Device capable of enabling crosshead and piston rod of compressor to be connected stably

A crosshead and piston rod technology, which is used in the field of devices for stable connection between the compressor crosshead and the piston rod, can solve the problem that the piston rod and the crosshead cannot be locked with each other, so as to improve reliability, safety, and tightening. Good effect, the effect of protecting the teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

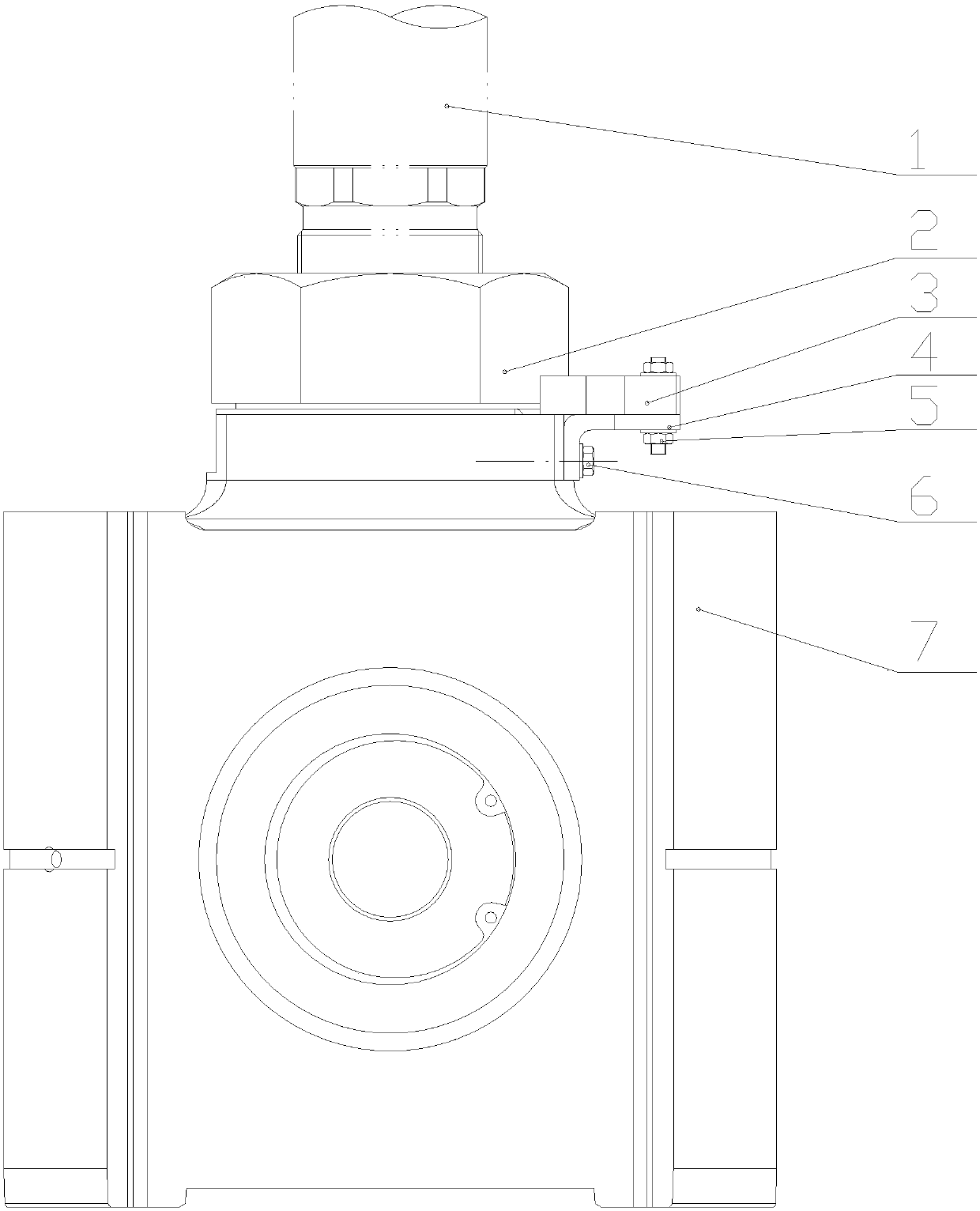

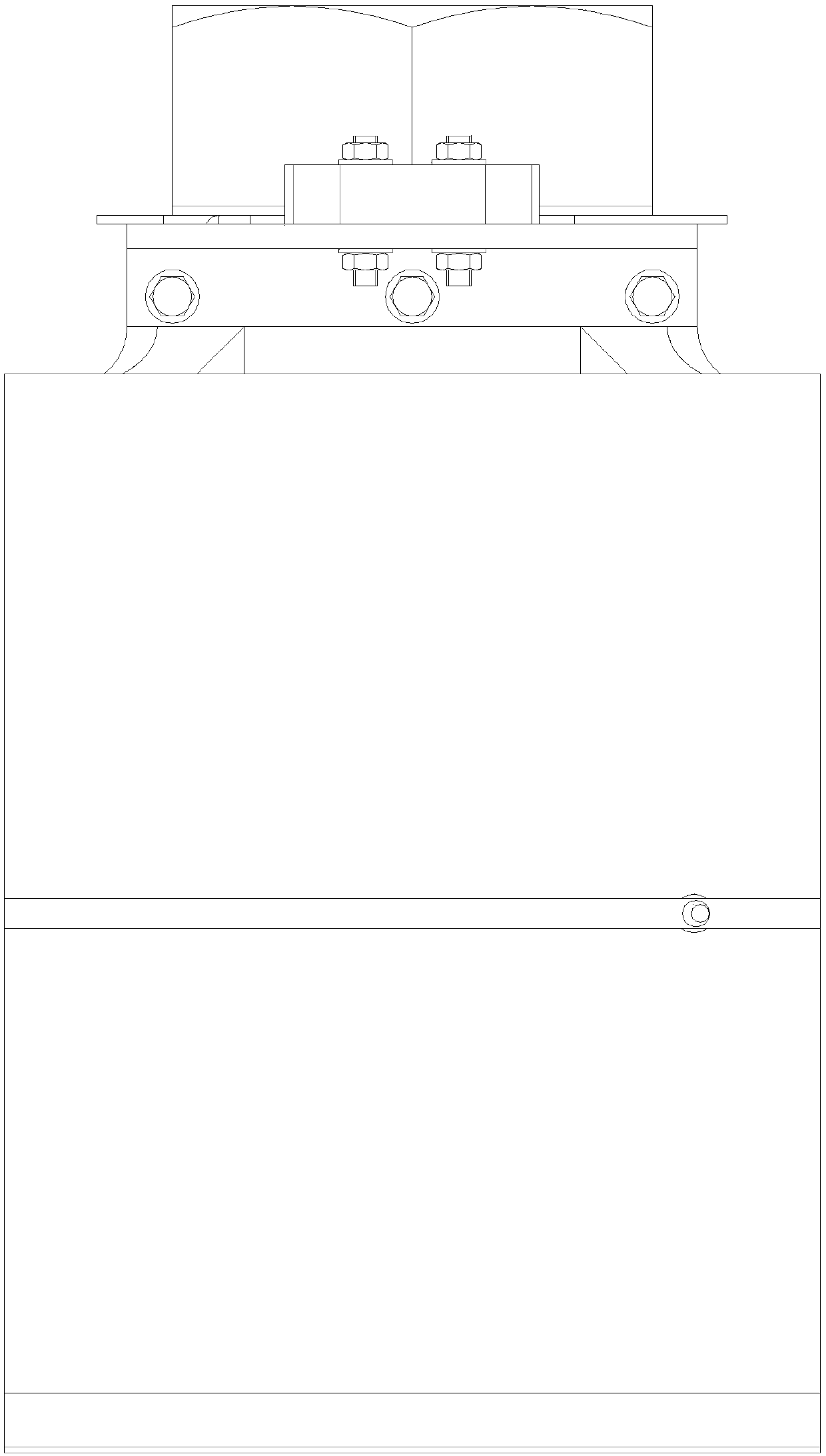

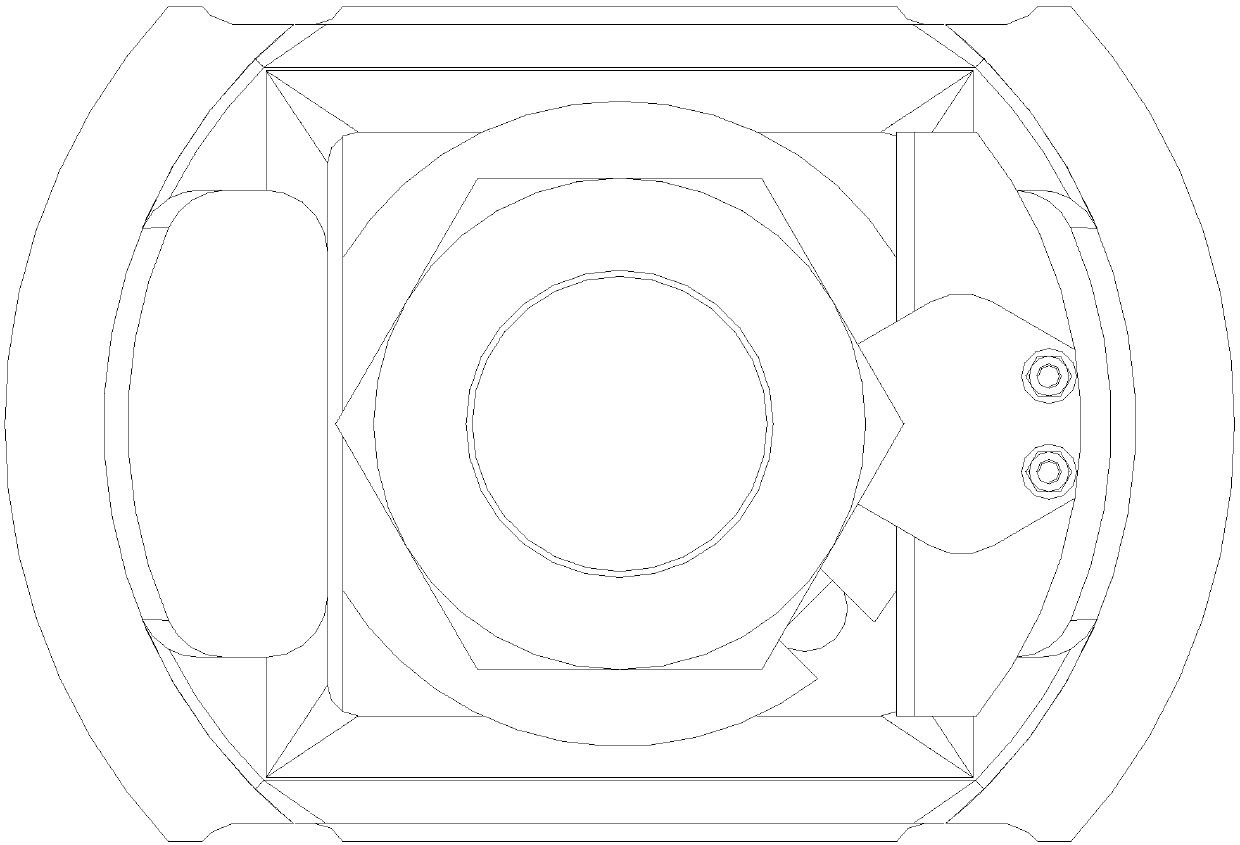

[0019] refer to Figure 1-3 , a device for stabilizing the connection between the compressor crosshead and the piston rod, including a fastening steel plate 3, a right-angle steel plate 4 and a crosshead body 7, which is vertically drilled and installed on the right side of