Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce fit area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

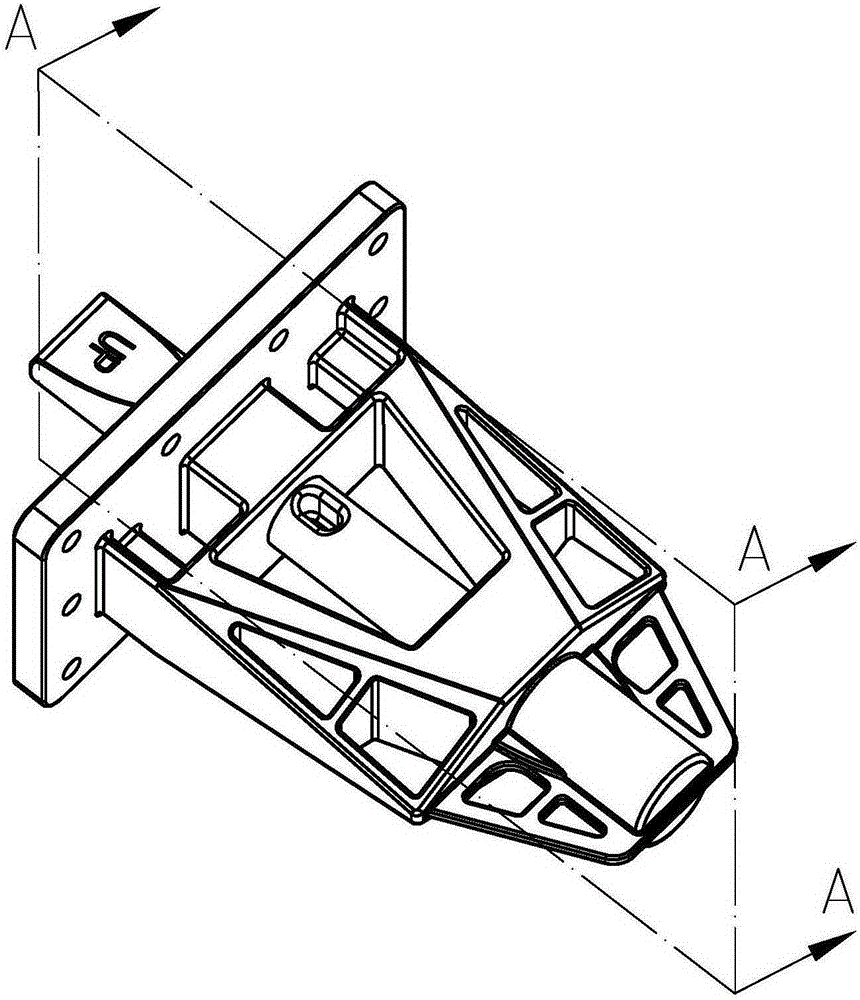

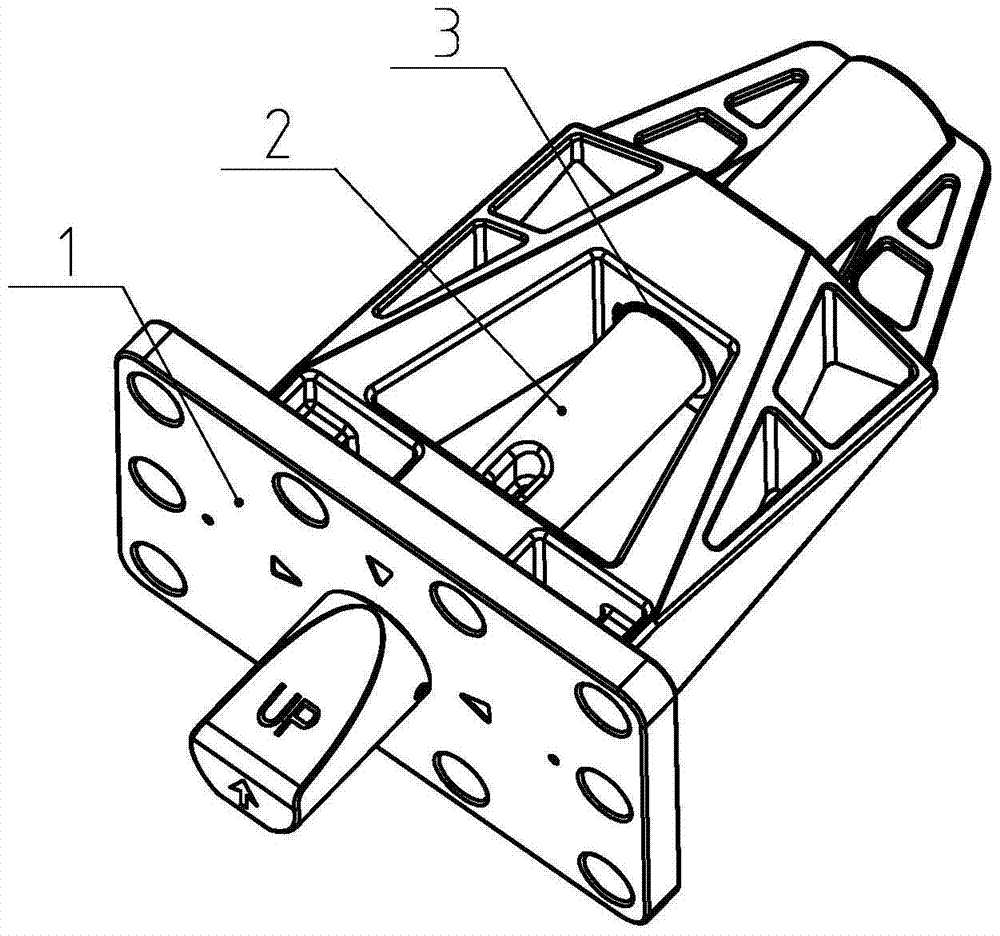

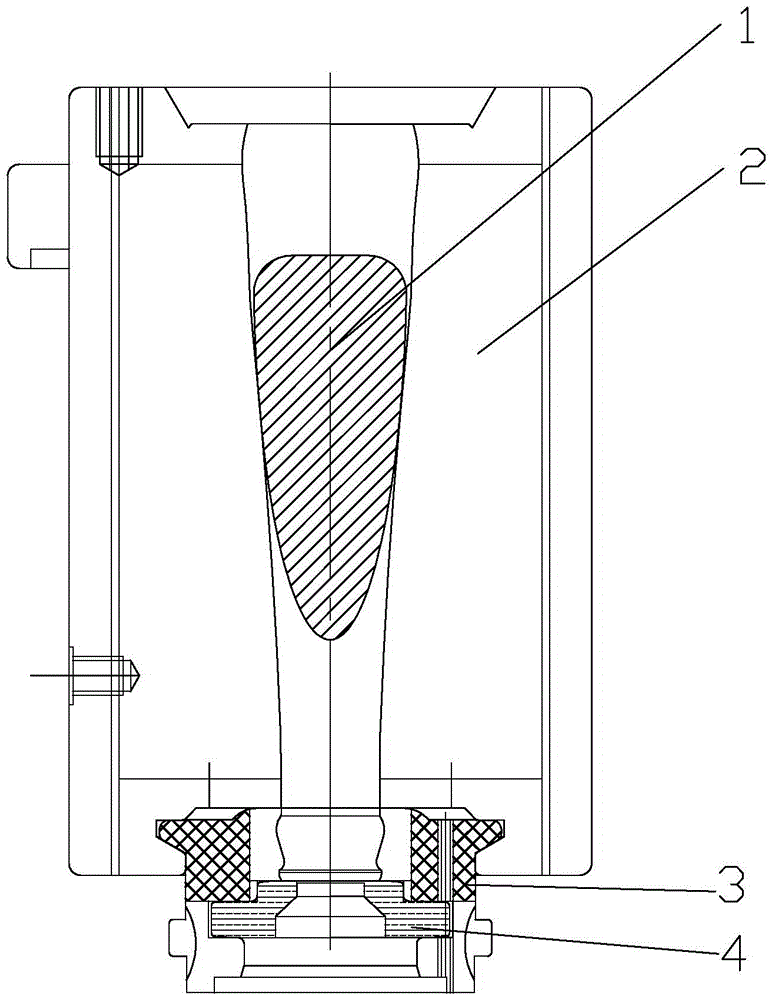

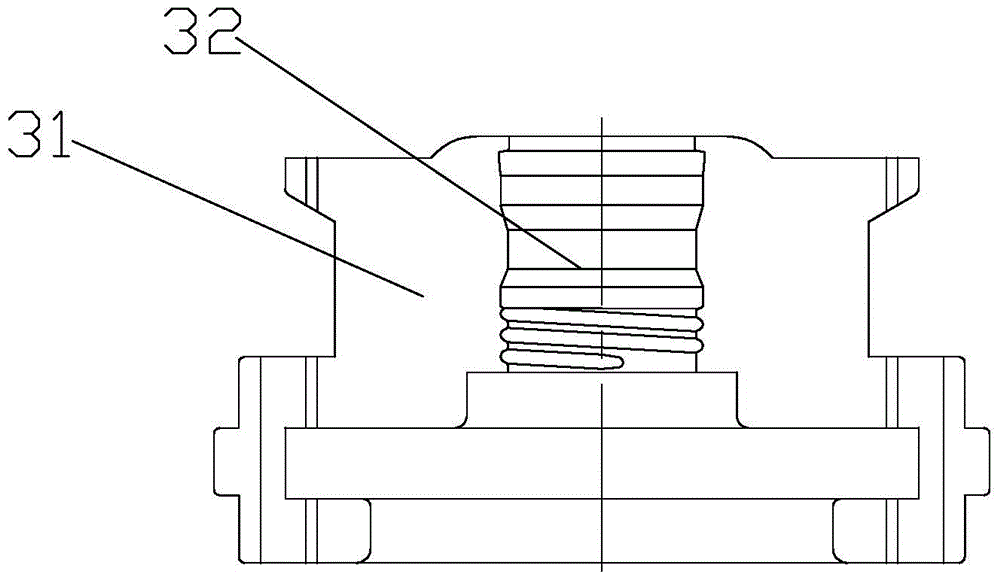

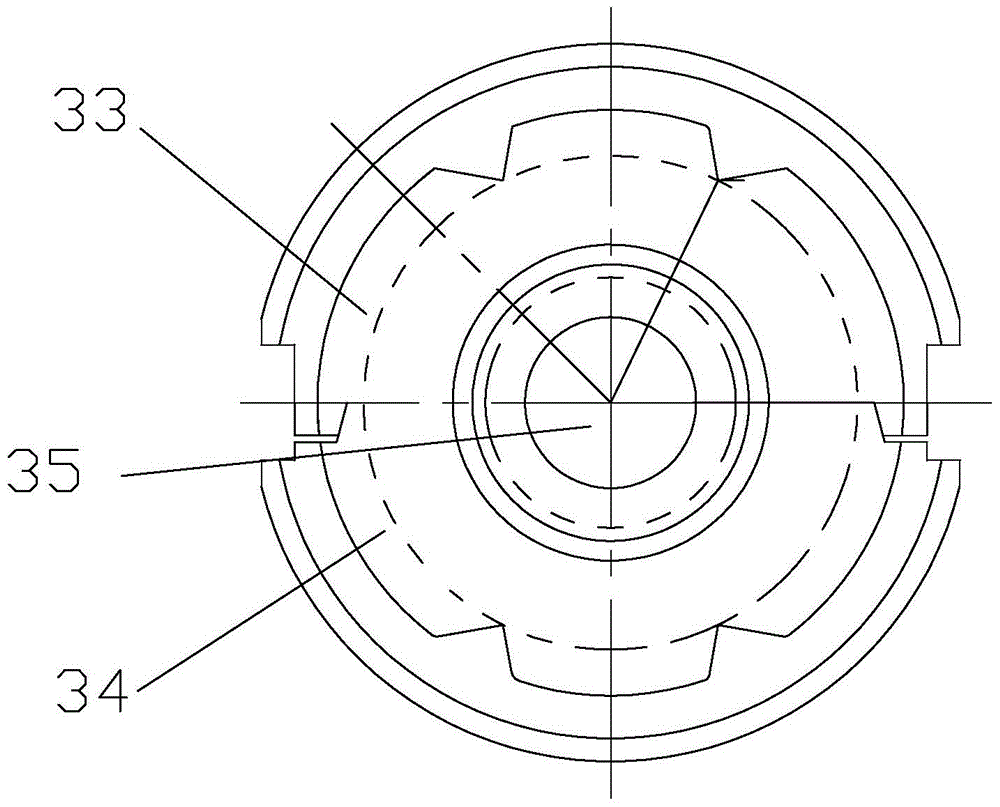

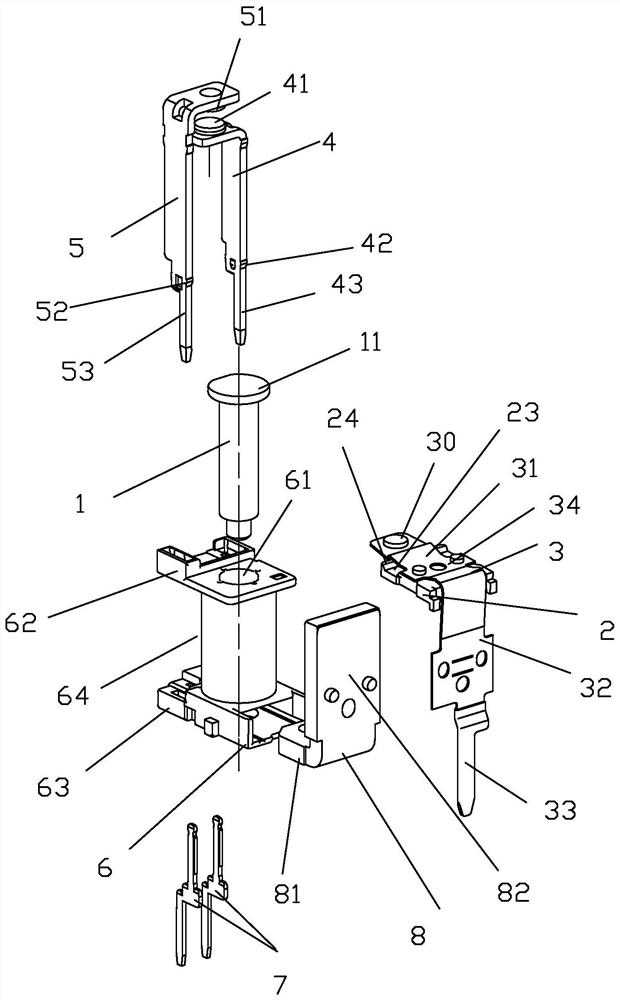

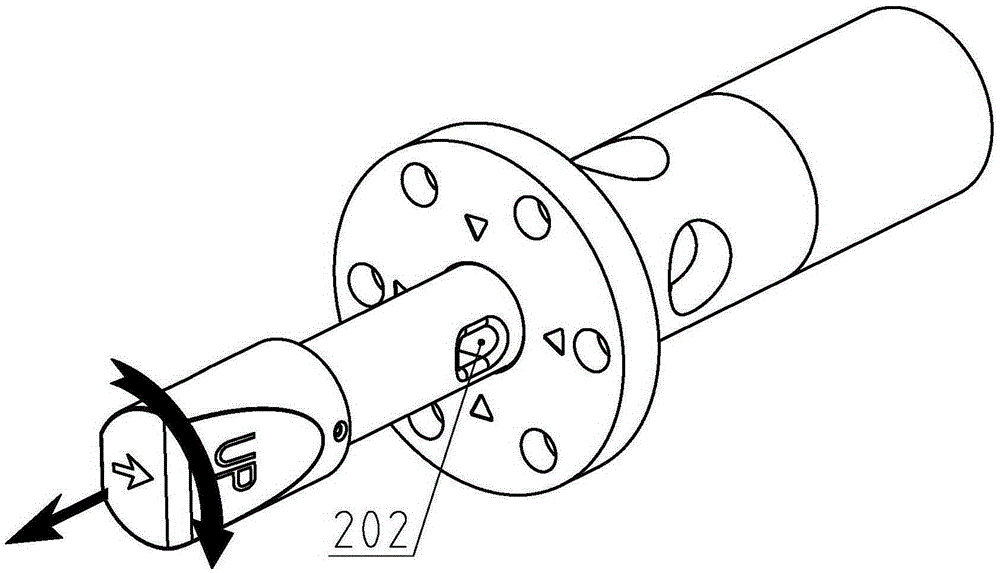

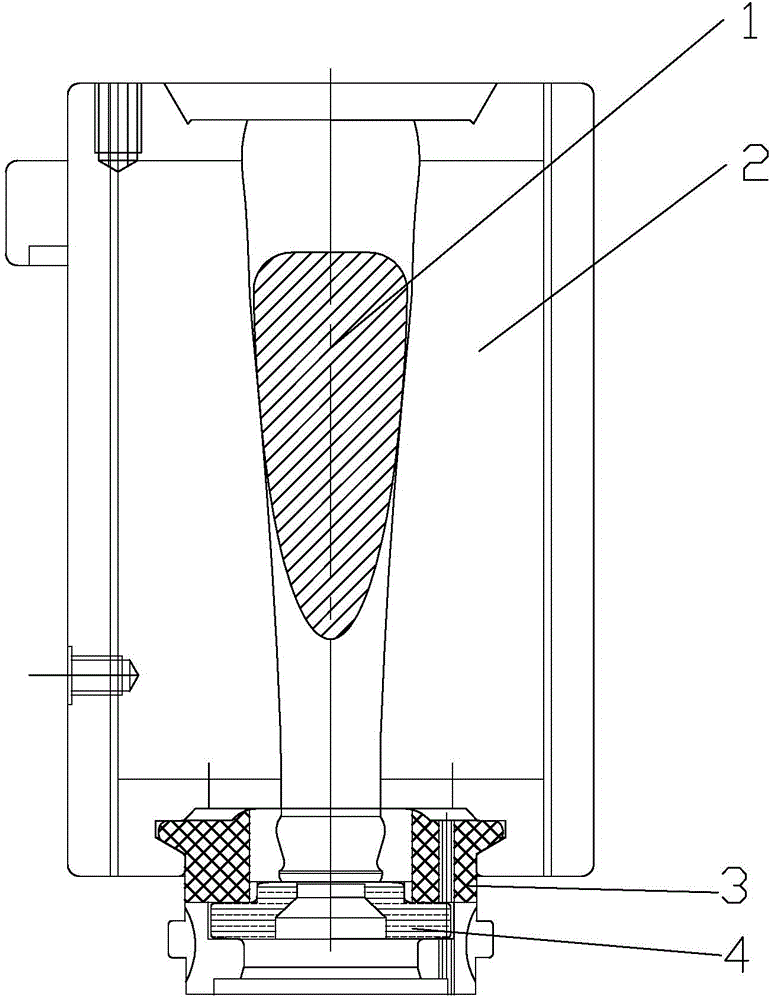

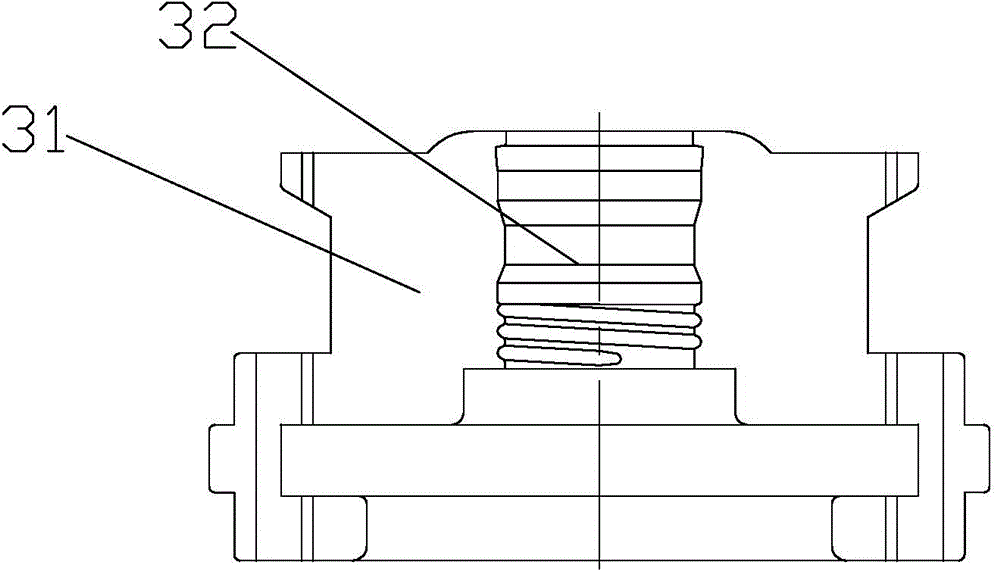

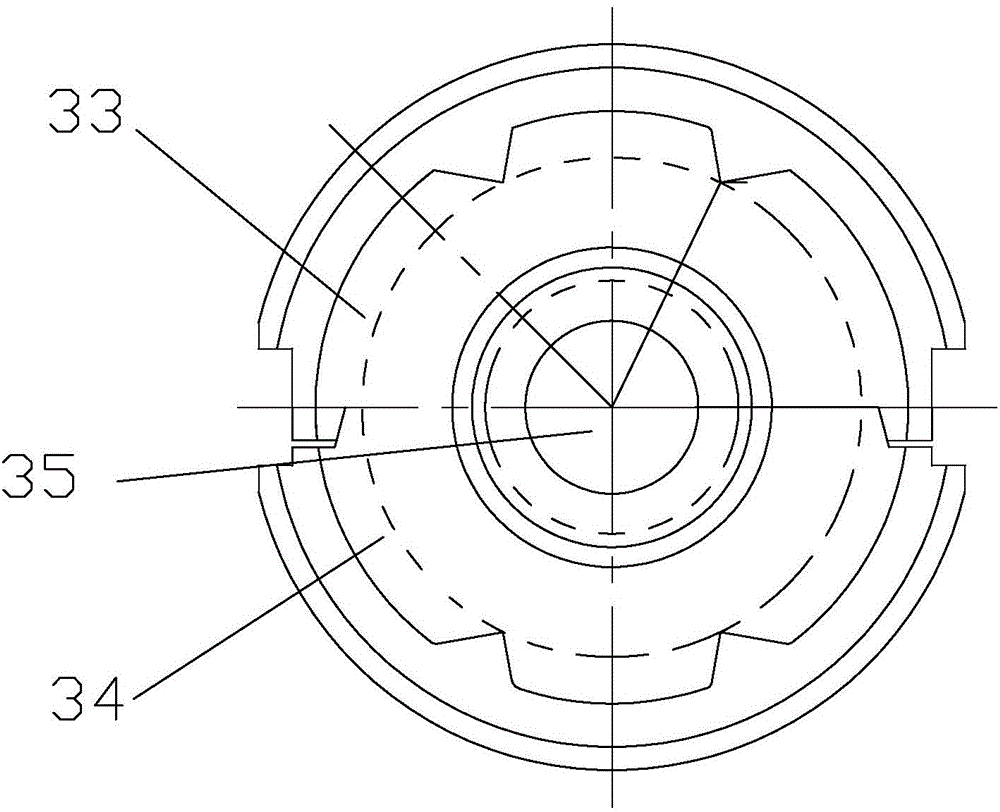

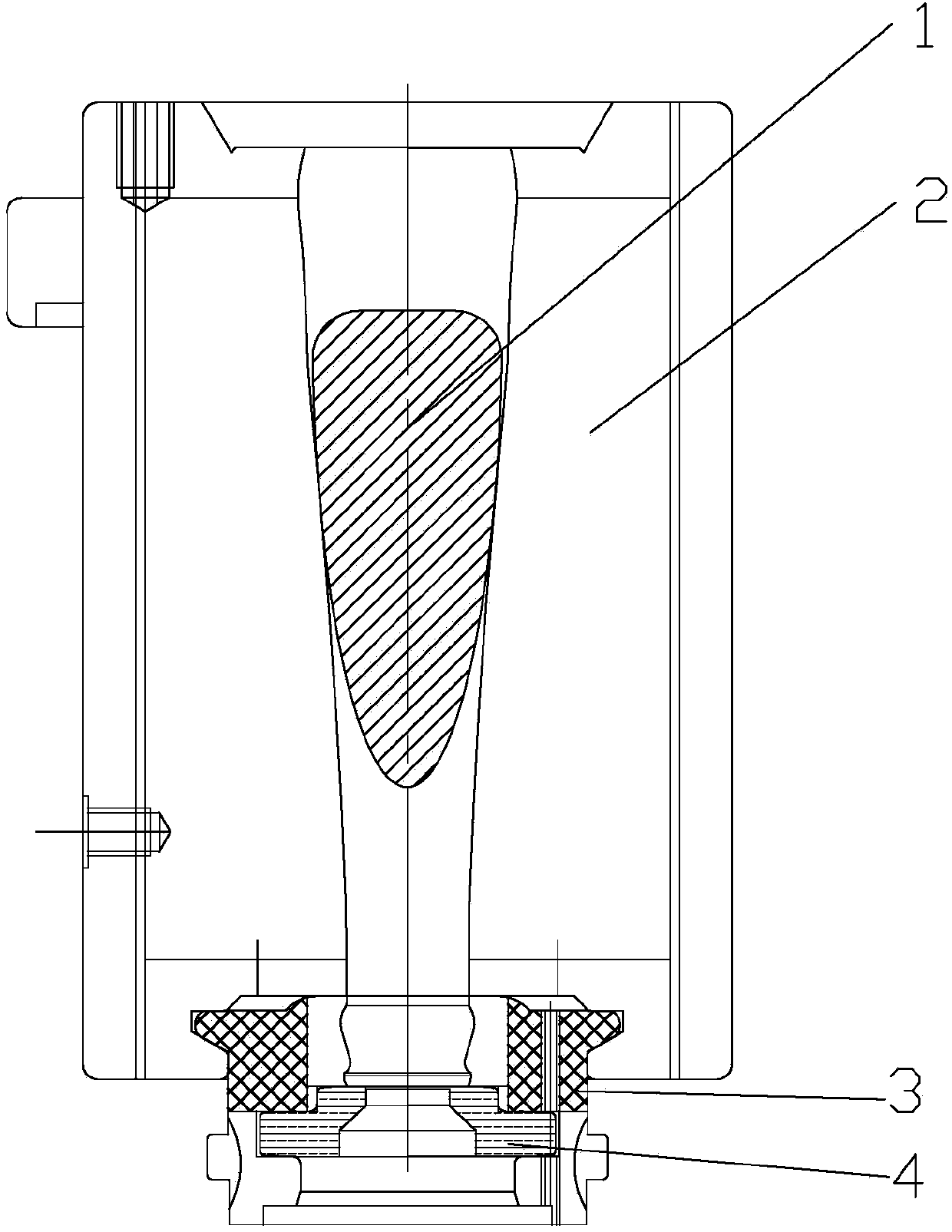

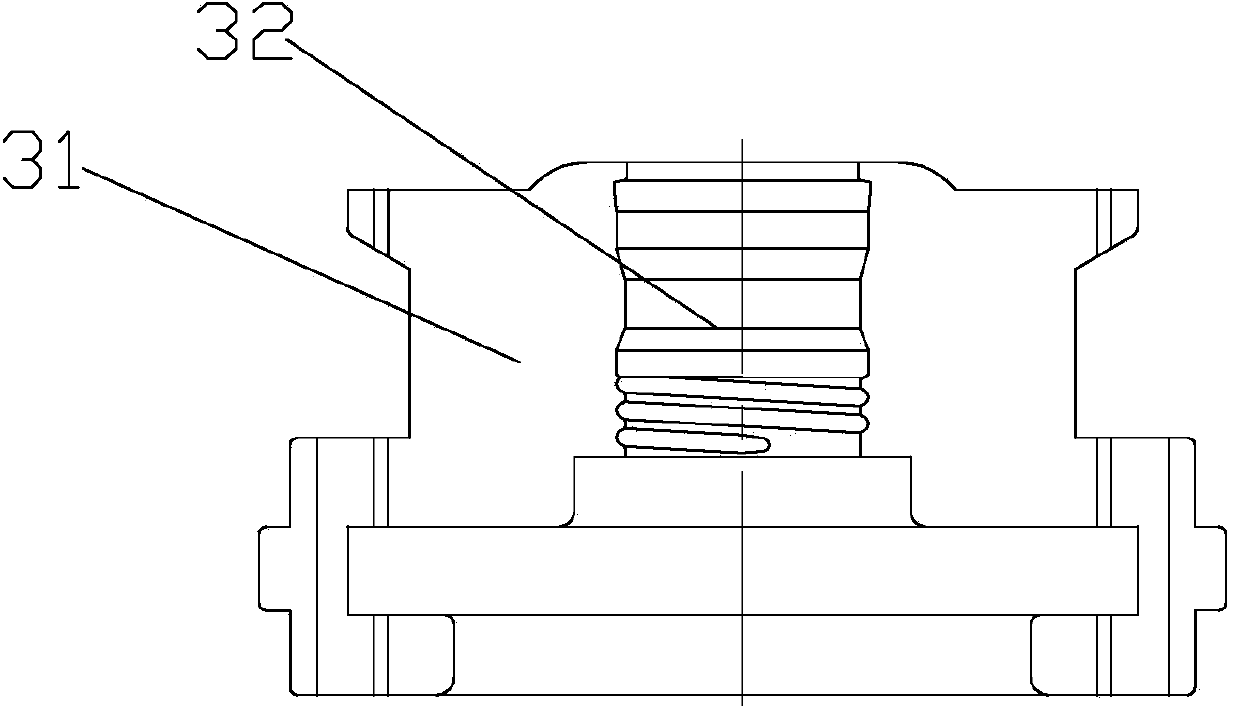

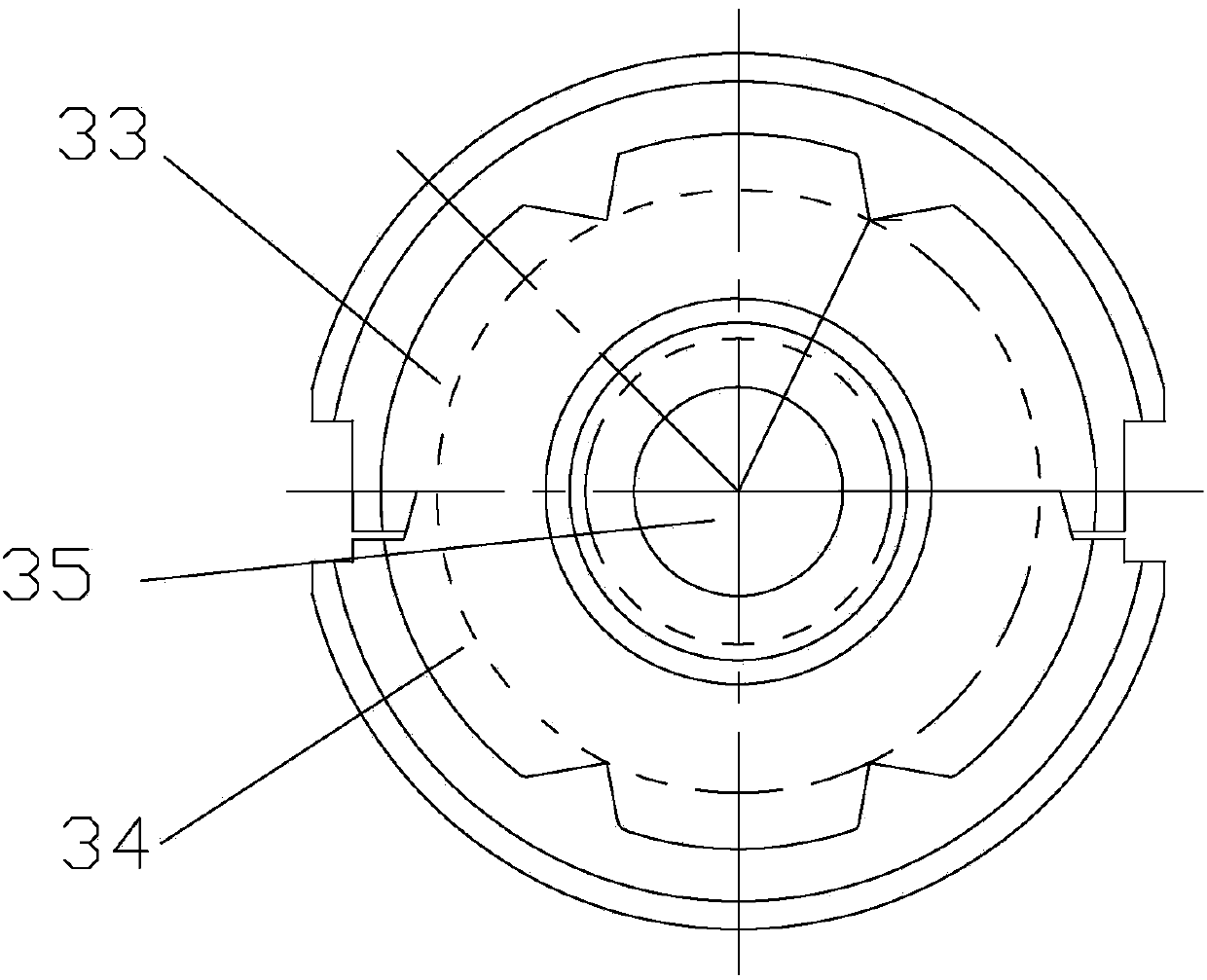

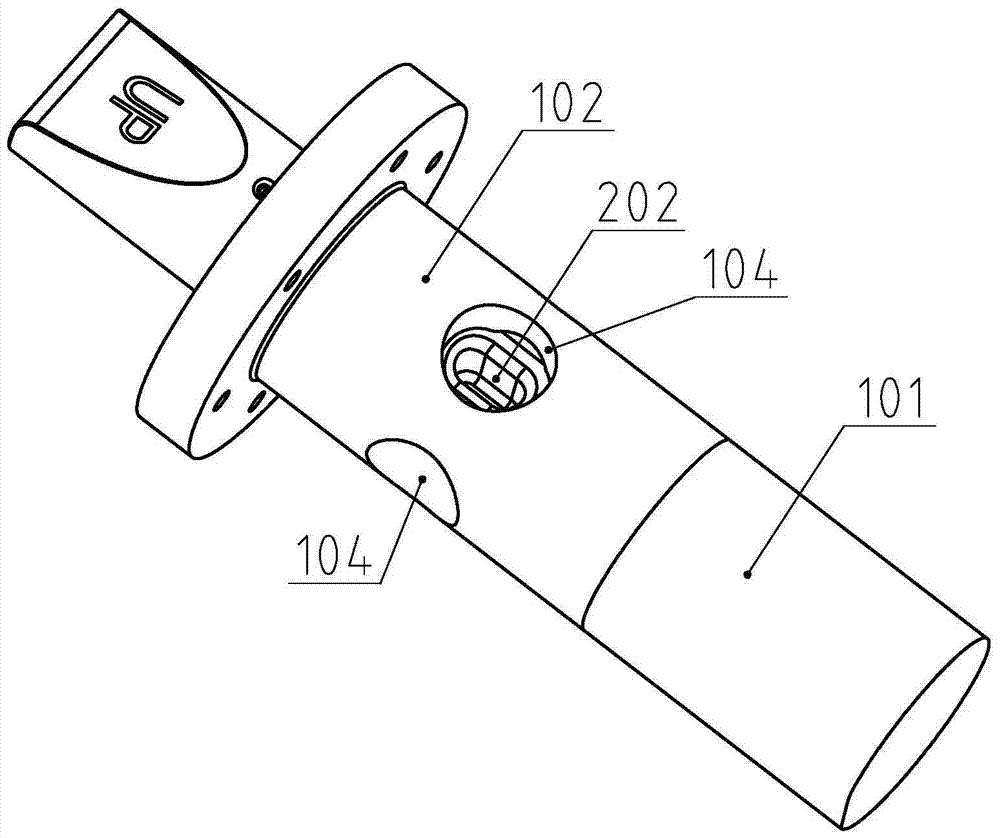

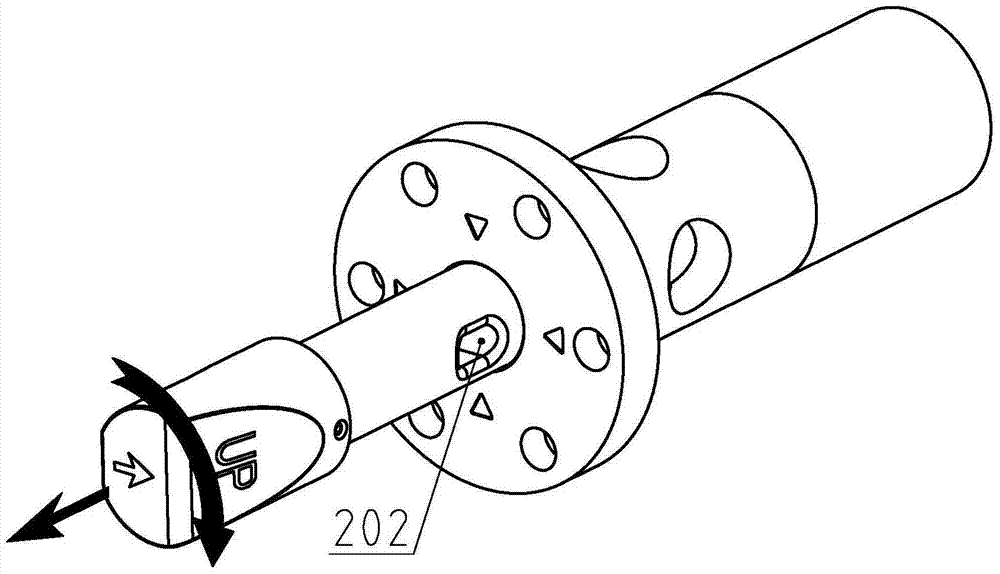

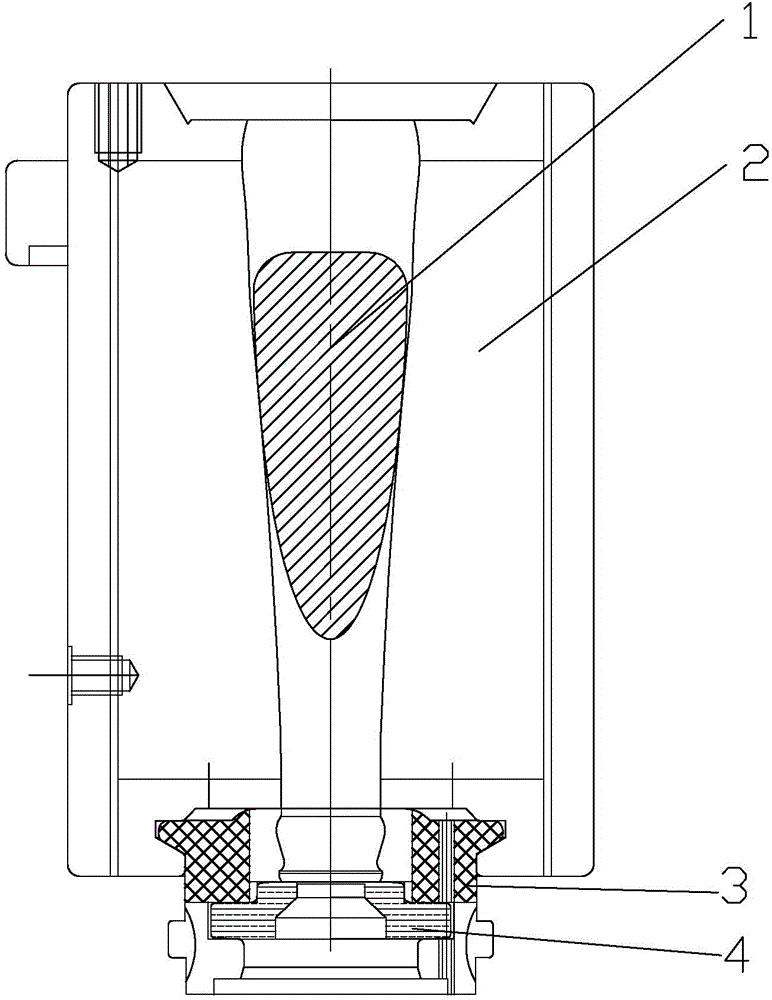

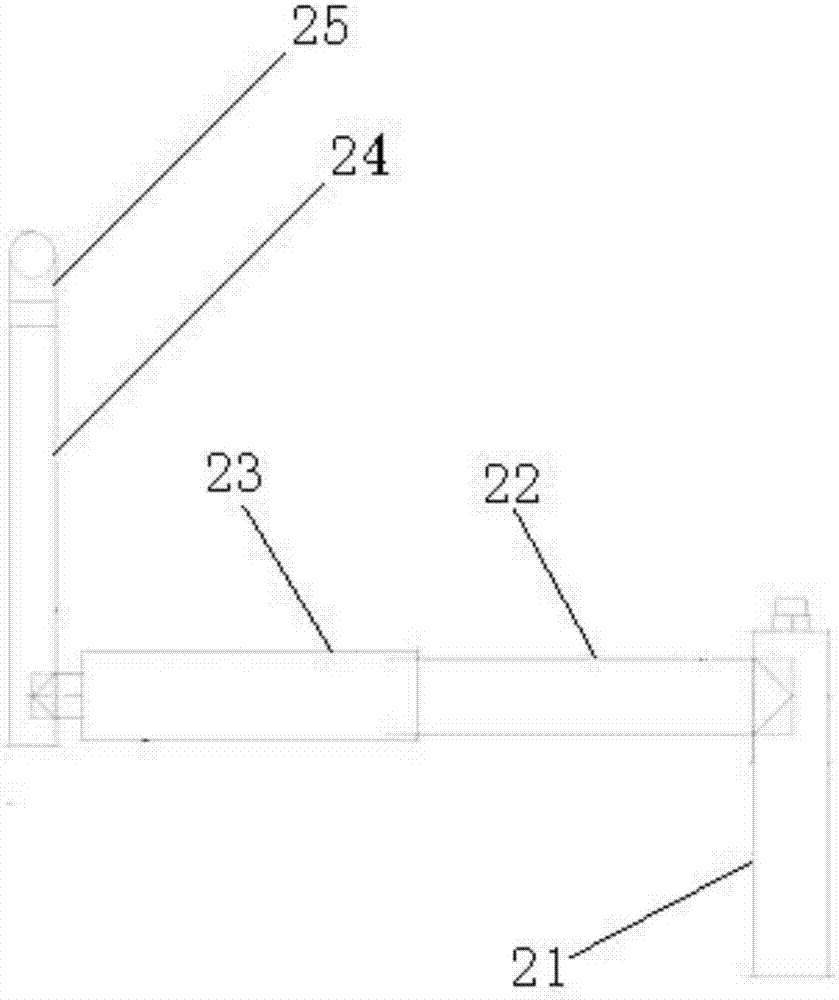

Sliding nozzle

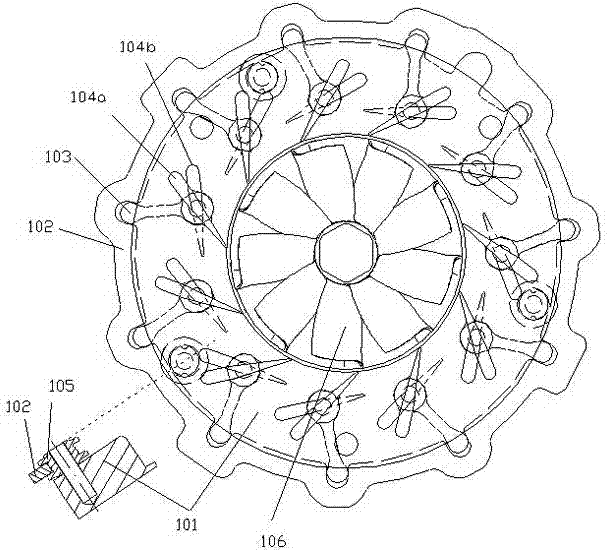

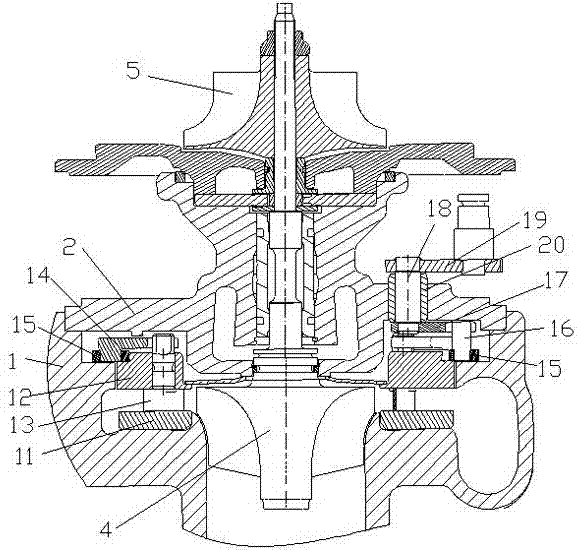

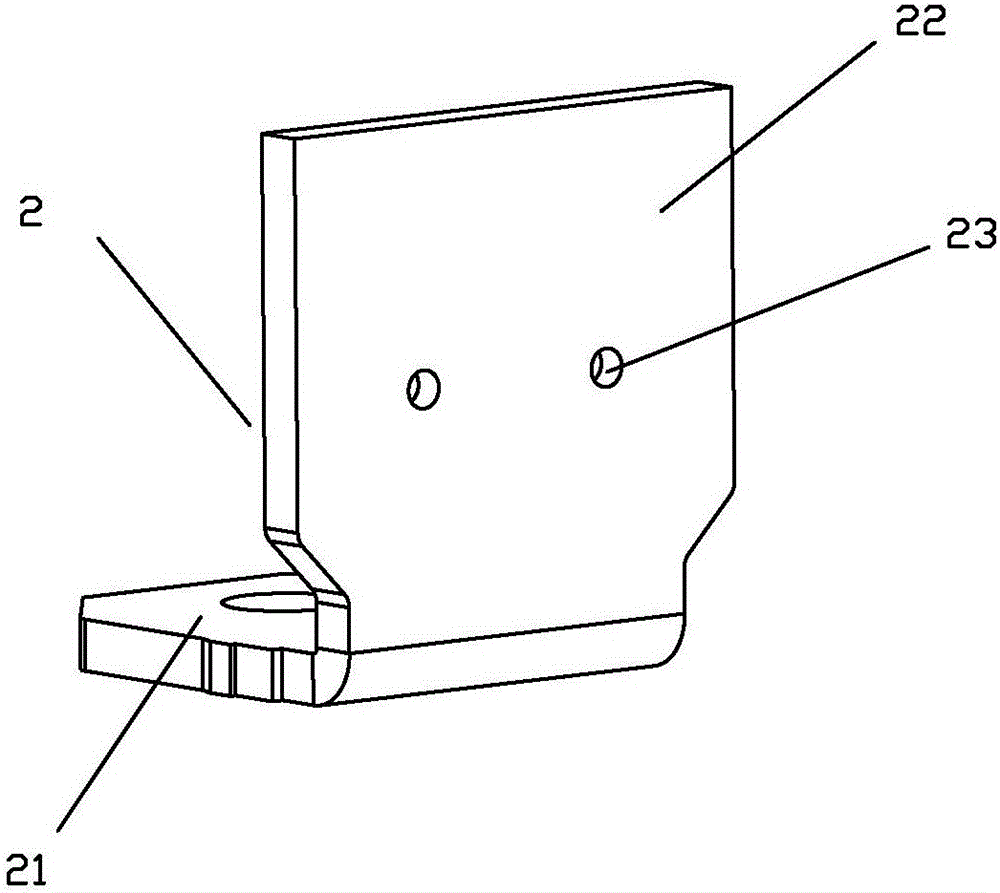

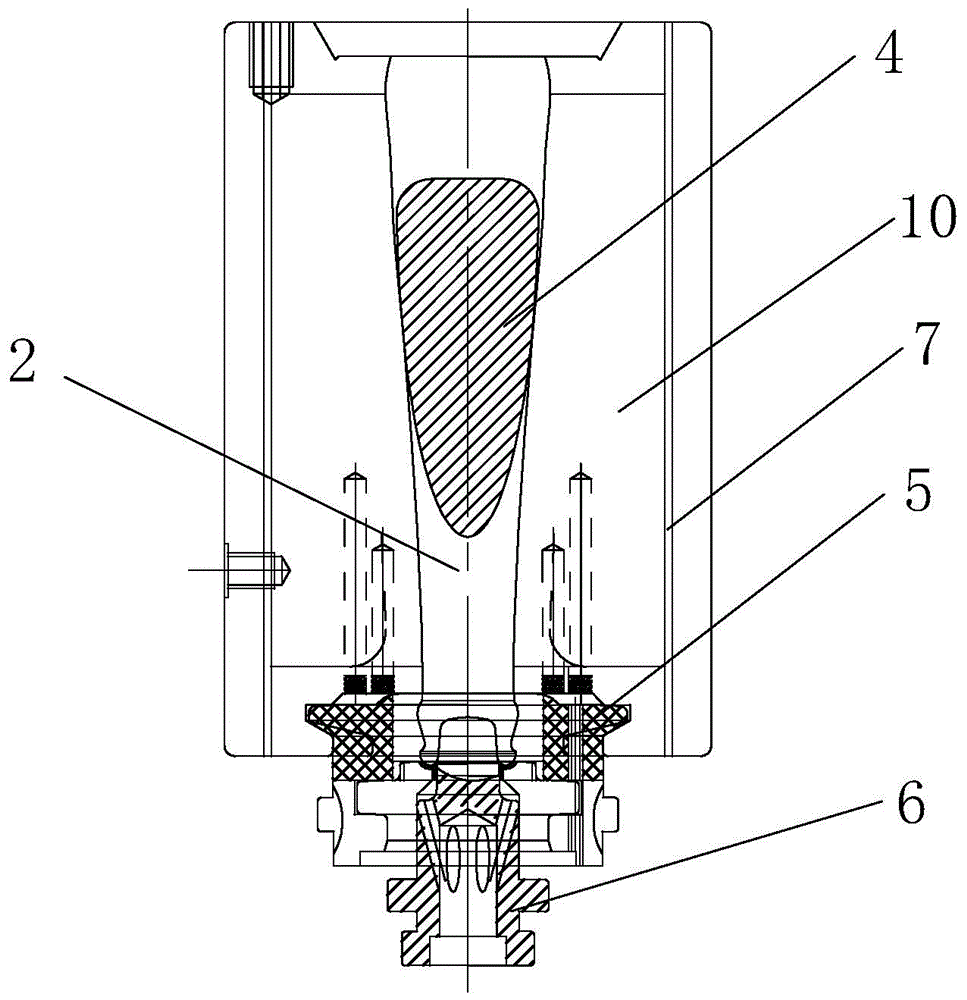

InactiveCN103527264AAvoid precision lossHigh control precisionInternal combustion piston enginesStatorsThermal deformationEngineering

