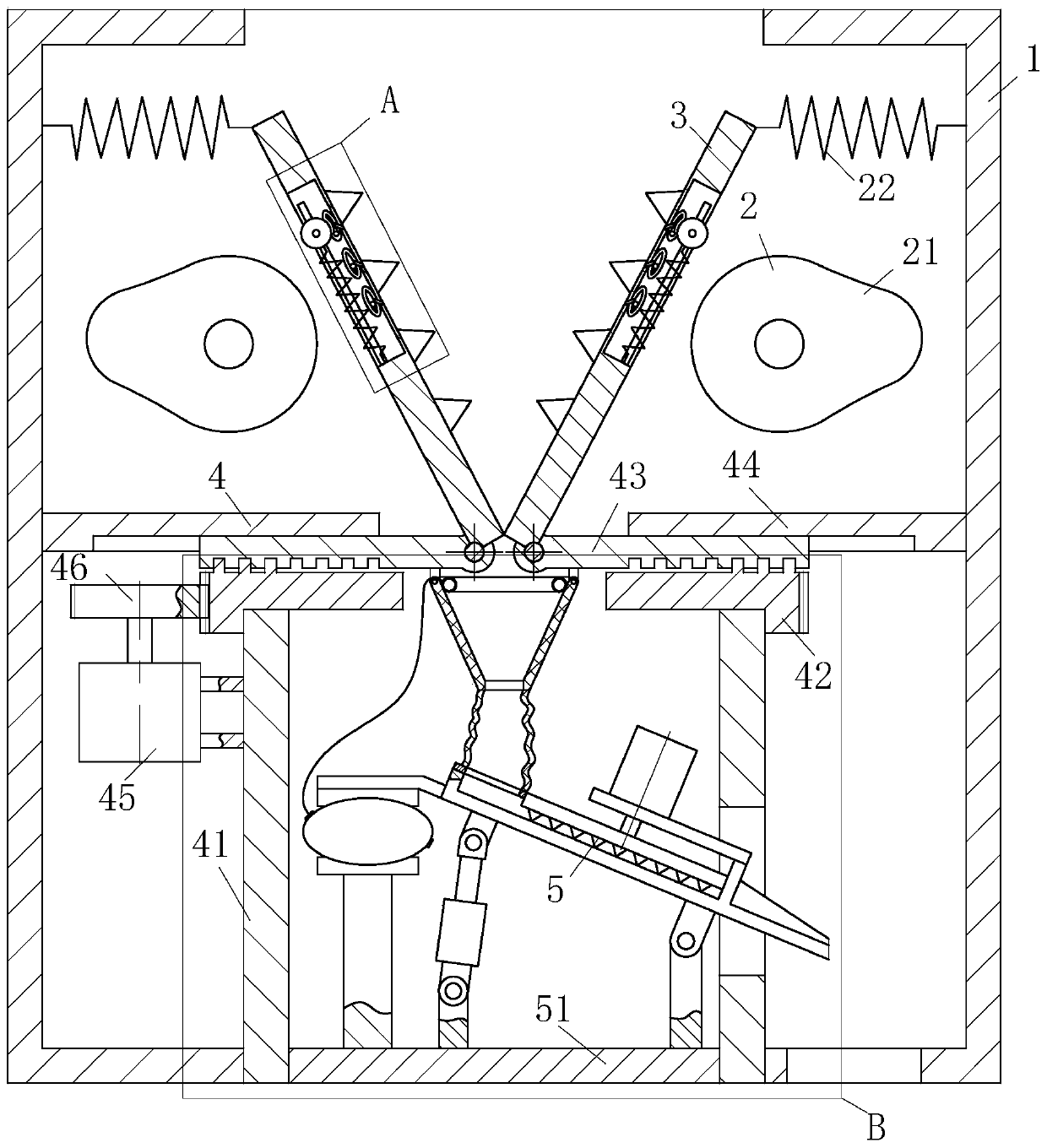

A talc crushing and grinding system for silicone rubber production

A technology of crushing and grinding, silicone rubber, applied in the field of rubber production, can solve the problems of insufficient grinding, affecting grinding efficiency, poor mechanical properties and unfavorable high-speed grinding, etc., to achieve the effect of full grinding and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

