Anti-blocking chemical grinding equipment

An anti-clogging, chemical technology, applied in chemical instruments and methods, solid separation, filtration and screening, etc., can solve problems such as inability to screen, blockage of screening device screen holes, single grinding function, etc., to avoid blockage of screen holes and ensure continuous Sexuality, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

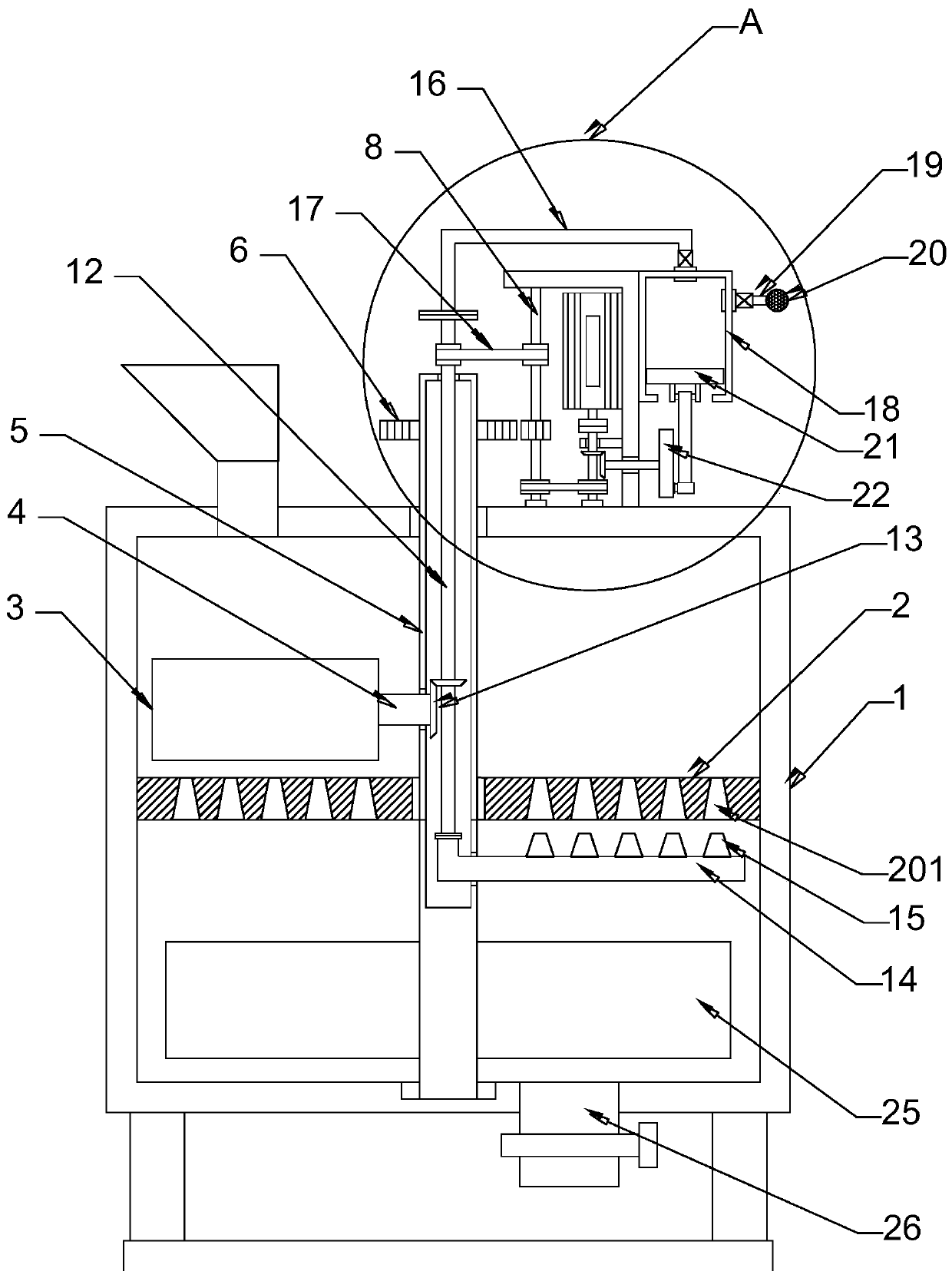

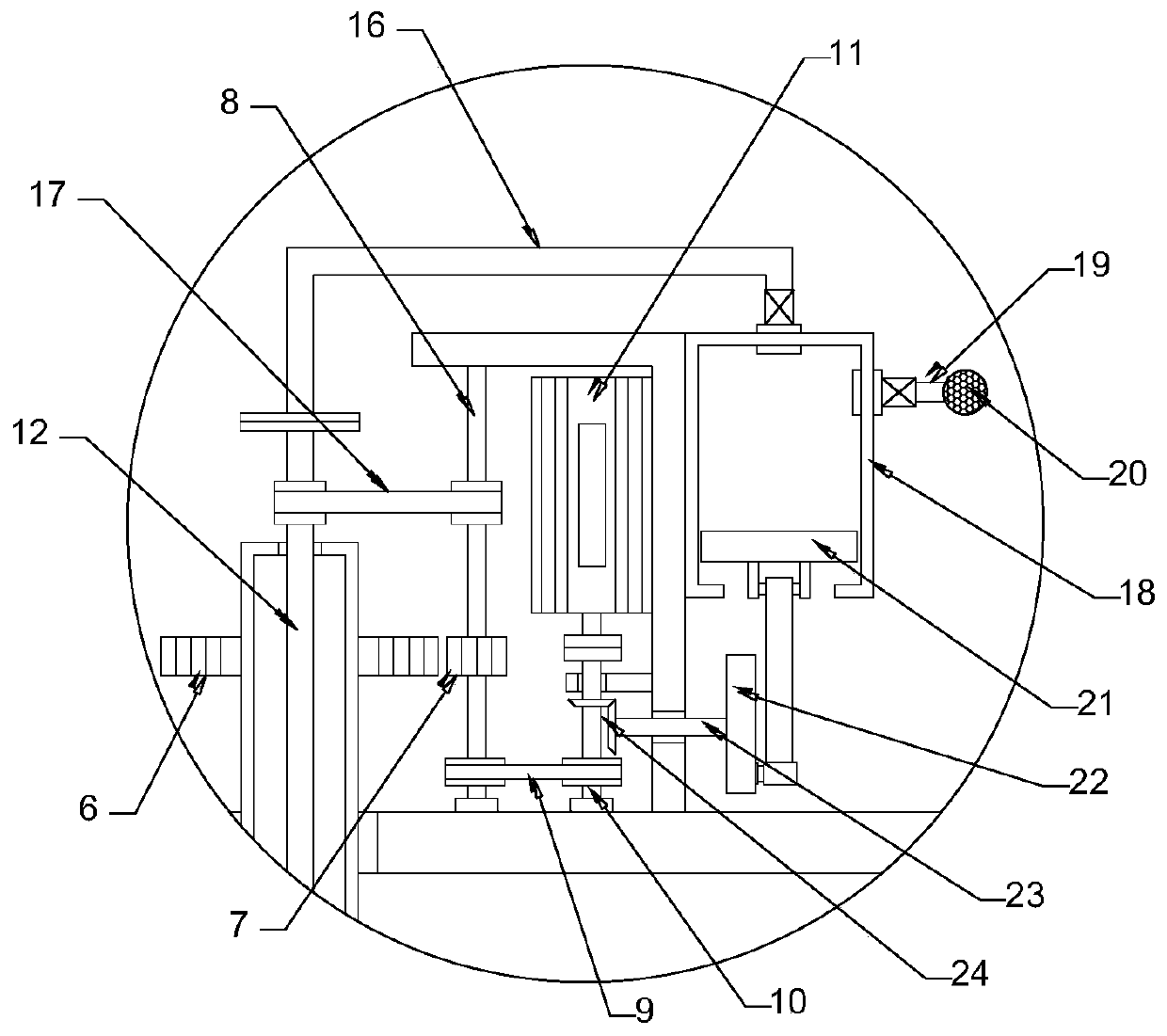

[0021] see Figure 1-4 , in the embodiment of the present invention, a kind of anti-clogging chemical grinding equipment comprises a grinding box 1 and a stirring plate 25; the grinding box 1 is provided with a grinding disc 2, and the grinding disc 2 is fixedly connected with the inner wall of the grinding box 1, and the grinding disc 2 is provided with evenly