Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Prevent moisture infiltration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

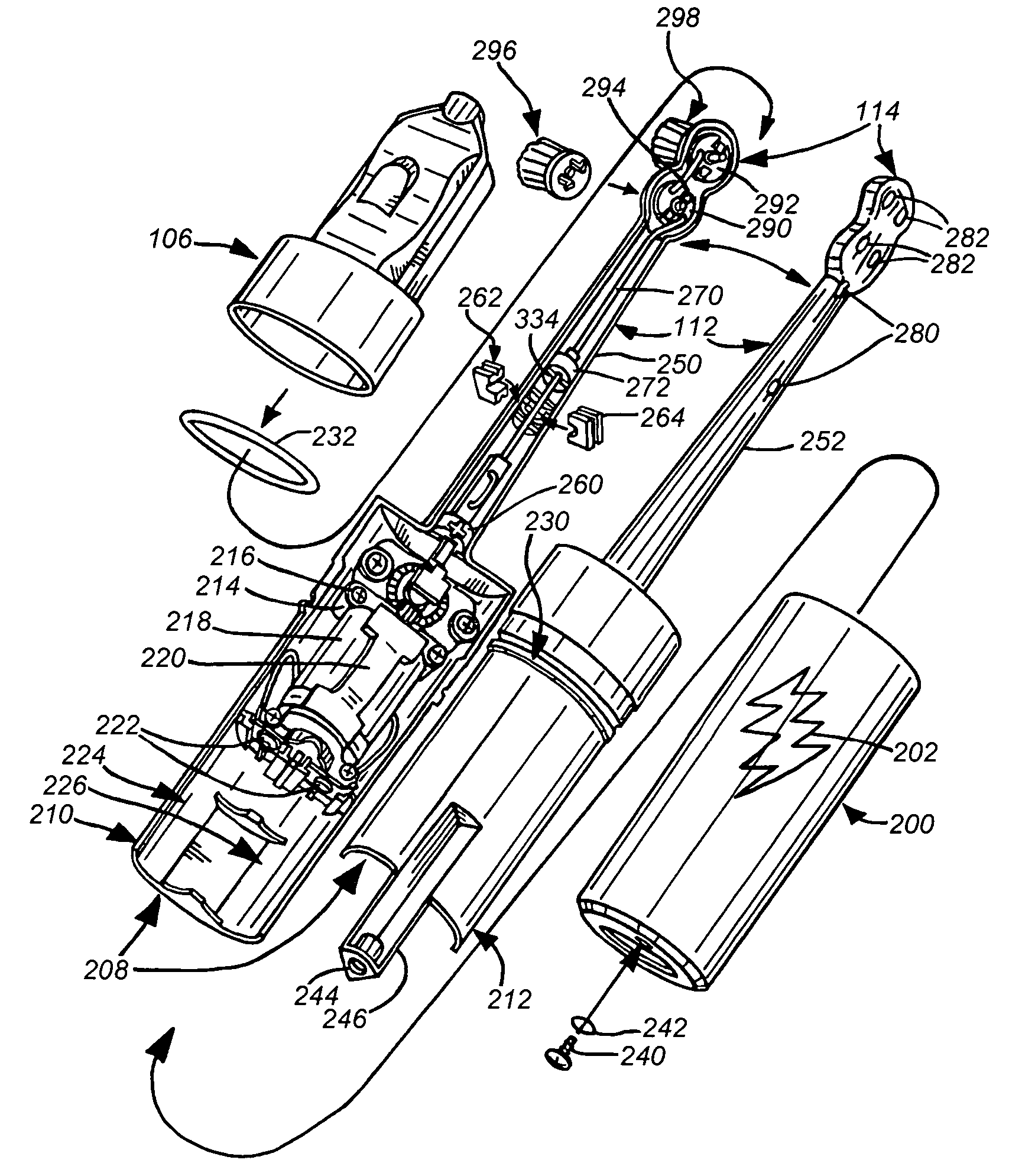

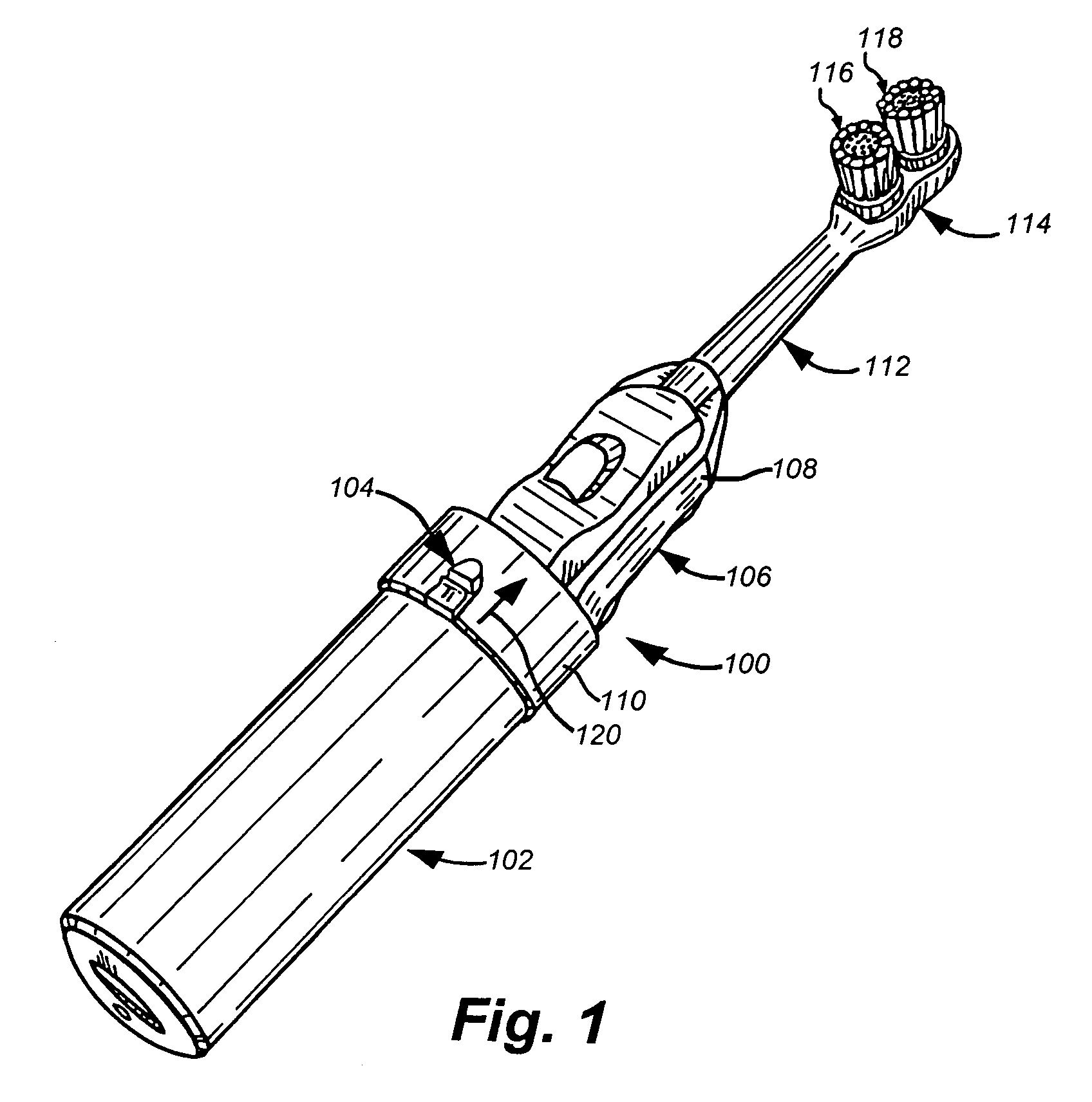

Power toothbrush

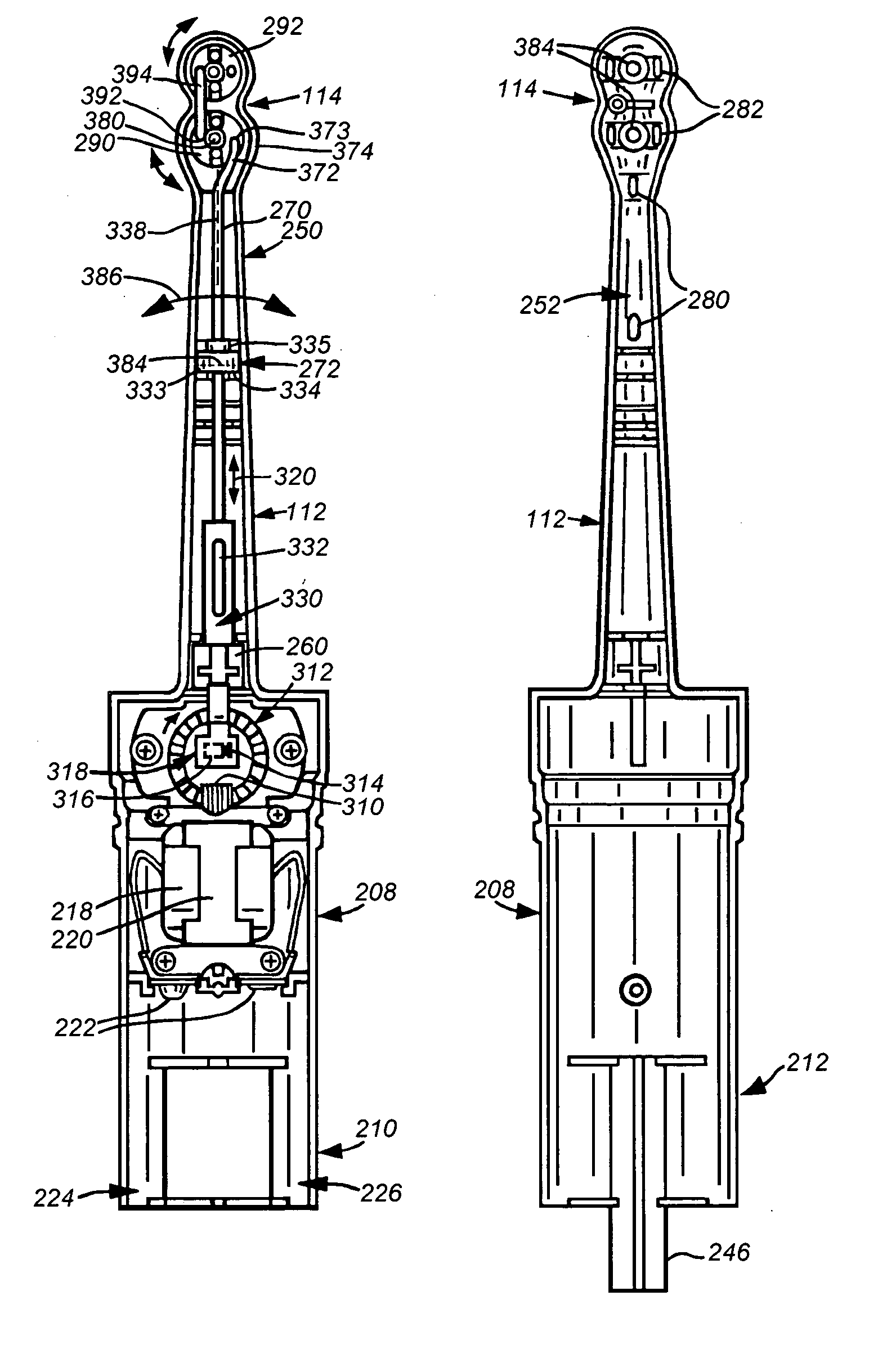

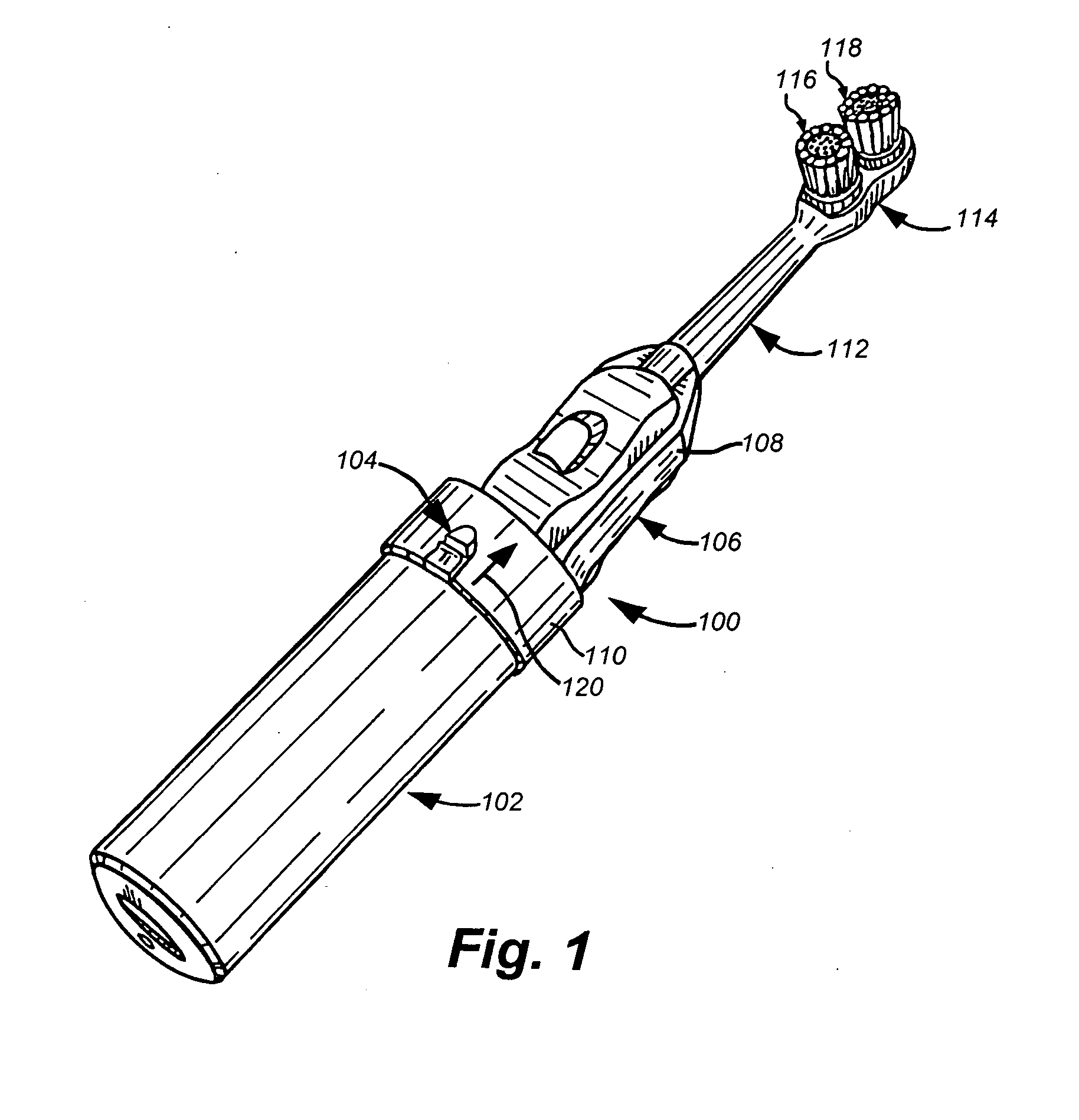

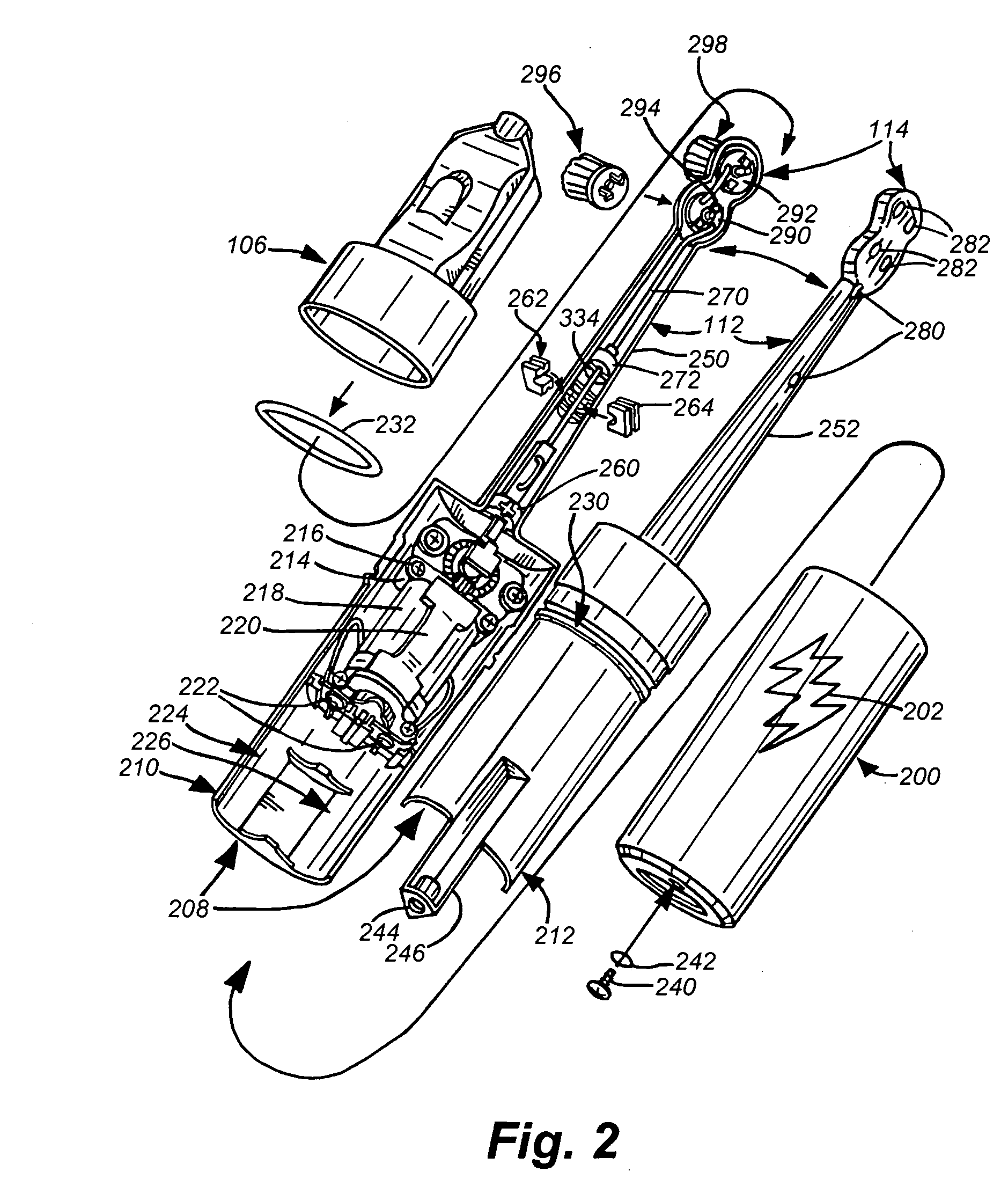

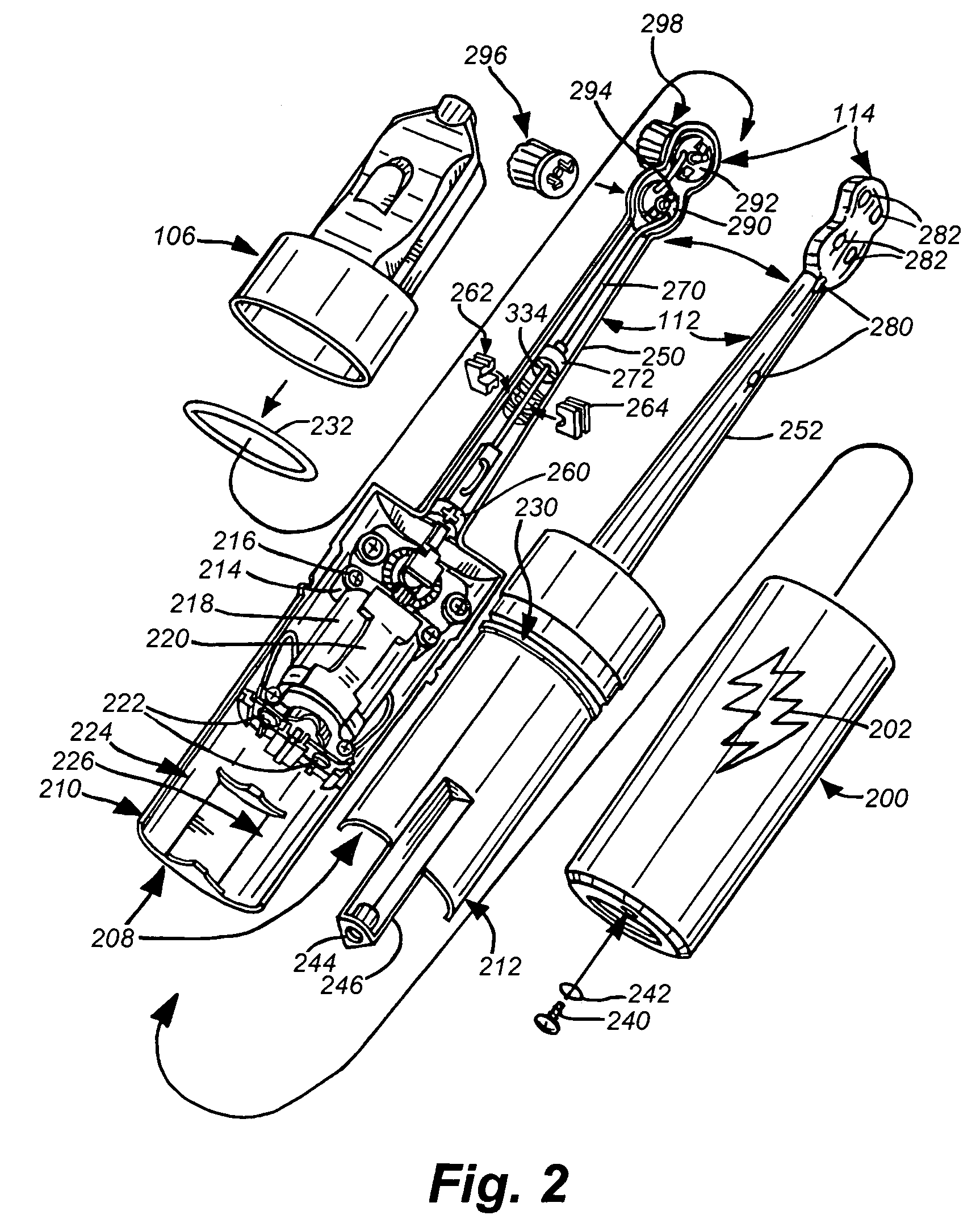

InactiveUS20060254007A1Easy to manufactureReliable serviceCarpet cleanersKitchenware cleanersCircular discReciprocating motion

A power toothbrush with a drive train that is easy to manufacture, reliable in service and that enables multiple heads or other complex design or functional elements is provided. In an illustrative embodiment, the power toothbrush includes a sealed case that encloses a motor with a pinion gear joined to an eccentric link. This eccentric link can be a circular rack having an eccentric pin that rides in a slot on a drive plate. The drive plate is joined to a push rod, typically constructed of metal that passes up a hollow toothbrush shaft through an elastomeric seal to a head assembly. The head assembly includes one or more moving disks that are each connected to generally circular brush heads, which project outwardly from the head assembly. One disk receives a bent end of the drive shaft in a hole located eccentrically to the axis of rotation. When the circular rack rotates in a single direction, it drives the shaft in a reciprocating motion that, thereby, rotates the disk in a corresponding reciprocating circular motion about its axis. Additional disks can be linked by a short connecting shaft or link to the first disk via eccentric holes—other linkages, such as mating gears between disks can be used to simultaneously drive further disks, thereby providing a multiple moving-head power toothbrush.

Owner:THE GILLETTE CO

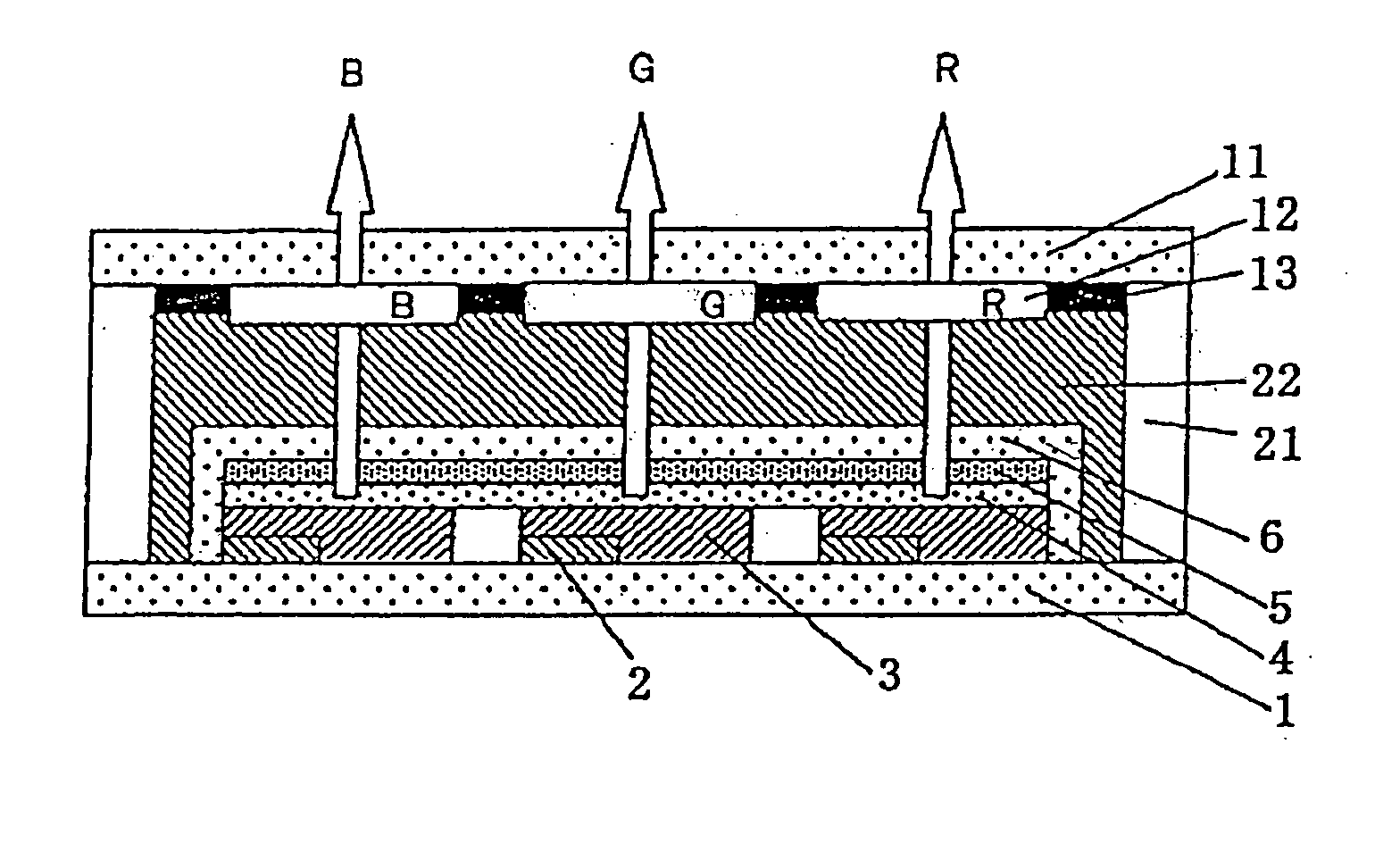

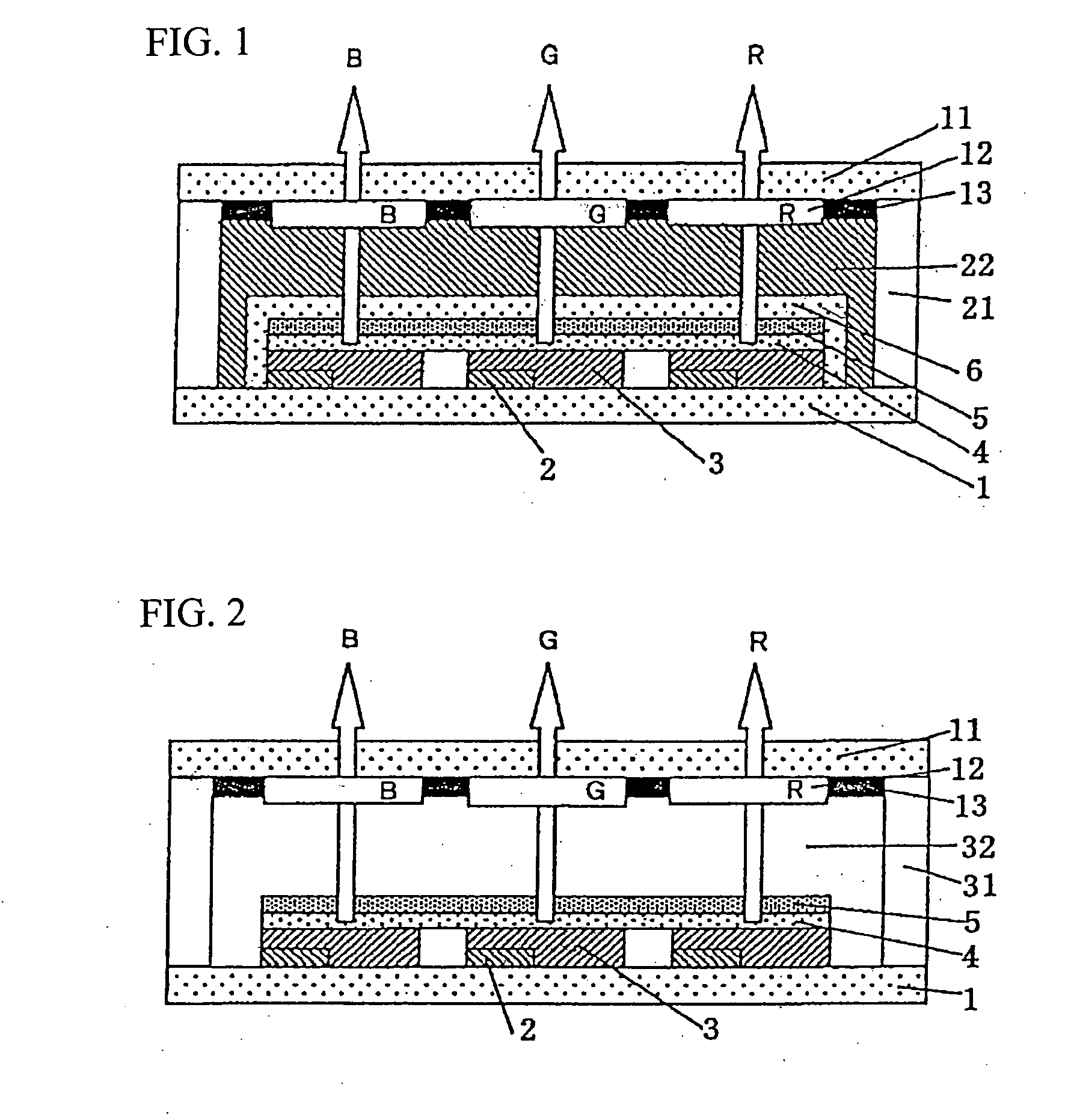

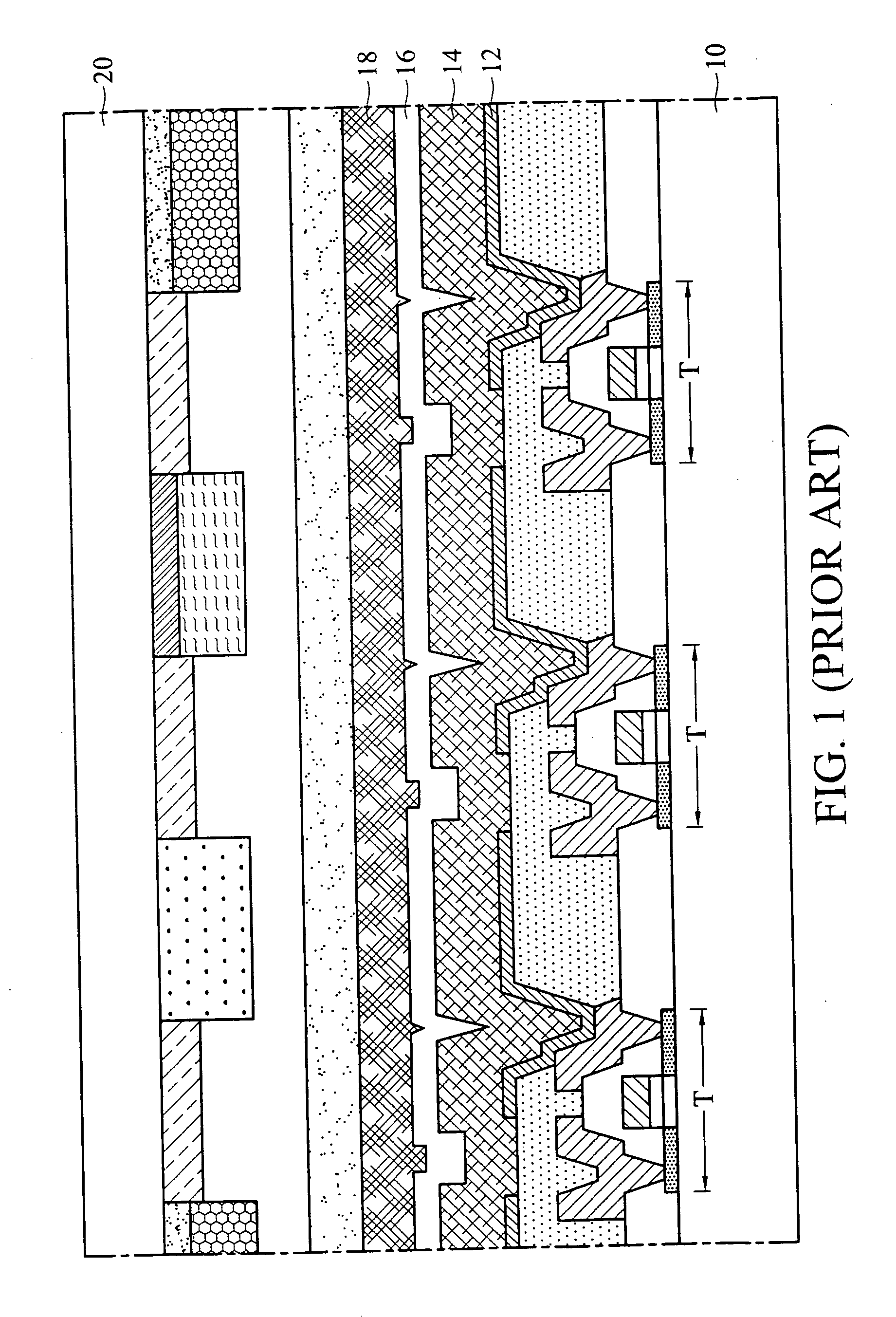

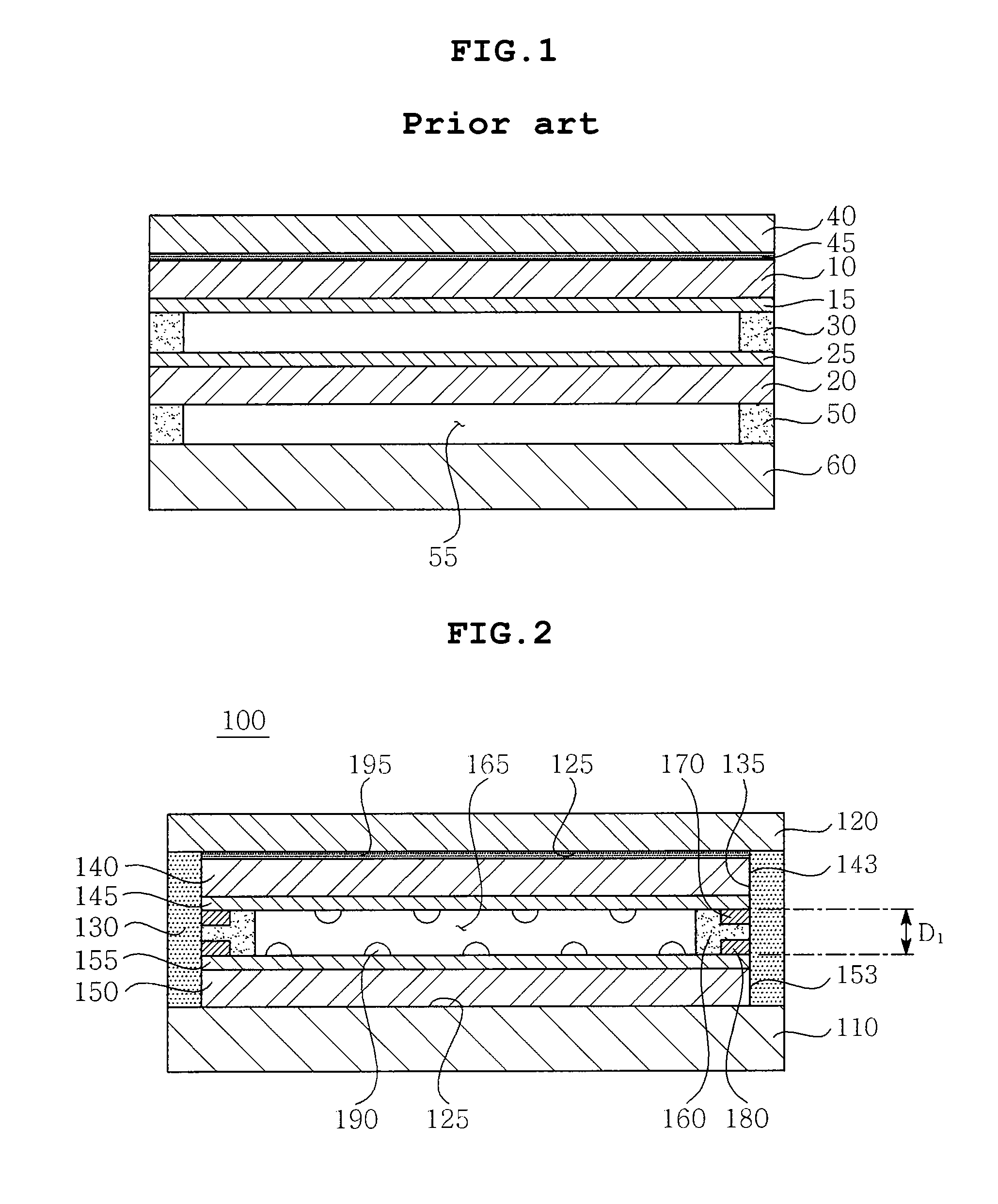

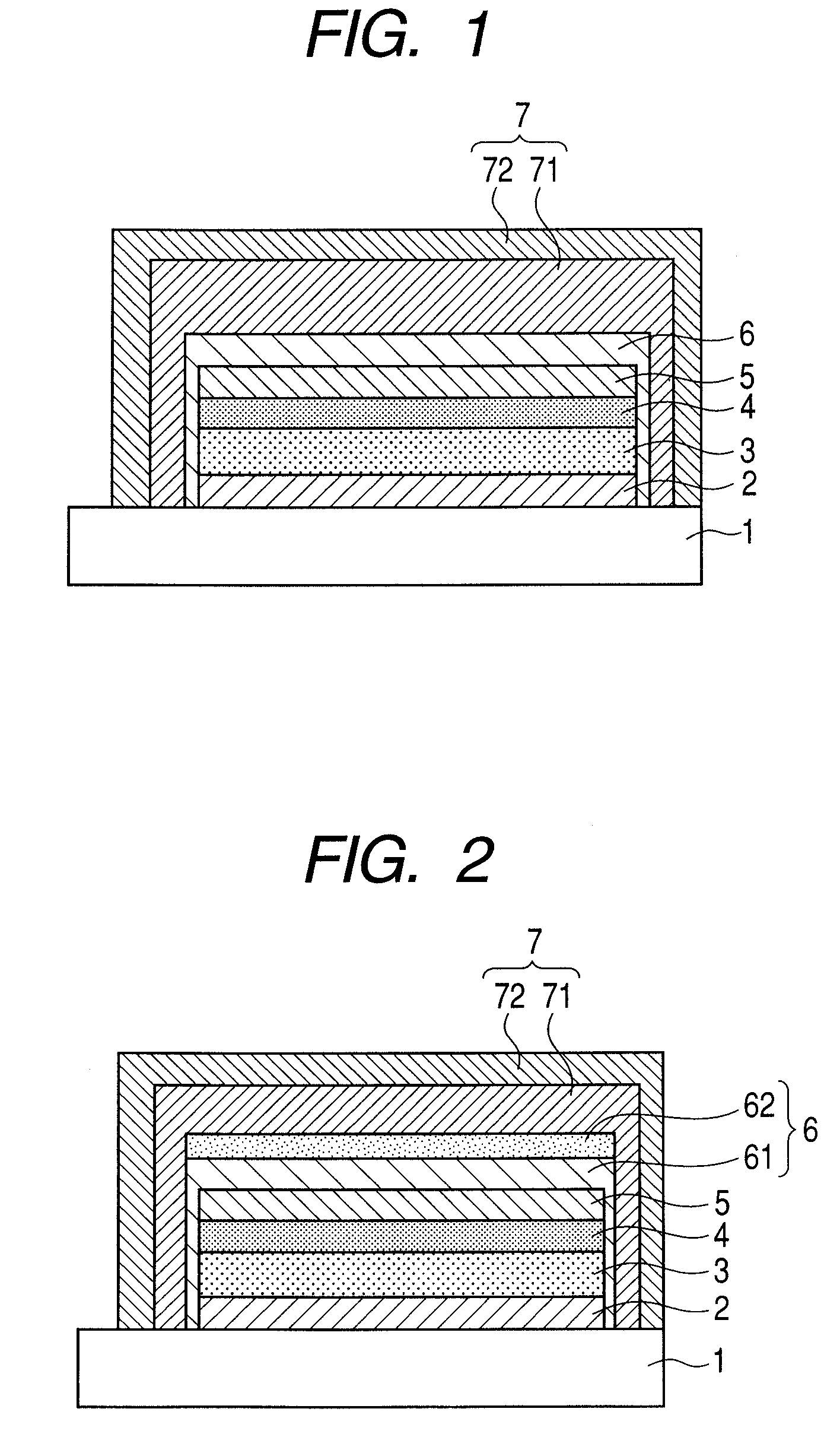

Organic EL display and method of manufacturing the same

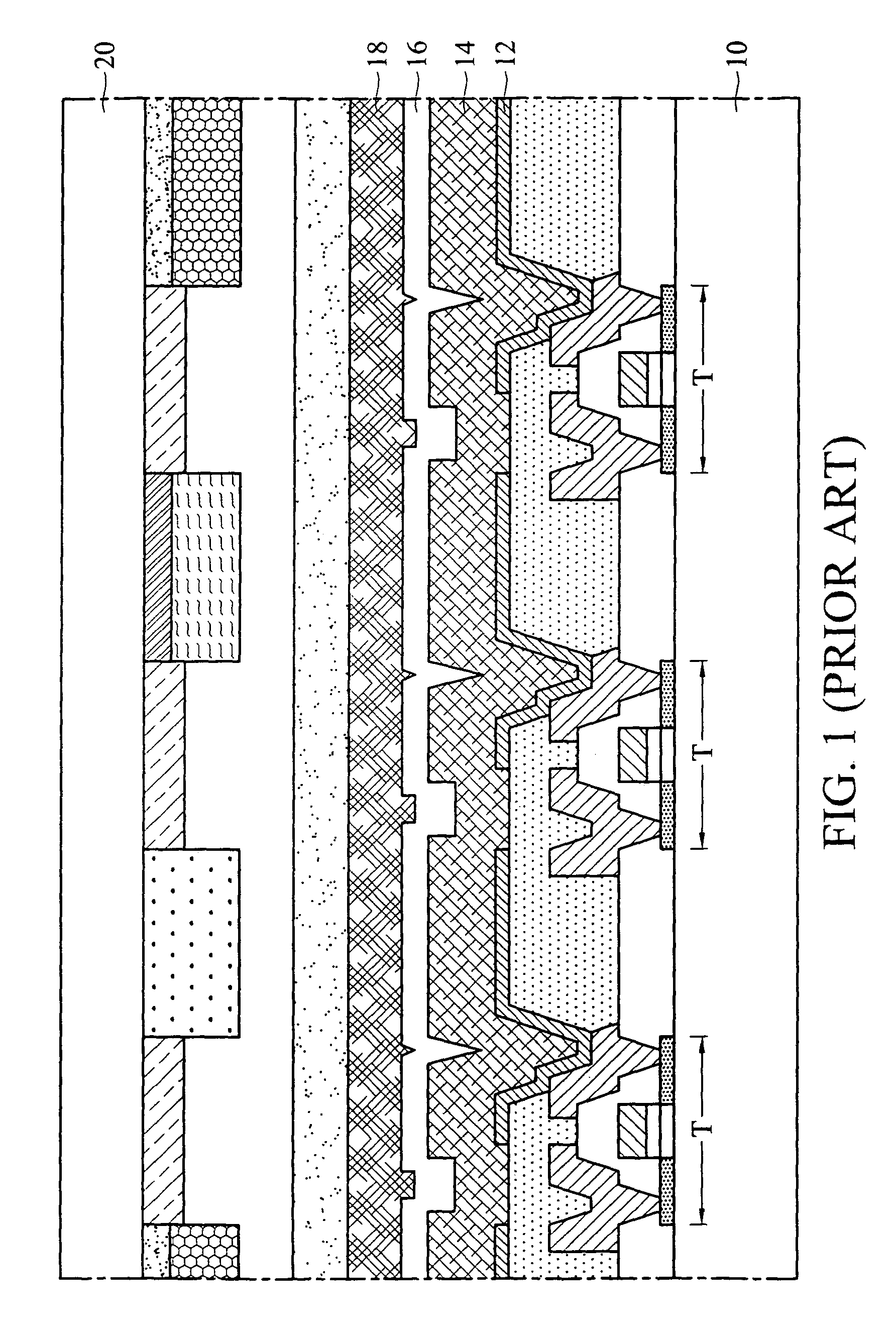

InactiveUS20050275342A1Short curingInfiltration of moistureDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceThin membrane

An organic EL display is displayed. The display is manufactured sealing and joining an organic light emitter constituted from thin film transistors, anodes, a light-emitting layer, a cathode and a protective layer which are laminated on a substrate, together with a laminated body of color filters and a black mask formed on a transparent substrate. The organic EL light-emitting layer is aligned with the color filters during the process of sealing the substrate and the transparent substrate using an outer periphery sealing layer and an internal sealing layer. The outer periphery sealing layer provides precise alignment between the organic EL light-emitting layer and the color filters and rapid fixing between them can be carried out, and prevents infiltration of moisture from the outside environment. The internal sealing layer prevents reflection of light from the organic EL light-emitting layer, and hence the light can be transmitted to the color filters effectively. The device and method prevent peeling apart due to cure shrinkage, peeling apart due to thermal stress from the temperature of the environment, and infiltration of moisture from the outside environment, so that stable light emission characteristics can be maintained over a long period.

