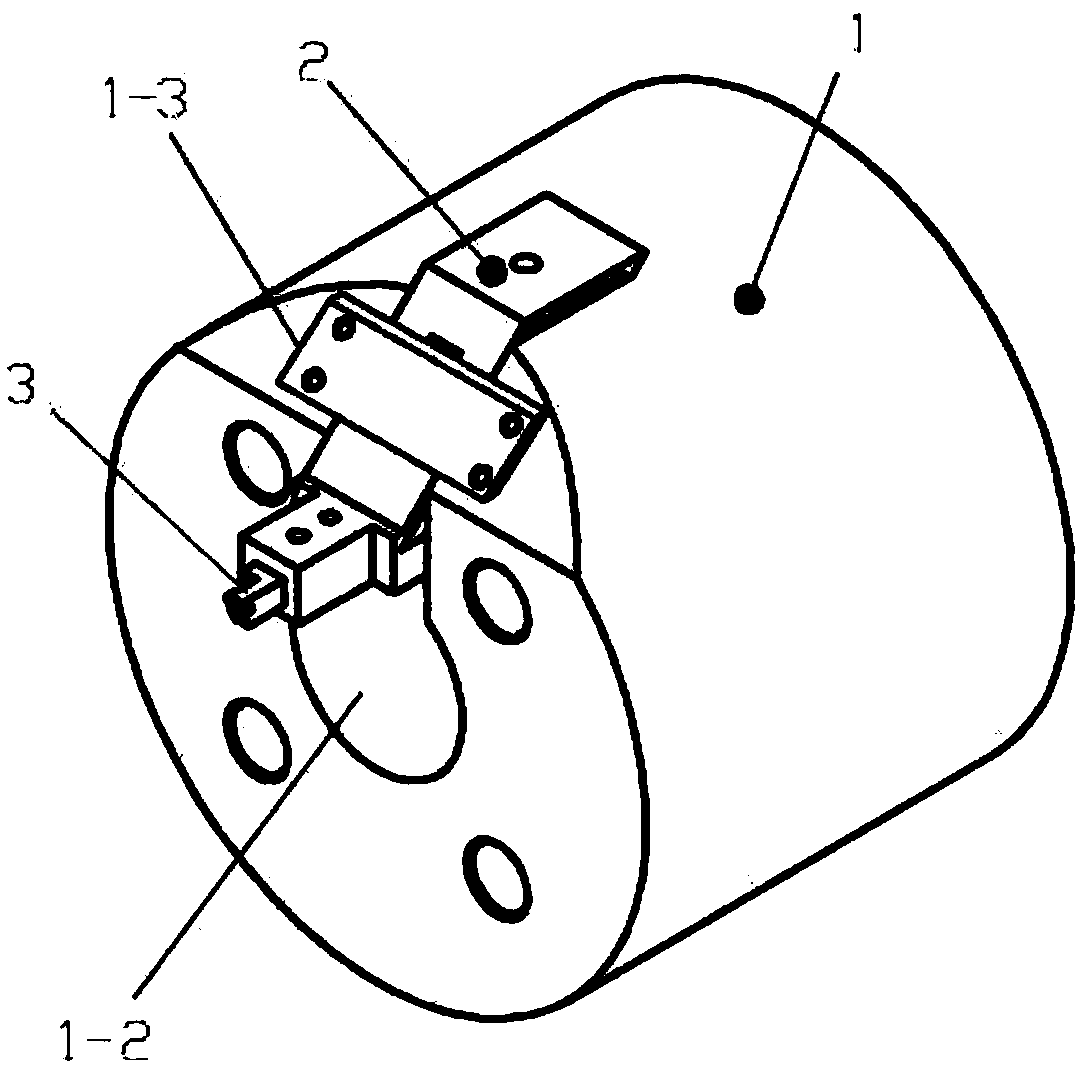

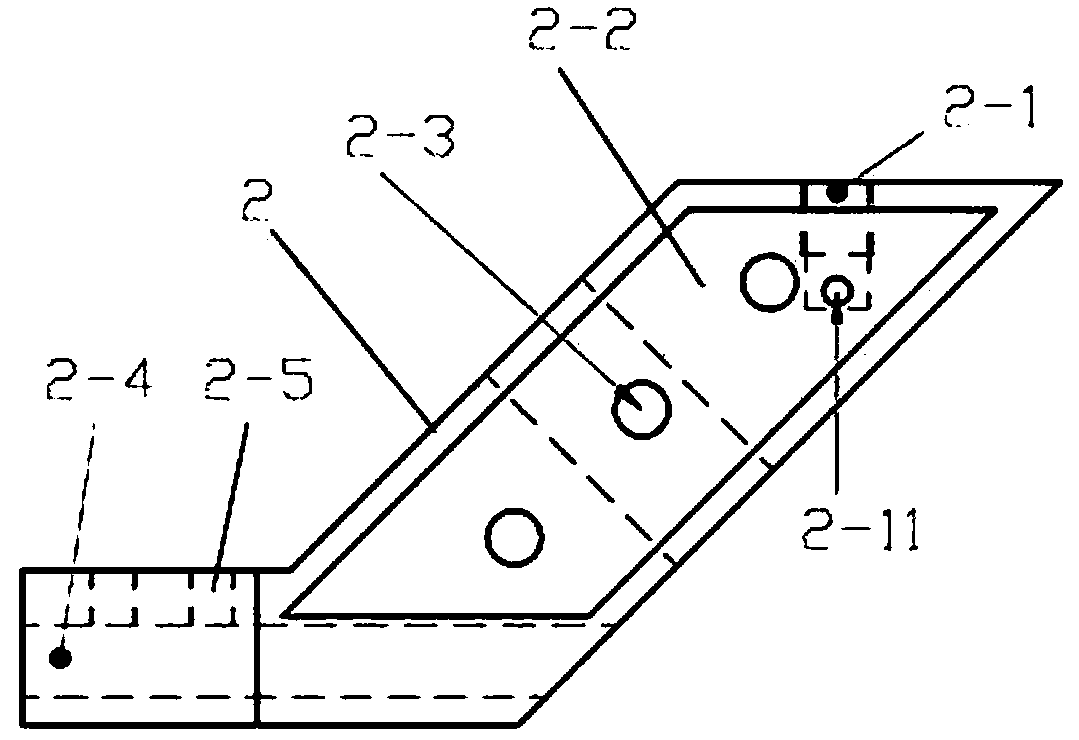

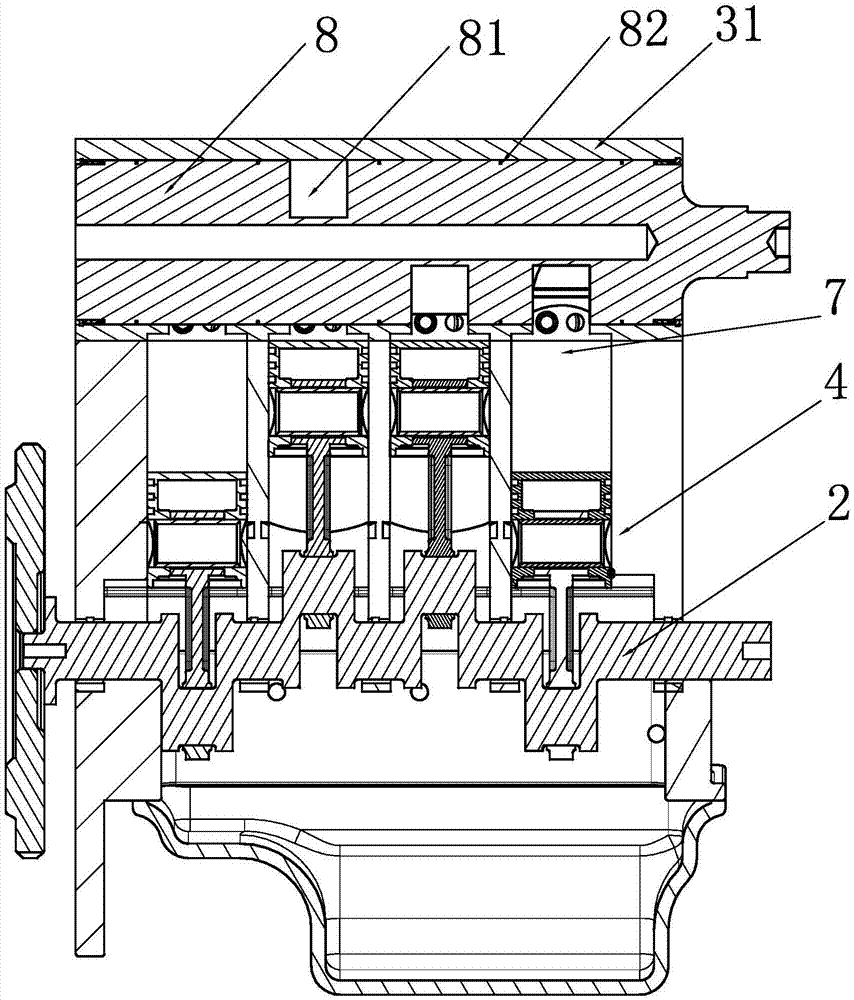

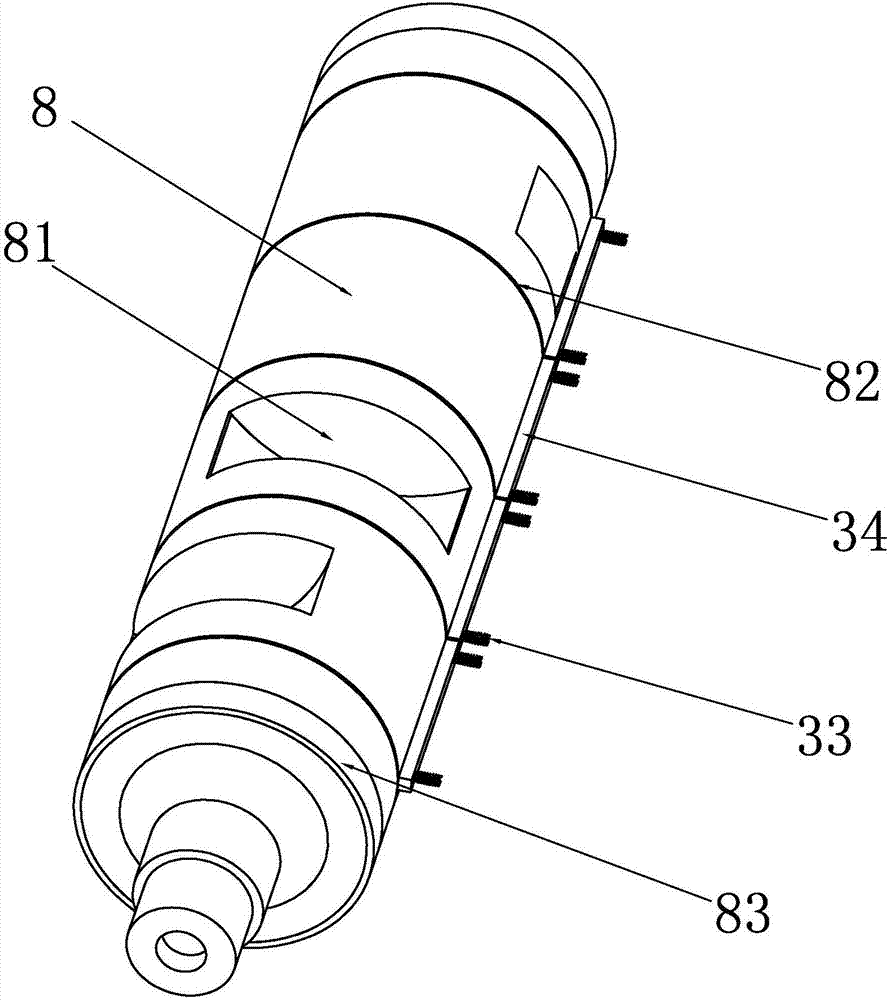

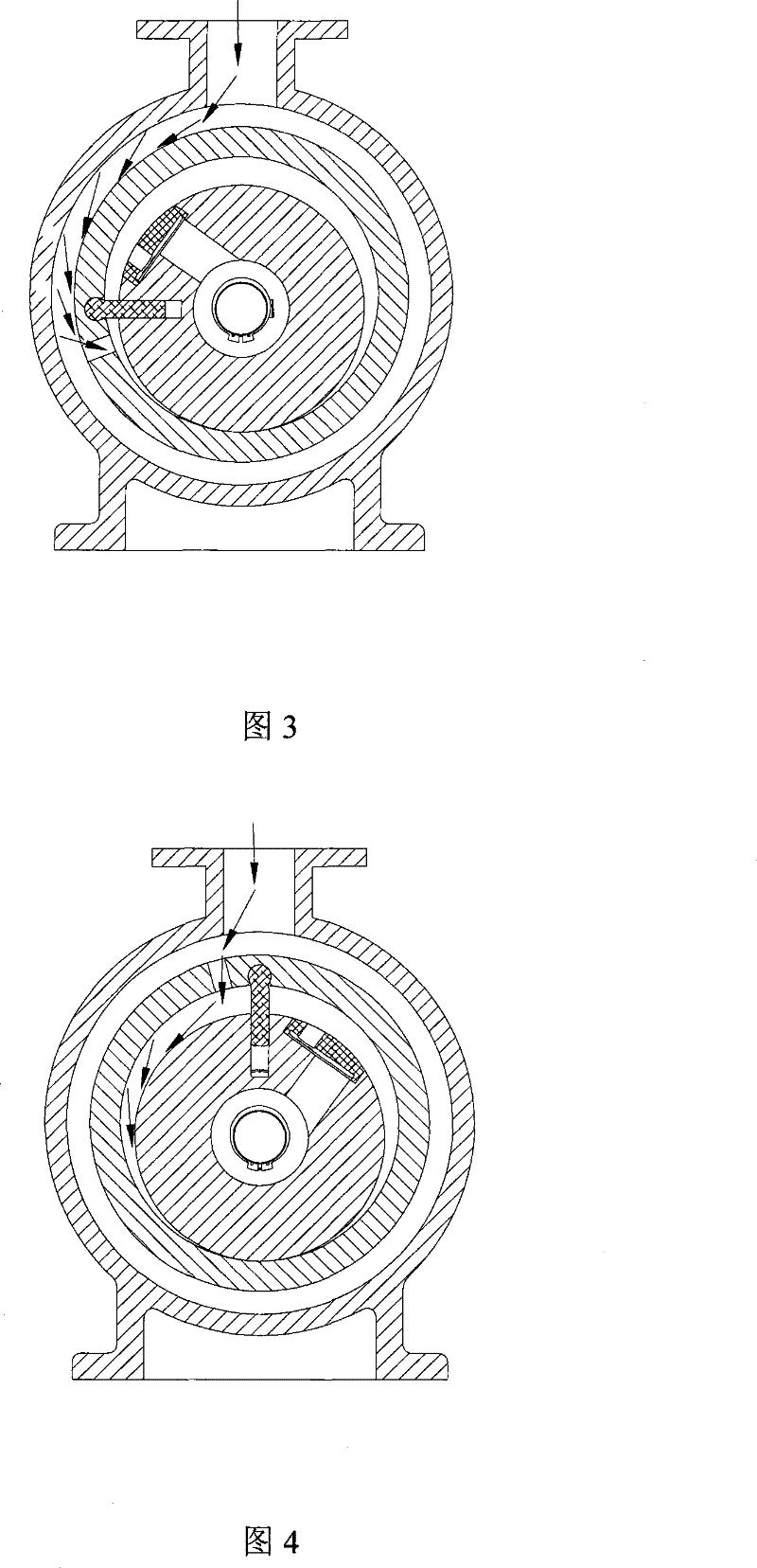

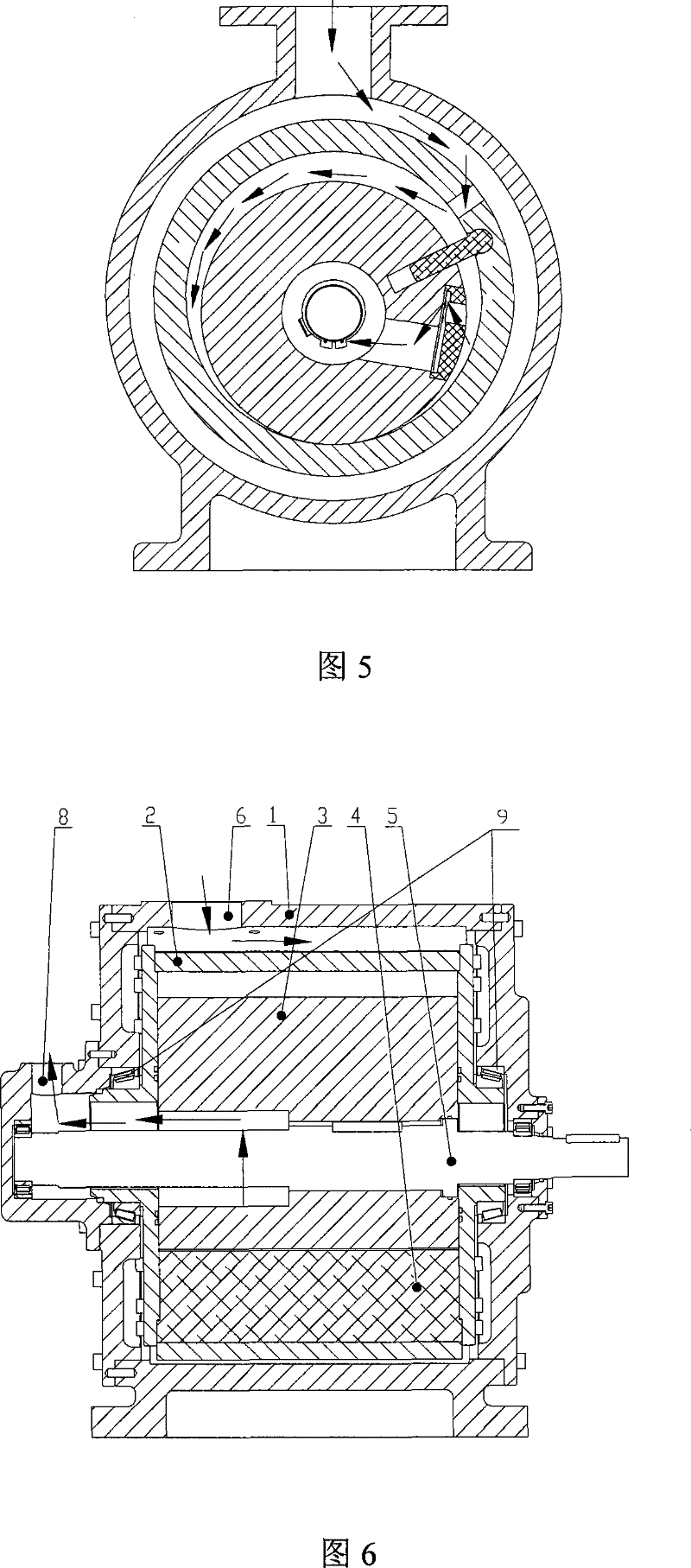

Rotary compressor

ActiveCN101498306AThe machine runs smoothlyReduce flow rateRotary piston pumpsRotary piston liquid enginesCylinder blockEngineering

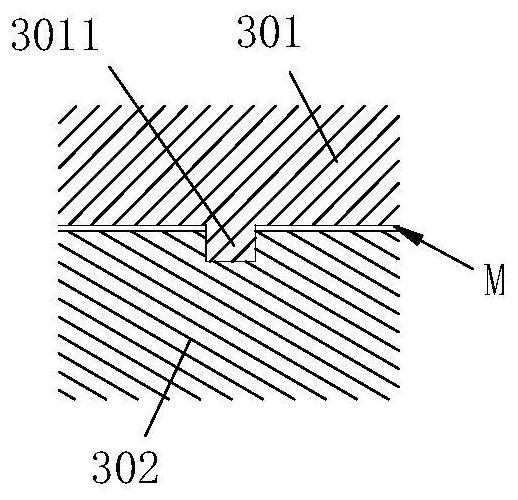

The invention discloses a rotary type compressor which comprises a shell (1), a cylinder body (2), a rotor (3), a sliding plate (4) and an exhaust valve (7), wherein an air suction hole (6) and an exhaust hole (8) are arranged on the shell (1), rotating central axes of the cylinder body (2) and the rotor (3) are offset into a state that the outer circumferential surface of the rotor (3) is tangential with the inner circumferential surface of the cylinder body (2), the head of the sliding plate (4) is embedded into a cylinder of the cylinder body (2), the main body of the sliding plate (4) extends into a sliding plate groove of the rotor (3), the exhaust valve (7) is arranged on the outer circumference of the rotor (3) and the front of the rotating direction of the sliding plate (4), a cylinder body air inlet (12) which is positioned at the rear of the rotating direction of the sliding plate (4) is arranged on the cylinder body (2), and the sliding plate (4) and an internally tangent point are used for dividing crescent working volume between the inner circumferential surface of the cylinder body (2) and the outer circumferential surface of the rotor (3) into an air inlet cavity and an exhaust cavity.

