Primary mold capable of exhausting air

A technology of exhaust groove and male mold, applied in the direction of glass blowing mold, etc., can solve the problems of glass frit rebound, wire sticking in the bottle, hidden dangers, etc., and achieve the effect of reducing tolerance, improving production quality and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

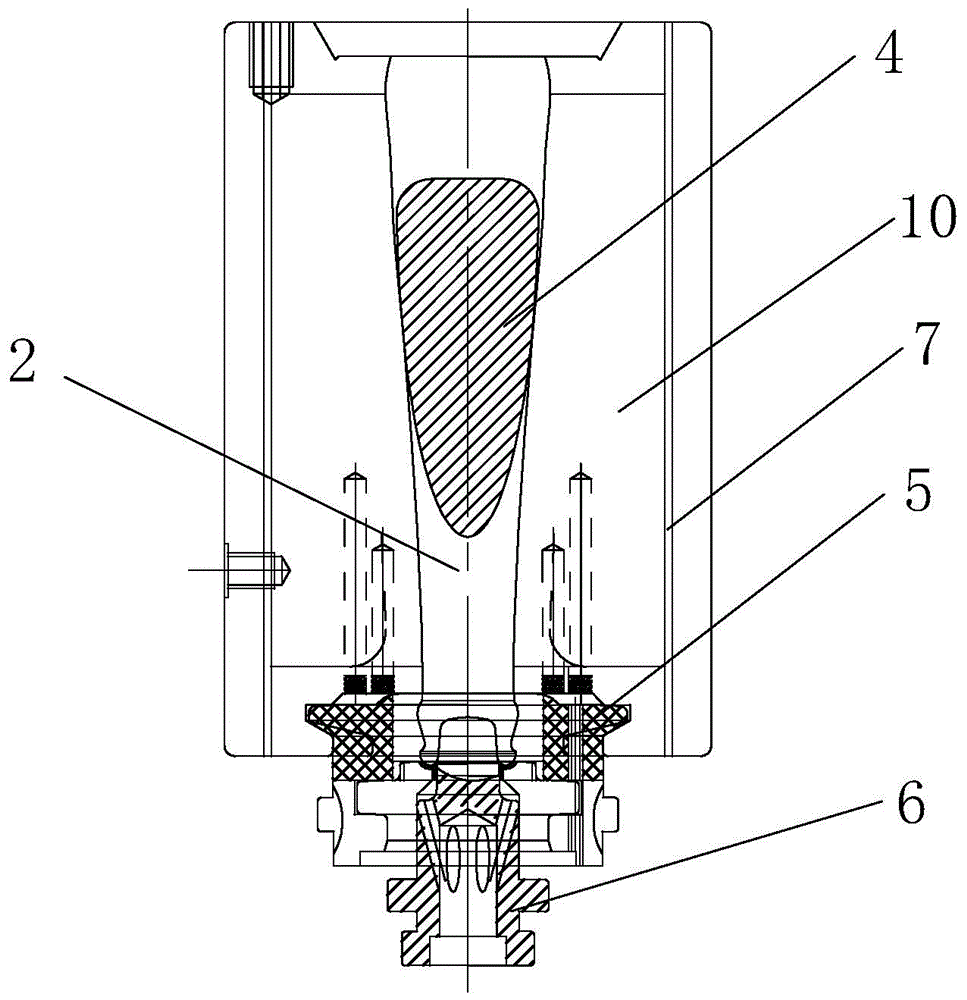

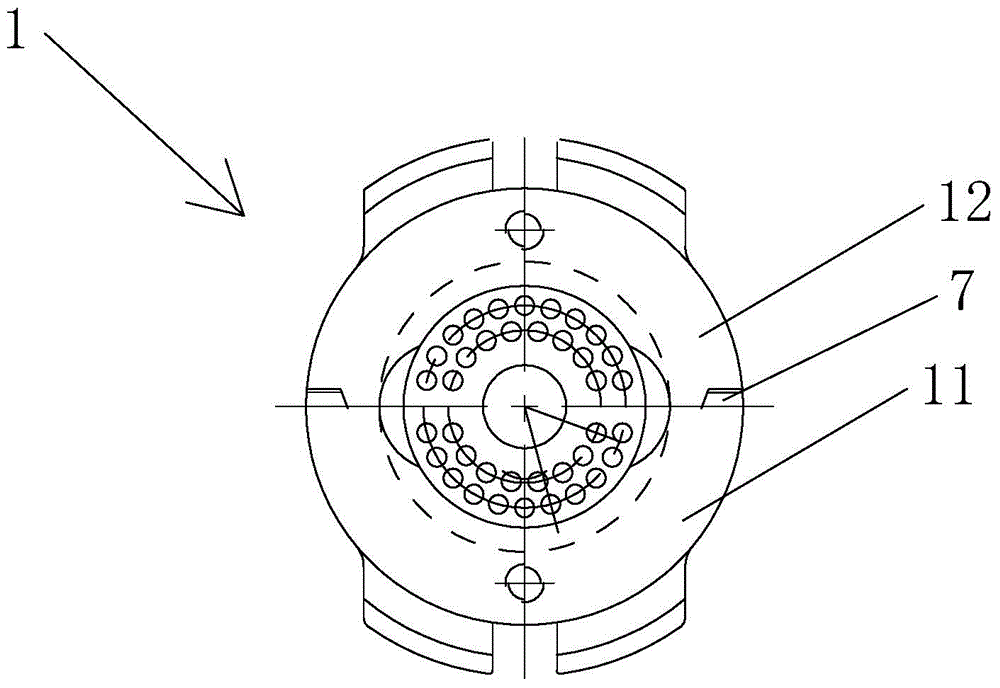

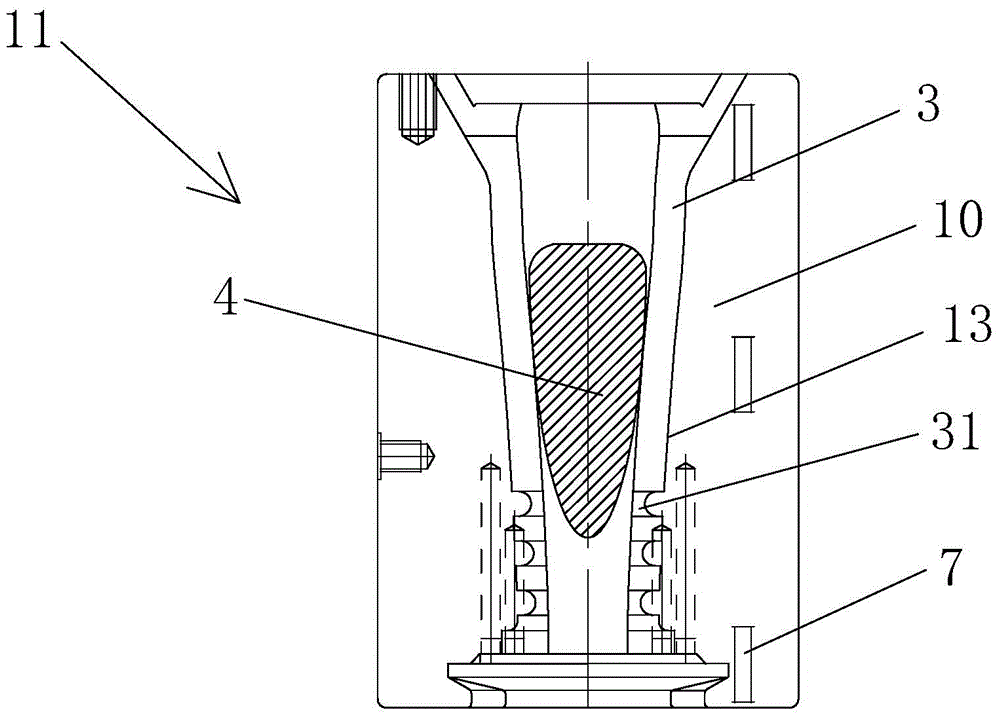

[0020] Embodiment: a kind of degassable preliminary mold, as Figure 3-5 As shown, the primary mold 1 is made up of two male molds 11 and female molds 12 that are matched together. On the plane part 10 of the male mold 11 and the female mold 12, a mold cavity 2 that penetrates up and down is provided. The two mold cavities 2 cooperate with each other so that a bottle body cavity is formed inside the entire primary mold 1, and the surface where the male mold 11 and the female mold 12 are closely fitted when they are matched is the seam surface 3, and the seam surface 3 protrudes from the plane part 10, a boundary line 13 is formed between the joint surface 3 and the plane part 10; a boundary line 13 is formed on both sides of a cavity 2 respectively, and the boundary line 13 is set along the contour line of the edge of the cavity, and the The seam surface 3 is the surface formed between the boundary line 13 and the contour line of the cavity edge; on the seam surface 3, there a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com