Testing device and testing method for dust removing effect of dust suppressant and dust preventive

A technology of effect testing and dust suppressant, which can be used in measuring devices, suspension and porous material analysis, particle suspension analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

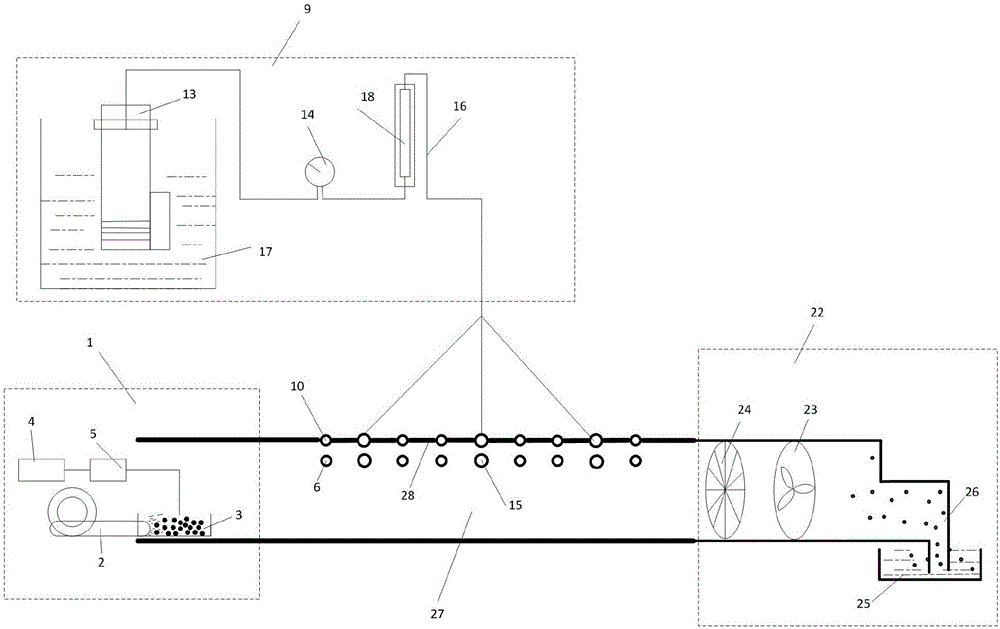

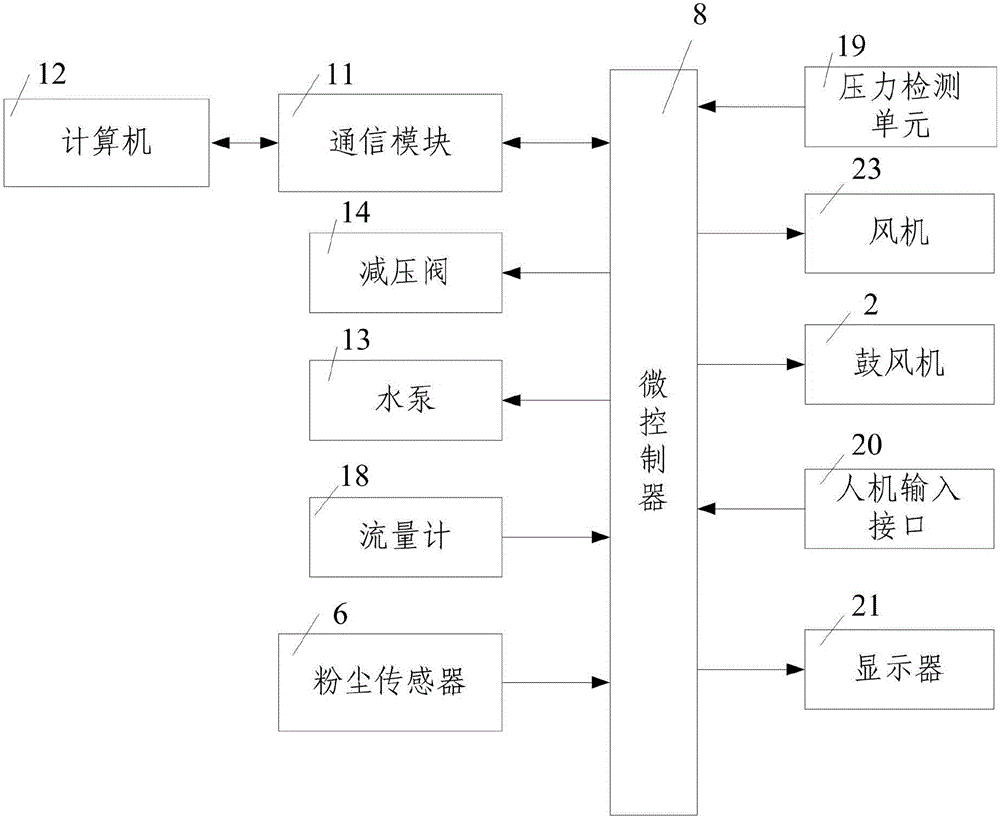

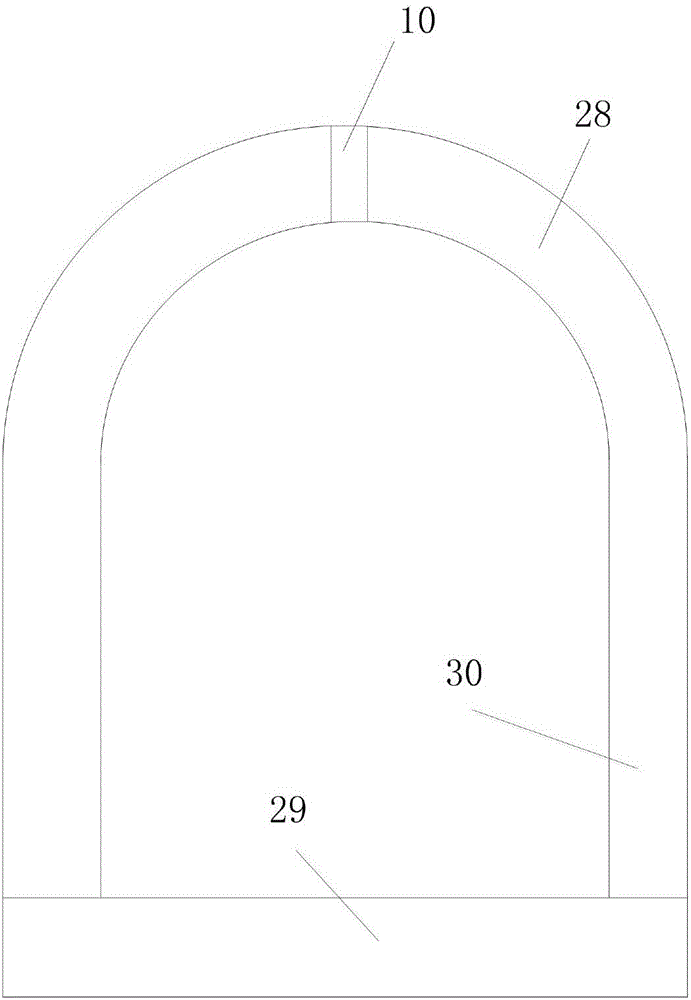

[0058] Such as figure 1 and figure 2 As shown, the dust suppression agent of the present invention, the dust removal effect test device of the dustproof agent include a data acquisition and processing device, a simulated roadway device 27 for simulating the actual coal mine roadway, a dust generating device 1 for transporting dust in the simulated roadway device 27, and a simulation The dust-proof agent spraying device 9 and the dedusting device 22 for dust removal in the roadway device 27, the data collection and processing device includes a microcontroller 8 and a communication module 11 connected with the microcontroller 8 and bidirectionally communicating with a computer 12, The input terminal of the microcontroller 8 is connected with a dust sensor 6 for detecting the dust concentration in the simulated roadway device 27, and the output terminal of the microcontroller 8 is connected with a display 21;

[0059] The dust generating device 1 includes a crusher 4 for crushi...

Embodiment 2

[0072] Include the following steps in this embodiment:

[0073] Step 1. Prepare the dust not soaked in the dust suppressant solution: use the dust generating device 1 to prepare the dust not soaked in the dust suppressant solution, the process is as follows:

