Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Reduce dark areas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

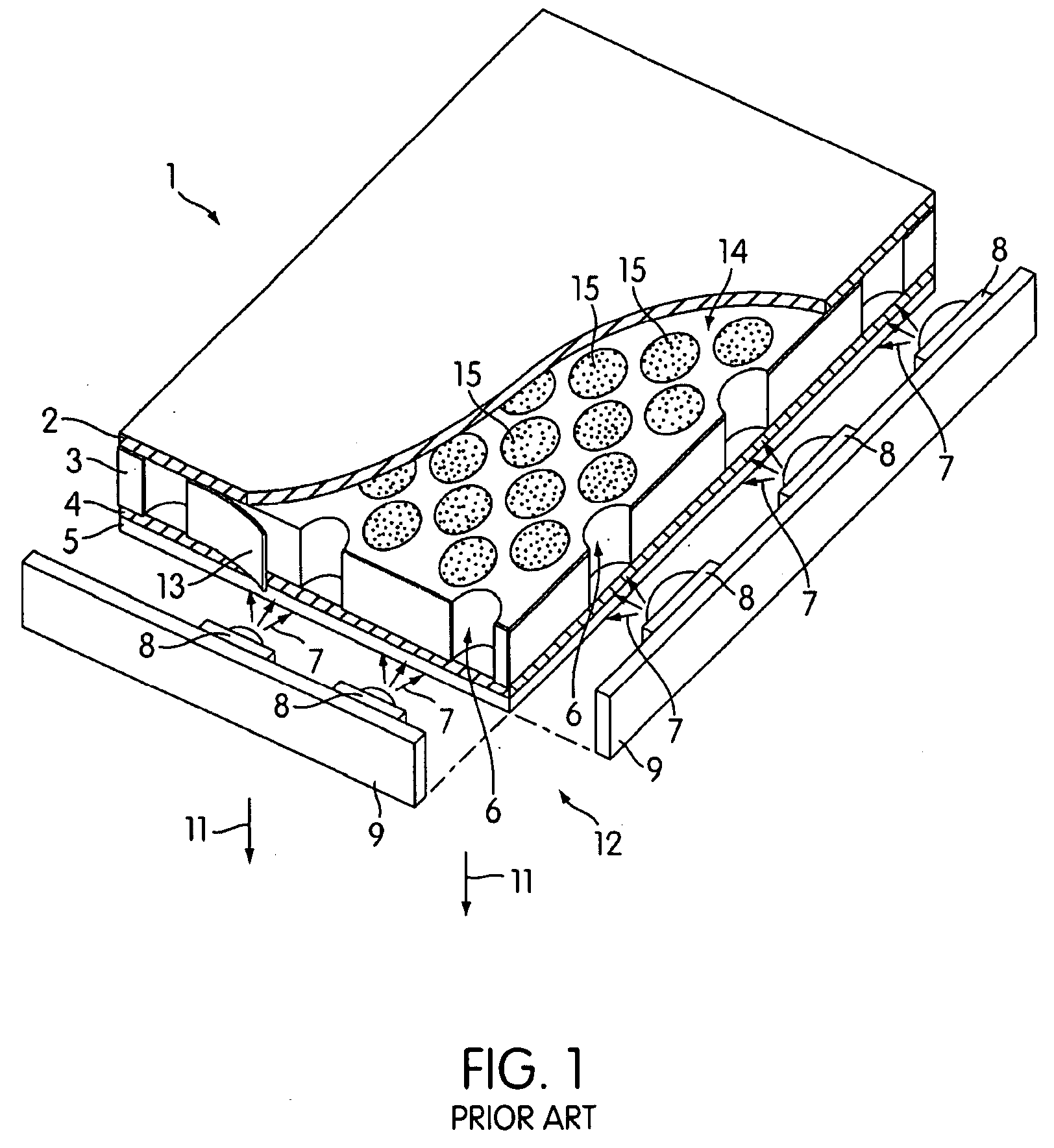

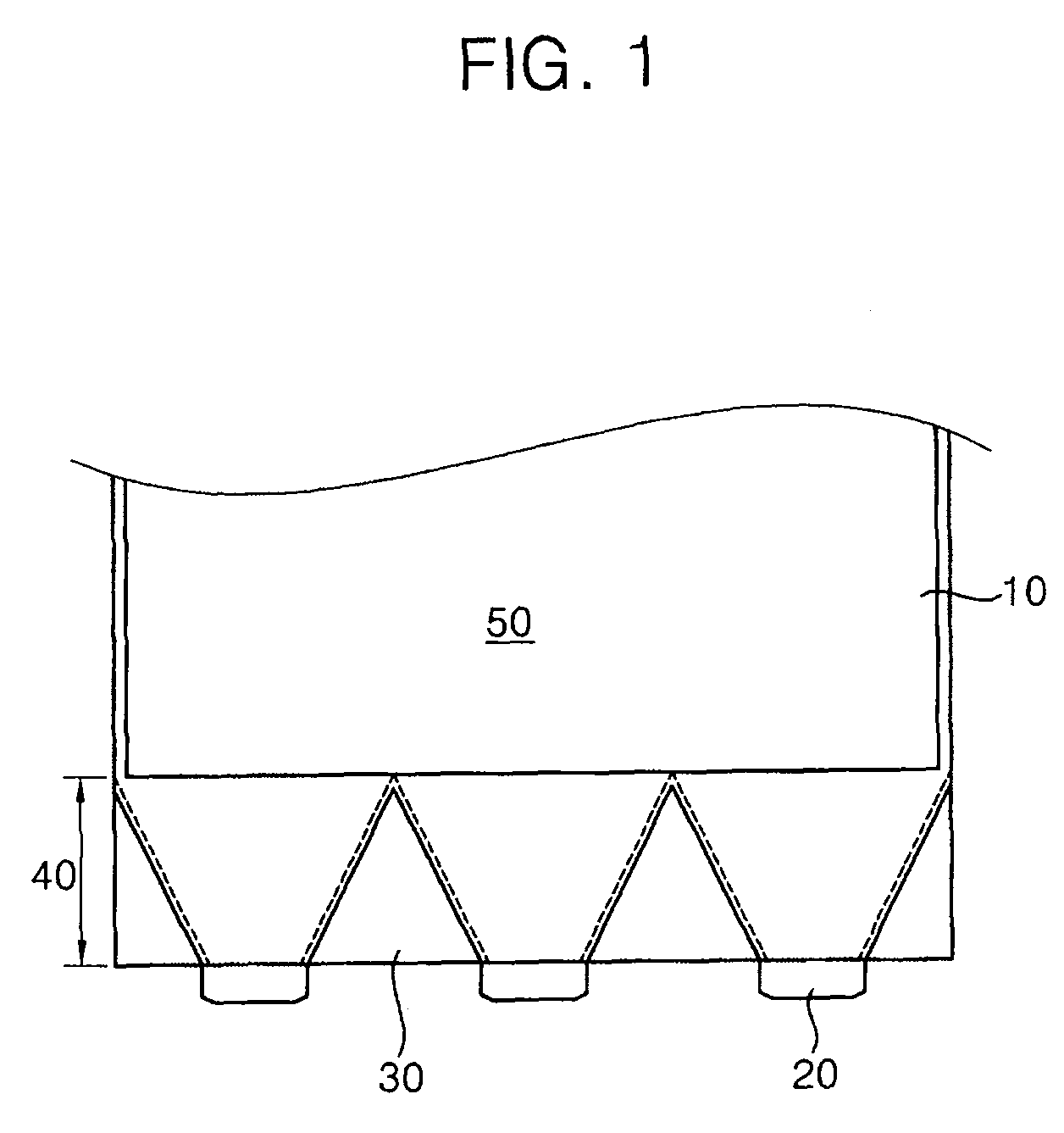

Light Emitting Panel

InactiveUS20100027293A1Increase distanceReduce spacingMechanical apparatusPlanar/plate-like light guidesLight guideLight-emitting diode

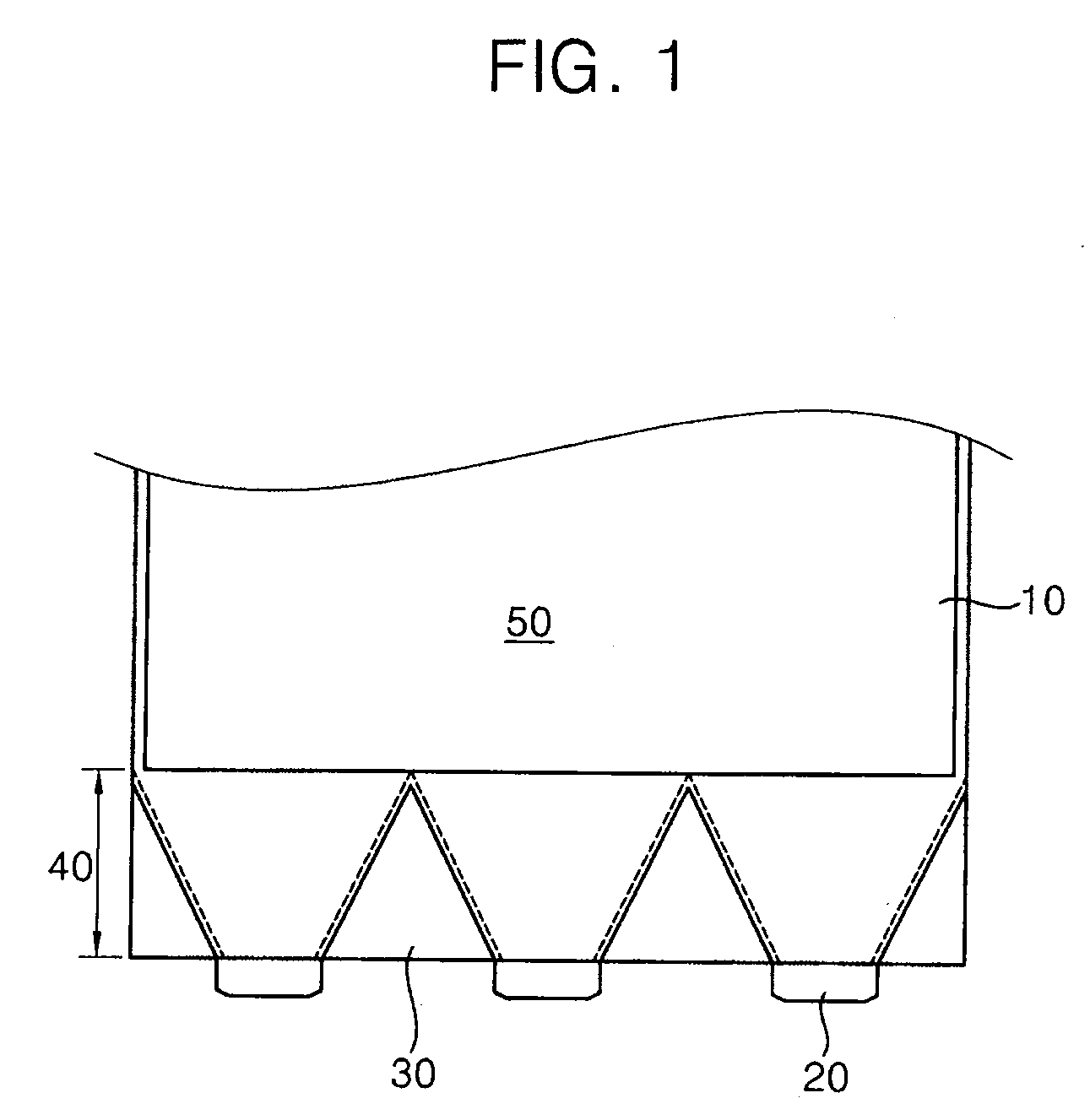

A light emitting panel comprises a light guiding medium having at least one light emitting face and a plurality of light sources (LEDs) configured to couple light into an edge of the light guiding medium at four or fewer locations around the edge. A pattern of optical features (discontinuities) is provided on at least one face of the light guiding medium for promoting emission of light from the light emitting face. The pattern of features is configured such as to reduce a variation in emitted light intensity over substantially the entire surface of the light emitting face such that the variation is less than or equal to about 25%. The pattern of features is configured in part in dependence on a light intensity distribution within the light guiding medium and the spacing, size, shape and / or number of features per unit area can depend on distance from each light source.

