Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Prevent air lock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

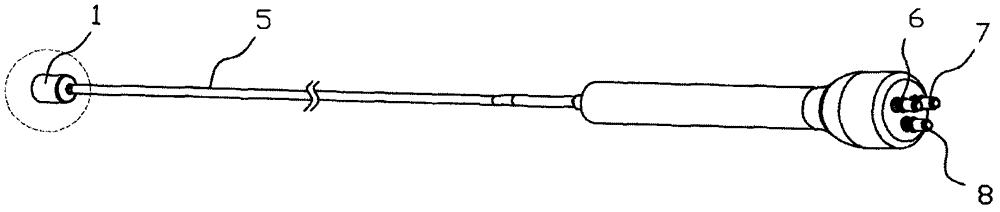

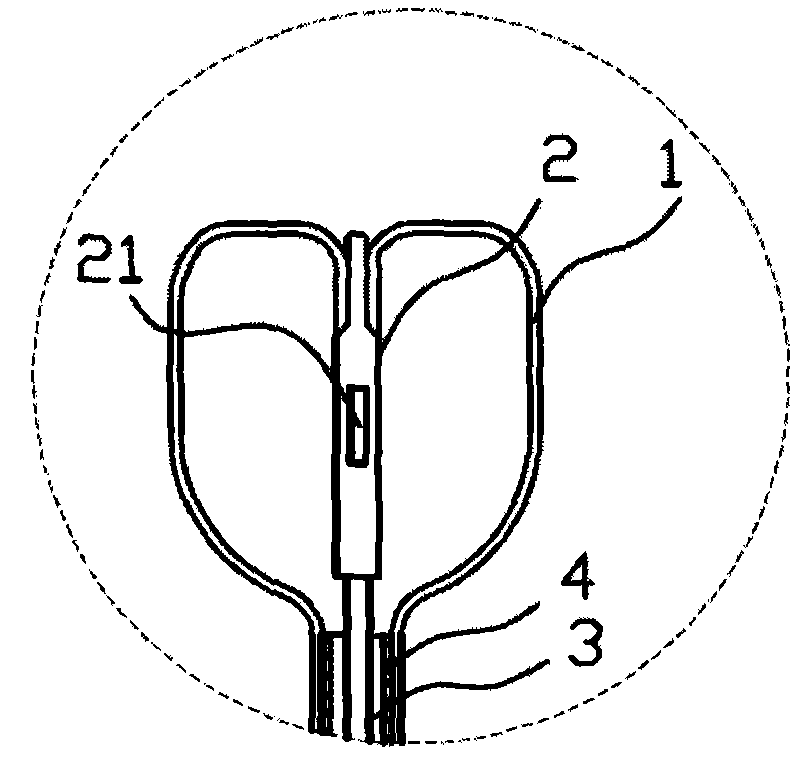

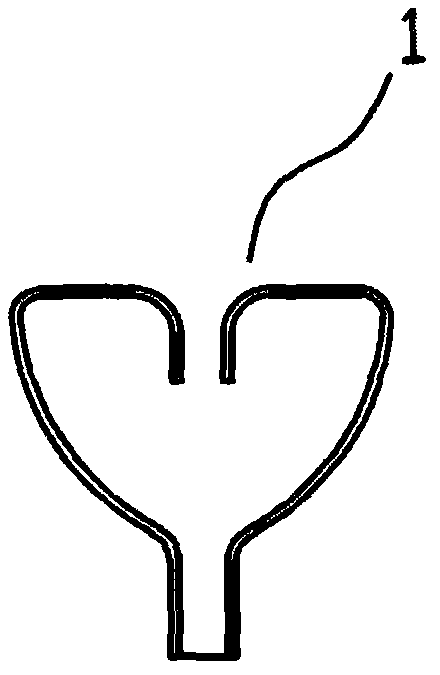

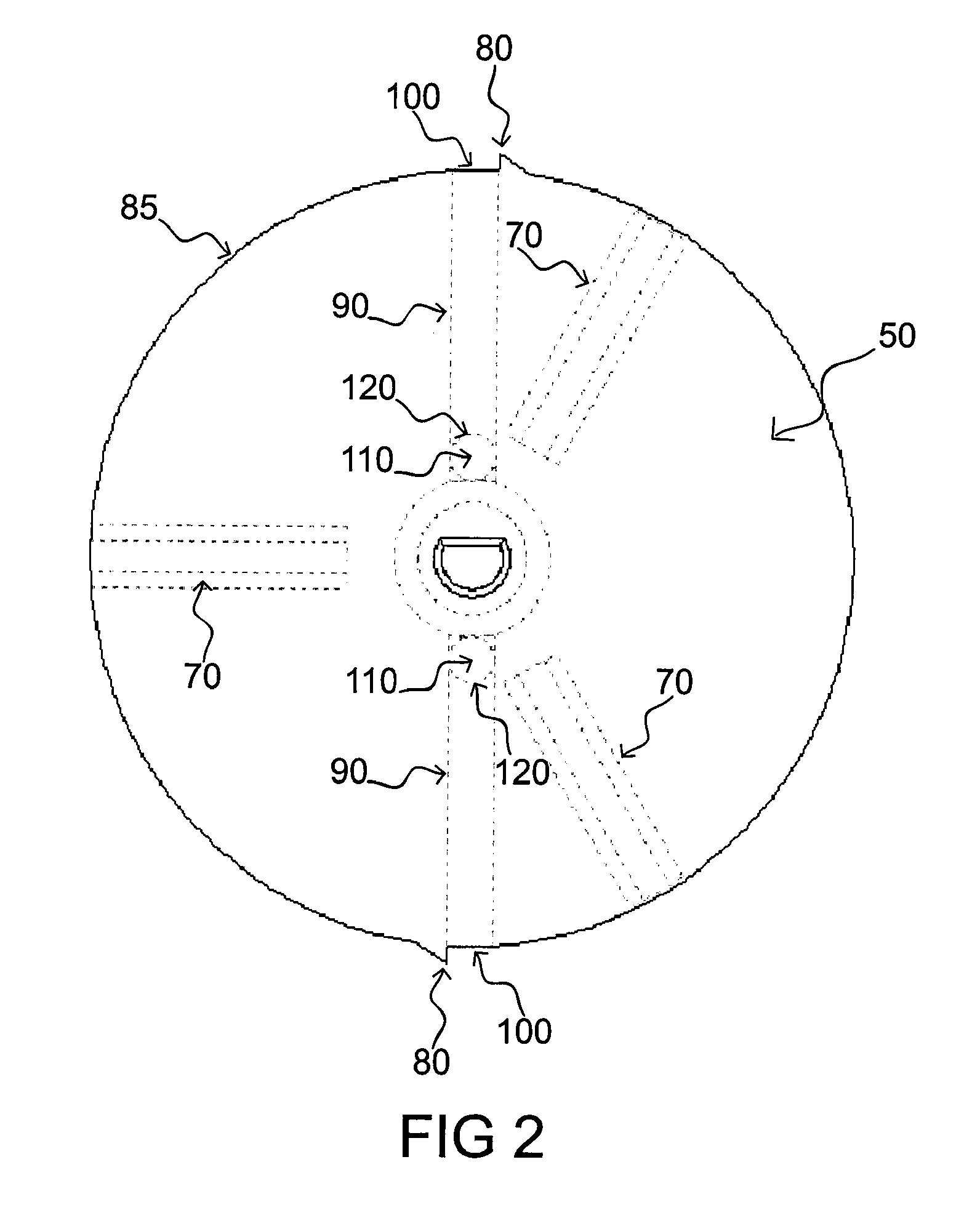

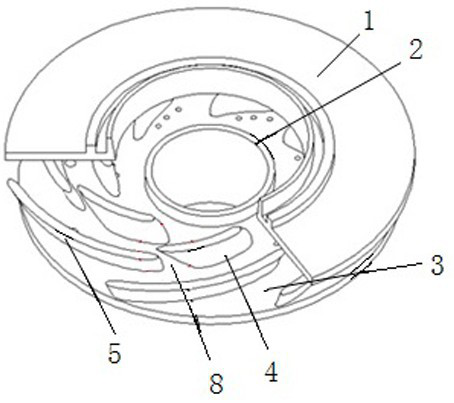

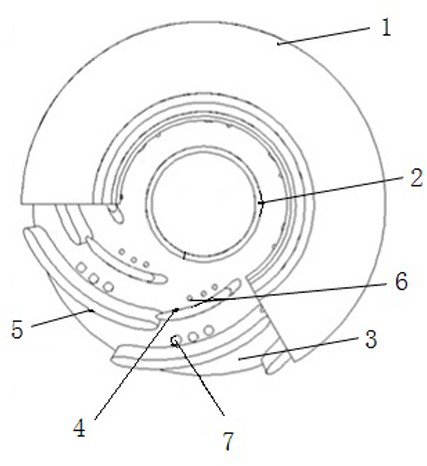

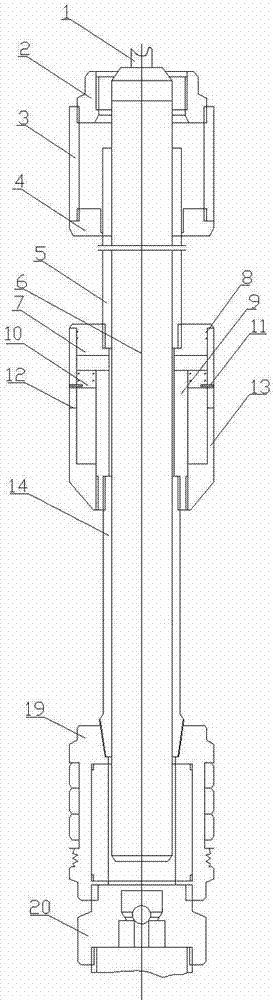

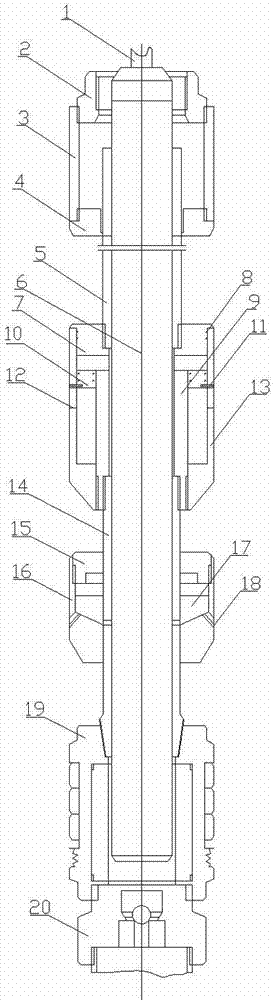

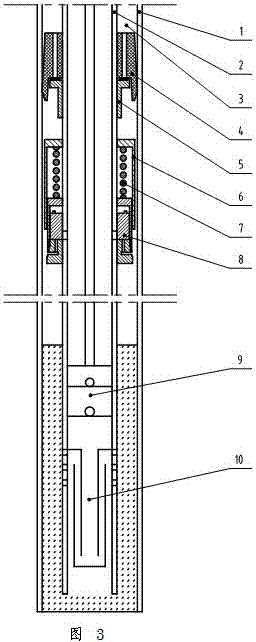

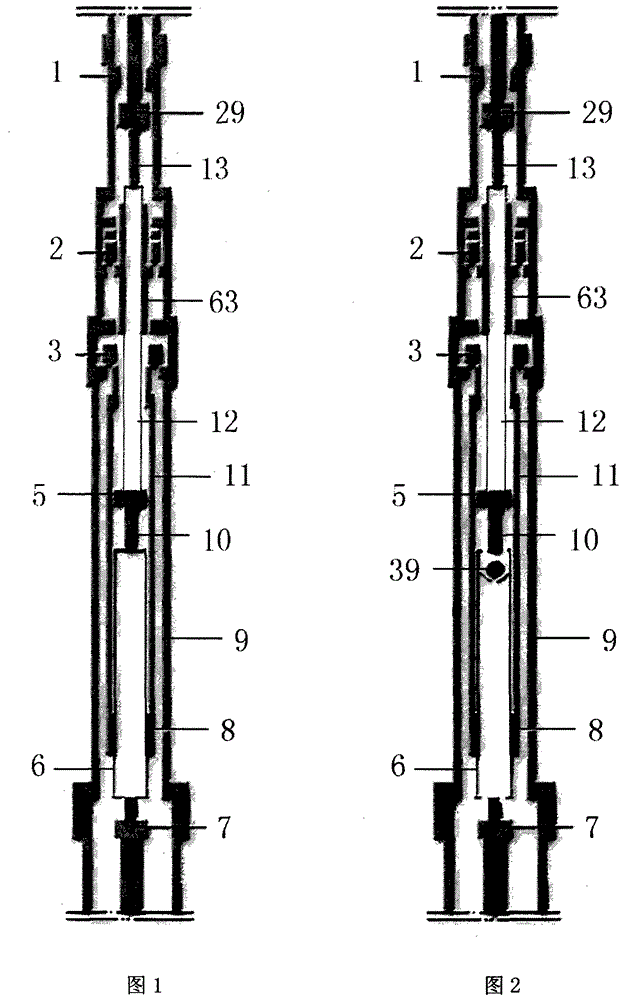

Novel intraluminal tumor cryosurgery ablation catheter and operation method thereof

ActiveCN104905873ARelieve air pressureAvoid destructionSurgical instruments for coolingFar-redEngineering

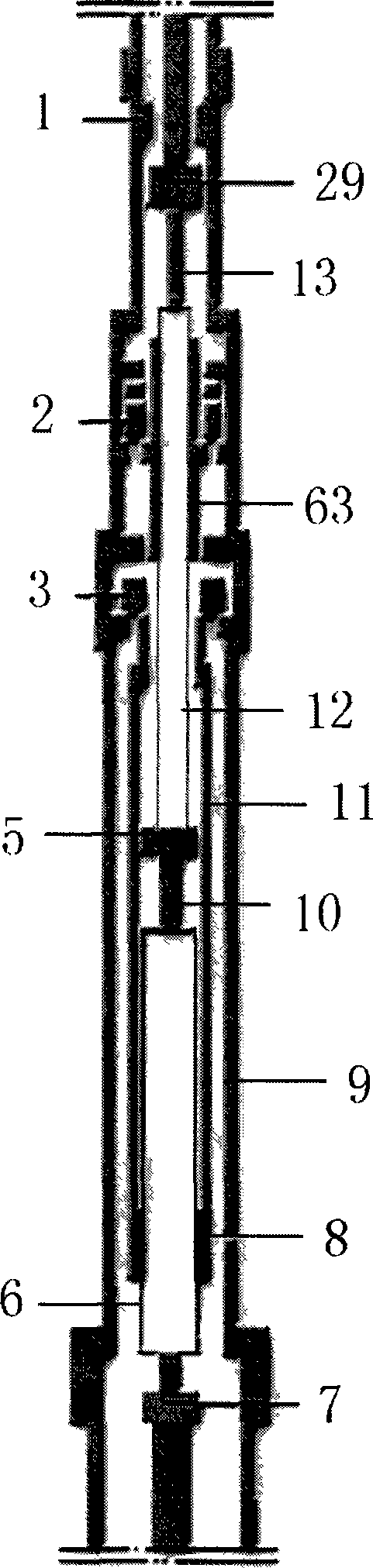

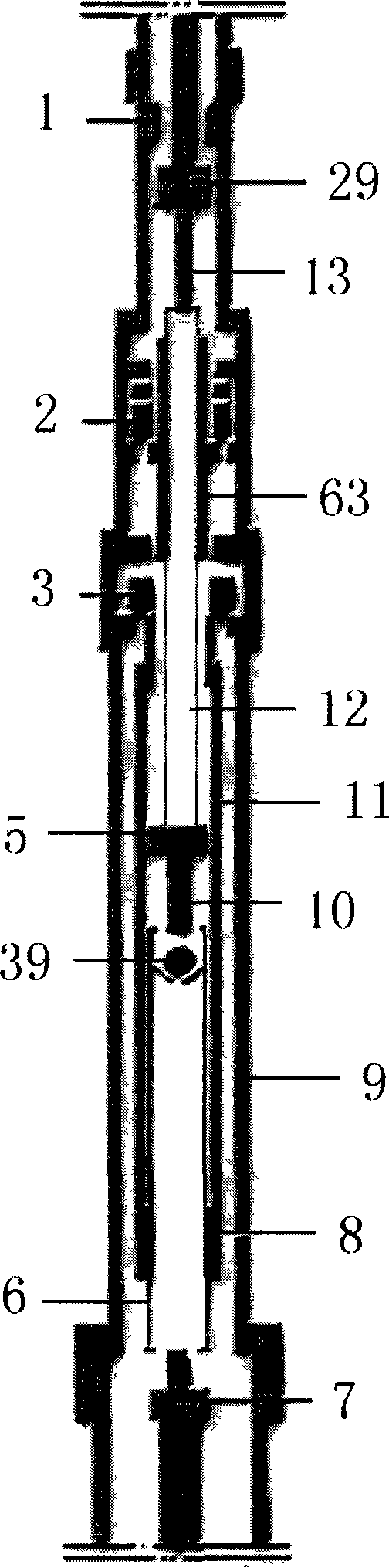

The invention relates to a novel intraluminal tumor cryosurgery ablation catheter and an operation method thereof. The novel intraluminal tumor cryosurgery ablation catheter comprises a balloon, an air inlet pipeline, an air return pipeline, a vacuum pipeline, and an air inlet connector, an air return connector and a vacuum connector, which are respectively connected with near ends of the air inlet pipeline, the air return pipeline and the vacuum pipeline in seal mode, wherein the vacuum pipeline is located on the exteriors of the air inlet pipeline and the air return pipeline. The novel intraluminal tumor cryosurgery ablation catheter further comprises a buffer unit, wherein the buffer unit is arranged at the far end of the air inlet pipeline, and arranged in the balloon, the buffer unit is provided with a buffer air outlet, the near end of the buffer unit is connected with the far end of the air inlet pipeline or the air return pipeline in seal mode, the far end face of the balloon is in a concave shape, the far end of the buffer unit is connected with the far end of the balloon in seal mode, and a connection point between the far end of the buffer unit and the balloon is arranged at the middle of the concave portion of the far end of the balloon or in the far end of the balloon. The novel intraluminal tumor cryosurgery ablation catheter cooperates with an endoscope so as to adapt to complex cavity environments, and the far end of the balloon is large in contact area, and thereby guarantees a large freezing range.

