Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Prevent stuck pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil well sand prevention method for heavy oil reservoir

The invention discloses an oil well sand prevention method for a heavy oil reservoir, which is applied to heavy oil exploitation in oil fields. The method comprises the following steps of: preparing, namely pulling a production pipe column out, inserting a sand removal pipe column, exploring a sand surface, removing sand, throwing a ball for pressure tests, and pulling the sand removal pipe column out; pigging, cleaning a pipe, washing a well, and pulling a pigging pipe column out; performing sand prevention construction, namely inserting a sand prevention pipe column for magnetic positioning depth calibration; making the pressure tests qualified; performing seat sealing, and opening a filling channel; filling direct circulation sand carrying liquid and quartz sand; washing hands, lifting the sand prevention pipe column upwards and pulling a hand washing pipe column; and inserting an oil exploitation production pipe column into the whole well. The invention has the advantages that: the method is applied to oil well sand prevention and has the one-time success rate of 100 percent, and a single well can be used for continuous production for more than 600 days.

Owner:PETROCHINA CO LTD

Long plunger type double barrel anti-coal powder drainage pump

InactiveCN102287358AAvoid swingingAvoid depositionPositive displacement pump componentsFlexible member pumpsCouplingInlet valve

The invention provides a long-plunger type dual-barrel coal-dust resistant discharging and extracting pump capable of preventing eccentric wear and coal dust from burying pump, blocking pump and prolonging the pump detection period. The pump consists of a centering body, a pump barrel assembly, a piston assembly, a liquid outlet valve and a liquid inlet valve assembly; a centering locking claw is inserted in a lock sleeve of an upper coupling to realize positioning and sealing of the centering body and avoiding eccentric wear between the plunger and the pump barrel; an internal barrel can prevent the deposited coal dust in the annulus of a bar pipe from entering the gap between the plunger and the pump barrel; the coal dust is dropped back to a tail pipe through the annual cavity between the external barrel and the pump barrel to prevent the coal dust from burying the pump; the structure of the long-plunger short pump barrel can promptly discharge the coal dust in the gap between the plunger and the pump barrel, so as to protect the internal and external working surfaces of the pump barrel and preventing the pump from being blocked; the well liquid stored in the coal-dust resistant tank washes the coal dust in the liquid outlet valve cover and the coal dust deposited at the upper part of the liquid outlet valve through a jet orifice, so as to realize an automatic washing function of the liquid outlet valve and preventing the coal dust from jamming the pump; and a spring is cooperated with a liquid inlet valve ball positioning pin, so that the liquid inlet valve ball can be fast reset, and the pump valve under a low submergence can be realized in smooth on and off.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

