A bubble crushing hybrid transmission submersible pump impeller

A technology of bubble crushing and pump impeller, applied in non-variable-capacity pumps, pumps, pump components, etc., can solve the problem of easy gas lock when high gas-containing oil is lifted, so as to improve the anti-air lock ability and reduce the Flow loss, the effect of improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

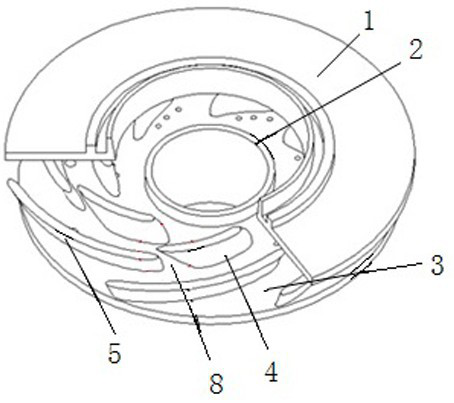

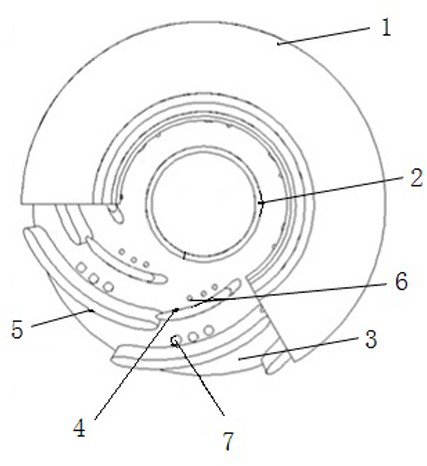

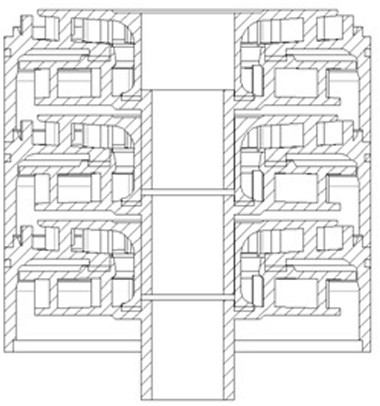

[0023] combine figure 1 , figure 2 As shown, the impeller of this bubble-breaking hybrid transmission submersible pump includes a front cover plate 1, a shaft sleeve 2, a rear cover plate 3, and blades. The blades are segmented blades, and there are bubble-breaking jet slots 8 , the fracture of the bubble breaking jet is disconnected in the span direction of the segmented blade, and the shape is the gap between the trailing edge of the front blade and the leading edge of the rear blade; the front blade 4 is in front of the bubble breaking jet slit 8, and the bubble breaking jet Behind the slot 8 is the rear blade 5 . The fracture of the bubble breaking jet is located between 1 / 3-1 / 2 of the chord distance of the segmented blade, the opening width is 2-5mm, the opening height is the same as the spanwise height of the blade, and the opening is inclined, which is consistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com