Owner:NINGBO SHENGJIEKANG BIOTECH

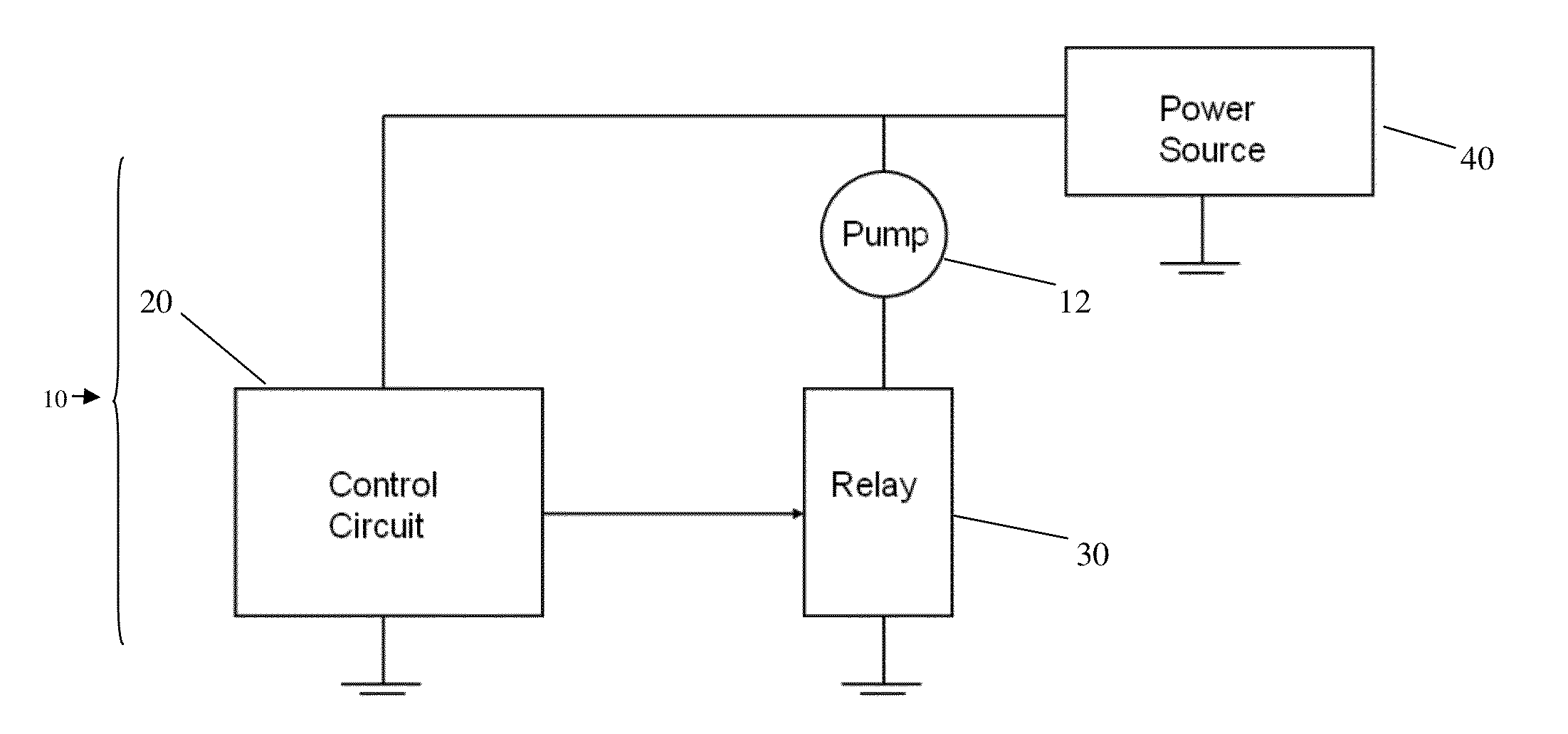

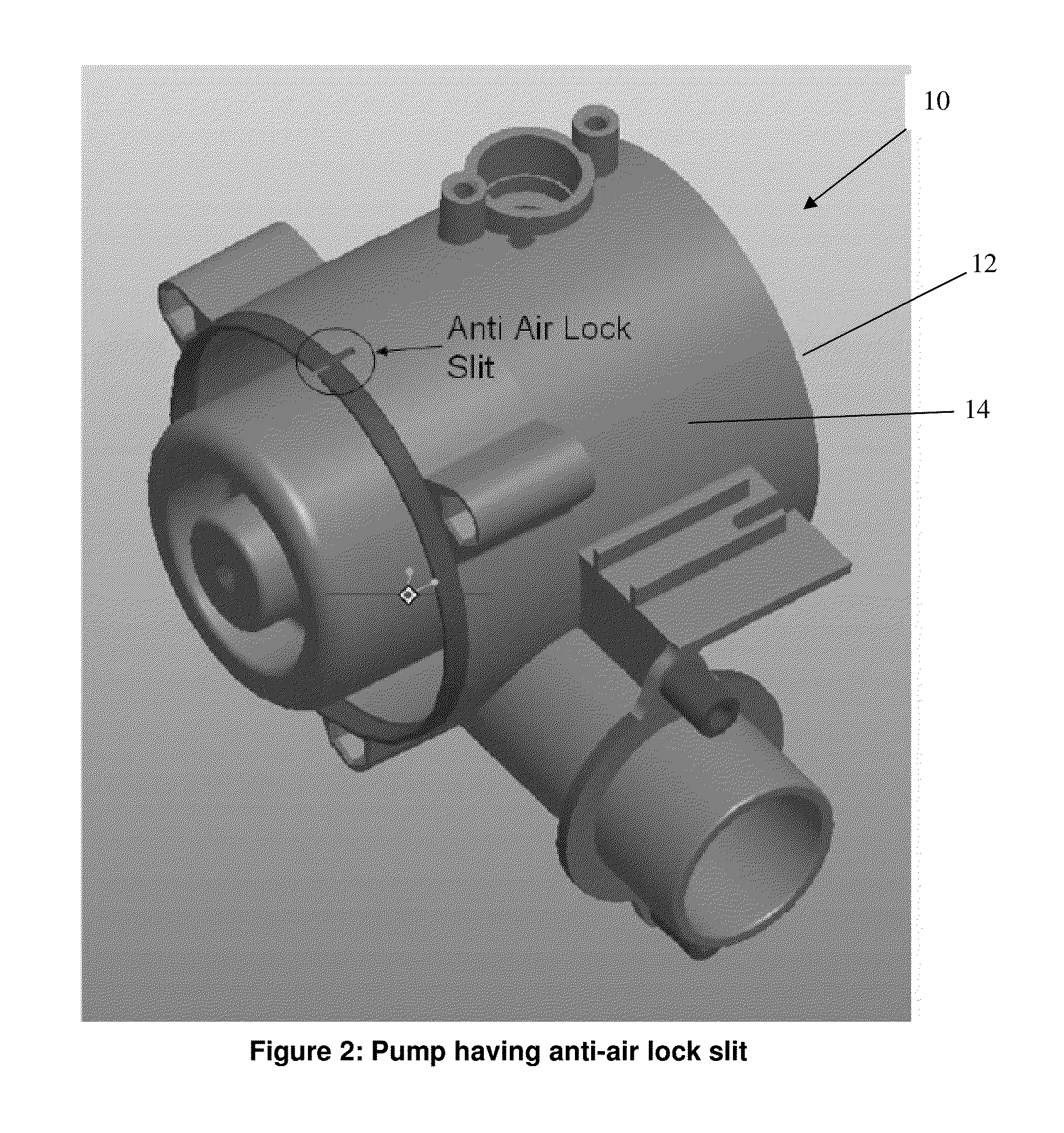

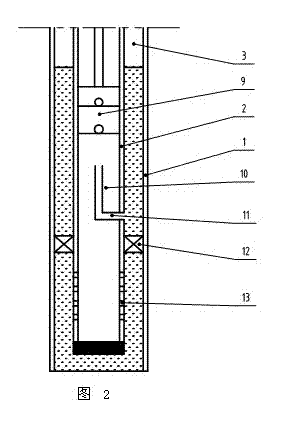

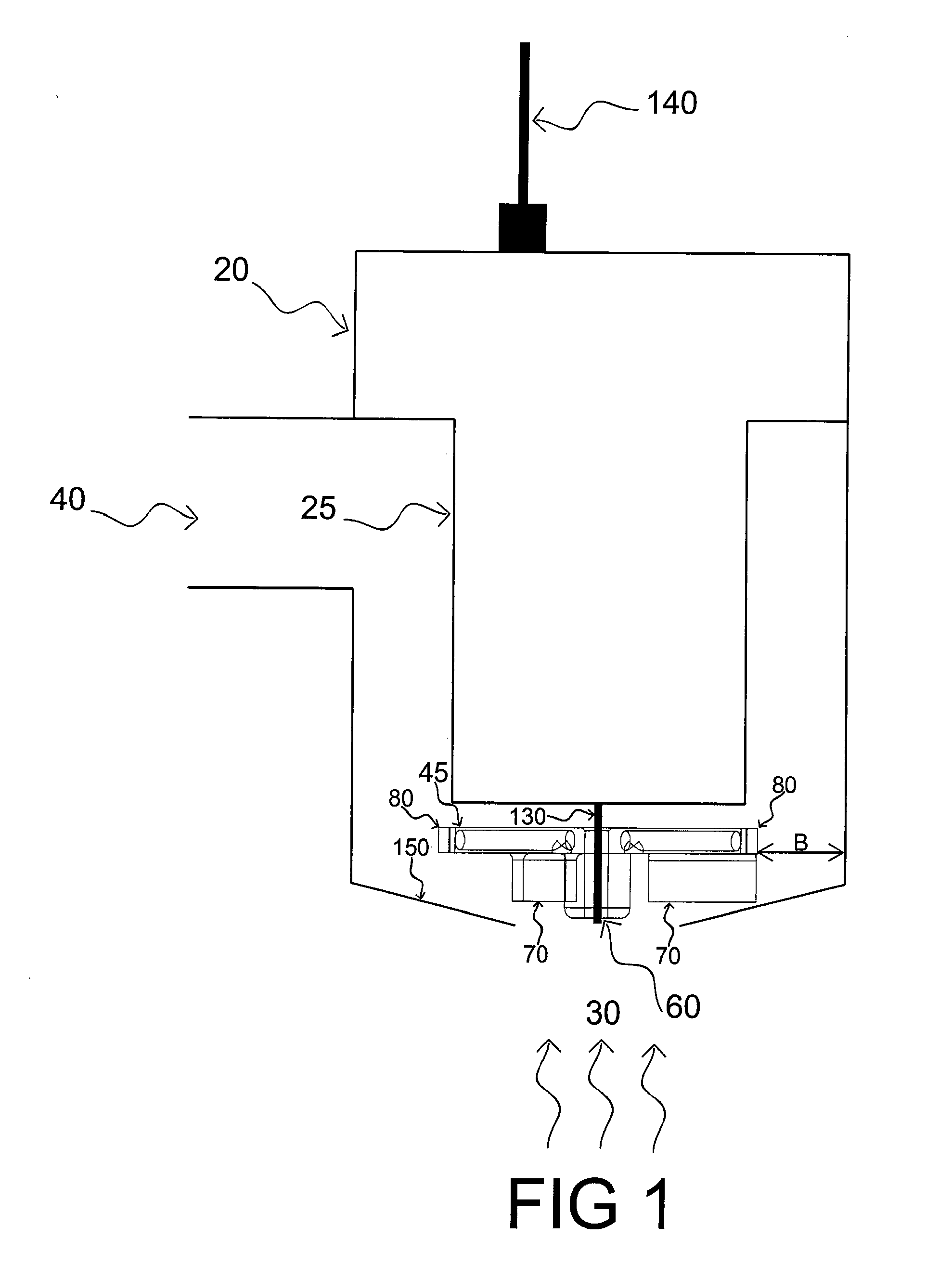

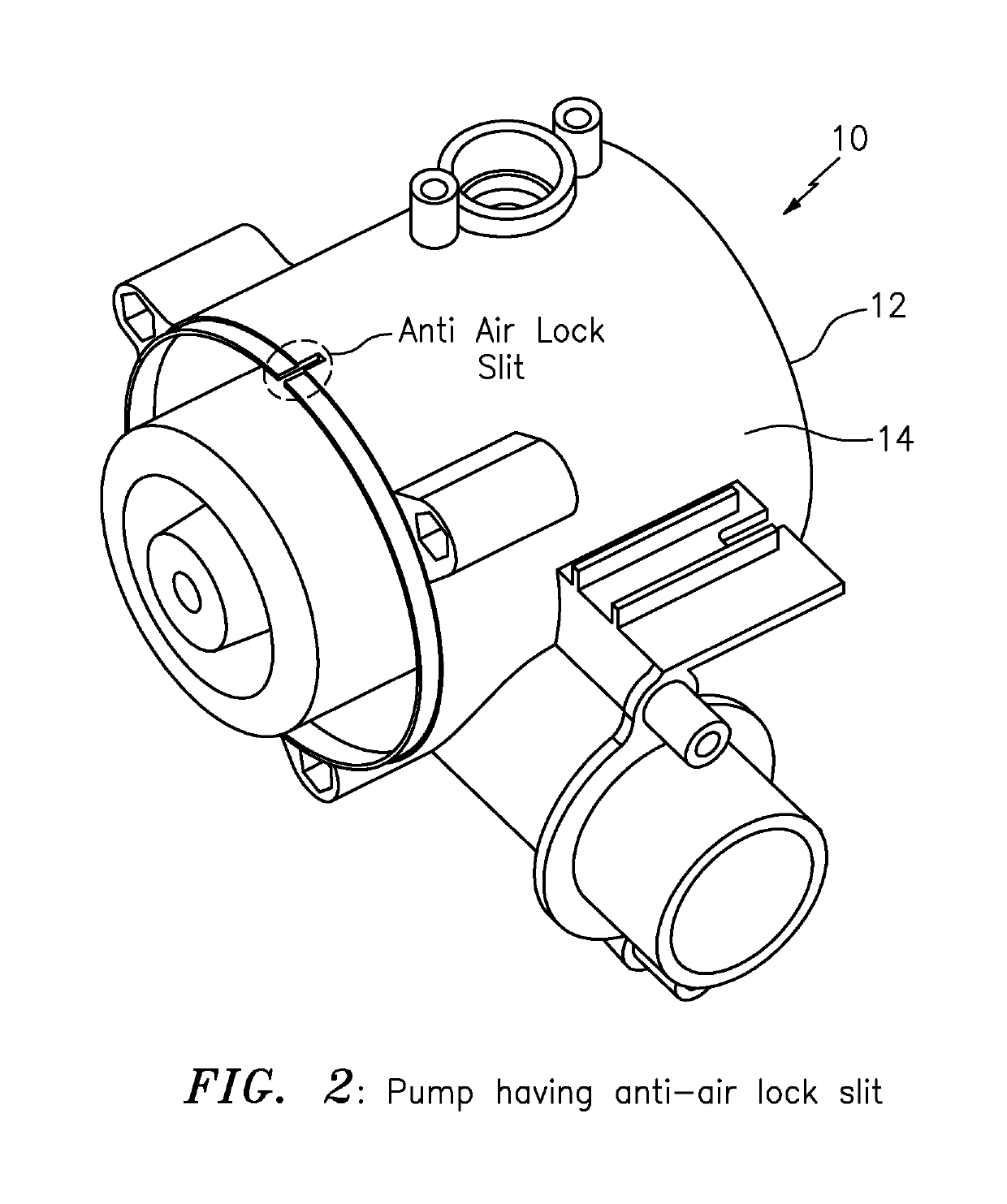

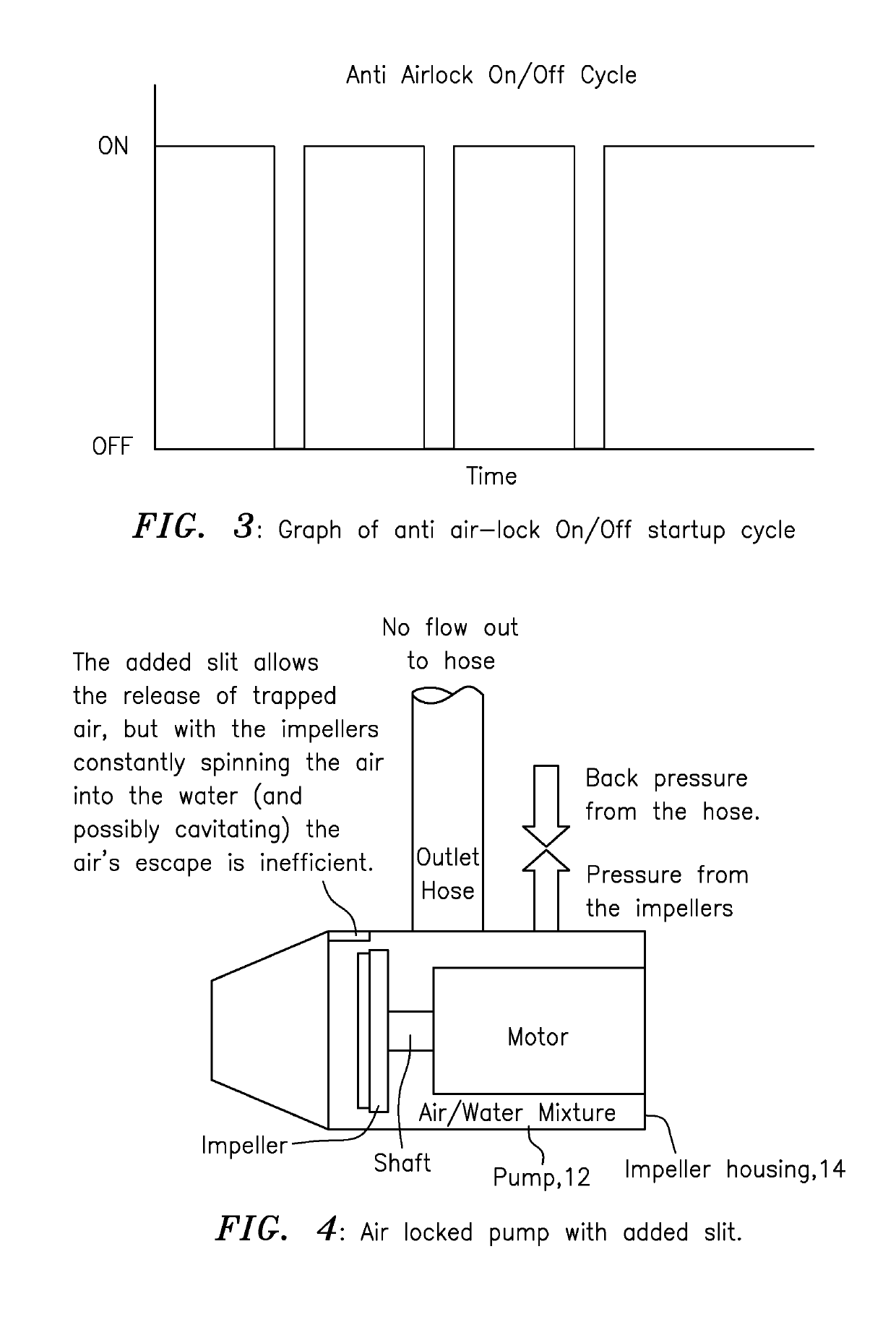

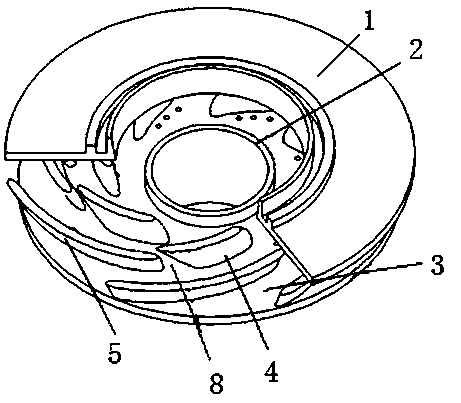

Technique for preventing air lock through stuttered starting and air release slit for pumps

ActiveUS20130336763A1Good and more cost-effectivePrevent air lockEngine fuctionsPriming pumpImpellerEngineering

Apparatus, including a pumping system, is provided featuring a pump and a control circuit. The pump has an impeller housing configured with a slit at the top for trapped air to leave the impeller housing once the pump has been submerged. The control circuit is configured to cycle the pump on and off for a predetermined number of cycles so that the trapped air will float to the top and be expelled out the slit when the pump is cycled off. The control circuit is configured to leave the pump on after the predetermined number of cycles.

Owner:FLOW CONTROL LLC

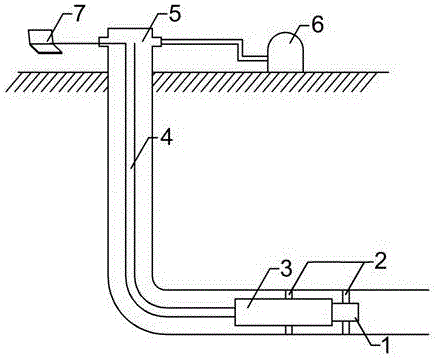

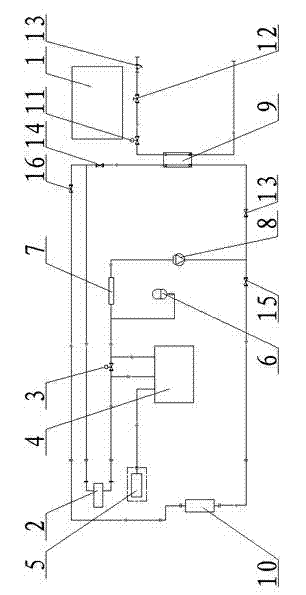

Water pumping and draining and gas producing system of horizontal gas well machine

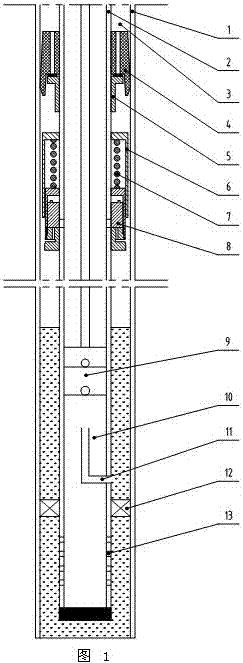

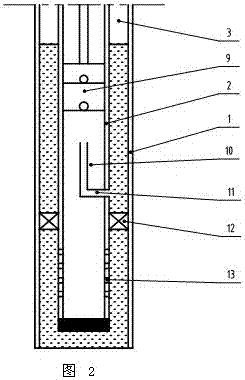

The invention relates to a water pumping and draining and gas producing system of a horizontal gas well machine, which is used for underground water drainage and gas production. By adopting the system, normal production of a gas well can be kept, the productivity of the gas well is increased, and the lifting capacity of a pump to formation water is increased. The system adopts the technical scheme that in an underground gas-liquid separation lifting part, a gas-water separator is connected and fixed with a linear motor pump by a fixator at a production interval of the well; in a ground treatment operation part, the linear motor pump is connected with a gas producing tree by an intelligent coiled tubing, and then the gas producing tree is connected with a ground treatment device by a pipeline; in an intelligent control device, a cable is arranged in the intelligent coiled tubing, one end of the cable is connected with the linear motor pump and the inlet cross section of the gas-water separator, the other end of the cable is connected with a ground intelligent control terminal, and a set of intelligent control program and microcomputer equipment are installed in the intelligent control terminal. The water draining and gas producing system has the functions of preventing sand jamming, increasing the lifting capacity to the formation water and optimizing the productivity of the gas well and is used for water drainage and gas production operation, and maintenance is convenient.

Owner:SOUTHWEST PETROLEUM UNIV

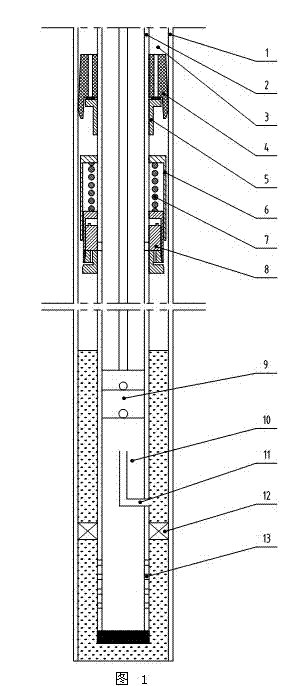

