Droplet deposition apparatus

A droplet and actuator technology, applied in printing, inking devices, etc., can solve problems such as uneven shrinkage and crossing of piezoelectric materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In the drawings, similar elements are denoted by the same reference numerals.

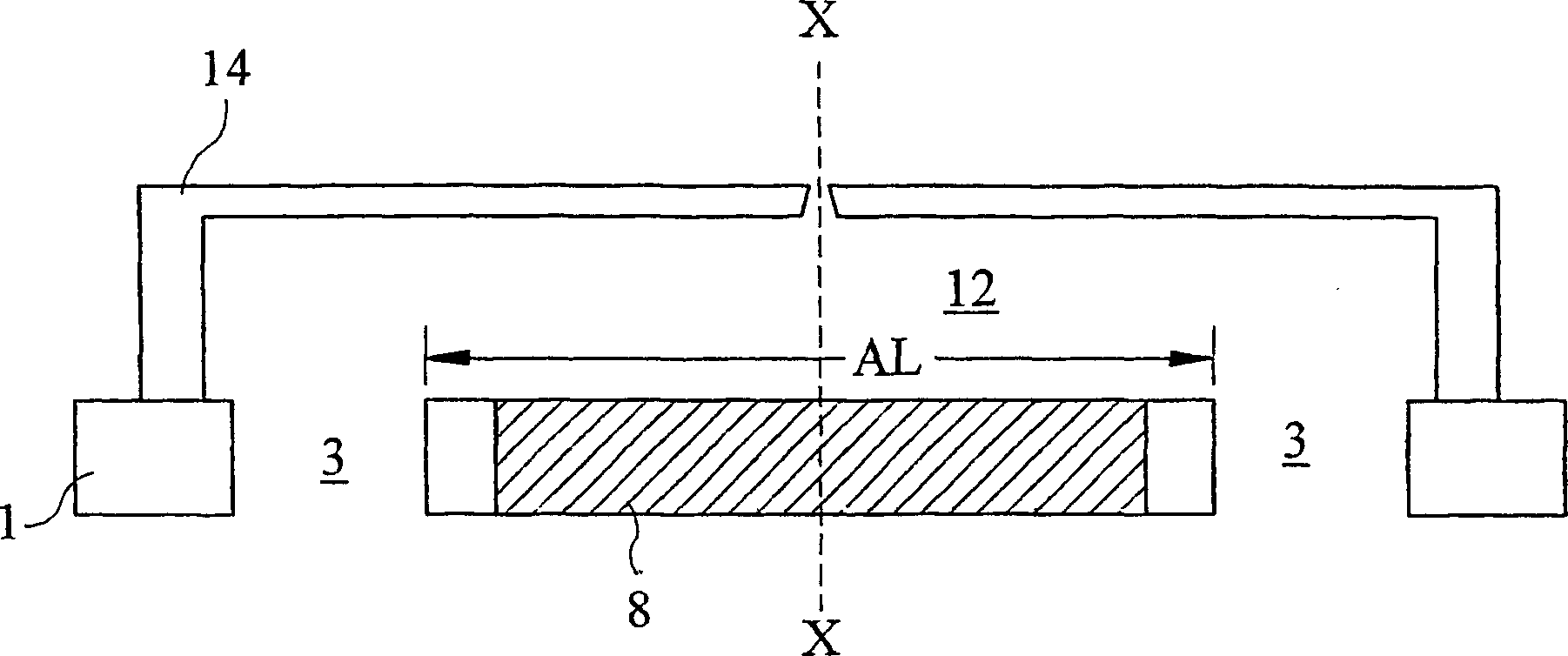

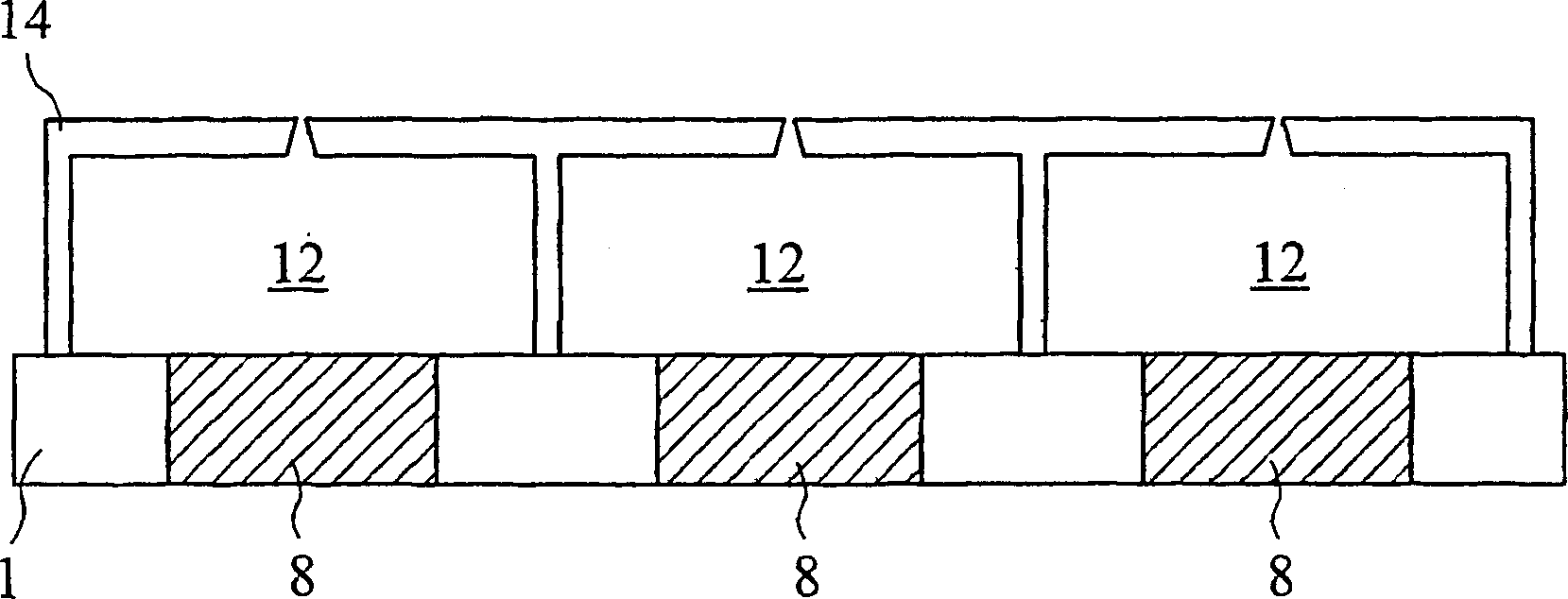

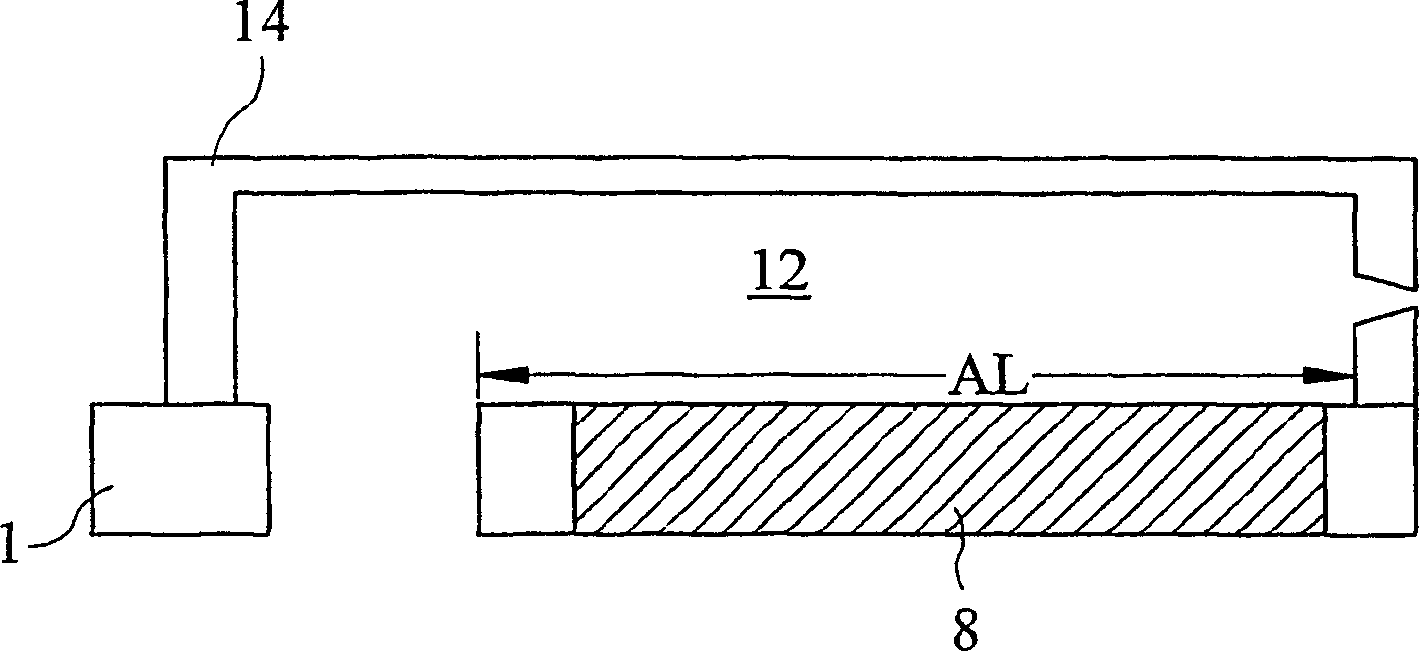

[0062] refer to Figure 1A with 1B ,in Figure 1B is along Figure 1A In the cross-sectional view of line X-X, the impulse droplet printing head consists of a cover element 14 and an actuator element 1, and has an ejection chamber 12 defined between these elements.

[0063] The cover element 14 is made of a nickel alloy, which is a material thermally matched to the material of the actuator element 12 , which is mainly silicon but also includes the active part 8 . The firing chamber is elongate and has an acoustic length AL defined by the distance between ink supply ports 3 formed through the actuator elements. The variation in ink depth at the ink supply port provides an acoustic boundary that effectively reflects sound waves propagating in the ink.

[0064] The ink supply port 3 is arranged to supply ink into the chamber or to allow a jetting fluid to circulate through the chamber by pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com