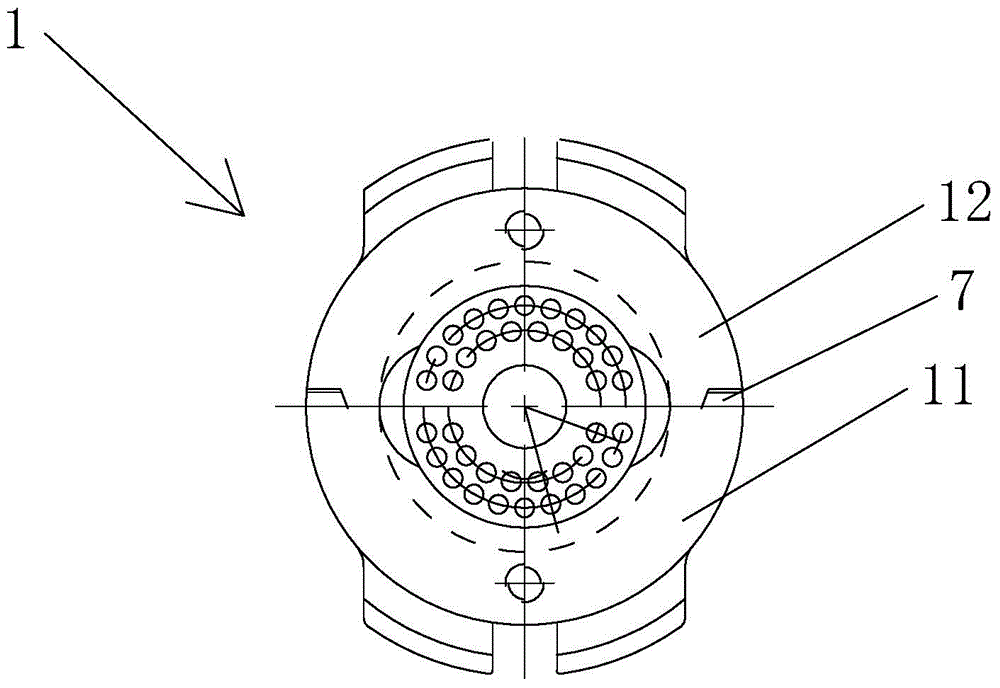

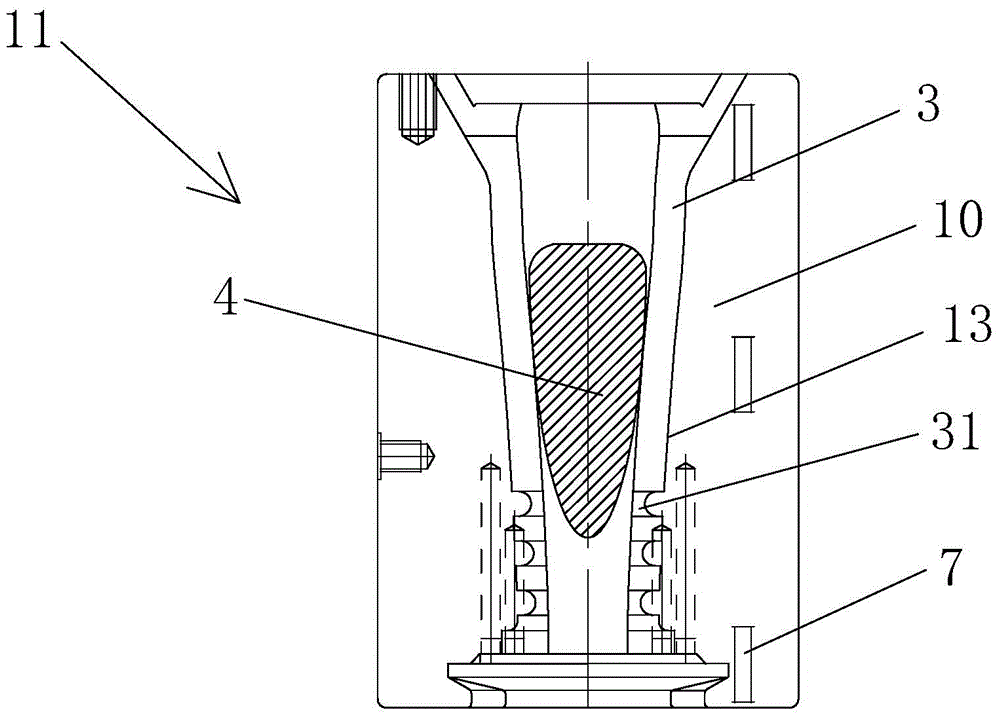

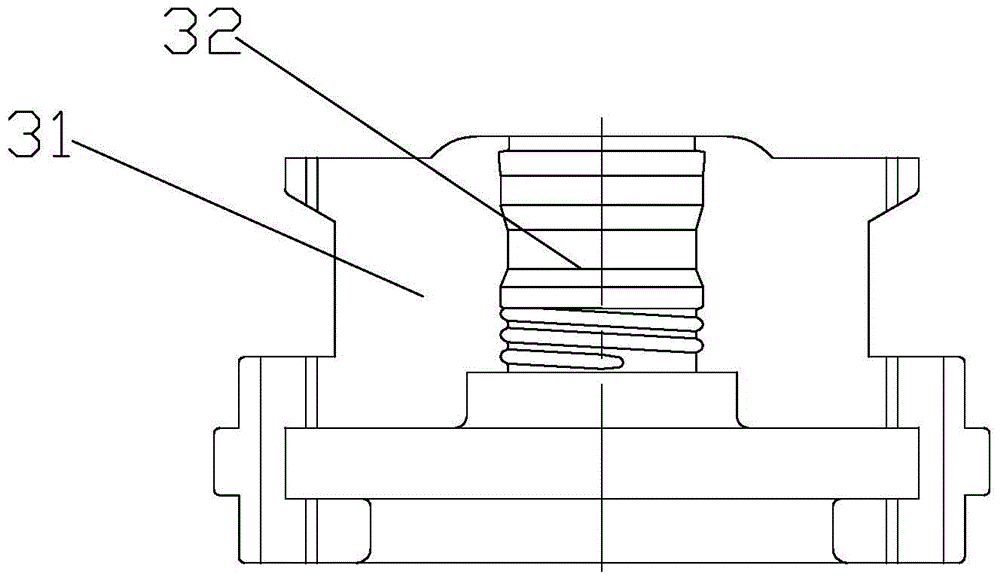

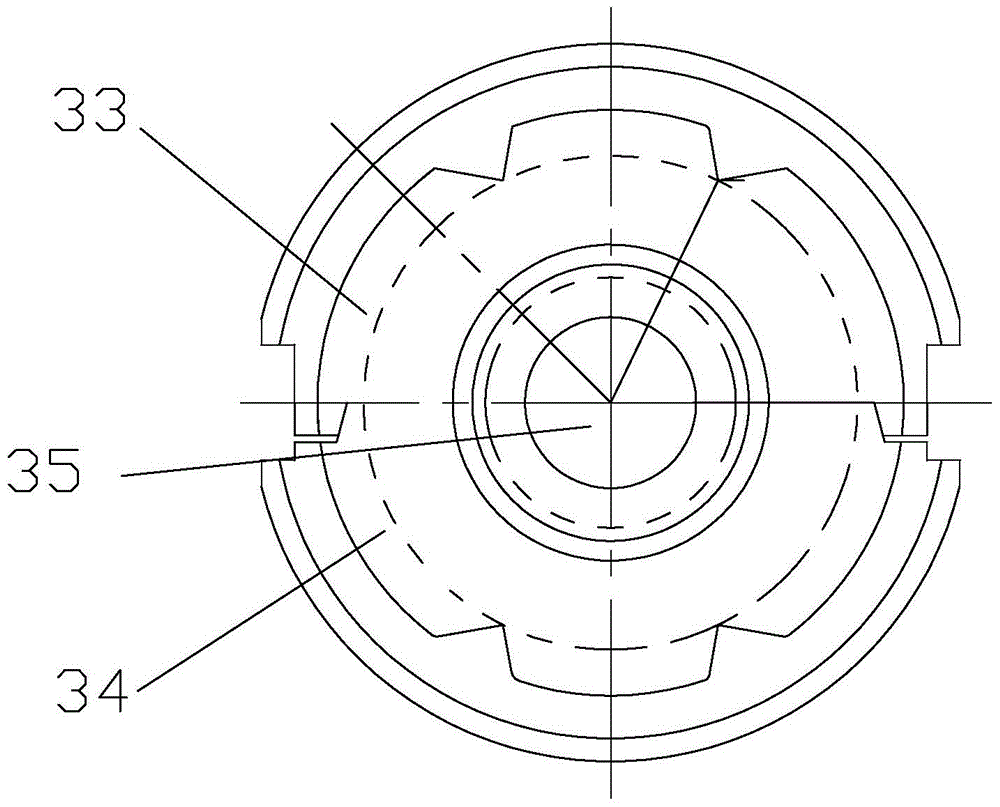

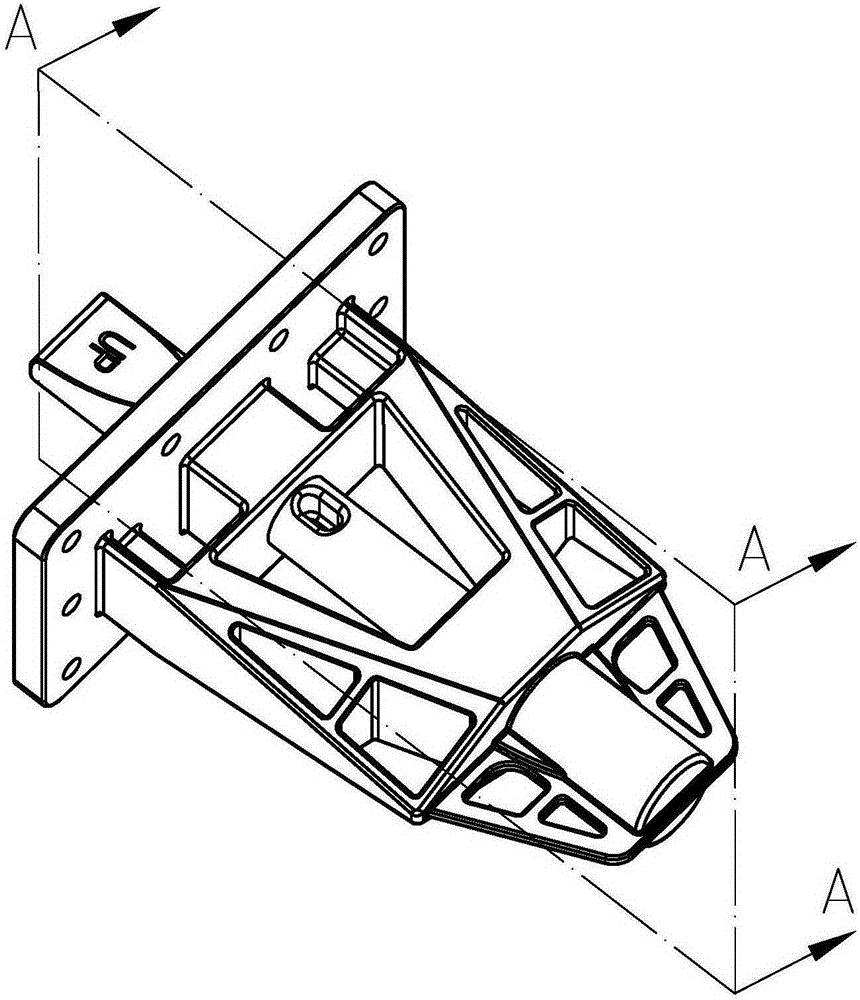

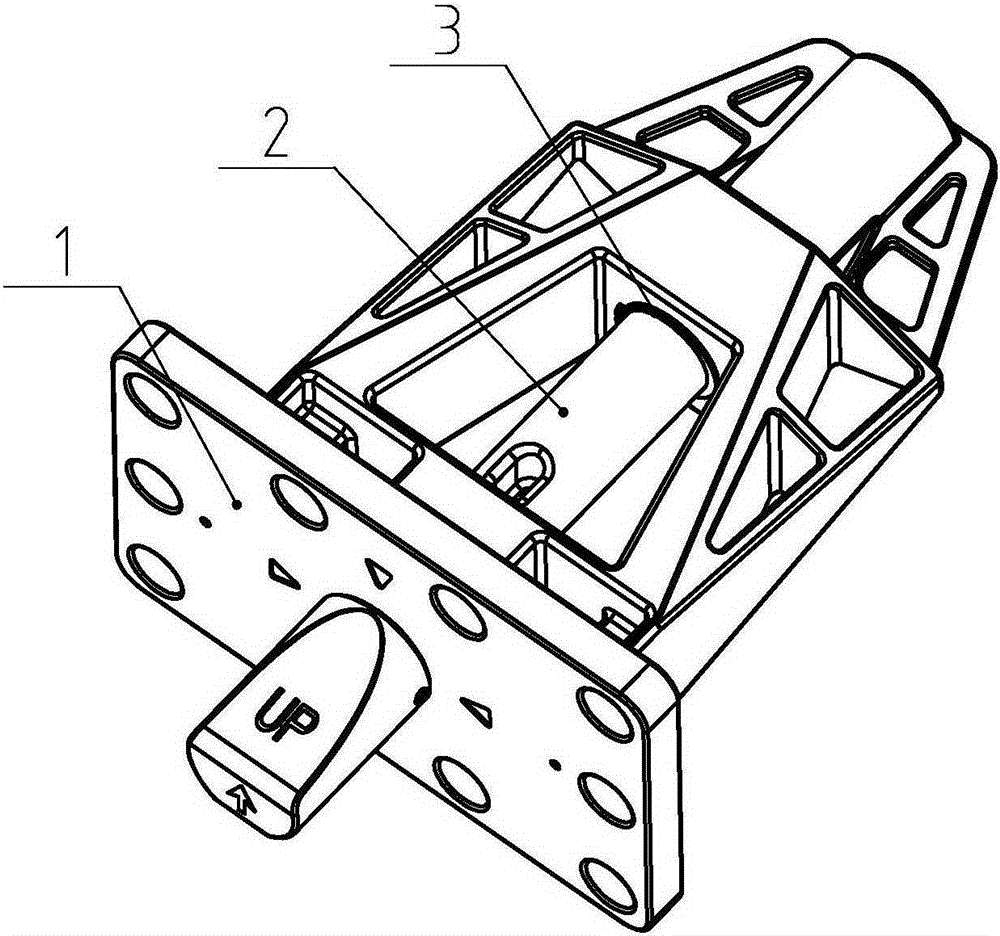

The invention discloses a sliding nozzle. A rotatable synchronous ring is arranged on an upper nozzle ring in a coaxial mode, and a synchronous ring inner circle connected with the upper nozzle ring in an assembling mode is of an interrupted structure in the radial direction. A first sliding block device comprises a flow guiding vane and an open shifting fork connected with the shaft end of the flow guiding vane. The shaft end of the flow guiding vane is provided with two parallel lateral planes. One end of the open shifting fork is connected with the two lateral planes in a matched mode. A second sliding block device comprises a main shifting fork assembly, one end of the main shifting fork assembly is connected with an actuator, and the other end of the main shifting fork assembly is connected with the synchronous ring through a synchronous pin. By means of the sliding nozzle, precision loss caused by fast abrasion of a line-plane friction pair in actual use is effectively avoided. Transmission precision and abrasion resistance are effectively improved. The inner circle is of an interrupted synchronous ring structure, matching area of the synchronous ring and the upper nozzle ring is reduced, and the phenomenon that the synchronous ring and the nozzle ring are clamped due to thermal deformation is effectively prevented.

Owner:汉美综合科技(常州)有限公司

Mould for manufacturing glass container

ActiveCN102617015AReduce fit areaExtended service lifeGlass blowing apparatusGlass productionBottle neckPhysics

The invention provides a mould for manufacturing a glass container, belonging to the technical field of a glass mould. The mould comprises a pair of bottle half modules, wherein each bottle half module is provided with a joint close surface and a bottle mould chamber composed of a bottleneck chamber, a neck shoulder chamber, a bottle body chamber and a bottle bottom chamber; the joint close surface comprises a bottle opening matching region located at the chamber opening part of the bottleneck chamber, a middle matching region corresponding to the chamber opening part of the bottle body chamber, a bottle bottom matching region corresponding to the chamber opening part of the bottle bottom chamber, and a peripheral matching region located at the outer side of the middle matching region. The mould is characterized in that: the planes of the bottle opening matching region and the bottle bottom matching region are located at the same height, the plane of the middle matching region is lower than the plane of the bottle opening matching region, and the plane of the peripheral matching region is lower than the middle matching region. The mould provided by the invention has the advantages that: a matching area of the matching surface is reduced, the deformation amount of the mould in a work process is compensated, the production efficiency is improved, the service life is prolonged, and the resource is saved.

Owner:CHANGSHU JIANHUA MOLD TECH

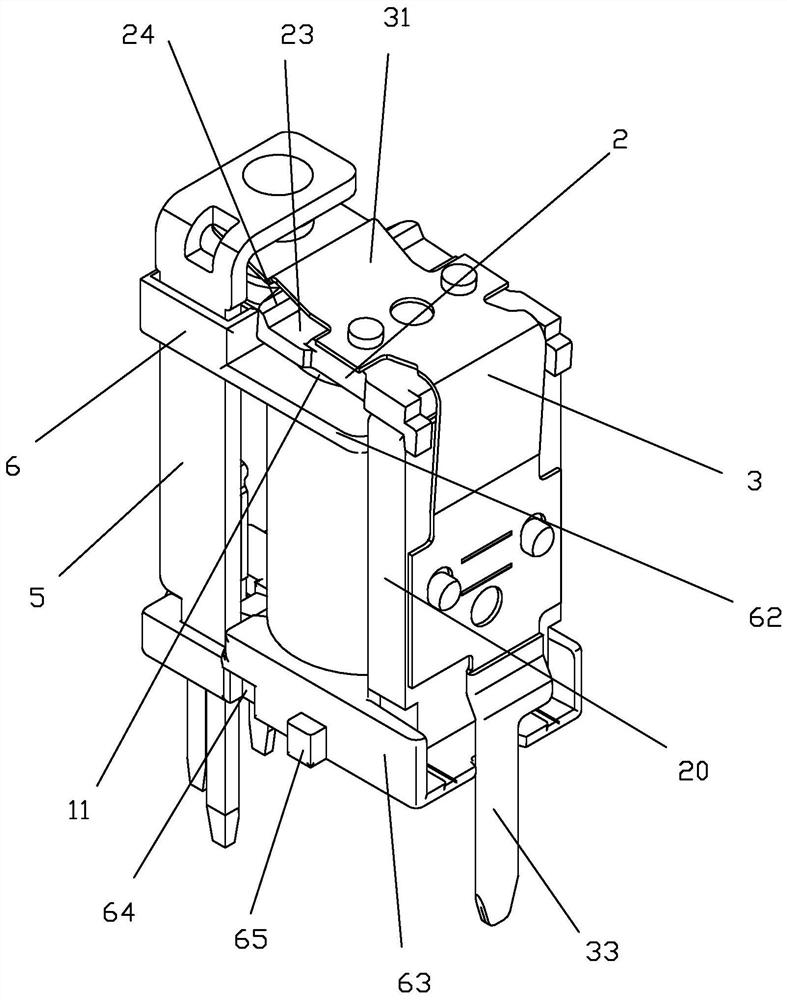

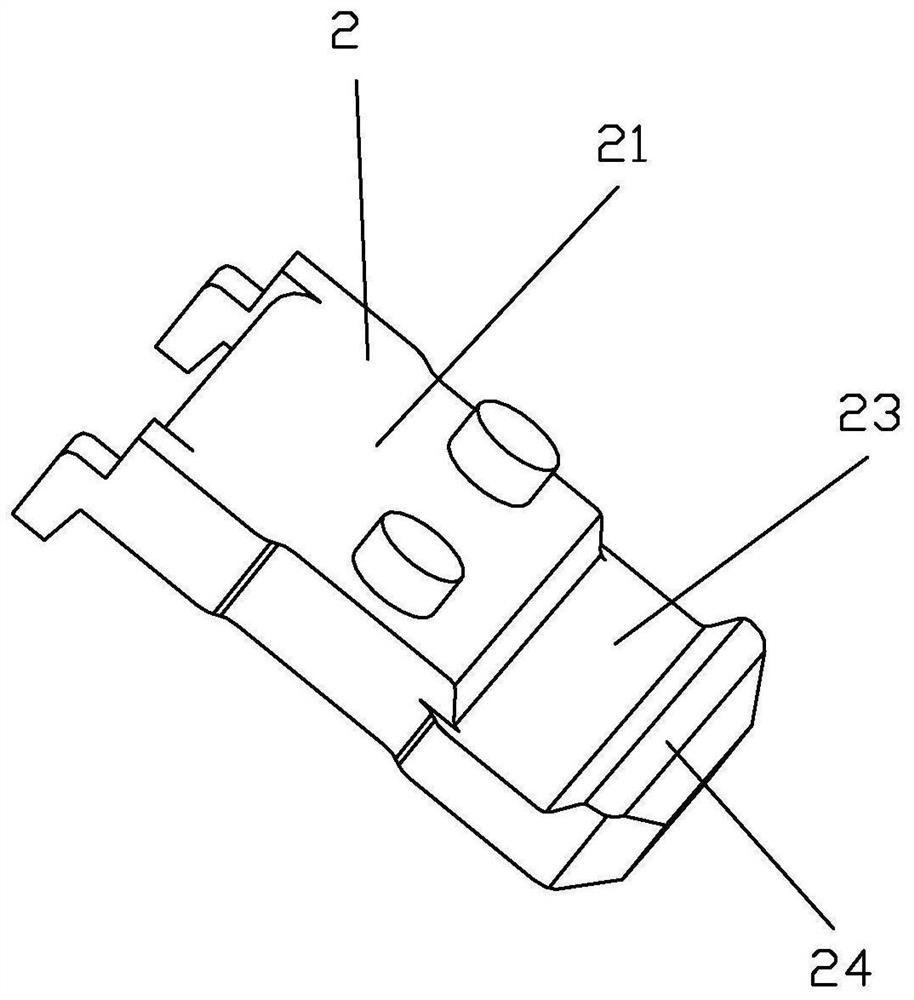

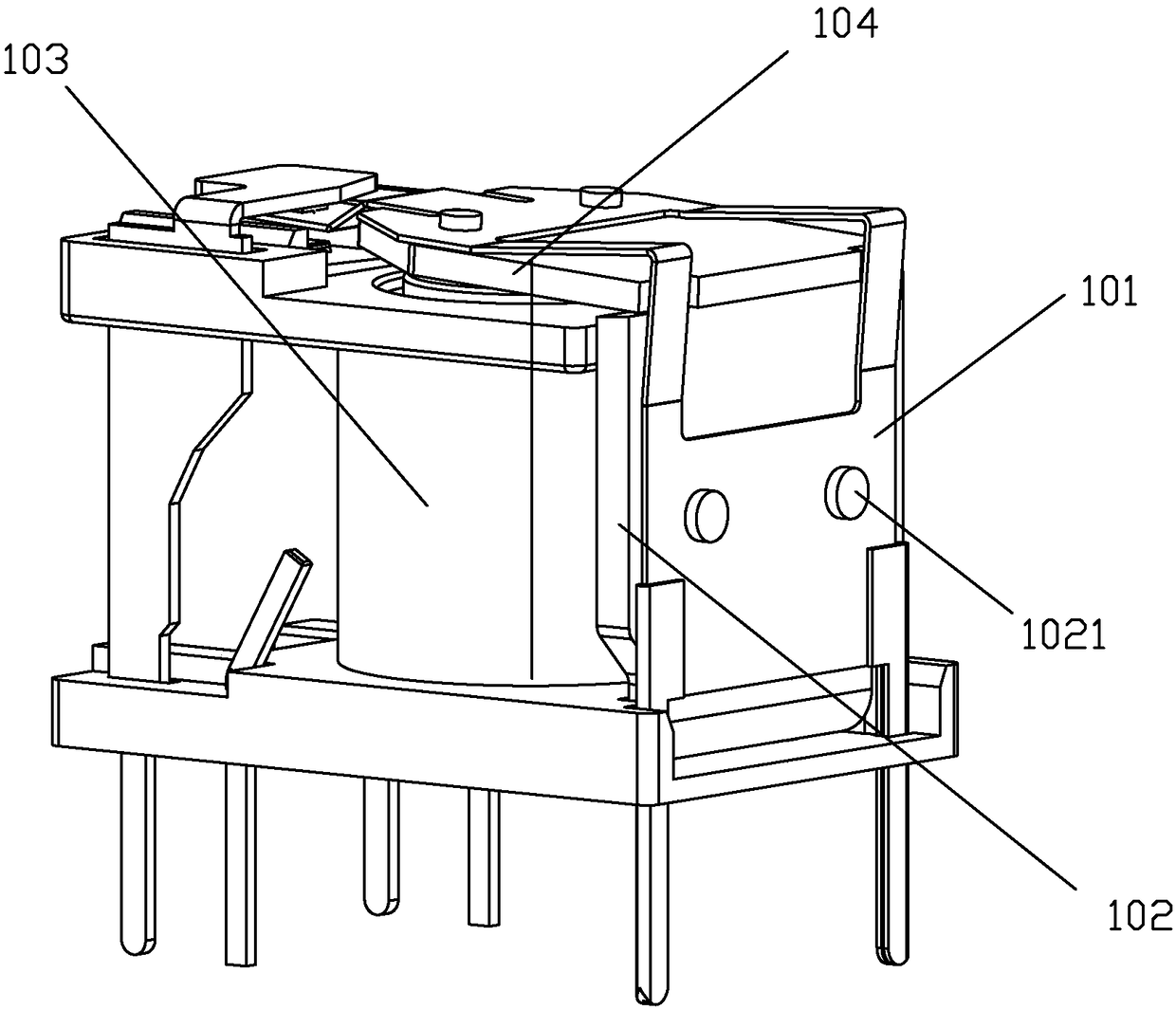

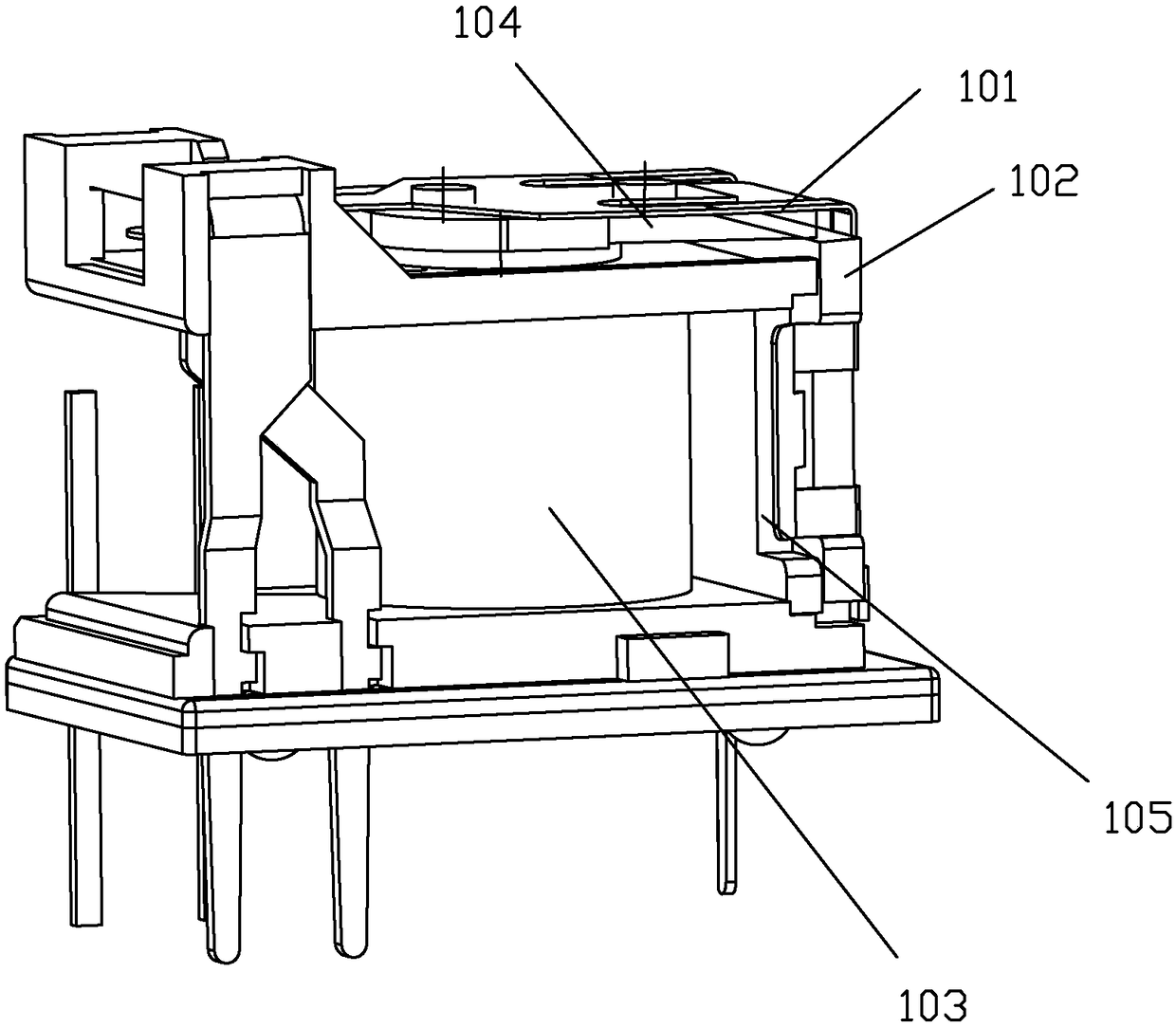

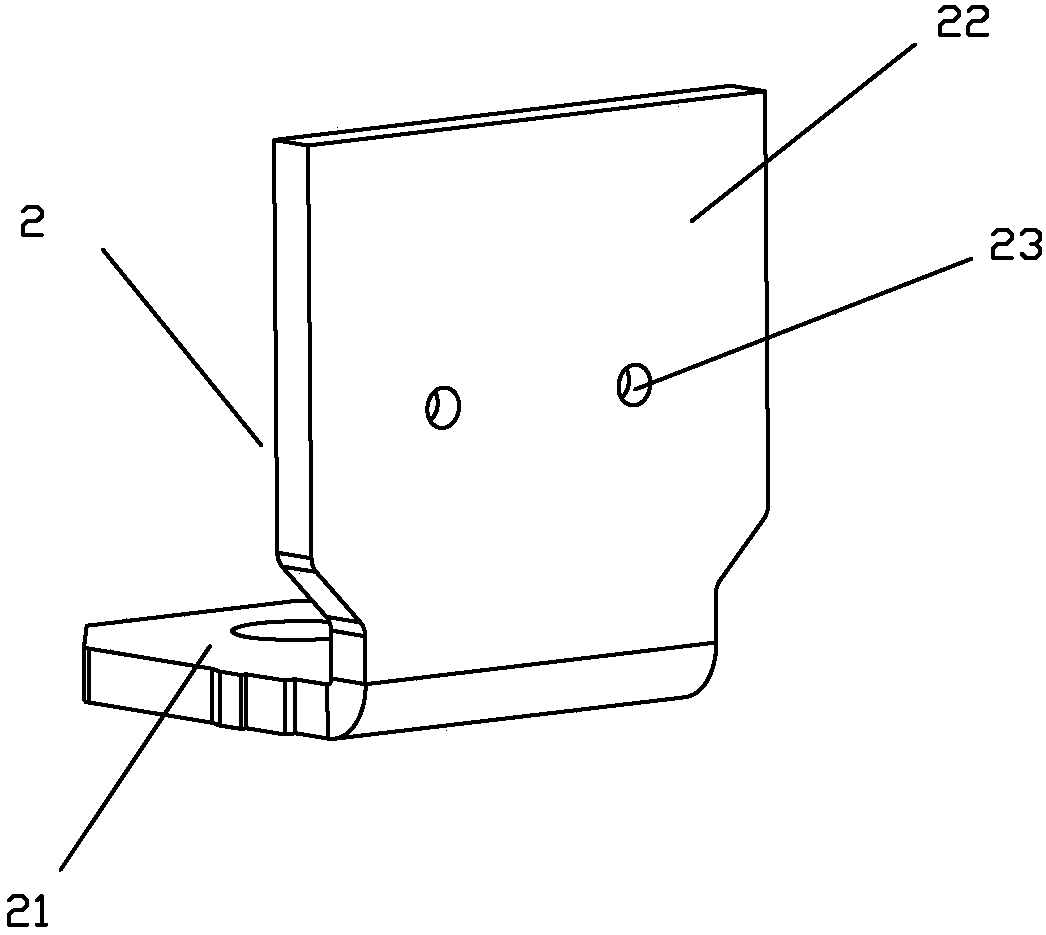

Electromagnetic relay with injection molded yoke

ActiveCN106206166AHigh degree of insulationWill not deformElectric switchesElectromagnetic relay detailsInjection mouldingRelay

The invention discloses an electromagnetic relay with an injection molded yoke. The electromagnetic relay comprises a movable spring, the yoke and a coil. The yoke is in an L shape, the horizontal side of the yoke and an iron core in the coil are fixed at the bottom of the coil, and the vertical side of the yoke is parallel to the axis of the iron core. In the vertical side of the yoke, a plastic layer is formed on the face facing the coil in an injection molding mode and is used for being arranged between the yoke and the coil in an insulation mode, a plastic protruding bud is formed on the face opposite to the coil in an injection molding mode, and the yoke and the movable spring are fixed through the plastic protruding bud. By means of the electromagnetic relay, on one hand, on the premise that the winding space is not influenced, the insulation degree of the yoke and the coil can be improved, the position precision of an insulation component can be ensured, and assembling procedures are effectively reduced; on the other hand, when the yoke and the movable spring are fixed, it can be avoided that the movable spring is deformed due to stress generated on the movable spring, and the size uniformity of the movable spring is improved.

