Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Realize back and forth motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

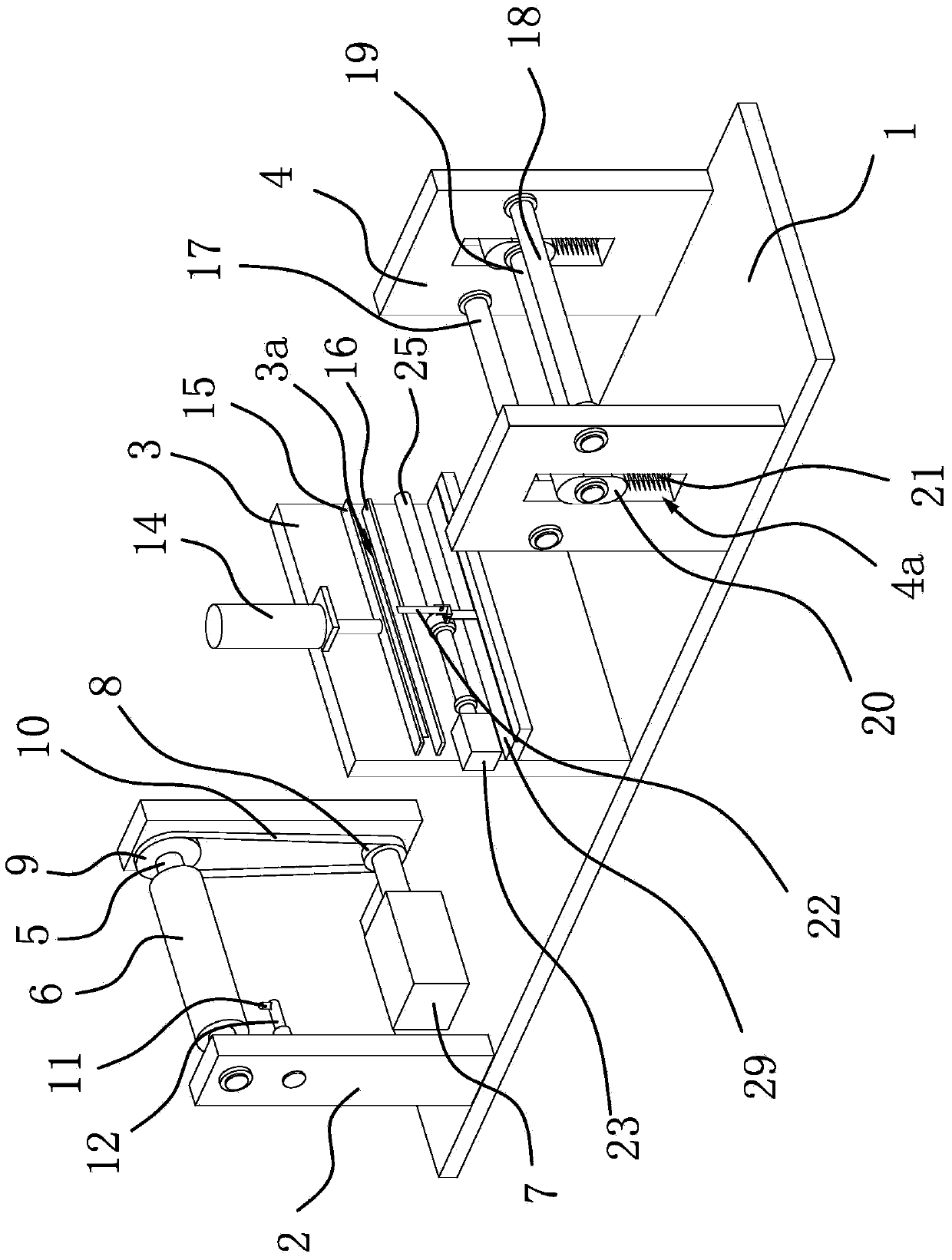

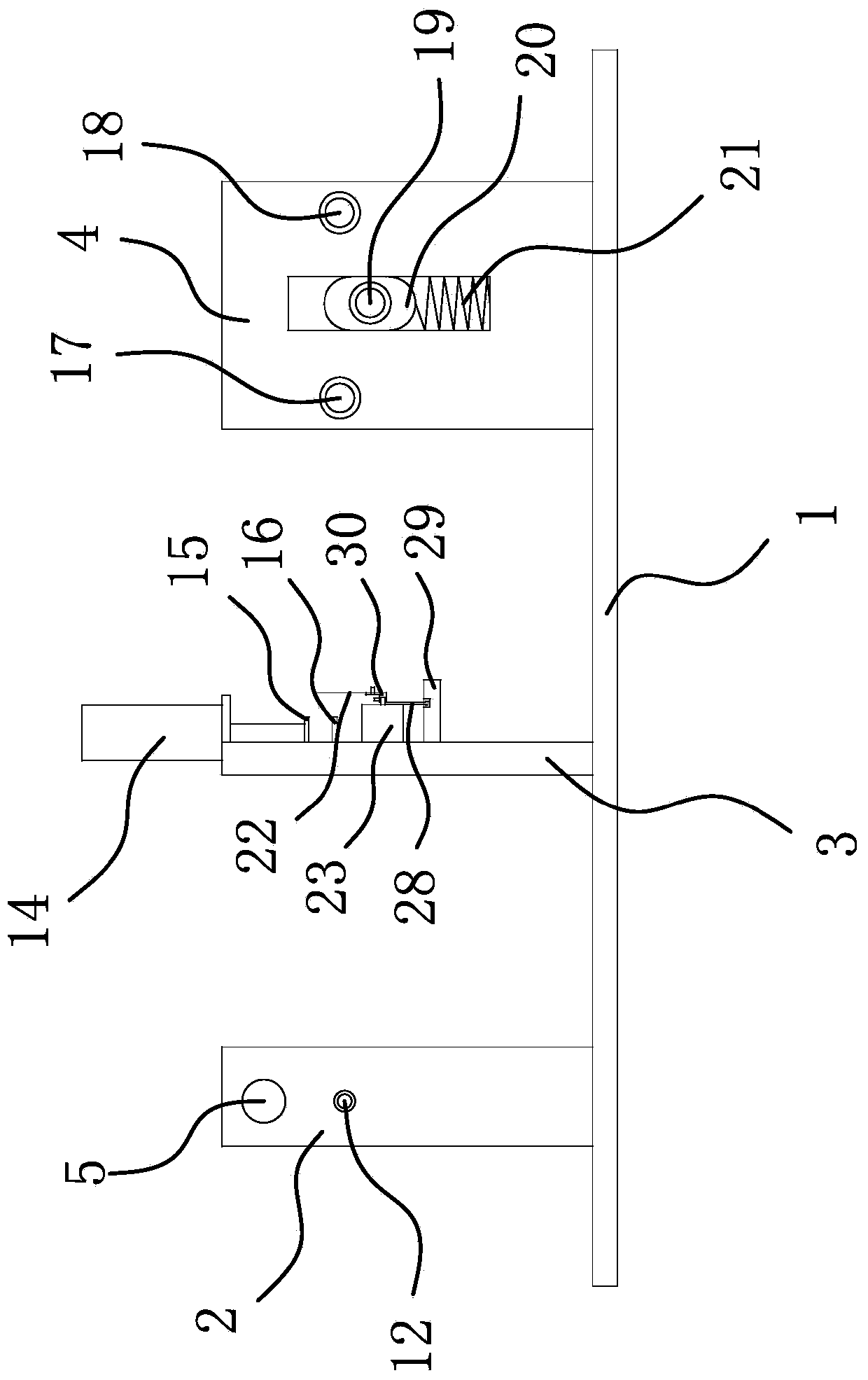

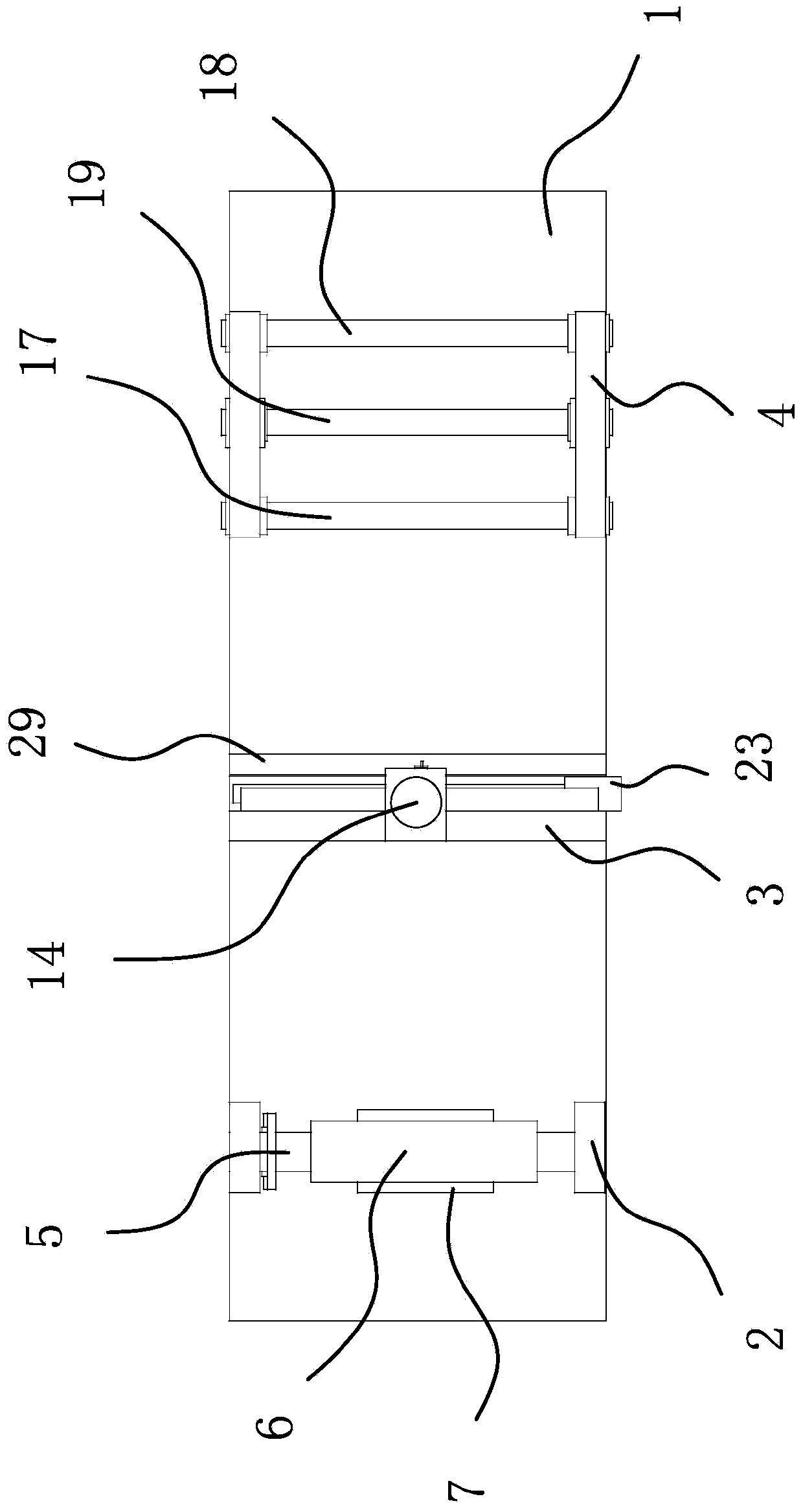

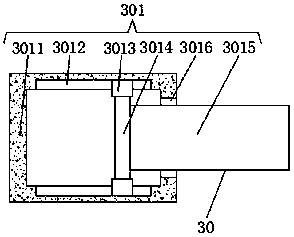

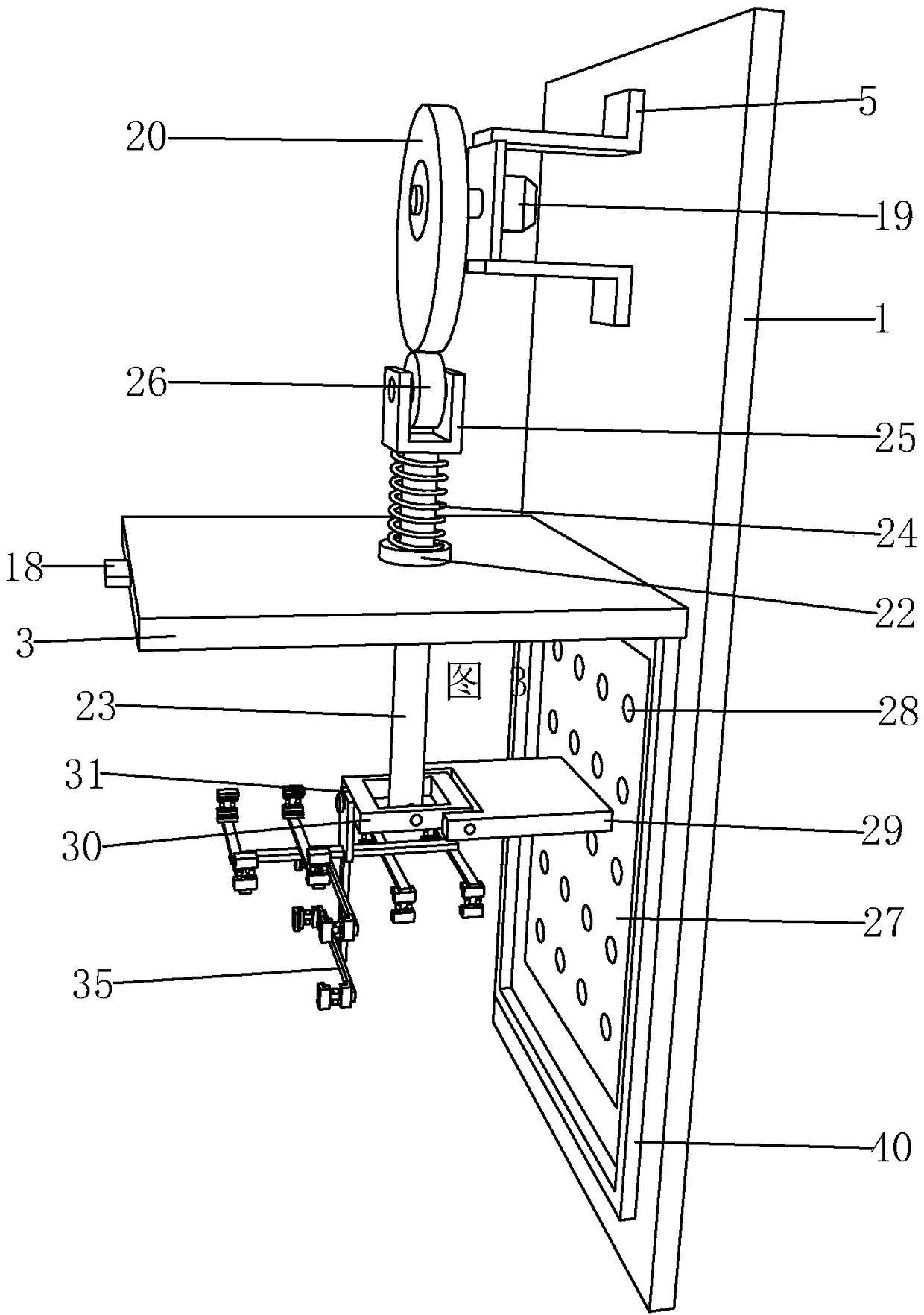

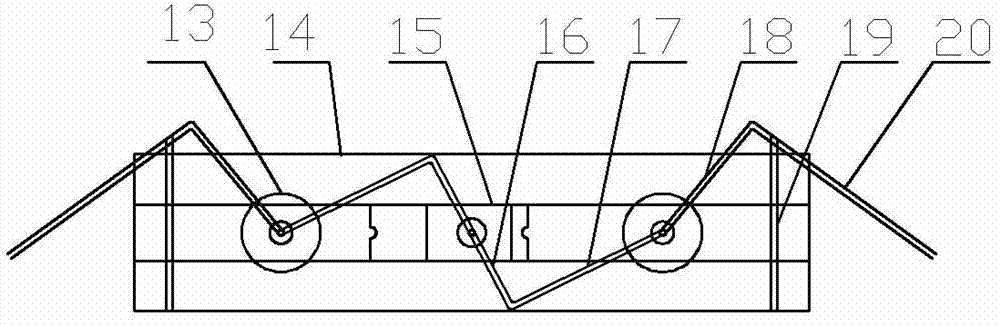

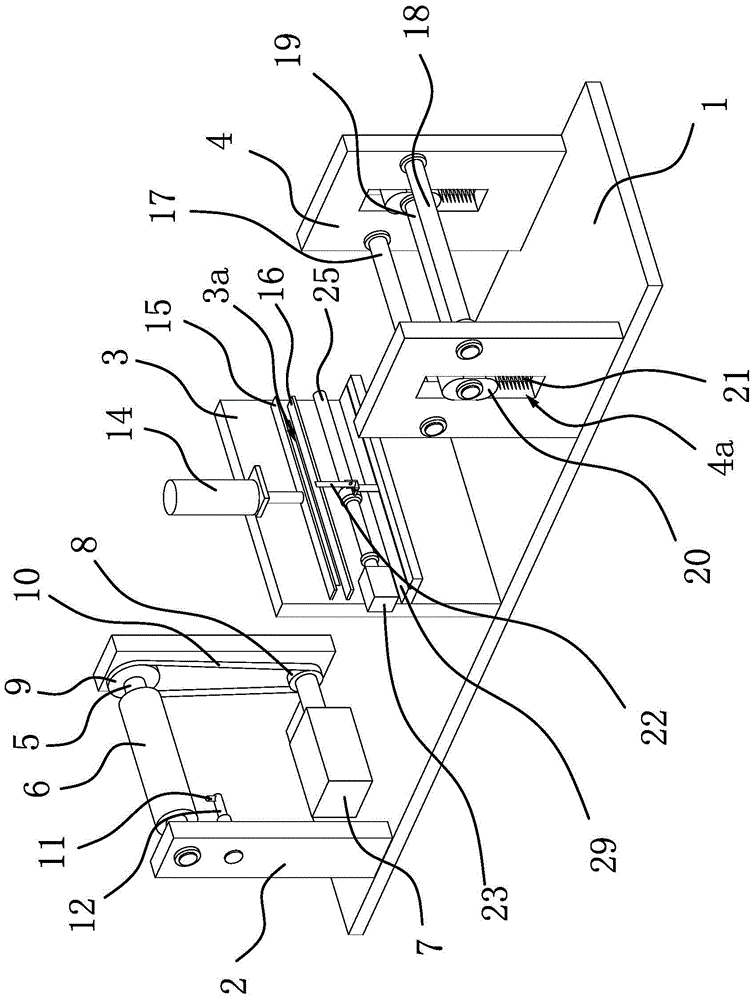

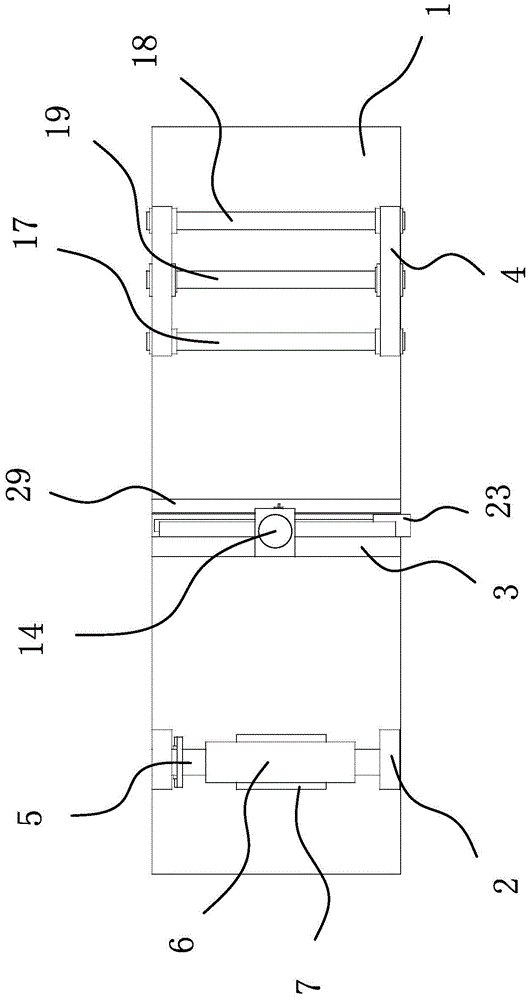

Winding device of BOPP thin film

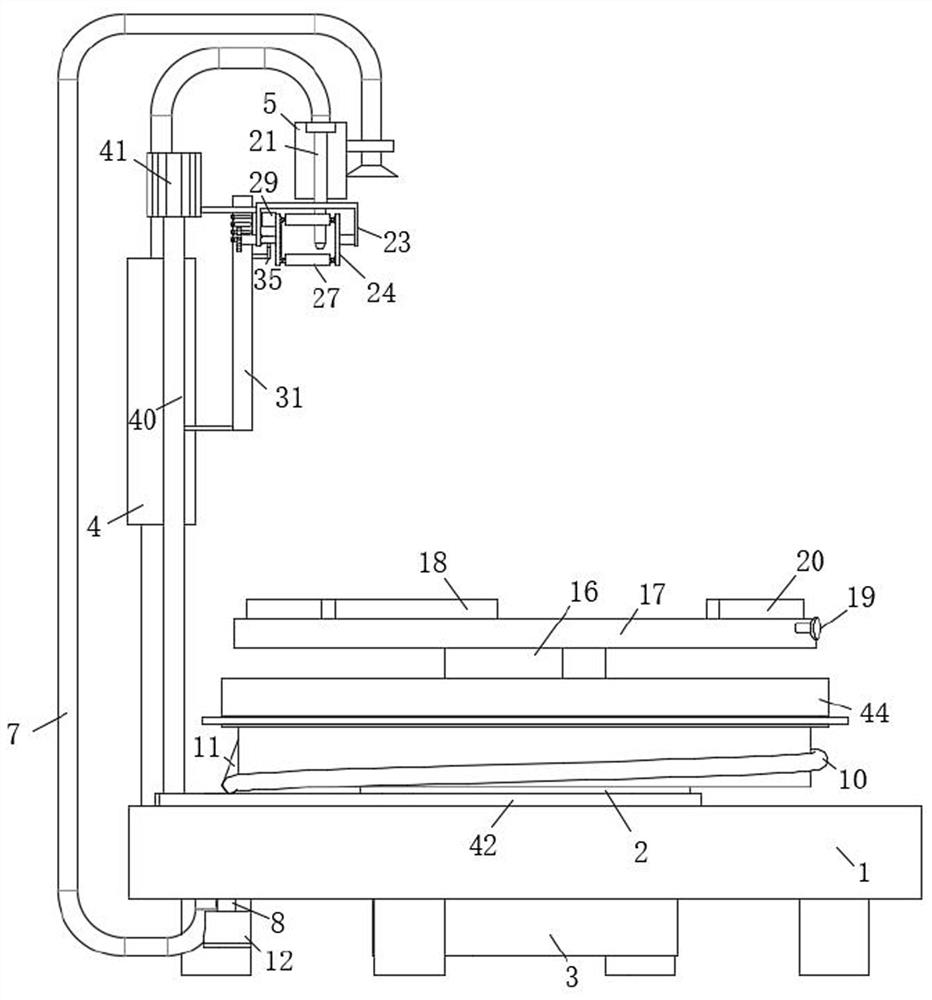

The invention provides a winding device of a BOPP thin film, and belongs to the technical field of machines. The winding device solves the problems that in the prior art, the thin film needs to be manually cut off after being wound, and time and labor are wasted. The winding device of the BOPP thin film comprises a base and a first support arranged on the base; the first support comprises two stand columns; a winding shaft is arranged between the two stand columns, and a winding cylinder is arranged on the winding shaft; a power mechanism is arranged at one end of the winding shaft; a second support is arranged on the right side of the first support; the second support comprises a fixed plate; a clamping mechanism and a slitting blade are arranged on the fixed plate; the slitting blade is connected with a sliding mechanism which can drive the slitting blade to horizontally slide; a third support is arranged on the right side of the second support; the third support comprises two mounting plates; a tensioning mechanism which enables the thin film to be tensioned is arranged between the two mounting plates. According to the winding device, the aim that the thin film is cut off by the device after being wound can be achieved through the clamping mechanism.