Owner:FUJI ELECTRIC HLDG CO LTD

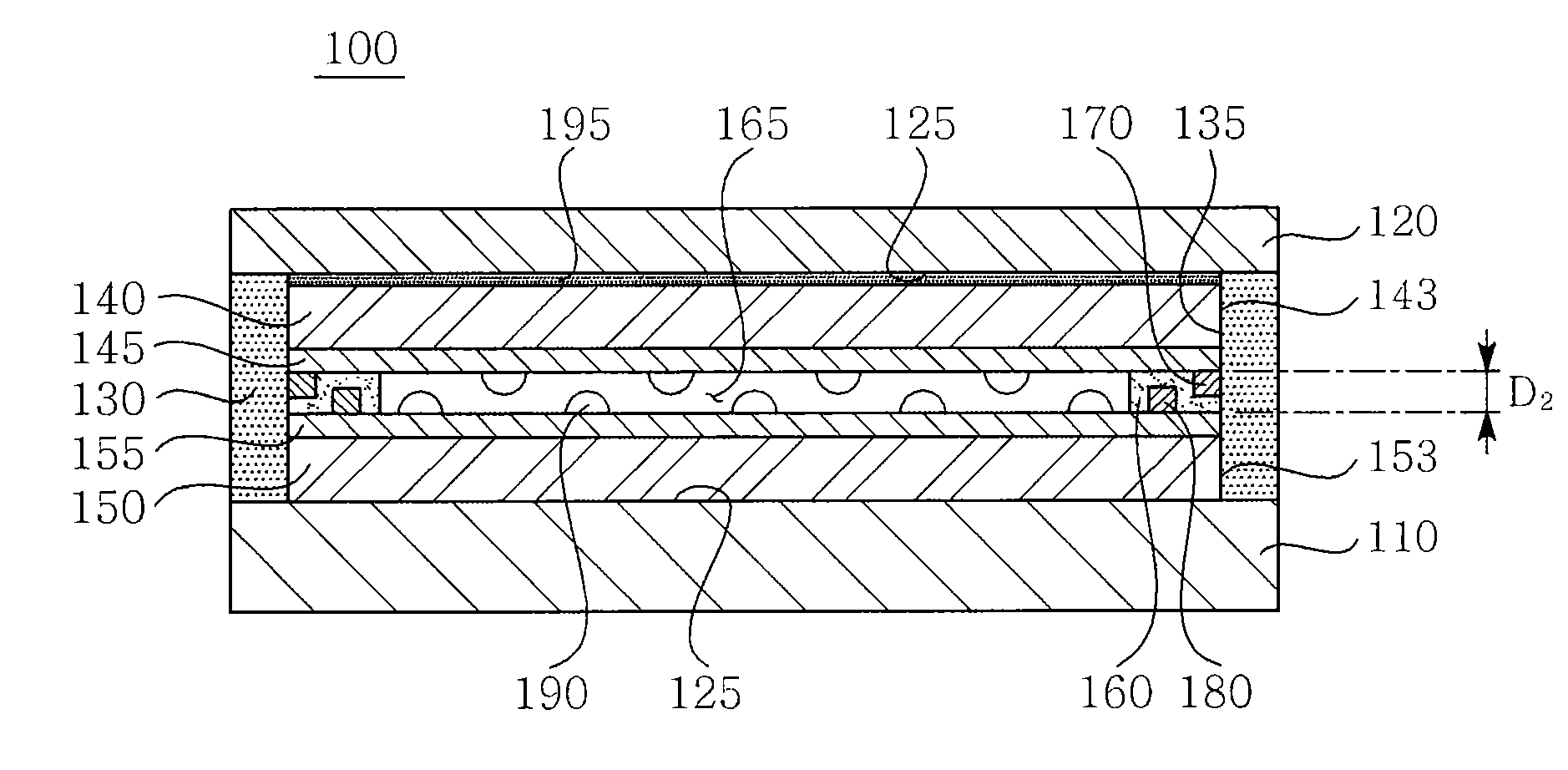

Scintillator panel and method of manufacturing the scintillator panel

InactiveUS20120288688A1Prevent moisture infiltrationUniform flatnessLayered productsThin material handlingLength waveScintillator

Disclosed is a scintillator panel, including a substrate, a scintillator layer formed on the substrate and including a plurality of columnar crystals so that radiation is converted into light at a predetermined wavelength, a dam structure formed on the substrate to be spaced apart by a predetermined interval from a peripheral edge of the scintillator layer, a protective layer formed on a surface of the scintillator layer, a surface of the substrate defined between the scintillator layer and the dam structure and a portion of a surface of the dam structure, a first coating layer formed on the protective layer to be disposed in a space between a peripheral surface of the scintillator layer and the dam structure, and a second coating layer formed on the first coating layer and the protective layer.