Owner:DAFENG FENGTAI FLUID MACHINERY TECHNOLOGY CO LTD

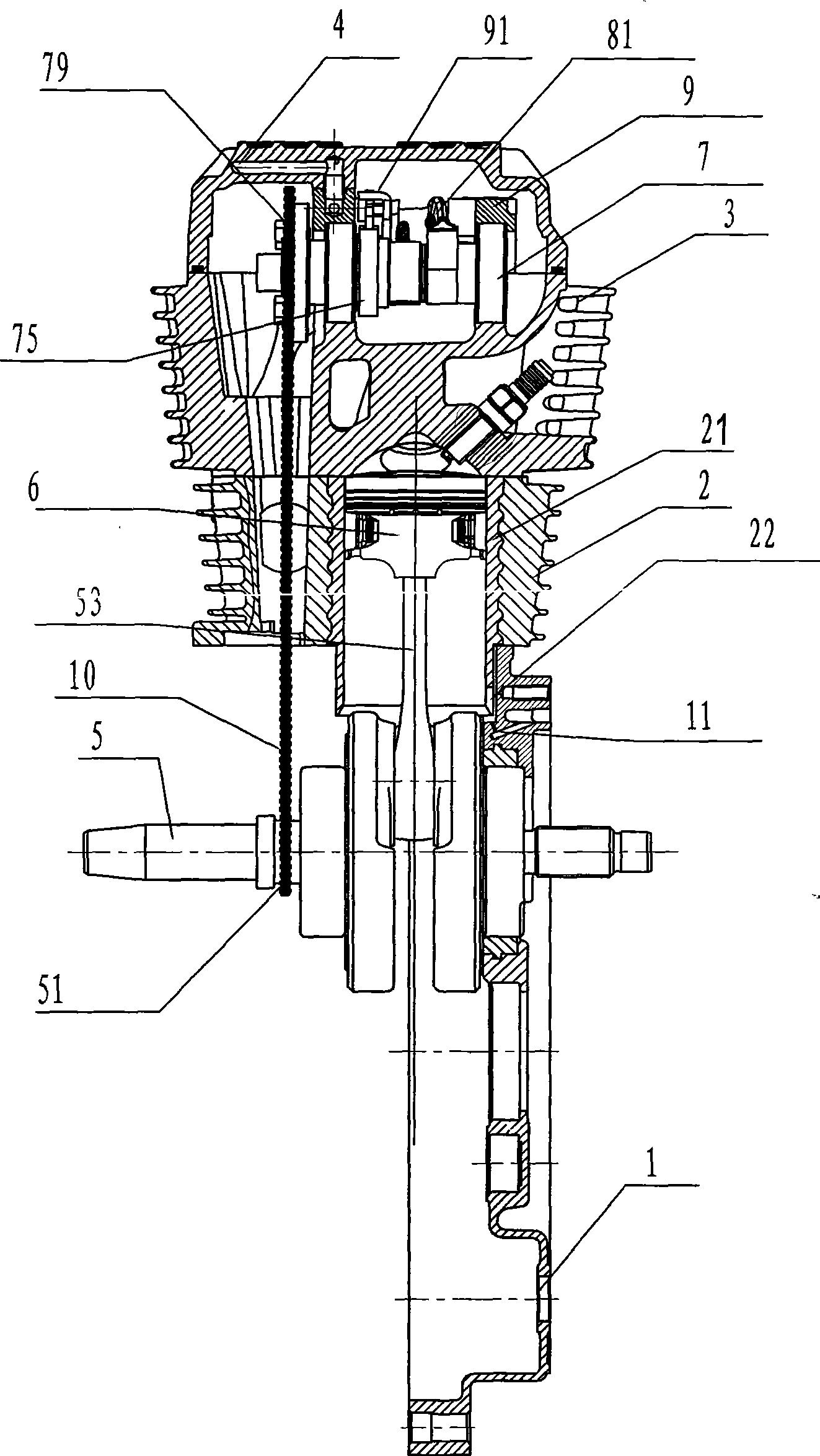

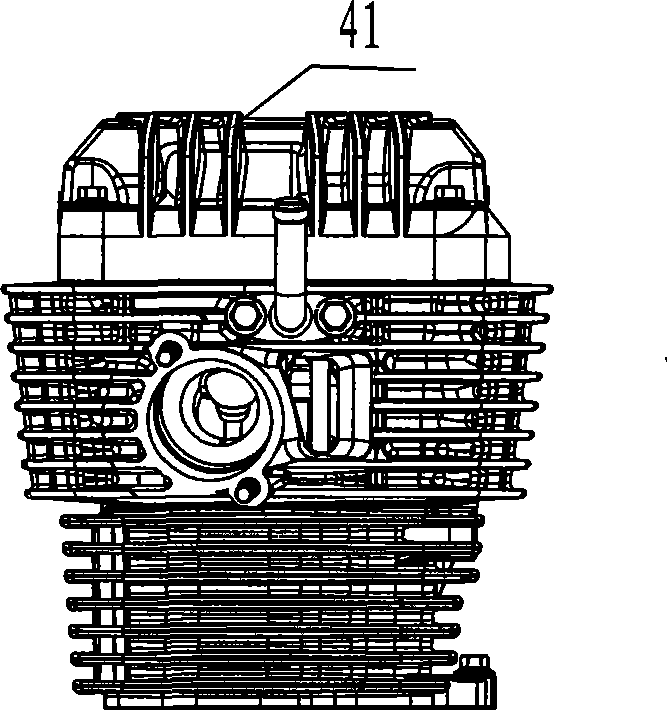

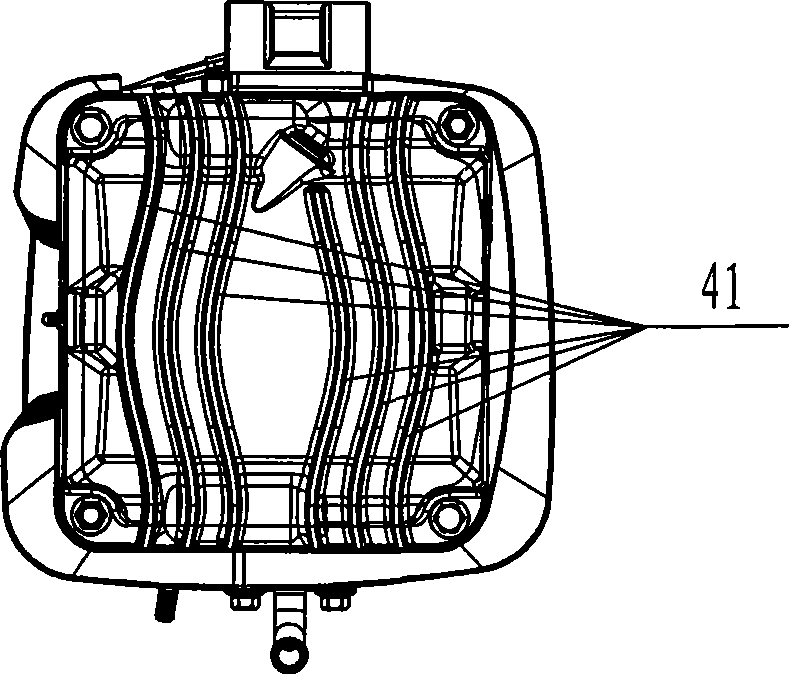

Motorcycle engine

InactiveCN101387209AIncrease the compression ratioReduce reciprocating inertia forceValve arrangementsLubrication of auxillariesLow noiseExhaust valve

The invention discloses a motorcycle engine, wherein the outerwall of a cylinder end cover is provided with a wavy radiating rib, and the inner wall of the cylinder end cover is provided with an oil duct; a heat-dissipation through hole is arranged beside an air outlet of a cylinder end, and is connected to the upper side of a mounting hole of a spark plug; an oil injection hole is arranged on a right tank and oriented to the top of an inner cavity of a piston; a driving chain wheel is arranged on a left crankshaft of a crankshaft; a crankshaft connecting-rod piston mechanism drives a top cam chain distribution structure for transmission through the driving chain wheel; a camshaft is arranged on the cylinder end and fixed by a camshaft cover; an oil hole is arranged on the camshaft cover and corresponds to an opening of the oil duct on the inner wall of the cylinder end cover; swinging arms of an inlet valve and an exhaust valve are fixed inside shaft holes of the swinging arms of the inlet valve and the exhaust valve of the camshaft cover through swinging arm shafts of the inlet valve and the exhaust valve respectively; a check plate is arranged on the camshaft cover and fixed through the swinging arm shafts of the inlet valve and the exhaust valve; and the swinging arm shafts of the inlet valve and the exhaust valve contact an inlet cam and an exhaust cam on the camshaft respectively. Because the motorcycle engine reasonably improves the heat dissipation, lubrication, transmission and so on, the engine has the advantages of strong dynamic property, low vibration, low noise and oil saving.

Owner:JIANGMEN TIANYI METAL IND

Double-crankshaft engine

ActiveCN105927380AReduce toughnessReduce manufacturing costCasingsConnecting rodsPiston GuideCylinder block

The invention discloses a double-crankshaft engine and belongs to the technical field of engines. The double-crankshaft engine comprises a piston and two crankshafts forming a double-crankshaft mechanism, and further comprises a cylinder block. The cylinder block comprises an air cylinder block part and a crankshaft supporting part. A piston guide rod is arranged at the lower end of the piston, the cylinder block is internally provided with a piston rod guide groove, the lower end of the piston is open and is provided with a piston end cover, and the piston end cover and the piston guide rod are detachably and fixedly connected; and the piston is a skirt-free piston with the piston guide end and the piston seal end separated, the piston seal end is a piston head, and the piston guide end is provided with the piston guide rod and the piston rod guide groove. The double-crankshaft engine is good in manufacturability, the piston is designed through isostress, strength is increased, abrasion-resisting design is adopted in a connecting part of a connecting rod and the piston, and the abrasion resisting performance and the reliability of the whole engine are improved.