Owner:湖南泰利恒友科技开发有限公司

Electromagnetic rocking chair

InactiveCN104106946ALarge swing spanLarge load driving forceChildren furnitureElectromagnets with armaturesMagnetic polesEngineering

The invention discloses an electromagnetic rocking chair. The electromagnetic rocking chair comprises a fixed portion and a movable portion, wherein the movable portion moves relative to the fixed portion; the fixed portion is provided with more than two fixed magnets; the fixed magnets are electromagnets of which magnetic pole directions can be respectively controlled; and the movable portion is provided with moving magnets matched with the fixed magnets. The fixed magnets are electrified, so that the magnetic pole directions of the fixed magnets are fixed, the upper ends of the fixed magnets are S poles, and the lower ends of the fixed magnets are N poles. The upper ends of the moving magnets are N poles, and the lower ends of the moving magnets are S poles. When the moving magnets move to positions right above the fixed magnets, the fixed magnets are electrified to generate magnetic force, repelling force is generated due to homopolar repulsion, and the repelling force and moving inertia of the moving magnets form resultant force which pushes the rocking chair to move smoothly.

Owner:邓美生

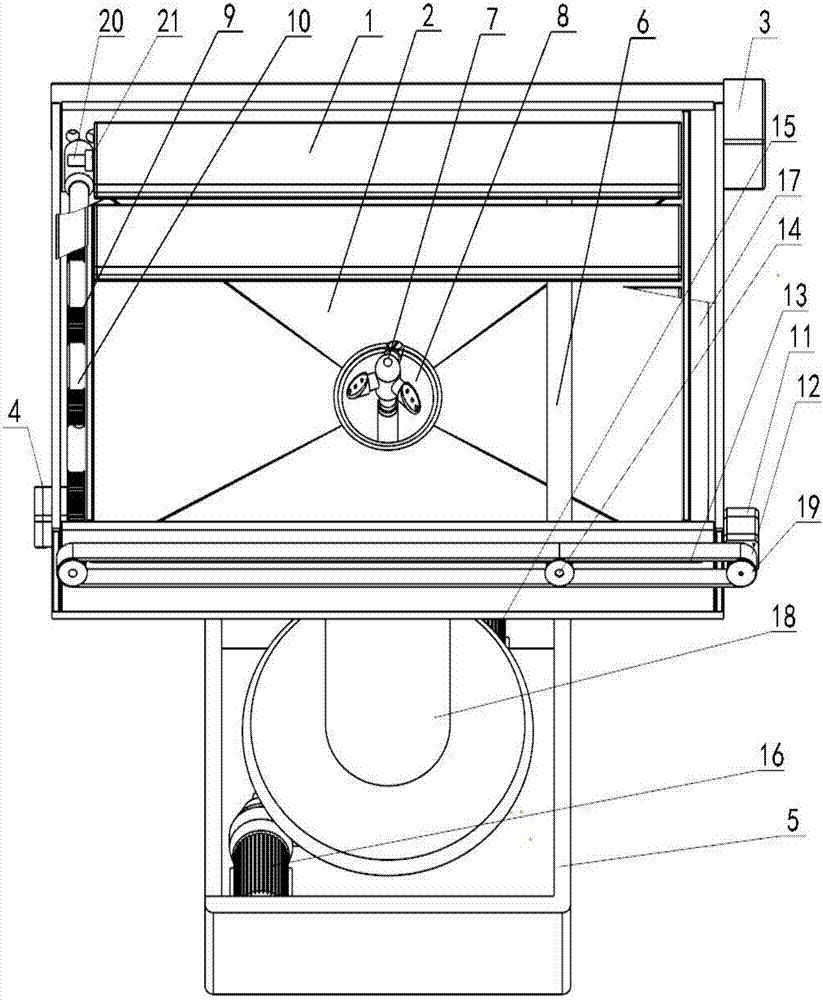

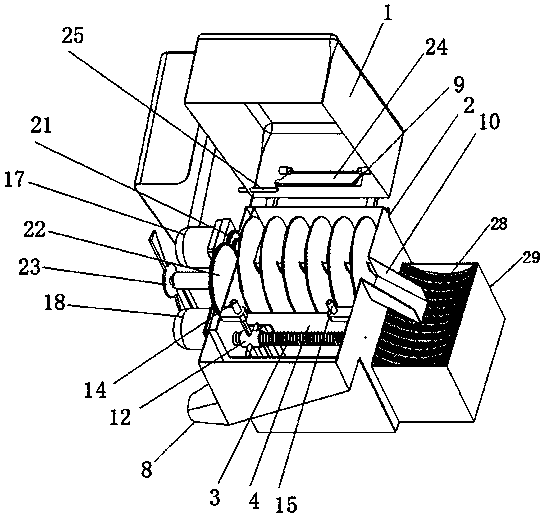

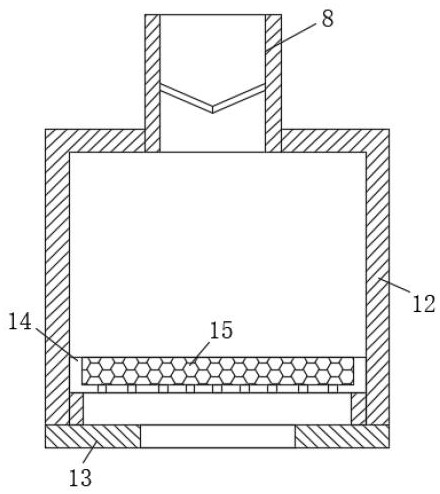

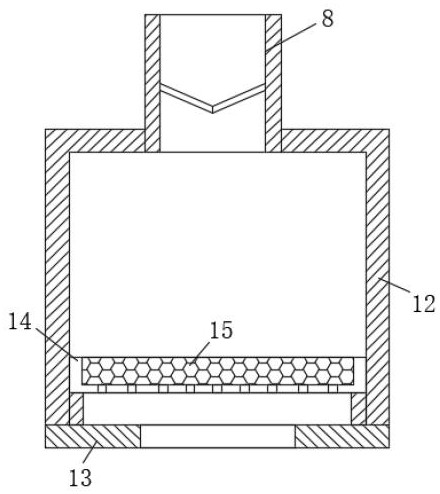

Mobile smoked beef product baking oven

InactiveCN108651597AImprove the quality of smokingAdd flavorMeat/fish preservationHydraulic cylinderCooking & baking

The invention relates to the technical field of beef processing, and discloses a mobile smoked beef product baking oven. The mobile smoked beef product baking oven comprises a bottom plate, wherein universal wheels and hydraulic driving machines are sequentially arranged at the bottom of the bottom plate from left to right; a baking box is fixedly connected to the top of the bottom plate; slidinggrooves are formed in the bottom of an inner cavity of the baking box; a sliding wheel is in slip connection to the inner part of each sliding groove; and a fire pan is fixedly connected to the tops of the sliding wheels. According to the mobile smoked beef product baking oven disclosed by the invention, a motor, a smoking cylinder and hooks are arranged, beef which needs smoking is placed on thehooks, and a driving wheel is driven by the motor to rotate, so that the smoking cylinder on one side of a rotating rod is driven to rotate; and besides, a hydraulic cylinder is utilized to drive thefire pan on one sides of the hydraulic rods to slide back and forth in the sliding grooves, so that the fire pan moves back and forth at the bottom of the smoking cylinder, the situation that the beefis always in dynamic smoking in the smoking process is guaranteed, the purpose of uniformly smoking the beef is realized, and the smoking quality of the beef is improved.

Owner:阜阳市三原食品股份有限公司

Agricultural straw treating device

The invention discloses an agricultural straw treating device. The device comprises a fixing plate, the upper surface of the fixing plate is fixedly connected with the lower surface of a first motor body, and an output shaft of the first motor is fixedly connected to the right side surface of a first gear; the first gear is meshed with a second gear, the second gear is meshed with a third gear, the left side surfaces of the second gear and the third gear are respectively connected to the right ends of two first rotary shafts, and first bearings sleeve the outer surfaces of the first rotary shafts. According to the agricultural straw treating device, by arranging the first motor, the first gear, the second gear, the third gear, the first rotary shafts, connecting rods and smashing blades, the two connecting rods rotate to drive several smashing blades on the two connecting rods to rotate, therefore straw fallen from a first feed inlet can be smashed and more easily compressed, people can more conveniently utilize the smashed straw, and the utilization rate of the straw is greatly improved.

Owner:安徽睿科智能制造技术研究院有限公司

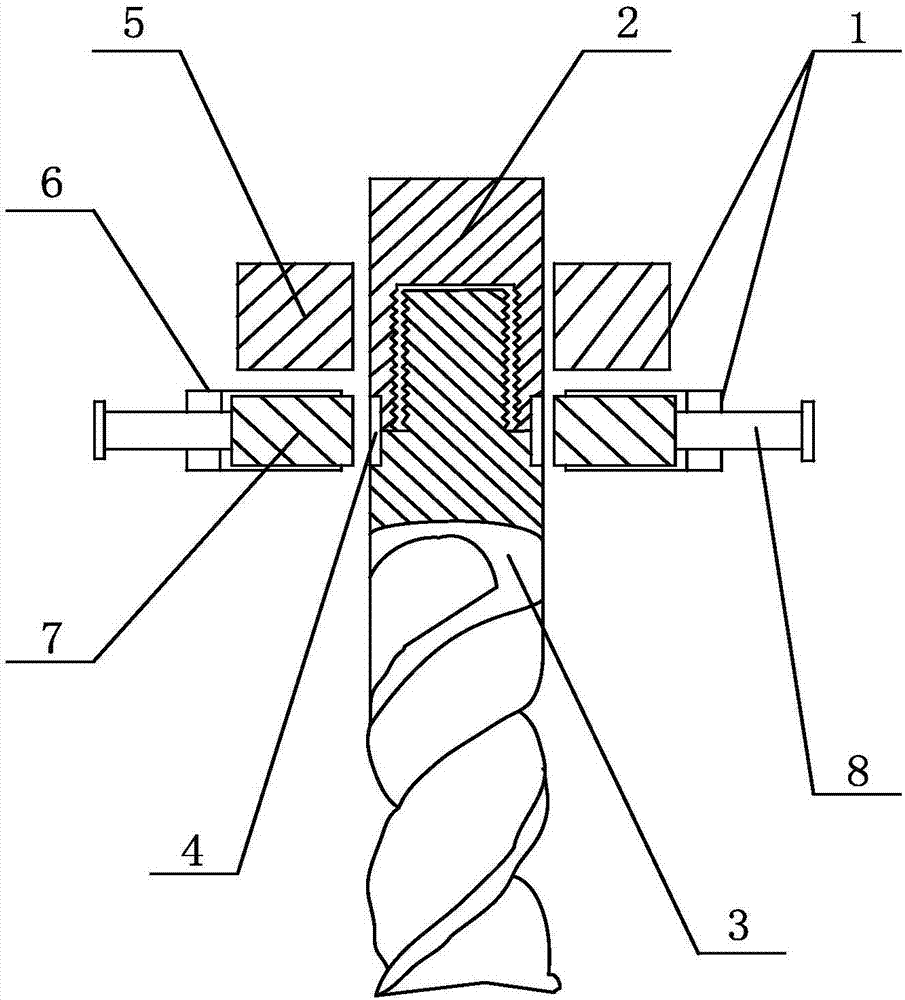

Milling cutter clamping device convenient to install

The invention discloses an easy-to-install milling cutter clamping device, which comprises a clamping seat, a milling cutter handle fixed on the clamping seat, the lower end of the milling cutter handle is connected with a milling cutter head, and the milling cutter handle is connected with the milling cutter holder. The milling cutter heads are connected by threads, and the connection between the milling cutter handle and the milling cutter head is provided with a plurality of limit grooves; the clamping seat includes a tool handle clamping seat and a limit clamping seat, and the cutter The shank clamping seat is used for clamping the milling cutter shank, and the limit clamping seat is located on the outside of the connection between the milling cutter shank and the milling cutter head, and the limit clamping seat is provided with a limit block, and the limit block The shape matches the shape of the limit groove, and the limit block moves back and forth along the direction of the limit groove. The milling cutter clamping device of the present invention can increase the clamping force on the milling cutter, prevent the cutter from deflecting or falling off, improve stability and safety, and at the same time realize rapid replacement of the cutter and improve work efficiency.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

