Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Improve the quality of smoking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

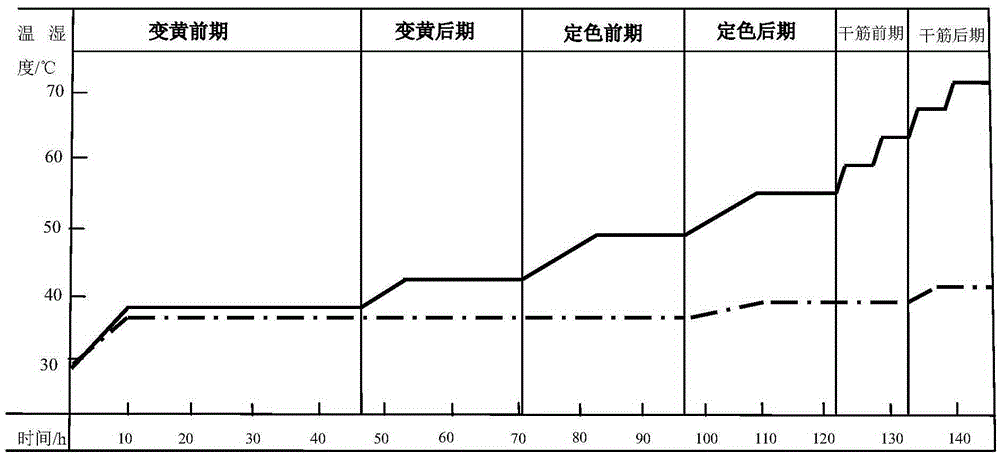

Tobacco flue-curing method for bulk curing barn

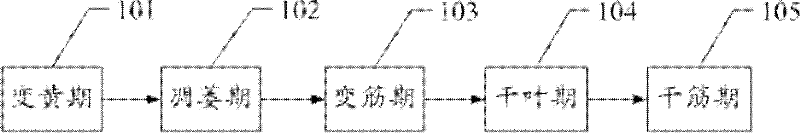

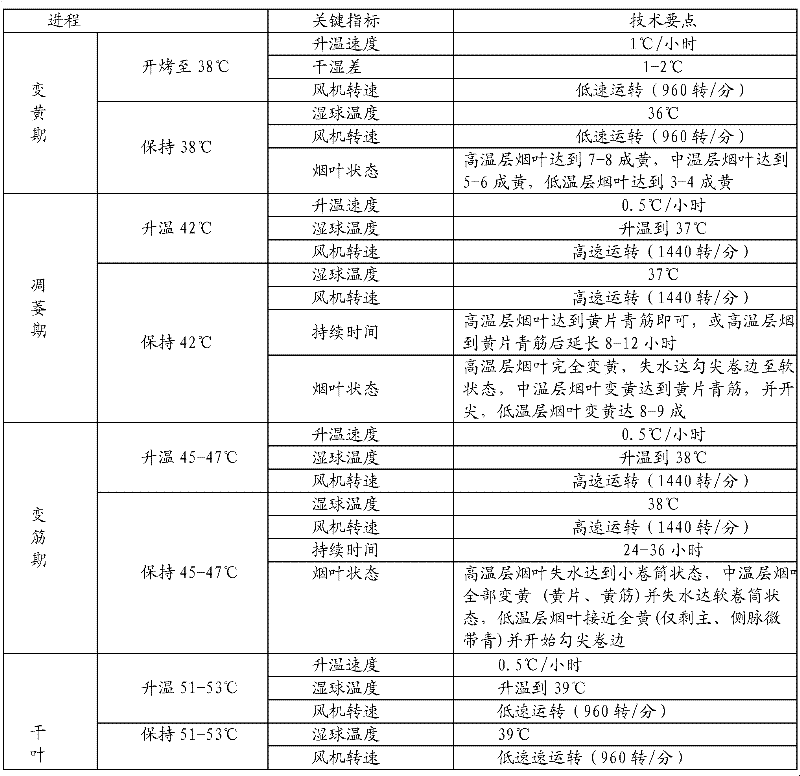

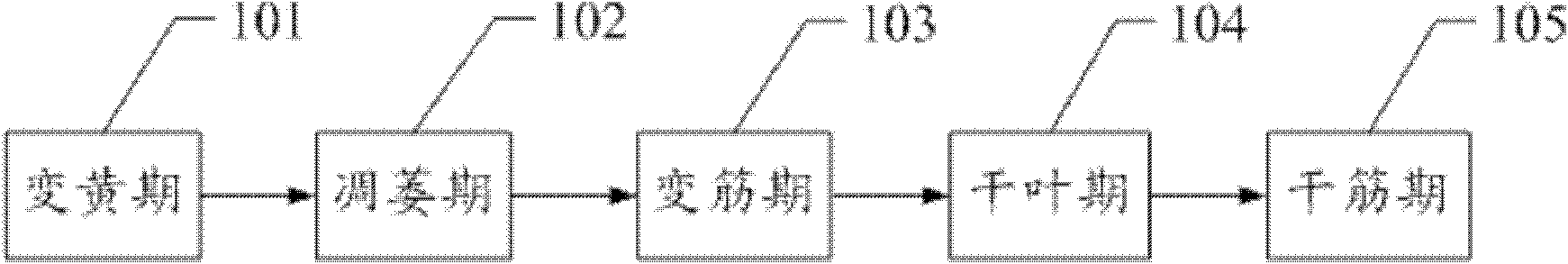

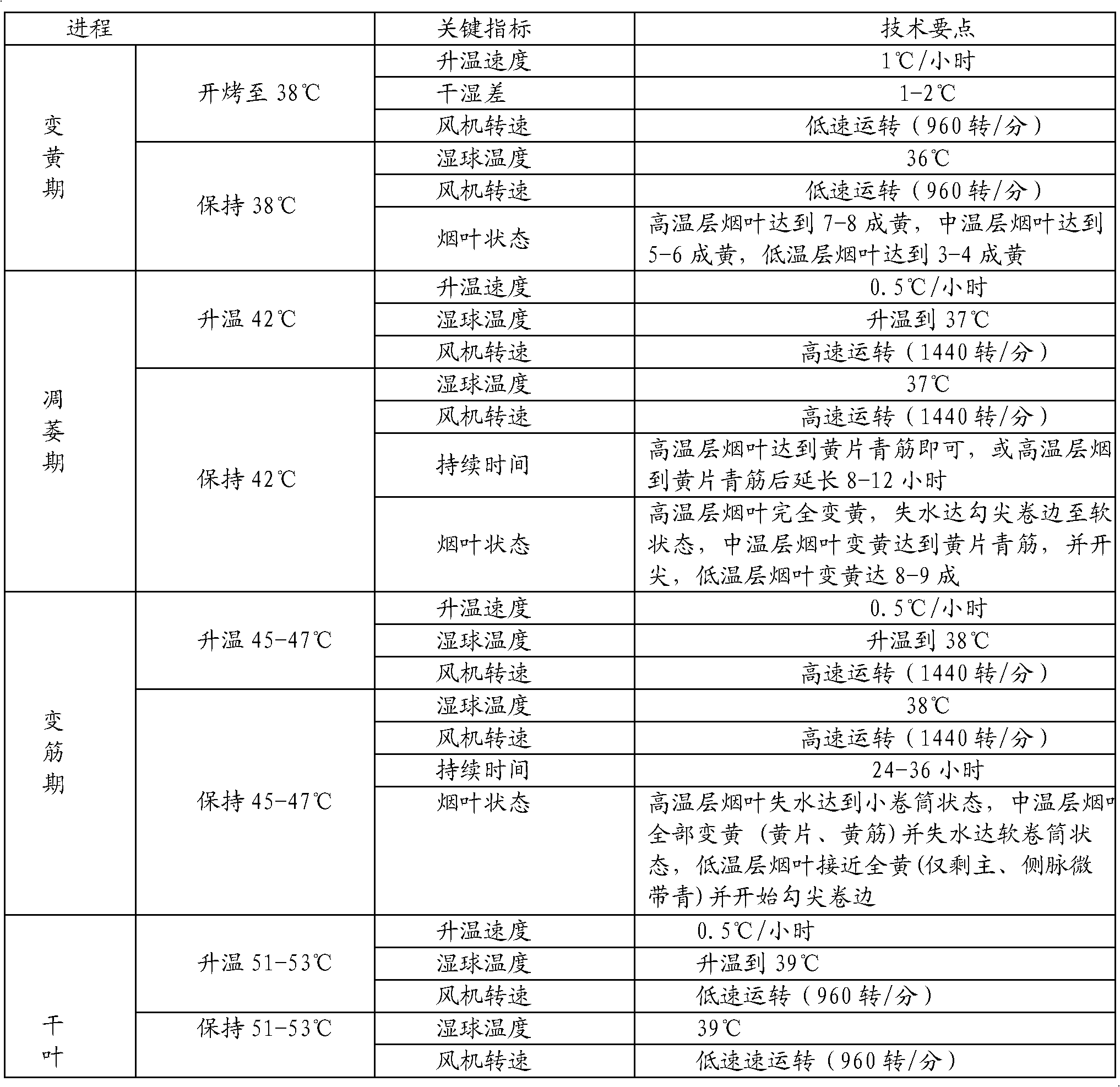

The invention relates to the technical field of flue-cured tobacco modulation, in particular to a tobacco flue-curing method for a bulk curing barn. The flue-curing process of the tobacco flue-curing method includes a yellowing period, a withering period, a stem yellowing period, a tobacco leaf drying period and a stem drying period according to factors such as dry-bulb temperature, wet-bulb temperature, drying time, heating rate, variable speed ventilation and tobacco leaf change targets, a color fixing period in the traditional tobacco flue-curing method is prolonged at a fixed point and steady temperature under the condition of hot air circulation, and sufficient decomposition and transformation of amylum, protein and other macromolecular substances in tobacco leaves and forming of aromatic matters are promoted. The tobacco flue-curing method for the bulk curing barn is easy to operate, safe and secure, can keep tobacco leaf yellow to be stable, leaf shrinking degree to be good, oil content to be increased and tobacco leaf aromatic amount to be increased greatly, further can reduce or avoid tobacco leaf roasting damage of green smoke roasting, ash smoke hanging, black bad smoke, lousy smoke roasting and the like, and can obtain high-quality tobacco leaves through roasting.

Owner:四川省烟草公司宜宾市公司

Tobacco field soil improving method

InactiveCN105859479ASimple structureImprove ventilationMagnesium fertilisersOther chemical processesGreen manureRoot system

The invention relates to a tobacco field soil improving method. The method comprises the following steps: green manure is applied to soil, the green manure is ploughed down 30-45d before next year tobacco seedling transplantation, and biomass charcoal is applied to soil 15-20d after the green manure is ploughed down. The green manure and the biomass charcoal are combined to restore tobacco field soil, so the content of organic matters in soil is improved, the water retention property of the soil is improved, the growth of roots in the earlier growing stage of tobacco plants is promoted, and early and fast growth of the tobacco plants is promoted; and the method also has the advantages of increase of the content of tobacco leaves, increase of the proportion of high-and-middle tobacco leaves, increase of the output value of the tobacco leaves, improvement of the quality of the tobacco leaves, coordination of chemical components, increase of the fragrance and the oil content of the tobacco leaves, improvement of the smoking quality of the tobacco leaves, reduction of the application amount of chemical fertilizers, and improvement of the utilization rate of the fertilizers.

Owner:陕西省烟草公司汉中市公司 +1

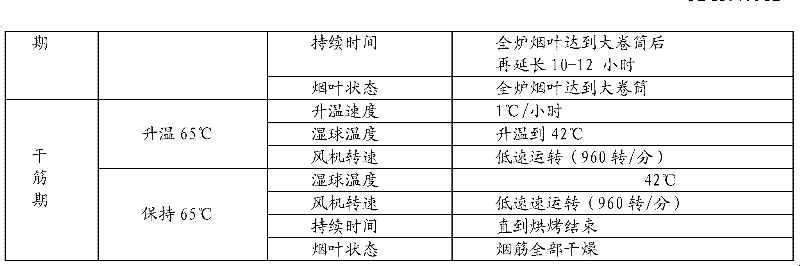

Method for solid-liquid separation during sheet production through papermaking process

ActiveCN101744357AHigh yieldSave resourcesTobacco preparationCentrifugal force sediment separationFiberSlag

The invention discloses a method for solid-liquid separation during tobacco sheet production through papermaking process, which includes steps: respectively extracting the fragments of tobacco stalk and tobacco leaf through hot water; respectively implementing horizontal centrifugal separation on the mixture of the fragments of tobacco stalk or tobacco leaf, and water, moving solid slag to the working procedure of defibrination, and moving the extract liquor eliminating coarse slag into a disc type separator, and feeding the obtained clear liquid into the working procedure of concentrating in next section; then concentrating the extract liquor, and spraying or coating the concentrated extract liquor on a formed fiber sheet substrate, drying, tabletting and forming. The production technique method adopted by the invention improves the use ratio for sheet production concentrators through papermaking technique and increases the inherent quality of the concentrated liquor, thereby improving the inherent quality of sheet products through papermaking technique.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Method for adding tobacco ash during paper-making method type prodn. of tobacco sheet

ActiveCN1757334AHigh fillingImproved physical properties including filling propertiesTobacco preparationPulp and paper industryCoating

A method for using the fume dust as the filler in the process for preparing tobacco sheet by paper making method features that the fume dust (5-30 Wt%) can be added at 5 technological sites: pulp pool, pipeline between pulp stabilizing tank and pulp flowing tank, long screen, the position between vacuum floating roller and primary pressing, and the coating unit. It can improve the quality of tobacco sheet and low cost.

