Integrated complete equipment and method for crushing, washing and separating discarded plastics

A complete set of equipment and plastic technology, which is applied in the field of waste plastic crushing, cleaning and sorting integrated complete equipment, can solve the problems of metal objects, and achieve the effects of saving cost and energy consumption, reducing water consumption, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

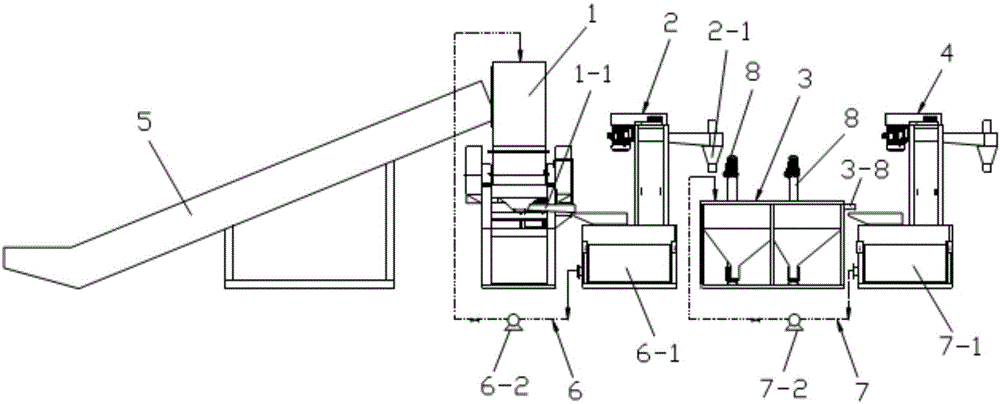

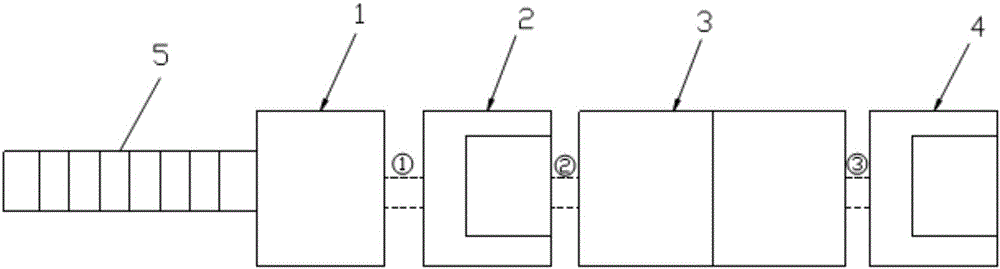

[0041] see figure 1 and figure 2 , the waste plastic crushing, cleaning and sorting integrated complete set of equipment in this embodiment includes a crushing device 1, a cleaning and sorting device, and a dehydration device connected in sequence; wherein, the cleaning and separation device includes a first dehydrator 2 with a washing cage and a separation device. Tank 3; the dehydration device includes a second dehydrator 4 with a washing cage, and the washing cage is used to clean materials and remove large particles of sediment and other impurities.

[0042] see figure 1 A first section of the cleaning water circulation system 6 is provided between the first dehydrator 2 and the crushing device 1, and the first section of the cleaning water circulation system 6 includes a skimmer 6-1 connected to the water outlet of the first dehydrator 2, Pipelines, pumps 6-2, valves, etc. connecting the skimmer 6-1 and the crushing device 1; a second stage of cleaning water circulatio...

Embodiment 2

[0061] see Figure 7 with Figure 8 , the difference between this embodiment and embodiment 1 is that in this embodiment:

[0062] The four combined modules are arranged in a right-angle shape, specifically, a 90-degree bend is performed between the second combined module and the third combined module.

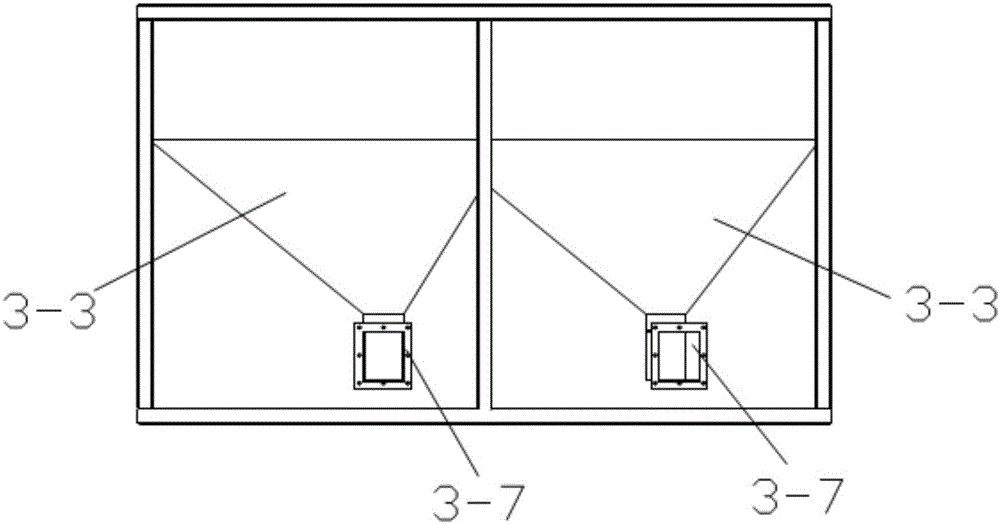

[0063] The separation tank 3 has a three-section structure, which is respectively a first separation section 3-1, a second separation section 3-2 and a third separation section 3-8, which can separate at least four kinds of materials with different densities.

Embodiment 3

[0065] see Figure 9 , the difference between this embodiment and embodiment 2 is that in this embodiment:

[0066] The arrangement of the four combined modules has two right-angled bending points, specifically a 90° bend between the second combined module and the third combined module; a 90° bend between the third combined module and the fourth combined module folded, and bent towards the material conveying direction in the first combination module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com