Miniaturized PCB relay

A relay, L-shaped technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems that affect the stability of relay parameters, reduce the pressure of static springs at the normally closed end, and affect the electrical life of products, etc., to achieve effective improvement The effects of magnetically permeable area, avoiding jitter, and avoiding magnetic saturation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

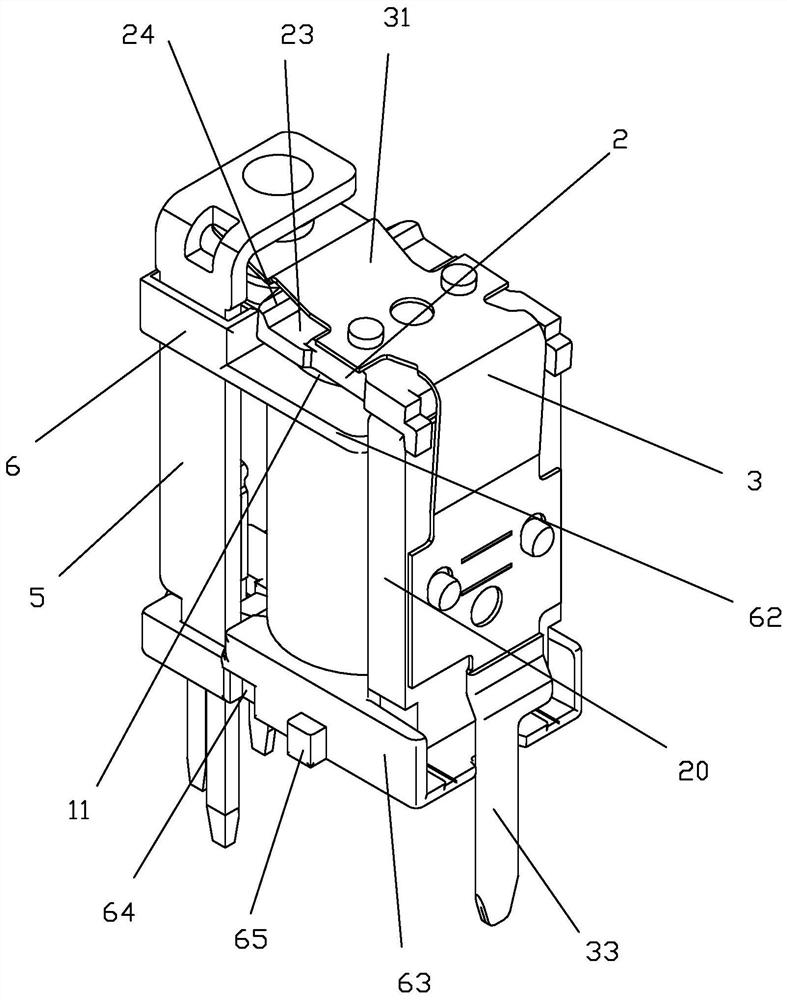

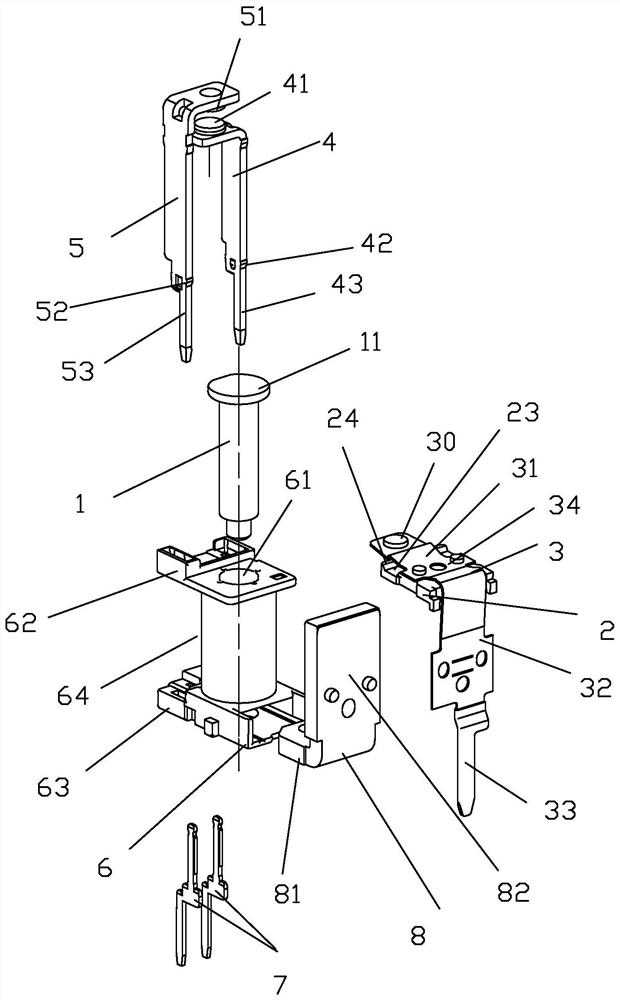

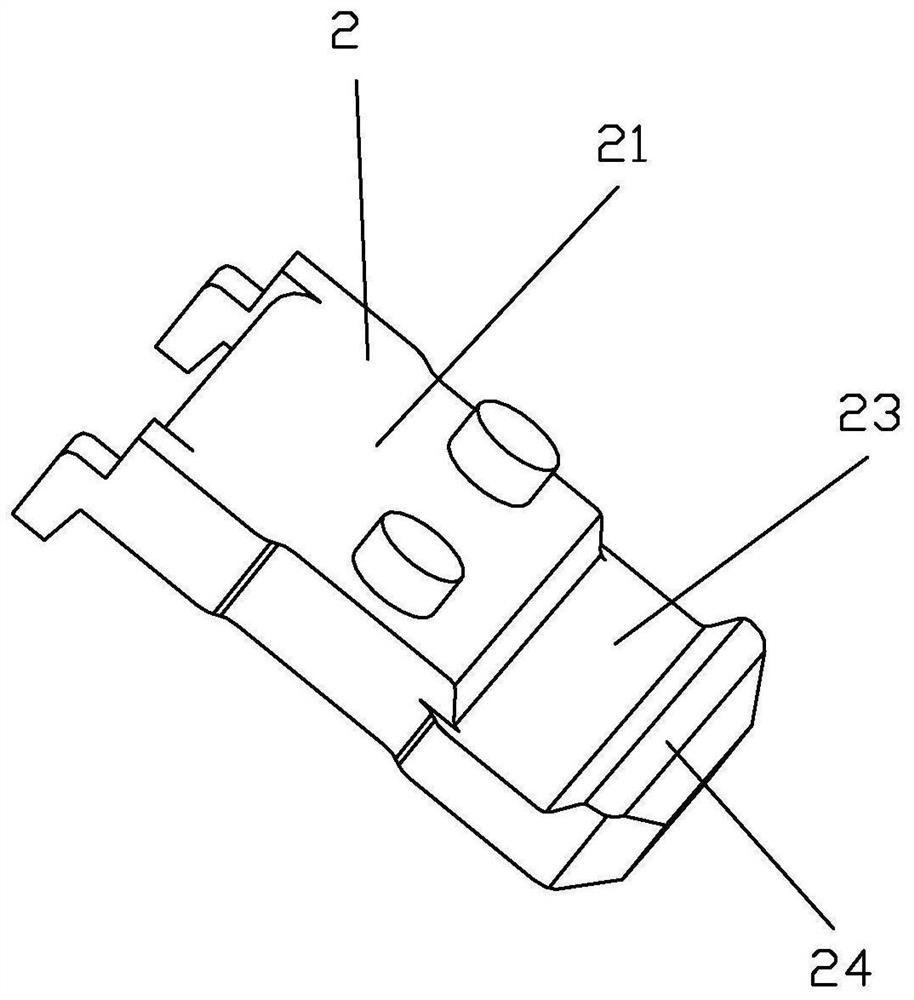

[0043] see Figure 1 to Figure 19 As shown, a miniaturized PCB relay of the present invention includes an iron core 1, an armature 2, a moving reed 3, a static spring normally open end 41 and a static spring normally closed end 51; the root of the swingable part 31 of the moving reed 3 34 is fixed in one side 21 of the armature 2 and makes the other side 22 of the armature 2 and the pole surface 11 of the iron core 1 be in the position of corresponding cooperation; Position) is equipped with a movable contact 30 and fits between the normally open end 41 of the static spring and the normally closed end 51 of the static spring respectively, and the normally open end 41 of the static spring is located on the pole surface 11 of the moving reed 3 facing the iron core 1 On this side of the static spring, the normally closed end 51 of the static spring is located on the side of the pole face of the moving reed 3 facing away from the iron core; 31 is provided with a groove 23 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com