Owner:ABYZ R

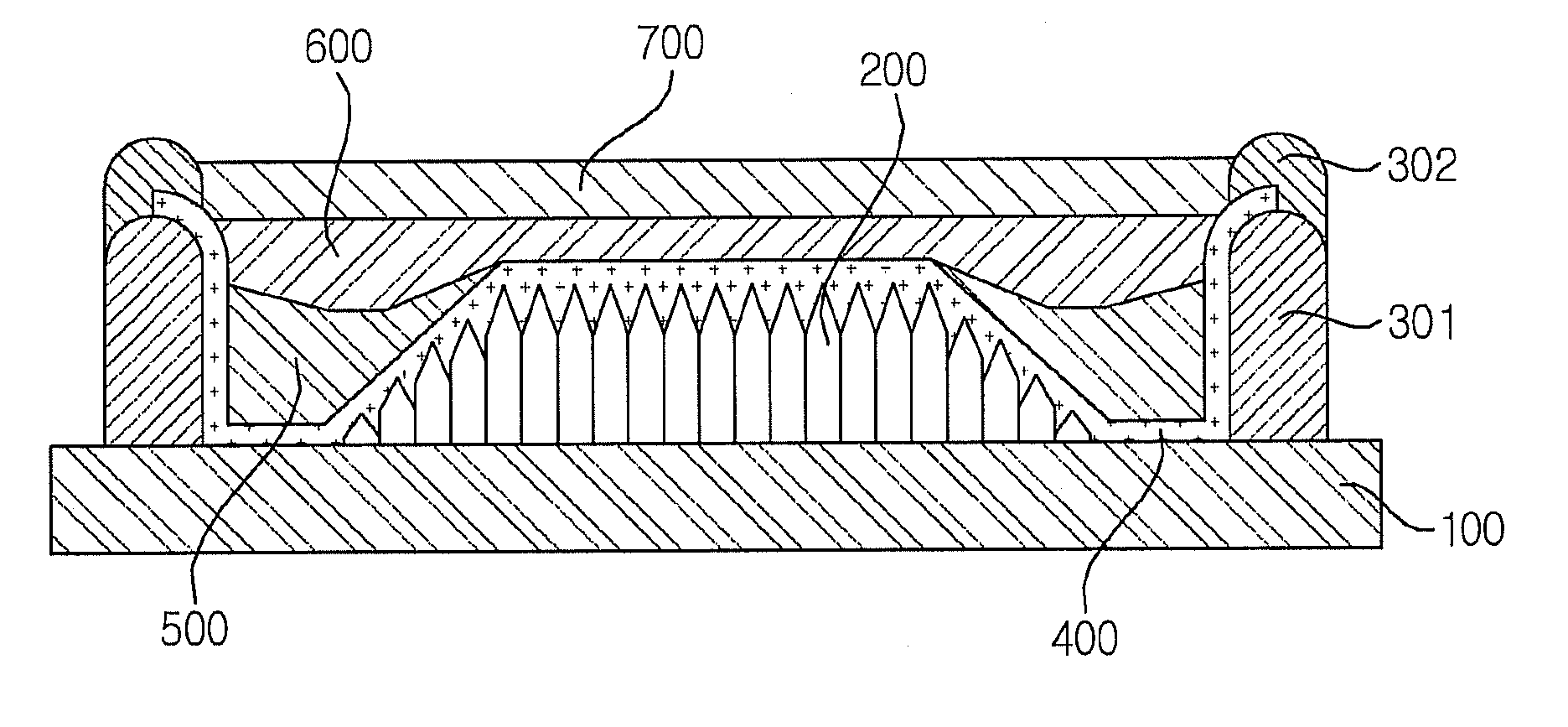

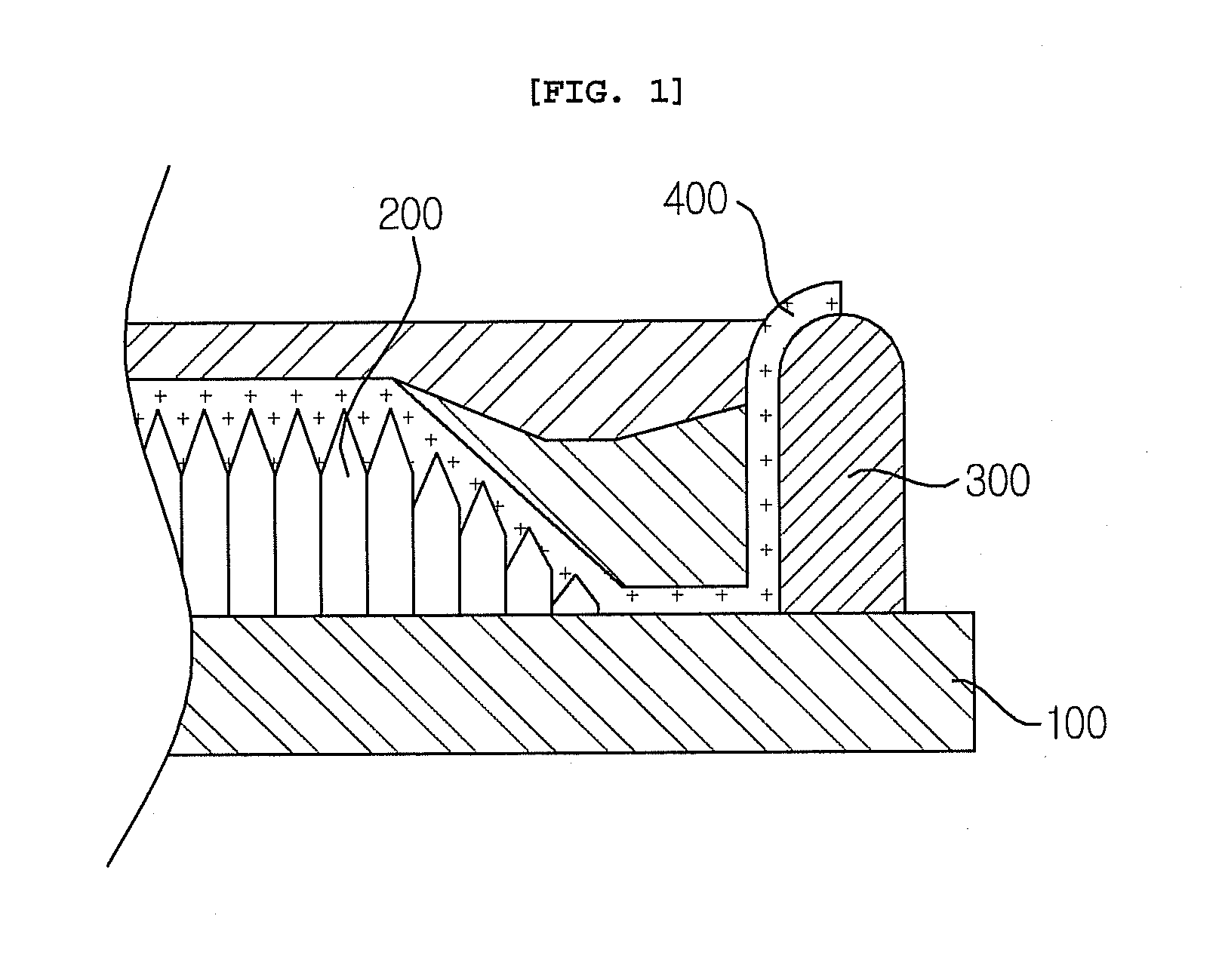

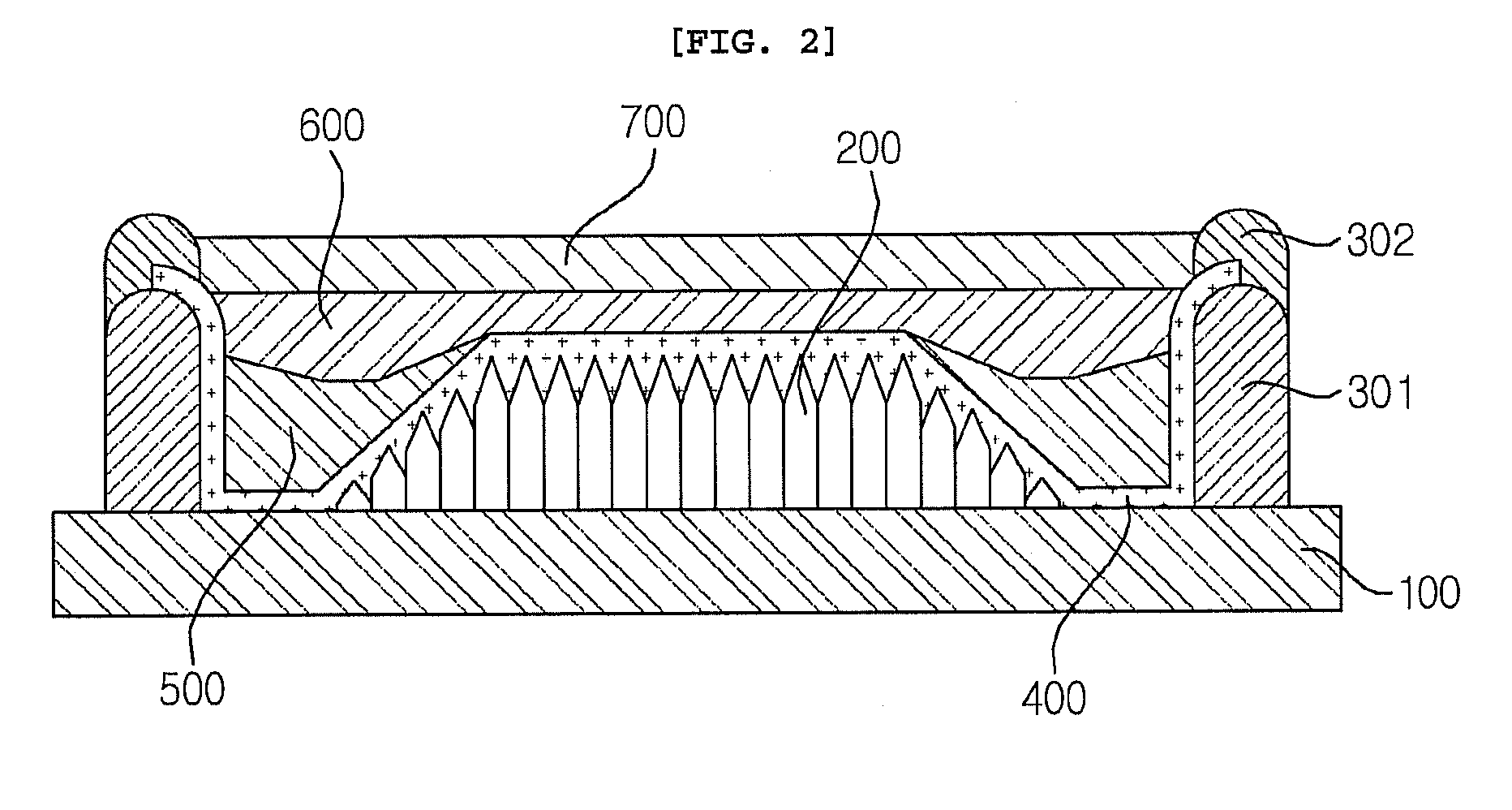

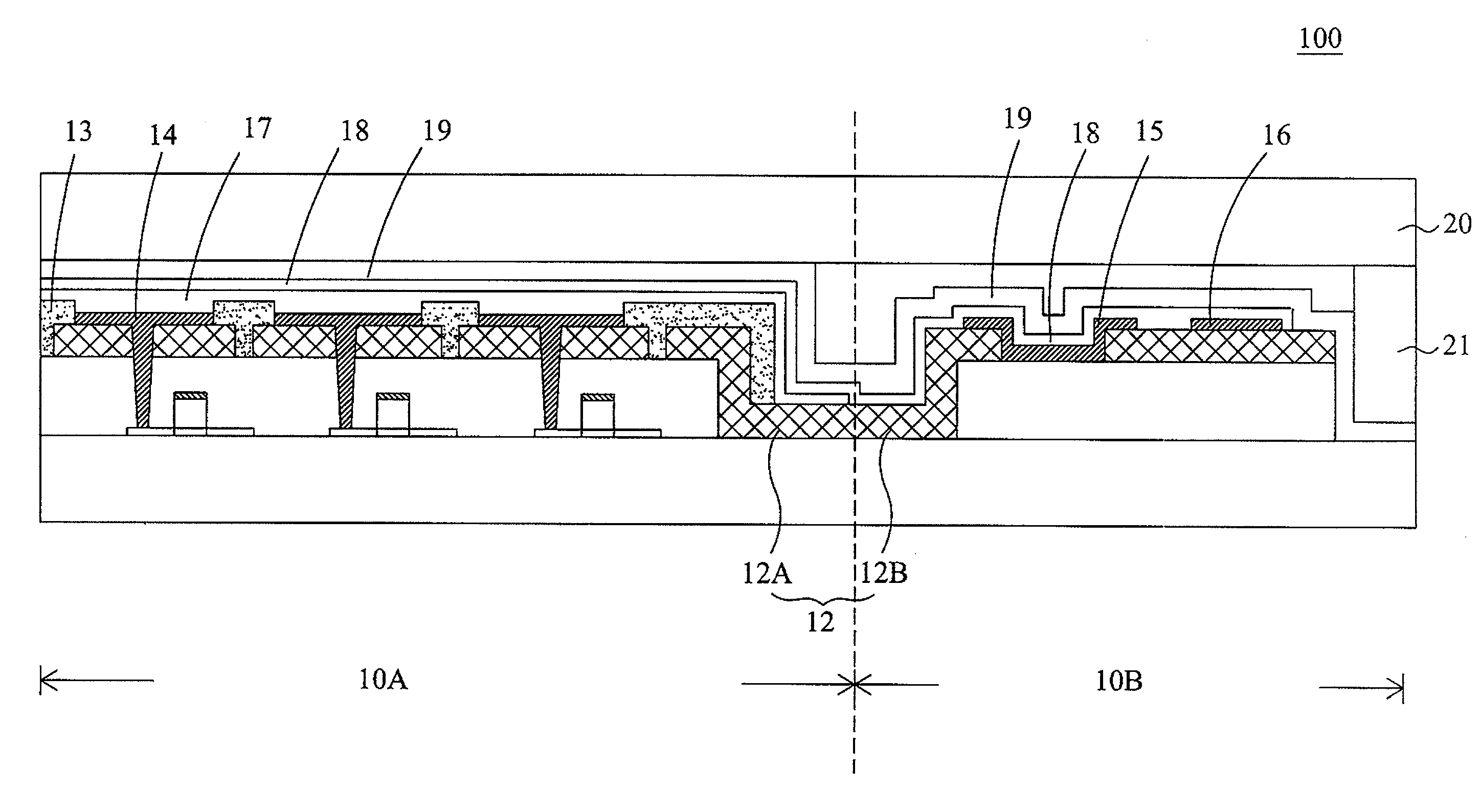

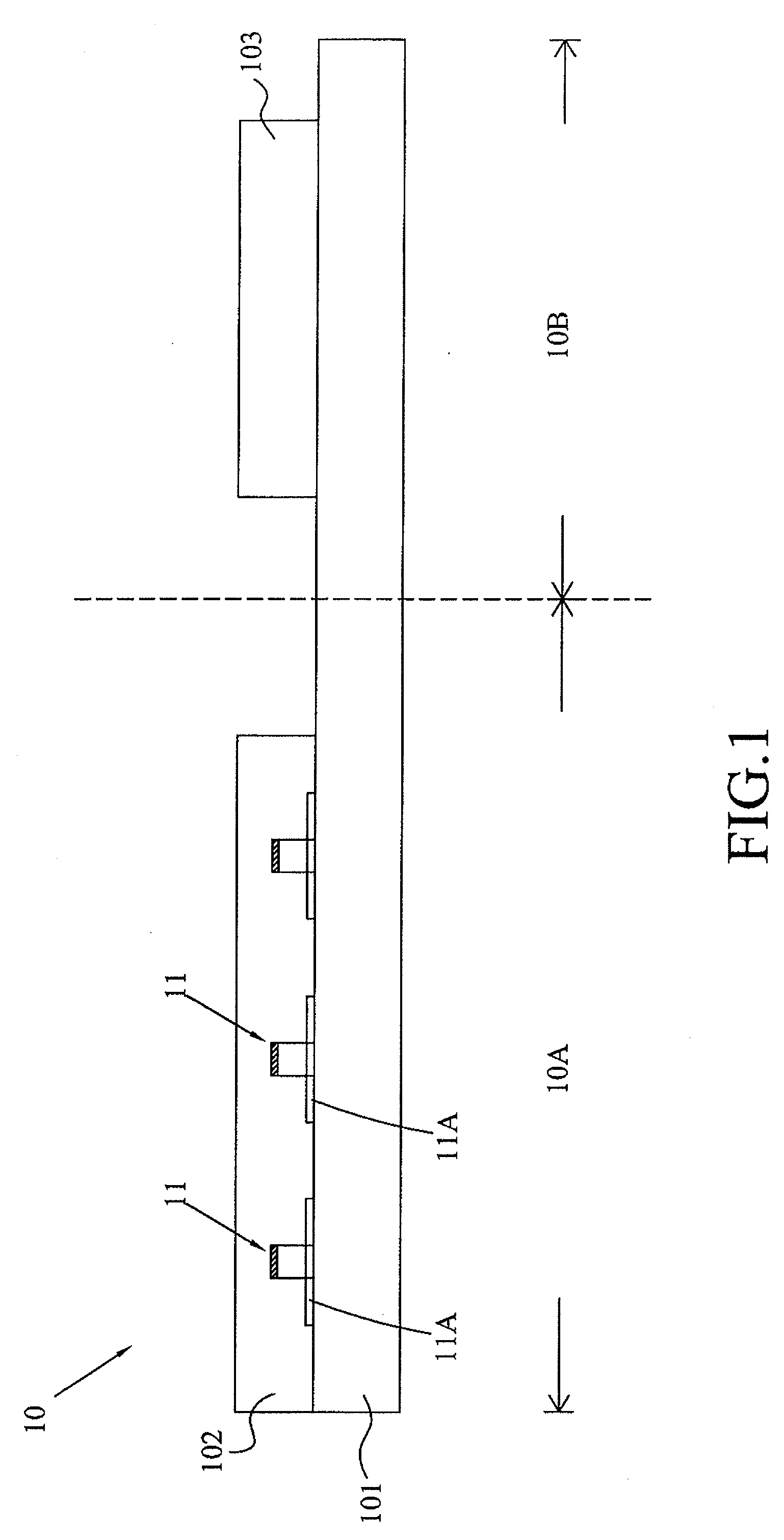

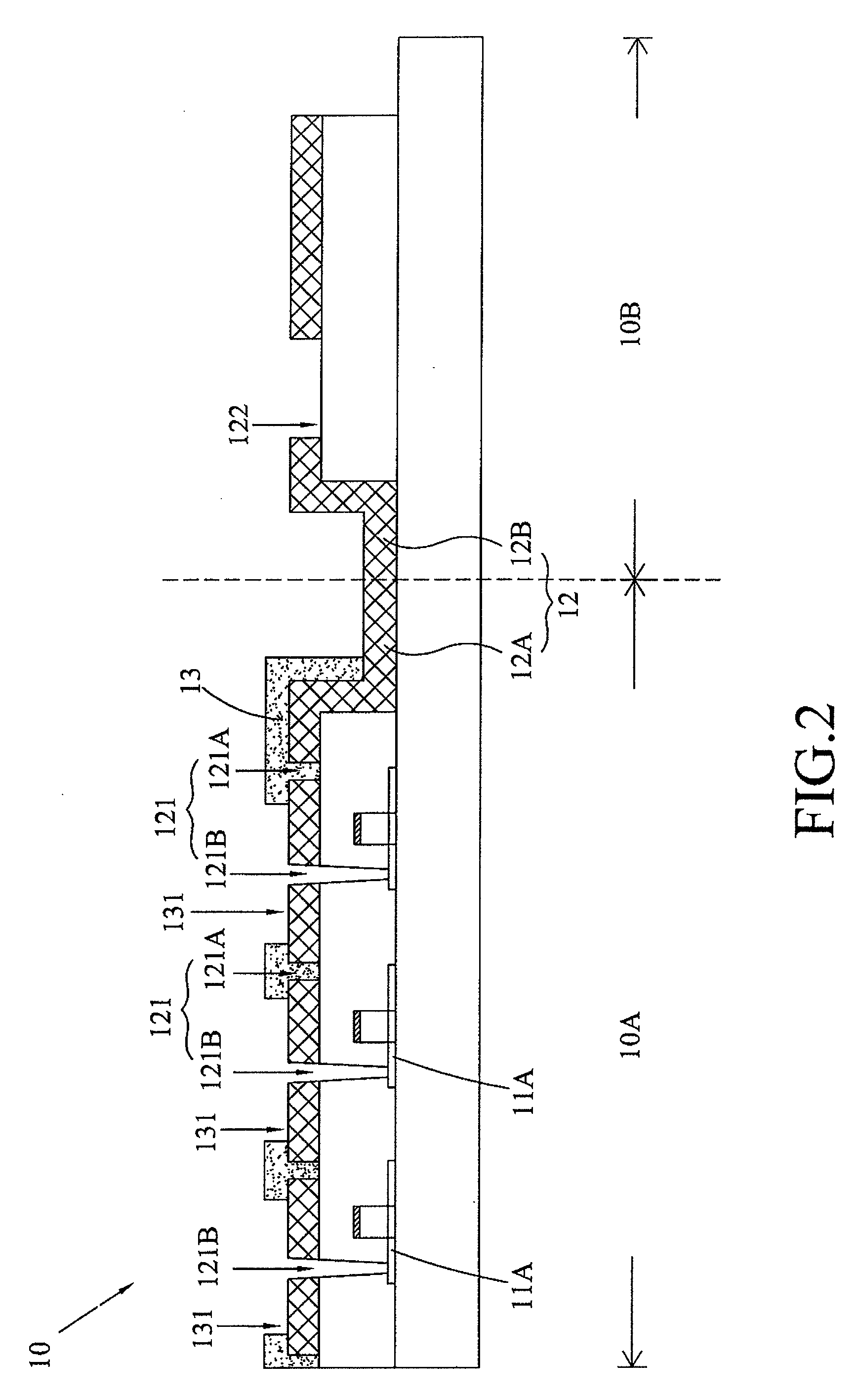

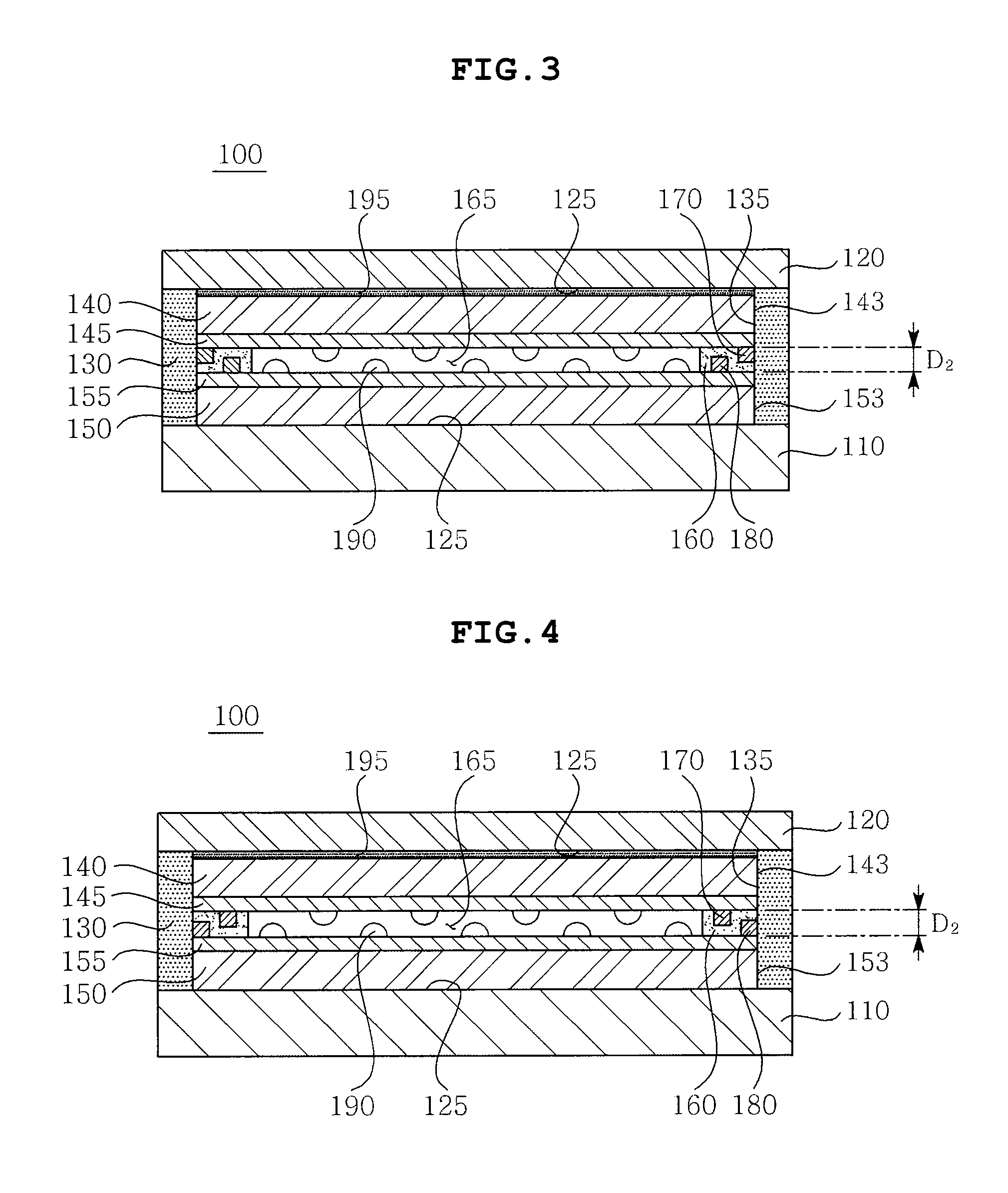

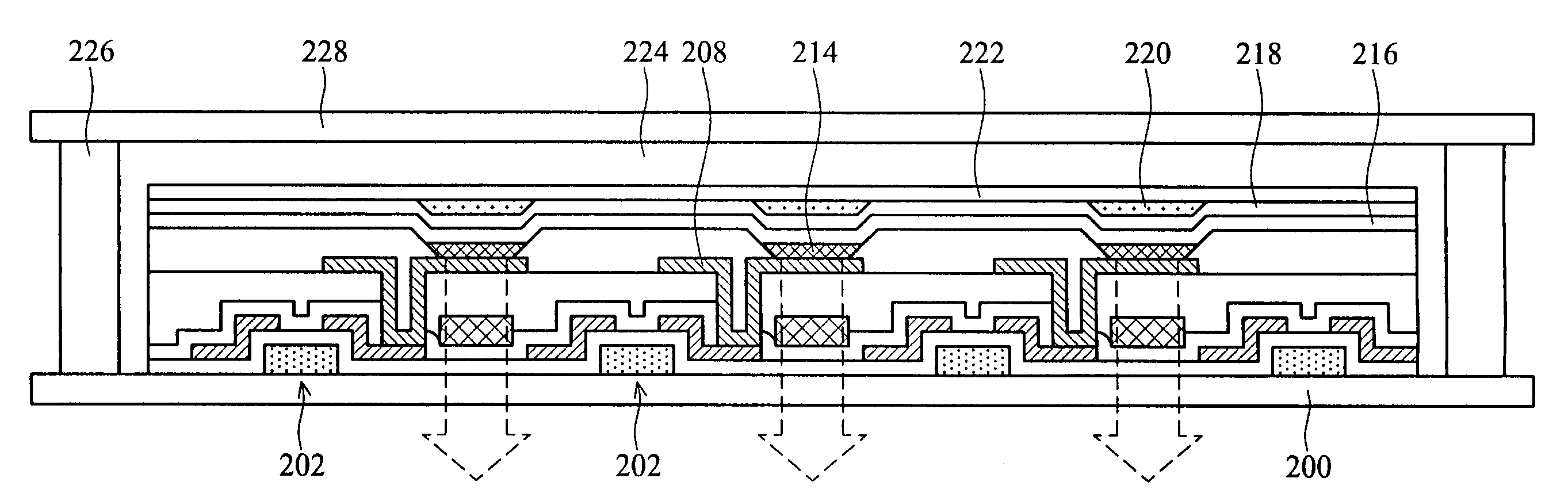

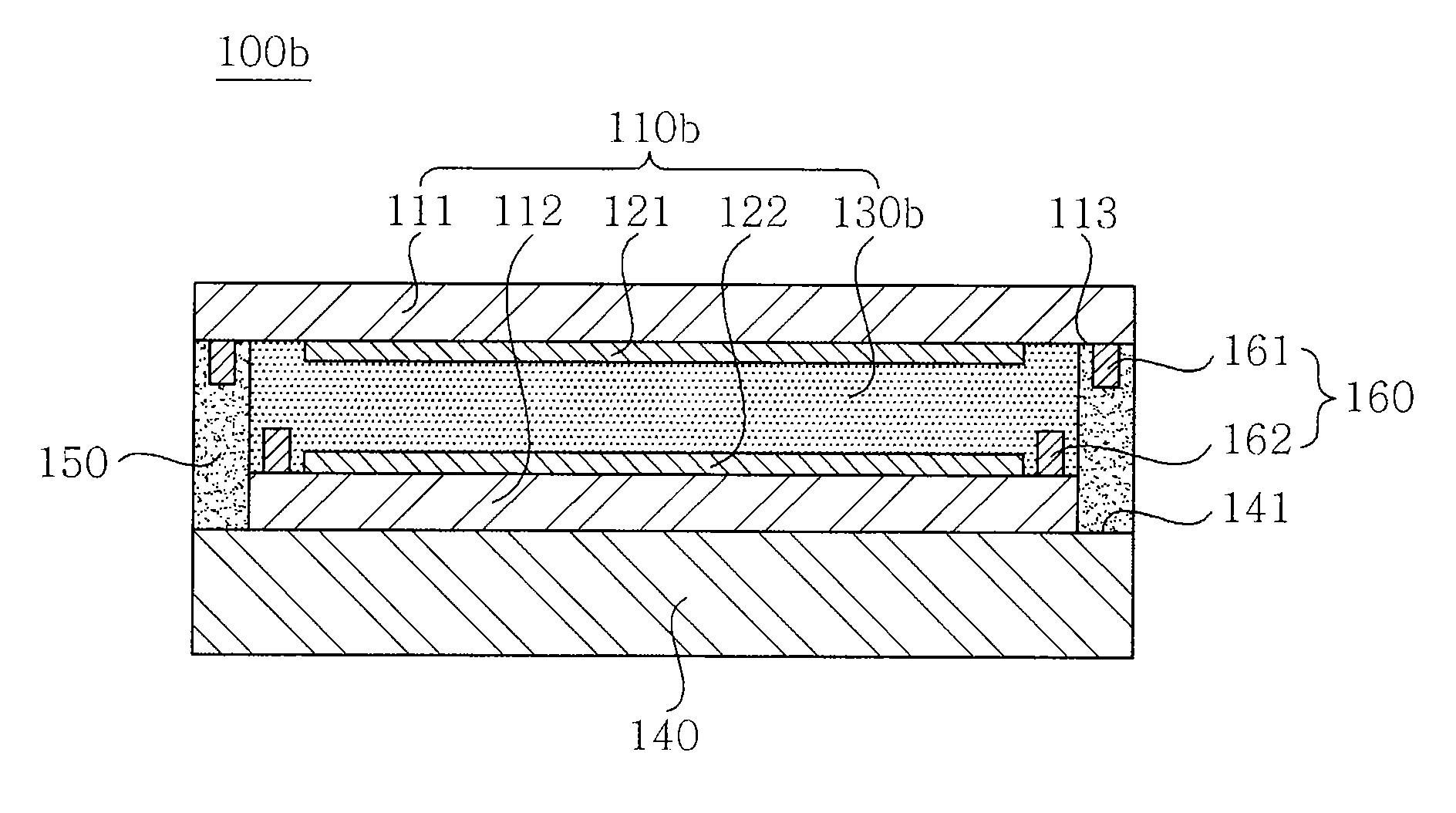

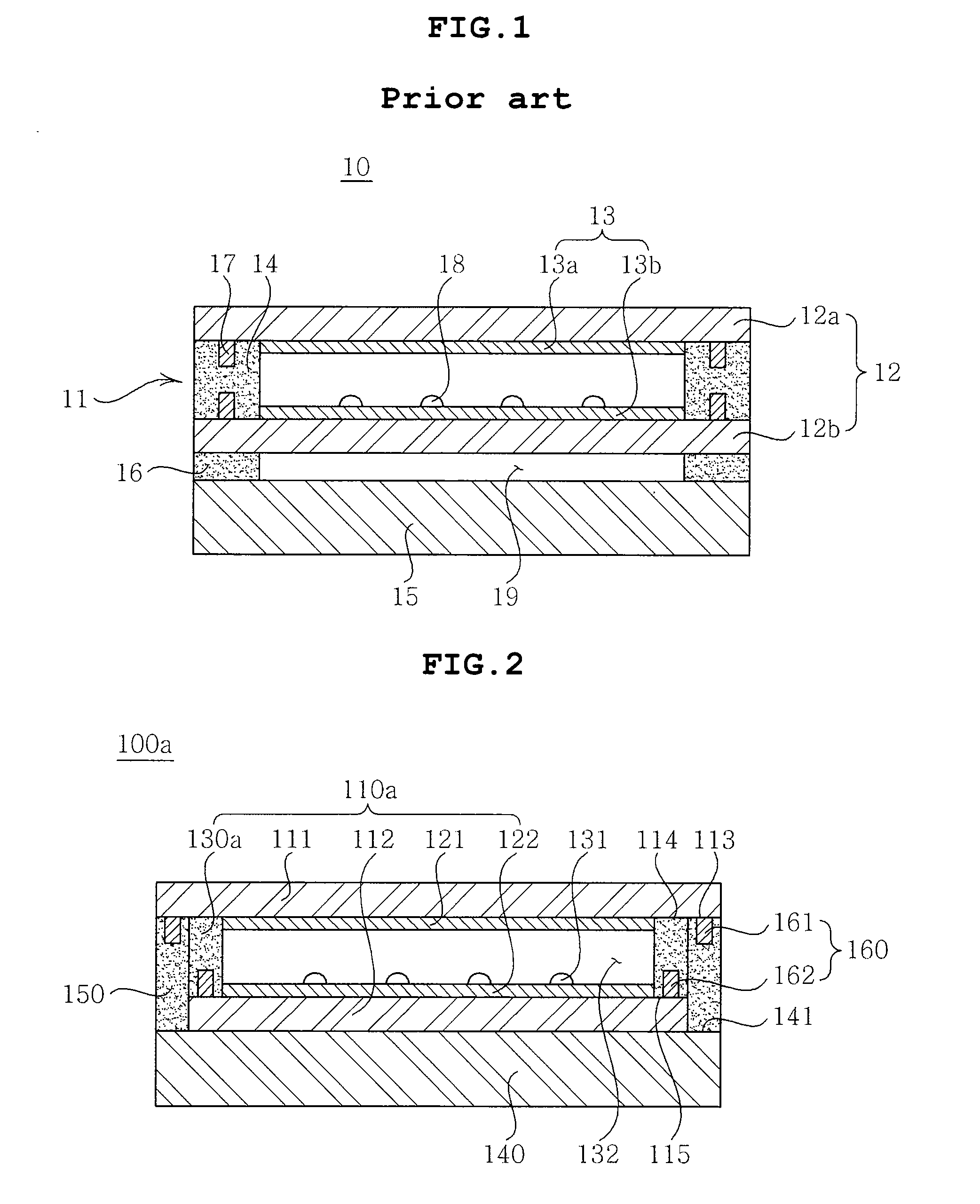

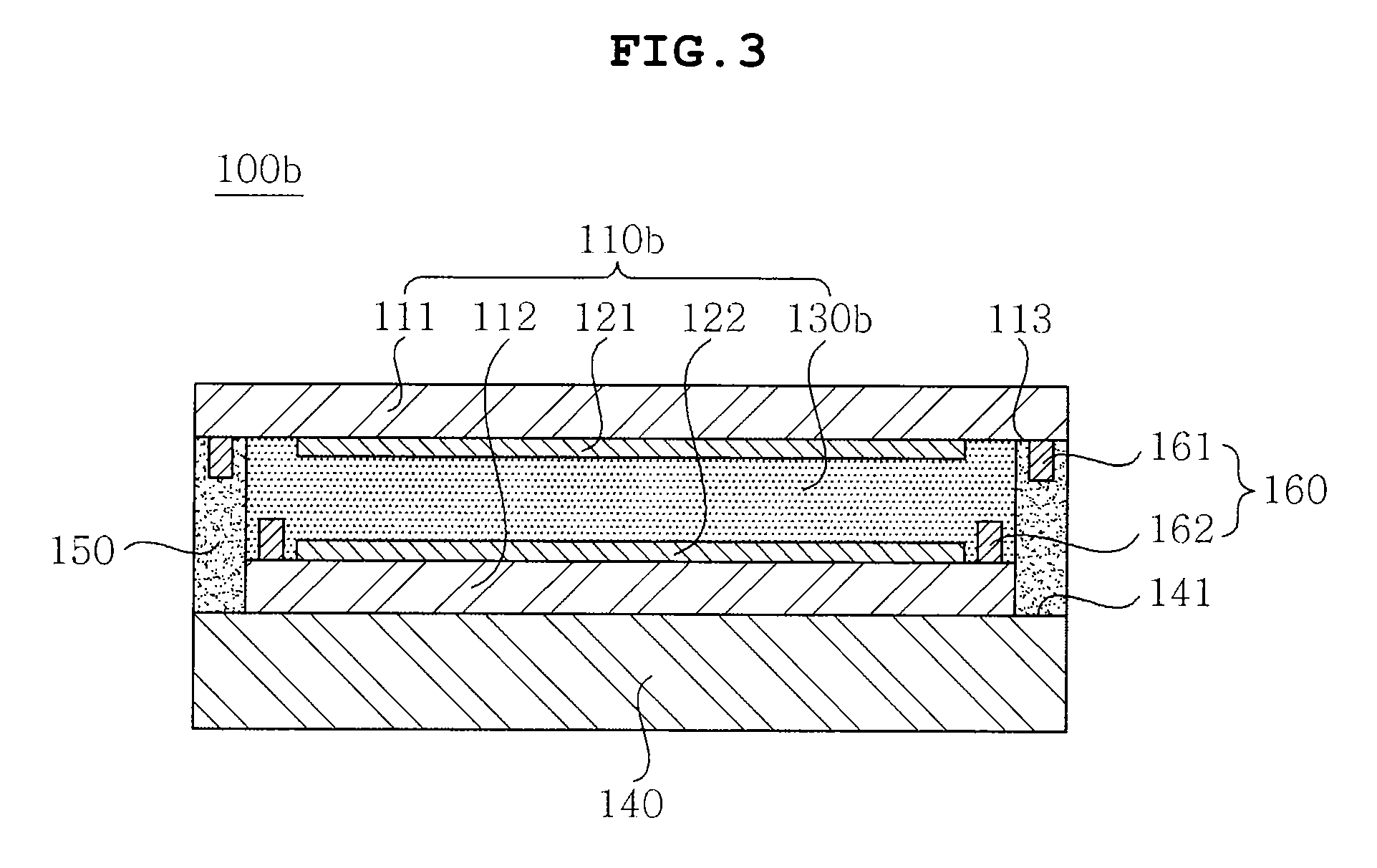

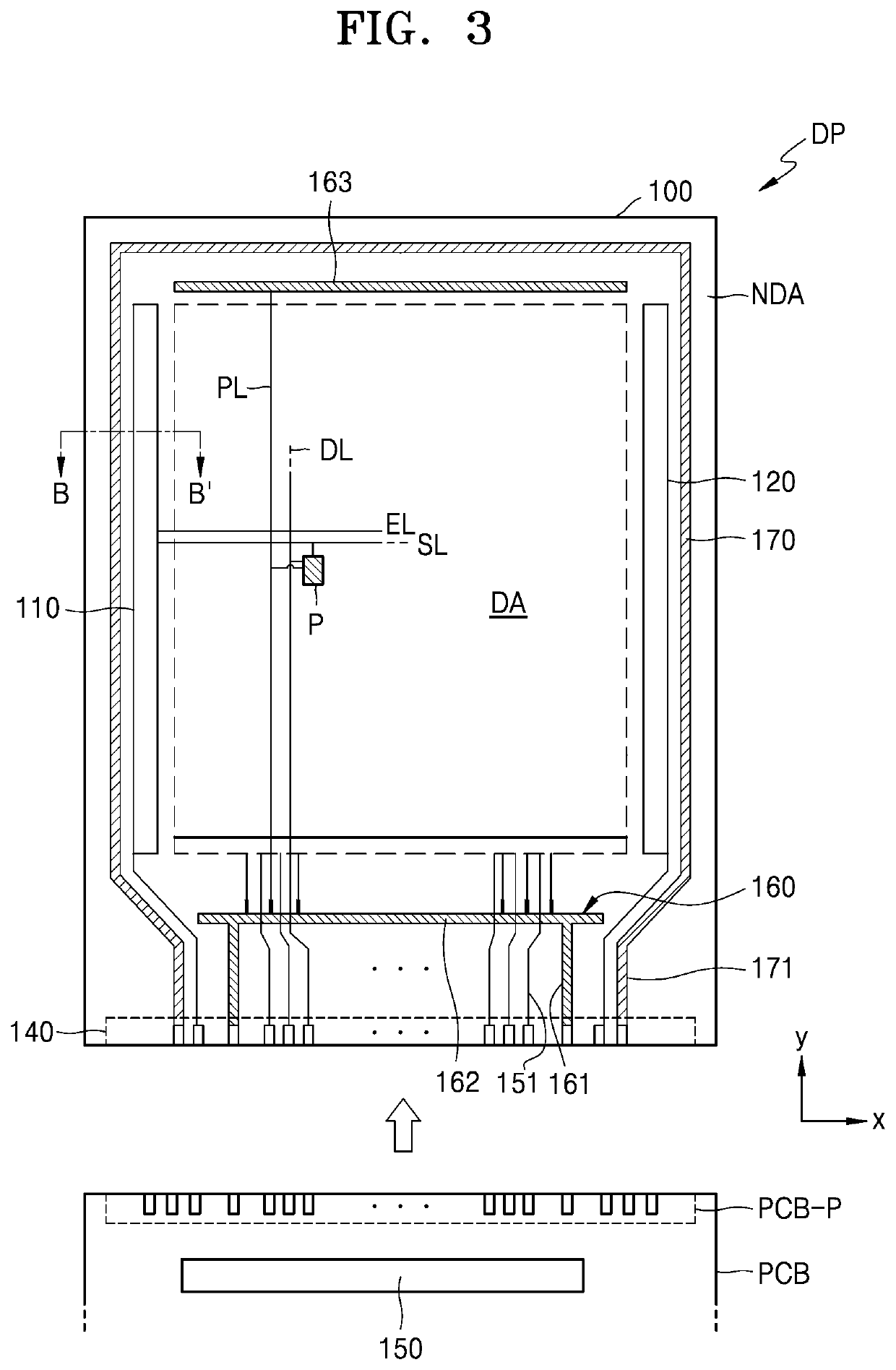

Organic light emitting display device

ActiveUS20100244057A1High life-span characteristicHigh mechanical reliabilityElectroluminescent light sourcesSolid-state devicesDisplay deviceOptoelectronics

An organic light emitting display device, including: a first substrate on which a plurality of light emitting elements are formed; a second substrate that is disposed to be opposed to the first substrate; a primary dam member that is provided between the first substrate and the second substrate in order to surround the plurality of light emitting elements; a filler that is filled between the first substrate and the second substrate and in a first region defined by the primary dam member, an auxiliary dam member that is between the first substrate and the second substrate and in a second region outside the first region, and is made of porous material; and an inorganic sealant that is provided between the first substrate and the second substrate and in a third region outside the first region and the second region, and is jointed to the first substrate and the second substrate.

Owner:SAMSUNG DISPLAY CO LTD

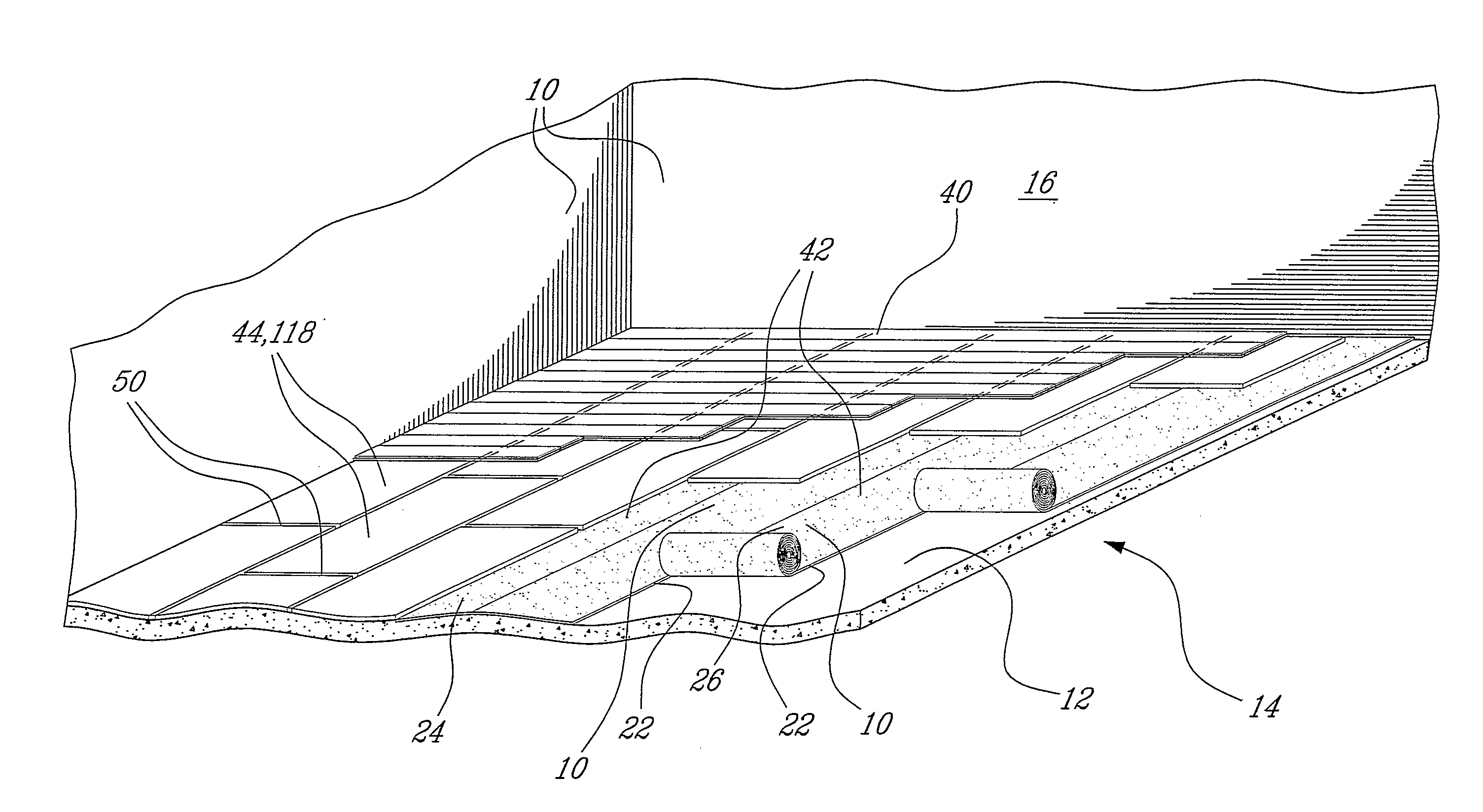

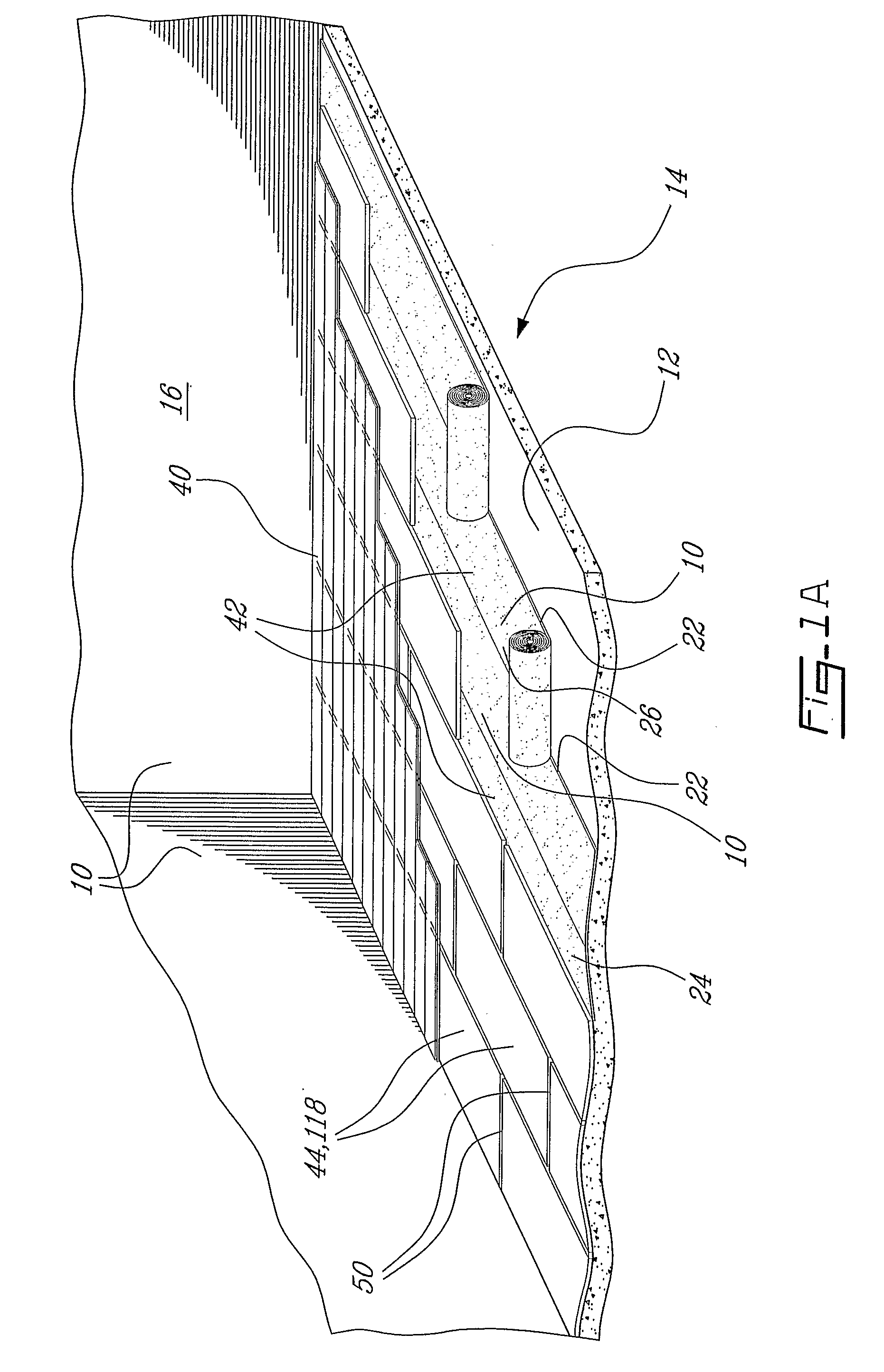

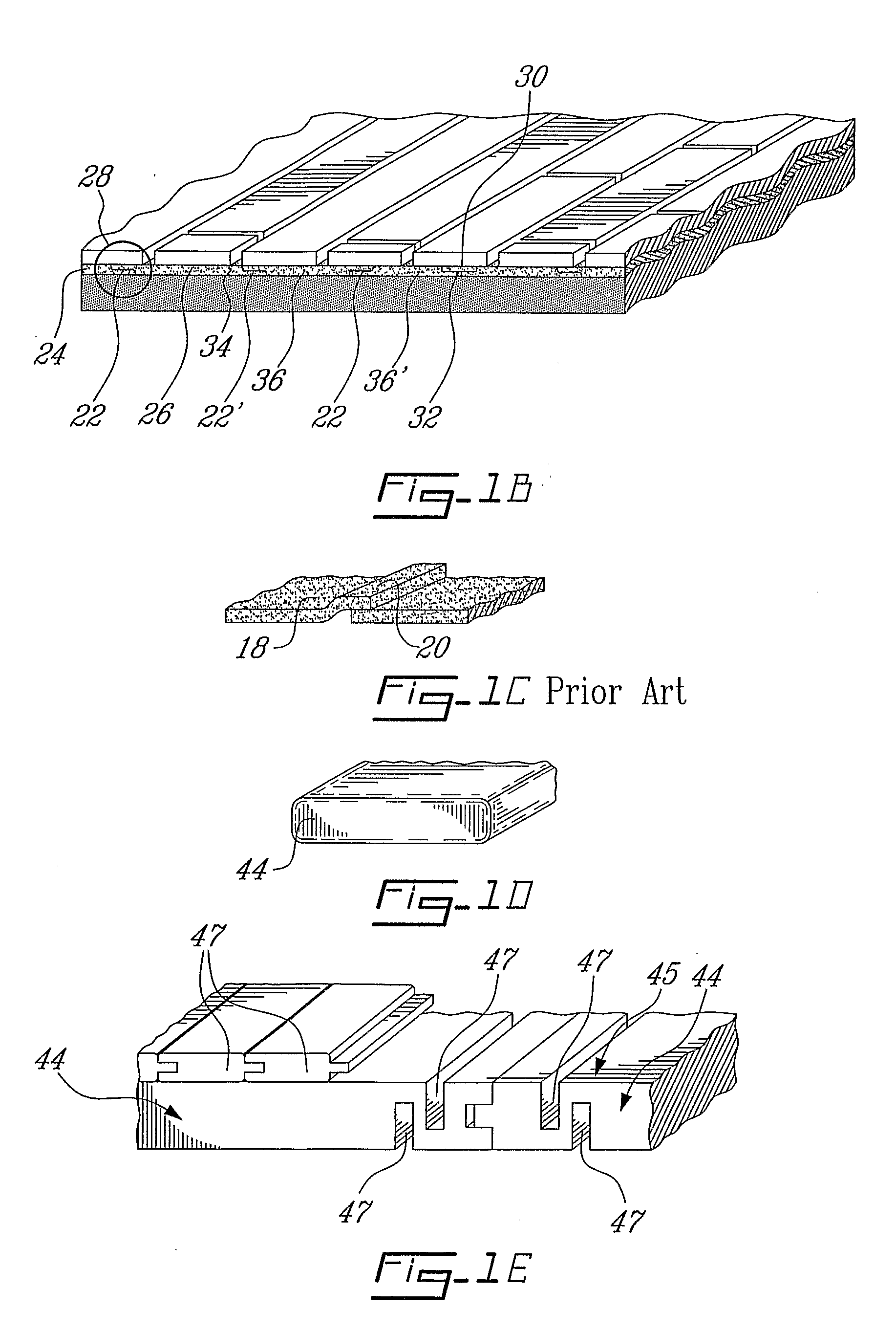

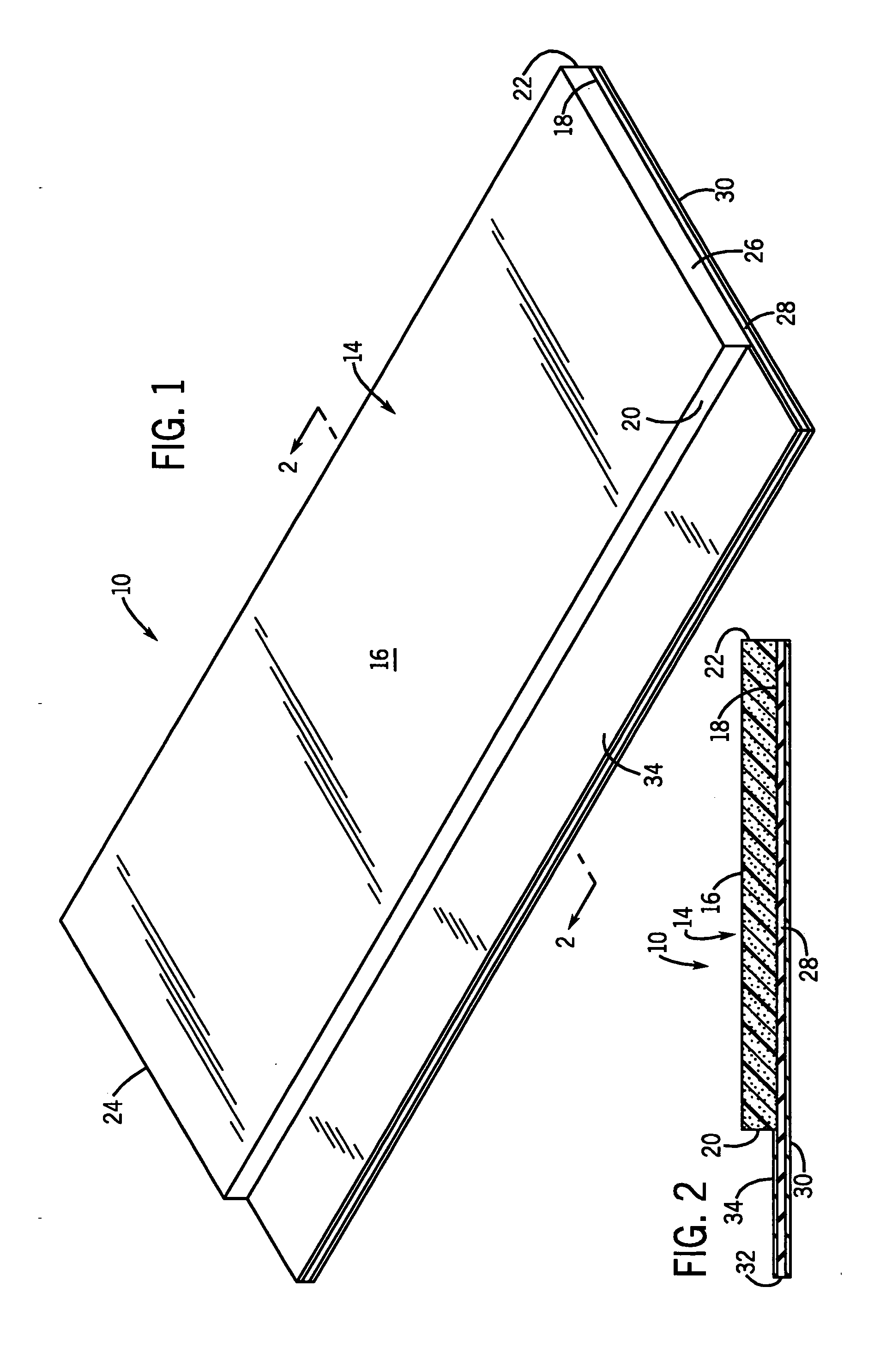

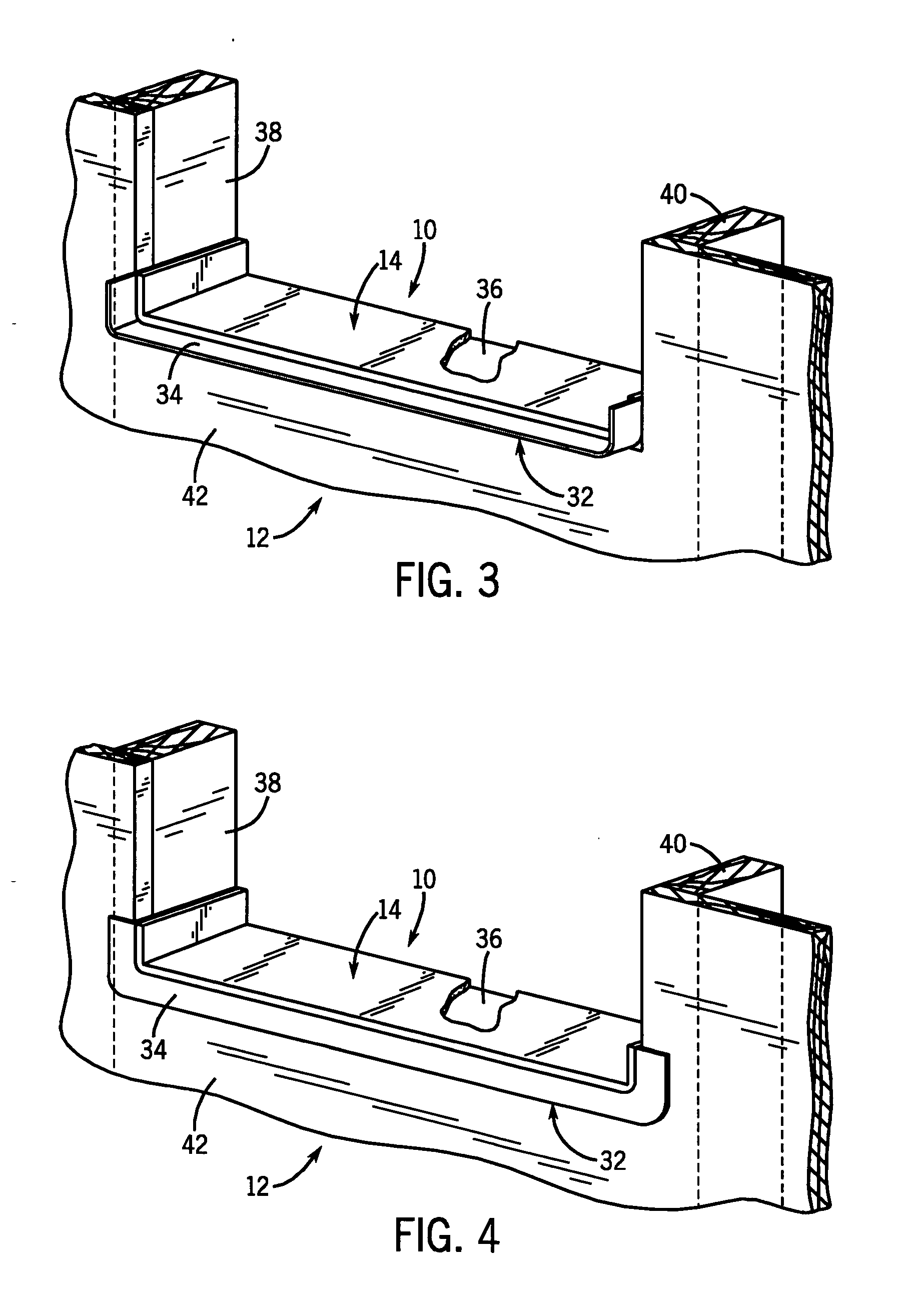

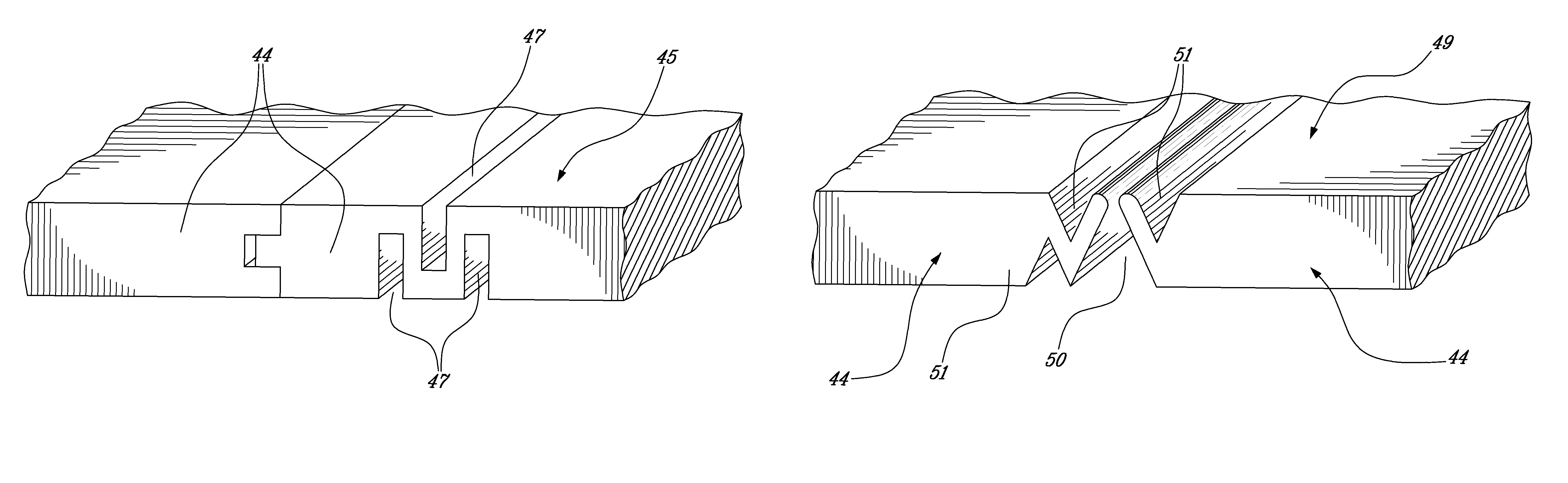

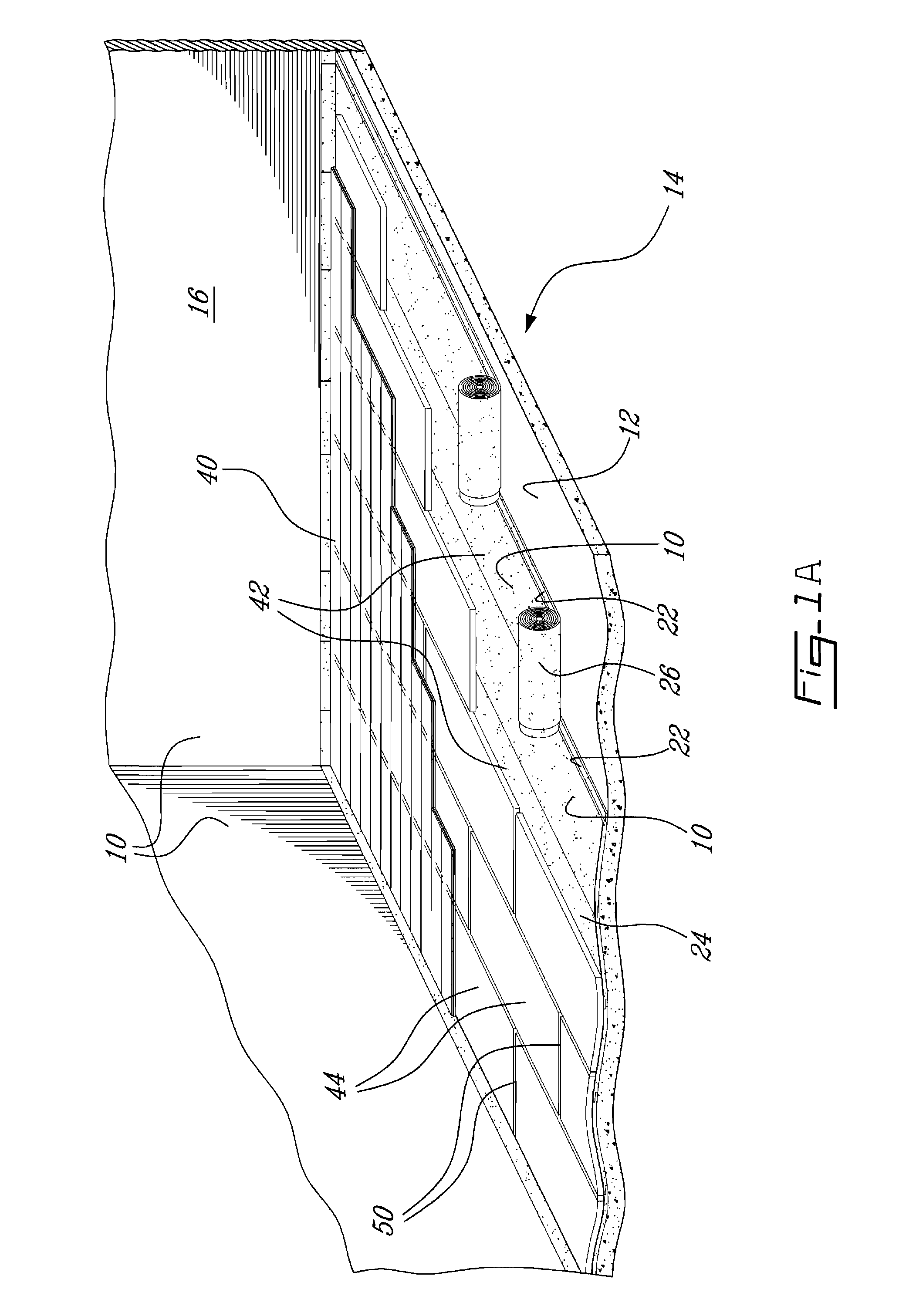

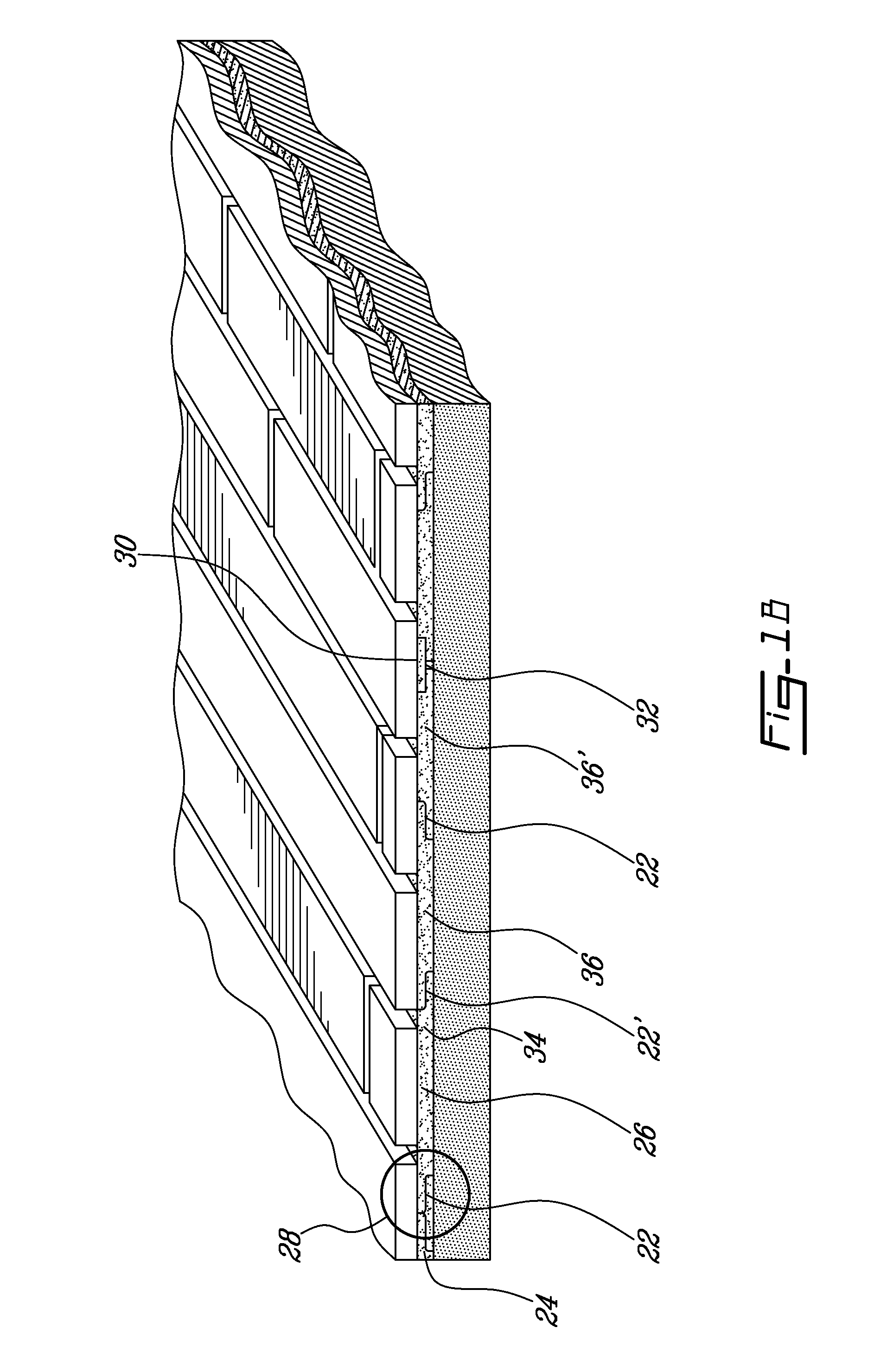

Flexible Insulation Membrane With Flat Overlapping Joints and Method of Installing the Same

InactiveUS20070227090A1Prevent moisture infiltrationCeilingsCovering/liningsEngineeringMoisture barrier

A sound and / or moisture barrier underlayment suited for use on a roof or floor surface to provide a substantially flat and level surface, comprises at least first and second strips of insulation membranes (10) laid down one next to the other in a coplanar relationship. The first and second strips (24, 26) have a thickness W1. An overlap joint (28) is provided between the first and second strips (24, 26). The overlap joint (28) has a thickness W2 substantially equal to or less than W1 to provide a free-bump transition between the first and second strips (24, 26) while preventing straight-through infiltration.