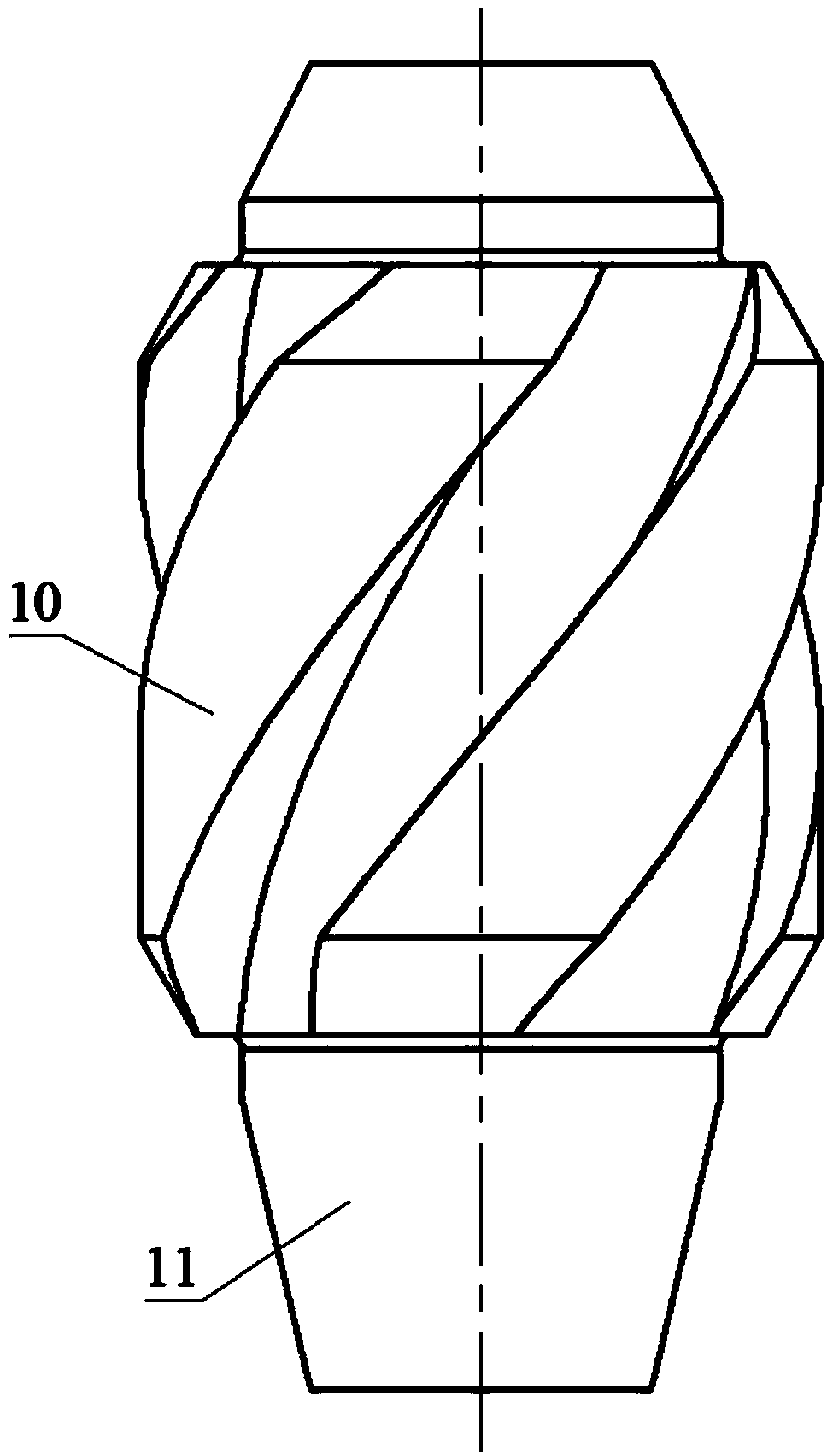

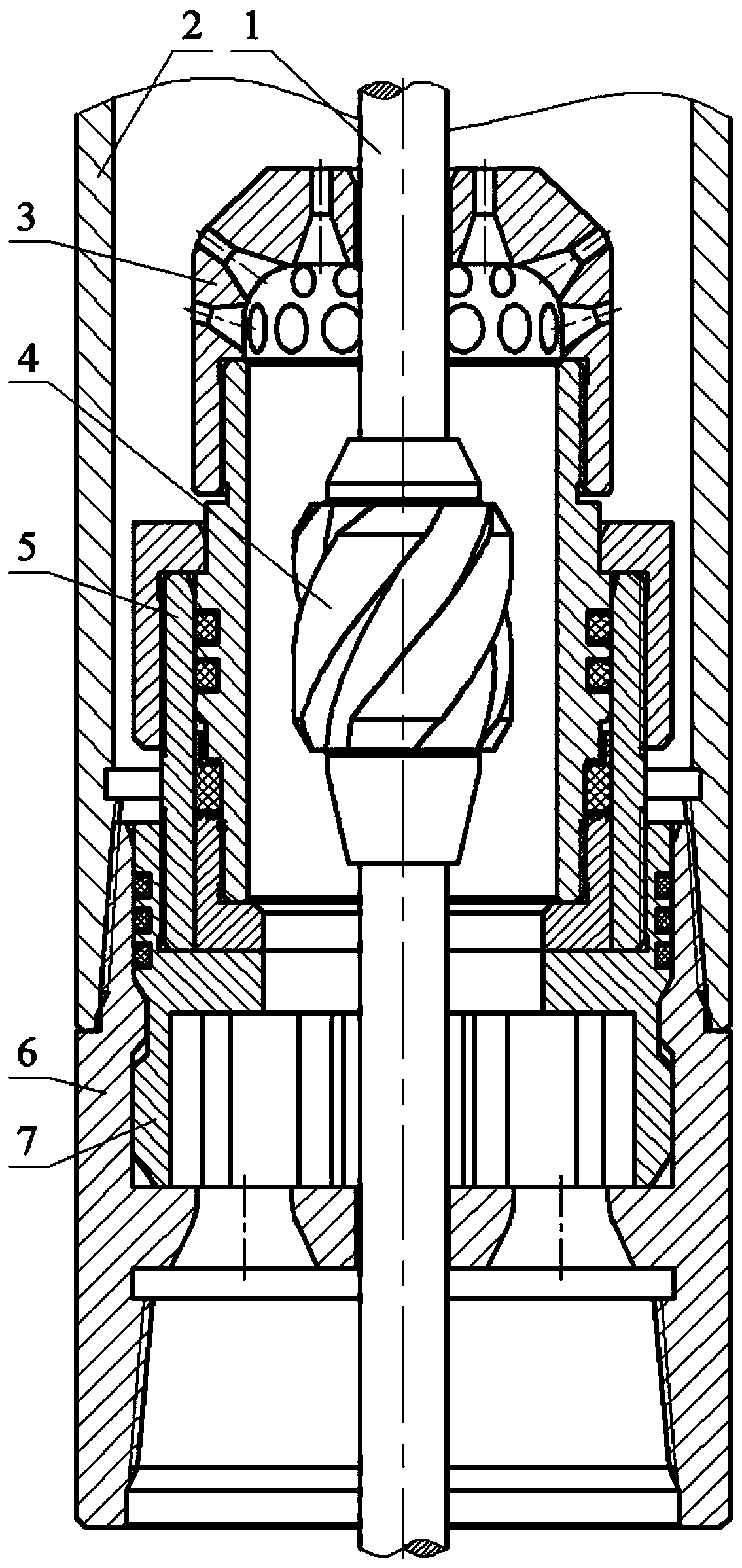

Separation and crushing device of downhole pulverized coals of coalbed methane and method thereof

InactiveCN104389560APrevent stuck pumpExtend the pump inspection cycleFluid removalGrain treatmentsCoalWorking range

The invention discloses a separation and crushing device of downhole pulverized coals of coalbed methane and a method thereof. The settling separation, the crushing and the filtration are performed for the pulverized coals, so that the particle size of the pulverized coals entering a screw pump reaches a normal working range of the screw pump, the accidents of pump blockage, blockage and abrasion caused by the pulverized coals with larger particles entering the screw pump can be effectively prevented, the pump detecting period is prolonged, the development cost of the coalbed methane is reduced, and the blockage of holes of a coalbed methane well by the pulverized coals is prevented; and the device has the advantages of simple structure, convenience for use and high efficiency.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Salt recrystallization inhibitor for oil and gas well and preparation method of salt recrystallization inhibitor

The invention discloses a salt recrystallization inhibitor for an oil and gas well. The salt recrystallization inhibitor is prepared from the following components according to the 100 percent proportion of volume sum: 60 to 80 parts of organo metallic complex, 10 to 35 parts of inorganic complex, 2 to 8 parts of corrosion inhibitor and 2 to 8 parts of antiswelling agent. A preparation method of the salt recrystallization inhibitor for the oil and gas well is characterized by comprising the following steps of firstly, taking the components according to the proportion, and sequentially placing the various taken component raw materials into a reaction kettle; secondly, reacting at the temperature of 50 to 90DEG C; thirdly, drying a product obtained by reaction and synthesis; fourthly, crushing the dried product to obtain the inhibitor. The shape of a sodium chloride crystal can be changed from a cubic shape into a branch shape or a snowflake shape, so that the adhesive power of the crystal on a solid surface is reduced, and further the dissolubility of sodium chloride in water is increased; in addition, the salt recrystallization inhibitor is free of influence from calcium and magnesium ions, and salt block or holddown can be effectively prevented.

Owner:成都西油华巍科技有限公司

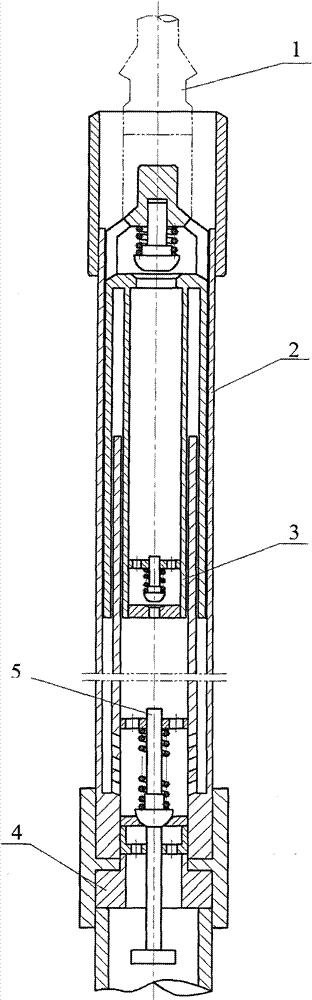

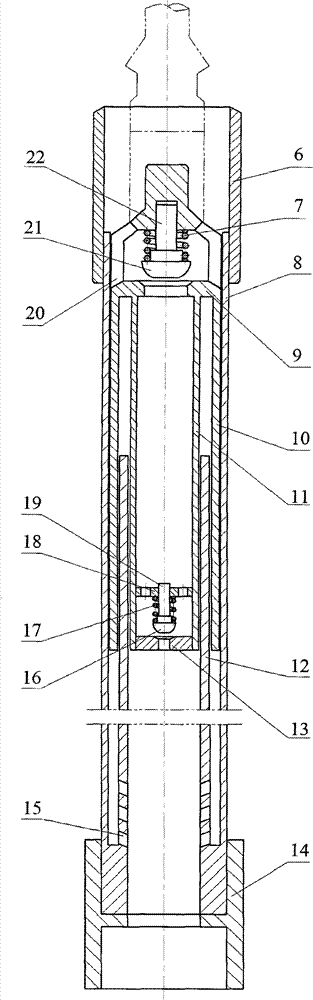

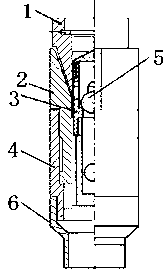

Multifunctional double-acting hydraulic oil producing device

ActiveCN101936147AForce balanceGreat driving forceFlexible member pumpsFluid removalHydraulic cylinderInlet valve

The invention relates to a multifunctional double-acting hydraulic oil producing device which is characterized in that a two-way oil-well pump is placed in an oil well running casing, a long plunger piston is arranged in the two-way oil-well pump, a hollow draw rod is arranged on the long plunger piston, and pistons and hydraulic cylinders are arranged in the hollow draw bar; a two-way oil-well pump barrel is arranged between every two hydraulic cylinders, a traveling oil outlet valve is arranged on the hollow draw rod, and fixed oil inlet valves are arranged on sealing end covers; the hydraulic cylinders are connected with the two-way oil-well pump barrels through the sealing end covers, the pump barrels are connected with the hydraulic cylinders through the sealing end covers, the fixed oil inlet valves are arranged on the sealing end covers, and the long plunger piston and the pistons are connected through the hollow draw rod; and the travelling oil outlet valve is arranged on the hollow draw rod, a packer is connected with an overflow valve, the overflow valve is connected with a bayonet socket, the bayonet socket is connected with an oil tube until being connected with a well port. The hydraulic cylinders are used as driving force to drive the two-way pump plunger piston to synchronously move, and two-way oil inlet and outlet during up and down strokes are actually achieved. The invention has the characteristics of no eccentric wear between the oil pumping rod and the oil tube, energy saving and high production efficiency.

Owner:刘学柱

Downhole cyclone desander

The invention discloses a downhole cyclone desander, the structure of which is divided into inner and outer pipes, the outer pipe is provided with an oil inlet hole, the outer wall of the inner pipe is provided with spiral leaves, and the lower part of the inner pipe is reduced in diameter as an oil suction port. A filter screen is arranged between the inner pipe and the outer pipe. Since the silt with larger particles is on the outside during swirling flow, the outer ring of the filter screen is a coarse-aperture net, and the inner ring of the filter screen is a fine-aperture net. The beneficial effect of the invention is that the mud and sand can be effectively separated from the oil, and a filter screen is arranged between the inner and outer pipes to prevent the mud and sand from being sucked in and causing the pump to be stuck during oil pumping.

