Water pumping and draining and gas producing system of horizontal gas well machine

A technology for pumping drainage and gas wells, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc. It can solve problems that have not been seen in other reports, and achieve the effects of optimizing gas well productivity, increasing service life, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] This set of drainage gas recovery system is installed for horizontal gas wells with high sulfur content and high production water. The depth of the horizontal production well section is 3050m, and the output gas-liquid ratio varies between 1500-1750. .

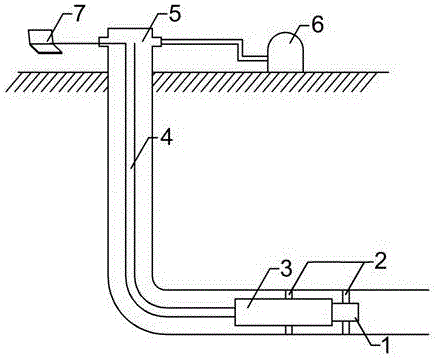

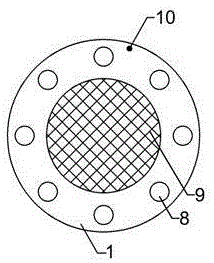

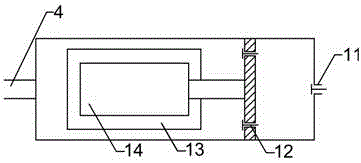

[0034] like figure 1 In the horizontal production well section, the gas-water separator 1 and the linear motor pump 3 are sequentially fixed and installed with the fixer 2, connected with the intelligent coiled tubing 4, and the gas tree 5, the related surface processing device 6, and the intelligent control terminal 7 are installed on the ground.

[0035] After the entire drainage and gas recovery system is put into operation, the high-sulfur formation water and natural gas produced in the production layer enter the gas-water separator 1, and the natural gas is connected to the annulus of the casing for output, and enters the surface treatment device 6 through the gas tree 5 for processing. For desulfurization purific...

example 2

[0039] For highly deviated wells and concave wells in cluster wells, such as Figure 4 (1) and Figure 4 (2) The gas-water separator 1 and the linear motor pump 3 are sequentially fixed and installed in the downhole production section with the fixture 2 at the maximum vertical depth of the well section, connected to the intelligent coiled tubing 4, and the ground equipment installation is consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com