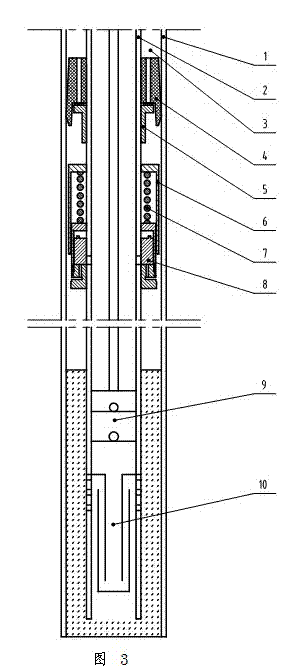

Anti-blocking and anti-gas drainage pump for coal-bed gas mechanical valve

InactiveCN103452833AAvoid stickinessPrevent air lockPositive displacement pump componentsFlexible member pumpsUpper jointEngineering

The invention discloses an anti-blocking anti-gas drainage pump for a coal-bed gas mechanical valve. An upper coupling of a pump barrel is connected with the pump barrel; the pump barrel is connected with a lower coupling of the pump barrel; the lower coupling of the pump barrel is connected with a fixed valve joint through a lengthened short joint; the fixed valve joint is connected with a tail tube joint through a fixed valve cover; pull rods are arranged in the inner cavities of the upper coupling of the pump barrel and the pump barrel; the pull rods are connected with a valve rod reducing joint; the pull rods are connected with a valve rod guide joint; the valve rod guide joint is connected with a mechanical valve pull rod; the mechanical valve pull rod is connected with a guide conical valve; the guide conical valve is matched with a mechanical valve base; the mechanical valve base is connected with a lower abrasion ring through a valve base joint; a plunger mandrel is connected with a plunger upper joint; the pull rods are used for driving the mechanical valve pull rod to move upwards, the guide conical valve moves upwards and is meshed with the mechanical valve base, a plunger assembly moves upwards, a fixed valve ball is opened, and well water enters the pump through a helical outlet, so that coal powder is prevented from being accumulated; the guide conical valve is separated from the mechanical valve base forcibly, and liquid in the pump barrel enters an oil tube through an overflow groove, so that pump clamping and blocking are avoided, and the pump detection period is prolonged.

Owner:XI'AN PETROLEUM UNIVERSITY

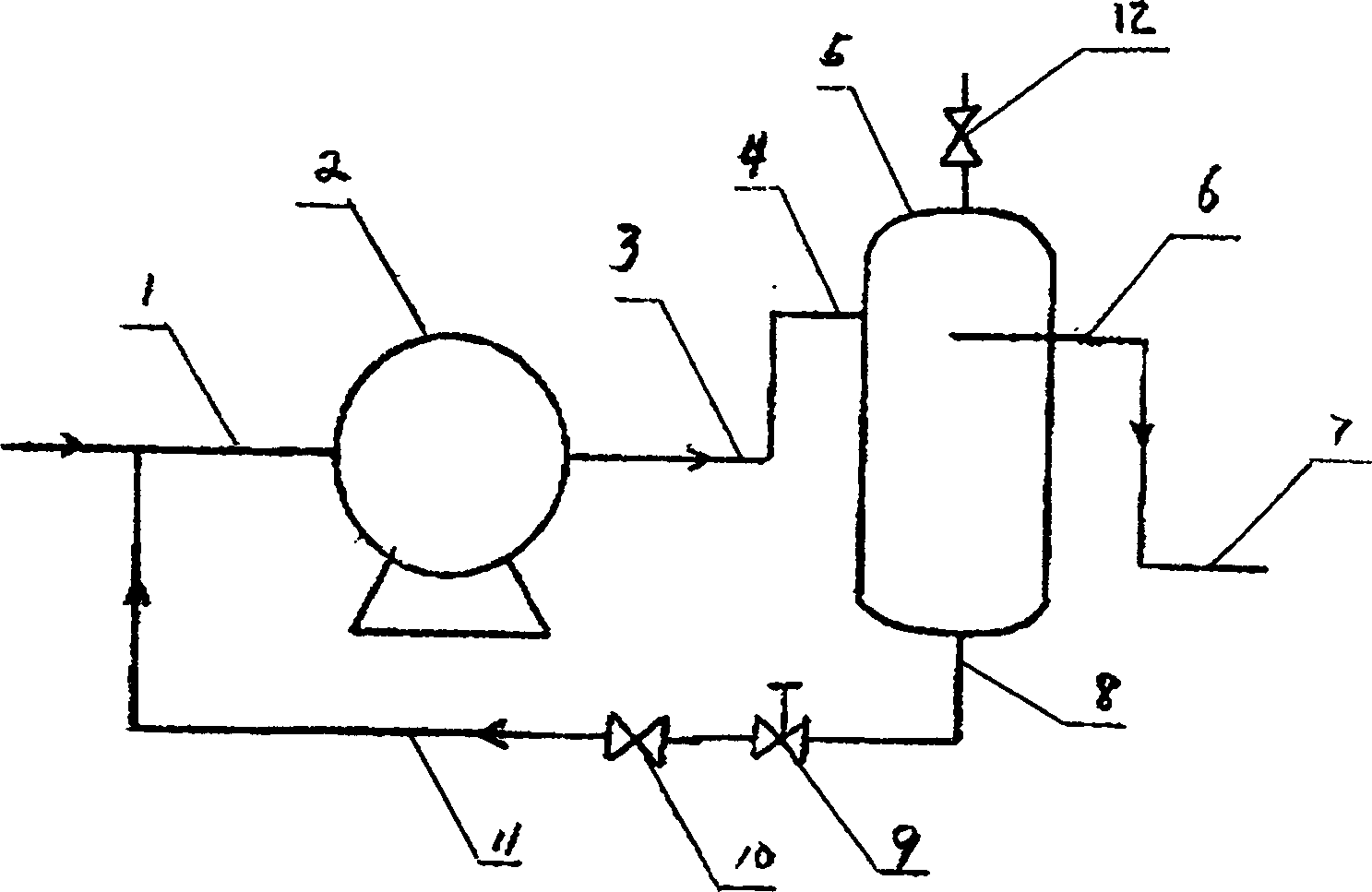

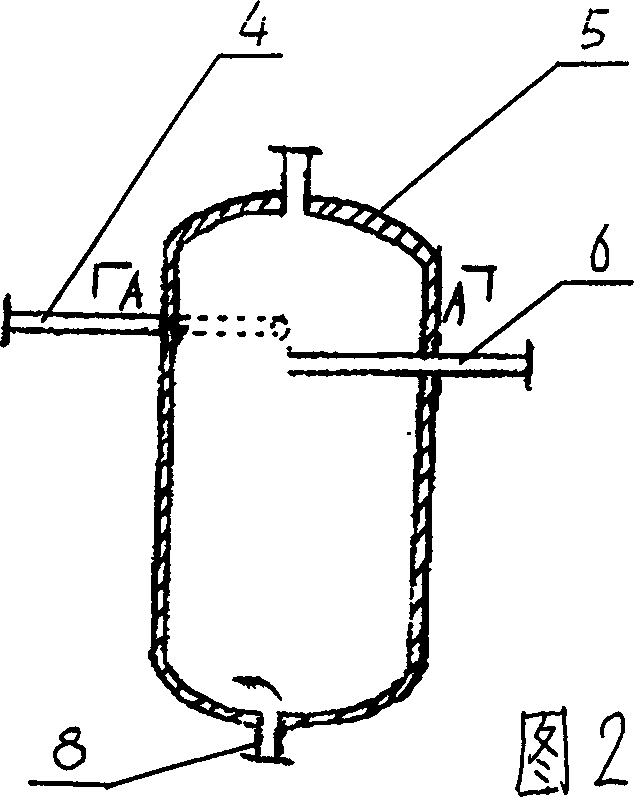

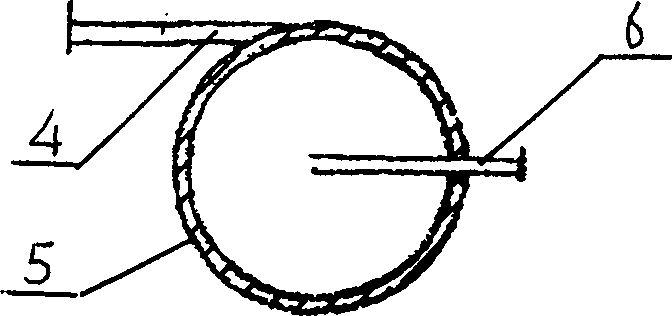

Oil Well gas-liquid mixed conveyor

InactiveCN1417515ADecrease the gas-liquid ratioGuaranteed to workPipeline systemsVapor–liquid separatorLiquid ratio

The oil well gas-liquid mixture conveyer consists of gas-liquid mixture conveying pump and gas-liquid separator connected via pipes. Oil well gas-liquid mixture entered by the inlet pipe is pressure raised in the pump before entering the gas-liquid separator by the outlet pipe. Partial liquid from the gas-liquid separator is returned via the lower outlet and reflux pipe to the inlet of the gas-liquid mixture conveying pump, and the separated gas and the other part of the liquid are output via the upper outlet and outer pipe. The reflux liquid flow rate is adjusted by the adjusting valve. The present invention has lowered gas / liquid ratio into the pump to avoid gas lock and to ensure the normal operation of the pump.

