Anti-blocking and anti-gas drainage pump for coal-bed gas mechanical valve

A technology of mechanical valves and drainage pumps, which is applied in the direction of mechanical equipment, liquid variable capacity machinery, pumps, etc., can solve the problems of drainage pump failure, high maintenance costs, coal powder blockage, etc., to avoid rigid wear and improve wear resistance , the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following combined with the attachment, the structural principles and working principles of the present invention are further described in detail.

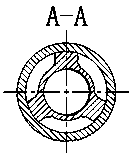

[0030] like figure 1 It shows that the present invention provides a coalbed methane mechanical valve to prevent blocking the gas drainage pump., Compose 23 of the fixed valve hood and 26 tail pipe joints, the lower end of the pump pump 2 is connected to the pump 5, the lower end of the pump tube 5 is connected to the pump pump 19, and the pump pump is connected to the pump.The fixed valve joint 21 is connected, and the fixed valve joint 21 is connected to the tail pipe 26 through the fixed valve hood 23; the inner pump lever assembly is composed of tie rods 4, valve stem guide connector 7, mechanical valve lever 8, guide cone valve 18 connector, can be ableWith the on -bottom of the oil pumping rod, it provides a source of power for the drainage pump; the soft secret sealing colonum assembly is connected by the plunger 9, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com