Owner:XIAMEN HONGFA SIGNAL ELECTRONICS CO LTD

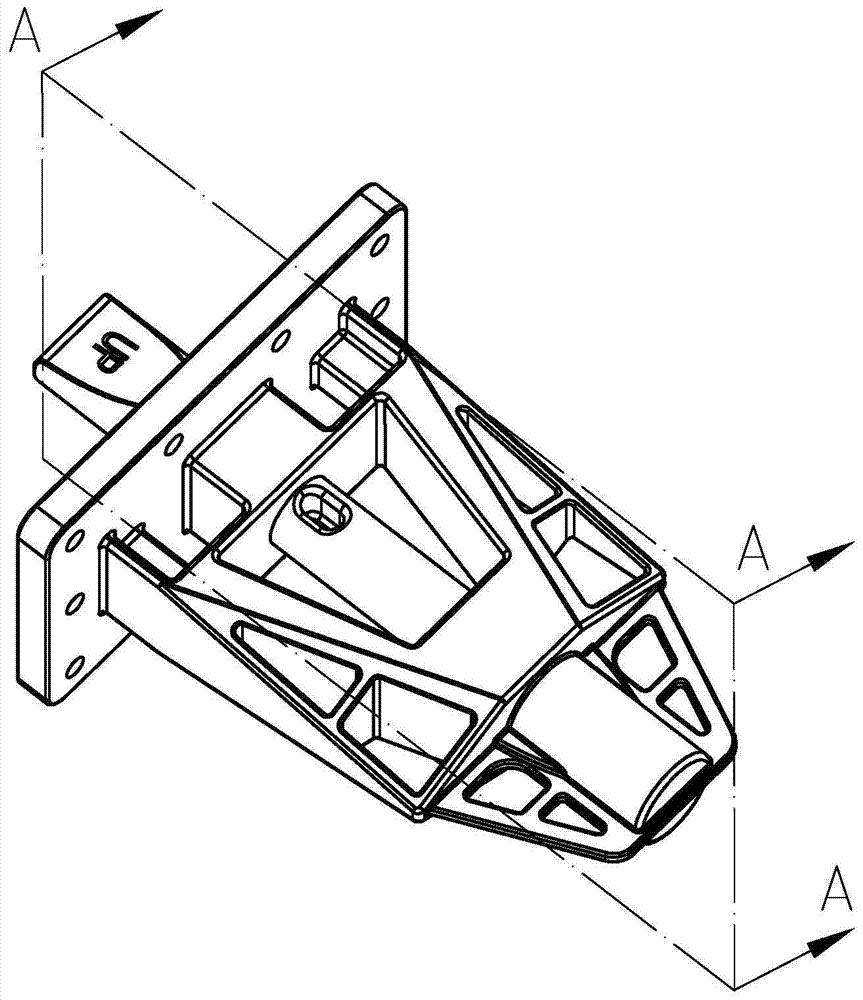

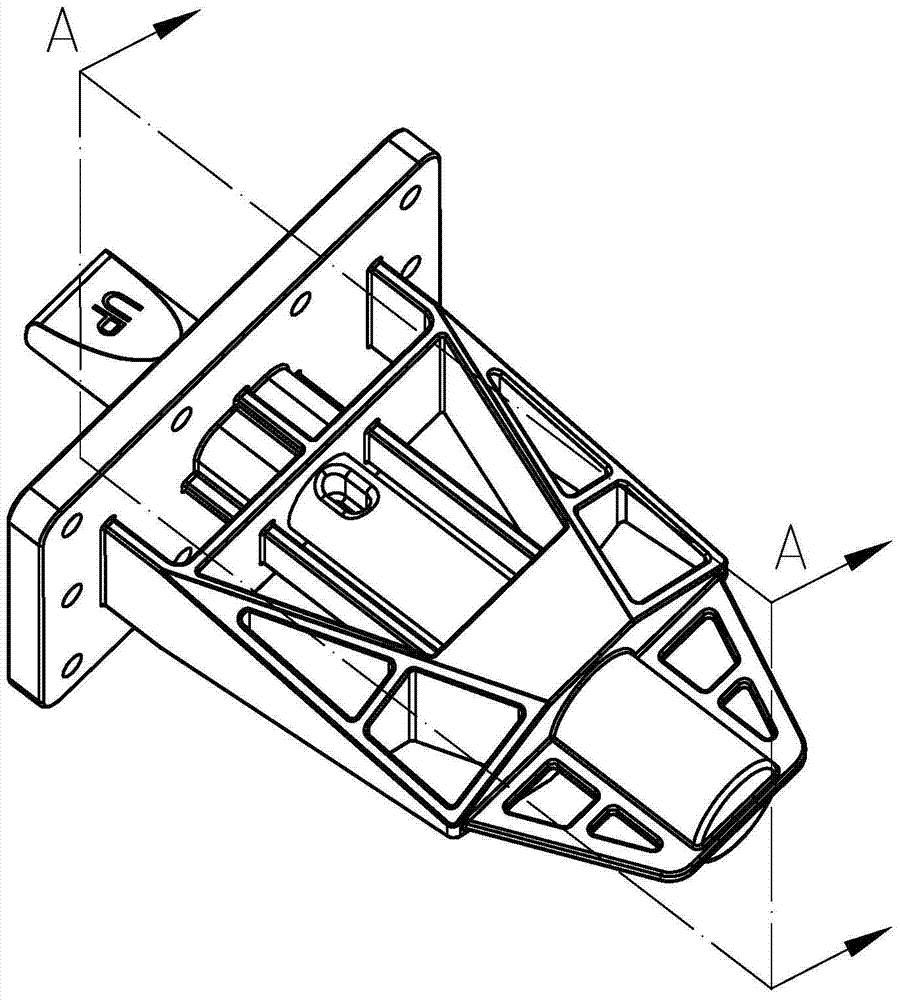

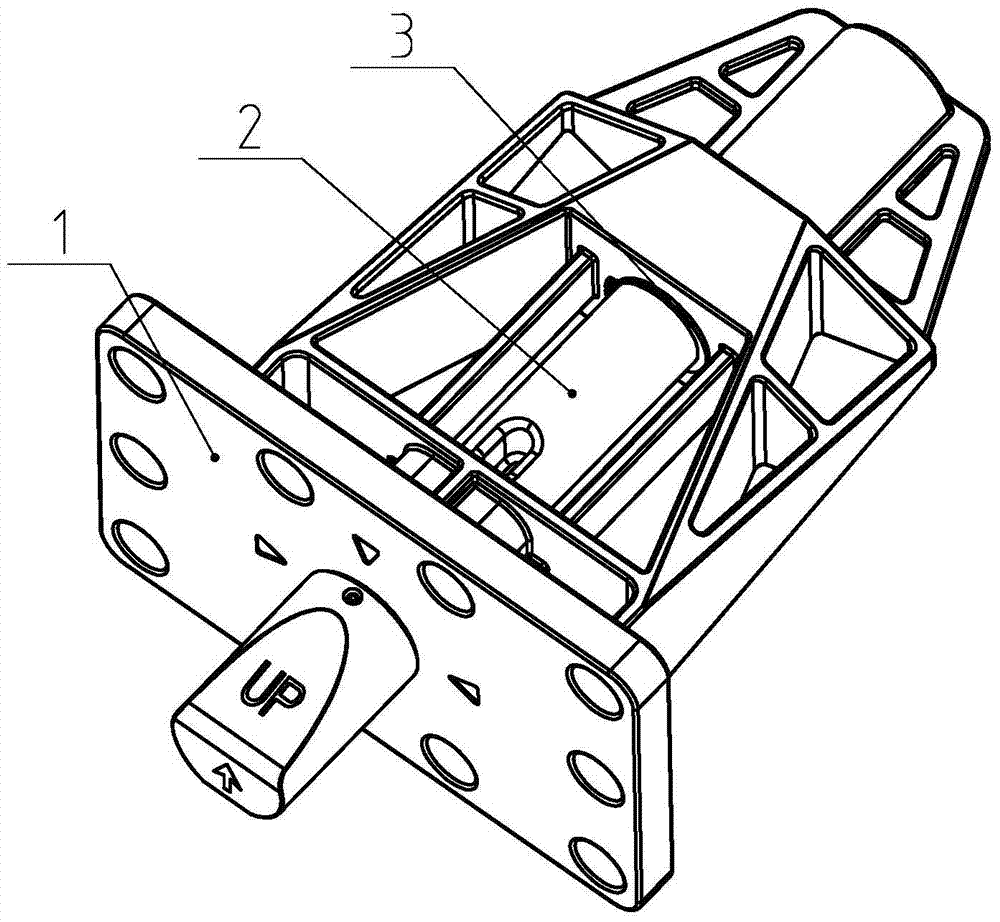

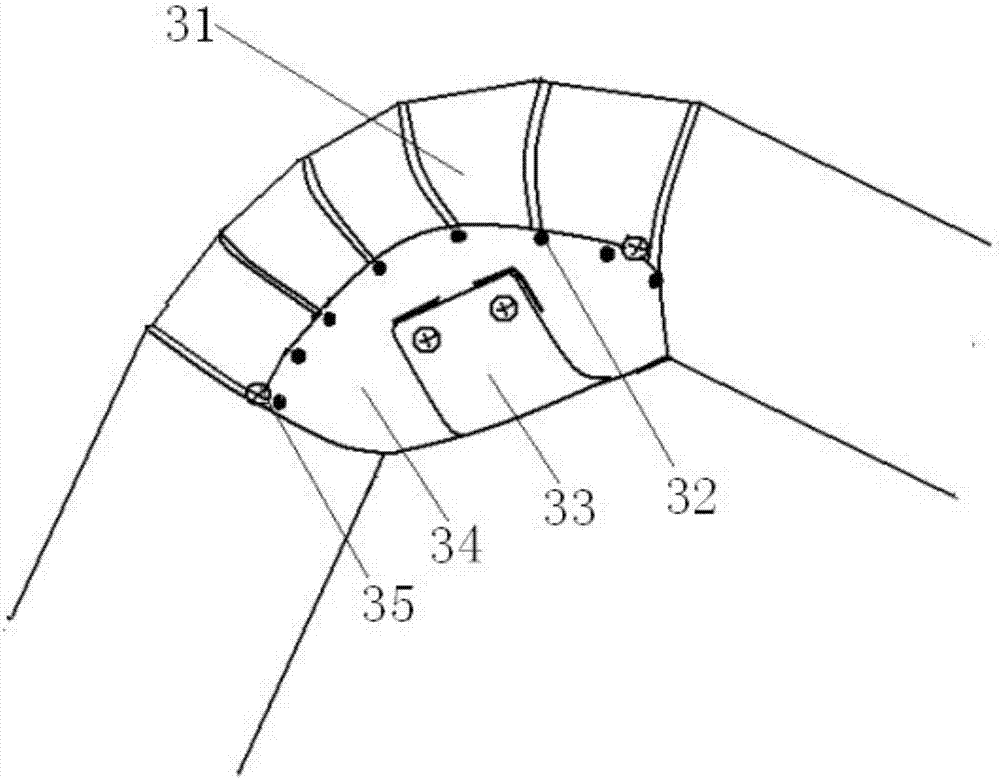

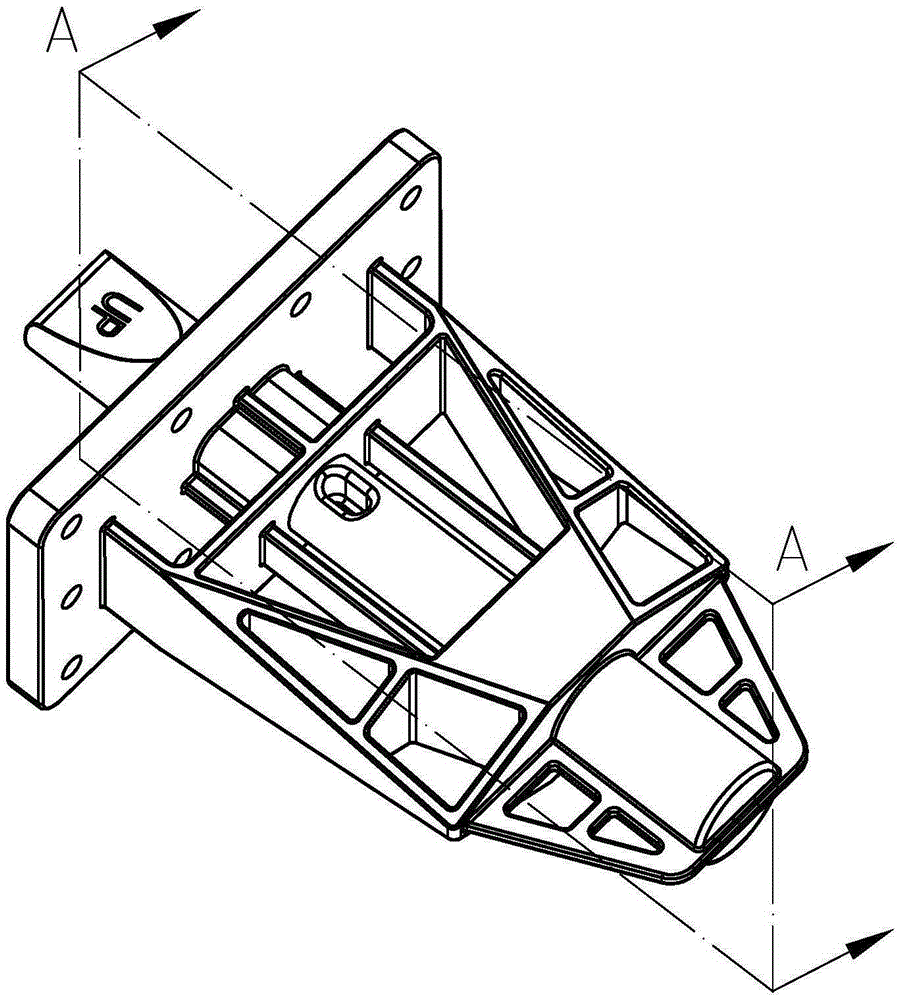

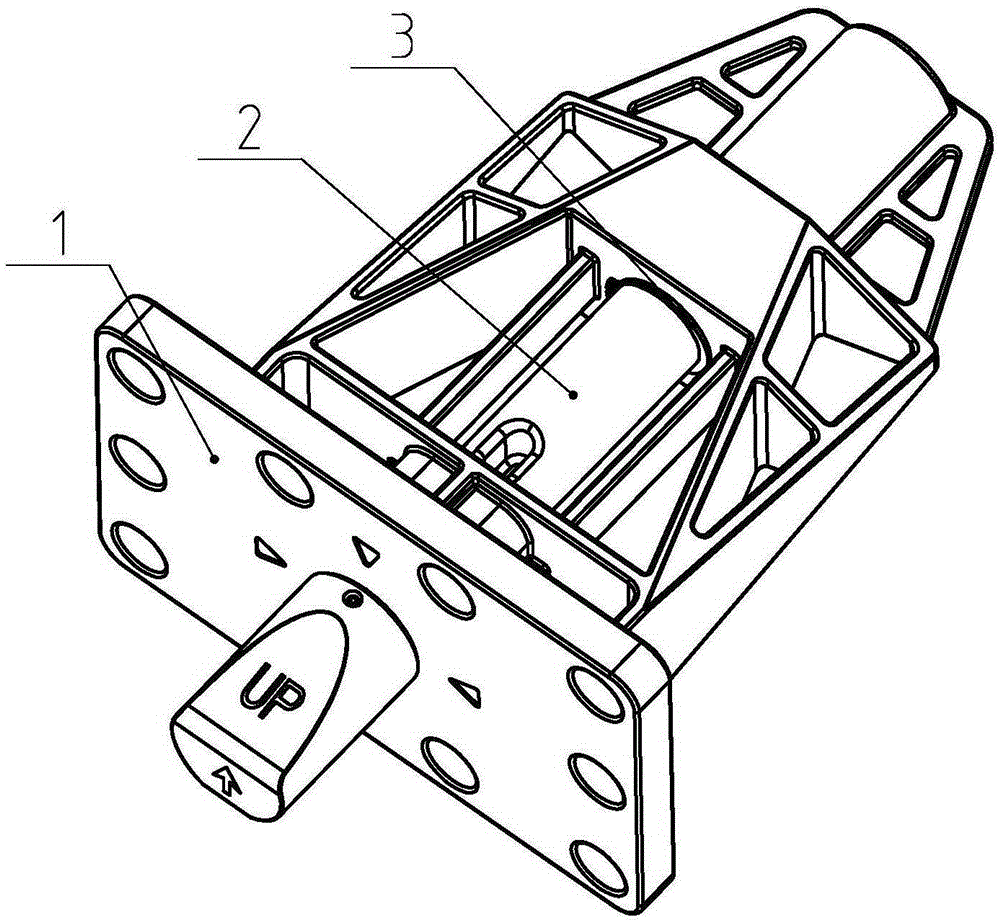

Primary mold capable of exhausting air

The invention relates to a primary mold capable of exhausting air. The primary mold consists of a male mold and a female mold, wherein surfaces, tightly adhered, of the male mold and the female mold which are matched with each other are joint surfaces; each joint surface is protruded out of each plane part; a dividing line is formed between each joint surface and each plane part; each dividing line is arranged along a contour line of the edge of each mold cavity; each joint surface is the surface formed between each dividing line and the contour line of the edge of each mold cavity; a plurality of air exhaust slots for communicating the inner part of a bottle body cavity with external air are formed in the joint surfaces. Compared with the prior art, the primary mold has the advantages that the air exhaust slots are formed in the joint surfaces, the phenomenon such as material skip caused by vacuum formed in material discharging in the bottle body cavity can be avoided, and the production quality can be improved; due to the arrangement of the joint surfaces, the matching area of the joint surfaces in the prior art is reduced and the tolerance is reduced; the joint surfaces are arranged to be higher than the plane parts so as to ensure that the plane parts on the male mold and the female mold cannot be in contact, and a gap can be provided for the air exhaust slots to exhaust air; the male mold is connected with the female mold by virtue of a plurality of triangular ribs so as to well exhaust air.

Owner:DEQING CAIFU GLASS

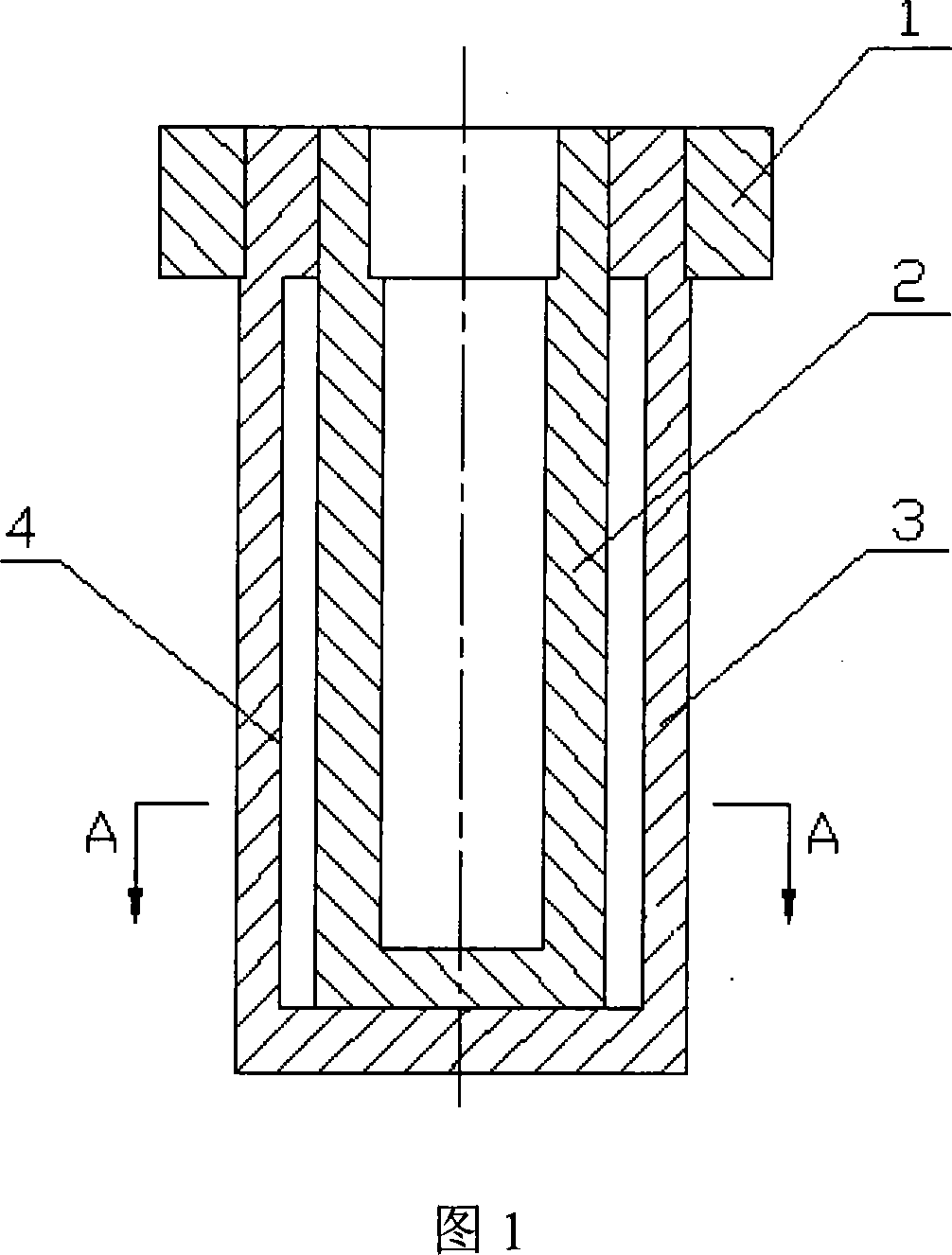

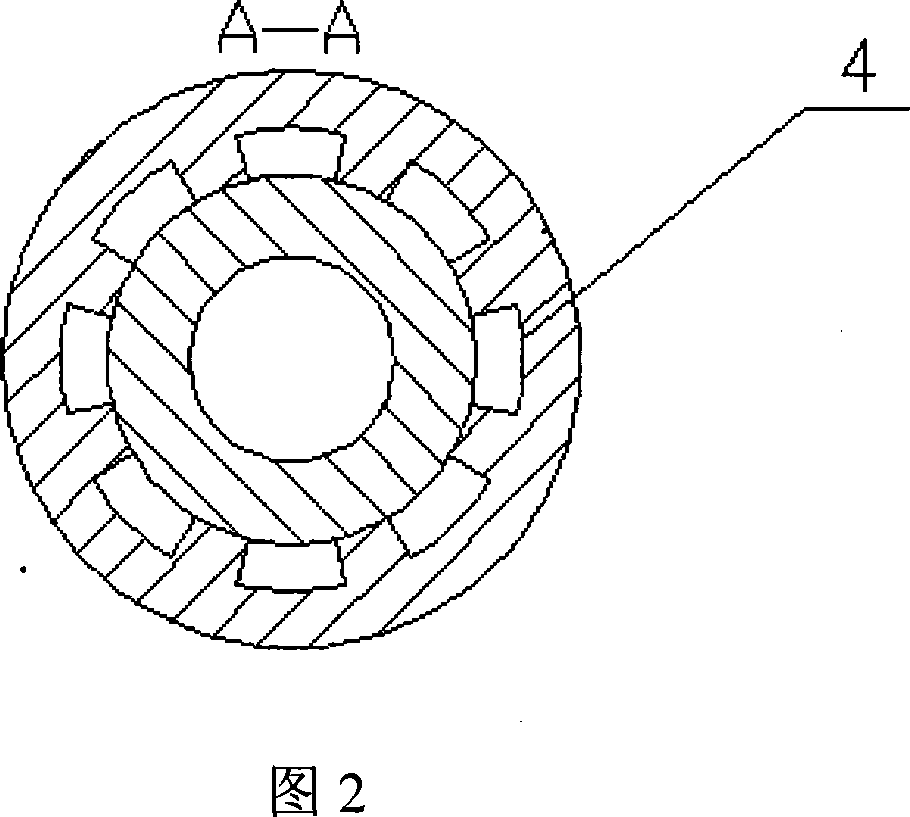

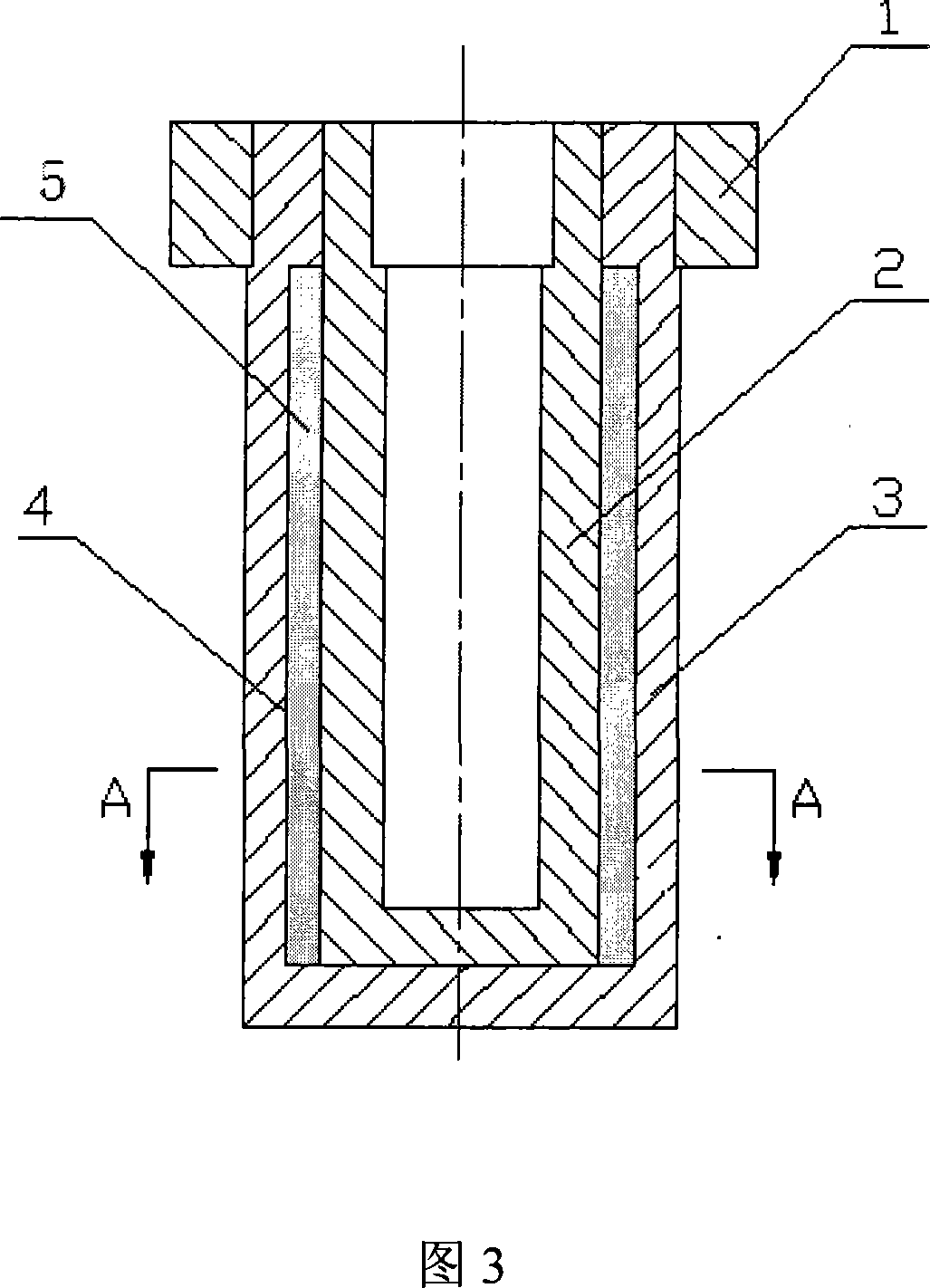

Composite type oil-hydraulic cylinder

InactiveCN101055033AReduce fit areaIncreased initial stressCylindersInterference fitHydraulic cylinder

The present invention improves the fault that the existing combination oil pressure cylinder is difficult in assembly and less in initial stress and provides a high material utilization and strong bearing capability composite type oil pressure cylinder under the condition that the wall thickness of the cylinder is not increased. The cylinder includes an outer cylinder and at least one inner cylinder, the inner wall of the outer cylinder is coupled with the outer wall of the inner cylinder, the coupling is interference fit packing coupling. The inner wall of the outer cylinder is disposed with at least four oil press channels that uniformly disposed between the inner cylinder and the outer cylinder along the circumferential direction of the inner wall of the outer cylinder. The invention has the characteristic of convenient in assembly and distinct reduction in the maximum stress value of the combination cylinder.