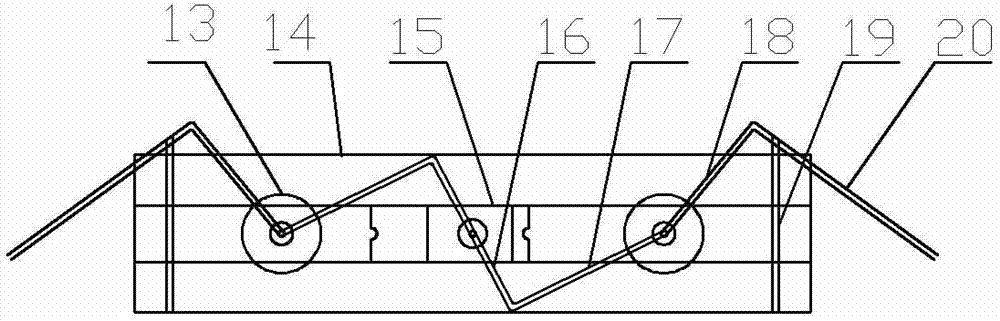

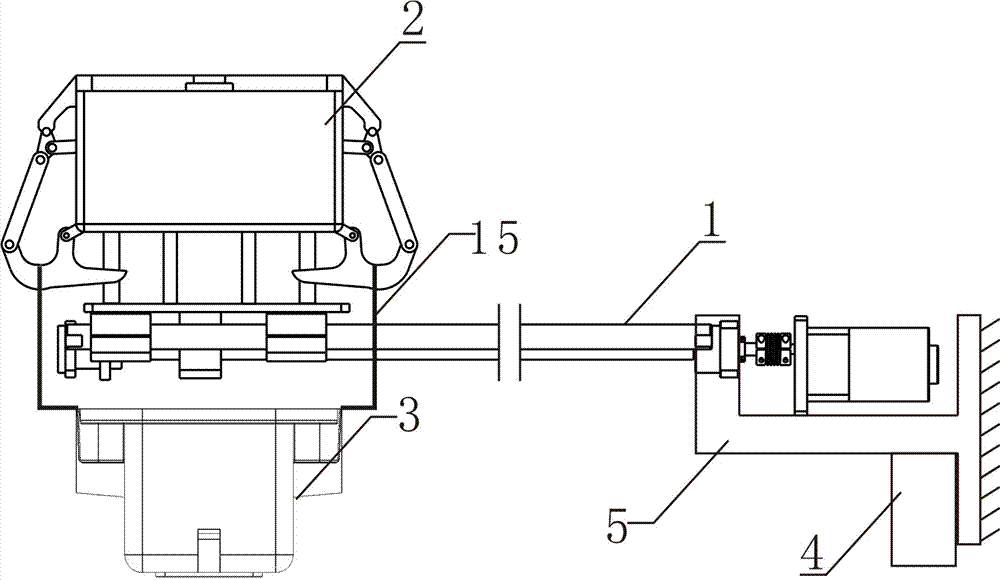

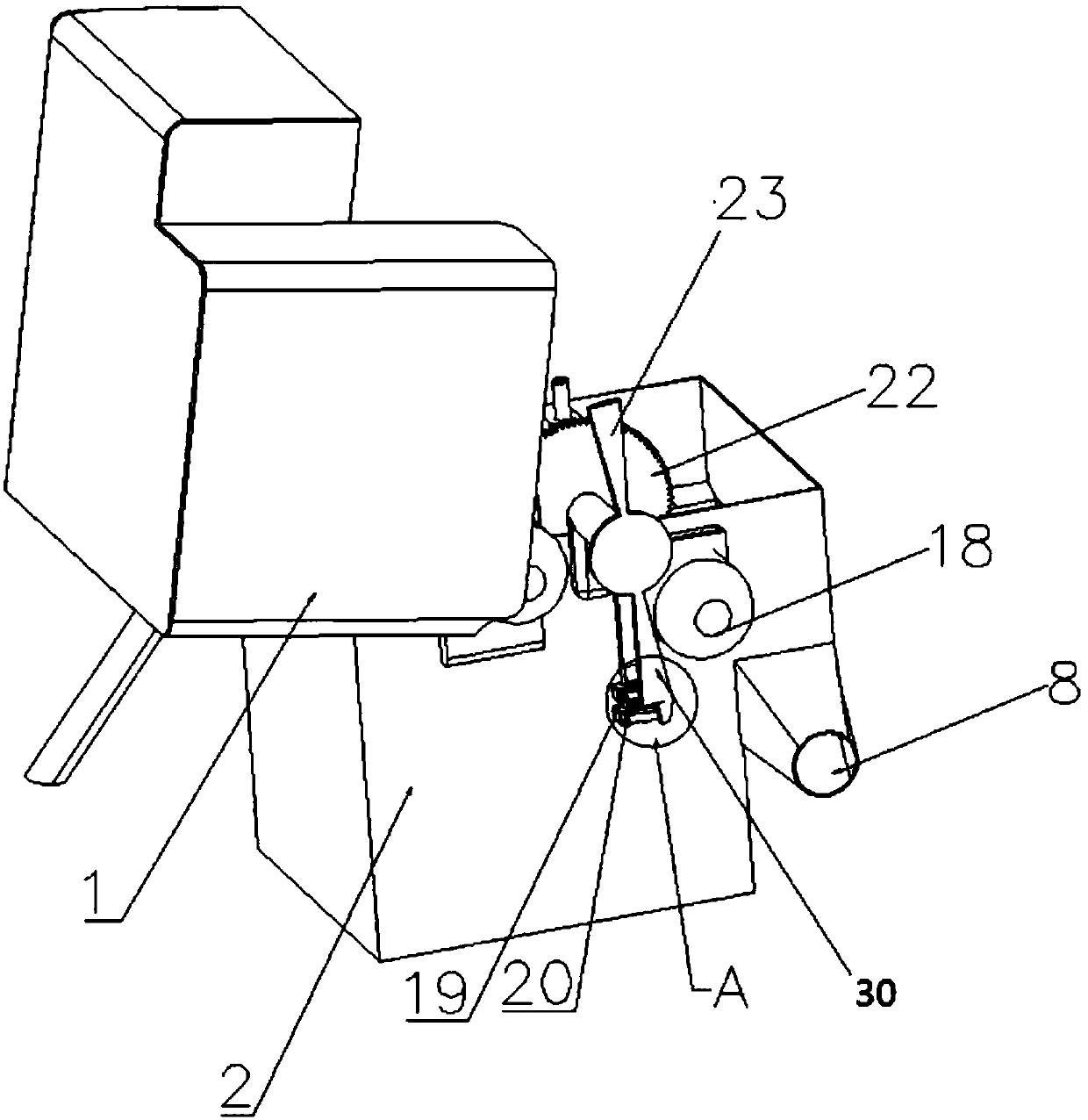

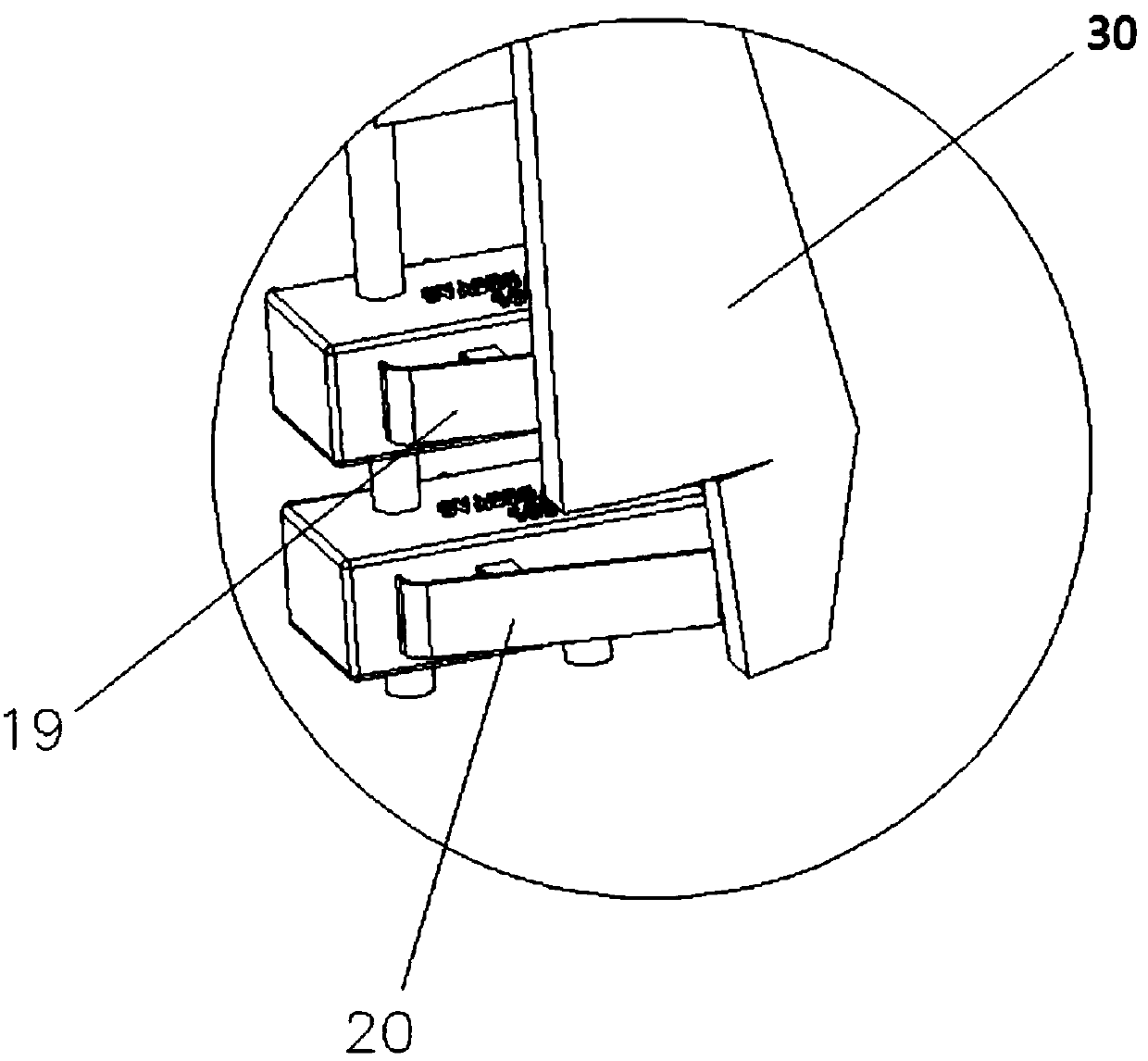

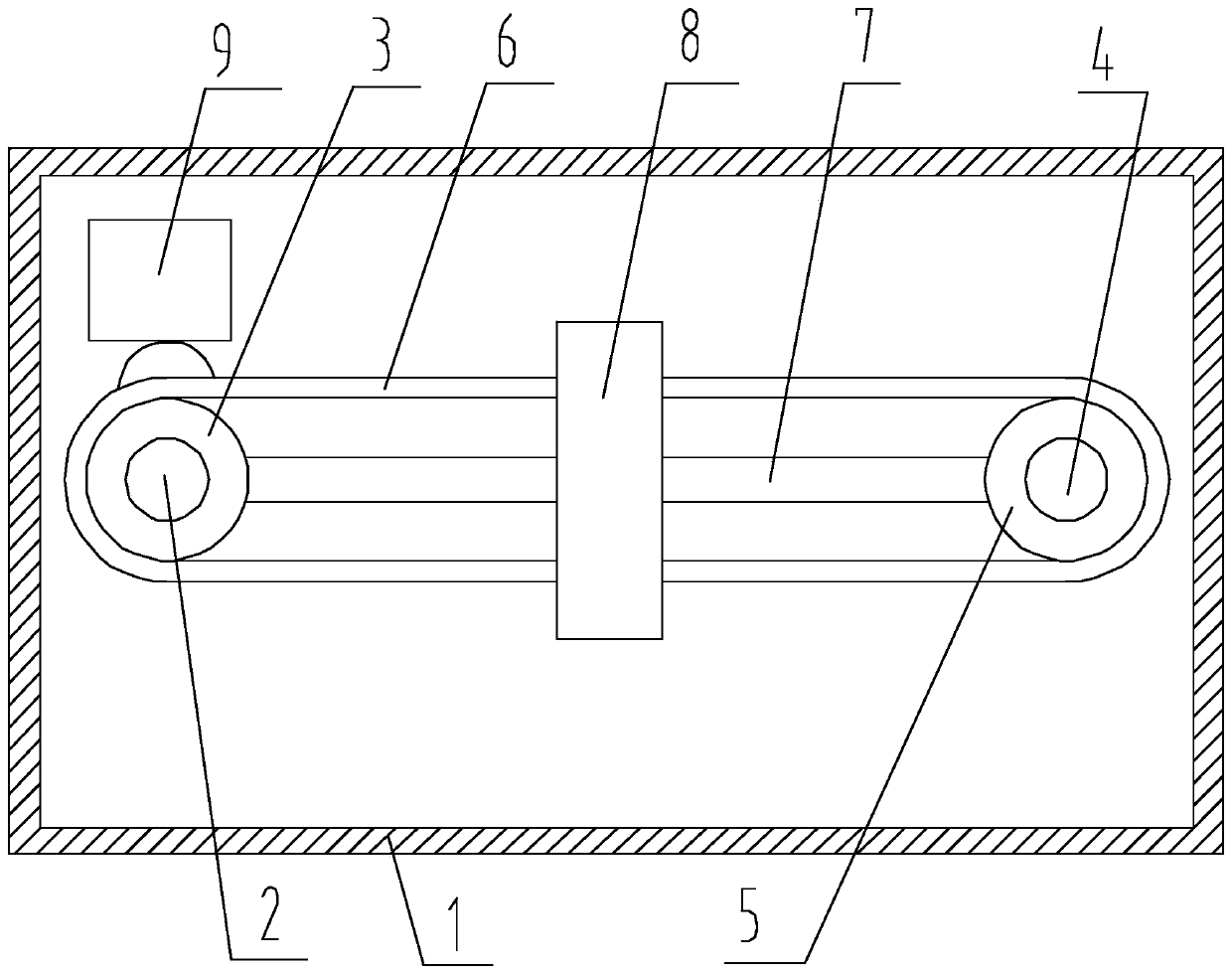

Swing type feeding device

InactiveCN105107987AReduce damageRun smoothlyMetal-working feeding devicesPositioning devicesDrive motorEngineering

The invention provides a swing type feeding device and belongs to the technical field of machining. The swing type feeding device comprises a material clamping mechanism, a feeding mechanism and a swing drive mechanism. The feeding mechanism can be arranged on a sliding rail in a left-right sliding mode. The lower end of a material clamping air cylinder of the material clamping mechanism is connected with an upper material clamping supporting plate. An upper material clamping plate is arranged at the lower end of the upper material clamping supporting plate. A lower material clamping plate is arranged on a material clamping supporting seat. An upper feed material clamping plate of the feeding mechanism is arranged at the lower end of an upper fed material supporting plate. A lower fed material clamping plate is arranged on a material feeding supporting seat. A connection support of the swing drive mechanism is arranged at the lower end of the material feeding supporting seat. One end of a swing arm is hinged to the connection support, and the other end of the swing arm is arranged on a rotary table. The rotary table is arranged on a seat in a rotating mode. One end of a connection rod is hinged to the rotary table, the other end of the connection rod is hinged to one end of a rocking bar, and the other end of the rocking bar is connected with a drive motor. By means of the swing type feeding device, intermittent feeding of panels is achieved, and the swing type feeding device is simple in structure, low in cost, stable in feeding and good in reliability.

Owner:TIANJIN CHAOMAI TECH DEV CO LTD

Remote control type machine sea turtle

The invention discloses a turtle robot. The turtle robot comprises a rectangular plastic box as a body of the turtle robot, wherein a sinking and floating mechanism controlling sinking and floating of the body of the turtle robot is formed in the rectangular plastic box; a plurality of water pumps distributed along three sides of the plastic box are fixedly connected to the outer wall of the rectangular plastic box, and the turtle robot is pushed to move forwards or leftwards and rightwards through the drainage of the water pumps; a rubbish filter is designed under the rectangular plastic box and comprises a water flow box; a propeller device is fixedly connected to the front of the water flow box and used for sucking water flow into the water flow box; a rubbish filtering net is formed behind the water flow box; a body movement driving mechanism is fixedly connected to the rubbish filter and is used for driving four limbs of the turtle robot to move; and a designed control system is used for controlling the sinking and floating mechanism, the water pumps, the body movement driving mechanism and the propeller device to work. The turtle robot is novel and reasonable in structure. Compared with other bionic turtles, the turtle robot is low in cost and integrates the functions of amusing and cleaning, thus having a high potential market value in places such as marine museums and swimming pools.

Owner:NANTONG UNIVERSITY

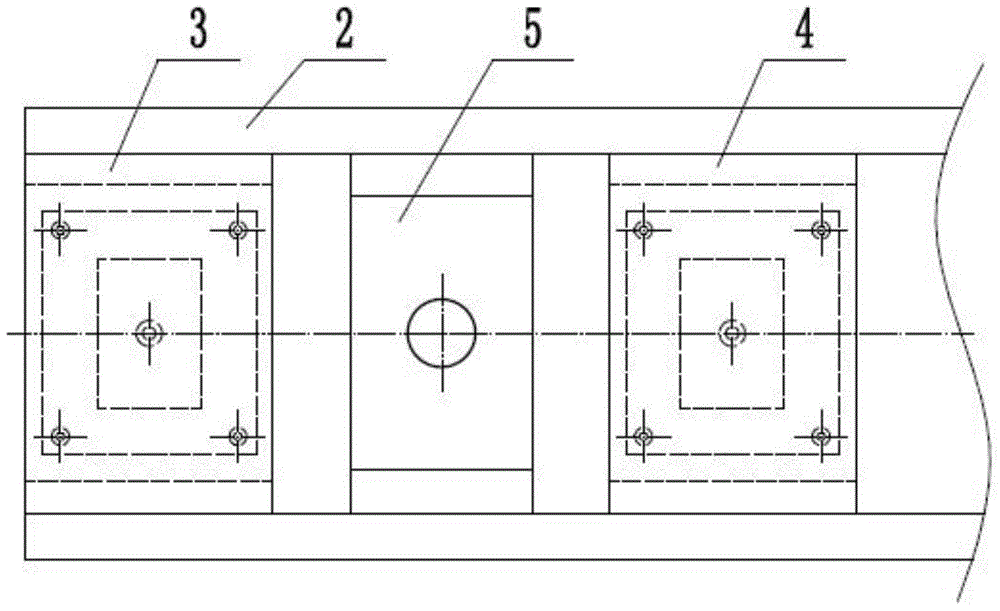

Multi-station continuous punching machine for machine part machining

ActiveCN113290127ARealize continuous punching processImprove work efficiencyMetal-working feeding devicesPositioning devicesMachine partsPunching

The invention discloses a multi-station continuous punching machine for machine part machining, which comprises a base, wherein a mounting seat is fixedly mounted at the bottom of the base, a rotating shaft is rotatably mounted in the mounting seat, two supporting plates are fixedly mounted on the upper surface of the rotating shaft, and a fixing frame is fixedly connected to the tops of the two supporting plates; a supporting mechanism used for placing a workpiece is connected to the fixing frame, a punching mechanism used for punching is fixed to the side wall, close to the top, of the base, the punching mechanism comprises a sliding rail, the sliding rail is fixedly mounted on the side wall of the base, a sliding block is slidably mounted in the sliding rail; two second connecting rods are rotationally mounted on the sliding block through fixing blocks, and a punching head used for punching is fixed to the bottom end of a vertical rod. According to the multi-station continuous punching machine, feeding of stations is driven in the punching rising process, so that the continuous punching process of workpieces can be achieved, and the working efficiency is greatly improved.

Owner:荆梅

Dining table capable of achieving automatic cleaning

The invention relates to a dining table that can be cleaned automatically, comprising a table body, a support column and a water tank; the support column is vertically placed on the water tank, and the table body is horizontally arranged on the top of the support column; the table The body is a square structure, and the upper surface of the table body is made up of a plurality of reversible panels. A clean room is provided in the table body, and a clean room is provided in the clean room by pumping the clean water in the water tank. And a cleaning device for automatically cleaning the bottom surface of the flipped panel. The beneficial effect of the invention is that the desktop with oil stains after eating can be automatically cleaned, the cleaning quality can be greatly improved, and manpower can be saved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Turtle robot

The invention discloses a turtle robot. The turtle robot comprises a rectangular plastic box as a body of the turtle robot, wherein a sinking and floating mechanism controlling sinking and floating of the body of the turtle robot is formed in the rectangular plastic box; a plurality of water pumps distributed along three sides of the plastic box are fixedly connected to the outer wall of the rectangular plastic box, and the turtle robot is pushed to move forwards or leftwards and rightwards through the drainage of the water pumps; a rubbish filter is designed under the rectangular plastic box and comprises a water flow box; a propeller device is fixedly connected to the front of the water flow box and used for sucking water flow into the water flow box; a rubbish filtering net is formed behind the water flow box; a body movement driving mechanism is fixedly connected to the rubbish filter and is used for driving four limbs of the turtle robot to move; and a designed control system is used for controlling the sinking and floating mechanism, the water pumps, the body movement driving mechanism and the propeller device to work. The turtle robot is novel and reasonable in structure. Compared with other bionic turtles, the turtle robot is low in cost and integrates the functions of amusing and cleaning, thus having a high potential market value in places such as marine museums and swimming pools.