Owner:YANCHENG HUAYI GASOLINEEUM MACHINERY

Hollow anti-scale oil pump

ActiveCN104564650AImprove wear resistanceReduce disengagementPositive displacement pump componentsFlexible member pumpsCouplingEngineering

The invention provides a hollow anti-scale oil pump which can effectively prevent scale deposition as well as preventing pumping from being blocked during pumping oil, so as to decrease the repair and maintenance cost of an oil production device as well as ensuring smooth oil production work. The hollow anti-scale oil pump comprises a pump barrel assembly, a long plunger piston assembly and a fixing valve assembly; the pump barrel assembly comprises an oil pipe coupling, an upper lengthening pumping barrel, a pump barrel coupling, a short pump barrel, and a lower lengthening pump barrel on the lower surface of the short pump barrel; the long plunger piston assembly comprises a hollow short rod, an upper reducing coupling, an upper one-way valve device, an one-way valve bus, an upper valve seat connector, a pulling rod bus, a hollow pulling rod, an oil outlet cover, a plunger piston, a floating valve seat, a floating valve ball, a lower reducing coupling, a lower one-way valve device and a piston block; the upper one-way valve device and the lower one-way valve device both comprise connectors, valve balls arranged in the connectors, and valve seats; the fixing valve assembly comprises a pump barrel valve cover, a fixing valve ball, a fixing valve seat and a pump barrel valve cover reducing connector.

Owner:SHANDONG NINE RING GASOLINEEUM MACHINERY

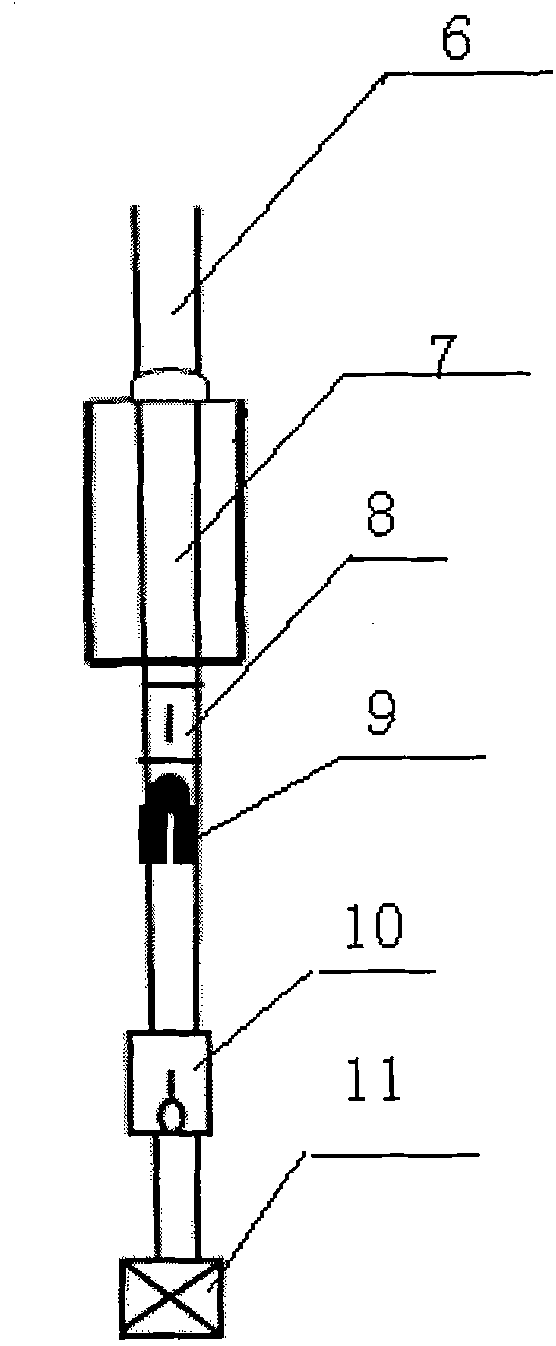

Clamping jaw type spiral tooth centering device of coal bed gas well drainage mining pump

ActiveCN108953132AAvoid depositionPrevent stuck pumpPositive displacement pump componentsFlexible member pumpsLower limitButt joint

The invention provides a clamping jaw type spiral tooth centering device of a coal bed gas well drainage mining pump, and applies to underground centering of the plunger and the pump cylinder. The centering device adopts a spiral tooth stirring and clamping jaw type butt joint technology, the low-sink-degree working condition coal powder can be effectively prevented from being deposited on the upper portion of the plunger and the middle cover body, and the coal powder clamping pump is avoided. The middle cover body is discharged according to the jet nozzles which are arranged in a layered modepumping the well liquid sucked by the pump into the annular space of the discharging and collecting rod and the discharging and collecting pipe, the spiral tooth stirrer is used for realizing the upper limit of the middle cover body and realizing the lower limit by centering the middle coupling, the centering base body is connected with the centering cover body and the butt joint clamping jaw ina three-in-one mode, the centering base body and the butt joint clamping jaw are arranged in a three-in-one mode, the butt joint clamping jaw realizes rapid butt joint between the middle cover body and the centering base body and the centering coupling, and meanwhile, the underground real-time alignment between the plunger and the drainage rod and the pump barrel is realized according to the double-column-surface moving pair between the centering coupling and the centering cover and the drainage rod, and the lifting speed of the well liquid above the plunger is completed through the middle coupling.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Anti-scaling and anti-sand device connected with oil pumping tubing string into whole and application method

The invention relates to an anti-scaling and anti-sand device connected with an oil pumping tubing string into a whole and an application method. The device comprises an oil well tubing, an oil well pump, a gas anchor and an end cap, wherein the oil well tubing is connected with the anti-scaling and anti-sand device, the anti-scaling and anti-sand device is connected with a tubing pup joint, the tubing pup joint is connected with the oil well pump, an outer tube of the oil well pump is connected with the gas anchor, the outer tube of the gas anchor is connected with the end cap, an upper joint of the anti-scaling and anti-sand device is connected with the oil well tubing through a tube ferrule, the upper joint is connected with an annular anti-scaling cover, a central tube is inserted in the middle of the annular anti-scaling cover, the outer diameter of the central tube is connected with the inner wall of the annular anti-scaling cover through a centering ring, and the bottom part of the annular anti-scaling cover is connected with a trumpet-shaped lower joint. The device has simple structure and low cost, an annular sand setting space is formed between the inner wall and the outer wall of the anti-scaling and anti-sand device, liquid flow is discharged from inner tubes to the outer tubes, and scales, sand and impurities settled from liquid are retained in the anti-scaling and anti-sand annular space, thereby preventing the pump from being locked during the pump-setting process and the production process of an oil well, effectively prolonging the pump detection period of the oil well and improving the oil production efficiency.

Owner:江苏海奇实业有限公司

Oil well sand prevention method for heavy oil reservoir

The invention discloses an oil well sand prevention method for a heavy oil reservoir, which is applied to heavy oil exploitation in oil fields. The method comprises the following steps of: preparing, namely pulling a production pipe column out, inserting a sand removal pipe column, exploring a sand surface, removing sand, throwing a ball for pressure tests, and pulling the sand removal pipe column out; pigging, cleaning a pipe, washing a well, and pulling a pigging pipe column out; performing sand prevention construction, namely inserting a sand prevention pipe column for magnetic positioning depth calibration; making the pressure tests qualified; performing seat sealing, and opening a filling channel; filling direct circulation sand carrying liquid and quartz sand; washing hands, lifting the sand prevention pipe column upwards and pulling a hand washing pipe column; and inserting an oil exploitation production pipe column into the whole well. The invention has the advantages that: the method is applied to oil well sand prevention and has the one-time success rate of 100 percent, and a single well can be used for continuous production for more than 600 days.

Owner:PETROCHINA CO LTD

Sand and gas preventing oil pump

ActiveCN113217362AAvoid enteringPrevent air lockLiquid degasificationPositive displacement pump componentsPumpjackPlunger

The invention provides a sand and gas preventing oil pump, which comprises a pump cylinder assembly, wherein a sliding plunger assembly is arranged in the pump cylinder assembly; a gas-liquid separation assembly is arranged at an end of the pump cylinder assembly; a liquid feeding channel is formed in one side of the gas-liquid separation assembly; oil containing sand and gas enters the pump cylinder assembly via the liquid feeding channel; and a short plunger in the plunger assembly abuts against the interior of the pump cylinder assembly and slides hermetically, thereby forming a multi-stage sand settling and exhausting compression cavity. By adopting a three-stage sand prevention and two-stage gas prevention structure, the oil pump can adapt to crude oil extraction under a well condition of serious sand production, also has a good gas prevention effect, belongs to a special oil pump, can adapt to crude oil extraction under a well condition of serious sand production and high gas ratio, achieves a good sand prevention and gas prevention effect, and has a high bearing capacity and a long service life.