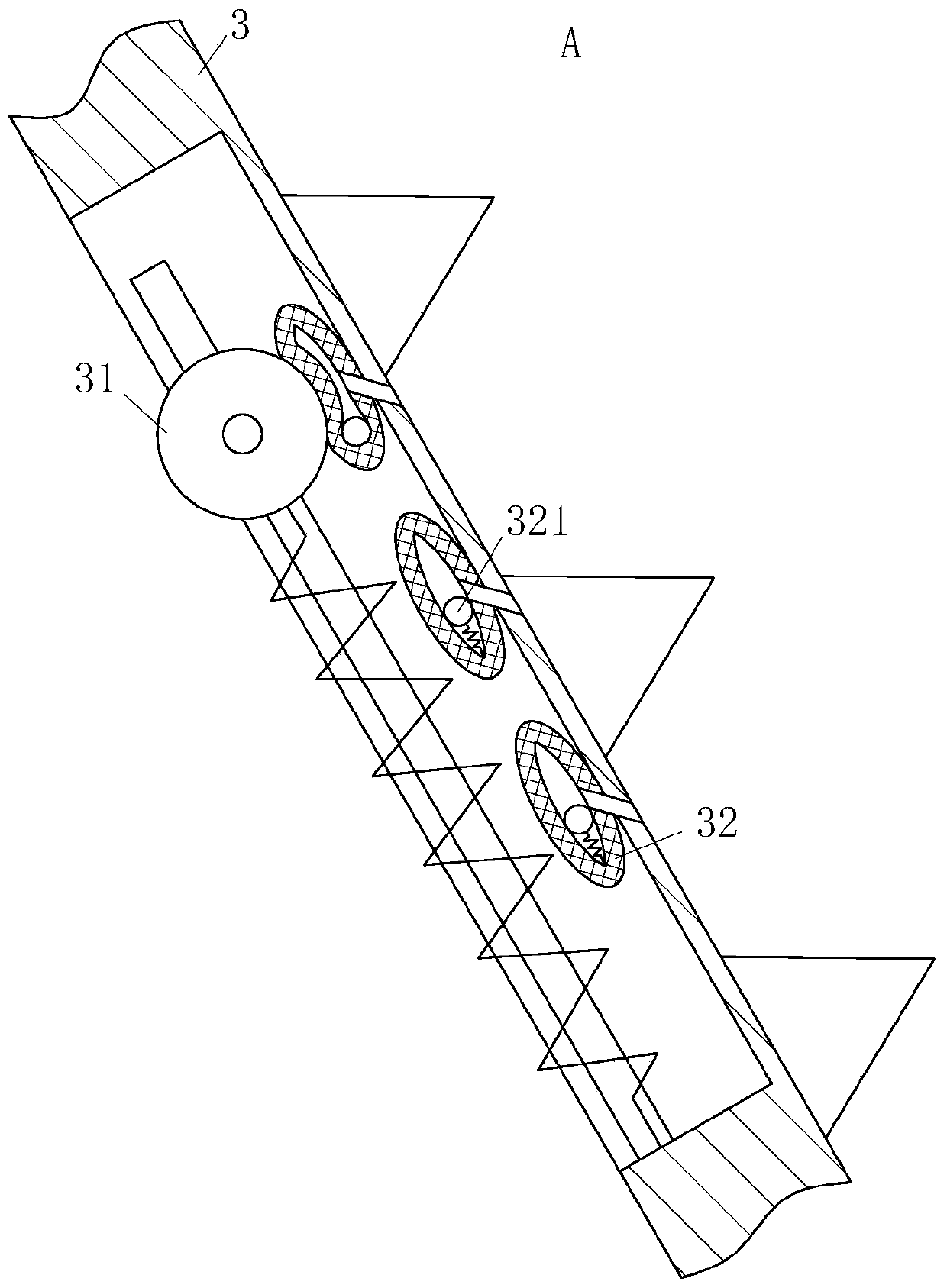

[0027] As an embodiment of the present invention, one end of the inner surface of the air bag 32 is fixedly connected to the spring; the other end of the spring is fixedly connected to the blocking ball 321; the ball 321 is used to stop the air bag 32 from blowing; the cam 21 When the crushing plate 3 is not squeezed, the extrusion block 31 slides back under the elastic force, the extrusion block 31 squeezes the blowing air bag 32, and first drives the blocking ball 321 to block the air outlet, so that the blowing air bag 32 stops blowing, realizing Prevent powdered talc from being raised.