Owner:XUZHOU XIAN BO ENGINE MACHINERY TECH CO LTD

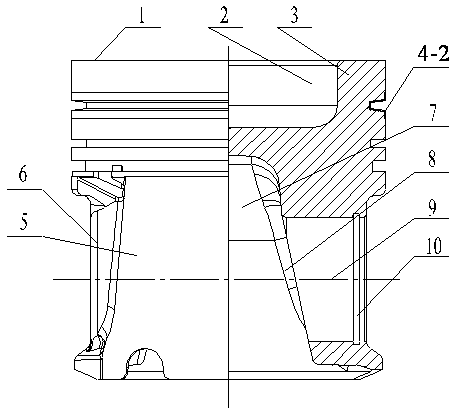

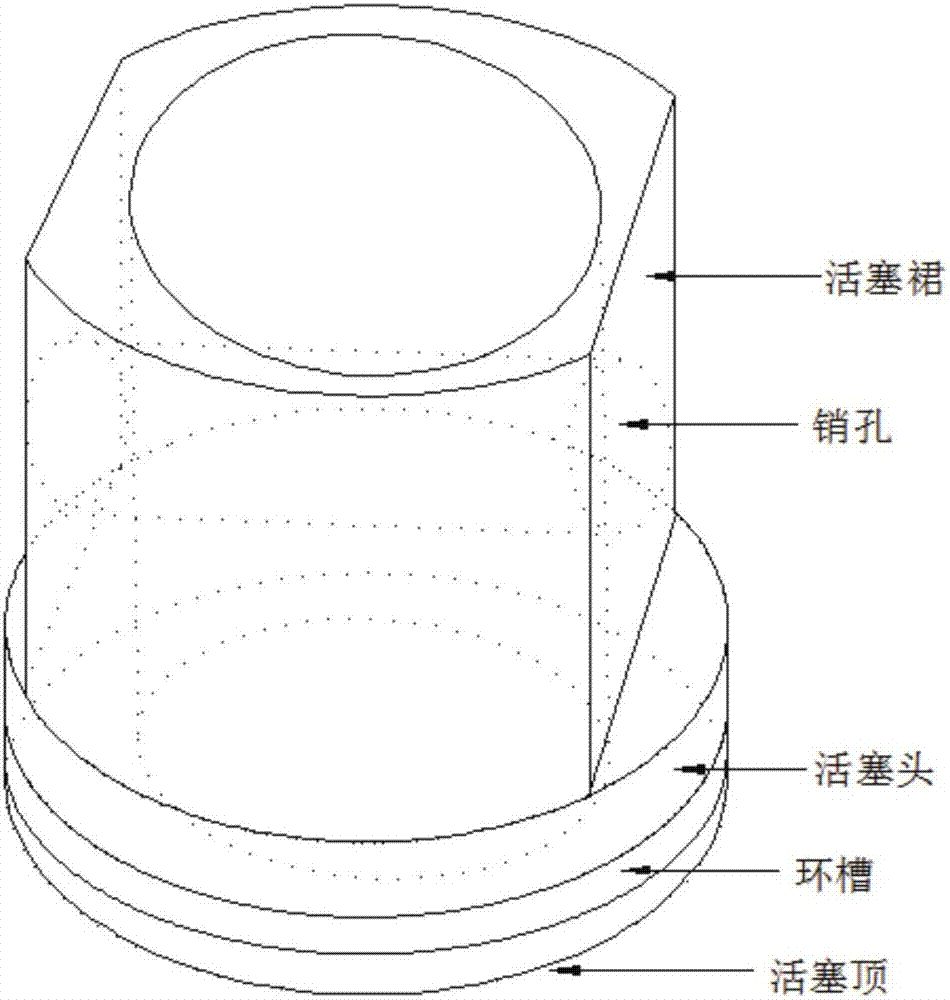

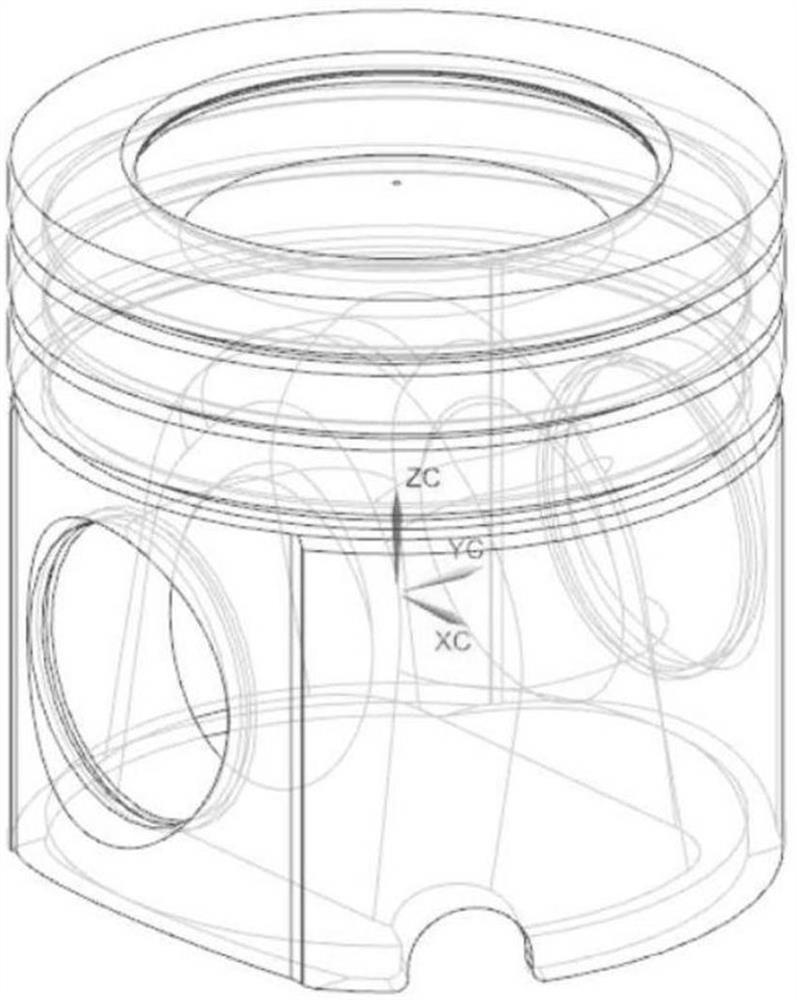

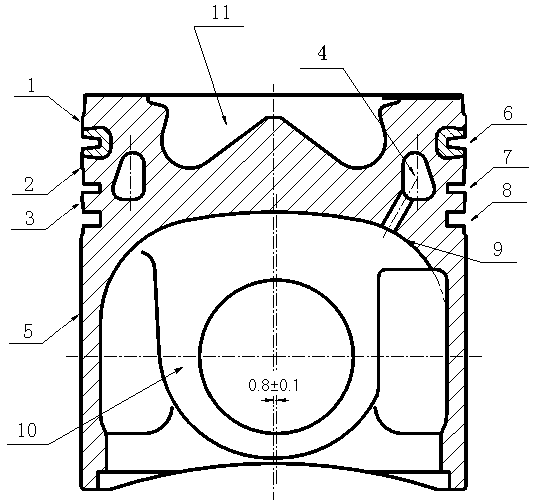

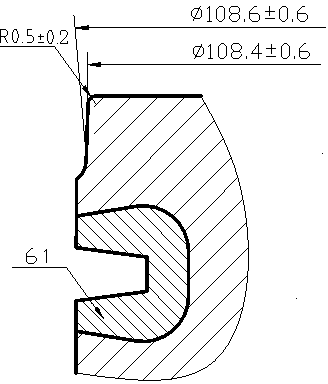

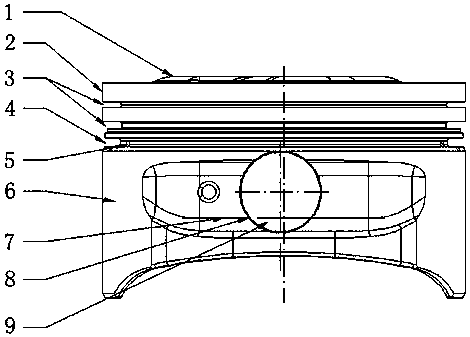

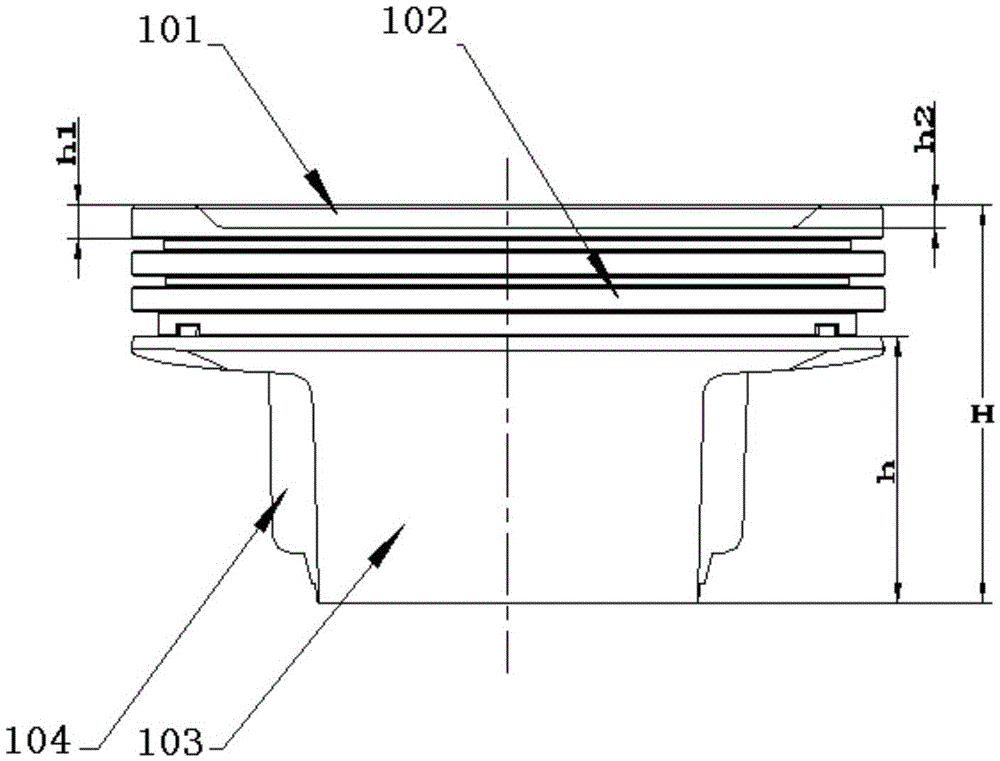

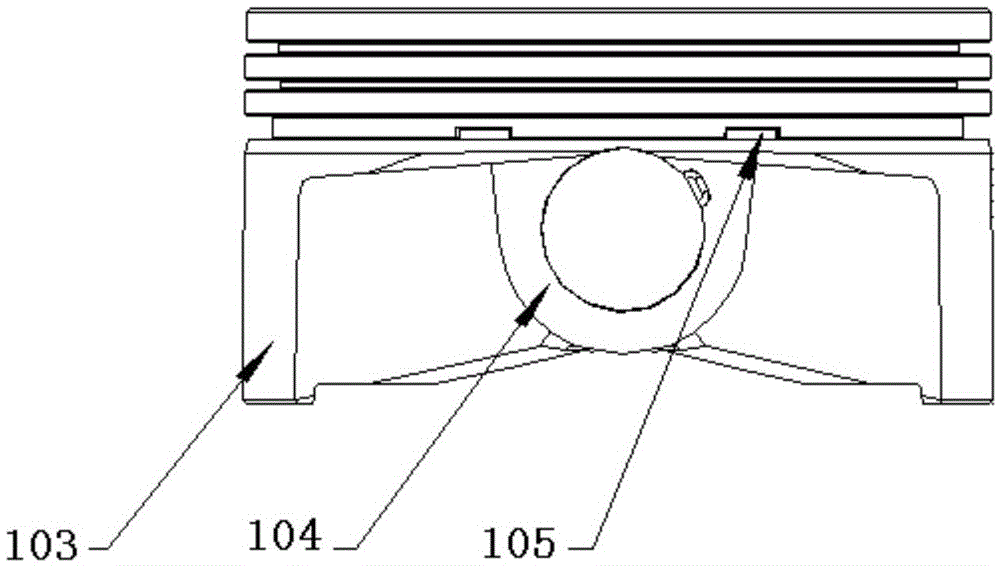

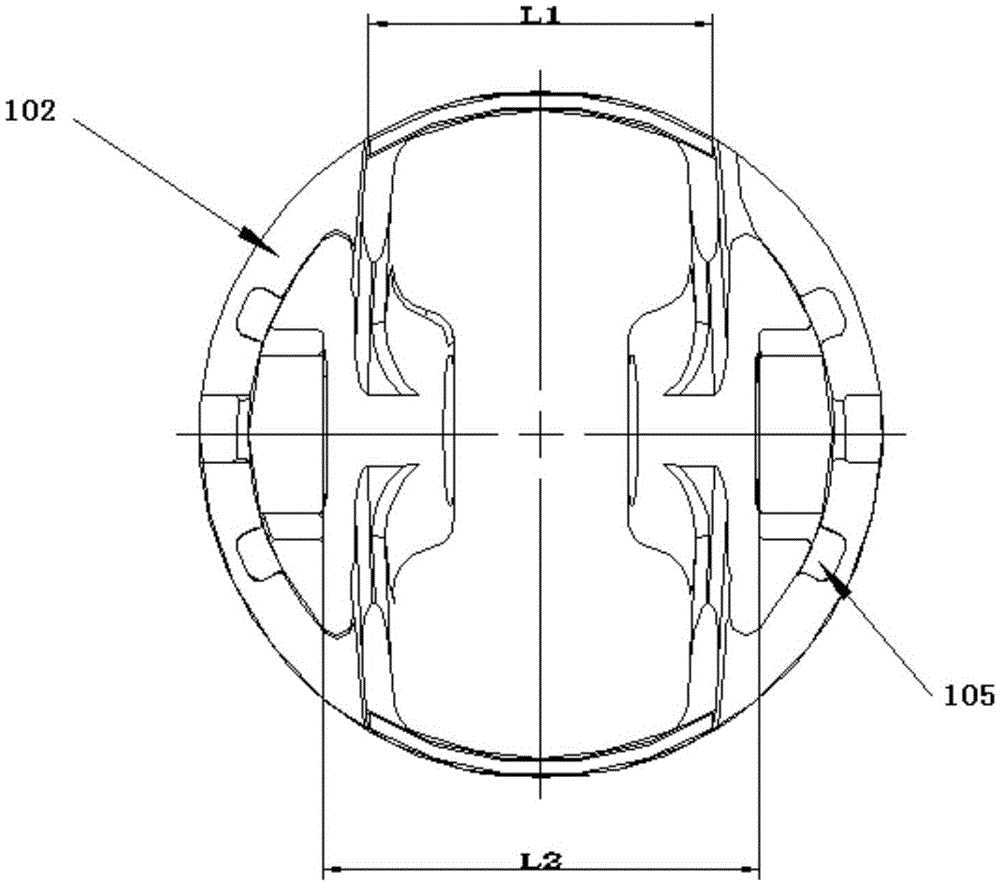

Energy-saving piston for gas engine

InactiveCN102797584AReduce weightReasonable structurePlungersMachines/enginesCombustion chamberPiston ring

The invention discloses an energy-saving piston for a gas engine, and solves the technical problem of the heavy piston in the prior art. The technical scheme is that the energy-saving piston for the gas engine comprises a piston top surface, a piston combustion chamber, a piston head, a piston ring groove, a piston skirt, a wedge-shaped pin seat arranged in the cavity of the piston, a piston pin hole provided with a clamp ring groove, and a piston pin, wherein the ratio of the height to the outside diameter of the piston is (1-1.035):1; and the piston pin comprises a piston pin outer cycle, a piston pin inner hole and a conical surface formed in the piston pin inner hole, wherein the ratio of the length of the piston pin to the diameter of the piston pin outer circle is (1.96-2.05):1. The piston and the piston pin provided by the invention are particularly used for a T6114ZLQ-type gas engine, wherein the diameter of a working cylinder is 114 mm, the number of the cylinders is 6, and the displacement is 8L and 9L; the piston is light in weight, reasonable in structure, and low in invalid friction power loss; and the aims of improving power, reducing fuel oil and engine oil consumption, saving energy resources, and reducing pollution and emission are fulfilled.

Owner:石家庄金刚内燃机零部件集团有限公司

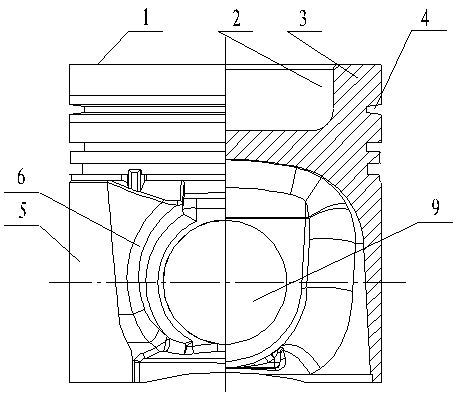

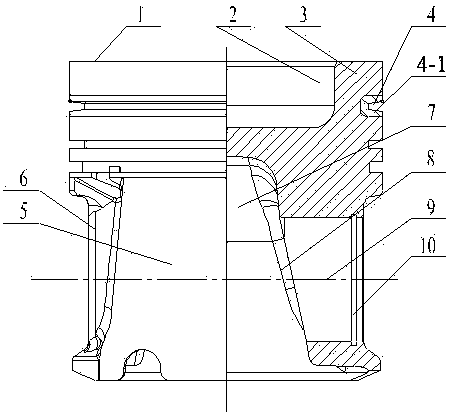

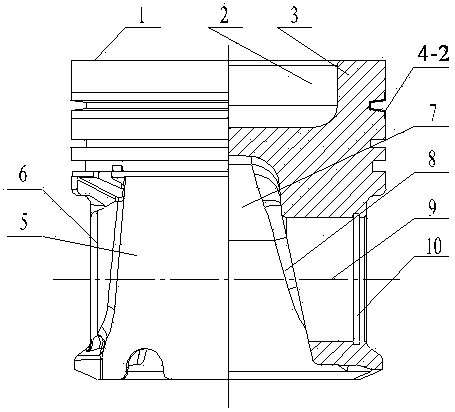

Piston and connecting rod assembly

InactiveCN105179100AWeakened functionReduce the overall heightPlungersMachines/enginesCombustion chamberCombustor

The invention discloses a piston and connecting rod assembly. The piston and connecting rod assembly comprises a piston, a ball socket lining and a connecting rod, wherein a ball socket concave towards a combustor of the piston is arranged at the upper end of the skirt section of the piston, two piston pin holes are symmetrically formed in the skirt section, and the ball socket lining is detachably installed in the ball socket of the piston; the small end of the connecting end is a ball head which is matched with the ball socket lining to form a ball socket matching pair, a connecting rod pin hole is formed in the small end of the connecting rod, and the connecting rod is connected to the piston through a piston pin penetrating through the piston pin holes and the connecting pin hole. According to the piston and connecting rod assembly, the function of the piston pin is weakened, and gas pressure is transmitted through ball socket hinging; through the arrangement of the ball socket matching pair, the height of the piston is reduced, the overall height is reduced, the weight of the piston is reduced, reciprocating inertial force is reduced, and the vibration damping purpose and the light-weight purpose are realized; besides, due to the fact that the piston pin does not need to bear transmission pressure, ablation of a lining of the small end of the connecting rod can be avoided, and the reliability of an engine can be improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

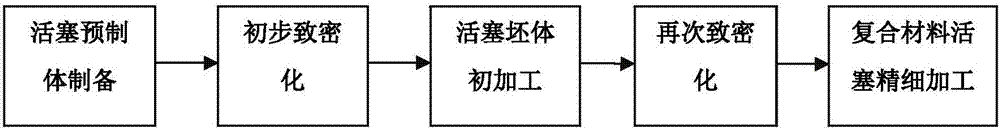

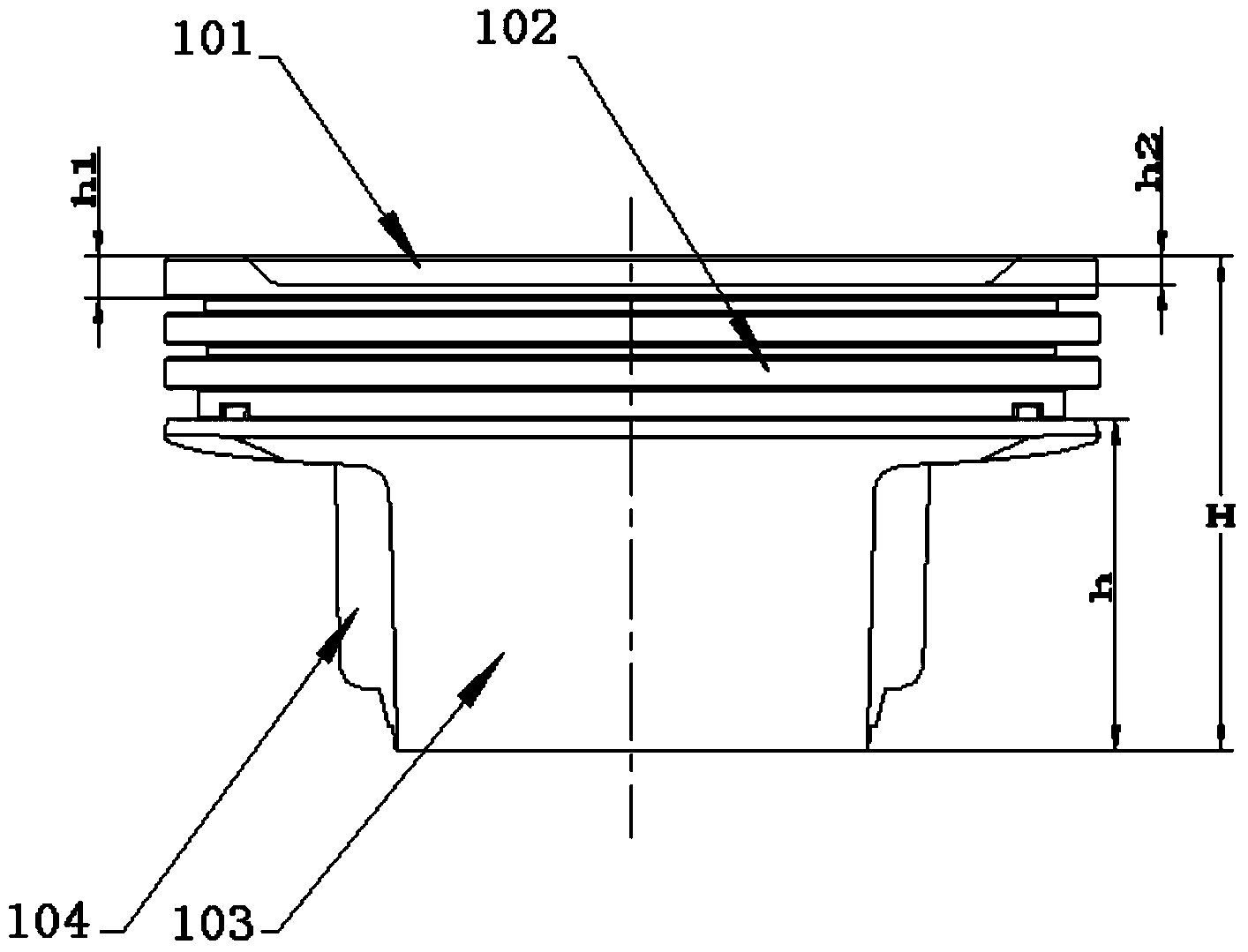

Multiple carbon and ceramic base composite material piston and preparation method and application thereof

ActiveCN106977218AReduce quality problemsLower coefficient of thermal expansionPlungersTrunk pistonsCarbon fibersVolumetric Mass Density

The invention relates to a multiple carbon and ceramic base composite material piston and a preparation method and application thereof. The preparation method is as follows: using carbon fiber or polyacrylonitrile based preoxidized silk to prepare a piston preform; using a chemical vapor infiltration method and / or precursor infiltration and pyrolysis method for preliminary densifying of the piston perform, using the chemical vapor infiltration method for further densifying of the obtained product to obtain a composite piston with the density of 1.74-2.0g / cm<3>; machining the obtained composite piston into final size design to obtain the composite piston finished product. The piston mass and the thermal expansion coefficient of the piston are reduced, the mechanical strength of the piston is improved, heat loss is effectively reduced, and noise and hydrocarbon and nitrogen oxide emissions can be reduced to achieve energy saving and environmental protection.

Owner:BEIHANG UNIV

Gasoline engine

ActiveCN103867296AImprove mechanical efficiencyReduce friction workValve arrangementsInternal combustion piston enginesGasolineEngineering

The invention relates to a gasoline engine, which comprises a piston, a combustion chamber and a fuel-oil supplying system, wherein the piston is formed by a piston top, a head, a pin seat and a skirt, wherein the ratio of the height of the skirt to the total height formed by the head and the skirt is 0.6 to 0.7, and the ratio of the chord length of the projection of the molded line of the skirt on a plane on the piston top to the diameter of a cylinder is 0.5 to 0.6; the combustion chamber is hemispheric and is jointly formed by a cylinder head, the piston top, a cylinder-head gasket and one part of a box body, and the surface-to-volume ratio delta of the combustion chamber is 0.15 to 0.25; the fuel-oil supplying system comprises a gasoline pump, a ventilating pipe and a negative-pressure pipe, wherein a negative-pressure impulse-type gasoline pump is adopted as the gasoline pump, the ventilating pipe is arranged on a cylinder head cover, one end of the negative-pressure pipe is connected with the ventilating pipe of the cylinder head cover, and the other end of the negative-pressure pipe is connected with the negative-pressure impulse-type gasoline pump. Through the improvement on structures, such as the piston, a connecting rod, a rocker and the like, the frictional work is reduced, and therefore the mechanical efficiency of the gasoline engine is greatly enhanced.