Owner:CHINA TOBACCO HUNAN INDAL CORP

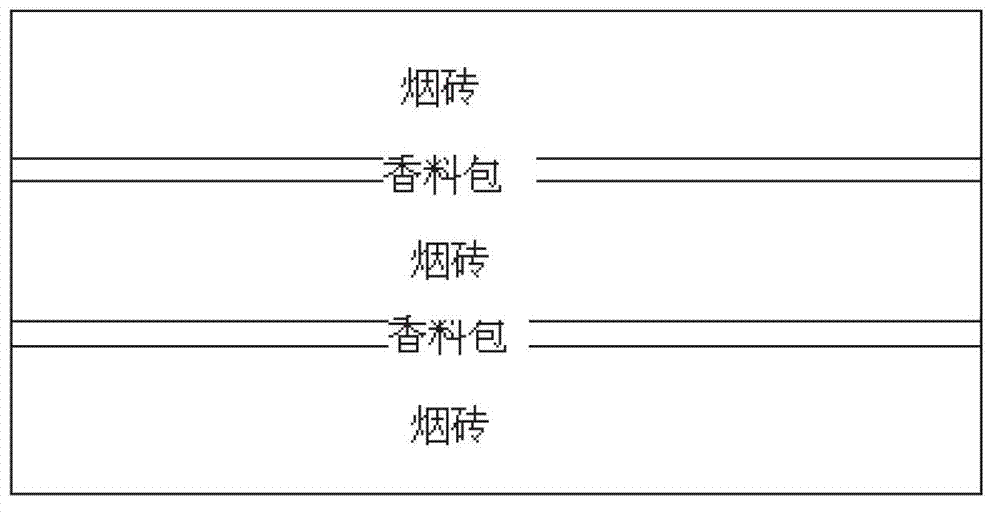

Method for carrying out scenting treatment to improve quality of tobacco leaves in tobacco leaf aging process

ActiveCN102948920AReach perfumingImprove the quality of smokingTobacco preparationTobacco treatmentAbsorbent cotton gauzeFlavor

The invention discloses a method for carrying out scenting treatment to improve the quality of tobacco leaves in the tobacco leaf aging process, which comprises the following steps of: carrying out mixed loading on the tobacco leaves with the water content of 13 to 15 percent and a perfume which is coated with absorbent cotton gauze and is selected from one of cinnamon and tangerine peel according to a mass ratio of (2 to 3):1; and after sealing, naturally purifying the mixture for 1.5 to 2 years. According to the invention, the adsorbability of the tobacco leaves is utilized to adsorb aroma of plants and a perfume material does not need to be prepared into the essence perfume by a fussy process, so that the aims of increasing the aroma of the tobacco leaves and improving the smoking quality are fulfilled. The method has the characteristics of simple process, low cost and the like.

Owner:HUBEI CHINA TOBACCO IND

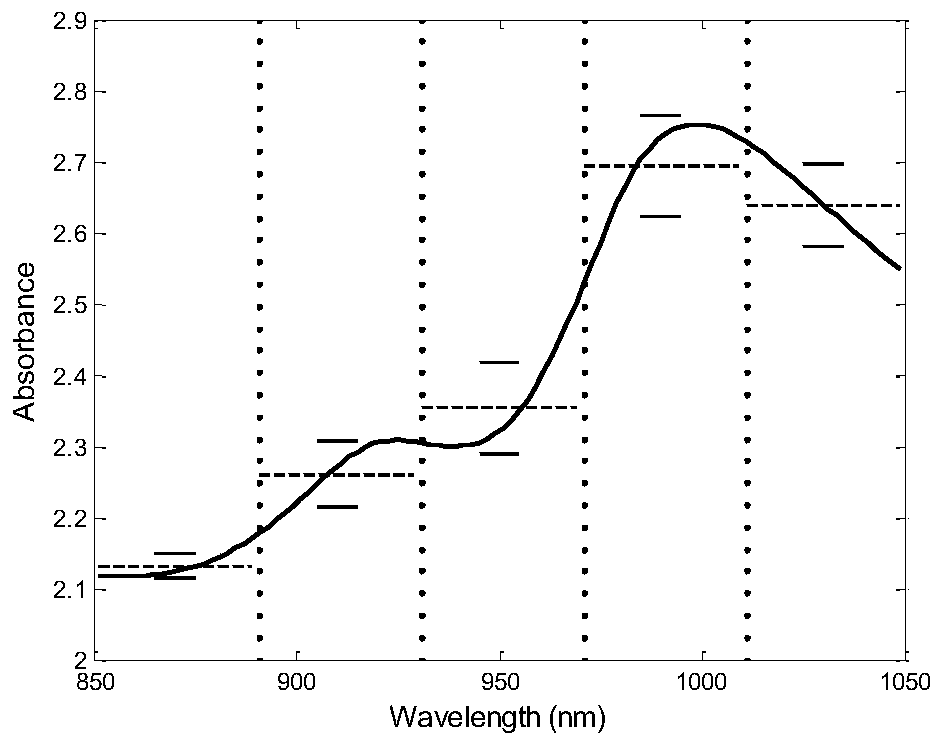

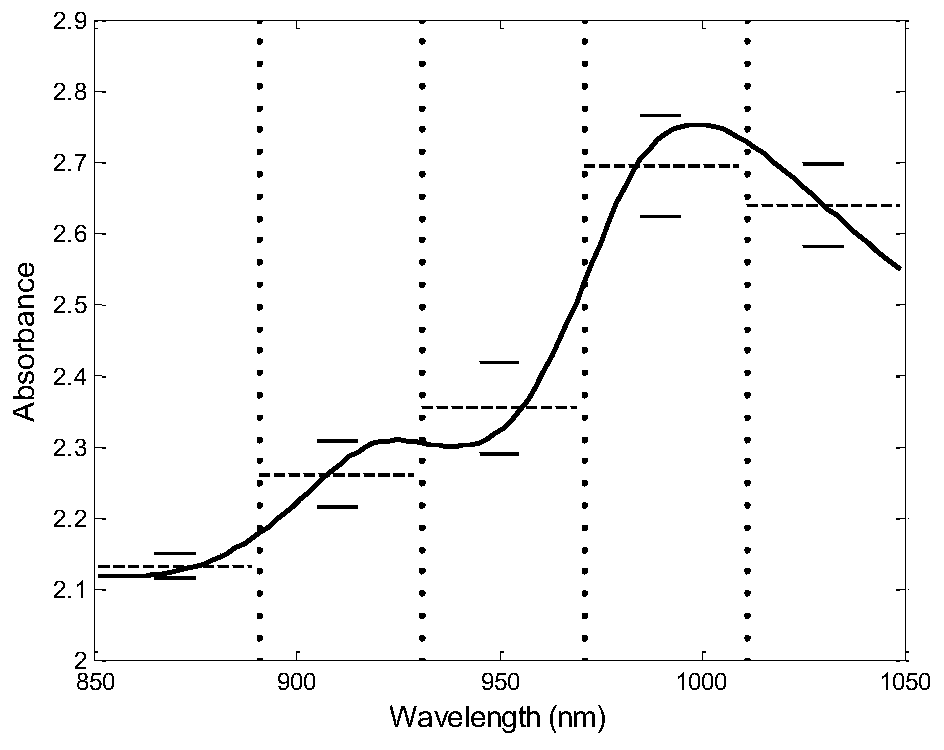

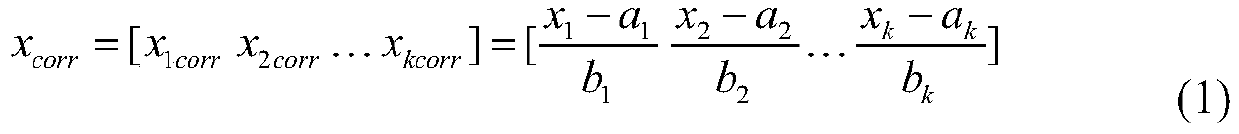

Alternative method for tobacco leaf and cigarette leaf group formula based on near infrared spectrum

ActiveCN109975238AAvoid stabilityAvoid errorsColor/spectral properties measurementsInterference factorInstability

The invention aims to provide an alternative method for a tobacco leaf and a cigarette leaf group formula based on a near infrared spectrum. The alternative method eliminates interference factors suchas base lines and scattering in the spectrum through adopting a locally correcting spectral preprocessing method and an integrated spectral similarity algorithm, realizes the conversion from spectralsimilarity to tobacco leaf similarity, realizes the tobacco leaf alternative method in the auxiliary cigarette leaf group formula maintenance process, reduces the smoke panel test amount of the formula maintenance personnel, and avoids the subjectivity and instability in the sensory smoke panel test process.

Owner:CHINA TOBACCO ZHEJIANG IND

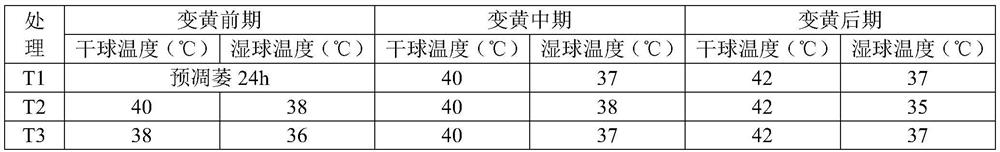

Starch-lowering aroma-improving baking process of flue-cured tobaccos

InactiveCN105192874AReduce starch contentImprove the quality of smokingTobacco preparationCooking & bakingHigh heat

The invention provides a starch-lowering aroma-improving baking process of flue-cured tobaccos. The starch-lowering aroma-improving baking process mainly comprises three baking phases including a high-temperature burning and low-temperature yellowing phase, an advanced dehumidifying and slow color fixing phase and a phased heating, aroma improving and drying phase. The starch-lowering aroma-improving baking process is characterized in that in a baking process, a circulating fan is intermittently run at the time with heat supplying and dehumidifying requirements in a whole yellowing period and a drying post-period; in the drying period, a heating manner of heating for four times and stopping for four times is adopted so that the staying time at a high-temperature period is shortened; three sections of humid ball temperature curves are set so that operation and control are facilitated. By virtue of adopting the baking process, about 15% of baking energy consumption can be saved; the ratio of badly baked tobaccos including green miscellaneous tobaccos, ash-containing tobaccos, steamed pieces and the like is obviously reduced, and the ratios of orange tobaccos and up first-class tobaccos are increased; baked tobacco leaves have much oil content, low starch content, coordinated chemical components, enough aroma and reduced irritation.

Owner:HUBEI TOBACCO SCI RES INST

Method for scenting and aroma adding of tobacco

ActiveCN102920002AReach perfumingImprove the quality of smokingTobacco preparationFlavorAbsorbent cotton gauze

The invention discloses a method for scenting and aroma adding of tobacco. The method comprises the following steps of: performing mixed loading of tobacco with the water content of 13 to 15 percent and a spice which is wrapped by a layer of absorbent cotton gauze and is one of sweet osmanthus flower and Chinese crossostepium leaf in a mass ratio of (2-3):1, sealing, and naturally purifying for 1.5 to 2 years. According to the method, the aroma of a plant is absorbed by utilizing the adsorption capacity of the tobacco, and an essence spice is not required to be prepared from a spice substance by a fussy process, so that the aims of adding the aroma into the tobacco and improving smoking quality are fulfilled. The method also has the characteristics of simplicity, low cost and the like.