Owner:姚瑞忠

Oil pump of flushing well

InactiveCN101482107AIncrease the effective strokeEasy to openPositive displacement pump componentsFlexible member pumpsInlet valveEngineering

The invention relates to an oil-well pump capable of direct flushing. The oil-well pump is underground equipment which has the effects of sand prevention, gas prevention, wax prevention and high pump efficiency and is applied to oil exploration industry. In the oil-well pump, an upper plunger piston and a lower plunger piston are equipped with sand prevention slots, can send the sands deposited in the sand prevention slots to the underside of the pump to realize sand prevention. When the plunger pistons fall to a pump-bumping position, oil pipes above and below the pump are in communicated state by a pump cavity, thereby realizing the function of direct flushing. In the oil-well pump, an oil inlet valve can be opened easily under the hydraulic feedback action, thereby increasing the fullness coefficient, reducing the bend of a sucker rod, increasing the effective stroke of the pump, preventing air lock, reducing the fatigue loss of the sucker rod, and the oil-well pump has the functions and the characteristics of gas prevention and high pump efficiency.

Owner:韩东明

Coolant circuit of an internal combustion engine, and compensating vessel designed for said coolant circuit

InactiveCN104066951AFlow speed decelerationAvoid foamingMachines/enginesEngine cooling apparatusExternal combustion engineEngineering

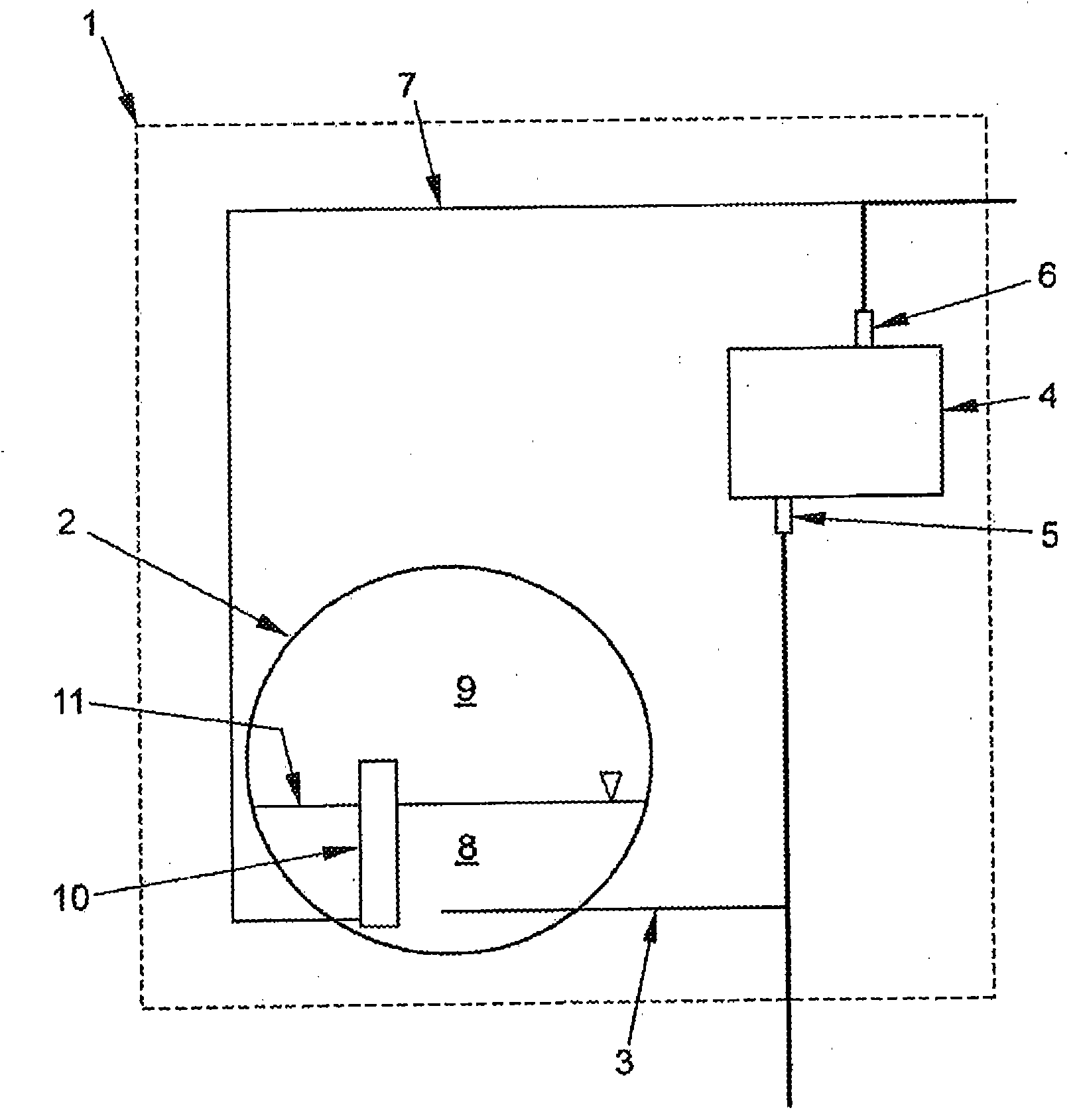

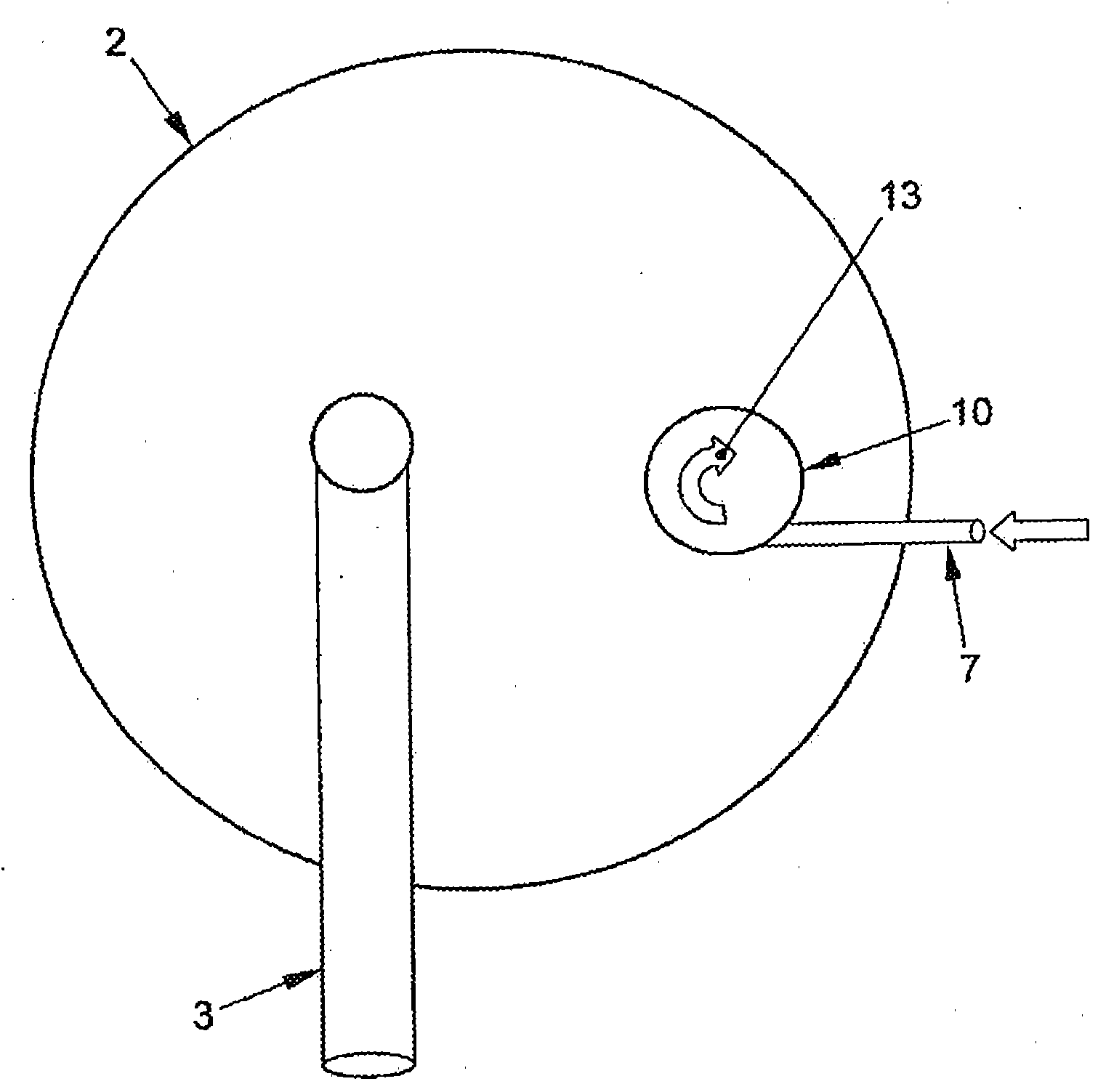

The invention relates to a coolant circuit (1) of an internal combustion engine, having a compensating vessel (2) and having a heat exchanger (4). The coolant passes into the exchanger (4) through a feed line (3). In an upper region of the heat exchanger (4) there is situated an outlet opening (6) for the coolant, having a branch through which, at one side, a main volume flow is supplied to a low-temperature region and through which, at the other side, a secondary volume flow is recirculated through a ventilation line (7) into the compensating vessel (2). Owing to the high flow speeds in the ventilation line (7), the air present in the heat exchanger (4) is supplied to the compensating vessel (2), which is positioned at a lower level. The ventilation line (7) is continued in the interior of the compensating vessel (2) as a vertical, hollow cylindrical tube portion (10) which therefore runs at least in sections below a water level (11) of the compensating volume (8) of the coolant in the compensating vessel (2). According to the invention, an arrangement of the compensating vessel (2) is attained in which the fill level (11) in the compensating vessel (2) is situated below the heat exchanger (4) during operation. By virtue of the ventilation line (7) being situated in sections below the fill level (11), pressure equalization between the heat exchanger (4) and the compensating vessel (2) is prevented. The negative pressure generated as a result of the extraction of the air present in the heat exchanger (4) is thus maintained, such that, despite the gradient existing within the coolant circuit (1), the coolant volume present in the heat exchanger (4) does not flow into those regions of the coolant circuit (1) which are situated at a lower level.

Owner:VOLKSWAGEN AG

Crude oil dissolved gas underground collecting apparatus

InactiveCN103244077ADoes not affect daily production managementReduce wasteFluid removalWorking fluidTransmission channel

The invention provides a crude oil dissolved gas underground collecting apparatus. The crude oil dissolved gas underground collecting apparatus includes an above-pump collecting device and a below-pump collecting device which are used for collecting dissolved gas above a pump and below the pump respectively, and the appropriate collecting device is selected for different oil wells. According to the above-pump collecting device, the interspace of an oil lantern ring is sealed with a sealing rubber sleeve on the periphery of the opening of the well, and the gas is collected by entering an oil pipe through a one-way valve; when the well is cleaned, the sealing rubber sleeve shrinks inwards through high pressure flushing fluid and further moves downwards continuously to push a sealing cover to seal and close the one-way valve, the flushing fluid cannot pass through the one-way valve to enter the oil pipe, and accordingly the well cleaning is guaranteed to be carried out smoothly; and when the working fluid level is measured, the interspace of the oil lantern ring above the sealing rubber sleeve is pressed, and a float valve moves downwards to open an inner hole of the sealing rubber sleeve to further form a sound wave transmission channel. According to the below-pump collecting device, the of the oil lantern ring below the pump is sealed and closed through a packer, the gas is collected by entering the pump, and the fluid enters the interspace of the oil lantern ring through an oil sleeve communicating valve above the packer to form the working fluid level. Both the above pump collecting device and the below pump collecting device do not affect the routine maintenance of the well, such as well cleaning and fluid level measurement.

Owner:CHINA PETROLEUM & CHEM CORP +1

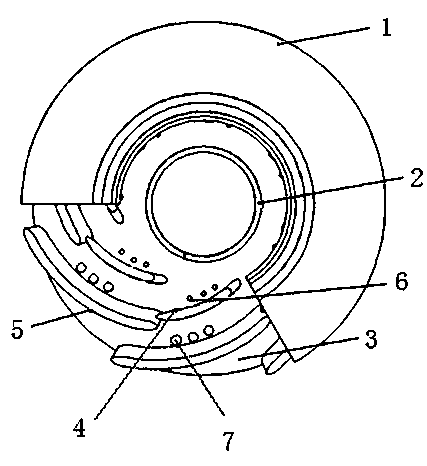

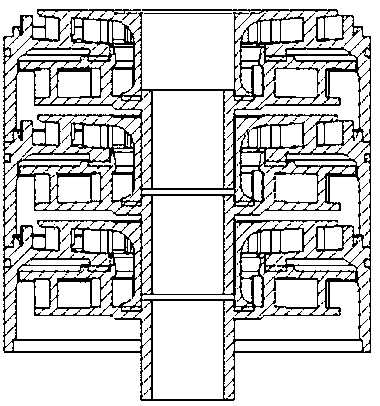

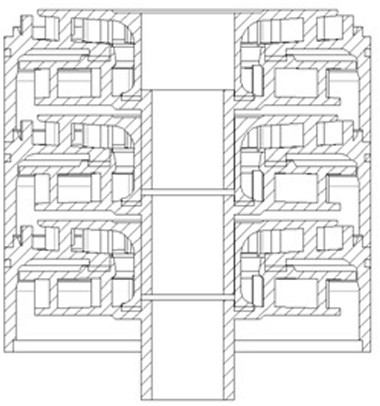

Impeller with Anti-vapor lock mechanism

InactiveUS20080226467A1Prevent air lockAir lock be preventPump componentsFlexible member pumpsCentrifugal pumpEngineering

An impeller for preventing air-lock in a pump, the impeller in its basic embodiment includes a top plate, the top plate having a center axis and a peripheral edge, a plurality of vanes, each vane attached to the top plate, at least one small protrusion projecting from the periphery of the top plate, and at least one ventilation channel having an outlet located near the protrusion, and an inlet located near the center axis of the top plate. The present invention also contemplates a centrifuge pump and an aerator device having the impeller of the present invention.

