Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Minimizes splashing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

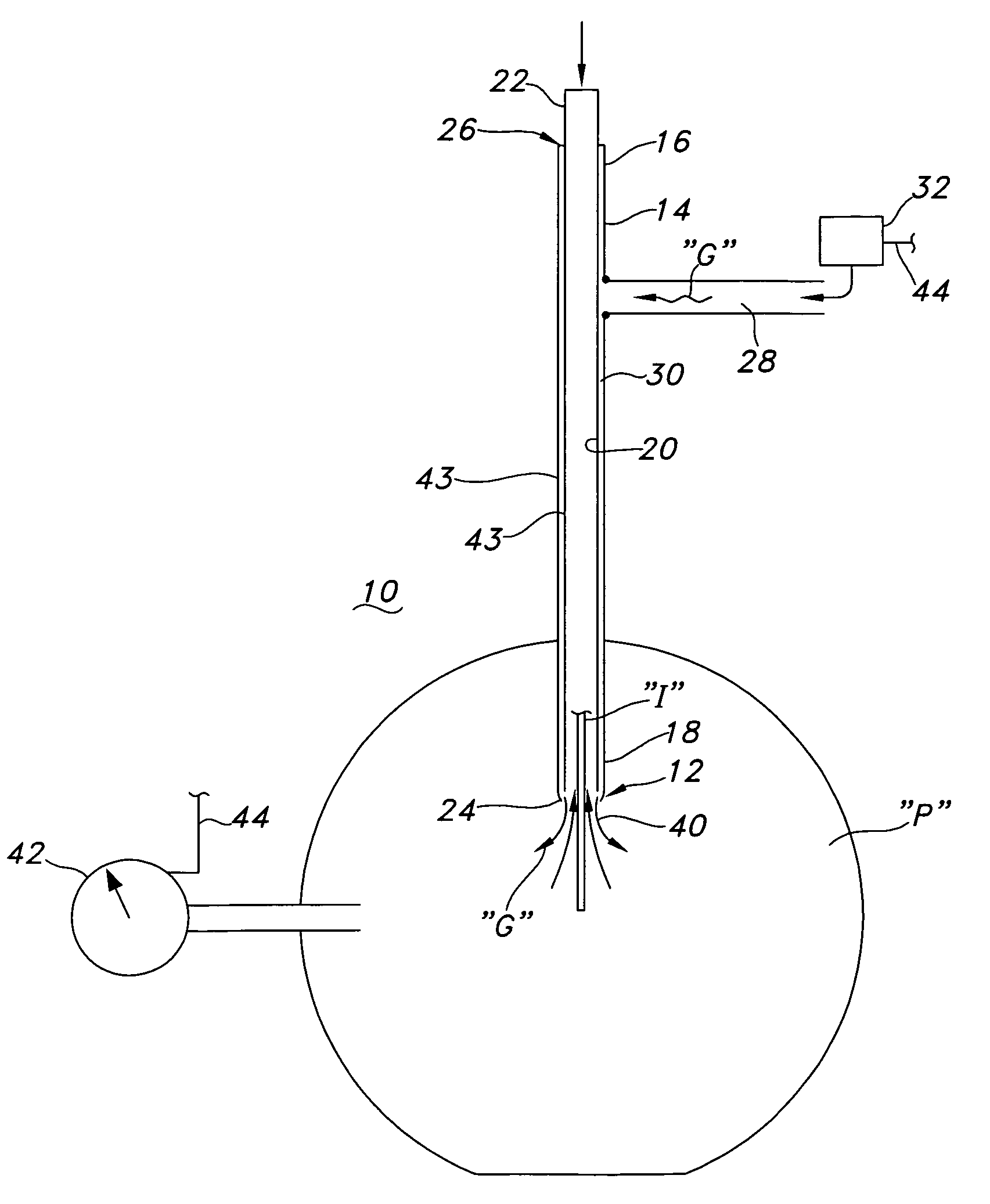

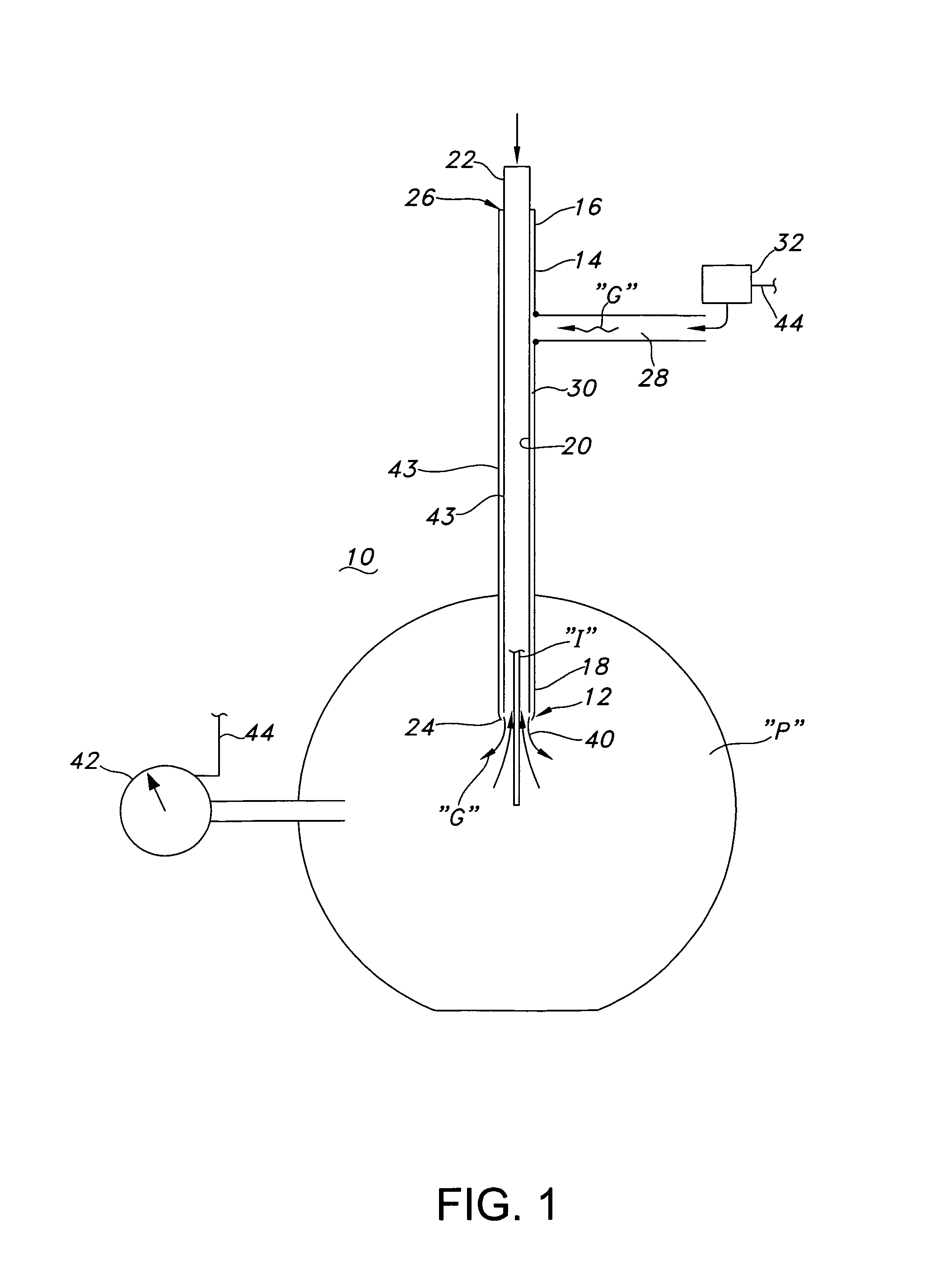

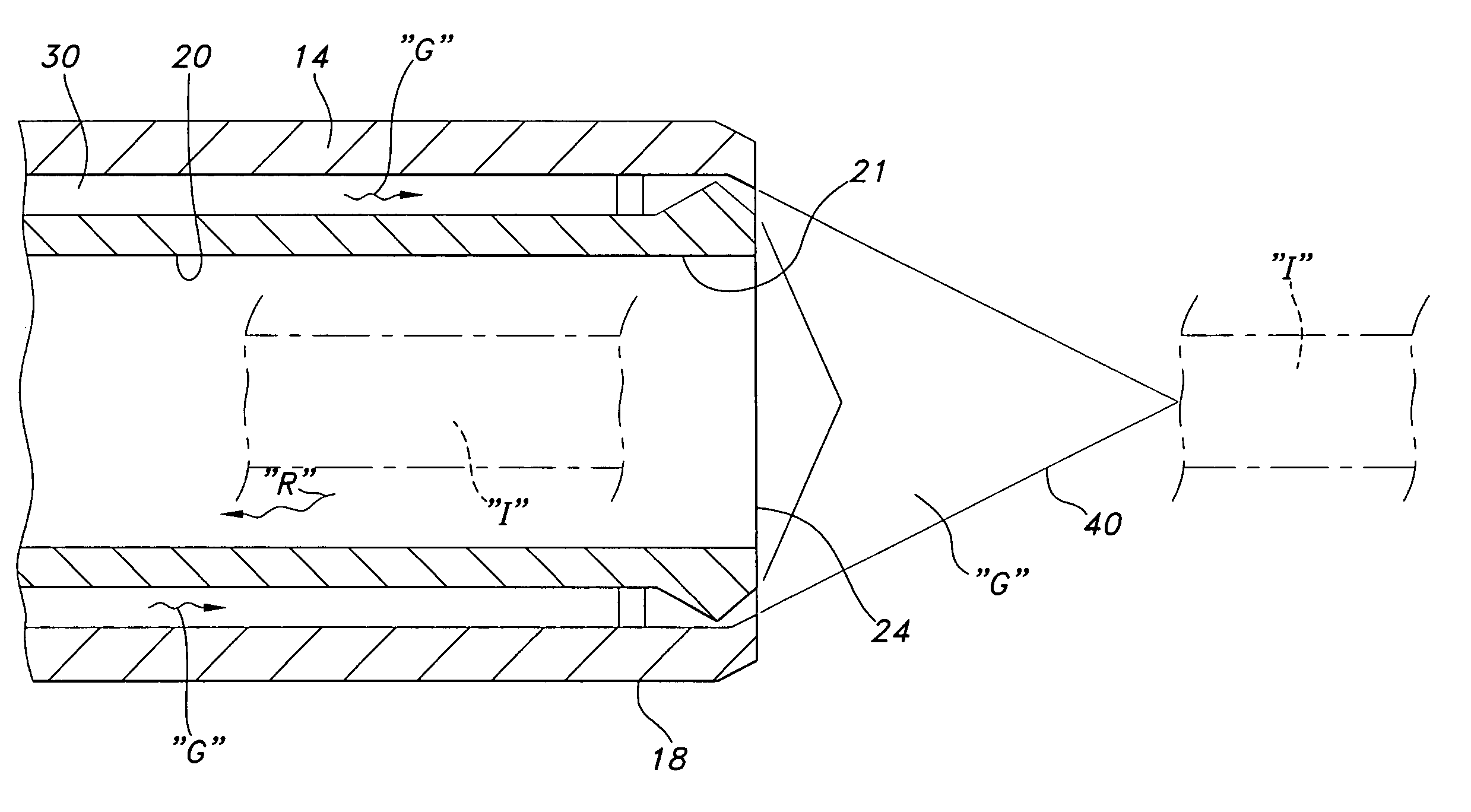

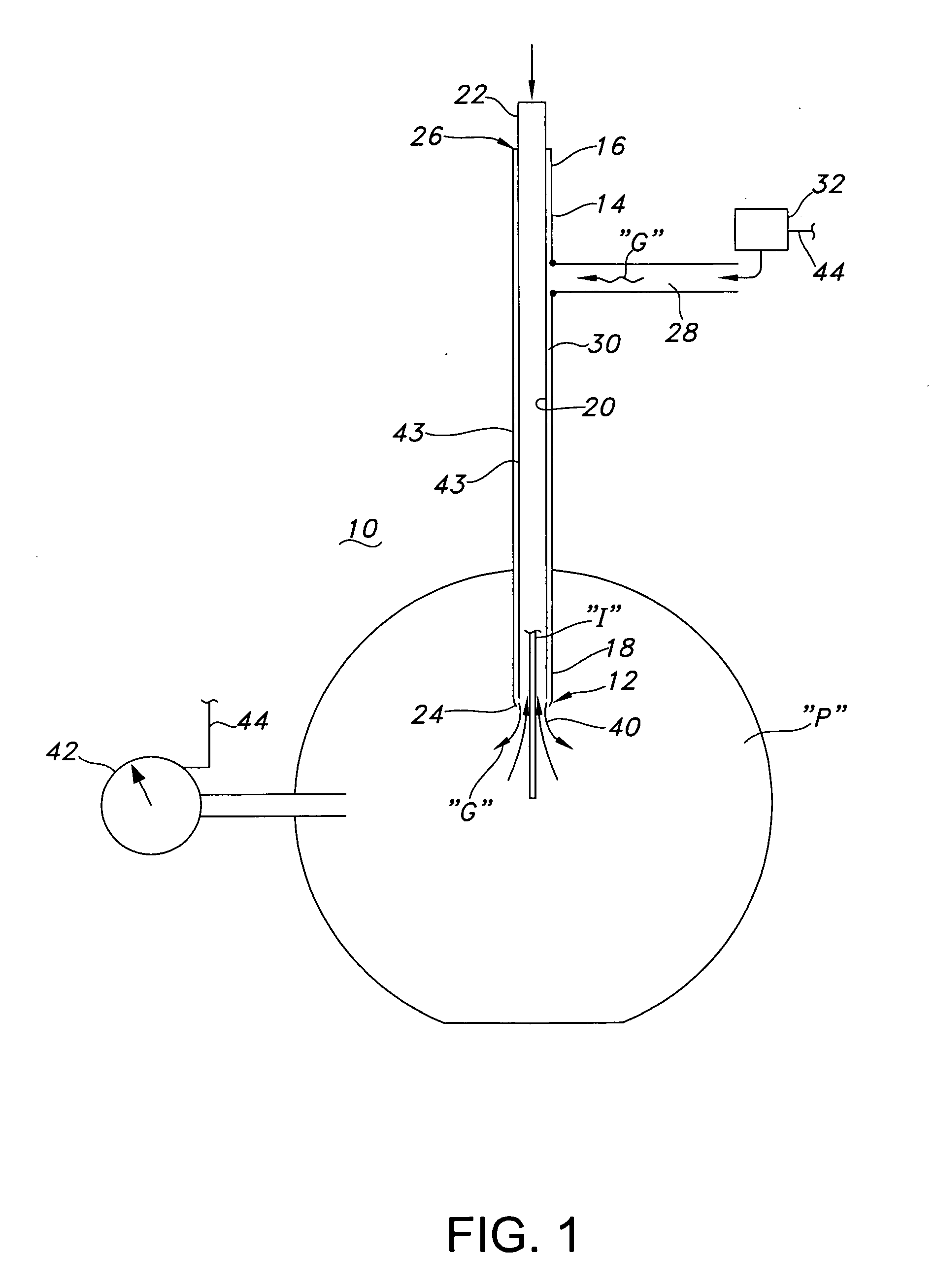

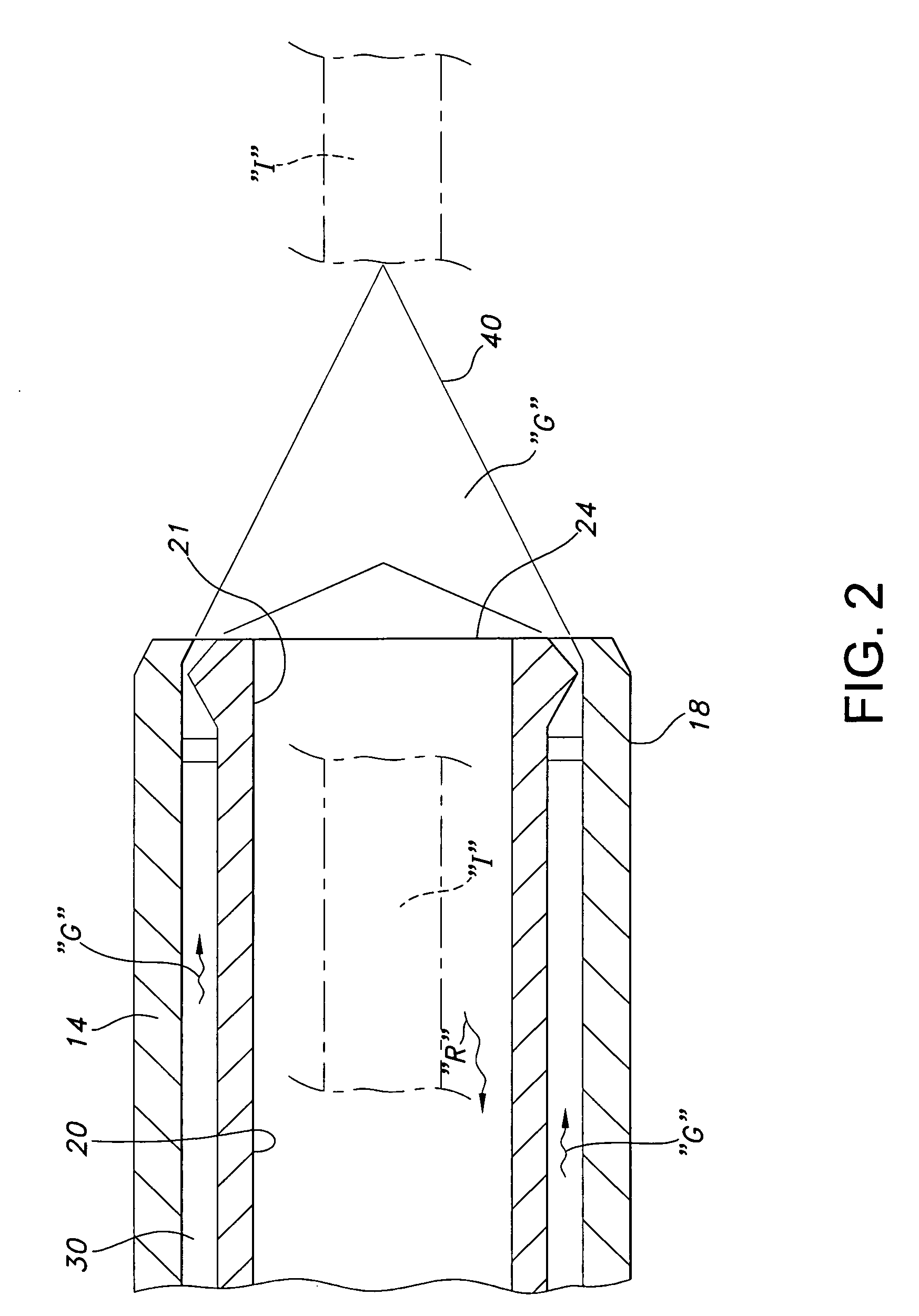

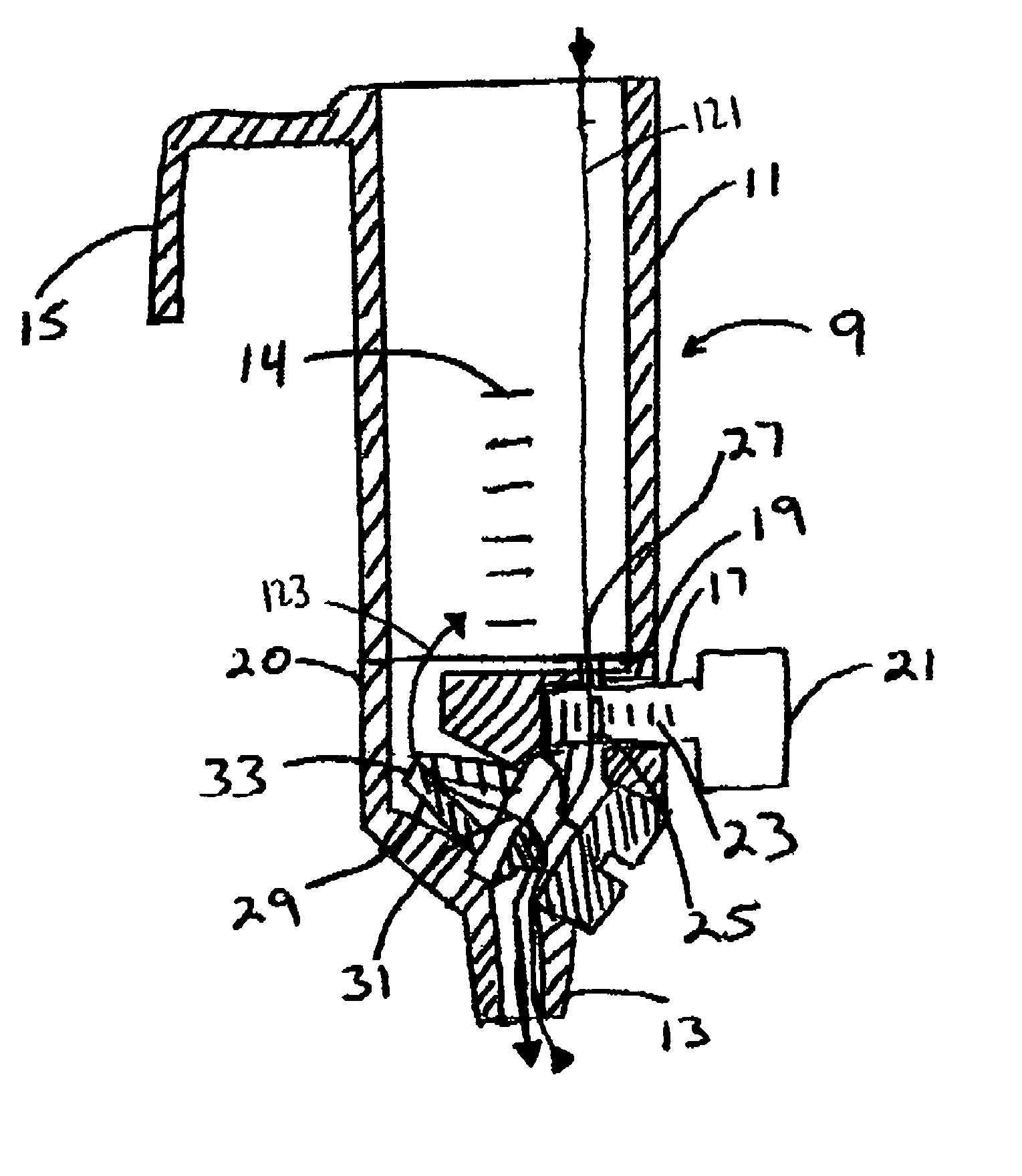

Continuous gas flow trocar assembly

InactiveUS7182752B2Maintain alignmentConstant pressureCannulasDiagnosticsSurgical deviceAbdominal trocar

A trocar assembly for providing a pressurized insufflation fluid into a patient cavity and for providing sealable access to the patient cavity by a surgical instrument. The assembly comprises an inner tubular member having a proximal end and a distal end. An outer tubular member is disposed about the inner tubular member, the outer tubular member having a proximal end and a distal end. The distal end of the inner tubular member and the distal end of the outer tubular member define a trocar seal nozzle arranged therebetween.