Owner:PLANTE REJEAN

Power toothbrush

InactiveUS7636976B2Easy to manufactureReliable serviceCarpet cleanersKitchenware cleanersCircular discDrive shaft

A power toothbrush with a drive train that is easy to manufacture, reliable in service and that enables multiple heads or other complex design or functional elements is provided. In an illustrative embodiment, the power toothbrush includes a sealed case that encloses a motor with a pinion gear joined to an eccentric link. This eccentric link can be a circular rack having an eccentric pin that rides in a slot on a drive plate. The drive plate is joined to a push rod, typically constructed of metal that passes up a hollow toothbrush shaft through an elastomeric seal to a head assembly. The head assembly includes one or more moving disks that are each connected to generally circular brush heads, which project outwardly from the head assembly. One disk receives a bent end of the drive shaft in a hole located eccentrically to the axis of rotation. When the circular rack rotates in a single direction, it drives the shaft in a reciprocating motion that, thereby, rotates the disk in a corresponding reciprocating circular motion about its axis. Additional disks can be linked by a short connecting shaft or link to the first disk via eccentric holes—other linkages, such as mating gears between disks can be used to simultaneously drive further disks, thereby providing a multiple moving-head power toothbrush.

Owner:THE GILLETTE CO

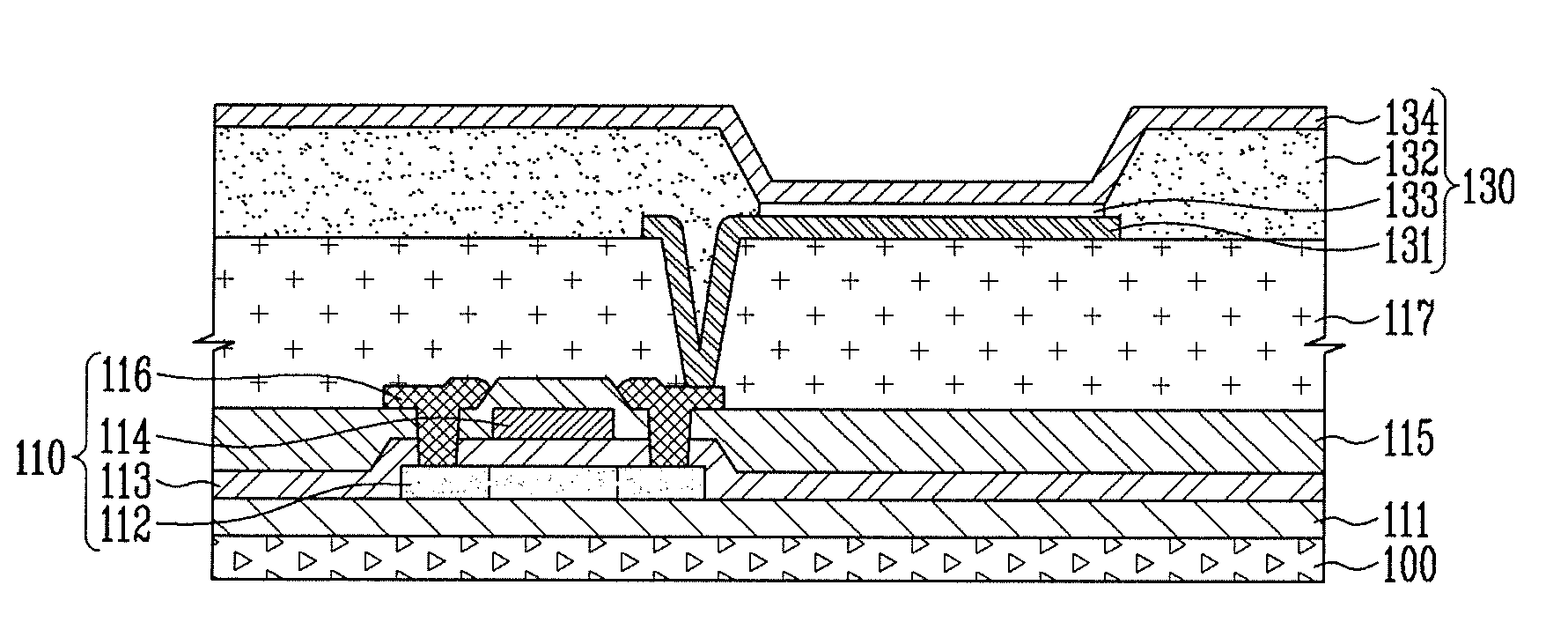

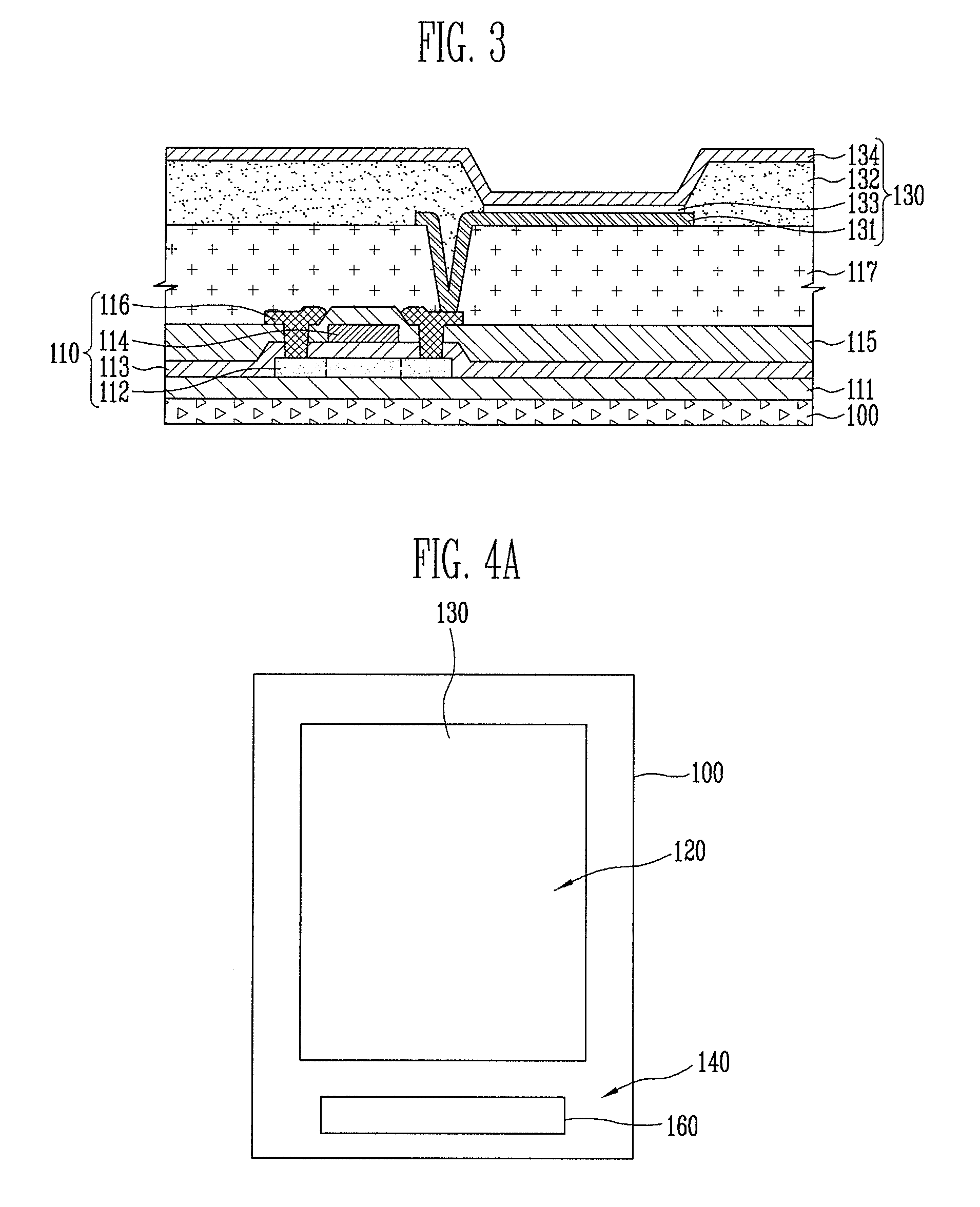

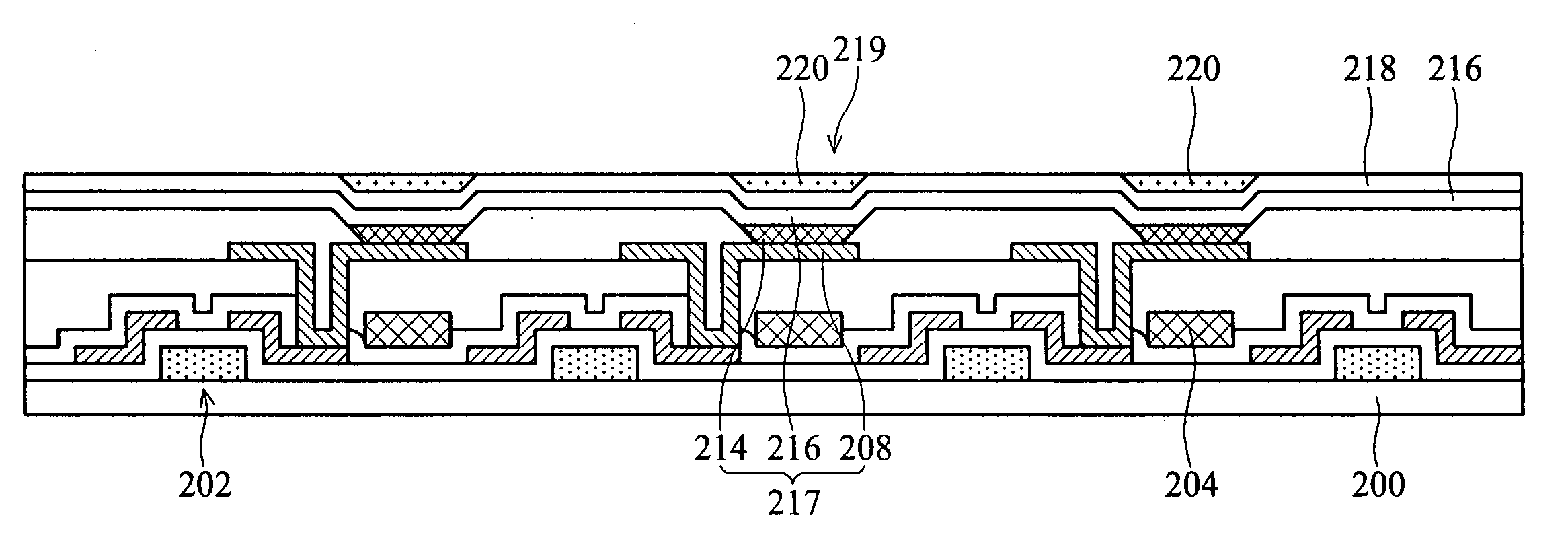

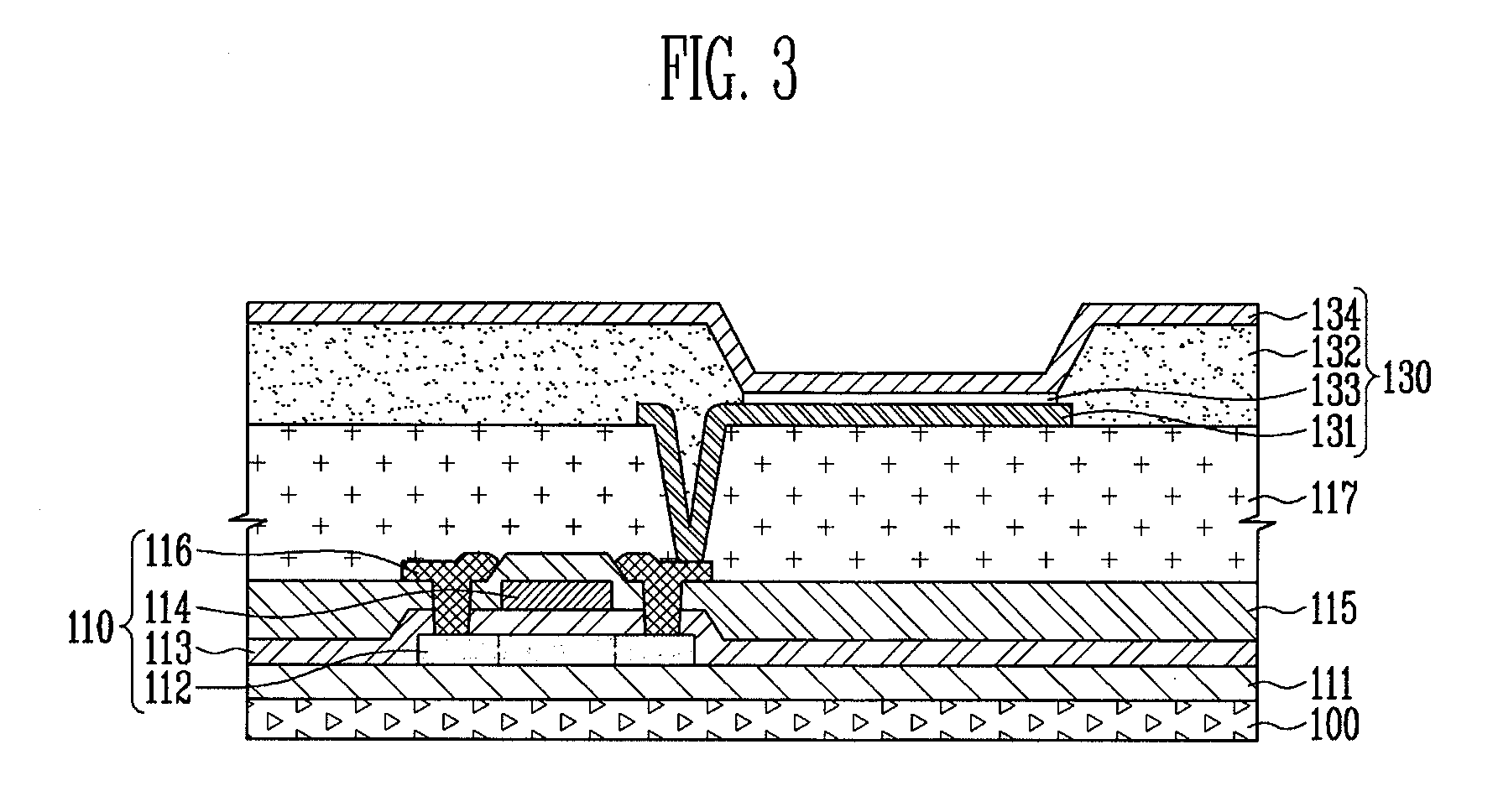

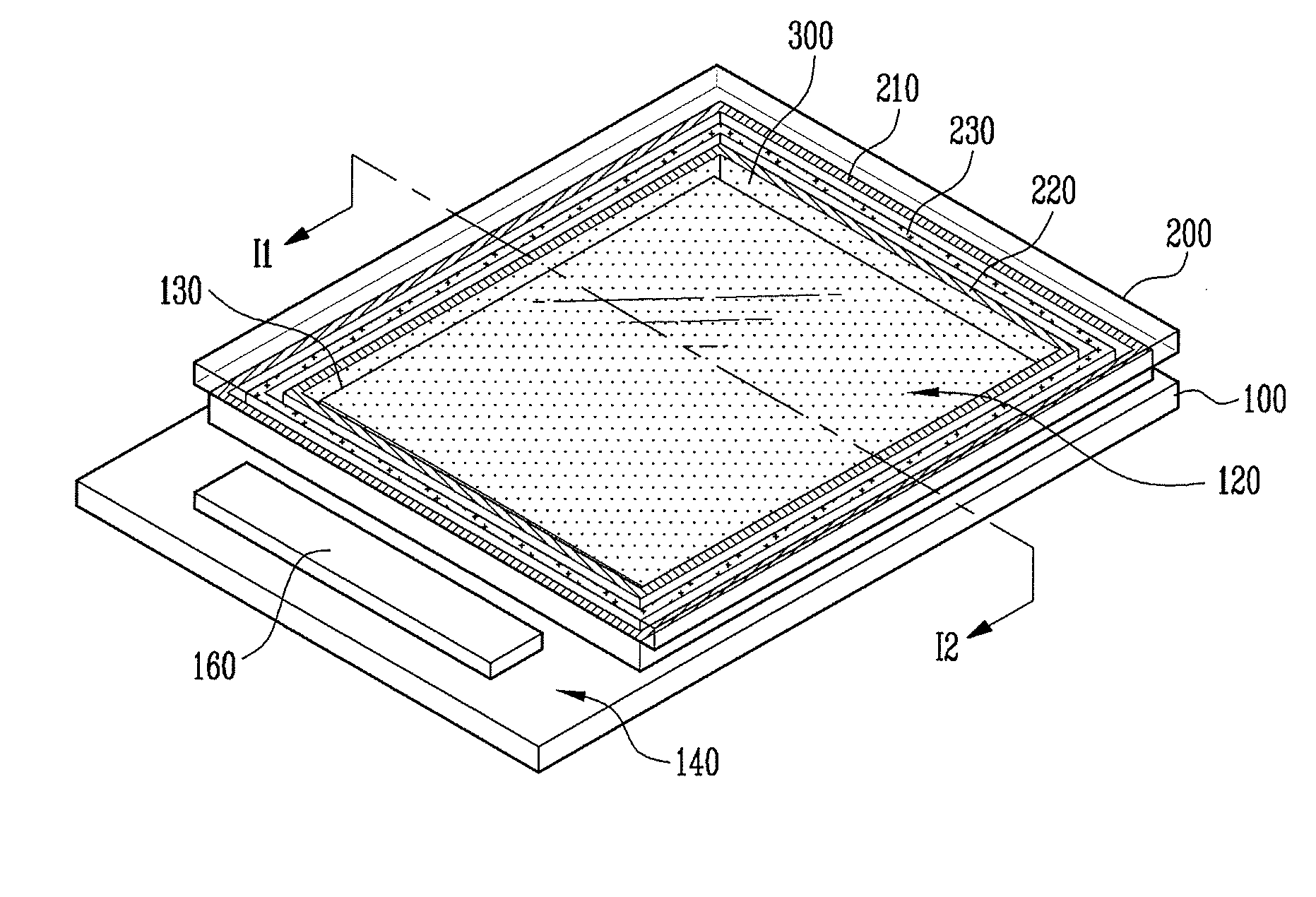

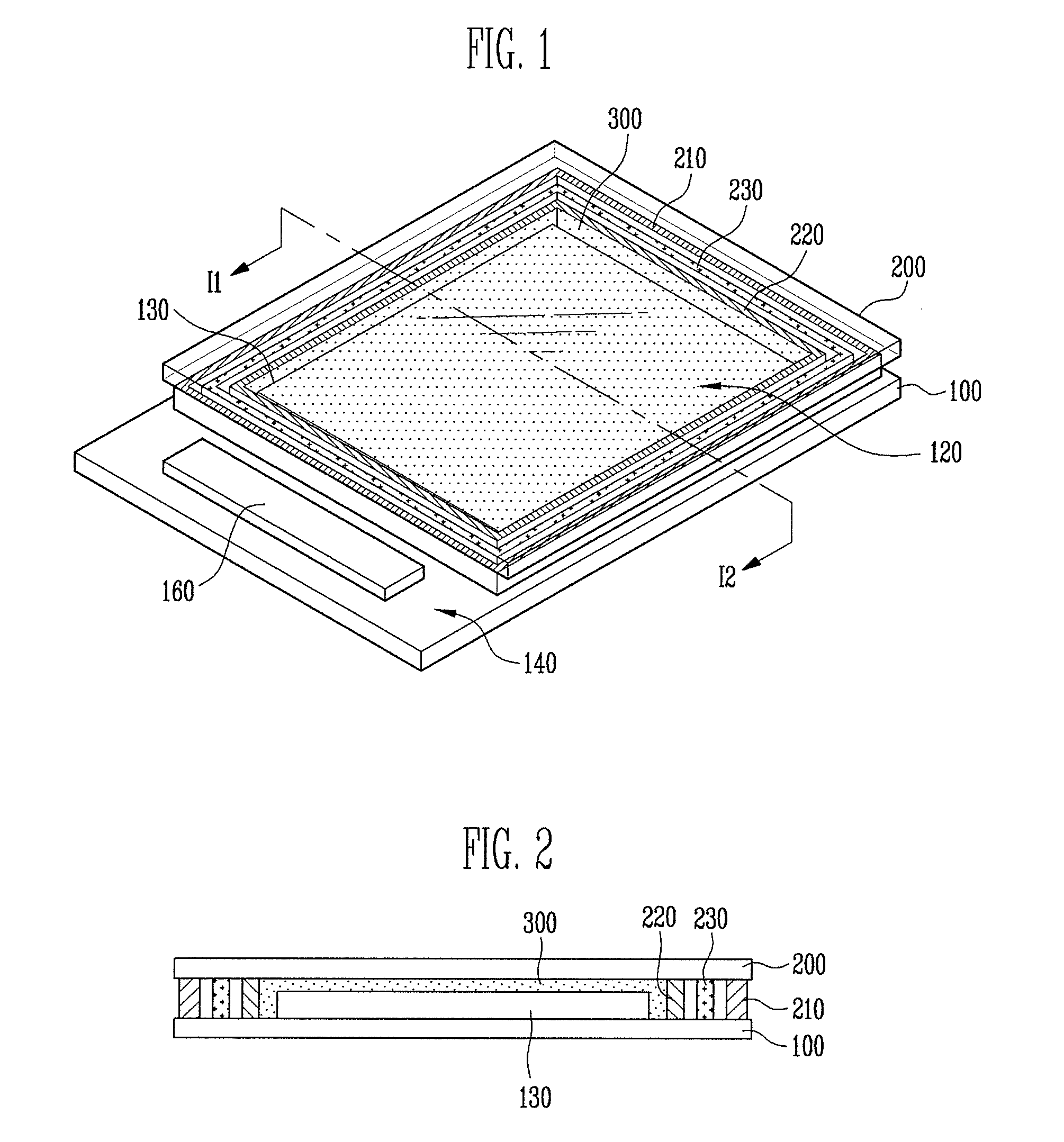

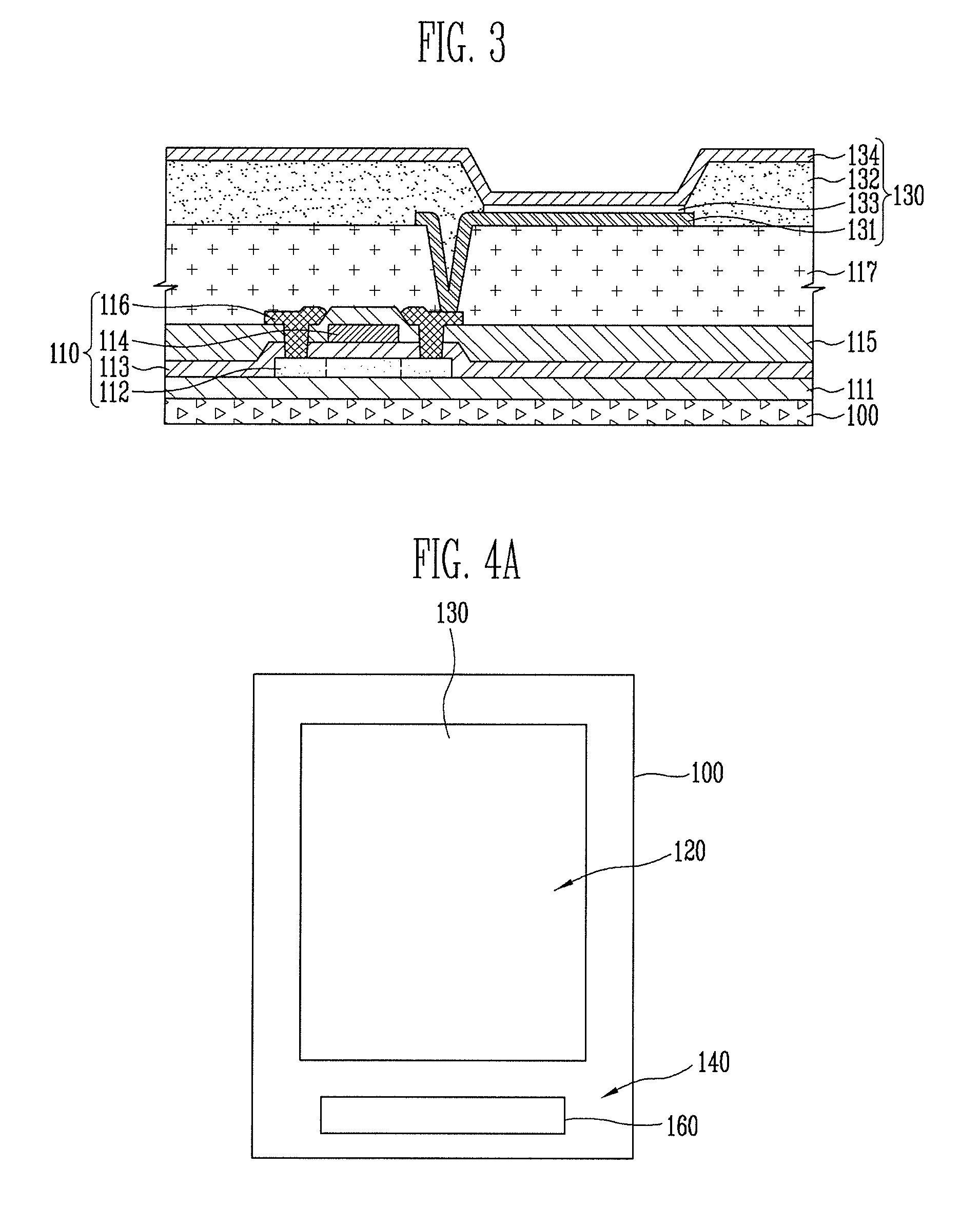

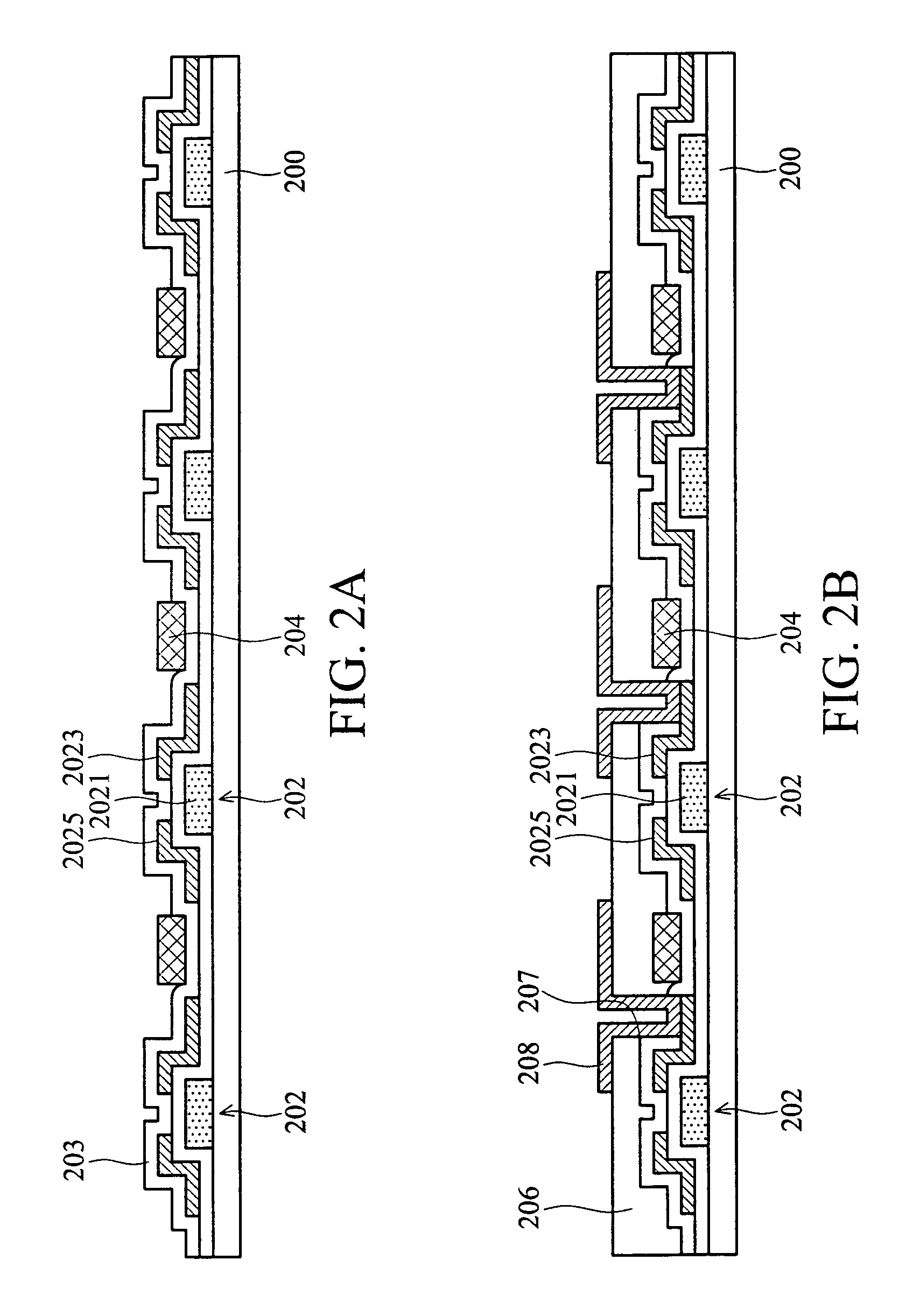

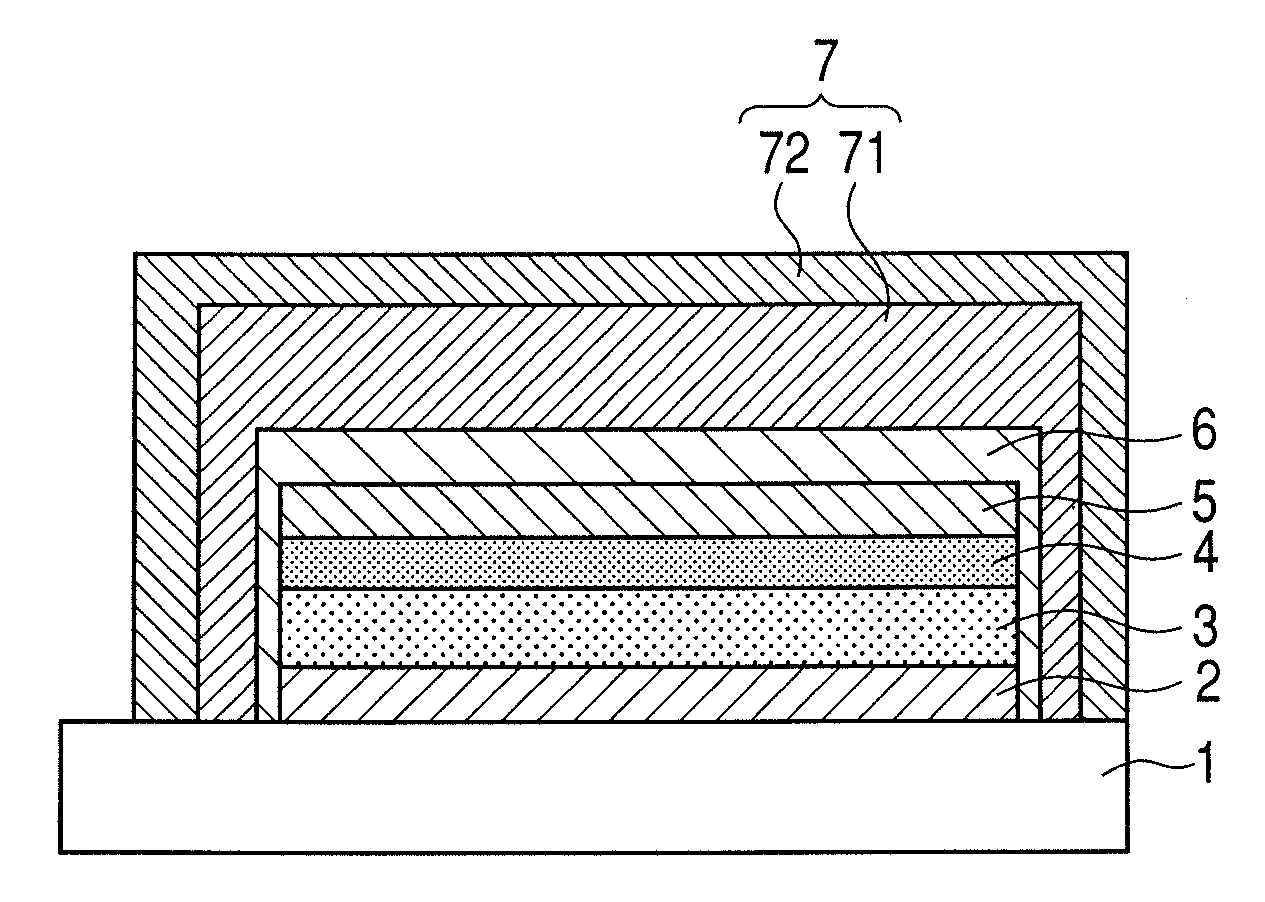

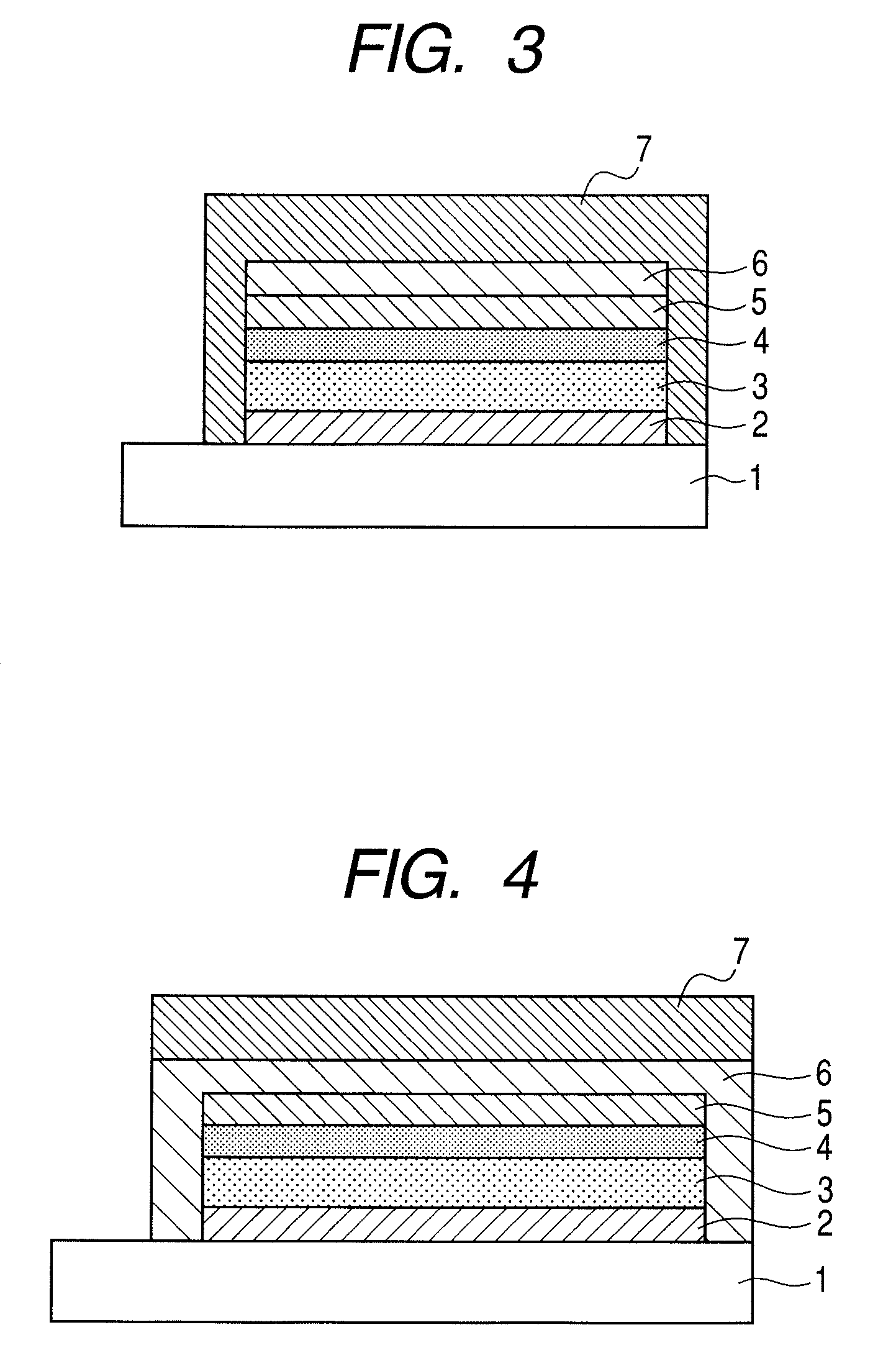

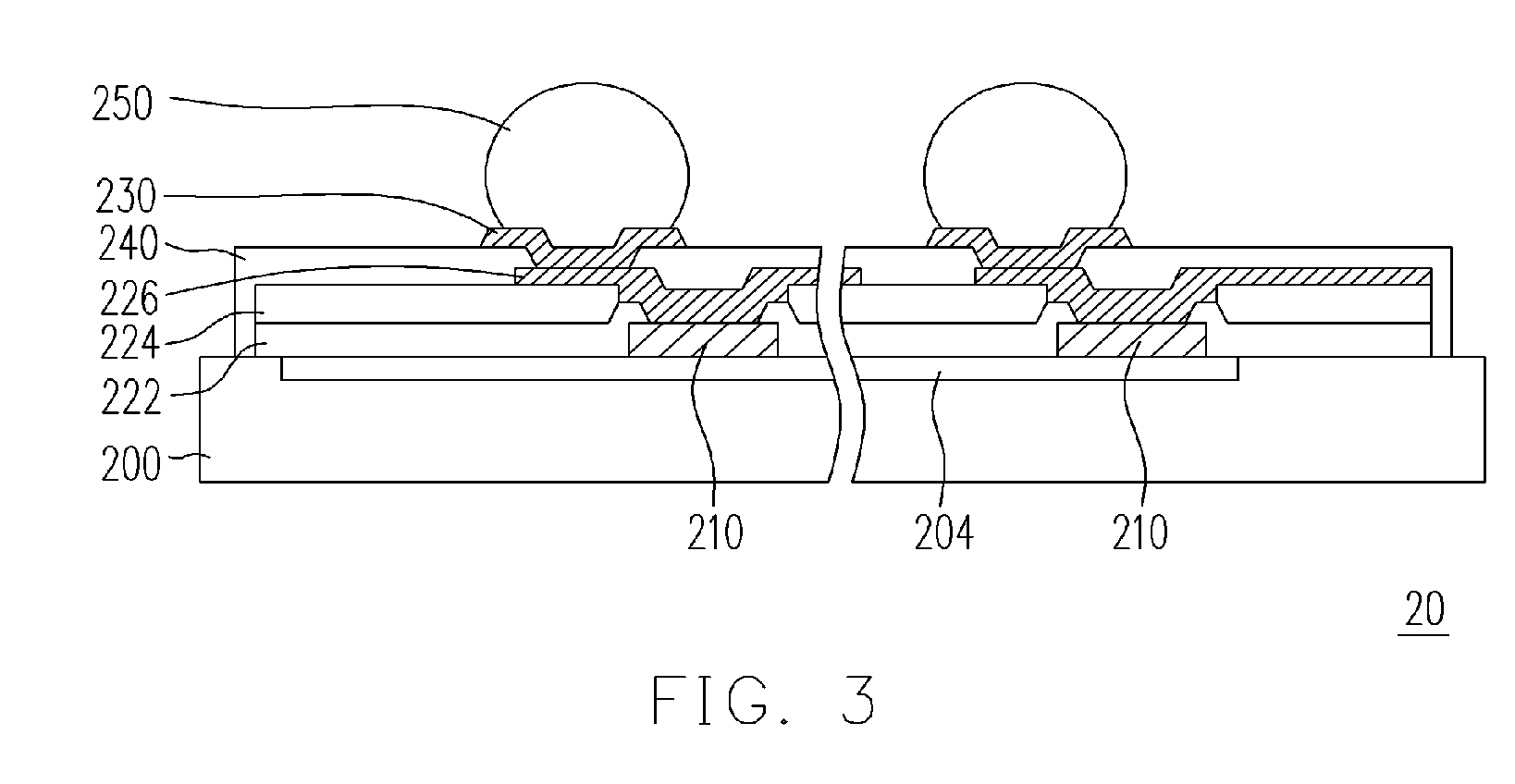

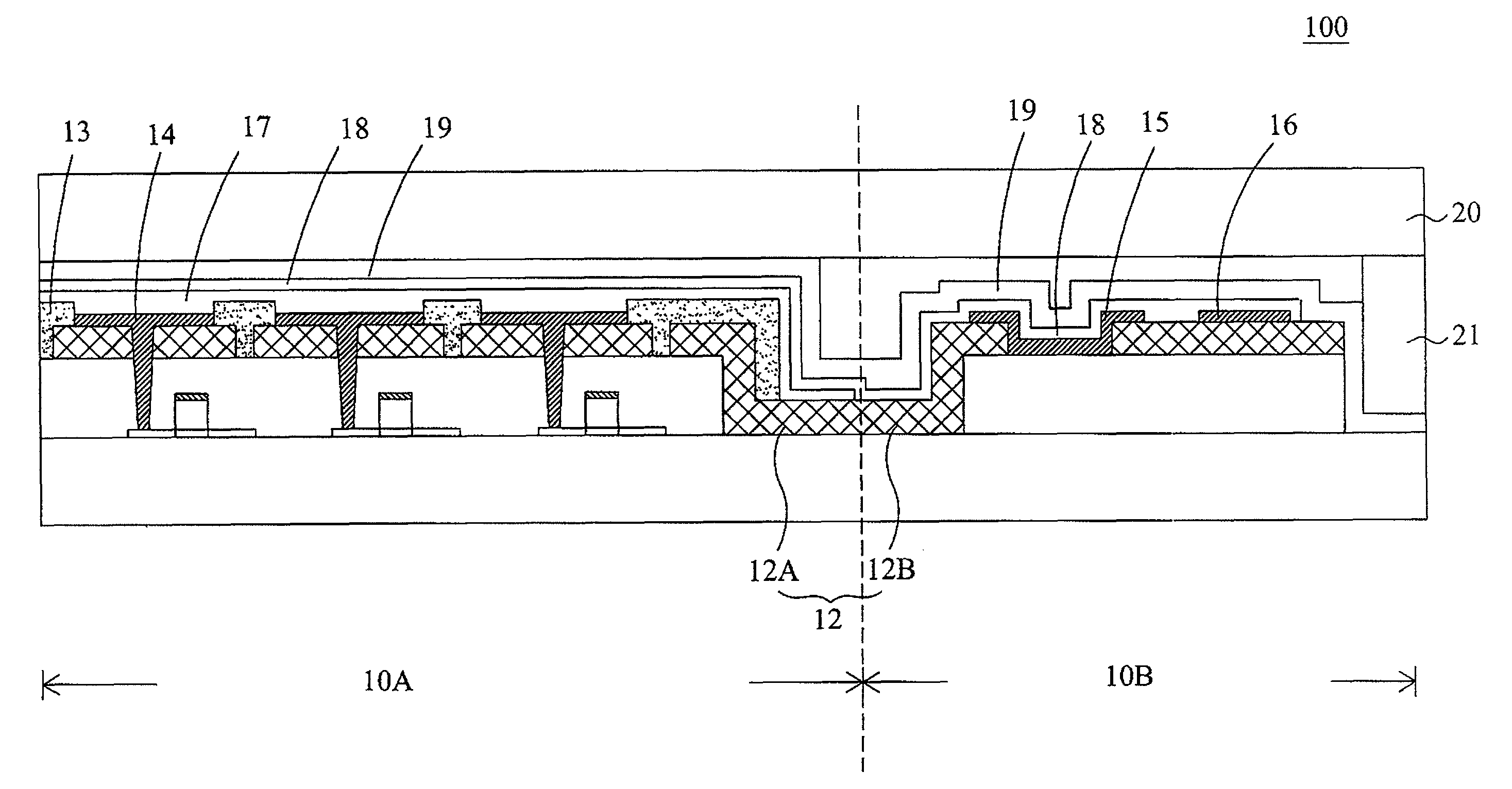

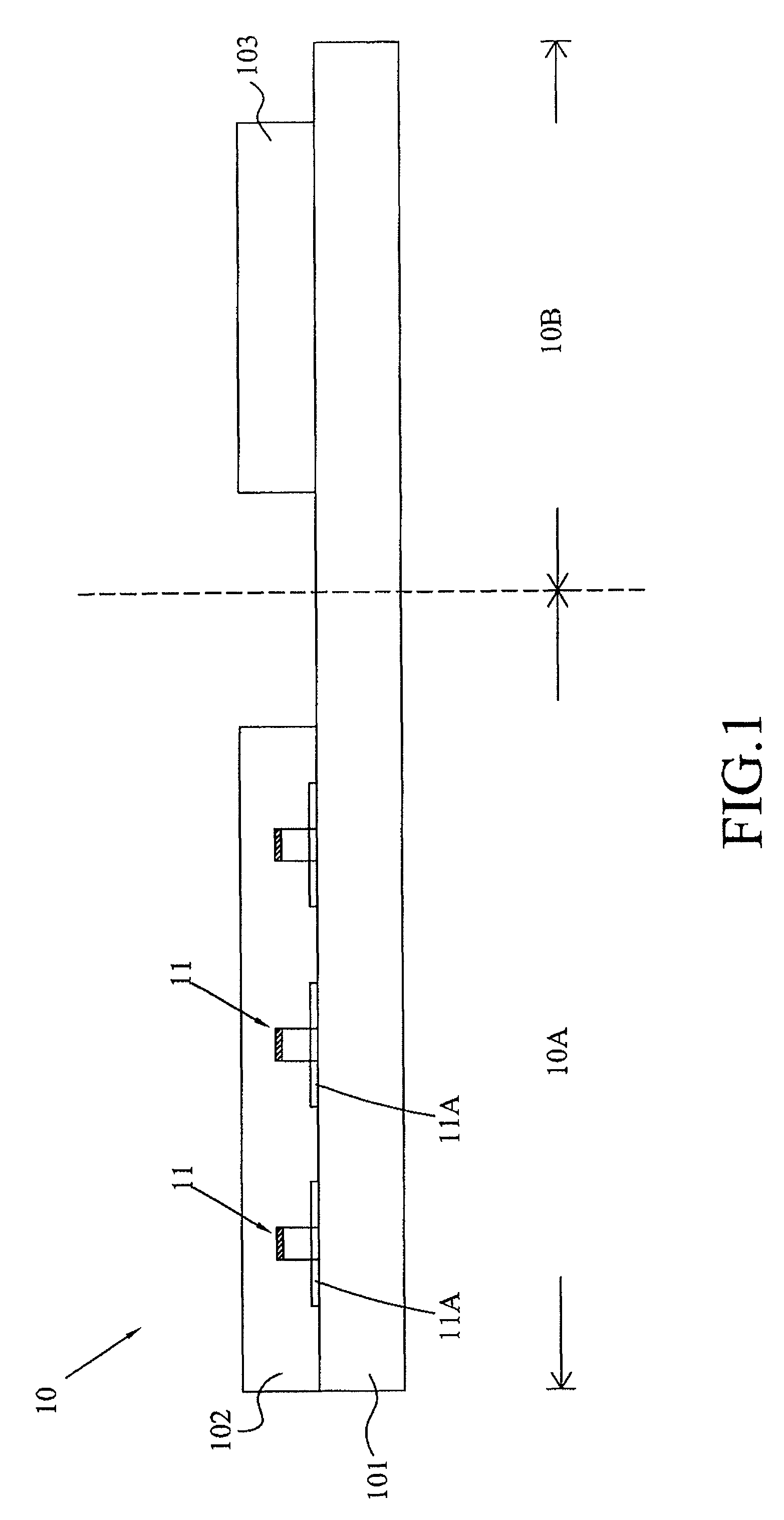

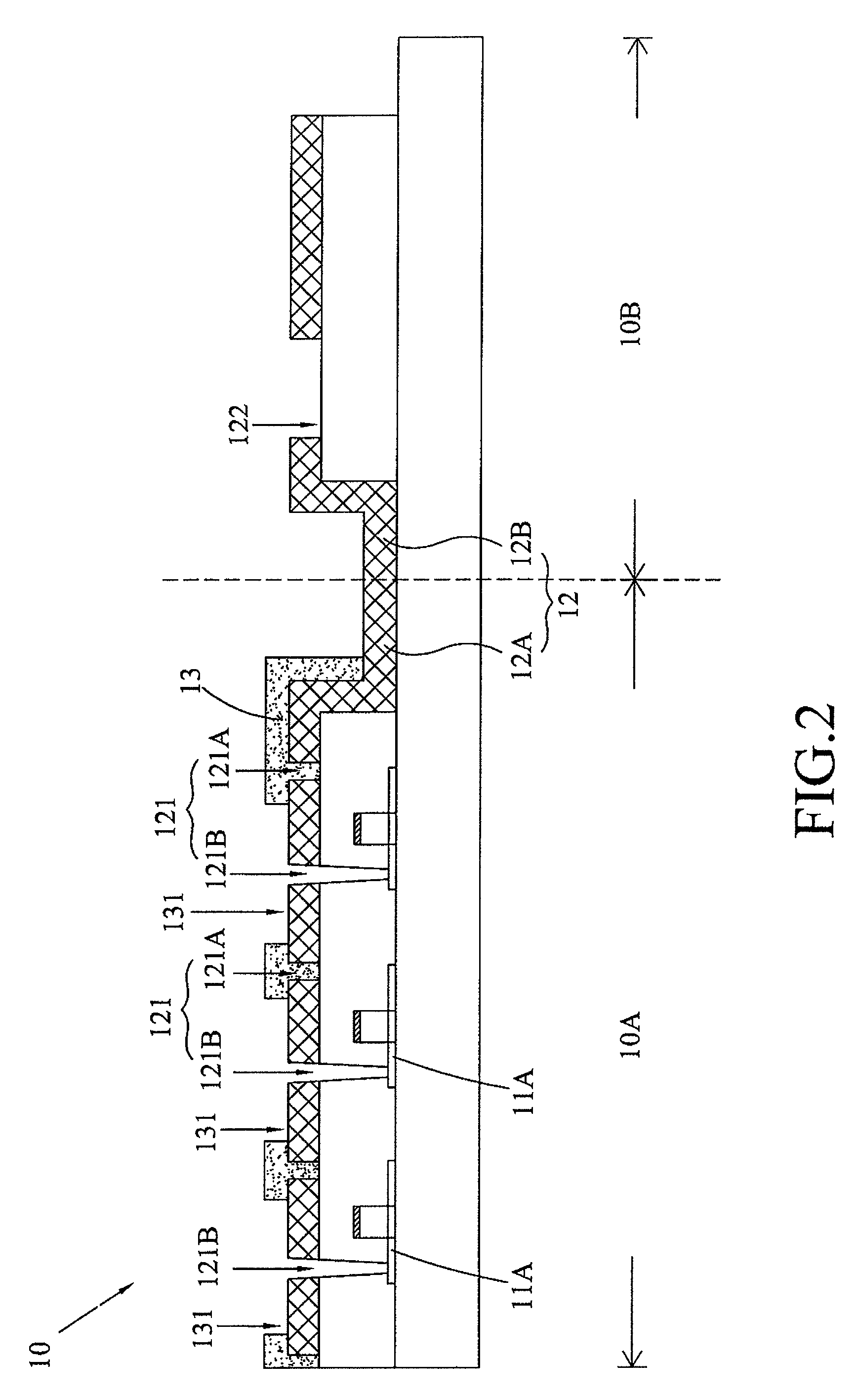

Organic electroluminescent display device and fabrication method thereof

ActiveUS20080211399A1Increase lifePrevent moisture infiltrationDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceMoisture

An organic electroluminescent display device and fabrication method thereof is provided. The device includes a first substrate having at least one thin film transistor; an electroluminescent unit formed on the first substrate and electrically connect to the thin film transistor; a first protective layer formed on the electroluminescent unit; a second protective layer formed on the first protective layer; and a third protective layer formed on the second protective layer and in contact with the first protective layer. The device further comprises a second substrate sealed to the first substrate to form the electroluminescent unit between the first substrate and second substrate. In the device, the first protective layer comprising inorganic material, the second protective layer comprising organic material and the third protective layer comprising inorganic material are formed on the electroluminescent unit to reduce oxidation of electrodes by preventing infiltration of moisture.