Owner:ZHEJIANG YAOFENG POWER TECH

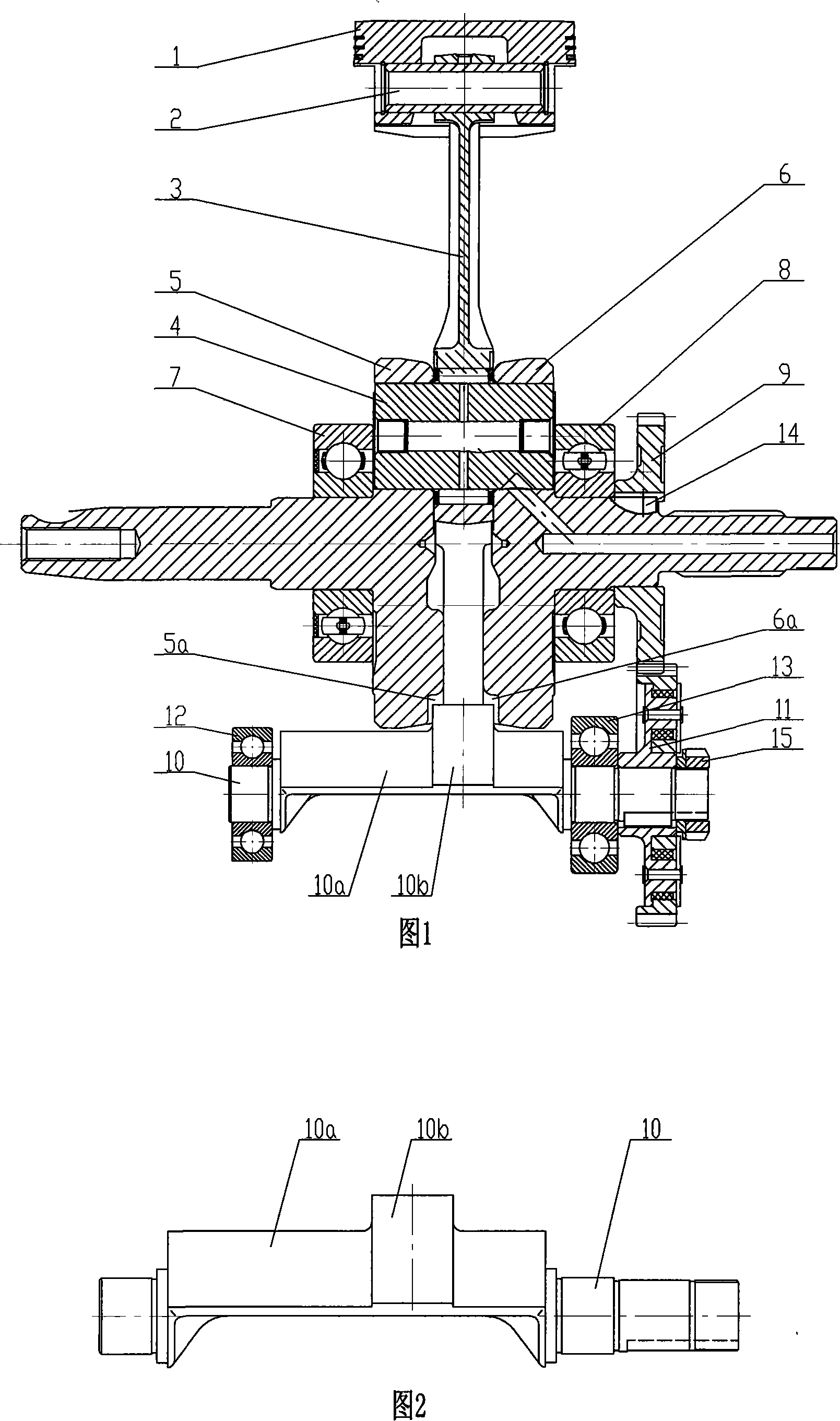

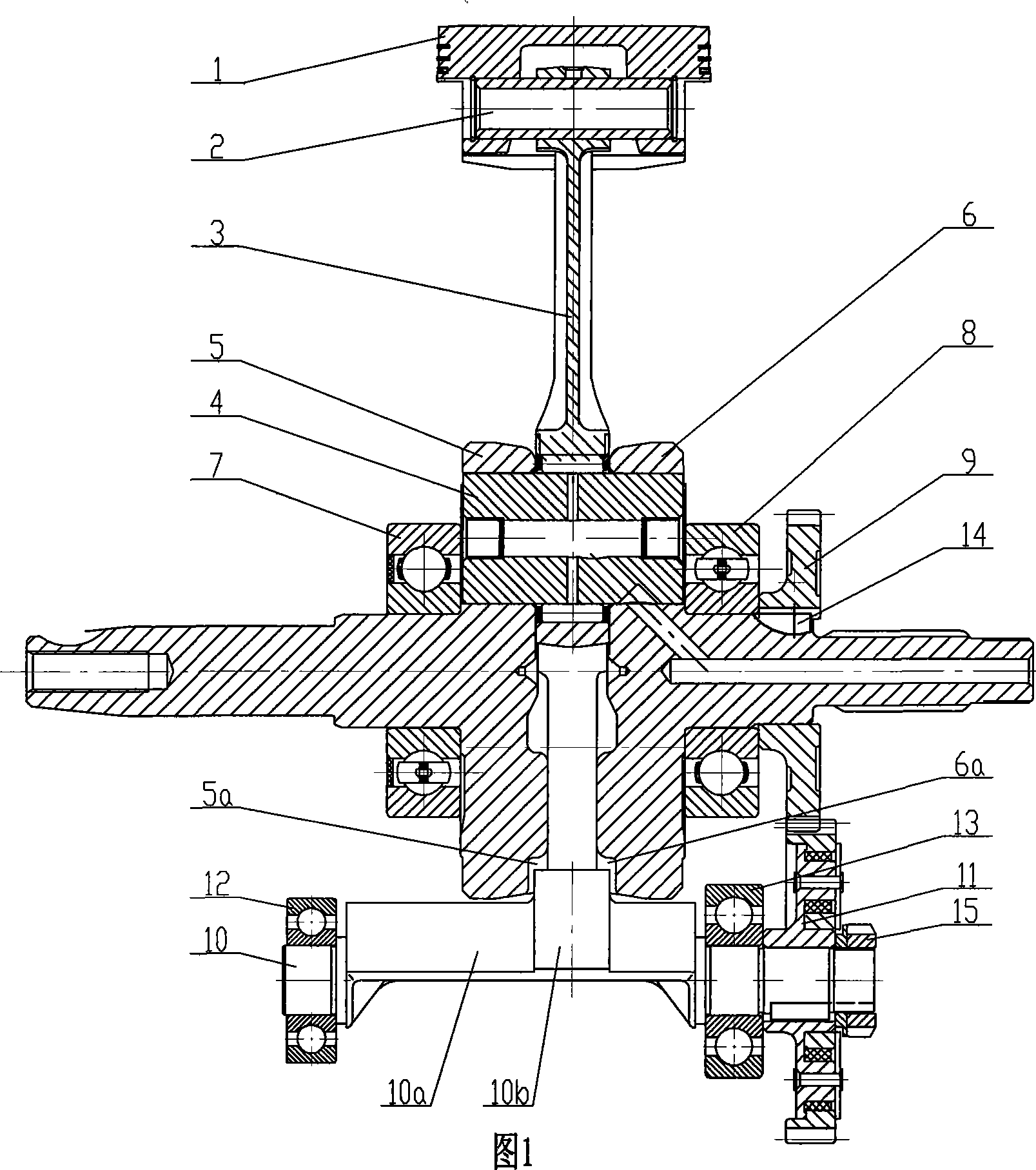

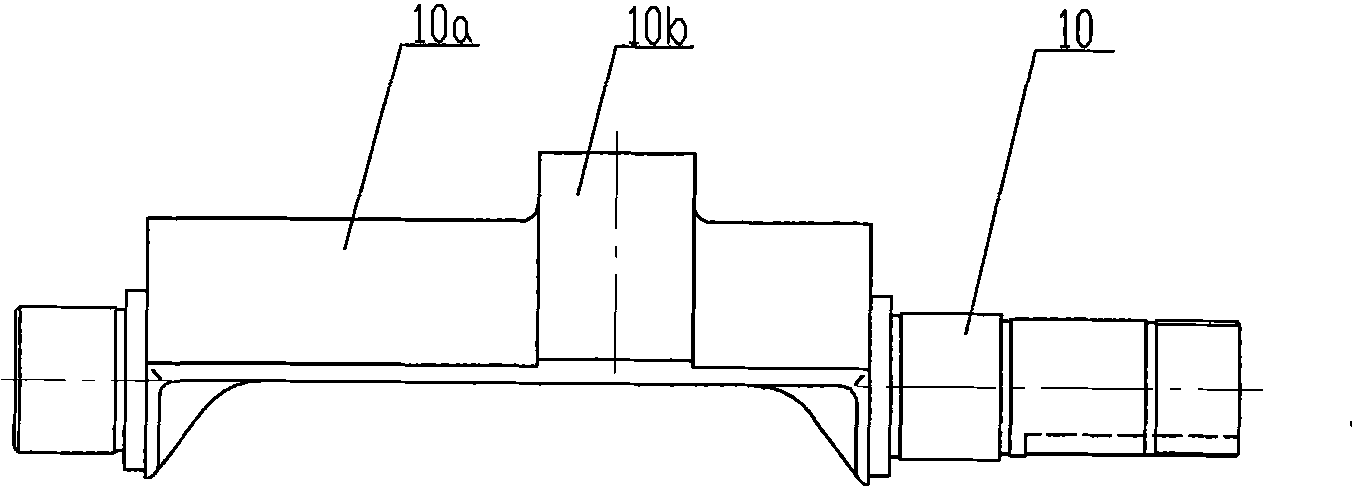

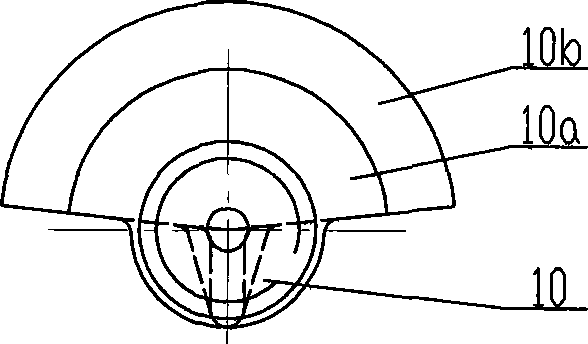

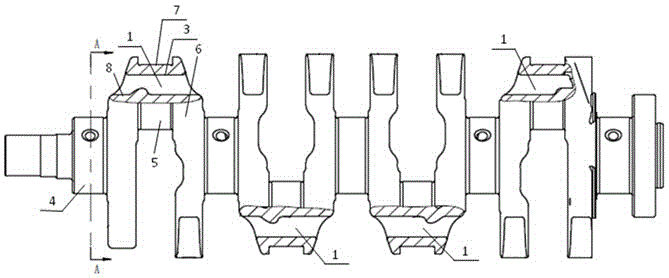

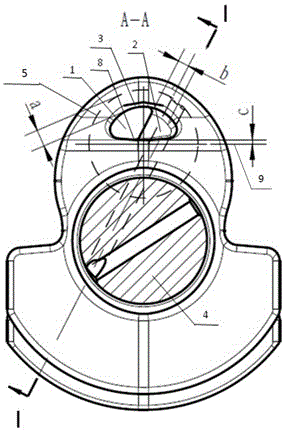

Motorcycle engine vibration damping device

InactiveCN101105206BLow costReduce weightInertia force compensationMachines/enginesEngineeringCrankcase

A vibration damping structure for motorcycle engine is provided. A piston is connected with a small end of a connecting rod through a piston pin, the big end of the connecting rod is arranged between a left crank and a right crank through a crack pin, a left crack shaft bearing is arranged on the left crank, a right crank shaft bearing and a balancing driving gear are sequentially arranged on theright crank, the balancing driving gear is engaged with an balancing driven gear disposed at the right end of a balancing shaft, a second balancing block is equipped in the middle (deviation to the right) position of a first balancing block, the opposite faces of the shank portion of the left and right crank are symmetrically opened with two notches, and when the balancing shaft rotates, the second balancing block can pass through between the two notches of the shank portion of the left and right crank. The invention can effectively balance the reciprocating inertial force generated when the large-discharge amount motorcycle engine running, so as to essentially improve the engine vibration, improve the usage comfort, service life and reliability of the motorcycle. The invention can be arranged with no need to change the structure of crank shaft case, so as to effectively reduce the manufacturing cost of the entire motorcycle.

Owner:力帆科技(集团)股份有限公司

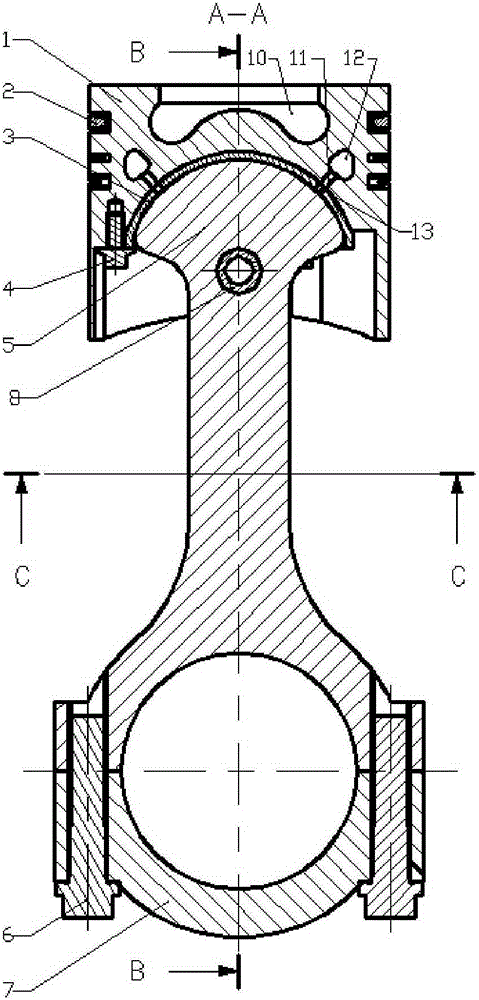

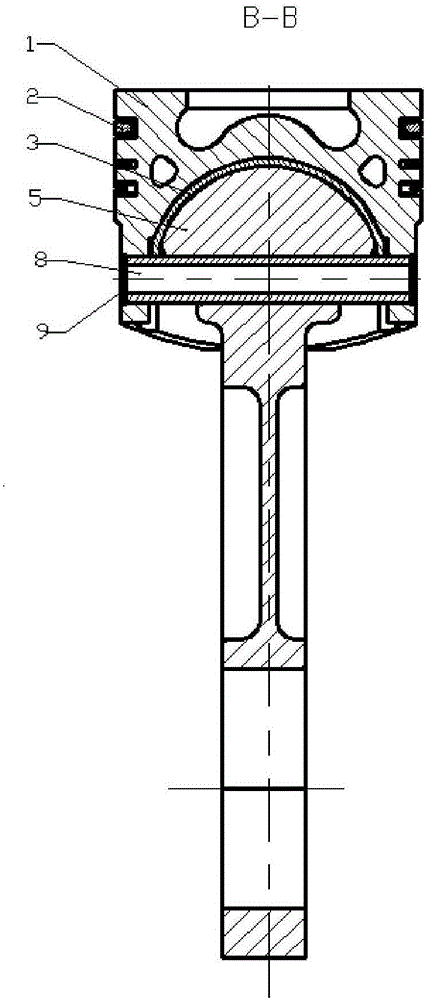

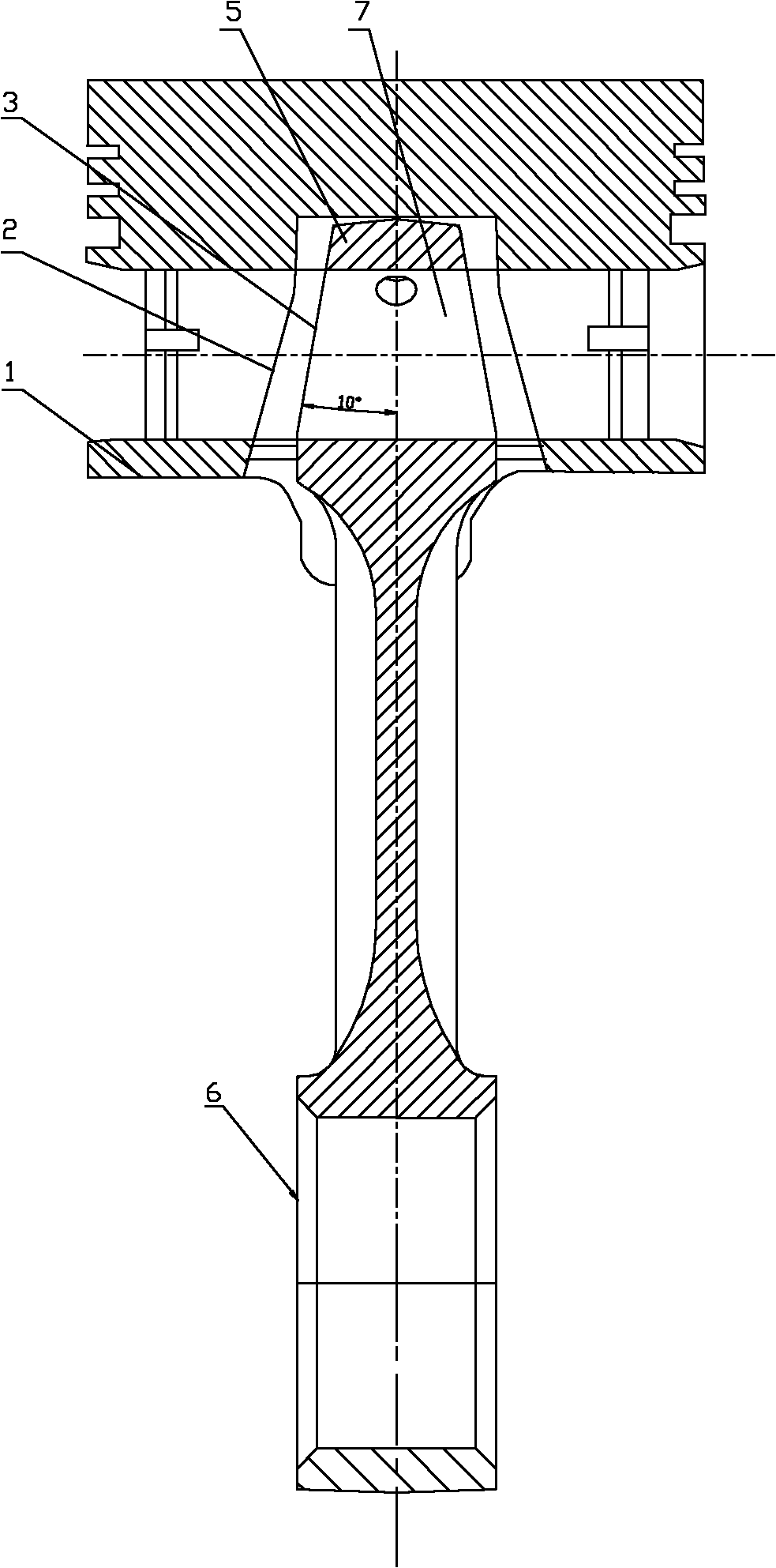

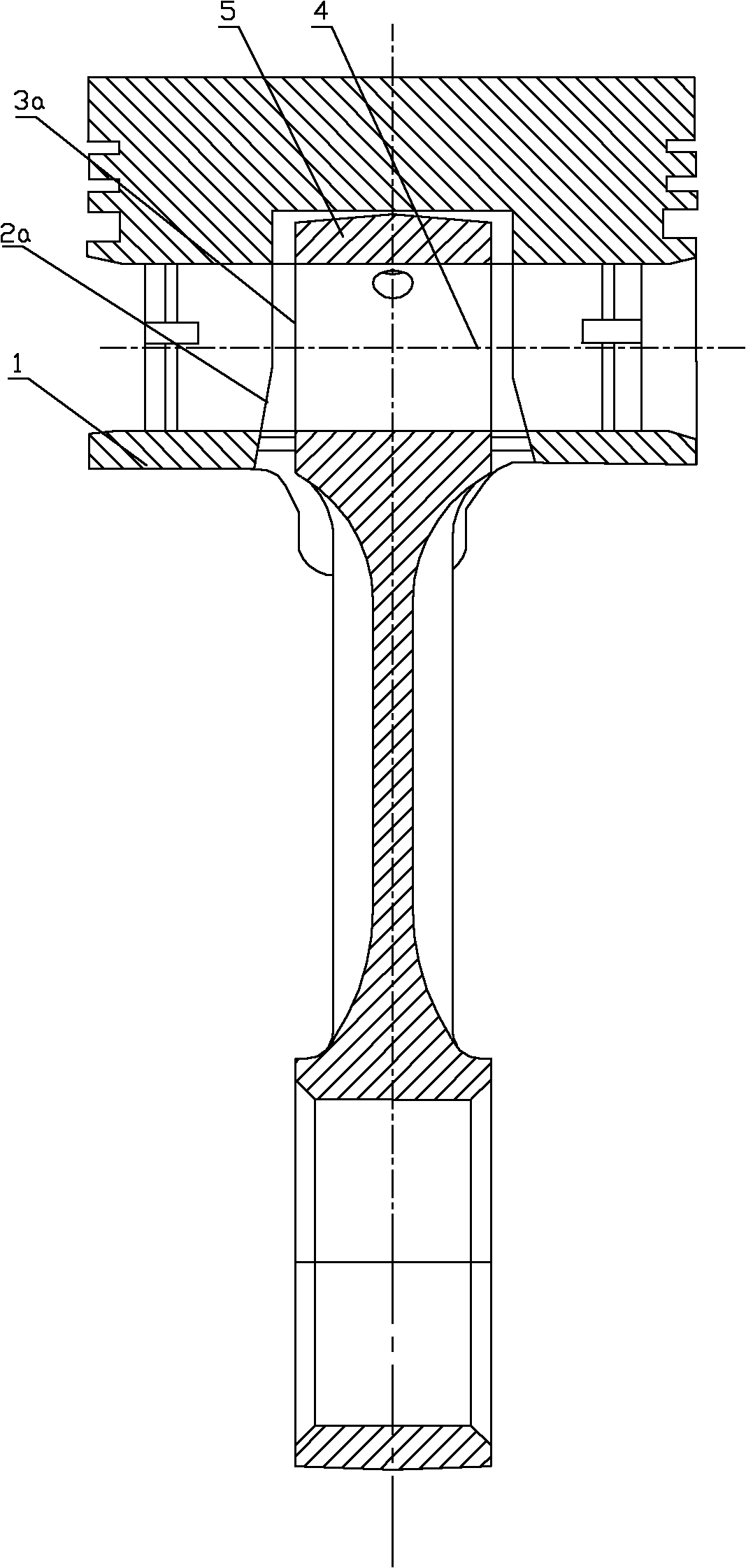

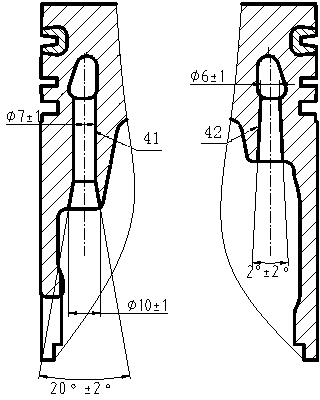

Piston connecting rod structure of internal-combustion engine

InactiveCN101806246AReduce excess massReduce reciprocating inertia forceConnecting rodsMachines/enginesEngineeringInternal combustion engine

The invention relates to a piston connecting rod structure of an internal-combustion engine. A piston is hinged with a connecting rod small end through a piston pin. The piston connecting rod structure is characterized in that the left and right symmetrical sides of the connecting rod small end are provided with inclined planes so that the connecting rod small end forms a wedge-shaped head; the center of the inclined plane at the symmetrical side of the wedge-shaped head is provided with a through hole for assembling the piston pin; the part of the piston for assembling a connecting rod is provided with a wedge-shaped groove; and a pin hole formed on a piston pin seat of the piston passes through the wedge-shaped groove. The connecting rod small end adopts a wedge-shaped structure, so a reciprocating inertia force of the connecting rod is reduced by subtracting the residual mass of the connecting rod, and meanwhile the strength and rigidity of the piston connecting rod can be satisfied.

