Sand and gas preventing oil pump

An oil well pump and sand control technology, which is applied to pumps, pumps with flexible working elements, components of pumping devices for elastic fluids, etc., can solve the problems of not being able to adapt to sand production, and the air pump does not have sand control characteristics, etc., to achieve The structure is simple and reliable, and the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

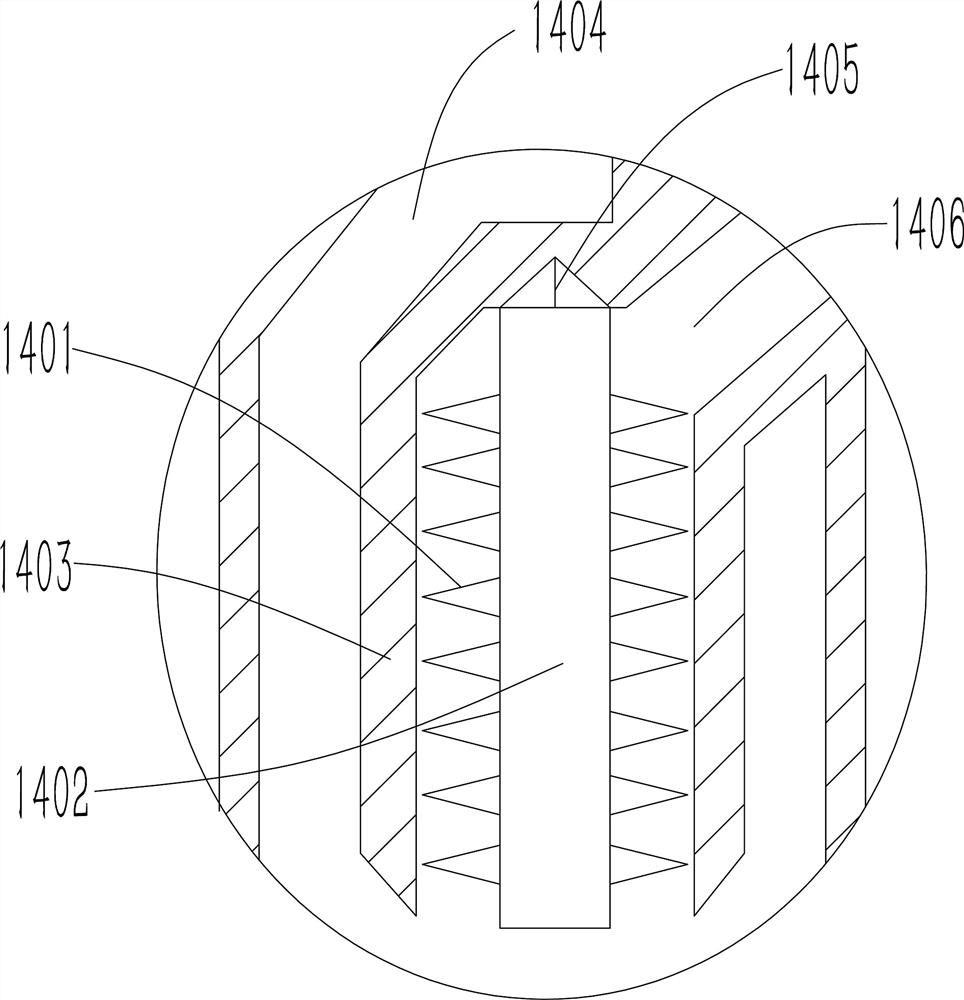

[0030] Such as Figure 1~2 As shown, the sand-proof and gas-proof oil well pump includes a pump barrel assembly, which is provided with a sliding plunger assembly, and the end of the pump barrel assembly is provided with a gas-liquid separation assembly 14, and the gas-liquid separation assembly One side of 14 is provided with a liquid inlet passage 1406, and the oil containing sand, gas and sand is passed into the pump barrel assembly through the liquid inlet passage 1406, and the short plunger 21 in the plunger assembly is sealed against the inside of the pump barrel assembly Sliding to form a compression chamber for multi-stage grit settling and exhaust.

[0031] In the preferred scheme, the pump barrel assembly consists of an upper collar 1, an elastic locking claw 2, a grit chamber 3, a support ring 4, a pump barrel extension barrel 5, an intermediate collar 6, a short pump barrel 7, a bridge pipe 8, a long The pump barrel 9, the lower coupling 10, the outer pipe 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com