Owner:INNOLUX CORP

Door and window sill gasket

InactiveUS20050252131A1Prevent moisture infiltrationFloorsSills/thresholdCompressible materialWindow sill

A door and window sill gasket is adapted to seal the frame of doors and windows against moisture, air and insects. The gasket includes a water resistant compressible material having an upper surface, a lower surface and at least one edge. The lower surface of the compressible material is attached to an adhesively-coated top face of a rubberized asphalt sealing membrane providing an air / water infiltration barrier and having an adhesively-coated lower face covered by a removable release liner. The membrane includes a flexible, covered flange extending outwardly from the at least one edge of the compressible material.

Owner:BUSHBERGER ENTERPRISES

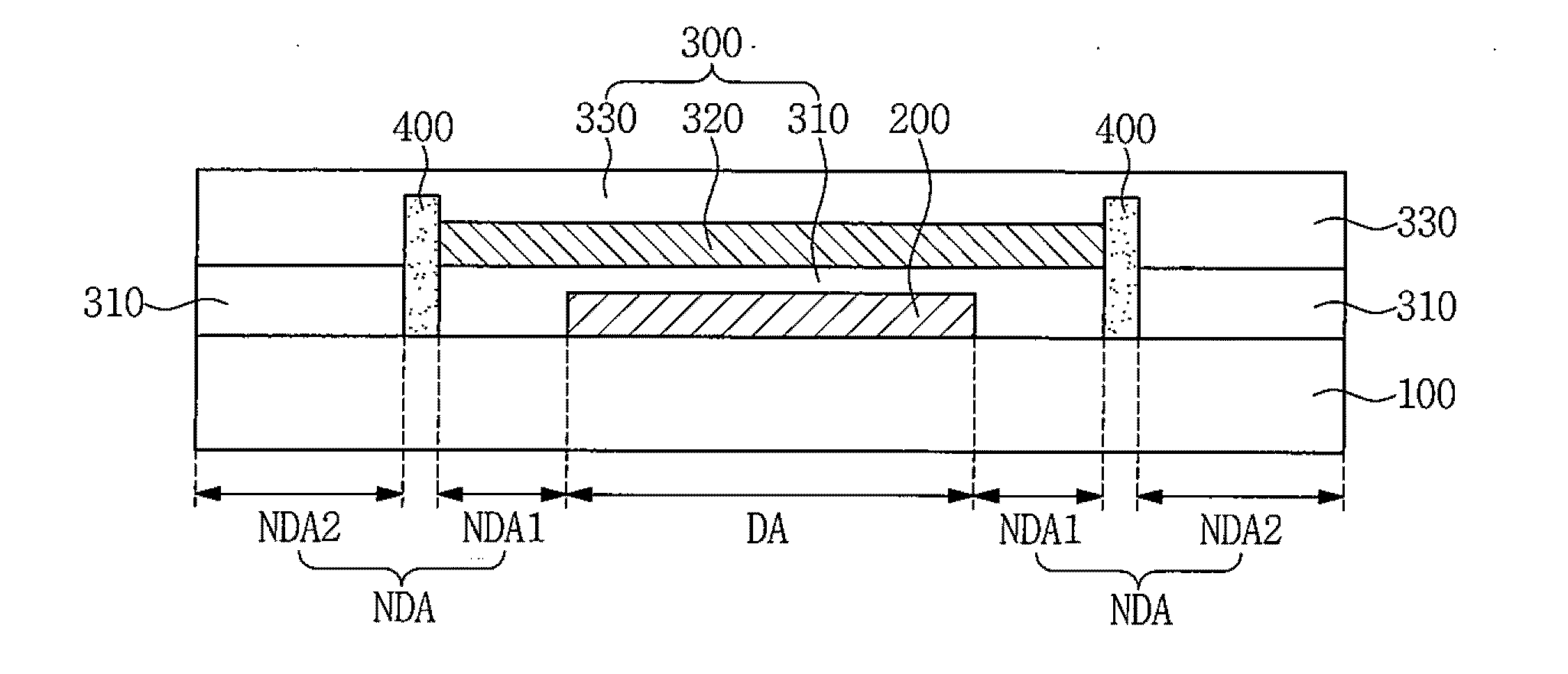

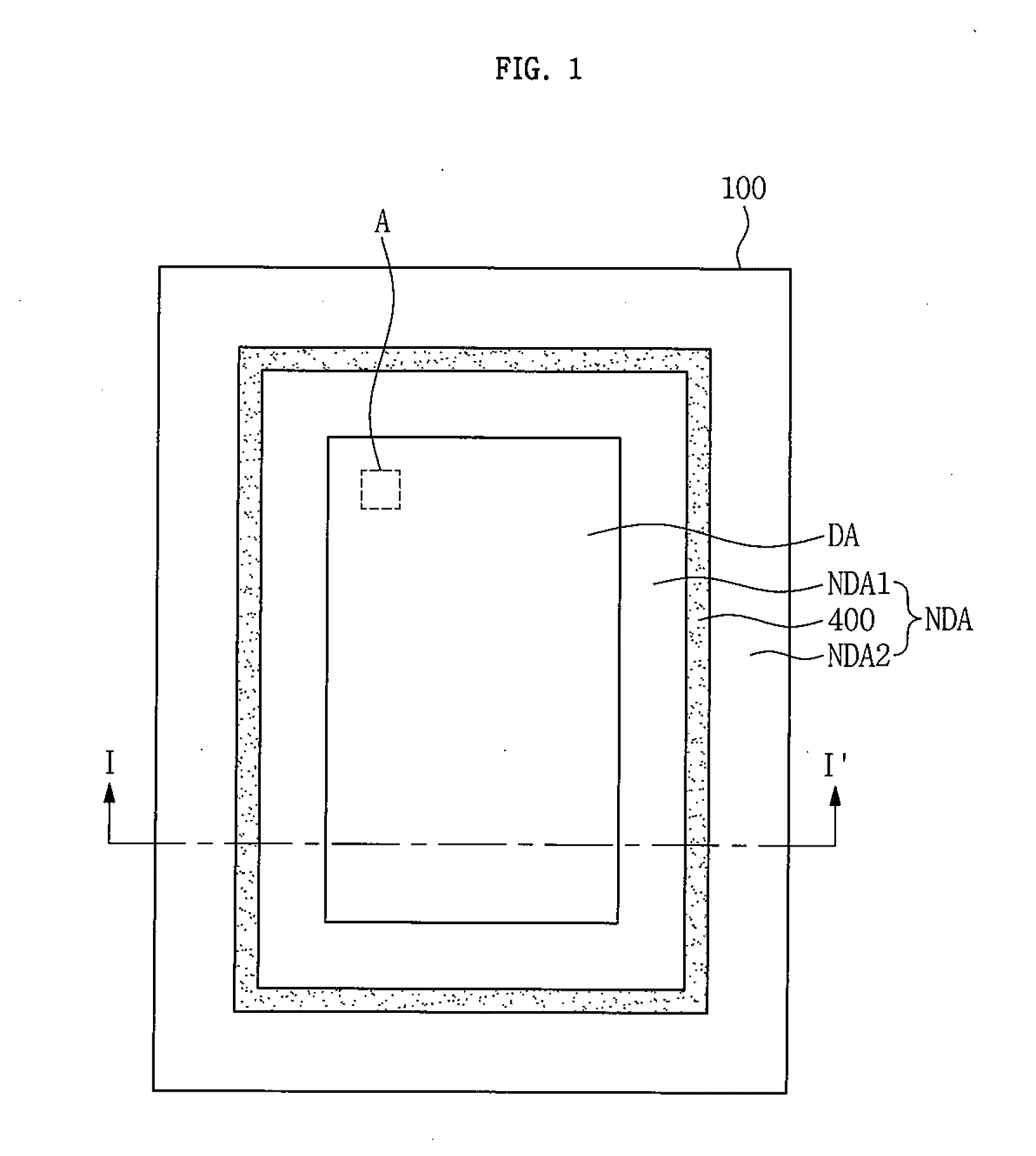

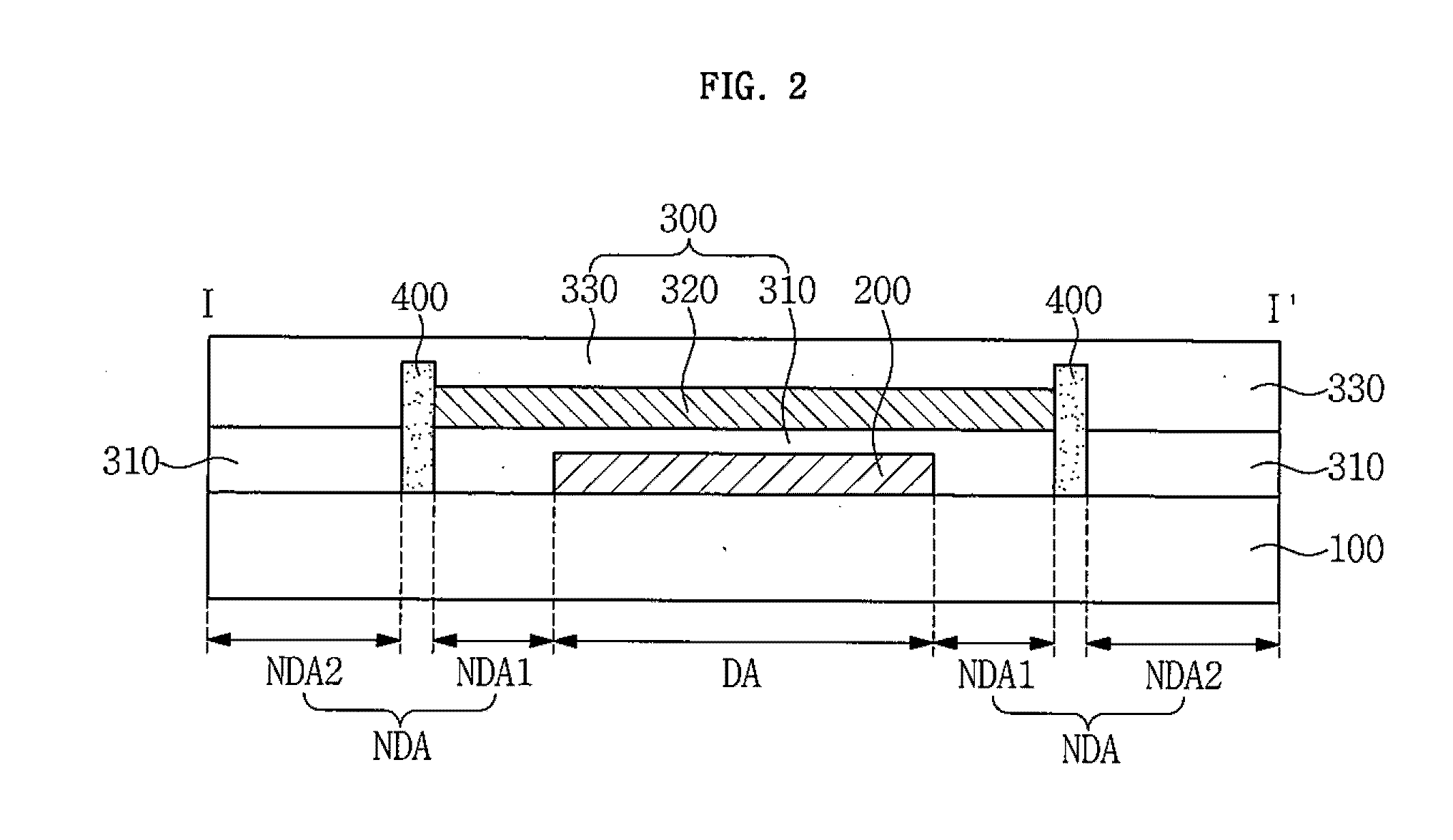

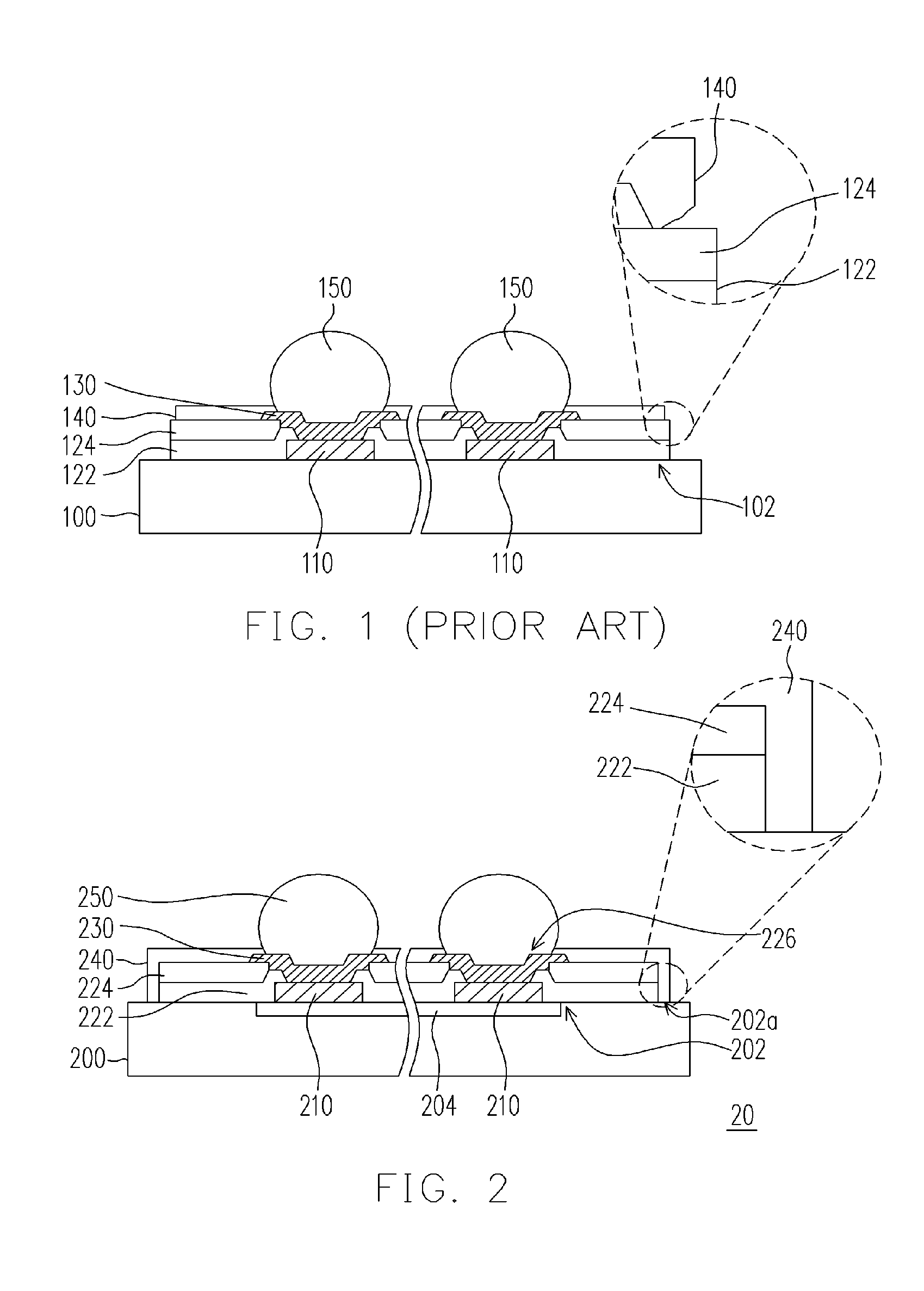

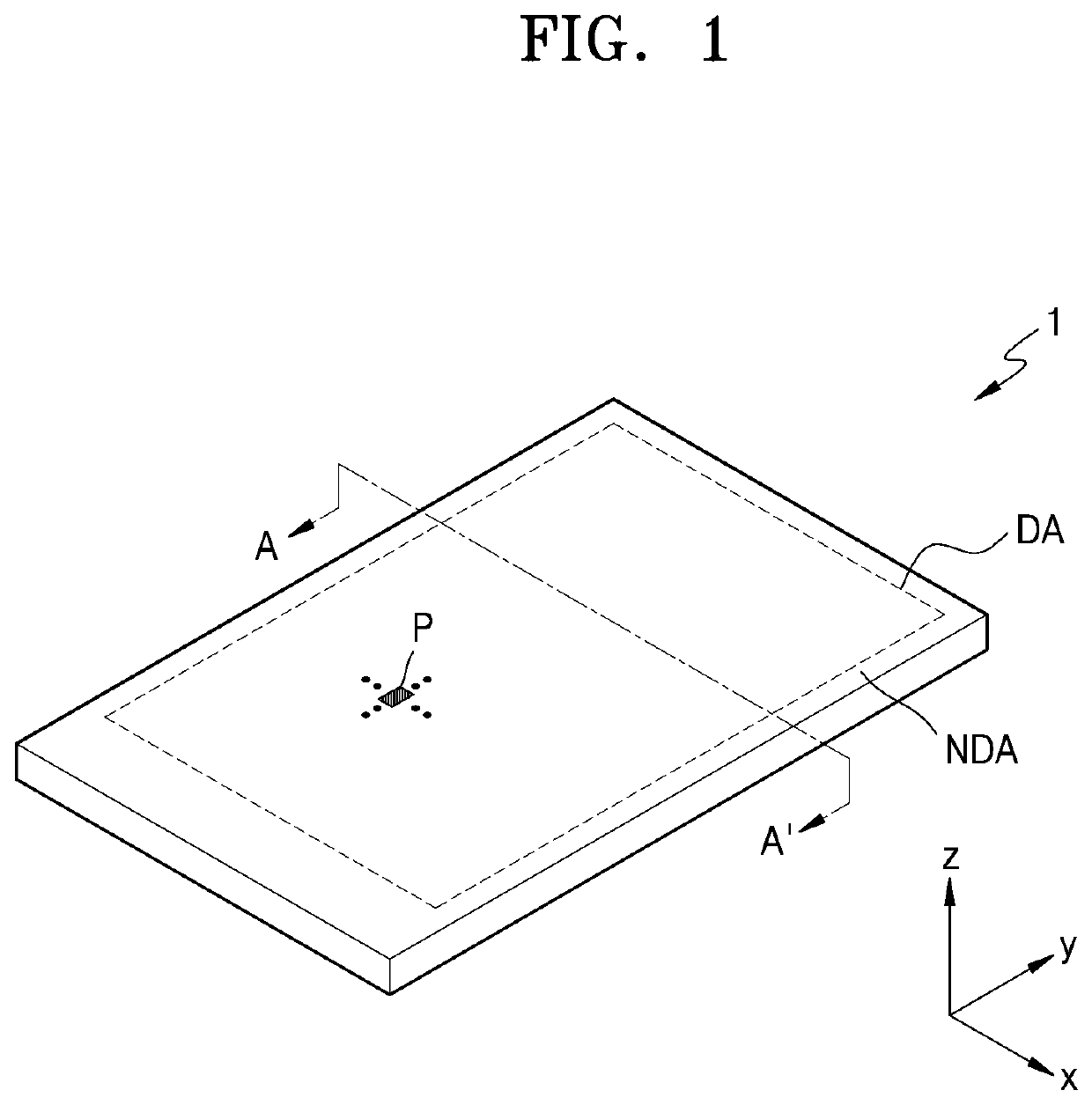

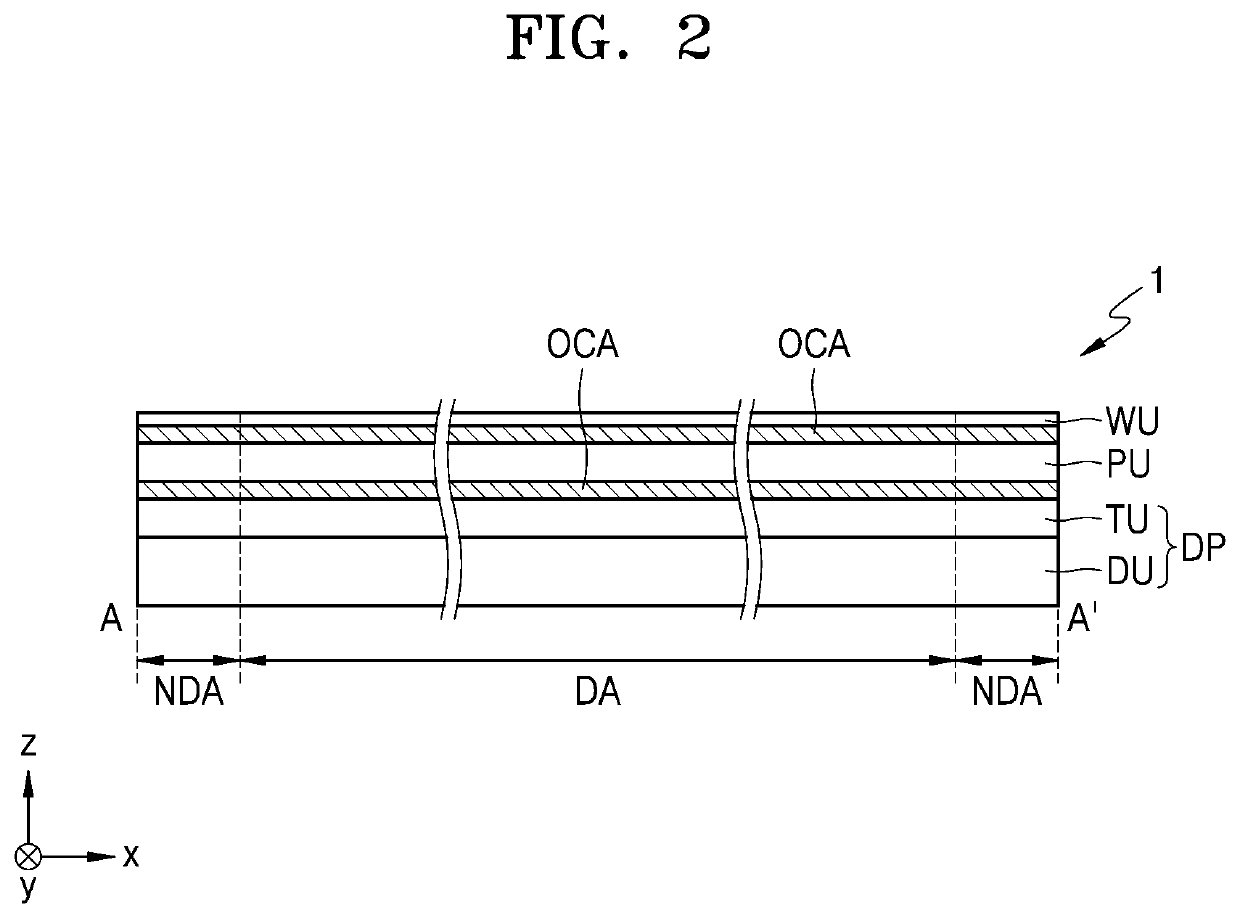

Organic light emitting diode display device and method of manufacturing the same

ActiveUS20160268547A1AdhesivenessPrevent moisture infiltrationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

A method of manufacturing an organic light emitting diode (OLED) display device includes: providing a substrate including a display area and a non-display area; forming an organic light emitting diode element in the display area; forming a barrier wall around the display area and spaced apart from the organic light emitting diode element; performing a plasma treatment on the substrate on which the organic light emitting diode element is formed; and forming a thin film encapsulation layer for coating the organic light emitting diode element, wherein forming the thin film encapsulation layer includes: forming at least one inorganic layer; and forming at least one organic layer inwardly of the barrier wall.

Owner:SAMSUNG DISPLAY CO LTD

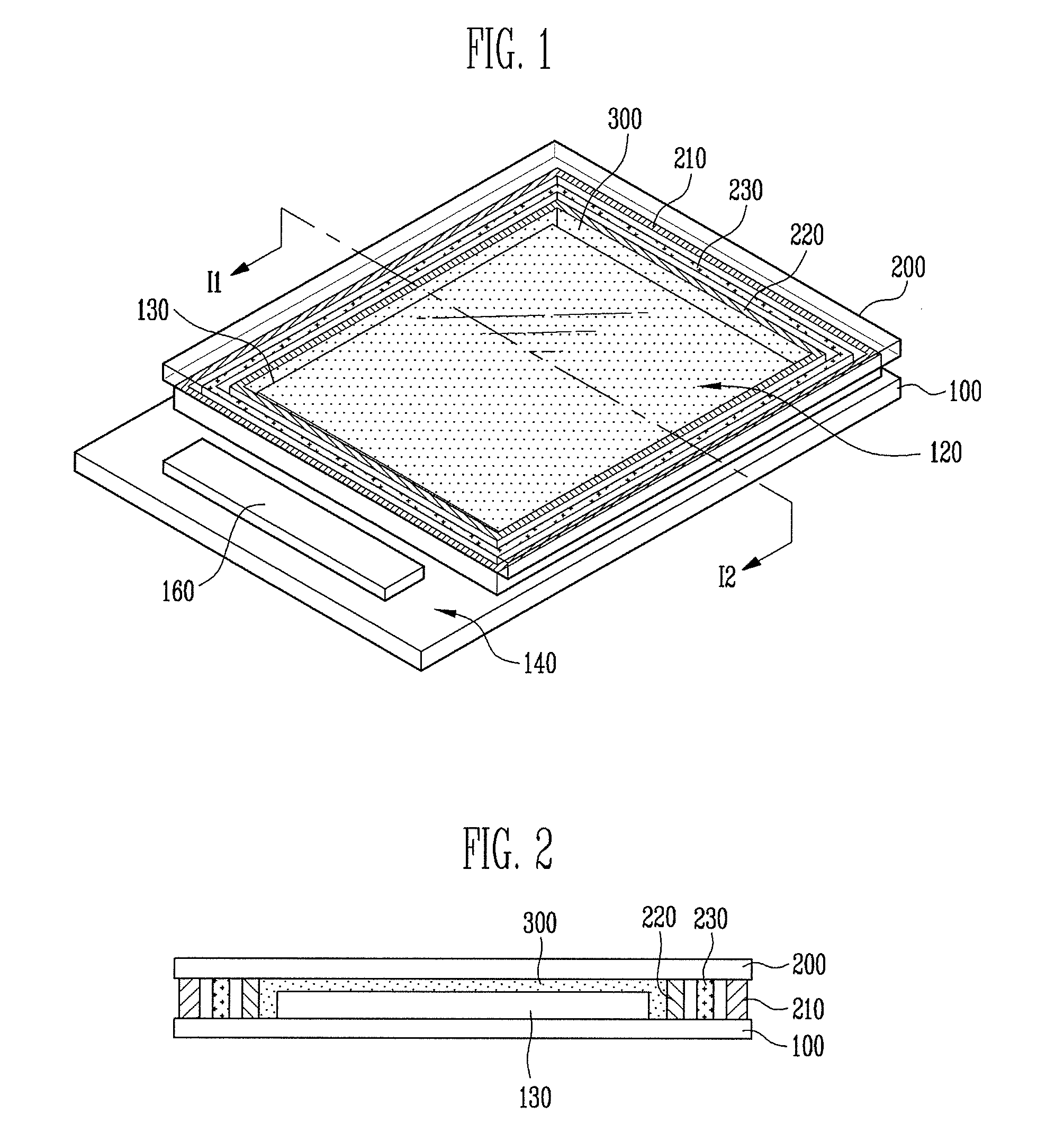

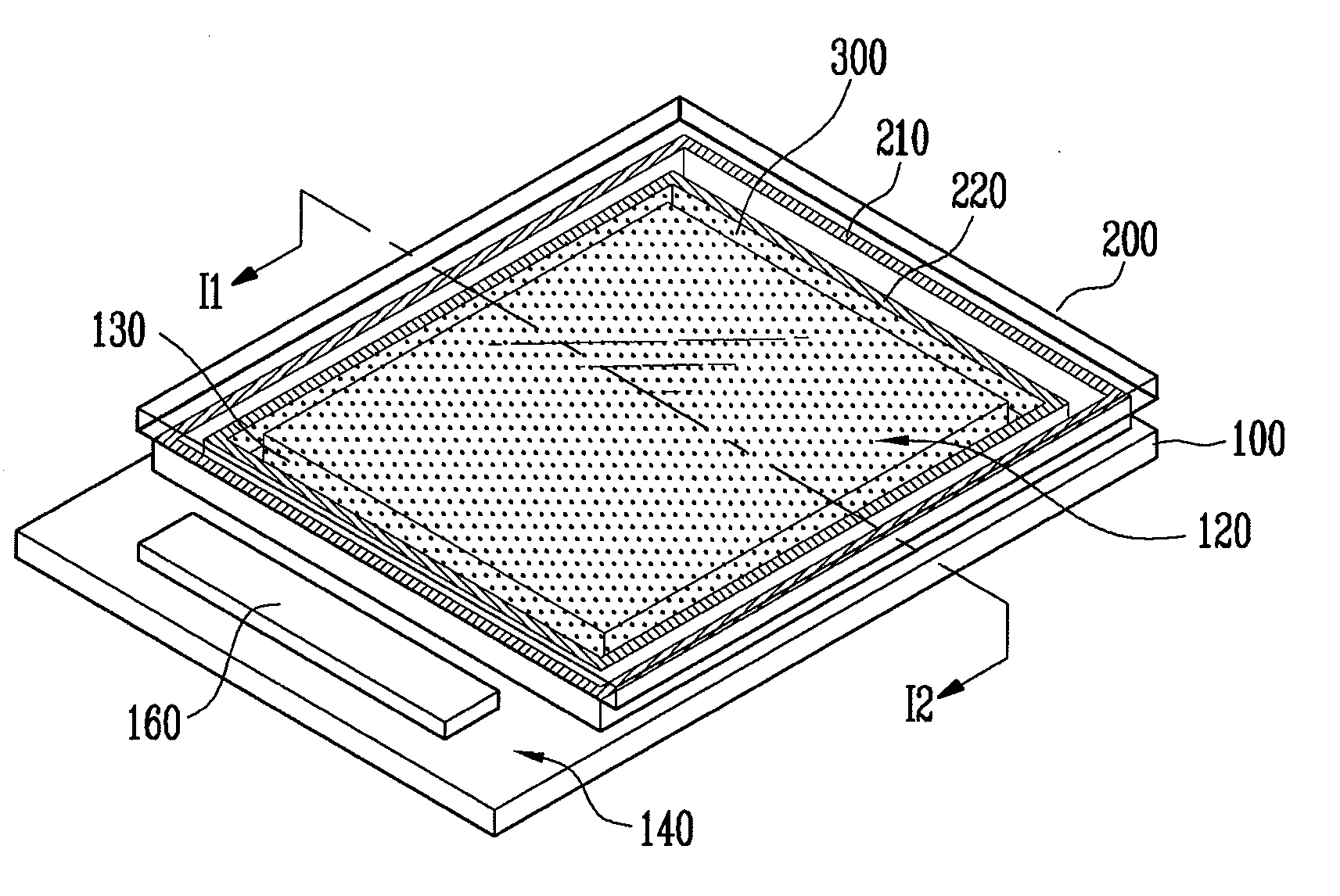

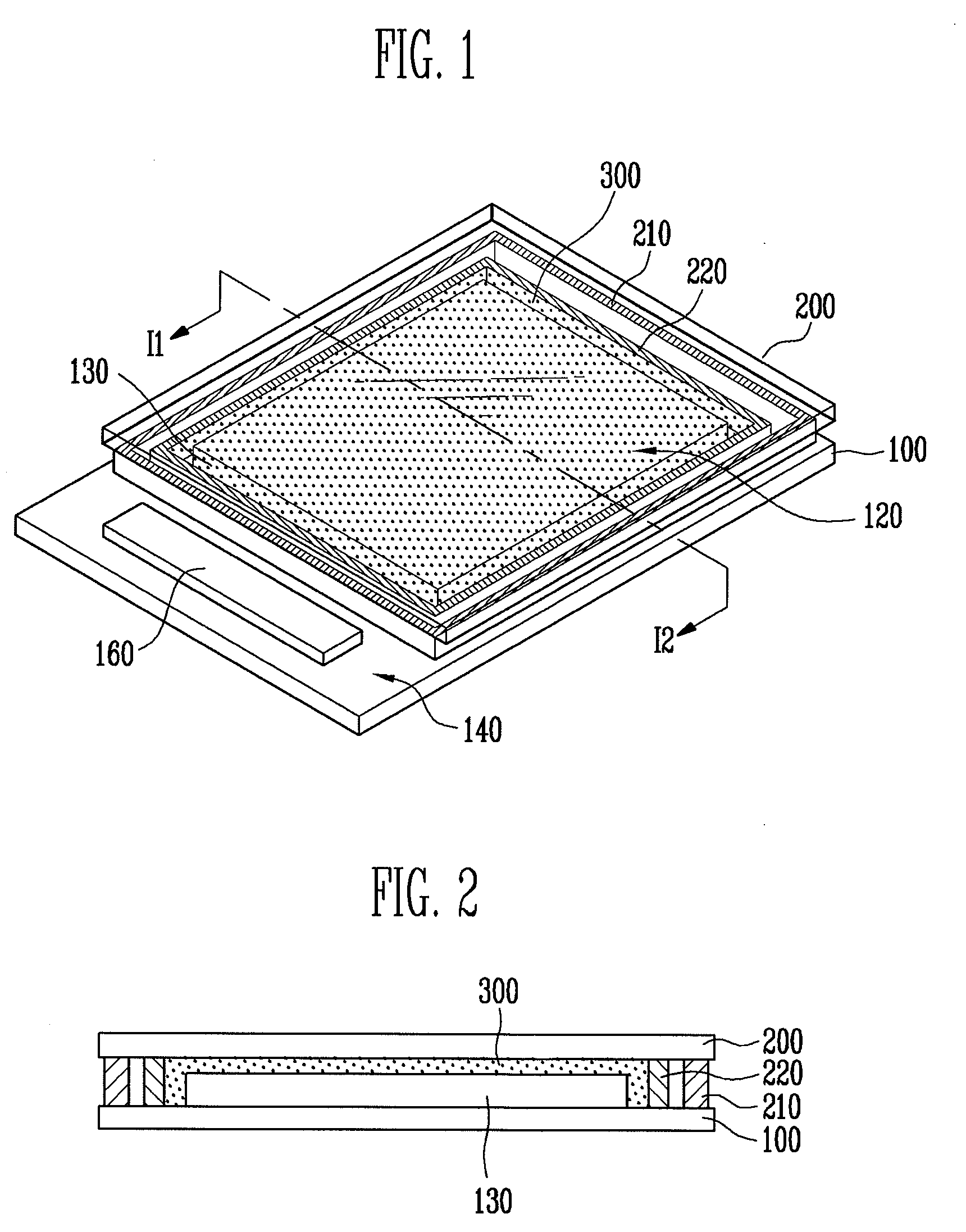

Light emitting display and method of manufacturing the same

ActiveUS20100045177A1Improve stress resistanceImprove stabilityDischarge tube luminescnet screensLamp detailsDisplay deviceLight emitting device

The present invention is to provide an organic light emitting display and a method of manufacturing the same. The light emitting display according to the present invention includes: a first substrate on which a plurality of light emitting devices having first electrodes, organic light emitting layers, and second electrodes are disposed; a second substrate disposed to face the first substrate; a dam member disposed between the first substrate and the second substrate to surround the plurality of light emitting devices; an inorganic sealing material disposed between the first substrate and the second substrate in an outer area of the dam member and attaching the first substrate to the second substrate; and a silicon filling material provided between the first substrate and the second substrate inward of the dam member to be in contact with the second electrodes.