Owner:LONCIN MOTOR

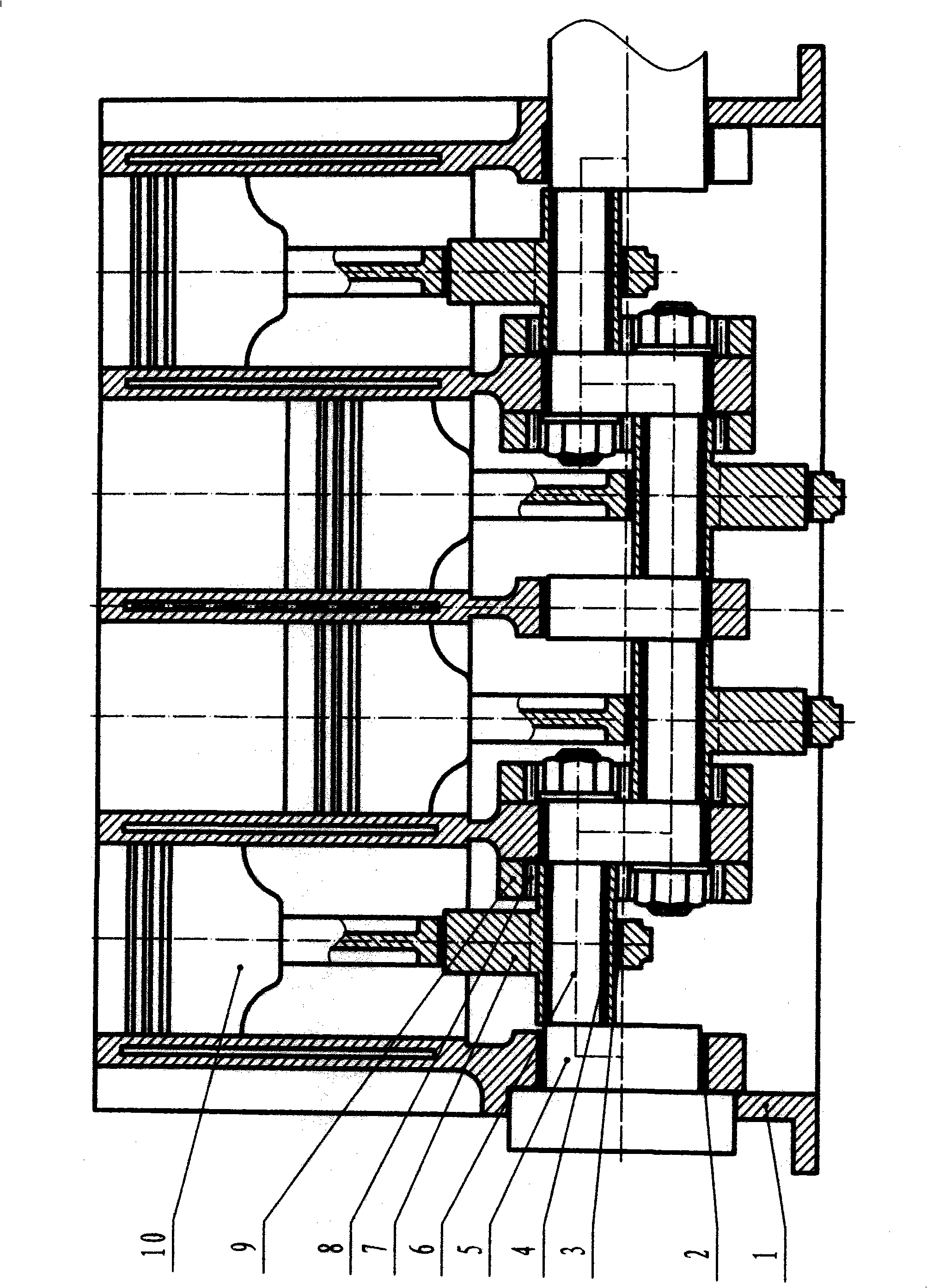

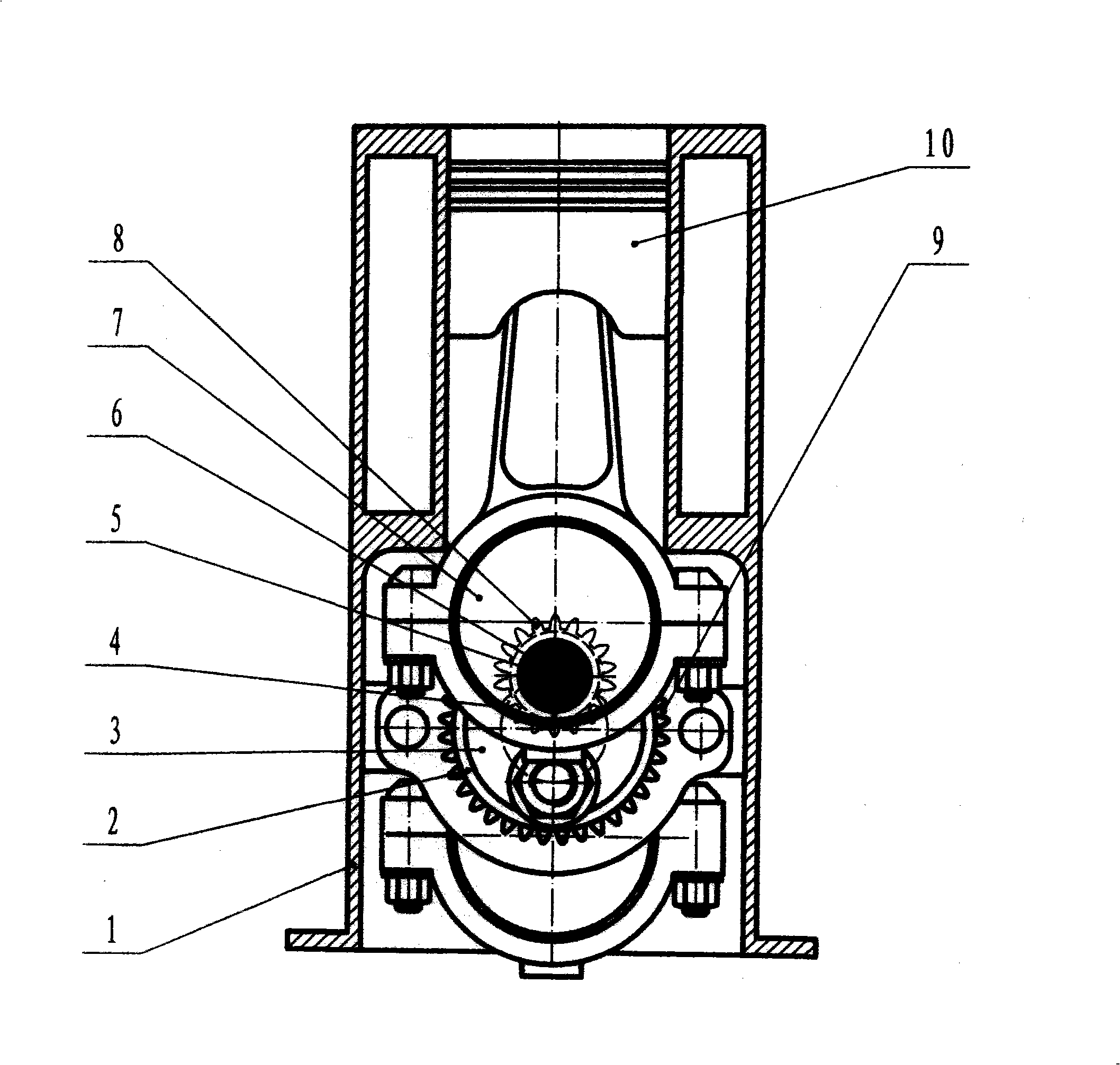

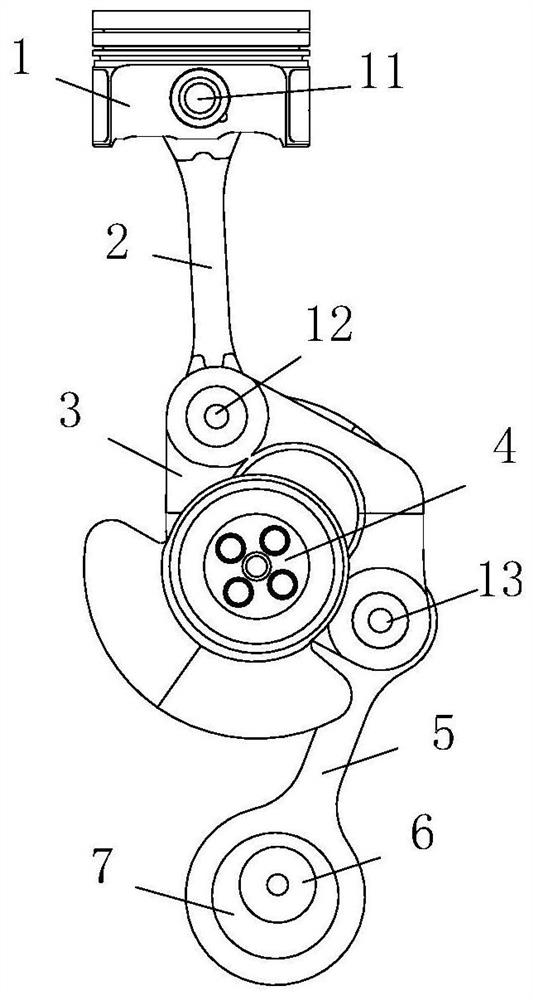

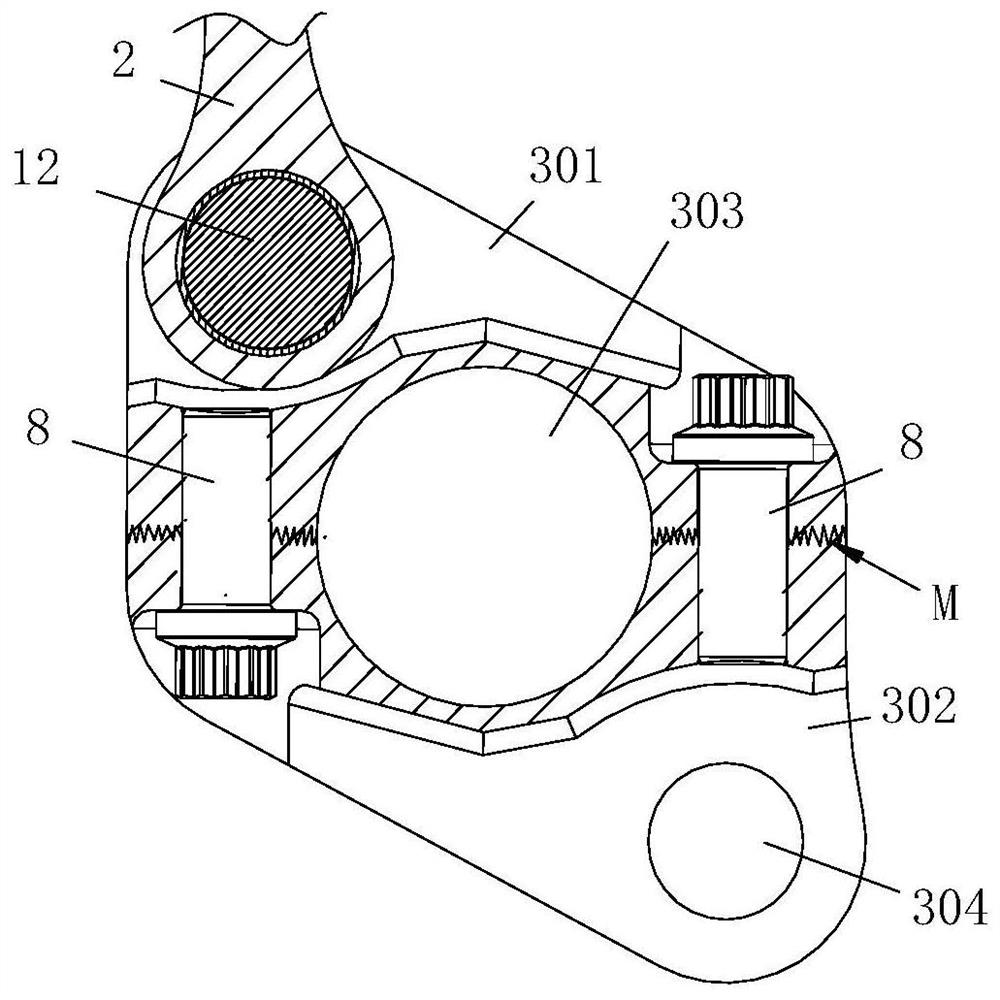

Piston type multi-stroke connecting bar non-oscillating engine

InactiveCN101324202AReduce weightLower the altitudeMachines/enginesManufacturing technologyCylinder block

The invention relates to a piston type stroke multiplication connecting rod non-swinging engine, comprising a stand, and a cylinder body, a bearing and an internal gear which are fixedly arranged on the stand, the cylinder body is internally matched with a piston, a back end of the piston is fixedly connected with a piston rod, the internal gear is correspondingly meshed with a planet wheel, the bearing is dynamically matched with a crankshaft, the crankshaft neck is dynamically matched and sheathed with the planet wheel and an eccenter connected with the planet wheel into a whole, the eccenter is dynamically matched and connected with the back end of the piston rod. The distance between the axle center of the eccenter and the axle center of the crankshaft neck is equal to that between the axle center of the crankshaft neck and the axle center of the crankshaft and also equal to the radius of the planet wheel, the radius and the number of teeth of the internal gear are two times of those of the planet wheel. Therefore, the crankshaft of the engine of the invention can be manufactured integrally, and the slide tolerance and compatibility of the moving parts of the whole engine can be guaranteed by using the integral manufacturing technology of the crankshaft.

Owner:孙德全 +1

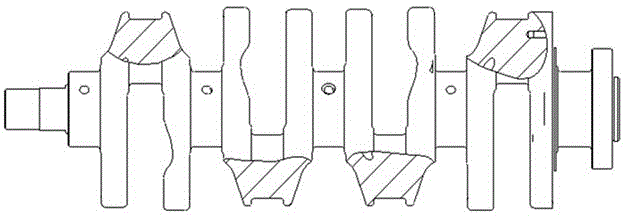

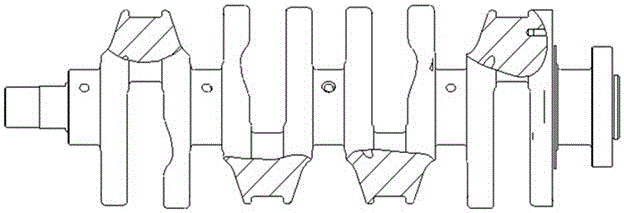

Gasoline engine crankshaft

The invention discloses a gasoline engine crankshaft which comprises a main journal and crank arms arranged at intervals on the main journal in order. A weight reducing through hole is formed in a connecting rod journal which is connected with the crank arms. The weight reducing through hole is a semicircular opening which is in smooth transition in the radial direction. The semicircular opening is positioned between the axis horizontal plane of the connecting rod journal and the top of the connecting rod journal. The straight bottom of the semicircular opening is close to the axis horizontal plane of the connecting rod journal and is a first wall thickness away from the axis horizontal plane of the connecting rod journal; a circular arc top of the semicircular opening is close to the outer edge of the top of the connecting rod journal and is a second wall thickness away from the outer edge of the top of the connecting rod journal. According to the gasoline engine crankshaft, the weight reducing through hole of a traditional crankshaft connecting rod journal is designed to achieve the purposes of weight reduction of the crankshaft, the improvement of the balance rate of the crankshaft and the reduction of engine fuel consumption.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Single-valve four-stroke internal combustion engine

ActiveCN107269387AReduce quality problemsReduce reciprocating inertia forceCylinder headsCylindersCombustionExhaust valve

The invention provides a single-valve four-stroke internal combustion engine. The single-valve four-stroke internal combustion engine comprises a piston, a cylinder, fuel injectors, a cylinder head and a valve. The cylinder is fixedly connected with the cylinder head. A gas flow passageway is arranged in the cylinder head. The gas flow passageway is composed of an intake way, an exhaust way and a cooling gas way which communicate with one another. An intake valve is arranged in the intake way. An exhaust valve is arranged in the exhaust way. A cooling valve is arranged in the cooling gas way. The piston moving in a reciprocating manner is mounted in the cylinder. The valve is mounted in the cylinder head and coaxial with the piston. Multiple first through holes are formed in the valve. The multiple fuel injectors are mounted in the cylinder head. When the valve interrupts the interior of the cylinder and the gas flow passageway through the reciprocating motion, the fuel injectors are in sealed fit with the first through holes in a one-to-one corresponding manner. By the adoption of the single-valve four-stroke internal combustion engine, the mass and the reciprocating inertial force of the valve can be reduced, the oil-gas mixing is more uniform, the combustion of fuel is more sufficient, and the fuel economy and harmful matter discharge are improved.

Owner:JIANGSU UNIV

Carbon nanotube modified composite material piston for engine as well as preparation method and application of carbon nanotube modified composite material piston

ActiveCN113831138AExtended service lifeLow failure rateMachines/enginesPistonsCombustion chamberOxidation resistant

The invention relates to a carbon nanotube modified composite material piston for an engine and a preparation method and application of the carbon nanotube modified composite material piston, and belongs to the technical field of piston materials and piston design and processing. The specific preparation method comprises the steps: designing and preparing a prefabricated body structure; performing high-temperature heat treatment; preparing a low-density C / C porous body by adopting a CVI method; performing high-temperature heat treatment on the C / C porous body; performing primary machining to form a piston blank, and growing carbon nanotubes in situ in pores of the C / C porous body by adopting a normal-pressure CVD method; densifying the piston blank through an RMI method, and performing secondary machining according to the requirement for the size of a finished piston; and after finish machining is completed, coating a piston combustion chamber and a piston top position with anti-oxidation coating layers, and thus obtaining the finished product of the nanotube modified composite material piston. The composite material piston provided by the invention has positive significance in improving the output power of an engine, reducing oil consumption, reducing noise, prolonging the service life of the piston, reducing emission and improving the environment.

Owner:湖北瑞宇空天高新技术有限公司

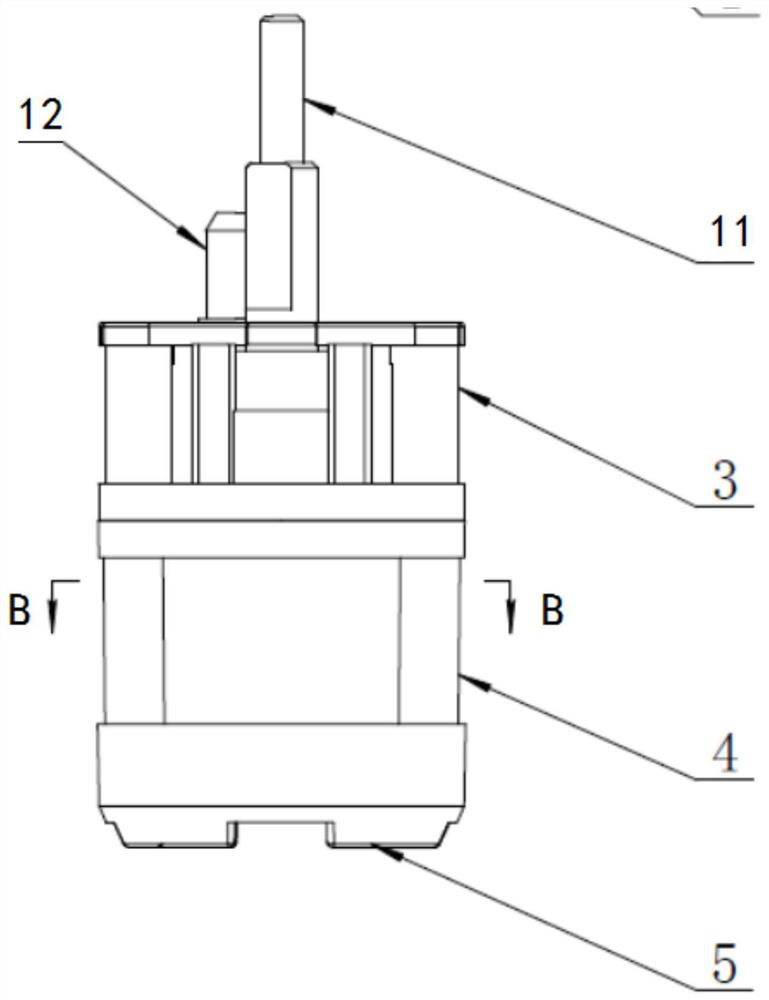

Infusion pump used for non-contact automatic hand sterilizer

PendingCN112502964AIncrease volumeRelieve pressureRotary/oscillating piston combinationsMachines/enginesMedicineEngineering

The invention discloses an infusion pump used for a non-contact automatic hand sterilizer. The infusion pump comprises an infusion pump body, the infusion pump body comprises a shell, a liquid discharging pipe, a pump body and a driving device, the pump body comprises a pump body cavity, an eccentric cam and a blocking assembly, the pump body cavity comprises a liquid inlet cavity and a liquid outlet cavity, the liquid outlet cavity of the pump body cavity communicates with the liquid discharging pipe, and a liquid inlet is arranged at the lower end of the pump body cavity. When the driving device drives the eccentric cam to rotate in the first direction, the volume of the liquid inlet cavity is increased, liquid enters the liquid inlet cavity, the volume of the liquid outlet cavity is reduced, and the liquid in the liquid outlet cavity is discharged into the liquid discharging pipe. When the driving device drives the eccentric cam to rotate in the second direction, the volume of the liquid outlet cavity is increased, liquid in the liquid discharging pipe flows into the liquid outlet cavity, the volume of the liquid inlet cavity is reduced, and the liquid in the liquid inlet cavityis discharged from the liquid inlet. According to the infusion pump, the driving device controls the eccentric cam to rotate so that liquid suction and discharging can be directly completed, inversion can be conducted after liquid suction is completed so that liquid can be sucked back, the structure is simple, and reliability is high.

Owner:上海荣安五金机电有限公司

Vertical cylinder piston type internal combustion engine

InactiveCN101526028BReduce reciprocating inertia forceReduce centrifugal forceInertia force compensationCylinder headsFuel oilInternal combustion engine

A vertical cylinder piston type internal combustion engine belongs to a power machine which takes fuel oil or combustible gas as fuel. Cylinders of the internal combustion engine are mutually perpendicular on different planes, and turn reciprocating motion of a piston (20) into rotary motion of crankshafts by an eccentric distance E of an eccentric shaft (25), an eccentric sleeve (7), a front crankshaft (5) and a rear crankshaft (22). The internal combustion engine has neither disadvantages resulting from centrifugal force and reciprocating inertia force of connecting rods nor internal gear pair of general internal combustion engines without connecting rods, reduces lateral pressure between the cylinders and the piston; lowers height of the cylinders, and leads the piston to do work in single direction or two directions. The internal combustion engine is well balanced owing to a main counterweight balance system and an auxiliary counterweight balance system. The internal combustion engine has the advantages of small size, light weight, high efficiency and small vibration. The internal combustion engine can be made into air-cooled type and water-cooled type double-cylinder or multi-cylinder gasoline engines, diesel engines or combustible gas engines.