Owner:INTEMATIX

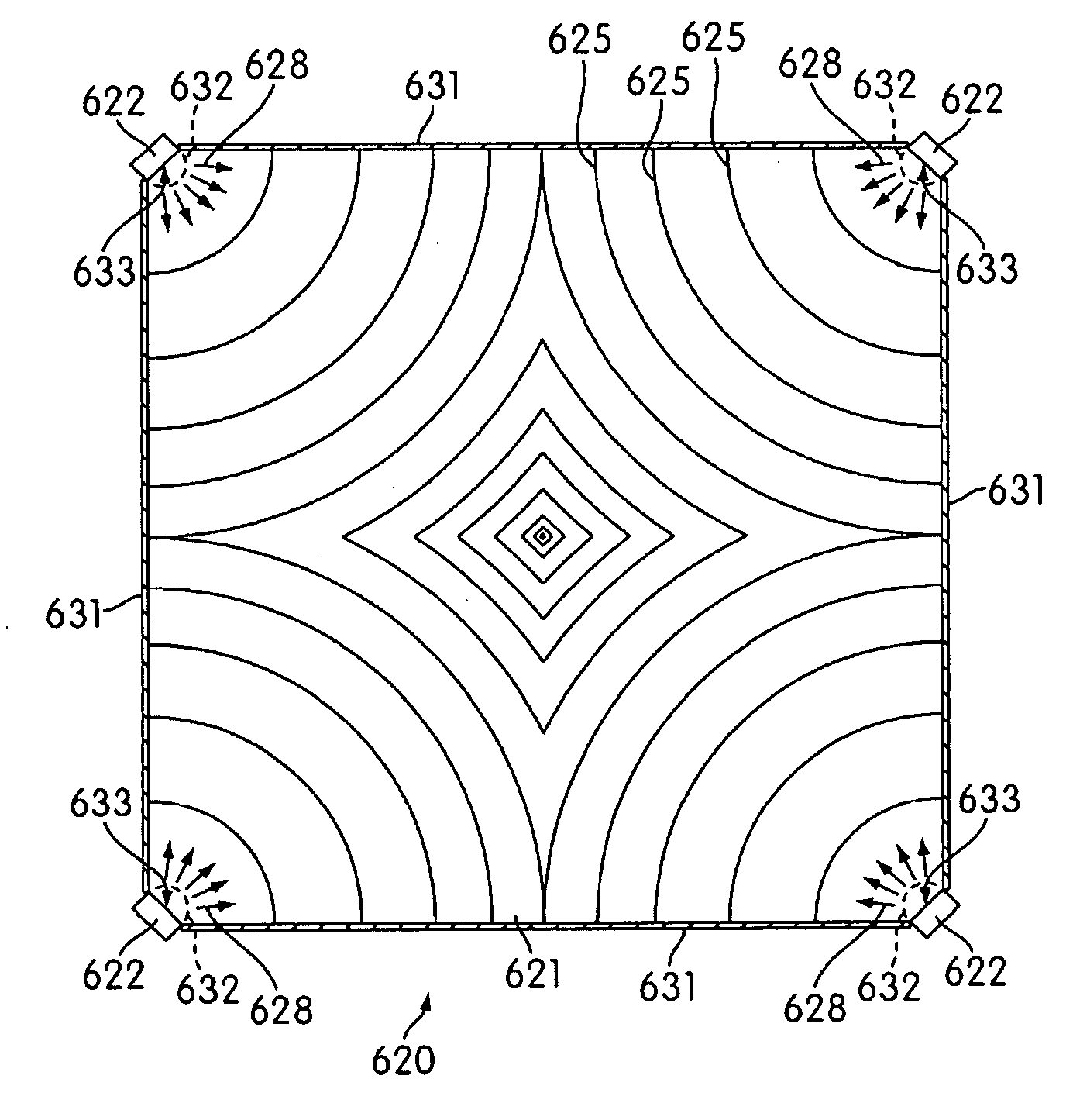

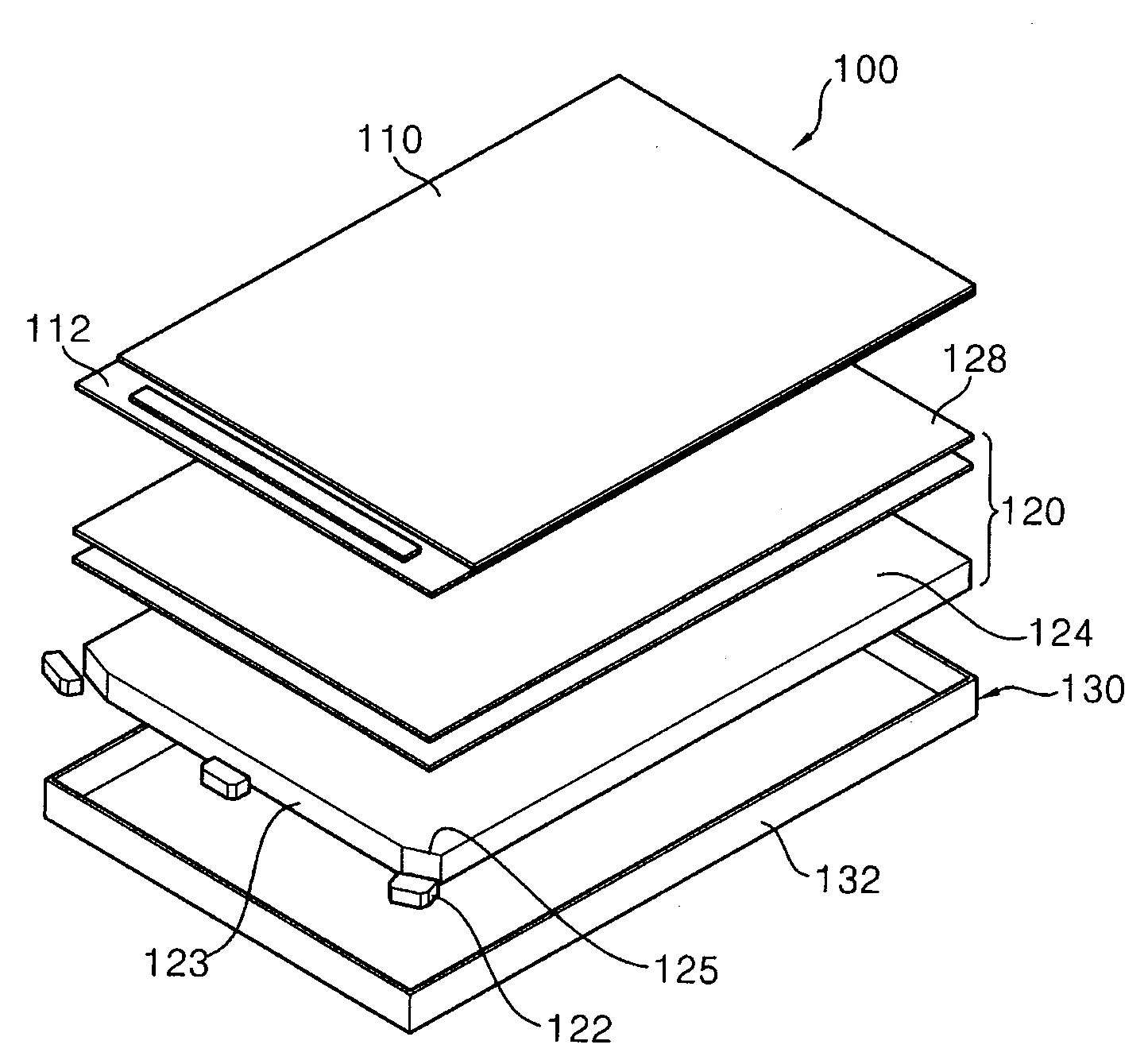

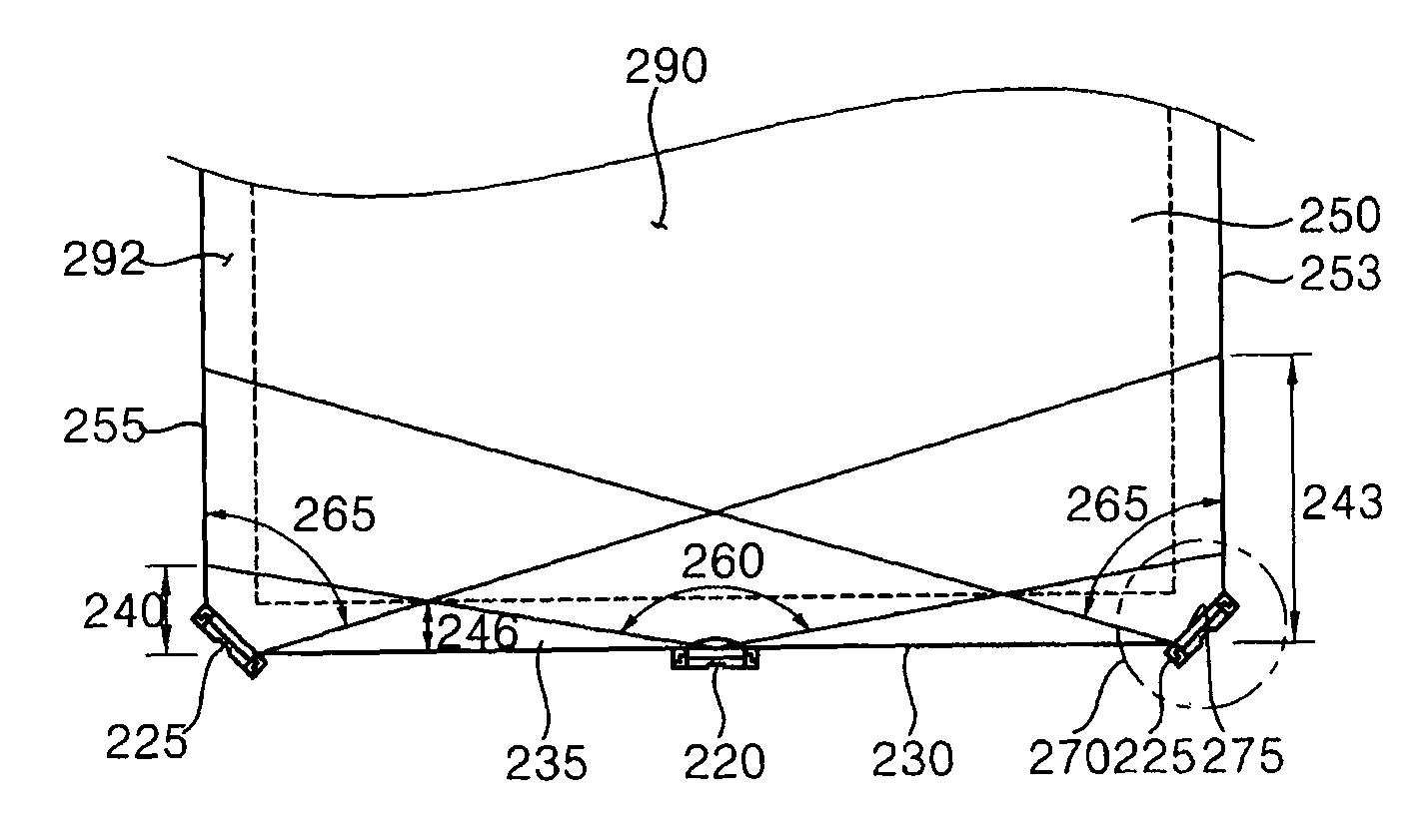

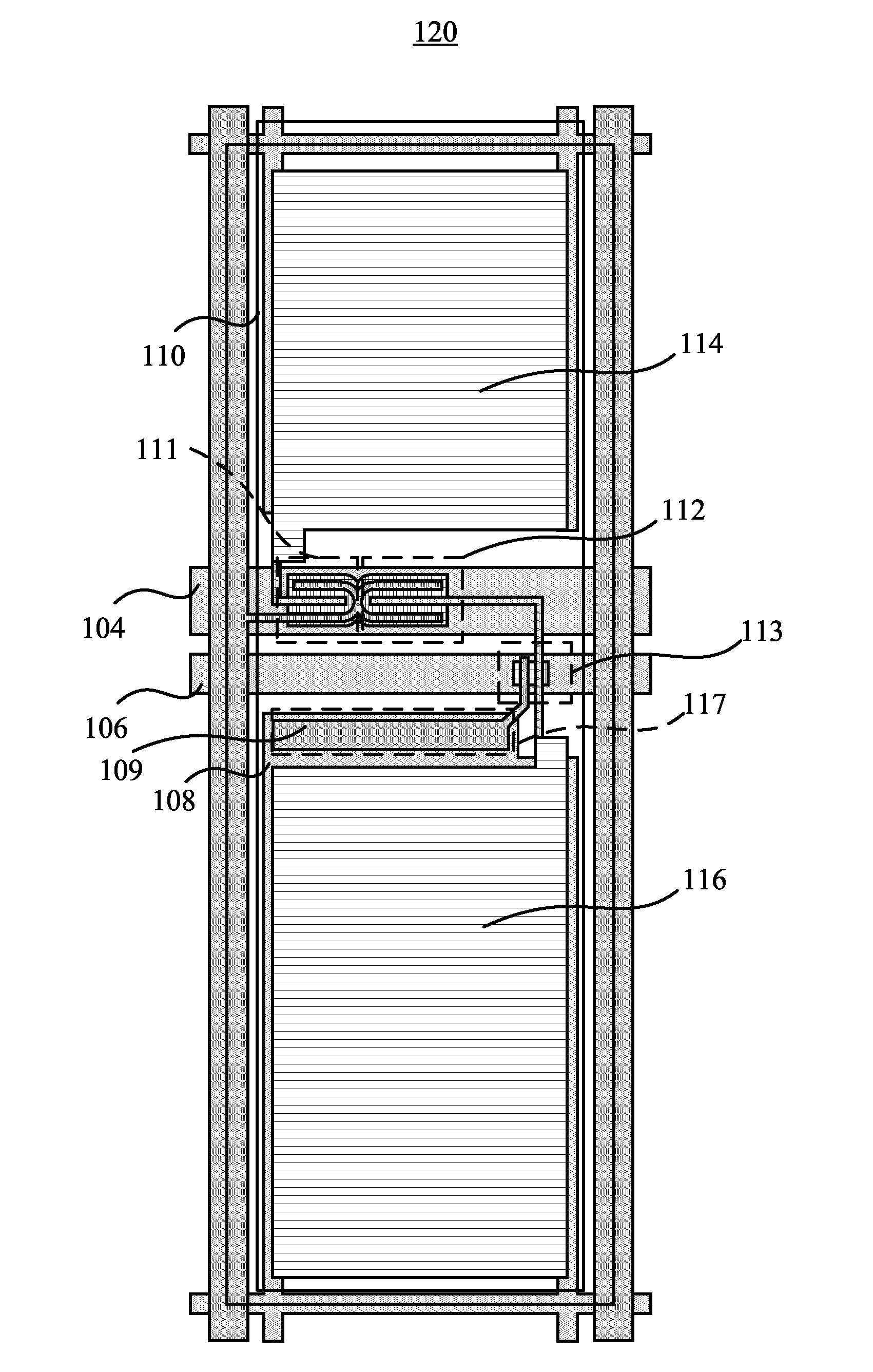

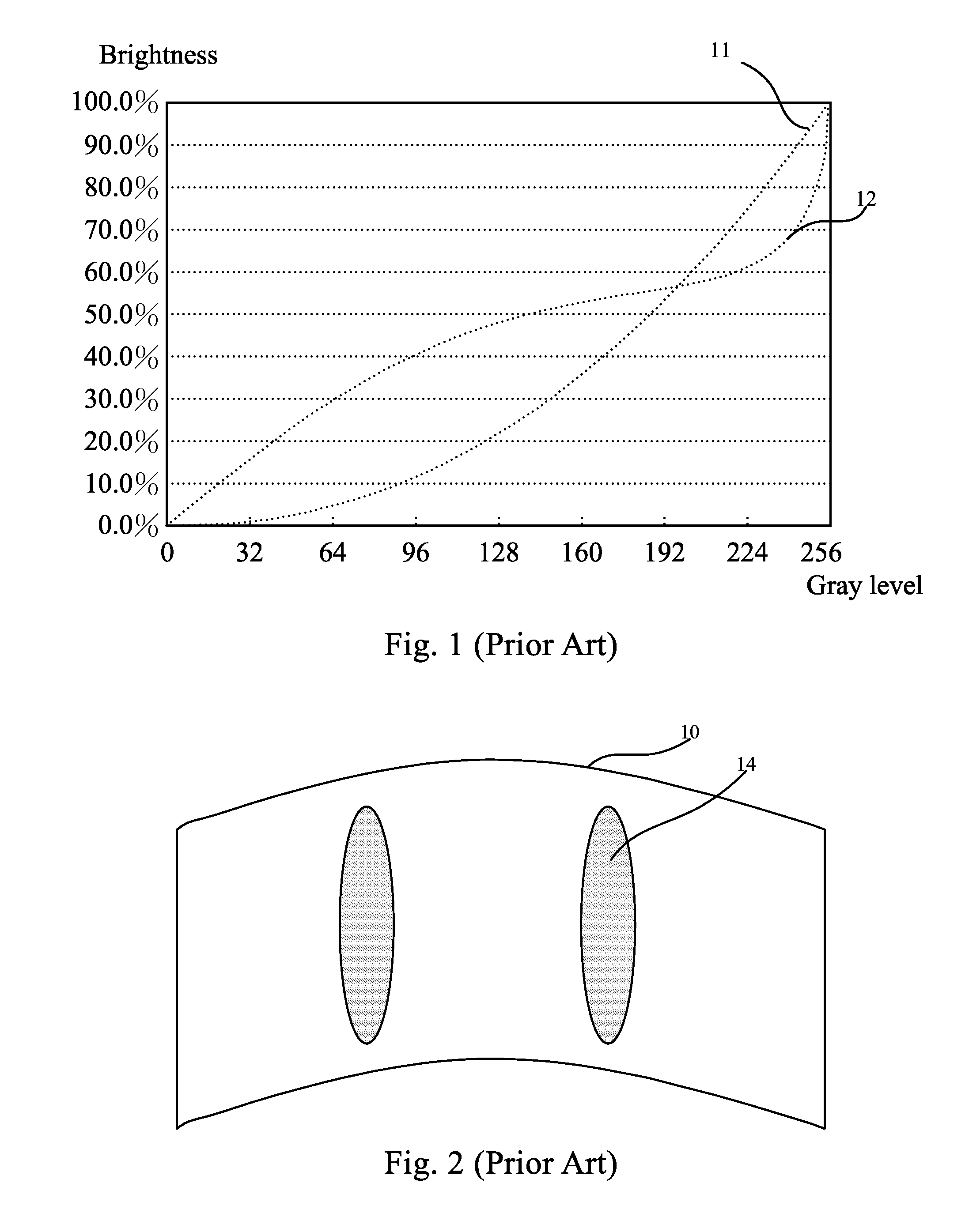

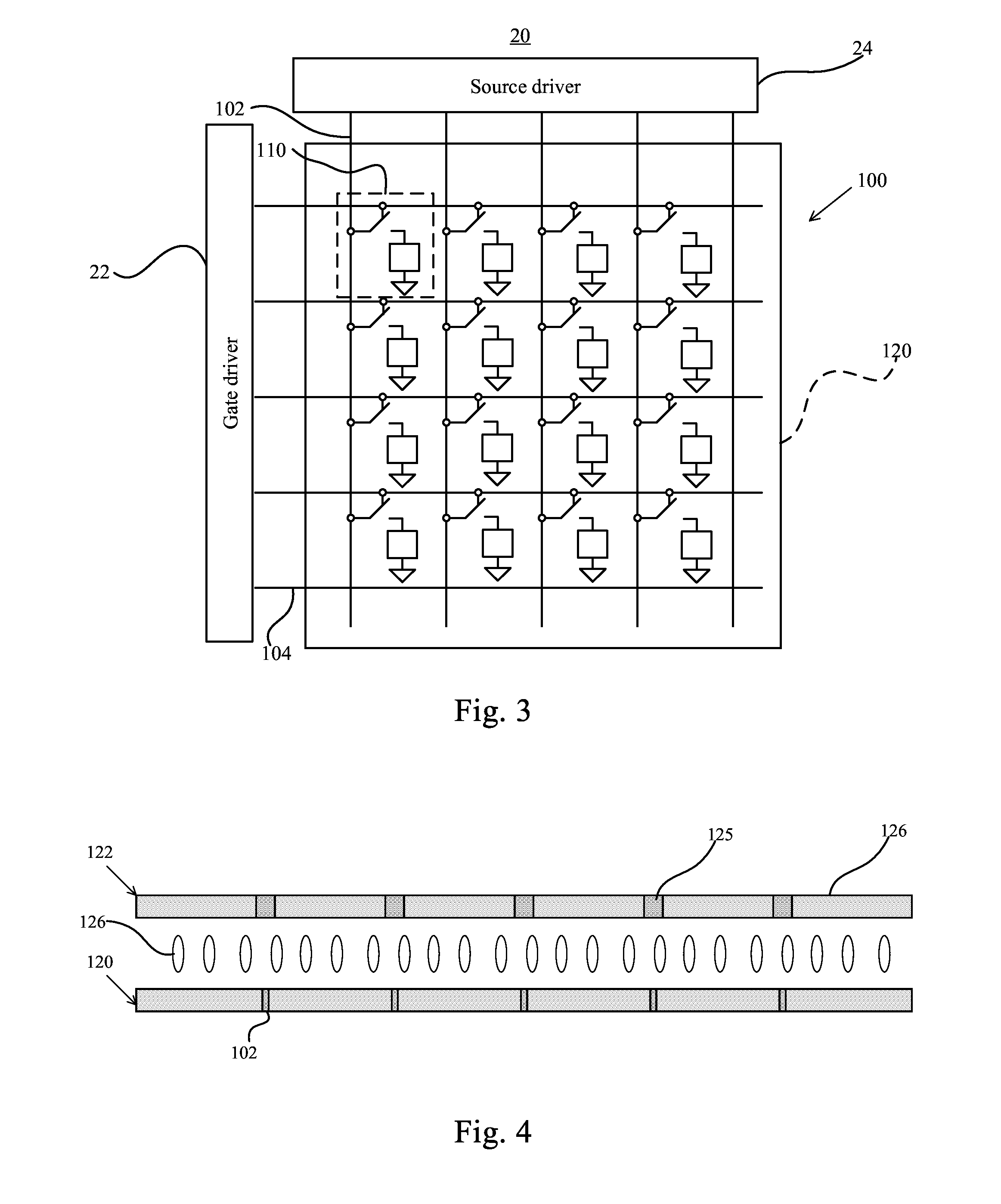

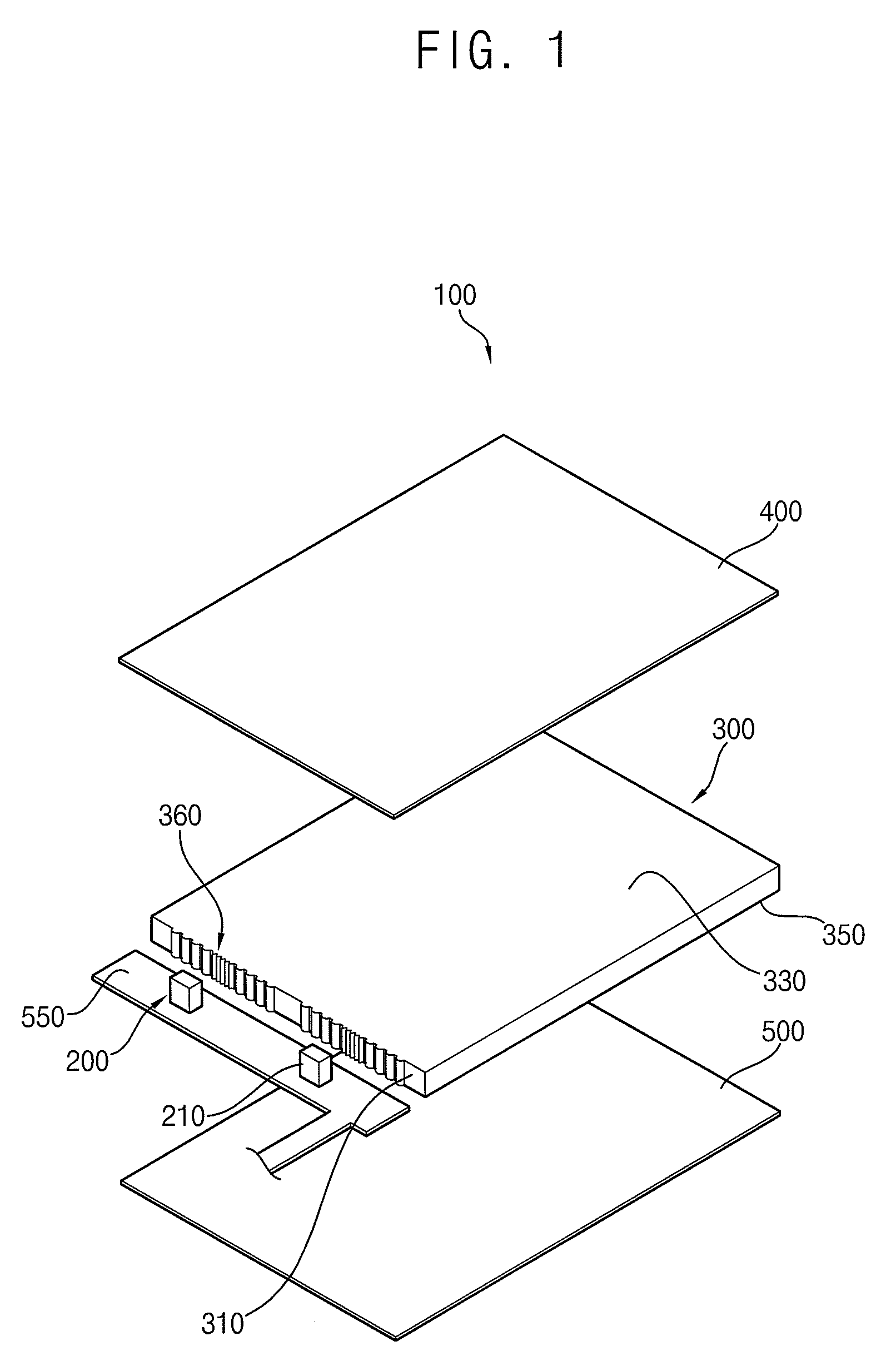

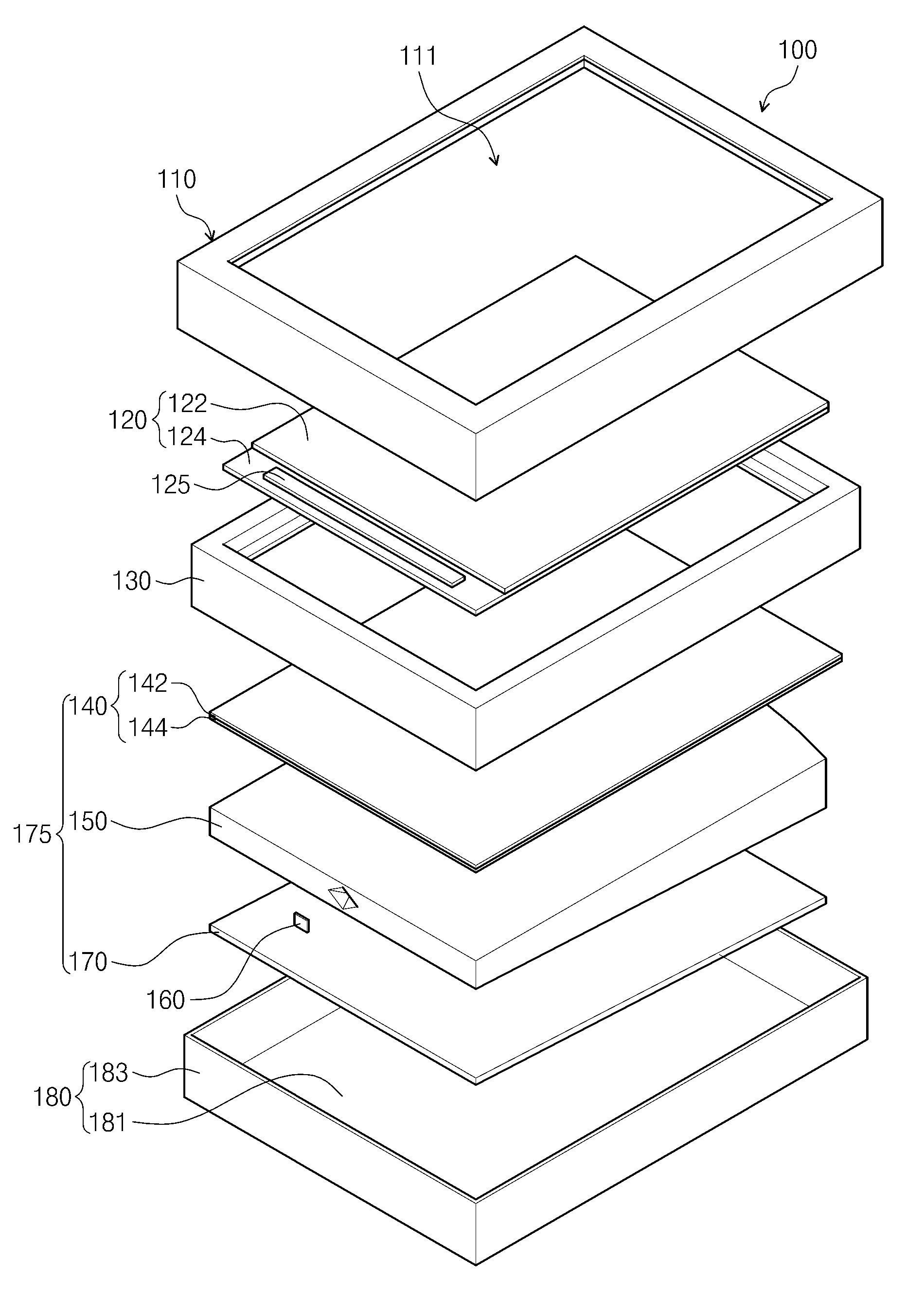

Liquid Crystal Display Using Different Light Radiation Angles Of Light Emitting Diodes

ActiveUS20080316767A1Less of dark areaReduce manufacturing costMechanical apparatusVessels or leading-in conductors manufactureLiquid-crystal displayLight guide

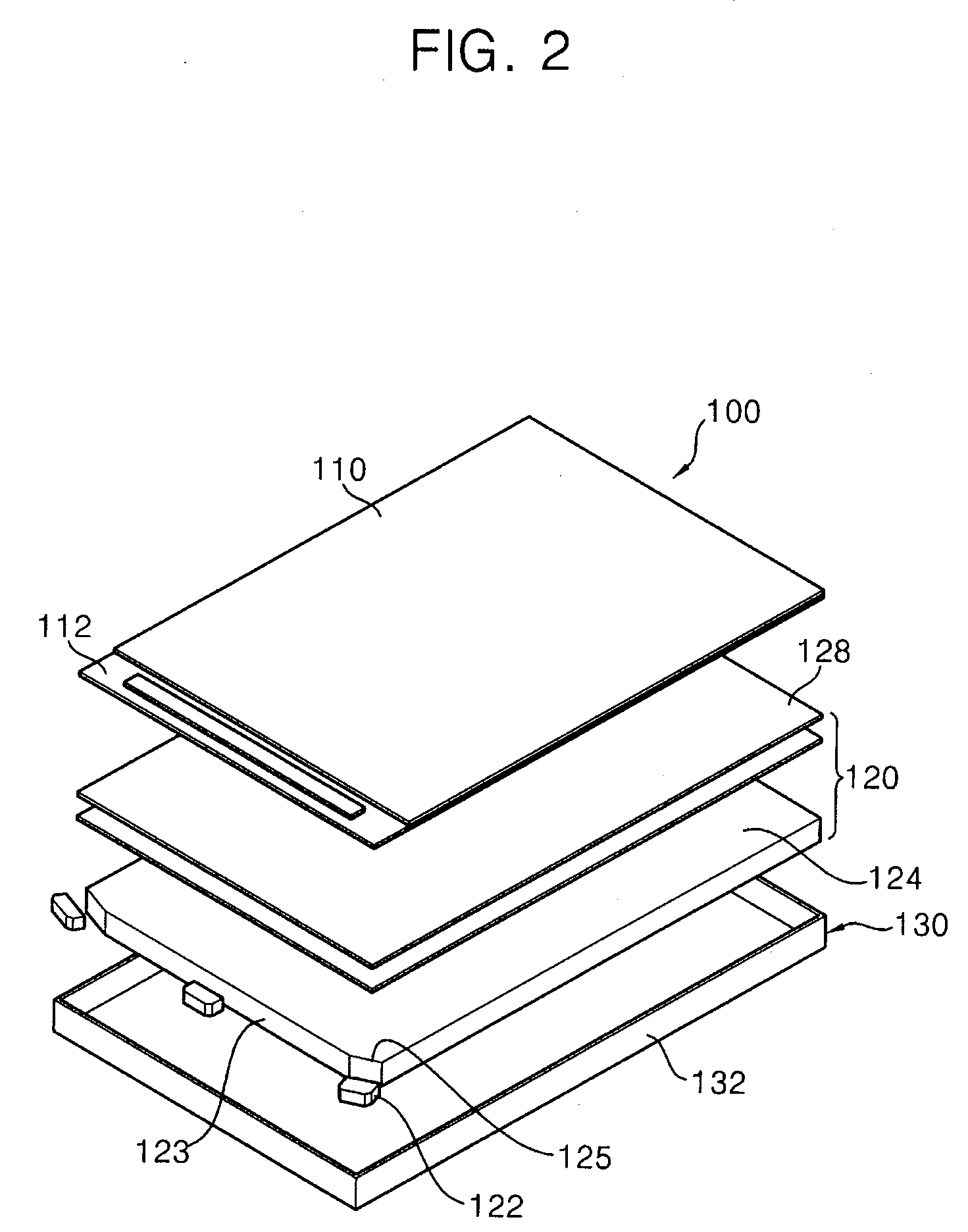

A liquid crystal display with low manufacturing cost, small dark area and compact exterior is provided by utilizing a plurality of differently radiating light emitting diodes at different angles. The liquid crystal of present invention includes a thin film transistor panel for displaying image, a backlight assembly for providing light to the thin film transistor panel with a plurality of light emitting diodes with different light radiation angles and a light guiding plate, and a frame unit for encompassing the thin film transistor panel and the backlight assembly. The light emitting diodes are placed either at the mid-point of light incident surface or the corner portion of the light guiding plate.

Owner:SAMSUNG DISPLAY CO LTD

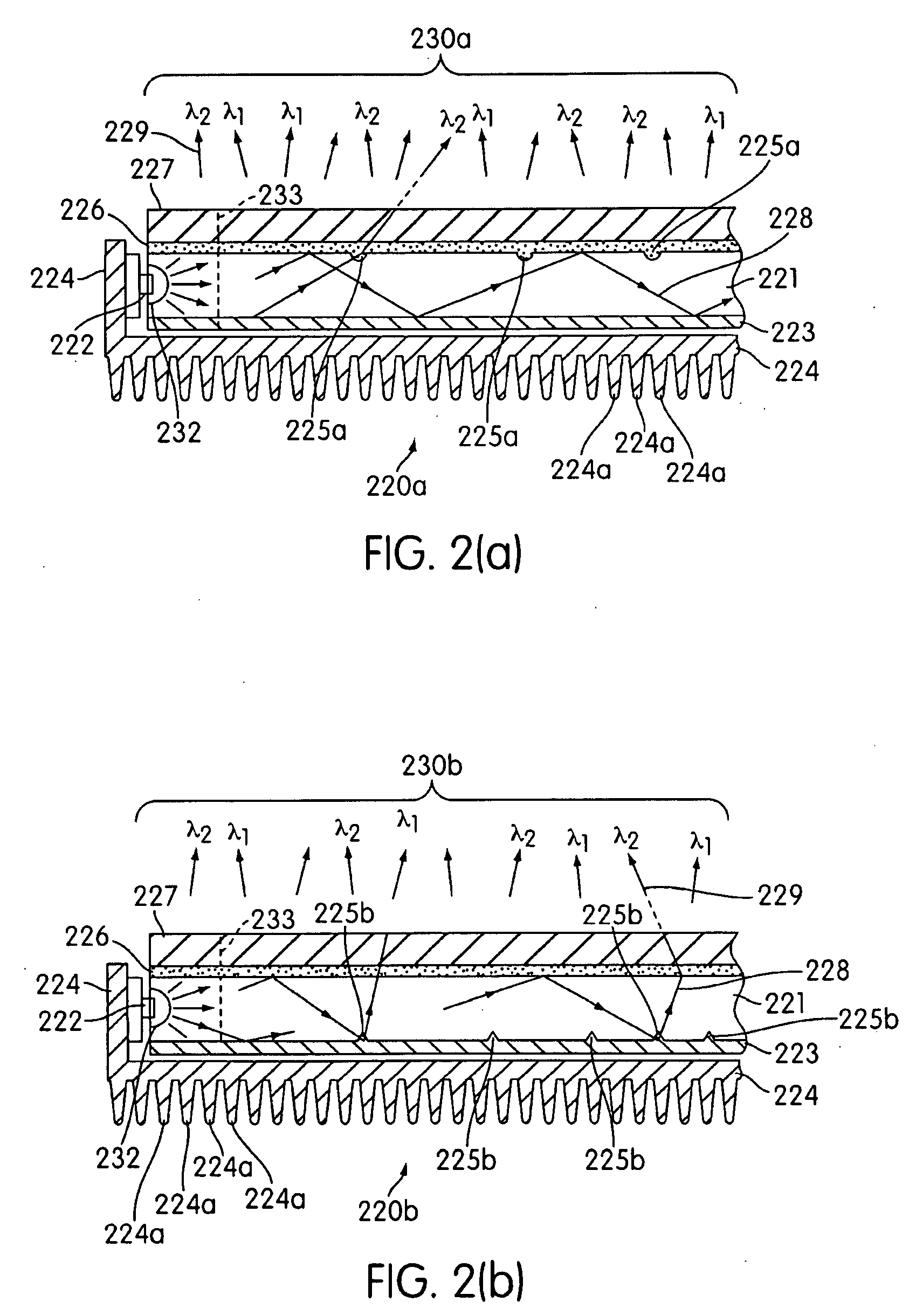

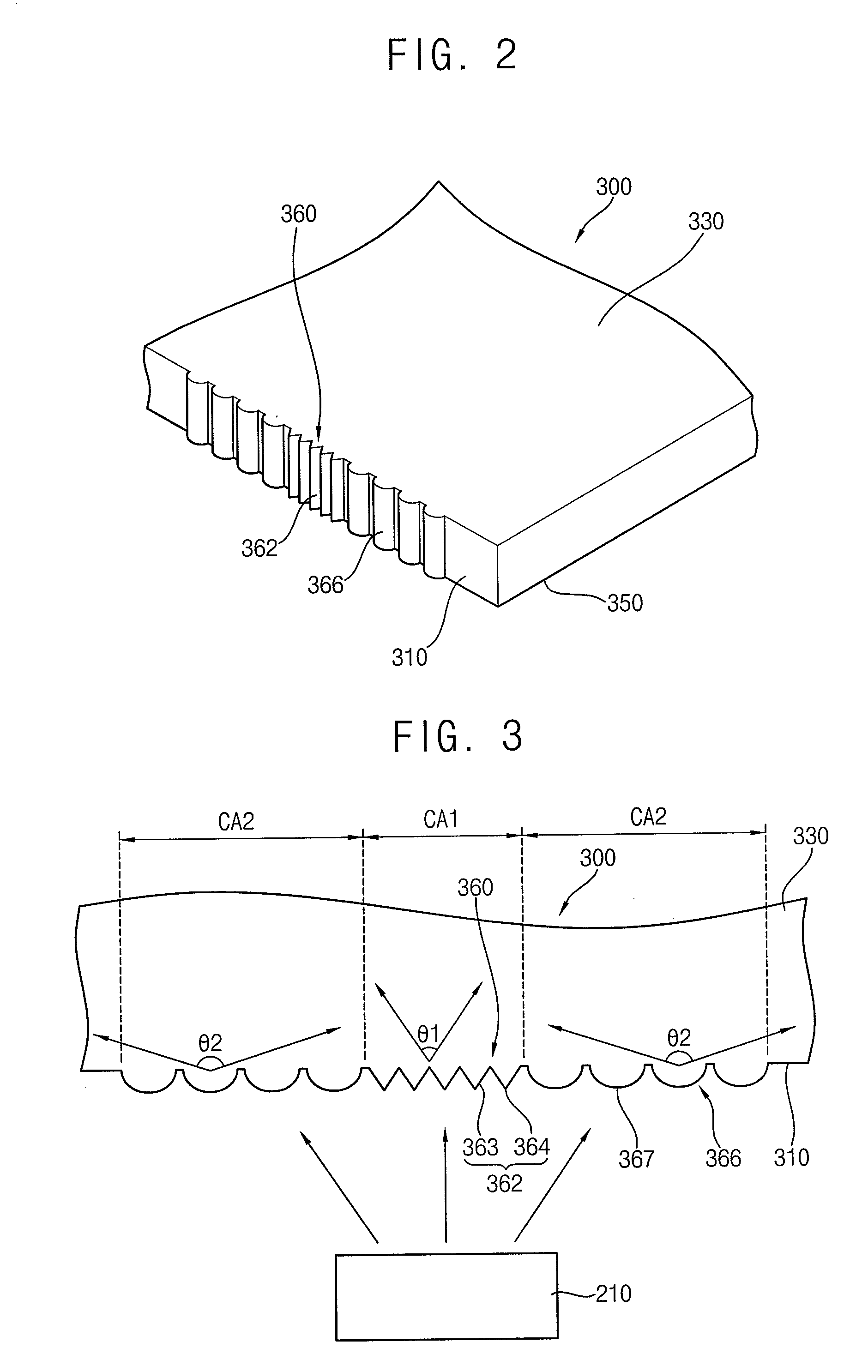

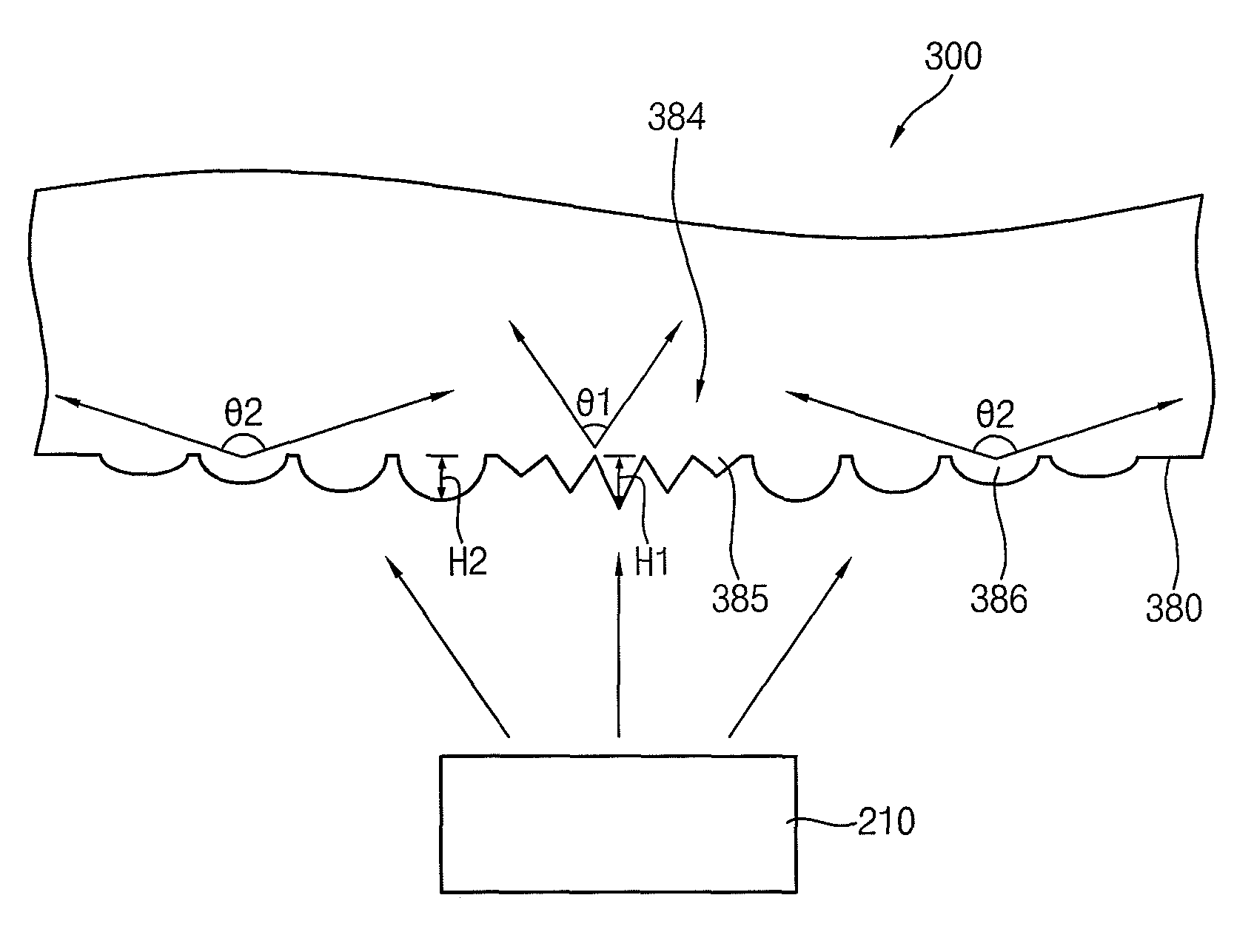

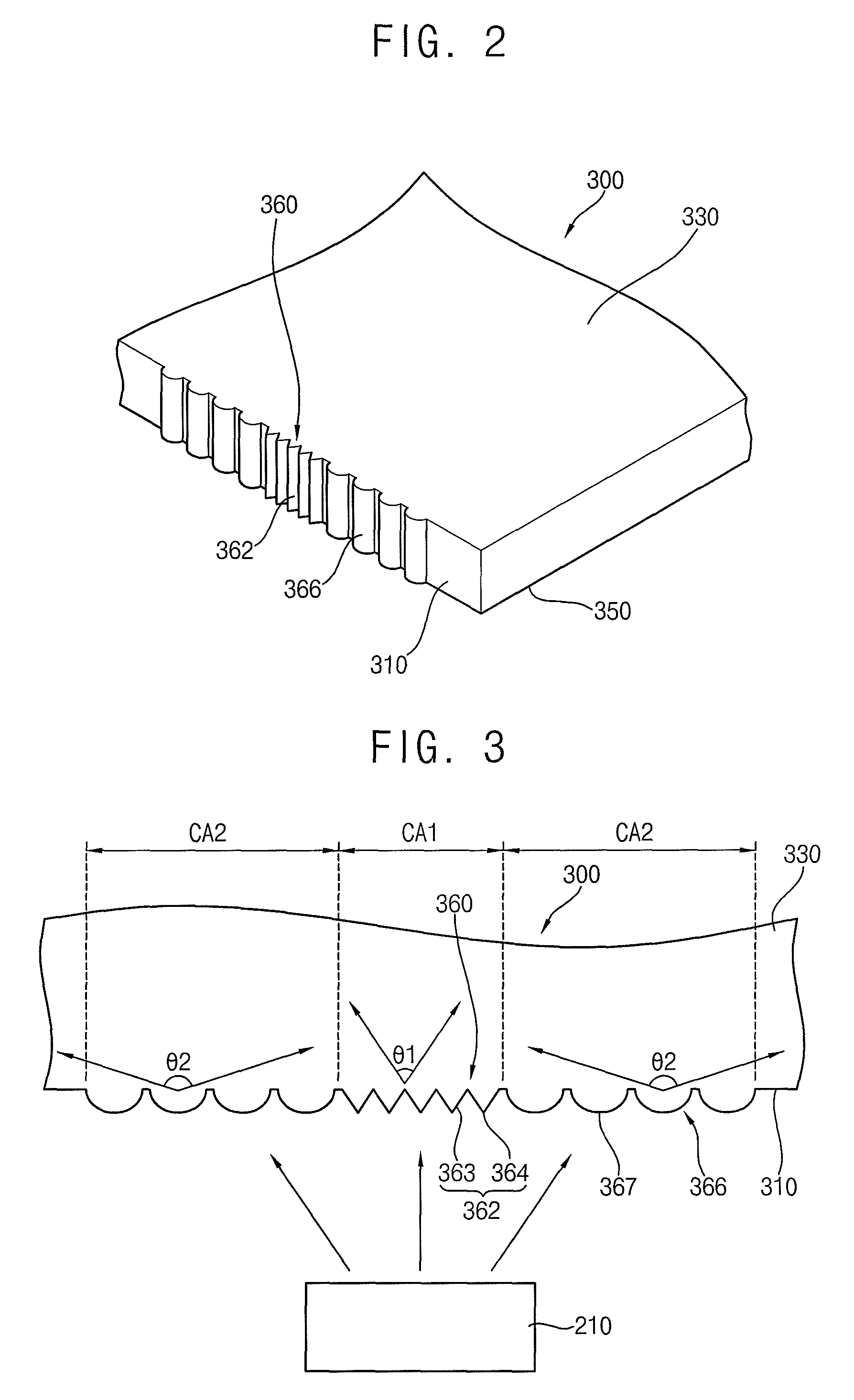

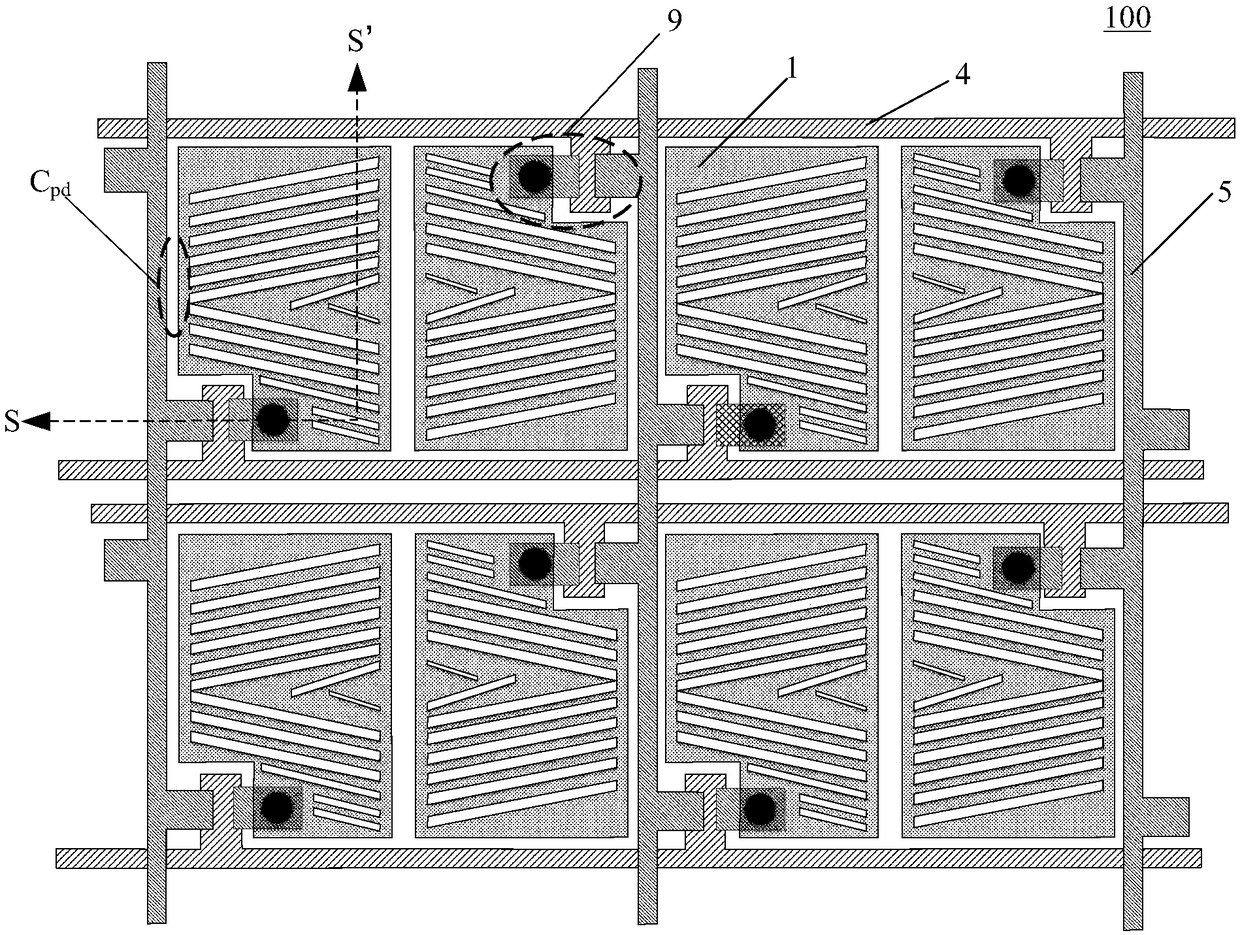

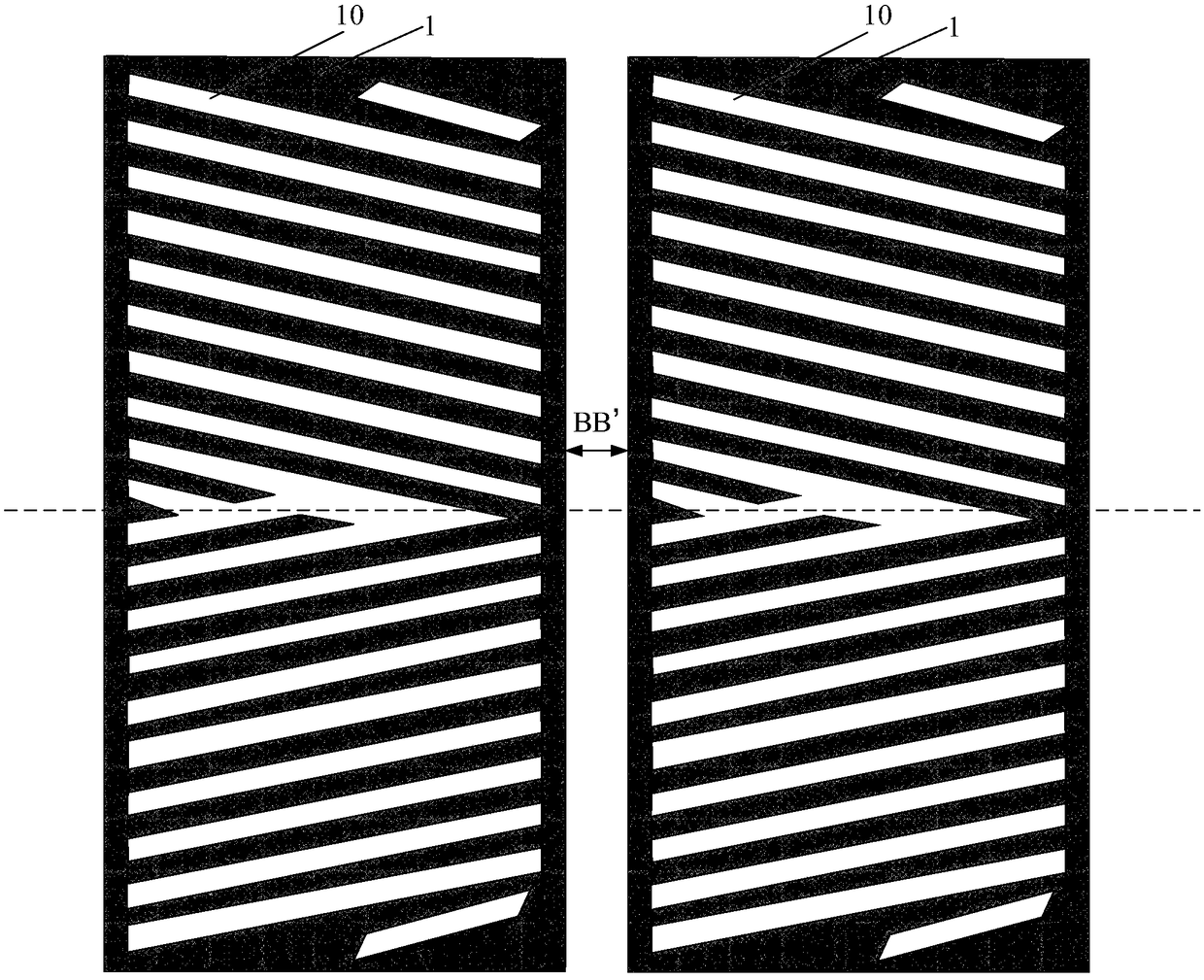

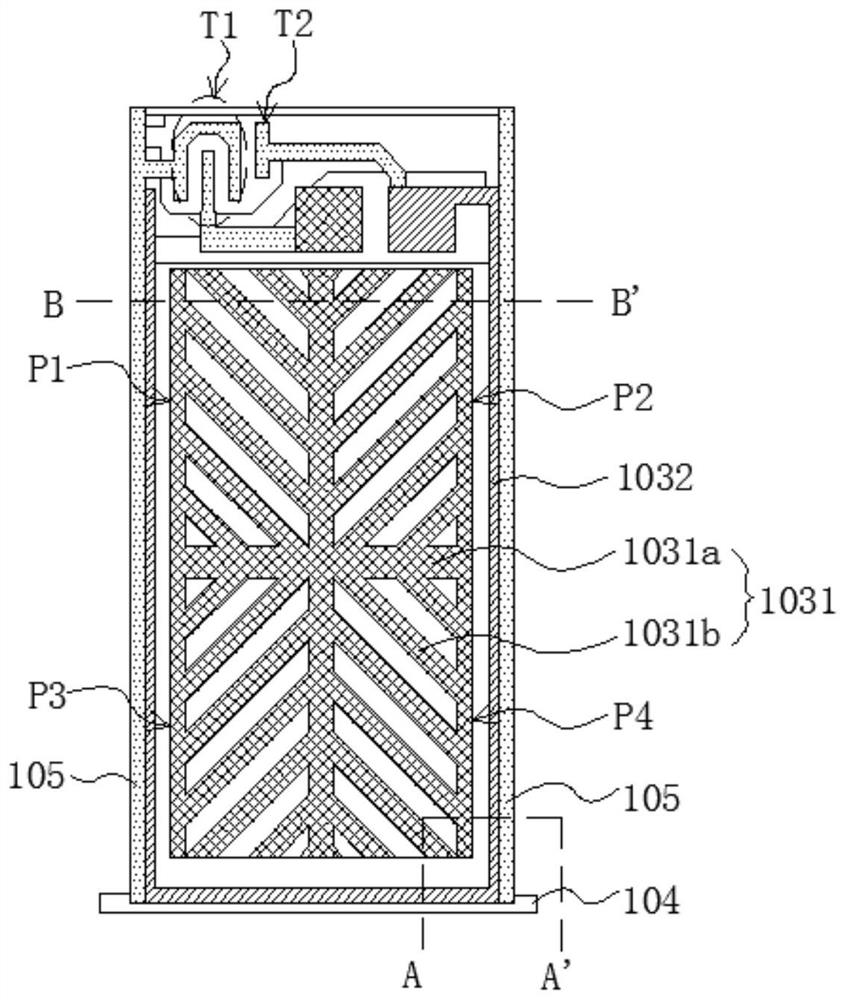

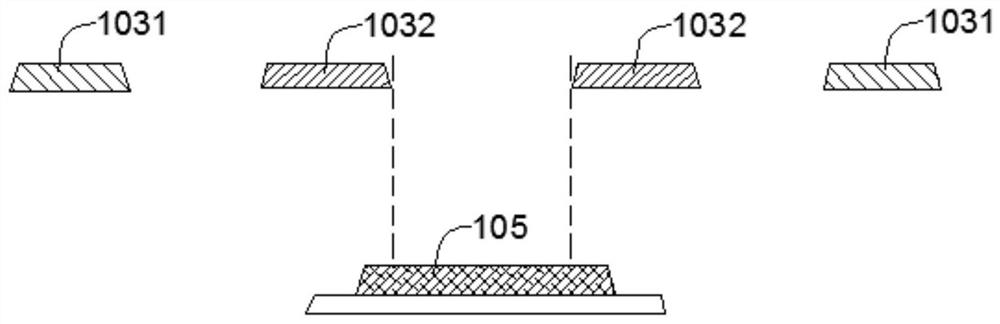

Light-Guide Plate, Method of Manufacturing the Same and Display Apparatus Having the Same