Owner:IP TCHNOLOGIES LLC

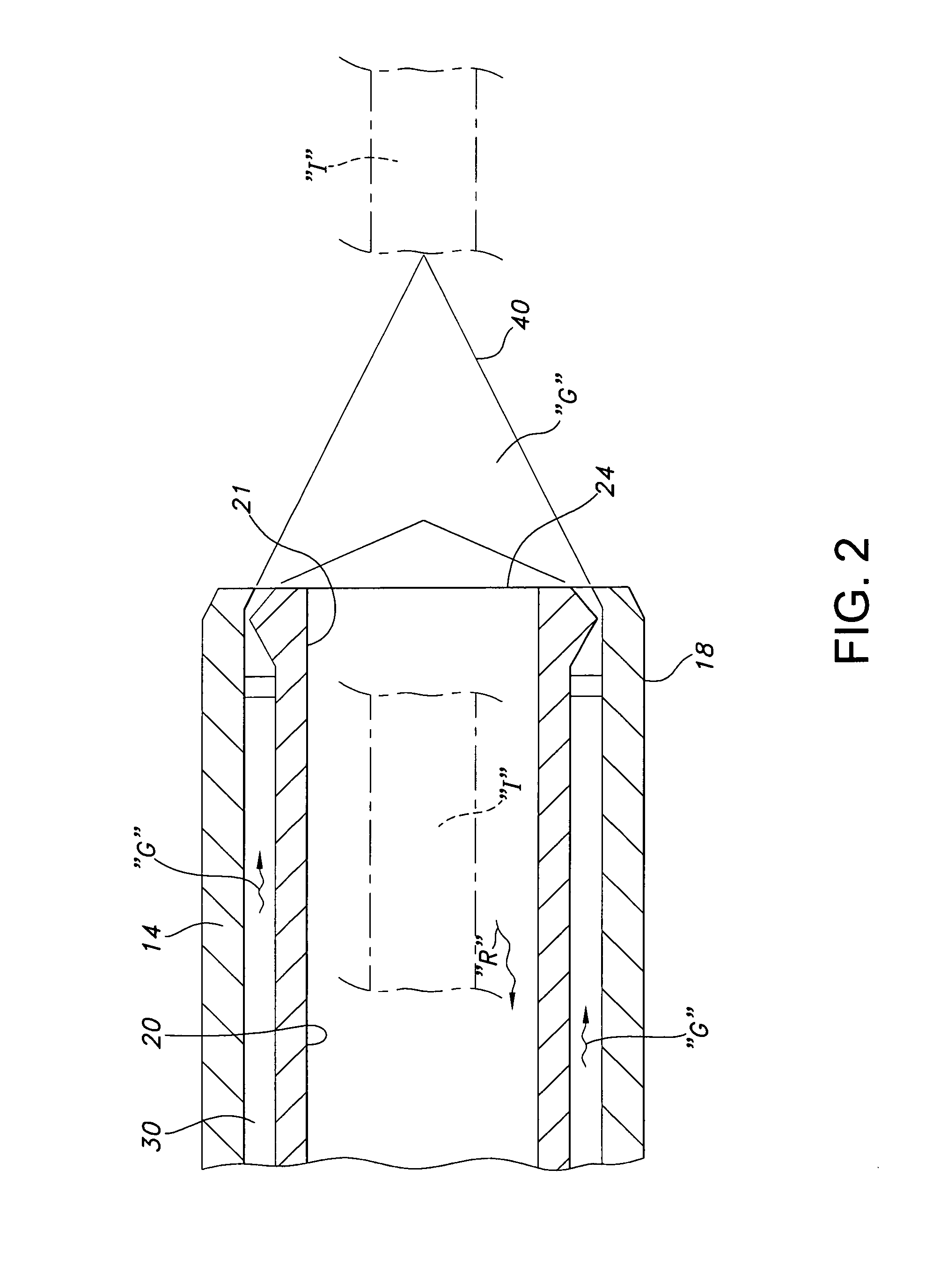

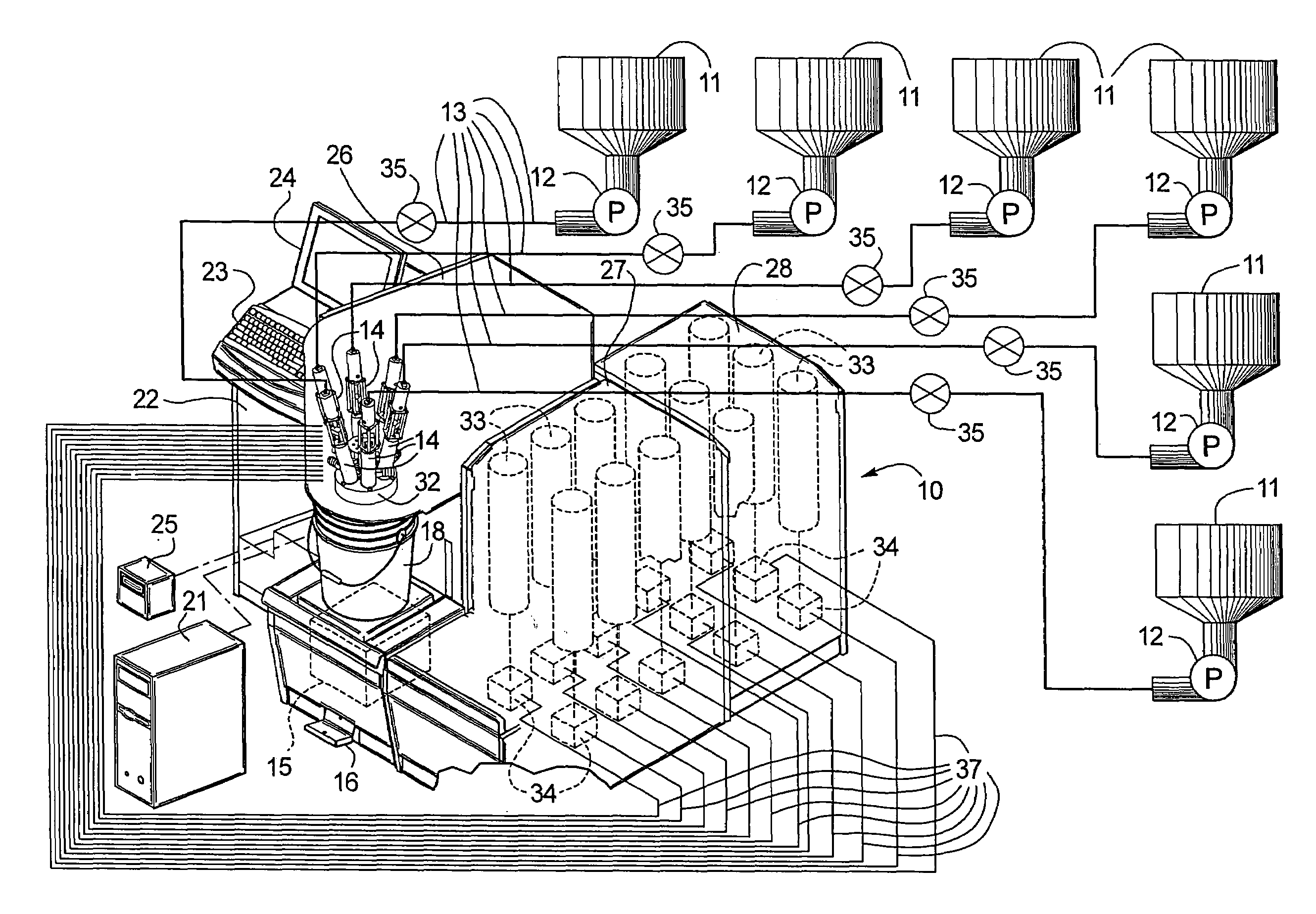