Owner:SAMSUNG DISPLAY CO LTD

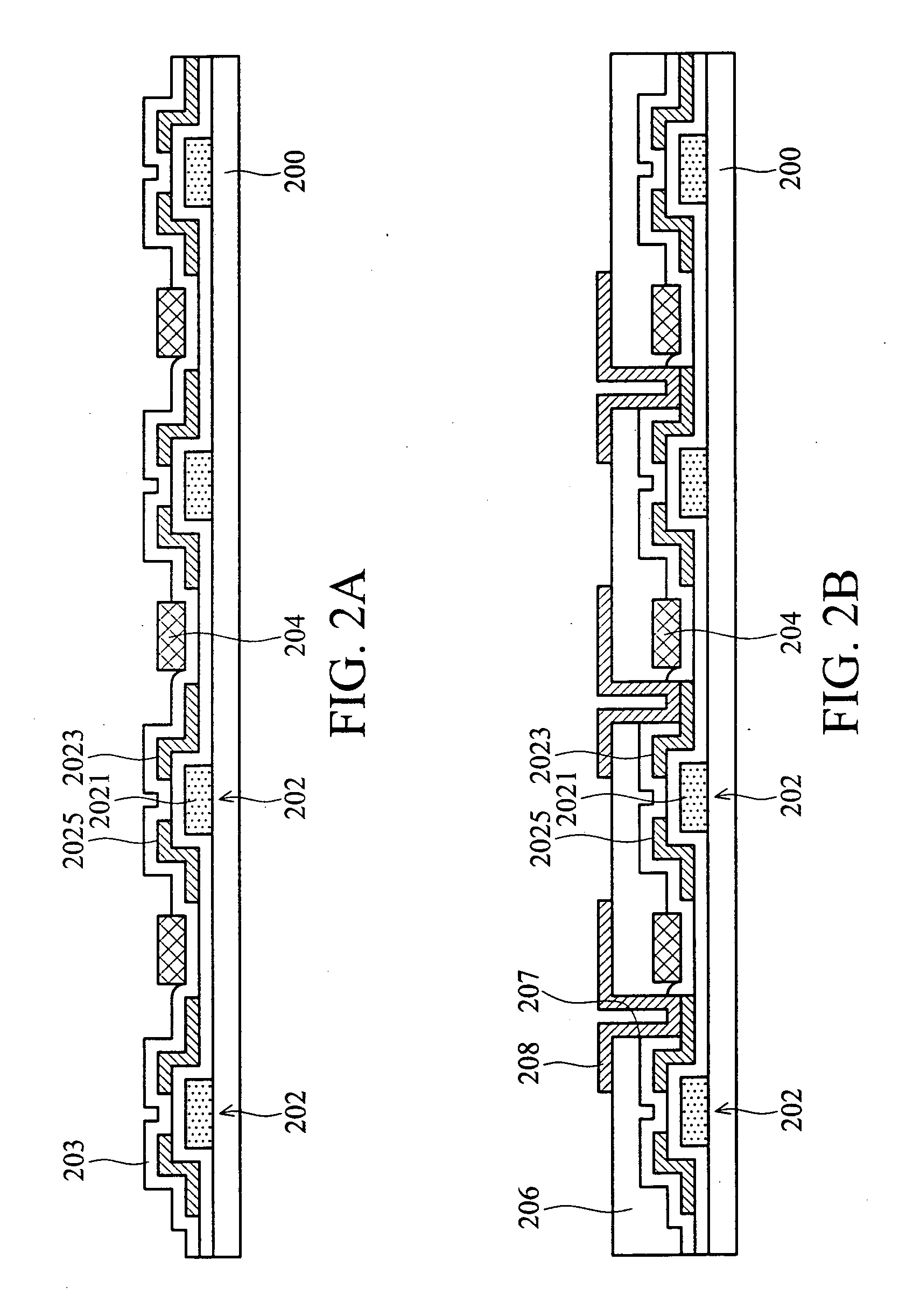

Organic light-emitting device and method for forming the same

ActiveUS20090174322A1Prevent moisture infiltrationEasy to operateDischarge tube luminescnet screensLamp detailsOrganic light emitting deviceOrganic layer

An organic light-emitting device and a method for forming the same are provided. The organic light-emitting device includes: a substrate including a pixel area and a peripheral circuit area; a passivation layer on the substrate, the passivation layer including a first part in the pixel area and a second part in the peripheral circuit area; a pixel definition layer defining a plurality of pixel openings corresponding to the pixel area of the substrate; a plurality of first electrodes in the pixel openings; an adhesion layer on the second part; an organic layer on the first electrodes; and a second electrode layer on the organic light emitting layer, wherein the second electrode extends to the peripheral circuit area to connect with the adhesion layer.

Owner:INNOLUX CORP

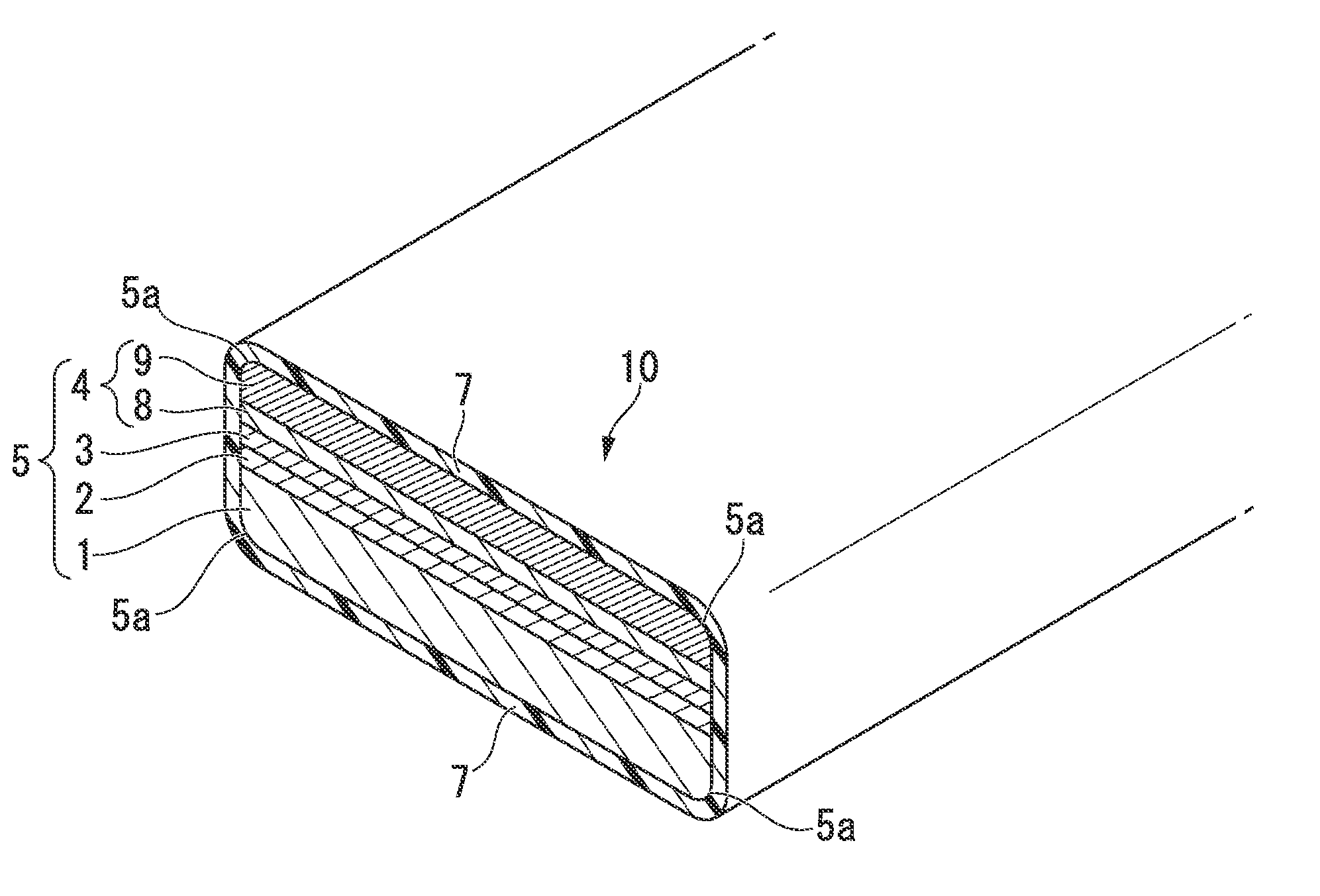

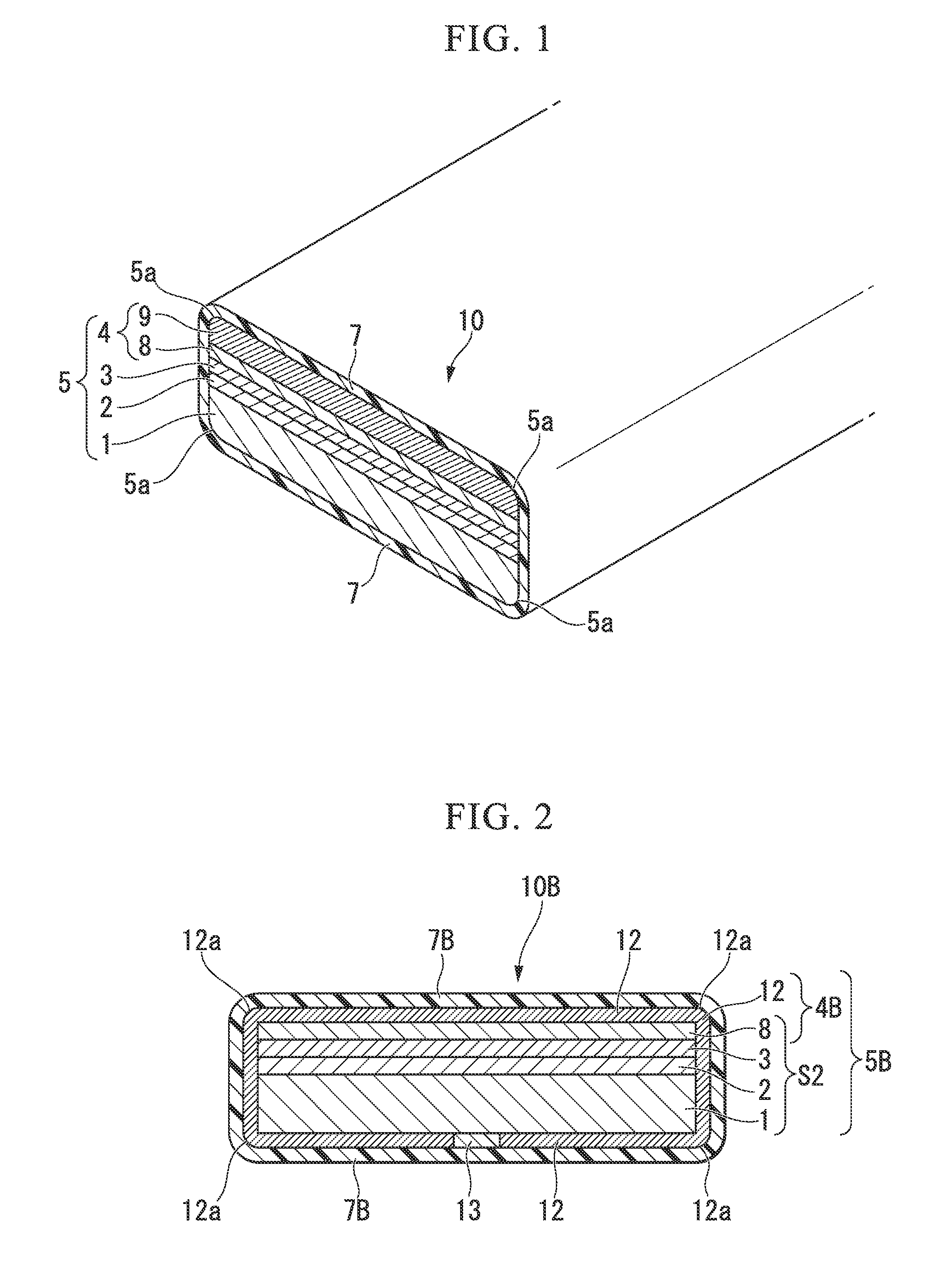

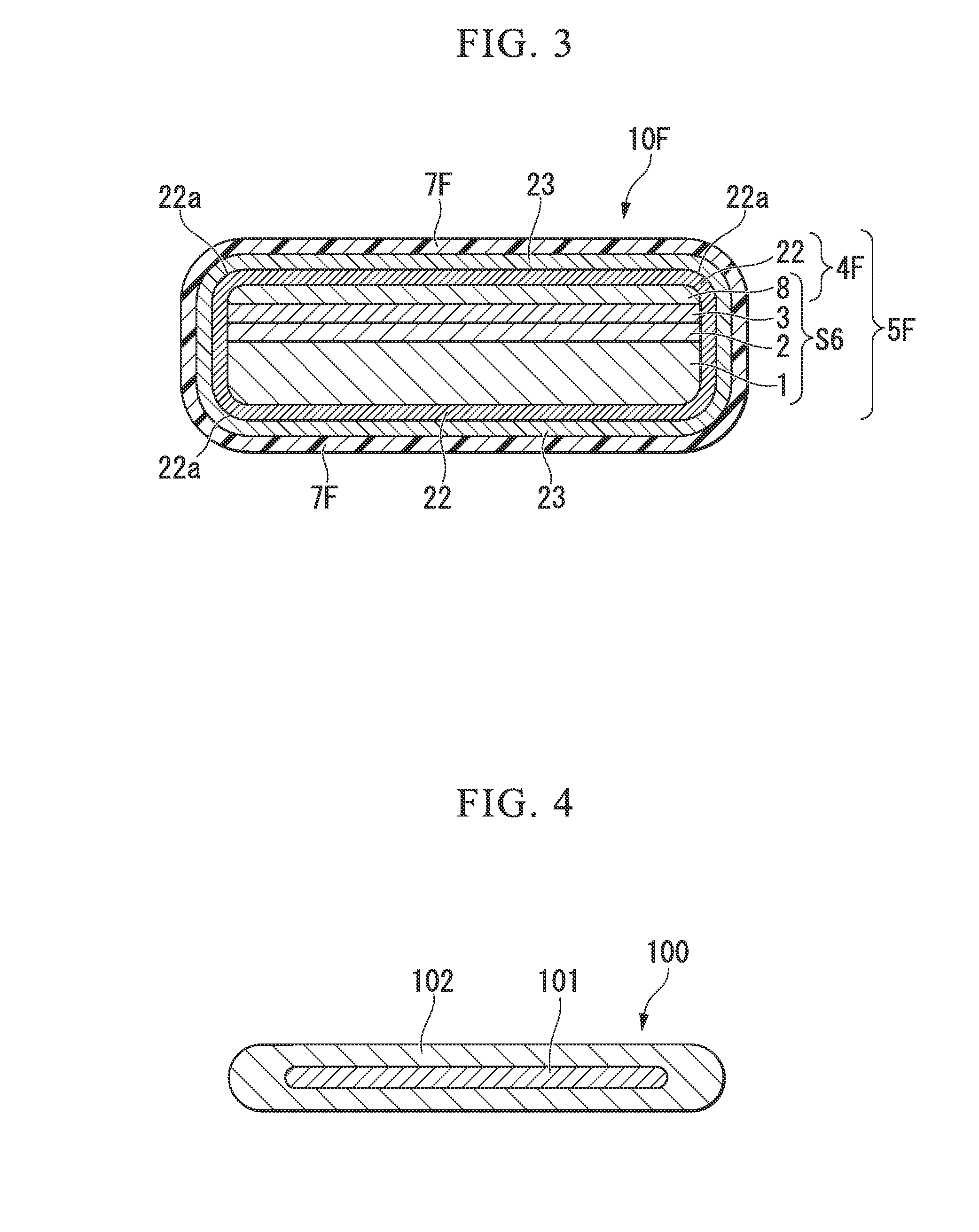

Superconducting wire and superconducting coil

ActiveUS20140357495A1High bonding strengthPrevent moisture infiltrationSuperconductors/hyperconductorsPlastic/resin/waxes insulatorsWire rodSuperconducting Coils

A superconductor wire includes: a superconducting laminate that includes: a substrate and an intermediate layer; a superconductor layer, and a metal stabilization layer which are laminated on the substrate; and an insulation coating layer that covers an outer surface of the superconducting laminate and is formed by baking a resin material. Further, a maximum height Rz of at least a part of the outer surface of the superconducting laminate covered with the insulation coating layer is 890 nm or less.

Owner:THE FUJIKURA CABLE WORKS LTD

Light emitting display and method of manufacturing the same

ActiveUS8258696B2Securing of durabilitySecuring reliabilityIncadescent screens/filtersDischarge tube luminescnet screensDisplay deviceLight-emitting diode

The present invention is to provide an organic light emitting display and a method of manufacturing the same. The light emitting display according to the present invention includes: a first substrate on which a plurality of light emitting devices having first electrodes, organic light emitting layers, and second electrodes are disposed; a second substrate disposed to face the first substrate; a dam member disposed between the first substrate and the second substrate to surround the plurality of light emitting devices; an inorganic sealing material disposed between the first substrate and the second substrate in an outer area of the dam member and attaching the first substrate to the second substrate; and a silicon filling material provided between the first substrate and the second substrate inward of the dam member to be in contact with the second electrodes.

Owner:SAMSUNG DISPLAY CO LTD

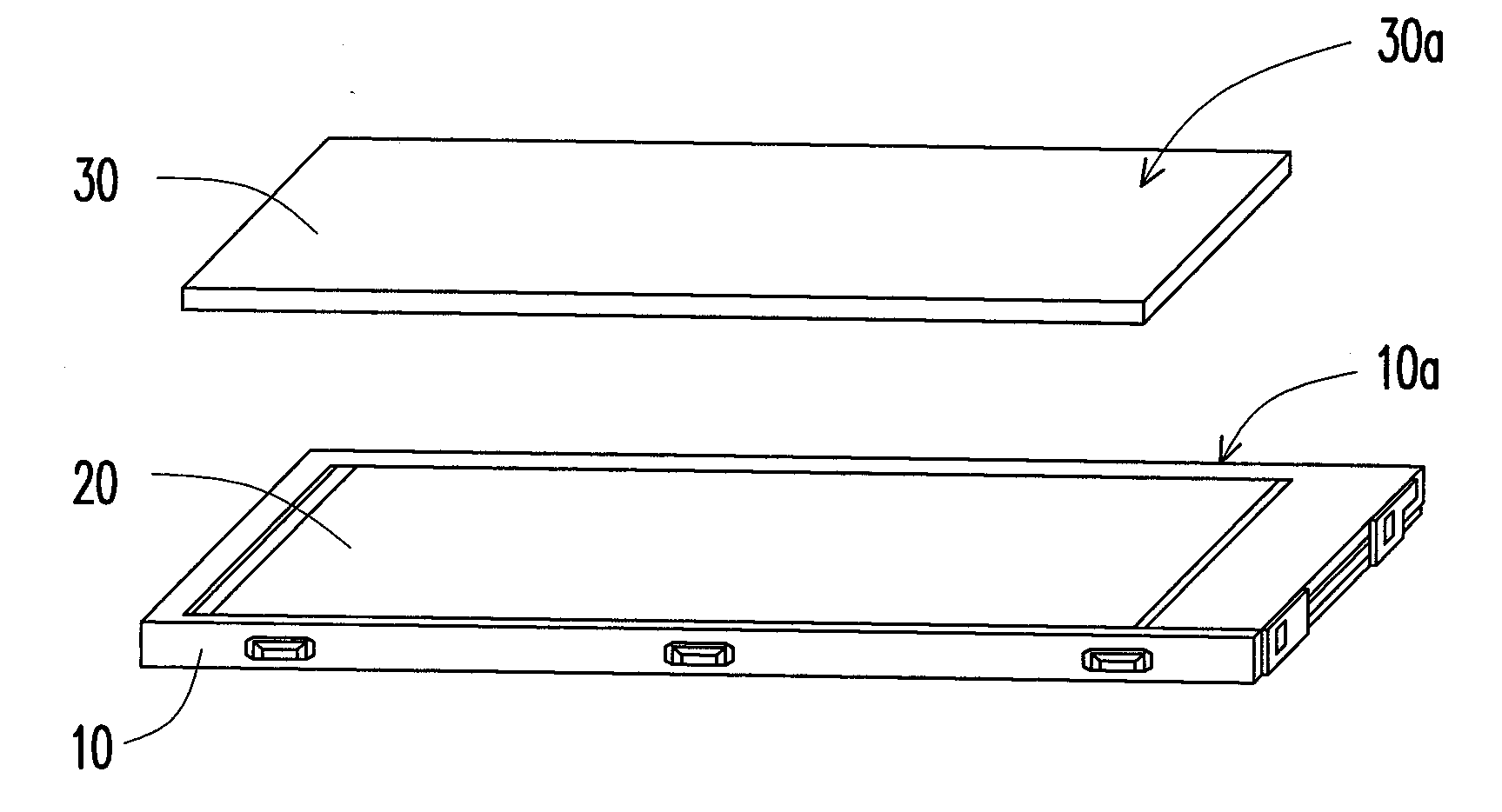

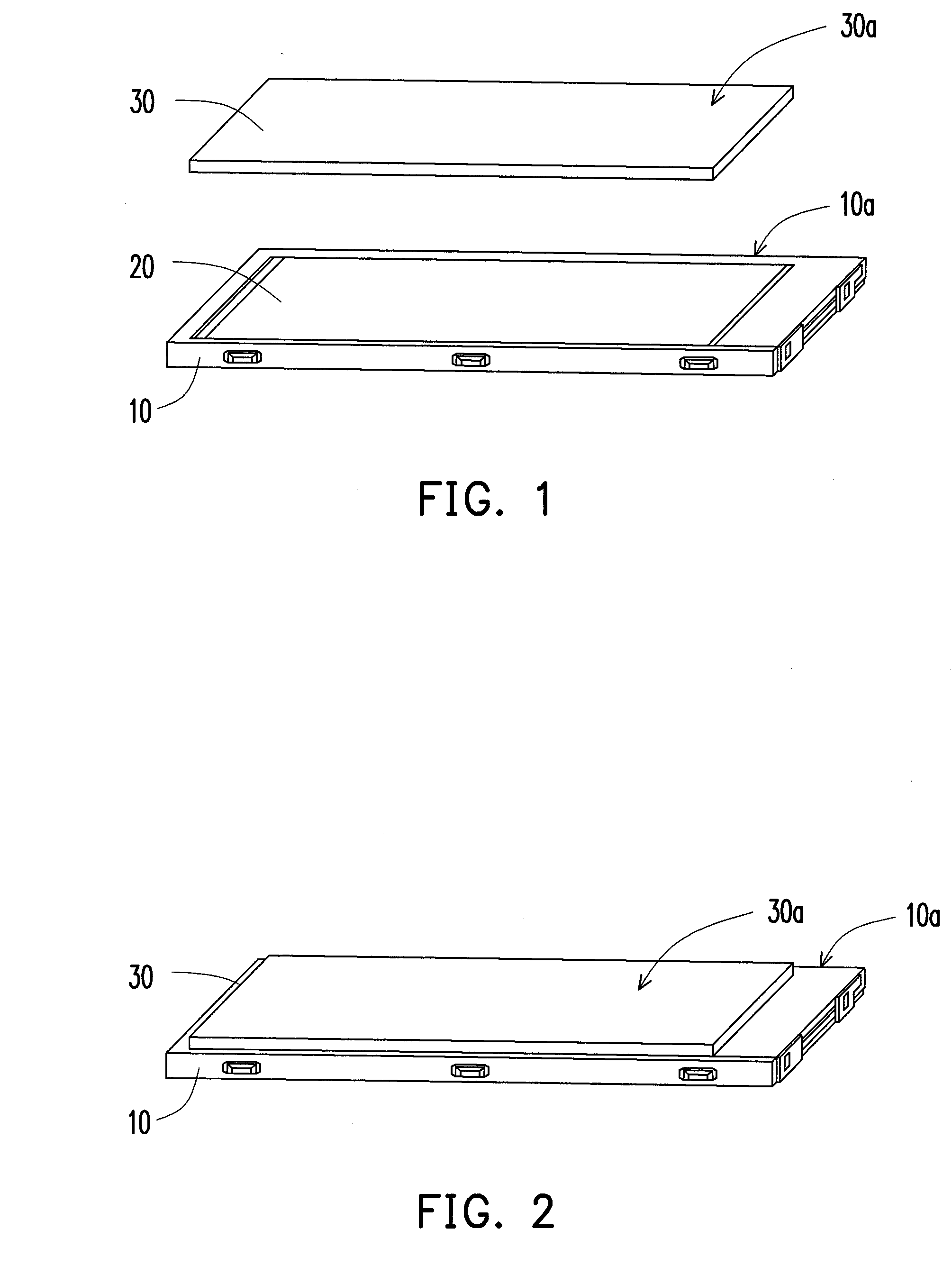

Touch panel

InactiveUS20120062478A1Thin thicknessPrevent moisture infiltrationInput/output processes for data processingDisplay deviceComputer science

Disclosed herein is a touch panel. The touch panel according to the present invention includes a first adhesive layer bonding an edge of an image display device to an edge of a window so that a predetermined space is partitioned between the image display device and the window; a first transparent substrate provided in the predetermined space and having a first transparent electrode formed on one surface thereof, a second transparent substrate provided in the predetermined space and having a second transparent electrode formed on one surface thereof, and a second adhesive layer bonding an edge of the first transparent electrode to an edge of the second transparent electrode so that the first transparent electrode faces the second transparent electrode and an air gap is provided between the first transparent electrode and the second transparent electrode.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

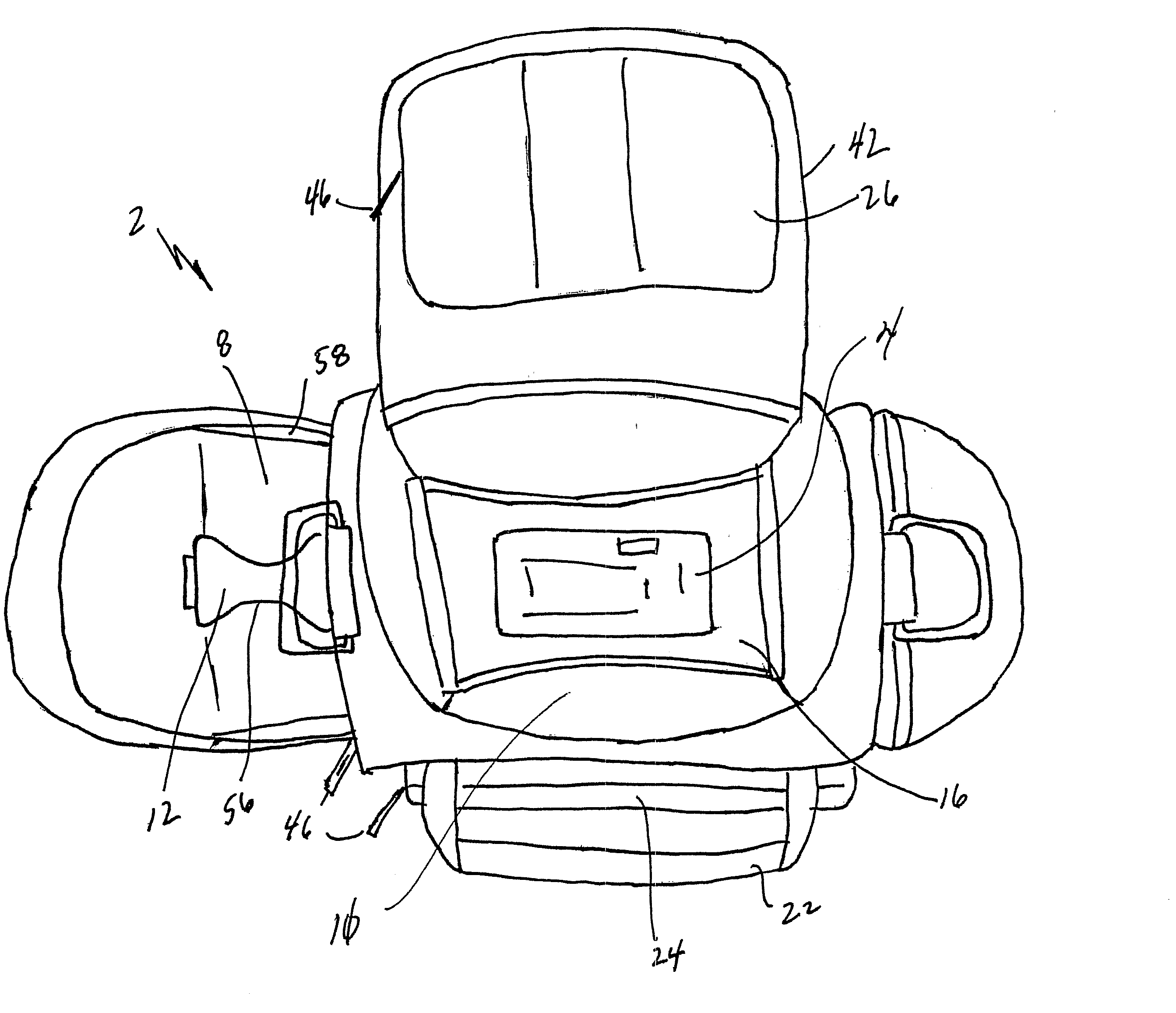

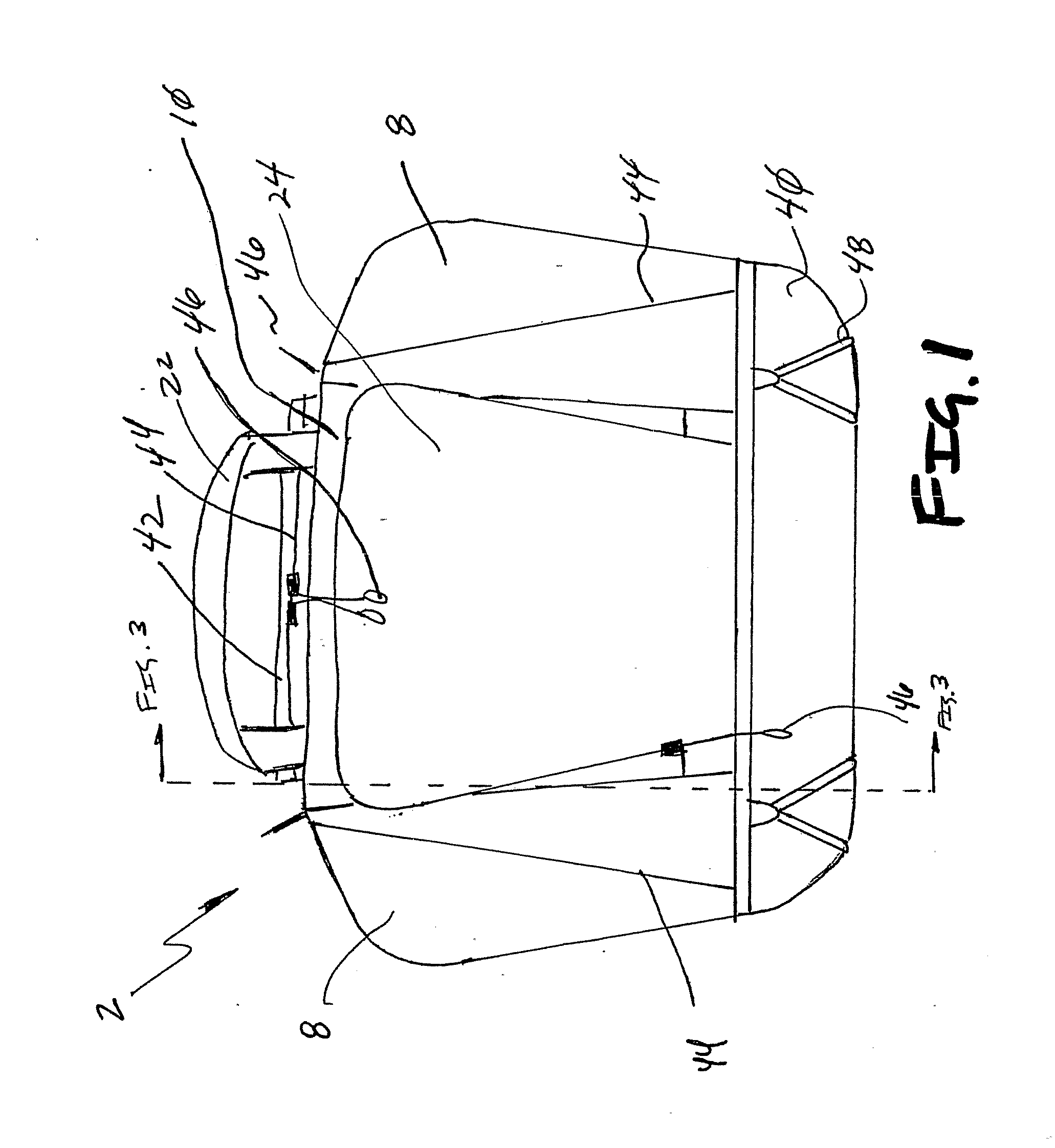

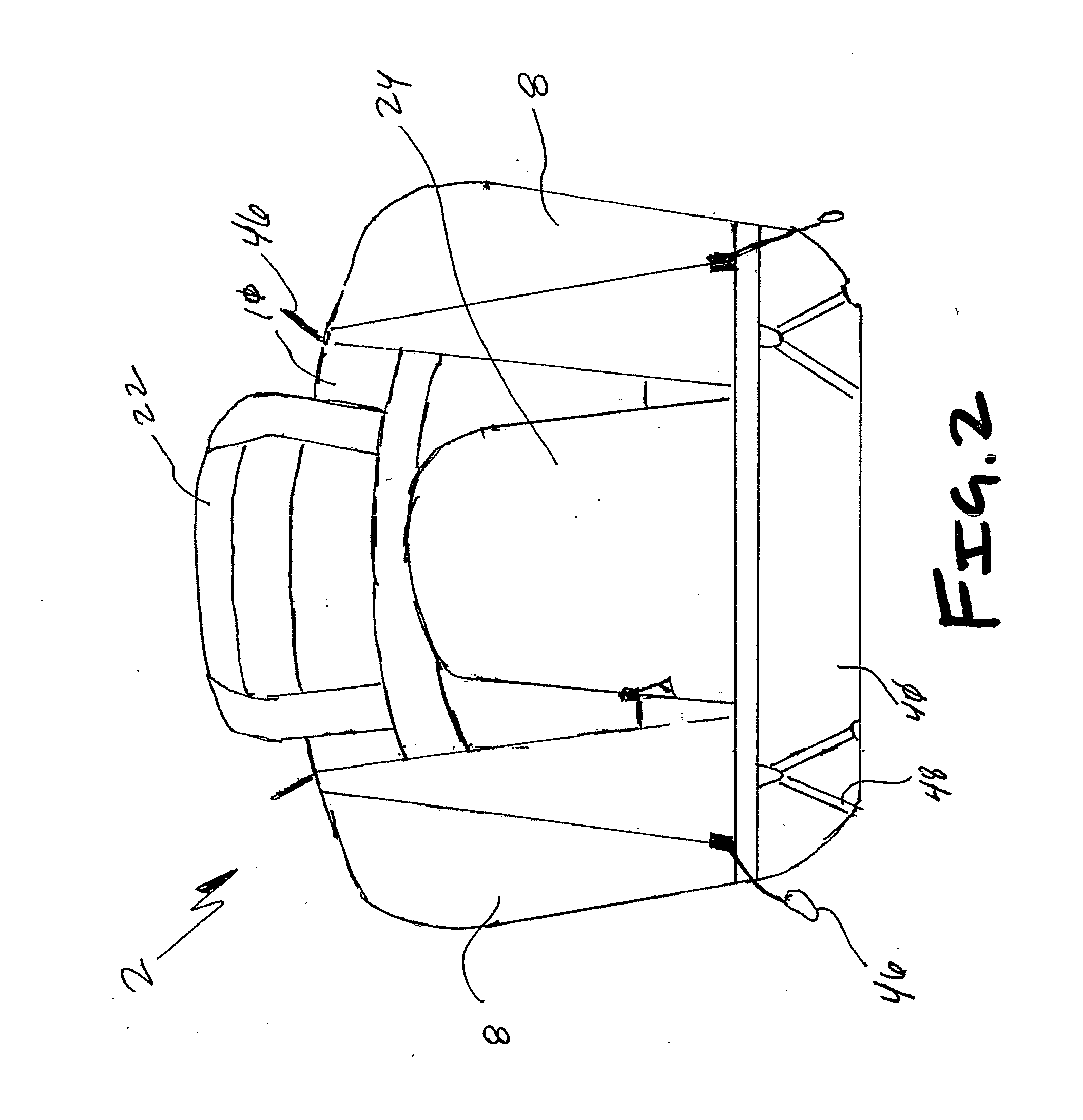

Camera Case With Suspension System

InactiveUS20060283737A1Easy to carryDurable and resistant to elementOther accessoriesContainer/bottle contructionEmbedded systemElectronics

A storage case for an electronics device is provided that includes a main storage compartment with a selectively adjustable suspension system that selectively interconnects to sidewalls of the main storage compartment, thus providing the user with the ability to customize the storage area within the main storage compartment. The suspension system also is resiliently deflectable to help dissipate shock loads resulting from drops, for example. The storage case in one embodiment is designed for cameras and may also include a plurality of lens storage compartments with selectively adjustable lens dividers, storage pockets, and storage compartments.