ActiveUS20080278659A1Reduce dark areasImprove lighting efficiencyLight guides detailsPlanar/plate-like light guidesLight guideLight control

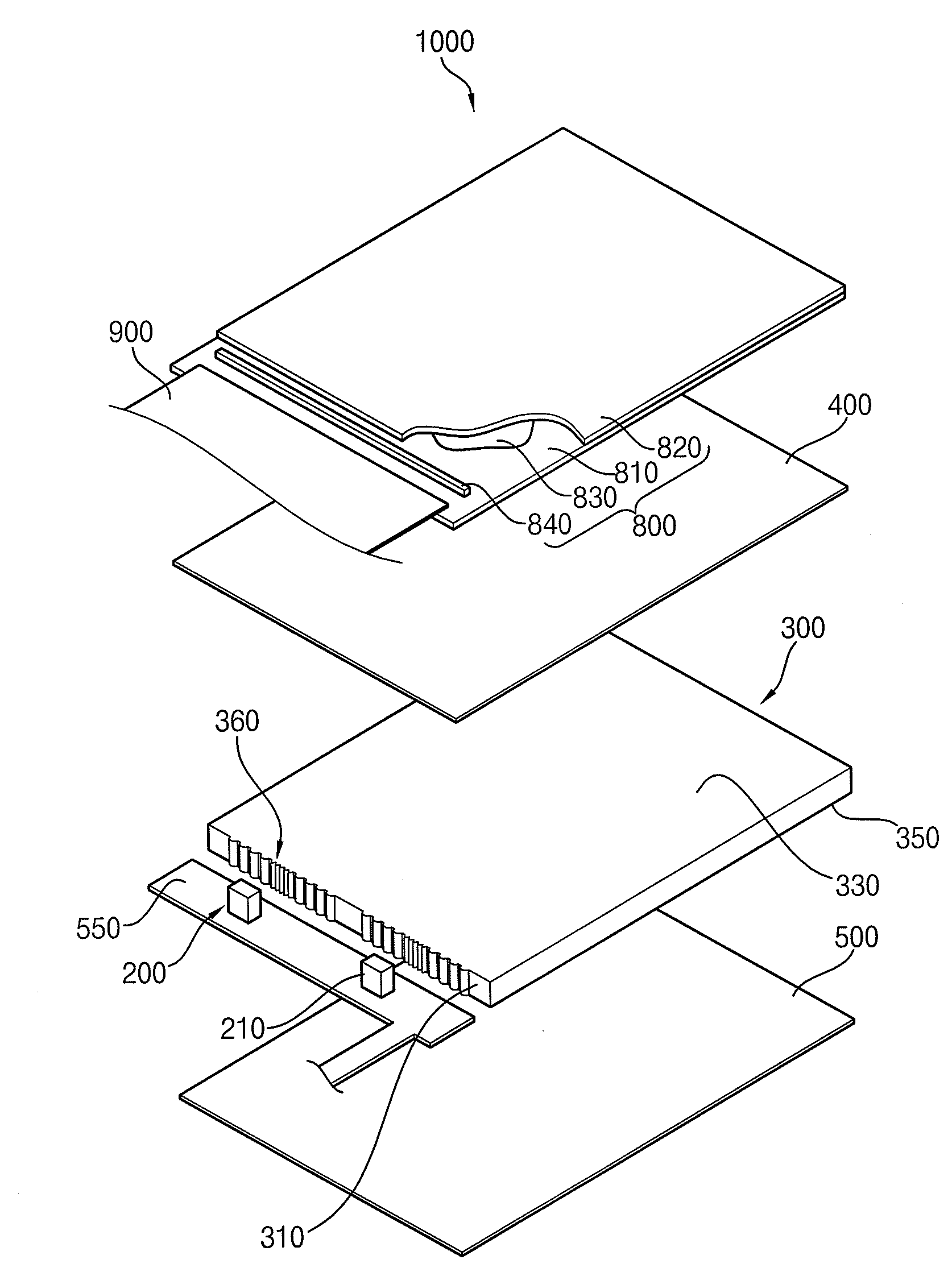

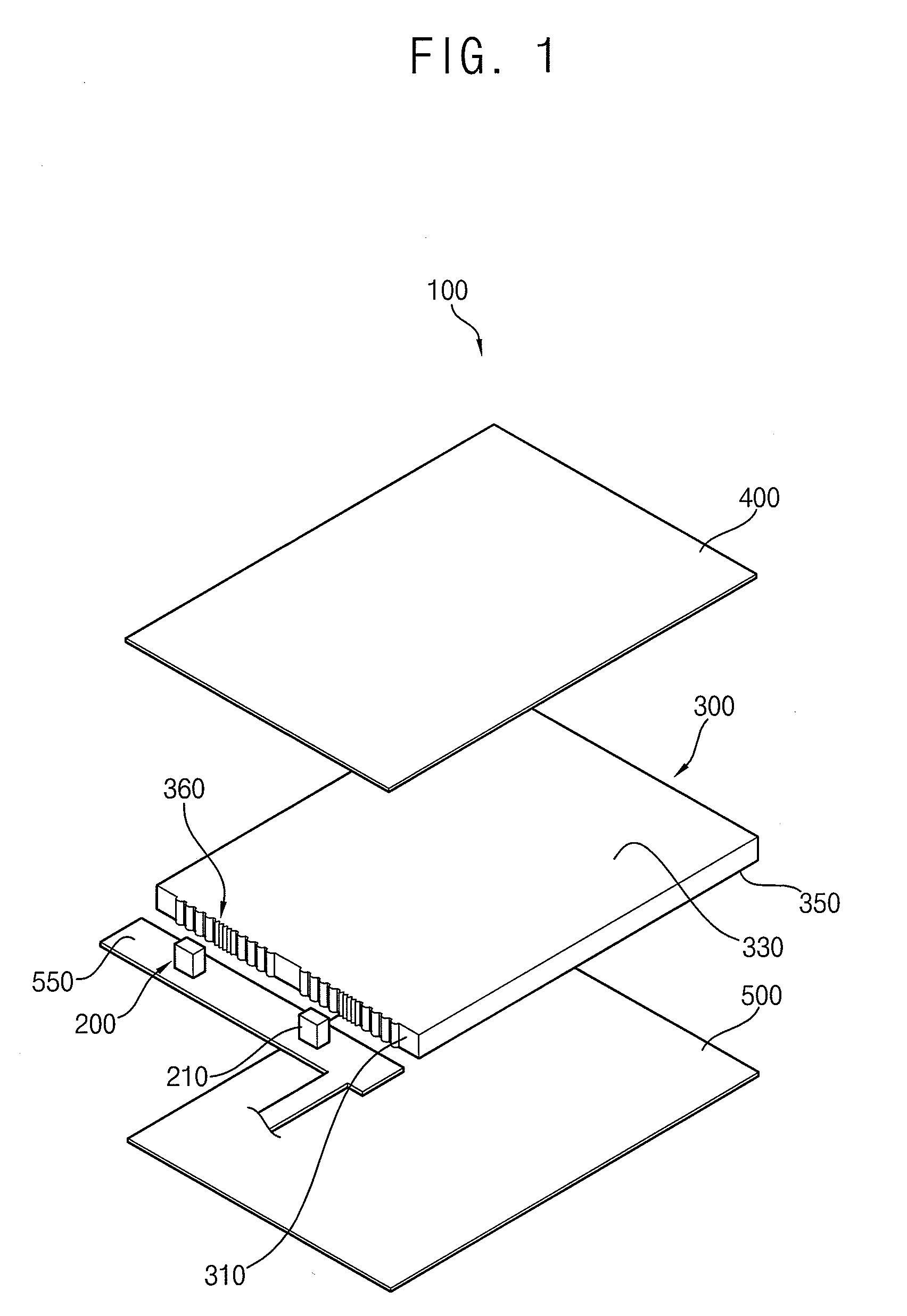

A light-guide plate includes an incident surface, a emissive surface and a reflective surface. The incident surface includes a plurality of light-control patterns formed in sectioned regions of the incident surface. The light-control patterns have shapes different from one another according to the regions corresponding to a position of a light source. The emissive surface is extended from a side of the incident surface. The reflective surface is opposite to the emissive surface.

Owner:SAMSUNG DISPLAY CO LTD

Liquid crystal display using different light radiation angles of light emitting diodes

InactiveUS8007158B2Reduce areaReduce manufacturing costVessels or leading-in conductors manufacturePlanar/plate-like light guidesLiquid-crystal displayLight guide

A liquid crystal display with low manufacturing cost, small dark area and compact exterior is provided by utilizing a plurality of differently radiating light emitting diodes at different angles. The liquid crystal of present invention includes a thin film transistor panel for displaying image, a backlight assembly for providing light to the thin film transistor panel with a plurality of light emitting diodes with different light radiation angles and a light guiding plate, and a frame unit for encompassing the thin film transistor panel and the backlight assembly. The light emitting diodes are placed either at the mid-point of light incident surface or the corner portion of the light guiding plate.

Owner:SAMSUNG DISPLAY CO LTD

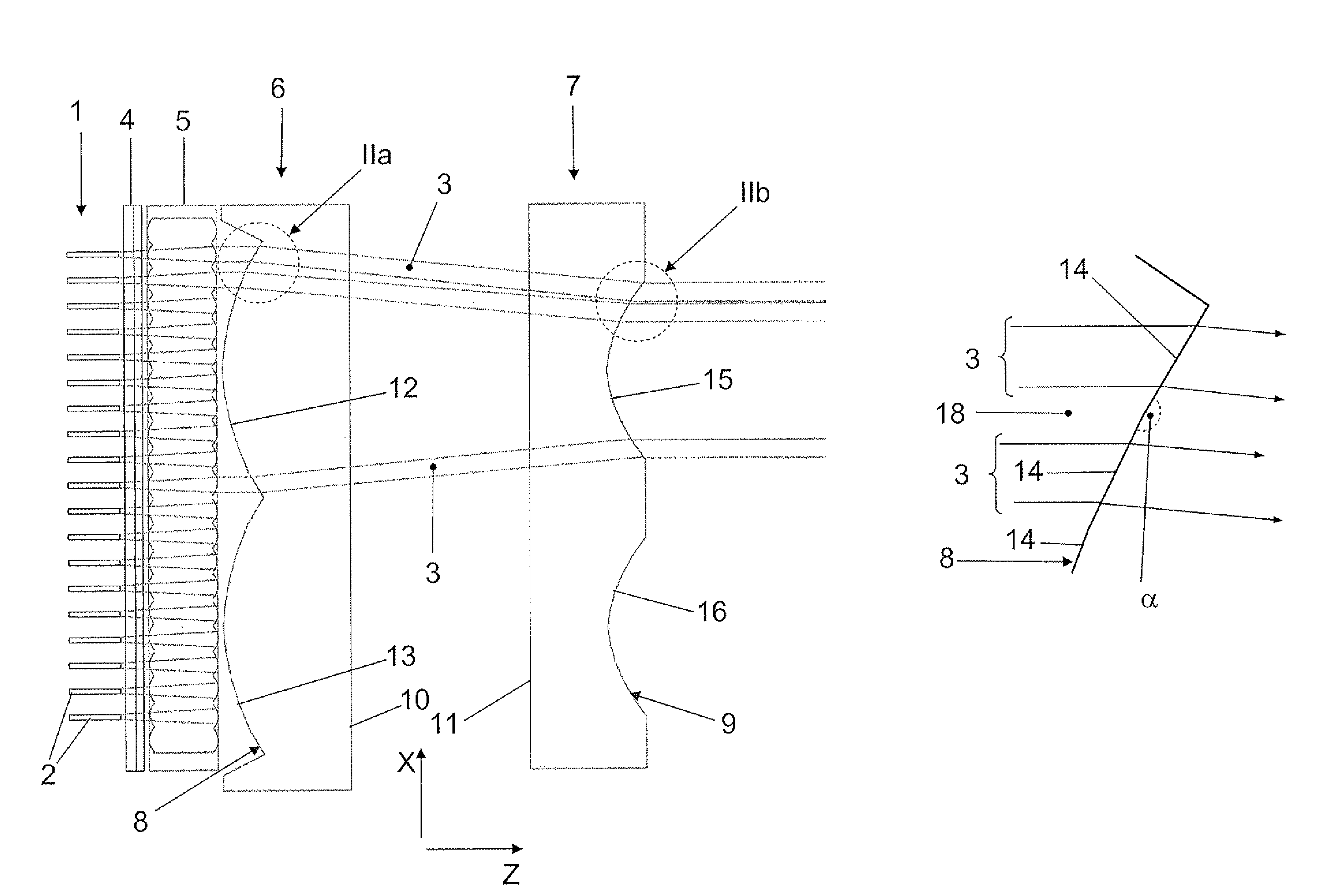

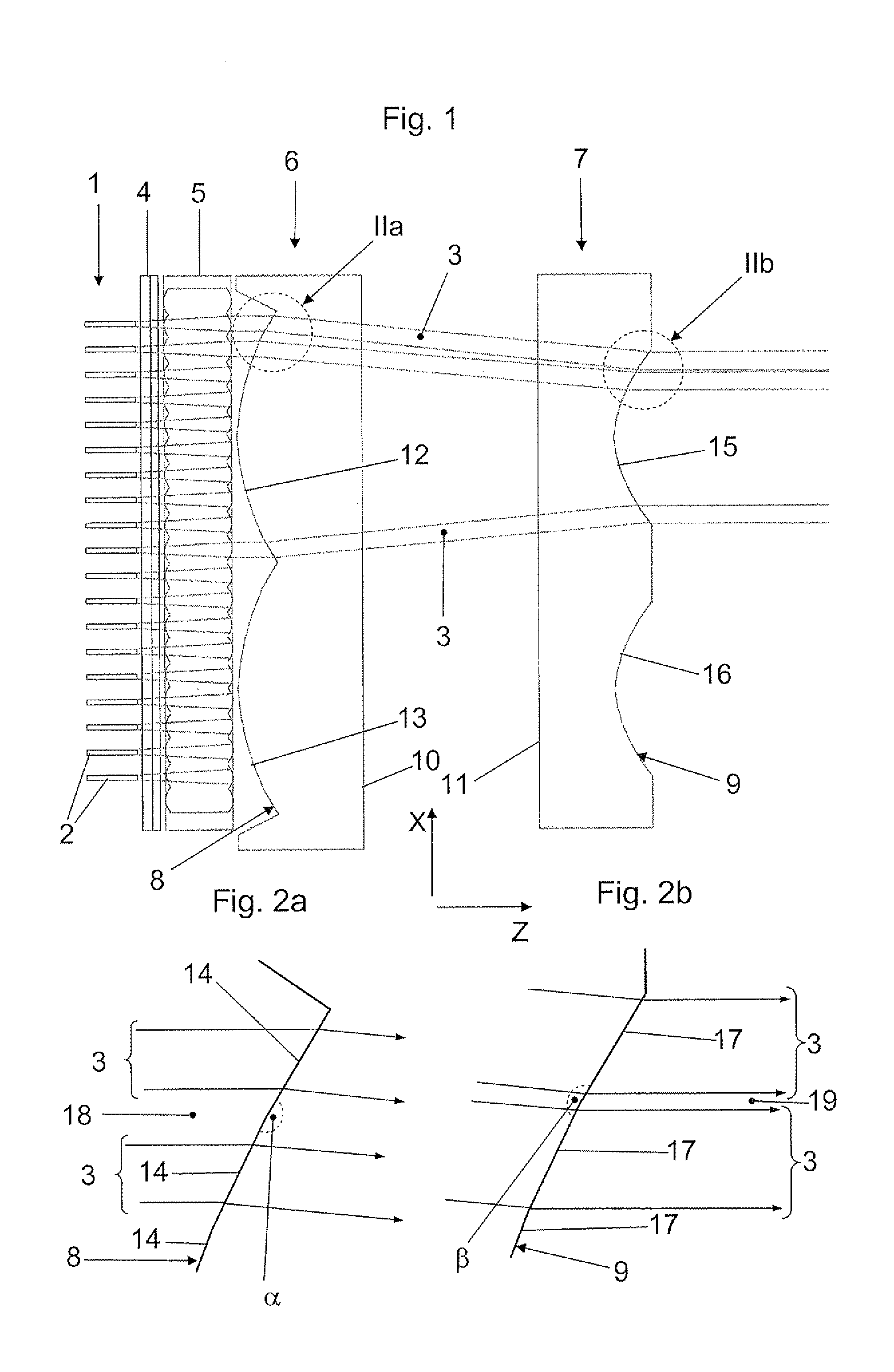

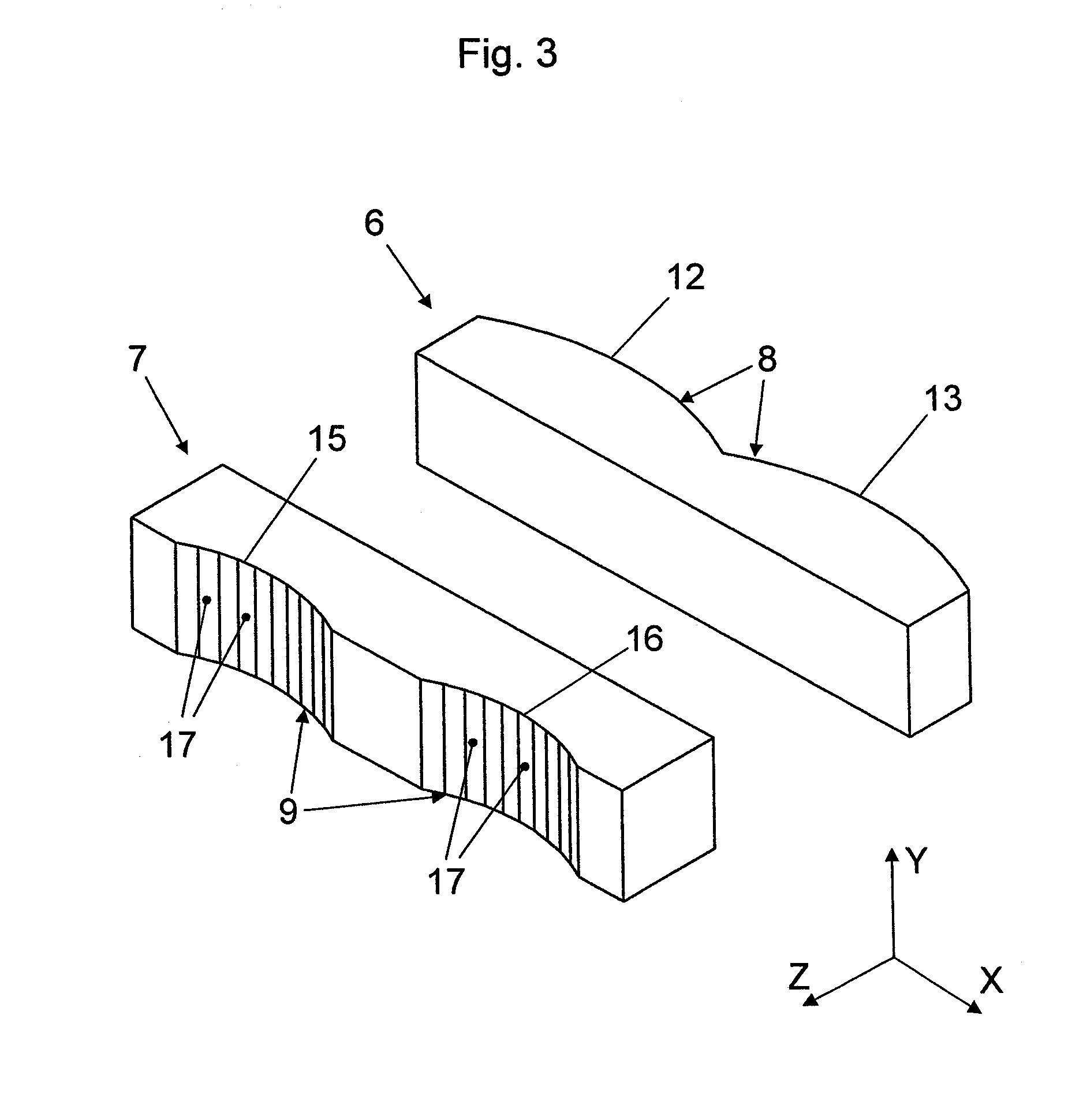

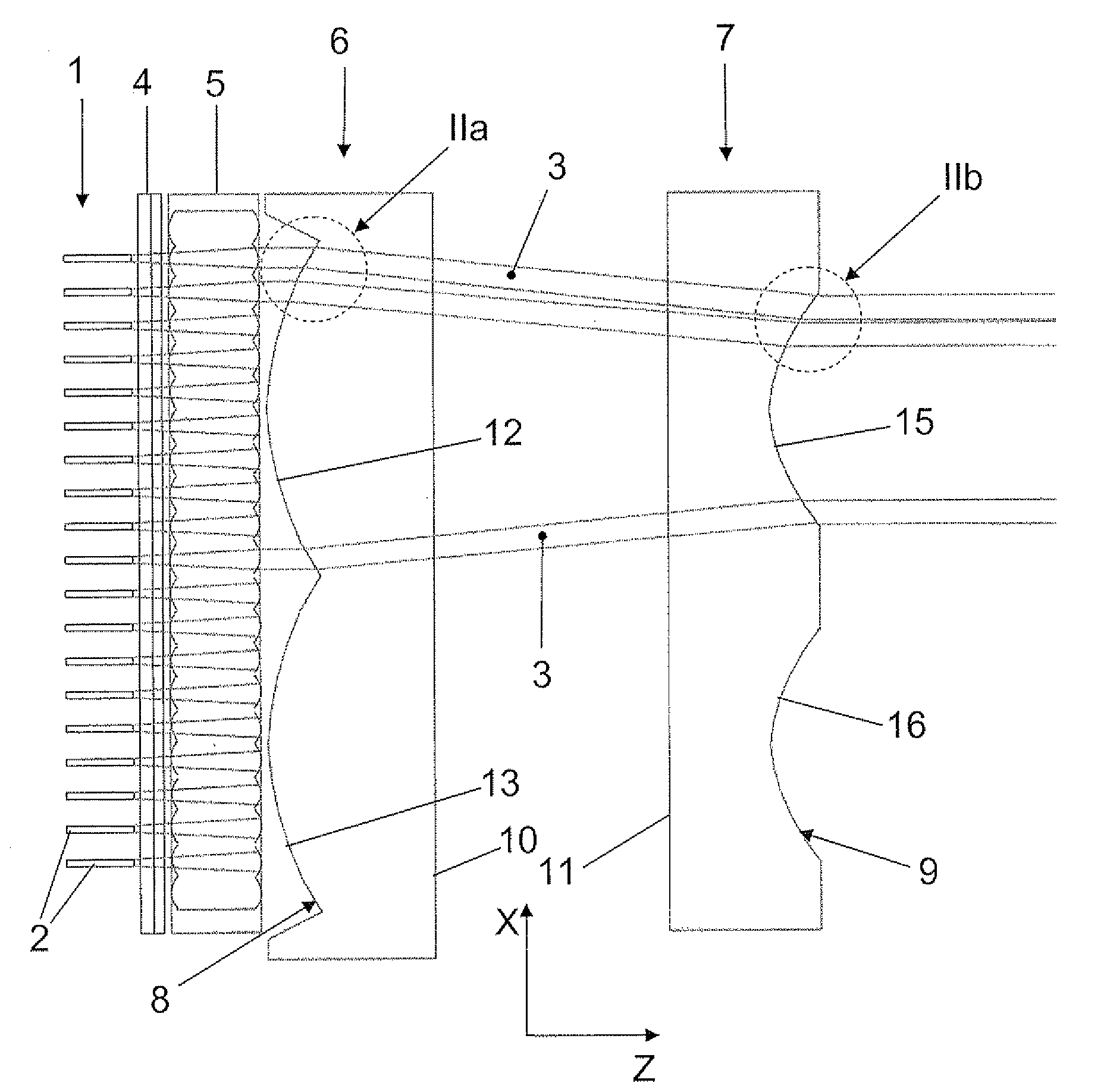

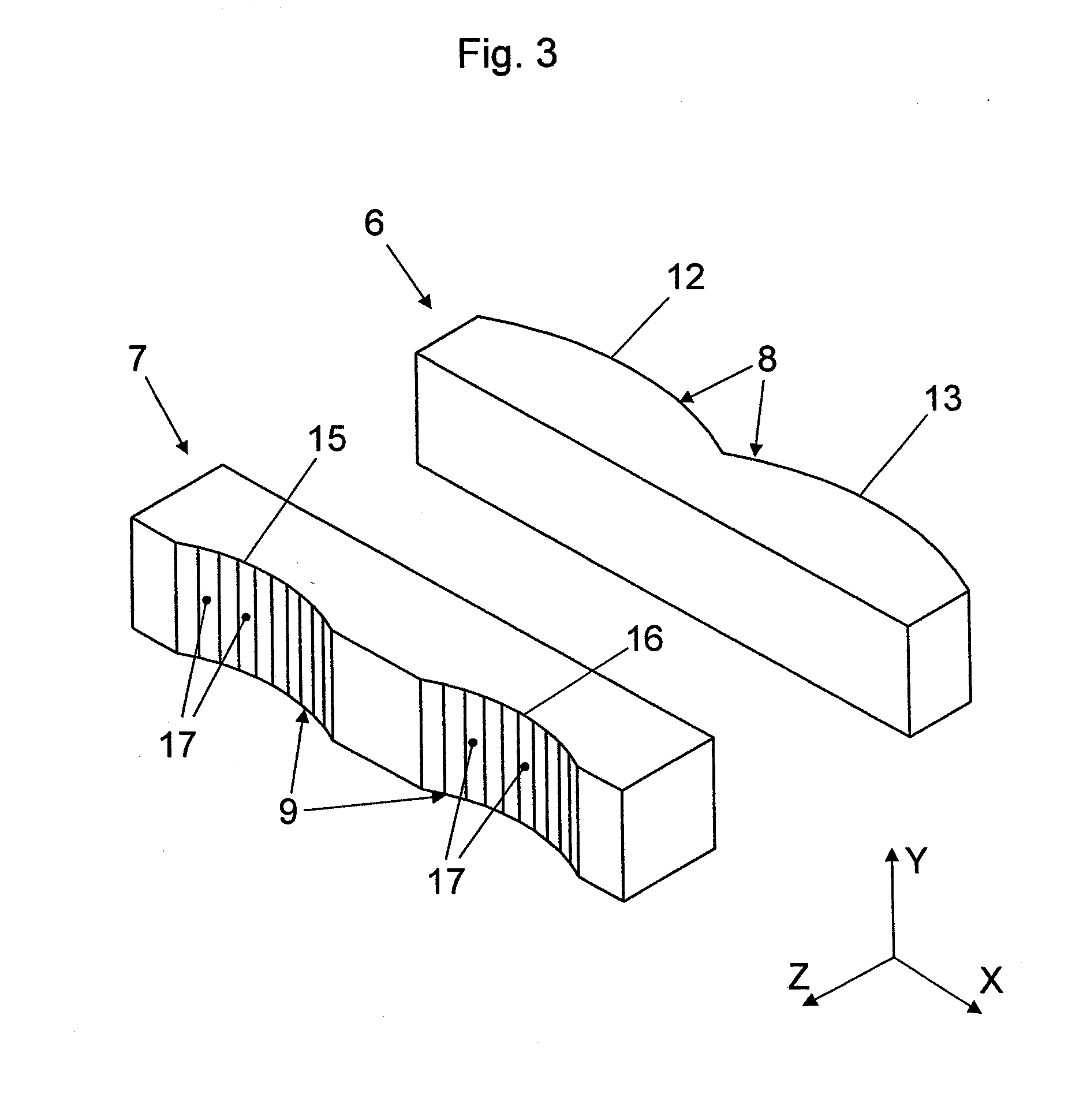

Device for shaping laser radiation

InactiveUS7986461B2Increase brightnessFocusRadiation/particle handlingElectrode and associated part arrangementsLight beamOptoelectronics

Device for shaping laser radiation which has sub-beams (3) spaced apart in a first direction (X) perpendicular to the propagation direction (Z) of the laser radiation, in particular for shaping laser radiation which is output by a laser diode bar (1), comprising a first refractive interface (8) which can differently deviate at least a multiplicity of the sub-beams (3) of the laser radiation to be shaped, so that they travel at least partially converging together after passing through the first interface (8) more than before passing through the first interface (8), and furthermore comprising a second refractive interface (9) through which the laser radiation can pass after having passed through the first interface (8), the second interface (9) being able to deviate at least some of the sub-beams (3) so that their convergence is reduced.