Owner:HUBEI CHINA TOBACCO IND

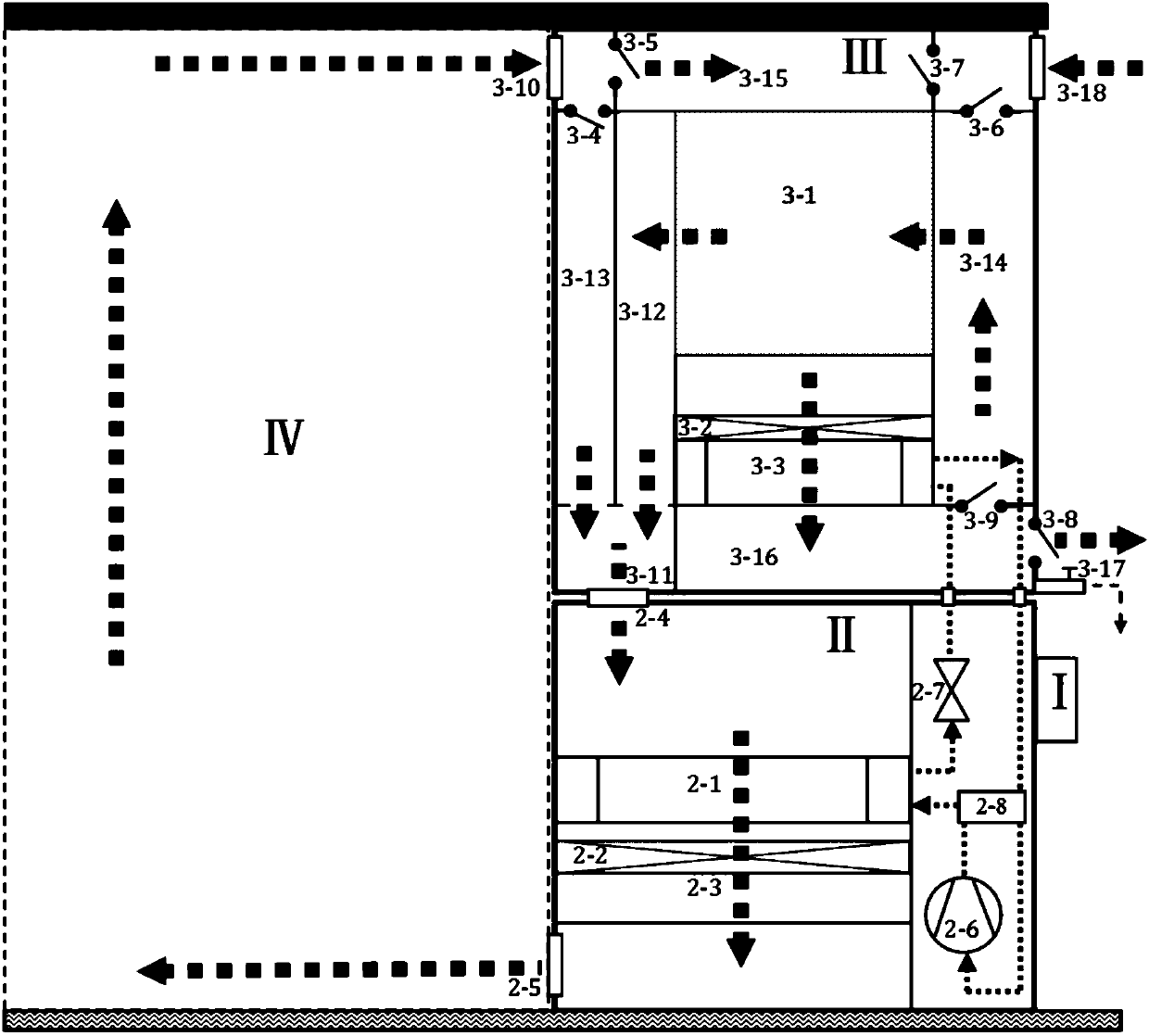

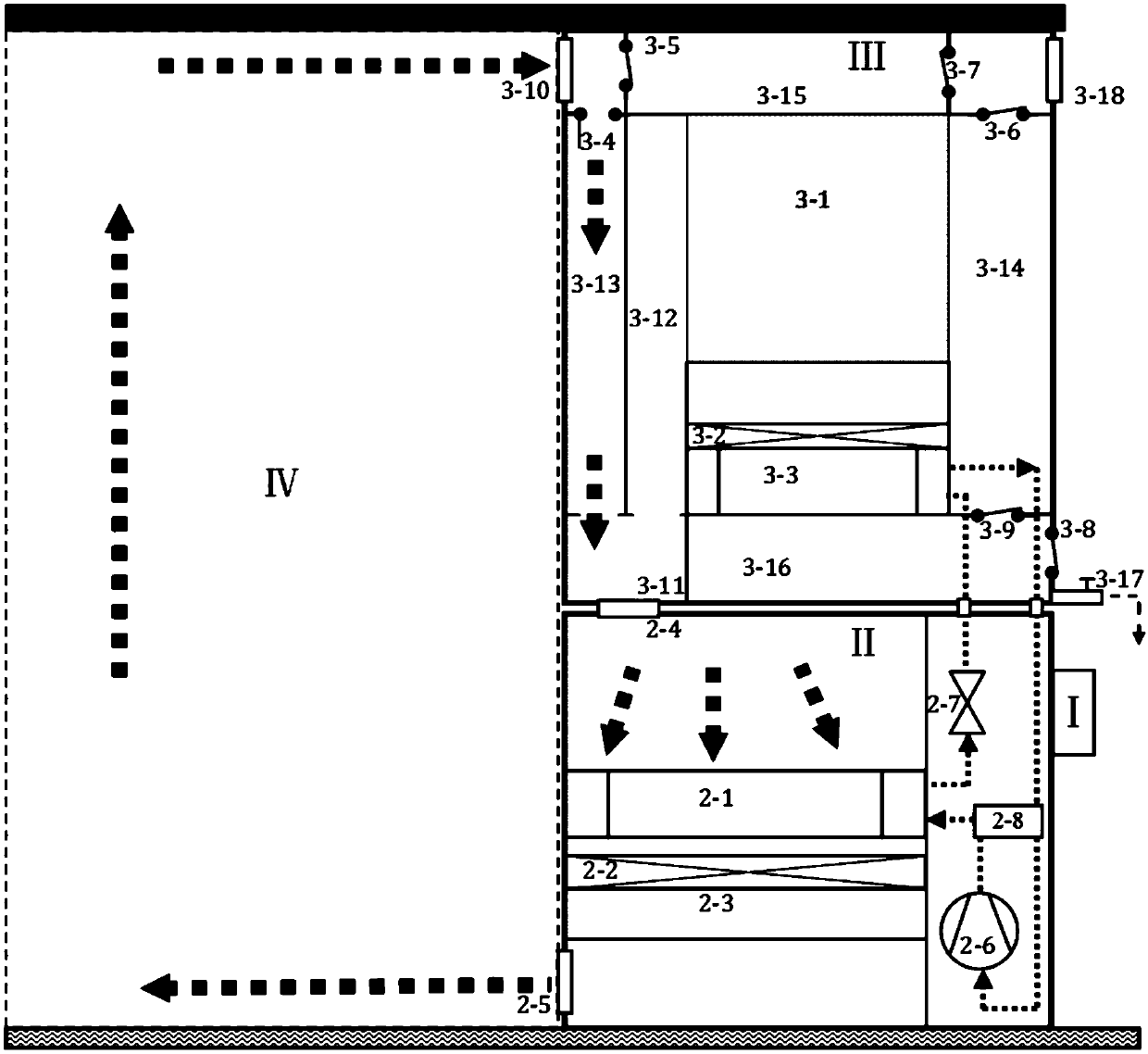

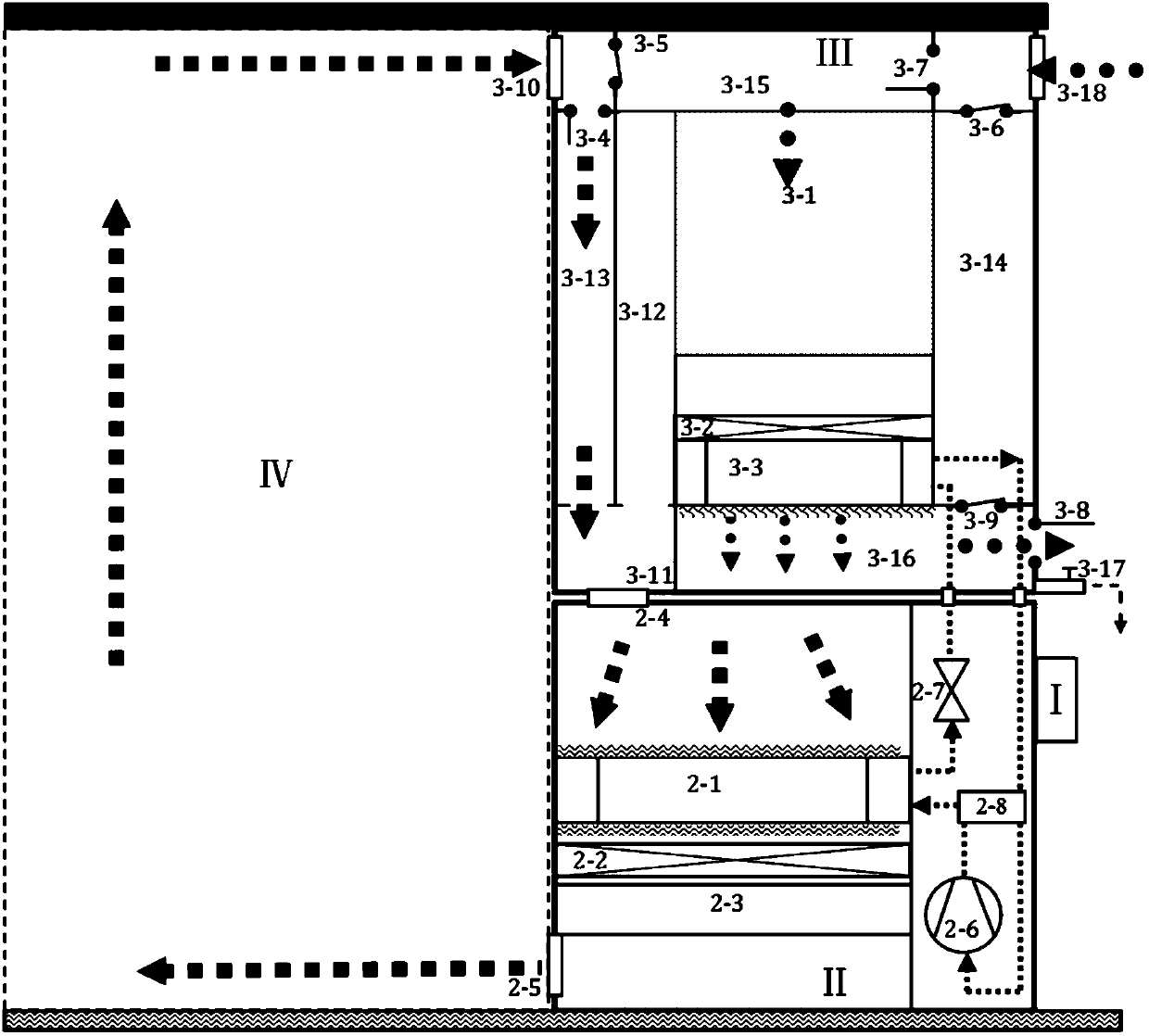

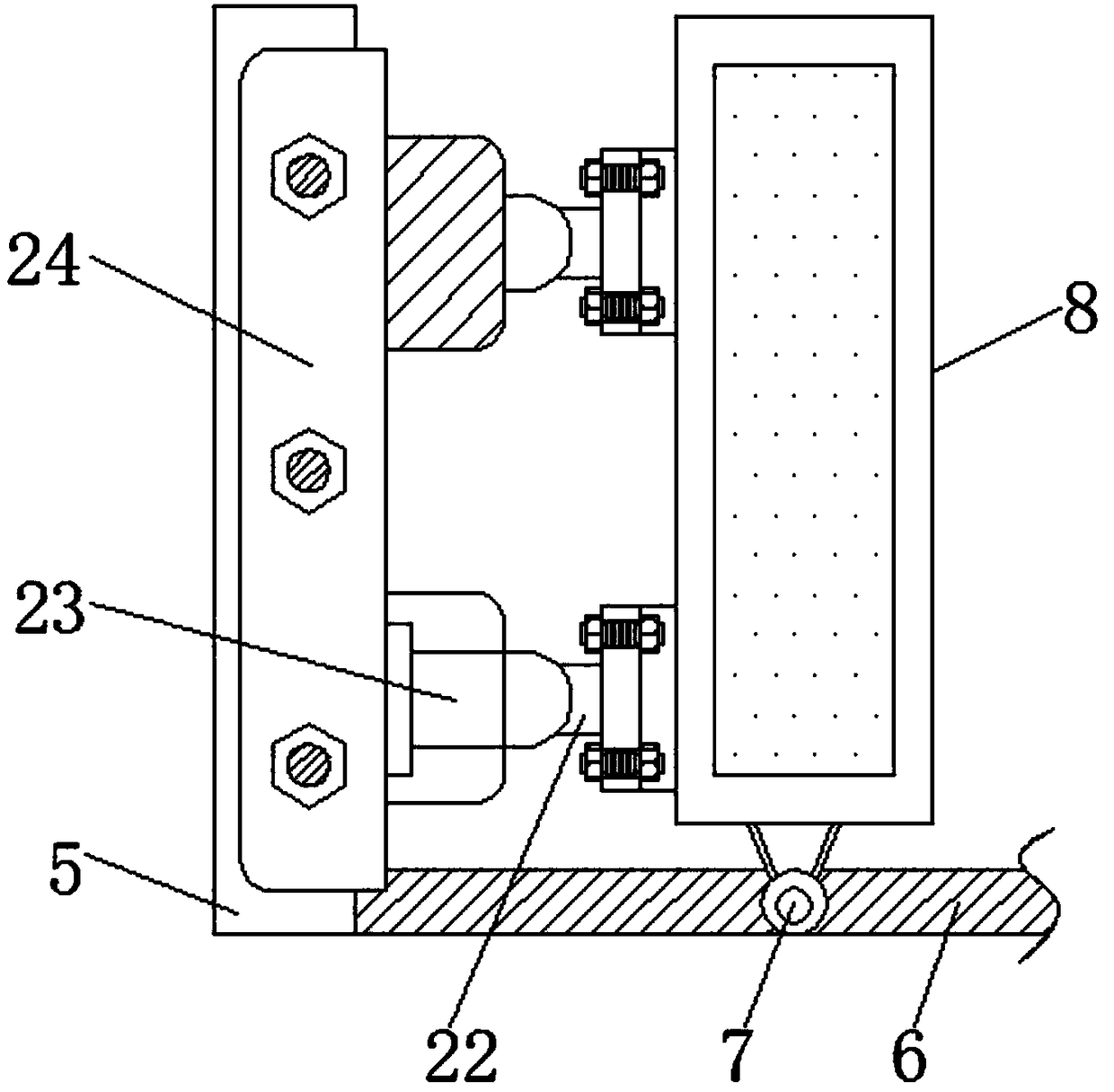

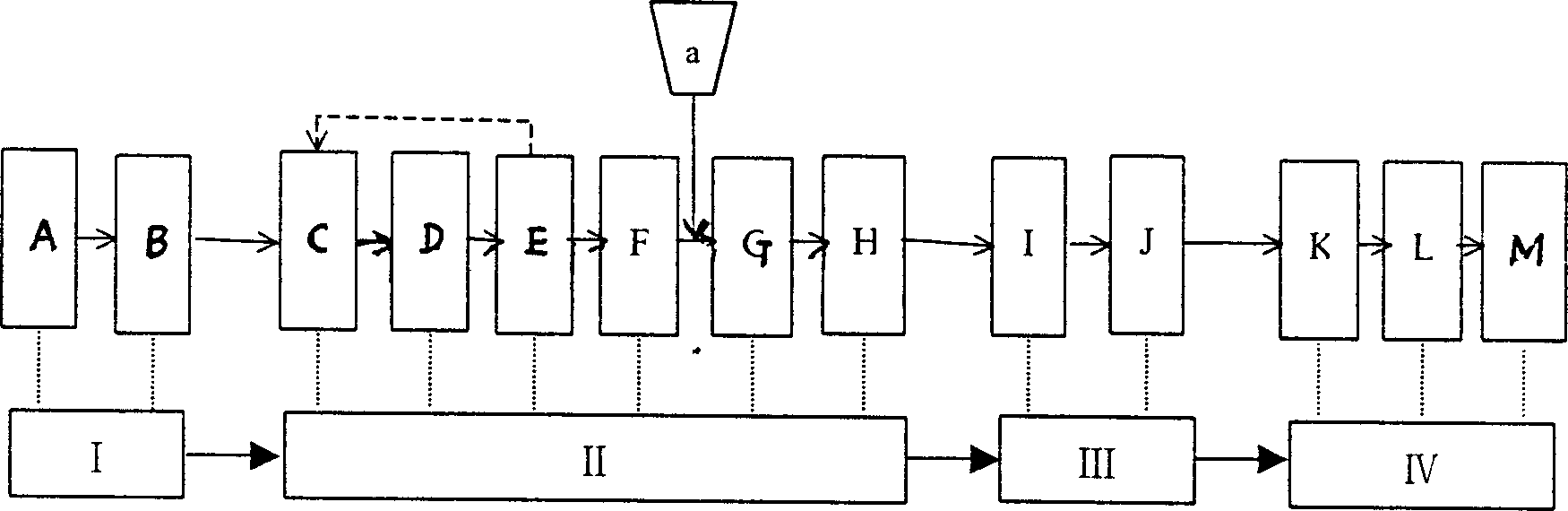

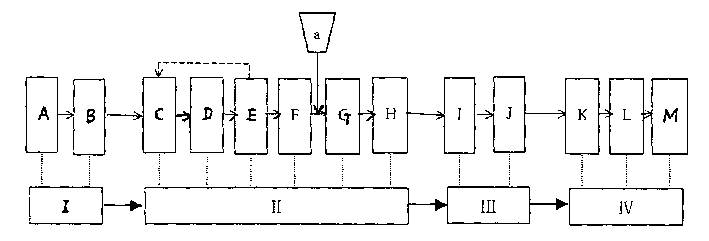

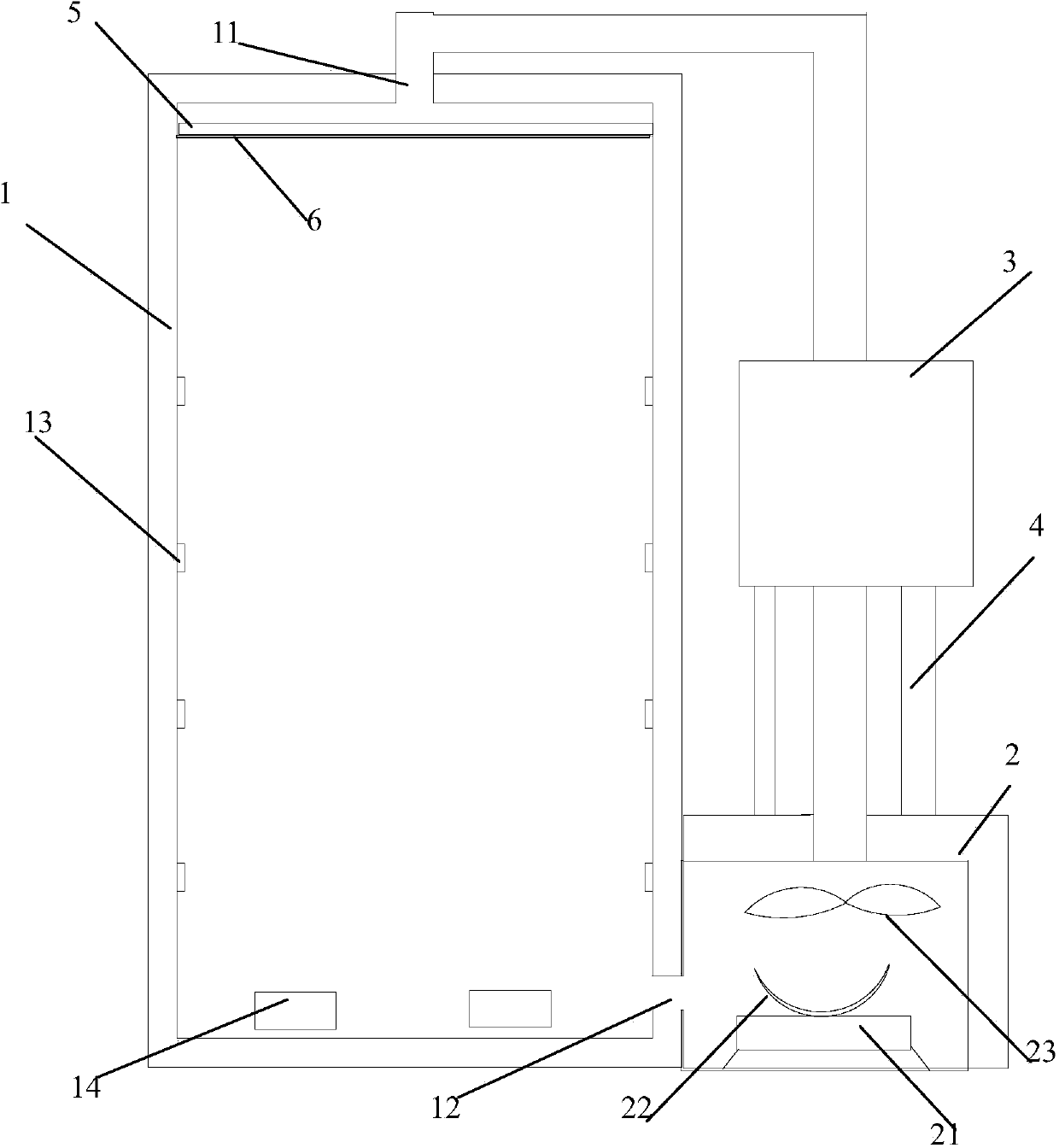

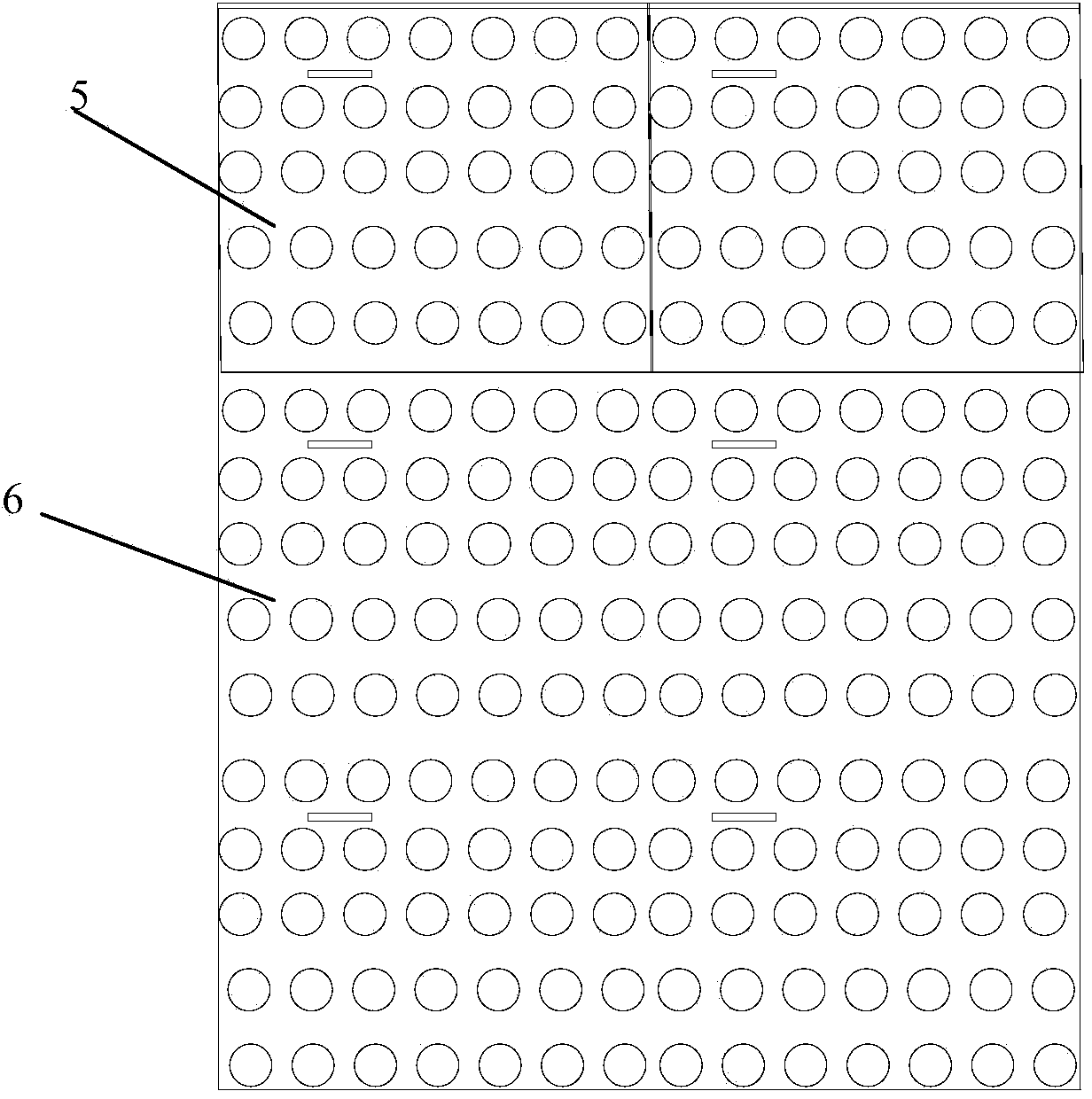

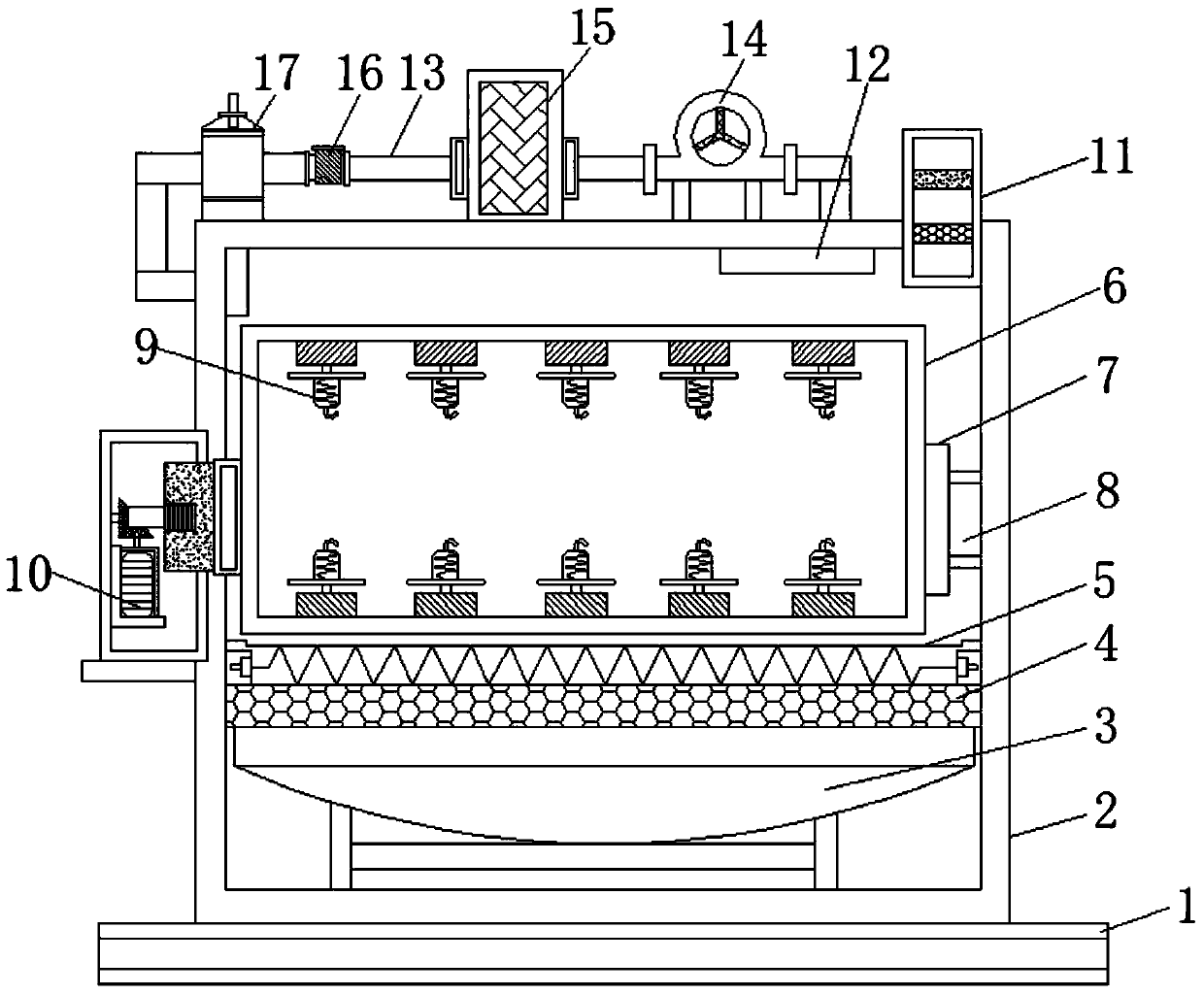

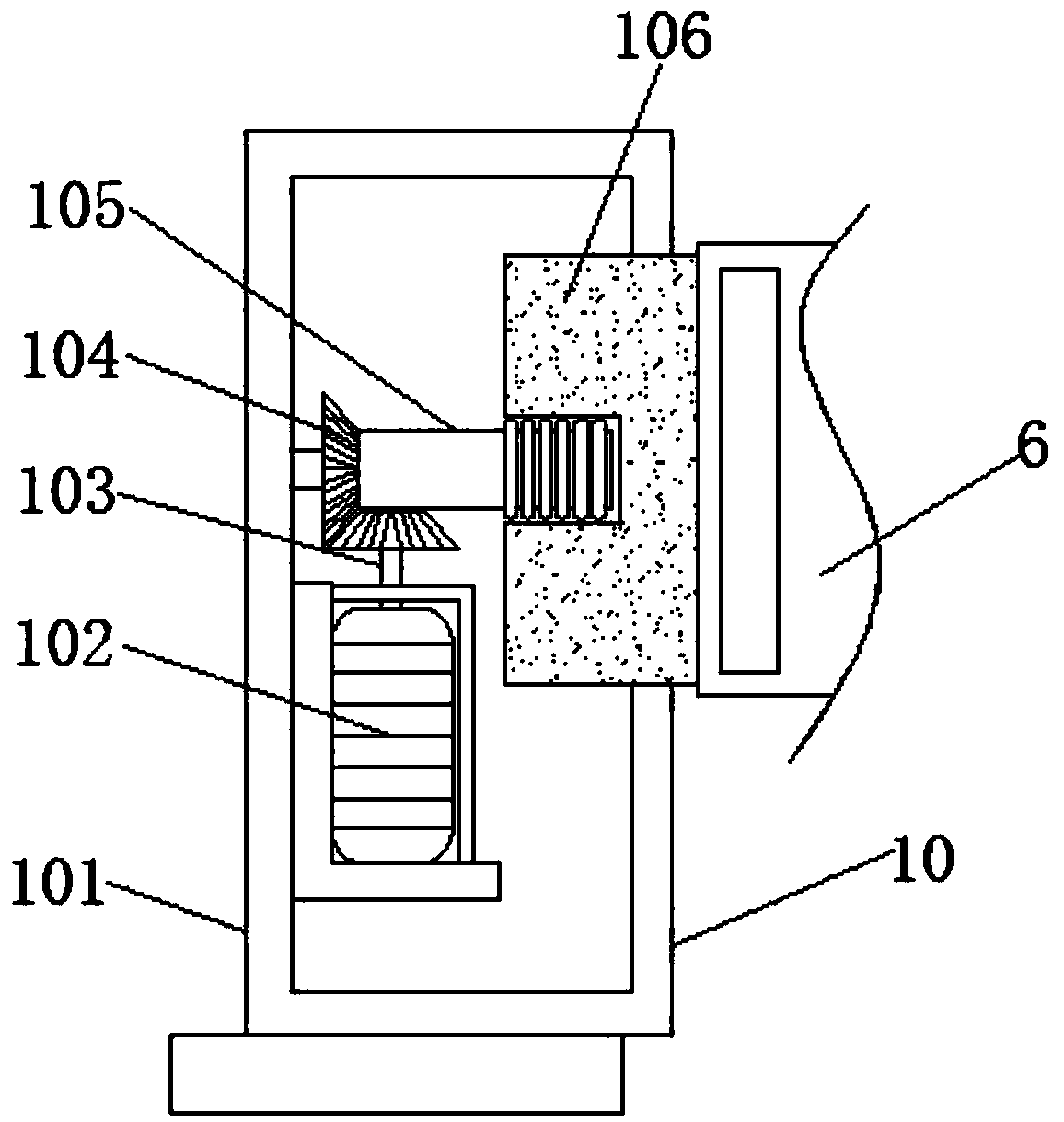

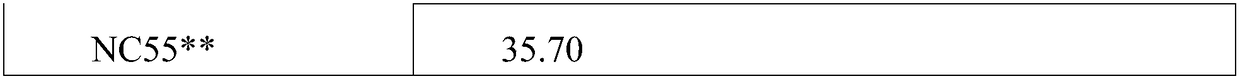

Airflow circulating type bulk curing barn air energy heating and dehumidification system

The invention discloses an airflow circulating type bulk curing barn air energy heating and dehumidification system. The system comprises a controller (1), a heating chamber (II), a dehumidification chamber (III), a smokebox (IV); the dehumidification chamber (III) is connected with the smokebox (IV) through a dehumidification air inlet (3-10), a dehumidification air outlet (3-11) is connected with a heating chamber air inlet (2-4) of the heating chamber (II), the heating chamber (II) is connected with the smokebox (IV) of the heating chamber air outlet (2-5), thereby forming an airflow circulating loop; the heating and dehumidification system is integrated with six working modes with different functions, airflow circulating loops and working processes; and the intelligent switching is performed through an embedded algorithm program based on a curing process curve in the controller between the modes. The system disclosed by the invention has the