Owner:SHAANXI UNIV OF SCI & TECH

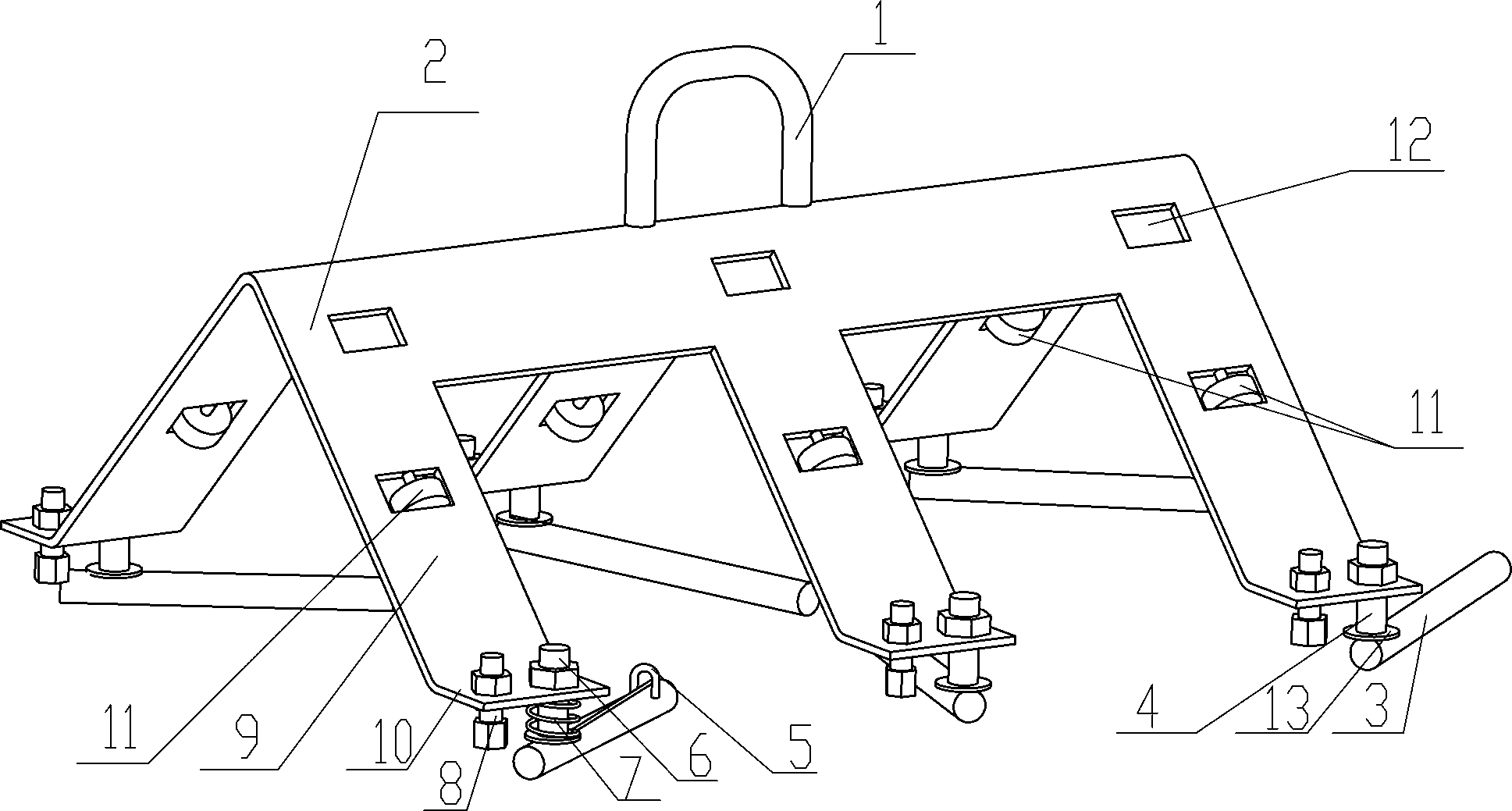

Mobile protector for substation maintenance

The invention discloses a mobile protector for substation maintenance. The mobile protector comprises a movable travelling support. A U-shaped ring is disposed on the travelling support. Two sides of the travelling support are provided with mounting platforms. A locking bar is disposed on each mounting platform. The travelling support comprises a steel angle. Two sides of the steel angle are provided with sliding arms. The middle of each sliding arm is provided with a sheave. The mounting platforms are horizontally arranged and integrated with the sliding arms. Each locking bar is L shaped and formed by welding a horizontal round bar and a vertical round bar, wherein the vertical round bar is sleeved with a torsion spring. Two ropes can be hung on the mobile protector; the mobile protector can slide over an elevated frame of a substation with personnel and is firmly attached to the elevated frame; during moving of the mobile protector, workers on the elevated frame are protected by the two ropes and the protector constantly; accordingly, the mobile protector is well practicable, small in size, light in weight, convenient to carry and convenient to mount and use, and work efficiency can be higher.