Owner:LIMO GMBH

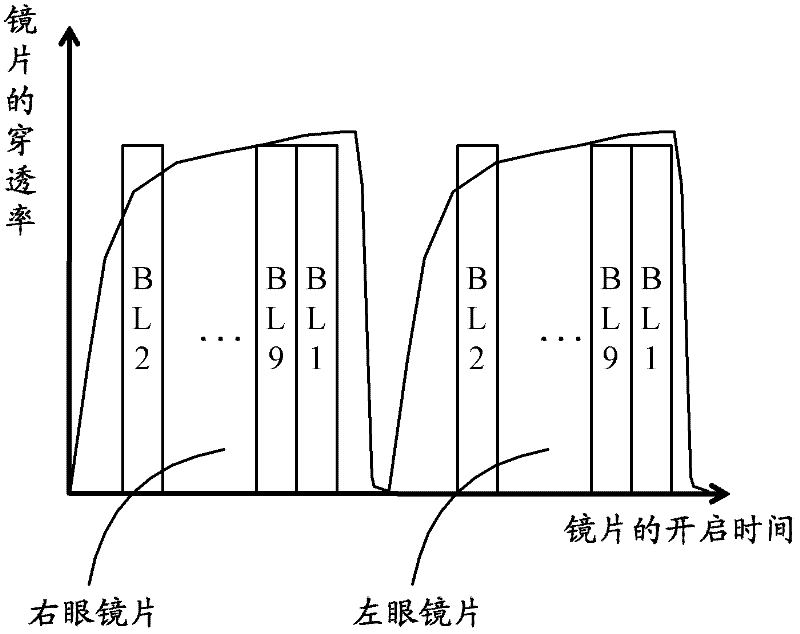

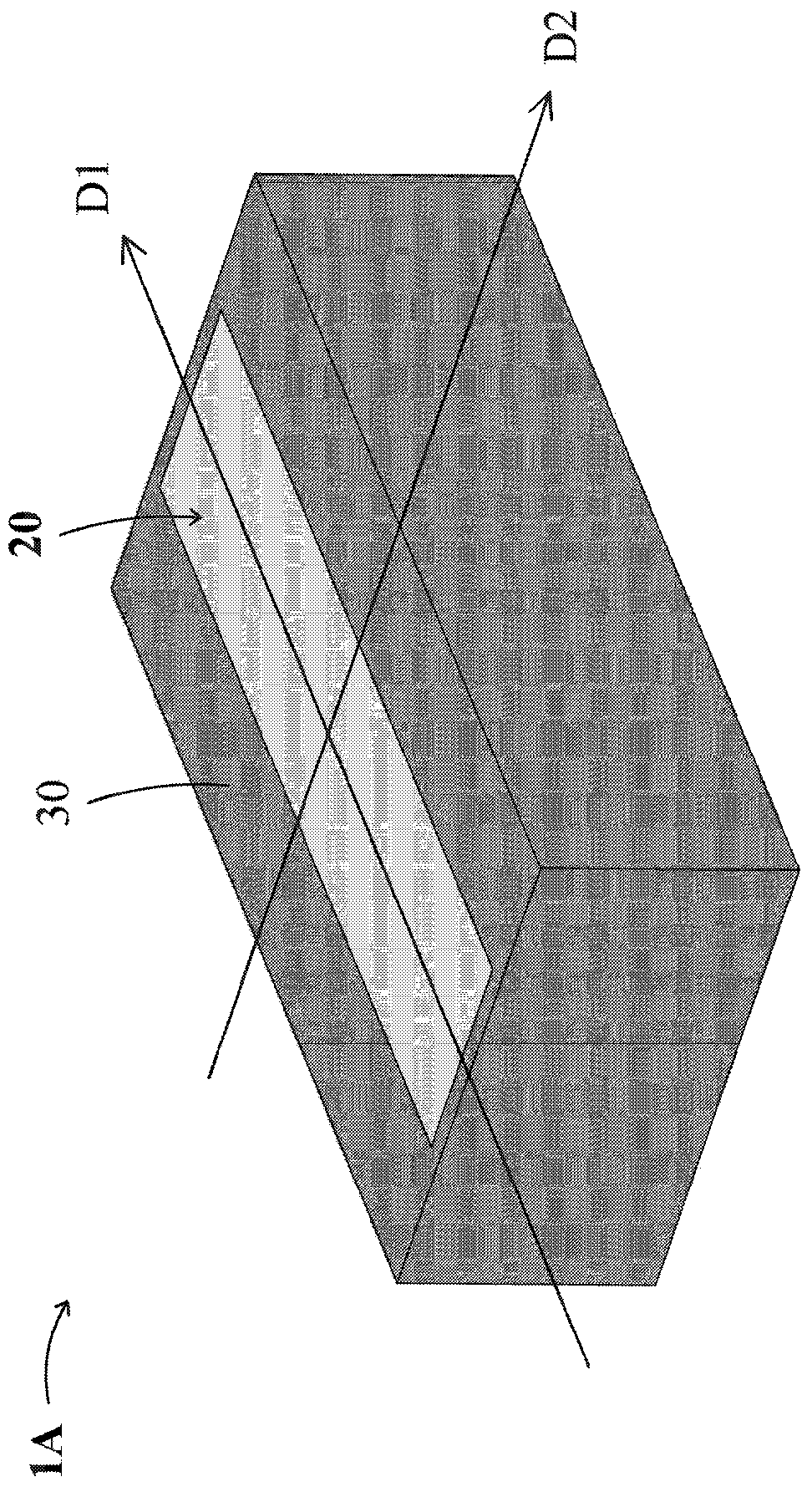

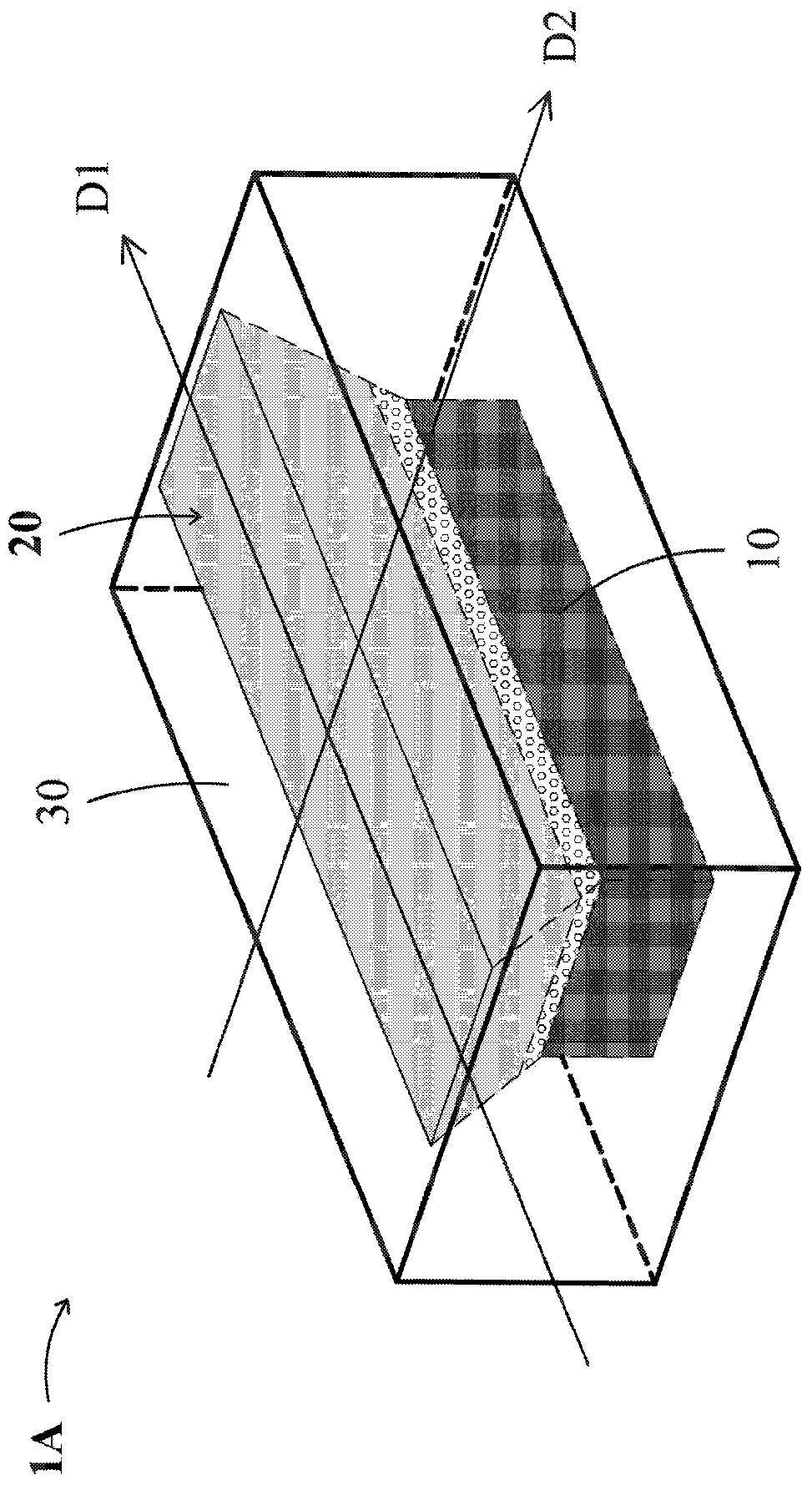

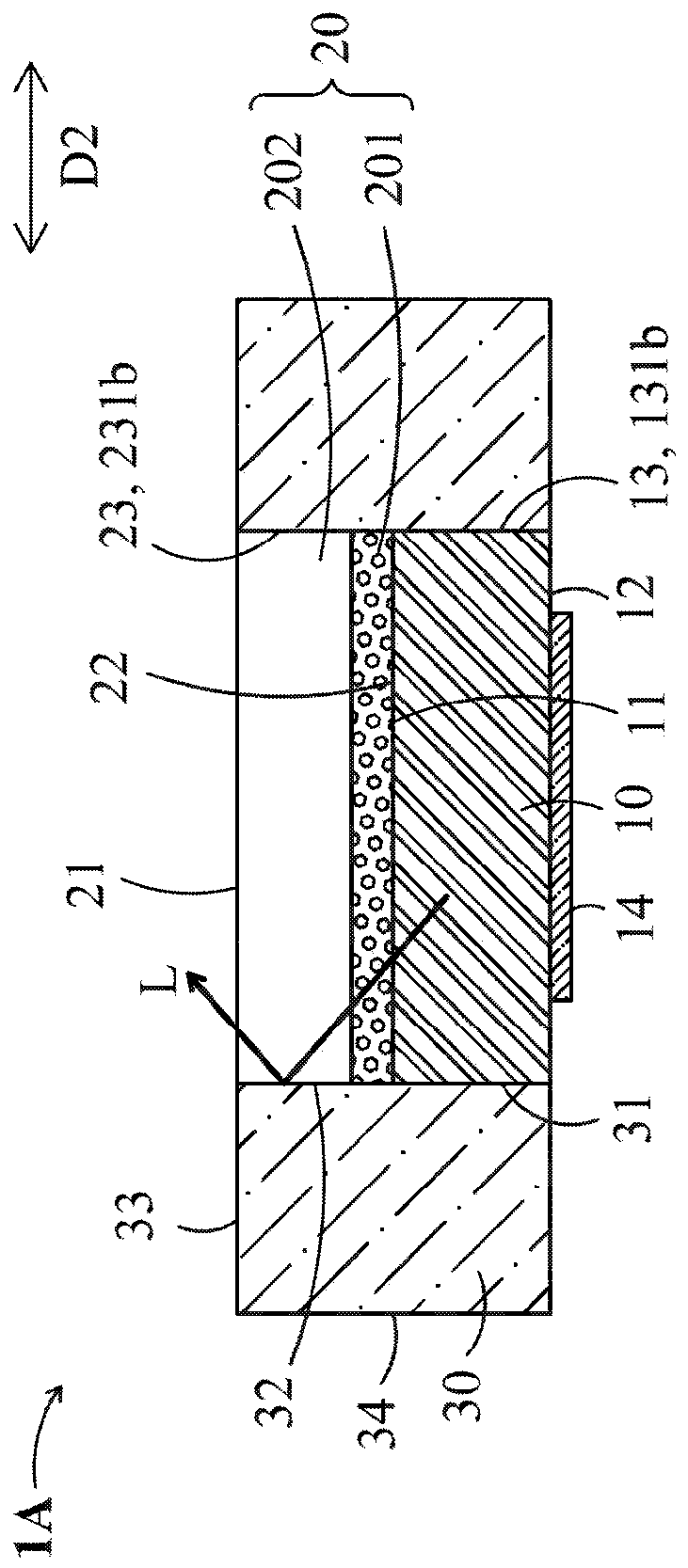

Stereo display system and driving method thereof

ActiveCN102510510AImprove display qualityImprove experienceSteroscopic systemsOptical elementsComputer scienceStereo display

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

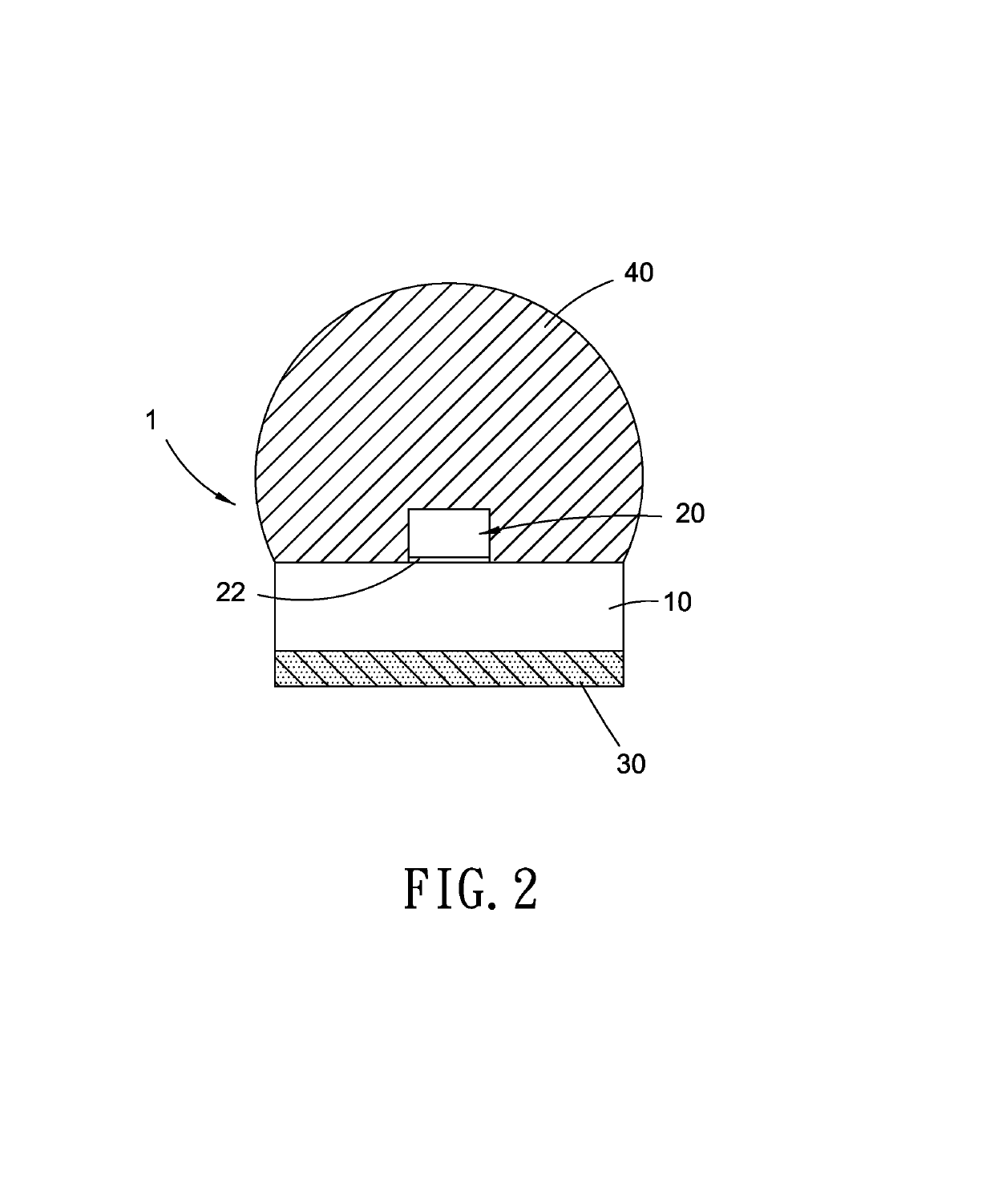

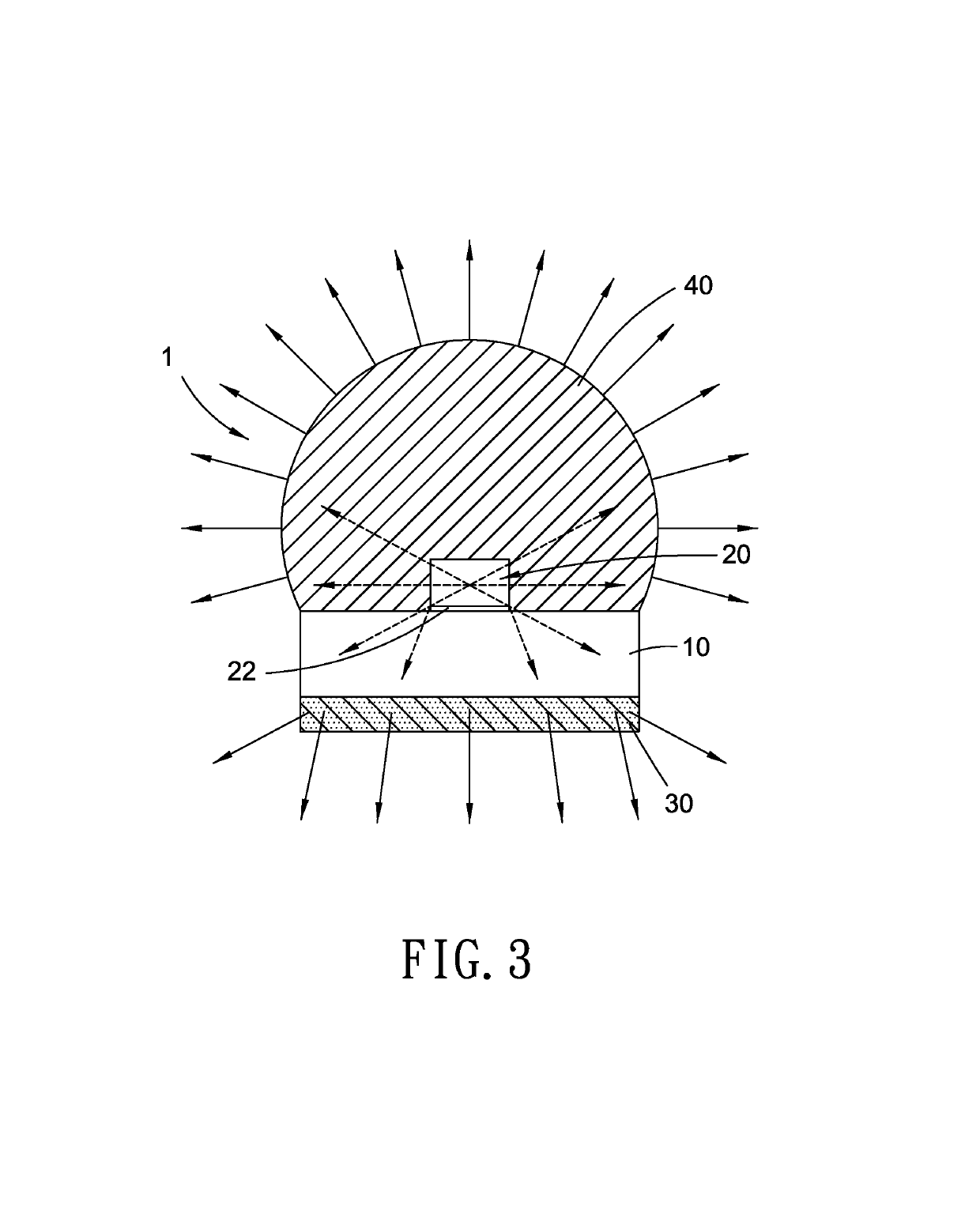

Light emitting device having asymmetric light shape and manufacturing method thereof

ActiveCN107039572AIncrease the separation distanceReduce usageSemiconductor devicesFluorescenceLight emitting device

The invention provides a monochromatic light chip scale packaging light emitting device having asymmetric light shape. The device comprises a flip-chip LED chip and a reflecting structure and can also comprise a florescent structure so as to form a white light chip scale packaging light emitting device having the asymmetric light shape. The florescent structure comprises a florescent layer and a light transmitting layer, and the bottom surface at least covers the upper surface of the LED chip. The reflecting structure at least partially shields the vertical surface of the LED chip and the side surface of the florescent structure. The invention also provides a manufacturing method of the light emitting device. Therefore, the light emitting angle of the chip scale packaging light emitting device can be effectively limited in a specific direction so as to provide the asymmetric light shape, and thus the application requirements of asymmetric lighting or light source can be met without using additional optical lens and the application advantage of small size can also be maintained.

Owner:MAVEN OPTRONICS CO LTD

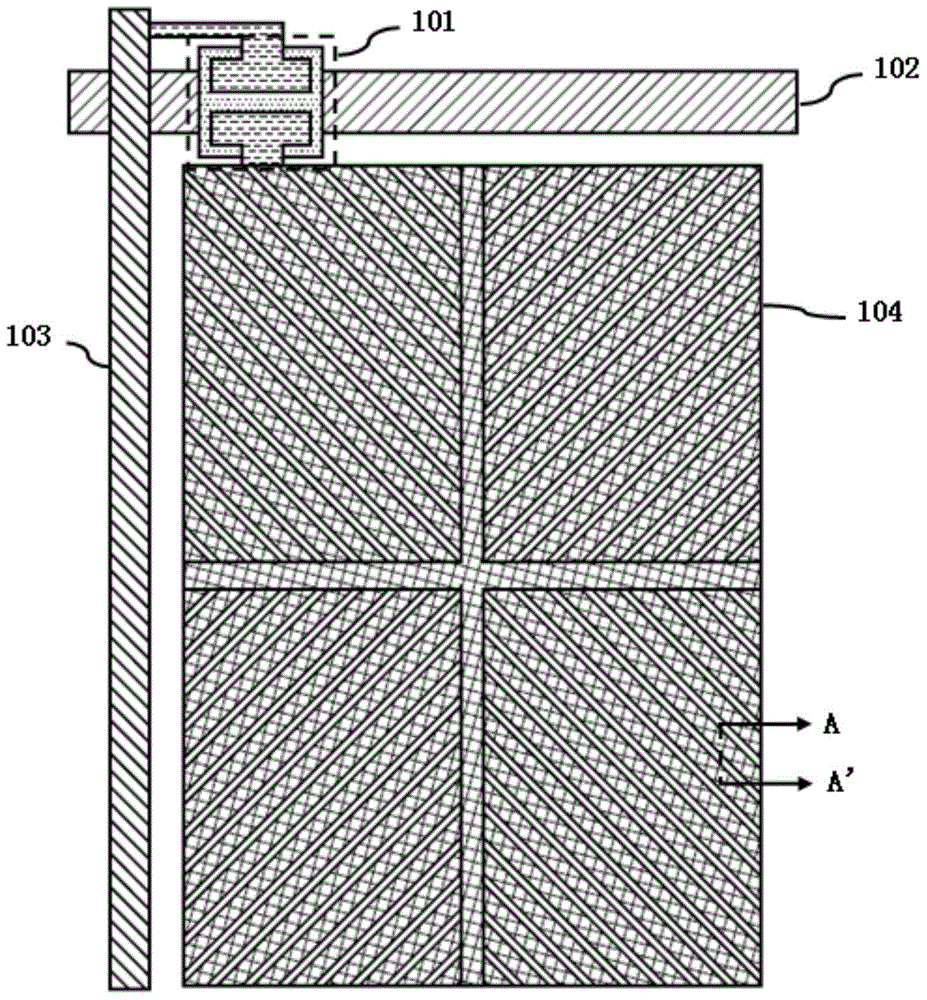

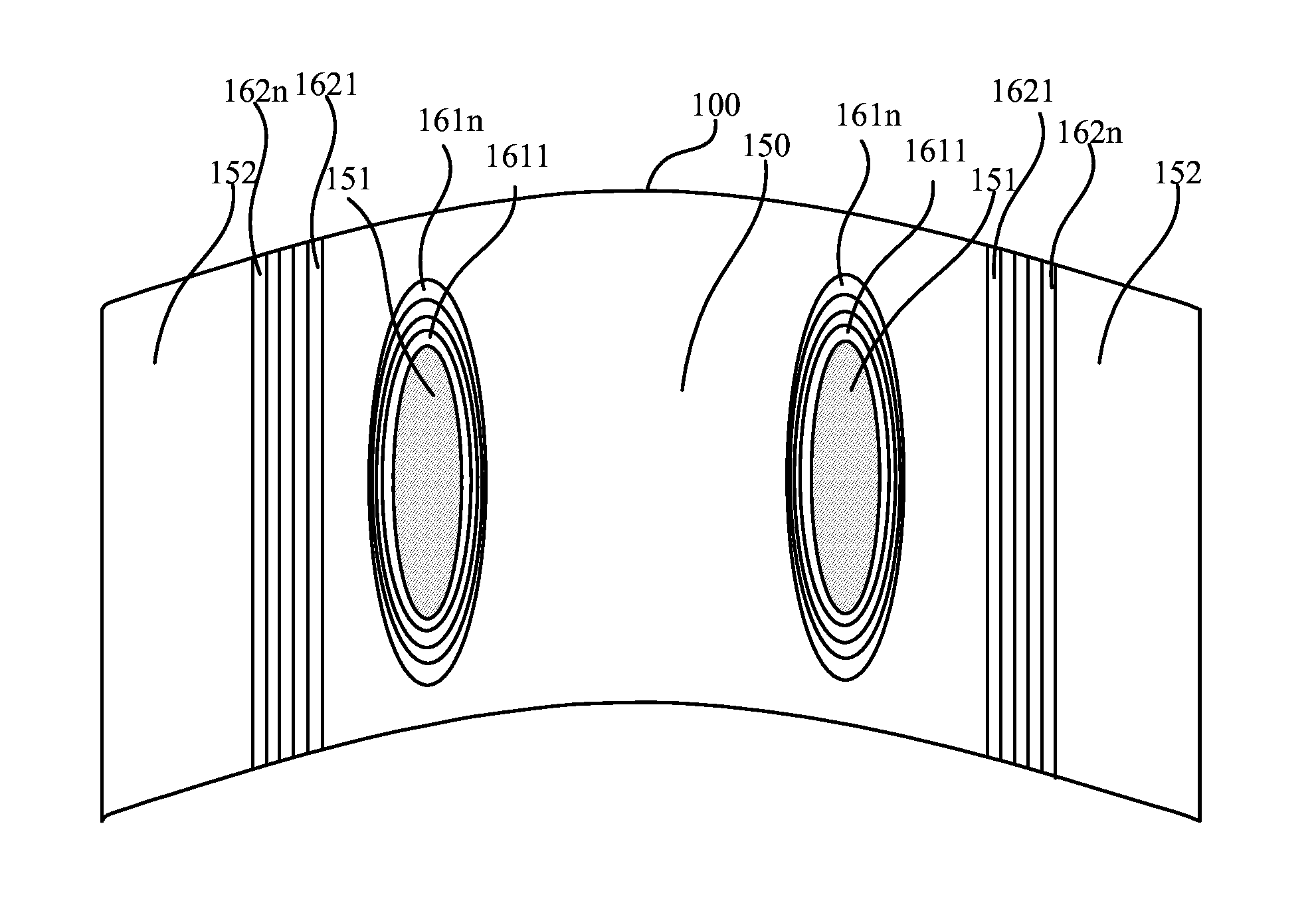

Liquid crystal display panel for curved screen

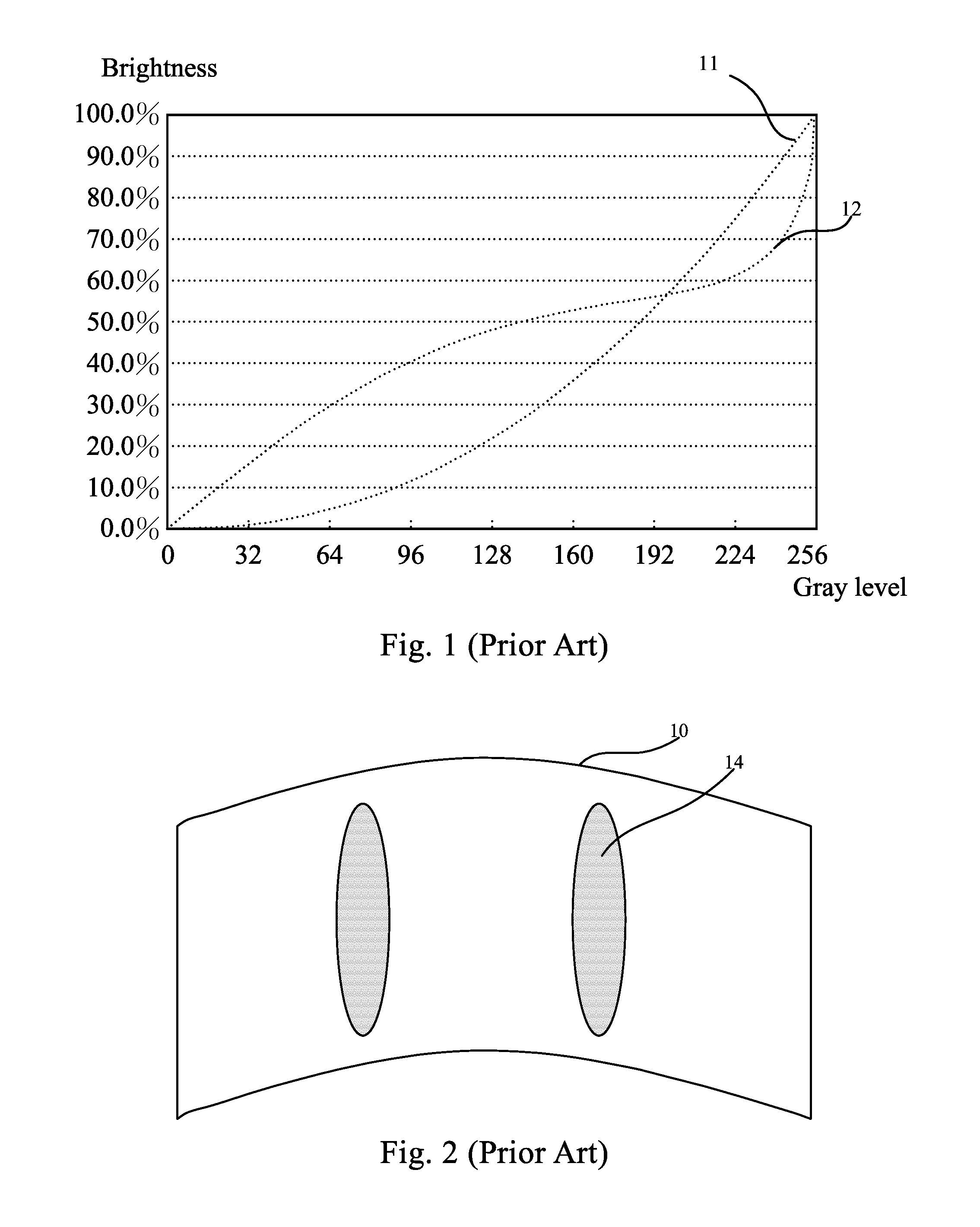

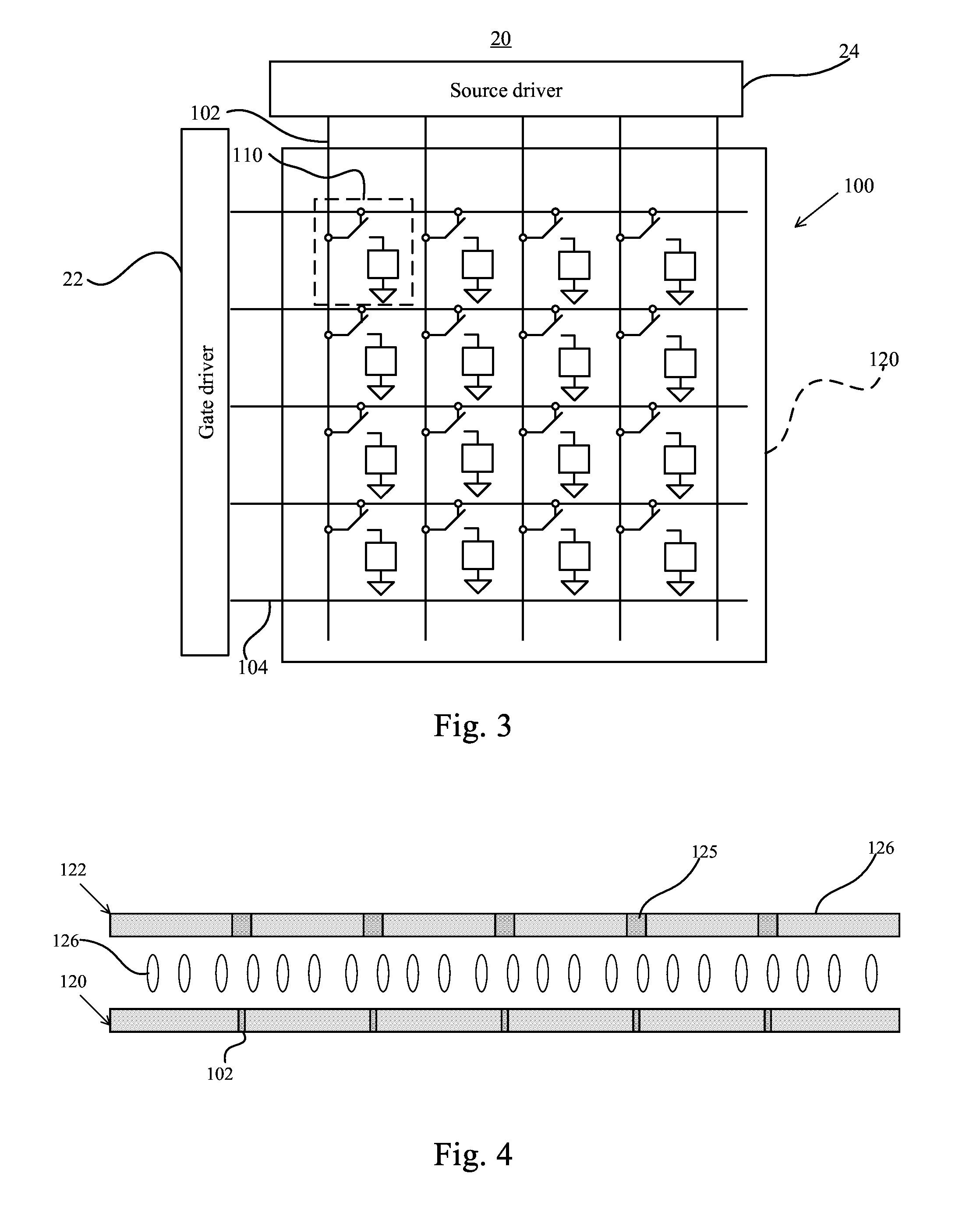

ActiveUS20160116811A1Reduce dark areasImprove uneven brightnessNon-linear opticsCapacitanceLiquid-crystal display

An LCD panel applied to a curved screen includes display sections, each of which includes pixel units. Each pixel unit includes a primary sub-pixel, a secondary sub-pixel, a common electrode, and a sharing capacitance sheet. An area of the sharing capacitance of each display section is adjusted using a sharing capacitance sheet. So a ratio of the charging voltage on the secondary sub-pixel to the charging voltage on the primary sub-pixel in the central display section is between the ratio of the charging voltage on the secondary sub-pixel to the charging voltage on the primary sub-pixel in the first display section and the ratio of the charging voltage on the secondary sub-pixel to the charging voltage on the primary sub-pixel in the second display section. Therefore, the brightness of the curved screen on display is improved. The quality of the curved screen on image display is improved as well.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Display apparatus and backlight assembly having a light guide plate comprising first and second light control patterns

ActiveUS7884896B2Reduce dark areasImprove lighting efficiencyLight guides detailsPlanar/plate-like light guidesLight guideOptoelectronics

A light-guide plate includes an incident surface, a emissive surface and a reflective surface. The incident surface includes a plurality of light-control patterns formed in sectioned regions of the incident surface. The light-control patterns have shapes different from one another according to the regions corresponding to a position of a light source. The emissive surface is extended from a side of the incident surface. The reflective surface is opposite to the emissive surface.

