Method capable of increasing nicotine content in cut tobacco and quality of cut tobacco

A tobacco leaf and content technology, applied in tobacco cultivation, etc., can solve problems such as side effects, rough smoke taste, and increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Test site: Xiguanzhuang Village and Dongzhou Village, Feixian County, Linyi City.

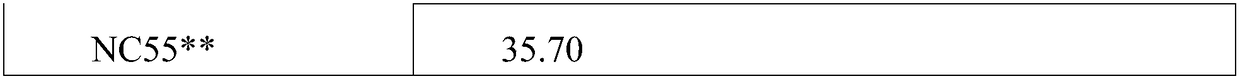

[0041] The variety of flue-cured tobacco tested: NC55.

[0042] Tobacco planting soil: select medium-fertile plots, nitrogen application rate is 5.0KgN / mu (local conventional nitrogen application rate), and the fertilizer used in the test is tobacco special fertilizer (Sun Island Compound Fertilizer; Shandong Longfu Fertilizer Co., Ltd.).

[0043] Field management requirements:

[0044] 1) Seedling raising: use greenhouse floating seedlings to cultivate disease-free 55-day-old strong seedlings.

[0045] 2) Transplanting density: the plant spacing is 50cm×120cm.

[0046] 3) Fertilization: The base fertilizer adopts the method of "strip application", which accounts for 60% of the total fertilizer consumption; the topdressing adopts the fixed-point quantitative topdressing method, and the fertilization points are located at the corresponding positions of the leaf tips on both sides of the...

Embodiment 2

[0056] (1) Tobacco leaf production:

[0057] Location: Xiguanzhuang Village and Dongzhou Village, Fei County, Linyi City.

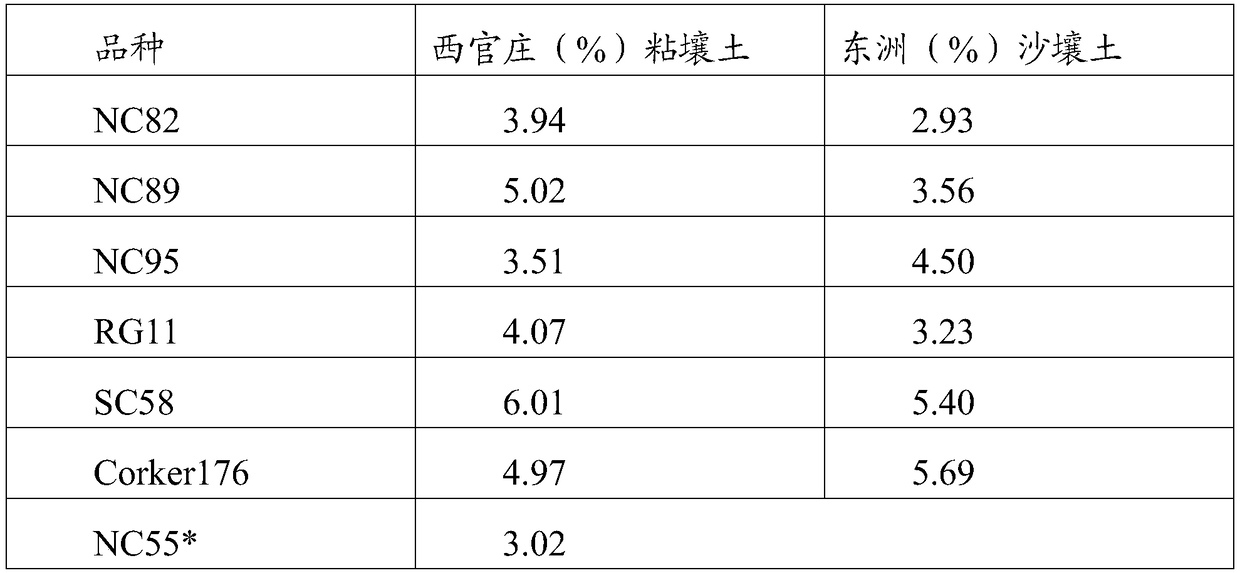

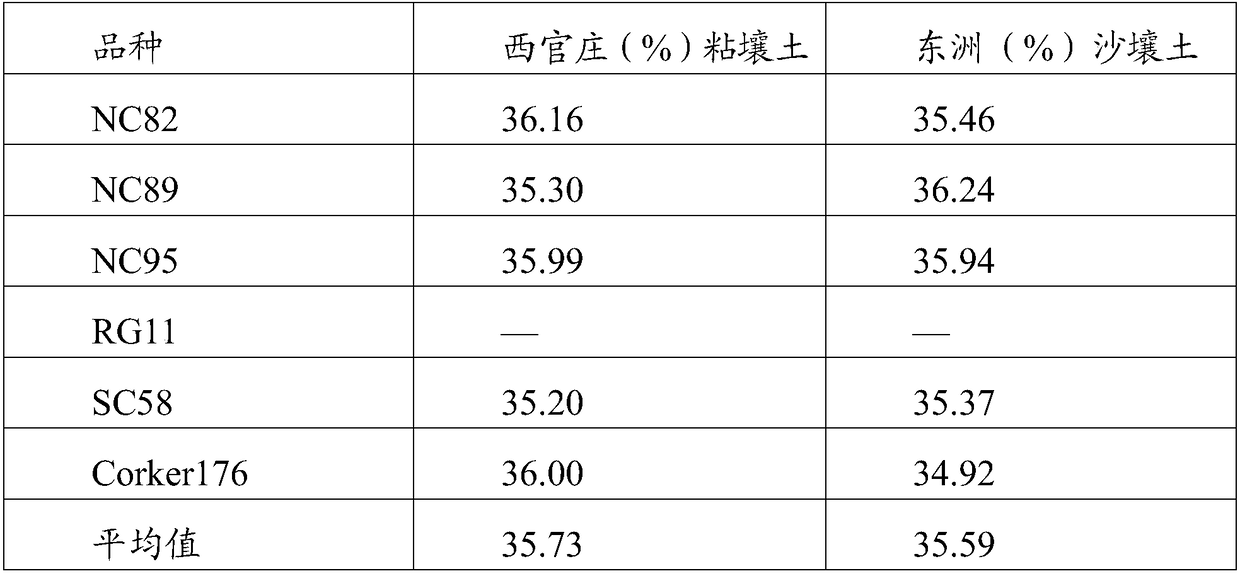

[0058] Varieties of flue-cured tobacco tested: NC55, NC82, NC89, NC95, RG11, SC58, Corker176.

[0059] Field test design: the nitrogen application rate is 5.0KgN / mu (local conventional nitrogen application rate), and the fertilizer used in the test is a special fertilizer for tobacco (Sun Island Compound Fertilizer; Shandong Longfu Fertilizer Co., Ltd.). Choose medium-fertile plots, and plant 400 flue-cured tobacco plants for each variety. Each test variety was listed and roasted at each test site.

[0060] Experimental field management requirements:

[0061] ①Raising seedlings: use greenhouse floating seedlings to cultivate disease-free and healthy seedlings of the right age.

[0062] ②Transplanting density: the plant spacing is 50cm×120cm.

[0063] ③Fertilization: The base fertilizer adopts the method of "strip application", which accounts for 60% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com