advantages that a heat pump heating anddehumidification system unit is used as a heat supply device and the tobacco leaf curing is performed by adopting multiple airflow circulating work modes, the energy utilization rate and the tobacco quality are improved, and the curing cycle and the cost a reduced.

Owner:HUNAN UNIV OF SCI & TECH

Method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology

InactiveCN101933655AFluffy structureImprove the smoke effectTobacco preparationTobacco treatmentProcess engineeringAnaerobic microorganisms

The invention discloses a method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology. The method comprises the following steps of: performing steam explosion on tobacco stalks by using a steam exploder; placing the exploded tobacco stalks in a sealed container, adding anaerobic microorganisms into the container and forming an anaerobic environment in the container to perform anaerobic treatment by vacuuming or filling the container with an inert gas; taking the tobacco stalks out of an anaerobic treatment container and quickly dehydrating at the low temperature to control water content to be about 20 to 30 percent; and finally slicing the dehydrated tobacco stalks for the production of cigarette. The method can improve the amount of the tobacco stalk added during the production of the cigarette on the premise of not influencing the aesthetic quality of the cigarette, so that the cigarette cost is effectively reduced.

Owner:CHINA TOBACCO CHUANYU IND

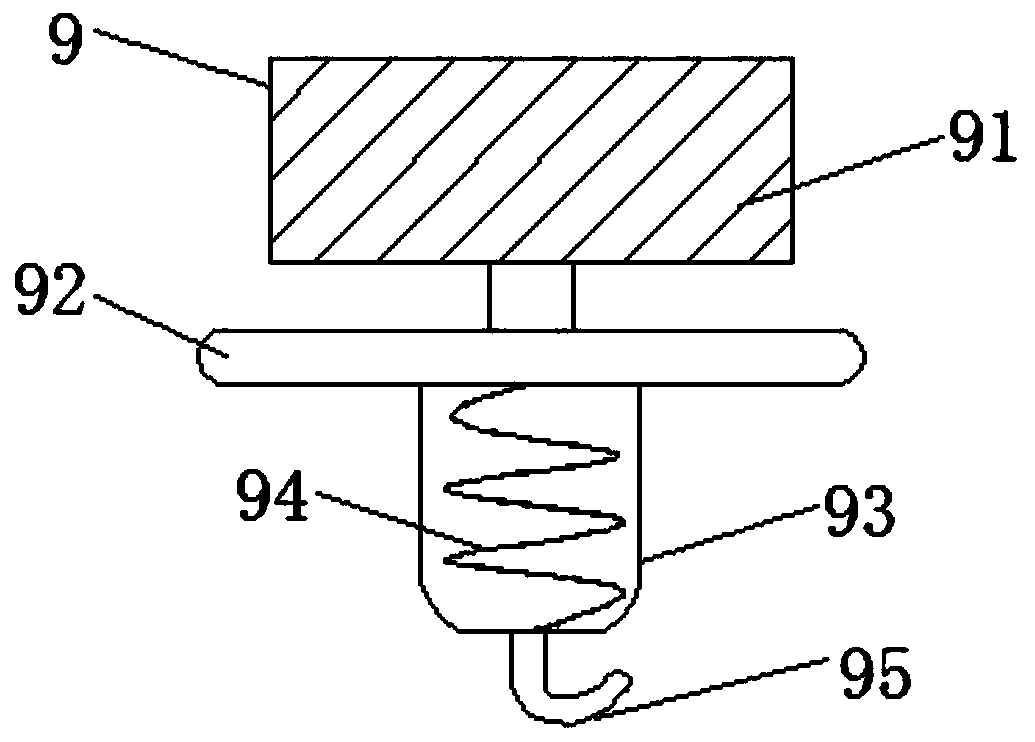