Owner:CSIC ZHONGNAN EQUIP

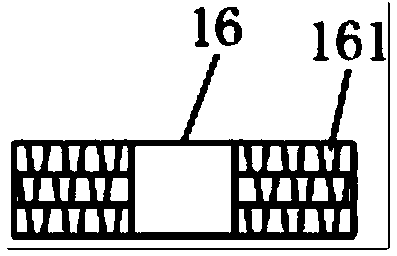

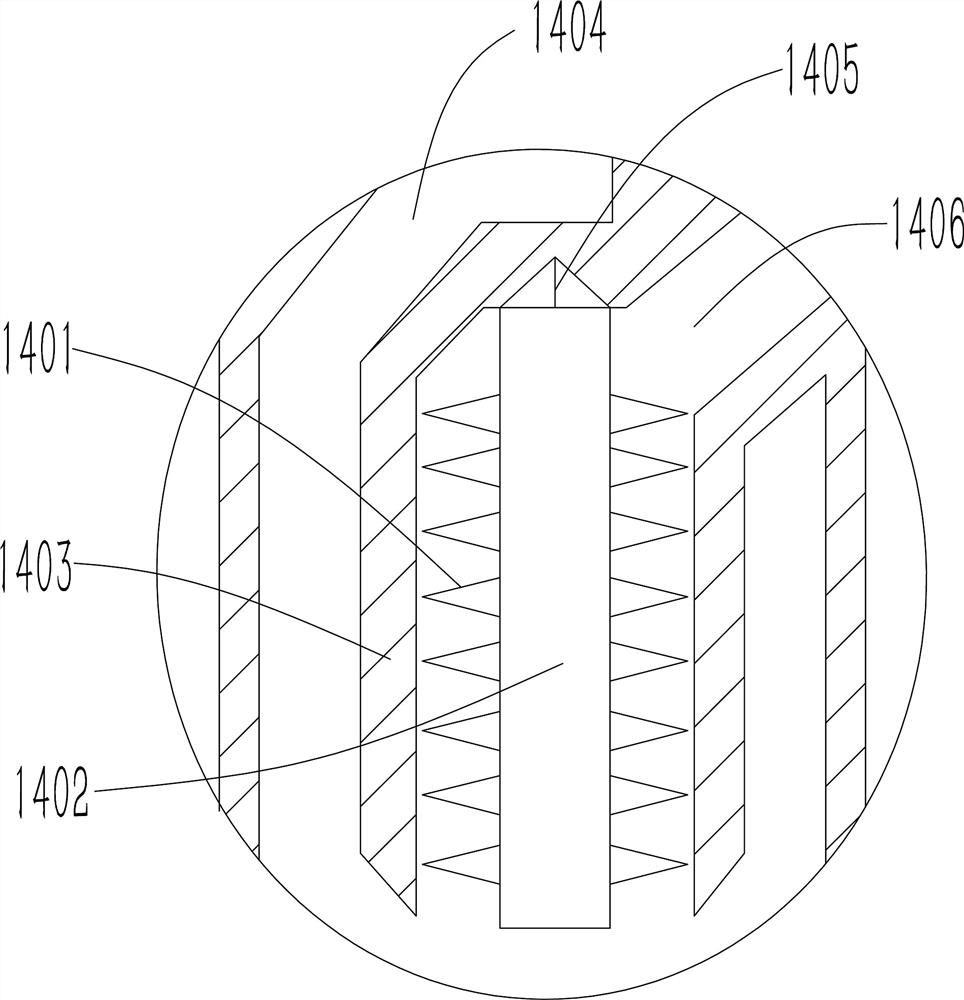

Flushable blockage removing and sand filtering device and blockage removing and sand filtering pipe column

ActiveCN113494276APlay the role of blocking filterRestoration of sandFluid removalStructural engineeringSand filter

The invention discloses a flushable blockage removing and sand filtering device and a blockage removing and sand filtering pipe column. The flushable blockage removing and sand filtering device comprises a central pipe and outer pipes arranged on the outer side of the central pipe in a sleeving mode at intervals; the intervals form an annular cavity; and a spring, a supporting sleeve and a sand blocking stacked ring assembly are arranged in the annular cavity in a sleeved mode. A plurality of first liquid passing holes and a plurality of second liquid passing holes are formed in the side walls of the central pipe and the outer pipes correspondingly, the sand blocking stacked ring assembly comprises a plurality of sand blocking ring pieces which are stacked up and down, a plurality of upper through grooves and a plurality of lower through grooves are formed in the upper end face and the lower end face of each sand blocking ring piece at intervals correspondingly, and the longitudinal extension lines of the upper through grooves and the lower through grooves are arranged in an up-down crossed mode. According to the flushable blockage removing and sand filtering device and the blockage removing and sand filtering pipe column, the sand blocking particle size can be designed to be small, so that the situation that sand enters a pump to cause pump clamping is prevented; and when an overflowing channel is blocked, blocking objects can be washed away in a liquid beating washing mode, so that the sand blocking and overflowing capacity is recovered.

Owner:PETROCHINA CO LTD

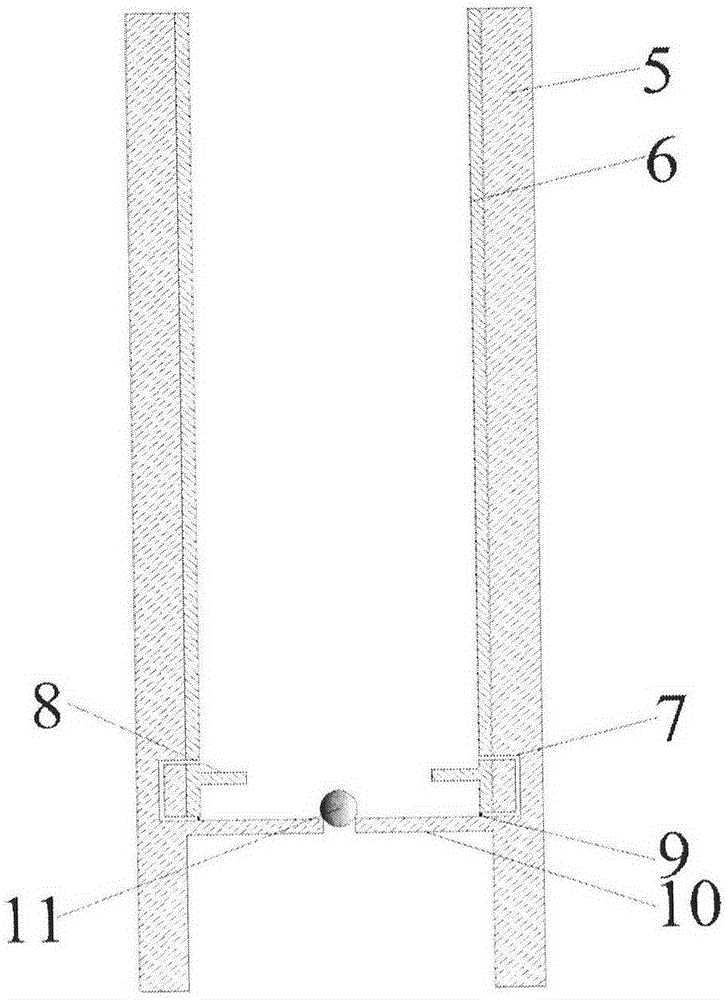

Multi-stage lifting pump-blockage-prevention device for coalbed methane well

The invention relates to the technical field of coalbed methane exploration and development, in particular to a multi-stage lifting pump-blockage-prevention device for a coalbed methane well. A plurality of pumping improvement devices are connected among a plurality of sucker rods of the device. The pumping improvement devices comprise central rods, the upper portions of the central rods and the lower portions of the central rods are connected with upper limiting blocks and lower limiting blocks respectively, the upper ends of the upper limiting blocks are connected with upper joints, the lower ends of the lower limiting blocks are connected with lower joints, the outer sides of the central rods are sleeved with outer hollow steel sleeves, and the outer hollow steel sleeves can move upwards and downwards along the central rods. The multi-stage lifting pump-blockage-prevention device can prevent coal dust from blocking a pump, greatly prolongs the pump inspection cycle, effectively lowers the operation cost and the coalbed methane draining and collection cost, enables the coalbed methane well to keep stable and continuous draining and collection and facilitates step-down analysis, thereby improving the coalbed methane yield; besides, the multi-stage lifting pump-blockage-prevention device can play a role in blockage relieving on a wellbore immediate vicinity coal seam which is blocked due to serious output of coal dust or coal tar and can make a well of which draining and collection is interrupted due to a large amount of output coal dust of the coal seam resume production.