Owner:SAMSUNG DISPLAY CO LTD

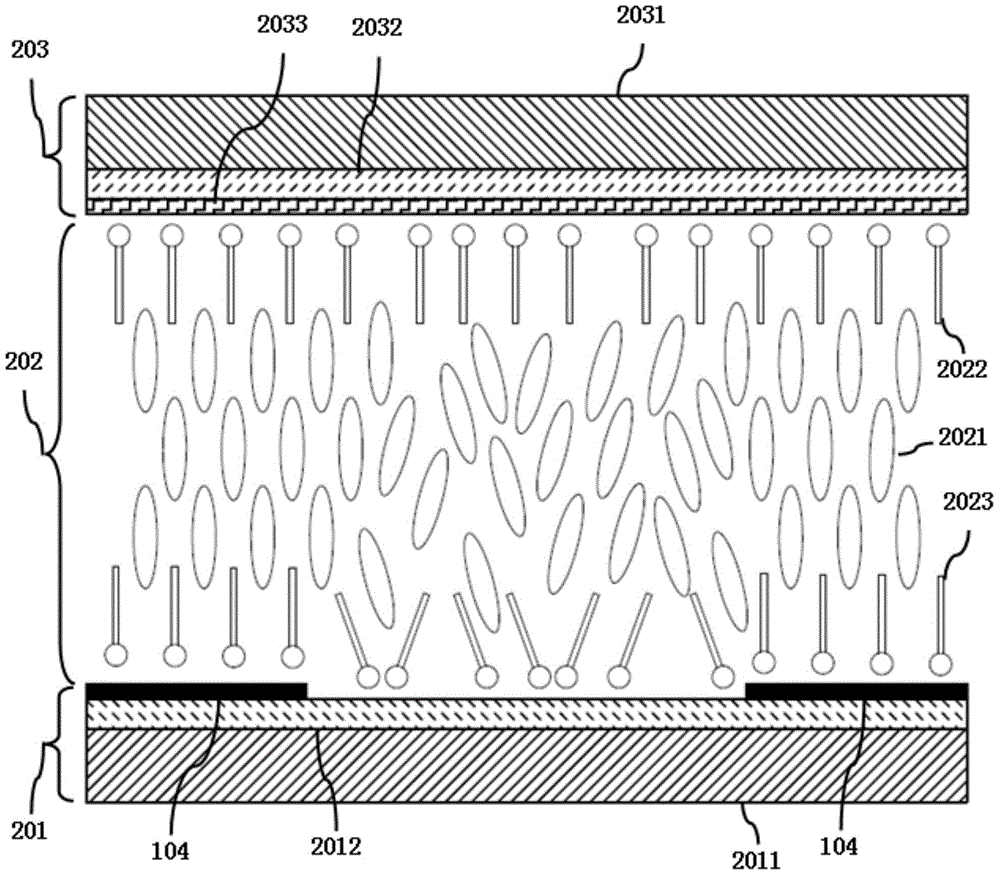

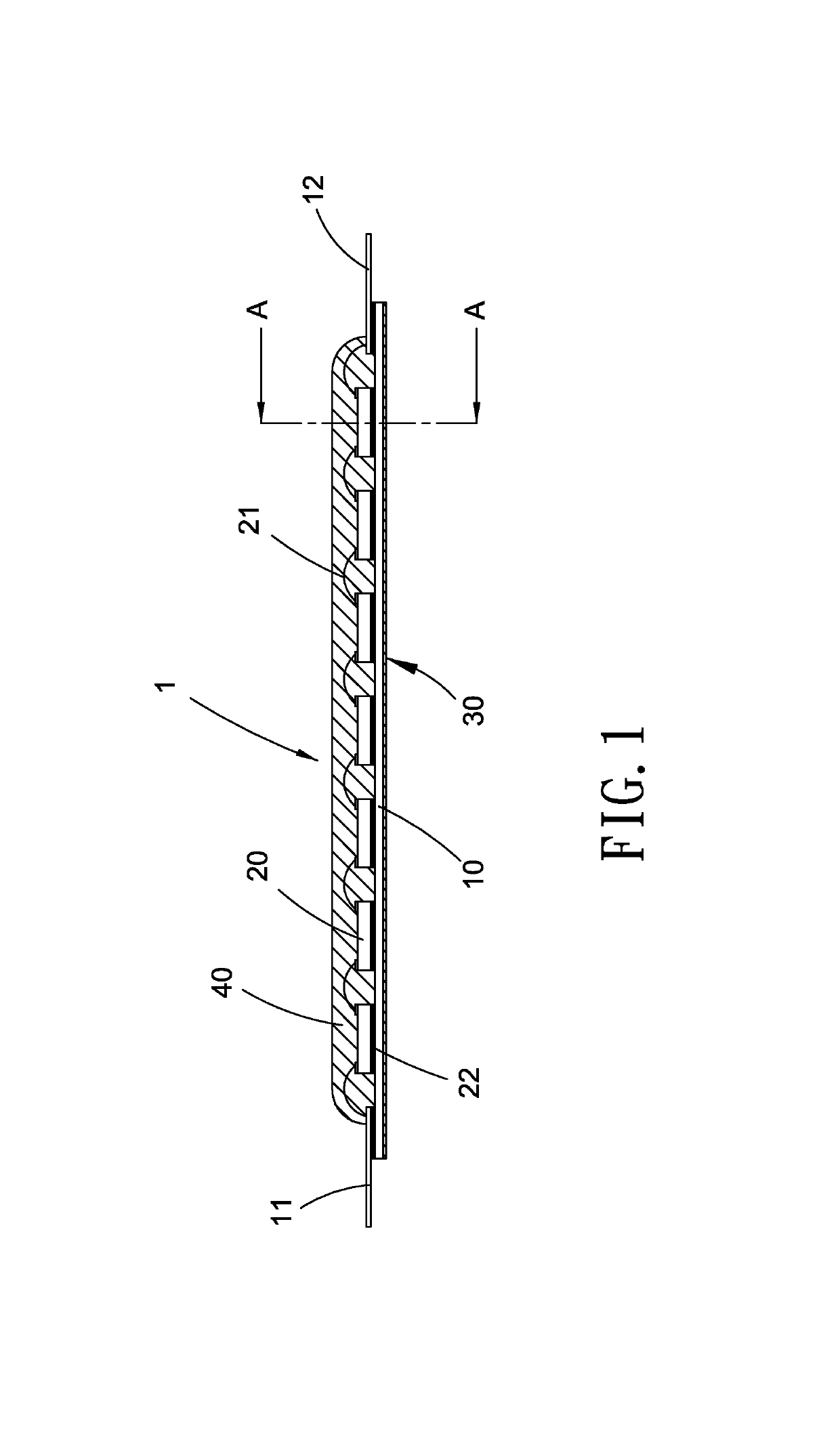

Display panel and display device

InactiveCN104460168AEliminate differences in adhesionReduce dark areasNon-linear opticsTransistor arrayColor gel

The invention discloses a display panel and a display device. The display panel comprises a color filter substrate, a liquid crystal layer and a thin film transistor array substrate. The color filter substrate is provided with a first protection layer and a common electrode layer, the thin film transistor array substrate is provided with a second protection layer and a pixel electrode, and the common electrode layer and the pixel electrode are oppositely arranged; the liquid crystal layer comprises liquid crystal molecules, first auxiliary orientation agent molecules and second auxiliary orientation agent molecules, the color filter substrate and the thin film transistor array substrate are aligned and combined into a whole, and the liquid crystal layer is arranged between the color filter substrate and the thin film transistor array substrate. The display panel and the display device can eliminate differences of adhesive force of the second auxiliary orientation agent molecules on different portions of a pixel region, and therefore the occurrence frequency of dark spaces is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Array substrate and display device

Owner:BOE TECH GRP CO LTD +1

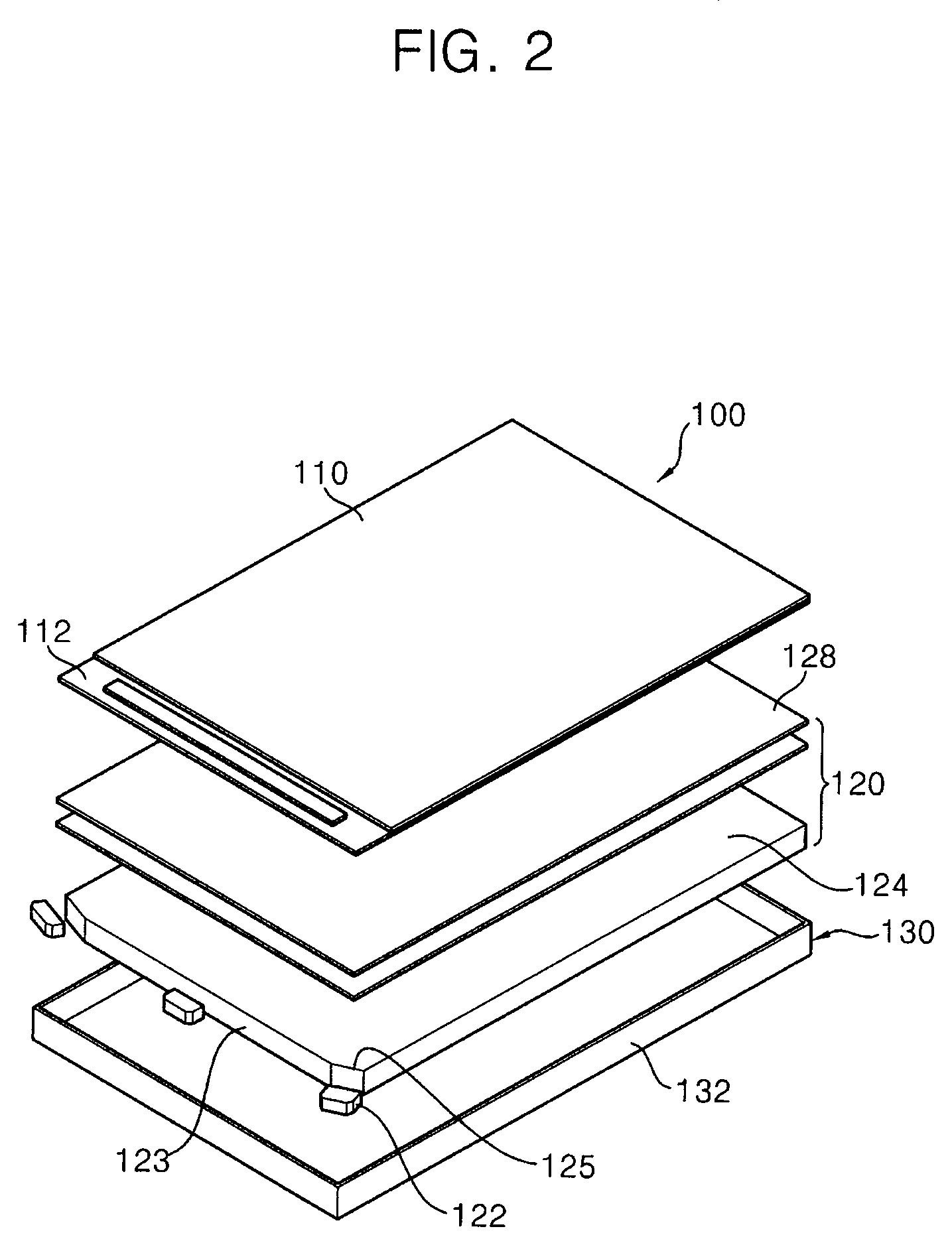

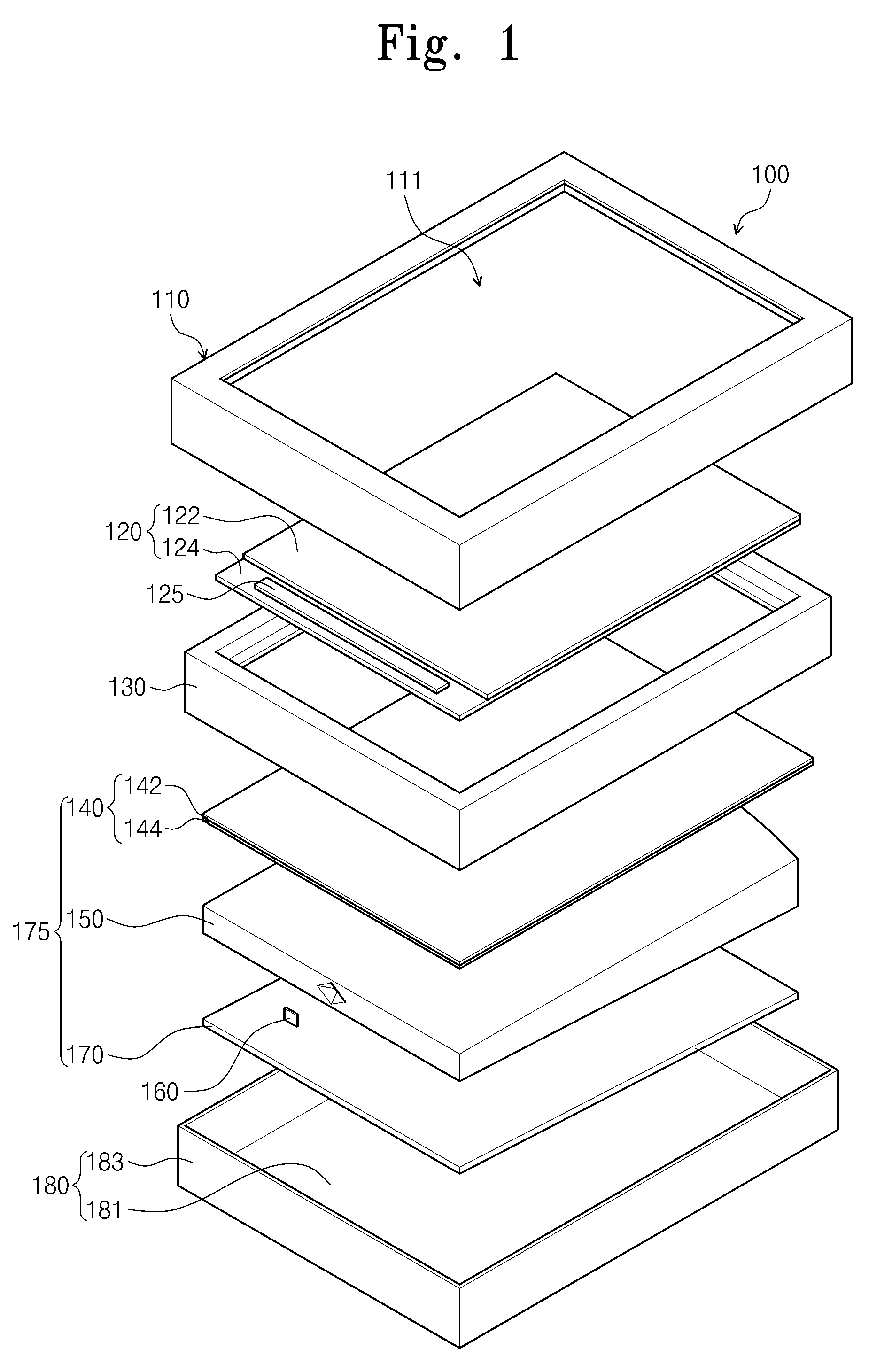

Display apparatus

ActiveUS20120294034A1Reduce light areaImprove display qualityMechanical apparatusPlanar/plate-like light guidesLight guideOptoelectronics

A display apparatus includes a light source and a light guide plate including a light incident surface facing the light source and which receive the light, an opposite surface opposite to the light incident surface and which reflects the light and has an arc shape, connection surfaces at opposing sides of the light incident surface and which connect the light incident surface and the opposite surface, an upper surface connected to the light incident surface, the opposite surface and the connection surfaces and which outputs the light, and a lower surface opposite to the upper surface. The light incident surface of the light guide plate includes a first surface extending in a predetermined direction, and second surfaces inclined from the first surface in an area corresponding to the light source such that an optical recess having a polygonal pyramid shape is defined by the second surfaces.

Owner:SAMSUNG DISPLAY CO LTD

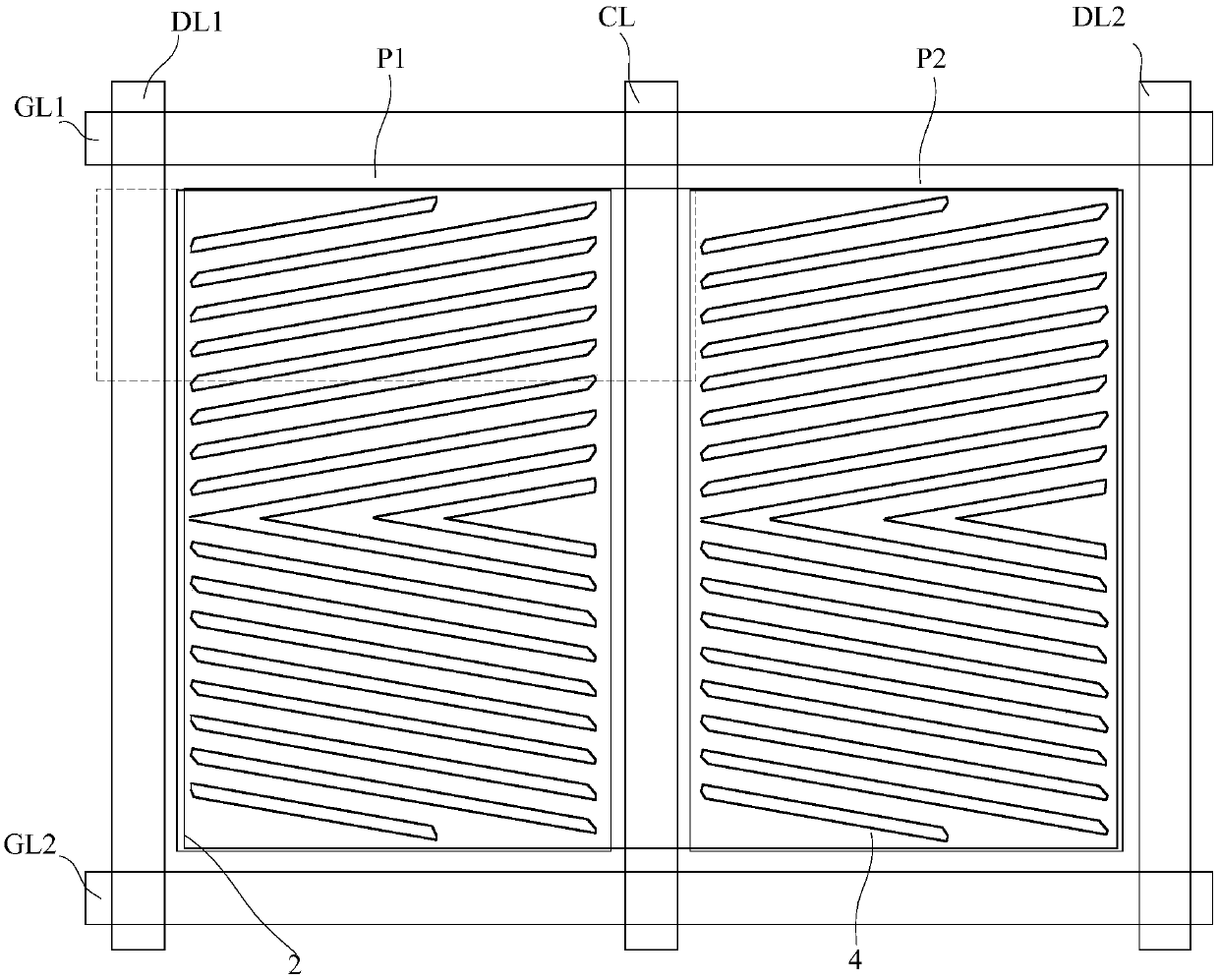

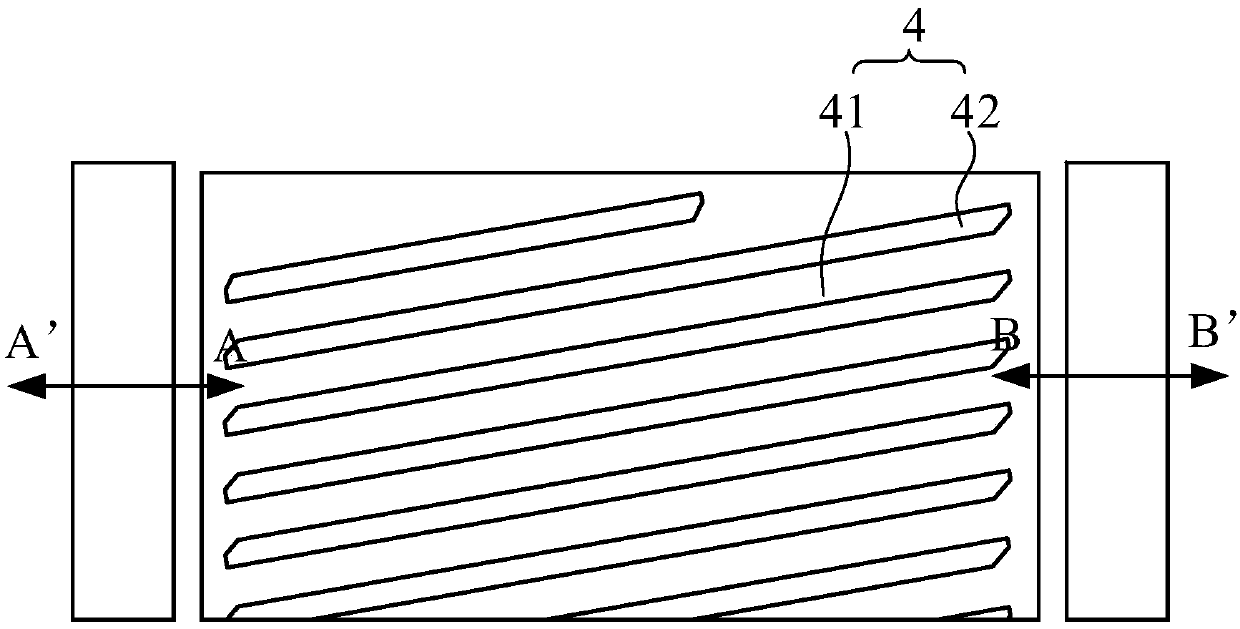

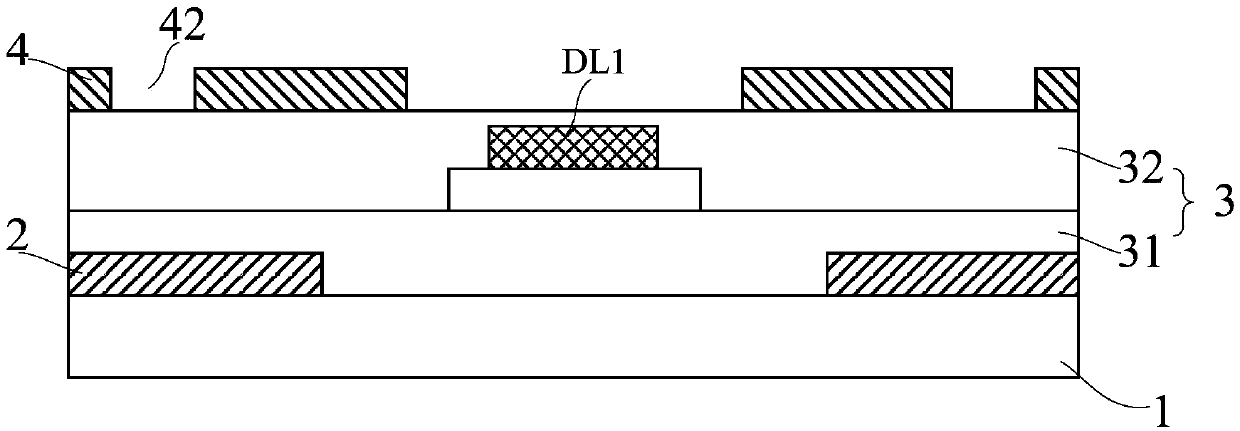

Array substrate, display panel and display device

PendingCN111103734AReduce dark areasHigh light transmittanceNon-linear opticsDisplay deviceMaterials science

The invention provides an array substrate, a display panel and a display device. The array substrate comprises a substrate, a first data line and a common electrode line arranged on the substrate; anda first grid line and a second grid line arranged on the substrate, and the first grid line and the second grid line intersect with the first data line and the common electrode line to define a firstsub-pixel. The first sub-pixel comprises a pixel electrode arranged on a substrate base plate; a common electrode disposed on the pixel electrode; and an insulating layer disposed between the pixel electrode and the common electrode. The common electrode comprises a plurality of slits, and the extending direction of the slits is the same as that of the first data lines.

Owner:BOE TECH GRP CO LTD +1

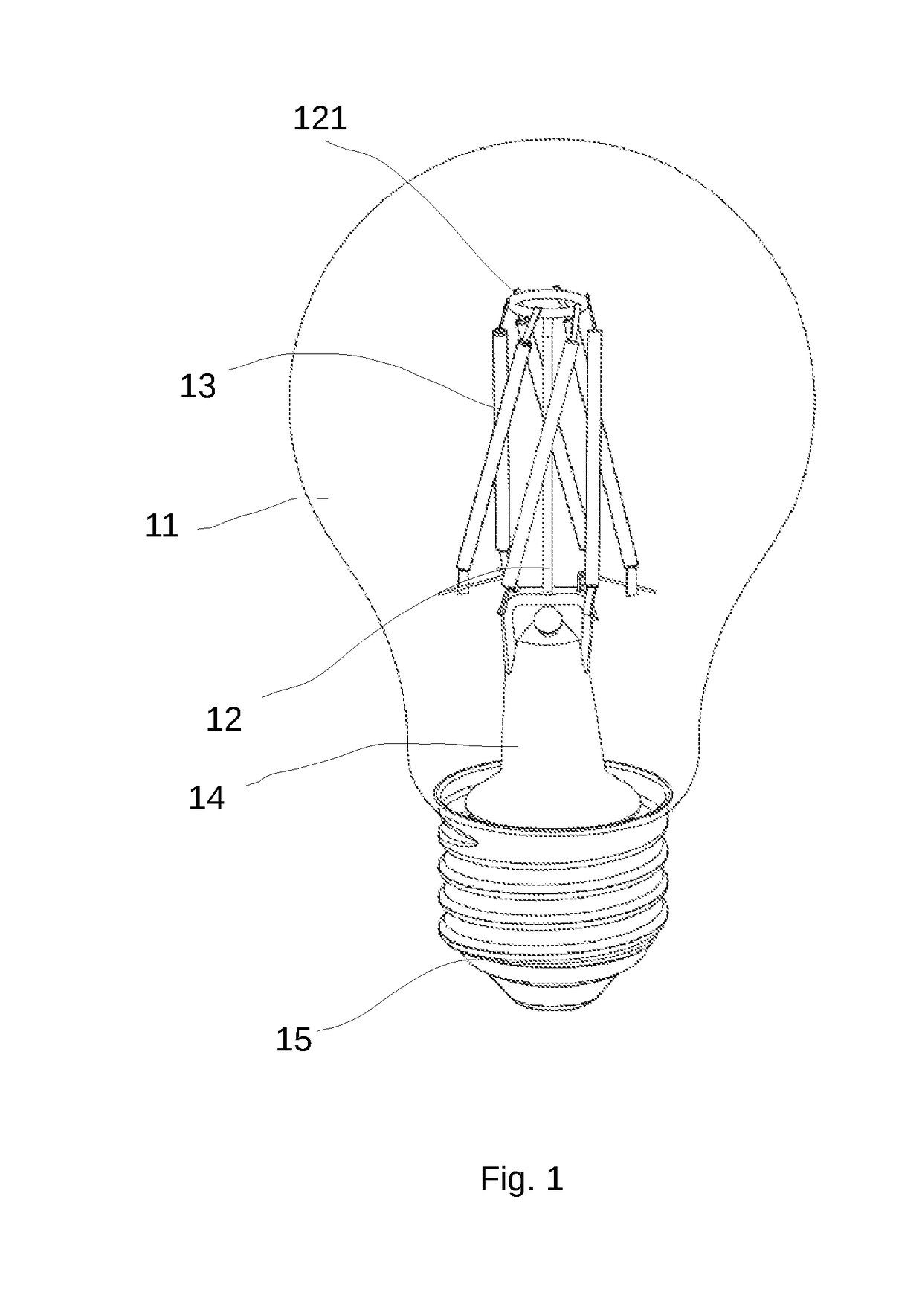

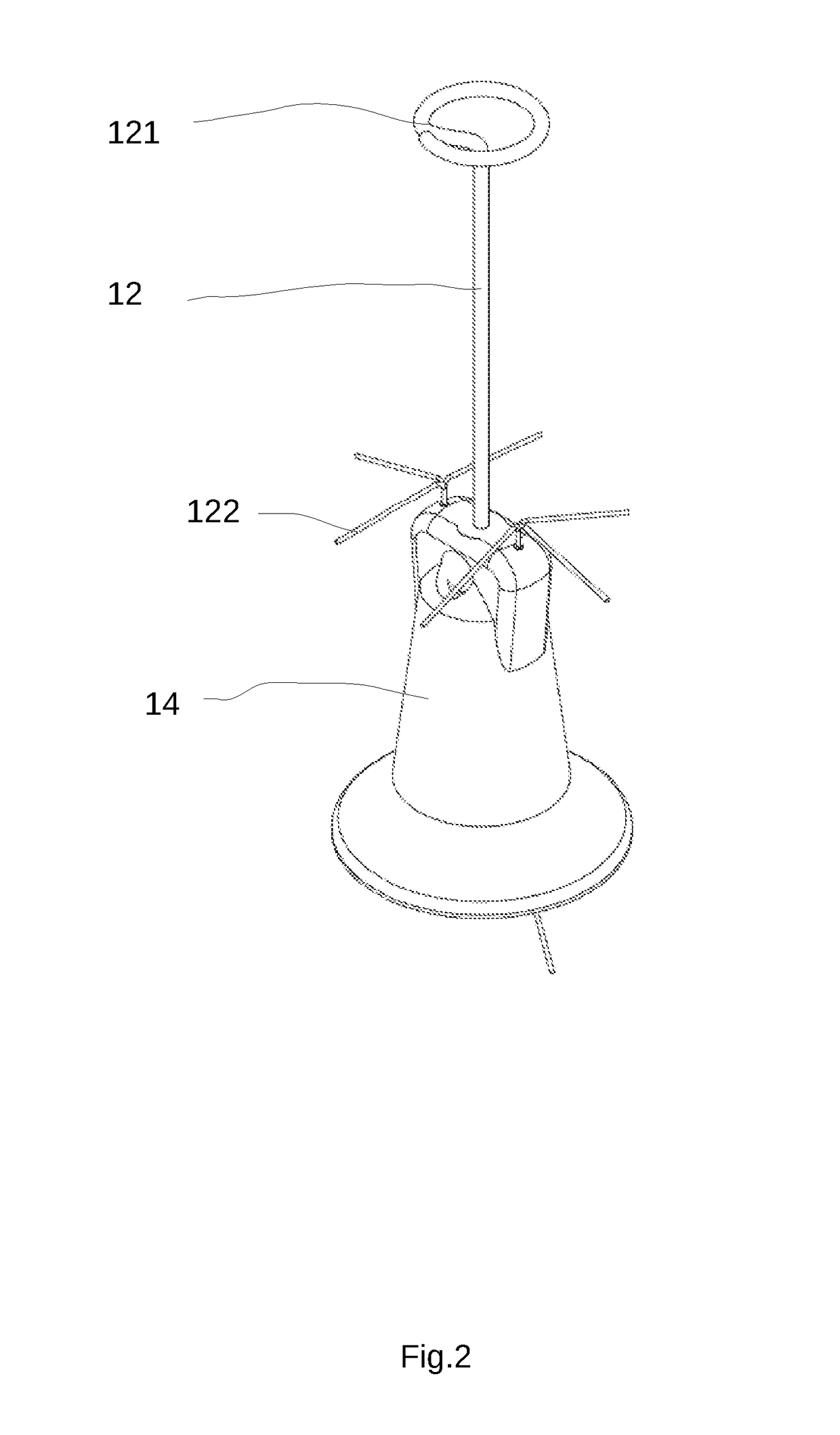

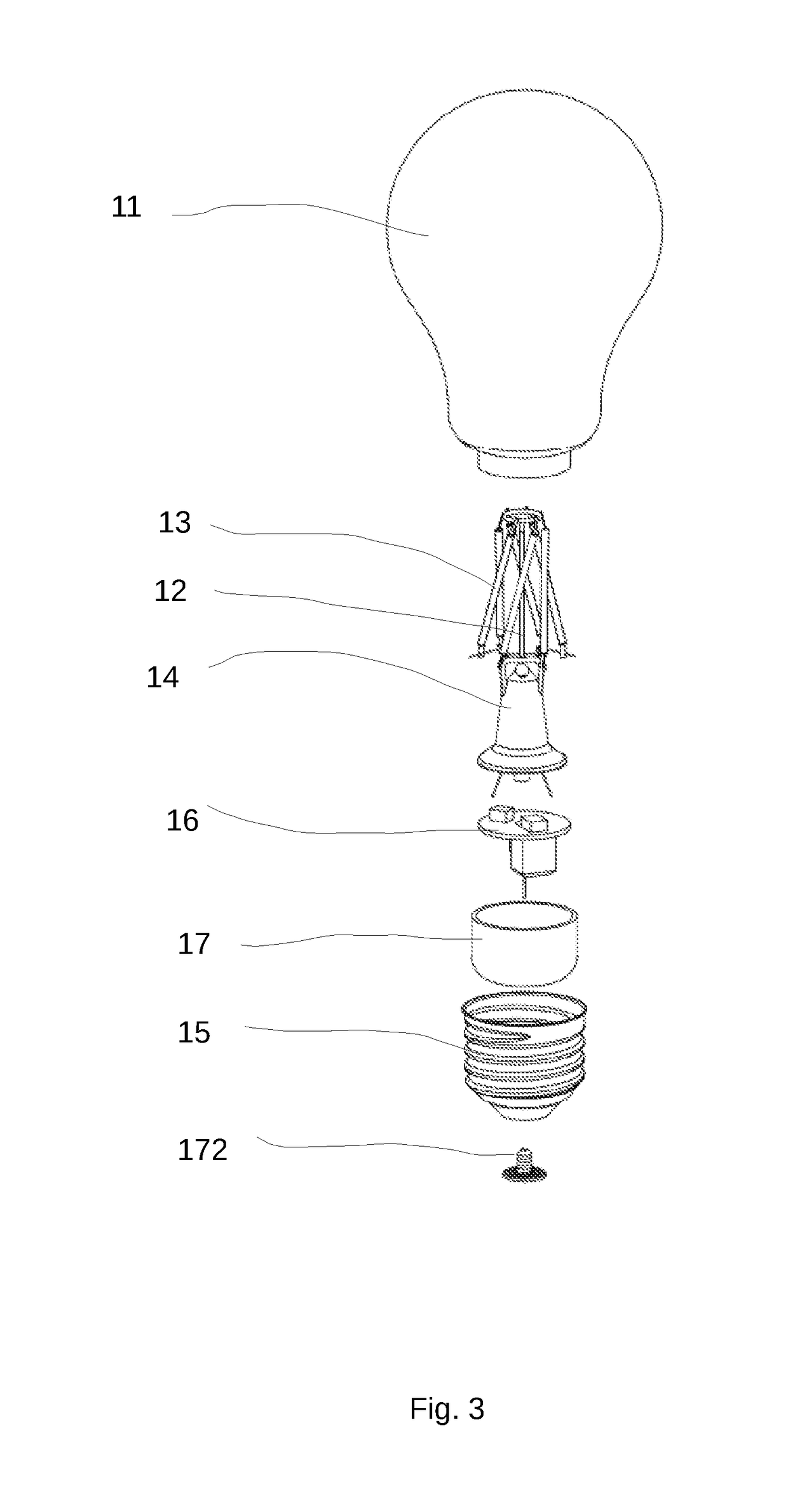

Filament structure and LED light bulb having the same

ActiveUS10283683B1Improve heat dissipationReduce dark regionDirect heating destructive distillationSolid-state devicesFluorescenceLED filament

An LED filament contains: a light transmissive substrate, at least one LED chip, a first electrode pin, a second electrode pin, a light emitting layer, and a phosphor layer. The phosphor layer packages the at least one LED chip, and the first electrode pin and the second electrode pin expose outside the phosphor layer. The light emitting layer is made of electromagnetic wave material of different radiation waves, the at least one LED chip produces excitation light source to excite the phosphor layer to illumine lights, and a part of the excitation light source of the at least one LED chip excites the light emitting layer to illuminate the lights after passing through the substrate. The part of the excitation light source excites phosphors of the light emitting layer to illuminate the lights toward the LED filament or the light emitting layer absorbs visible lights converted from infrared lights.