Mobile smoked beef product baking oven

InactiveCN108651597AImprove the quality of smokingAdd flavorMeat/fish preservationHydraulic cylinderCooking & baking

The invention relates to the technical field of beef processing, and discloses a mobile smoked beef product baking oven. The mobile smoked beef product baking oven comprises a bottom plate, wherein universal wheels and hydraulic driving machines are sequentially arranged at the bottom of the bottom plate from left to right; a baking box is fixedly connected to the top of the bottom plate; slidinggrooves are formed in the bottom of an inner cavity of the baking box; a sliding wheel is in slip connection to the inner part of each sliding groove; and a fire pan is fixedly connected to the tops of the sliding wheels. According to the mobile smoked beef product baking oven disclosed by the invention, a motor, a smoking cylinder and hooks are arranged, beef which needs smoking is placed on thehooks, and a driving wheel is driven by the motor to rotate, so that the smoking cylinder on one side of a rotating rod is driven to rotate; and besides, a hydraulic cylinder is utilized to drive thefire pan on one sides of the hydraulic rods to slide back and forth in the sliding grooves, so that the fire pan moves back and forth at the bottom of the smoking cylinder, the situation that the beefis always in dynamic smoking in the smoking process is guaranteed, the purpose of uniformly smoking the beef is realized, and the smoking quality of the beef is improved.

