Pile and soil interaction visual testing device and method

A test device and pile-soil technology, which is applied in foundation structure test, construction, foundation structure engineering, etc., can solve problems such as difficulty in vertical wall-attachment, inconsistency, displacement of soil around piles, etc., and achieve the goal of improving test controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

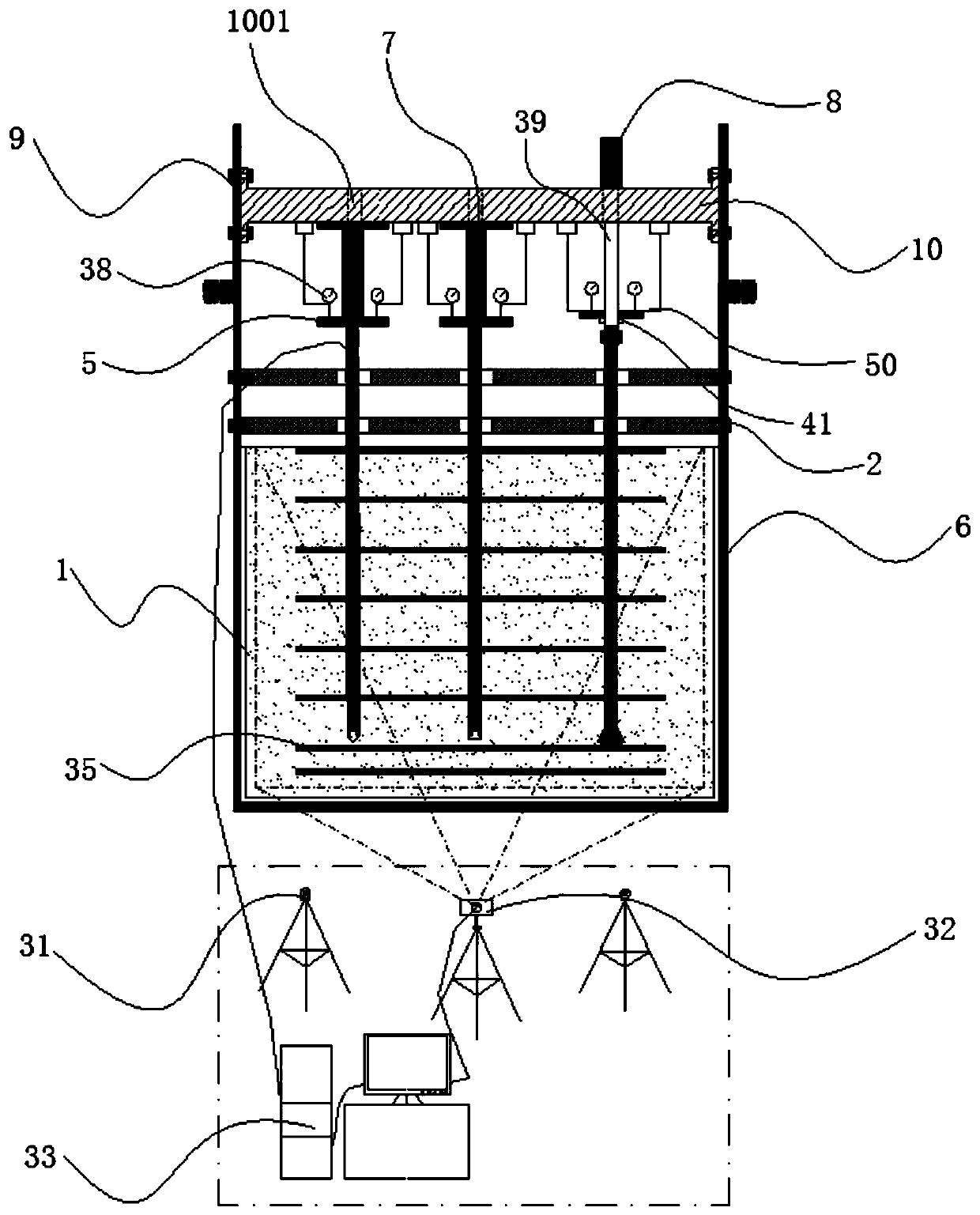

[0069] see figure 1 , this embodiment discloses a pile-soil interaction visualization test device, including a plexiglass box 1, two pile stoppers 2, a box supporting steel frame 6, two movable supports 9, and a movable reaction beam 10 , model half-pile and visualization system.