Owner:NANTONG UNIVERSITY

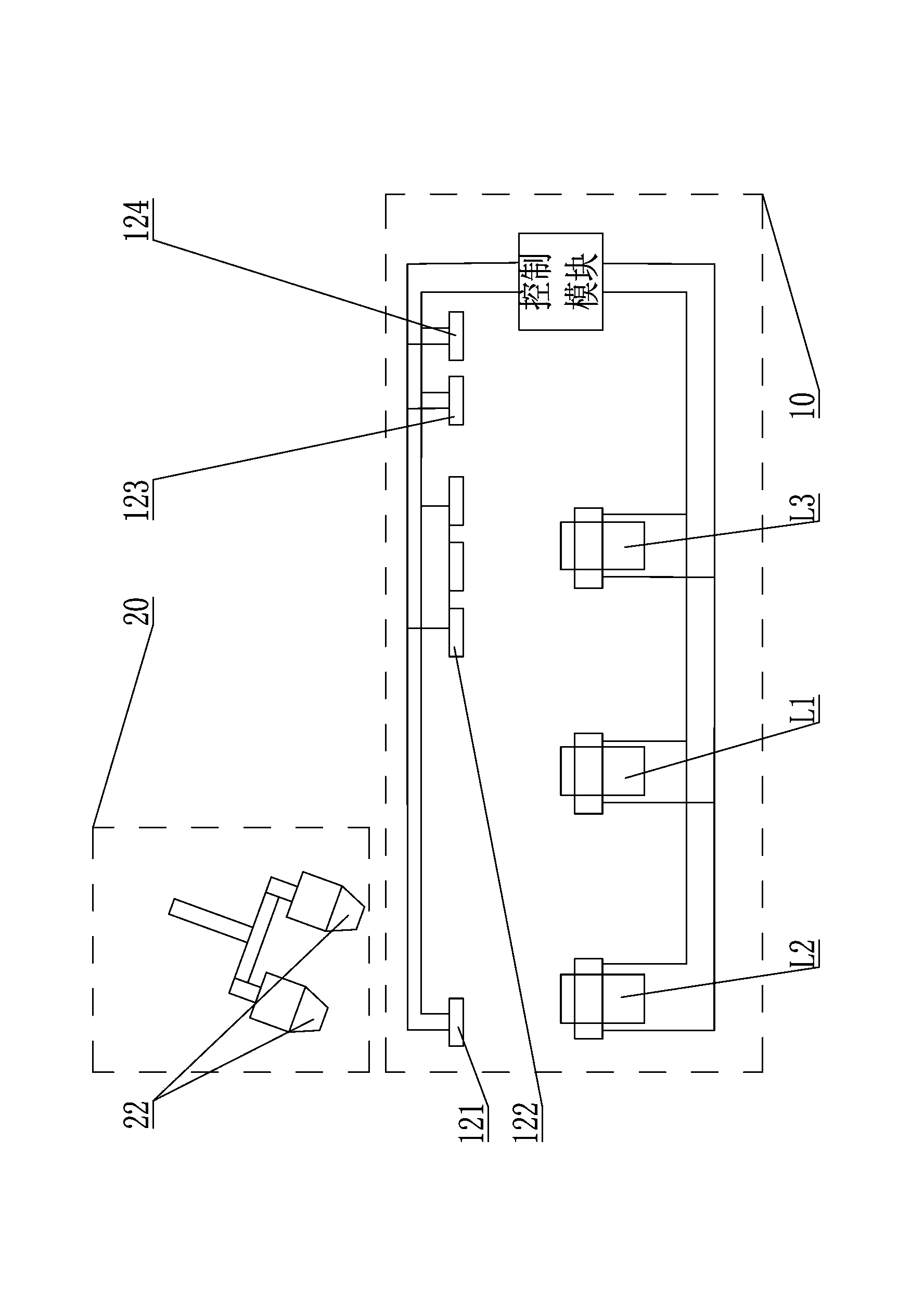

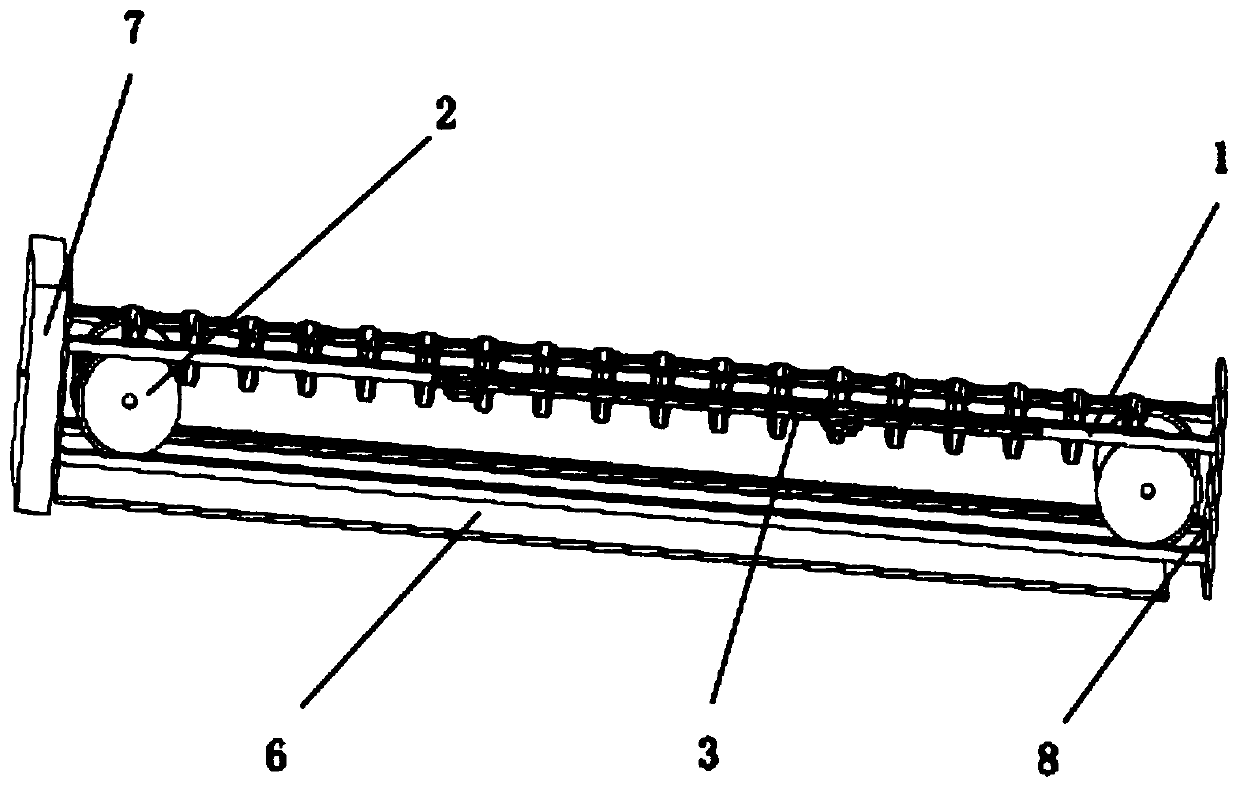

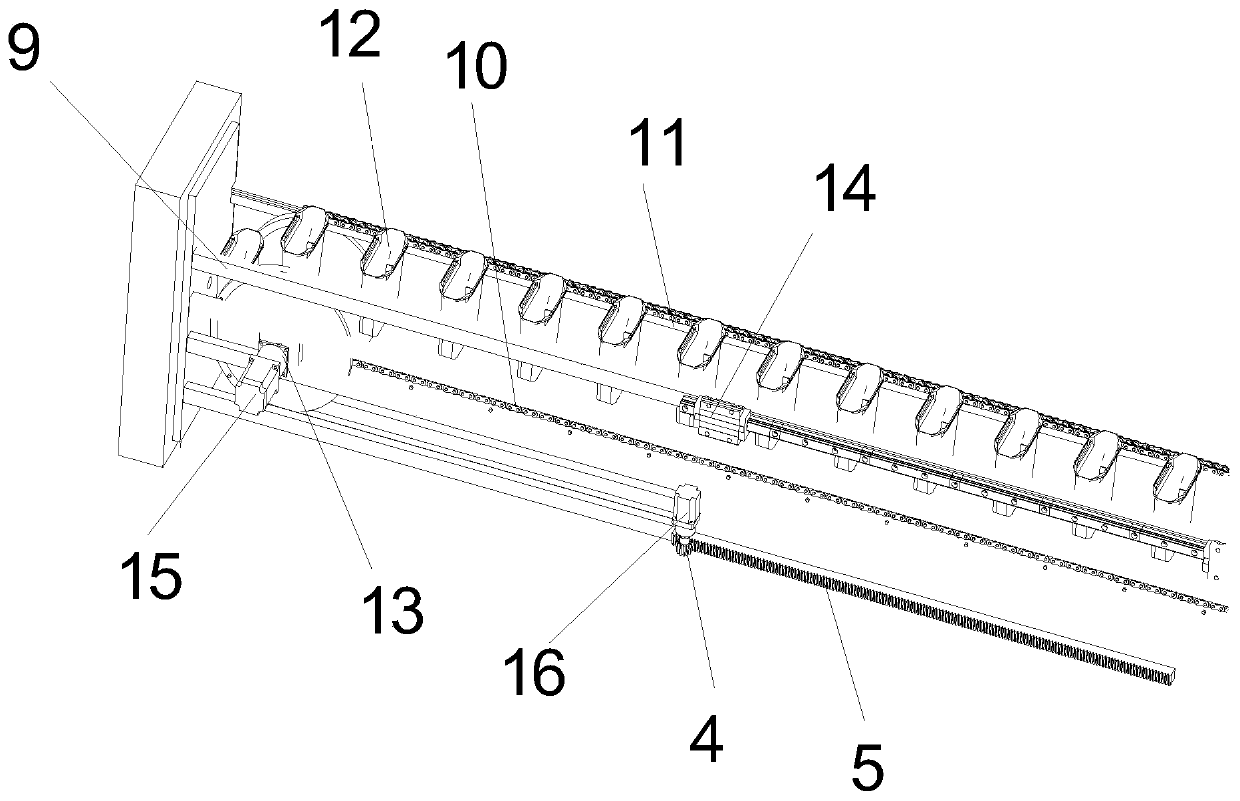

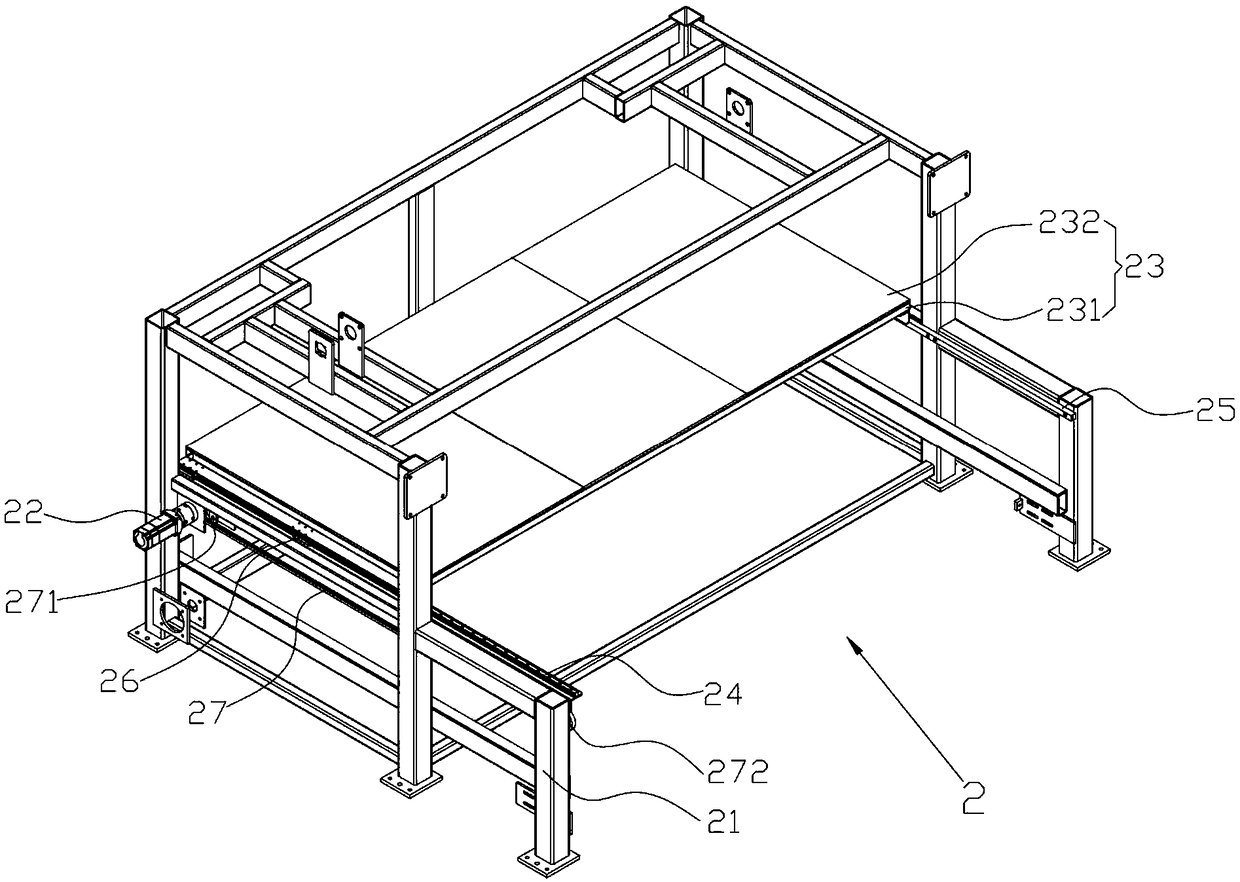

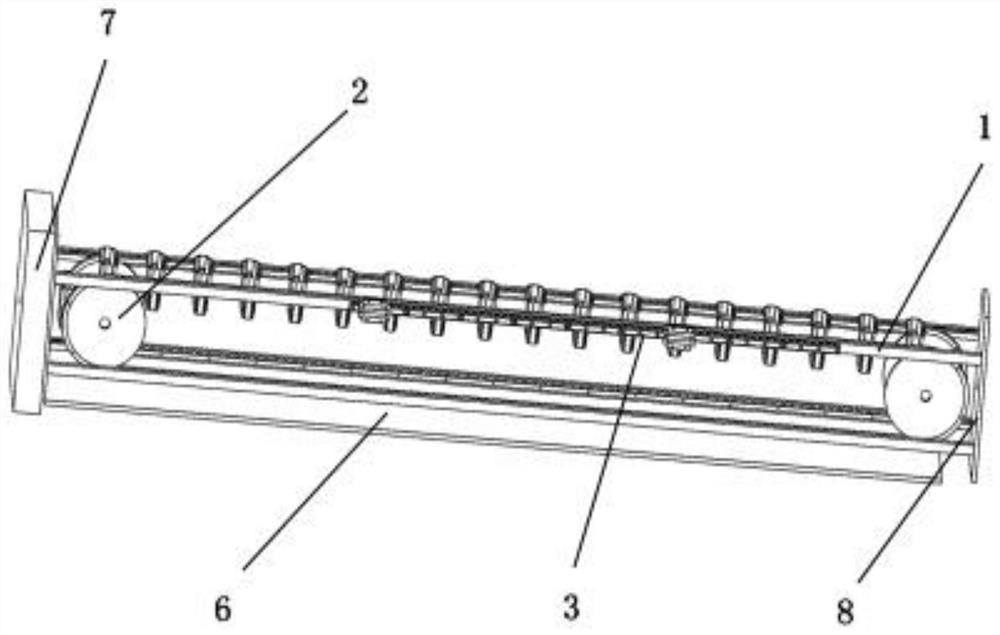

Servo chain conveyor belt based on intelligent cold storage application of blood station

ActiveCN109760980AMovement precisionLow temperature requirementConveyorsStorage devicesSprocketChain conveyor

The invention discloses a servo chain conveyor belt based on the intelligent cold storage application of a blood station. The servo chain conveyor belt includes a frame, sprockets, a sliding rail, gears and a gear rack, wherein the frame is composed of a bottom plate, and a cold storage door and an inner baffle that are arranged at two ends of the bottom plate, and a plurality of supporting aluminum profiles which are sequentially connected with the same side of the cold storage door and the inner baffle; the sprockets are arranged inside the cold storage door and the inner baffle; the sprockets are sleeved with chains; the sliding rail is fixed to the outside of the upper connecting sides of the supporting aluminum profiles; a sliding block is arranged on the sliding rail; the gear rack is arranged outside the lower connecting sides of the supporting aluminum profiles; and the gears are arranged on the gear rack. According to the chain conveyor belt, light aviation aluminum profiles are used as a frame, is not deformed under a large temperature difference, and has stable mechanical properties and light weight; at the same time, a servo is used to drive the chain conveyor belt so that the belt can accurately move to a designated position; and the chain conveyor belt has a lower-temperature requirement, can adapt to low-temperature environment, and is conducive to usage and popularization.