Owner:STATE GRID CORP OF CHINA +1

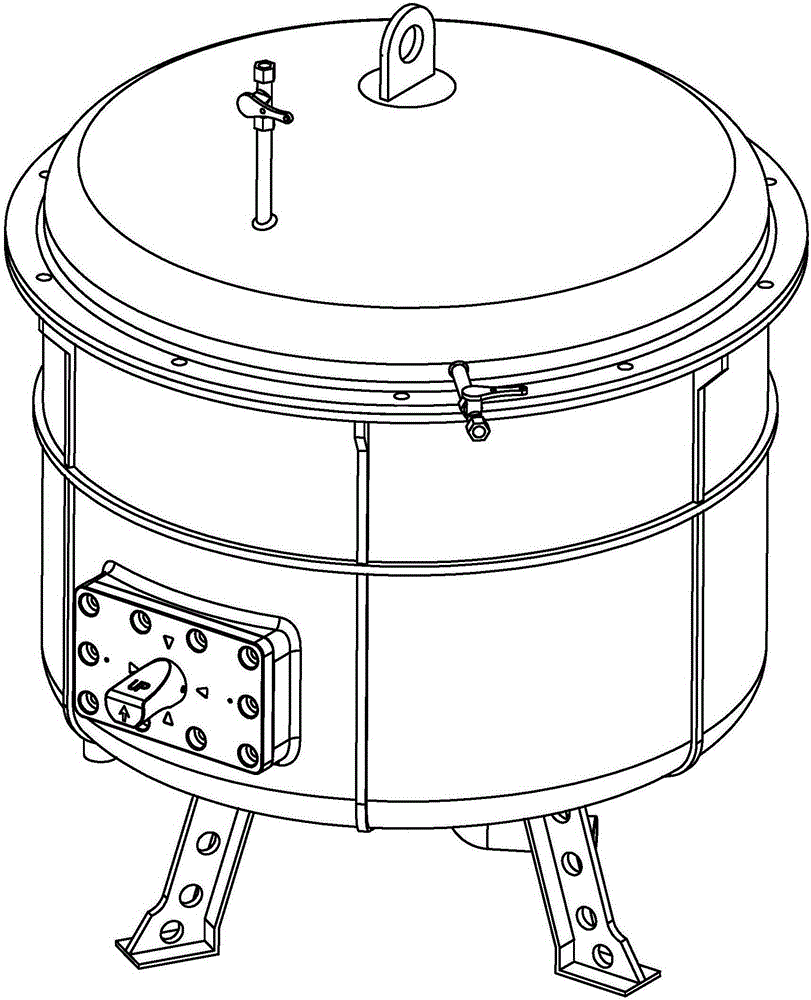

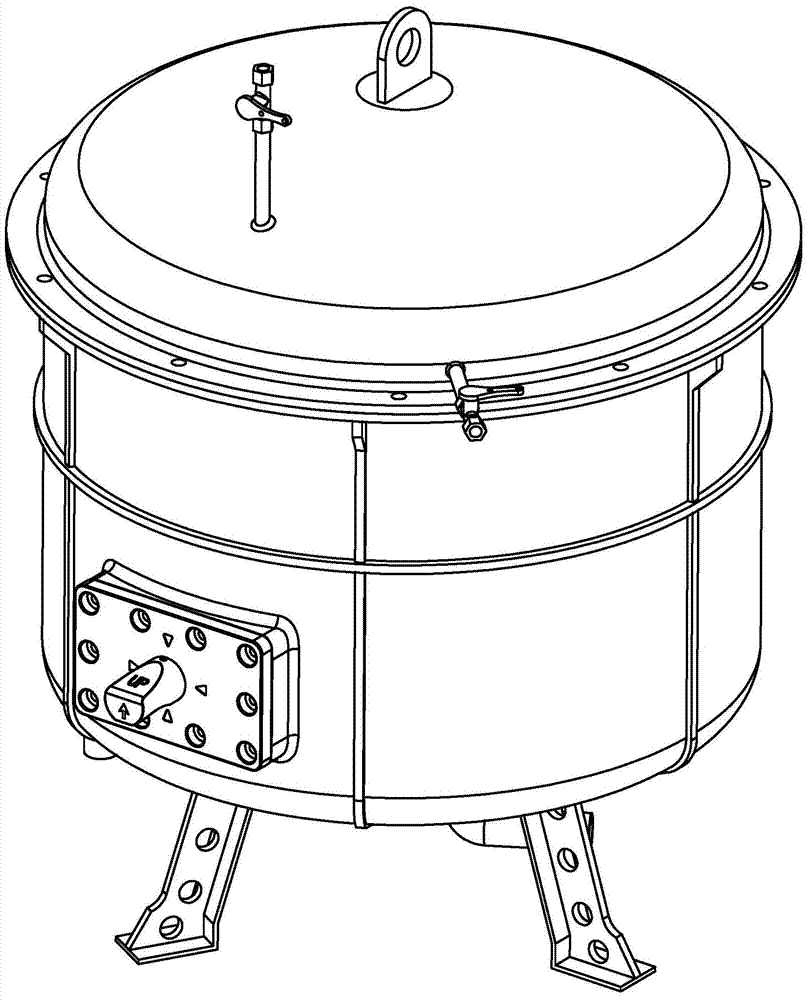

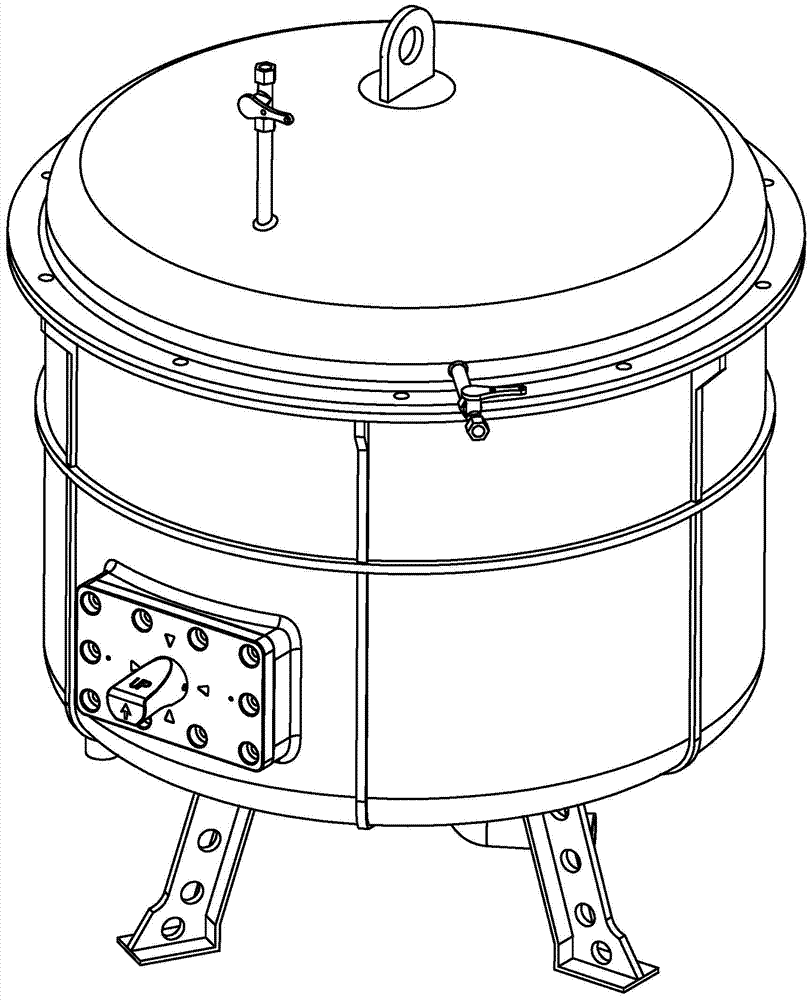

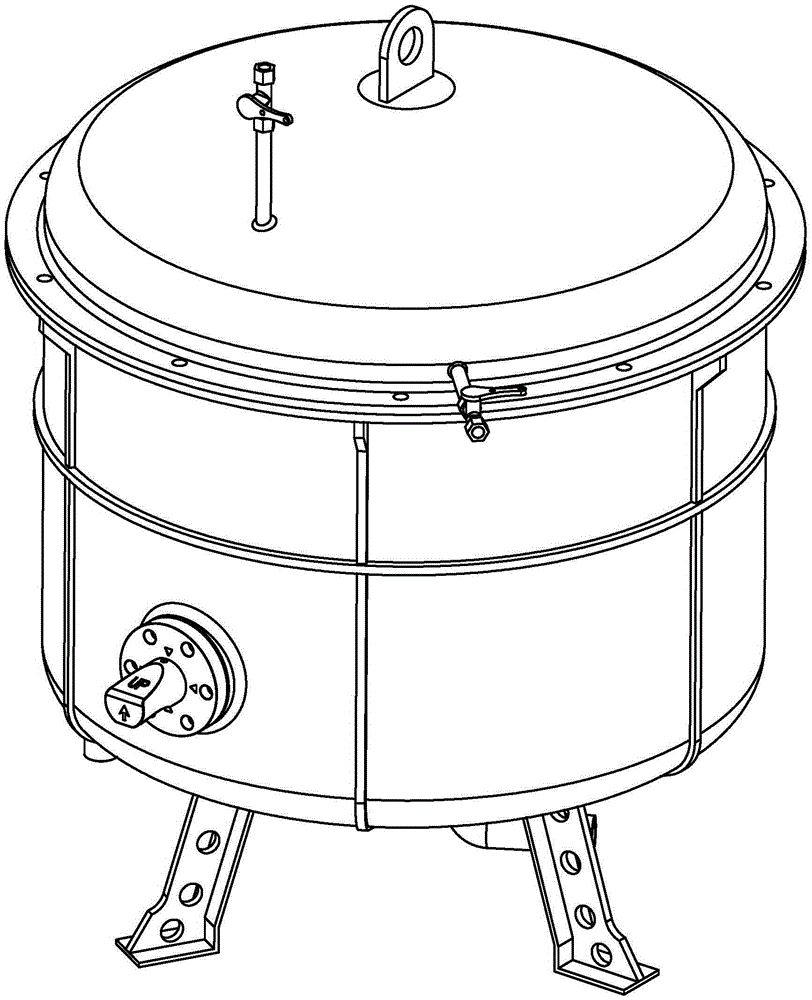

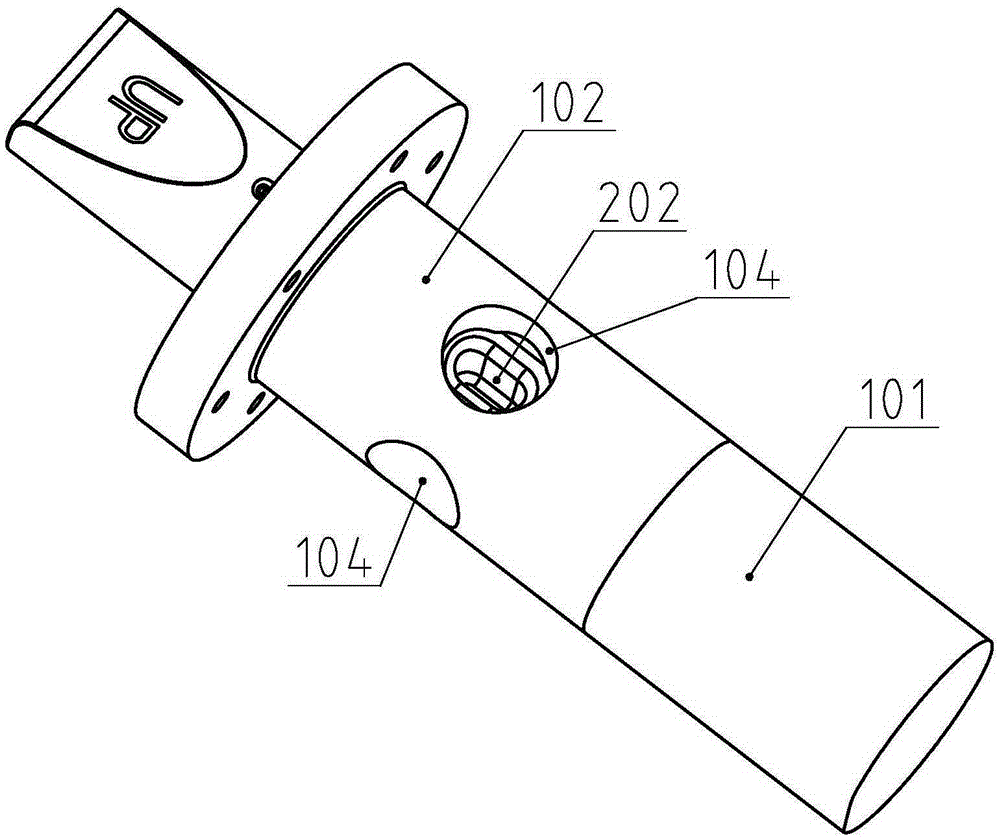

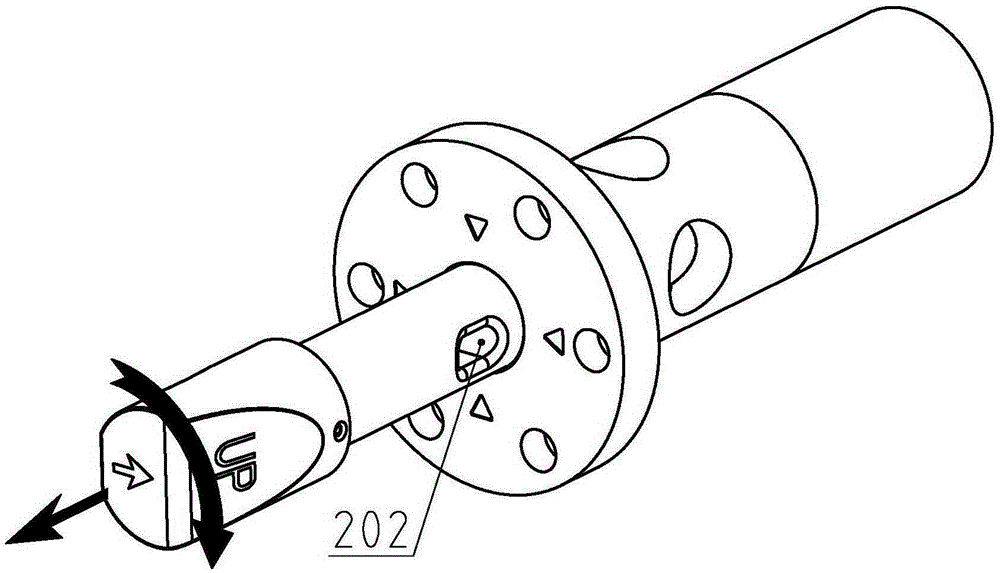

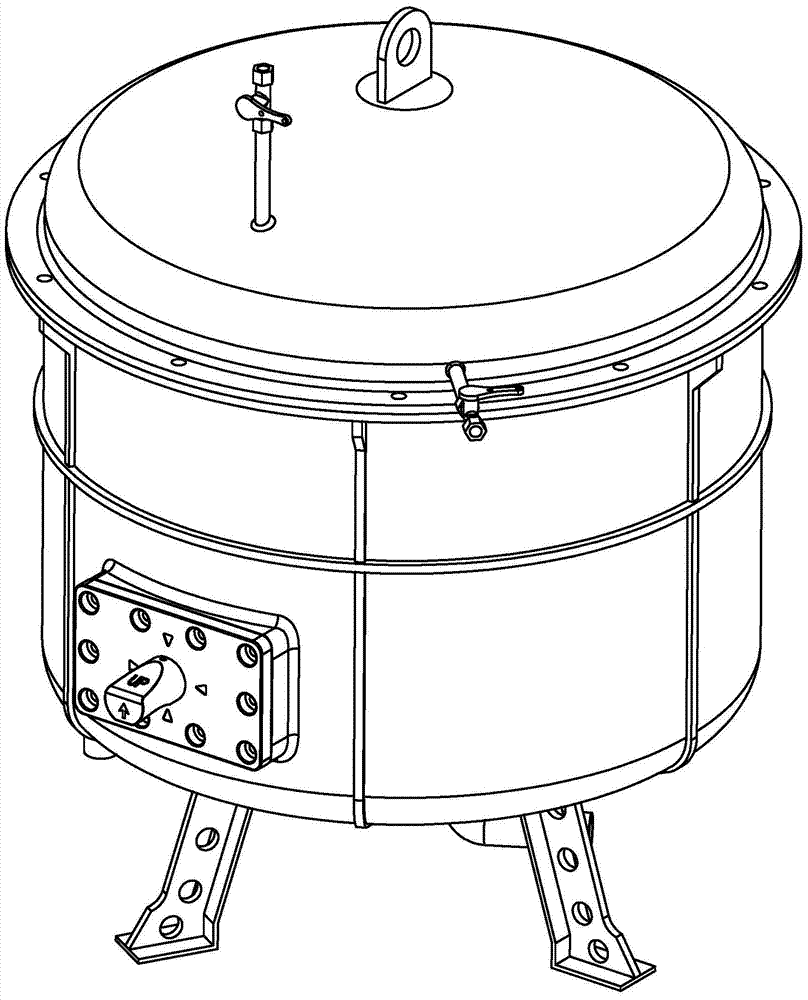

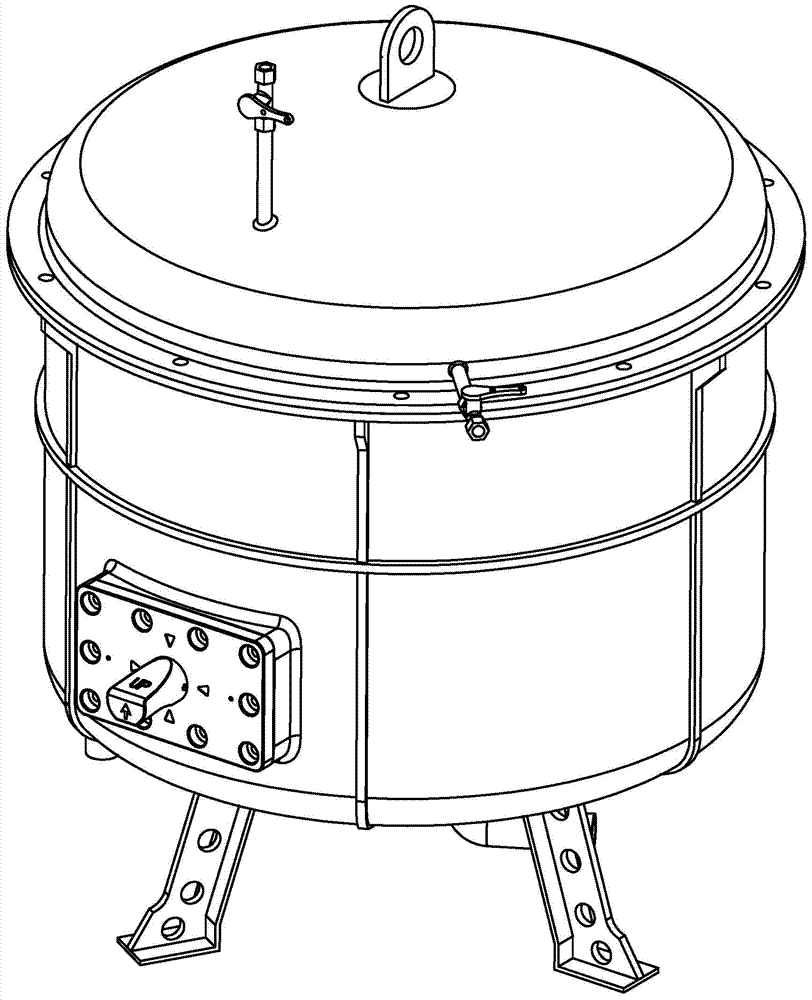

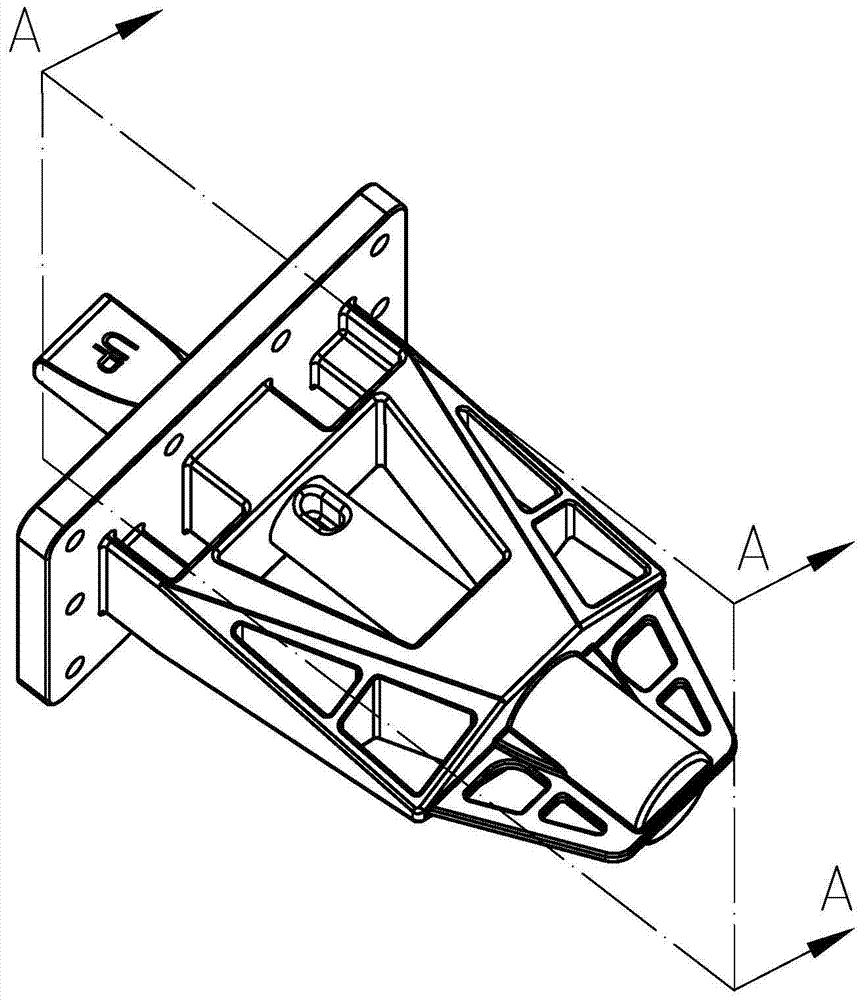

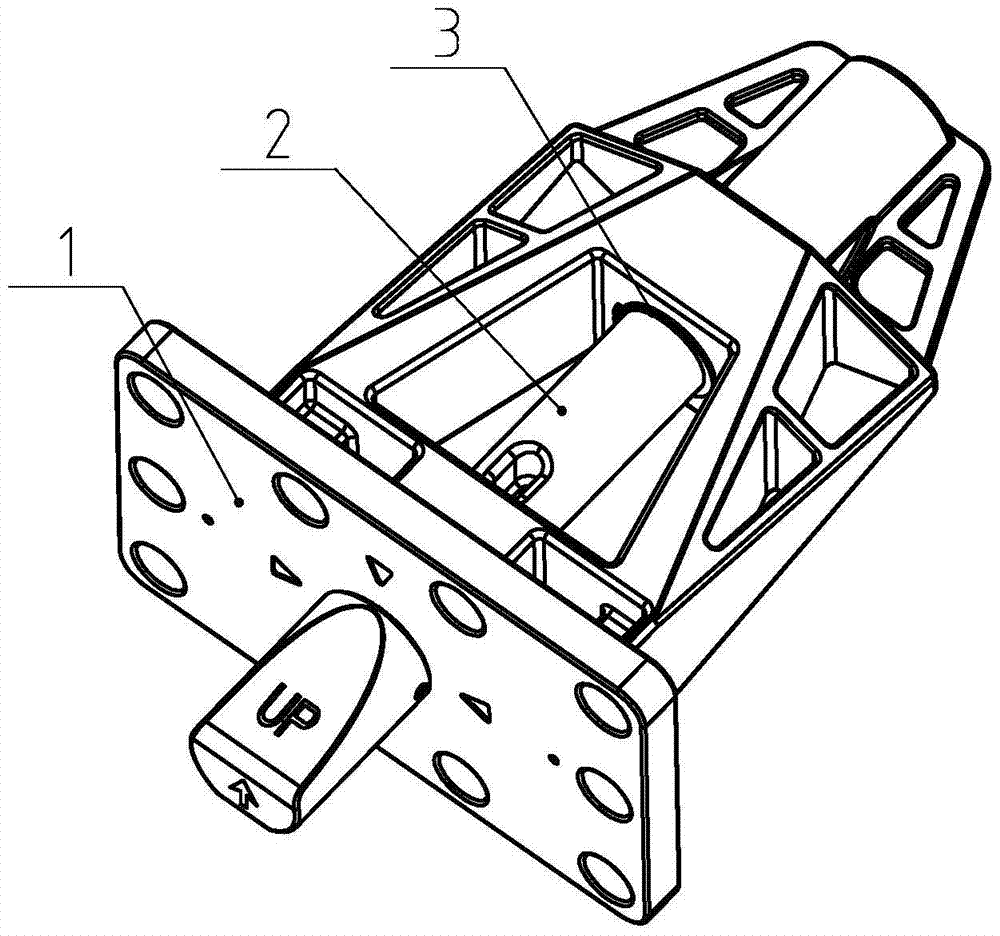

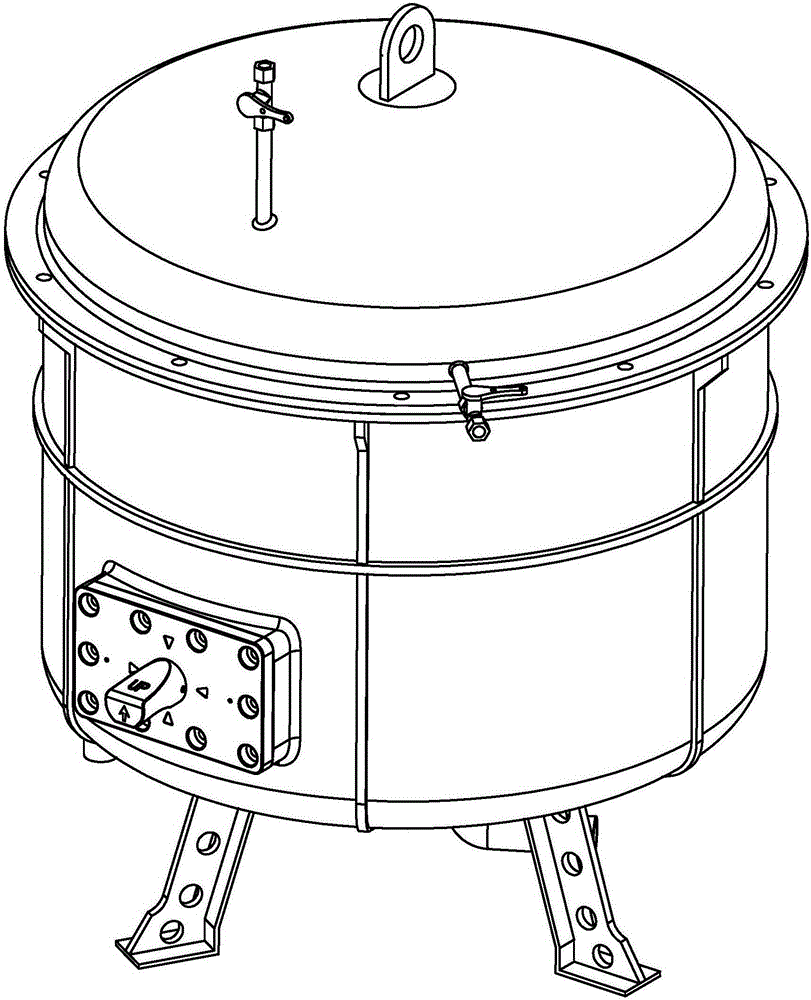

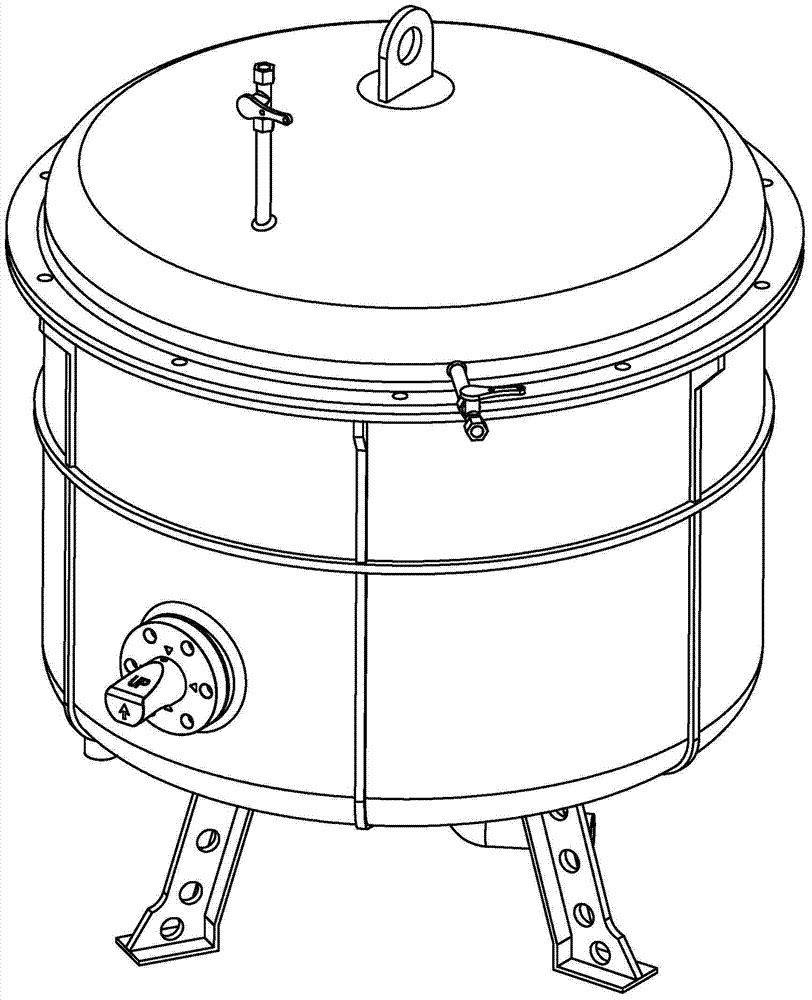

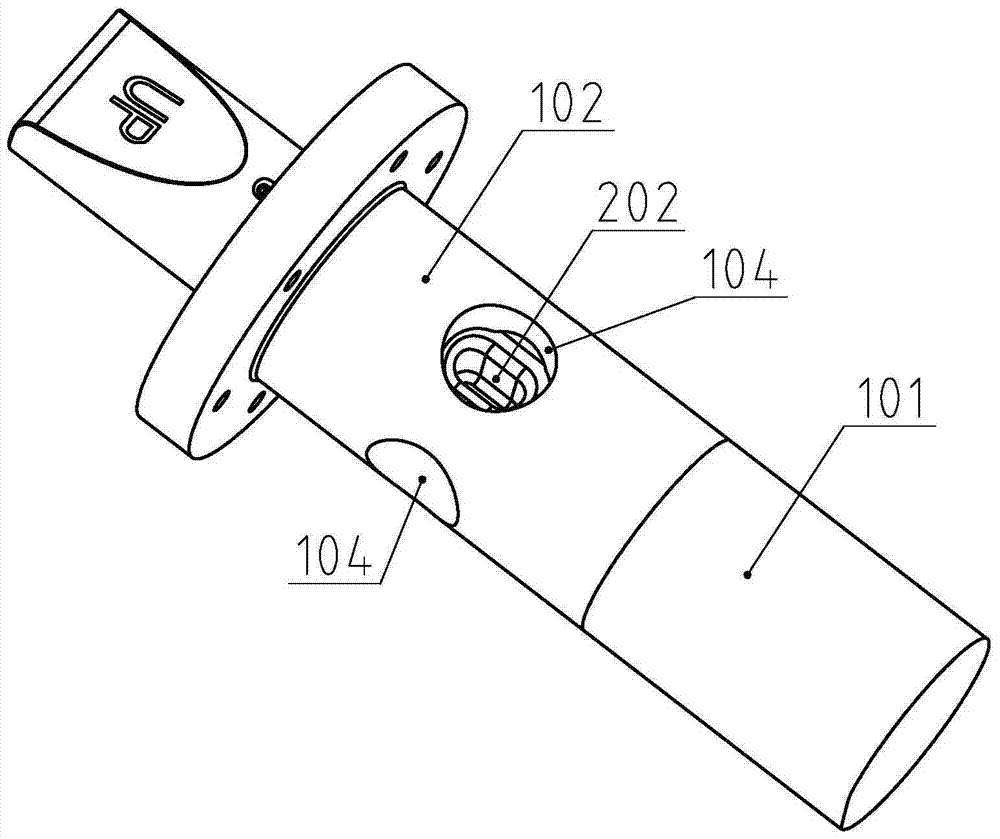

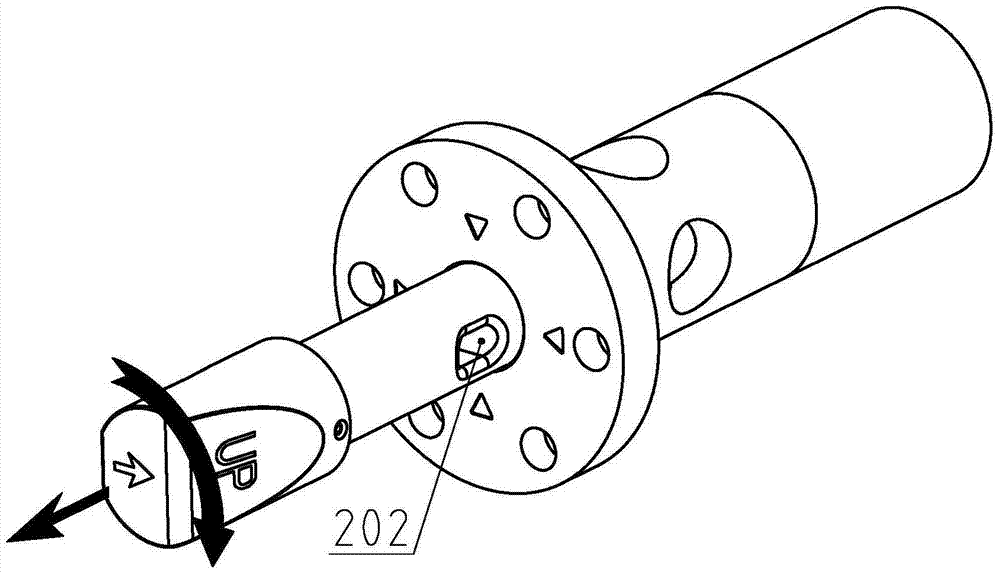

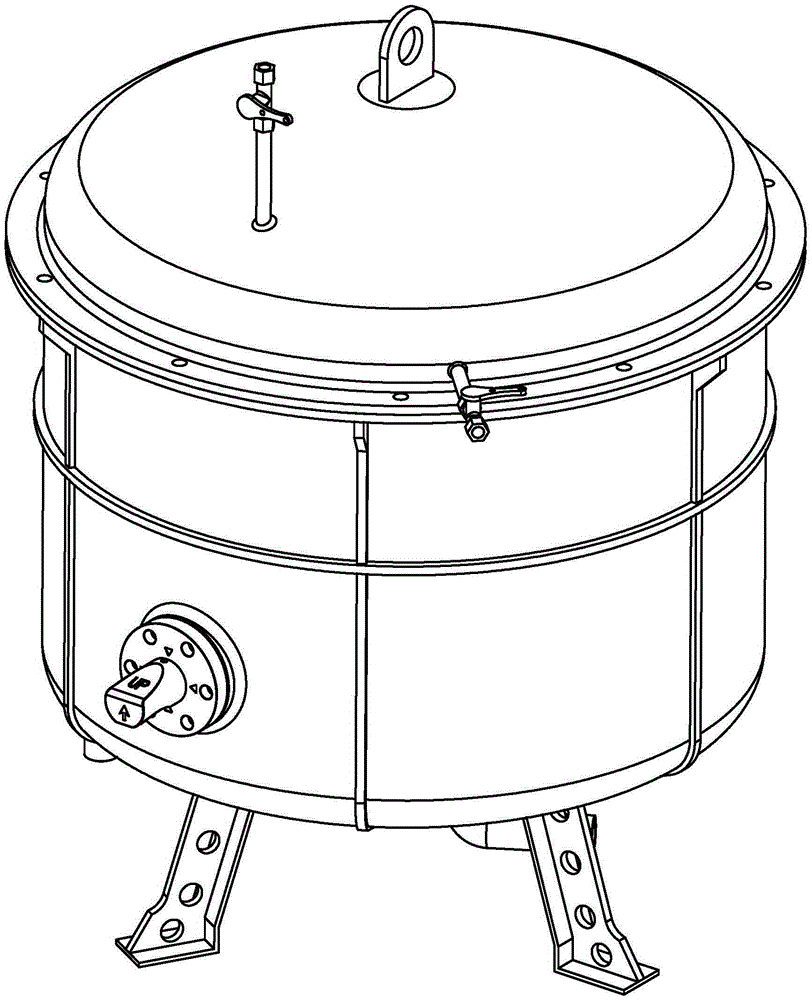

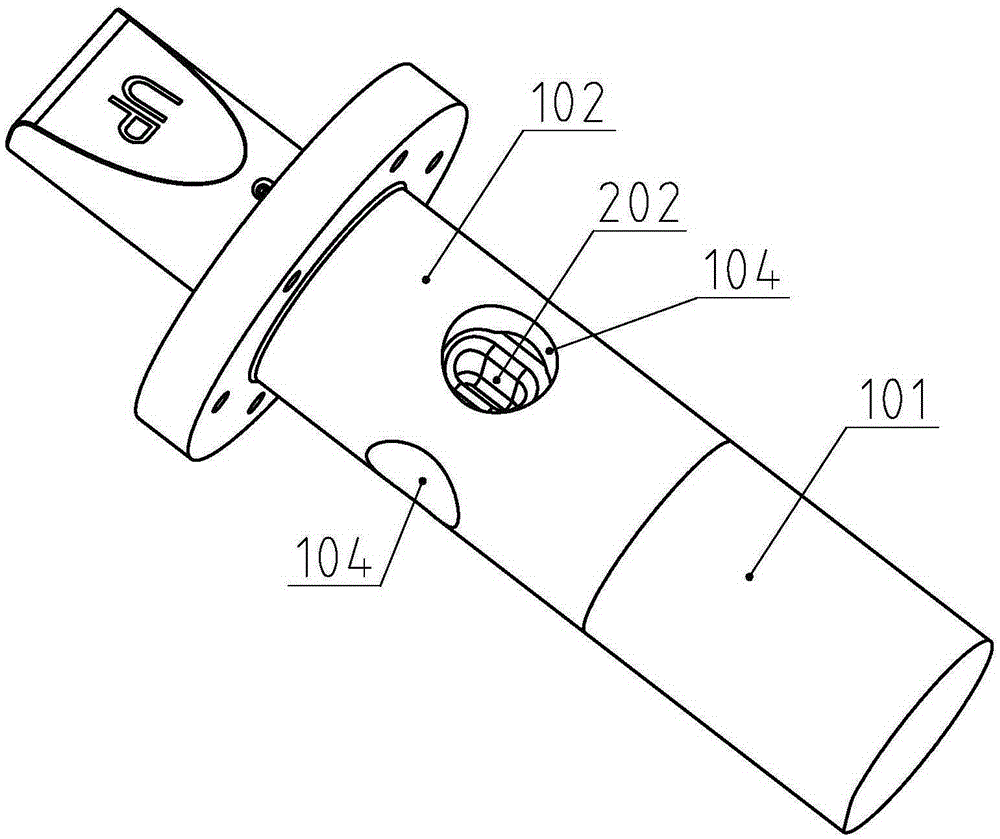

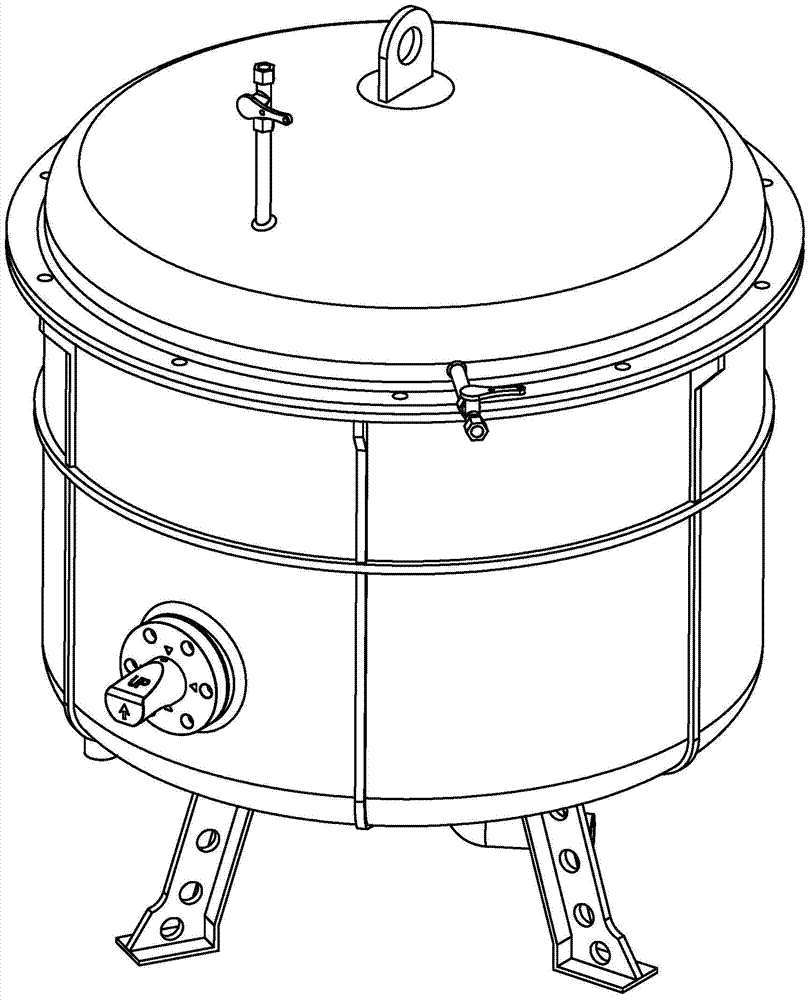

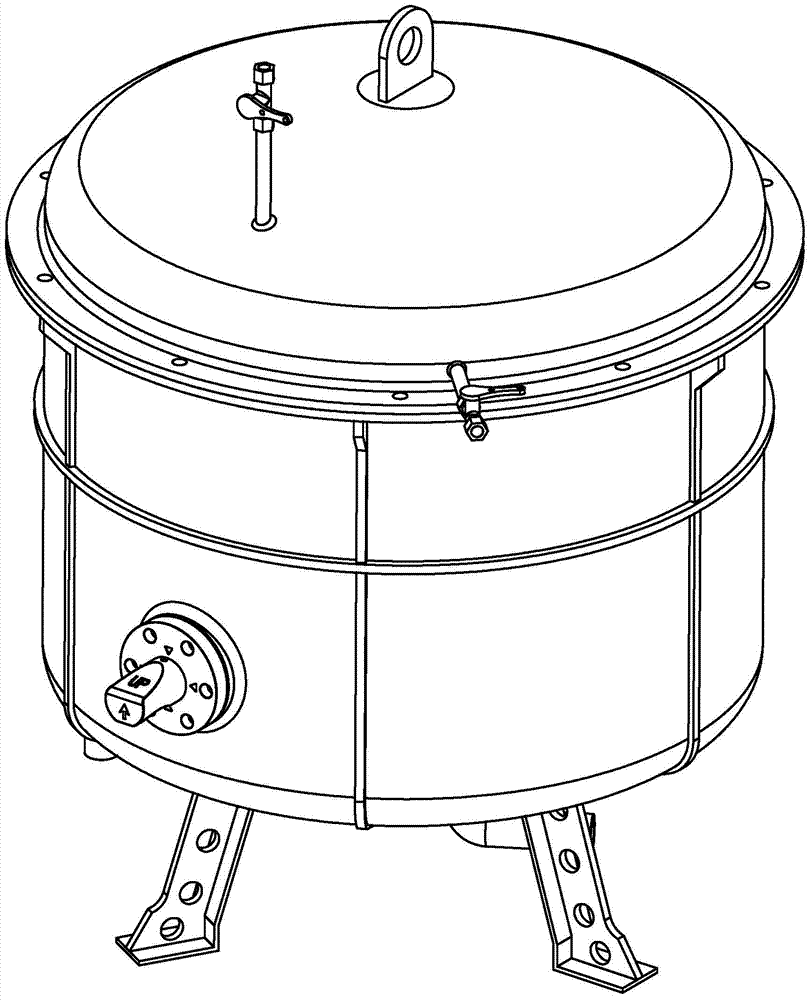

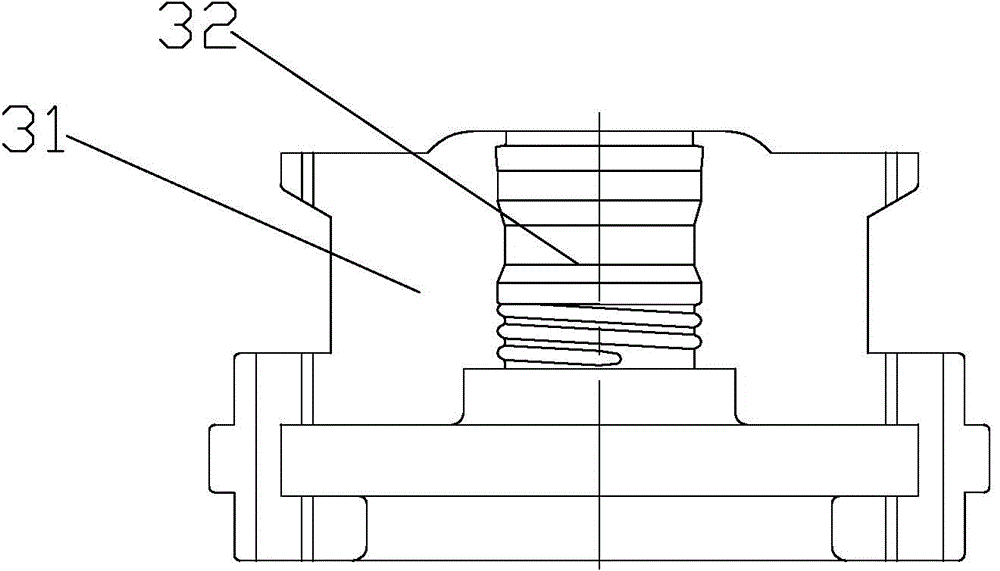

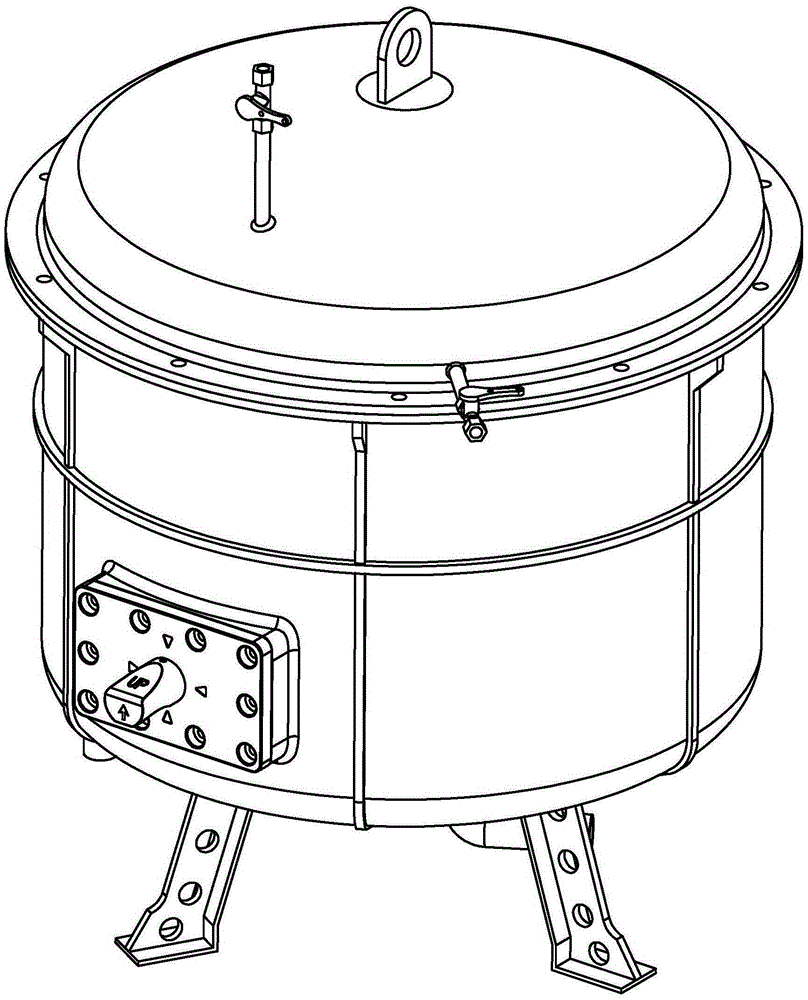

Design method for fast sampling boiler

The invention relates to a design method for a fast sampling boiler. The boiler is internally provided with a feed port, a discharge port and a heating unit; a sampler is arranged on the side wall of the boiler, a sampling cavity is made to be communicated with the inside of the boiler, and a sampling hole of the sampler can slide or rotate between the outside and the inside of the boiler. A sliding cavity can be partially communicated with the outside through