Slant push device and method for pushing off products of stacking machine

A stacker and product technology, which is applied in the field of stacker product pushing device, can solve the problem of not being suitable for the high-speed operation of the stacker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

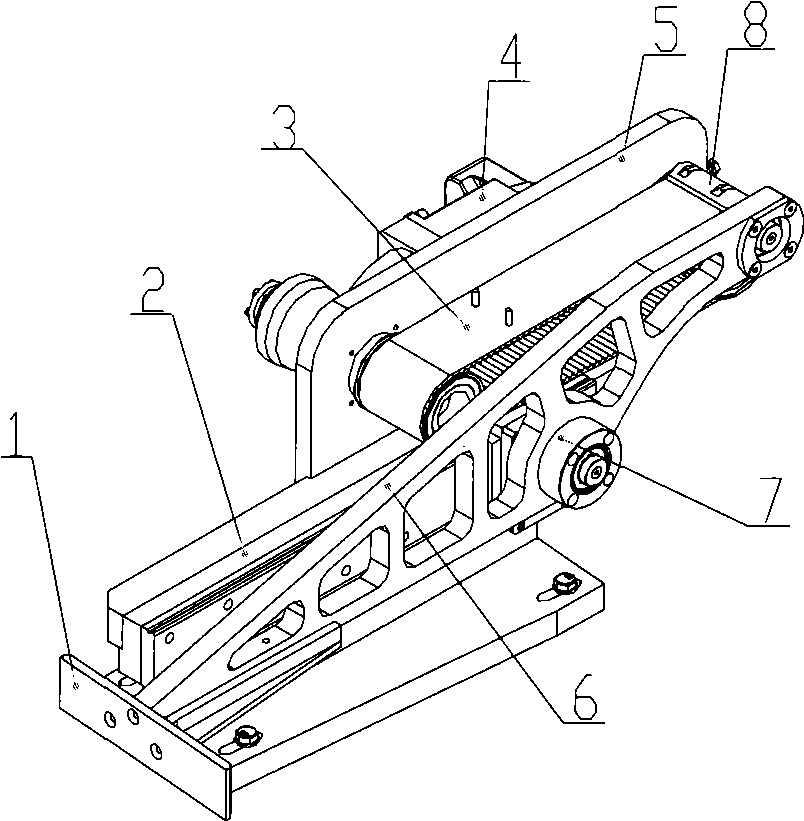

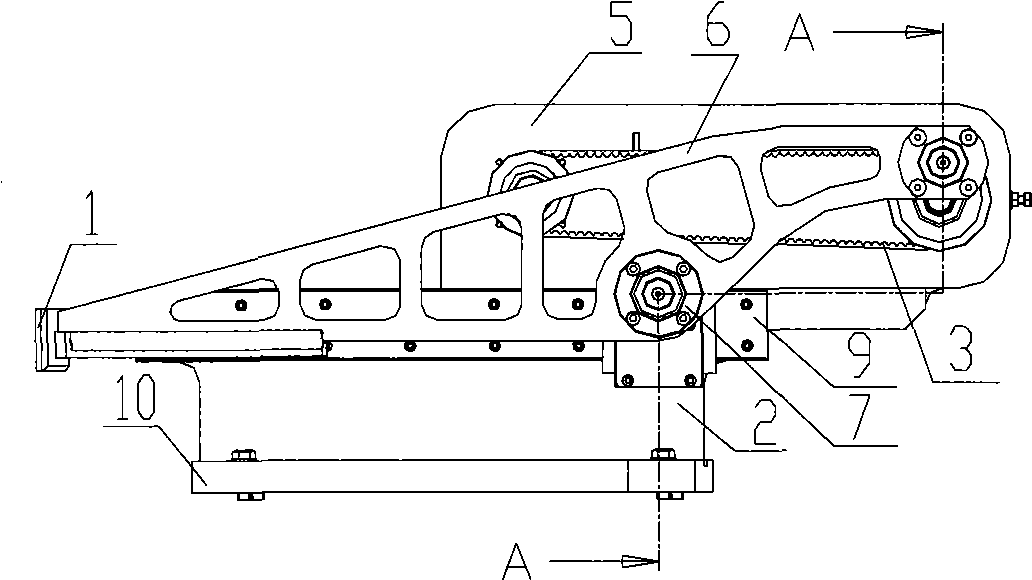

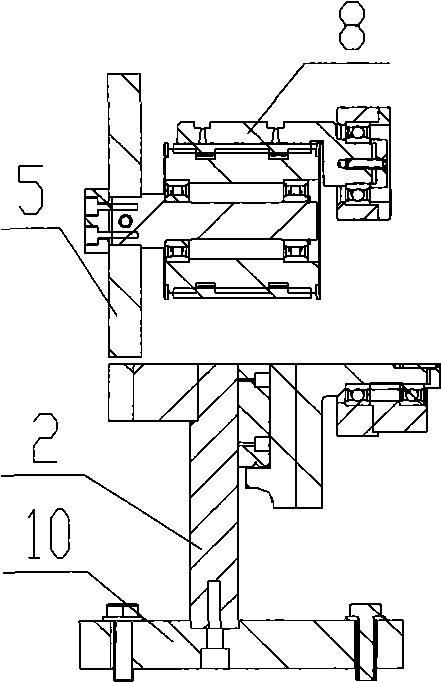

[0015] Embodiment 1: refer to Figure 1-7 . The stacker product pushes out the oblique push device, the push plate 1 is connected to the front end of the movement plate 6 and the connection surface of the push plate 1 is obliquely connected to the end face of the movement plate 6, and the middle part of the movement plate 6 cooperates with the slider 9 and the connecting shaft 7 through the dovetail guide rail 2 The dovetail groove guide rail 2 is a sliding fit and slides along the dovetail groove guide rail 2, one side of the dovetail groove guide rail 2 is connected with the lower part of the installation frame 10, and the timing belt 3 is set on the timing belt driving shaft and the timing belt driven shaft and is located on the wall plate 5 The synchronous belt 3 drive shaft is driven by the servo motor 4 to drive the synchronous belt 3 to rotate, and the synchronous belt 3 is connected to the coupling shaft on the moving plate 6 through the connecting plate 8 thereon and ...

Embodiment 2

[0016] Embodiment 2: On the basis of Embodiment 1, the stacker product pushes out the oblique push method of the oblique push device, the servo motor 4 drives the synchronous belt drive shaft, the synchronous belt drive shaft drives the synchronous belt 3 to rotate, and the synchronous belt 3 drives the motion plate 6 movement and the synchronous movement of the ejection plate 1 connected with the movement plate 6. When the ejection plate 1 pushes out the products in the stacker and reaches the designated position, the connecting plate 8 in the synchronous belt 3 turns over the synchronous belt drive shaft, and the synchronous belt 3 Force motion plate 6 to be fulcrum with connecting shaft 7, force push-out plate 1 upwards to sway, and now synchronous belt 3 continues to drive connecting plate 8 and push-out plate 1 on motion plate 6 and motion plate and walks up the return movement of rocking. When the synchronous belt 3 drives the connecting plate 8 to move to its initial pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com