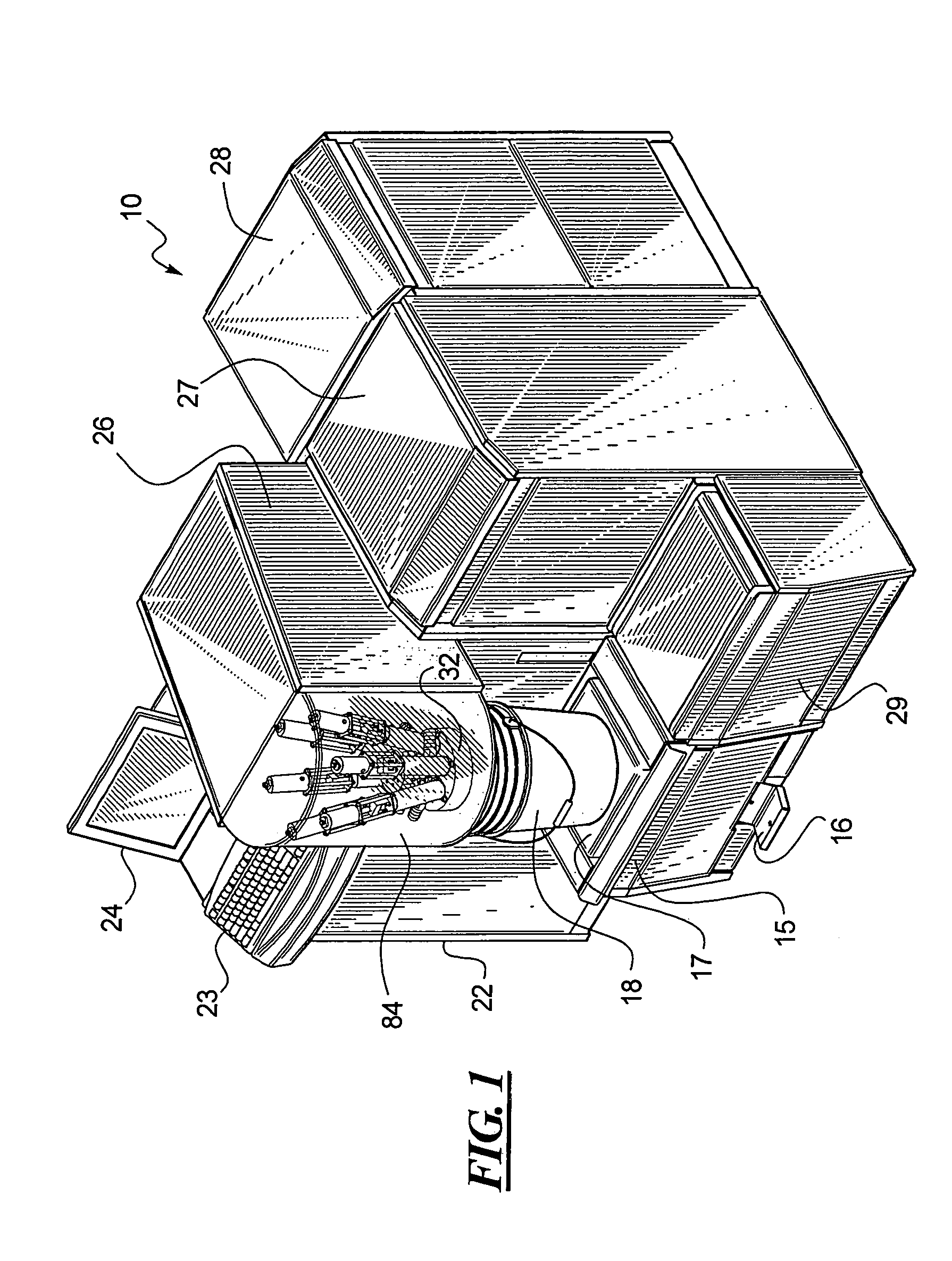

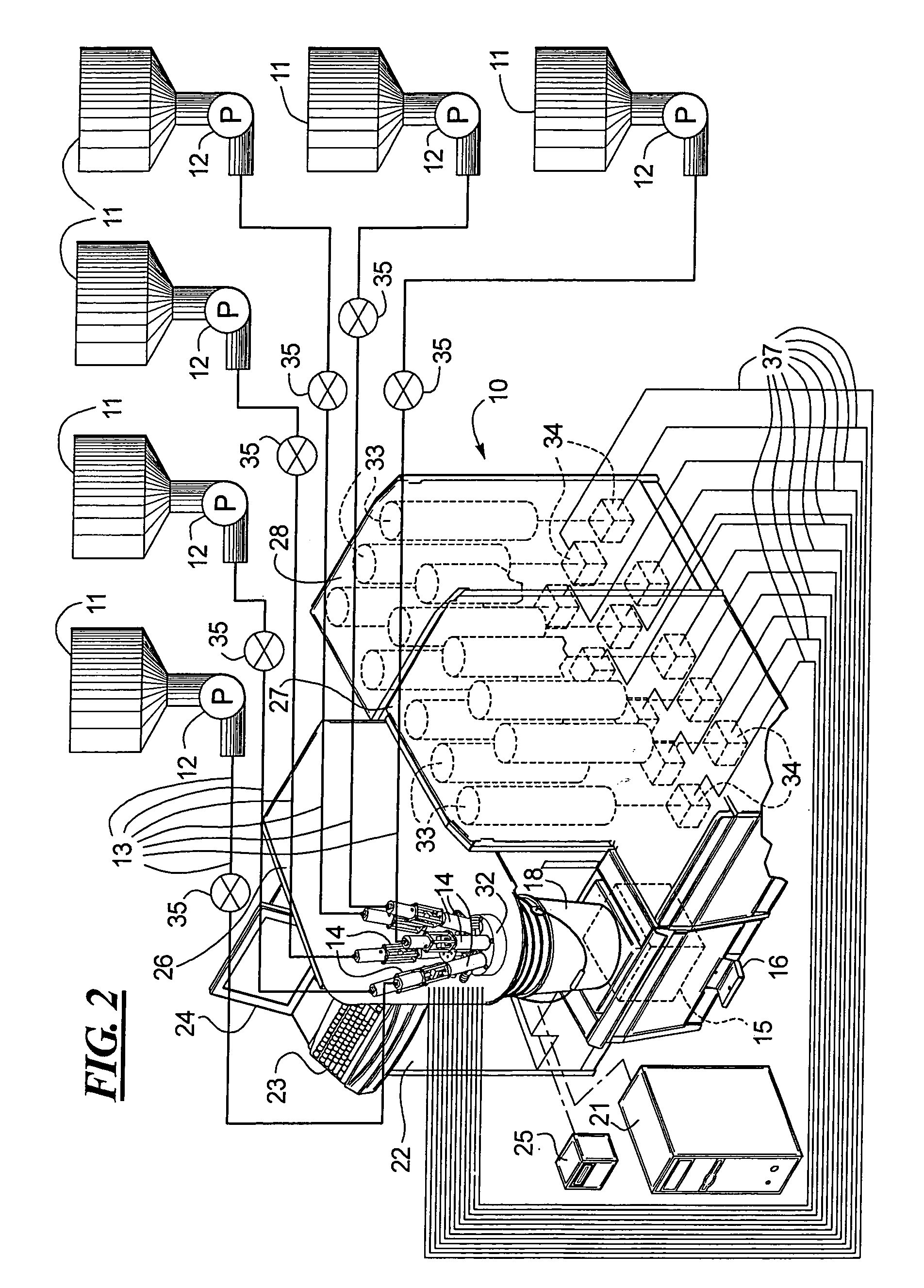