venting channels, a first seal ring is arranged at the position, close to the sampling cavity, of the head of the sliding cavity, a second seal ring and a third seal ring are arranged at the position, close to the sampling cavity, of the tail of the sliding cavity, the distance between the second seal ring and the third seal ring is larger than the width of the sampling hole, the sampling cavity and the sliding cavity are isolated through the first seal ring, and the sampling cavity is isolated from the outside through the second seal ring and the third seal ring. A first blind hole and a second blind hole are formed in the head end and the tail end of a sampling rod respectively, and therefore the sampling hole is isolated from the first blind hole and the second blind hole. Due to the design of the blind holes in the sampling rod, the seal effect is improved, and the service life is prolonged; by adopting the two seal rings with the small line diameter, pull force or push force during sampling can be reduced, and the sampling speed is increased.

Owner:泰州市海洲消防器材有限公司

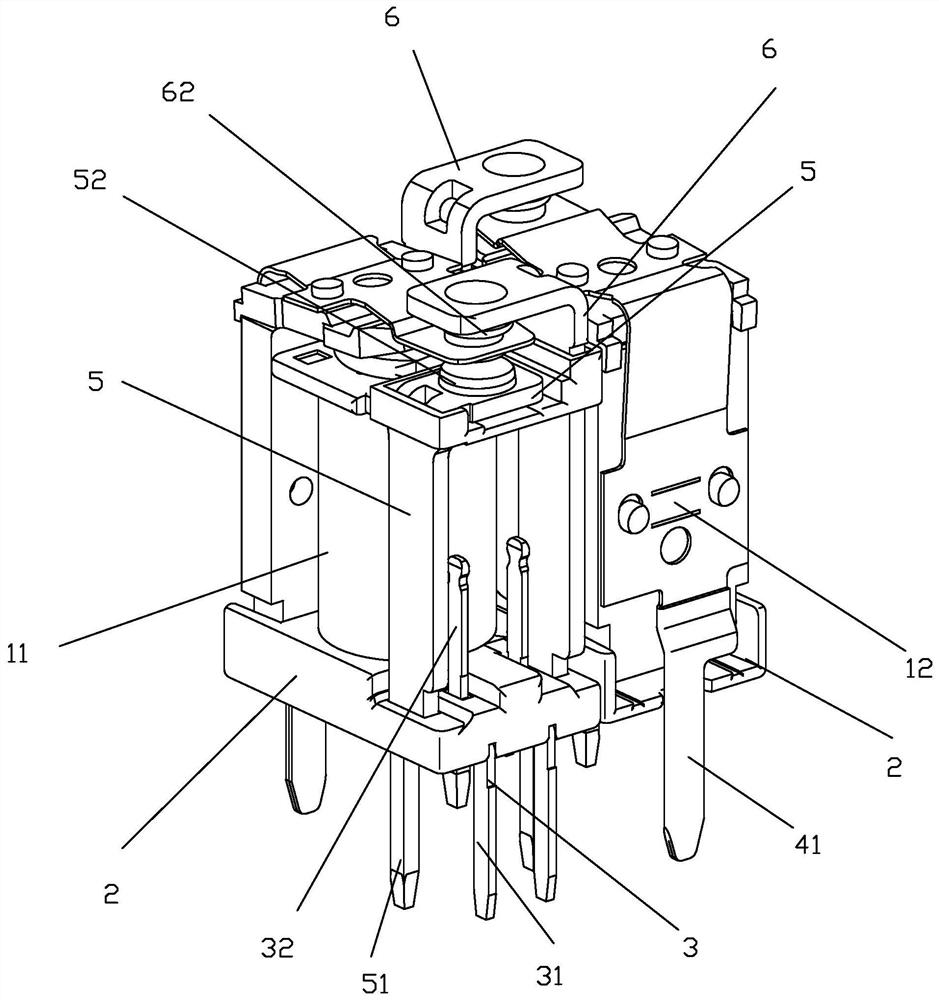

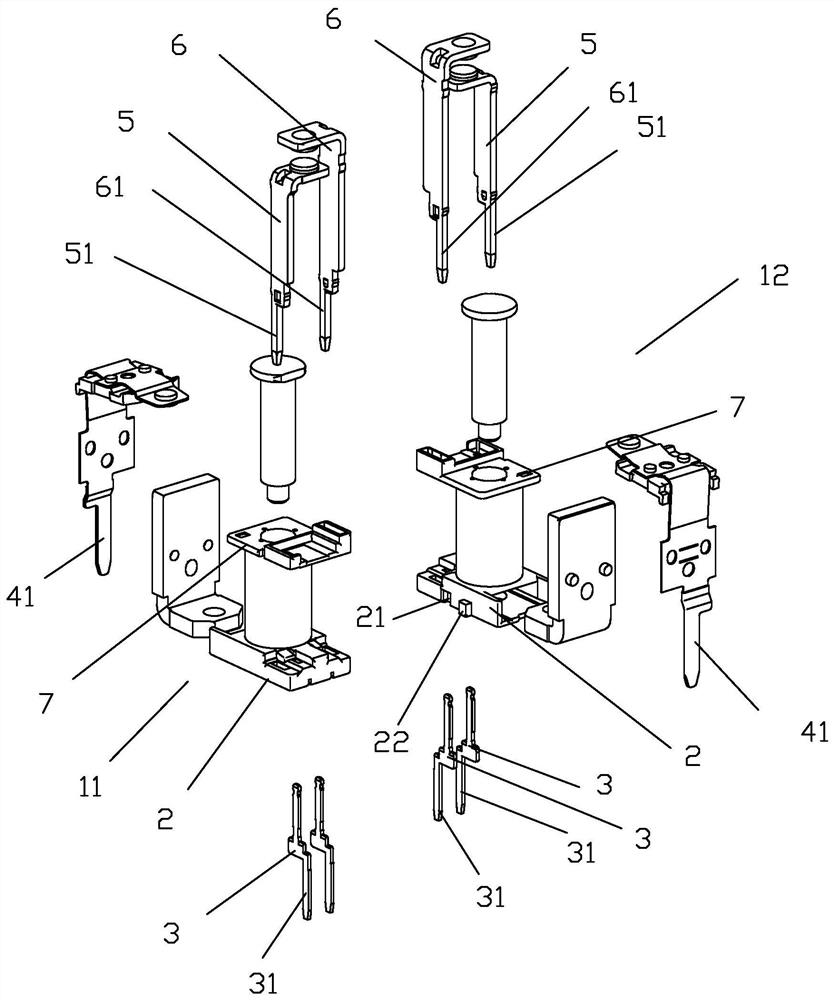

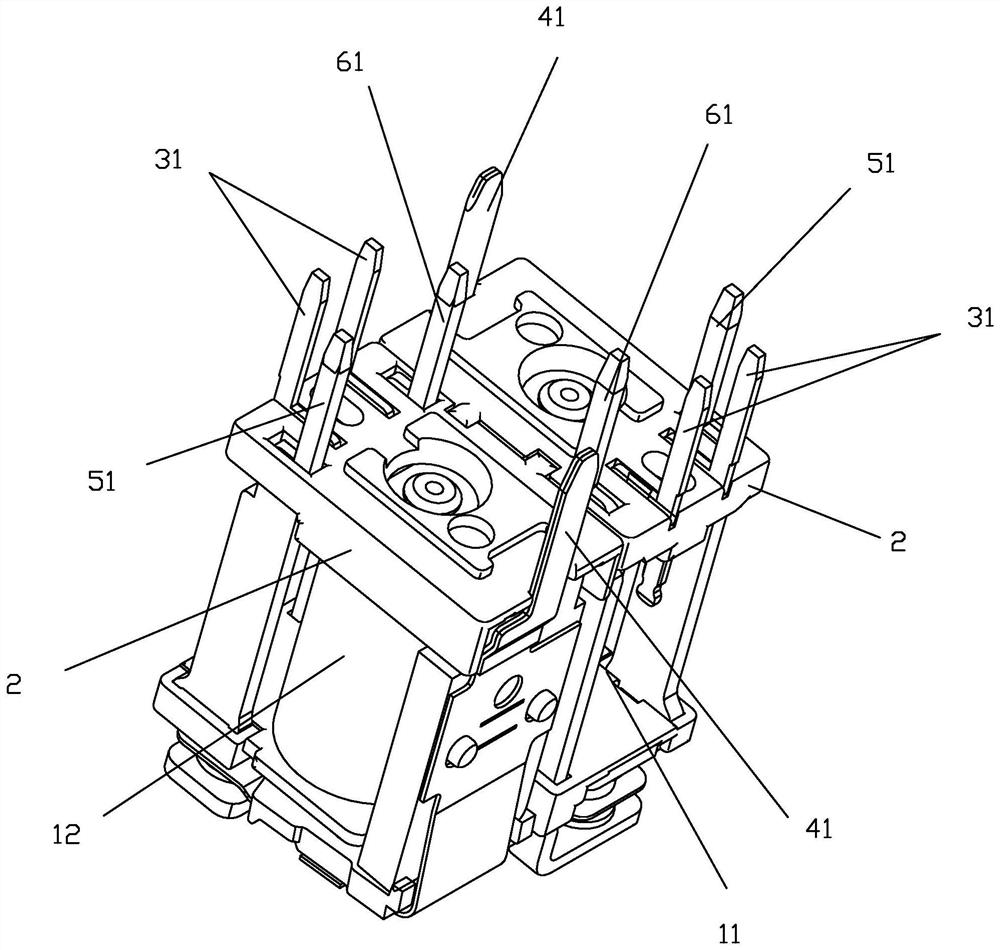

Combined relay based on double-miniature PCB relay

PendingCN112117163ASimple structureMiniaturizationElectromagnetic relay detailsTelecommunicationsMiniaturization