Owner:BGT MATERIALS

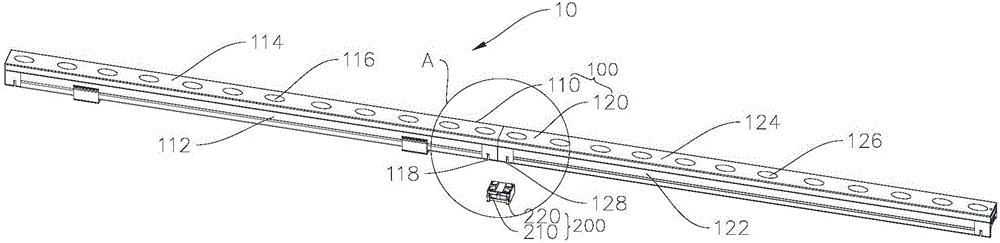

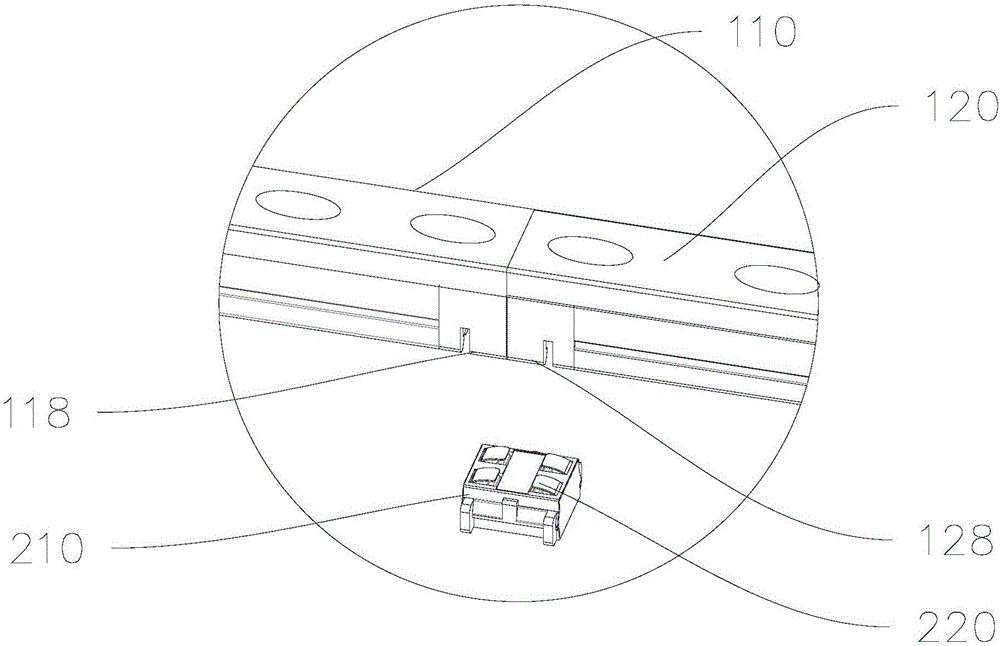

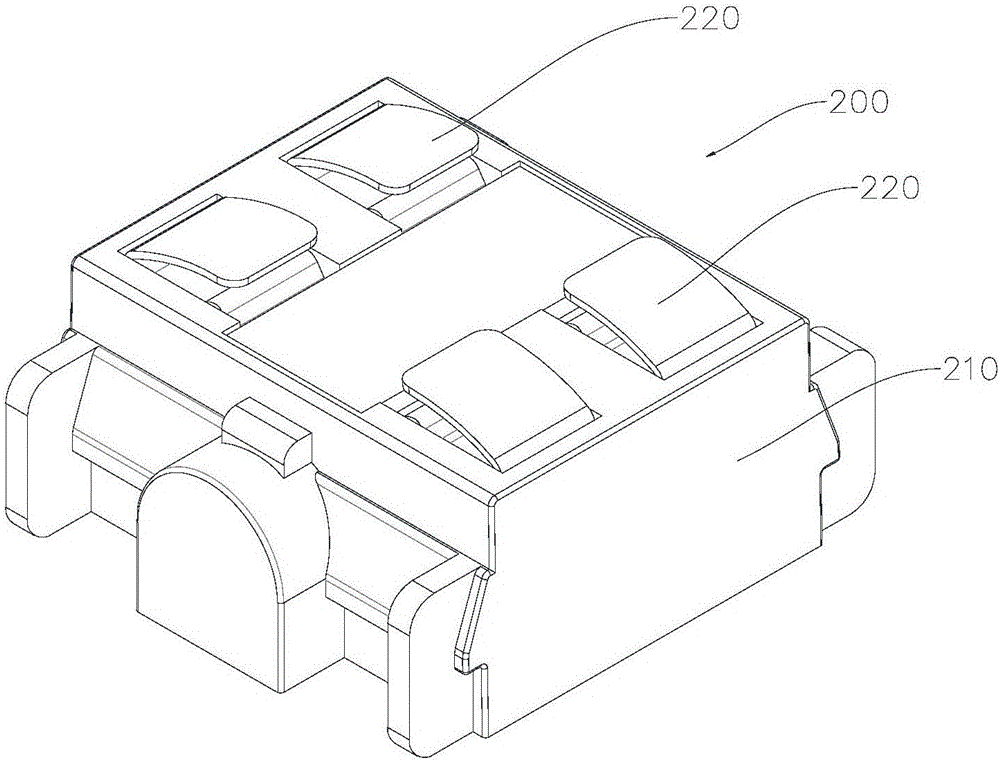

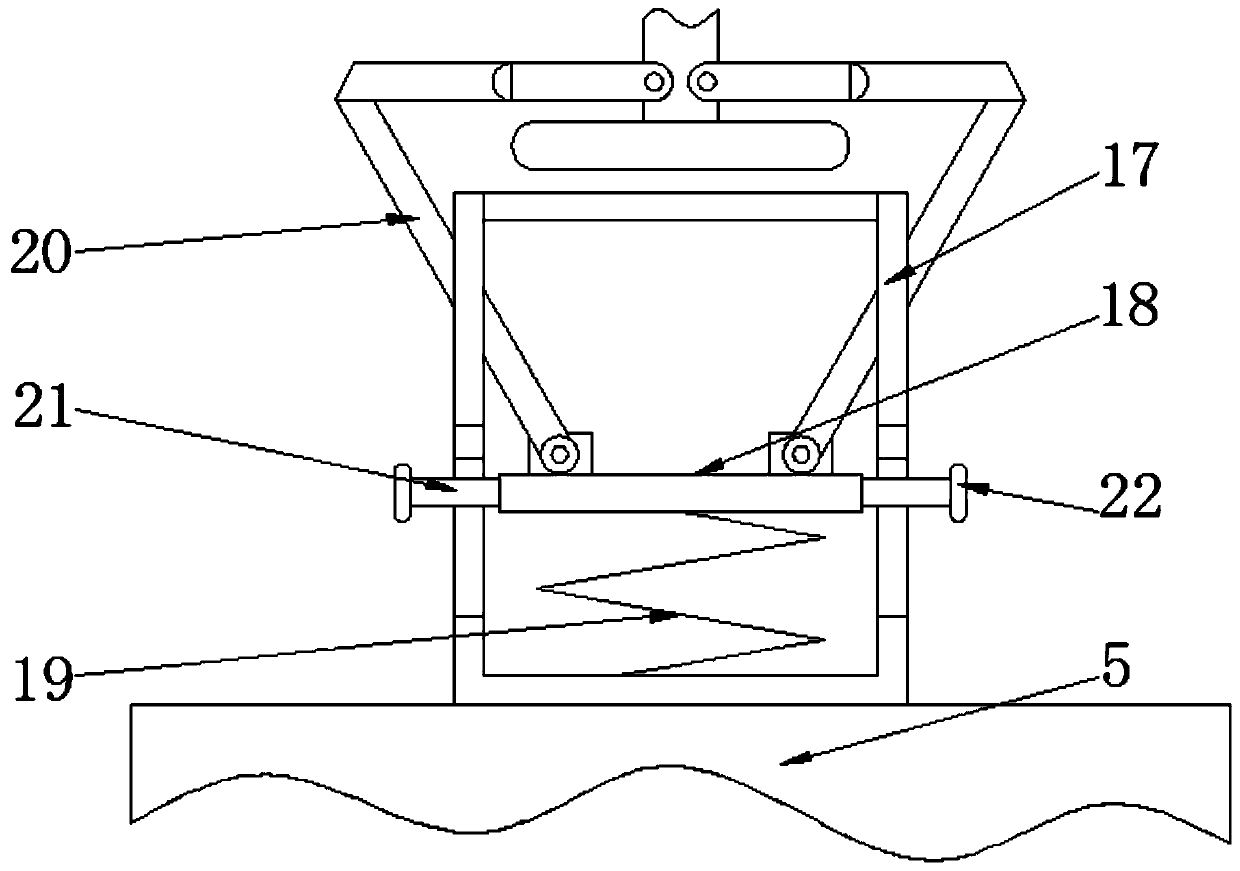

Spliced lamp bar and lamp bar splicing device

PendingCN106838686AAchieve seamless physical connectionAchieve electrical connectionElectric circuit arrangementsElectric lightingLight equipmentFirst light

The invention provides a spliced lamp bar and a lamp bar splicing device and relates to the technical field of lighting equipment. The spliced lamp bar comprises lamp bar bodies and splicing parts; the lamp bar bodies include the first lamp bar body and the second lamp bar body, wherein the first lamp bar body comprises a first shell, a first light source plate arranged in the first shell and a plurality of lamp beads axially arranged along the first light source plate; a first metal conductive piece is arranged at one end of the first light source plate; the second lamp bar body comprises a second shell, a second light source plate arranged in the second shell and a plurality of second lamp beads axially arranged along the second light source plate, and a second metal conductive piece is arranged at one end of the second light source plate; each splicing part comprises a clamping piece and a third metal conductive piece, the clamping pieced is connected with the first shell and the second shell in a clamped manner, the third metal conductive piece is arranged on the clamping piece, and the third metal conductive piece contacts with the first metal conductive piece and the second metal conductive piece respectively. By the arrangement, electric connection and seamless physical connection of the neighboring lamp bars are realized, and the effect of reducing dark areas is achieved.

Owner:GUANGZHOU DONGLIN ELECTRONICS

Composition for treating a dermal anomaly

InactiveUS7731993B2Poor circulationPromote circulationBiocidePharmaceutical delivery mechanismCITRATE ESTERArginine

Owner:KENILIN +1

Lighting device

ActiveUS20190032857A1Large light angleImprove heat transfer efficiencyElectric circuit arrangementsLighting heating/cooling arrangementsElectricityEffect light

A lighting device includes a bulb shell, a base portion, a light bar module, a core stem, a lamp cap and a driving piece. The light bar module is composed of a plurality of light bars. Each light bar houses a plurality of LED chips. Electrical connectors are set at the two ends of each light bar respectively. The core stem extends upwardly from the base portion and has an expansion portion at the top. The electrical connector of light bars is fixed to the expansion portion. The open end of the lamp cap is connected to the bottom of the bulb shell. The driving piece is placed in the lamp cap. The lighting device achieves a technical effect in which the lighting effect is uniform and the lighting angle is large.

Owner:LEEDARSON GREEN LIGHTING

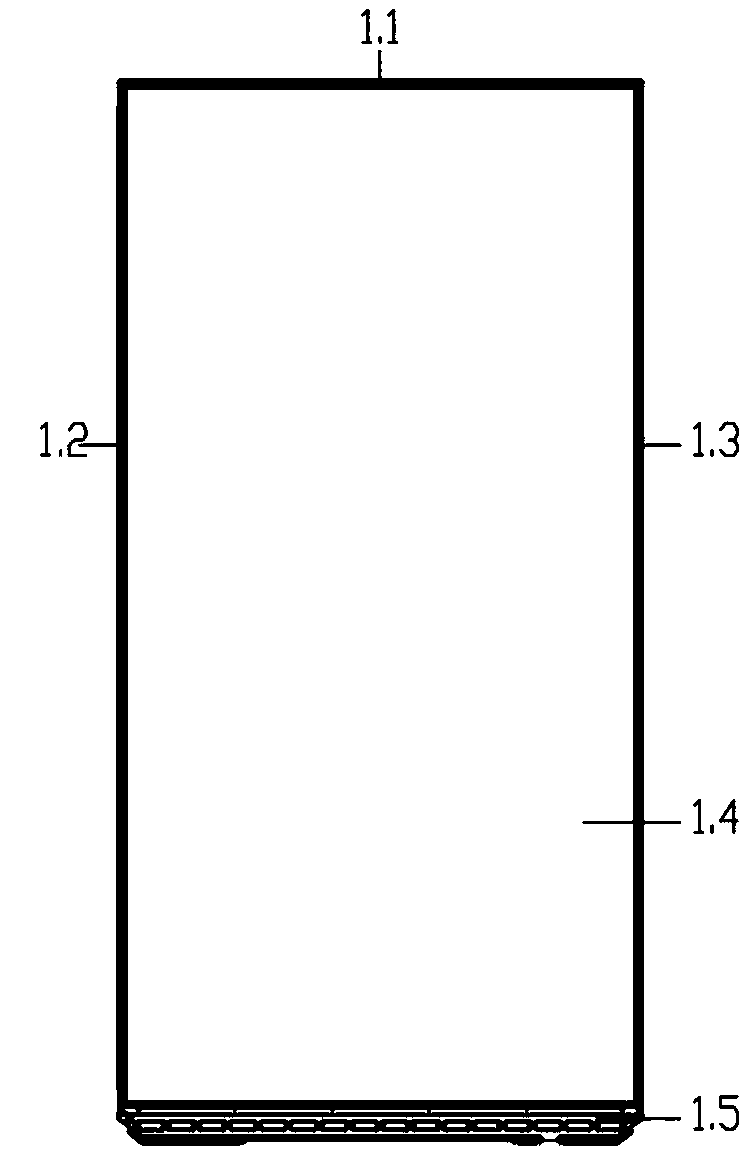

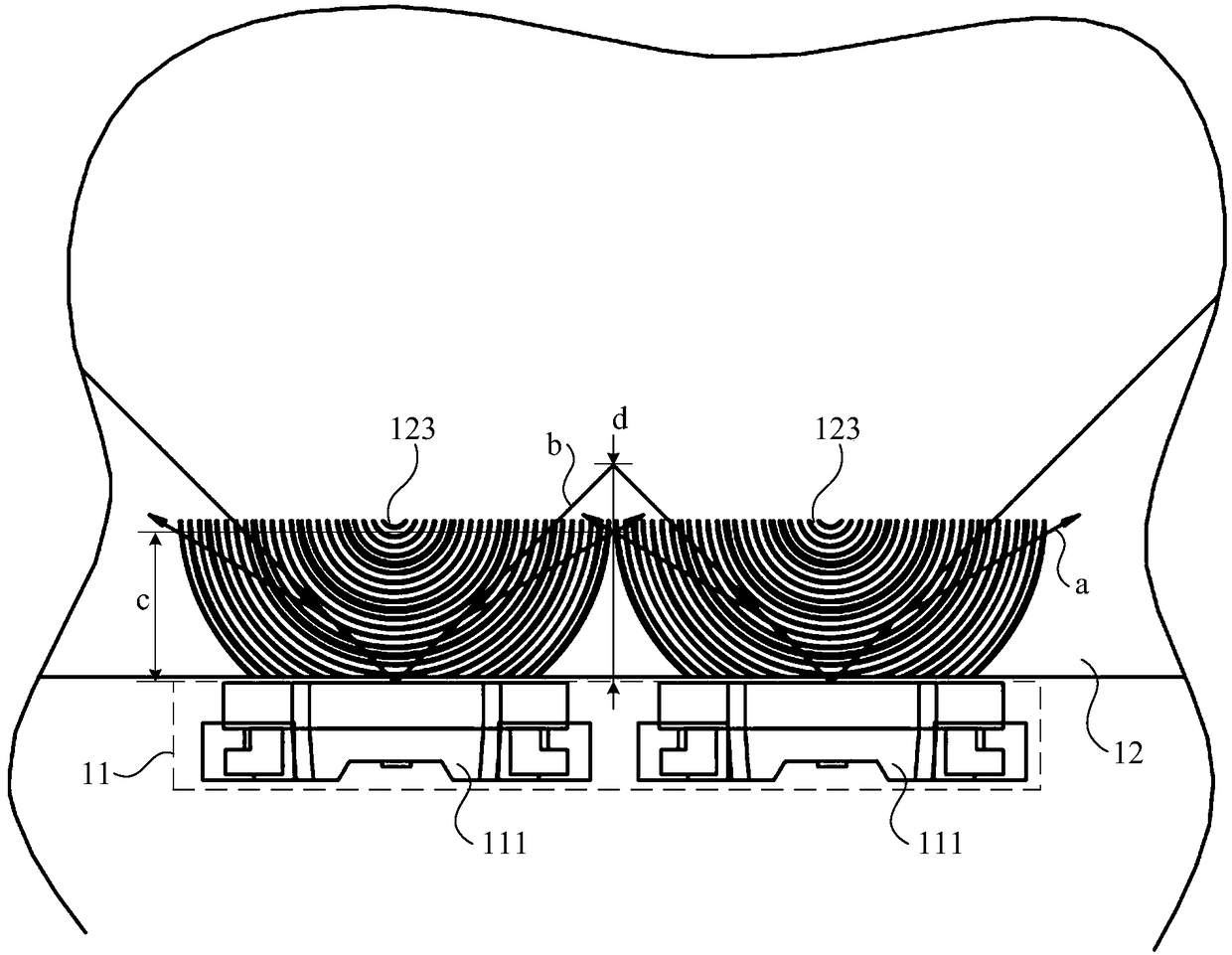

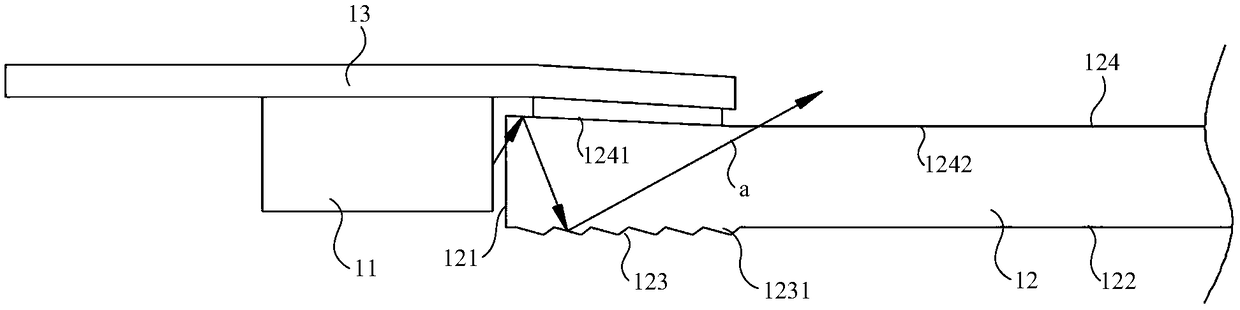

Backlight module and display device

InactiveCN109116633AReduce thicknessIncrease the exit angleOptical light guidesNon-linear opticsLight guideAngle of departure

The invention provides a backlight module and a display device. The backlight module comprises a light-emitting element and a light guide plate; multiple light guide slot regions are arranged at one side, close to the light-emitting element, of a reflecting plane of the light guide plate, each light guide slot region comprises multiple light guide slots, and a positive projection of each light guide slot on the reflective plane is arc, and a bending direction of the arc is towards the light-emitting element; a light ray emitted towards an in-light surface of the light guide plate by the light-emitting element is reflected to an out-light surface of the light guide plate through the light guide slots. An angle of departure of the light ray of the light-emitting element after entering the light guide plate can be increased, a dark area and light mixing distance of the light-emitting element are reduced, thereby reducing lower black edge size of the backlight module, and then reducing thelower black edge size of the entire display device, and realizing lower narrow edge design of the display device; furthermore, the thickness of the light guide plate can be reduced on the basis of guaranteeing that all light rays enter the light guide plate, and the thinner and lighter design is realized.

Owner:VIVO MOBILE COMM CO LTD

Light guide plate of display apparatus

ActiveUS8714805B2Improve display qualityReduce light lossMechanical apparatusPlanar/plate-like light guidesLight guideOptoelectronics

A display apparatus includes a light source and a light guide plate including a light incident surface facing the light source and which receive the light, an opposite surface opposite to the light incident surface and which reflects the light and has an arc shape, connection surfaces at opposing sides of the light incident surface and which connect the light incident surface and the opposite surface, an upper surface connected to the light incident surface, the opposite surface and the connection surfaces and which outputs the light, and a lower surface opposite to the upper surface. The light incident surface of the light guide plate includes a first surface extending in a predetermined direction, and second surfaces inclined from the first surface in an area corresponding to the light source such that an optical recess having a polygonal pyramid shape is defined by the second surfaces.

Owner:SAMSUNG DISPLAY CO LTD

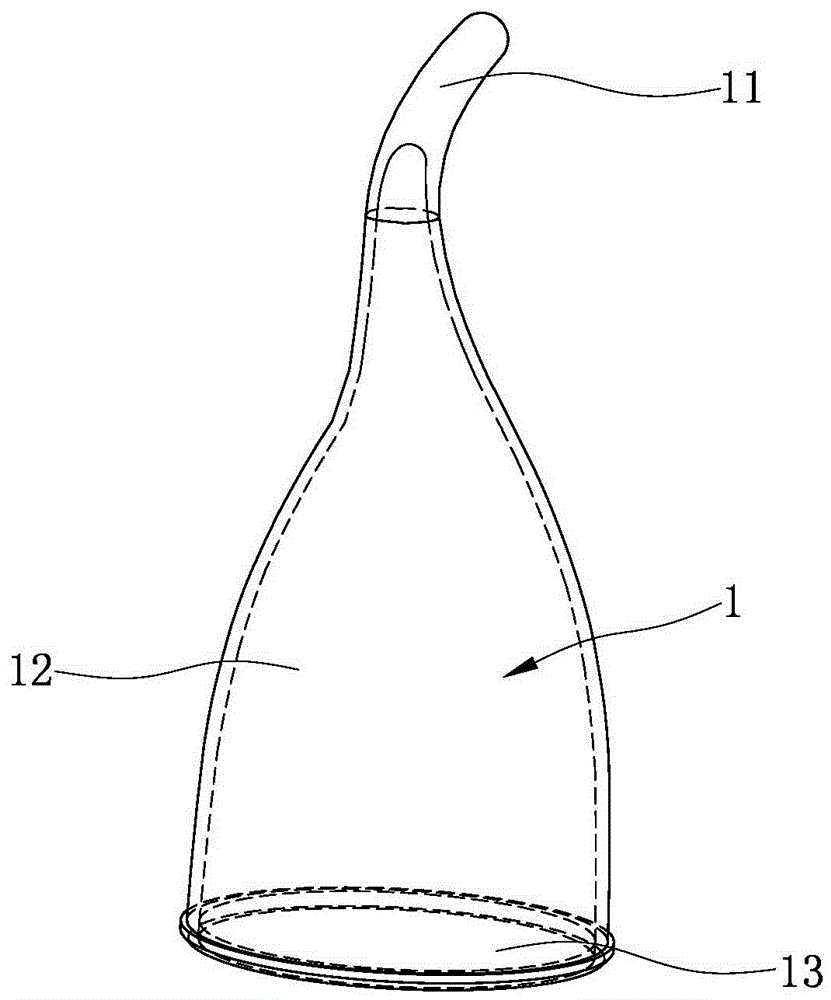

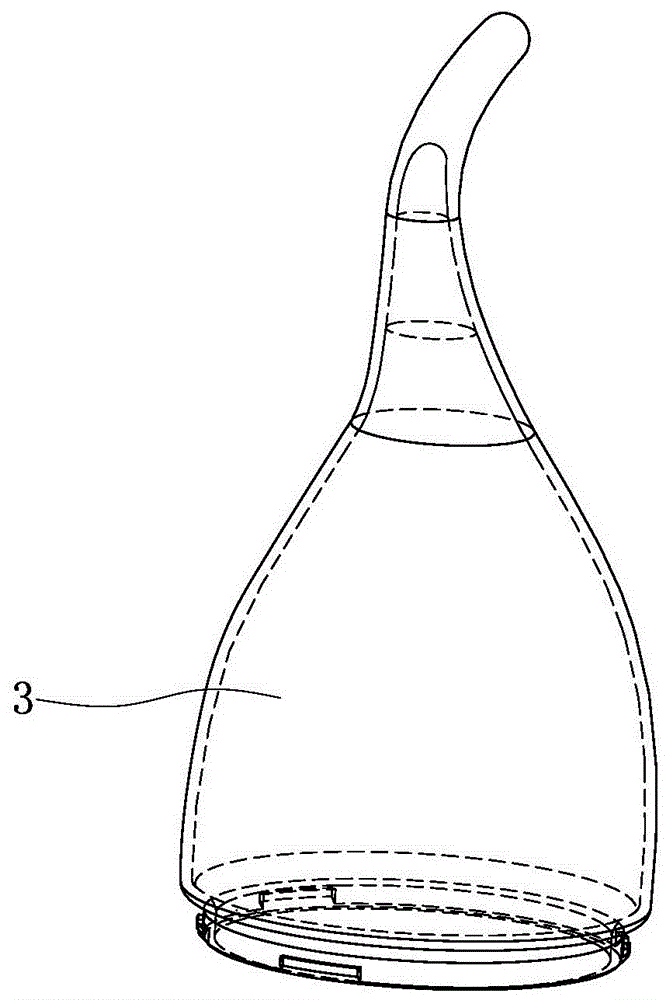

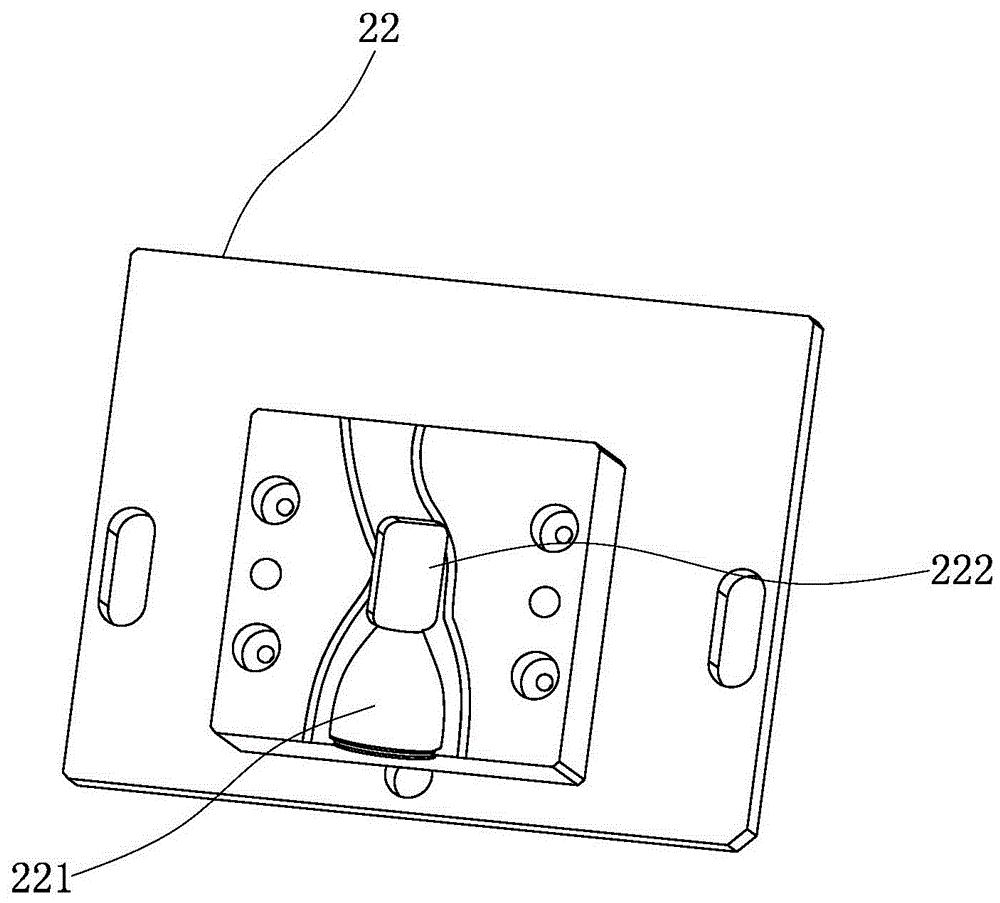

Manufacturing process and device for LED plastic pulled-tail bubble shells

The invention discloses a manufacturing process for LED plastic pulled-tail bubble shells. The manufacturing process includes the following steps that firstly, plastic is subjected to injection molding to form tube blanks which are cooled and shaped, and a central symmetry area is formed on each tube blank; secondly, a tip portion consistent with a blow-molded finished product in shape is formed on the part above the central symmetry area of each tube blank; thirdly, the tube blanks are baked and softened, the tip portions above the central symmetry areas are not baked, while the portions below the central symmetry areas are baked; fourthly, when the blanks are transferred and mold closing is conducted, the central symmetry areas are kept in mold cavity avoidance from a bottom mold body and a cover mold body of a blowing mold, and avoidance cavities are formed in the portions, above and below the central symmetry areas of the tube blanks, of the blowing mold; and fifthly, the baked and softened portions below the central symmetry areas are subjected to blow-molding, and the LED plastic pulled-tail bubble shells are formed. The invention further discloses a manufacturing device for the LED plastic pulled-tail bubble shells. By means of the manufacturing process and device for the LED plastic pulled-tail bubble shells, the illumination angle of the blow-molded LED plastic pulled-tail bubble shells is large, and the LED plastic pulled-tail bubble shells are free of deformation and attractive in appearance.