Owner:黄安陶

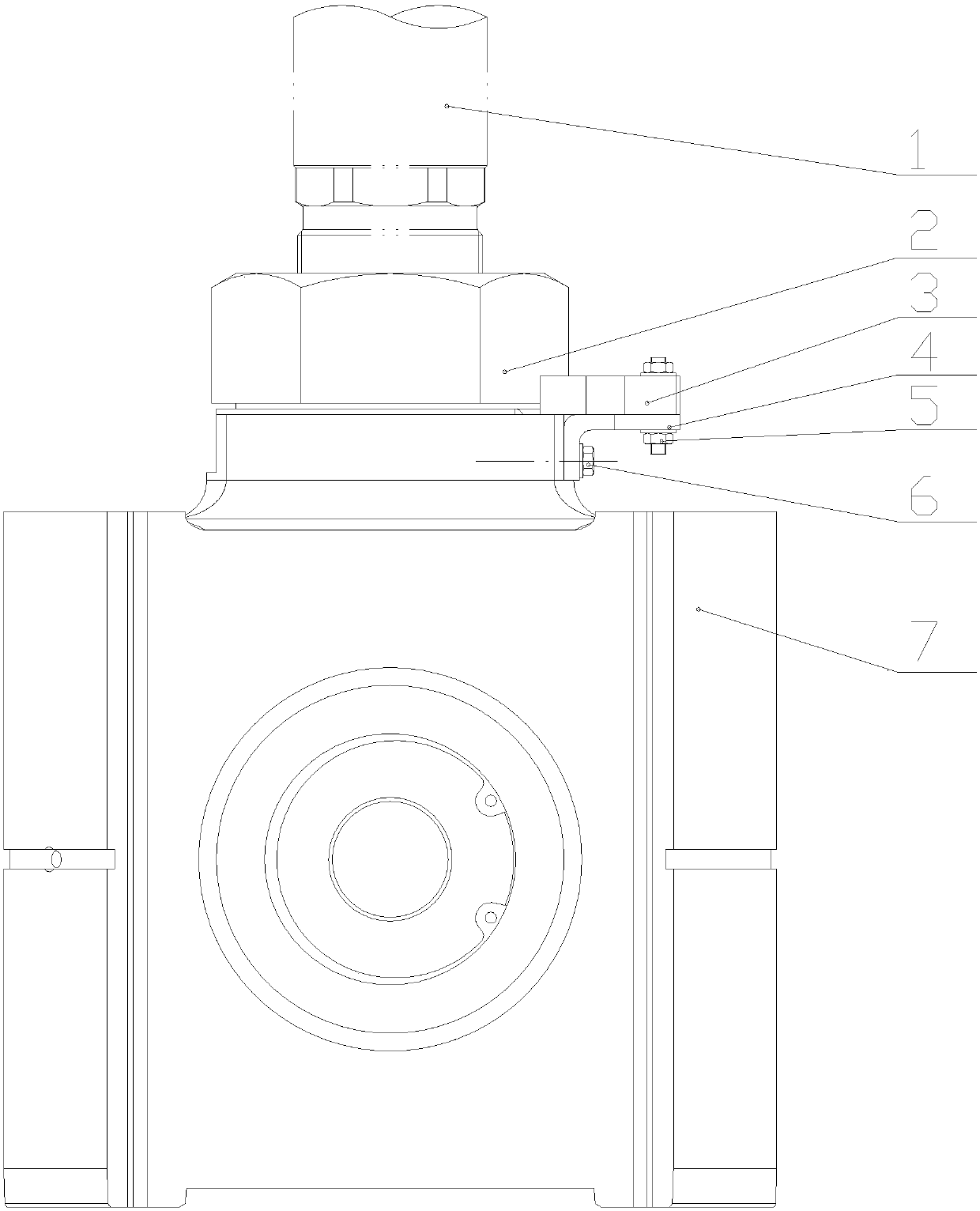

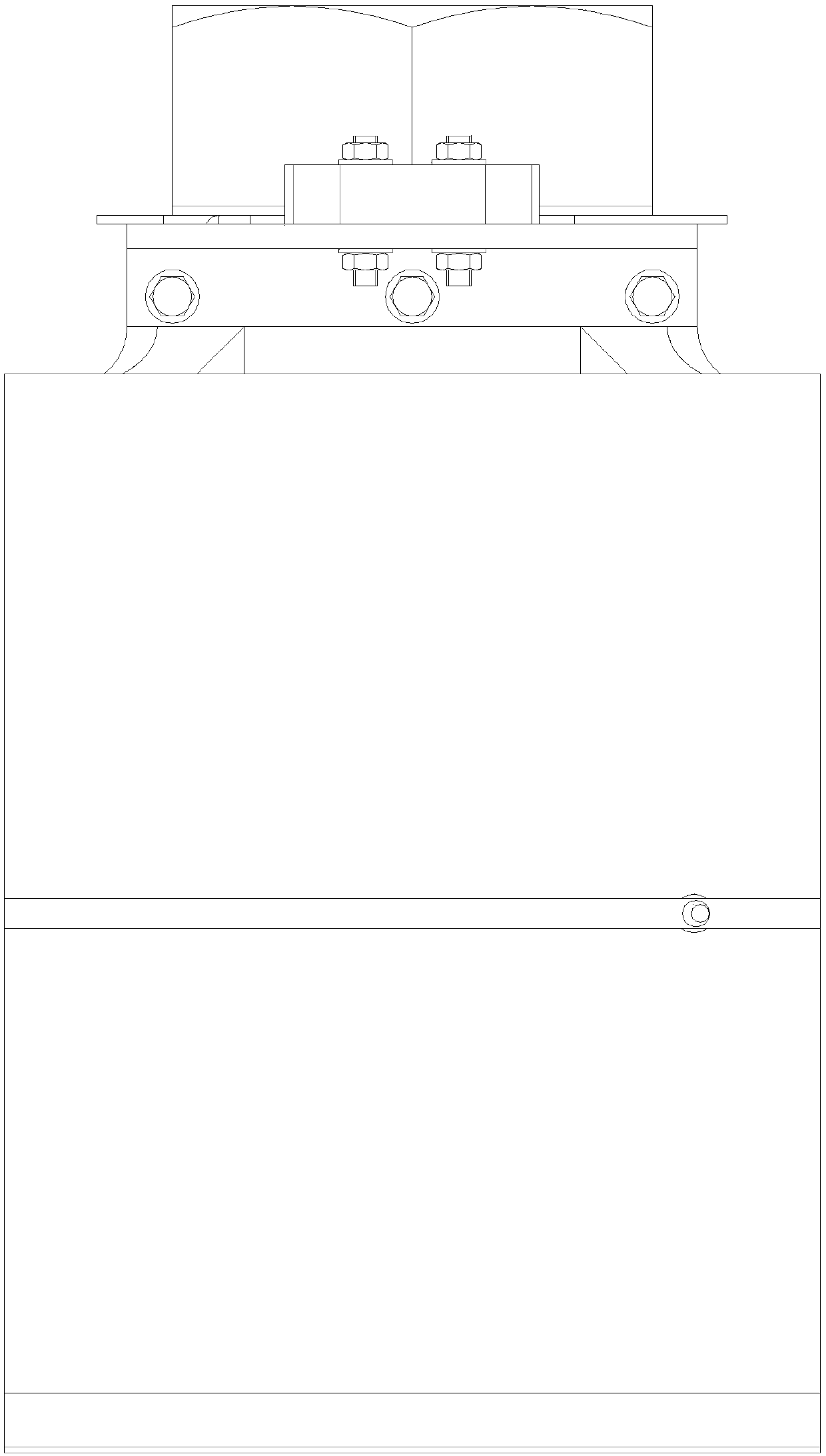

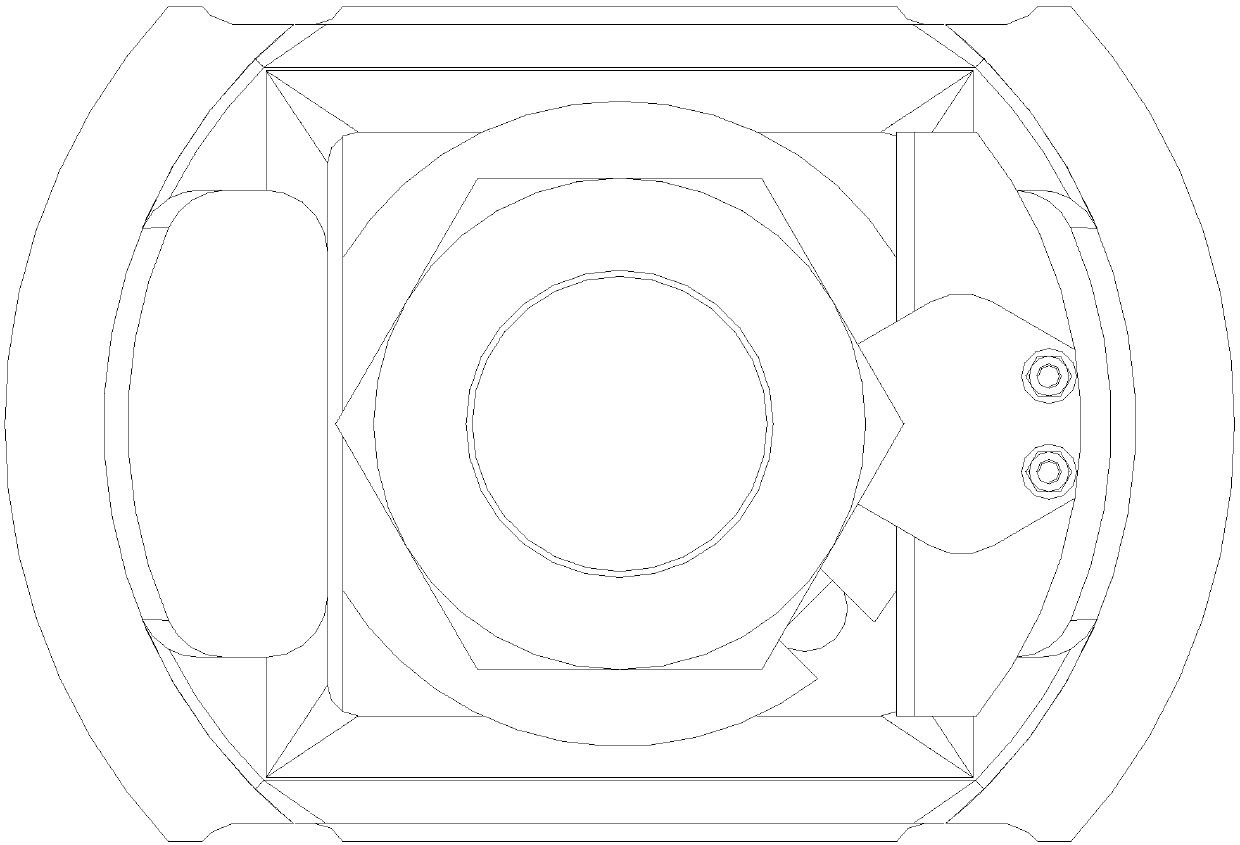

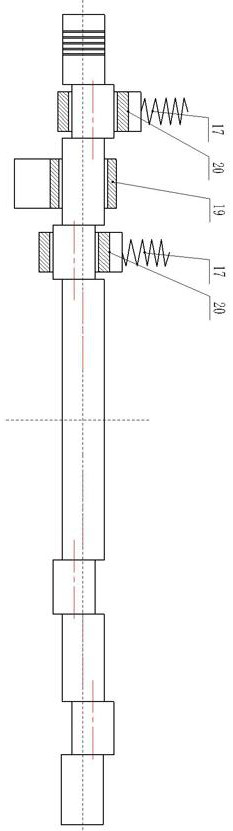

Device capable of enabling crosshead and piston rod of compressor to be connected stably

InactiveCN107559173AReduce reciprocating inertia forcePrevent looseningPositive displacement pump componentsPositive-displacement liquid enginesLateral rightEngineering

The invention discloses a device capable of enabling a crosshead and a piston rod of a compressor to be connected stably and relates to the field of small and medium size compressors. The device comprises a fastening steel plate, a right-angled steel plate and a crosshead body. An inner threaded hole for mounting the right-angled steel plate is drilled vertically in the right side of a pin hole ofthe crosshead at the top end of the crosshead body, a hole with the same dimension is drilled in the position, corresponding to the inner threaded hole in the top end of crosshead body, in a verticalplate of the right-angled steel plate, and the two holes are connected through a bolt; a hole is formed in a transverse plate of the right-angled steel plate, a hole is drilled in the position, corresponding to the hole in the transverse plate of the right-angled steel plate, in the fastening steel plate, and the holes are connected through a stud. In connection, the right-angled steel plate andthe fastening steel plate as well as a fastener are not directly connected to the piston rod, so that the reciprocating inertial force of the right-angled steel plate, the fastening plate and the fastener is relatively small, and the right-angled steel plate, the fastening plate and the fastener do not loosen if being fixed.

Owner:BENGBU GAOKE ENERGY EQUIP

Eccentric rotor engine and combusting and working method thereof

PendingCN107587936ASimple structureIngenious designInternal combustion piston enginesAir compressionCombustion

The invention relates to an eccentric rotor engine and a working method thereof. The eccentric rotor engine structurally comprises a cylinder body and a cylindrical eccentric rotor arranged in the inner cavity of the cylinder body, wherein the cylinder body is provided with a plurality of movable partition plates, the movable partition plates are in contact with the side wall of the eccentric rotor and divide the inner cavity into a plurality of independent cavities, the movable partition plates perform reciprocating motion in strip-shaped through grooves with rotation of the eccentric rotor,the volumes of the cavities correspondingly change, and the working process of air inflow, compression, ignition, expansion working and exhausting is correspondingly completed. Multiple working modessuch as external air compressor two-stroke continuous combustion cycle, internal air compression two-stroke cycle, four-stroke re-expansion cycle and common four-stroke cycle are designed according todifferent air inlet modes and different movable partition plate controls. The eccentric rotor engine is simple and durable in structure, is good in torque under maximum explosion pressure, and is stable and sufficient in working medium combustion, high in output power, high in power density, low in hazard waste emission, high in fuel economy, stable in operation, small in shake, low in noise andhigh in heat efficiency.

Owner:狄庆会

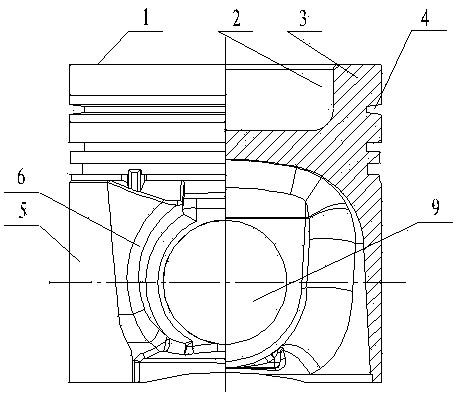

Pressurizing oil-saving type piston of diesel engine

ActiveCN102444496BReduce weightReduce the overall heightMachines/enginesPistonsFriction reductionCombustion chamber

The invention discloses a pressurizing oil-saving type piston of a diesel engine, which comprises a piston pin boss, a skirt portion and a head portion, wherein the head portion is composed of a piston top end and a ring groove, the ratio of the total height of the piston to the cylinder diameter is from 1.024 to 1.028, the ratio of the height of a piston junk to the cylinder diameter is from 12.6% to 12.8%, and the largest point gap between the head portion of the piston and the inner diameter of the cylinder is 2.2mm. A top end combustion chamber in a shape of a w-shaped pit is arranged at the head portion of the piston, a cooling oil cavity composed of a cooling oil channel, an oil inlet hole and an oil outlet hole is arranged in the head portion of the piston below the top end combustion chamber, and the oil inlet hole and the oil outlet hole are located at two ends of the cooling oil channel and communicated with a cavity inside the piston. The skirt portion is a variable elliptic type surface with the middle portion protruding outwards and both the ellipticity and the diameter variable. The pressurizing oil-saving type piston of the diesel engine can reduce inertia force of reciprocating movement, friction contact area and invalid friction work loss and can reduce clearance of cylinder matching by means of optimizing piston structure, and achieve the purposes of improving valid power and reducing consumption of fuel oil and lubricating oil and environment pollution.

Owner:石家庄金刚内燃机零部件集团有限公司

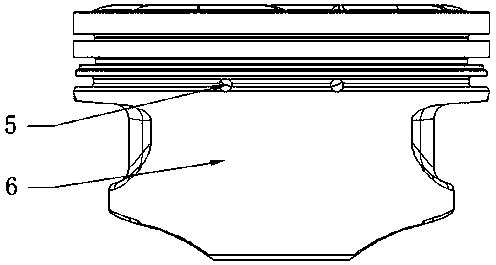

Piston of alcohol fuel internal combustion engine

PendingCN111255592AInsulate from high temperatureAvoid ablationMachines/enginesPistonsAlcohol fuelGasoline

The invention relates to a piston of an alcohol fuel internal combustion engine. At present, conventional gasoline engine pistons are corroded by alcohol fuel and combustion products thereof in the alcohol internal combustion engine, meanwhile, the compression ratio of the alcohol internal combustion engine is high, the burst pressure is large, the instantaneous temperature is high, the top of thegasoline engine piston and the head of a piston are easy to ablate at high temperature, and the heat isolation and heat resistance are poor. The piston of the alcohol fuel internal combustion enginecomprises a piston top (1), a piston head (2), a piston skirt (6) and a piston pin seat (8), wherein the piston top is a forming top, the section of the protruding portion is approximately in an ovaloid shape, and the remaining part of the piston top is of a flat top structure; the piston top is provided with a valve avoiding pit; the piston head is mainly composed of a rectangular fire bank, twogas ring annular grooves (3) and an oil ring annular groove (4); the two air ring annular grooves are filled with air rings for sealing and heat conduction; and the oil ring annular groove is placed into a combined oil ring for oil scraping, oil distribution and gas sealing assistance. The piston is applied to the alcohol fuel internal combustion engine.

Owner:营口福泰科技有限责任公司

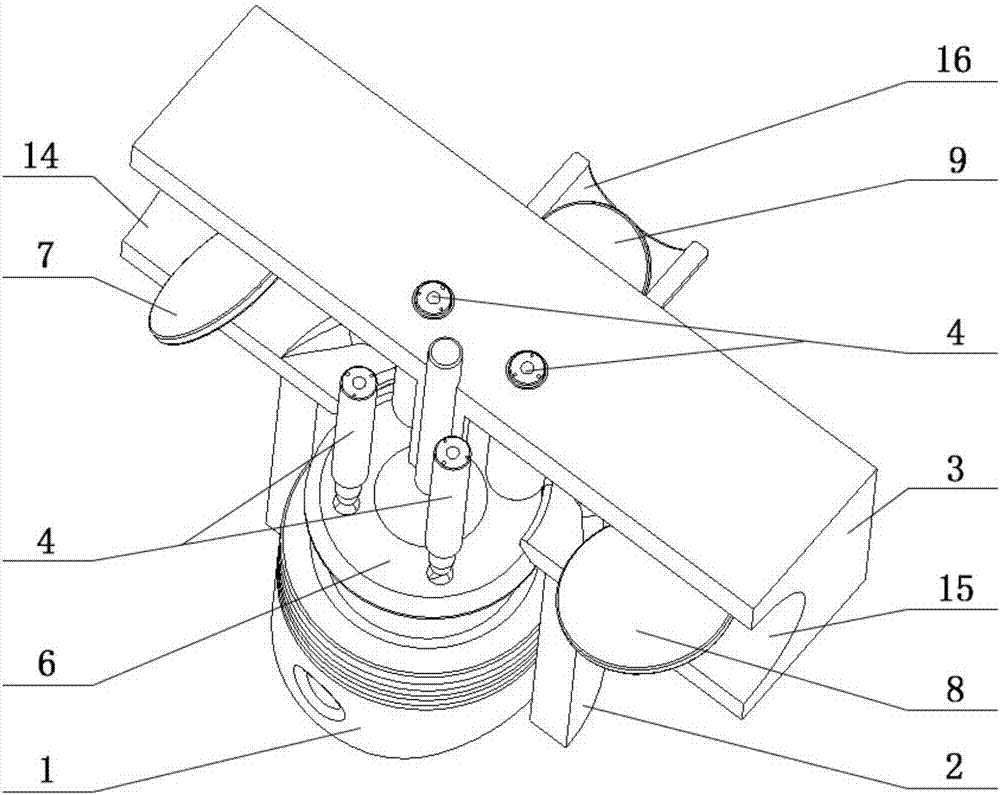

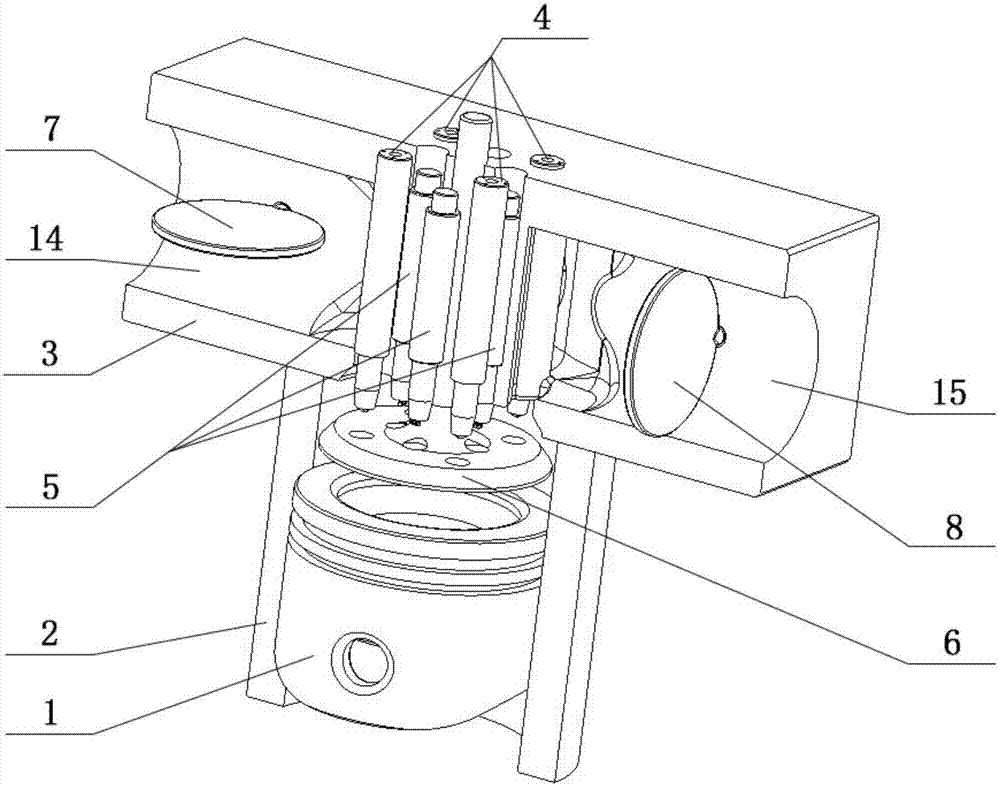

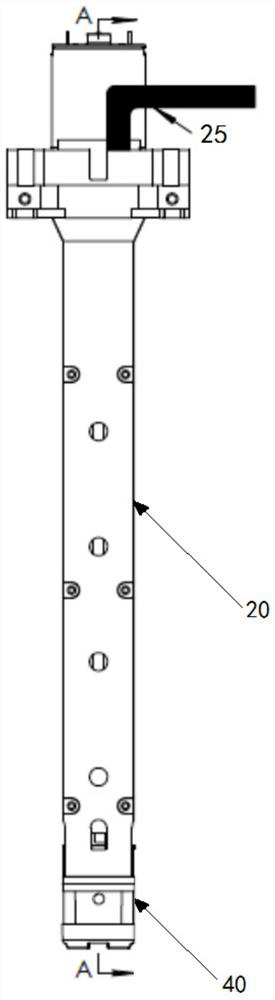

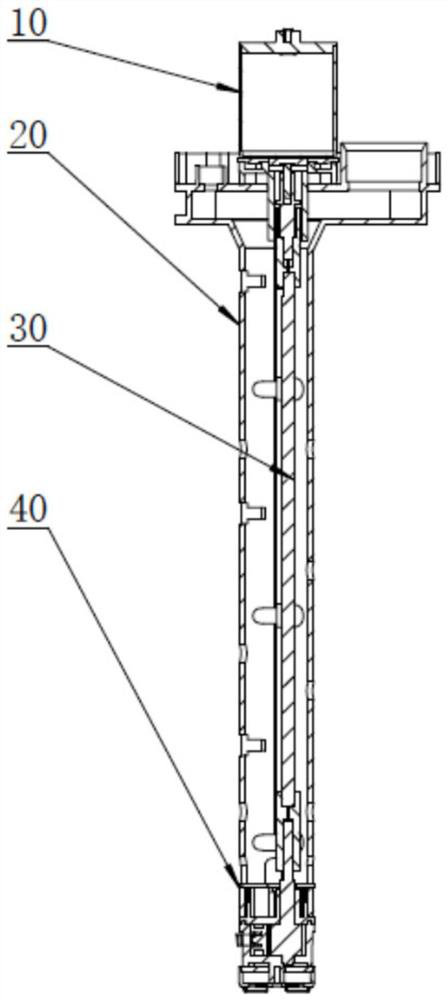

High-precision boring device

PendingCN109262001AImprove sliding stabilityImprove stabilityBoring headsReciprocating motionEngineering