Owner:CNPC GREATWALL DRILLING ENG

Jaw-type helical tooth centering device for coalbed gas well drainage pump

ActiveCN108953132BAvoid depositionPrevent stuck pumpPositive displacement pump componentsFlexible member pumpsLower limitButt joint

The invention provides a clamping jaw type spiral tooth centering device of a coal bed gas well drainage mining pump, and applies to underground centering of the plunger and the pump cylinder. The centering device adopts a spiral tooth stirring and clamping jaw type butt joint technology, the low-sink-degree working condition coal powder can be effectively prevented from being deposited on the upper portion of the plunger and the middle cover body, and the coal powder clamping pump is avoided. The middle cover body is discharged according to the jet nozzles which are arranged in a layered modepumping the well liquid sucked by the pump into the annular space of the discharging and collecting rod and the discharging and collecting pipe, the spiral tooth stirrer is used for realizing the upper limit of the middle cover body and realizing the lower limit by centering the middle coupling, the centering base body is connected with the centering cover body and the butt joint clamping jaw ina three-in-one mode, the centering base body and the butt joint clamping jaw are arranged in a three-in-one mode, the butt joint clamping jaw realizes rapid butt joint between the middle cover body and the centering base body and the centering coupling, and meanwhile, the underground real-time alignment between the plunger and the drainage rod and the pump barrel is realized according to the double-column-surface moving pair between the centering coupling and the centering cover and the drainage rod, and the lifting speed of the well liquid above the plunger is completed through the middle coupling.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

No gap adaptive scraper assembly

InactiveCN102777150BSimple structureImprove performanceCleaning apparatusEngineeringMechanical engineering

The invention relates to a gapless self-adapting scraper assembly. The problems that existing scrapers cannot adapt to the diameter of a pump barrel and a pump is jammed easily are solved. The scraper assembly is characterized in that an upper scraper (2) is arranged outside an upper connecting rod (1), a lower scraper (4) is arranged outside a middle connecting rod (5), the lower portion of a lower connecting rod (7) is connected with a plunger (10), a leather cup (8) is arranged outside the lower connecting rod (7), a plurality of flow channels (9) are arranged on the side wall of the leather cup (8), a groove is arranged on the outer periphery of an inner mandrel (11) of the scraper, a centering supporting body (13) is embedded in the groove, a scrapping sheet (14) is fixed on the side surface of the centering supporting body (13) and a spring (15) is arranged between the centering supporting body (13) and the mandrel (11) radially. The gapless self-adapting scraper assembly can scrap completely, no gap exists, the scraper can adapt to pump barrels with different diameters, scraped dirt can flow out of a well along with well liquid and pumps cannot be jammed.

Owner:DAQING DAHUA HONGYE PETROLEUM ENG TECH +1

Multi-functional double-acting hydraulic oil extraction device

ActiveCN101936147BForce balanceGreat driving forceFlexible member pumpsFluid removalHydraulic cylinderInlet valve

Owner:刘学柱

Coal powder-prevention tubular discharging and extracting pump

InactiveCN101956694BOpen smoothlyReduce the difficulty of openingPositive displacement pump componentsFlexible member pumpsReciprocating motionInlet valve

The invention provides a coal powder-prevention tubular discharging and extracting pump for pumping liquid in coal bed gas wells, which especially can prevent coal powder from burying pump, blocking the pump and extending the period of pump inspection. The coal powder-prevention tubular discharging and extracting pump comprises a pump cylinder assembly, a plunger assembly, a liquid inlet valve assembly and a fixing device. A hemispherical valve ball enlarges the flow area of a pump valve, improves the speed for well liquid to enter the pump, is beneficial to the discharging of well liquid outof the pump together with the coal powder to prevent the coal powder from blocking the pump; a resetting spring is matched with a positioning pin to reinforce the resetting capacity of the valve ballso that the tubular discharging and extracting pump reduces loss and realizes the purpose of smoothly opening the pump valve under low sinking degree; a coal powder-prevention slot can temporarily contain the coal powder to reduce the abrasion of the coal powder for plungers and pump cylinders; the bottom of the coal powder-prevention slot is provided with jetting holes so that the coal powder ina valve cover is washed by utilizing the well liquid stored in the slot, thereby the discharging and extracting pump realizes the function of self washing to prevent the blockage of the liquid inlet valve from blocking the pump; and a stirrer drives vanes to rotate along with the reciprocating motion of a plunger of the liquid inlet valve to constantly stir the well liquid and deposited coal powder in a sieve tube, thereby preventing coal powder particles from rapidly settling in the sieve tube to result in that the pump is buried by the coal powder.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

