Oil Well gas-liquid mixed conveyor

A gas-liquid mixed transport pump, oil well gas technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as heat generation, damage to pump efficiency, and failure to work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

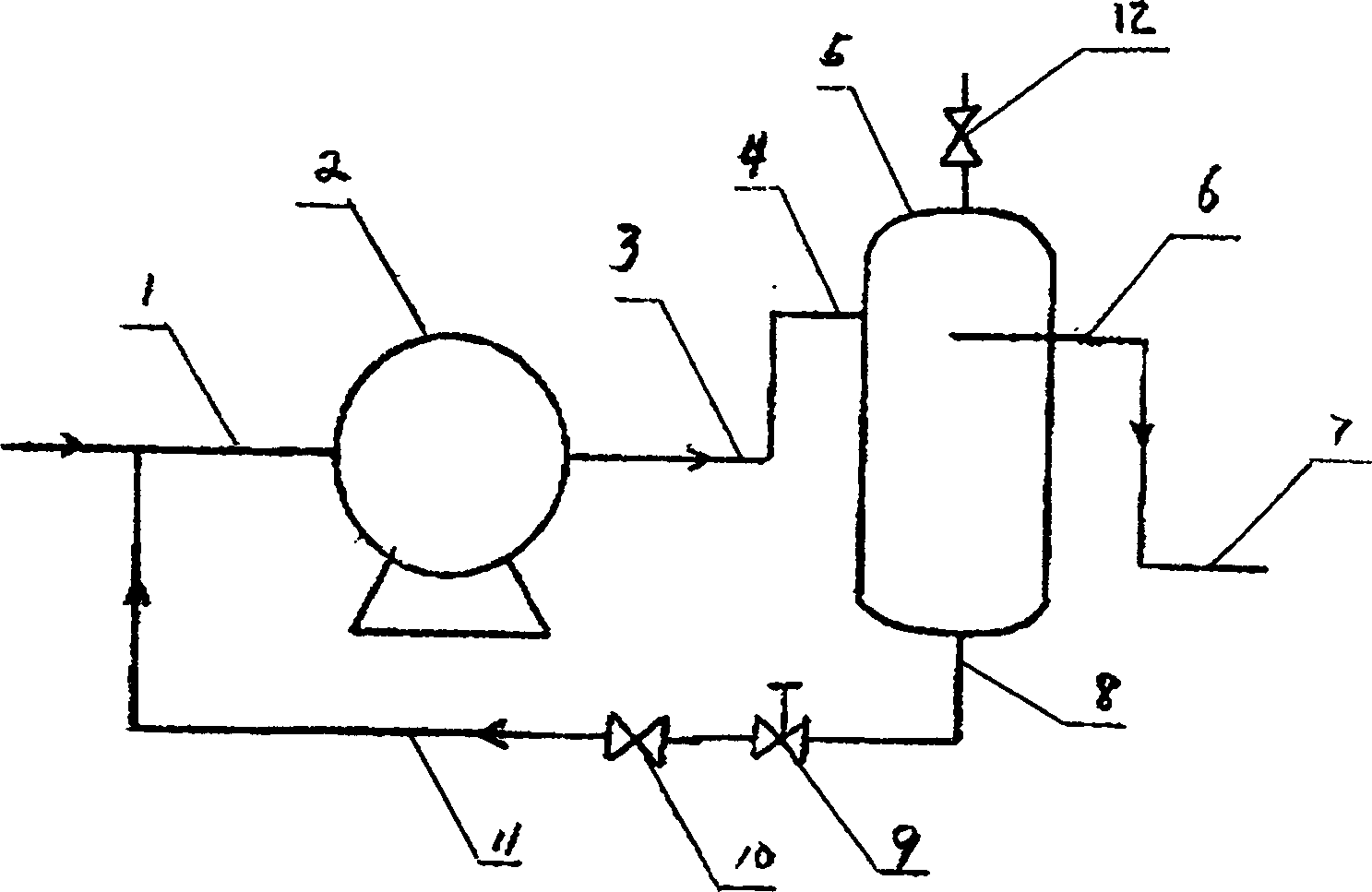

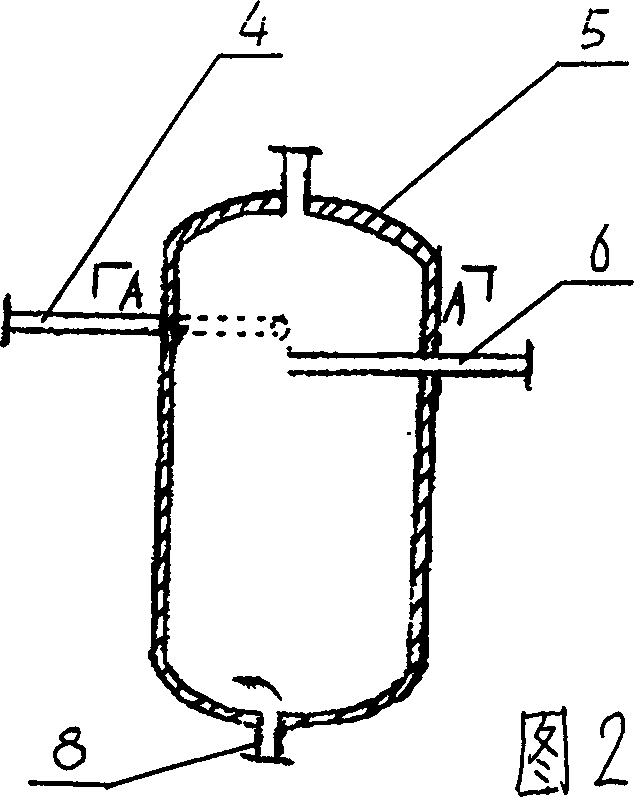

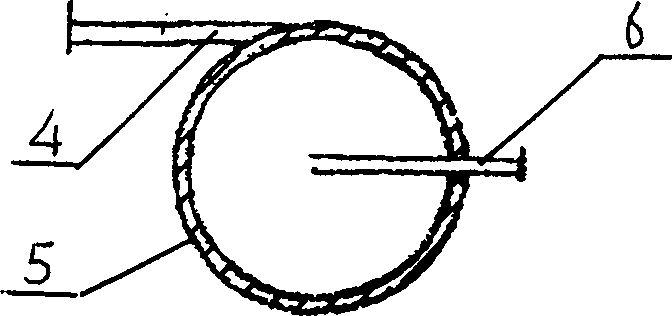

[0009] Such as Figure 1-3 As shown, the oil well gas-liquid mixed transportation device of the present invention is mainly composed of a gas-liquid mixed transportation pump and a gas-liquid separator connected by pipelines. The inlet 4 of the empty tank type gas-liquid separator 6 with a safety valve 12 on the top is connected to the outlet pipeline 7 of the gas-liquid mixed pump 2, and the lower outlet 8 of the gas-liquid separator 5 is connected to the gas-liquid mixed pump 2 through the return line 11. 2 is connected to the inlet pipeline 1, and the return pipeline 11 is provided with a solenoid valve 9 and a regulating valve 10.

[0010] When the present invention works, the mixed gas-liquid produced by the oil well enters the gas-liquid mixed transport pump 2 through the inlet pipeline 71 and enters the gas-liquid separator 5 through the outlet pipeline 3 after being boosted by the gas-liquid mixed transport pump 2, and the gas-liquid separator 5 A part of the separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com