Owner:KEEPALIVE

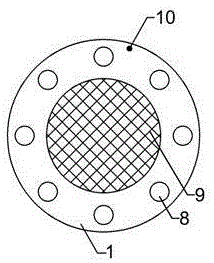

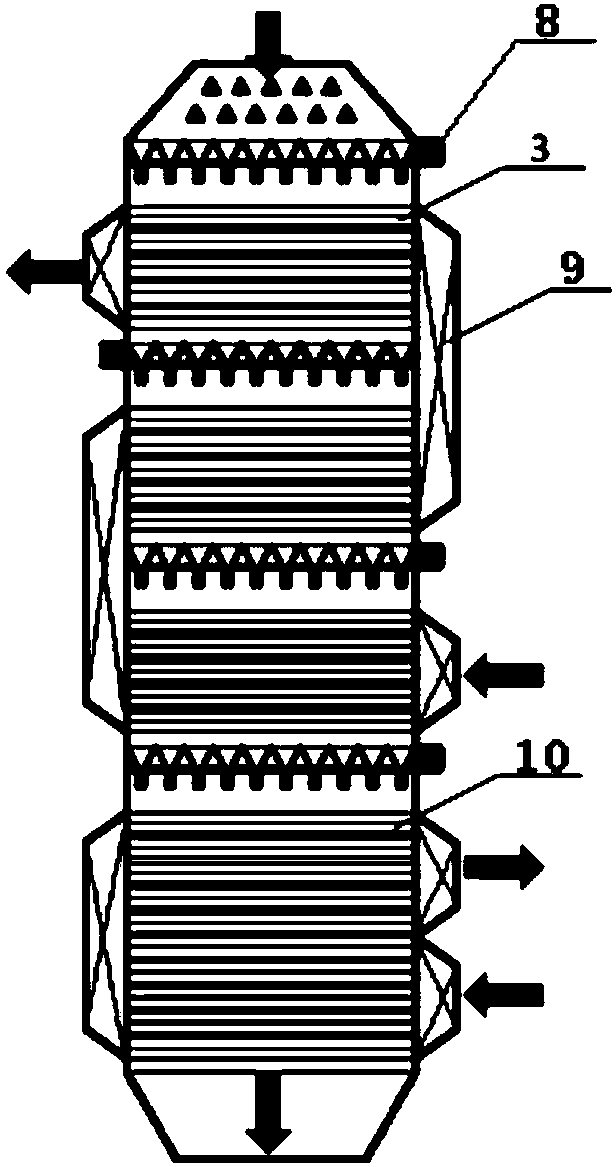

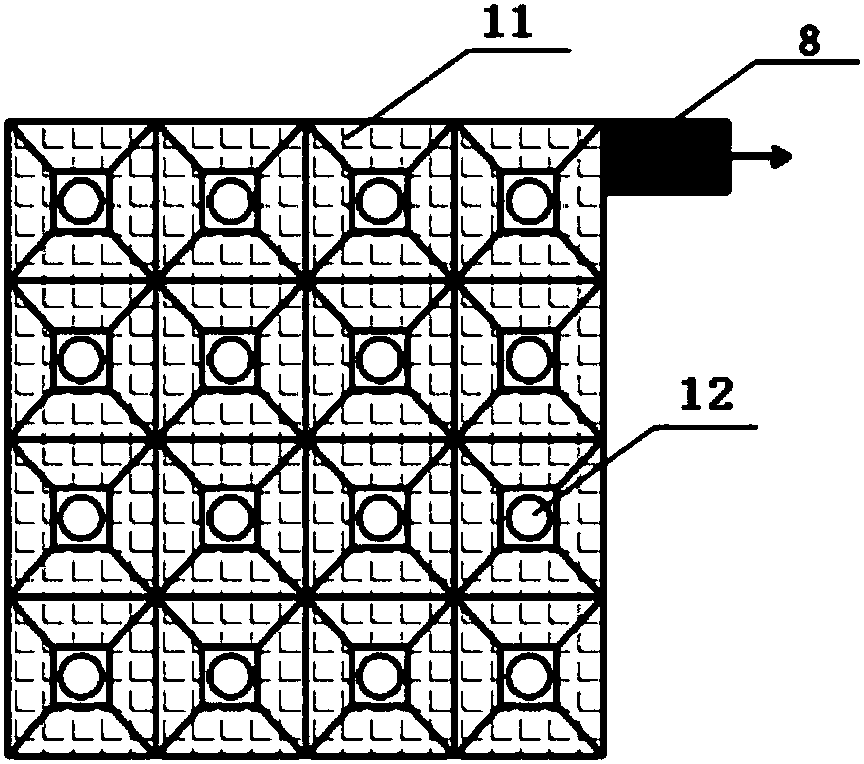

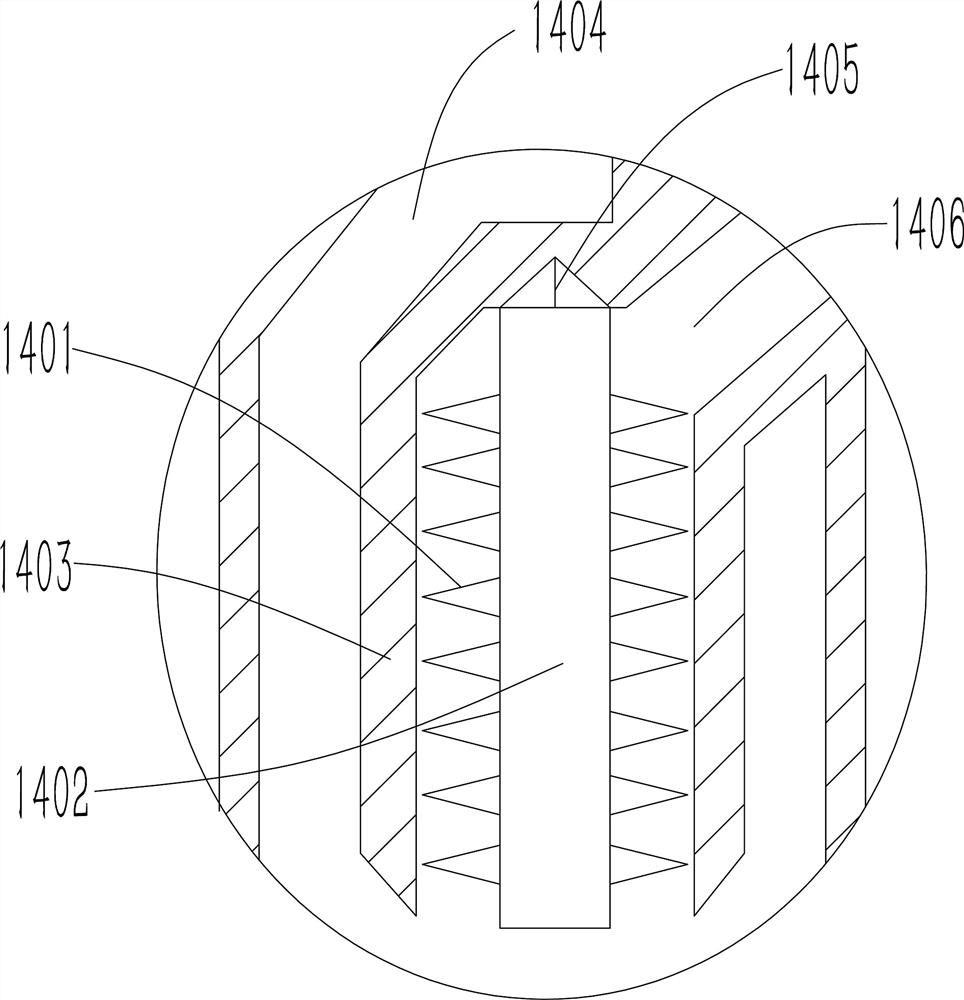

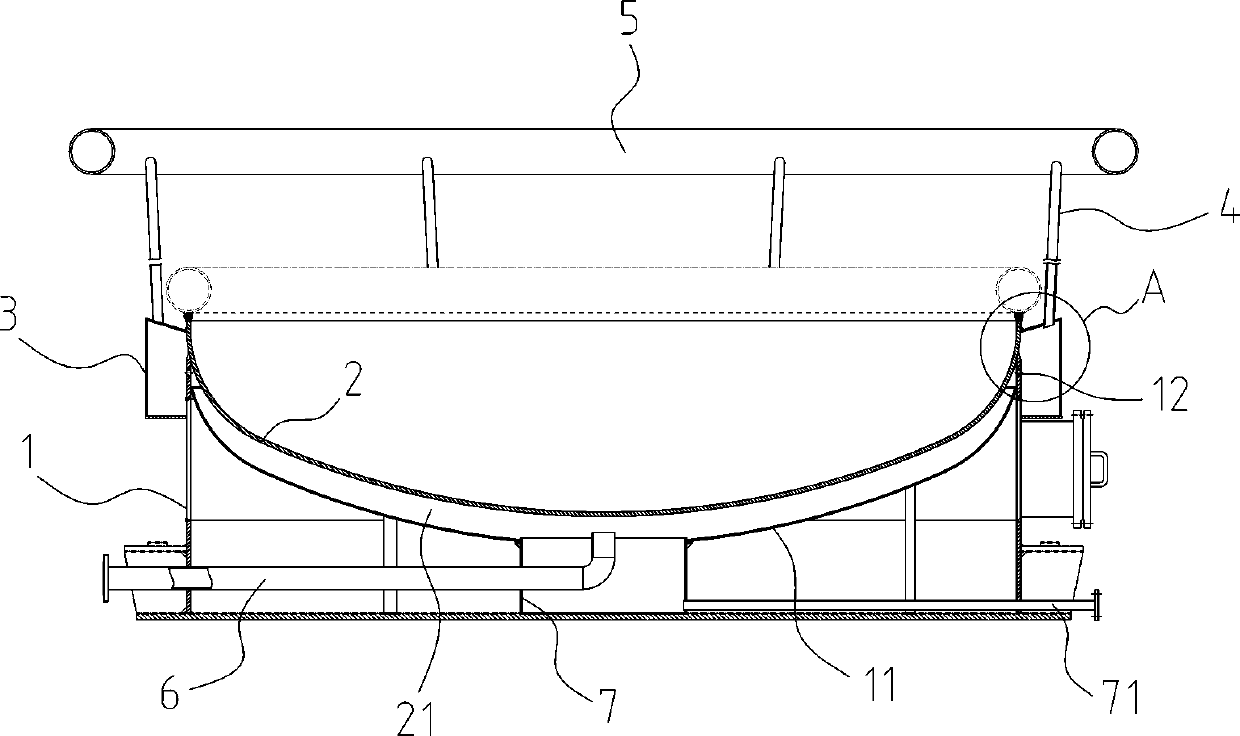

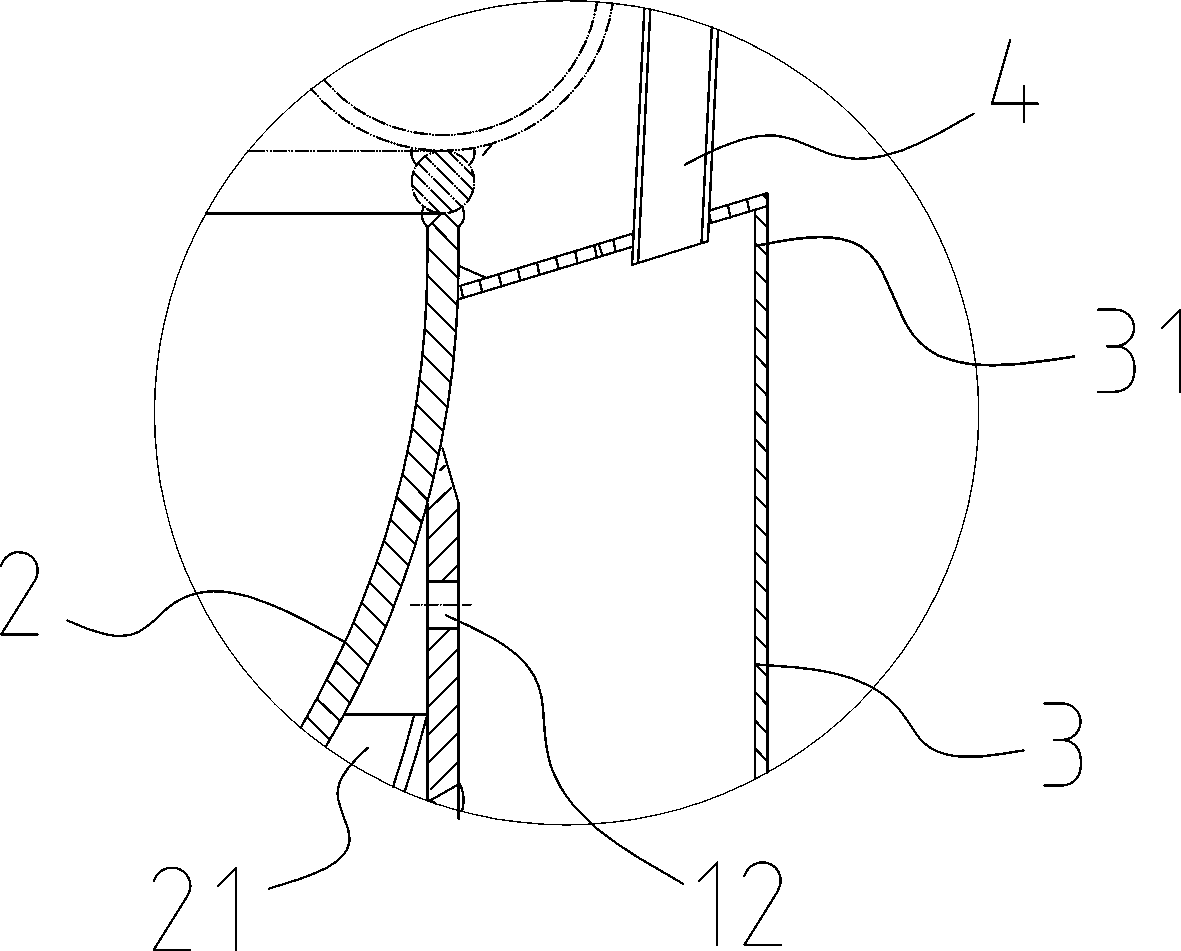

Powdered adsorbing material heating and precipitation device

PendingCN108579712AImprove heat transfer efficiencyUniform heat exchangeGas treatmentOther chemical processesResource utilizationProduct gas

The invention belongs to gas source recovery and resource utilization in the fields of energy saving and emission reduction, and particularly relates to a powdered adsorbing material heating and precipitation device. The powdered adsorbing material heating and precipitation device comprises a resolution tower body; a resolution tower is vertically placed, a material inlet is formed in the top of the resolution tower and a material outlet is formed in the bottom of the resolution tower; a heating layer and a cooling layer are arranged in the resolution tower body sequentially from top to bottom; a gas exporting and uniformizing device is arranged above each layer; a material heating pipe is arranged in the space of the heating layer; a cooling pipe is arranged in the space of the cooling layer; a heat exchange medium pipe box is arranged at the positions, corresponding to the heating layer and the cooling layer in the resolution tower body, of the outer wall of the resolution tower body; and the gas exporting and uniformizing device is formed by combining a supporting plate, a material conveying funnel, a porous net-shaped plate and an exhaust pipe. By a layered heating mode, the adsorbing material can resolute different gases in different heating areas; and a gas uniformizing device is provided, so that the gases with different components can be exported timely, the heat exchange uniformity of the materials is improved and the heat exchange efficiency is improved.