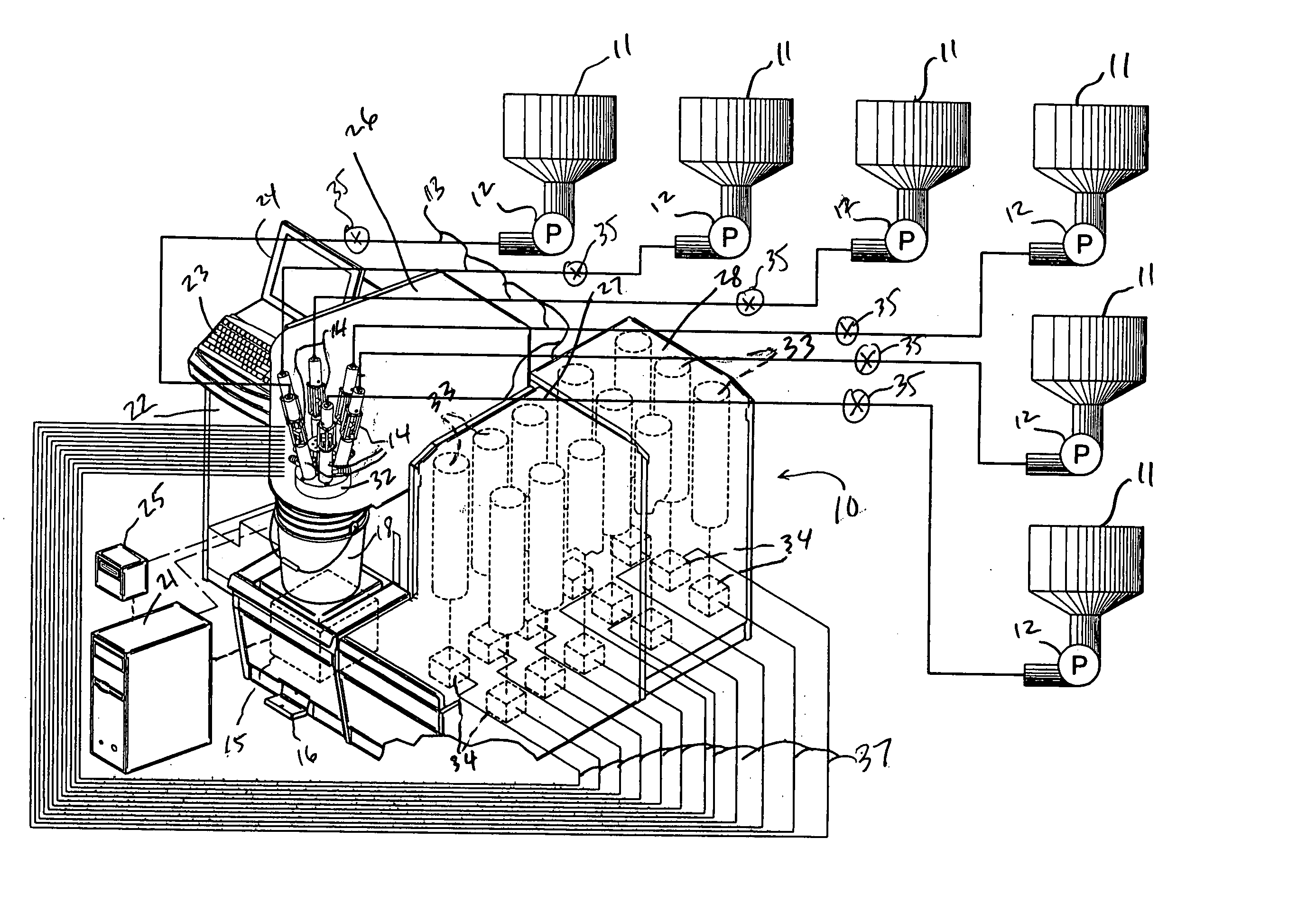

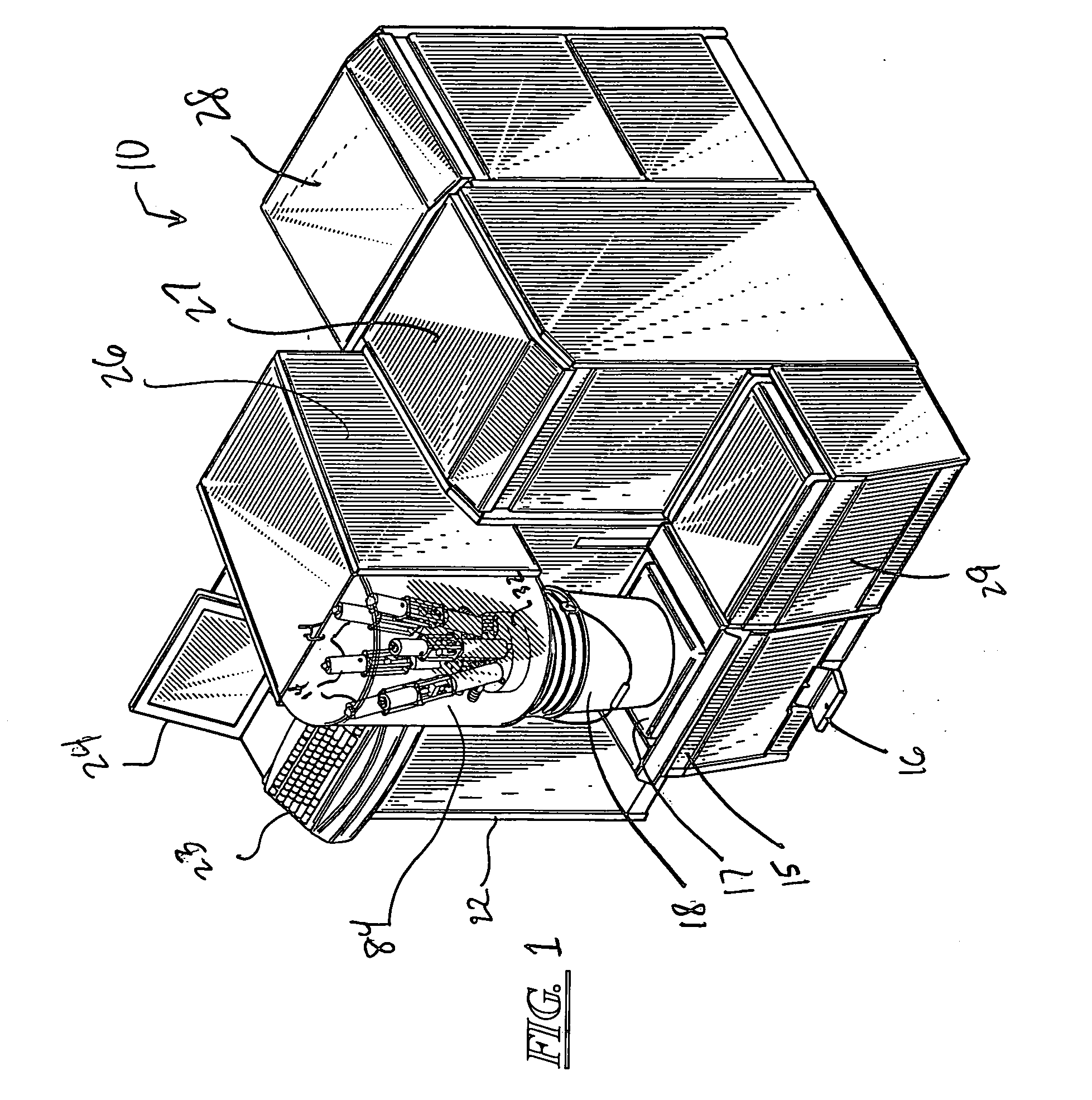

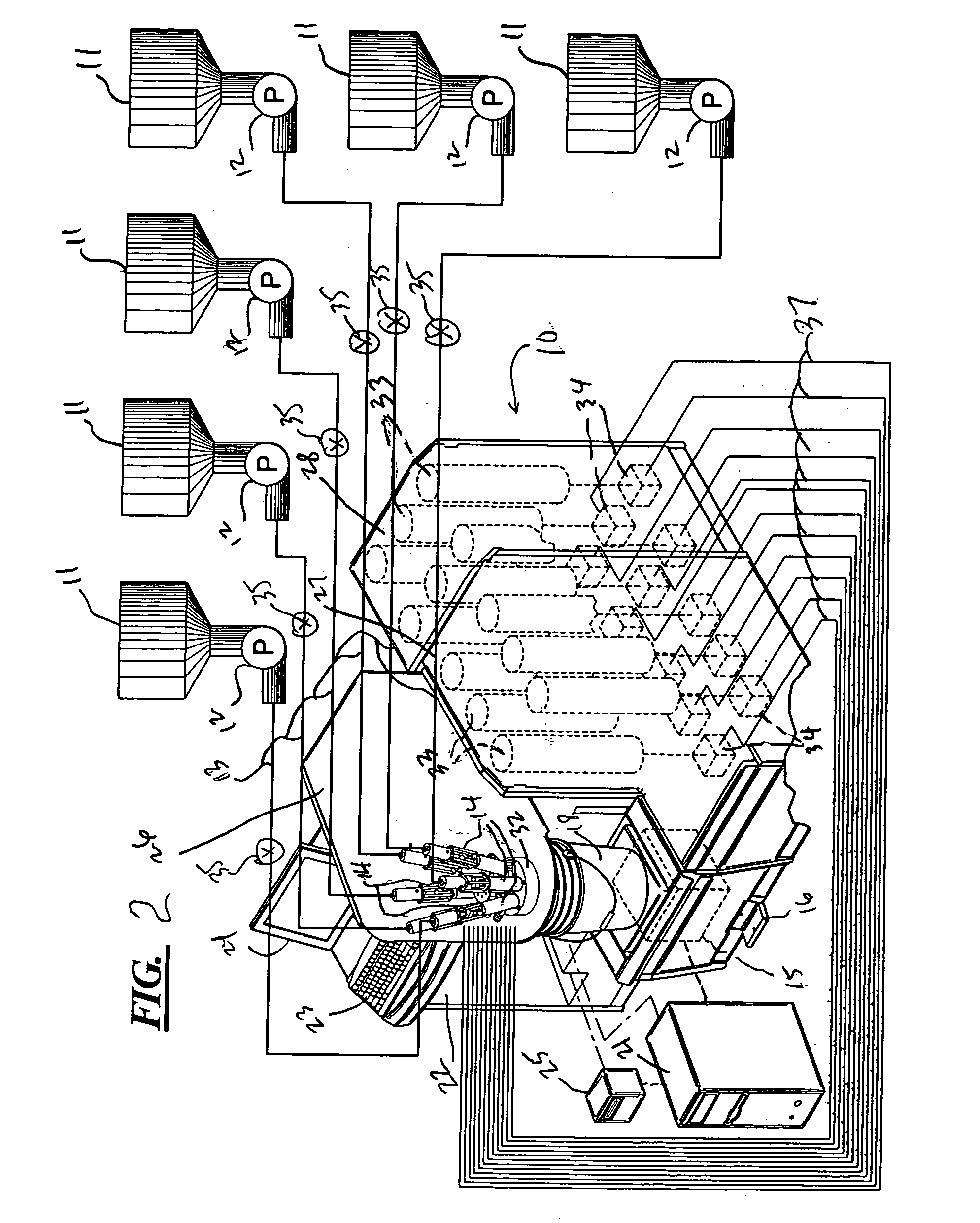

