Separation and crushing device of downhole pulverized coals of coalbed methane and method thereof

A pulverizing device and a technology for coalbed methane wells, which are used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as affecting the use effect of screw pumps, declining coalbed methane well production, and unfavorable coalbed methane drainage and production. Simple, prevent stuck pump, prolong the effect of pump inspection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

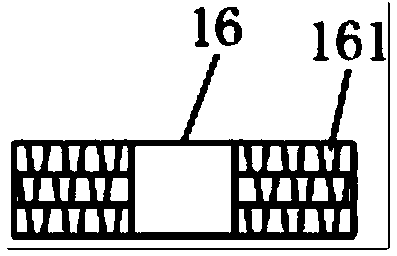

[0037] see Figure 1-Figure 3 , the present invention provides a coalbed methane downhole pulverized coal separation and crushing device, comprising: working cylinder 8, separation working cylinder 10, shaft 7, separation and crushing device, filtering device,

[0038] The bottom end of the separation work cylinder 10 is fixedly connected to the top of the work cylinder 8, and the inner wall of the bottom end of the separation work cylinder 10 extends downwards to form an annular cylinder wall 18, which is inserted into the work cylinder 8 and A gap 14 is formed on the inner wall of the working cylinder 8. Through the setting of the gap 14, the incoming water, gas, and coal powder will be separated and crushed after falling for a certain distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com