Owner:CASE LOGIC

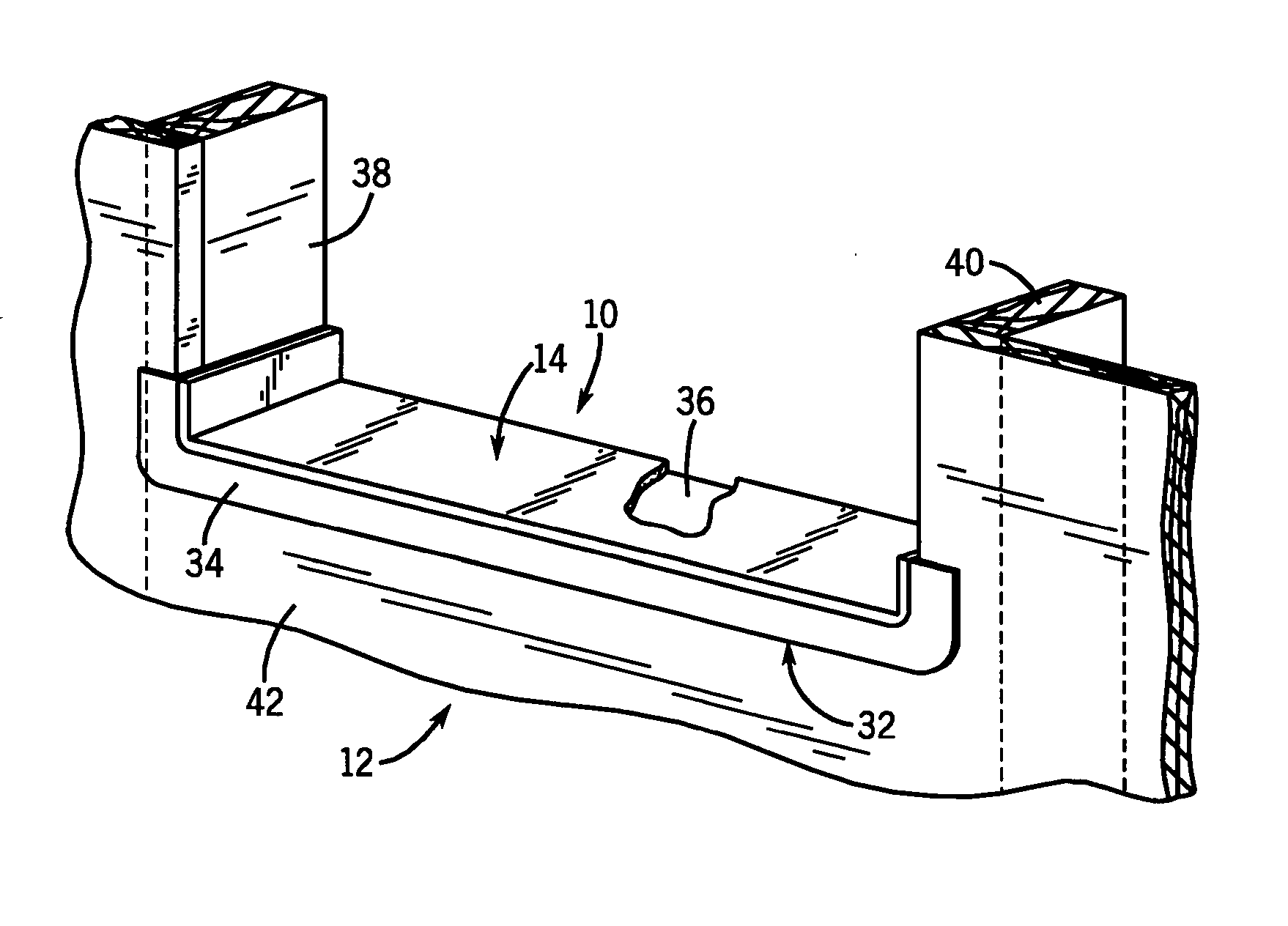

Moisture barrier underlayment with intermediate layer to accommodate expansion and contraction

A sound and / or moisture barrier underlayment suited for use on a roof or floor surface to provide a substantially flat and level surface, comprises at least first and second strips of insulation membranes (10) laid down one next to the other in a coplanar relationship. The first and second strips (24, 26) have a thickness W1. An overlap joint (28) is provided between the first and second strips (24, 26). The overlap joint (28) has a thickness W2 substantially equal to or less than W1 to provide a free-bump transition between the first and second strips (24, 26) while preventing straight-through infiltration.

Owner:PLANTE REJEAN

Organic light emitting display device

ActiveUS8357929B2High mechanical reliabilityPrevent moisture infiltrationElectroluminescent light sourcesSolid-state devicesDisplay deviceOptoelectronics

An organic light emitting display device, including: a first substrate on which a plurality of light emitting elements are formed; a second substrate that is disposed to be opposed to the first substrate; a primary dam member that is provided between the first substrate and the second substrate in order to surround the plurality of light emitting elements; a filler that is filled between the first substrate and the second substrate and in a first region defined by the primary dam member, an auxiliary dam member that is between the first substrate and the second substrate and in a second region outside the first region, and is made of porous material; and an inorganic sealant that is provided between the first substrate and the second substrate and in a third region outside the first region and the second region, and is jointed to the first substrate and the second substrate.

Owner:SAMSUNG DISPLAY CO LTD

Organic electroluminescent display with improved barrier structure

ActiveUS7928646B2Reduce oxidationIncreasing the thicknessDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceProtection layer

Owner:INNOLUX CORP

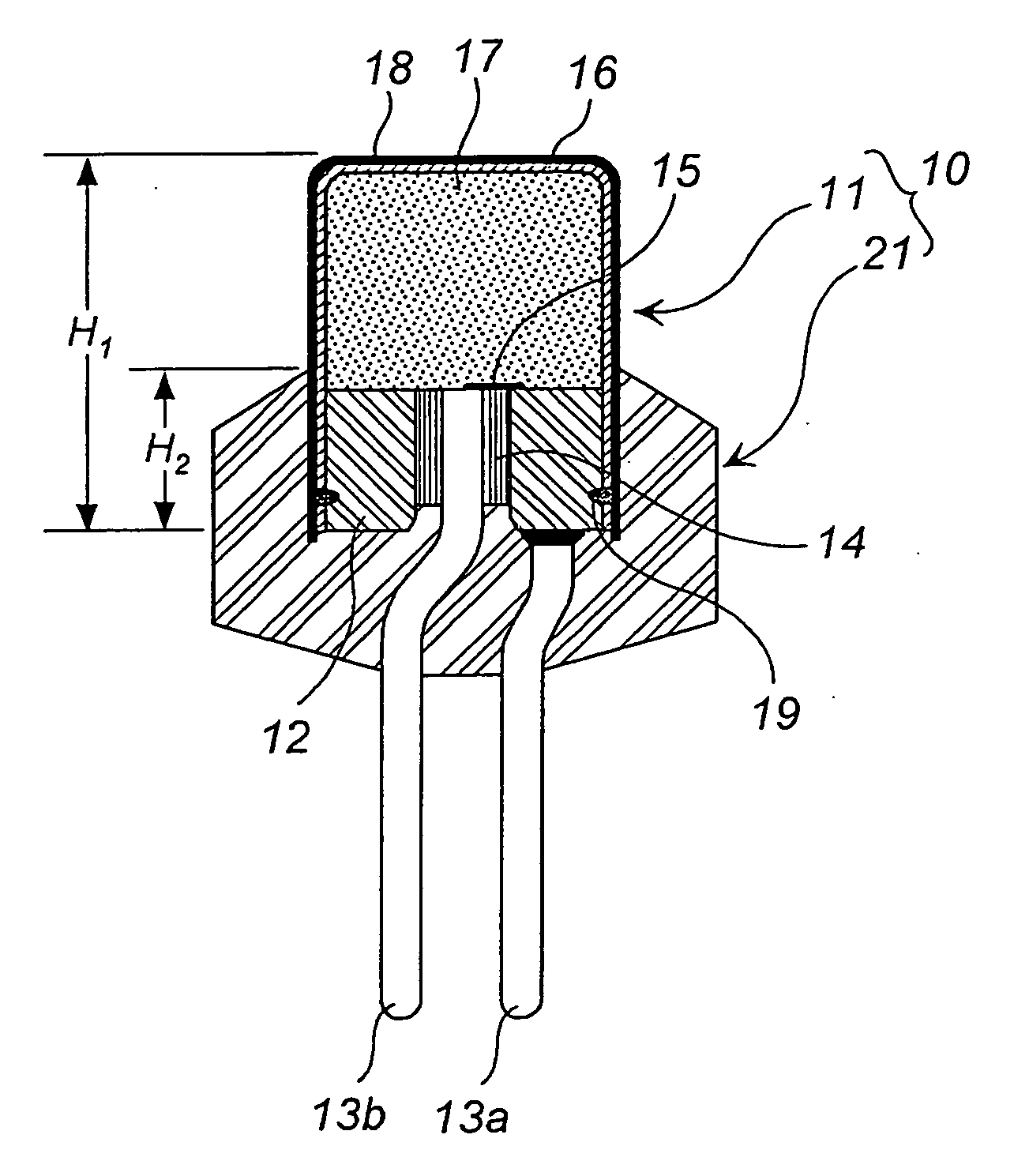

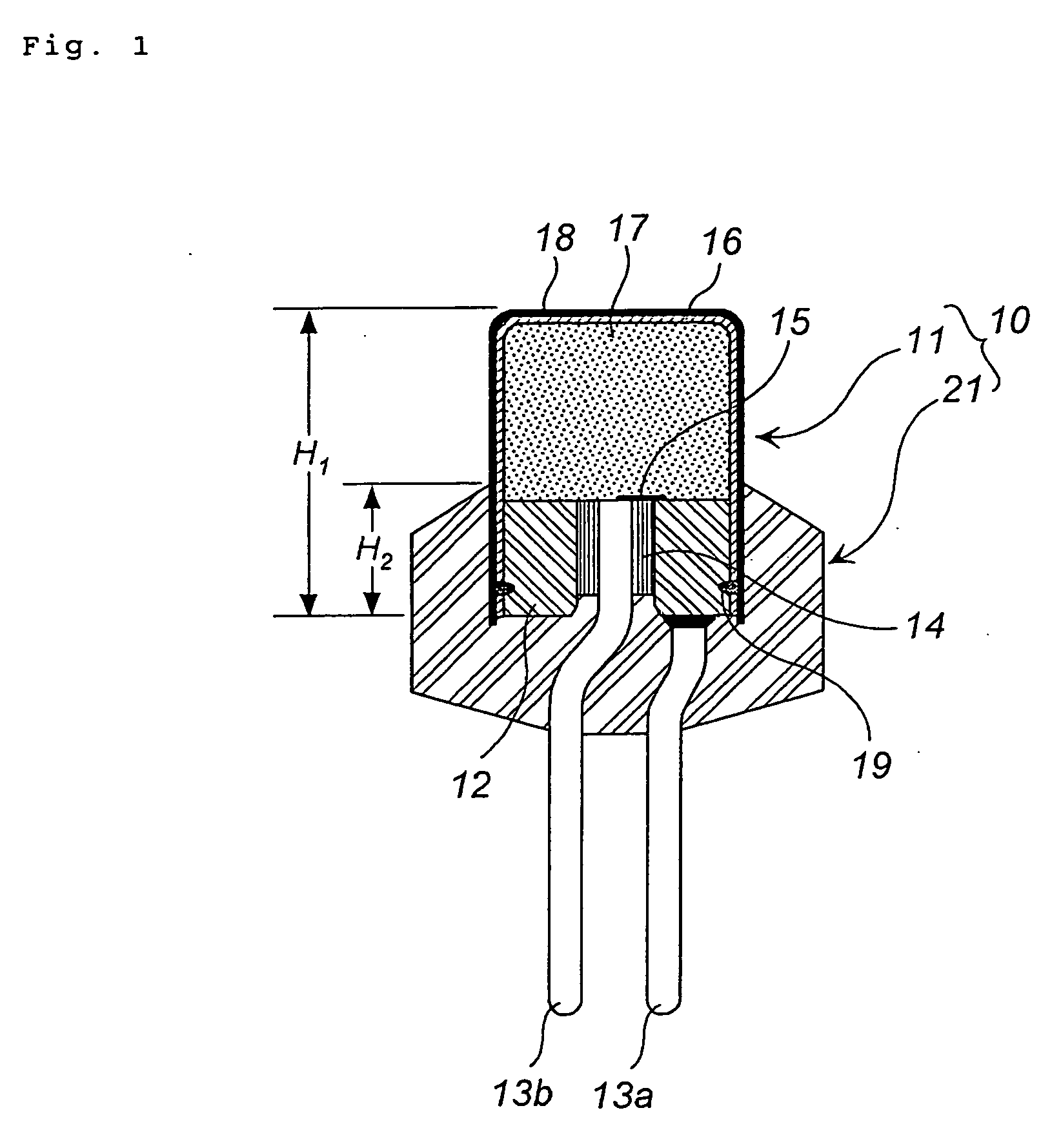

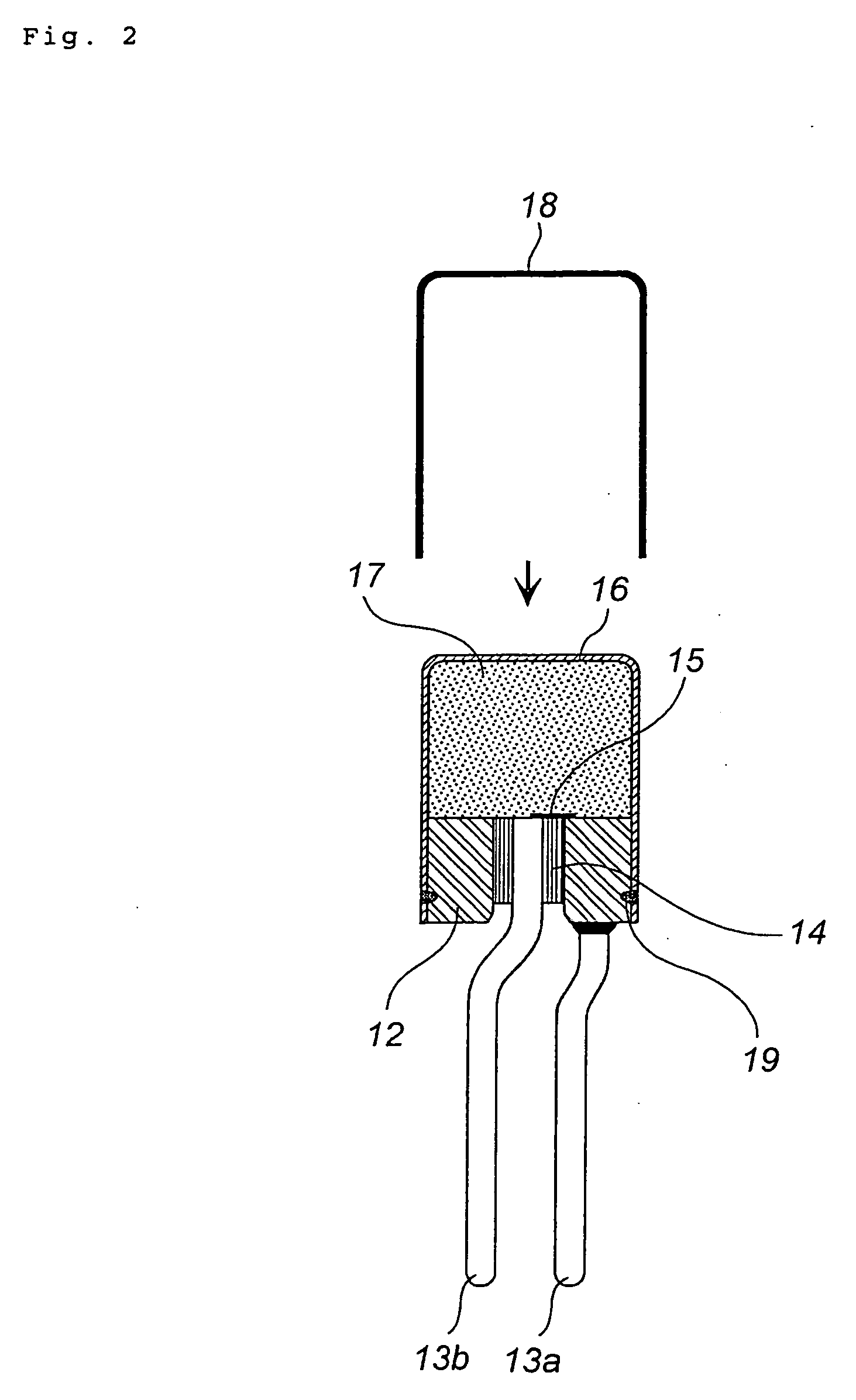

Igniter assembly

InactiveUS20060017269A1Prevent moisture infiltrationGuaranteed long-term operationPedestrian/occupant safety arrangementEngineeringMoisture

The present invention provides an igniter assembly which is capable of preventing the infiltration of moisture, thus enabling long-term operational reliability. The periphery of a metallic cup 16 charged with an ignition charge 17 is covered by a resin sheet 18. A lower end portion of the resin sheet 18 and a resin molded body 21 are integrated at a contact portion therebetween to prevent the infiltration of moisture. The resin sheet 18 and resin molded body 21 integrated during the manufacturing process by cooling and hardening the resin molded body 21 and resin sheet 18 in a fused state.

Owner:DAICEL CHEM IND LTD

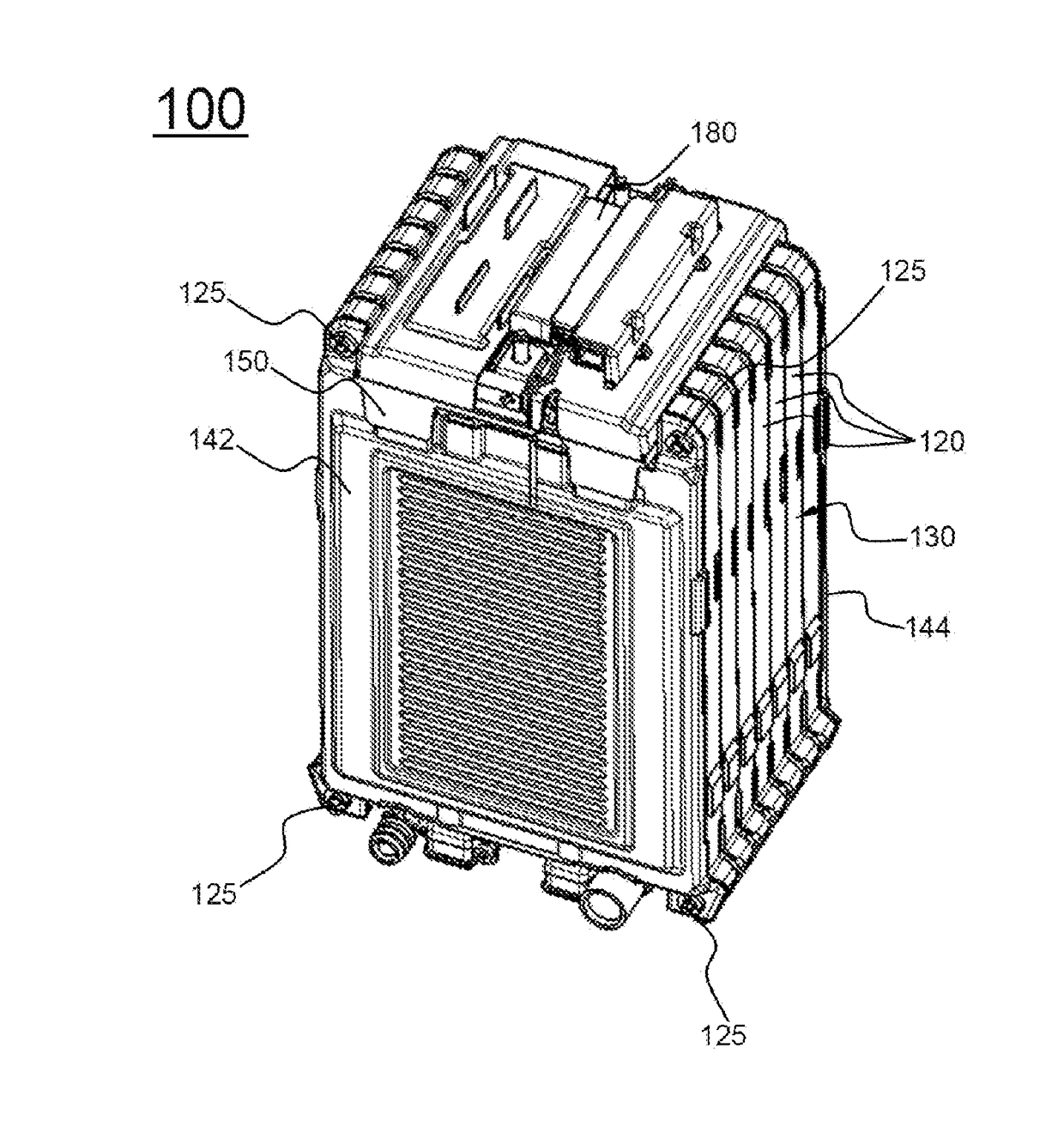

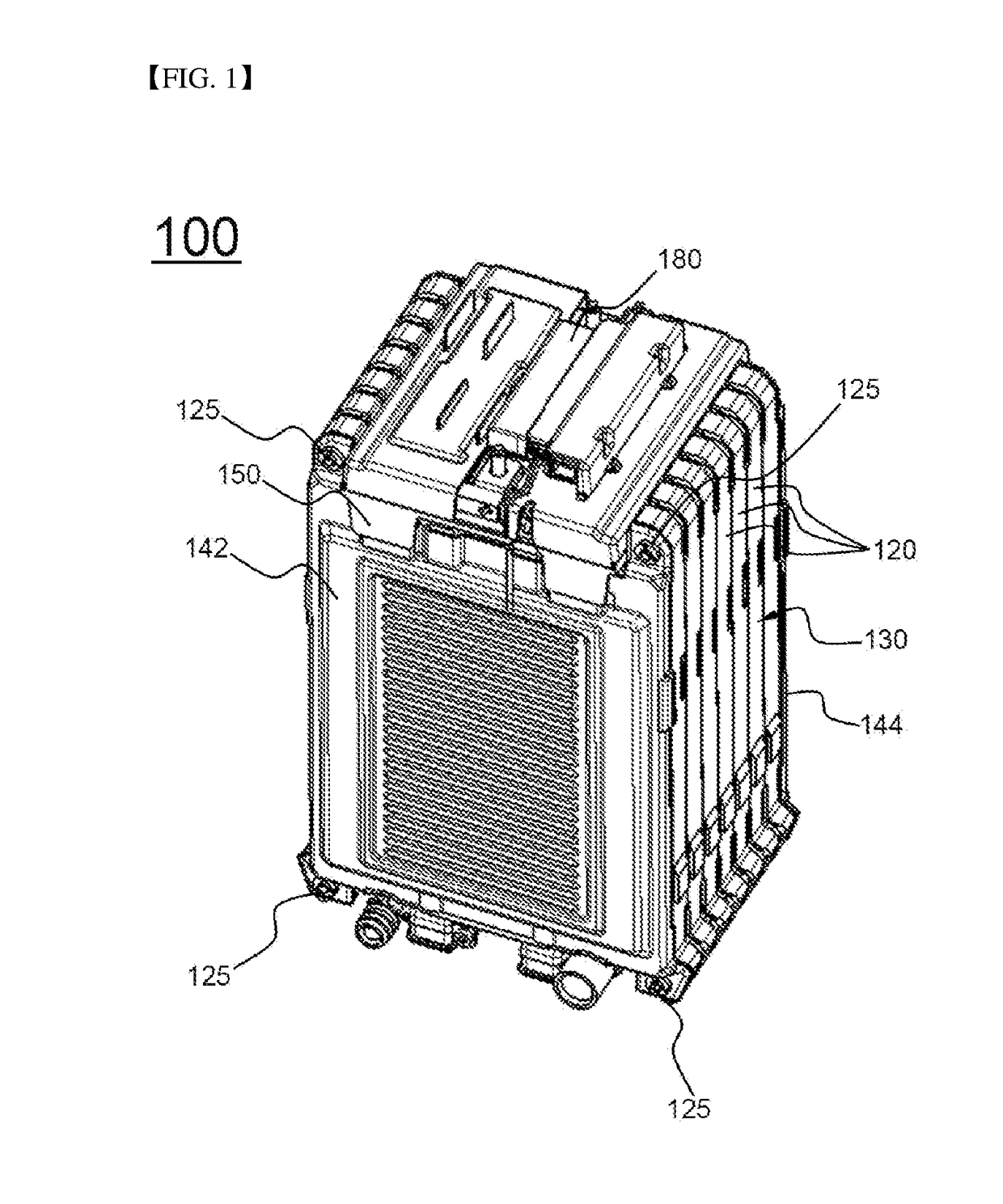

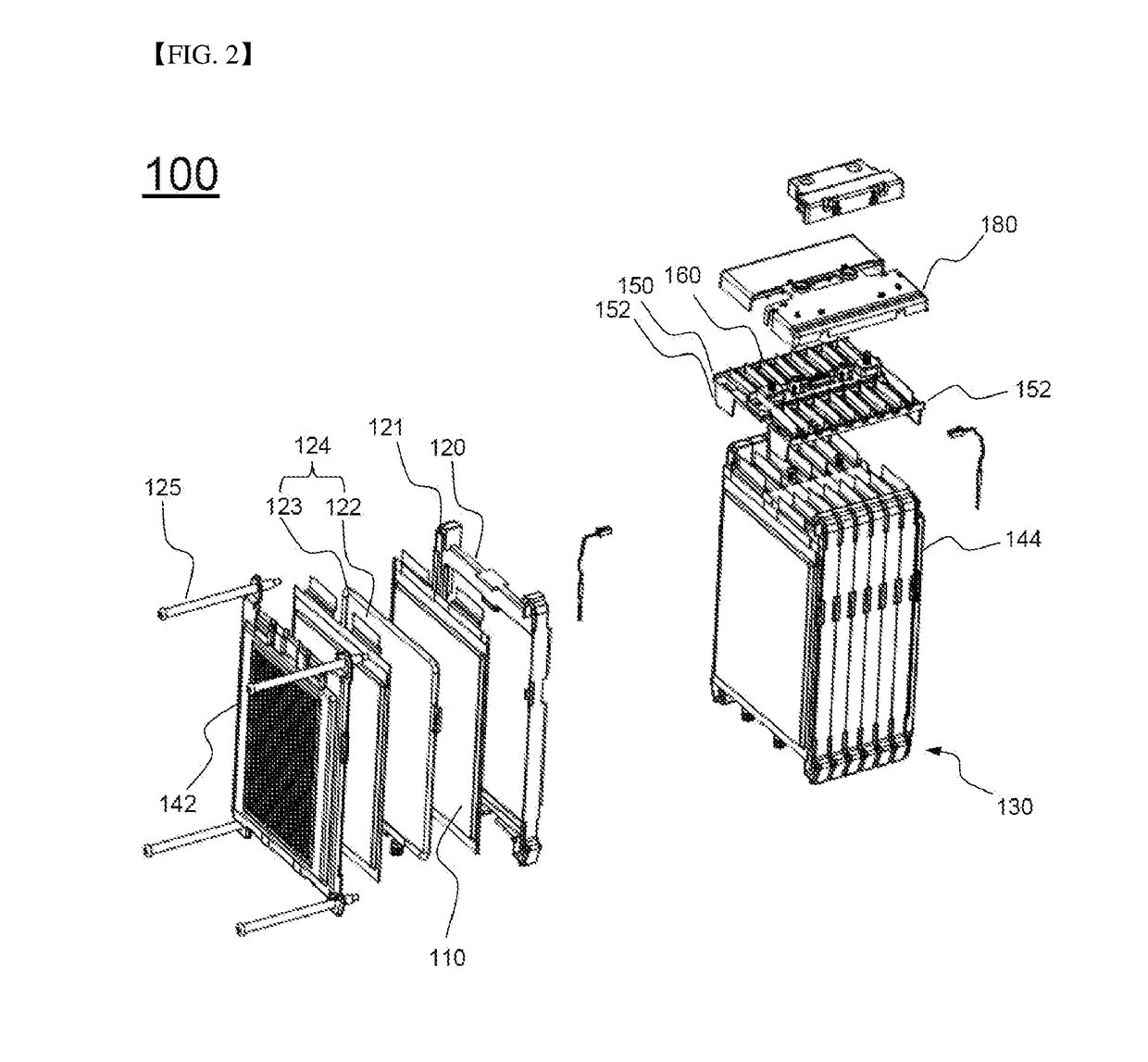

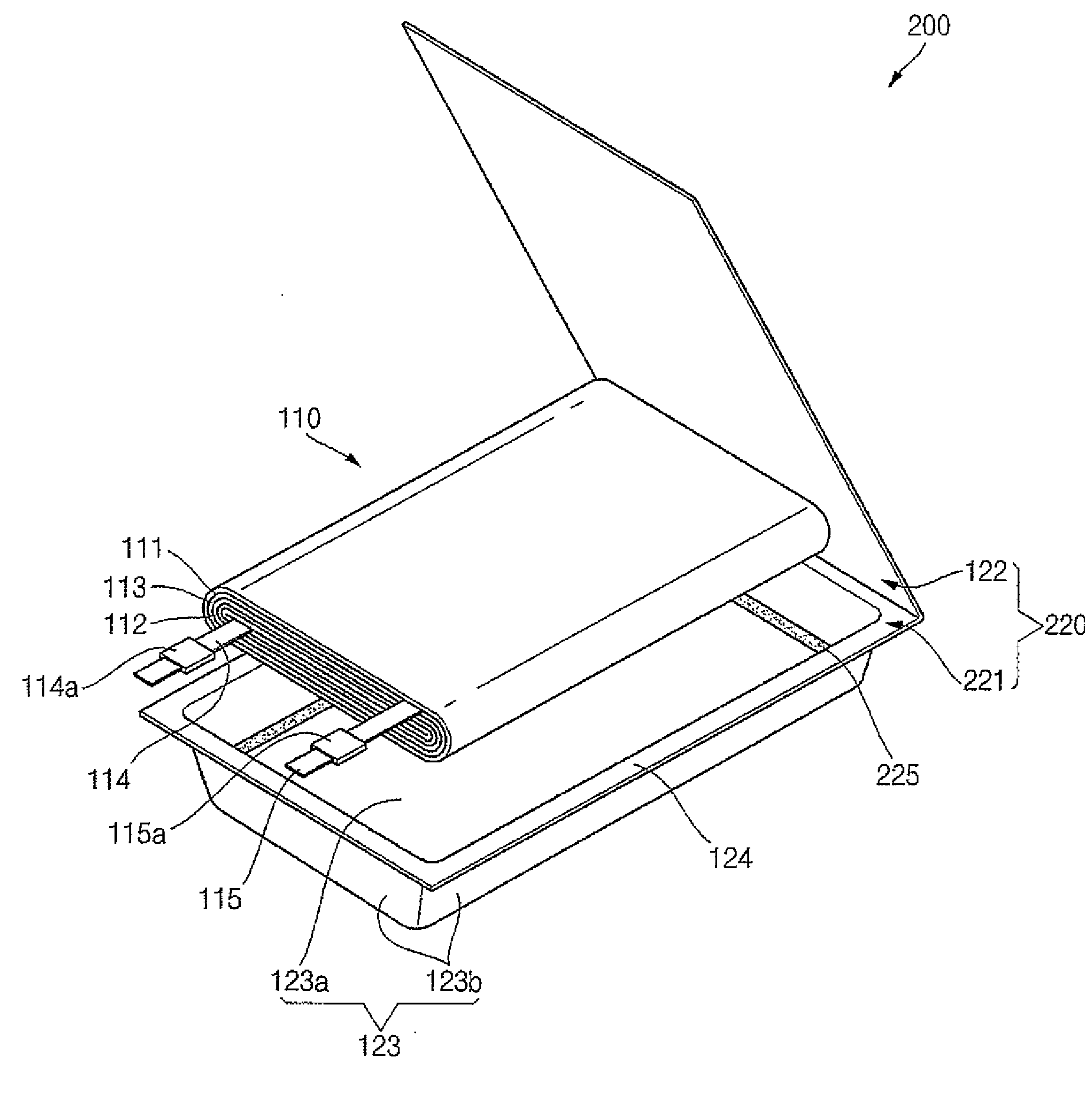

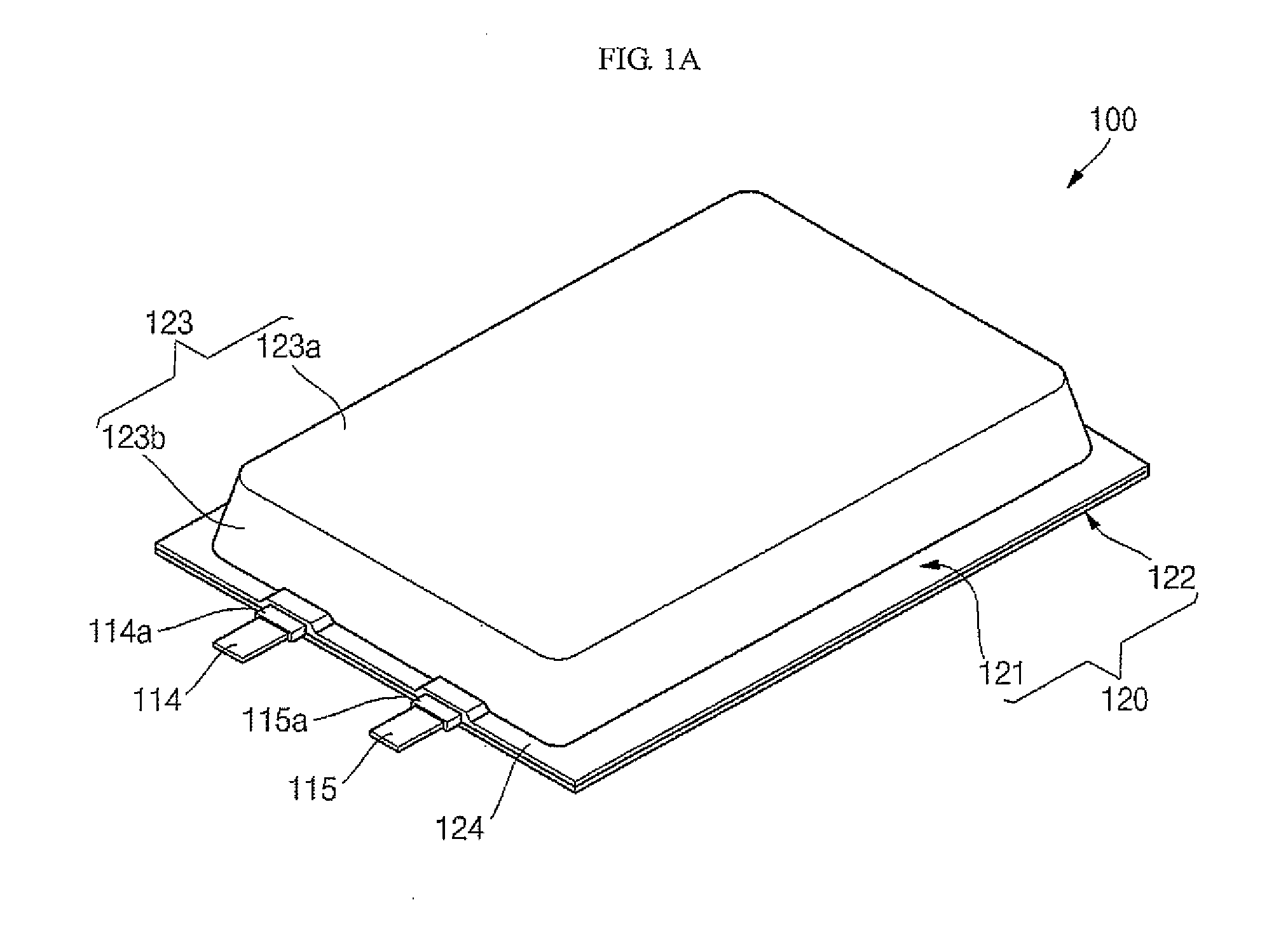

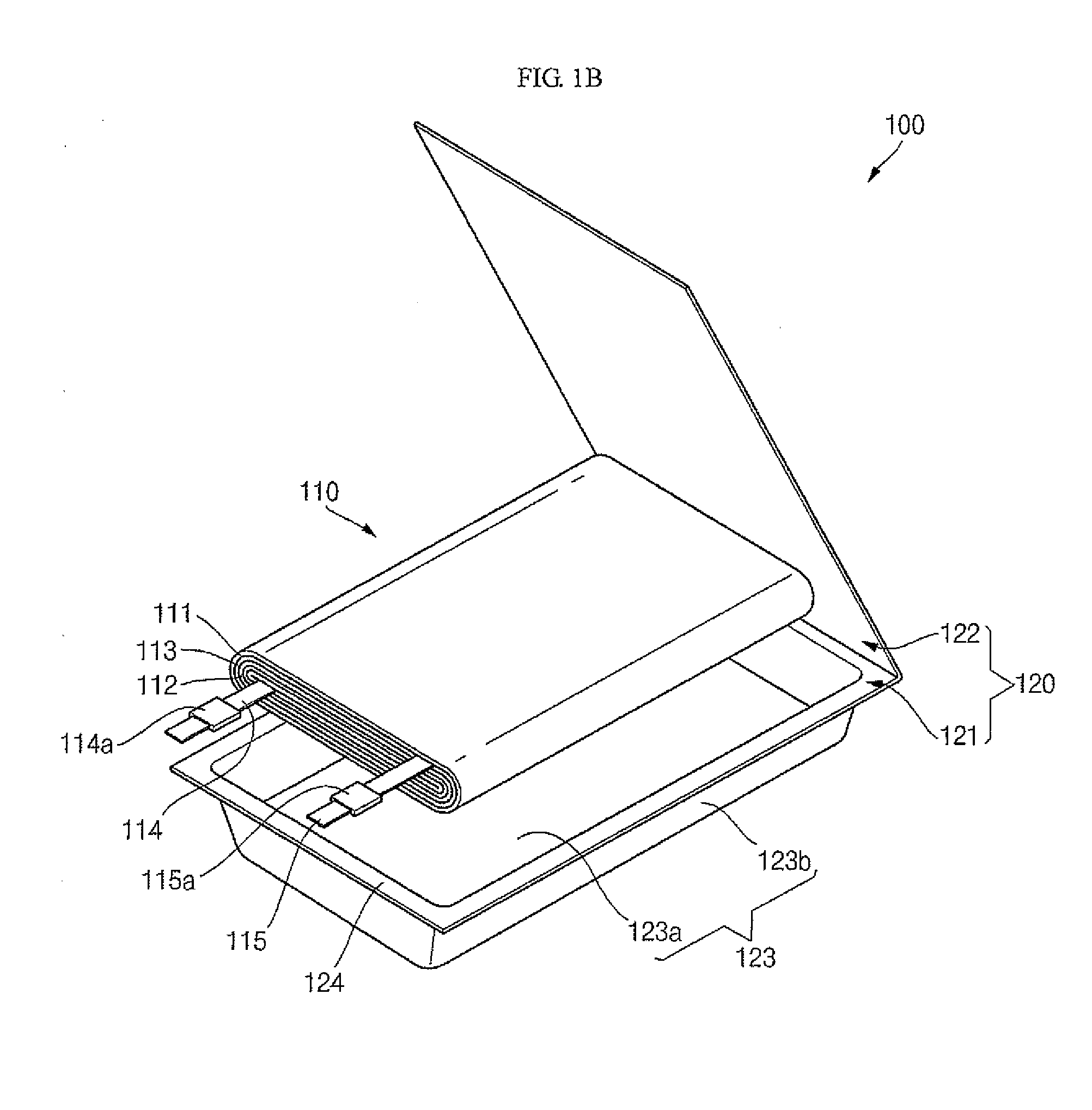

Battery module having molding part for insulating

ActiveUS20170125752A1Avoid it happening againReduce defective rateBatteries circuit arrangementsCells structural combinationEngineeringBattery cell

Disclosed herein is a battery module including a battery cell assembly constituted by at least two battery cells, a front plate and a rear plate fixed to the battery cell assembly such that the front plate and the rear plate cover outermost ones of the battery cells, an electrically insulative cover member mounted at an upper end of the battery cell assembly, the electrically insulative cover member being provided with through holes, through which electrode terminals of the battery cells extend, a PCB mounted on a bottom of the cover member, a plurality of conductive connection parts arranged on the cover member, the conductive connection parts being connected to the electrode terminals of the battery cells and the PCB, and a lower molding part located on the PCB at the bottom of the cover member, the lower molding part covering the connection between the PCB and the conductive connection parts.

Owner:LG ENERGY SOLUTION LTD

Pouch battery and manufacturing method thereof

ActiveUS20150024263A1Improve battery safetySolve the blockageFinal product manufacturePrimary cellsEngineeringElectrode

Owner:SAMSUNG SDI CO LTD

Organic el device and method of producing the device

ActiveUS7994707B2Block compoundPrevent infiltrationDischarge tube luminescnet screensLamp detailsSimple Organic CompoundsHydrogen

Provided is an organic EL device including a substrate, a lower electrode, an organic compound layer containing one of an alkali metal and an alkali metal compound, an upper electrode formed of an oxide film, and passivation layers for covering the lower electrode, the organic compound layer, and the upper electrode, the lower electrode, the organic compound layer, the upper electrode, and the passivation layers being stacked in the stated order on the substrate, in which the passivation layers include a first passivation layer formed on the upper electrode, which contains silicon as a main component, and which is free of hydrogen and a second passivation layer formed on the first passivation layer which contains silicon as a main component and hydrogen.

