Combined relay based on double-miniature PCB relay

A relay and combined technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of high production cost, limited PCB installation space, cumbersome production process, etc., to ensure a safe distance, reduce production costs, The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

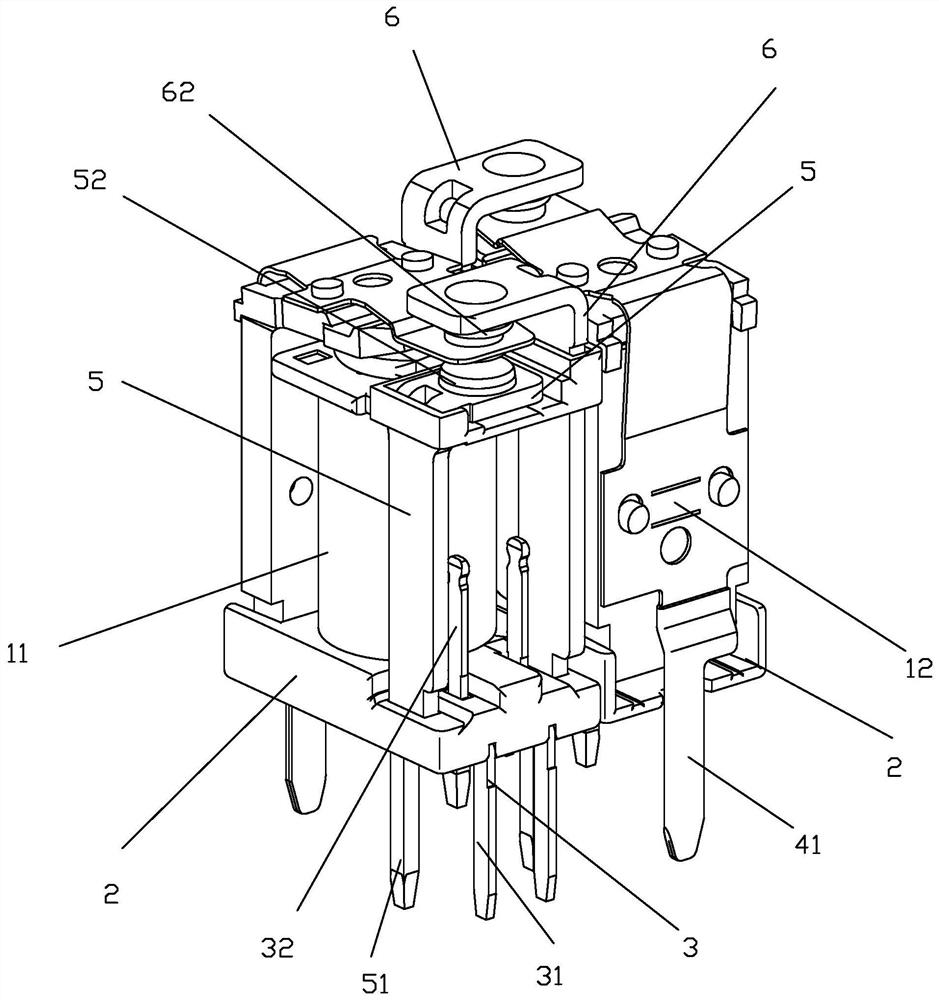

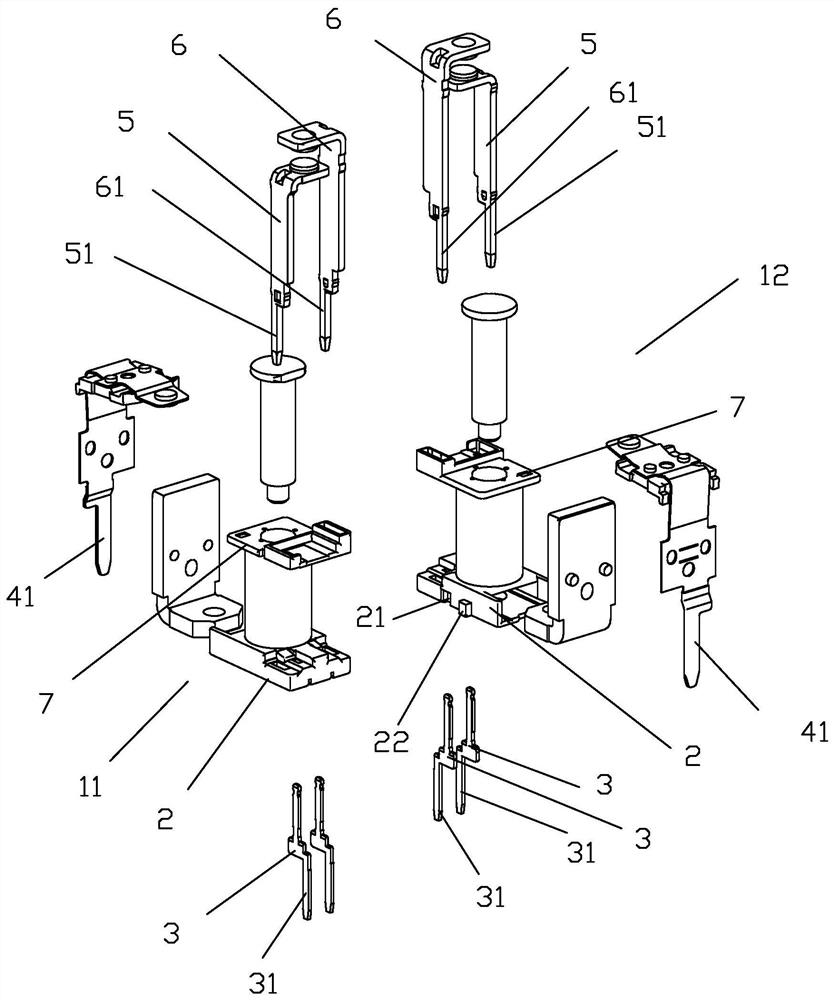

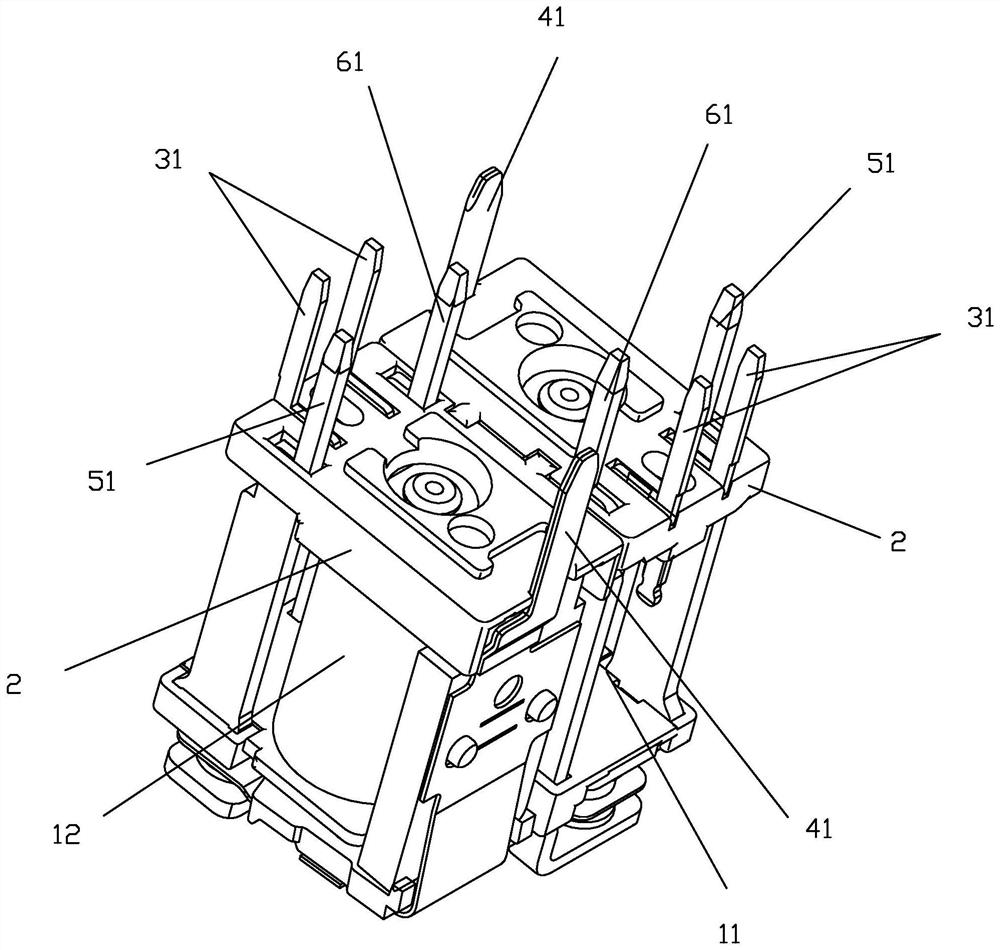

[0039] see Figure 1 to Figure 17 As shown, a combined relay based on dual small PCB relays of the present invention includes two relays 11 and 12 with the same structure and without a housing; the relay includes a base 2 and coil pins 31 distributed on the base , moving spring lead-out pin 41 and static spring lead-out pin, wherein, the quantity of coil lead-out pin 31 is two, static spring lead-out pin has normally open static spring lead-out pin 51 and normally closed static spring lead-out pin 61; Described base 2 is in The projection on the bottom plane has a rectangular shape; the coil lead-out pin 31 and the static spring lead-out pin 51, 61 are arranged at one end of the length of the base 2, and the moving spring lead-out foot 41 is arranged at the other end of the length of the base 2; One side of the lengthwise direction of the base 2 is respectively provided with a groove 21 and a bump 22 at equidistant positions corresponding to both sides of the median line of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com