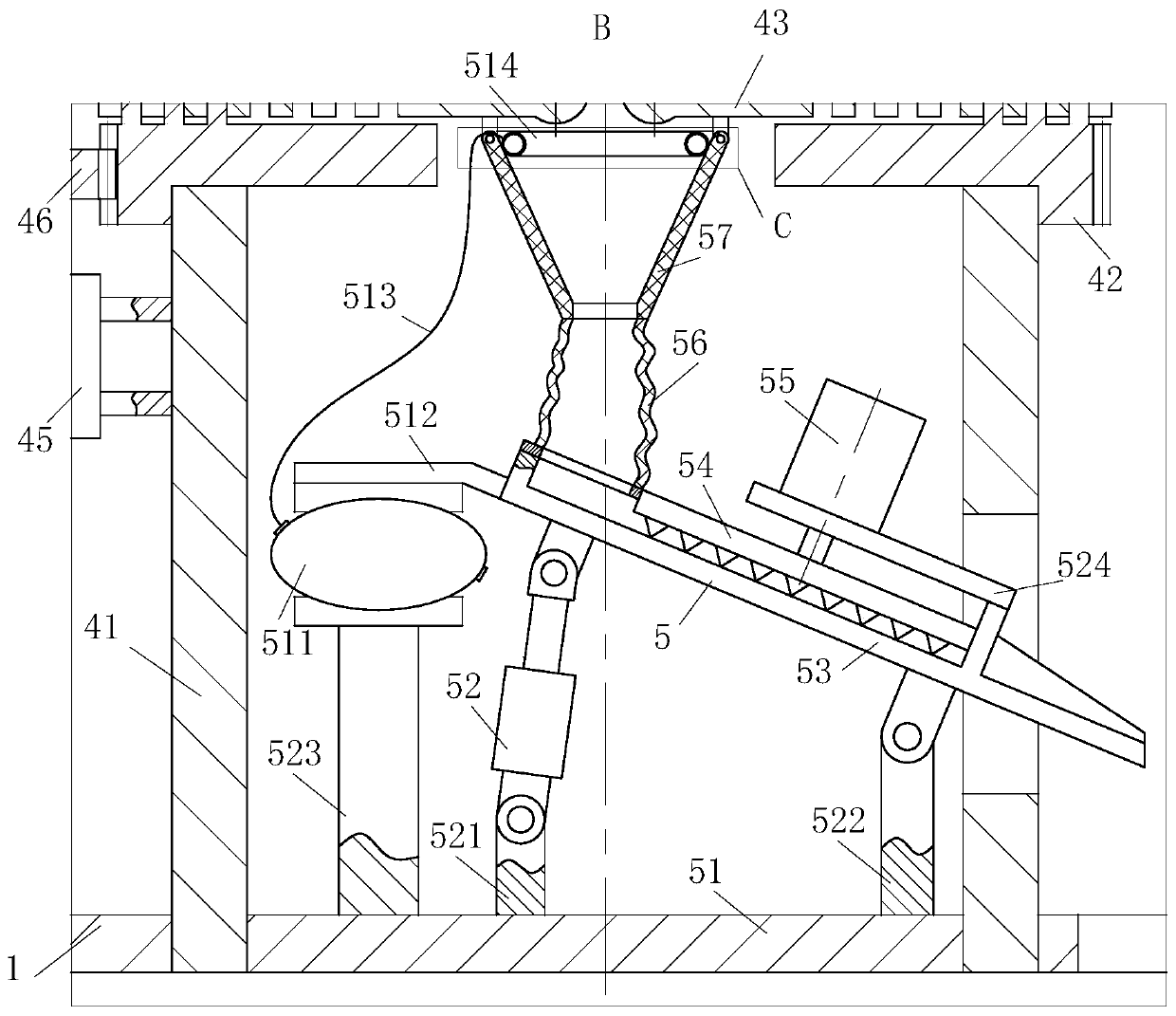

[0028] As an embodiment of the present invention, the grinding device 5 includes a mounting base 51, a cylinder 52, a swing plate 53, a grinding disc 54, a No. 3 motor 55, a bellows 56, and an elastic funnel 57. The mounting base 51 is fixedly connected to At the bottom of the inner wall of the support seat 41; the middle part of the mounting seat 51 is provided with a No. 1 support 521; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com