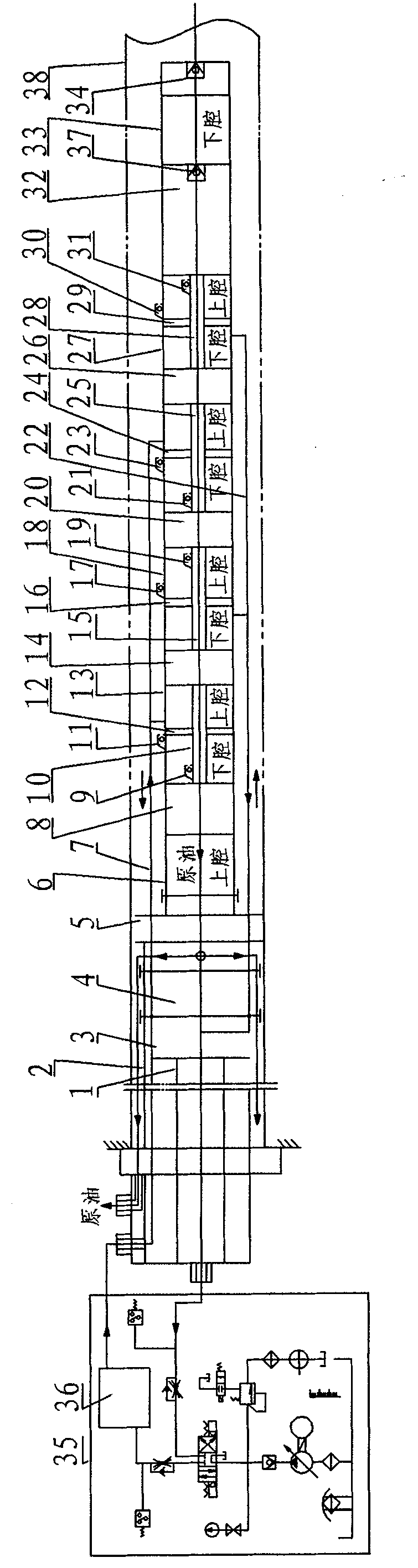

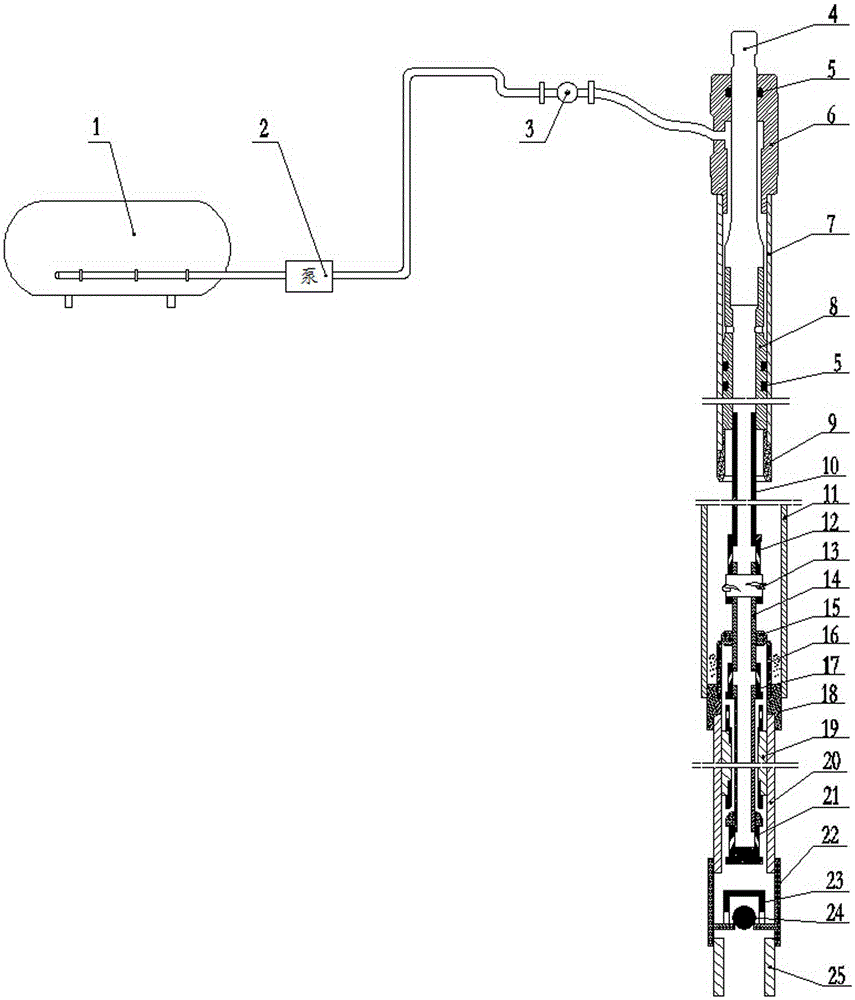

Stable-pressure extraction and washing system for coal-bed gas well without halting production and method

PendingCN111706273AHas supercharging effectHigh trafficFlushingWell/borehole valve arrangementsSafety valveCoal

The invention relates to the technical field of development of coal-bed gas, in particular to a stable-pressure pumping system for a coal-bed gas well without halting production. The stable-pressure pumping system for the coal-bed gas well without halting production comprises a plunger pump, an oil pipe and an extraction pump, wherein the oil pipe and the extraction pump are put in a shaft, and the oil pipe communicates with an oil jacket annulus through a bottom suction port; the portion, above the shaft, of the oil pipe is provided with a three-way structure, extraction and washing liquid isinjected into the oil jacket annulus through a safety valve after being pressurized by the plunger pump, under a certain working system of the extraction pump, extraction and washing liquid enters the oil pipe through the suction port, and then coal powder and mud in the extraction pump and the oil pipe are washed, and discharged to the ground through a second connector of the three-way structure. The plunger pump has the effect of pressurizing so that the extraction and washing liquid on the ground can be constantly injected into the oil jacket annulus, and by increasing the flow and flow speed of the extraction and washing liquid, the purpose of washing solid-phase substances in the extraction pump and oil pipe, and avoiding pump from getting stuck is avoided. The stable-pressure pumping system does not need special cooperation with tubular columns in the shaft, and thus the safety risk is lowered.

Owner:应急管理部信息研究院

Inclined shaft sand prevention oil well pump

PendingCN110966169ASimple structureStable structurePositive displacement pump componentsFlexible member pumpsCouplingInlet valve

The invention discloses an inclined shaft sand prevention oil well pump. The inclined shaft sand prevention oil well pump comprises a plunger assembly and a pump cylinder assembly, a pump cylinder comprises a gap bridge pipe, a middle coupling and a two-way connector, a pump cylinder lengthening cylinder is arranged in the pump cylinder assembly, a sand setting annulus is formed between the pump cylinder lengthening cylinder and the gap bridge pipe, a short pump cylinder is arranged at the upper end of the pump cylinder lengthening cylinder, the short pump cylinder and a long plunger are in sliding seal, an oil inlet valve cover is arranged in the middle coupling, the oil inlet valve cover and the two-way connector form a sand falling annulus, a check block is arranged above the oil inletvalve cover, the outer circumferential ring of the check block is a conical surface structure, when sand grains in the pump cavity are deposited downwards, the sand can slide into a sand falling annulus space on the outer side of the oil inlet valve cover along the outer conical surface of the stop block, when sand grains in an oil pipe on the upper portion of the oil well pump fall onto the upperoil outlet valve cover, the sand grains can slide into the annular sand setting annulus space on the two sides along the upper conical surface of the upper oil outlet valve cover and cannot directlyfall into the upper oil outlet valve cover or the matching surface between the pump cylinder and the long plunger, so that the phenomenon that the sand grains enter the pump to cause sand blocking ordeposit on the valve cover to cause sand burying is reduced.

Owner:CSIC ZHONGNAN EQUIP

Novel anti-settling sand stuck pump device

InactiveCN102840127AAvoid enteringReasonable structural designPositive displacement pump componentsFlexible member pumpsEngineeringScrew thread

The invention refers to an anti-sand device used for an oilfield well. Especially, the invention relates to a novel anti-settling sand stuck pump device, wherein the technical scheme of the novel anti-settling sand stuck pump device is that: the device consists of a taper body, a taper base, a valve body, a fixing base, a valve ball and a joint; one end of the fixing base is connected with the joint, and the other end of the fixing base is connected with the taper base by screw thread; the valve body is fixed at the inner part of the taper base, the valve ball is arranged in the valve body; the valve body is vertically provided with a liquid through hole. The novel anti-settling sand stuck pump device has the following beneficial effects: the novel anti-settling sand stuck pump device is reasonable in structural design and good in anti-sand effect; the problem that the grit enters the pump along with the output liquid is effectively solved; the stuck pump is prevented; the device can be freely lifted up and down along with a sucker rod; so that the other work cannot be affected, and any other additional work load cannot be taken to the work.

Owner:NANTONG TIANHUA HERUI TECH VENTURES

Anti-blocking and anti-deflection tubular oil-well pump

PendingCN107893749AConvenient rightingPrevent running deviation impactPositive displacement pump componentsFlexible member pumpsCycloneEngineering

The invention discloses an anti-blocking and anti-deflection tubular oil-well pump. The tubular oil-well pump comprises a bushing, a plunger, a pump bucket, an oil pipe and a straightening joint hoop,wherein the oil pipe is arranged in the bushing, the pump bucket is arranged at the bottom of the oil pipe, a second valve seat is arranged in the pump bucket, a second through hole is formed in themiddle of the second valve seat, and a second valve ball is arranged above the second through hole; the plunger is inserted into the pump bucket, the straightening joint hoop is arranged between the plunger and the inner wall of the oil pipe, a first valve seat is arranged in the plunger, a first through hole is formed in the first valve seat, and a first valve ball is arranged above the first through hole; and a first rotational flow structure and a second rotational flow are respectively arranged above the first valve ball and the second valve ball. The anti-blocking and anti-deflection tubular oil-well pump is reasonable in structural design; by arranging the straightening node hoop and a straightening body, the plunger is conveniently straightened, and the situation that the plunger isdeflected to strike the edge the pump bucket is prevented; and by utilizing the rotational flow structures, to-be-sucked crude oil can form vortexes, and coal powder or sand is suspended in liquid flow and is taken away, so that the blockage of the pump is prevented.