The invention discloses a high-precision boring device which comprises a boring head, guide sliders, a slider cover plate, a boring rod and slider pushing hooks. Boring cutter holders are distributedon the boring head, slider sliding grooves are further formed in the boring head, the side projection of each guide slider is approximately in an 'L' shape, the guide sliders are correspondingly distributed in the slider sliding grooves, pushing hook limit grooves are further formed in the guide sliders and formed upwards from the top surfaces of the guide sliders, the guide sliders are combined with the boring cutter holders, the lower ends of the slider pushing hooks are connected with the boring rod, the upper ends of the slider pushing hooks are distributed in the pushing hook limit grooves, the boring rod is connected with a machine tool spindle, the boring head is driven to rotate, and the guide sliders are driven by telescopic movement to reciprocate in the slider sliding grooves along slopes of the slider sliding grooves. The high-precision boring device is strong in stability, high in accuracy and good in use effect.

Owner:GUANGXI YUCHAI MASCH CO LTD

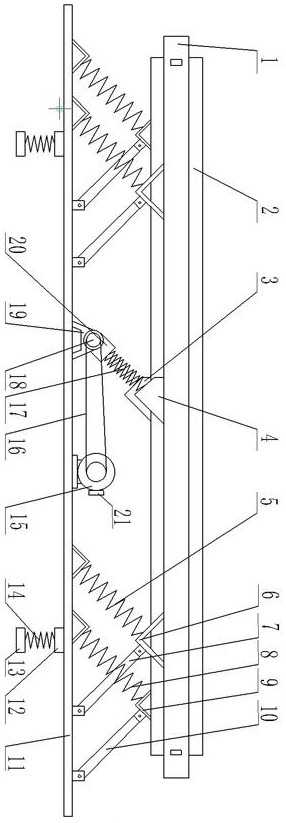

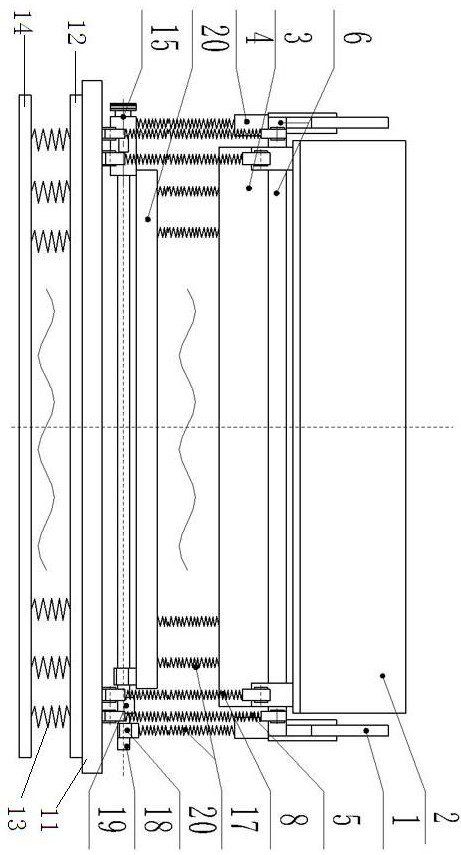

A self-balancing multi-position sustainable vibration device

The invention discloses a self-balancing multi-station sustainable vibrating device, which comprises a vibrating bed and balance beams arranged on both sides thereof, the balancing beam and a supporting beam below the vibrating bed, and the balancing beam and vibrating bed are passed through an exciting spring They are respectively connected to the eccentric crankshaft. The eccentric crankshaft is symmetrical at both ends. Each end sleeve includes an outer shaft body, an intermediate shaft body and an inner shaft body. The intermediate shaft body is connected to the crankshaft support through a bearing. Both the shaft body and the inner shaft body are connected to the rotating shaft seat through the bearing, and the two rotating shaft seats are respectively connected to the vibrating bed through the exciting spring and the balance beam. Vibrating force is generated during the operation of the vibrating bed of the present invention, and the vibration direction of the vibrating bed and the balance beam has a phase difference of 180°, which enables the vibrating device to achieve self-balancing, reduces the reciprocating inertial force generated during the vibrating process, and reduces the impact of vibration on the equipment. Destruction improves the long-term continuity and stability of the vibrating bed device and prolongs the service life of the equipment.

Owner:NANJING INST OF TECH

Rotary shaft type gas valve engine

PendingCN107448288AReduce vibration and noiseReduce reciprocating inertia forceCylinder headsCylindersCombustion chamberGas cylinder

The invention discloses a rotary shaft type gas valve engine. The rotary shaft type gas valve engine comprises a gas cylinder body, a crankshaft and a gas cylinder cover assembly, wherein the gas cylinder cover assembly comprises a gas distributing mechanism, a gas cylinder cover and a gas valve chamber positioned inside the gas cylinder cover; the gas distributing mechanism comprises four gas inlet paths which are arranged into one row and four gas outlet paths which are arranged into one row, and the gas inlet paths and the gas outlet paths separately communicate with the left end and the right end of a vent valve; the lower end of the gas valve chamber separately communicates with combustion chambers of four gas cylinders through four gas inlets; a gas valve shaft capable of sealing the gas valve chamber is rotatably arranged in the gas valve chamber; rotation speed of the crankshaft is twice that of the gas valve shaft; and four vent slots which are staggered with one another are correspondingly formed in the gas valve shaft axially. According to the rotary shaft type gas valve engine disclosed by the invention, a gas valve group is simplified into one gas valve shaft for controlling gas valves to open and close, and the gas valve shaft controls gas introduction and gas exhaustion, so that reciprocating inertial force brought to a cam shaft is reduced as the transmission way does not need the cam shaft, the structure is greatly simplified, and vibration noises of the gas cylinder cover are reduced.

Owner:ZHUHAI COLLEGE OF JILIN UNIV

Rotary compressor

ActiveCN101498306BReduce volumeReduce weightRotary piston pumpsRotary piston liquid enginesExhaust valveSlide plate

Owner:DAFENG FENGTAI FLUID MACHINERY TECHNOLOGY CO LTD

Variable compression ratio mechanism and engine

ActiveCN110671199BReduce friction lossReduce wearEngine controllersMachines/enginesCrankFriction loss

The present invention provides a variable compression ratio mechanism, which includes sliding a piston disposed in the engine block, rotating a crankshaft disposed in the engine block and an eccentric shaft with an eccentric wheel, and rotating a crankpin disposed in the crankshaft the adjusting connecting rod, and the executing connecting rod and the driving connecting rod hinged at both ends of the adjusting connecting rod and respectively hinged with the piston and the eccentric wheel; The swing angle of the actuator link is set to be lower than 30°, and the swing angle of the drive link is set to be less than 27° with the eccentric wheel as the swing center. The variable compression ratio mechanism of the present invention can reduce the friction loss and reciprocating inertial force of the connecting rod by limiting the swing angle of the connecting rod during operation, thereby reducing the wear of the connecting rod.