Owner:阜阳市三原食品股份有限公司

Making process of gingko leaf cigarette with mellow taste

InactiveCN1440698AImprove qualityGood physical propertiesTobacco treatmentCigar manufactureGinkgo bilobaFermentation

The gingko leaf cigarette is made with gingko leaf as main material and through four stages of preparing material, making shreds, wrapping and packing. The shred making stage incldues six steps of green keeping or artificial fermentation, eliminating stem, adding material, slicing, sweentening and shred storing and balancing; and features the addition of extractive liquid of gingko leaf and white ginseng in the amount not less than 25% through spraying or soaking. Owing to the relatively low saccharide content in ginkgo leaf, sweetening agent in great amount than traditional cigarette is added. In order to mask the bad smell of burnt ginkgo leaf and extractive matter, the present invention has perfuming matter amount greater than traditional cigarette.

Owner:陈建青

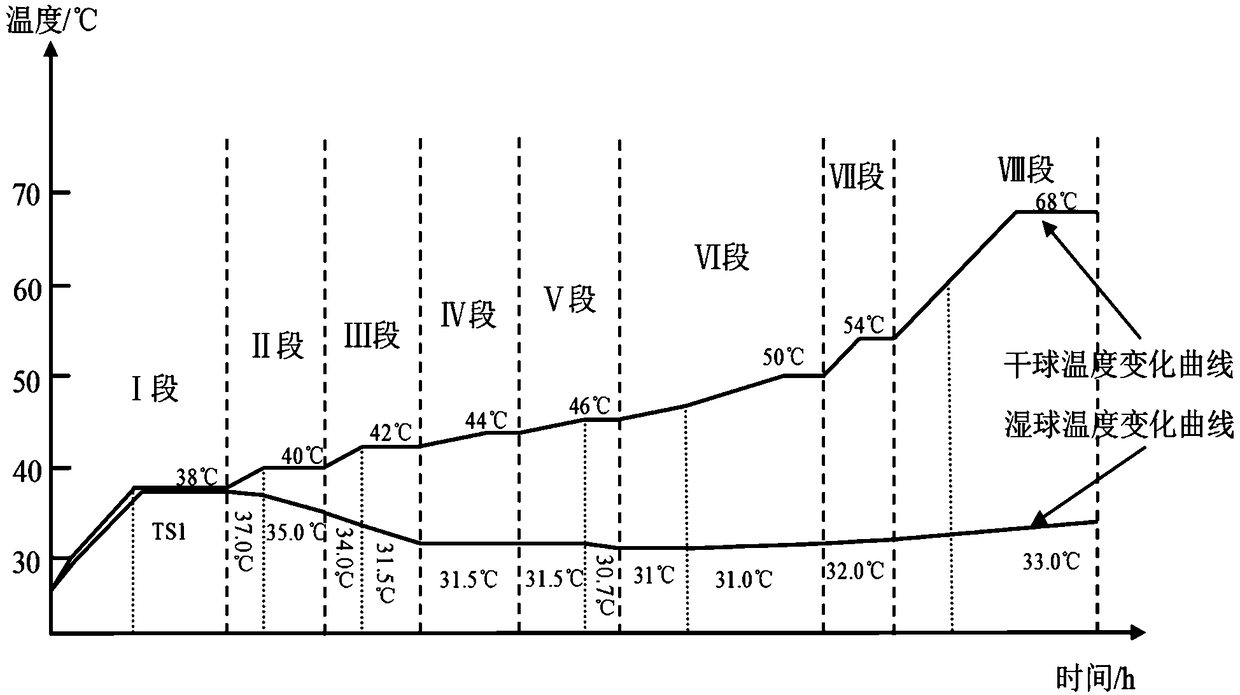

Eight-section baking process for upper tobacco leaves of NC102

The invention discloses an eight-section baking process for upper tobacco leaves of NC102, which comprises a control section I, a control section II, a control section III, a control section IV, a control section V, a control section VI, a control section VII and a control section VIII, wherein each section is provided with a heating process and a temperature stabilizing process, and the setting of error controlling; in the control sections II, III, and V, a dry bulb temperature and a wet bulb temperature are used as controlling targets; in the other control sections, the dry bulb temperatureis used as the controlling targets. The baking process has the beneficial effects that the operability of the baking process is strong, the dry bulb temperature can be uniformly increased according tothe set heating rate during the heating process, and the heating is not too fast; the dry bulb temperature and the wet bulb temperature can fluctuate within the set range during the temperature stabilizing process. According to the baking process, appearance chromaticity of the tobacco leaves can be enhanced, yield of high-quality tobacco leaves can be improved, smoking evaluation quality can beimproved, energy consumption can be reduced, and baking cost can be reduced.

Owner:HUNAN UNIV OF SCI & TECH

Sauced product smoking furnace with uniform inlet air

InactiveCN103431366AGuaranteed temperatureGuaranteed Smoke ConcentrationFood preparationEngineeringMechanical engineering

The invention discloses a sauced product smoking furnace with uniform inlet air. The sauced product smoking furnace comprises a smoking chamber, a smoke generation chamber and a control cabinet, wherein an air uniformizing mechanism is arranged at the top of a cabinet body of the smoking chamber; the air uniformizing mechanism comprises an upper hole plate which is spaced from a top plate of the cabinet body and in which a plurality of through holes are densely formed, and a plurality of adjusting plates which are adjustably arranged below the upper hole plate and in which vent holes corresponding to the through holes of the upper hole plate are formed; outlet air can be adjusted by changing an stagger angle, relative to the upper hole plate, of each adjusting plate. According to the smoking furnace, the air uniformizing mechanism is arranged at an air inlet and can be used for directly and separately adjusting and controlling each region by adopting two hole plates and adjusting the stagger angle of each hole plate and the upper hole plate, so that the uniformity of smoke in the smoking chamber can be enhanced and the smoking quality is further improved.

Owner:天津市天宝楼食品研发有限公司

Tobacco bits pulping process for producing tobacco flake in method similar to papaermaking

ActiveCN1739410AKeep favorable componentsImprove the quality of smokingTobacco treatmentFiberPapermaking

The tobacco bits pulping process for producing tobacco flake in method similar to papermaking includes: soaking tobacco bits in hot water of 20-60 deg.c for 0.5-1.5 hr to extract and solid-liquid separation to obtain solid tobacco bits and tobacco bits extracting liquid; beating tobacco bits fiber in conventional process with final beating degree of 14-30 deg SR and preferably 18-25 deg SR. The present invention has improved technological process and indexes and the tobacco flake have raised filling performance and capacity of lowering tar releasing amount of cigarette. The present invention can meet the requirement of industrial production and raise the utilization rate of tobacco flake.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Tobacco flue-curing method for bulk curing barn

InactiveCN102511917BFully convertedFully formedTobacco preparationDecompositionMacromolecular Substances

The invention relates to the technical field of flue-cured tobacco modulation, in particular to a tobacco flue-curing method for a bulk curing barn. The flue-curing process of the tobacco flue-curing method includes a yellowing period, a withering period, a stem yellowing period, a tobacco leaf drying period and a stem drying period according to factors such as dry-bulb temperature, wet-bulb temperature, drying time, heating rate, variable speed ventilation and tobacco leaf change targets, a color fixing period in the traditional tobacco flue-curing method is prolonged at a fixed point and steady temperature under the condition of hot air circulation, and sufficient decomposition and transformation of amylum, protein and other macromolecular substances in tobacco leaves and forming of aromatic matters are promoted. The tobacco flue-curing method for the bulk curing barn is easy to operate, safe and secure, can keep tobacco leaf yellow to be stable, leaf shrinking degree to be good, oil content to be increased and tobacco leaf aromatic amount to be increased greatly, further can reduce or avoid tobacco leaf roasting damage of green smoke roasting, ash smoke hanging, black bad smoke, lousy smoke roasting and the like, and can obtain high-quality tobacco leaves through roasting.

Owner:四川省烟草公司宜宾市公司

Smoking device for smoking beef

InactiveCN109964996AAchieve the purpose of rotationKeep the smoke dynamicMeat/fish preservationDispersed particle filtrationEngineeringSmoking device

The invention relates to the technical field of beef processing, and discloses a smoking device for smoking beef. The smoking device comprises a bottom plate, wherein a machine body is fixedly connected to the top of the bottom plate, a fire pot is fixedly connected to the bottom of an inner cavity of the machine body, a filter screen which is located in the machine body is arranged directly abovethe fire pot, a heating plate is fixedly connected to the top of the filter screen, a smoking box located in the machine body is arranged directly above the heating plate, and a rotating disk is fixedly connected to one side of the smoking box. According to the smoking device for smoking the beef, rotating devices and a driving device are arranged, beef to be smoked is placed on a hook, and a first motor is used for driving a disk to rotate so as to further drive the hook to rotate, so that the purpose that the beef rotates in a smoking cylinder is realized; and besides, a second motor rotates to drive a rotating block to rotate, so that the rotating block drives the smoking cylinder to rotate, the condition that the beef can always maintain dynamic smoking in the smoking process can be guaranteed, the purpose of uniform smoking of the beef can be realized, and the smoking quality of the beef can be improved.

Owner:阜阳市三原食品股份有限公司

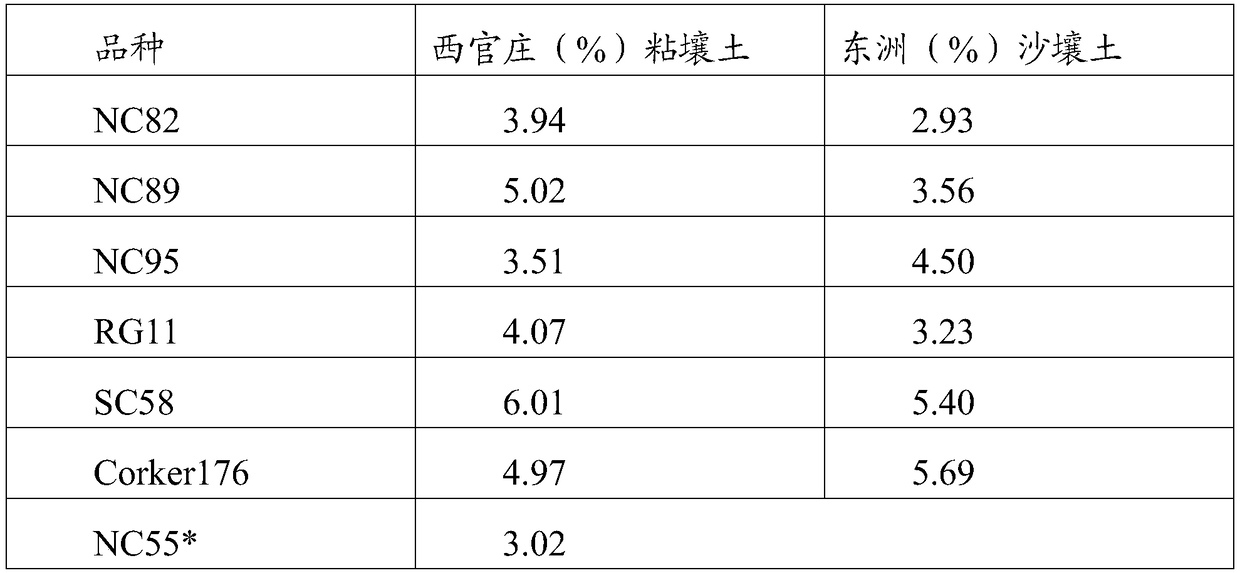

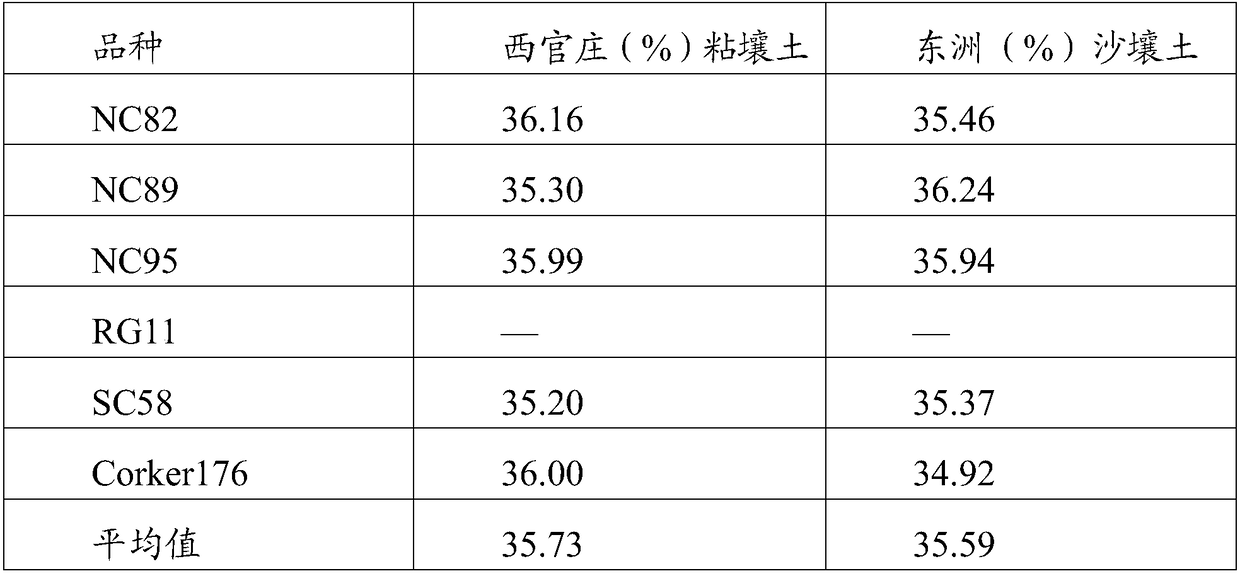

Dedicated organic inorganic compound fertilizer for K236, Yunnan tobacco, and NC series flue-cured tobacco