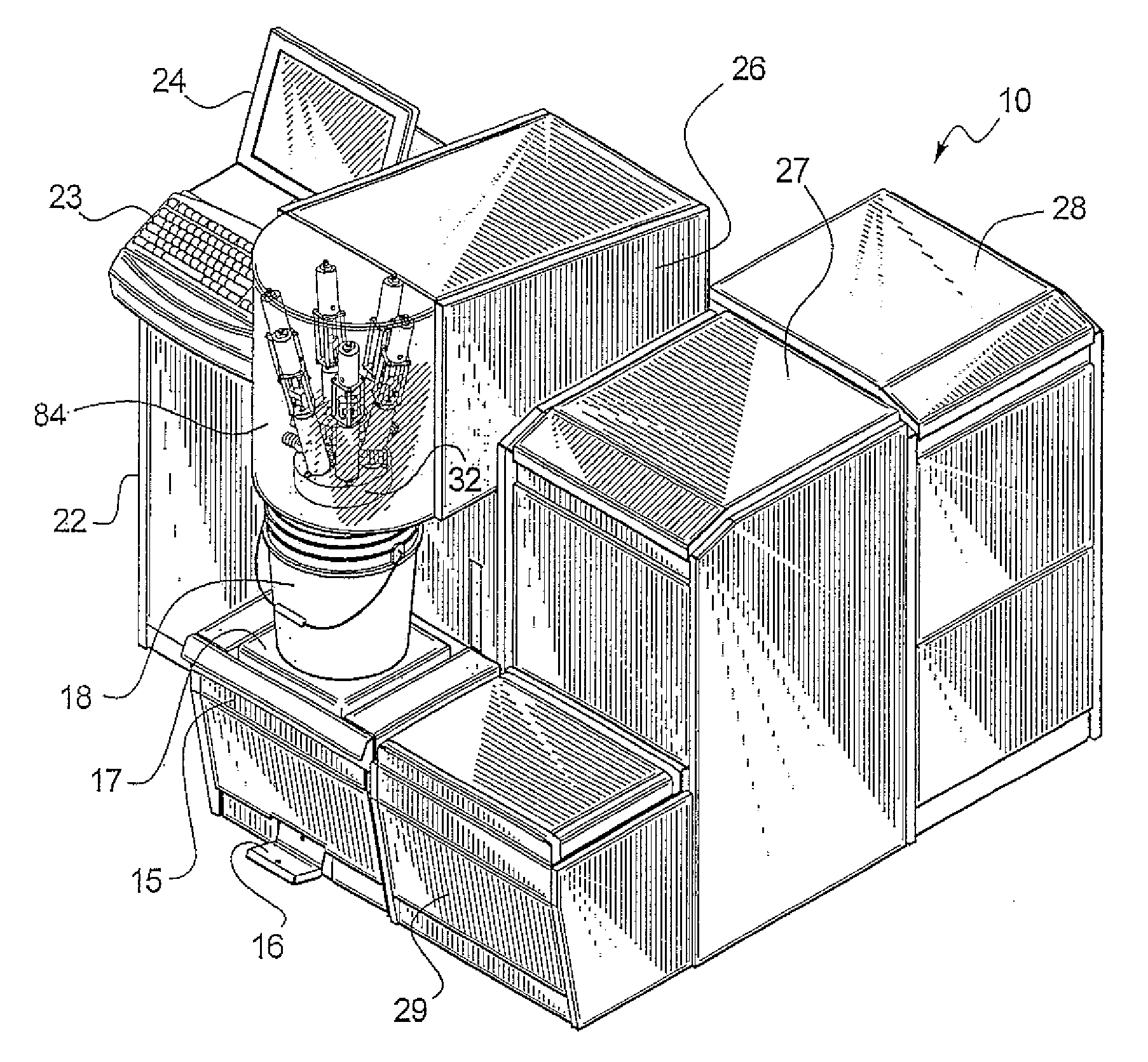

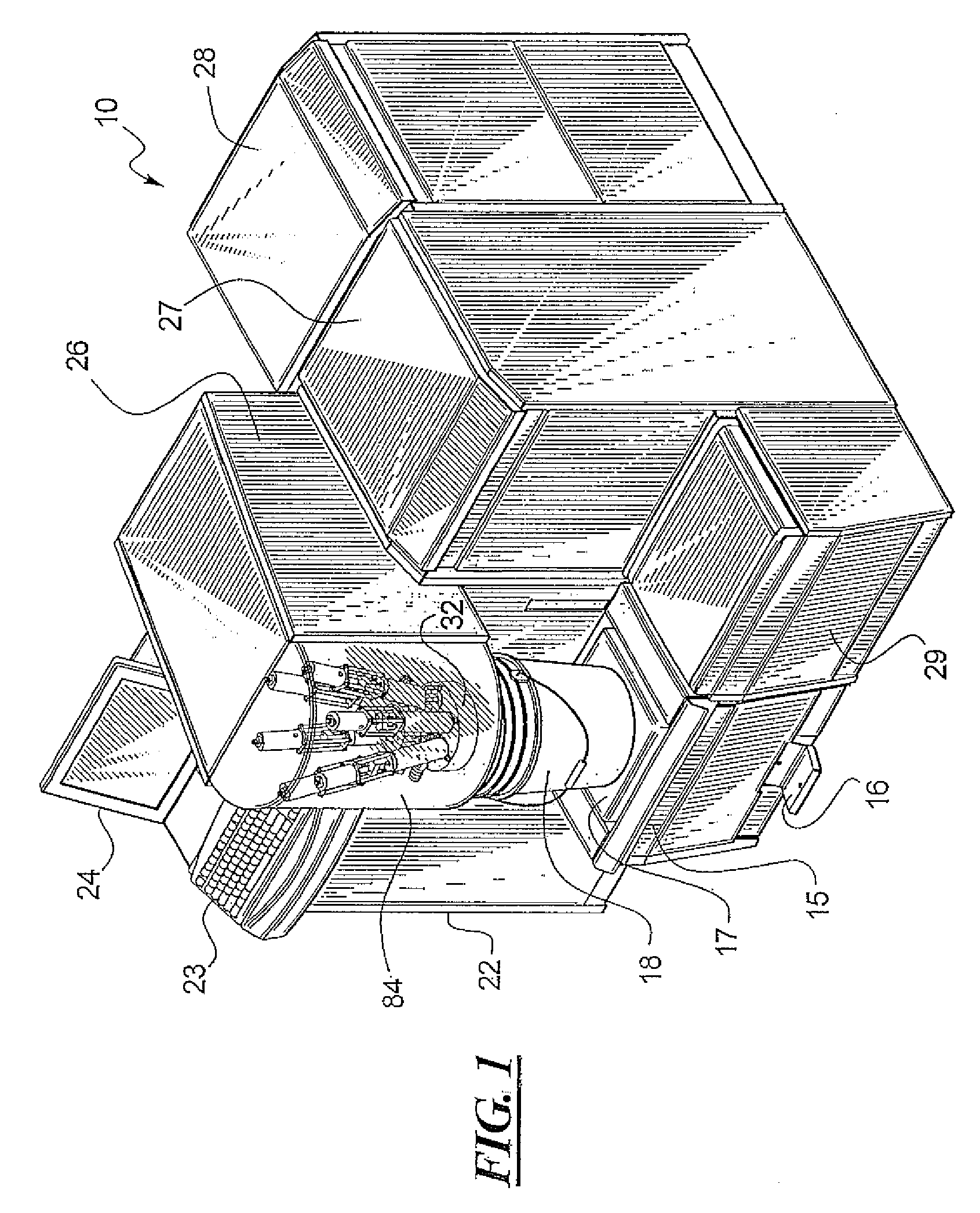

