Clamping jaw type spiral tooth centering device of coal bed gas well drainage mining pump

A technology for coalbed methane wells and centering devices, which is applied in the directions of components, pumps, pump elements, etc. of pumping devices for elastic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

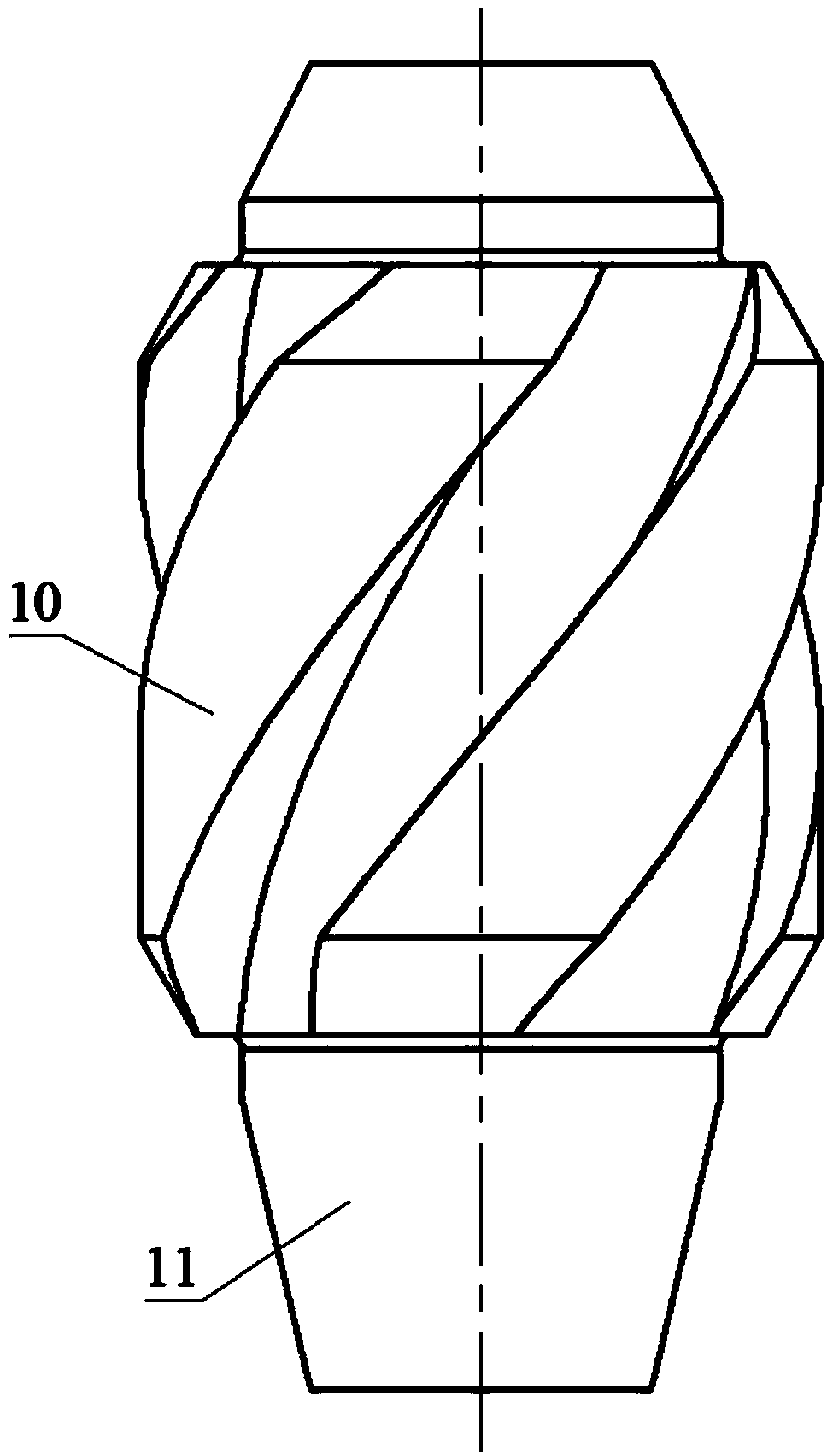

[0034] in figure 1 In the CBM well drainage pump jaw type spiral tooth centering device, it is mainly composed of a centering cover 3, a spiral tooth agitator 4, a centering base body 5, a centering coupling 6 and a docking jaw 7. The centering device It is connected to the bottom end of the extraction pipe 2 through the centering coupling 6, while the extraction rod 1 sequentially penetrates the centering cover 3, the spiral tooth agitator 4 and the centering coupling 6 and is connected to the plunger of the extraction pump , According to the double-cylindrical movement pair between the centering cover 3 and the centering coupling 6 and the extraction rod 1 to realize the downhole real-time centering between the plunger and the extraction rod 1 and the pump barrel.

[0035] in figure 1 The specifications of the claw-type spiral tooth centering device of the coalbed methane well drainage pump are consistent with the diameter of the extraction rod 1 and the diameter of the extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com