The invention provides a dedicated organic inorganic compound fertilizer for K236, Yunnan tobacco, and NC series flue-cured tobacco. The fertilizer is prepared by the following steps: evenly mixing the following components in parts by weight: 17 to 57 parts of thoroughly decomposed rapeseed oil cake, 0 to 10 parts of monoammonium phosphate, 3 to 13 parts of diammonium phosphate, 18 to 24 parts of potassium sulfate, 13 to 19 parts of potassium nitrate, 3 to 4 parts of potassium chloride, 0.5 to 1 part of anhydrous borax, 0.5 to 1 part of zinc sulfate, 0.5 to 1 part of magnesium sulfate, 1 to 3 parts of amino acid, 3 to 7 parts of potassium humate, fully grinding the mixture, and completely sieving the grinded mixture so as to obtain the fertilizer. The compound fertilizer can be used for the K326 / Yunnan tobacco series and the NC series flue-cured tobacco. The water solubility of the fertilizer is good. The fertilizer can better coordinate the nutrients in soil, promotes the growth of tobacco plant in the early stage, and assists the timely maturity and yellowing in the later stage. Furthermore, the fertilizer utilization rate is improved. The tobacco leaf is easy for baking and the quality of tobacco leaf is improved. The fertilizer is easy to use for farmers, thus the workload for farmers is reduced, and the work efficiency is improved.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Isatis root extract essence spice for cigarette and preparation method thereof

InactiveCN101676372AGood effectImprove qualityTobacco treatmentEssential-oils/perfumesMaillard reactionFlavor

The invention relates to an essence spice and a preparation method thereof, in particular to an isatis root extract essence spice for cigarette and preparation method thereof. The preparation method comprises the following steps: adding isatis root in water to perform refluxing and extracting and adding sugar to perform Maillard reaction and obtain the product at the same time, wherein the refluxing and extracting process is performed in two steps, in the first step, 5 times of water is added to perform refluxing and extracting for 3-5h, in the second step, 3 times of water is added to performrefluxing and extracting for 0.5-2h and in the two steps of the refluxing and extracting process, 5g-20g of sugar is added to perform Maillard reaction. The isatis root extract essence spice used asbottom material can be added in the cigarette to improve the quality of the cigarette and increase the thickness and abundance of the perfume of the cigarette, and the drug effect can reduce the bad effect of the cigarette.

Owner:HUBEI CHINA TOBACCO IND

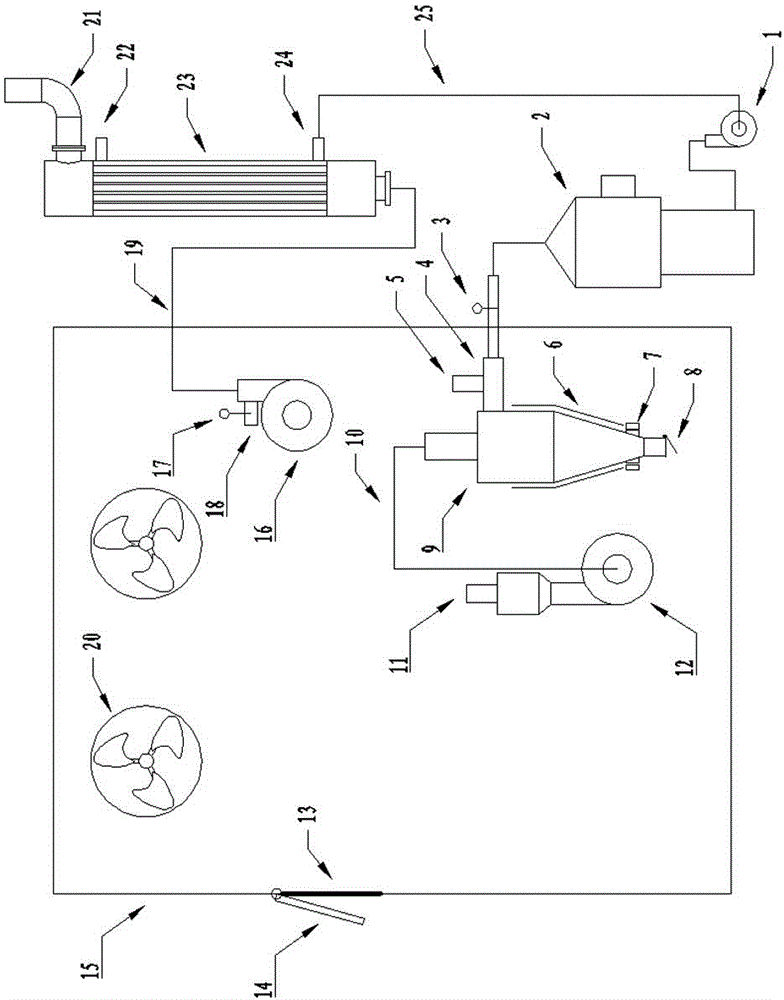

Green dried and salted product smoking and roasting device by use of afterheat recovery

InactiveCN104605004ACyclone separation is simple and reliableLow costMeat/fish preservationFood processingEngineeringAir blower

The invention discloses a green dried and salted product smoking and roasting device by use of afterheat recovery. The green dried and salted product smoking and roasting device comprises a smoke chamber wall body, wherein a cloth curtain and a louver window are arranged on the smoke chamber wall body; a smoke formation pipeline of a smoke formation stove penetrates through the wall body to be connected with an air inlet pipe of a cyclone separator, the cyclone separator is connected with an exhaust fan in the wall body by a pipeline, a damper is arranged on the smoke formation pipeline of the smoke formation stove, a light valve is arranged at the bottom of the cyclone separator, a heat radiator and a vibrator are arranged on the surface of the cyclone separator, a smoke exhaust fan in the smoke chamber wall body is connected with a tube type heat exchanger outside the wall body, and a hot air outlet of the tube type heat exchanger is connected with the smoke formation stove by a hot air pipeline and an air blower. According to the green dried and salted product smoking and roasting device, the cyclone separator is skillfully utilized to realize smoke particle separation and achieve the purpose of removing toxic and harmful substances; soot is subjected to high heat treatment to improve the smoking quality and can be cleaned conveniently, and heat energy cannot be lost; afterheat recovery can further reduce the energy consumption, dried and salted products can be smoked and roasted in a green and high efficiency manner, the operation is convenient and the application prospect is wide.

Owner:JISHOU UNIVERSITY

Method capable of increasing nicotine content in cut tobacco and quality of cut tobacco

ActiveCN108967102AIncrease nicotine contentPromote maturityTobacco cultivationEngineeringGrowth point

The invention provides a planting method capable of increasing nicotine content in cut tobacco and the quality of the cut tobacco and belongs to the technical field of cut tobacco production. The method includes the steps of firstly, removing 2-3 tobacco leaves near the ground 30-45 days after flue-cured tobacco transplanting; secondly, removing tobacco leaves away from the ground and growth points to keep 17-18 tobacco leaves 3-8 days after the removing of the tobacco leaves close to the ground to obtain flue-cured tobacco seedlings after topping; thirdly, when the top tobacco leaves of the flue-cured tobacco seedlings after topping are parallel to the top, removing imperfect tobacco leaves to keep 13-14 tobacco leaves to obtain finely trimmed flue-cured tobacco seedlings; fourthly, harvesting the tobacco leaves 20-30 days after the maturity of the finely trimmed flue-cured tobacco seedlings. By the method, the nicotine content in cut tobacco can be increased while the high-quality taste of the cut tobacco can be guaranteed, the contradiction between 'high nicotine content' and 'high quality' is solved, and both 'high nicotine content' and 'high quality' can be achieved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Environment-friendly roast smoking device for preserved products

InactiveCN104381417ACyclone separation is simple and reliableLow costMeat/fish preservationCyclonic separationHazardous substance

The invention discloses an environment-friendly roast smoking device for preserved products. The environment-friendly roast smoking device comprises a smoking room wall body, wherein the smoking room wall body is provided with a cloth curtain and a gas window; a smoke formation pipeline of a smoke formation furnace penetrates through the wall body and is connected with a gas inlet pipe of a cyclone separator; the cyclone separator is connected with an exhaust fan by a pipeline; an air outlet of the exhaust fan is formed in the wall body; the smoke formation pipeline of the smoke formation furnace is provided with a gate; a light movable door is arranged at the bottom of the cyclone separator; and a heat radiator and a vibrator are arranged on the surface of the cyclone separator. According to the environment-friendly roast smoking device for the preserved products, smoke dust and grain separation is realized by ingeniously utilizing the cyclone separator so that the aim of removing toxic and harmful substances is realized; the cyclone separation is simple and reliable, the cost is low and the operation is easy to realize; a liquid phase is circularly utilized after the high heat treatment of soot so that the smoking quality is improved; after the high heat treatment of the soot, the vibration cleaning is convenient to realize at the later period, and the heat energy can circulate in a smoking room and is not lost; and the preserved products are roasted and smoked in an environment-friendly and efficient manner, the operation is simple and convenient and the application prospect is wide.

Owner:JISHOU UNIVERSITY

Cold smoking device

InactiveCN101380067AWill not change the original tasteAdjustable temperatureMeat/fish preservationClimate change adaptationElectricityDisplay device

A cold smoking machine relates to a smoking device for fish, meat and the similar food, comprising a refrigerator and a smoke generating chamber arranged at the bottom of the refrigerator, the smoke generating chamber is communicated with the bottom wall of the refrigerator, thus the smoke generated by the smoke generating chamber can enter the refrigerator; in addition, the shell of the smoke generating chamber and the shell of the refrigerator integrated into a whole structure; the smoke generating chamber is a drawer structure which can be drawn, and the drawer can be loaded with wood chips or sawdust, and the drawer of the smoke generating chamber is connected with the wall of the shell thereof by a slide rail; the drawer of the smoke generating chamber is internally provided with a smoke generating controller which consists of a plurality of sets of electric heating parts, a smoking switch, an electric heating part working display device and a circuit board; the smoking switch includes a smoking time regulating knob and a smoking time pause regulating knob. The cold smoking machine has the advantages that: cold smoking can be realized by combining the refrigerator structure and the smoking structure, the temperature, time and smoke amount of smoking can be adjusted, the smoking quality is high, and the taste of smoked products can be adjusted according to personal preference.

Owner:邱瑞钟

Special compound fertilizer for being sprayed to flue-cured tobacco leaves

ActiveCN104140308ASolve potassium deficiencySolve micronutrient deficienciesFertilizer mixturesSulfate zincManganese sulphate

The invention relates to a special compound fertilizer for being sprayed to flue-cured tobacco leaves. The special compound fertilizer includes, by weight, 3-6% of copper sulfate, 15-25% of zinc sulfate, 3-6% of borax, 2-3% of epsom salt, 2-3% of manganese sulfate monohydrate, 5-7% of citric acid anhydrous food grade and 50-70% of monopotassium phosphate. The fertilizer can be sprayed to the tobacco leaves and absorbed by the tobacco leaves during the resettling stage, the fast growing stage and the dome stage of flue-cured tobaccos, nutrition is supplemented for the flue-cured tobaccos, elements are coordinated to be balanced, metabolic intermediates are increased, potassium deficiency and microelement nutrient deficiency symptom of the flue-cured tobaccos are well solved, growth and development of the flue-cured tobaccos and substance metabolism and composition are promoted, the potassium content of the flue-cured tobacco leaves is increased, and the appearance quality and the sensory evaluation quality of the flue-cured tobaccos are improved.

