Gasoline engine crankshaft

A gasoline engine and crankshaft technology, which is applied to the crankshaft and other directions, can solve the problems affecting the strength of the crankshaft, the balance of the crankshaft, and the complexity of the casting process, and achieve the effects of simplifying development costs, simple casting process, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings.

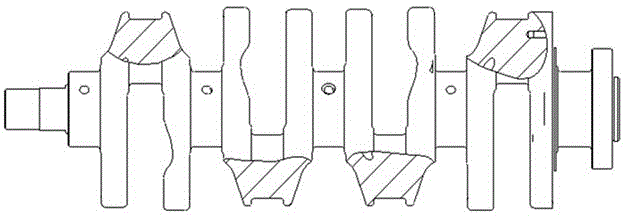

[0018] figure 1 For the traditional crankshaft structure, the connecting rod journal on the crank arm is a solid structure, and the weight of the crankshaft can be reduced by removing the weight of the crankshaft balance weight, and this solution will sacrifice the balance of the crankshaft to meet the requirements.

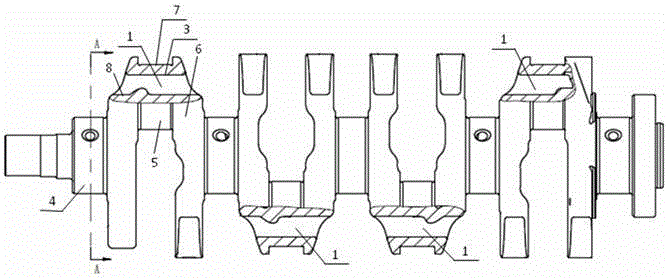

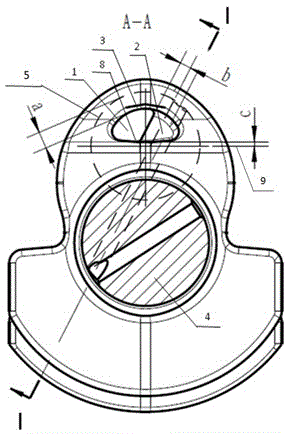

[0019] Such as figure 2 As shown, the crankshaft structure of the present invention includes a main journal 4, a crank arm 6 arranged at intervals on the main journal 4, and a connecting rod journal 5 connected to the crank arm 6 has a weight reduction through hole 1 along the axial direction. The radial direction of the weight reduction through hole 1 is a semicircular opening with a smooth transition. The semicircular opening is located between the horizontal plane 9 of the connecting rod journal and the top 7 of the connecting rod journal, and the flat bottom of the sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com