Calculation method for quantitative optimization of working system of coal-bed gas well

A technology for quantitative optimization of coalbed methane wells, applied in calculation, earthwork drilling, wellbore/well components, etc., can solve the problems of no quantification, less influence of pressure drop funnel expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

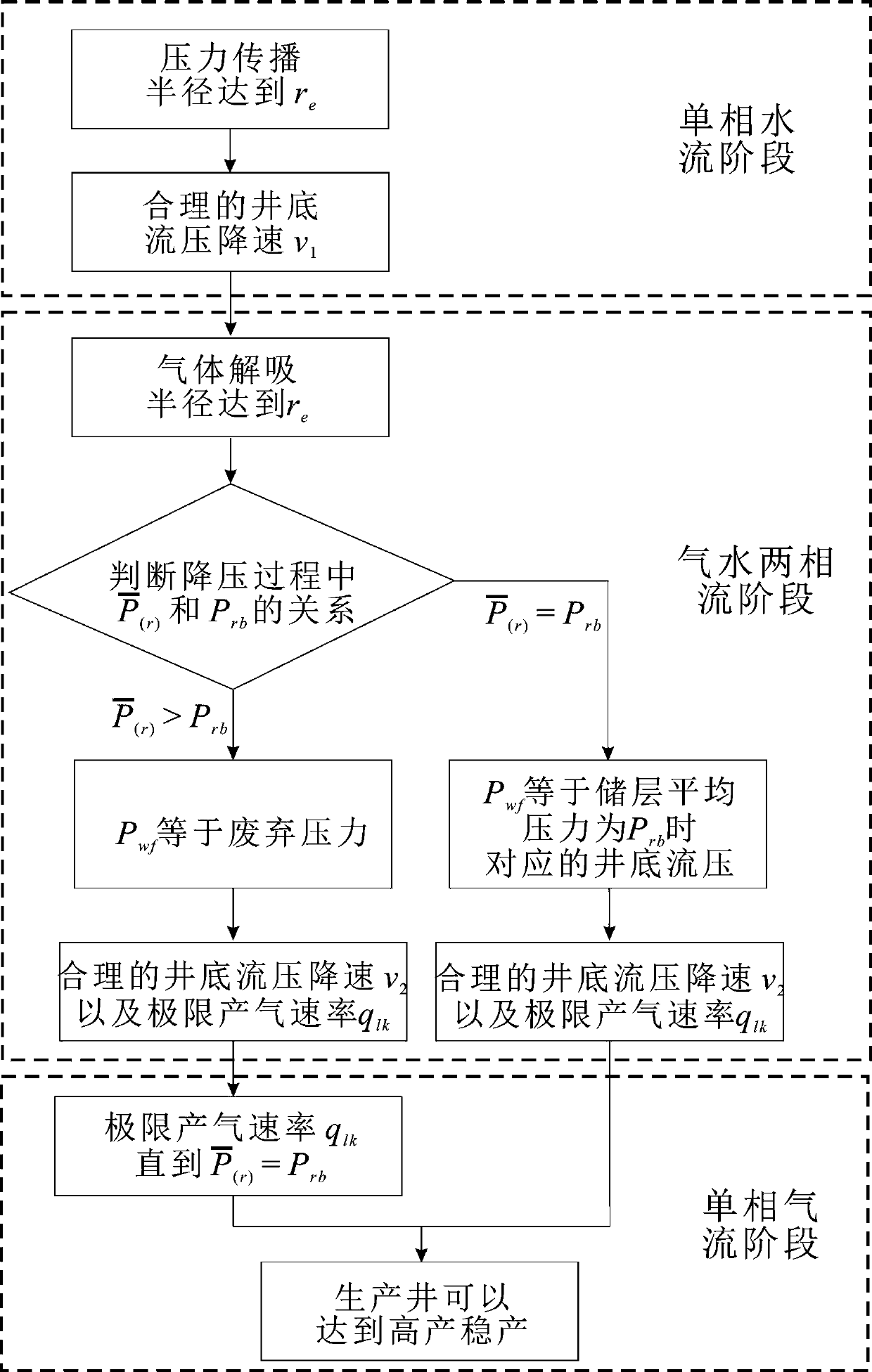

[0066] The calculation method for quantitative optimization of the working system of coal-bed methane wells of the present invention, and the calculation method for quantitative optimization of the working system of coal-bed methane wells of the present invention include the following steps

[0067] (1) Divide the coalbed methane production stage: It is divided into single-phase water flow stage, gas-water two-phase flow stage and single-phase gas flow stage in sequence;

[0068] (2) Establish an optimization model for the drainage system;

[0069] (3) Optimize the single-phase flow drainage system;

[0070] (4) Optimize the two-phase flow stage drainage system;

[0071] (5) Optimize the single-phase gas flow stage drainage system.

[0072] The specific division process of step (1) is to use numerical simulation and numerical analysis methods to characterize the dynamic changes of the pressure drop funnel during the development of CBM, such as figure 1 with figure 2 Shown:

[0073] Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com