Owner:GREAT WALL MOTOR CO LTD

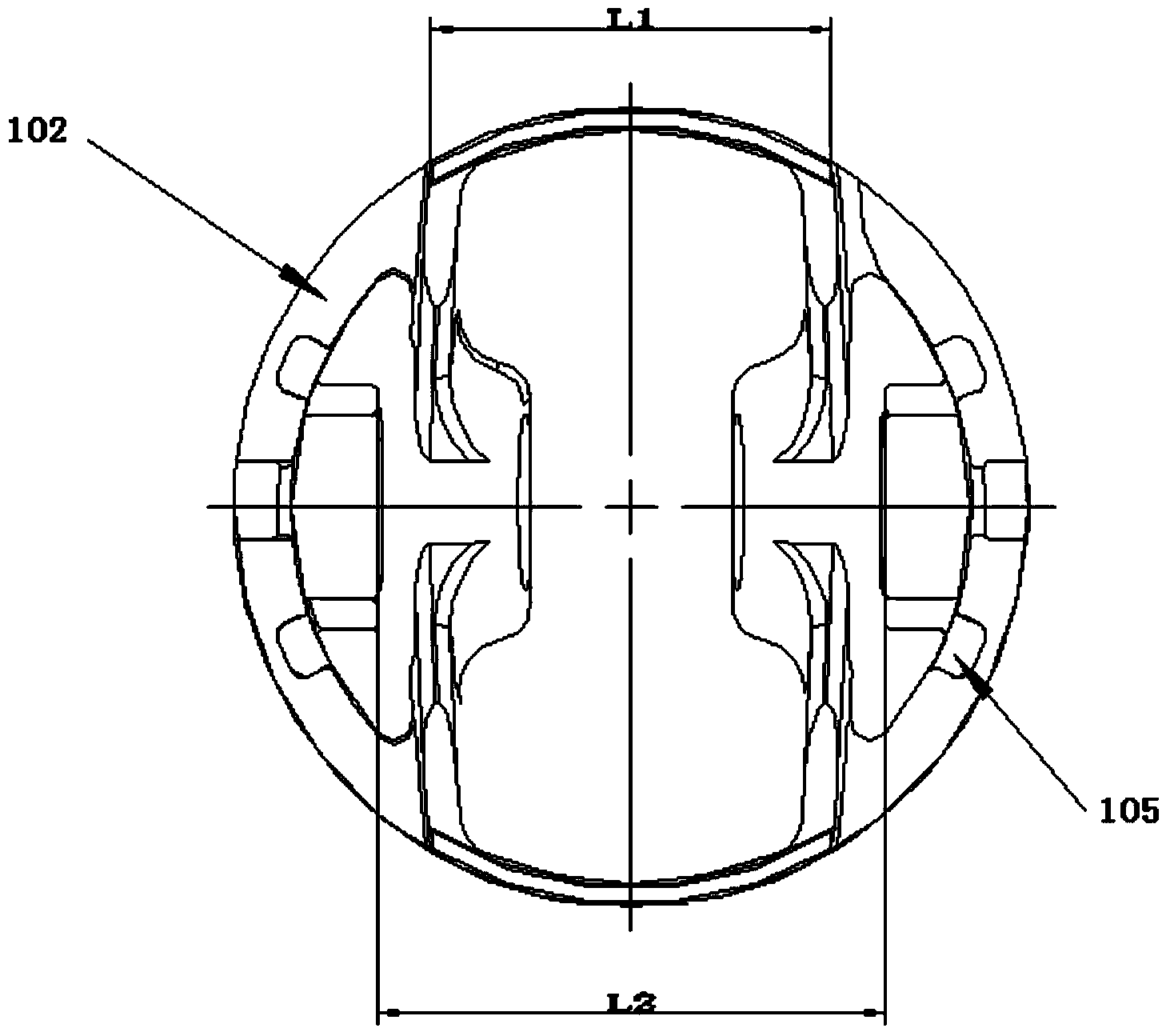

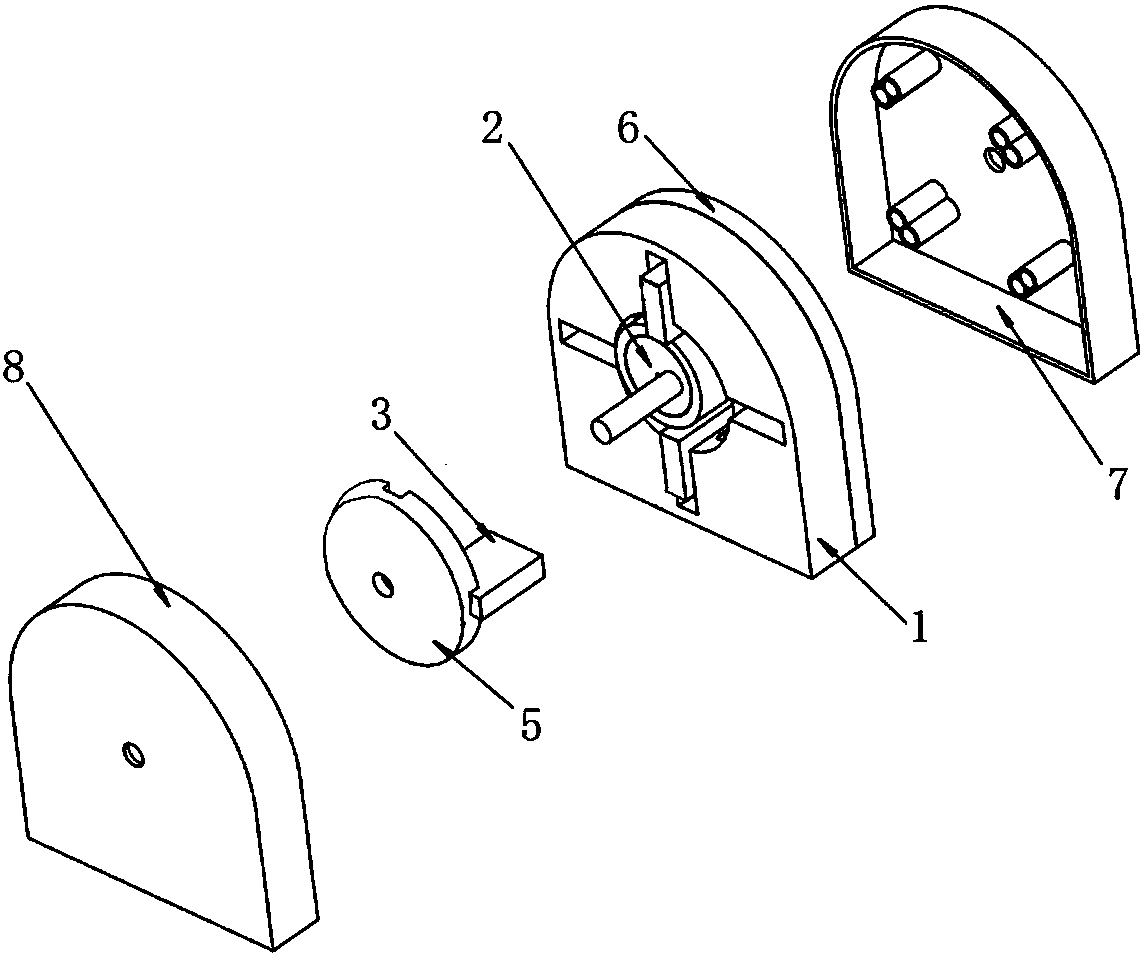

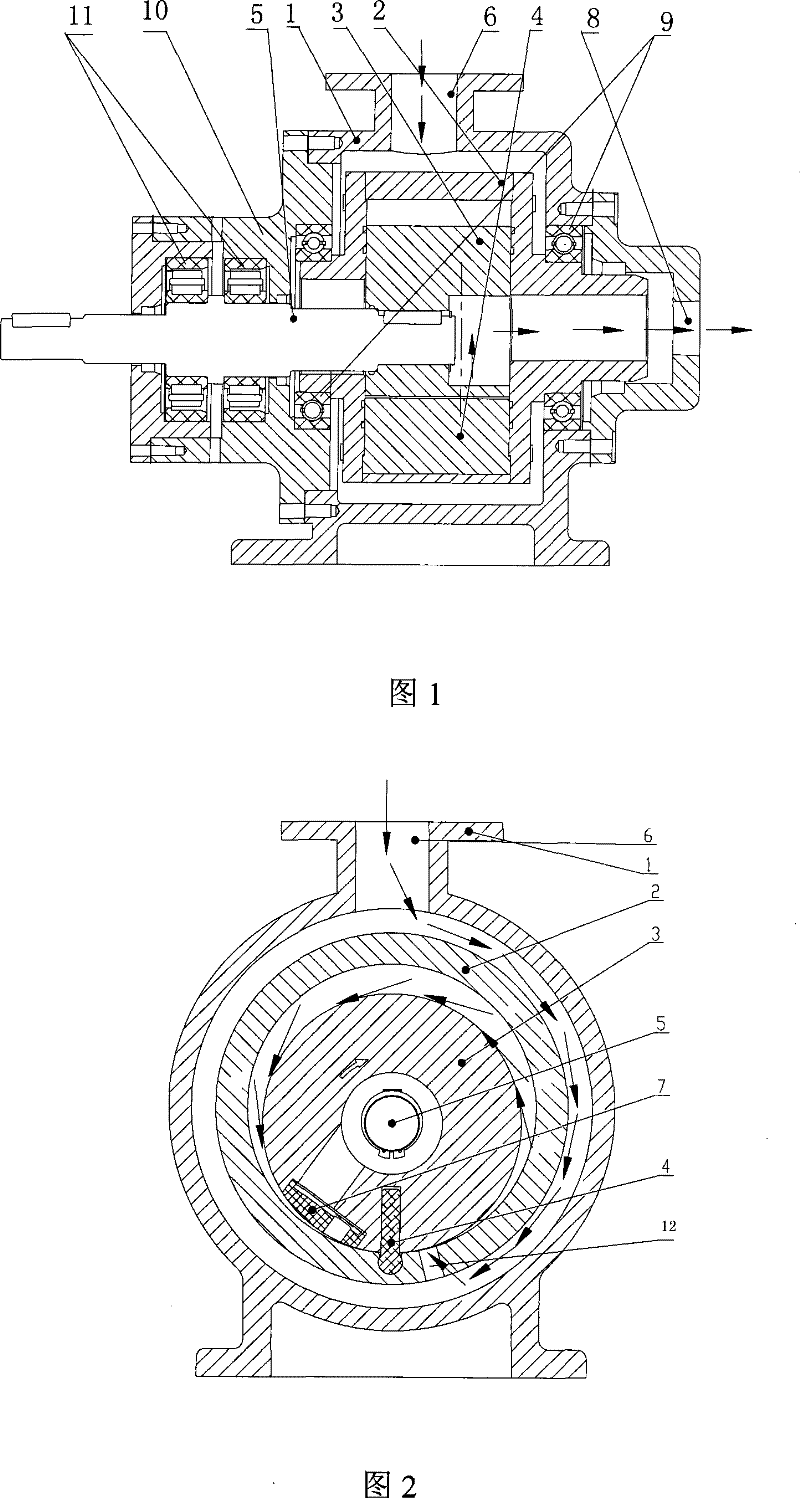

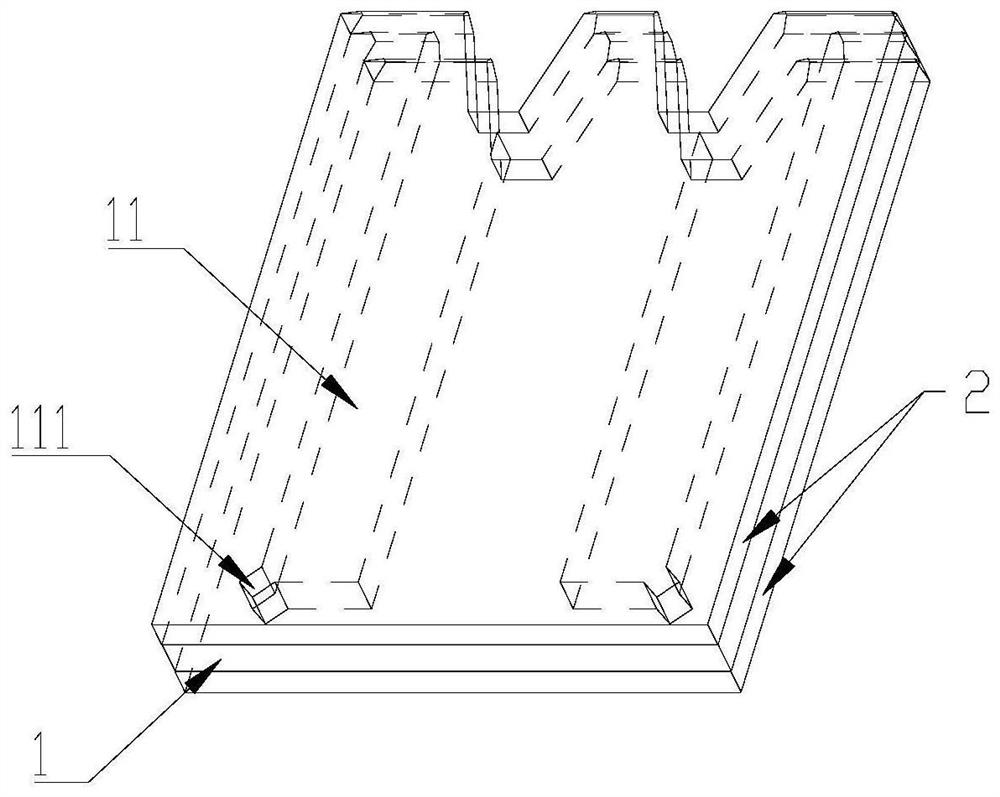

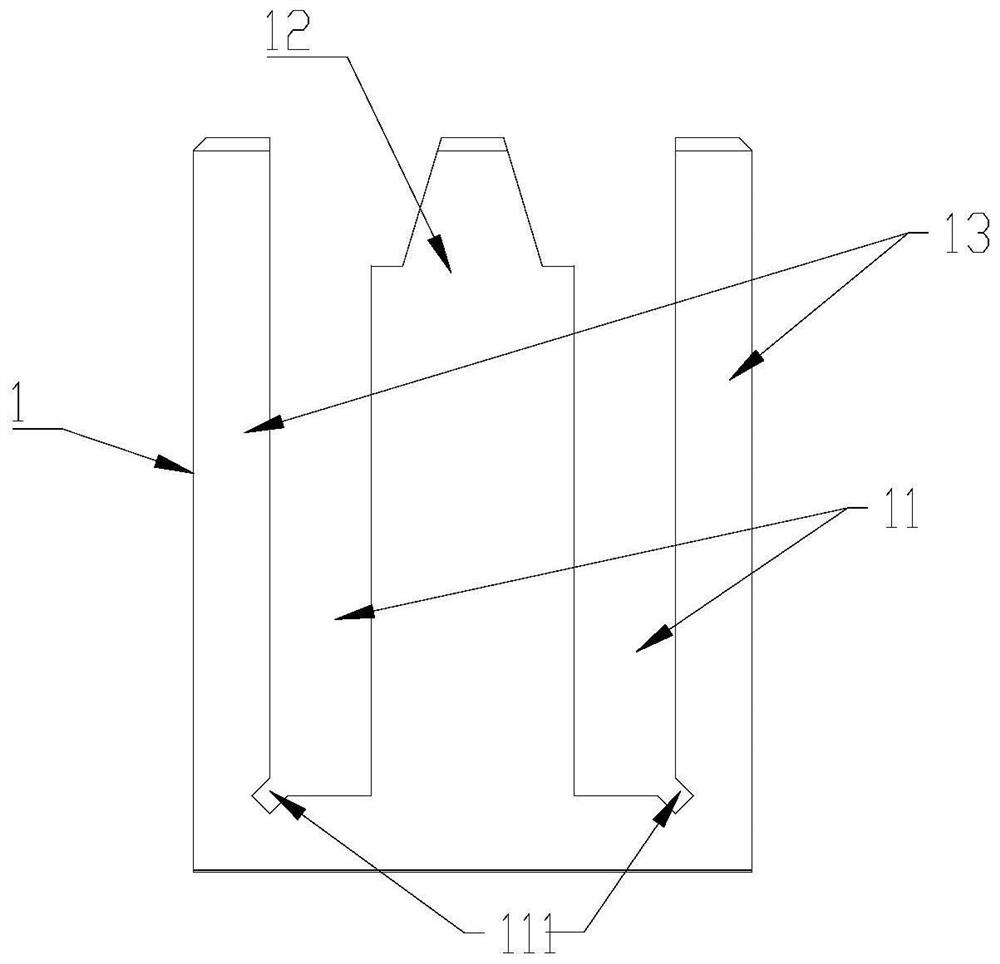

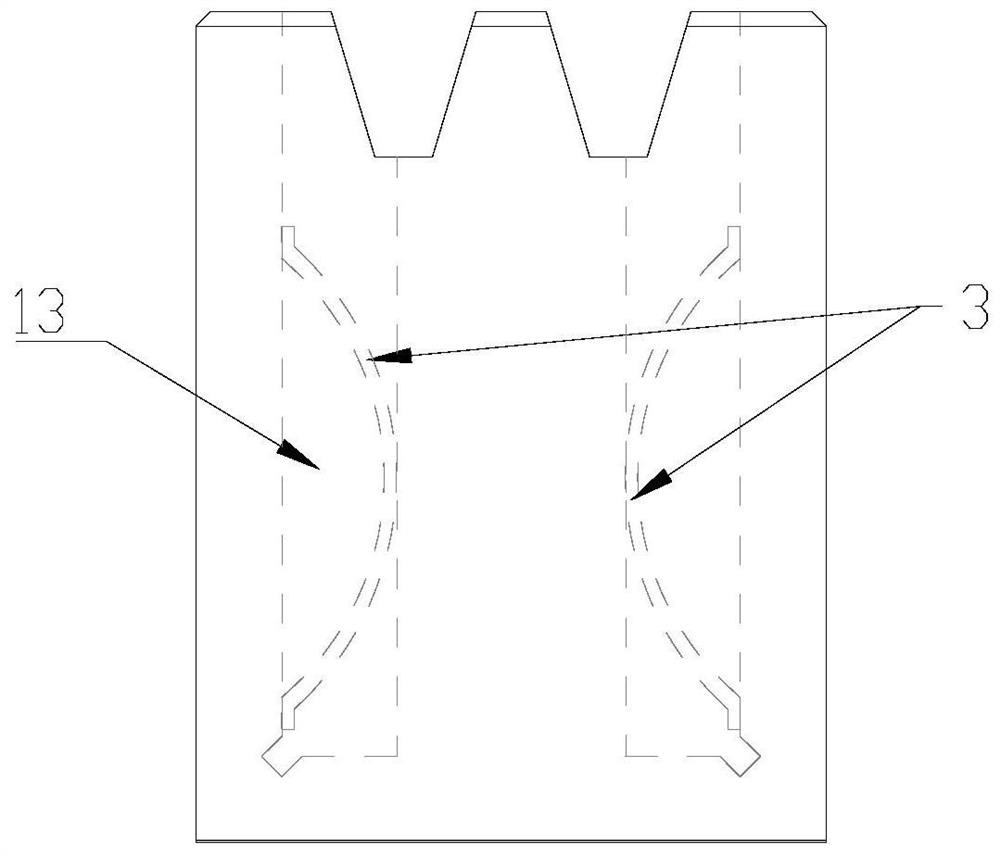

Sliding vane structure and compressor with sliding vane structure

PendingCN111852862AReduce weightReduce reciprocating inertia forceSealing arrangement for pumpsRotary piston pumpsInertia forceEngineering

The invention provides a sliding vane structure and a compressor with the sliding vane structure, and relates to the technical field of compressors. The sliding vane structure and the compressor withthe sliding vane structure solve the technical problem that an existing sliding vane has a relatively large impact on a roller. The sliding vane structure comprises N middle-layer sliding vanes and N+1 outer-layer sliding vanes, wherein the middle-layer sliding vanes and the outer-layer sliding vanes are alternately arranged in sequence; N is a positive integer greater than or equal to 1; and eachmiddle-layer sliding vane is provided with open grooves, so that a cavity structure is formed between each middle-layer sliding vane and the corresponding two adjacent outer-layer sliding vanes. Eachmiddle-layer sliding vane is provided with the corresponding open grooves so as to reduce the weight of the sliding vanes, decrease the reciprocating inertia force in the working process, decrease the impact on the roller, and reduce vibration and noise. In addition, each cavity structure formed between the corresponding middle-layer sliding vane and the corresponding two adjacent outer-layer sliding vanes can be used for storing a certain amount of lubricating oil so as to facilitate the reduction in the internal temperature of a pump body, increase the volumetric efficiency of the compressor, increase the cooling capacity, and improve the comprehensive performance of the compressor.

Owner:ZHUHAI LANDA COMPRESSOR +1

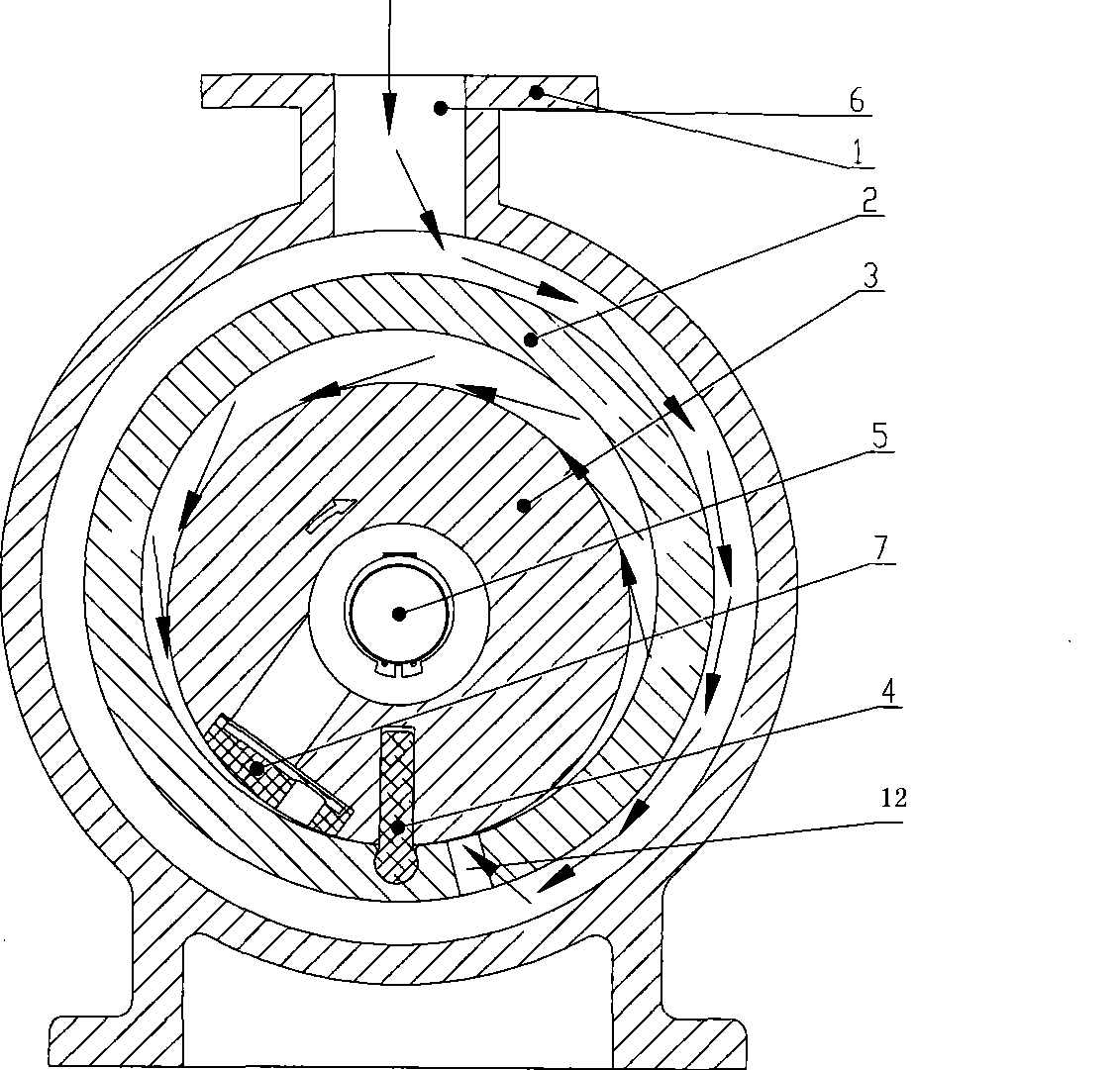

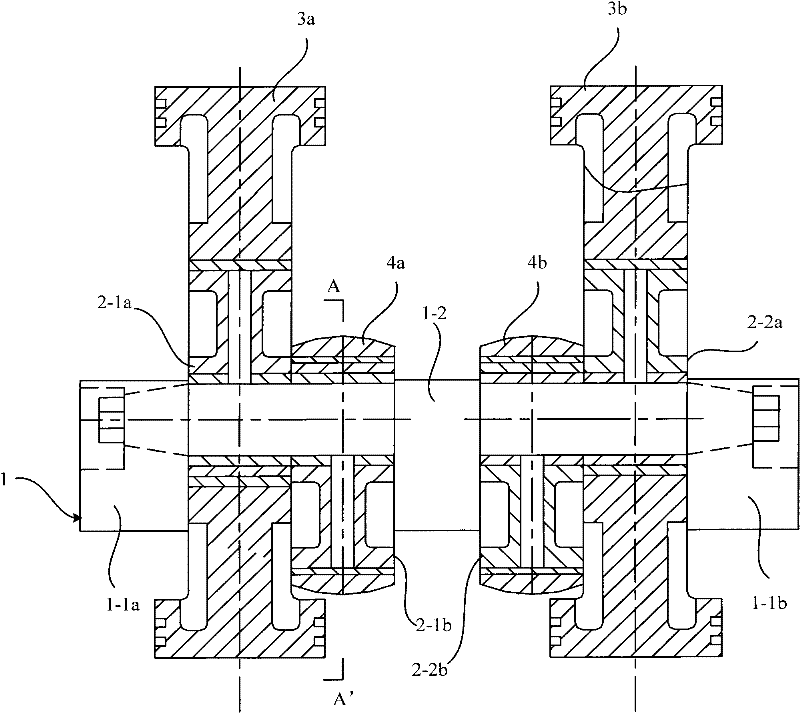

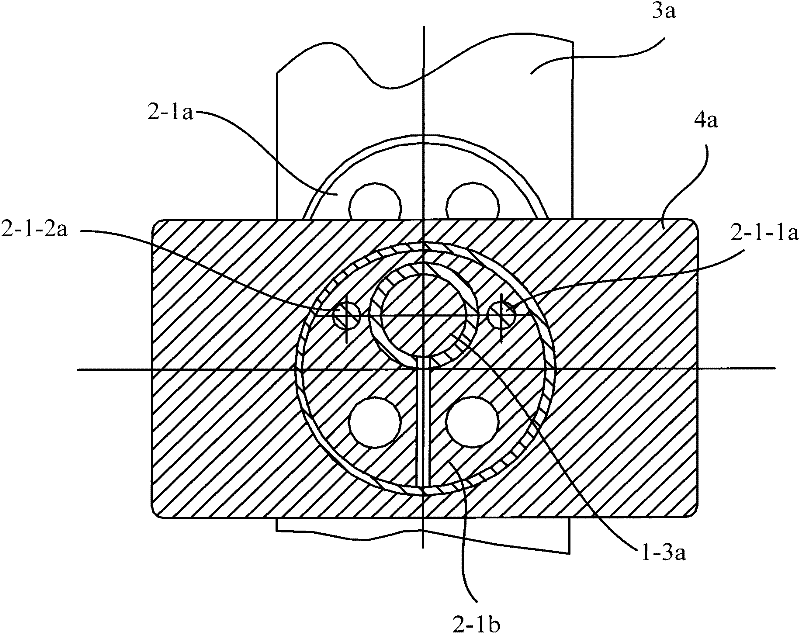

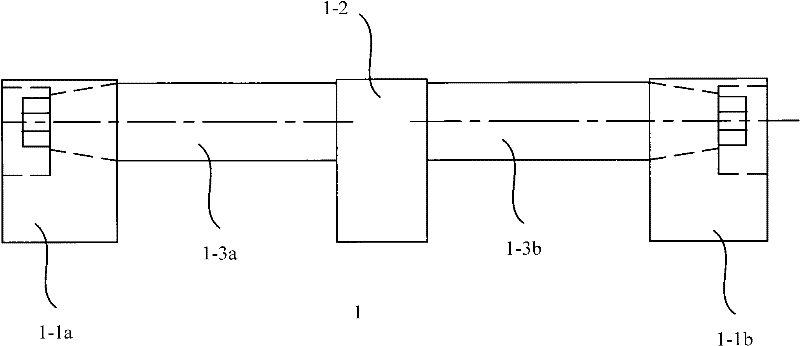

Crank-round slider mechanism, crank shaft thereof and equipment using same

ActiveCN101865268BReduce spanImprove the ability to resist bending deformationCrankshaftsGearingRotational axisCrank

The invention discloses a crank-round slider mechanism, which comprises round sliders, a reciprocating component, a crank shaft and a machine frame, wherein the crank shaft comprises cranks positioned at two ends and main journals positioned between the two cranks; the cranks and the main journals have a common rotating shaft which is a crank rotating shaft; two coaxial crank pins extend out fromtwo ends of the main journal respectively to the end faces of the two cranks, which face the main journals; the distance between the axes of the two crank pin and the crank rotating shaft is e; the round slider is provided with an eccentric round hole; two round sliders having a phase difference of 180 degrees and fixed together are sleeved on each crank pin and the two round sliders of adjacent main journals have the same phase; the reciprocating component is arranged in a guide rail on the machine frame; each round slider can be rotationally arranged in a round slider accommodating hole of the reciprocating component; the guide rails of the reciprocating component corresponding to the round sliders with the same phase are arranged in parallel; and the guide rails of the reciprocating component corresponding to the round sliders with the phase difference of 180 degrees are vertical to each other. The mechanism of the invention can improve the bending resistance and deformation resistance of the crank shaft so that the stability of the mechanism is effectively improved. The invention also provides the crank shaft of the crank-round slider mechanism and equipment using the mechanism.

Owner:BEIJING SINOCEP ENGINE TECH

A gasoline engine crankshaft

The invention discloses a crankshaft of a gasoline engine, which comprises a main journal and crank arms arranged at intervals in sequence on the main journal, and a connecting rod journal connected with the crank arm is provided with a weight-reducing through hole, and the weight-reducing through hole is smooth in the radial direction Transitional semicircular opening, the semicircular opening is located between the axial level of the connecting rod journal and the top of the connecting rod journal, and the flat bottom of the semicircular opening is close to the axial level of the connecting rod journal and at a distance from it The first wall thickness, the arc top of the semicircular opening is close to the outer edge of the top of the connecting rod journal and has a second wall thickness therefrom. The invention achieves the purpose of reducing the weight of the crankshaft, improving the balance rate of the crankshaft and reducing the oil consumption of the engine by designing the through hole for reducing the weight of the journal of the traditional crankshaft connecting rod.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Petrol Engine

ActiveCN103867296BImprove mechanical efficiencyReduce friction workValve arrangementsInternal combustion piston enginesGasolineFuel oil

The invention relates to a gasoline engine, which comprises a piston, a combustion chamber and a fuel-oil supplying system, wherein the piston is formed by a piston top, a head, a pin seat and a skirt, wherein the ratio of the height of the skirt to the total height formed by the head and the skirt is 0.6 to 0.7, and the ratio of the chord length of the projection of the molded line of the skirt on a plane on the piston top to the diameter of a cylinder is 0.5 to 0.6; the combustion chamber is hemispheric and is jointly formed by a cylinder head, the piston top, a cylinder-head gasket and one part of a box body, and the surface-to-volume ratio delta of the combustion chamber is 0.15 to 0.25; the fuel-oil supplying system comprises a gasoline pump, a ventilating pipe and a negative-pressure pipe, wherein a negative-pressure impulse-type gasoline pump is adopted as the gasoline pump, the ventilating pipe is arranged on a cylinder head cover, one end of the negative-pressure pipe is connected with the ventilating pipe of the cylinder head cover, and the other end of the negative-pressure pipe is connected with the negative-pressure impulse-type gasoline pump. Through the improvement on structures, such as the piston, a connecting rod, a rocker and the like, the frictional work is reduced, and therefore the mechanical efficiency of the gasoline engine is greatly enhanced.

Owner:ZHEJIANG YAOFENG POWER TECH

Energy-saving piston for gas engine

InactiveCN102797584BReduce weightReduce reciprocating inertia forcePlungersMachines/enginesCombustion chamberPiston ring

Owner:石家庄金刚内燃机零部件集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com