Owner:CHANGSHA IMADEK INTELLIGENT TECH CO LTD

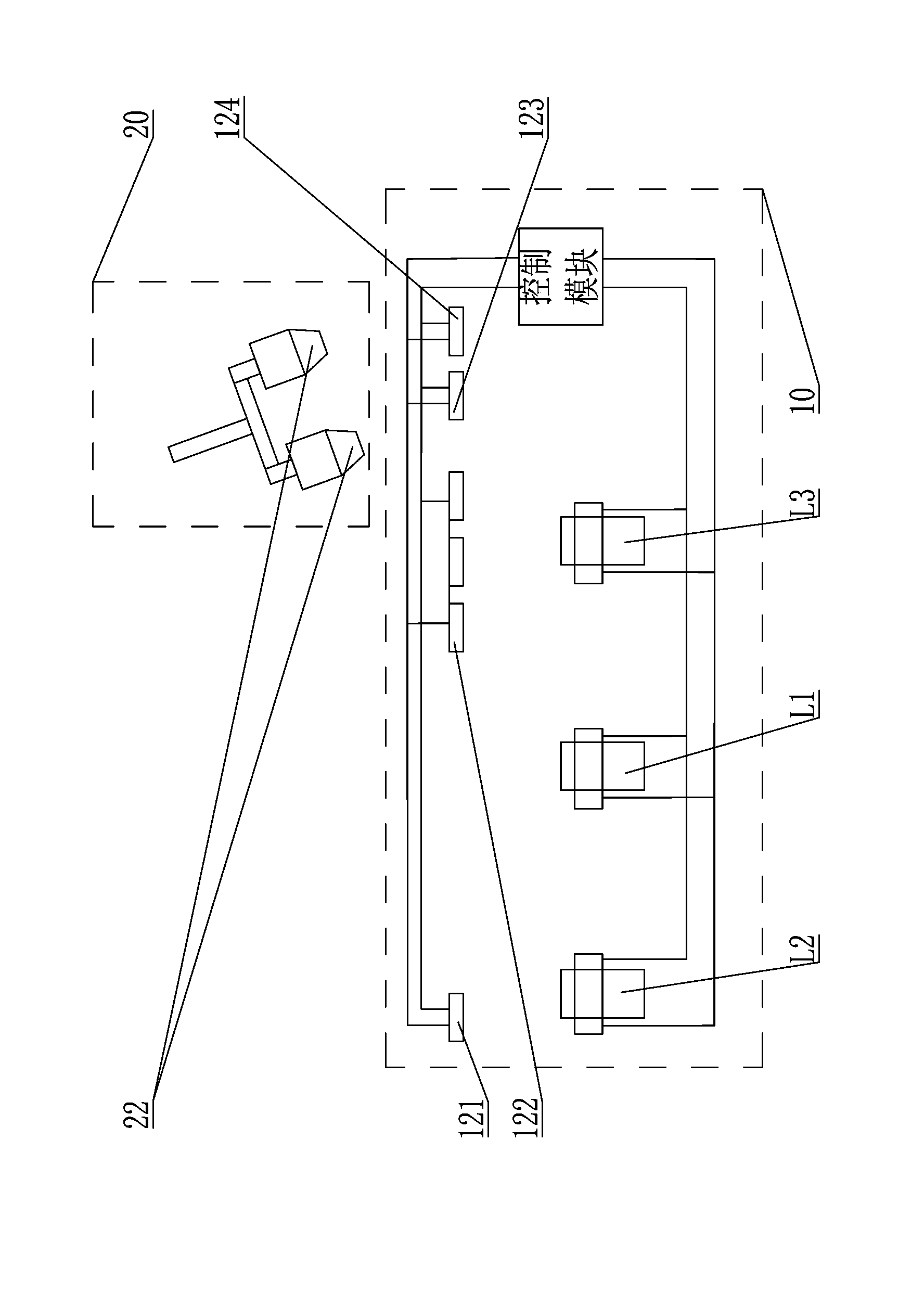

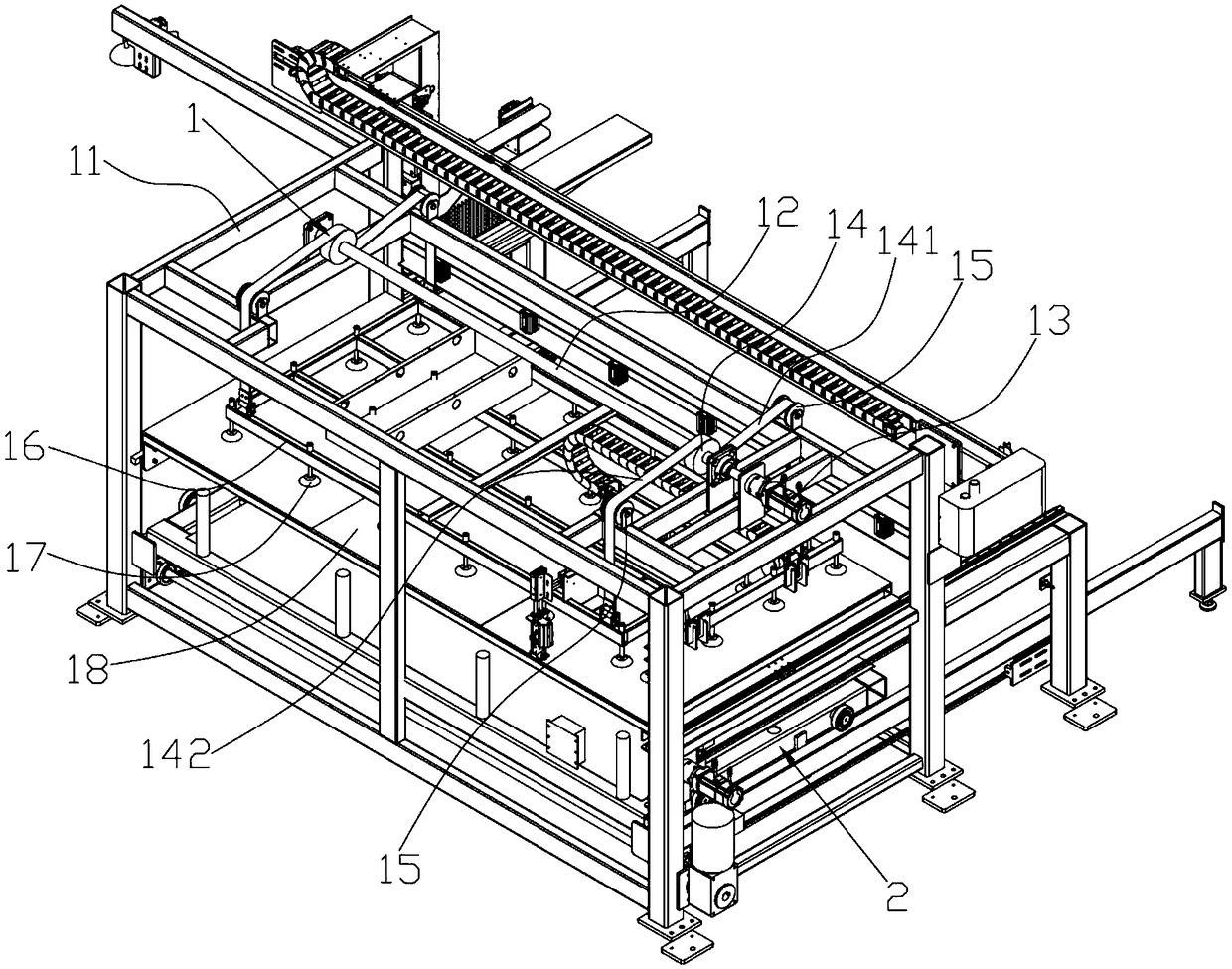

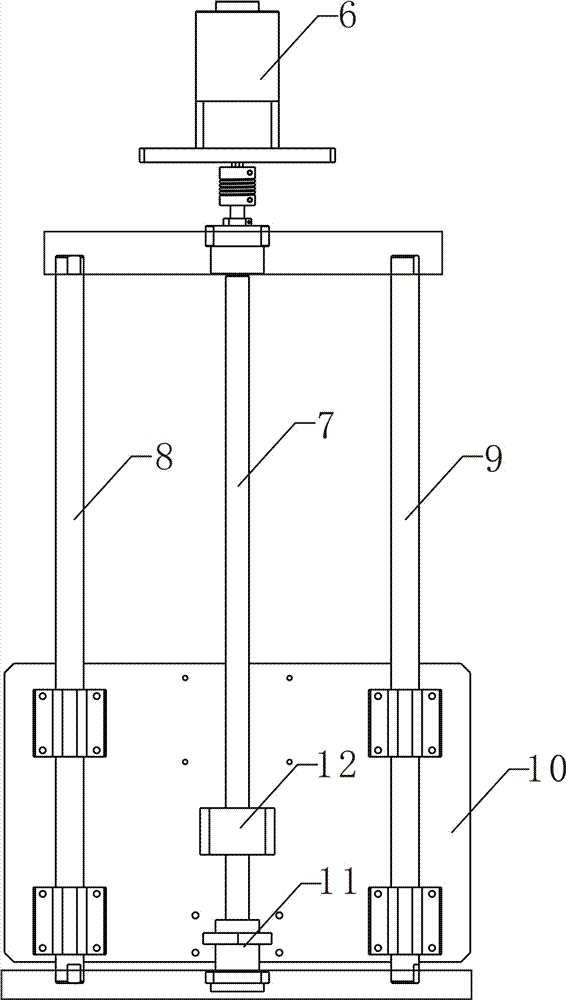

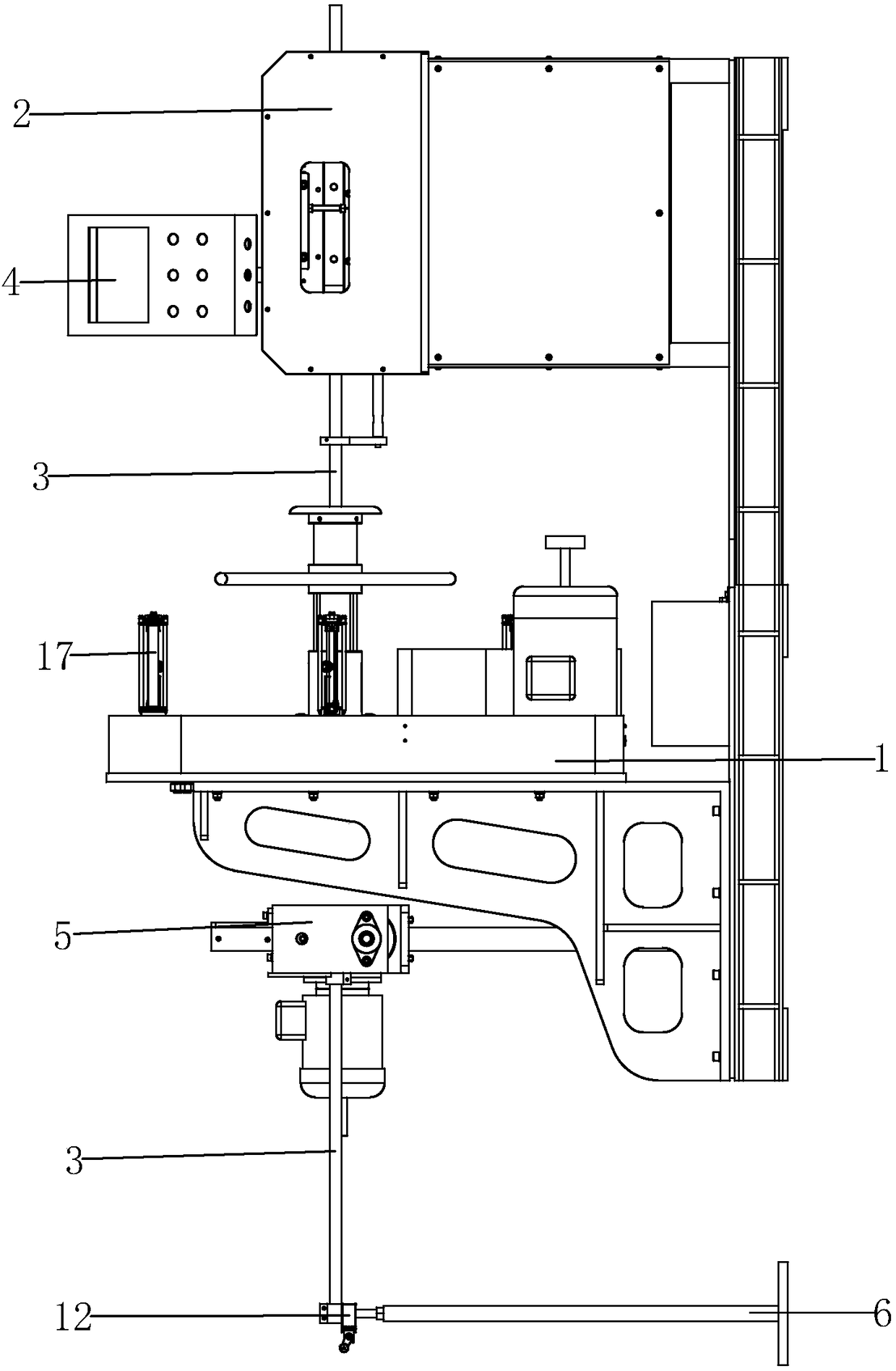

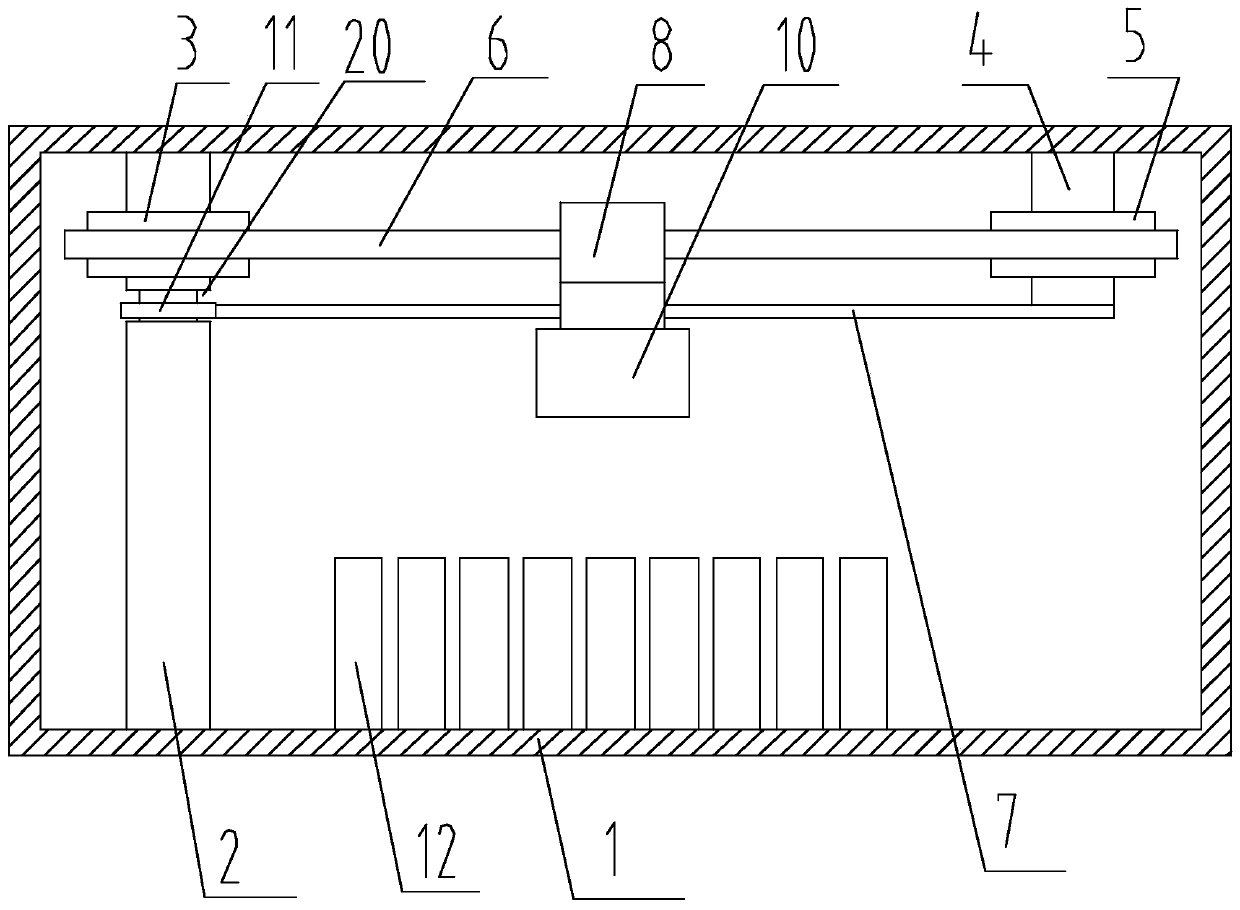

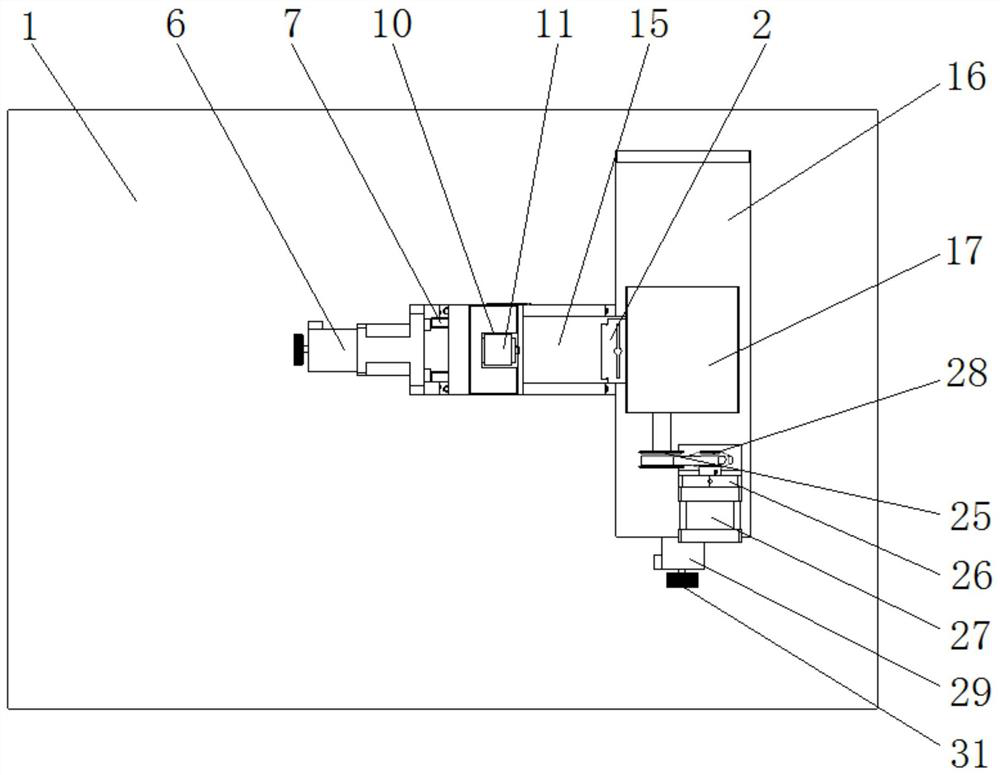

Automatic feeding and discharging equipment for numerical control press

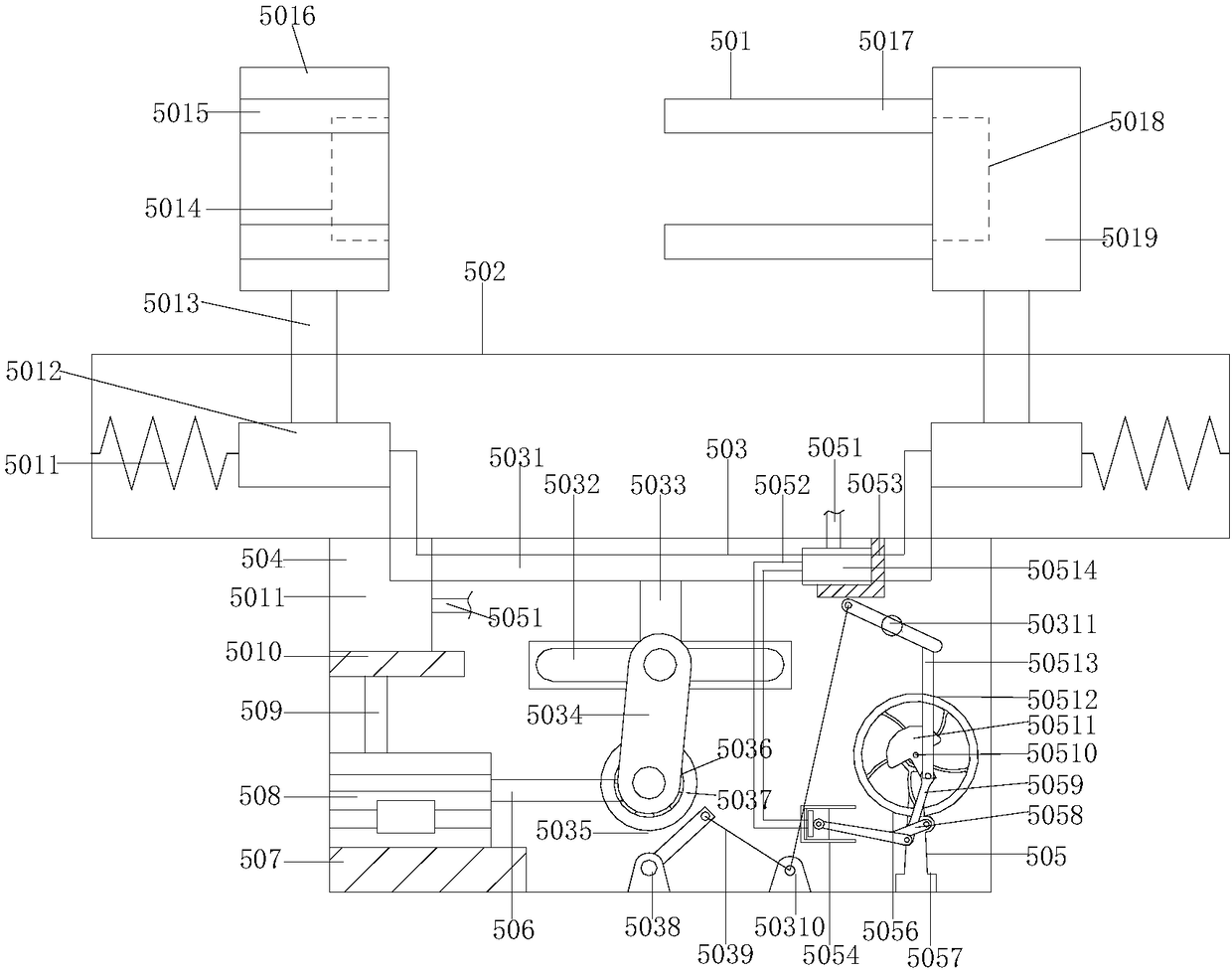

PendingCN108746388AImprove processing efficiencyIncrease productivityMetal-working feeding devicesPositioning devicesNumerical controlPunching

The invention provides automatic feeding and discharging equipment for a numerical control press. The automatic feeding and discharging equipment comprises a feeding device, a material conveying device and a discharging device. The feeding device adsorbs material plates to be processed and puts the material plates on the material conveying device, the material conveying device transports the material plates to be processed to a numerical control punching hole for processing, and the discharging device receives the punched material plates. The processing efficiency is significantly improved, the problems of high maintenance cost and low production efficiency which are caused by a chain wheel and chain structure of a feeding device in the prior art are solved, the problem that the movement of a material conveying plate is hindered due to the fact that a material conveying device in the prior art adopts two guide rails is solved, and the problems of the inconvenience of manually taking out a waste plate and the inability to take out the waste plate in time of a discharging device in the prior art are solved.