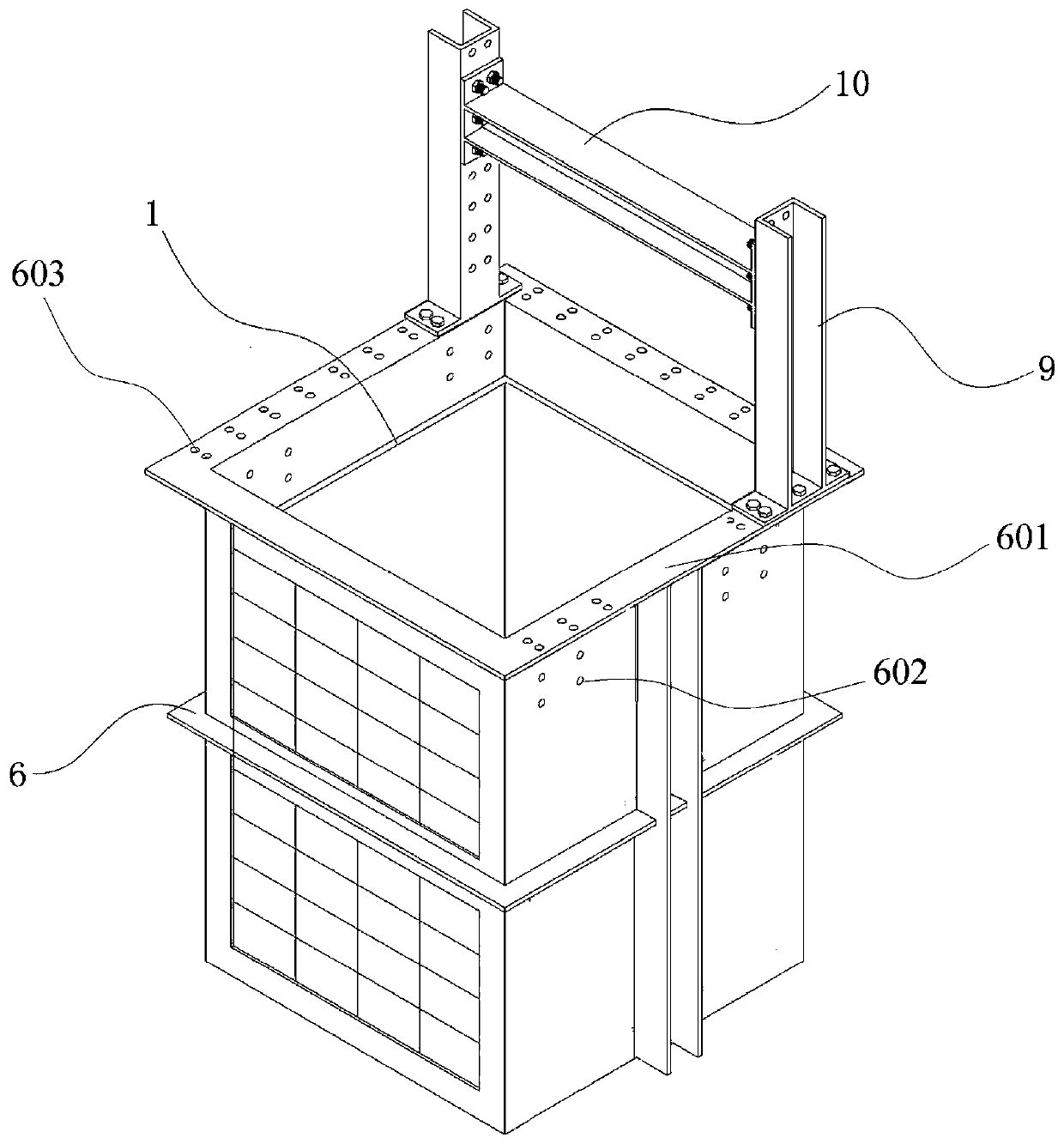

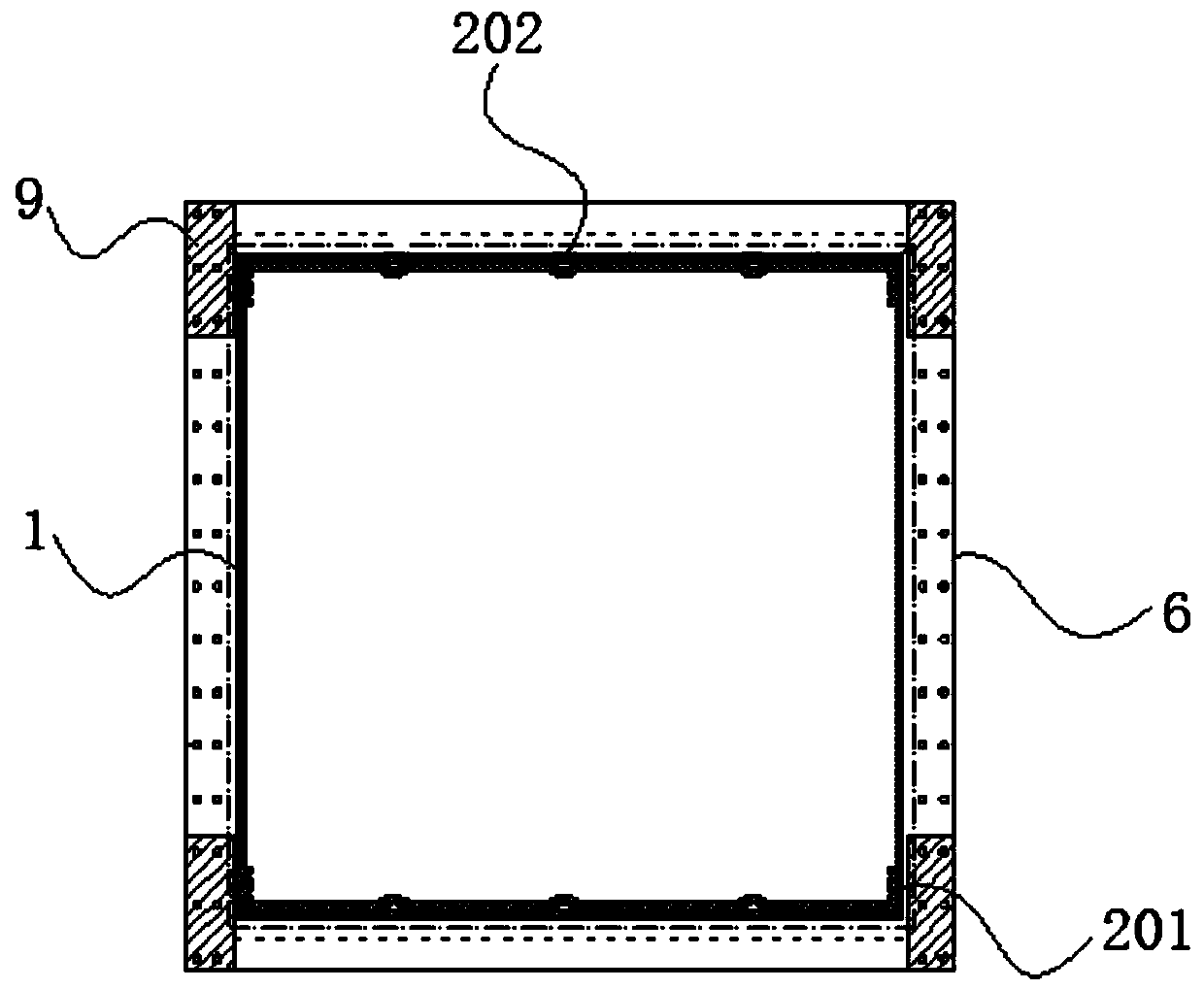

[0070] see figure 2 , the box supporting steel frame 6 is a rectangular box as a whole. The upper end surface of this rectangular box is provided with a top steel plate reinforcing hoop 601 . The plexiglass box 1 is a rectangular box. The plexiglass box 1 is embedded in the inner cavity of the box supporting steel frame 6 . The height difference between the box supporting steel frame 6 and the plexiglass box 1 is 25-35 cm. The inner cavity of the plexiglass box 1 is filled with soil materials. The soil material includes multiple layers of undyed soil particles and layers of colored soil particles 35 arranged at intervals.

[0071] The four side walls of the box supporting steel frame 6 are t...

Embodiment 2

[0081] This embodiment discloses a pile-soil interaction visualization test device, which includes a plexiglass box 1, a plurality of pile stoppers 2, a box supporting steel frame 6, two movable supports 9, a movable reaction beam 10, Model semi-pile and visualization system.

[0082] The box supporting steel frame 6 is a rectangular box as a whole. The upper end surface of this rectangular box is provided with a top steel plate reinforcing hoop 601 . The plexiglass box 1 is a rectangular box. The plexiglass box 1 is embedded in the inner cavity of the box supporting steel frame 6 . The height difference between the box supporting steel frame 6 and the plexiglass box 1 is 25-35 cm. The inner cavity of the plexiglass box 1 is filled with soil materials. The soil material includes several layers of undyed soil particle layers and colored soil particle layers 35 arranged at intervals.

[0083] The four side walls of the box supporting steel frame 6 are the first side wall, t...

Embodiment 3

[0090] This embodiment discloses a kind of test method about the test device described in embodiment 1 or 2, comprising the following steps:

[0091] 1) According to the simulated working conditions, select the model half pile with the corresponding pipe diameter, and arrange the pressure sensor 23 and the strain gauge 29 as required.

[0092] 2) According to the simulated working conditions, select soil granular materials and corresponding industrial dyes.

[0093] 3) Sieve the soil particle material into multiple particle size groups, dye the soil particle materials of different particle size groups into different colors for calibration, and obtain dyed soil particles with different particle sizes and different colors after drying.

[0094] 4) Evenly mixing the dyed soil particle material according to the particle size gradation ratio to prepare a mixed soil particle material.

[0095] 5) Clean up the plexiglass box 1. Combined with the working conditions, the colored soil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com