The invention discloses a combined relay based on a double-miniature PCB relay. The combined relay comprises two relays which are the same in structure and do not comprise shells. Each relay comprisesa base, and a coil lead-out pin, a movable spring lead-out pin and a static spring lead-out pin which are distributed on the base; a groove and a protruding block are arranged on one side edge of thebase in the length direction at equal intervals and located on the two sides of a median line corresponding to the length of the base respectively, when two relays are spliced, one relay is rotated by 180 degrees and then is paired with the other relay, and the grooves and the protruding blocks of the two relays are matched in an oppositely-inserted mode respectively. According to the invention,the safe distance between the static spring lead-out pins and the safe distance between the movable spring lead-out pins of the two relays can be effectively ensured by adopting one mold, so that thepurposes of simplifying the manufacturing process and reducing the manufacturing cost are achieved; and a complex limiting structure does not need to be arranged on the shell, so that the structure ofthe shell is simplified, and the miniaturization of the product is realized.

Owner:XIAMEN HONGFA AUTOMOTIVE ELECTRONICS

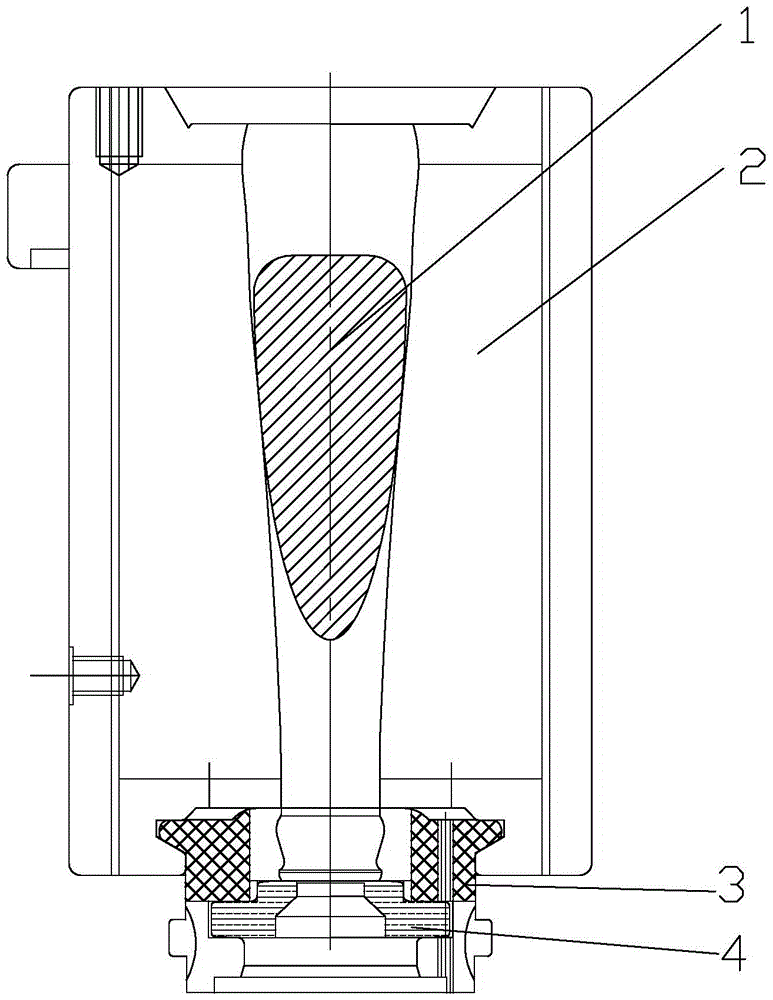

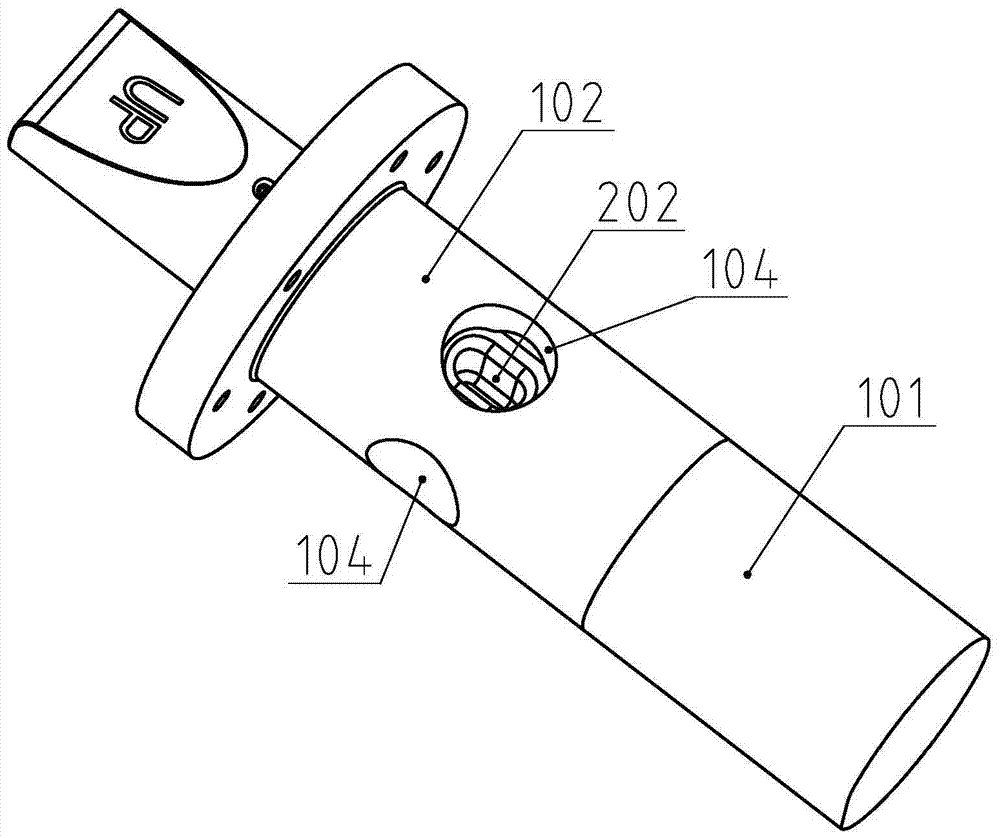

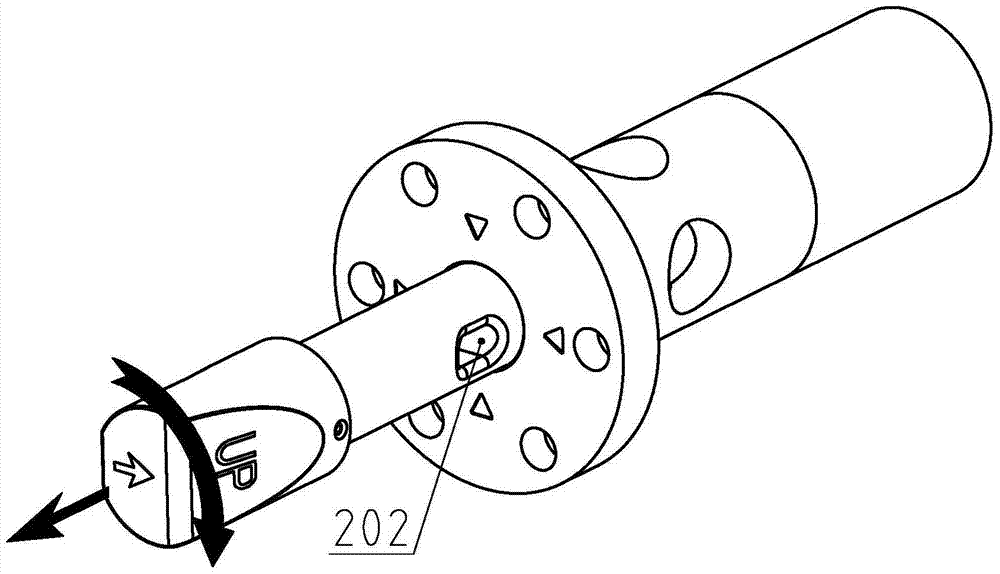

Design Method of Rapid Sampler

ActiveCN105300734BImprove experienceReduce movementWithdrawing sample devicesEngineeringAxial distance

The invention relates to a design method of a quick sampler used in a boiler, which comprises providing a base body and a sampling rod, so that the sampling rod and the base body can be slidingly or rotatably matched in a closed manner; it is characterized in that the head of the sliding cavity of the base body is close to the sampling cavity. Set the first sealing ring, and set the second and third sealing rings at the end of the sliding cavity of the base body near the sampling cavity, so that the axial distance between the second and third sealing rings is greater than the width of the sampling hole, and the first sealing ring The sampling cavity is isolated from the sliding cavity, and the sampling cavity is isolated from the outside atmosphere through the second and third sealing rings. A first blind hole is set at the head end of the sampling rod, and a second blind hole is set at the tail end of the sampling rod, so that the sampling hole is isolated from the first blind hole and the second blind hole, and the first blind hole and the second blind hole are separated by the ventilation channel. Blind vias are connected. The blind hole design on the sampling rod improves the sealing effect and service life of the sealing ring. The use of two small diameter sealing rings can reduce the pulling force or pushing force during sampling and improve the sampling speed.

Owner:吴江市民福电缆附件厂

A ventable die

ActiveCN104150748BImprove product qualityImprove quality and efficiencyGlass blowing apparatusGlass productionBottle neckEngineering

The invention relates to a neck mould capable of exhausting. The neck mould consists of a male mould and a female mould. Joint surfaces on the male neck mould and the female neck mould are arranged along exteriors of the two sides of a moulding cavity and are protruded from a plane portion. A gas guiding groove is vertically arranged on each joint surface. A plurality of transversally-arranged exhausting grooves A are disposed on joint surface portions on the two sides of each gas guiding groove. The gas guiding groove communicates an interior of a bottle neck cavity with external air through the exhausting groove A. A plurality of exhausting grooves B are arranged on an upper end surface of the neck mould and enables the interior of the bottle neck cavity to be communicated with the external air. Compared with a neck mould in the prior art, phenomena that a bottle neck is not round in shape and material jump and material deviation of a glass material can be avoided through arrangement of the gas guiding groove and the exhausting grooves A on the joint surfaces and arrangement of the plurality of exhausting grooves B on the upper end surface so that production quality and production efficiency of glass bottles are increased. Meanwhile, by means of arrangement of the joint surfaces, a match area of joint surfaces and a match tolerance in the prior art are reduced. The joint surfaces are manufactured in a manner of being protruded from the plane portion so that a clearance is provided for enabling gas to be exhausted to the exterior through the exhausting groove A.

Owner:DEQING CAIFU GLASS

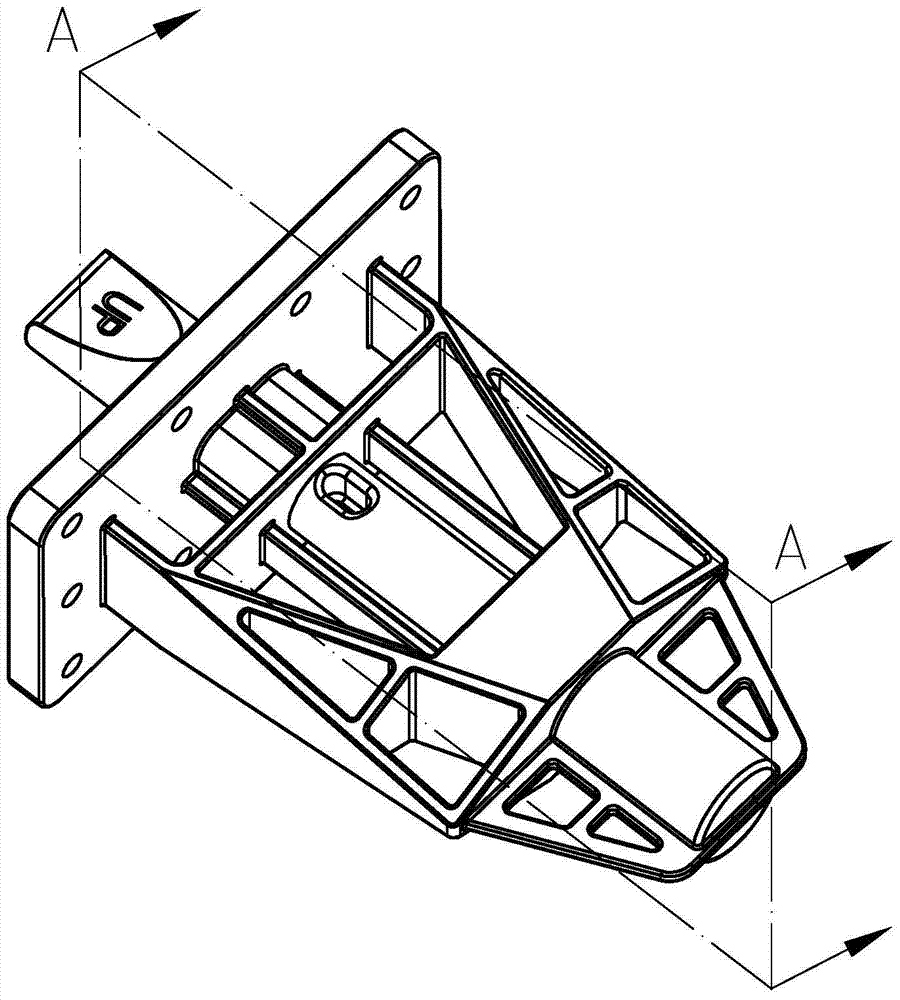

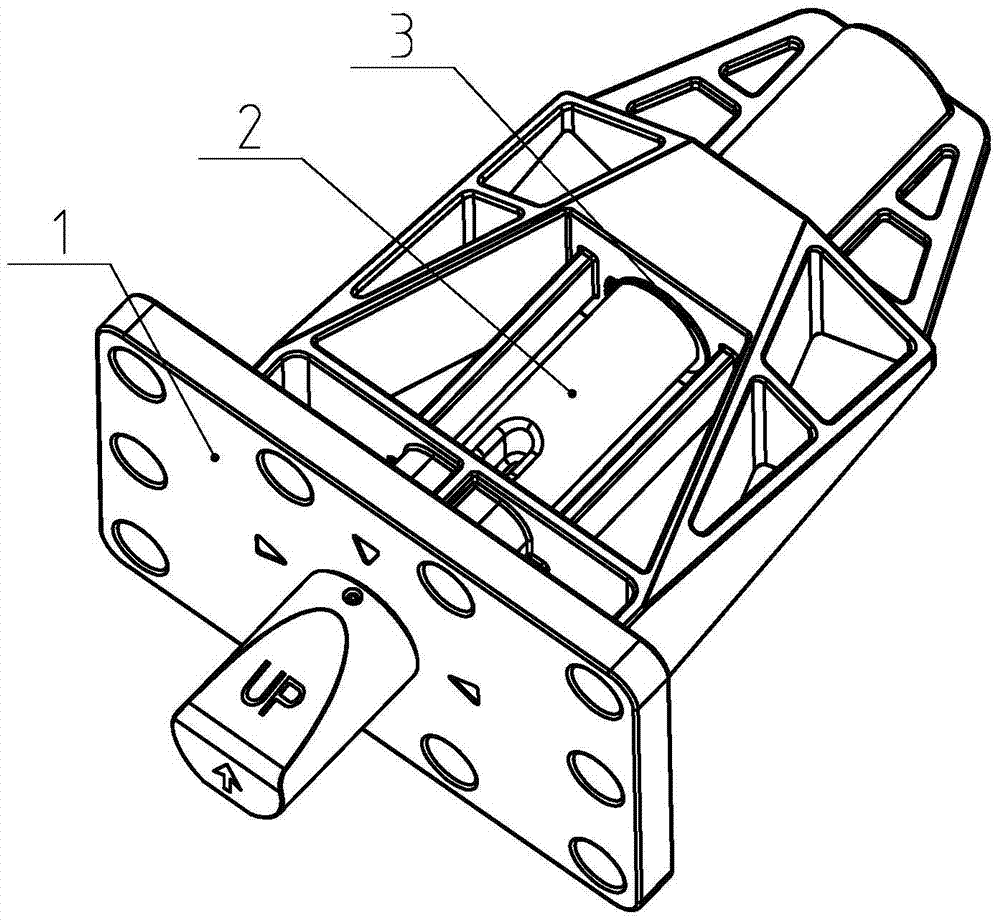

fast sampler

The invention relates to a fast sampler used on a boiler. The fast sampler comprises a matrix and a thief rod which are in closed sliding or running fit. Part of a sliding cavity is communicated with the outside air through a ventilating channel. The fast sampler is characterized in that the head part of the matrix's sliding cavity, close to a sampling cavity, is provided with a first seal ring; the tail part of the matrix's sliding cavity, close to the sampling cavity, is equipped with second and third seal rings; axial distance between the second seal ring and the third seal ring is greater than width of a thief hole in the axial direction of the thief rod; the sampling cavity is isolated from the sliding cavity through the first seal ring; the sampling cavity is isolated from the outside air through the second and third seal rings; the head end of the thief rod is coaxially provided with a first blind hole; the tail end of the thief rod is coaxially provided with a second blind hole; and the thief hole is isolated from the first and second blind holes. By the design of the blind holes in the thief rod, sealing effect of the seal rings is enhanced and service life of the seal rings is prolonged. By the adoption of the two seal rings with small wire diameter, pulling force or thrust during sampling can be reduced, and user experience is improved.

Owner:曹县绚酷服饰有限公司

Design method of boiler capable of rapidly sampling

ActiveCN105277387AImprove experienceReduce movementWithdrawing sample devicesEngineeringDesign methods

The invention relates to a design method of a boiler capable of rapidly sampling. The boiler comprises a feeding hole, a discharging hole and a heating unit, wherein a sampling device is arranged on a side wall of the boiler so that a sampling hole is communicated with the inner part of the boiler, and the sampling hole can slide or rotate between the inner part and the outer part of the boiler. The sampling device is further provided with a cover which can be in detachable sealed match with a base; the cover is coaxially provided with a containing cavity for containing a sampling rod; when the sampling rod is located at an inserting position, the connection part of the cover and the base is located between a first groove and a limiting part; a first counter bore is formed in the head of the base and the diameter of the first counter bore is greater than that of a first through hole to form a step surface; the head of the sampling rod is detachably provided with the limiting part; and when the limiting part is matched with the step surface of the base, the sampling hole is located at the outer part of the base. A base body is split into the base and the cover so that the axial machining length of the base is reduced and the machining difficulty is reduced; and the limiting part is arranged at the front end of the sampling rod so that the axial sizes of the base and the sampling rod are reduced and materials are saved.

Owner:SUZHOU SHENGXIN OPTOELECTRONICS TECH

A method of manufacturing a venting die

ActiveCN104193145BImprove product qualityImprove quality and efficiencyGlass blowing apparatusBottle neckEngineering

The invention relates to a method for making a neck mold capable of exhausting. The method comprises the following steps: (1) milling a plane part to be lower than joint-closing surfaces which are arranged at the outer edges along both sides of a cavity; (2) milling a longitudinally arranged gas guide groove on each of joint-closing surfaces; (3) milling transversely arranged air exhaust grooves A on joint-closing surfaces located at both sides of each gas guide groove and (4) milling at a joint-closing line of the neck mold corresponding to a neck ring. Compared with the prior art, by arranging the gas guide grooves and the air exhaust grooves A on the joint-closing surfaces and reserving a gap between the neck mold and the neck ring, the phenomena that the bottle neck is not round, the size is not uniform and the like are avoided, the production quality and the production efficiency of the glass bottle are improved; and meanwhile, by arranging the joint-closing surfaces, the fit area of the joint-closing surfaces in the prior art is reduced, and thus the tolerance of fit is reduced and since the joint-closing surfaces are higher than the plane part so as to provide a gap for the air exhaust grooves A to discharge gas to the outside.