Owner:东莞市星桥钣金智能装备有限公司

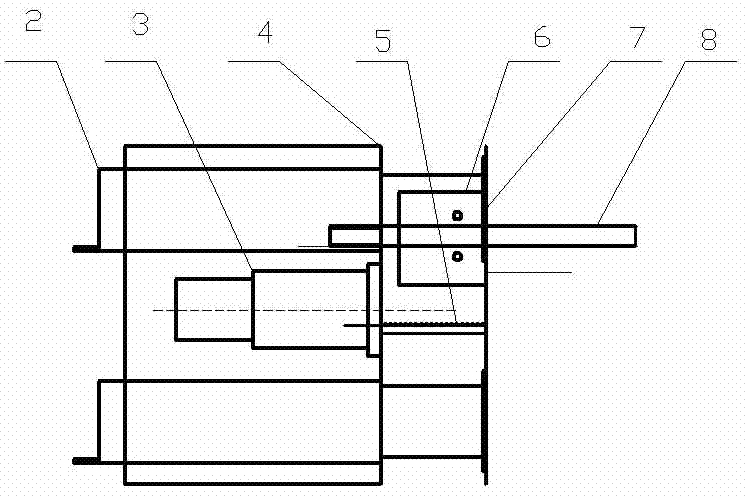

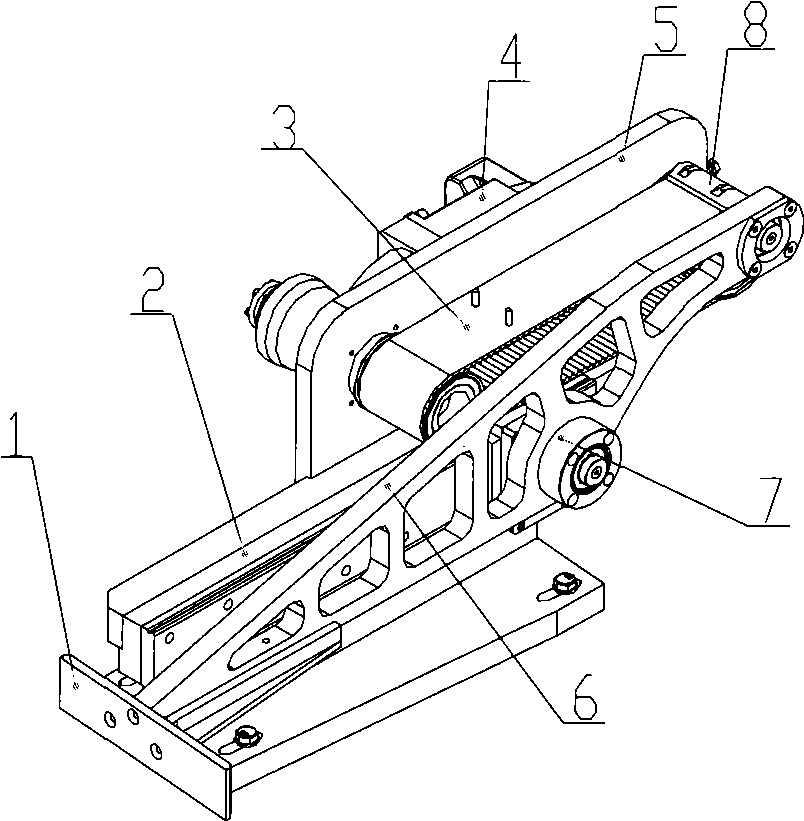

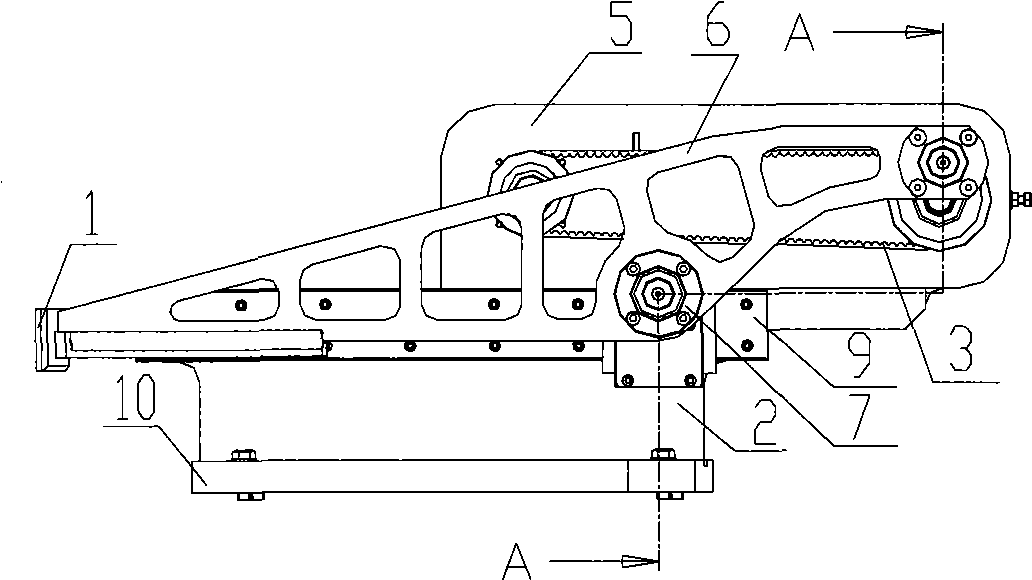

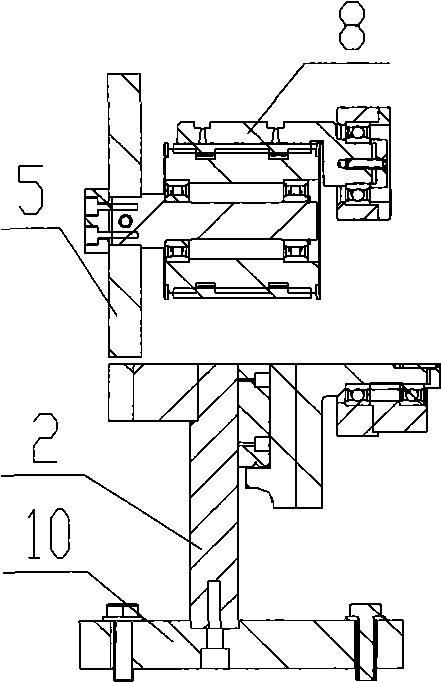

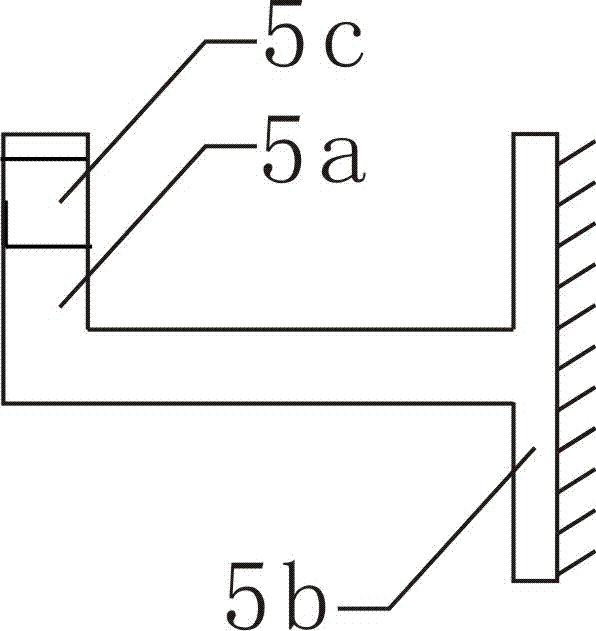

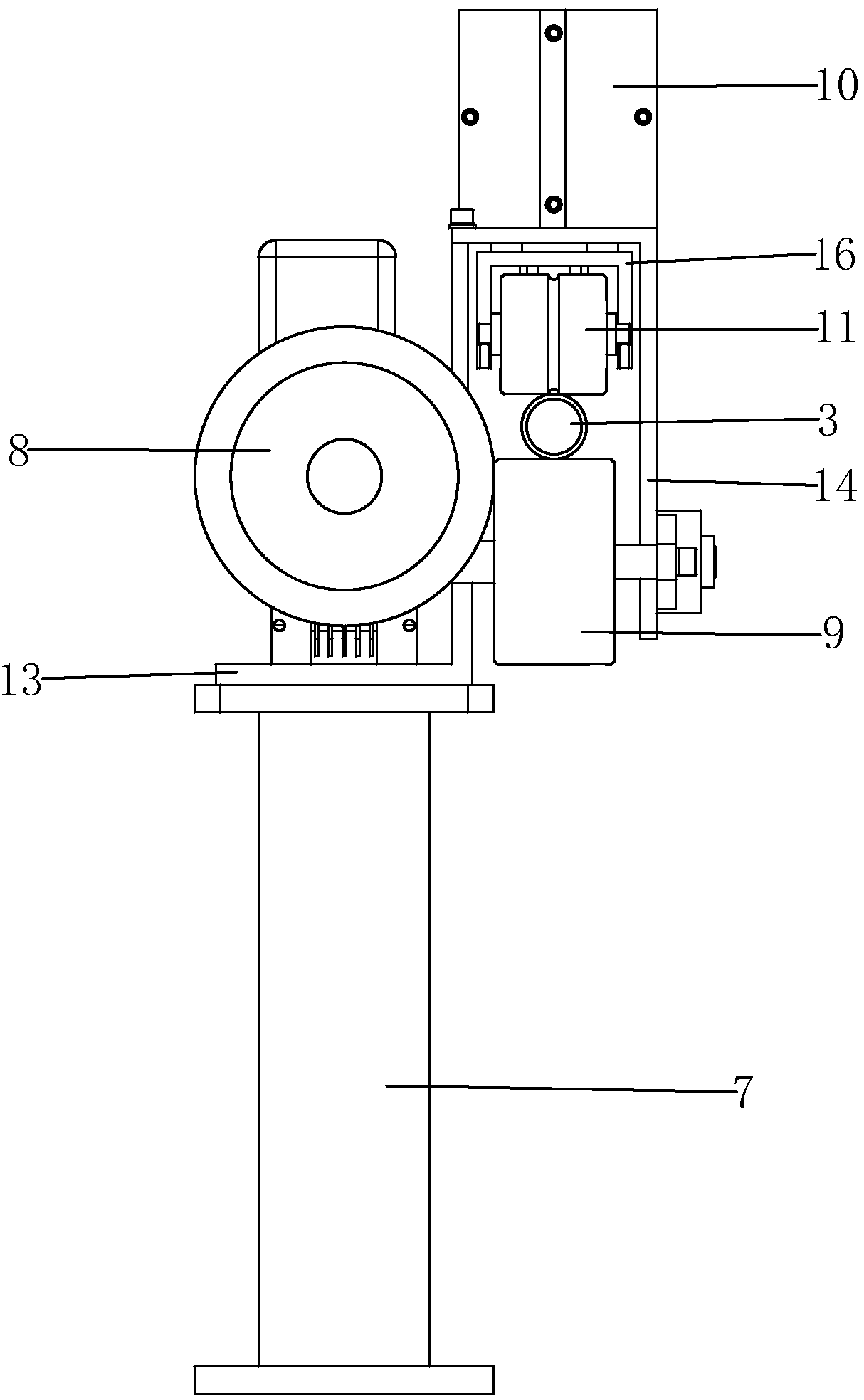

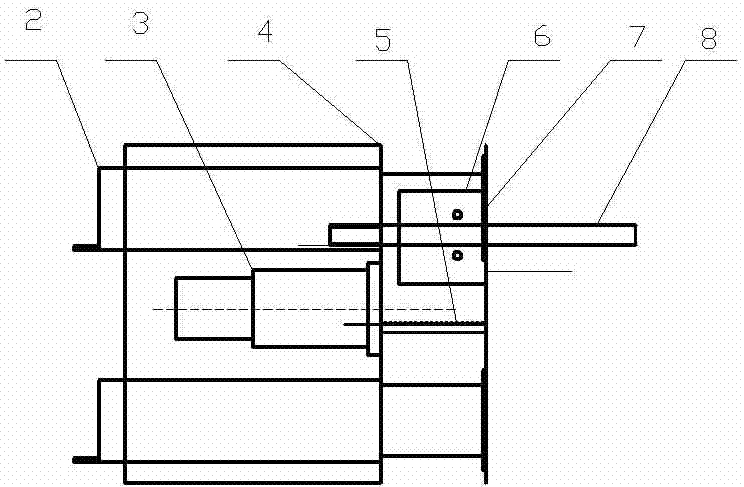

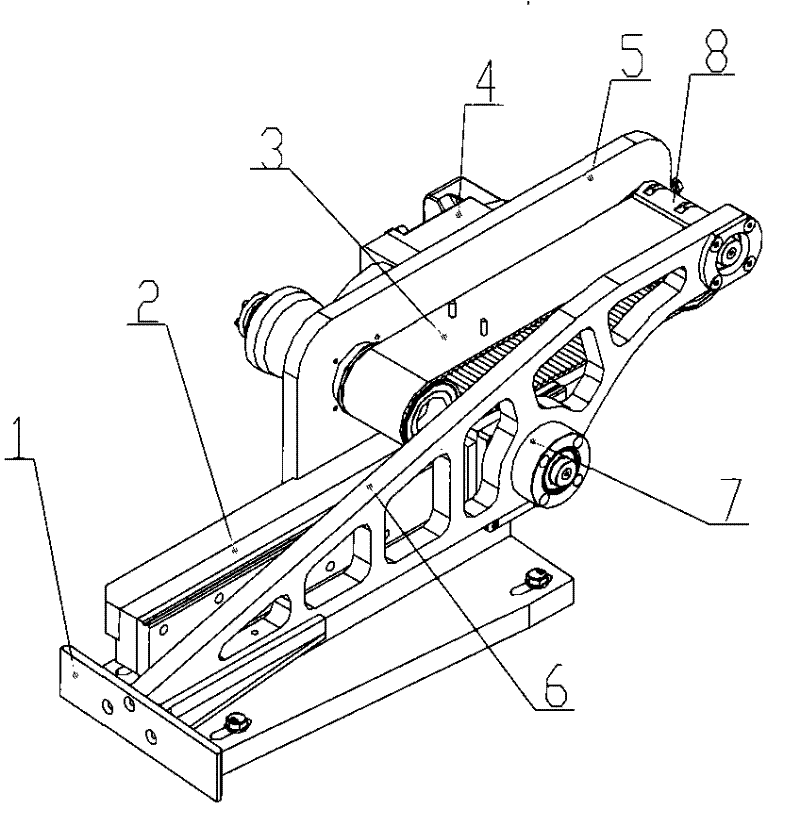

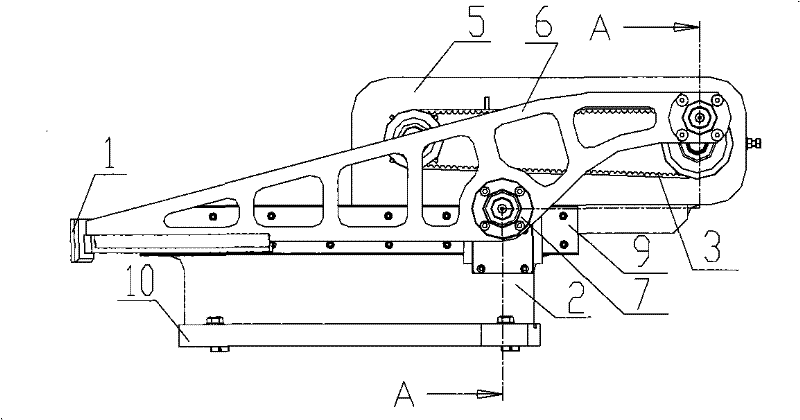

Slant push device and method for pushing off products of stacking machine

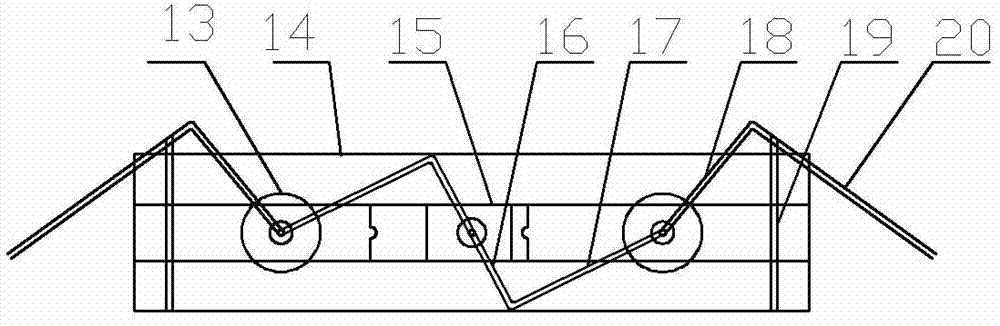

ActiveCN101508387ARealize back and forth motionImplement cyclic rolloutStacking articlesDrive shaftReciprocating motion

The invention relates to an oblique pushing device and an oblique pushing method for pushing a product in a stacker. A pushing plate is connected with the front end of a moving plate; the middle part of the moving plate is matched with a slide block and a connecting shaft through a dovetail groove guide rail, is in slide fit with the dovetail groove guide rail, and slides along the dovetail groove guide rail; one side of the dovetail groove guide rail is connected with the lower part of a mounting rack; a synchronous belt is sleeved on a driving shaft and a driven shaft of the synchronous belt, and the driving shaft of the synchronous belt is driven by a servomotor to drive the synchronous belt to rotate; and the synchronous belt is connected with the connecting shaft on the moving plate through a connecting plate on the synchronous belt and drives the connecting shaft to move. The device and the method have the advantages of achieving the aim of forward and backward motion of the moving plate driven by the synchronous belt and the pushing plate on the moving plate, achieving the reciprocating motion of the moving plate and the pushing plate on the moving plate in the dovetail groove guide rail and achieving the upward warping return stroke motion after the moving plate drives the pushing plate to finish the pushing motion so as to achieve circular pushing and rotary resetting of the pushing plate, and achieving the match of the oblique pushing device in the same PLC controller with the high-speed stacker.

Owner:ZHEJIANG YONGCHUANG MACHINERY

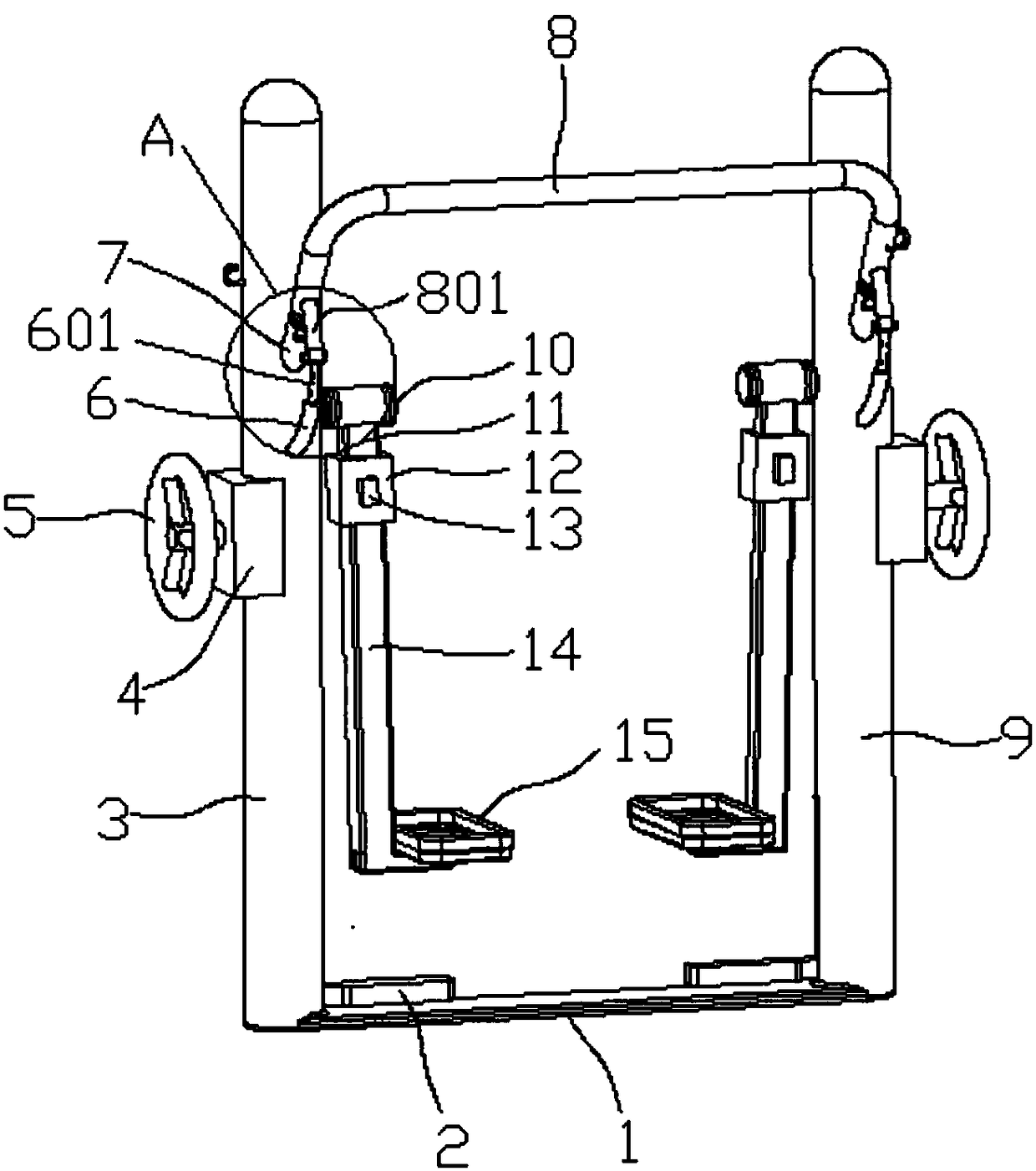

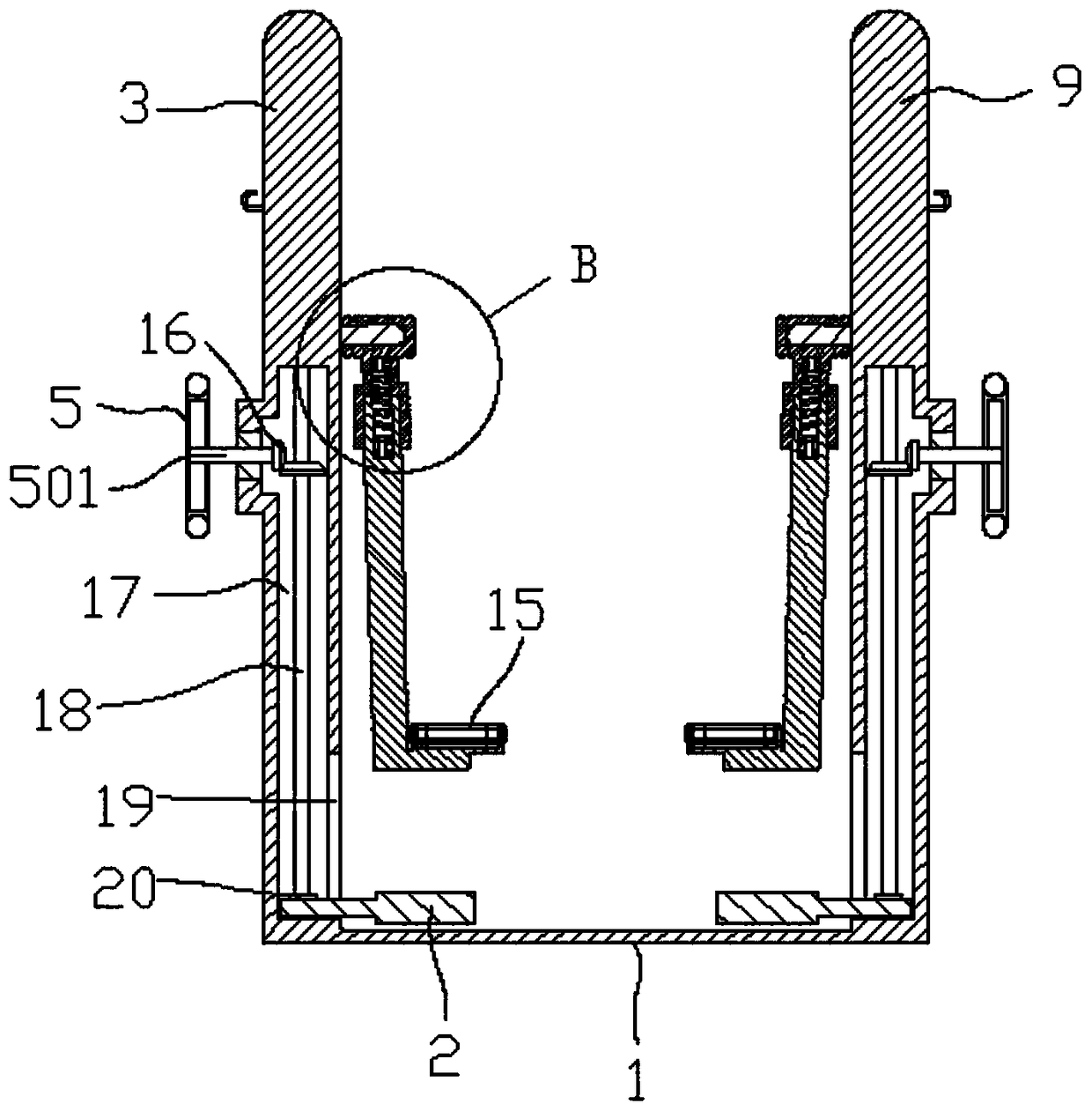

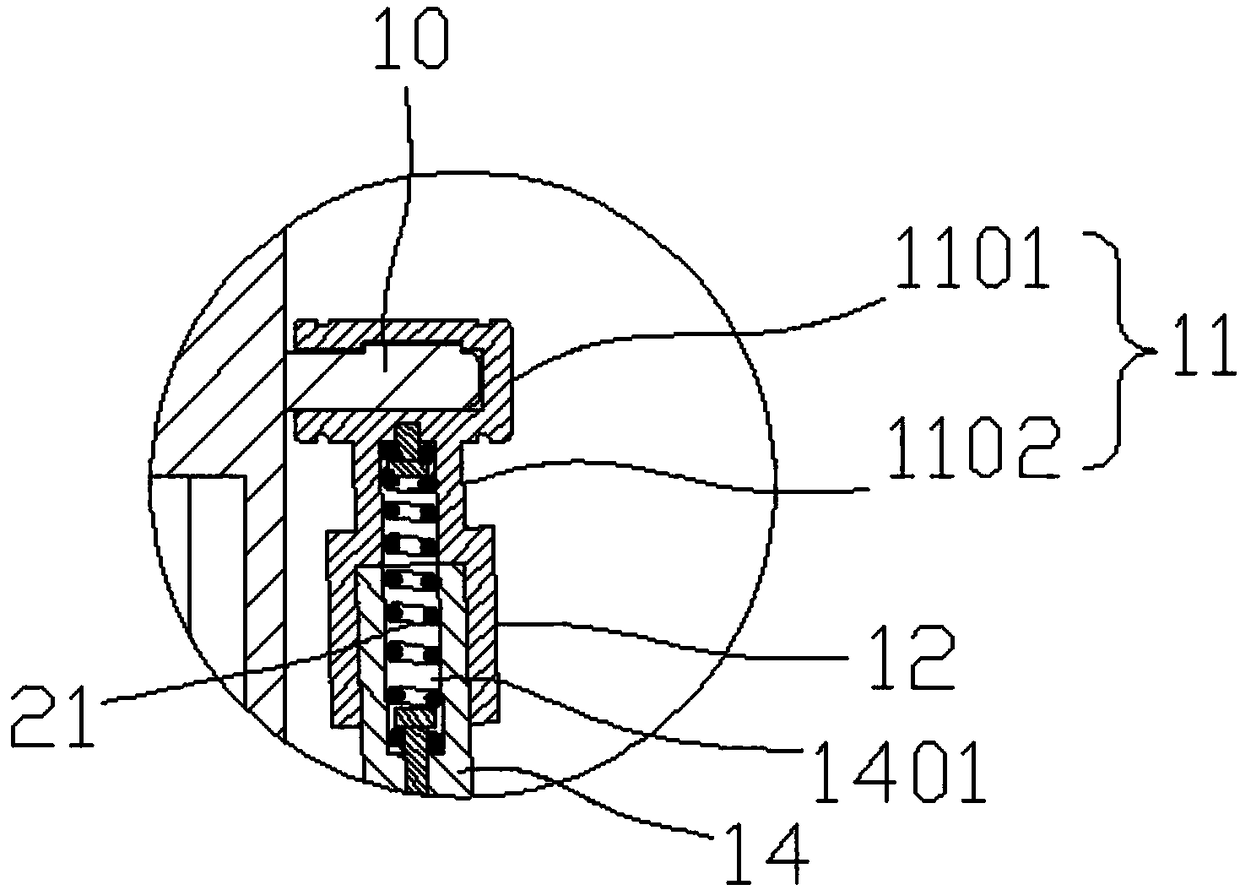

Spacewalker

InactiveCN108525199ARealize back and forth motionRealize three-dimensional movementMovement coordination devicesCardiovascular exercising devicesEngineeringArm moving

The invention discloses a spacewalker which comprises a base. A first stand column and a second stand column are arranged at the upper end of the base. Armrests and two pedal swing arm assemblies arearranged between the first stand column and the second stand column. Each pedal swing arm assembly comprises a first-stage swing arm sleeving a fixed shaft. A shell is arranged at the bottom of each first-stage swing arm and provided with a telescopic lock. A second-stage swing arm is arranged at the lower end of each first-stage swing arm. A pedal is arranged at the bottom of each second-stage swing arm. Each first-stage swing arm is connected with the corresponding second-stage swing arm through an elastic part. Each second swing arm moves up and is fixed to the corresponding first-stage swing arm through a telescopic lock after the elastic part is compressed. By means of the spacewalker, legs can move back and forth and can also move stereoscopically, and the requirements of a trainee are met.

Owner:GUANGDONG UNIV OF SCI & TECH

Automatic self-controlled telescopic mechanism of windowsill or balcony used for enhancing plant light

InactiveCN107231957AAchieve stretch outReduce volumeSelf-acting watering devicesReceptacle cultivationInterior spaceAutomatic control

The invention discloses an automatic self-controlled telescopic mechanism of windowsill or balcony used for enhancing plant light. The mechanism only comprises a telescopic moving system, a plant movement bearing system, a plant nutrition liquid suspension and storing box and a motion controlling box, the four portions make the entirety have a smaller volume and a lower weight, thereby the mechanism is appropriate to be arranged on the windowsill or balcony, and whether the mechanism is used or not the interior space cannot be occupied. The interior of the plant movement bearing system is used for cultivating plants, and then the motion controlling box is in charge of controlling the telescopic moving system to drive the integral stretching movement of the plant movement bearing system, the nutrition liquid suspension holder and the plant nutrition liquid suspension and storing box, and realize the lighting of the outdoor-stretched plants.