Owner:HENAN ACAD OF AGRI SCI

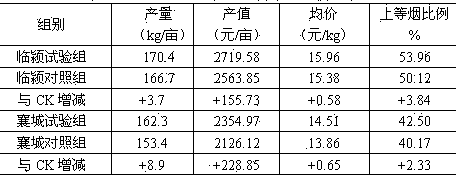

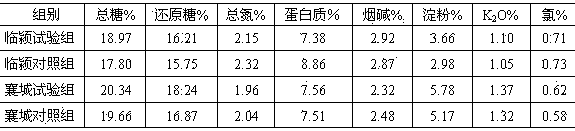

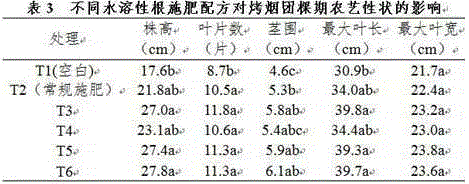

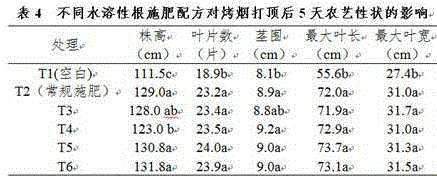

Topdressing method of water soluble root fertilizer of flue-cured tobacco

InactiveCN105409415APromote accumulationIncrease productionFertilising methodsSoil scienceN fertilizer

The invention discloses a topdressing method of a water soluble root fertilizer of flue-cured tobacco. Additional fertilizer is applied to soil in three times. The additional fertilizer is applied to soil for the first time when the flue-cured tobacco is transplanted, the additional fertilizer is prepared from N, P and K according to the proportion of 1: 0.6: 0.5, 0.5 kg of N fertilizer is applied to each mu of soil, and the additional fertilizer is applied as root setting water after being diluted for 100 times. The additional fertilizer is applied to soil for the second time 20-25 days after the flue-cured tobacco is transplanted, the additional fertilizer is prepared from N, P and K according to the proportion of 1: 1.4: 1.4, 1.2 kg of N fertilizer is applied to each mu of soil, and the additional fertilizer is applied to soil at the position 10 cm away from the flue-cured tobacco after being diluted for 5-10 times. The additional fertilizer is applied to soil for the third time after a membrane of the flue-cure tobacco is removed, the flue-cured tobacco is earthed up, the additional fertilizer is prepared from N, P and K according to the proportion of 1: 0.3: 3.5, 1.3 kg of N fertilizer is applied to each mu of soil, and the additional fertilizer is applied to soil at the position 10 cm away from the flue-cured tobacco after being diluted for 5-10 times. Compared with a conventional fertilizer application method, topdressing is performed with the method, the accumulation amount of dry matter of the flue-cured tobacco is increased by 6.74%, the yield and the production value of tobacco leaves are increased by 5.08% and 6.66% respectively, the potassium content of upper tobacco leaves is increased by 25.35% after treatment, and the smoking quality of the upper and middle tobacco leaves is remarkably improved.

Owner:GUIZHOU TOBACCO SCI RES INST

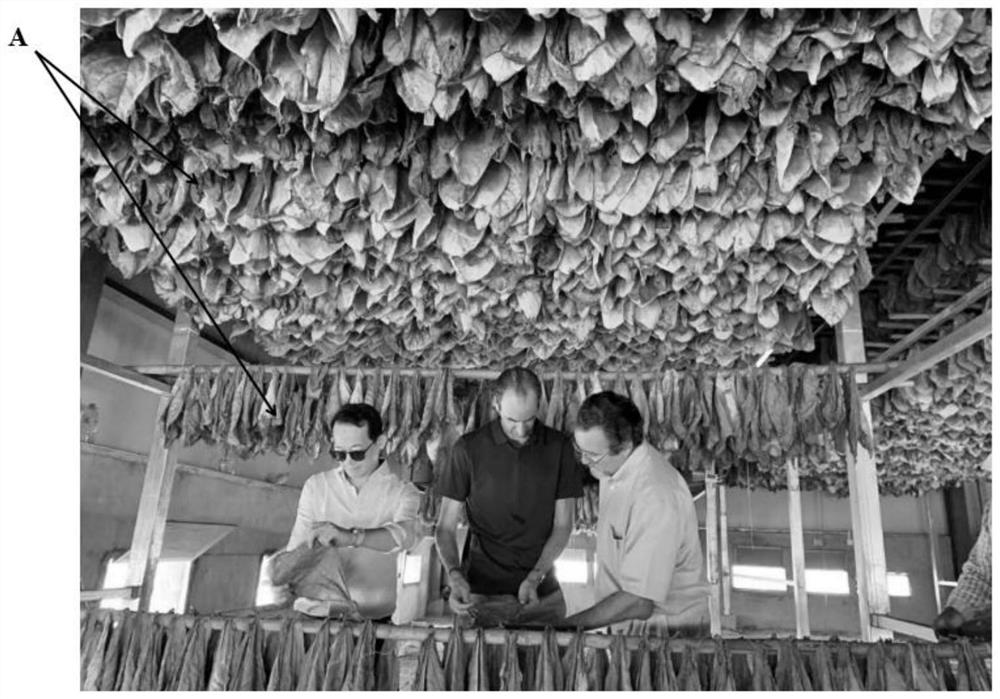

Preparation method of cigar tobaccoleaves

The invention provides a preparation method of cigar tobacco leaves, which belongs to the technical field of tobacco leaf airing. The preparation method comprises the following steps of 1) stacking fresh cigar tobacco leaves under the conditions that the temperature is 20-35 DEG C and the humidity is 60%-90% until the tobacco leaves become yellow and green, and 2) airing the stacked cigar tobacco leaves to obtain the cigar tobacco leaves. According to the method, fresh cigar tobacco leaves are heated and become yellow due to hunger metabolism, and then a needle penetrates through a hanging rod for airing or a tobacco rod is bound with tobacco leaves for airing; compared with the mode that the penetrated (bound) tobacco leaves are directly hung indoors or aired in a conditioning shed after being harvested, the natural yellowing time is shortened by 7-9 days. As the tobacco leaves obtained by the method are stacked and yellowed uniformly, the green content of the tobacco leaves is low, and dead green components do not exist; the tobacco leaves are consistent in water loss speed and inherent quality.

Owner:中国烟草总公司海南省公司

Method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology

InactiveCN101933655BFluffy structureImprove the smoke effectTobacco preparationTobacco treatmentProcess engineeringAnaerobic microorganisms

The invention discloses a method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology. The method comprises the following steps of: performing steam explosion on tobacco stalks by using a steam exploder; placing the exploded tobacco stalks in a sealed container, adding anaerobic microorganisms into the container and forming an anaerobic environment in the container to perform anaerobic treatment by vacuuming or filling the container with an inert gas; taking the tobacco stalks out of an anaerobic treatment container and quickly dehydrating at thelow temperature to control water content to be about 20 to 30 percent; and finally slicing the dehydrated tobacco stalks for the production of cigarette. The method can improve the amount of the tobacco stalk added during the production of the cigarette on the premise of not influencing the aesthetic quality of the cigarette, so that the cigarette cost is effectively reduced.

Owner:CHINA TOBACCO CHUANYU IND

Method for improving tobacco stalk quality by combining steam explosion and enzyme treatment technology

InactiveCN101912149BFluffy structureAchieve conversionTobacco preparationTobacco treatmentEngineeringMoisture

The invention relates to a method for improving tobacco stalk quality by combining steam explosion and enzyme treatment technology, which comprises the following steps of: performing steam explosion on tobacco stalks by using a steam explosion machine; adding lignin enzymes and cellulase into the exploded tobacco stalks; treating the tobacco stalks which are added with enzymes under the conditions of constant temperature and wet temperature, and keeping the treatment temperature of between 30 and 35 DEG C and the relative humidity of 90 percent; dehydrating and drying the tobacco stalks whichare subjected to enzyme treatment at low temperature, and controlling moisture content to about 20 to 30 percent; and finally, shredding the dehydrated tobacco stalks for cigarette production. The method for improving the tobacco stalk quality can reduce the influence of the lignin and cellulose on the tobacco stalk quality, improve the addition rate of the tobacco stalks in the cigarette production and reduce the production cost of cigarettes.

Owner:CHINA TOBACCO CHUANYU IND

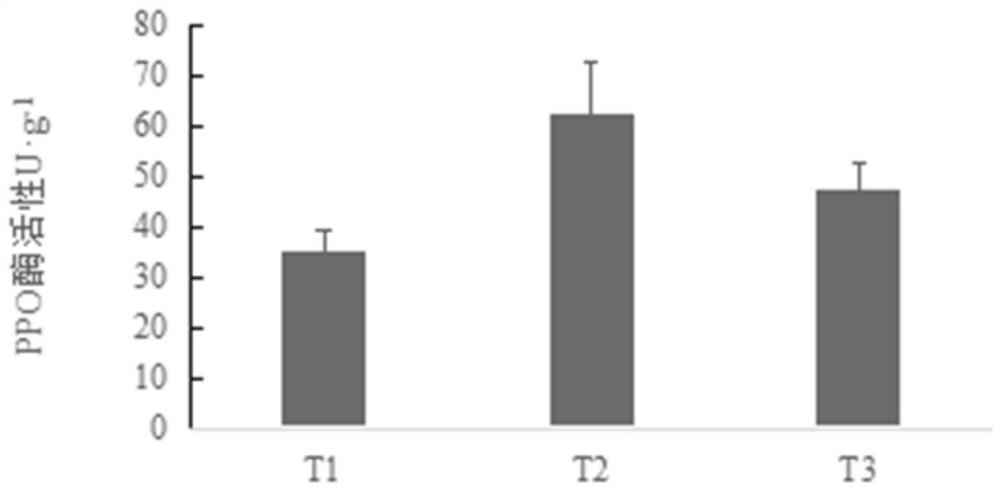

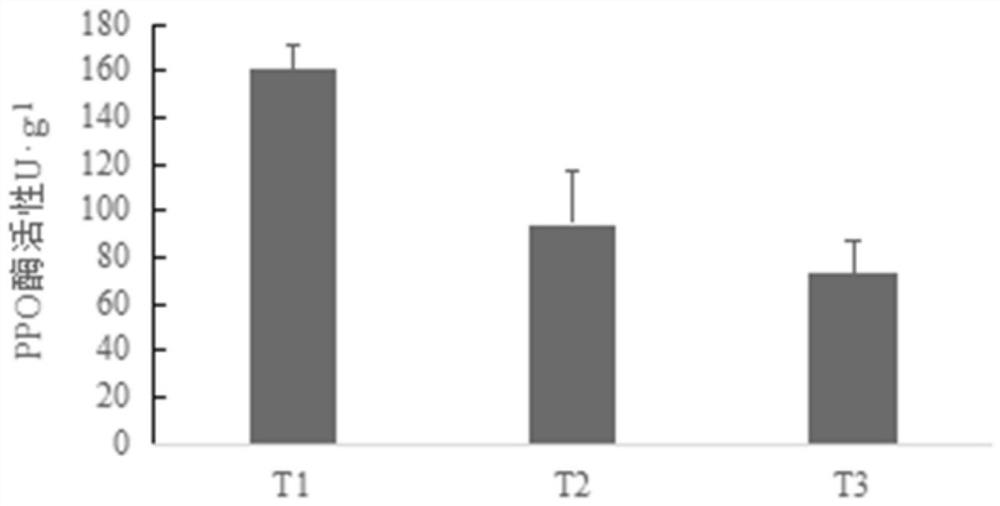

Tobacco leaf curing method and application

ActiveCN113854615ADifferent polyphenol oxidase activity expressionDifferent humidityTobacco preparationNicotiana tabacumHorticulture

The invention belongs to the technical field of tobacco treatment, and particularly relates to a tobacco leaf curing method and application. According to the method, the relationship between the change of substances in the tobacco leaves and the browning of the tobacco leaves under different curing conditions is explored, the key technology of tobacco leaf curing is further adjusted, the tobacco leaf aroma is improved while the loss of the tobacco leaves due to browning is reduced, and a scientific and effective curing scheme is provided for tobacco growers; meanwhile, an effective method for inhibiting browning of the tobacco leaves is explored, and a theoretical basis and effective measures are provided for regulating and controlling the browning reaction of the tobacco leaves in the curing process.

Owner:HUBEI TOBACCO SCI RES INST

A kind of preparation method of low alkaloid burley tobacco extract

The invention provides a preparation method of low-alkaloid burley tobacco extract. According to the low-alkaloid burley tobacco extract, burley tobacco is taken and added into water of 5-10 times volume to be heated till boiling backflow is carried out two times, and burley tobacco crude extract is extracted and obtained; large-particle impurities are filtered away through gauze; then after filter liquor obtained after rough filtering is filtered again through a filtering film, the filter liquor and activated macroporous resin particles special for alkaloid extraction are mixed according to the mass ratio of (5-10):1, and stirring is carried out for 30 min to 60 min at the speed ranging from 20 turns / min to 40 turns / min; and then after gauze is adopted for filtering, a filtering film is used for filtering, concentration is carried out, and the low-alkaloid burley tobacco extract is obtained. According to the preparation method, the adsorption character of macroporous resin is utilized for reducing the content of alkaloid in the burley tobacco crude extract, and safe, low-alkaloid and high-quality tobacco flavor can be obtained.

Owner:HUBEI CHINA TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com