Owner:SHANDONG UNIV

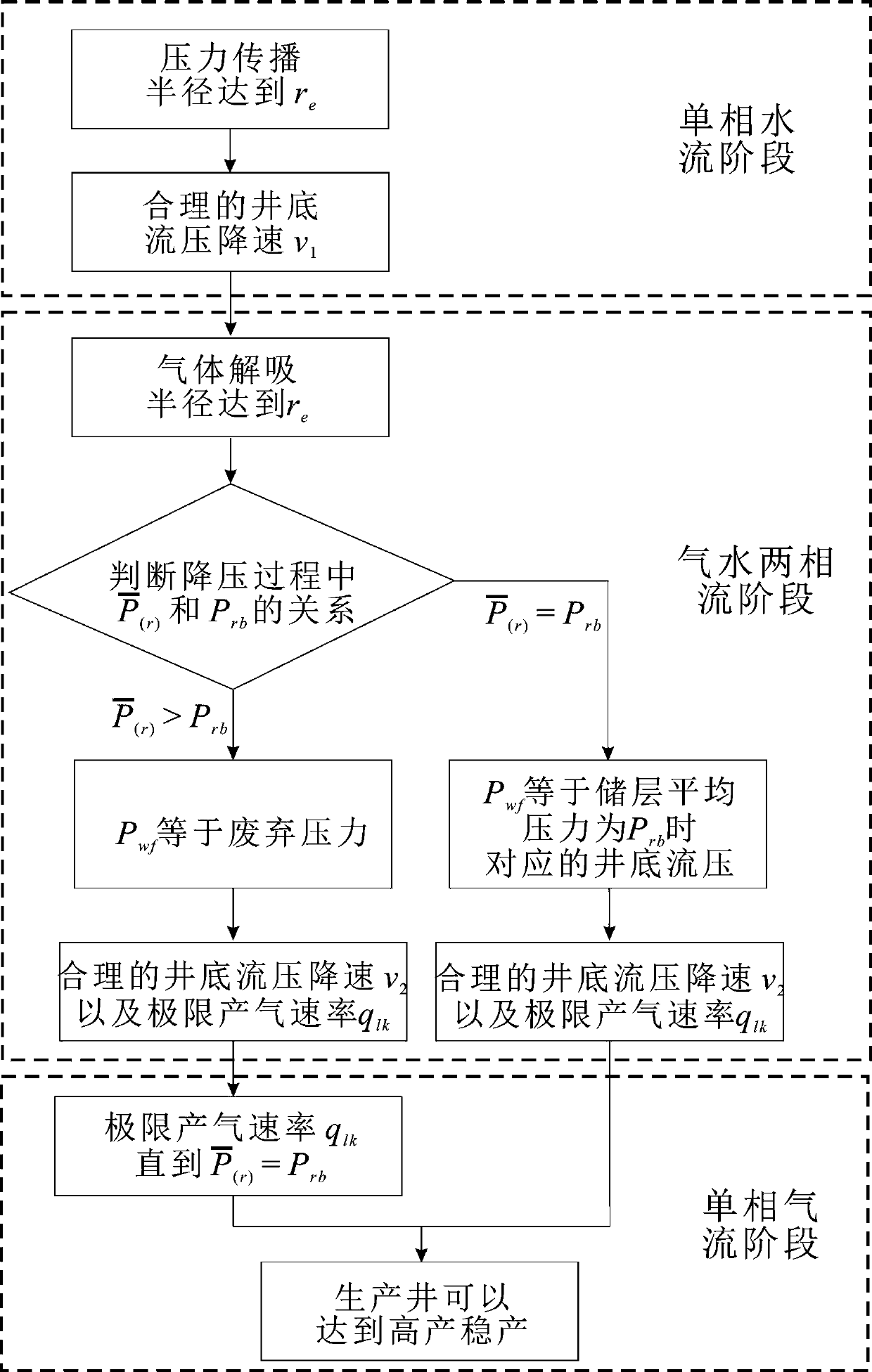

Calculation method for quantitative optimization of working system of coal-bed gas well

ActiveCN111027789ARealize pressure interferenceNot conducive to stress interferenceForecastingFluid removalBottom hole pressureThermodynamics

The invention discloses a calculation method for quantitative optimization of a working system of a coal-bed gas well. The calculation method comprises the following steps: (1) dividing a coal-bed gasproduction stage, namely sequentially dividing into a single-phase water flow stage, a gas-water two-phase flow stage and a single-phase gas flow stage; (2) establishing a drainage system optimization model; (3) optimizing a single-phase water flow stage drainage system; (4) optimizing a two-phase water flow stage drainage system; and (5) optimizing a single-phase airflow stage discharge and mining system. A working system optimization model established by the invention can reasonably guide the maximum bottom hole pressure reduction of the coal-bed gas well in the single-phase water flow stage and the gas-water flow stage, and the limit gas flow can effectively prevent the airlock caused by the large-scale desorption of the coal-bed gas until the average pressure of the reservoir reachesthe rebound pressure.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

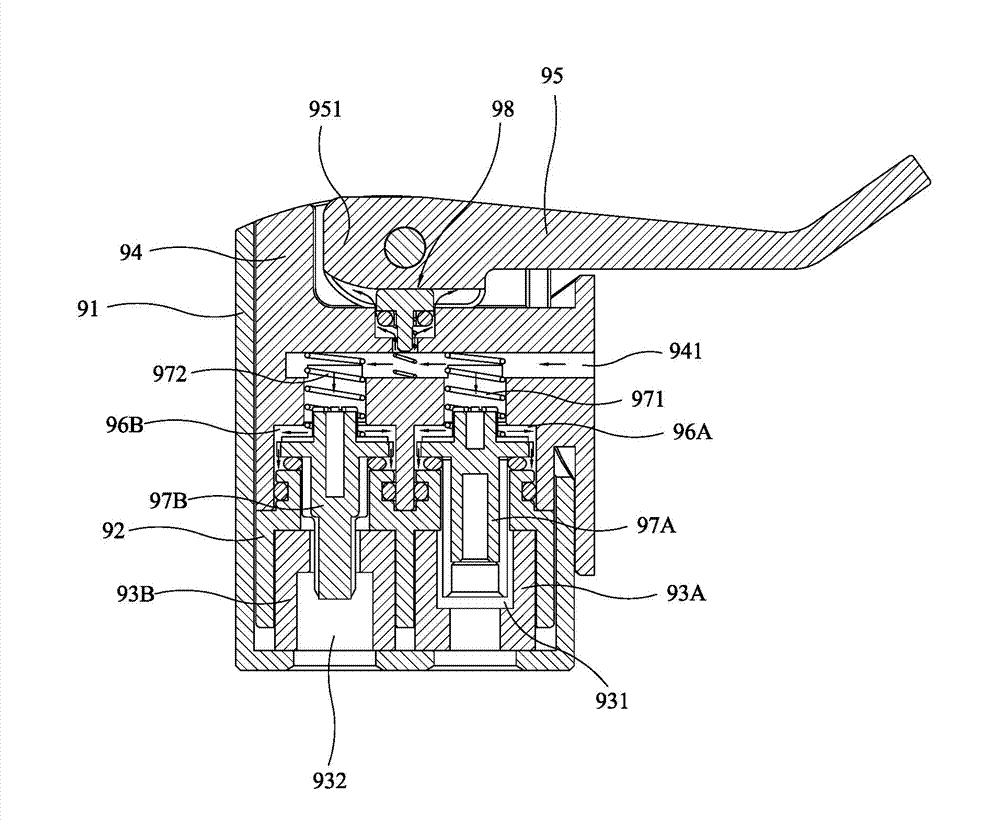

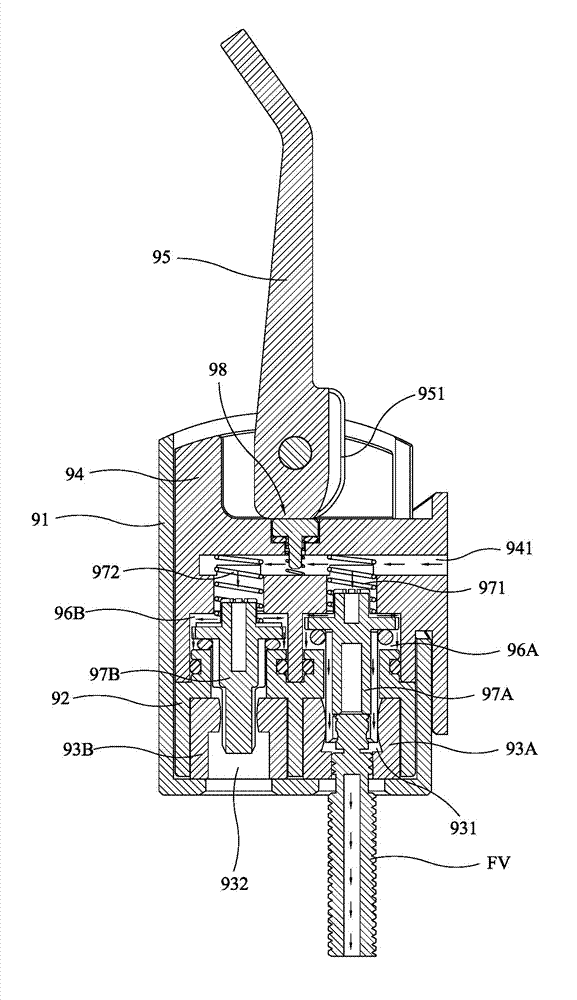

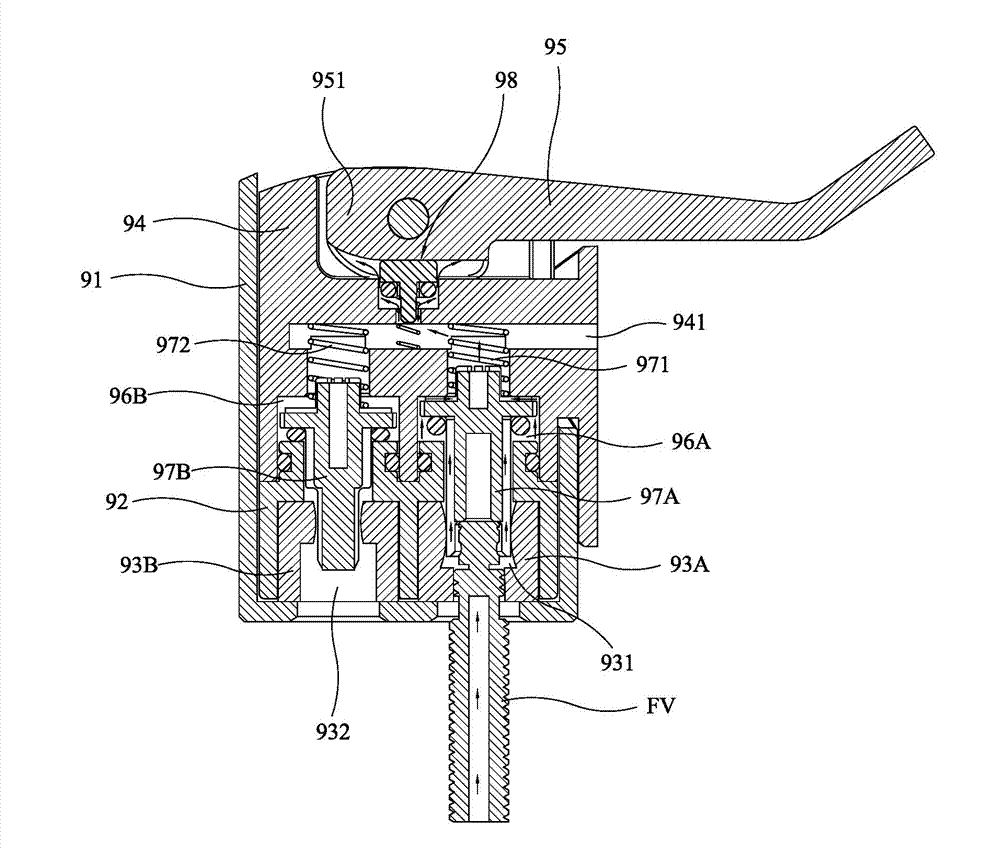

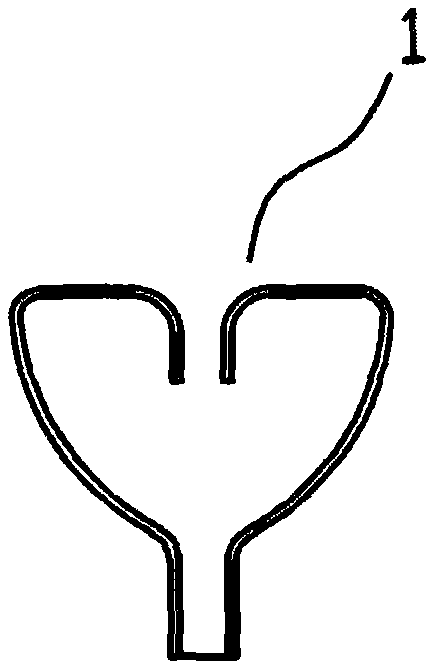

Inflating nozzle device

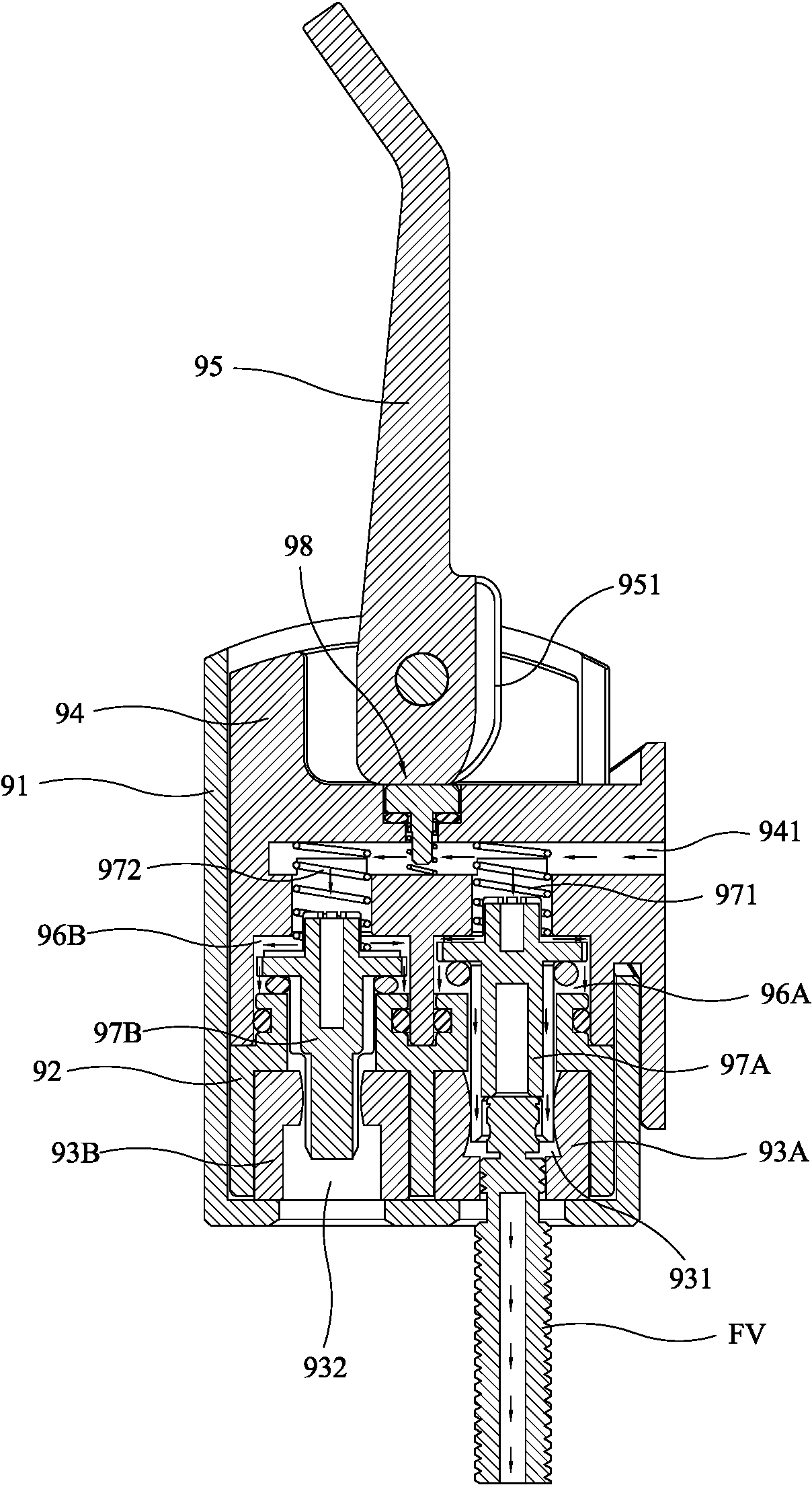

ActiveCN103090063AImprove massive deflationImprove the disadvantage of easy large-scale pressure reliefOperating means/releasing devices for valvesCheck valvesWrenchRelief valve

Owner:BETO ENG & MARKETING

Technique for preventing air lock through stuttered starting and air release slit for pumps

ActiveUS10267317B2Good and more cost-effectivePrevent air lockEngine fuctionsPriming pumpImpellerControl circuit

Apparatus, including a pumping system, is provided featuring a pump and a control circuit. The pump has an impeller housing configured with a slit at the top for trapped air to leave the impeller housing once the pump has been submerged. The control circuit is configured to cycle the pump on and off for a predetermined number of cycles so that the trapped air will float to the top and be expelled out the slit when the pump is cycled off. The control circuit is configured to leave the pump on after the predetermined number of cycles.

Owner:FLOW CONTROL LLC

Bubble breaking type mixing power transmission submersible pump impeller

ActiveCN110094358ASolve the problem of prone to air lockImprove air lock resistancePump componentsPumpsImpellerFront edge

The invention relates to a bubble breaking type mixing power transmission submersible pump impeller. The bubble breaking type mixing power transmission submersible pump impeller comprises a front cover plate, a shaft sleeve, a rear cover plate and a blade; the blade is a segmented blade, and a bubble breaking jet fracture opening breaks in the unfolding direction of the segmented blade and forms abubble breaking jet seam; a front blade is arranged in front of the bubble breaking jet seam, a rear blade is arranged behind the bubble breaking jet seam, and the shape of the bubble breaking jet seam is matched with the gap between the tail edge of the front blade and the front edge of the rear blade; the rear cover plate is provided with a plurality of gas breaking jet hole sets, each gas breaking jet hole set is composed of a plurality of round holes, the gas breaking jet hole set located at the front blade is a front jet hole set, and the gas breaking jet hole set located at the rear blade is a rear jet hole set. The bubble breaking type mixing power transmission submersible pump impeller can avoid gas locking under the condition that the gas content reaches 70% and normally jack gas-liquid mixed liquid.