Owner:CANON KK

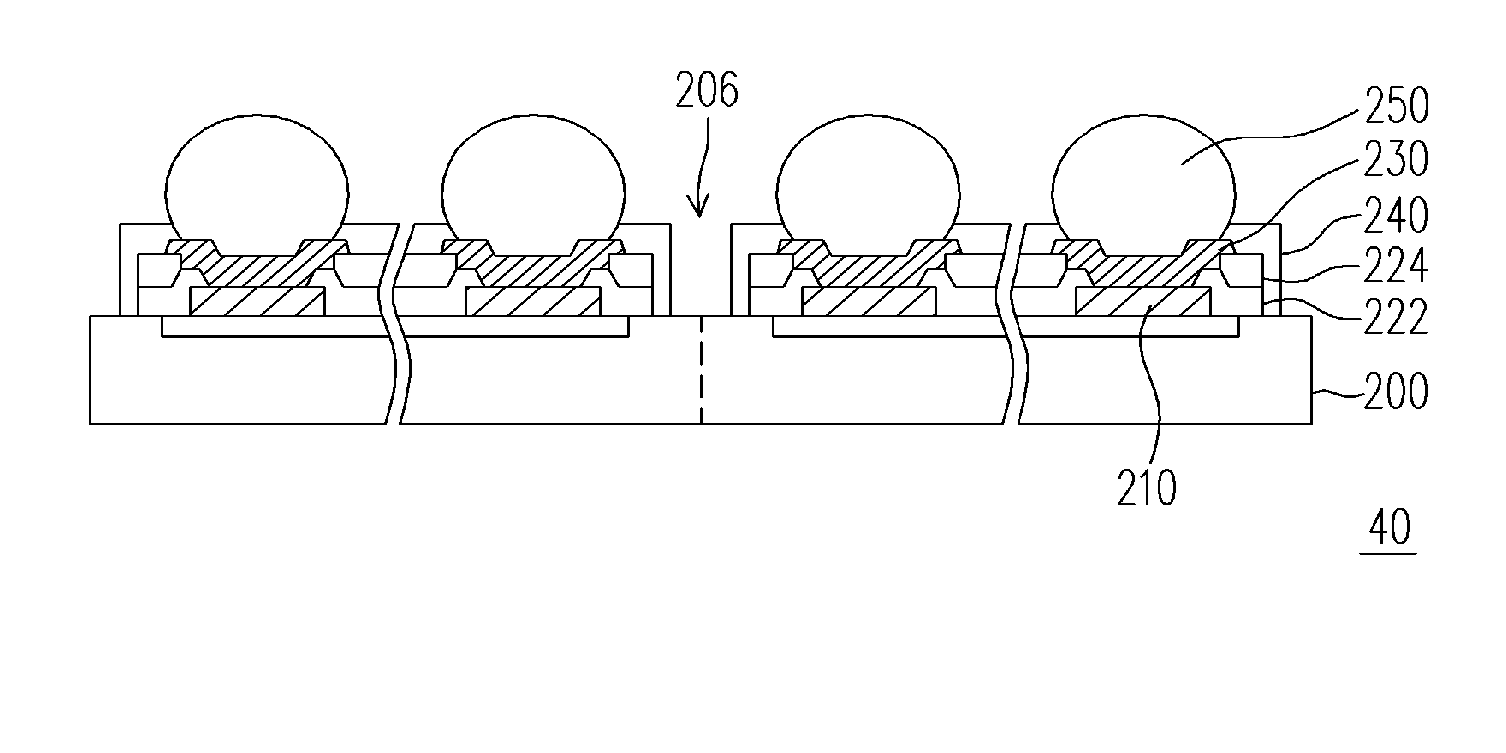

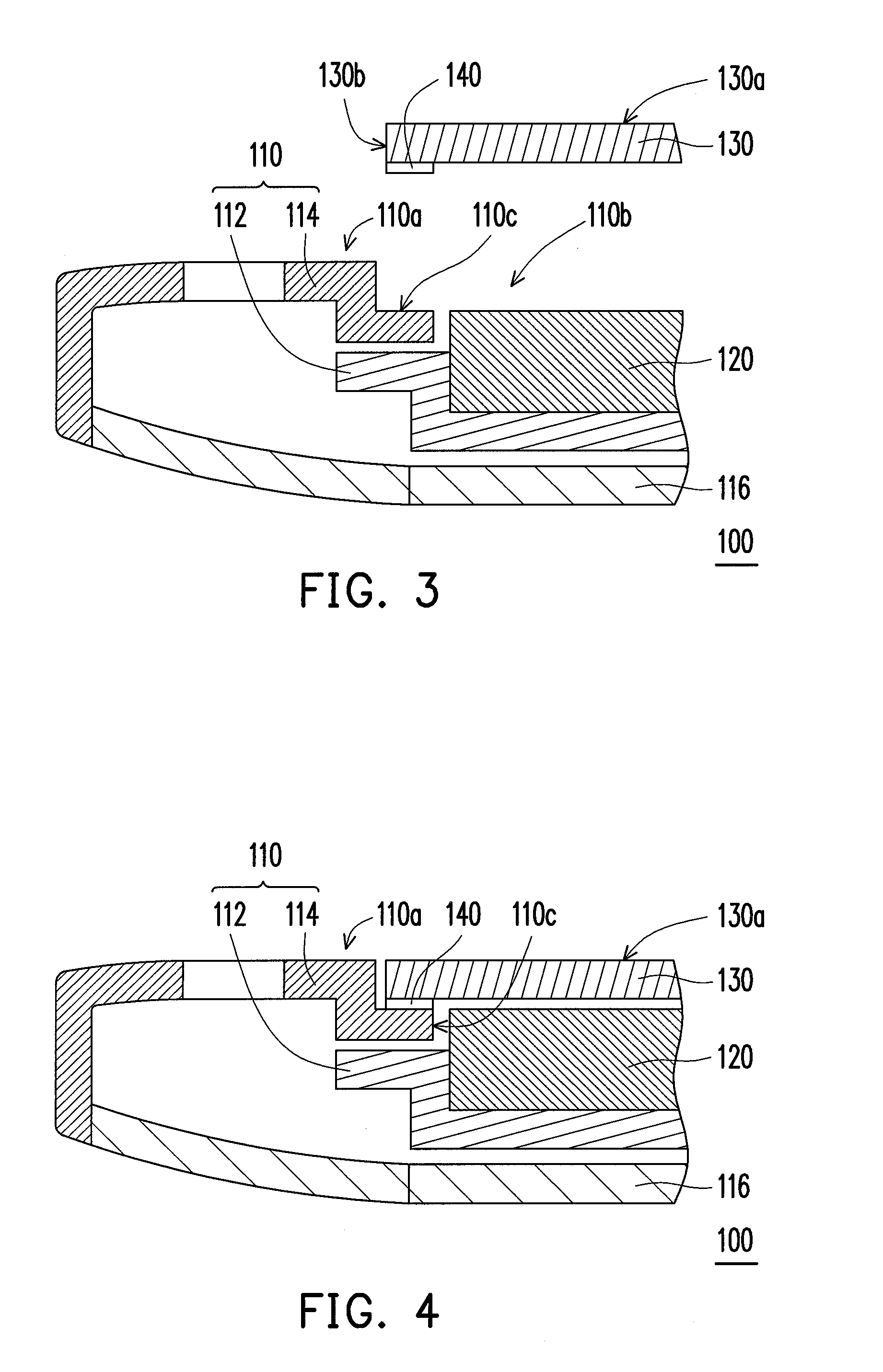

Chip structure and manufacturing process thereof

InactiveUS20060199306A1Improve reliabilityAvoid structureSemiconductor/solid-state device detailsSolid-state devicesEngineeringMoisture

A chip structure and the manufacturing process thereof are provided. The feature of the present application is that the chip structure has a first passivation layer covering a substrate of the chip and exposing each of bonding pads and a portion of the substrate surface, and a second passivation layer covering the sidewalls of the first passivation layer and the portion of substrate surface exposed by the first passivation layer, to prevent moisture infiltration from the edge of the substrate. Therefore, the reliability of the chip structure is enhanced.

Owner:ADVANCED SEMICON ENG INC

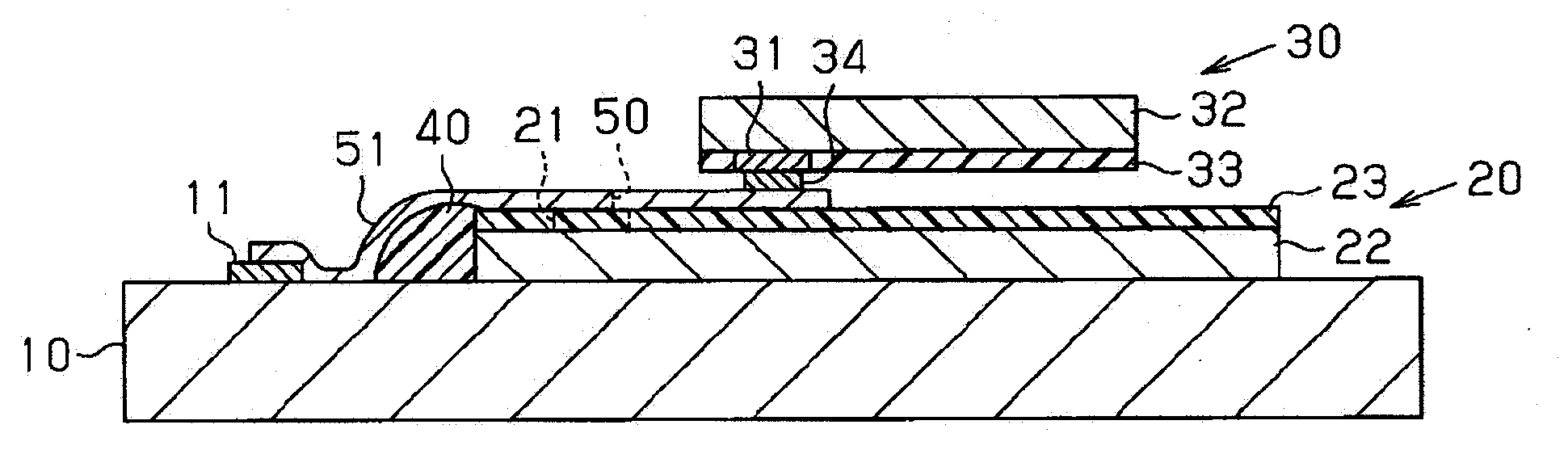

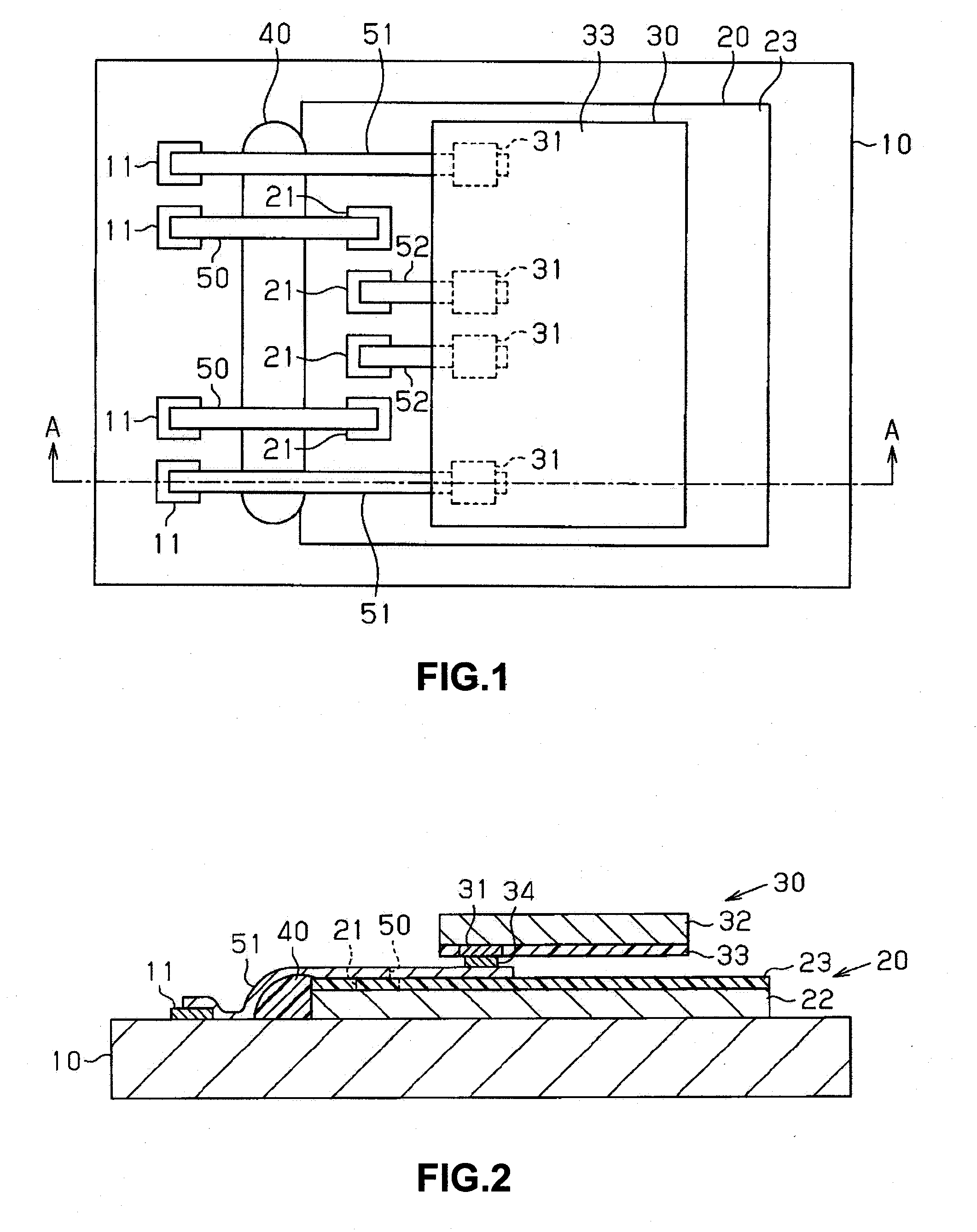

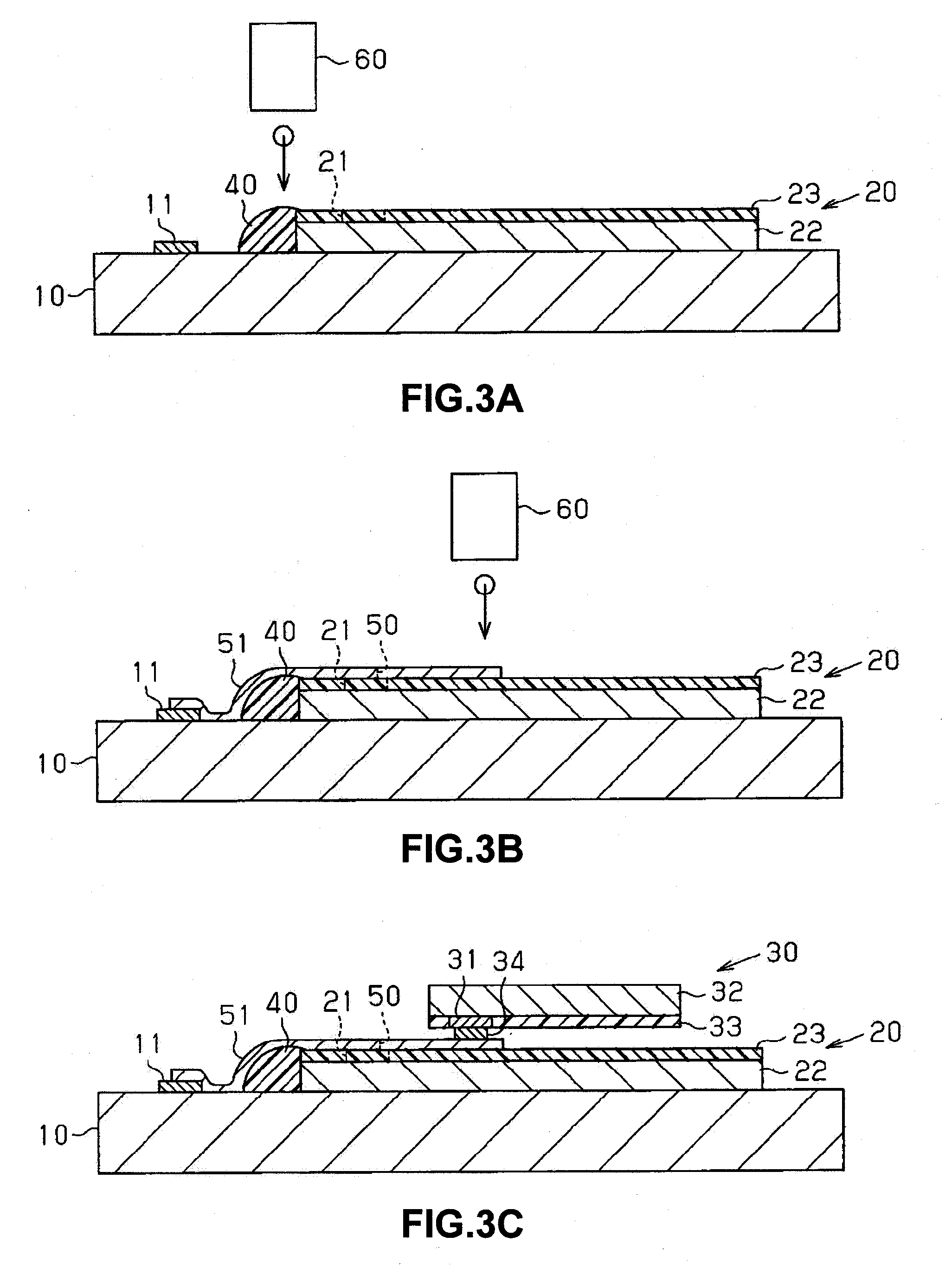

Semiconductor device and method of manufacturing the same

InactiveUS20100327434A1Reduce lengthSimple and easy methodSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor chip

A semiconductor device includes: a first semiconductor chip having a first active surface and a bonding surface forming an opposite side of the first active surface, the bonding surface being bonded to a mounting surface of a substrate; a second semiconductor chip having a second active surface facing the first active surface, and stacked on the first semiconductor chip; a slope section having a sloping surface with a shape of smoothing a step between the first active surface and the mounting surface, and adapted to bury the step in at least a part of a periphery of the first semiconductor chip; and a first wiring wire laid down between the mounting surface and the first active surface via the sloping surface of the slope section, and connected to a first bump provided to the second active surface on the first active surface.

Owner:SEIKO EPSON CORP

Touch screen device

InactiveUS20120038594A1Reduce in quantityPrevent moisture infiltrationNon-linear opticsInput/output processes for data processingDisplay deviceOptoelectronics

Disclosed herein is a touch screen device, including: a first transparent electrode formed on one surface of a first transparent substrate to sense a touched input; a second transparent electrode formed on one surface of a second transparent substrate formed to be opposite to the first transparent electrode to sense a touched input; a display formed on the other surface of the second transparent substrate; a first adhesive layer bonding the first transparent substrate to the second transparent substrate; and a second adhesive layer bonding a first connection part formed on an outer side of first transparent substrate to a second connection part formed on an outer side of the display. The touch screen device directly bonds the first transparent substrate to the display, thereby making it possible to provide a high definition image to a user and to reduce infiltration of moisture or the like.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Organic light-emitting device and method for forming the same

ActiveUS8231423B2Prevent moisture infiltrationEasy to operateDischarge tube luminescnet screensLamp detailsOrganic light emitting deviceOrganic layer

An organic light-emitting device and a method for forming the same are provided. The organic light-emitting device includes: a substrate including a pixel area and a peripheral circuit area; a passivation layer on the substrate, the passivation layer including a first part in the pixel area and a second part in the peripheral circuit area; a pixel definition layer defining a plurality of pixel openings corresponding to the pixel area of the substrate; a plurality of first electrodes in the pixel openings; an adhesion layer on the second part; an organic layer on the first electrodes; and a second electrode layer on the organic light emitting layer, wherein the second electrode extends to the peripheral circuit area to connect with the adhesion layer.

Owner:INNOLUX CORP

Display apparatus

ActiveUS20210043715A1Improve reliabilityConstant thicknessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

A display apparatus that includes a substrate comprising a display area and a non-display area on a periphery of the display area. A display device is on the display area. The display device comprises a light-emitting device electrically connected to a thin film transistor. A first barrier wall is on the non-display area. The first barrier wall surrounds the display area and comprises a first layer and a second layer. The first layer comprises a first portion having a first height from an upper surface of the substrate, and a second portion having a second height from the upper surface of the substrate that is less than the first height. The second layer is on the second portion.

Owner:SAMSUNG DISPLAY CO LTD

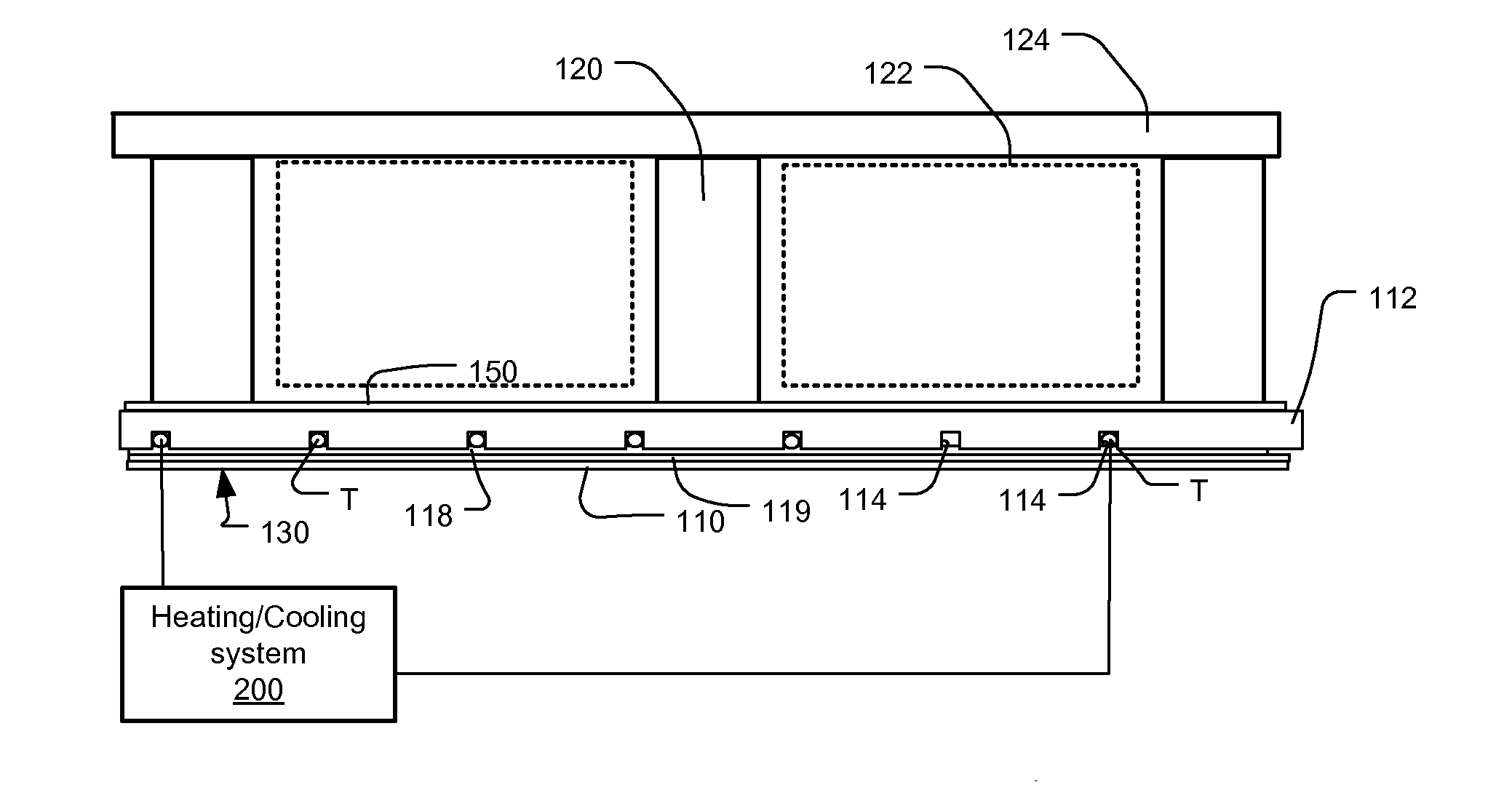

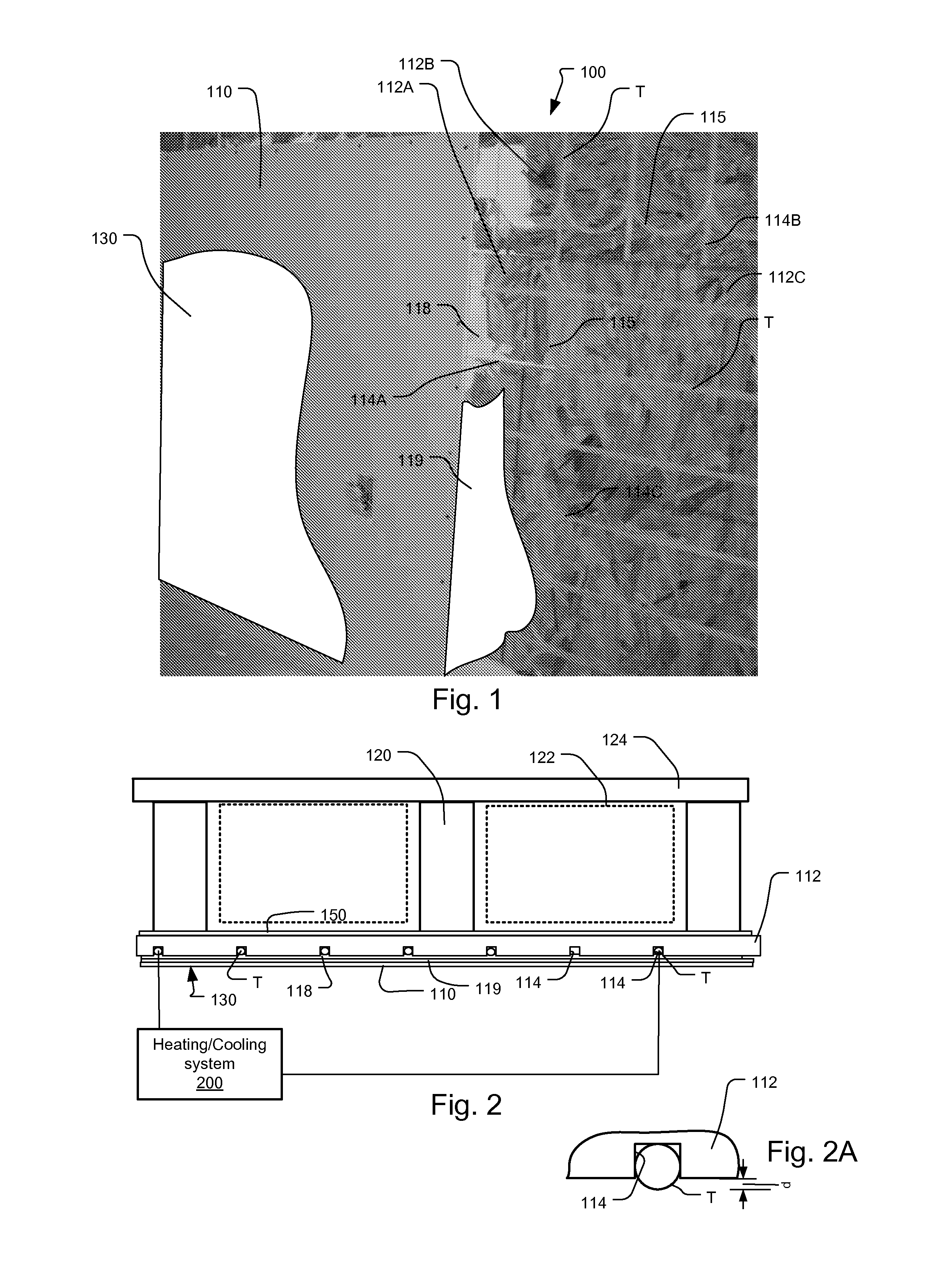

In-Wall Hydronic Thermal Control System and Installation Method

ActiveUS20130255912A1Prevent permeationStable incorporationFluid heatersWallsFilling materialsThermal conductivity

A system for installing tubing of hydronic thermal control systems in the walls, including ceilings, of buildings. It allows for the stable incorporation of the tubing in the walls while ensuring good thermal conductivity between the tubing and the building's room. The system features a wall including a hydronic thermal management system. The wall comprises a vertically-extending wall support structure, tubing panels secured to the wall support structure, the panels being constructed from wood material, tubing in the tubing panels for carrying a heat transfer fluid, and drywall panels secured over the tubing panels. A filling material is applied between the tubing and the drywall panels. Also a high thermally conductive layer, such as aluminum foil, is used between the filling material and the drywall panels or between the filling material and the tubing panels.

Owner:FIEDRICH JOACHIM

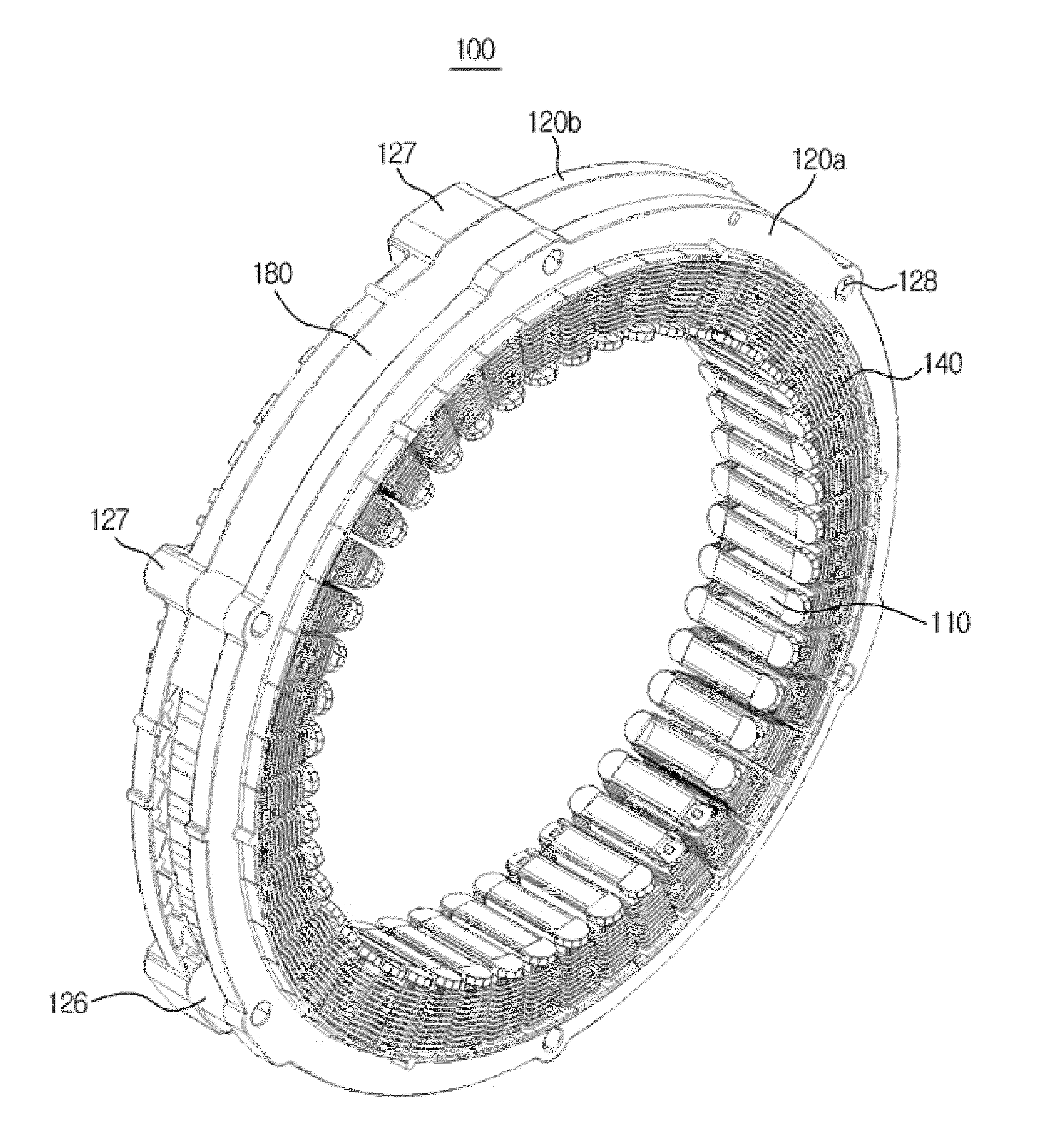

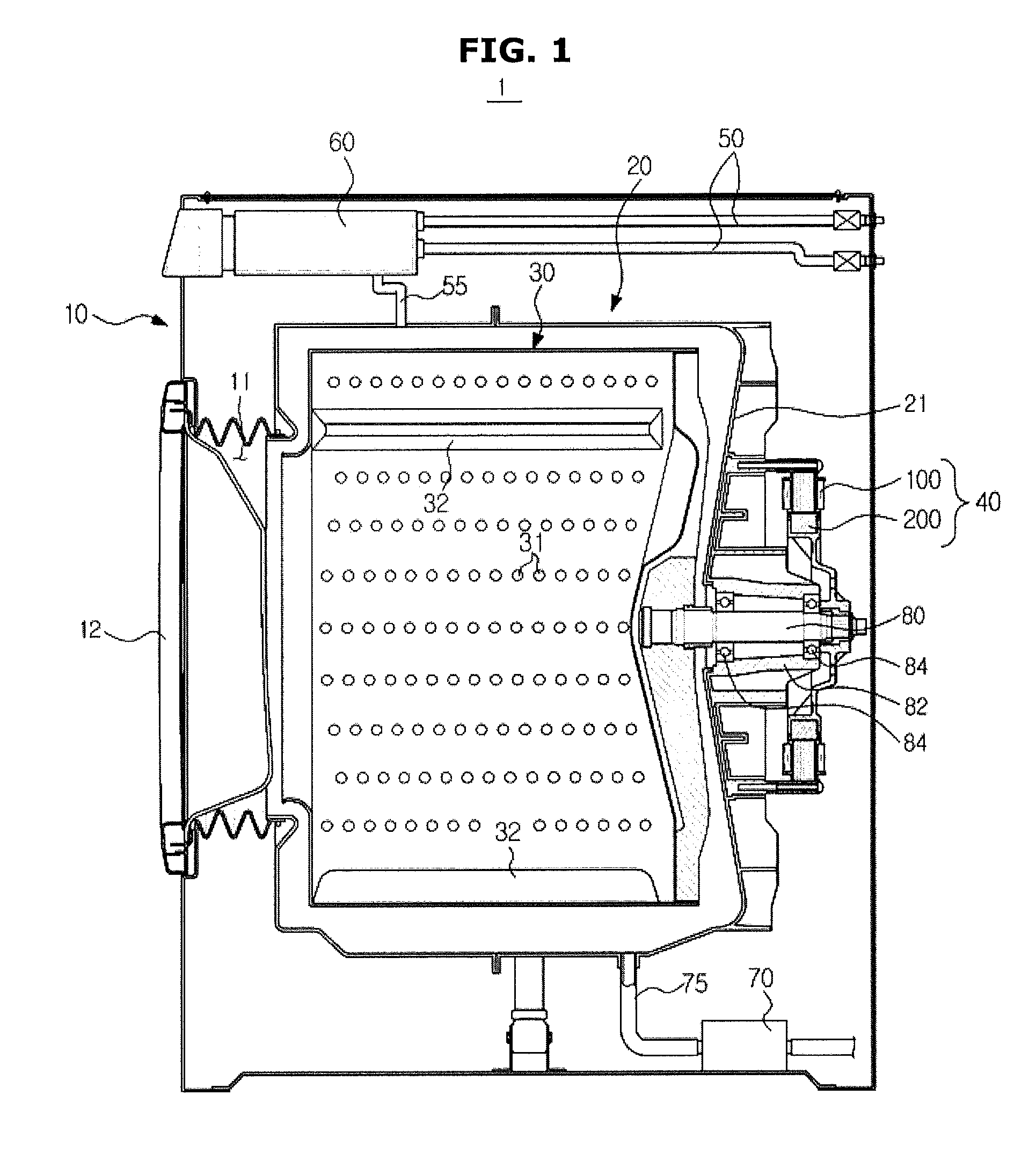

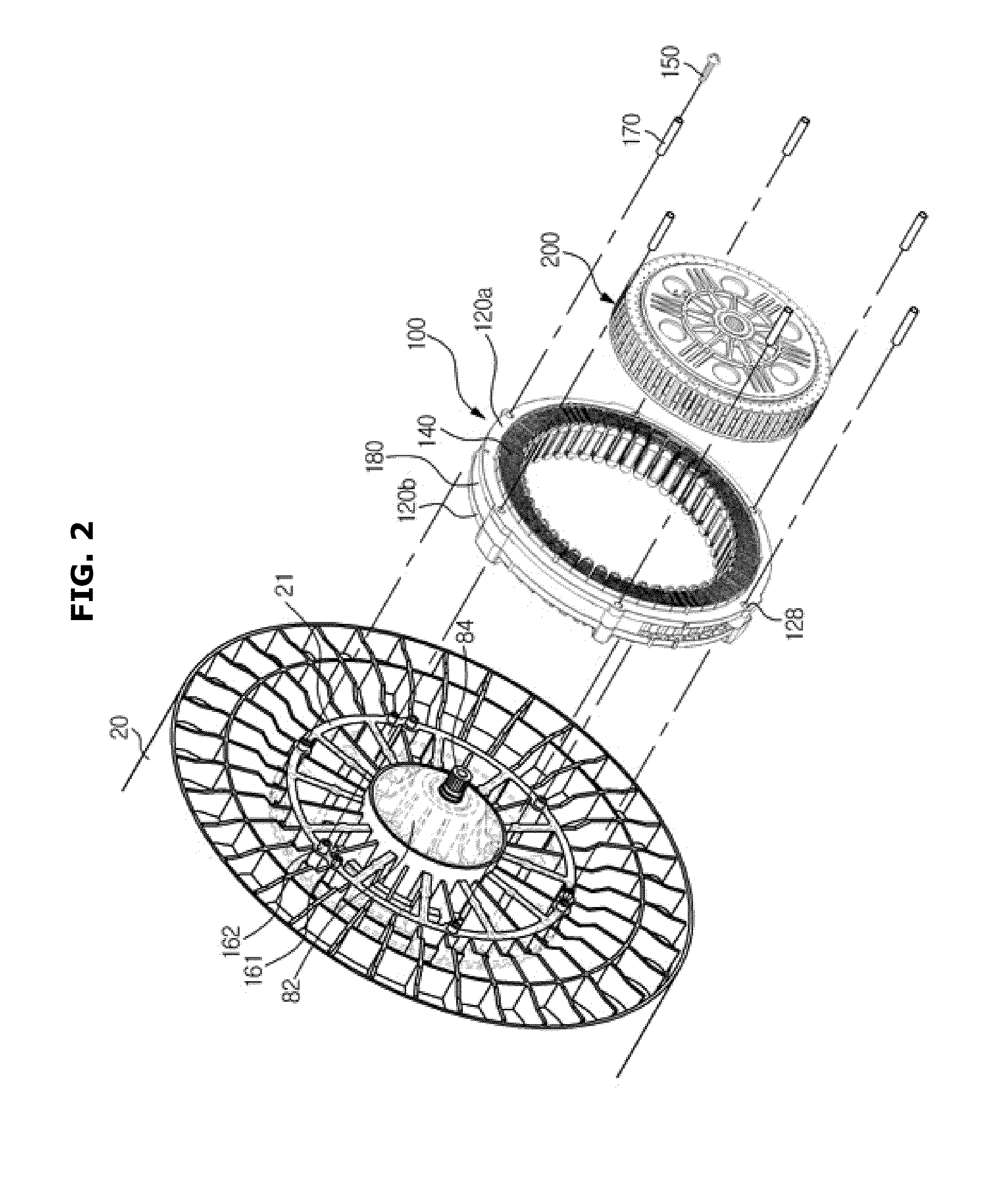

Motor and washing machine having the same

ActiveUS20140069150A1Simple structurePrevent moisture infiltrationWindings insulation shape/form/constructionOther washing machinesEngineeringMechanical engineering

A motor having an improved structure that prevents infiltration of moisture into the motor and a washing machine having the same. A washing machine includes a body, a tub disposed in the body, a drum rotatably disposed in the tub, and a motor including a stator coupled to a rear surface of the tub and a rotor rotatably disposed inside the stator. The stator includes a stator core, a first insulator and a second insulator to cover both ends of the stator core, and at least one moisture infiltration prevention member disposed between the first insulator and the second insulator to prevent infiltration of moisture into the stator core.

Owner:SAMSUNG ELECTRONICS CO LTD

Touch-control display device

InactiveUS20100259501A1Improve product reliabilityReduce assemblyDigital data processing detailsInput/output processes for data processingDisplay deviceEngineering

A touch-control display device includes a frame, a touch-control panel and a display module. The frame has a top surface and a frame rim extending from the top surface, wherein there is a step height between the top surface and the frame rim so as to form a cavity. The touch-control panel is disposed in the cavity and the frame rim supports at least two sides of the touch-control panel. The display module is disposed in the frame and correspondingly assembled under the touch-control panel.

Owner:COMPAL ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com