distributed sieve holes 201; the grinding roller 3 is arranged above the grinding disc 2, and the grinding roller 3 cooperates with the grinding disc 2 to grind and crush the chemical raw materials; the inner side of the grinding roller 3 is fixedly connected with a rotating shaft 4, and the rotating shaft 4 runs through a central cylinder 5 and is rotatably connected with the central cylinder 5; the central cylinder 5 penetrates through the grinding disc 2 and is rotatably connected with the grinding disc 2, the central cylinder 5 extends above the grinding box 1 and is sleeved and fixed with the first gear 6, The firs...

Embodiment 2

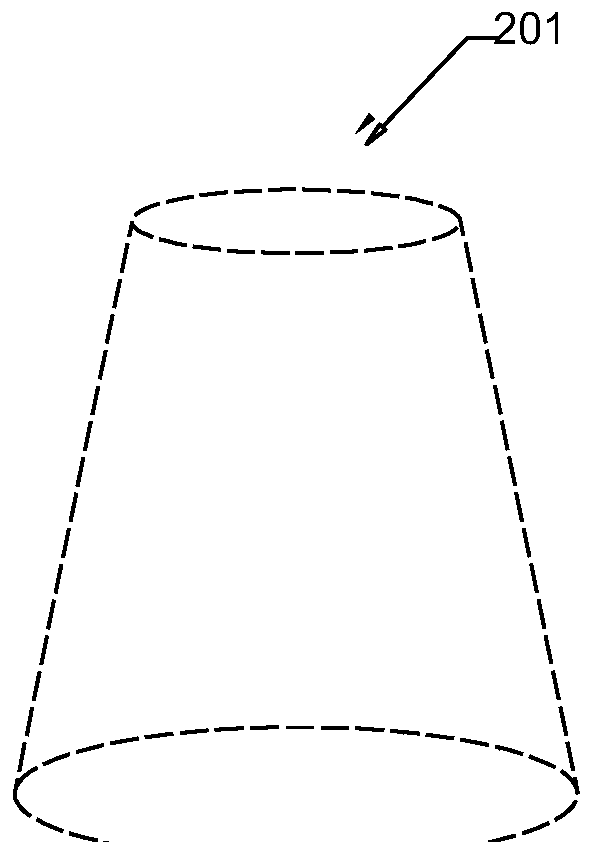

[0025] The difference between this embodiment and Embodiment 1 is that: the sieve hole 201 is in the shape of a circular platform, and the upper end opening of the sieve hole 201 is smaller than the lower end opening; The straight line where the diameter is located is parallel; the air injection pipe 14 is provided with evenly distributed air injection nozzles 15, and the air injection nozzle 15 is arranged opposite to the screen hole 201 on the grinding disc 2; the air injection pipe 14 runs through the central cylinder 5 and is fixed with the central cylinder Connection, the end of the jet pipe 14 is connected with a nested pipe 12 through a rotary joint, and the upper end of the nested pipe 12 is connected with an air intake pipe 16 through a rotary joint, and the air intake pipe 16 is connected with an air filling mechanism, which includes a piston cylinder 18 and a piston cylinder 18 It is connected with the intake pipe 16, the piston cylinder 18 is connected with the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com