Owner:厦门普拉米达光电科技有限公司

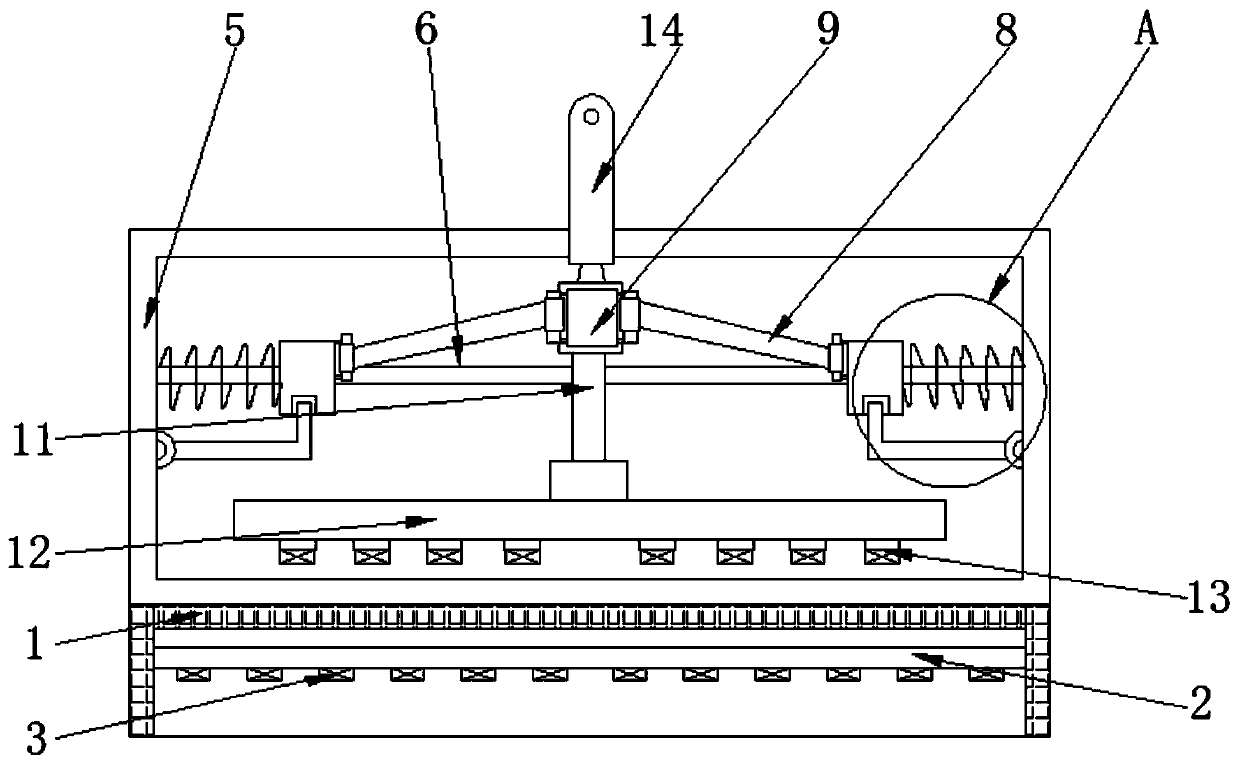

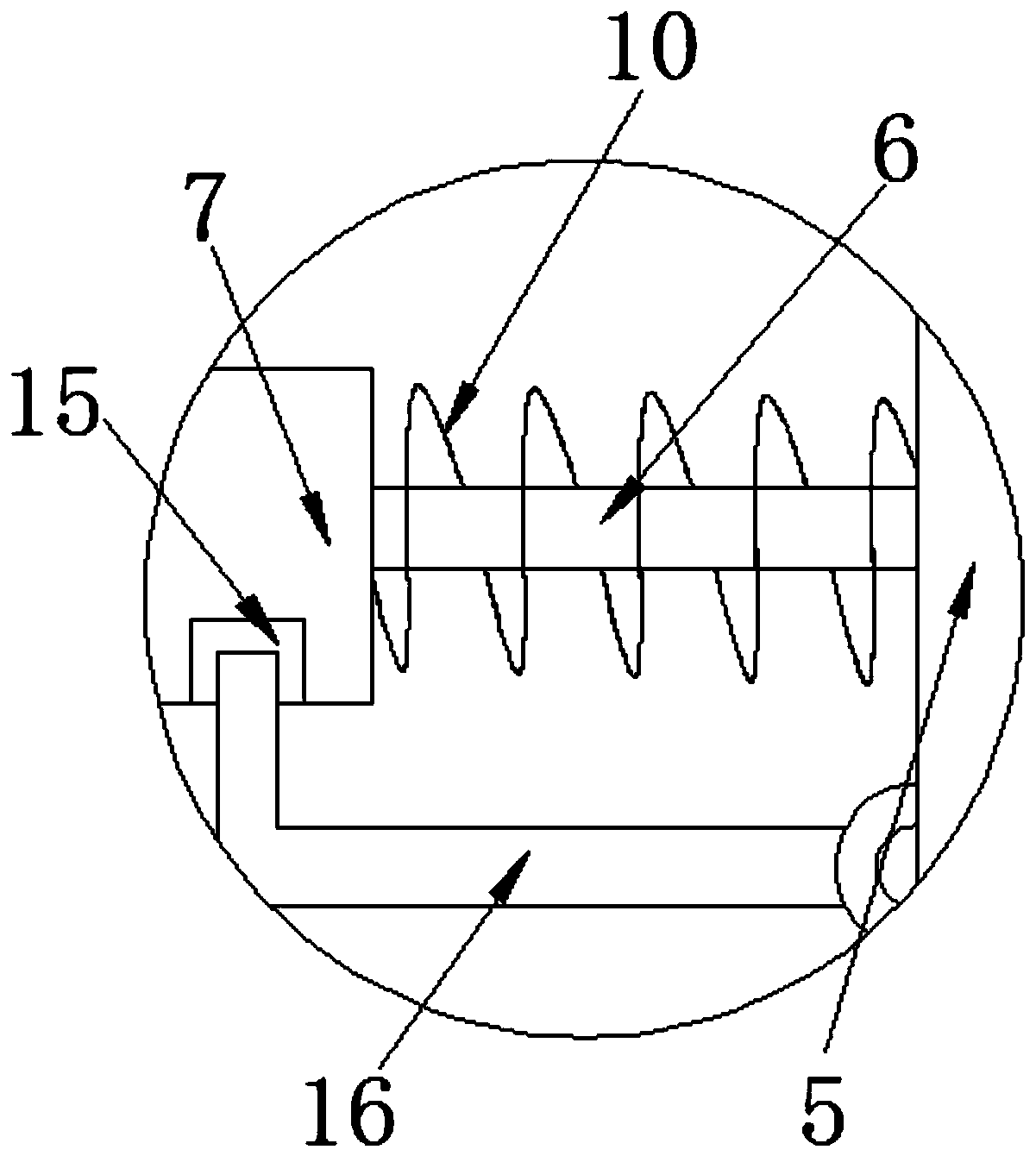

Self-adaptive lawn trimmer

ActiveCN109429674AEnhance bright areasReduce dark areasMowersCharacter and pattern recognitionSelf adaptiveLawn

The invention relates to a self-adaptive lawn trimmer. The trimmer comprises a dragging-type grass trimming structure and an electronic control switch; the dragging-type grass trimming structure comprises a back frame, an accelerator switch assembly, a flexible shaft assembly, a connecting disc, a gasoline engine, a handlebar, an aluminum tube and a soil loosening and weeding head; the soil loosening and weeding head is arranged at the bottom of the aluminum tube, and the handlebar is arranged at the top of the aluminum tube; the gasoline engine is arranged on the connecting disc, the back frame is arranged on the connecting disc, and the accelerator switch assembly is arranged at the top of the handlebar; the electronic control switch is connected with the gasoline engine and object extracting equipment separately and used for controlling the gasoline engine to enter a dormant state when a second authentication instruction is received; the electronic control switch is further used for controlling the gasoline engine to enter an operating state when a first authentication instruction is received. By means of the trimmer, the self-adaptive control level of the lawn trimmer can be increased.

Owner:浙江昌新生物纤维股份有限公司

LED lamp capable of increasing light saturation

InactiveUS20140071670A1Increasing light saturationEnhancing light saturationNon-electric lightingPoint-like light sourceDisplay deviceDot-matrix display

An LED lamp capable of increasing light saturation utilizes a mixing layer to be formed on a reflecting layer since the mixing layer is arranged by multiple dots that are distributed at intervals and formed as a dot-matrix layer. At least one color formed on the dots to present the colored dot-matrix display allows the light beams from the LED lamp to be mixed with the color on the dot-matrix layer and then reflected for promoting the color temperature uniformity of the light beams and decreasing the generation of dark zone, which efficiently provides light beams with a uniform saturation for illuminating.

