A method for controlling alignment of pre-fabricated segmental beams based on a short-line matching method

A linear control and short-line matching technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of deviation from the theoretical design of the section at the I end of the prefabricated block n# block, adjustment of prefabricated beams, and failure to consider the connection of control points Issues such as the angle between the axis of the precast section and the axis of the prefabricated section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0238] The present invention will be further described below in conjunction with drawings and embodiments.

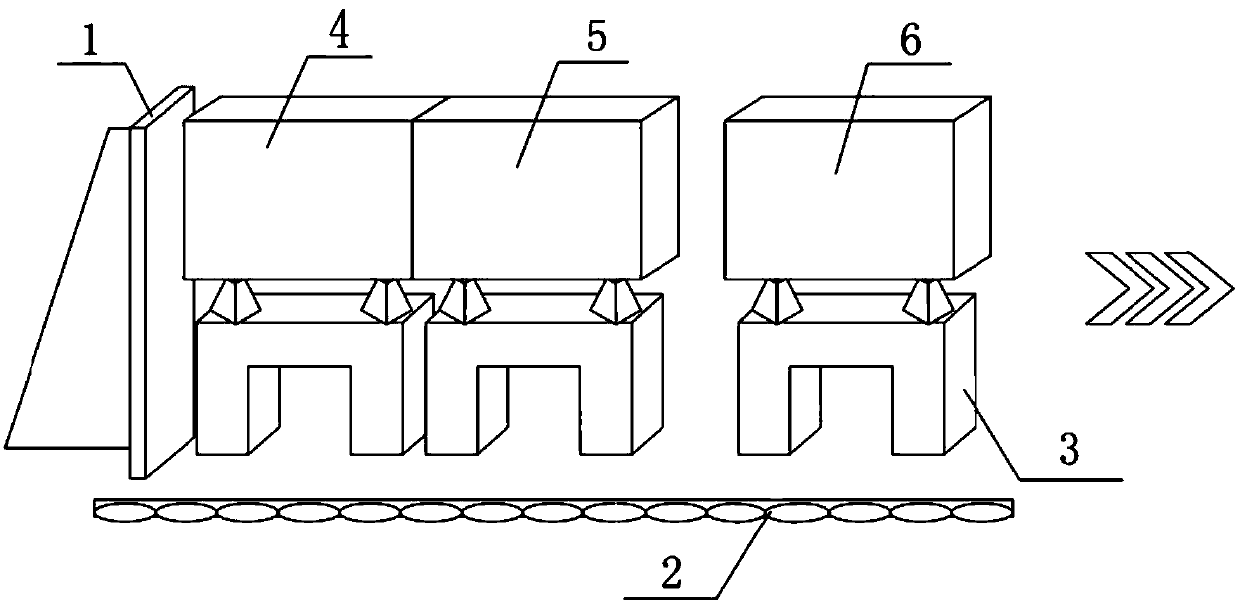

[0239] Such as figure 1 A segmental beam prefabrication linear control method based on the short-line matching method is shown, including the following steps:

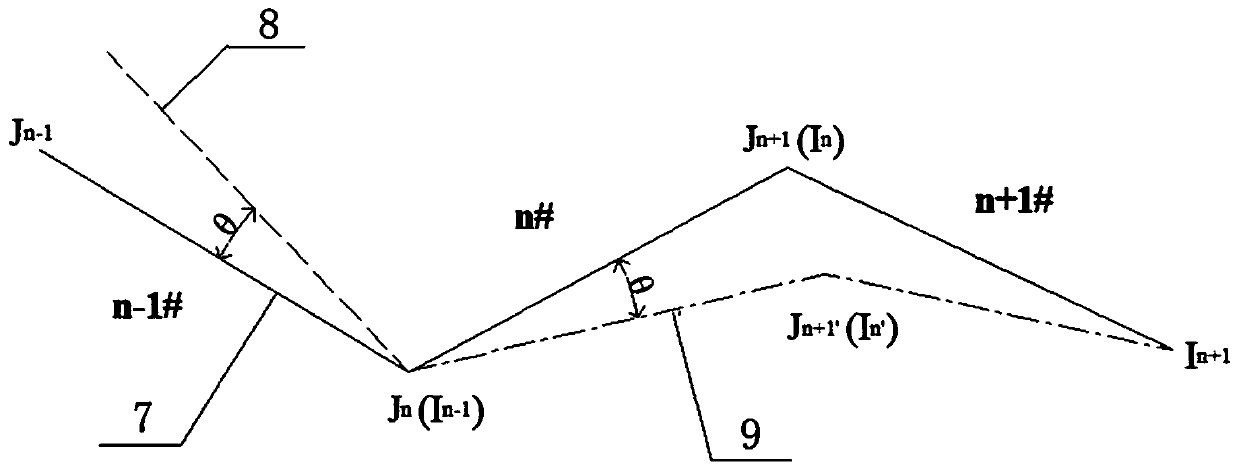

[0240] S1. On-site data measurement to obtain local measured coordinate data BL of 6 control points of prefabricated block n# LT,n ,BR LT,n ,FL LT,n , Fr LT,n , BH LT,n , FH LT,n And the local coordinate number BL of the 6 control points of the matching block n-1# block LT,n-1 ,BR LT,n-1 ,FL LT,n-1 , Fr LT,n-1 , BH LT,n-1 , FH LT,n-1 ; Among them, BL, BR, FL, FR measuring point data are used to analyze the vertical elevation (XZ) deviation, BH, FH are used to analyze the horizontal direction (XY) deviation (see figure 2 ). In the formula: L in the subscripts and subscripts indicates the coordinates of the local coordinate system, G indicates the coordinates of the overall coordinate system, T indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com