[0074] Using the crusher 4 to crush the material to be crushed to obtain a first powder, then screen the first powder, and put the screened first powder into a constant temperature box for constant temperature drying treatment to obtain a first dust sample, Then weigh two parts of the first dust of the same quality from the first dust sample and put them into two dust boxes 3 respectively; The two dust boxes 3 of the first dust are respectively called the first dust box and the second dust box;

[0075] Step 2. Prepare the dust soaked in the dust suppressant solution: use the dust generating device 1 to prepare the dust soaked in the dust suppressant solution, the process is as follows:

[0076] First of all, put the m...

Embodiment 3

[0106] The difference between this embodiment and embodiment 2 is: the temperature of the constant temperature drying treatment in step 1 and step 2 is 50°C, and the time of constant temperature drying treatment is 30h; The residual dust of the dust is removed for 120min, the concentration of the dust suppressant mixed solution is 5%, the concentration of the dust suppressant mixed solution is 25%, the flow rate of the infusion tube 16 is 5L / h, and the pressure of the infusion tube 16 is 0.5 MPa.

[0107] In this embodiment, the remaining steps and process parameters are the same as those in Embodiment 2.

[0108] In this embodiment, the dust removal efficiency of the dust suppressant is 92.3%, the dust removal efficiency of the dust remover is 93.7%, and the dust removal efficiency of the dust suppressant and the dust remover is 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com