Owner:NORTHEAST GASOLINEEUM UNIV

Sand and gas preventing oil pump

ActiveCN113217362AAvoid enteringPrevent air lockLiquid degasificationPositive displacement pump componentsPumpjackPlunger

The invention provides a sand and gas preventing oil pump, which comprises a pump cylinder assembly, wherein a sliding plunger assembly is arranged in the pump cylinder assembly; a gas-liquid separation assembly is arranged at an end of the pump cylinder assembly; a liquid feeding channel is formed in one side of the gas-liquid separation assembly; oil containing sand and gas enters the pump cylinder assembly via the liquid feeding channel; and a short plunger in the plunger assembly abuts against the interior of the pump cylinder assembly and slides hermetically, thereby forming a multi-stage sand settling and exhausting compression cavity. By adopting a three-stage sand prevention and two-stage gas prevention structure, the oil pump can adapt to crude oil extraction under a well condition of serious sand production, also has a good gas prevention effect, belongs to a special oil pump, can adapt to crude oil extraction under a well condition of serious sand production and high gas ratio, achieves a good sand prevention and gas prevention effect, and has a high bearing capacity and a long service life.

Owner:CSIC ZHONGNAN EQUIP

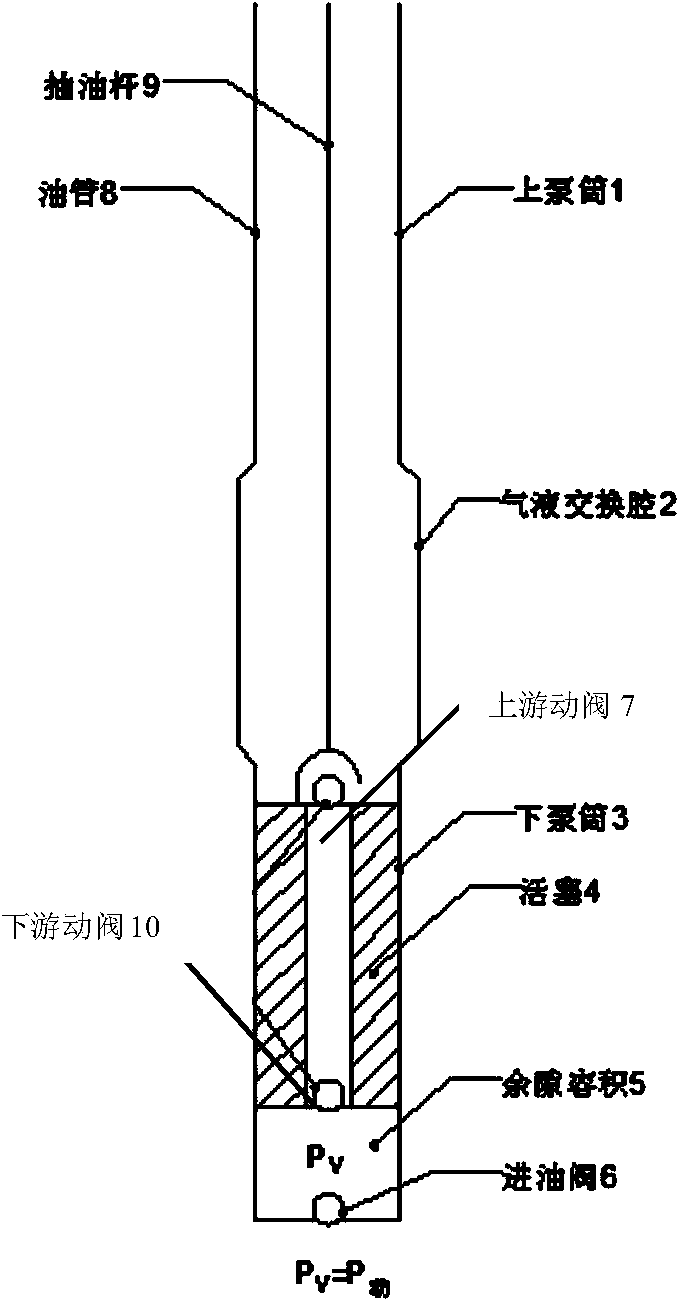

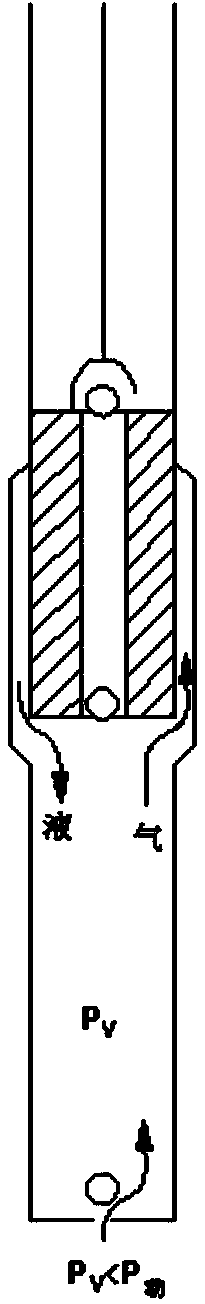

Anti-airlock oil well pump

InactiveCN104033366APrevent air lockImprove fill factorPositive displacement pump componentsFlexible member pumpsGas oil ratioPumpjack

An anti-airlock oil well pump can normally work in a high gas-oil-ratio oil well, associated gas and dissolved gas in the oil well will not make the pump locked by itself. The oil well pump comprises an upper cylindrical pump cylinder, a gas and liquid exchange cavity and a lower pump cylinder, an upper traveling valve, a piston and a lower traveling vale are arranged in the whole pump cylinder and connected in sequence, and a sucker rod is connected to the top end of the upper traveling valve; a spherical oil inlet valve is arranged in the center of the bottom end of the lower pump cylinder. The gas and liquid exchange cavity arranged between the upper pump cylinder and the lower pump cylinder is cylindrical, the piston arranged in the whole pump cylinder is matched with the inner surface of the upper pump cylinder and the inner surface of the lower pump cylinder for sealing, and annular space is formed between the piston and the inner surface of the gas and liquid exchange cavity. The anti-airlock oil well pump has the advantages that airlock of the oil well pump can be prevented, the fullness coefficient of the oil well pump is effectively increased, and the pump efficiency is improved; the oil well pump is used in the high gas-oil-ratio oil well for pumping oil, gas enters an upper pump and an oil pipe through the exchange cavity so that the specific gravity of a liquid column in the oil pipe is lowered, blowing is induced, spraying can be performed with pumping, and the yield is increased.

Owner:天津广兴万达石油科技有限公司

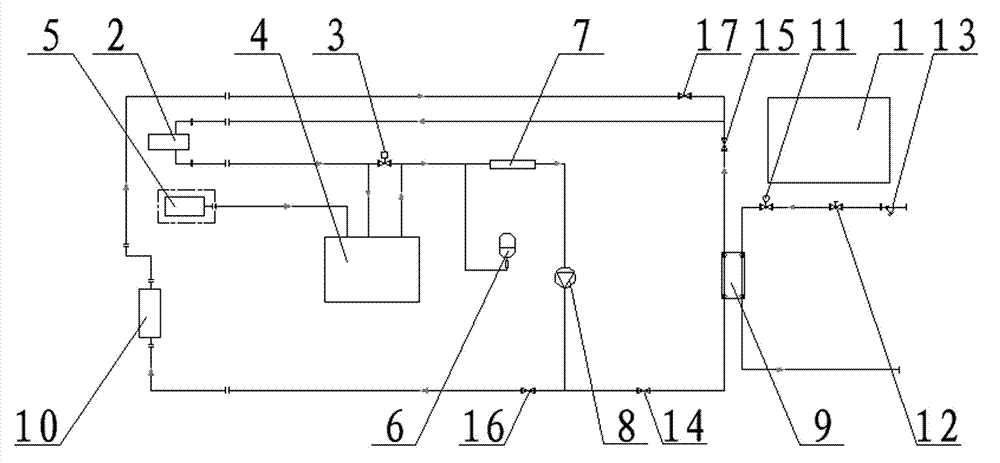

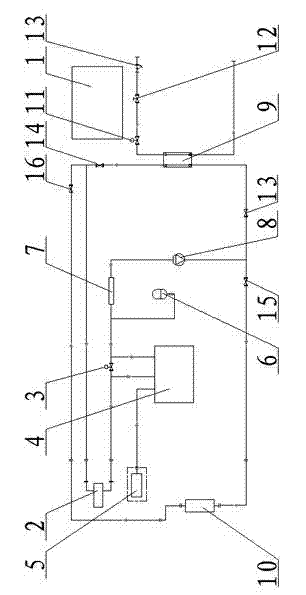

Constant-pressure hot water module for ships

ActiveCN102901171AEfficient exclusionSolve corrosiveSpace heating and ventilation safety systemsLighting and heating apparatusExpansion tankEngineering

The invention relates to a constant-pressure hot water module for ships. The constant-pressure hot water module for ships comprises an indirect air conditioner, a constant-pressure expansion tank, an ionized water processor, a water pump, a steam heating machine set, a water cooling machine set and a control box, wherein the indirect air conditioner is connected to the water pump sequentially through the constant-pressure expansion tank and the ionized water processor; the water pump is respectively connected with the steam heating machine set and the water cooling machine set; the steam heating machine set and the water cooling machine set are connected with the indirect air conditioner; an electromagnetic valve and a vacuum jet type exhausting device both of which are in mutually parallel connection are arranged between the indirect air conditioner and the constant-pressure expansion tank; the electromagnetic valve and the vacuum jet type exhausting device are connected to the control box. As the pressure fixing, water replenishing and exhausting devices are arranged on a set of pipe system which is shared by a heat source and coolant water system of an air-conditioning system, the constant-pressure hot water module for ships, disclosed by the invention, has the advantages of greatly saving manufacturing cost, and achieving the functions of removing gas in the system, adjusting the pressure in the water system, replenishing water of the system, filtering impurities in the water system and removing dirt in the system.

Owner:JIANGSU JOSUN AIR CONDITIONER

A bubble crushing hybrid transmission submersible pump impeller

ActiveCN110094358BSolve the problem of prone to air lockImprove air lock resistancePump componentsPumpsImpellerJet flow

The invention relates to an impeller of a bubble crushing type hybrid transmission submersible pump. The impeller of the bubble crushing type hybrid transmission submersible pump includes a front cover plate, a shaft sleeve, a rear cover plate and blades. The blades are segmented blades, and the bubble crushing jet The fracture is broken in the span direction of the segmented blade to form a bubble breaking jet slit. The front of the bubble breaking jet slit is the front blade, and the back of the bubble breaking jet slit is the rear blade. The shape of the bubble breaking jet slit is the tail of the front blade. The gap between the edge and the leading edge of the rear blade; there are multiple sets of gas fragmentation jet hole groups on the rear cover, each group of gas fragmentation jet holes is composed of multiple circular holes, and the gas fragmentation jet hole group at the front blade is The jet hole group in the front section, and the jet hole group in the rear section of the blade are the jet hole groups in the back section. The invention can avoid air lock under the condition that the gas content rate reaches 70%, and normally lift the gas-liquid mixture to produce liquid.

Owner:NORTHEAST GASOLINEEUM UNIV

A new intracavitary tumor cryoablation catheter and its operating method

ActiveCN104905873BRelieve air pressureAvoid destructionSurgical instruments for coolingCatheterCryoablation

The invention relates to a novel intraluminal tumor cryoablation catheter and an operation method thereof. The catheter comprises a balloon, an air intake pipeline, a return air pipeline, a vacuum pipeline, and proximal ends respectively connected to the intake pipeline, the return air pipeline and the vacuum pipeline. The air inlet joint, the air return joint and the vacuum joint are sealed and connected, and the vacuum pipeline is located outside the intake pipeline and the return gas pipeline. The conduit also includes a buffer unit, and the buffer unit is arranged at the far end of the inlet pipeline and is set In the balloon, the buffer unit is provided with a buffer air outlet, the proximal end of the buffer unit is sealedly connected with the distal end of the air intake pipeline or the air return pipeline, the distal surface of the balloon is concave, and the distal end of the buffer unit is far away from the balloon. The end is sealed and connected, and the connection point between the distal end of the buffer unit and the balloon is arranged in the middle of the inner recess of the distal end of the balloon or inside the distal end of the balloon. The catheter can cooperate with the endoscope to adapt to the complex cavity environment, and the distal end of the balloon has a larger contact area to ensure that it has a larger freezing range.

Owner:NINGBO SHENGJIEKANG BIOTECH

Constant-pressure hot water control method for ship

ActiveCN102889711BEfficient exclusionSolve corrosiveAuxillariesVessel ventillation/heating/coolingProduct gasEnvironmental engineering

Owner:JIANGSU JOSUN AIR CONDITIONER

Constant-pressure hot water control method for ship

ActiveCN102889711AEfficient exclusionSolve corrosiveAuxillariesVessel ventillation/heating/coolingProduct gasEnvironmental engineering

The invention relates to a constant-pressure hot water control method for a ship. Constant pressure, water supplement and air exhaust devices are arranged on a set of pipe system shared by a heat source of an air-conditioning system and a refrigerant water system, so that the manufacturing cost is greatly saved, and the method has the functions of removing gas in the system, setting the pressure of the water system, supplementing water in the system, filtering impurities in the water system and removing dirt in the system.

Owner:JIANGSU JOSUN AIR CONDITIONER

Long plunger anti-air separation and mixed out oil well pump

ActiveCN102661270BImprove pump efficiencyPrevent air lockPositive displacement pump componentsFlexible member pumpsThermodynamicsEngineering

The invention relates to a long-plunger-piston gas-locking-prevention respective pumping mixing oil well pump, which comprises an oil rod, an oil well pump joint, a dirt storage tube, a first pump tube joint, an upper pump tube, a plunger piston, a second pump tube joint, a piston, a constant pressure slide sleeve outer tube, a lower pump tube, a packer and a fixed valve, wherein the lower end of the oil rod is connected with the plunger piston, the plunger piston is arranged in the upper pump tube and the lower pump tube in a penetrating way, the upper part of the upper pump tube is sequentially provided with the oil well pump joint and the dirt storage tube, the second pump tube joint and the constant pressure slide sleeve outer tube are arranged between the upper pump tube and the lower pump tube, the piston is arranged in the constant pressure slide sleeve outer tube, the lower part of the piston is provided with a copper pin, and the tail end of the lower pump tube is sequentially connected with the packer and the fixed valve. The problems of poor oil extraction effect and interlayer mutual invasion caused by nonuniform energy of each storage layer and the like can be effectively solved, the gas locking can be effectively prevented, and the pump efficiency is improved.