Owner:刘俊

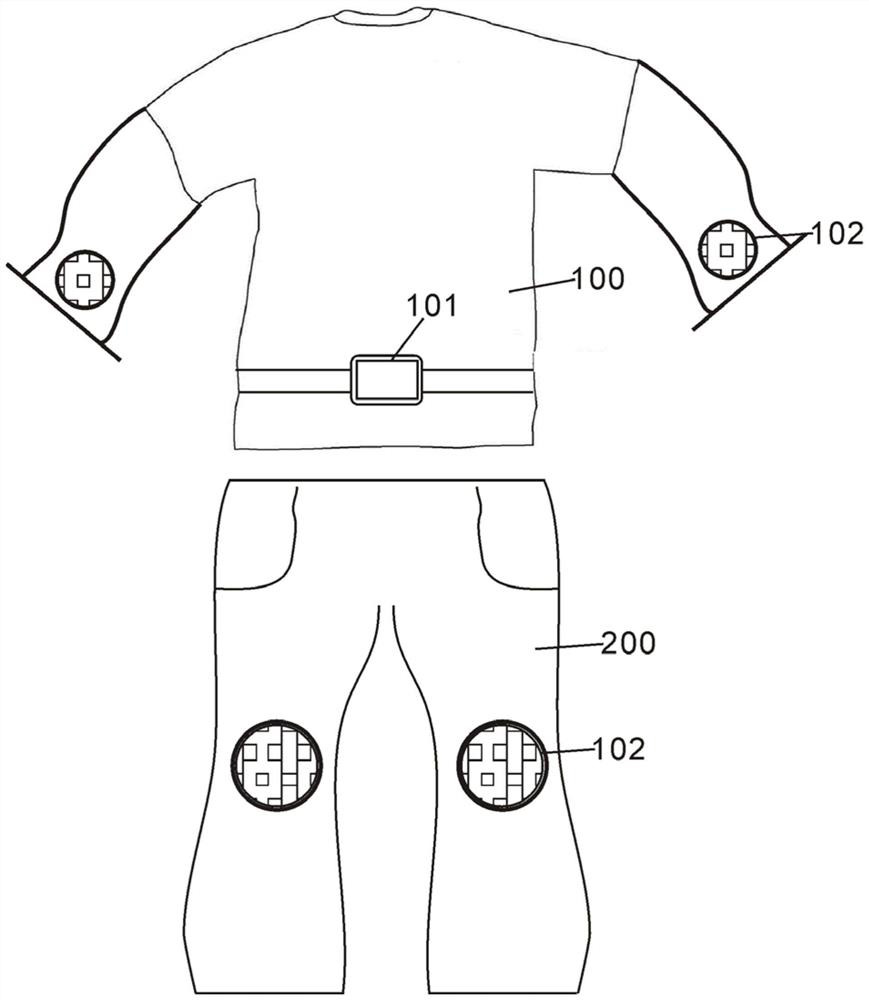

Sportswear with antibacterial, moisture-absorbing and sweat-releasing functions

InactiveCN112773012AWith antibacterial moisture wicking functionImprove breathabilityTrousersDrying machines with non-progressive movementsStructural engineeringSweat measure

The invention discloses sportswear with antibacterial, moisture-absorbing and sweat-releasing functions. The sportswear comprises a sportswear upper garment and sportswear lower pants. The sports upper garment and the sports lower pants are respectively made of an antibacterial sweat-absorbent fabric; an exercise monitoring terminal is arranged on the front surface or the back surface of the sports upper garment; and anti-collision motion buffer elements are respectively arranged at the corresponding elbow joints of the sports upper garment and the corresponding knee joints of the sports lower pants. The sportswear shown in the figure 1 has antibacterial and sweat-absorbing effects, and is good in air permeability and comfortable to wear; and the functions of heartbeat detection, sweating amount detection, exercise counting and the like are realized through the exercise monitoring terminal. The antibacterial sweat-absorbent fabric is composed of a fabric outer layer, a fabric inner layer and an antibacterial sweat-absorbent layer. The fabric outer layer, the fabric inner layer and the antibacterial sweat-absorbing layer are bonded and dried into a whole.

Owner:甘秒锋

Cleaning device for production of brake pad and cleaning method

ActiveCN109290254AExtended wash rangeImprove washing effectCleaning using liquidsCleaning methodsEngineering

The invention discloses a cleaning device for production of a brake pad and a cleaning method. The cleaning device comprises a supporting flat plate and supporting feet; a backup plate, a cleaning cover, fixing brackets and a liquid pumping pump are arranged on the supporting flat plate, the backup plate is provided with a transmission assembly, and the transmission assembly comprises a supportingblock, a transmission rod, a pressure spring and a U-shaped seat; one end of the transmission rod is arranged on the U-shaped seat, the supporting flat plate is provided with a liquid draining plate,and the liquid draining plate is provided with a mounting base; and the mounting base is movably connected with a swinging plate, and the swinging plate is movably connected with the other end of thetransmission rod. The cleaning method comprises the following steps of (a) mounting of the brake pad, (b) preparation, (c) cleaning, (d) still standing and (e) removing. The cleaning device is novelin structure, flexible in connection, high in cleaning efficiency and good in cleaning effect, and thus the quality of the brake pad is ensured; and the cleaning method is easy to operate and control,segmented cleaning is achieved, the cleaning effect is improved, and the comprehensive and thorough effects are achieved.

Owner:SHAOXING WISDOM AUTO PARTS

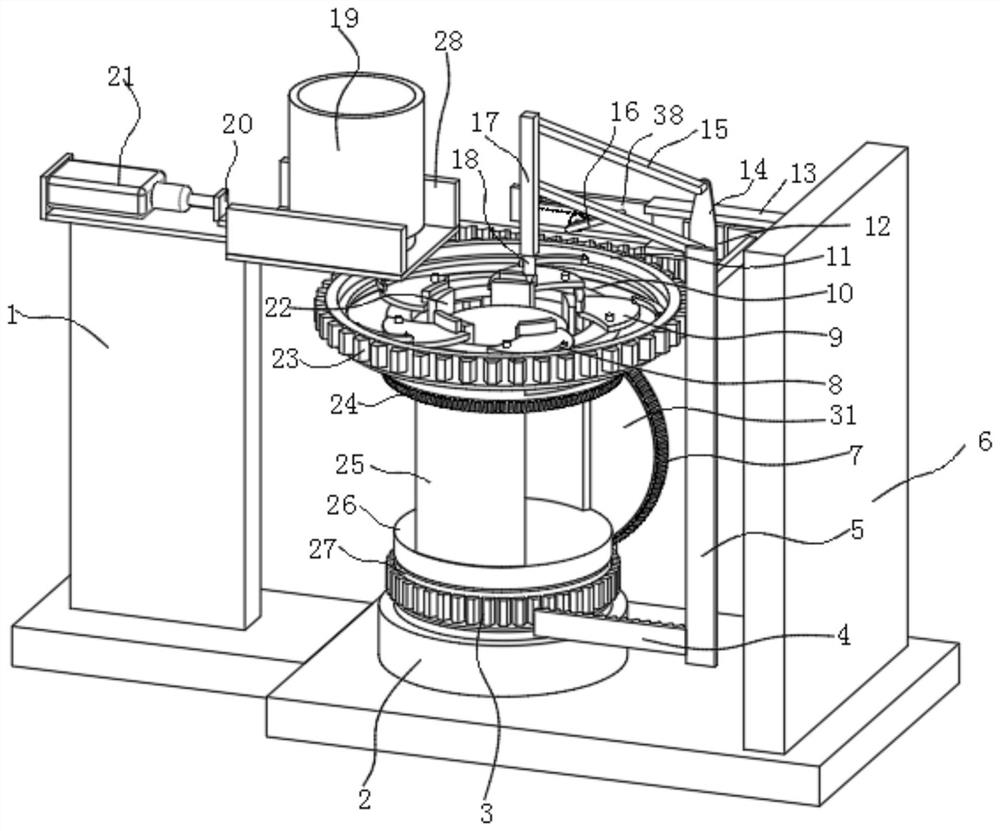

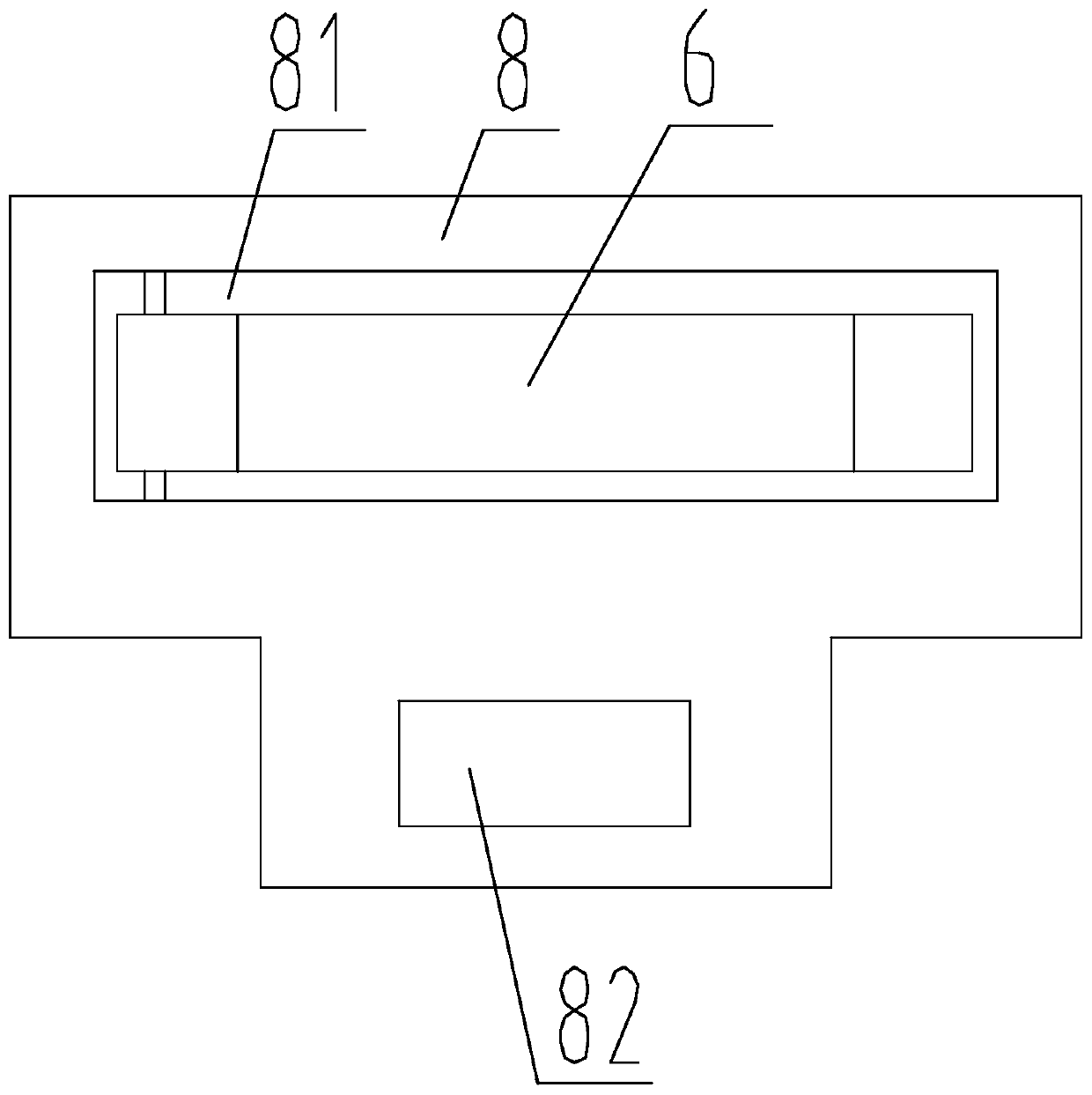

Braiding core rod transfer device of net weaving equipment

PendingCN108532121ARealize back and forth motionRealize automatic continuous weavingBraidControl systemEngineering

The invention discloses a braiding core rod transfer device of net weaving equipment. The braiding core rod transfer device of net weaving equipment comprises a braiding main machine, a braiding fronttractor, a braiding core rod, and an electric control system, and also comprises a braiding core rod rear tractor, and a braiding core rod supporting frame; the braiding core rod is designed to passthrough the braiding core rod supporting frame, the braiding core rod rear tractor, the braiding main machine, and the braiding front tractor successively; the braiding core rod rear tractor comprisesa supporting seat and a clamping traction mechanism; the clamping traction mechanism is arranged on the supporting seat; a limit detection device is arranged on the braiding core rod supporting frame; the electric control system is connected with the limit detection device and the clamping traction mechanism respectively. The braiding core rod transfer device is automatic, is high in efficiency,is capable of realizing continuous braiding, is beneficial for increasing of braiding quality, is capable of reducing human labor intensity, and increasing production efficiency.

Owner:浙江本发科技有限公司

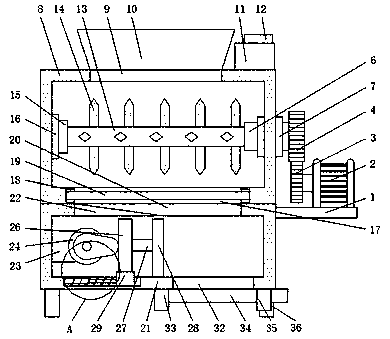

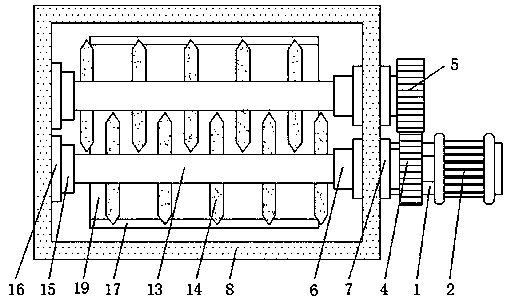

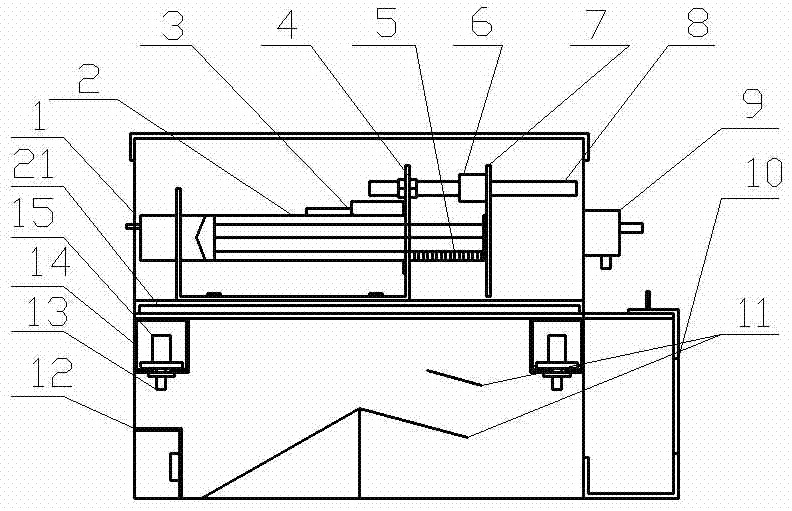

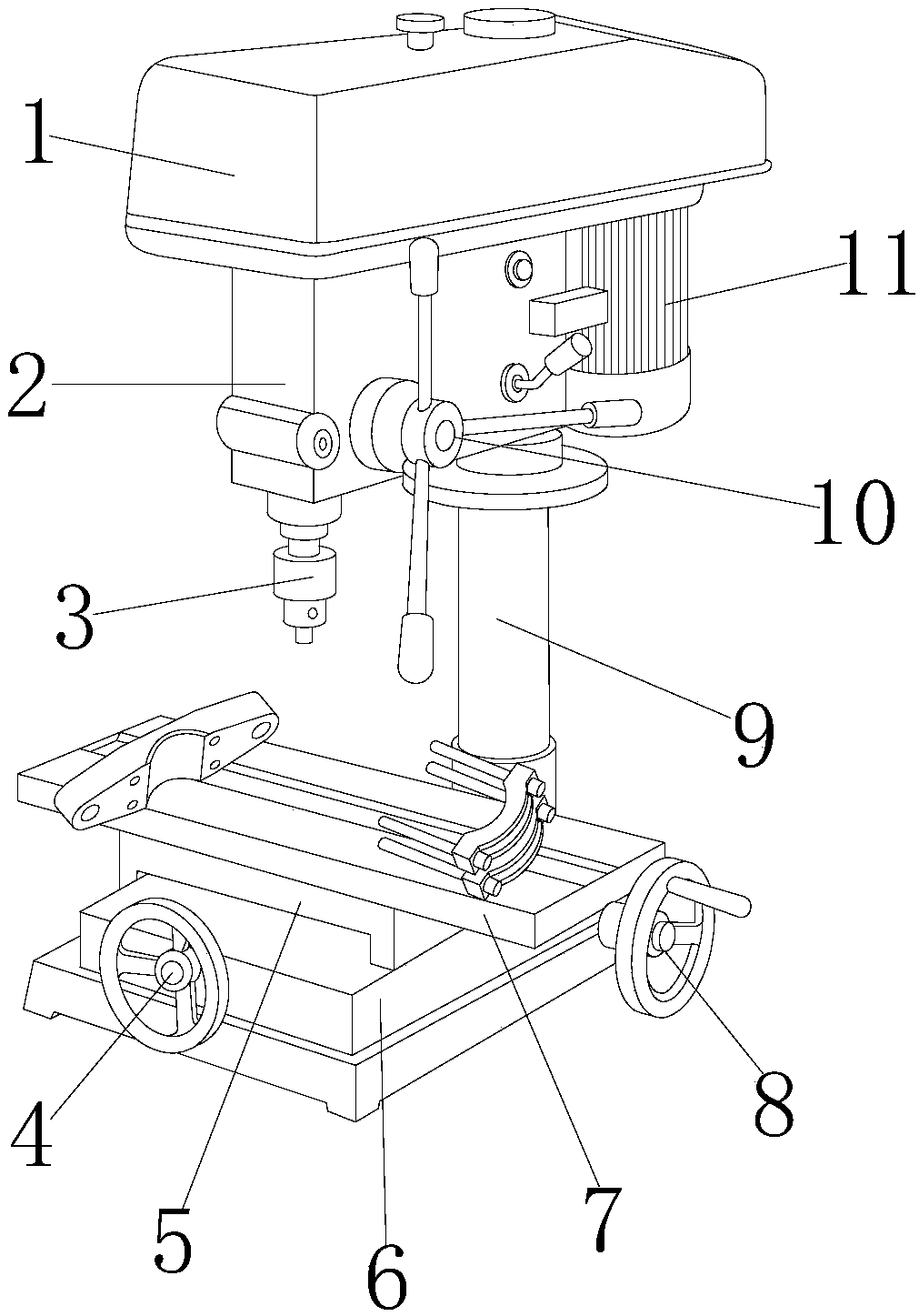

Milling machine for machining plastic products

InactiveCN108356334ARealize waste separationRealize back and forth motionWork clamping meansMilling equipment detailsEngineeringMachining process

The invention discloses a milling machine for machining the plastic products. The milling machine for machining the plastic products structurally comprises an upper fixing seat, a connection arm, a machining head, a first hand wheel, a workpiece fixing device, a base, a workbench, a second hand wheel, a supporting column, a third hand wheel and a first motor. The upper fixing seat is arranged on the upper side of the base. The two ends of the supporting column are mechanically connected with the base and the upper fixing seat. The supporting column is perpendicularly connected with the base. The connection arm is arranged on the lower side of the upper fixing seat. The bottom of the connection arm is provided with the machining head. The machining head is mechanically connected with the mechanical arm. The third hand wheel is installed on the side face of the connection arm. The third hand wheel penetrates through a side face plate of the connection arm to be mechanically connected with the machining head. According to the milling machine for machining the plastic products, under the combined action of a clamping plate fixing device, a lifting device and a drive device, a workpieceto be machined is fixed and prevented from moving in the machining process, and therefore the product quality is improved.

Owner:曾淑敏

Oil-water separator

PendingCN107697962ARealize continuous reciprocating back and forth motionRealize back and forth motionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesParticulatesSpiral blade

The invention relates to an oil-water separator, which comprises a tank cover, a tank body and a screw rod; a partition plate is arranged in the tank body; a gap is remained between the bottom of thetank body and the partition plate; the interior of the tank body is divided into a spiral groove and a turbulence groove by the partition plate; a flume which communicates with the turbulence groove is formed in one side, far away from the spiral groove, of the turbulence groove, and is provided with a water outlet; an inlet is formed in the tank cover; an oil residue outlet is formed in the top of the side wall of the spiral groove; the spiral groove is internally provided with a screen and a spiral blade; and the screw rod is arranged at the upper portion in the turbulence groove, and is provided with a turbulator which stirs fine particulate matters in the spiral groove and enables the fine particulate matters to be discharged from the water outlet with water together. The oil-water separator can thoroughly separate oil and large-particle oil residues from small-particle oil residues and the water in an oil-water mixture to finish a first step of purification of the oil-water mixture, and a mixture of the small-particle oil residues and the water can be treated by a special sewage purification treatment plant.