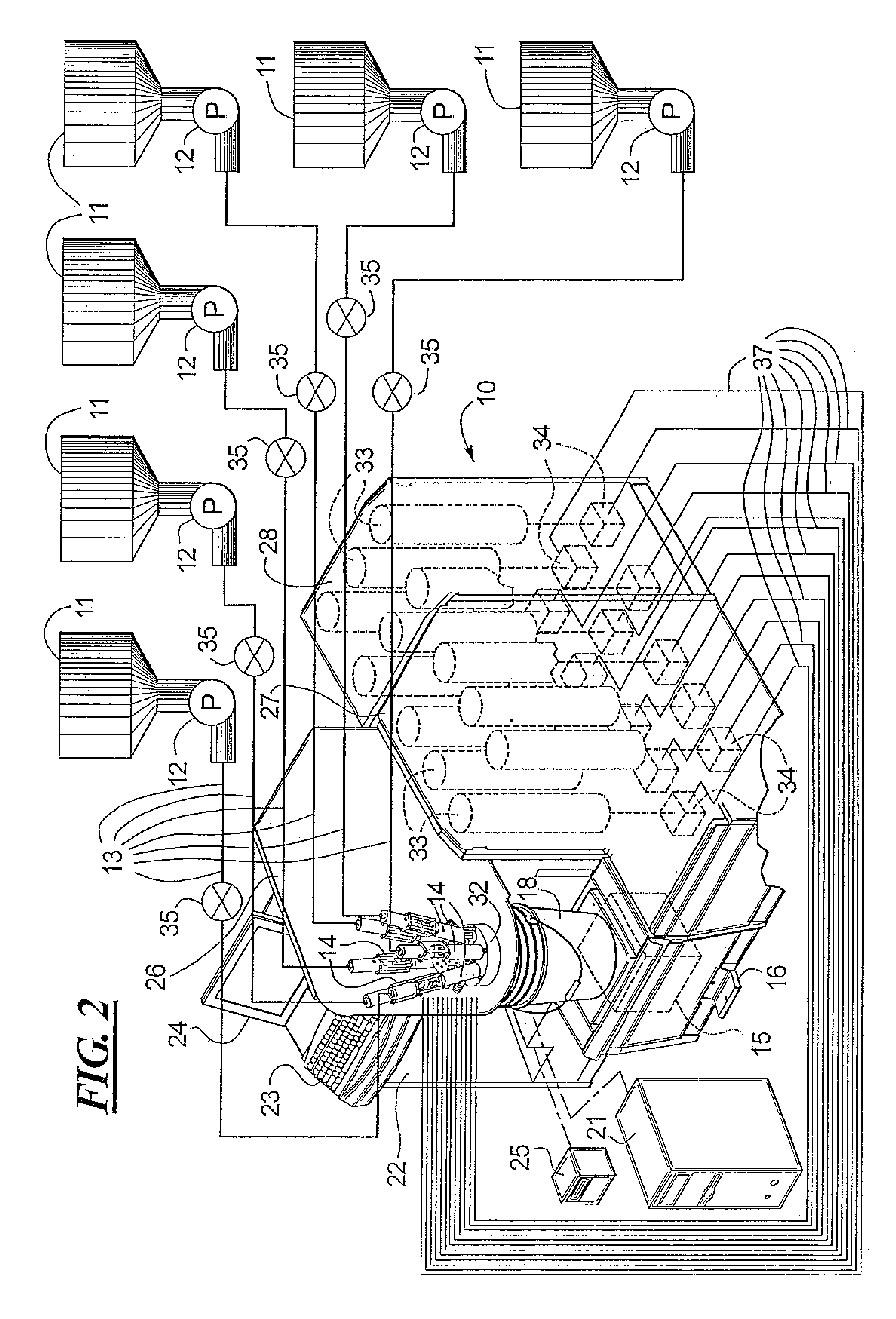

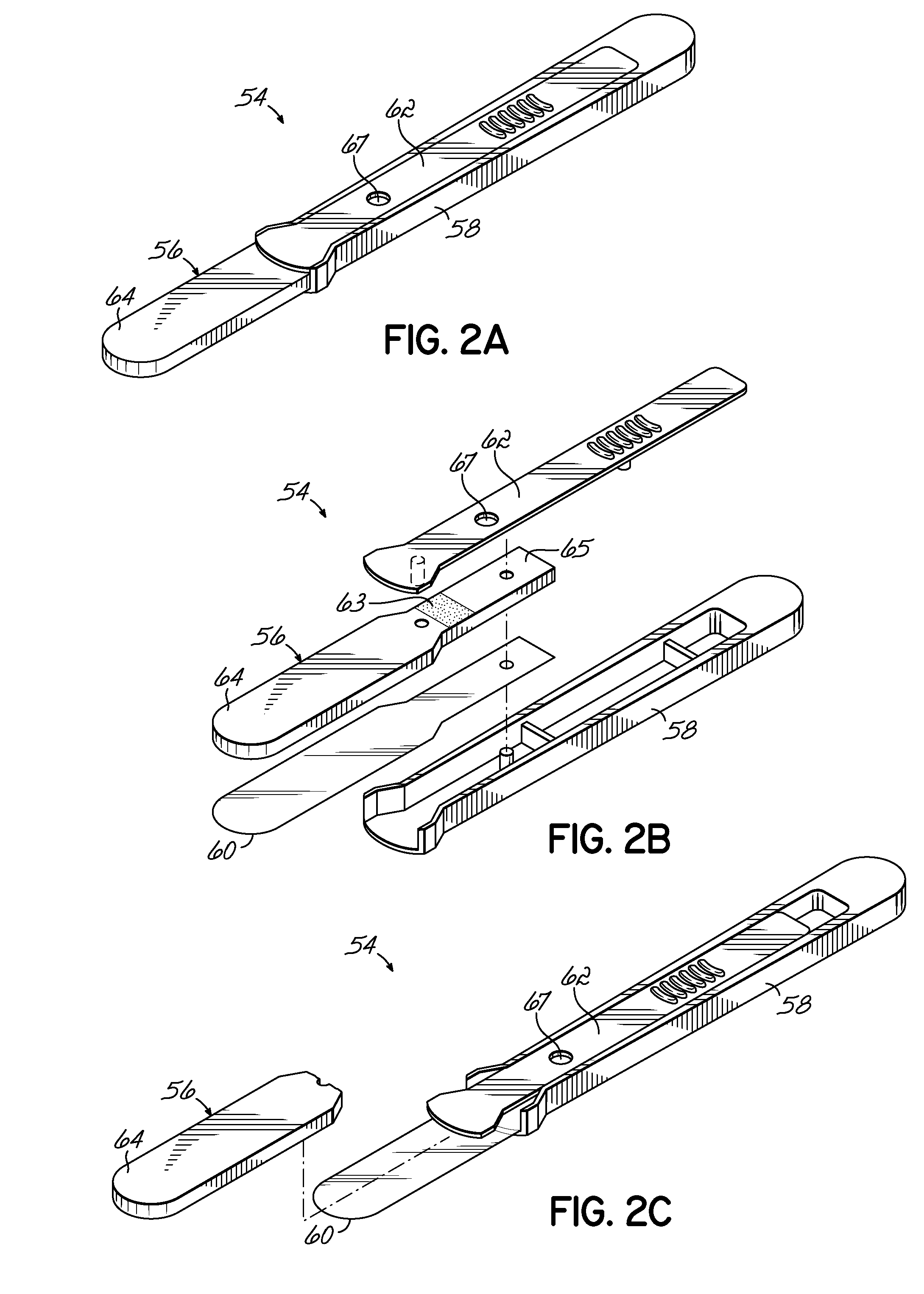

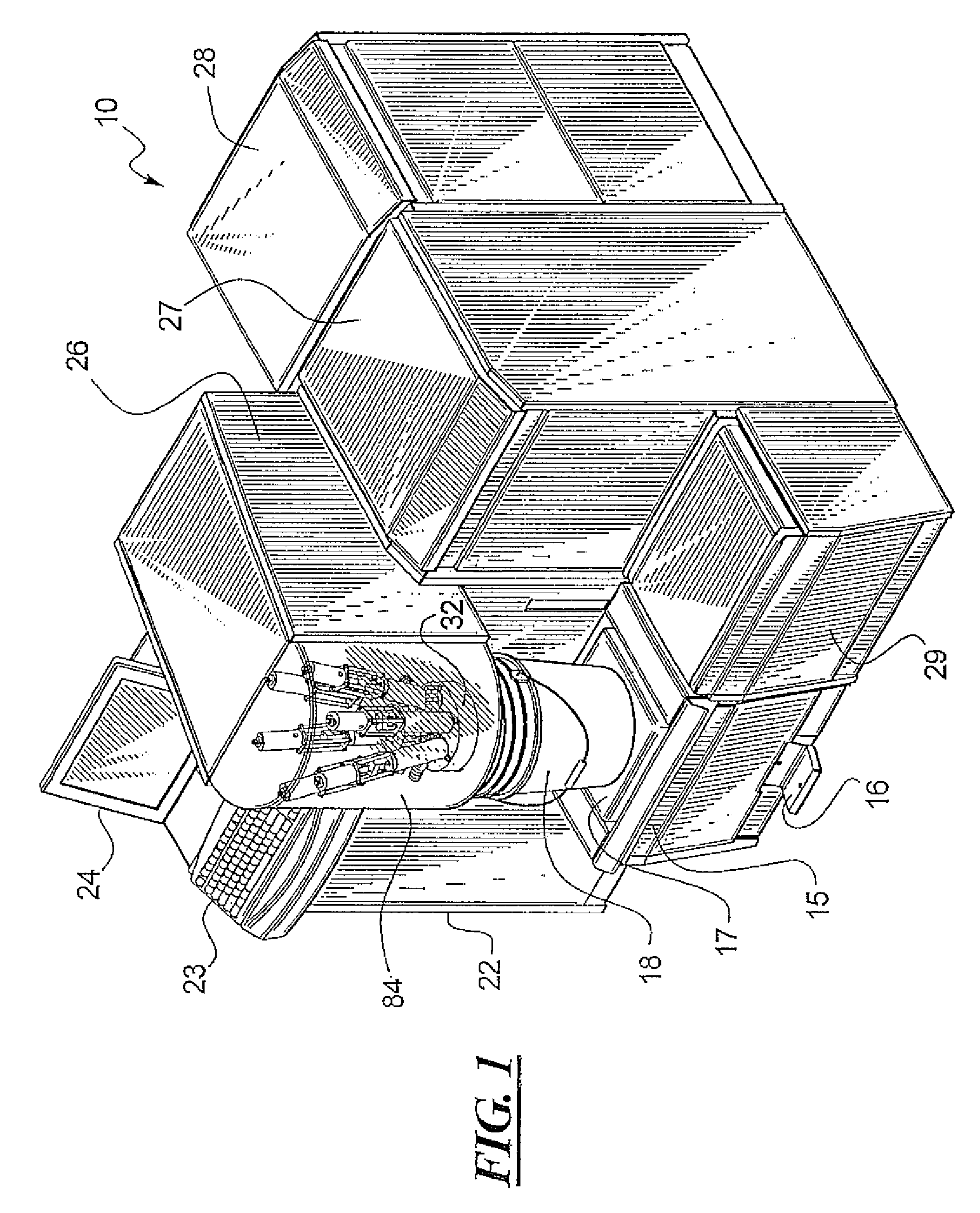