Owner:西安格知石油科技有限责任公司

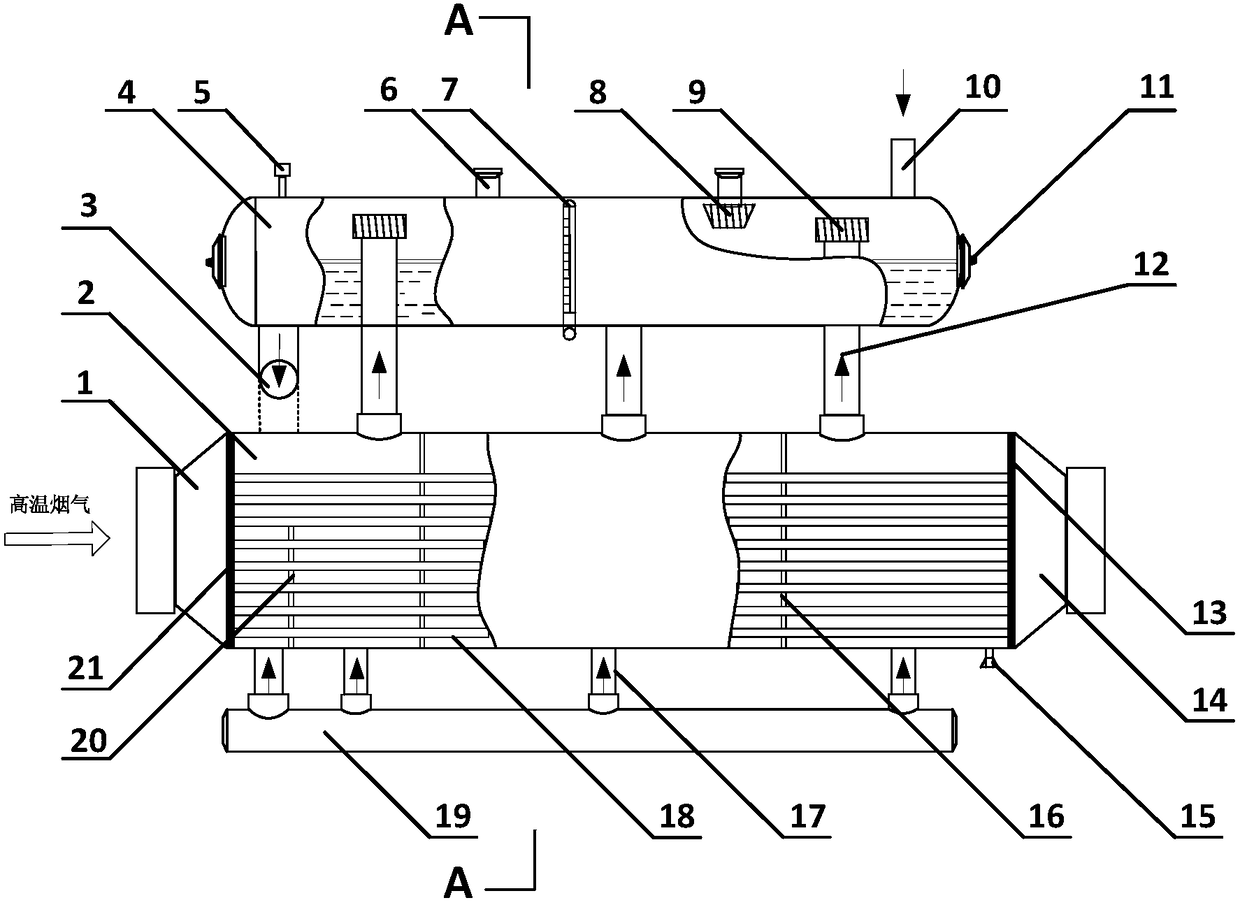

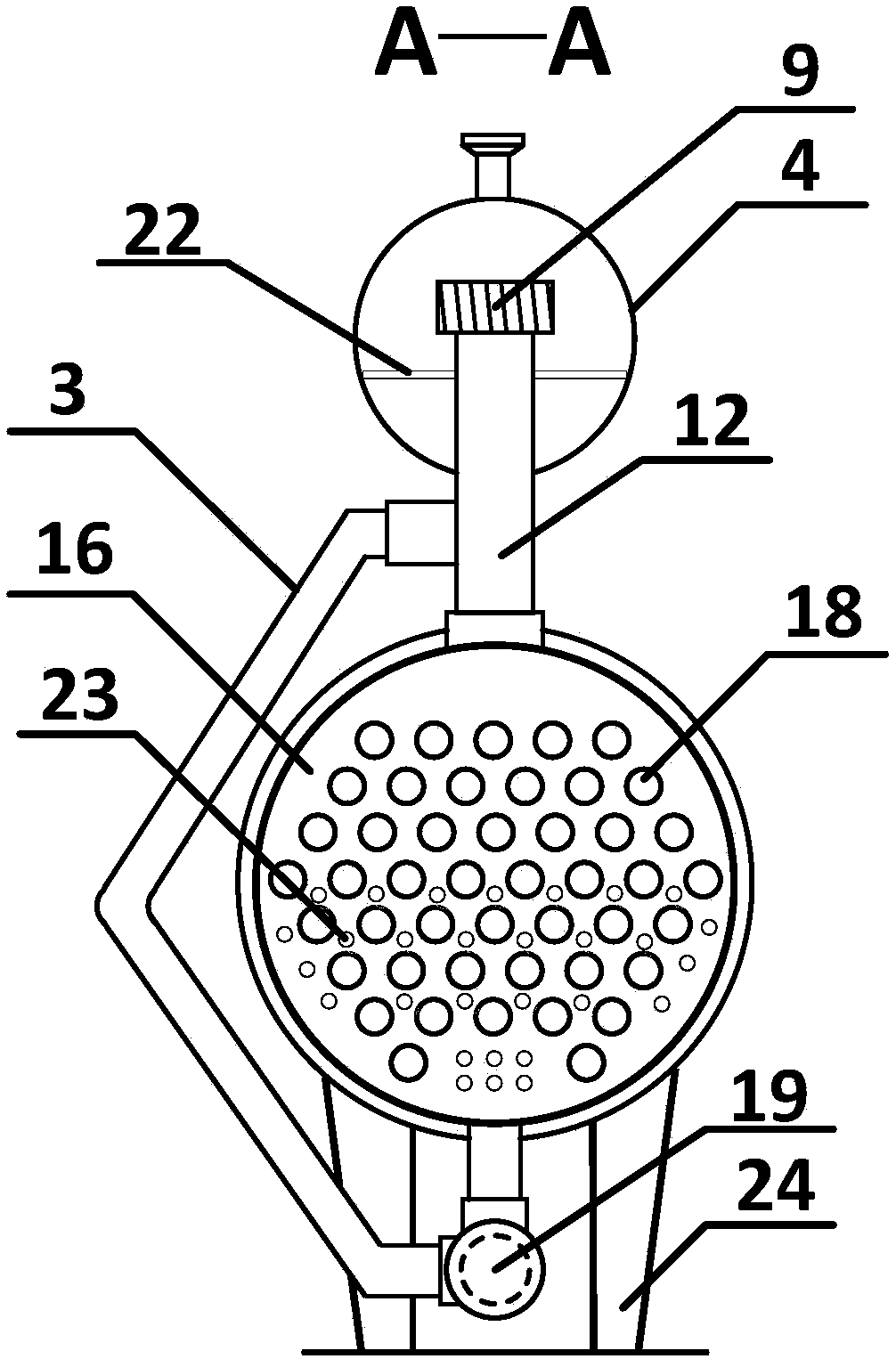

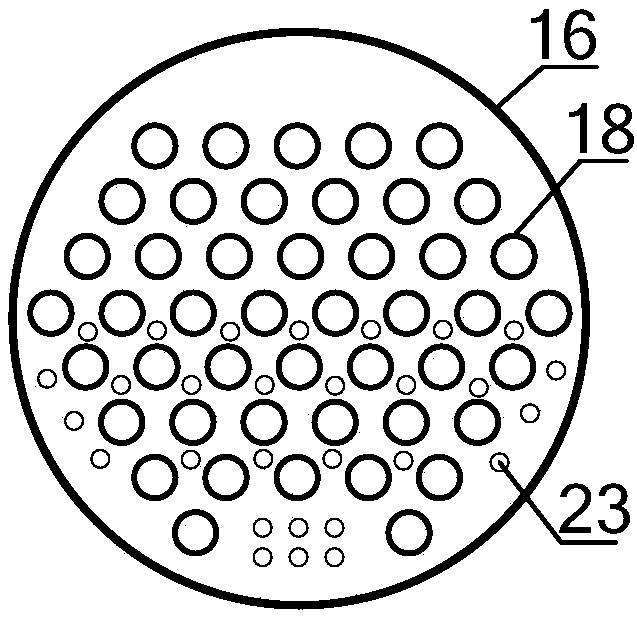

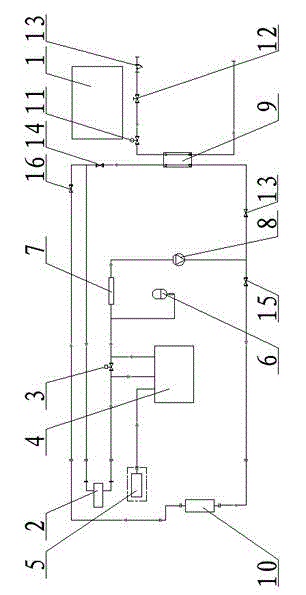

A Natural Circulation Split Tube Shell Waste Heat Boiler with Optimized Flow Field Arrangement

ActiveCN106287627BAvoid flow turbulenceResolve disorderSteam separation arrangementsWater-tube boilersThermodynamicsFlue gas

The invention relates to a natural circulation split shell-and-tube waste heat boiler with optimized flow field layout, which includes a drum and a steam drum. The drum is divided into a flue gas inlet, a heat exchange chamber and a flue gas outlet; The water pipe is connected to the water collection pipe; the heat exchange chamber is arranged with a heat exchange tube bundle; the heat exchange chamber is divided into several heat exchange units by arranging vertical support baffles, and each heat exchange unit is connected to the steam drum through a riser pipe. The upper ends of the ascending tubes extend into the steam drum and are always above the liquid level in the steam drum; there are tube holes on the support baffle for the passage of the heat exchange tube bundle, and there are holes between the tube holes on the lower part of the support baffle. The baffle hole; the steam drum is provided with a steam drum water supply port and several steam outlets; the steam drum is connected with the water collection pipe through the downpipe. The invention can solve the problem that the vapor-liquid two-phase flow in the middle and lower drum of the split-tube shell type waste heat boiler is disordered and the vapor-liquid two-phase flow in the rising pipe is stagnant or even reversed.

Owner:XI AN JIAOTONG UNIV

Constant-pressure hot water module for ships

ActiveCN102901171BEfficient exclusionSolve corrosiveSpace heating and ventilation safety systemsLighting and heating apparatusExpansion tankEngineering

Owner:JIANGSU JOSUN AIR CONDITIONER

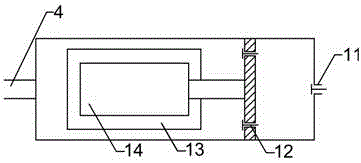

Flow pattern controllable type bubble atomizing nozzle

InactiveCN103225579BIncreased turbulence intensityIncrease the frequency of disengagementFuel injection apparatusMachines/enginesCombustionFuel oil

The invention discloses a flow pattern controllable type bubble atomizing nozzle, which belongs to the diesel engine fuel oil injection technology, and aims to solve the problem that the conventional bubble atomizing nozzle can not control the size of a bubble inside the nozzle, and the change of flow patters both in a nozzle and near nozzle hole. According to the flow pattern controllable type bubble atomizing nozzle, a liquid filling pipe (1), a liquid filling pipe sleeve (2), and the nozzle (6) of the bubble atomizing nozzle are connected through threads; opposite direction liquid filling holes (3) are formed in the end face of the liquid filling pipe (1); hydraulic diameter adjuster (7) at a bubble generating part and the nozzle are in threaded connection; the hydraulic diameter adjuster is coaxially arranged with a gas filling pipe (13) and a bubble generator (14); a first nozzle hole near geometry adjuster (8) and a second nozzle hole near geometry adjuster (12) are symmetrically arranged on two sides of a nozzle axis; and the first nozzle hole near geometry adjuster, the second nozzle hole near geometry adjuster, and the nozzle are in threaded connection. The bubble atomizing nozzle provided by the invention can control geometry conditions inside the nozzle to realize the adjustment of generated sizes and the flow patterns of the bubble, so as to improve the atomizing quality of the fuel injection, improve the combustion efficiency of a diesel engine, and reduce exhaust gases.

Owner:BEIJING JIAOTONG UNIV

Inflating nozzle device

ActiveCN103090063BImprove the disadvantage of easy large-scale pressure reliefImprove leakageOperating means/releasing devices for valvesCheck valvesCouplingCounter pressure

The invention discloses an inflating nozzle device. A first air nozzle, a cylinder, a valve block, and a lever are sequentially disposed in a head seat from bottom to top. The first air nozzle is provided with a first positioning hole allowing a Guillemin coupling to be inserted in. The cylinder is provided with a first cylinder hole communicated with the first positioning hole. A counter pressure passageway communicated with the first cylinder hole is formed at the top of the cylinder. A first valve is mounted in the first cylinder hole. A first spring is disposed at the top end of the first valve. The valve block is available for positioning the top end of the first spring and is provided with an inlet passage allowing inflation of an inflator and upper and lower containing holes communicated with the inlet passage. The lower containing hole is communicated with the top of the counter pressure passageway and receives a stopper. A normally open relief valve is mounted in the upper containing hole. One end of the lever is pivoted to the top edge of the head seat through a pin, and a cam capable of limiting the top end of the valve block is formed on the periphery of the pivoted end of the lever. The cam can be turned to switch off the relief valve so as to continuously push the valve block to move down to clamp and inflate the Guillemin coupling.

Owner:BETO ENG & MARKETING

Crude oil dissolved gas downhole collection device

InactiveCN103244077BDoes not affect daily production managementReduce wasteFluid removalLevel measurementProduct gas

The invention provides a downhole collection device for crude oil dissolved gas, which includes two sets of collection devices for collecting dissolved gas above and below the pump respectively, and suitable collection devices are selected for different oil wells. The collection device on the pump uses a sealing rubber tube to close the oil casing annulus near the wellhead, and the gas enters the tubing through the one-way valve to collect; when the well is flushed, the high-pressure well flushing fluid makes the sealing rubber tube inward, so as to continue downward, pushing the sealing sleeve to close the unit The well flushing fluid cannot enter the oil pipe through the one-way valve to ensure the smooth progress of well flushing; when measuring the dynamic fluid level, pressurize the oil sleeve annulus on the upper part of the sealing rubber cylinder, and the floating valve moves down to open the inner hole of the sealing rubber cylinder , forming a sound wave propagation channel. The collection device for collecting dissolved gas under the pump uses the packer to close the oil jacket annulus under the pump, the gas enters the pump to collect, and the liquid enters the oil jacket annulus through the oil jacket communication valve above the packer to form a dynamic liquid surface. Both sets of collection devices do not affect the daily maintenance of oil wells such as well washing and liquid level measurement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Positive well flushing oil well pump

InactiveCN101482107BIncrease the effective strokeEasy to openPositive displacement pump componentsFlexible member pumpsInlet valveEngineering

The invention relates to an oil-well pump capable of direct flushing. The oil-well pump is underground equipment which has the effects of sand prevention, gas prevention, wax prevention and high pump efficiency and is applied to oil exploration industry. In the oil-well pump, an upper plunger piston and a lower plunger piston are equipped with sand prevention slots, can send the sands deposited in the sand prevention slots to the underside of the pump to realize sand prevention. When the plunger pistons fall to a pump-bumping position, oil pipes above and below the pump are in communicated state by a pump cavity, thereby realizing the function of direct flushing. In the oil-well pump, an oil inlet valve can be opened easily under the hydraulic feedback action, thereby increasing the fullness coefficient, reducing the bend of a sucker rod, increasing the effective stroke of the pump, preventing air lock, reducing the fatigue loss of the sucker rod, and the oil-well pump has the functions and the characteristics of gas prevention and high pump efficiency.

Owner:韩东明

Furnace bottom sealing head for phosphorus burning furnace

The invention relates to a furnace bottom sealing head for a phosphorus burning furnace. The furnace bottom sealing head for the phosphorus burning furnace comprises a skirt seat, an upper sealing head and a disc-shaped sealing head connected onto the bottom of the phosphorus burning furnace, wherein the lower sealing head is provided with a disc-shaped recessed part; the disc-shaped sealing headis fixedly connected into the disc-shaped recessed part; the outer surface of the disc-shaped sealing head and the surface of the disc-shaped recessed part form a sealed cavity; the bottom of the sealed cavity is communicated with a water inlet pipe; an annular water sleeve sleeves outside the upper end of the lower sealing head; the upper end of the sealing cavity is communicated with the annularwater sleeve through a plurality of water outlet holes; a plurality of water outlet pipes are communicated with the upper end of the annular water sleeve; each water outlet hole and each water outletpipe are uniformly distributed around the axial line of the annular water sleeve.

Owner:HUBEI LIUSHUGOU CHEM TECH

Split pressure reducing valve and method

PendingCN112814619AExclude influenceImprove pump efficiencyWell/borehole valve arrangementsSealing/packingEngineeringStructural engineering

The invention discloses a split pressure reducing valve. The split pressure reducing valve comprises an outer pipe, a lower inner pipe, a lower valve seat and a lower pressure reducing valve element, wherein the lower end of the outer pipe is connected to the outer wall of the upper end of a lower connector; the lower end of the lower inner pipe is connected to the inner wall of the upper end of the lower connector; an annular channel is formed between the outer wall of the lower inner pipe and the inner wall of the outer pipe; the lower end of the lower valve seat is connected to the upper end of the lower inner pipe; and the lower pressure reducing valve element is arranged on the outer wall of a pull rod in a sleeving mode, an outwards-protruding annular table is arranged on the outer wall of the lower pressure reducing valve element, and the outer diameter of the outwards-protruding annular table is larger than the inner diameter of the minimum position of the inner wall of the lower valve seat. According to the split pressure reducing valve, when an oil pumping pipe column stretches out and draws back alternately, a sleeve cannot be abraded, the service life of the sleeve is long, the production time of an oil well can be prolonged, and the economic benefits of the oil well can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com