Owner:JIAHE FUSHUN MACHINERY IND

Anti-jamming pump for coalbed methane well drainage

InactiveCN105840483BPrevent stuck pumpNovel structurePositive displacement pump componentsLiquid fuel engine componentsEngineeringPressure difference

The invention provides a hydraulic force feedback-type discharge and mining pump preventing pulverized coal used for discharge and mining of a coal-bed gas well. The discharge and mining pump mostly comprises a pump cylinder assembly, a plunger assembly and capsule assemblies. During upstroke of the discharge and mining pump, a discharge and mining rod drives the plunger to move upwards and a floating valve is closed. A fixed valve is opened under effect of pressure difference and liquid is absorbed. In the meantime, press rings on capsules are separated from the capsules and the capsules are swelled under elasticity of springs and liquid is absorbed through a filter net and a check valve so that liquid is stored in the capsules. During downstroke, the discharge and mining rod drives a plunger to move downwards and the fixed valve is closed. After the floating valve is opened, liquid below the plunger enters the upper part of the plunger via the floating valve and liquid is discharged. While a press rod and a press ring move downwards to touch the capsule assemblies, the capsule assemblies are extruded. Liquid in the capsules are compressed to feedback liquid flowing channels and sprayed out of the check valve. Pulverized coal particles falling down to a fixed valve seat are flushed and the plunger is driven to suck such that pulverized coal can be discharged. The pump is not buried and stuck by pulverized coal.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

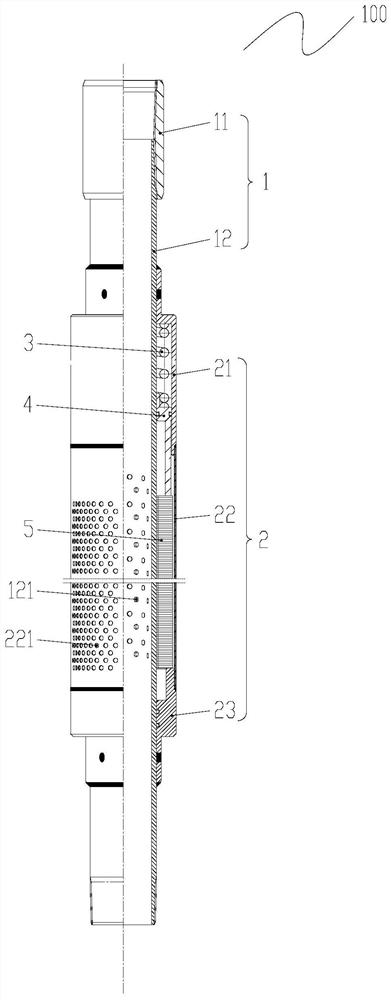

Anti-scaling pumping system for ASP flooding well

ActiveCN104612945BEasy injectionEfficient scrapingFlexible member pumpsFluid removalCouplingEngineering

The invention provides an antiscale oil pumping system for a three-component compound flooding well. Scales can be effectively prevented from being deposited, the stuck pump phenomenon in the oil pumping process is avoided, the repairing and maintaining cost of oil production equipment is lowered, and it can be better guaranteed that oil production operation is conducted smoothly. The antiscale oil pumping system for the three-component compound flooding well comprises a chemical dosing device, a liquid injecting device, an oil well pump, an oil tube, an oil pumping rod and a hollow sliding rod, wherein the oil pumping rod and the hollow sliding rod are arranged in the oil tube. The upper portion of the liquid injecting device is communicated with a chemical dosing pipeline of the chemical dosing device through a tee joint, the lower portion of the liquid injecting device is communicated with the oil pumping rod of a hollow structure, and the lower end of the liquid injecting device is provided with a plug cap in a packaging mode, and a through liquid injecting channel is formed in the liquid injecting device. The oil well pump comprises a pump barrel assembly, a plunger assembly and a fixed valve assembly. The upper end and the lower end of the oil well pump are connected with a thickened oil tube and a tail tube through a coupling and a fixed valve cover respectively. An antiscale device is arranged on the hollow sliding rod in the oil tube, and the antiscale device comprises a scale scraping mechanism and a scale blocking and storing mechanism.

Owner:SHANDONG NINE RING GASOLINEEUM MACHINERY

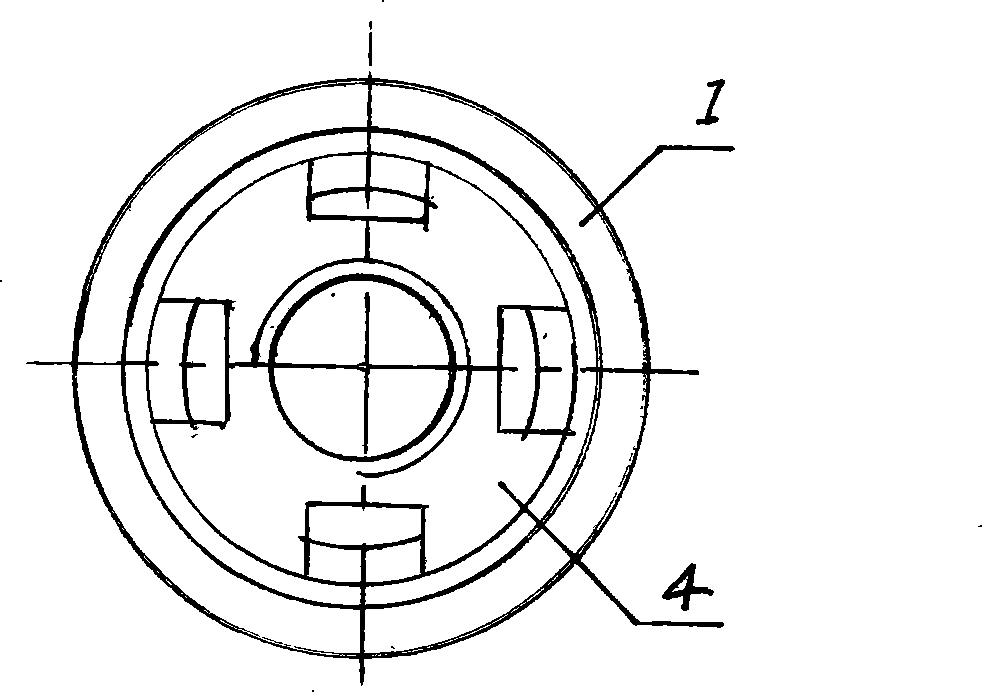

An annular plunger small displacement rod type oil well pump

InactiveCN103883503BStructure does not decreaseIncreased Strength ReliabilityFlexible member pumpsPositive-displacement liquid enginesCouplingInlet valve

A small-displacement rod type oil well pump with an annular plunger comprises an outer pump barrel, an inner pump barrel and the annular plunger. The upper end of the outer pump barrel is connected with a supporting leather cup assembly through a lengthening coupling, and the lower end of the outer pump barrel is connected with a valve housing of an oil inlet valve through a pump barrel coupling. The upper end of the inner pump barrel is connected with a sealing segment joint, and the lower end of the inner pump barrel is connected with the pump barrel coupling through a valve housing of an oil outlet valve. An annular work cavity is formed between the inner pump barrel and the outer pump barrel, the annular plunger is in small clearance fit with the inner pump barrel and the outer pump barrel, the annular plunger is connected with a valve rod through a valve rod lower joint, and the lower end of the valve housing of the oil inlet valve is connected with a tail pipe joint in a threaded mode through the lower joint. The annular plunger moves upwards along with the oil pump, an oil outlet valve ball is closed, an oil inlet valve ball is opened, well fluid is sucked in, fluid with a receding size of the plunger is discharged out of a well mouth, the oil inlet valve is closed, and well fluid stops from entering. In the downstroke, fluid in a pump cavity is extruded downward, and liquid is discharged into an oil pipe through a liquid outlet of a valve rod guiding sleeve after passing through the oil outlet valve assembly. The small-displacement rod type oil well pump with the annular plunger has the advantages of being high in efficiency and free of pump seizure and blocking.

Owner:XI'AN PETROLEUM UNIVERSITY

Sand prevention stop-adding oil-well pump device

InactiveCN101251100ALow costImprove oil recoveryPositive displacement pump componentsFlexible member pumpsOil fieldEngineering

The invention belongs to a sand blockage-preventing pumping-increasing oil pump device used in an underground oil field production well, wherein a pump barrel is in the shape of a cylinder; an upper expanding ring and a lower expanding ring are provided with screw threads inside; the ring wall of each ring is provided with an opening in longitudinal direction; a pump cap is a cylindrical body with the top provided with internal threads; the periphery of a pump cap cylinder is provided with external threads, while the internal lower part is provided with internal threads; a valve ball is a spherical body; a pump body is a cylindrical body with the center provided with a through hole and the periphery of the lower part is provided with external threads. The lower expanding ring and the upper expanding ring are screwed in the periphery of the upper part of the pump cap, while the valve ball is arranged inside the pump cap; the upper part of the pump body is assembled together with the lower part of the pump cap; the external threads of the lower part of the pump body is screwed in the screw holes of the lower expanding ring and the upper expanding ring; the pump cap is fixed with the pump body and is arranged inside the pump barrel; moreover, the periphery of each end of the defueling pump is provided with an expanding ring. Obviously, the gap of the pump barrel is closed under the expansion action and the contraction action of the expanding ring. The sand blockage-preventing pumping-increasing oil pump device prevents oil return during pumping oil and also prevents sand from blocking a pump, thereby reducing well repair frequency, saving service charge and increasing oil production to 8 to 20 percent.