Owner:SHENZHEN JIAWEI PHOVOLTAIC LIGHTING +1

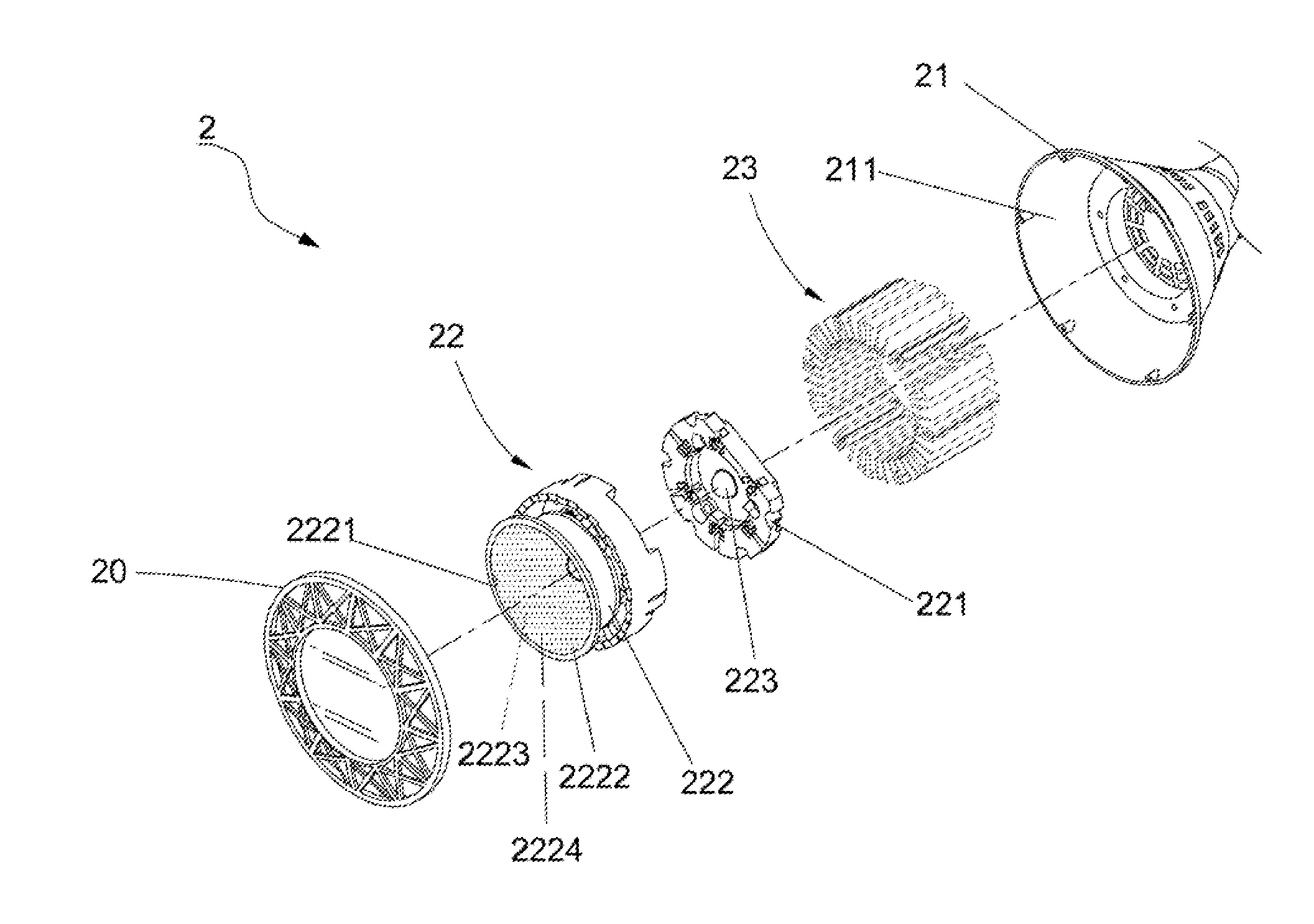

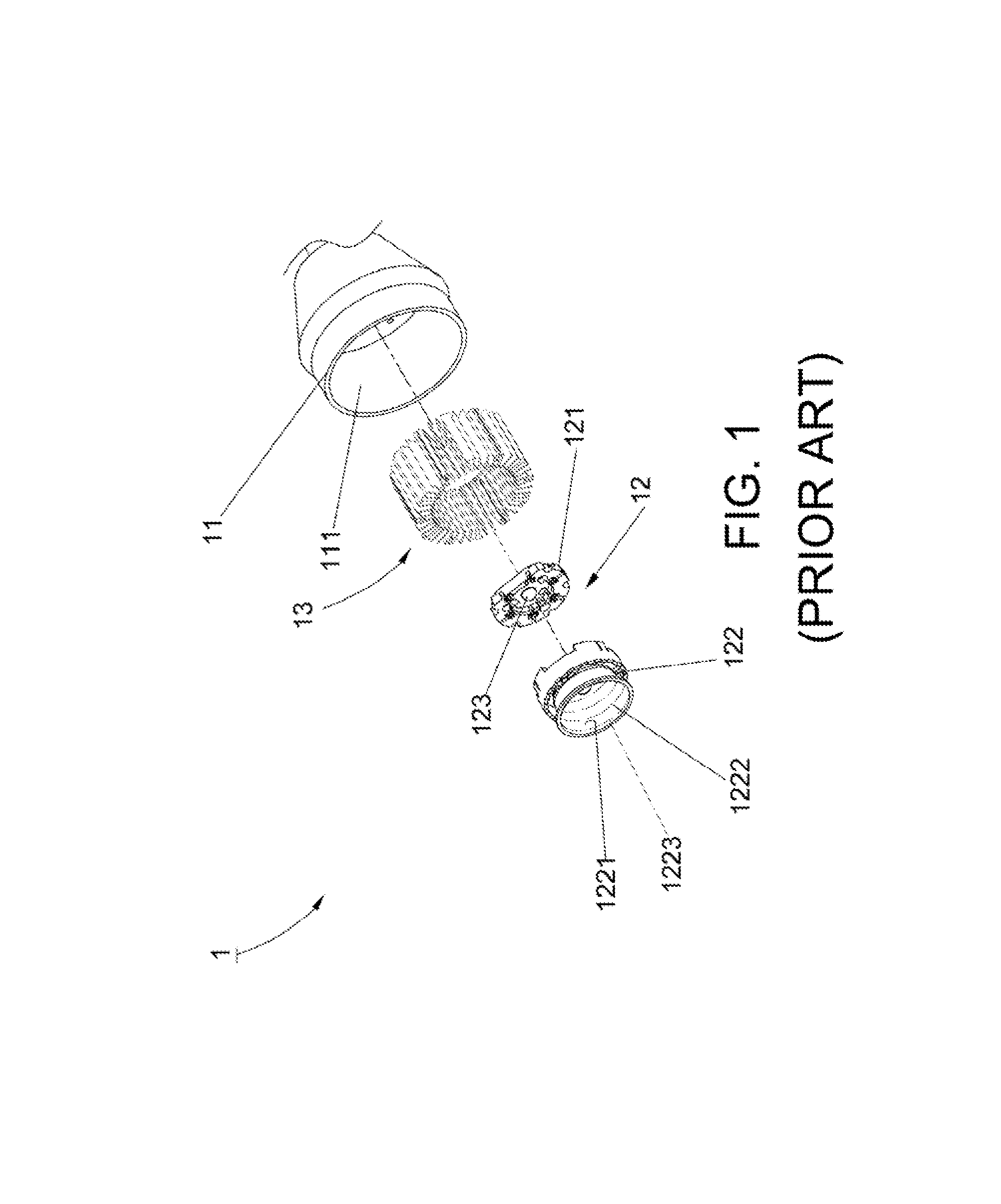

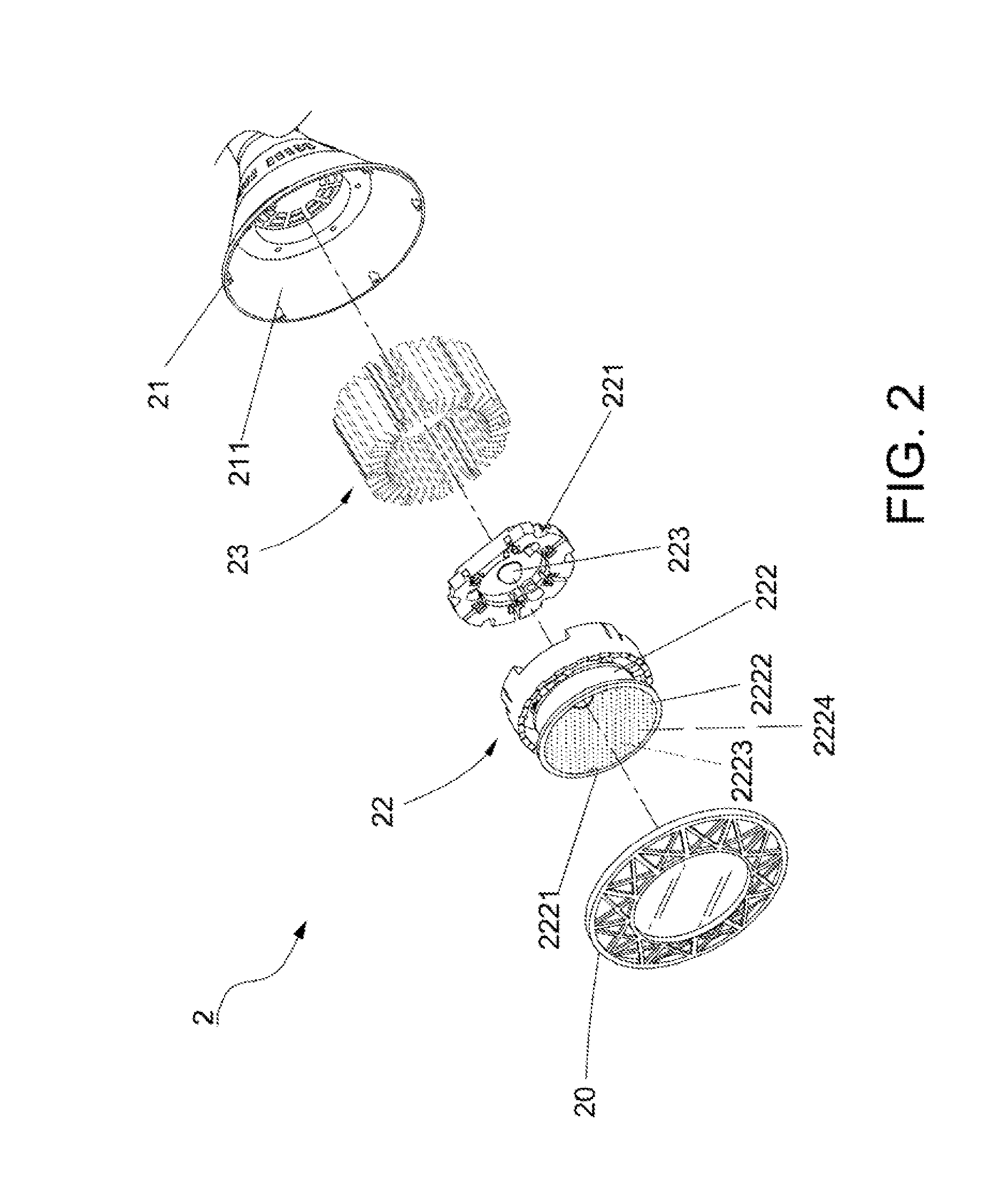

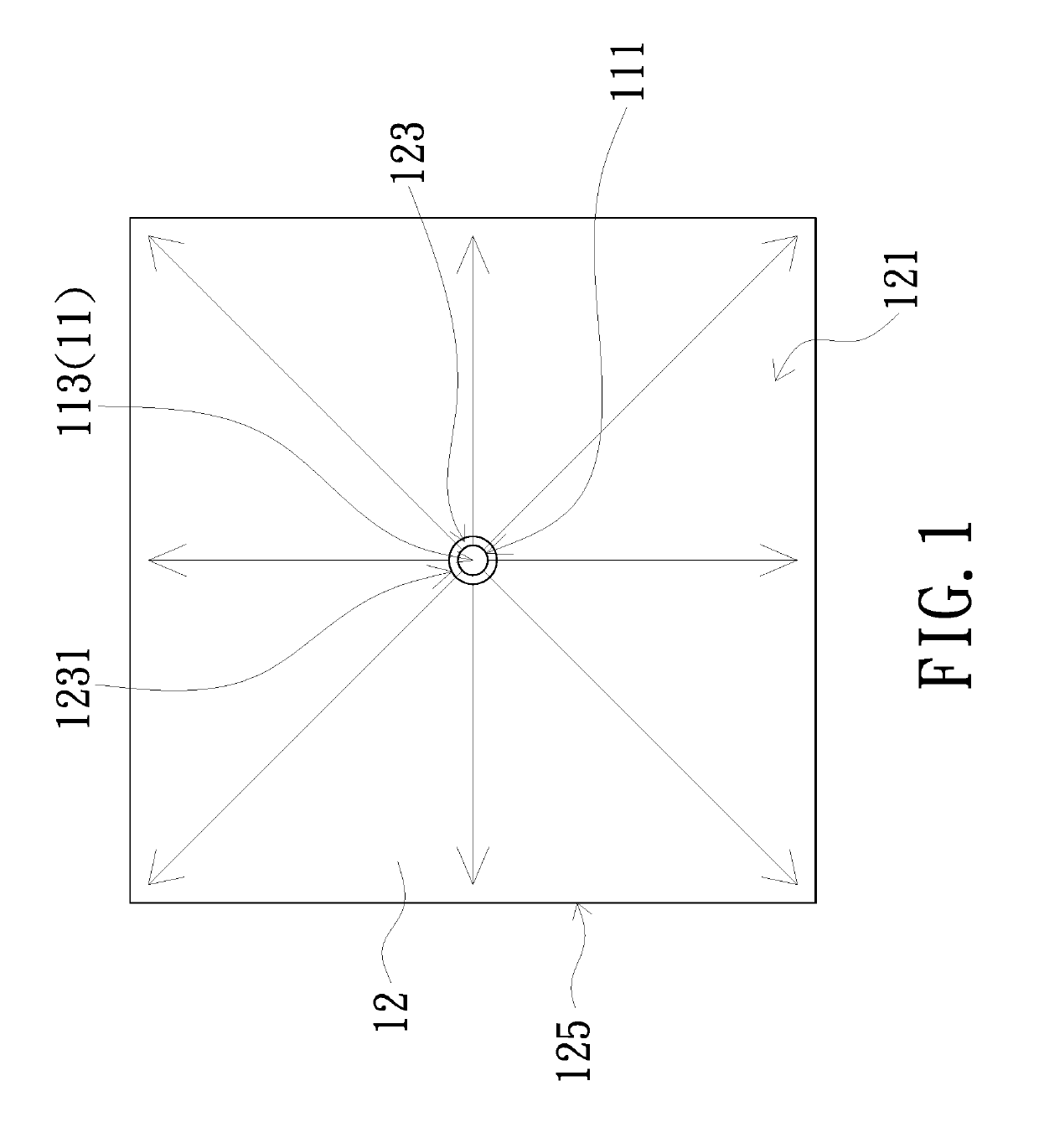

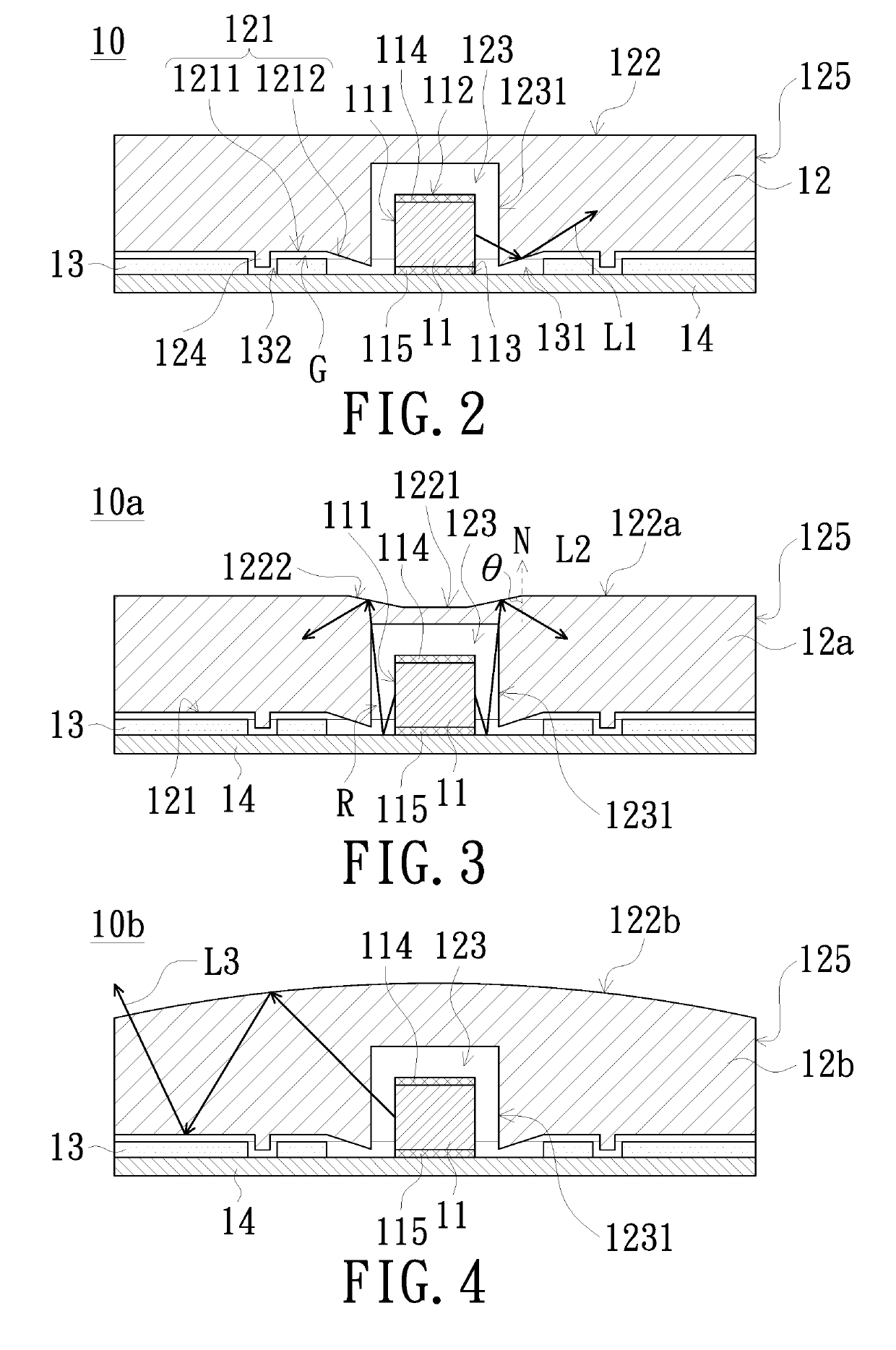

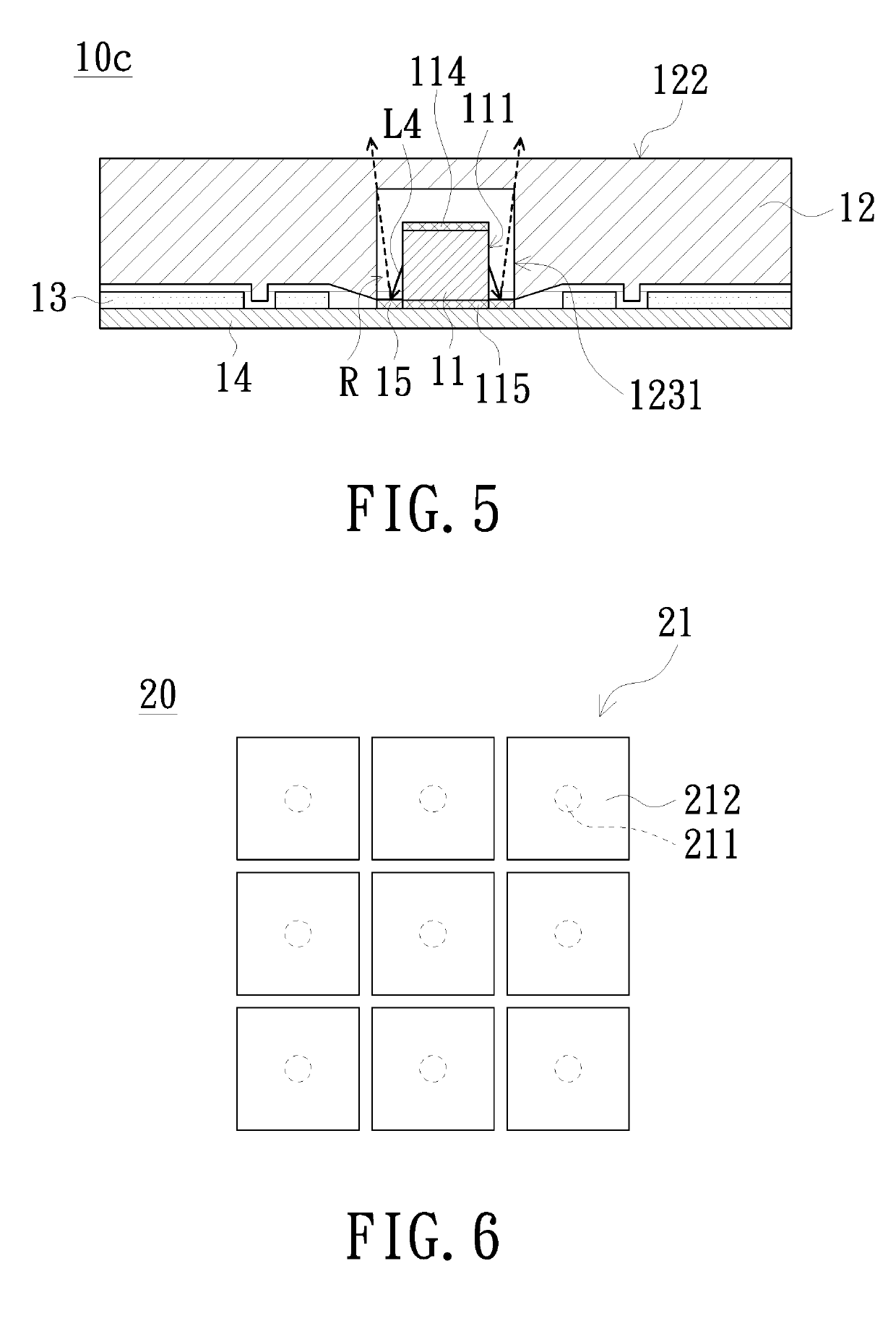

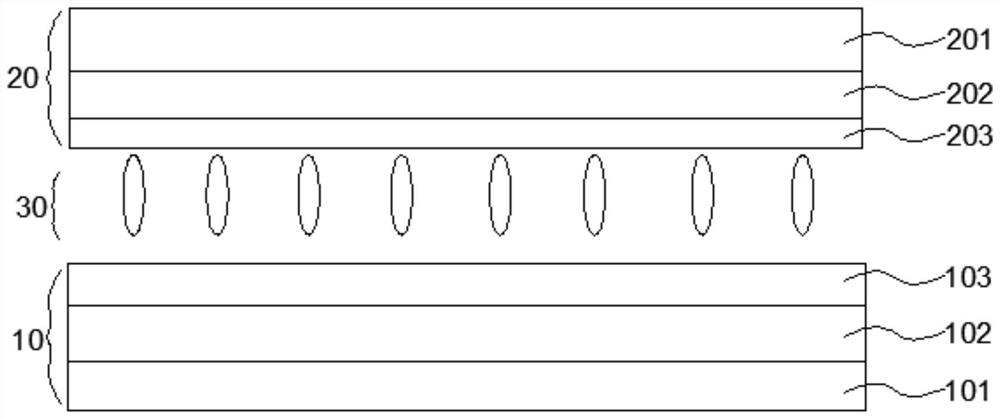

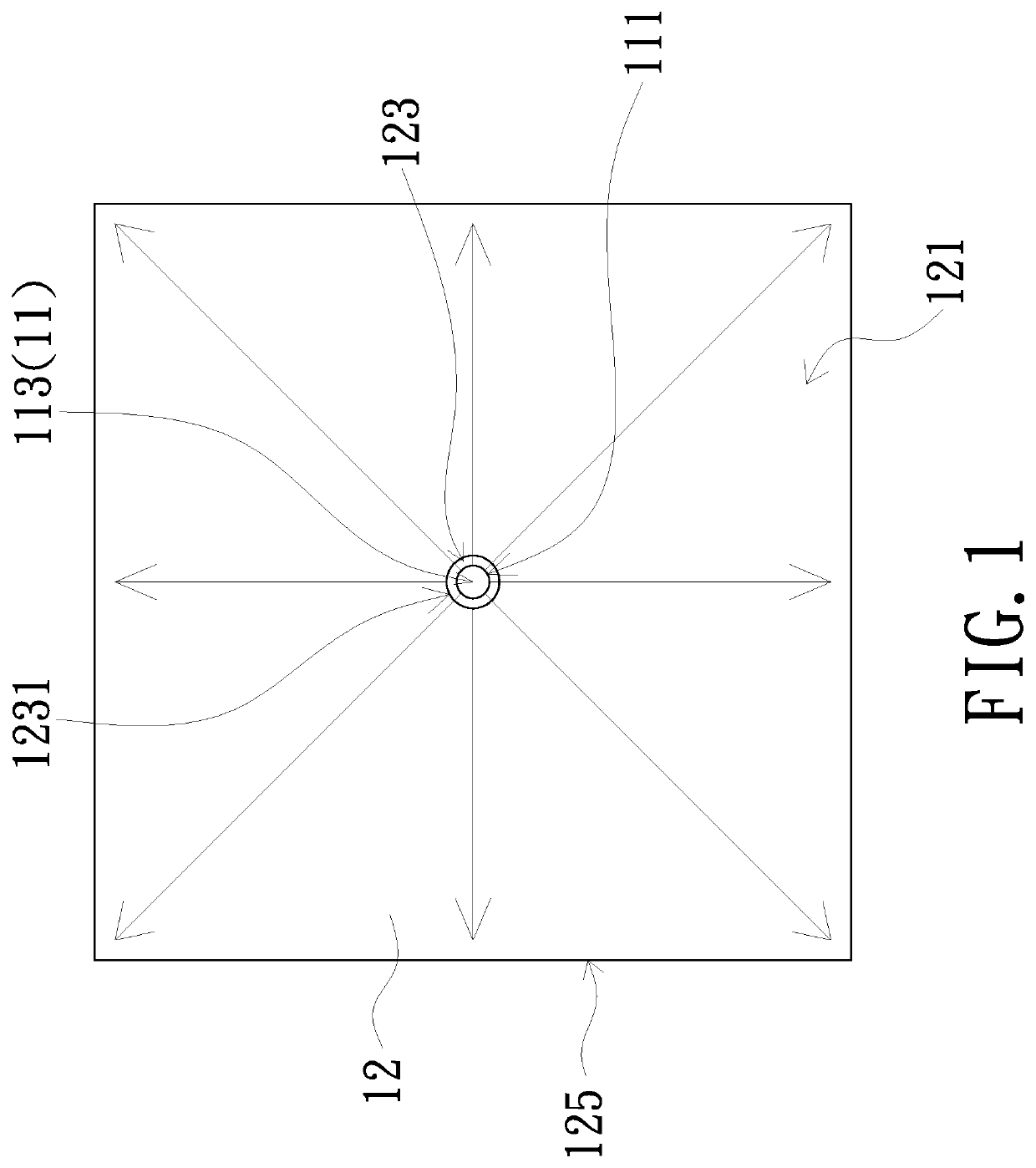

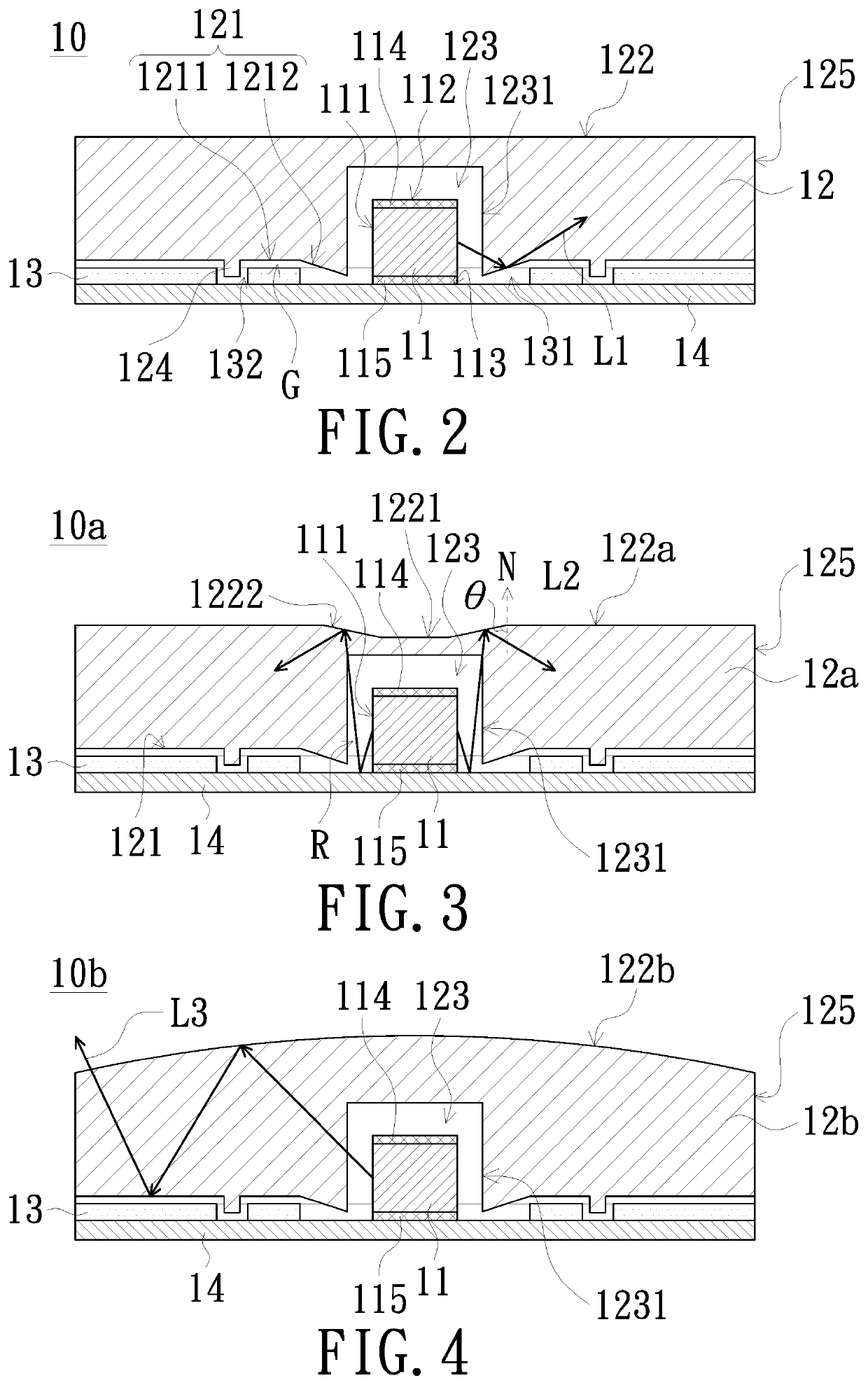

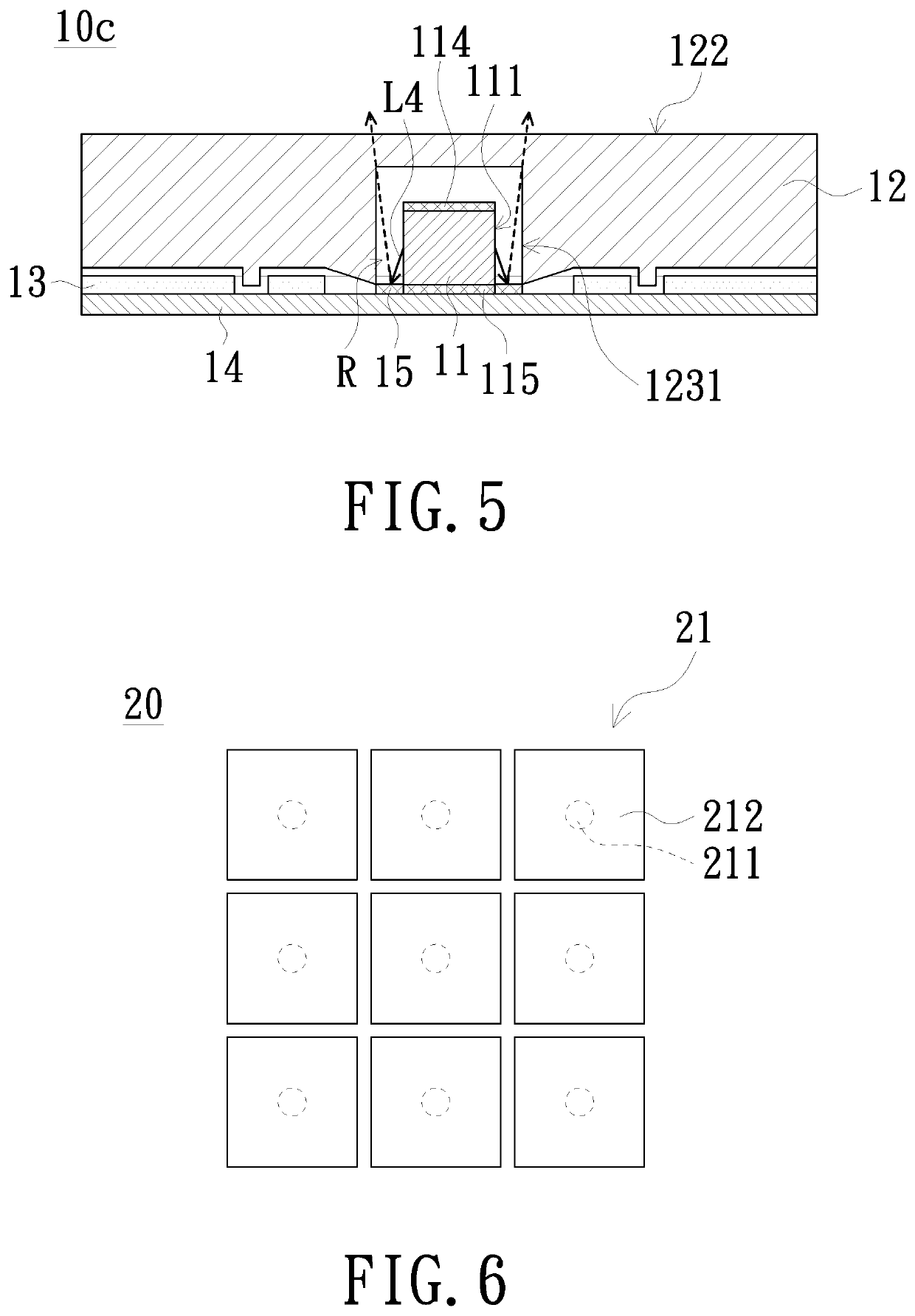

Light source module and surface light source assembly thereof

ActiveUS20190227214A1Reduce brightness unevennessInhibition formationMechanical apparatusLight guides for lighting systemsLight guideOptoelectronics

A surface light source assembly includes at least one light emitting element, a light guide plate and a reflective sheet. Each of the light emitting elements has an annular light emitting side surface. The light guide plate has a bottom surface and a light exit surface opposite to the bottom surface. The bottom surface has at least one accommodating recess to accommodate at least one light emitting element. Each of the accommodating recesses has a light incident surface. The bottom surface further has a flat portion and at least one inclined surface portion. Each of the inclined surface portions is connected between the flat portion and the light incident surface of the corresponding accommodating recess. The reflective sheet is disposed below the flat portion. A light source module having the surface light source assembly is further provided.

Owner:CORETRONIC

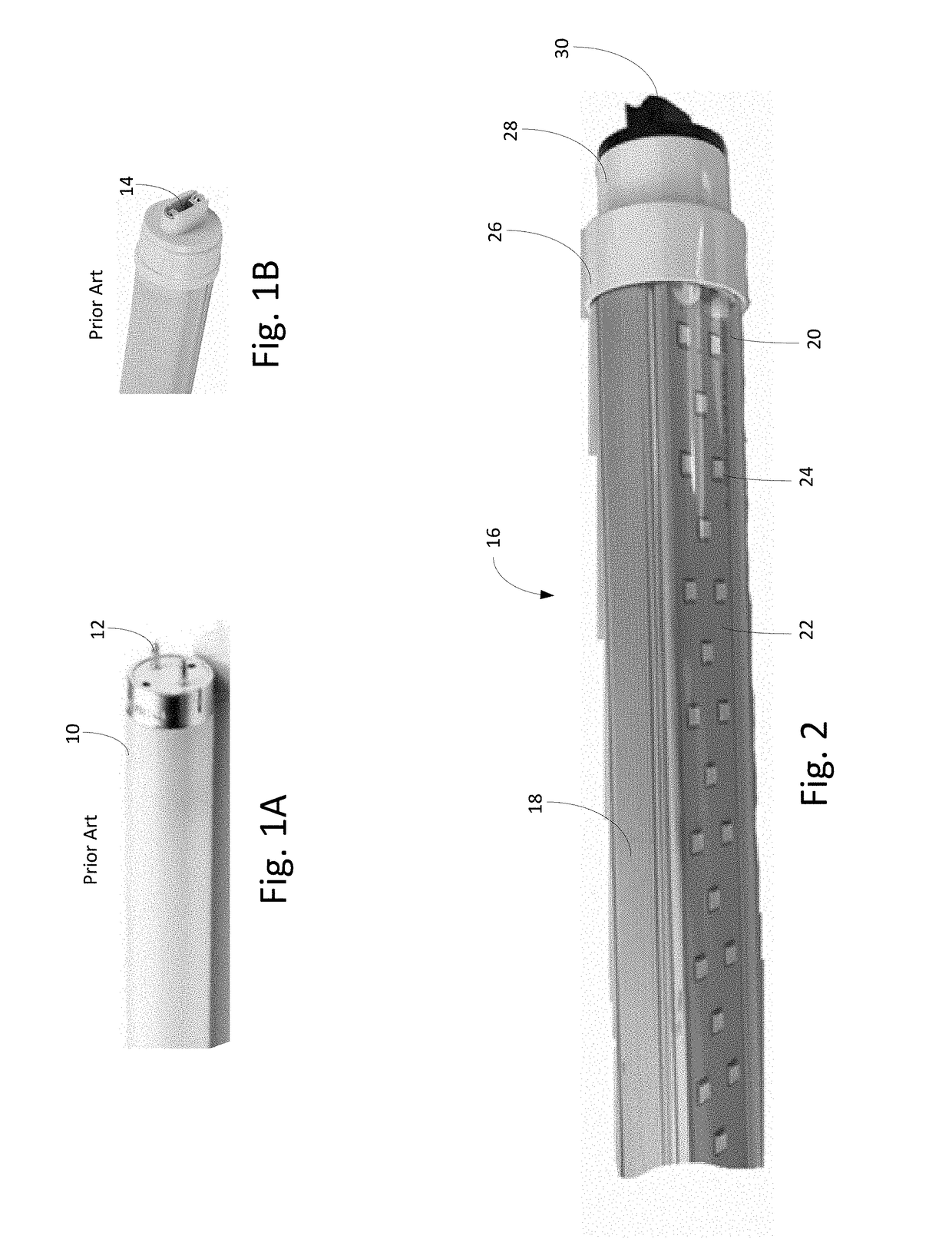

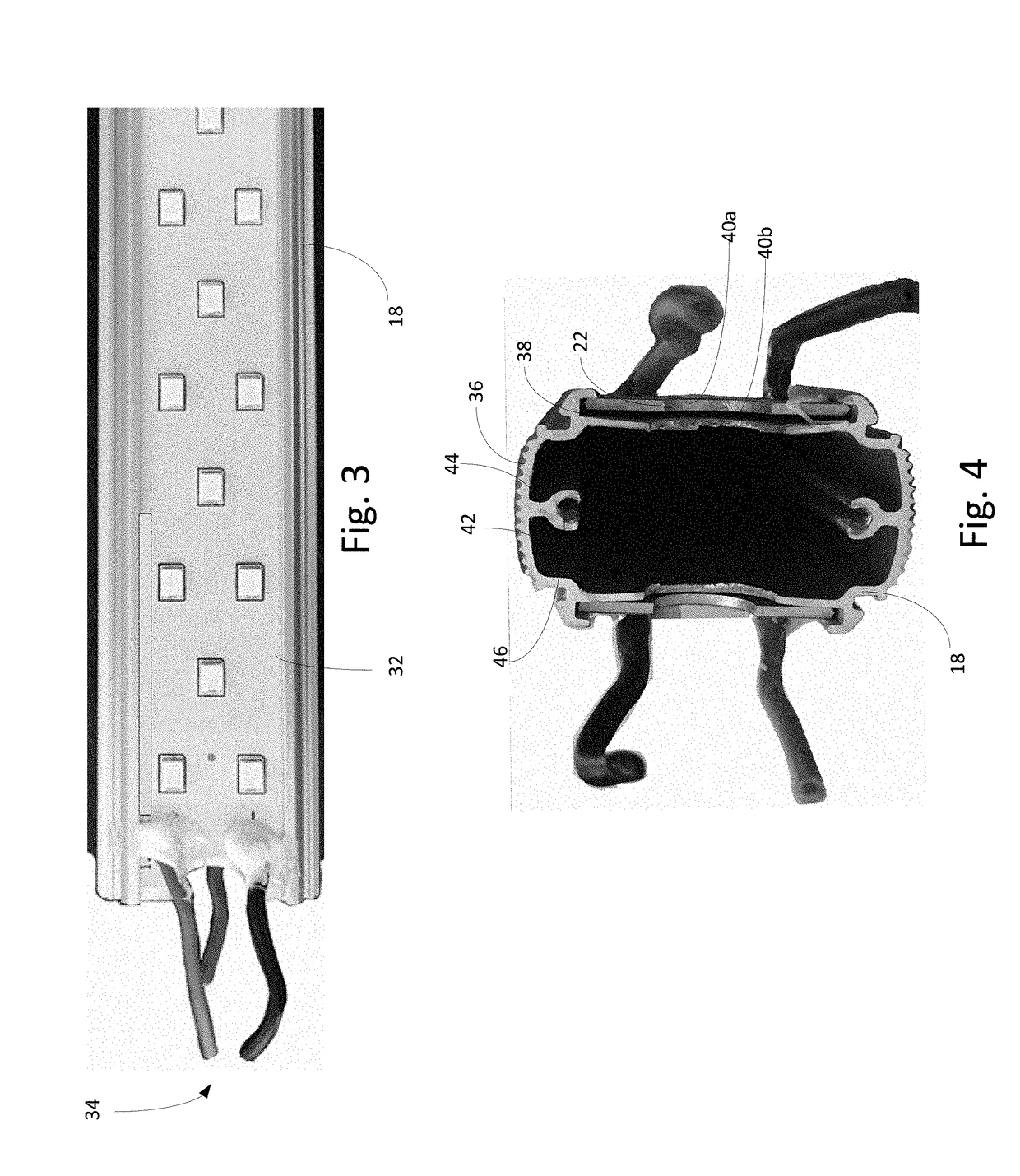

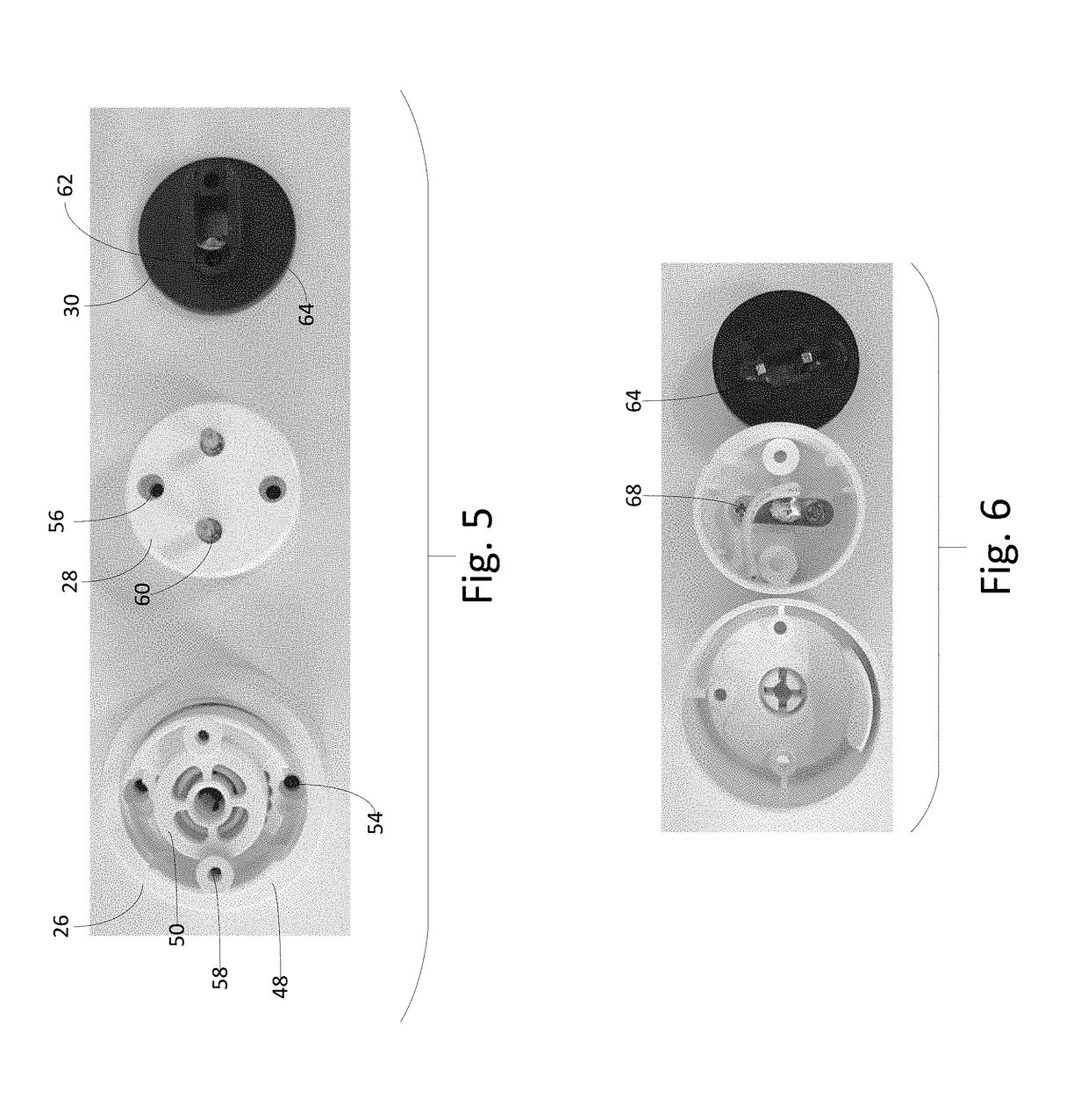

Multi Oriented, Power Source Agnostic Replacement For Lighting Assembly

ActiveUS20190003656A1Reduce hot spotReduce dark areasElongate light sourcesElectric lightingElectricityEffect light

This invention is a replacement lighting system for signs that can include a first lighting assembly having LED strips disposed on opposite sides. The lighting assembly can be rotatably attached to the lamp holders. A hub can be removably connected to an external power supply, a first lighting assembly and a second lighting assembly. The lighting system can be used to replace existing lighting such as fluorescent tubes and accompanying ballasts without the need to understand remove or rewire the sign electrical components other than attaching the lighting system to the power source. The lighting assemblies can be rotated in the lamp holders to reduce or remove hot spots or dark areas. Multiple lighting assemblies can be connected end to end and be in electrical communication with the power source without necessarily needing to wire each lighting assembly to the power source.

Owner:SIGNLIGHTSLED LLC

Device for Shaping Laser Radiation

InactiveUS20090159820A1Increase brightnessFocusRadiation/particle handlingElectrode and associated part arrangementsLight beamOptoelectronics

Device for shaping laser radiation which has sub-beams (3) spaced apart in a first direction (X) perpendicular to the propagation direction (Z) of the laser radiation, in particular for shaping laser radiation which is output by a laser diode bar (1), comprising a first refractive interface (8) which can differently deviate at least a multiplicity of the sub-beams (3) of the laser radiation to be shaped, so that they travel at least partially converging together after passing through the first interface (8) more than before passing through the first interface (8), and furthermore comprising a second refractive interface (9) through which the laser radiation can pass after having passed through the first interface (8), the second interface (9) being able to deviate at least some of the sub-beams (3) so that their convergence is reduced.

Owner:LIMO GMBH

a display panel

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Energy-saving LED strip light without dark area

ActiveCN110131598AReduce Luminance InterferenceReduce dark areasLighting support devicesLight fasteningsResistEffect light

The invention discloses an energy-saving LED strip light without dark area, and relates to the technical field of LEDs. The LED strip light comprises a strip light outer light box and a main lamp placement board, the two sides of the inner wall of the strip light outer light box are fixedly connected with the surface of the periphery of the main light placement board, LED luminous main light bodies are fixedly connected with the surface of the main light placement board, and elastic photo-resist resin is arranged on the surface of the main light placement board. By the adoption of the energy-saving LED strip light without the dark area, the light of LED luminous auxiliary light bodies can be completely isolated in the situation of turning on the LED luminous auxiliary light bodies, and disturbance caused by the brightness is reduced; besides, through combination arrangement of a lamp tube brightness adjusting box, a horizontal connection transverse rod, a horizontal adjusting sliding block, connecting swinging rods, sliding connection reset springs, a vertical connecting stabilizing rod and a horizontal auxiliary lighting board, a worker can conduct adjustment manually to push theLED luminous auxiliary light bodies at the bottom of the horizontal auxiliary light board to penetrate through the elastic photo-resist resin, then, the LED luminous auxiliary light bodies can work together with the LED luminous main light bodies, and thus the dark area is reduced.

Owner:江苏仁创建设集团有限公司

Light source module and surface light source assembly thereof

ActiveUS10670791B2Reduce brightness unevennessInhibition formationMechanical apparatusLight guides for lighting systemsLight guideEngineering

A surface light source assembly includes at least one light emitting element, a light guide plate and a reflective sheet. Each of the light emitting elements has an annular light emitting side surface. The light guide plate has a bottom surface and a light exit surface opposite to the bottom surface. The bottom surface has at least one accommodating recess to accommodate at least one light emitting element. Each of the accommodating recesses has a light incident surface. The bottom surface further has a flat portion and at least one inclined surface portion. Each of the inclined surface portions is connected between the flat portion and the light incident surface of the corresponding accommodating recess. The reflective sheet is disposed below the flat portion. A light source module having the surface light source assembly is further provided.

Owner:CORETRONIC

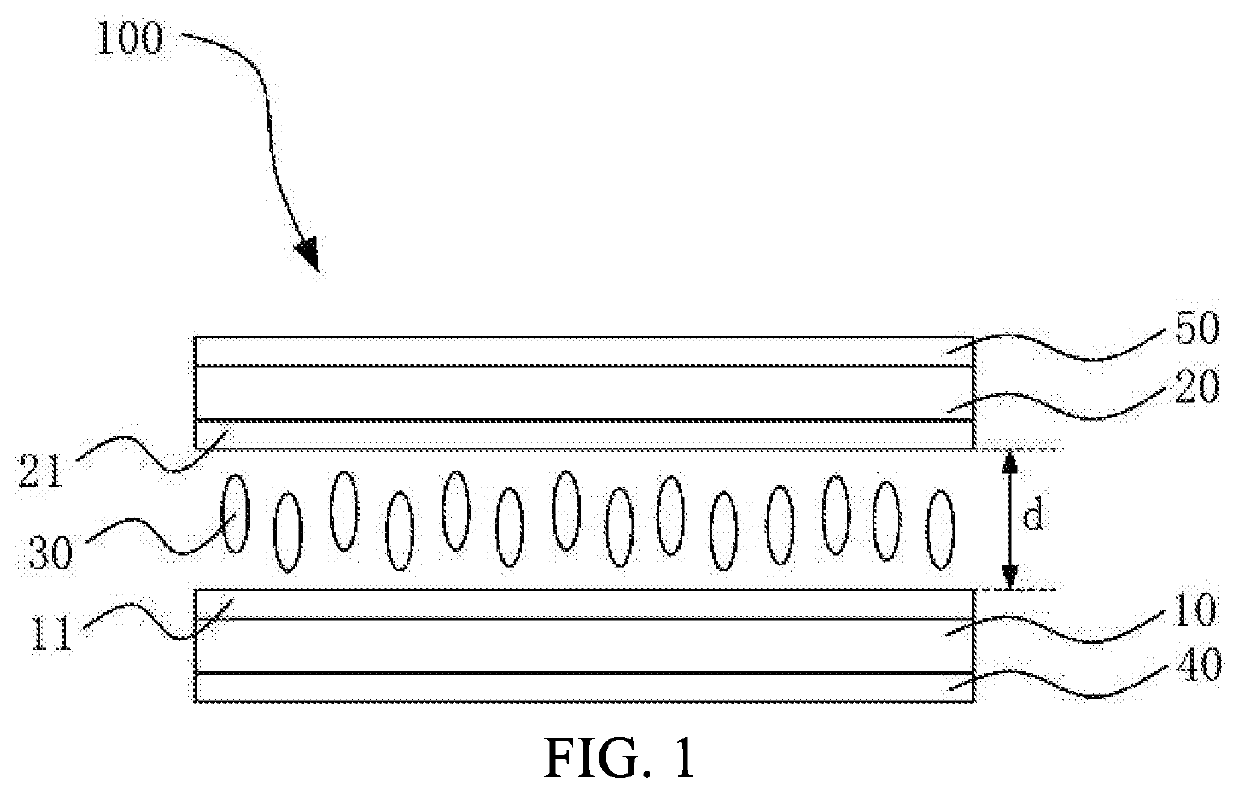

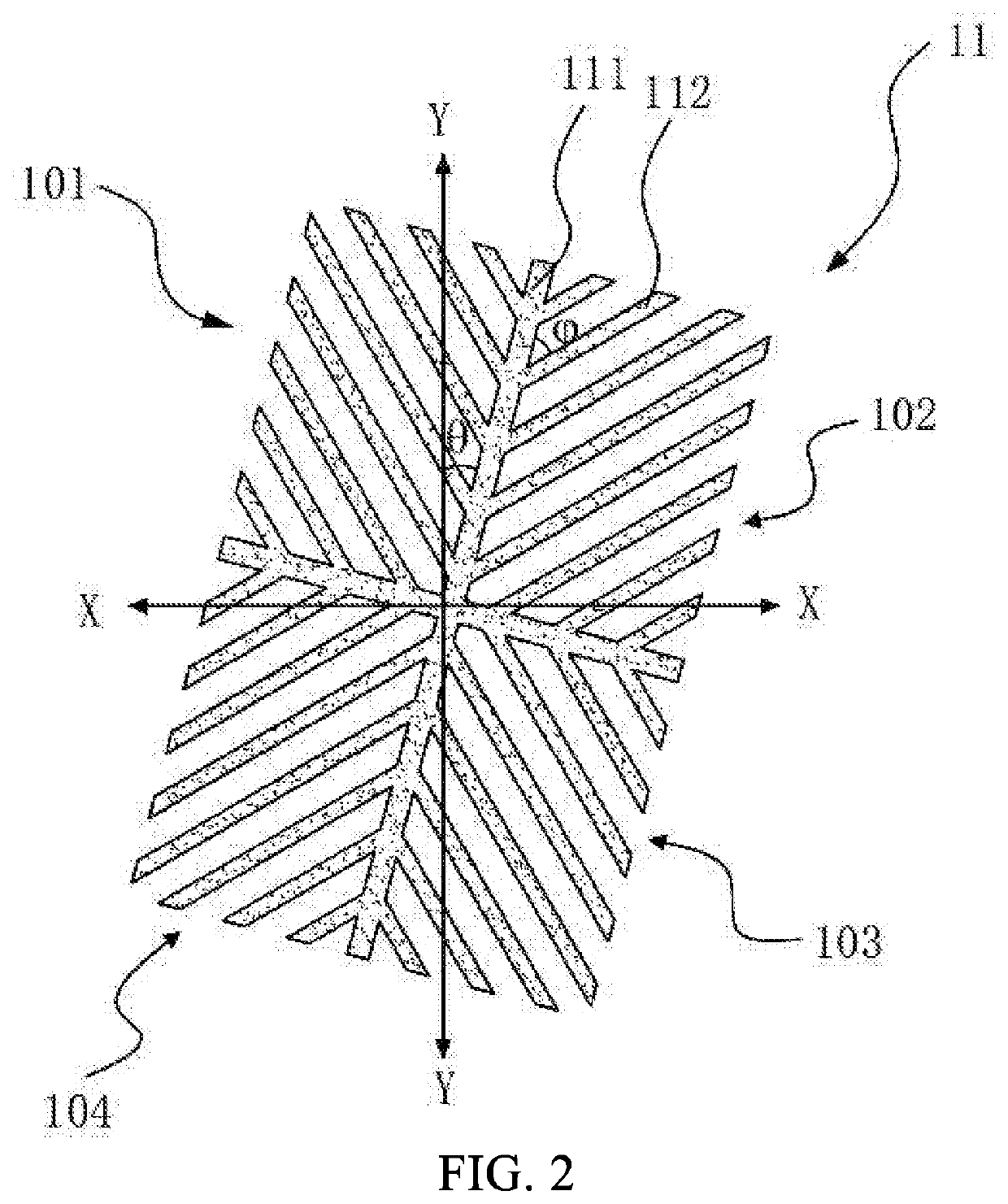

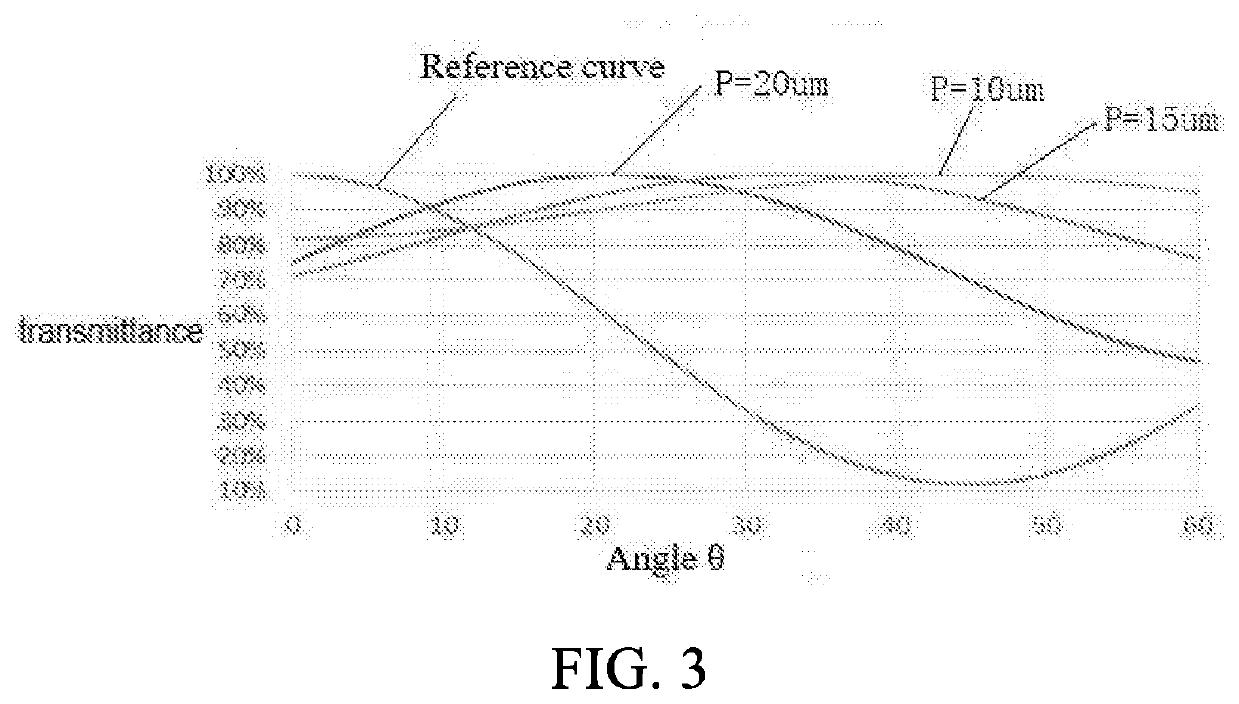

Liquid crystal display device

ActiveUS20210165288A1Reduce dark areasMaximizing transmittanceNon-linear opticsLiquid crystallineLiquid-crystal display

A liquid crystal display device includes a first substrate having a first electrode, a second substrate having a second electrode, a liquid crystal layer, a first polarizer, and a second polarizer. A chiral agent is added in a liquid crystal filled in the liquid crystal layer, a pitch of the liquid crystal is about 8-60 μm; an effective optical path difference of the liquid crystal is about 300-550 nm. By adding a chiral agent to the liquid crystal, changing the angle between the stem electrode and the branch electrode or the angle between the polarization axis of the polarizer and the stem electrode, the transmittance is maximized, thereby achieving high transmittance display.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display panel for curved screen

ActiveUS20160131948A1Increase brightnessQuality improvementNon-linear opticsLiquid-crystal displayArea ratio

An LCD panel applied to a curved screen includes display sections and a black matrix layer. The black matrix layer is used for adjusting an area of the primary sub-pixel and an area of the secondary sub-pixel in each of display section, so that an area ratio of the secondary sub-pixel to the primary sub-pixel in the first display section equals to an area ratio of the secondary sub-pixel to the primary sub-pixel in the central display section, an area ratio of the secondary sub-pixel to the primary sub-pixel in the second display section is greater than that of the secondary sub-pixel to the primary sub-pixel in the first display section, an area of the primary sub-pixel in the central display section is lower than that of the primary sub-pixel in the first display section. Therefore, brightness and quality of the curved screen on image display are improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com