Automatic feeding and discharging equipment for numerical control press

A technology of automatic loading and unloading and CNC punching, which is applied in the field of sheet metal processing, can solve the problems of reducing processing efficiency, safety hazards, and taking out waste boards, etc., to achieve the effects of ensuring normal operation, improving processing efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

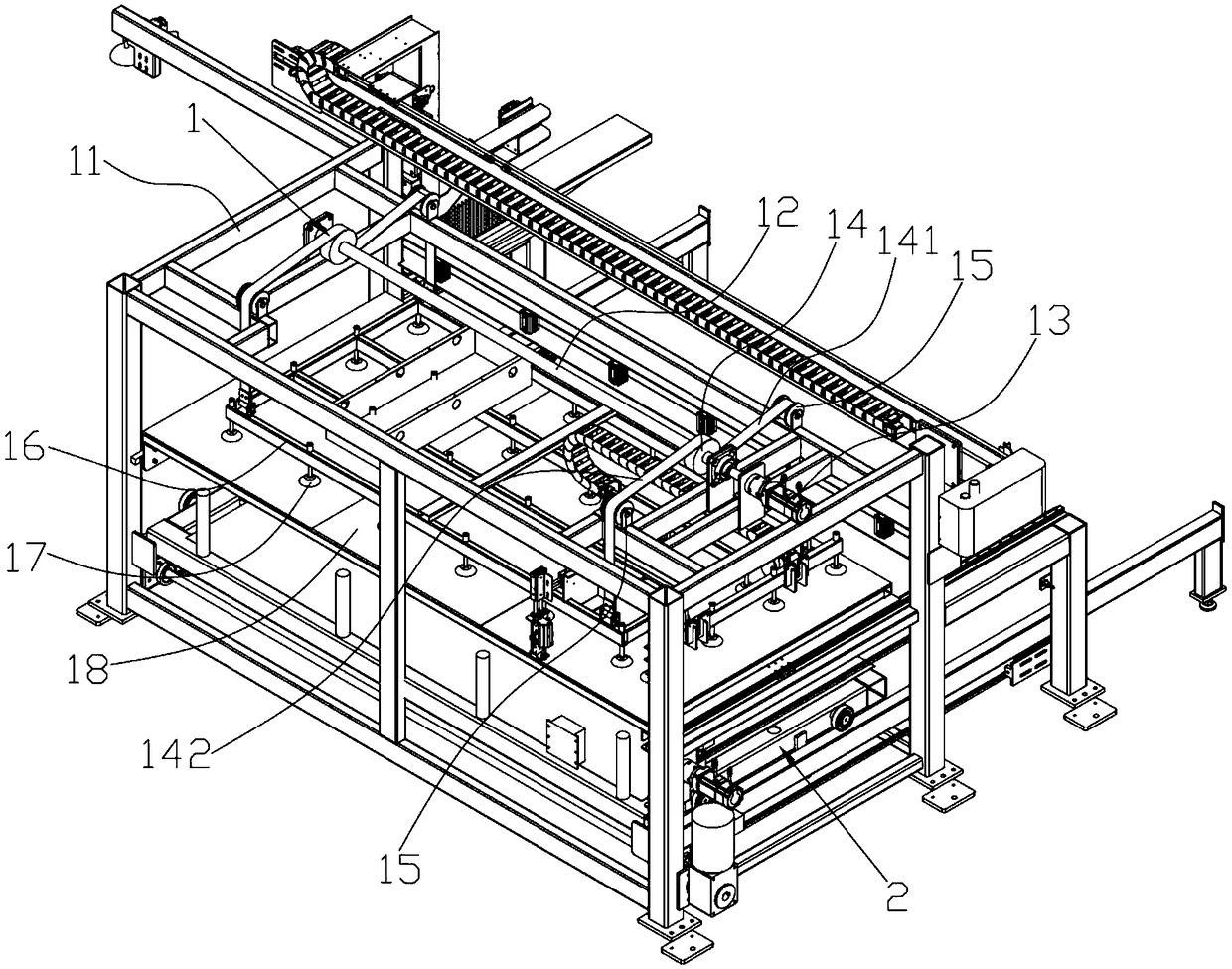

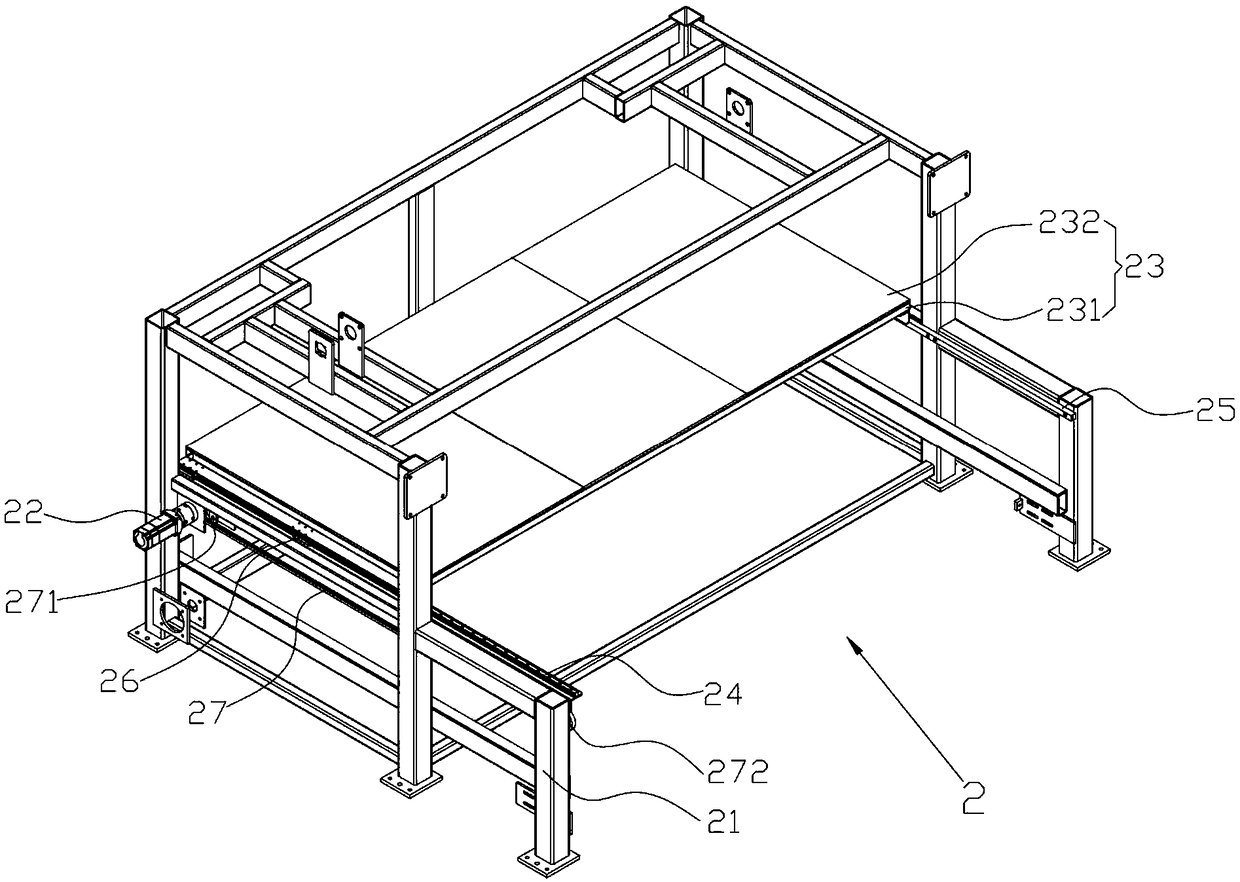

[0032] Such as figure 1 , 2 As shown in , 6, a kind of automatic loading and unloading equipment for CNC punch provided by the embodiment of the present invention includes a feeding device 1, a feeding device 2 and a feeding device 3, and the feeding device 1 is used to absorb the material plate to be processed Get up and put it on the feeding device 2, the feeding device 2 is used to transport the material board to be processed to the numerical control punching for processing, and the unloading device 3 is used to receive the punched material board (ie waste board);

[0033] Such as figure 1 As shown, specifically, the feeding device 1 includes a feeding frame 11, the feeding frame 11 is provided with a rotating shaft 12 arranged along its length direction, the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com