Cutting-type unmanned under-ice icebreaking submersible vehicle

A cutting-type, submersible technology, applied to icebreakers, underwater ships, underwater operating equipment, etc., can solve the problems of single means, difficult to control the ice-breaking effect, high structural strength requirements of drill bits and submersibles, etc., to improve the ice-breaking ability , expanding the range of navigation, the effect of simple internal structure and control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

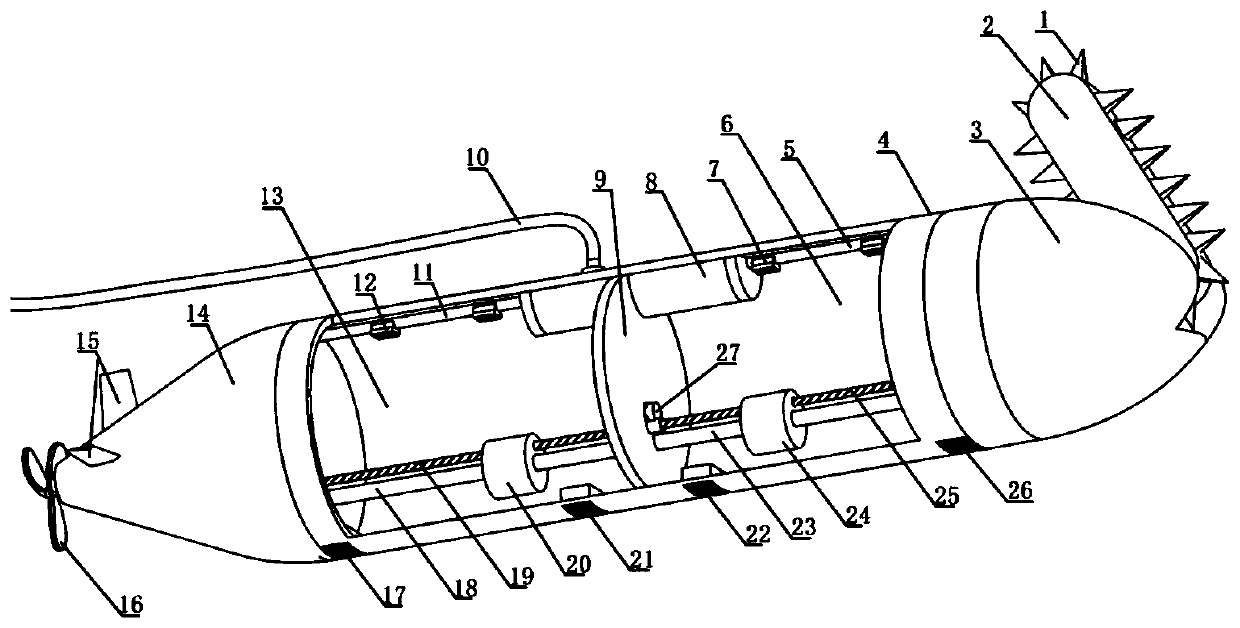

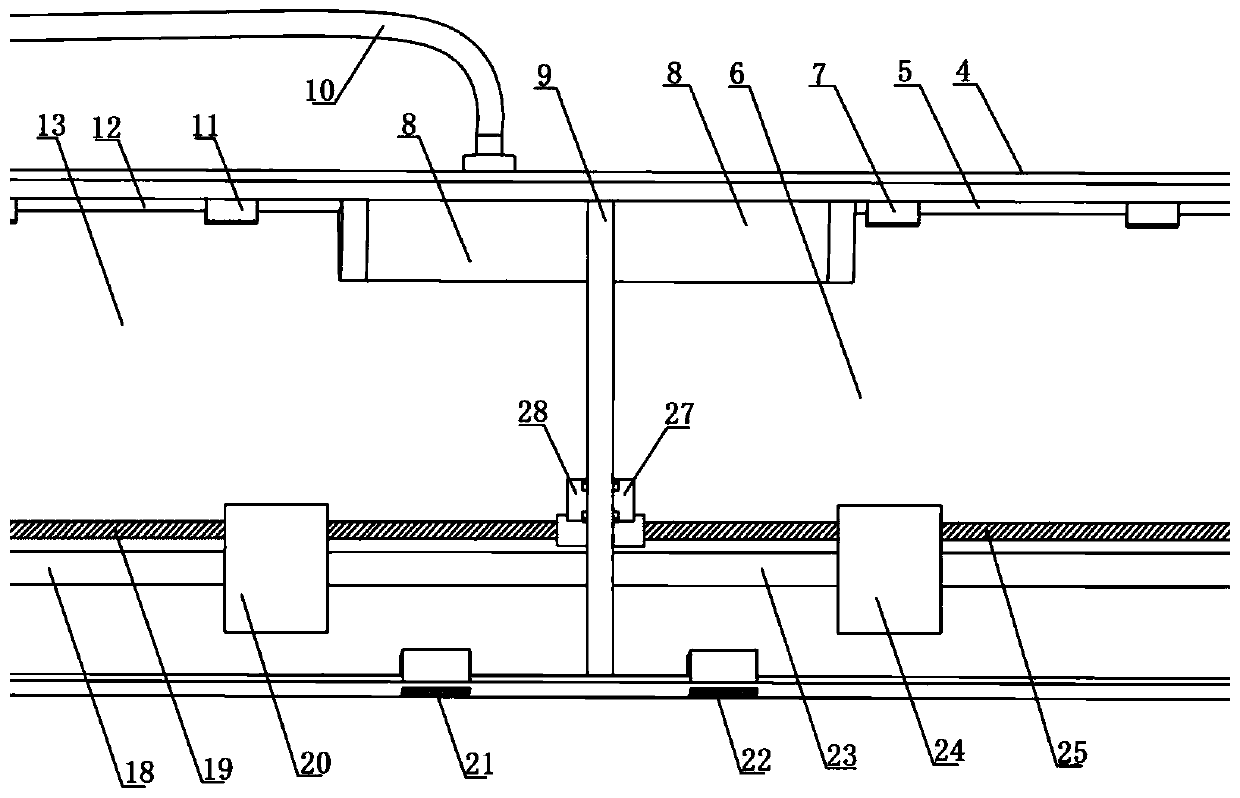

[0016] In the figure: 1. Sawtooth, 2. Ice-breaking saw, 3. Head of submersible, 4. Middle part of submersible, 5. Front air passage, 6. Front ballast water tank, 7. Front air valve, 8. High-pressure gas Cavity, 9. Watertight transverse bulkhead, 10. Umbilical cable, 11. Rear air passage, 12. Rear air valve, 13. Rear ballast water tank, 14. Tail of submersible, 15. Rudder, 16. Propeller , 17. Rear sea valve, 18. Rear slide rail, 19. Rear screw, 20. Rear attitude adjustment counterweight, 21. Rear air valve, 22. Front sea valve, 23. Front slide Rail, 24. the front portion attitude adjustment counterweight, 25. the front portion screw mandrel, 26. the front portion breather valve, 27. the front portion attitude adjustment motor, 28. the rear portion attitude adjustment motor.

[0017] The invention relates to the field of mechanical technology, in particular to a cutting-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com