Owner:DEQING CAIFU GLASS

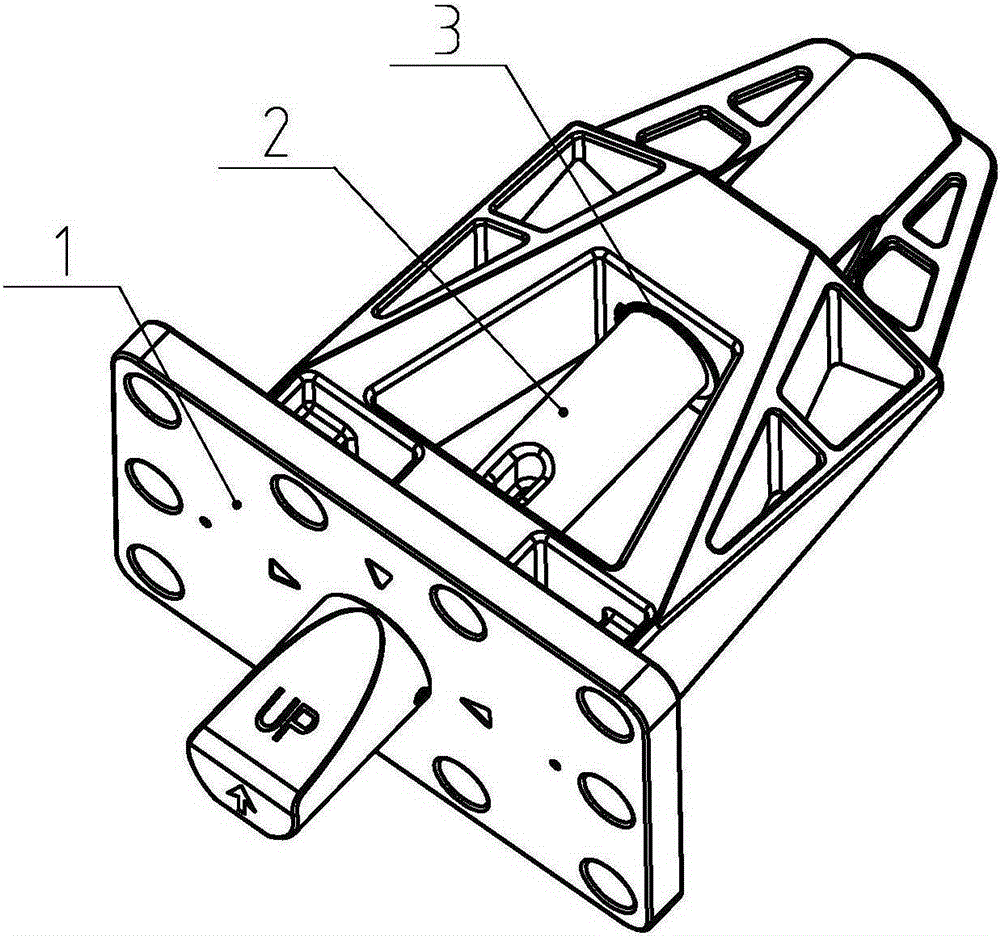

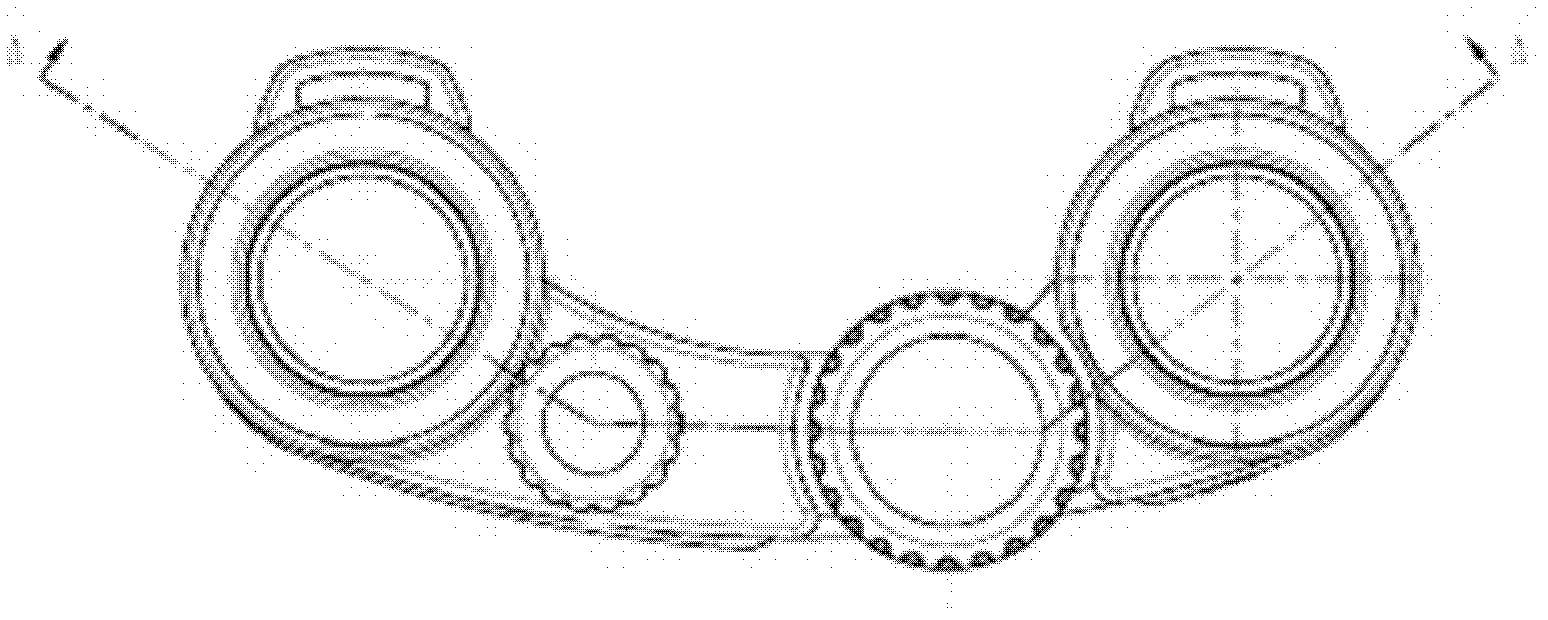

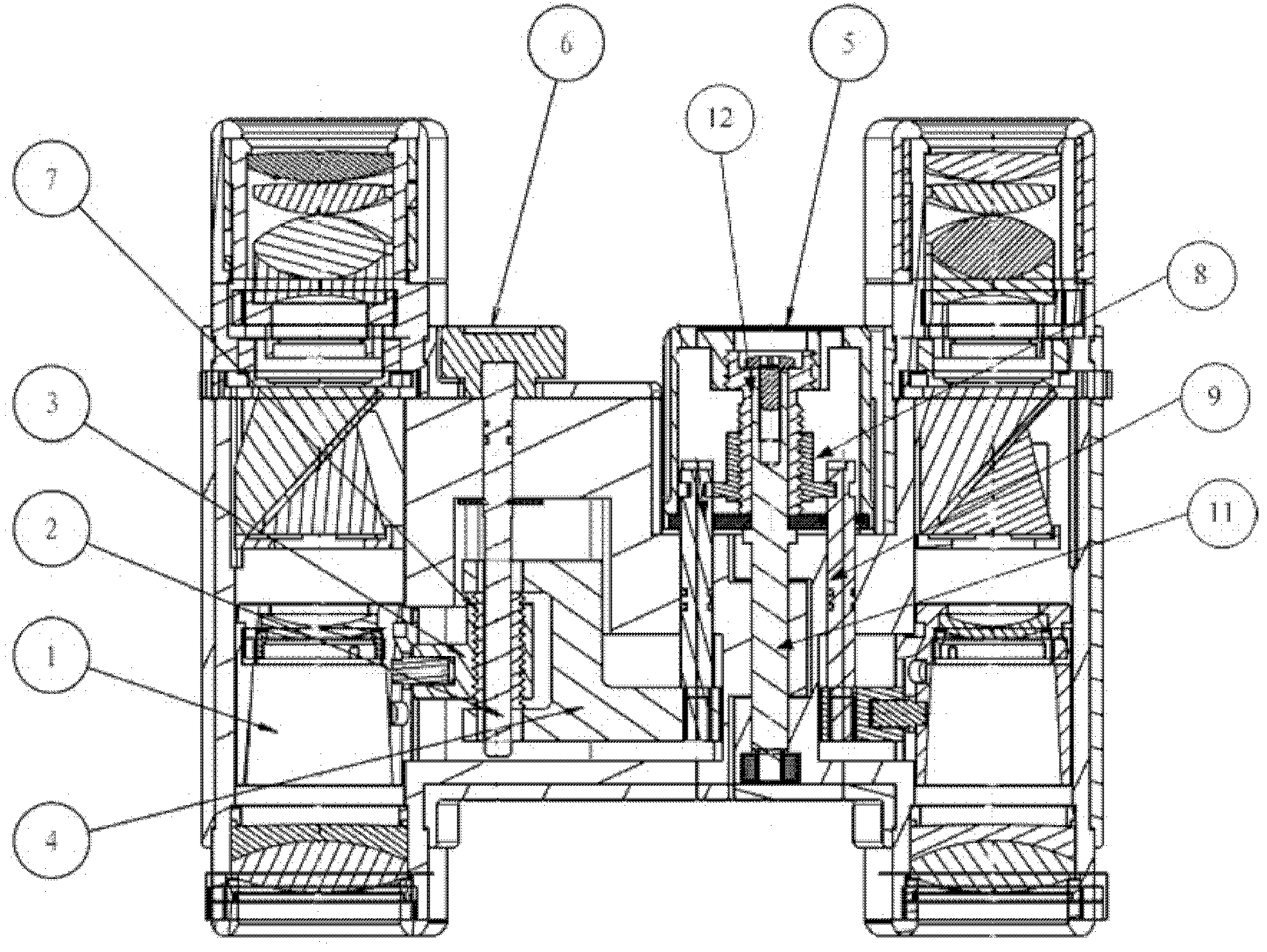

Binocular telescope and adjustment method for binocular telescope

The invention relates to the field of optical instruments, in particular to a binocular telescope and an adjustment method for the binocular telescope. The binocular telescope comprises a visual acuity adjustment component and a focal length adjustment component, wherein the visual acuity adjustment component is used for adjusting the visual acuity of a first lens barrel based on the visual acuity of a second lens barrel; and the focal length adjustment component is used for adjusting the focal length of the first lens barrel and the focal length of the second lens barrel at the same time. The adjustment method comprises the following steps of: taking the visual acuity of the second lens barrel as a reference, adjusting the visual acuity of the first lens barrel; and on the basis of keeping the visual acuity of the first lens barrel and the visual acuity of the second lens barrel unchangeable, adjusting the focal length of the first lens barrel and the focal length of the second lens barrel at the same time. The adjustment device provided by the invention has a simple structure and a small matching area with the main body of the binocular telescope, the production cost is greatly reduced, and the adjustment device is convenient to seal, and is simple and convenient to operate during adjustment.

Owner:冯影

Design method of rapid sampling boiler

Owner:JIANGSU XINDA COMM TECH

Rapid Sampling Boiler

ActiveCN105277388BImprove experienceReduce movementWithdrawing sample devicesEngineeringAxial distance

The present invention specifically relates to a fast sampling boiler, which is provided with a feed inlet, a discharge outlet and a heating unit, a sampler is provided near the bottom of the side wall of the boiler, the sampling cavity communicates with the inside of the boiler, and the sampling hole of the sampler can be Slide or turn between boiler exterior and interior. Part of the sliding cavity communicates with the outside world through a ventilated channel. The first sealing ring is set near the sampling cavity at the head of the sliding cavity, and the second and third sealing rings are set at the tail of the sliding cavity close to the sampling cavity. Between the second sealing ring and the third sealing ring The axial distance is greater than the width of the sampling hole, the sampling cavity is isolated from the sliding cavity by the first sealing ring, and the sampling cavity is isolated from the outside by the second and third sealing rings. First and second blind holes are arranged at the head and tail ends of the sampling rod respectively, and the sampling hole is isolated from the first and second blind holes. The blind hole design on the sampling rod improves the sealing effect and service life of the sealing ring. The use of two small-diameter sealing rings can reduce the pulling or pushing force during sampling and increase the sampling speed.

Owner:四川东实电气有限公司

Boiler capable of rapidly sampling

ActiveCN105277388AImprove experienceReduce movementWithdrawing sample devicesEngineeringAxial distance

The invention particularly relates to a boiler capable of rapidly sampling. The boiler is provided with a feeding hole, a discharging hole and a heating unit, wherein a sampling device is arranged at the part, close to the bottom, of a side wall of the boiler; a sampling cavity is communicated with the inner part of the boiler; and a sampling hole of the sampling device can slide or rotate between the outer part and the inner part of the boiler. Part of a slide cavity is communicated with the outside through a ventilation channel; a first sealing ring is arranged at the part, close to the sampling cavity, of the head of the slide cavity; a second sealing ring and a third sealing ring are arranged at the part, close to the sampling cavity, of the tail part of the slide cavity; the axial distance between the second sealing ring and the third sealing ring is greater than the width of the sampling hole; and the sampling cavity is separated from the slide cavity through the first sealing ring, and the sampling cavity is separated from the outside through the second sealing ring and the third sealing ring. A first blind hole and a second blind hole are formed in the front and tail ends of a sampling rod respectively; and the sampling hole is separated from the first blind hole and the second blind hole. The design of the blind holes in the sampling rod is adopted, so that the sealing effect of the sealing rings is improved and the service life of the sealing rings is prolonged; and the two sealing rings with small linear diameters are adopted so that the tensile force or thrust in a sampling process can be reduced and the sampling speed is accelerated.

Owner:四川东实电气有限公司

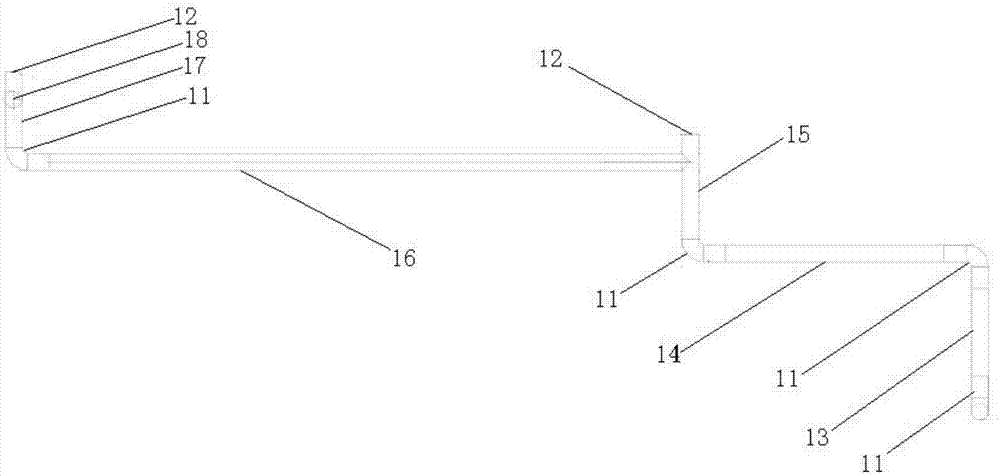

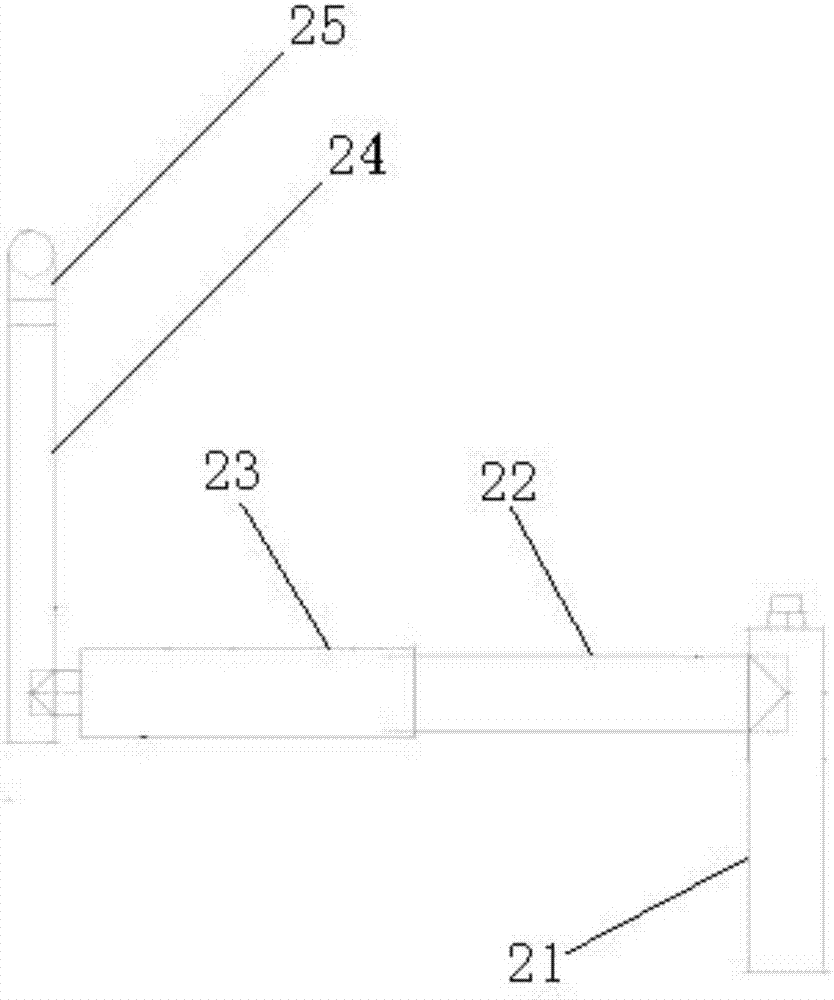

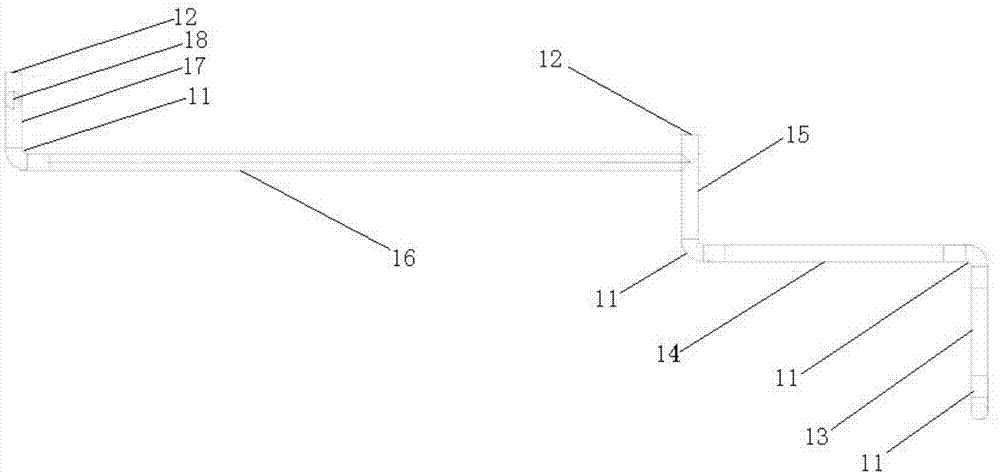

Industrial and civil pipe

The invention discloses an industrial and civil pipe. The industrial and civil pipe comprises a first-phase pipe; the first-phase pipe is provided with a straight pipe section 1; one end of the straight pipe section 1 is connected with a straight pipe section 2 through an arc section; the straight pipe section 2 is connected with a straight pipe section 3 through an arc section; the straight pipe section 3 is perpendicularly intersected with a straight pipe section 4; a stifle is arranged at the end part of the straight pipe section 3; the straight pipe section 4 is connected with a straight pipe section 5 through an arc section; a stifle is arranged at the end part of the straight pipe section 5; and a connecting port is formed in the straight pipe section 5. Through arrangement of multiple straight pipe sections and arc sections, the industrial and civil pipe can be converted and adjusted with an installation environment during installing, so that the pipe cooperation is excellent, and the cooperation area can be saved.

Owner:上海涵昊机电设备制造有限公司

fast sampler

InactiveCN105510080BImprove experienceReduce movementWithdrawing sample devicesEngineeringCountersink

The invention relates to a fast sampler used on a boiler. The fast sampler is provided with a thief rod which is in closed sliding or running fit with a matrix. The matrix is also provided with a cover. The cover and a pedestal are in detachable closed fit. The cover is coaxially provided with a holding cavity for holding the thief rod. When the thief rod is positioned at an insert position, the junction between the cover and the pedestal is positioned between a first groove and a stopper. The head part of the pedestal is provided with a first countersink, diameter of which is greater than diameter of a first through hole. The first countersink and the first through hole form a step surface. The stopper is detachably arranged at the head part of the thief rod. When the stopper matches the step surface of the pedestal, a thief hole is positioned on the outside of the pedestal. By dismounting the matrix into the pedestal and the cover, axial processing length of the pedestal is reduced so as to lower processing difficulty. It is convenient to assemble the stopper by arranging the junction between the first groove and the stopper. By arranging the stopper at the head end of the thief rod, axial dimension of the pedestal and axial dimension of the thief rod are both decreased so as to save materials.

Owner:山东亿泰粮油食品有限公司

Miniaturized PCB relay

PendingCN112086317AReduce weightAvoid jitterElectromagnetic relay detailsMiniaturizationControl theory

The invention discloses a miniaturized PCB relay. The relay comprises an iron core, an armature, a movable reed, a static spring normally open end and a static spring normally closed end. wherein a root part of a swingable part of the movable contact spring is fixed in one surface of the armature, and the other surface of the armature and the pole surface of the iron core are positioned at a corresponding matching position; a movable contact is arranged at the tail end of the swinging part of the movable contact spring and is respectively matched between the normally open end of the static spring and the normally closed end of the static spring; and in one surface of the armature, a groove is arranged between a fixed position corresponding to the root part of the swinging part of the movable contact spring and the movable contact of the movable contact spring and corresponds to the position of the pole surface of the iron core. According to the relay, the weight of the armature can bereduced on the basis of ensuring the effective magnetic conduction area of the armature so as to avoid the shaking problem generated when the normally open end contact is closed, and the pressure of the normally closed end contact can also be ensured so as to ensure stability of relay parameters.

Owner:XIAMEN HONGFA AUTOMOTIVE ELECTRONICS

Boiler capable of achieving quick sampling

The invention relates to a boiler capable of achieving quick sampling. The boiler is provided with a material inlet, a material outlet and a heating unit, the side wall of the boiler is provided with a sampler, and a sampling hole is communicated with the interior of the boiler and can slide or rotate between the exterior and the interior of the boiler. The sampler is provided with a cover which is detachably matched with a base in a closed type, the cover is coaxially provided with a containing cavity for containing a sampling rod, and when the sampling rod is located at an inserting position, the joint of the cover and the base is located between a first groove and a limit part; the head of the base is provided with a first sunk hole, and the diameter of the first sunk hole is larger than that of a first through hole, so that a stepped surface is formed; the head of the sampling rod is detachably provided with the limit part, and when the limit part is matched with the stepped surface of the base, the sampling hole is located outside the base. A base body is split into the base and the cover, the axial processing length of the base is decreased, and therefore the processing difficulty is reduced; the limit part is arranged at the head end of the sampling rod, the axial size of the base and the axial size of the sampling rod are both decreased, and therefore the materials are saved.

Owner:扬州华大锅炉有限公司

Neck mould capable of exhausting

ActiveCN104150748AImprove product qualityImprove quality and efficiencyGlass blowing apparatusGlass productionBottle neckEngineering

The invention relates to a neck mould capable of exhausting. The neck mould consists of a male mould and a female mould. Joint surfaces on the male neck mould and the female neck mould are arranged along exteriors of the two sides of a moulding cavity and are protruded from a plane portion. A gas guiding groove is vertically arranged on each joint surface. A plurality of transversally-arranged exhausting grooves A are disposed on joint surface portions on the two sides of each gas guiding groove. The gas guiding groove communicates an interior of a bottle neck cavity with external air through the exhausting groove A. A plurality of exhausting grooves B are arranged on an upper end surface of the neck mould and enables the interior of the bottle neck cavity to be communicated with the external air. Compared with a neck mould in the prior art, phenomena that a bottle neck is not round in shape and material jump and material deviation of a glass material can be avoided through arrangement of the gas guiding groove and the exhausting grooves A on the joint surfaces and arrangement of the plurality of exhausting grooves B on the upper end surface so that production quality and production efficiency of glass bottles are increased. Meanwhile, by means of arrangement of the joint surfaces, a match area of joint surfaces and a match tolerance in the prior art are reduced. The joint surfaces are manufactured in a manner of being protruded from the plane portion so that a clearance is provided for enabling gas to be exhausted to the exterior through the exhausting groove A.

Owner:DEQING CAIFU GLASS

Method for making neck mold capable of exhausting

ActiveCN104193145AImprove product qualityImprove quality and efficiencyGlass blowing apparatusEngineeringBottle neck

The invention relates to a method for making a neck mold capable of exhausting. The method comprises the following steps: (1) milling a plane part to be lower than joint-closing surfaces which are arranged at the outer edges along both sides of a cavity; (2) milling a longitudinally arranged gas guide groove on each of joint-closing surfaces; (3) milling transversely arranged air exhaust grooves A on joint-closing surfaces located at both sides of each gas guide groove and (4) milling at a joint-closing line of the neck mold corresponding to a neck ring. Compared with the prior art, by arranging the gas guide grooves and the air exhaust grooves A on the joint-closing surfaces and reserving a gap between the neck mold and the neck ring, the phenomena that the bottle neck is not round, the size is not uniform and the like are avoided, the production quality and the production efficiency of the glass bottle are improved; and meanwhile, by arranging the joint-closing surfaces, the fit area of the joint-closing surfaces in the prior art is reduced, and thus the tolerance of fit is reduced and since the joint-closing surfaces are higher than the plane part so as to provide a gap for the air exhaust grooves A to discharge gas to the outside.

Owner:DEQING CAIFU GLASS

Design method of rapid sampling boiler

The invention relates to a design method of a boiler capable of rapidly sampling. The boiler comprises a feeding hole, a discharging hole and a heating unit, wherein a sampling device is arranged on a side wall of the boiler so that a sampling hole is communicated with the inner part of the boiler, and the sampling hole can slide or rotate between the inner part and the outer part of the boiler. The sampling device is further provided with a cover which can be in detachable sealed match with a base; the cover is coaxially provided with a containing cavity for containing a sampling rod; when the sampling rod is located at an inserting position, the connection part of the cover and the base is located between a first groove and a limiting part; a first counter bore is formed in the head of the base and the diameter of the first counter bore is greater than that of a first through hole to form a step surface; the head of the sampling rod is detachably provided with the limiting part; and when the limiting part is matched with the step surface of the base, the sampling hole is located at the outer part of the base. A base body is split into the base and the cover so that the axial machining length of the base is reduced and the machining difficulty is reduced; and the limiting part is arranged at the front end of the sampling rod so that the axial sizes of the base and the sampling rod are reduced and materials are saved.

Owner:SUZHOU SHENGXIN OPTOELECTRONICS TECH

Electromagnetic relay of an injection molded yoke

ActiveCN106206166BHigh degree of insulationWill not deformElectric switchesElectromagnetic relay detailsInjection mouldingInjection molding machine

The invention discloses an electromagnetic relay of an injection molded yoke, which comprises a moving spring, a yoke and a coil, wherein the yoke is L-shaped; the horizontal side of the yoke is fixed to the iron core in the coil at the bottom of the coil, The vertical side of the yoke is parallel to the axis of the iron core; on the vertical side of the yoke, a plastic layer formed by injection molding is provided on the side facing the coil, so as to use the plastic layer to insulate the coil between the yoke and the coil. Between, on the side facing away from the coil, there is a plastic convex bud formed by injection molding, so that the plastic convex bud can be fixed with the moving spring. On the one hand, the present invention can improve the degree of insulation between the yoke and the coil and ensure the position accuracy of the insulating parts without affecting the winding space, and effectively reduce the assembly process. On the other hand, when the yoke and the moving spring are fixed When it is used, no stress will be generated on the moving spring to deform the moving spring, which improves the dimensional consistency of the moving spring.

Owner:XIAMEN HONGFA SIGNAL ELECTRONICS CO LTD

Rapid Sampling Boiler

The invention relates to a fast sampling boiler, which is provided with a material inlet, a material outlet and a heating unit, a sampler is arranged on the side wall of the boiler, the sampling hole communicates with the inside of the boiler, and the sampling hole can slide between the outside and the inside of the boiler or turn. The sampler is also provided with a cover that is detachably and hermetically fitted with the base. The cover is coaxially provided with an accommodating cavity for receiving the sampling rod. Between the position parts; the first counterbore is set on the head of the base, and its diameter is greater than the diameter of the first through hole to form a stepped surface; the head of the sampling rod is detachably provided with a limiter, when the limiter and the step of the base When face fit, the sampling hole is outside the base. The base is split into a base and a cover, which reduces the axial processing length of the base, thereby reducing the difficulty of processing; the limit piece is set at the head end of the sampling rod, the axial dimension of the base and the axis of the sampling rod The dimensions are reduced, saving material.

Owner:扬州华大锅炉有限公司

sliding nozzle

InactiveCN103527264BAvoid precision lossHigh control precisionInternal combustion piston enginesStatorsThermal deformationEngineering

The invention discloses a sliding nozzle. A rotatable synchronous ring is arranged on an upper nozzle ring in a coaxial mode, and a synchronous ring inner circle connected with the upper nozzle ring in an assembling mode is of an interrupted structure in the radial direction. A first sliding block device comprises a flow guiding vane and an open shifting fork connected with the shaft end of the flow guiding vane. The shaft end of the flow guiding vane is provided with two parallel lateral planes. One end of the open shifting fork is connected with the two lateral planes in a matched mode. A second sliding block device comprises a main shifting fork assembly, one end of the main shifting fork assembly is connected with an actuator, and the other end of the main shifting fork assembly is connected with the synchronous ring through a synchronous pin. By means of the sliding nozzle, precision loss caused by fast abrasion of a line-plane friction pair in actual use is effectively avoided. Transmission precision and abrasion resistance are effectively improved. The inner circle is of an interrupted synchronous ring structure, matching area of the synchronous ring and the upper nozzle ring is reduced, and the phenomenon that the synchronous ring and the nozzle ring are clamped due to thermal deformation is effectively prevented.

Owner:汉美综合科技(常州)有限公司

Neck mould being beneficial to exhausting

InactiveCN104150747AImprove production qualityImprove production efficiency and production qualityGlass blowing apparatusGlass productionBottle neckJoint surface

The invention relates to a neck mould being beneficial to exhausting. The neck mould consists of a male mould and a female mould. Joint surfaces on the male neck mould and the female neck mould are protruded from a plane portion. A gas guiding groove is vertically arranged on each joint surface. A plurality of transversally-arranged exhausting grooves A are disposed on joint surface portions on the two sides of each gas guiding groove. The gas guiding groove communicates an interior of a bottle neck cavity with external air through the exhausting groove A. A neck ring is arranged on and matched with the neck mould, wherein a clearance is formed between the neck ring and a joint line on the neck mould which is corresponding to the neck ring. Compared with a neck mould in the prior art, phenomena that bottle necks are not round in shape and are not uniform in sizes can be avoided through arrangement of the gas guiding groove and the exhausting grooves A on the joint surfaces and the clearance formed between the neck mould and the neck ring so that production quality and production efficiency of glass bottles are increased. Meanwhile, by means of arrangement of the joint surfaces, a match area of joint surfaces and a match tolerance in the prior art are reduced. The joint surfaces are manufactured in a manner of being higher than the plane portion so that a clearance is provided for enabling gas to be exhausted to the exterior through the exhausting groove A.

Owner:DEQING CAIFU GLASS

Method for manufacturing industrial and civil pipeline

InactiveCN107300081ACooperate wellReduced concentricity requirementsCouplingsBranching pipesCivil engineering

The invention discloses a method for manufacturing an industrial and civil pipeline. The method includes the steps that a first stage pipeline is manufactured, a second pipeline is manufactured, and a pipeline snap is manufactured. By arranging multiple straight pipelines and circular-arc sections, when the industrial and civil pipeline is installed, convertible adjustment between the industrial and civil pipeline and an installation environment is achieved, cooperation between the pipelines is good, and the cooperation area can be reduced; the pipeline snap is arranged between the ends of the two pipelines, and when the industrial and civil pipeline is placed, the pipeline snap can reinforce the ends of the pipelines; the pipeline snap is in clearance fit with the ends of the pipelines, so that connecting is convenient.

Owner:上海涵昊机电设备制造有限公司

Design method of quick sampling boiler

ActiveCN105300733AImprove experienceReduce movementWithdrawing sample devicesEngineeringDesign methods

The invention relates to a design method of a quick sampling boiler. The design method is characterized in that: the quick sampling boiler comprises a feed inlet, a feed outlet and a heating unit; a sampler is arranged on the side wall of the boiler; a sampling chamber is communicated with the interior of the boiler; a sampling hole of the sampler can slide or rotate between the outer part and inner part of the boiler; a first seal ring is arranged at the part, near the sampling chamber, of the head part of a sliding chamber of a base; a second seal ring and a third seal ring are arranged at the parts, near the sampling chamber, of the tail part of the sliding chamber of the base; the distance between the second seal ring and the third seal ring is larger than the width of the sampling hole; the sampling chamber is isolated from the sliding chamber through the first seal ring; the sealing chamber is isolated from the external air through the second seal ring and the third seal ring; a first blind hole is formed in the head end of a sampling rod, and a second blind hole is formed in the tail end of the sampling rod; the sampling hole is isolated from the first blind hole and the second blind hole; the first blind hole and the second blind hole are communicated through a ventilation channel. According to the design method, the sealing effect of the seal rings is improved and the service life of the seal rings is prolonged through the design of the blind holes; the two seal rings with a small wire diameter are adopted, so that the tensile force or thrust during sampling is decreased, and the sampling speed is increased.

Owner:JIANGSU XINDA COMM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com