Multi-stage lifting pump-blockage-prevention device for coalbed methane well

A technology for coalbed methane wells and pump devices, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of high operation cost and large pump inspection workload, and achieves reduction of operation cost, improvement of gas production, The effect of prolonging the pump inspection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

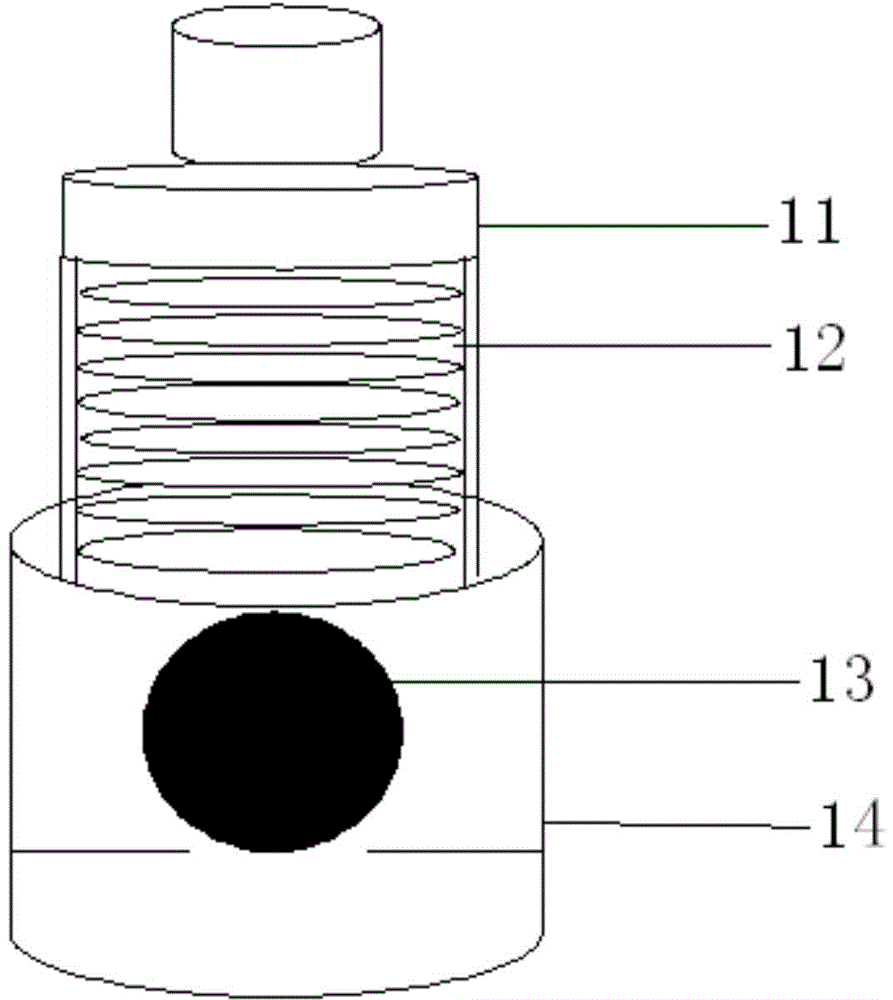

[0011] like figure 1 , figure 2 , image 3 As shown, a multi-stage lifting anti-seize pump device for coalbed methane wells includes a sucker rod 3 and a tubular oil pump, the lower end of the sucker rod 3 is connected to the tubular oil pump; A plurality of extractors 1, the extractor 1 includes a center rod 10, the center rod 10 is respectively connected with the upper limit block 6 and the lower limit block 8, the upper end of the upper limit block 6 is connected with the upper joint 5, and the lower end of the lower limit block 8 is connected with the lower joint 9. The outer side of the central rod 10 is equipped with a hollow outer steel sleeve 7, which can move up and down along the central rod 10; In the process of continuous contact and separation when the machine is running up and down, the multi-stage lifting of the liquid in the oil pipe 4 is realized, just like multiple small pistons are lifted at the same time to achieve the purpose of increasing pumping, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com