Furnace bottom sealing head for phosphorus burning furnace

A phosphorus-burning furnace and head technology, applied in the direction of phosphorus oxides, etc., can solve the problems of natural pressure, local steam is not easy to discharge, reduce the natural pressure of cooling water, etc., achieve uniform water flow, uniform local steam, prevent gas The effect of plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

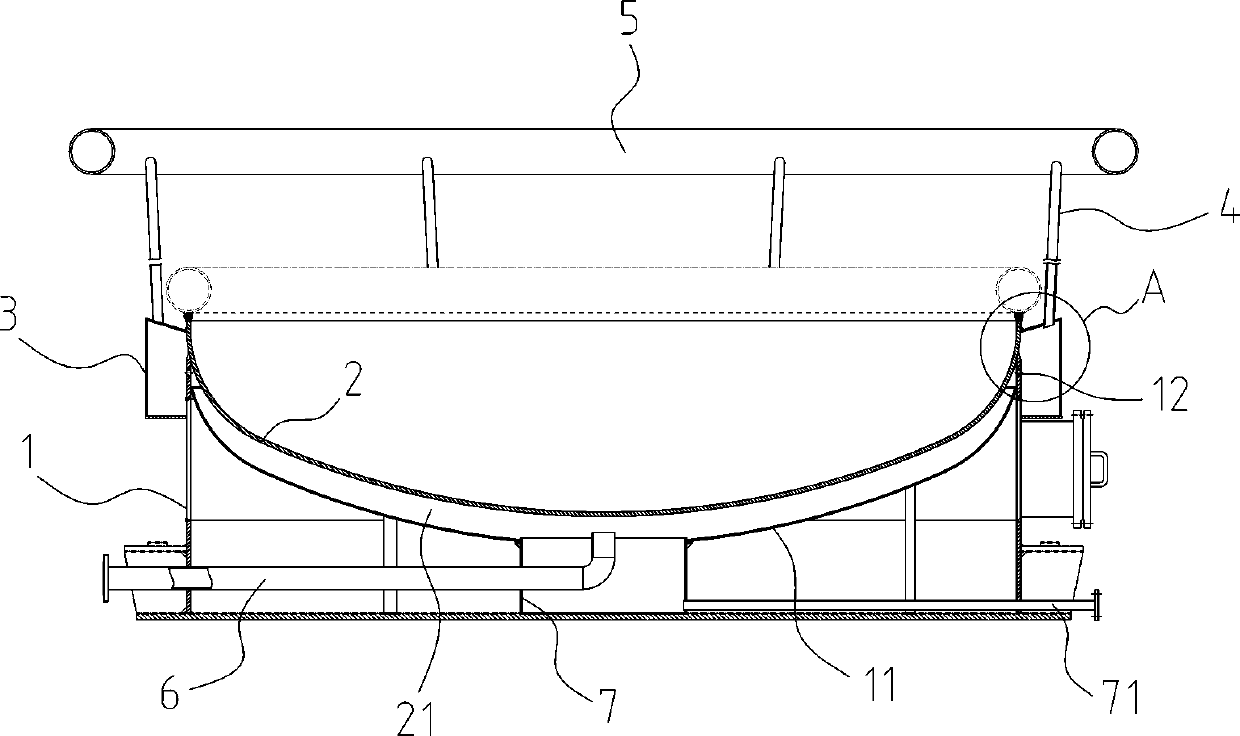

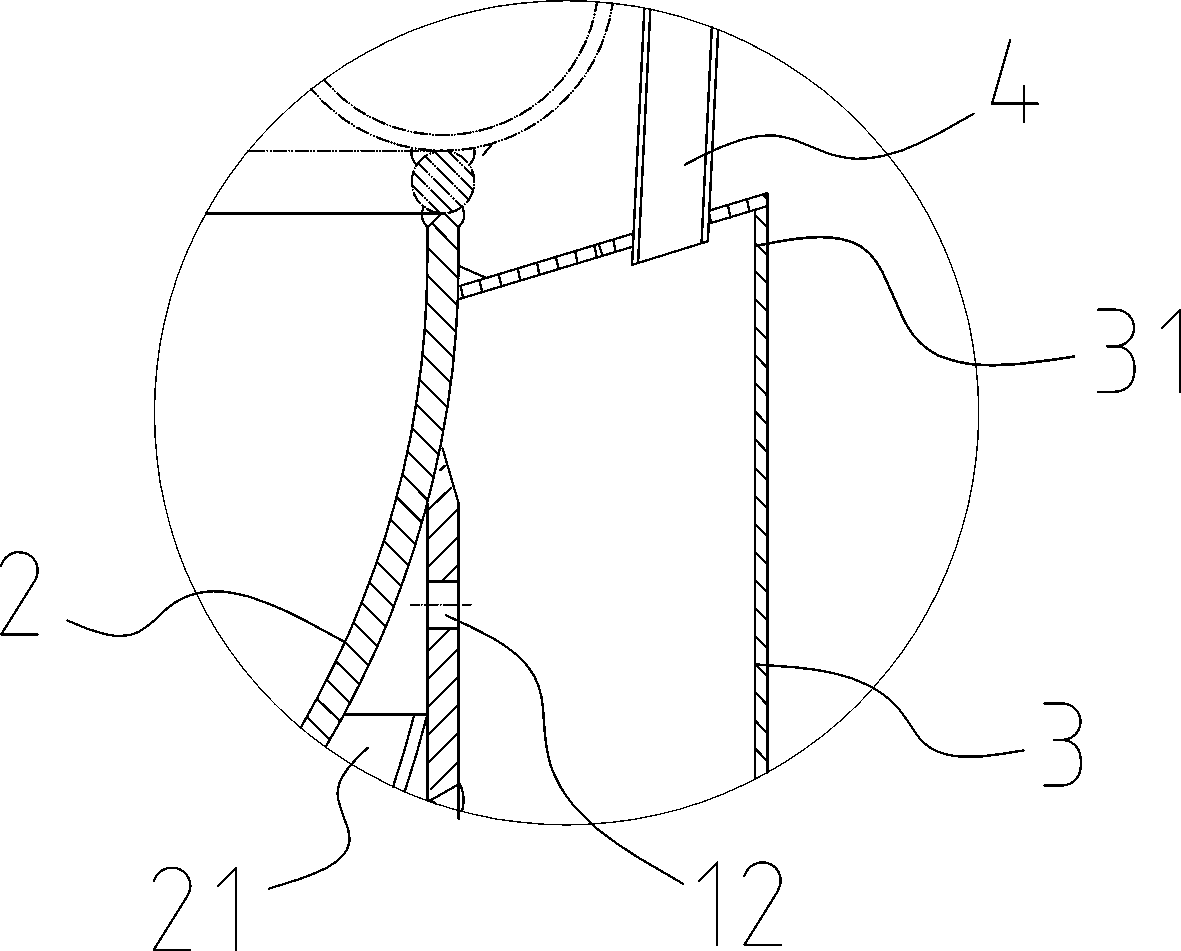

[0016] Such as Figures 1 to 3 As shown, a bottom head of a phosphorus-burning furnace includes a skirt 1, a lower head 11 and a dish-shaped head 2 connected to the bottom of a phosphorus-burning furnace. The lower head 11 has a dish-shaped depression, and the dish-shaped head 2 Fixedly connected in the dish-shaped depression, a sealed cavity 21 is formed by the outer surface of the dish-shaped head 2 and the surface of the dish-shaped concave. The water inlet pipe 6 is connected to the bottom of the sealed cavity 21, and there is an annular water jacket on the upper end of the lower head 11. 3. The upper end of the sealed cavity 21 communicates with the annular water jacket 3 through a plurality of water outlet holes 12, and a plurality of water outlet pipes 4 are connected at the upper end of the annular water jacket 3, and each water outlet hole 12 and each water outlet pipe 4 surround the annular water jacket 3 The axes are evenly distributed. The water flows into the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com