the crosshead pin hole at the top of the crosshead body 7 The internally threaded hole of the right-angle steel plate 4 is drilled on the vertical plate of the right-angle steel plate 4 vertically corresponding to the position of the internal thread hole of the crosshead body 7 tops. The position of the hole on the corresponding right-angle steel plate 4 transverse plates is drilled. The holes on the fastening steel plate 3 and the holes on the vertical plate and the transverse plate of the right-angle steel plate 4 are all through holes.

[0020] The hole on the vertical plate of the right-angle steel plate 4 is the same size as the internal threaded hole at the top of the crosshead body 7, and the hole o...

Embodiment 2

[0023] refer to Figure 1-4 , a device for stabilizing the connection between the compressor crosshead and the piston rod, including a fastening steel plate 3, a right-angle steel plate 4 and a crosshead body 7, which is vertically drilled and installed on the right side of the crosshead pin hole at the top of the crosshead body 7 The internally threaded hole of the right-angle steel plate 4 is drilled on the vertical plate of the right-angle steel plate 4 vertically corresponding to the position of the internal thread hole of the crosshead body 7 tops. The position of the hole on the corresponding right-angle steel plate 4 transverse plates is drilled. The holes on the fastening steel plate 3 and the vertical plates of the right-angle steel plates 4 and the holes on the transverse plates are all through holes, and the through holes on the vertical plates of the right-angle steel plates 4 are designed as counterbore holes.

[0024] The hole on the vertical plate of the right-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com