Owner:黄守洪

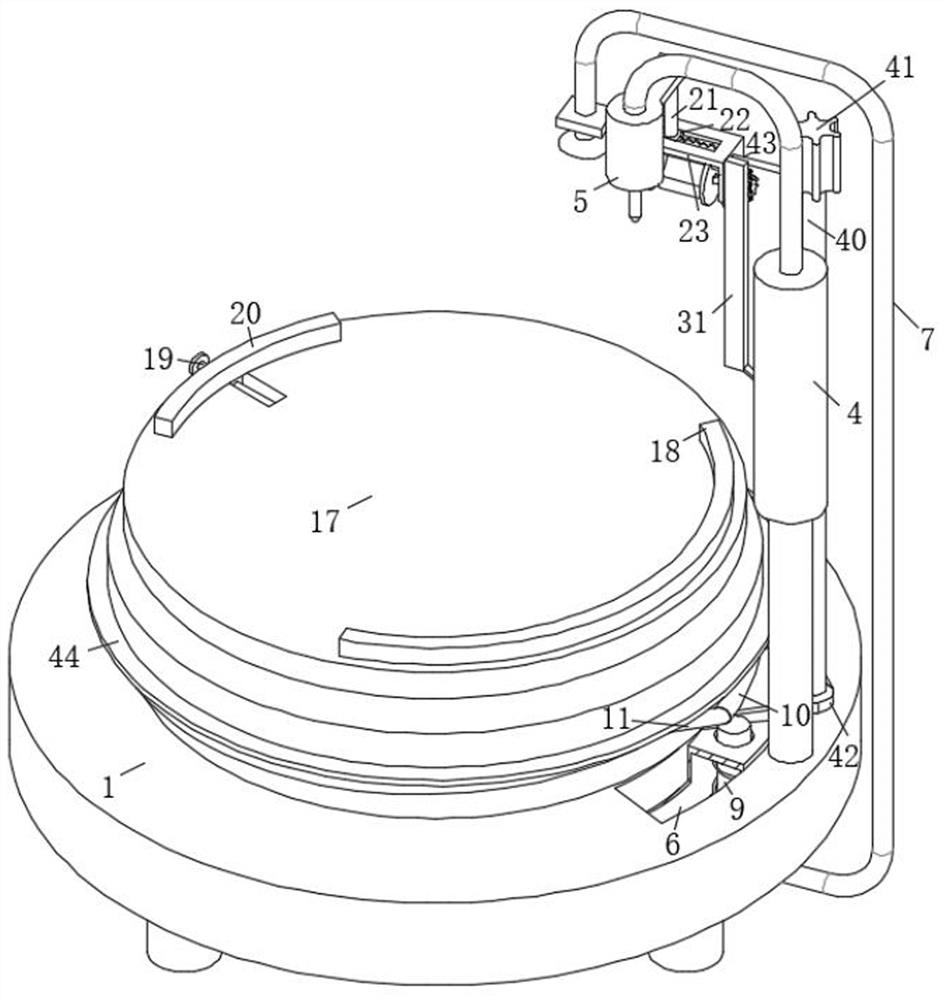

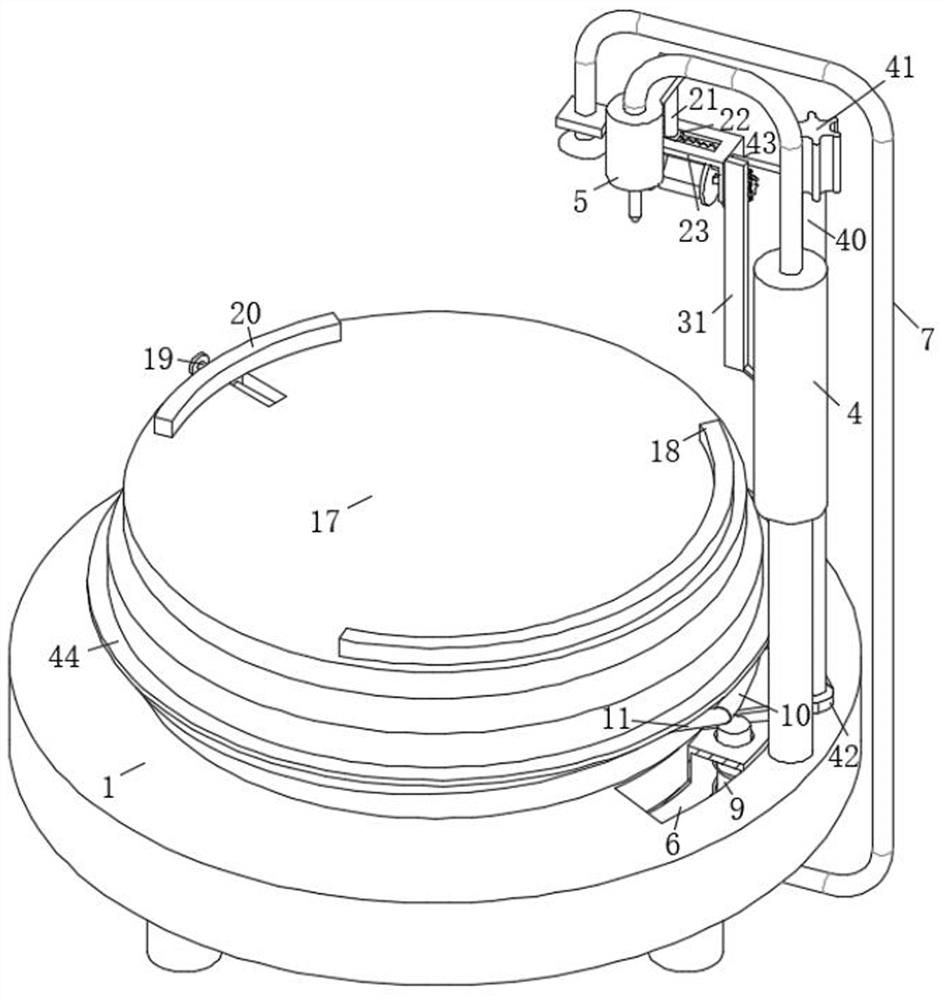

A kind of automatic welding equipment for single crystal furnace

ActiveCN114505632BInhibited DiffusionAvoid pollutionWelding/cutting auxillary devicesOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses an automatic welding equipment for a single crystal furnace, and relates to the technical field of welding equipment. The device includes a base plate, a support column is rotatably installed at the top middle of the base plate, and a first motor is fixedly installed at the bottom end of the base plate. The invention can collect, purify and discharge the waste gas generated in the welding process, avoid the waste gas from being diffused and pollute the air, so that the welding process is more environmentally friendly, and the burrs on the top wall of the furnace body can be polished at the same time of welding, so as to avoid the influence of the burrs. Welding, at the same time, the back and forth movement of the grinding rod can be realized, which can prevent one place from always in contact with the top wall of the furnace body for grinding, thereby prolonging the service life of the grinding rod and reducing the replacement frequency of the grinding rod. It can realize the grinding rod after welding. To avoid the situation where the same grinding rod is used all the time, its temperature continues to rise and the grinding rod is damaged.

Owner:CHANGZHOU LEMENG PRESSURE VESSEL CO LTD

Automatic battery fire extinguishing device for agricultural equipment

InactiveCN111167049AMeet the needs of fire fightingRealize back and forth motionFire rescueAgricultural scienceDrive wheel

The invention provides an automatic battery fire extinguishing device for agricultural equipment. The automatic battery fire extinguishing device for agricultural equipment comprises a battery box, arotating shaft, a driving wheel, a vertical rod, a driven wheel, a transmission chain, a supporting rod, a sliding bracket, a driving motor and a fire extinguishing mechanism. By arranging the supporting rod to support the sliding bracket, as the reliability of a horizontal position of the sliding bracket is ensured to prevent adverse influence of self weight of the sliding bracket on the transmission chain, deformation of the transmission chain is avoided favorably, the frictional force between the driving wheel and the transmission chain is reduced and it is favorable to ensure that the fireextinguishing mechanism moves in a reciprocating manner stably.

Owner:安徽逻根农业科技有限公司

Machine sea turtle for clearing garbage in water

Owner:NANTONG UNIVERSITY

Automatic welding equipment for single crystal furnace

ActiveCN114505632AInhibited DiffusionAvoid pollutionWelding/cutting auxillary devicesOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses automatic welding equipment for a single crystal furnace, and relates to the technical field of welding equipment. The equipment comprises a bottom plate, a supporting column is rotationally installed in the middle of the top end of the bottom plate, and a first motor is fixedly installed at the bottom end of the bottom plate. Waste gas generated in the welding process can be collected, purified and then exhausted, waste gas diffusion and air pollution can be avoided, the welding process is more environmentally friendly, burrs on the top wall of a furnace body can be polished while welding is conducted, the burrs are prevented from influencing welding, meanwhile, a polishing rod can move back and forth, and the welding efficiency is improved. One part of the grinding rod can be prevented from being in contact with the top wall of the furnace body for grinding all the time, so that the service life of the grinding rod can be prolonged, the replacement frequency of the grinding rod is reduced, the grinding rod can be switched after welding is finished, and the situation that the grinding rod is damaged due to continuous temperature rise caused by the fact that the same grinding rod is used all the time is avoided.

Owner:CHANGZHOU LEMENG PRESSURE VESSEL CO LTD

An Adaptive Blade Angle Measuring Instrument

ActiveCN109341497BSolve processing efficiencyEasy to testAngles/taper measurementsMeasuring instrumentEngineering

The invention discloses an adaptive blade angle measuring instrument. The adaptive blade angle measuring instrument comprises a fixed bottom plate, a blade and a soft rubber belt; the top of the fixedbottom plate is fixedly connected with an X-axis connecting plate and a Y-axis connecting plate in sequence through bolts from left to right; the left side of the X-axis connecting plate is fixedly connected with an X-axis power machine through bolts; a sliding rail is fixedly connected to the top of the X-axis connecting plate; the outer surface of the sliding rail is connected with a sliding plate in a sliding mode; and the top of the sliding plate is fixedly connected with an X working platform. The adaptive blade angle measuring instrument relates to the technical field of blade testing equipment. According to the self-adaptive blade angle measuring instrument, the blade is moved forward; the soft rubber belt in the front is cut open in the movement; when the blade is continuously moved forward, the resistance becomes larger and larger; the change of the resistance is recorded by utilizing a pressure sensor; all points are connected to form a curve; and based on this, whether an angle of the blade is correct or not is analyzed, so that the problems that in an existing detection mode, the structure is complex, the angle of the blade can be detected simply and rapidly, and the processing efficiency of an enterprise is seriously influenced can be solved.

Owner:WUHAN RUIFENG PHOTOELECTRIC TECH

Servo chain conveyor belt based on blood station intelligent cold storage application

ActiveCN109760980BMovement precisionLow temperature requirementConveyorsStorage devicesGear wheelEngineering

Owner:CHANGSHA IMADEK INTELLIGENT TECH CO LTD

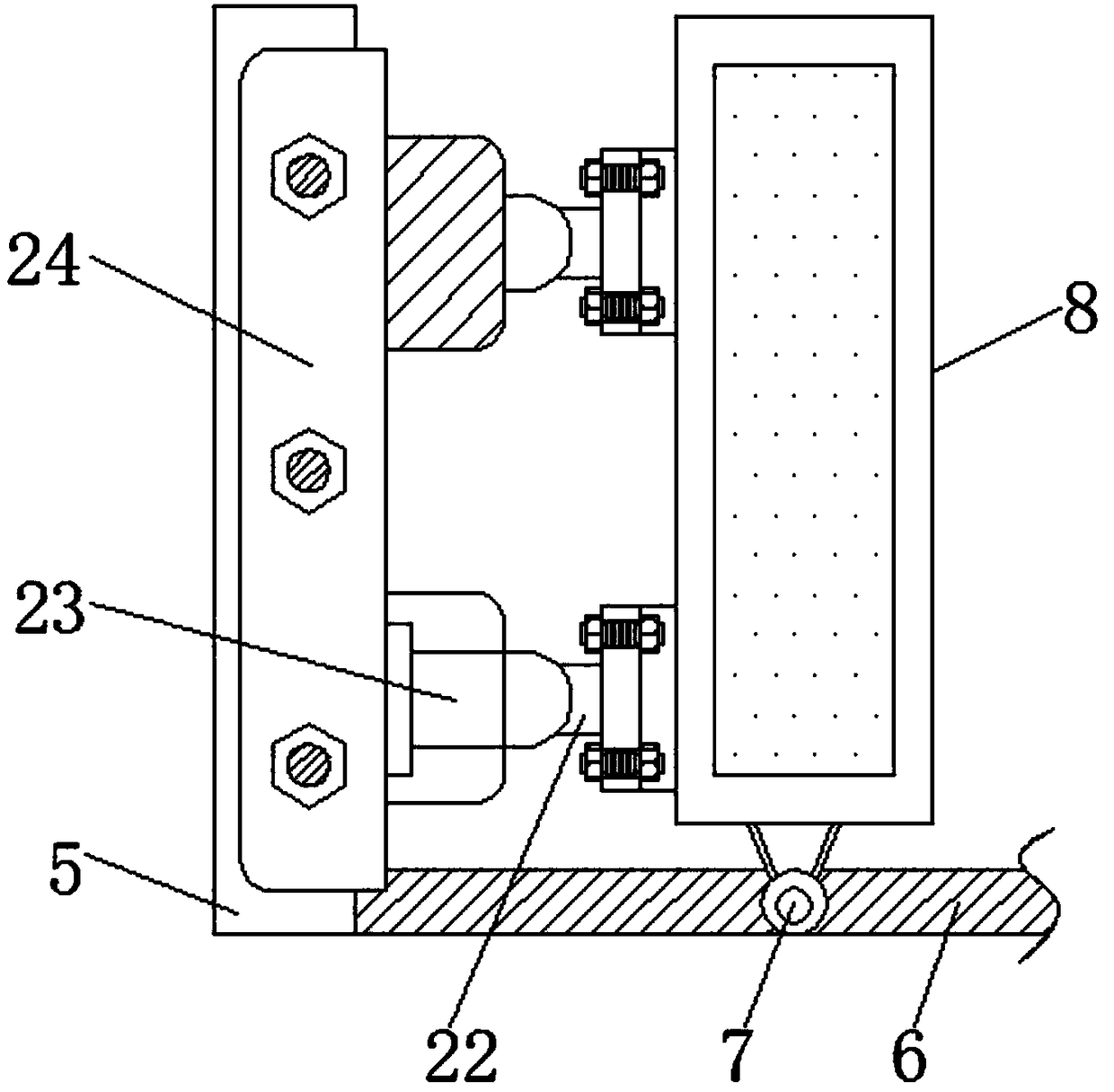

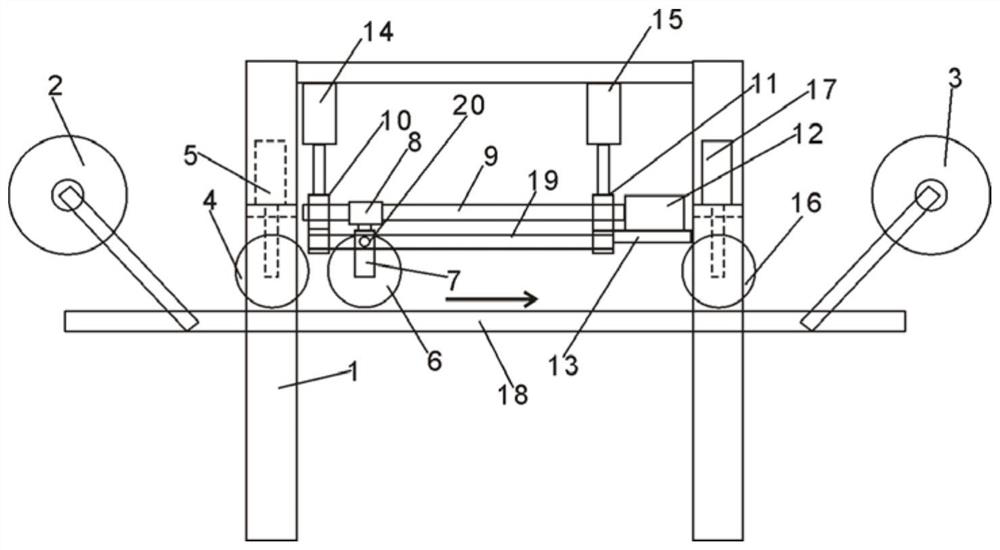

A winding device for bopp film

ActiveCN104261172BRealize back and forth motionEasy clampingWebs handlingEngineeringMechanical engineering

The invention provides a winding device for BOPP film, which belongs to the technical field of machinery. It solves the problems in the prior art that the film needs to be manually cut off after the winding is completed, which is time-consuming and labor-intensive. The winding device of the BOPP film includes a base and a bracket one arranged on the base. The bracket one includes two columns, a winding shaft is arranged between the two columns, a winding cylinder is arranged on the winding shaft, and one end of the winding shaft is arranged There is a power mechanism; the right side of the support one is provided with a support two, and the support two includes a fixed plate, and the fixed plate is provided with a clamping mechanism and a slitting blade, and the slitting blade is connected with a sliding mechanism that can drive it to slide horizontally; The right side of the frame is provided with a bracket three, and the bracket three includes two mounting plates, and a tensioning mechanism capable of tensioning the film is arranged between the two mounting plates. The present invention can realize the self-cutting of the film after winding through the clamping mechanism.

Owner:湖南泰利恒友科技开发有限公司

An engineering auxiliary platform for lathe monitoring

ActiveCN106695455BRealize back and forth motionMeasurement/indication equipmentsNoise monitoringRotary stage

The invention discloses an auxiliary engineering platform for lathe monitoring. The auxiliary engineering platform comprises a detector putting platform, a first hand wheel, a second hand wheel and a base, wherein a camera is positioned on the left end surface of a slide frame; a noise monitoring instrument and a vibration monitoring instrument are mounted at the top end of the platform; a rotary table is connected with a stand column; the first hand wheel and the second hand wheel are separately positioned on the front side end surface of a first slide frame and the front side end surface of a second slide frame; and a concentricity detector is arranged on the top end surface of the detector putting platform. According to the auxiliary engineering platform for lathe monitoring disclosed by the invention, the vibration monitoring instrument, the concentricity detector and the noise monitoring instrument are directly mounted at the upper end of the detector putting platform, and the noise monitoring instrument and the vibration monitoring instrument are used for performing related detection on lathe equipment; the movable camera is arranged and moves back and forth through matching of a motor and a limiting switch, so that monitoring records for a position of a positioning performing element and change monitoring for sensing a surrounding environment are completed.

Owner:GUIZHOU UNIV

Slant push device and method for pushing off products of stacking machine

ActiveCN101508387BRealize back and forth motionImplement cyclic rolloutStacking articlesReciprocating motionDrive shaft

The invention relates to an oblique pushing device and an oblique pushing method for pushing a product in a stacker. A pushing plate is connected with the front end of a moving plate; the middle part of the moving plate is matched with a slide block and a connecting shaft through a dovetail groove guide rail, is in slide fit with the dovetail groove guide rail, and slides along the dovetail groove guide rail; one side of the dovetail groove guide rail is connected with the lower part of a mounting rack; a synchronous belt is sleeved on a driving shaft and a driven shaft of the synchronous belt, and the driving shaft of the synchronous belt is driven by a servomotor to drive the synchronous belt to rotate; and the synchronous belt is connected with the connecting shaft on the moving plate through a connecting plate on the synchronous belt and drives the connecting shaft to move. The device and the method have the advantages of achieving the aim of forward and backward motion of the moving plate driven by the synchronous belt and the pushing plate on the moving plate, achieving the reciprocating motion of the moving plate and the pushing plate on the moving plate in the dovetail groove guide rail and achieving the upward warping return stroke motion after the moving plate drives the pushing plate to finish the pushing motion so as to achieve circular pushing and rotary resettingof the pushing plate, and achieving the match of the oblique pushing device in the same PLC controller with the high-speed stacker.

Owner:ZHEJIANG YONGCHUANG MACHINERY

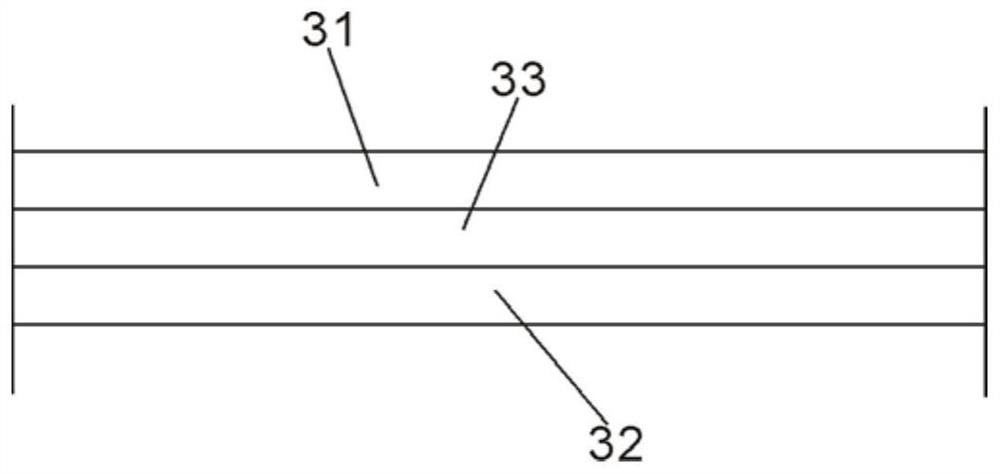

Production process of red bean velvet soft light antibacterial anti-ultraviolet fabric

InactiveCN112776455AFeel goodFeel comfortableLamination ancillary operationsProtective fabricsYarnRed bean

The invention discloses a production process of a red bean velvet soft light antibacterial anti-ultraviolet fabric. The preparation method comprises the following steps: 1, preparing antibacterial anti-purple yarn; 2, preparing an outer-layer fabric and an inner-layer fabric; 3, binding the outer layer fabric, the inner layer fabric and the antibacterial anti-purple yarn into a whole; and 4, circularly drying the whole formed in the step 3 through a circular drying device, and forming an integrated body through drying and heating. The production process of the antibacterial and anti-ultraviolet fabric is low in difficulty and easy to control, the production cost is reduced, the obtained fabric can be used on the front side and the back side, and the fabric is formed by compounding three layers of weave structures and has the advantages of being antibacterial, anti-ultraviolet, cool, moisture-permeable, breathable, discoloring, fashionable, unique in fabric style, high in strength, good in wear resistance, anti-ultraviolet, antibacterial and antibacterial, comfortable in hand feeling, breathable and warm and the like. Moreover, the preparation process is simple and reasonable, and the production efficiency is high.

Owner:甘秒锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com