Owner:毛国武

A kind of preparation method of salt recrystallization inhibitor for oil and gas well

The invention discloses a salt recrystallization inhibitor for an oil and gas well. The salt recrystallization inhibitor is prepared from the following components according to the 100 percent proportion of volume sum: 60 to 80 parts of organo metallic complex, 10 to 35 parts of inorganic complex, 2 to 8 parts of corrosion inhibitor and 2 to 8 parts of antiswelling agent. A preparation method of the salt recrystallization inhibitor for the oil and gas well is characterized by comprising the following steps of firstly, taking the components according to the proportion, and sequentially placing the various taken component raw materials into a reaction kettle; secondly, reacting at the temperature of 50 to 90DEG C; thirdly, drying a product obtained by reaction and synthesis; fourthly, crushing the dried product to obtain the inhibitor. The shape of a sodium chloride crystal can be changed from a cubic shape into a branch shape or a snowflake shape, so that the adhesive power of the crystal on a solid surface is reduced, and further the dissolubility of sodium chloride in water is increased; in addition, the salt recrystallization inhibitor is free of influence from calcium and magnesium ions, and salt block or holddown can be effectively prevented.

Owner:成都西油华巍科技有限公司

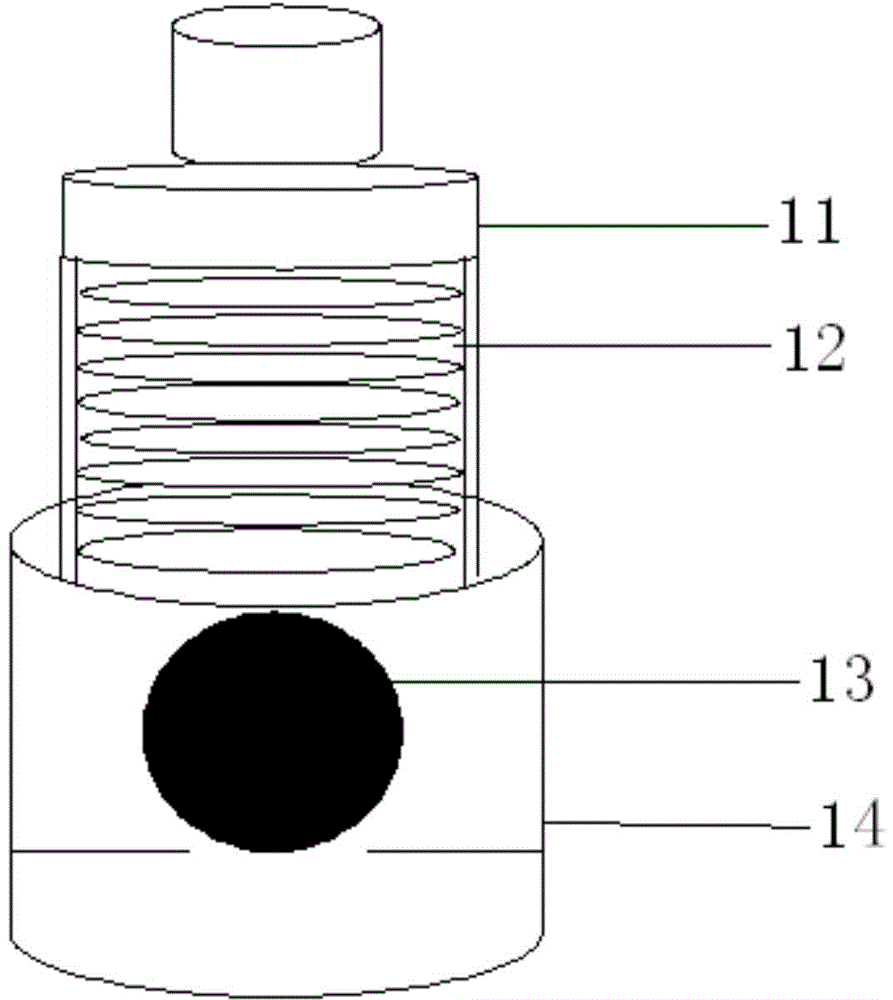

Foreline for vacuum pump, vacuum system and semiconductor manufacturing equipment

InactiveCN109869314APrevent stuck pumpReduce chamber component damageSealing arrangement for pumpsSemiconductor/solid-state device manufacturingContinuous operationForeline

The invention discloses a foreline for a vacuum pump, a vacuum system and semiconductor manufacturing equipment. The foreline comprises a main pipe, a receiver and a branch pipe. The main pipe is vertically mounted. The receiver is arranged at the bottom of the main pipe and provided with an opening, and the opening and the bottom of the main pipe are in sealed connection. The branch pipe is a non-linear pipeline, one end of the branch pipe is connected with the main pipe, and the other end of the branch pipe is connected with the vacuum pump. Airflow is used for sequentially passing through the main pipe and the branch pipe to enter the vacuum pump, meanwhile the receiver is used for receiving matter falling when the airflow passes through the main pipe through the opening. The foreline has the beneficial effects that dust of the airflow carrying a large quantity of dust impurities is filtered out in the foreline, then the airflow enters the vacuum pump, the dust entering a pump bodyis reduced, the possibility of the holddown phenomenon is reduced, the continuous operation time of the vacuum pump is prolonged, the capacity is improved, and the economic cost is reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Sticking and leakage preventing pump used for discharge and mining of coal-bed gas well

InactiveCN105840483ASolve the buried pumpSolve the problem of stuck pumpPositive displacement pump componentsLiquid fuel engine componentsCoal particlePressure difference

The invention provides a hydraulic force feedback-type discharge and mining pump preventing pulverized coal used for discharge and mining of a coal-bed gas well. The discharge and mining pump mostly comprises a pump cylinder assembly, a plunger assembly and capsule assemblies. During upstroke of the discharge and mining pump, a discharge and mining rod drives the plunger to move upwards and a floating valve is closed. A fixed valve is opened under effect of pressure difference and liquid is absorbed. In the meantime, press rings on capsules are separated from the capsules and the capsules are swelled under elasticity of springs and liquid is absorbed through a filter net and a check valve so that liquid is stored in the capsules. During downstroke, the discharge and mining rod drives a plunger to move downwards and the fixed valve is closed. After the floating valve is opened, liquid below the plunger enters the upper part of the plunger via the floating valve and liquid is discharged. While a press rod and a press ring move downwards to touch the capsule assemblies, the capsule assemblies are extruded. Liquid in the capsules are compressed to feedback liquid flowing channels and sprayed out of the check valve. Pulverized coal particles falling down to a fixed valve seat are flushed and the plunger is driven to suck such that pulverized coal can be discharged. The pump is not buried and stuck by pulverized coal.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Gas-liquid-solid separation device in shaft and design method thereof

ActiveCN112576233AAvoid cavitation damagePrevent stuck pumpFluid removalEngineeringStructural engineering

The invention provides a gas-liquid-solid separation device in a shaft. The upper end of an outer pipe is connected to an upper connector through matching with an outer buckle, and a plurality of liquid inlet holes penetrating through the outer pipe are formed in the upper end of the outer pipe; an inner pipe is inserted into the outer pipe and is spaced from the outer pipe, and the upper end of the inner pipe is connected to the upper connector through matching with an inner buckle; a diameter expanding short section is connected to the lower end of the inner pipe so as to be suspended in theouter pipe; the inner pipe, the diameter expanding short section and the outer pipe jointly define an inner pipe annular space and an outer pipe annular space, and the inner pipe annular space and the outer pipe annular space meet the preset flow area; the flow area of the diameter expanding short section is not smaller than the flow area of an externally-connected upper pump oil pipe; a lower connector is connected to the lower end of the outer pipe through a screw thread; and the lower end of a lifting short section is connected to the upper end of the upper connector in an inserted mode, and an oil pipe section hoop is connected to the upper end of the lifting short section in a sleeving mode. The invention further provides a design method of the gas-liquid-solid separation device in the shaft. Compared with the prior art, the gas-liquid-solid separation device in the shaft is good in reliability and long in service life.

Owner:梅瀚文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com