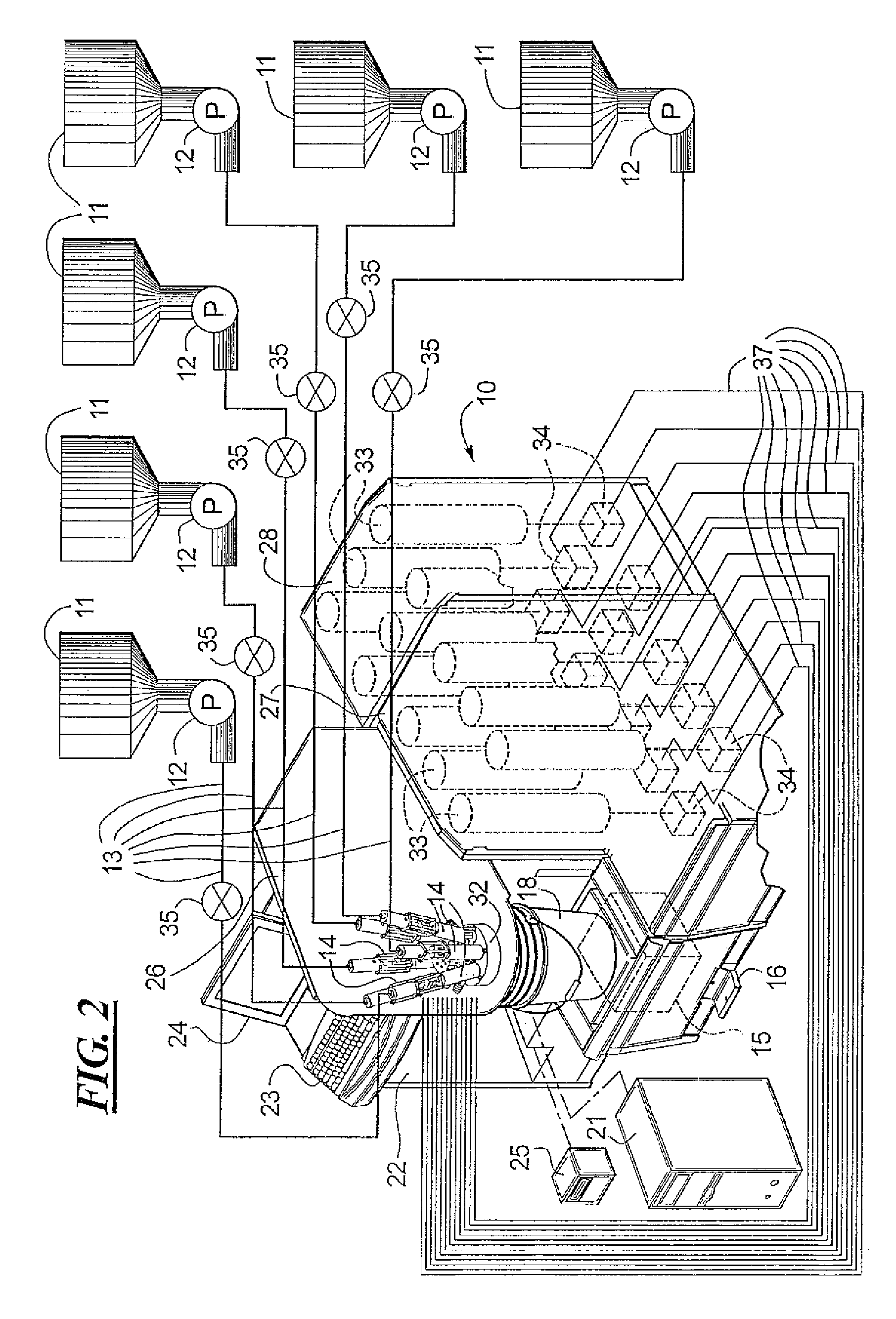

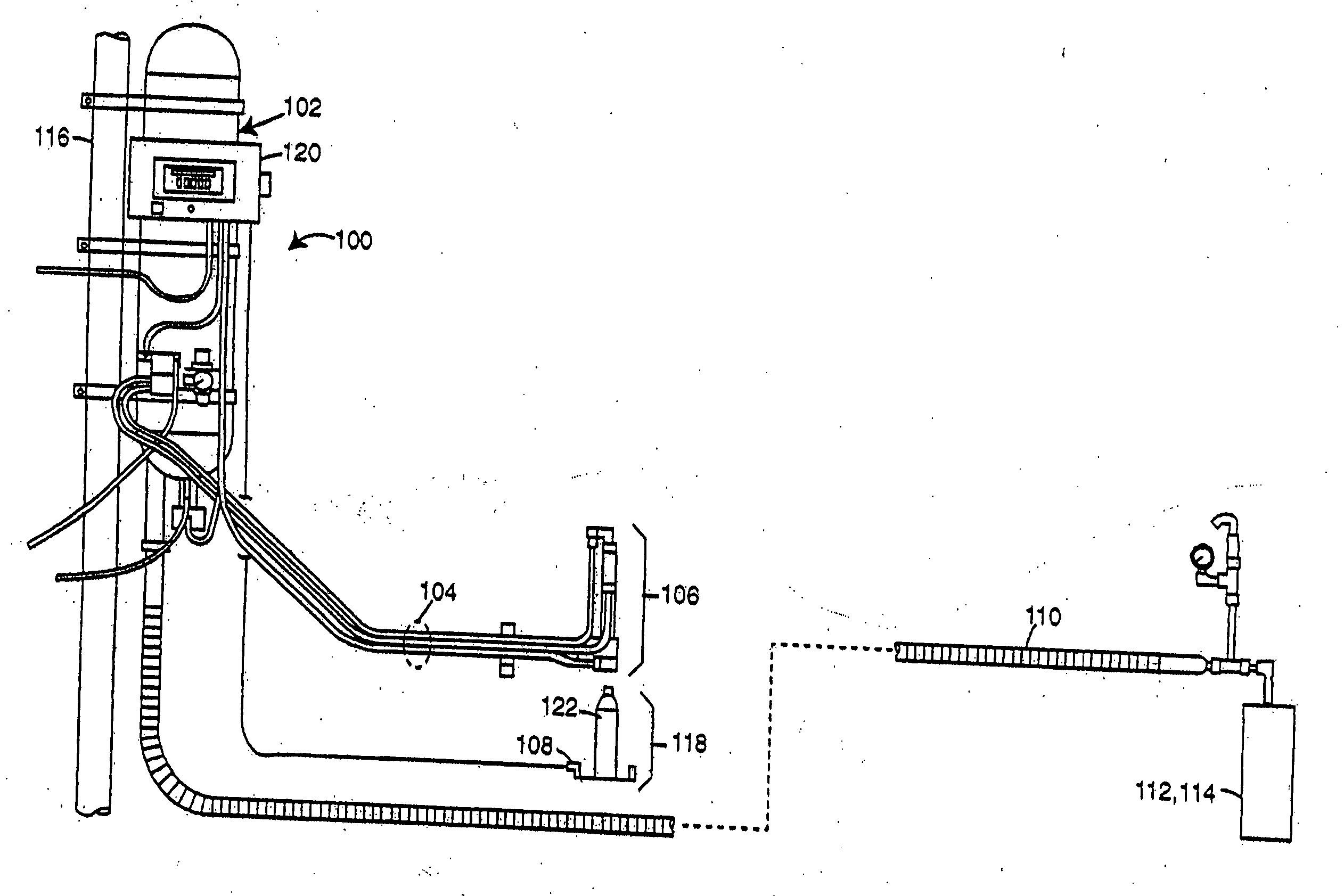

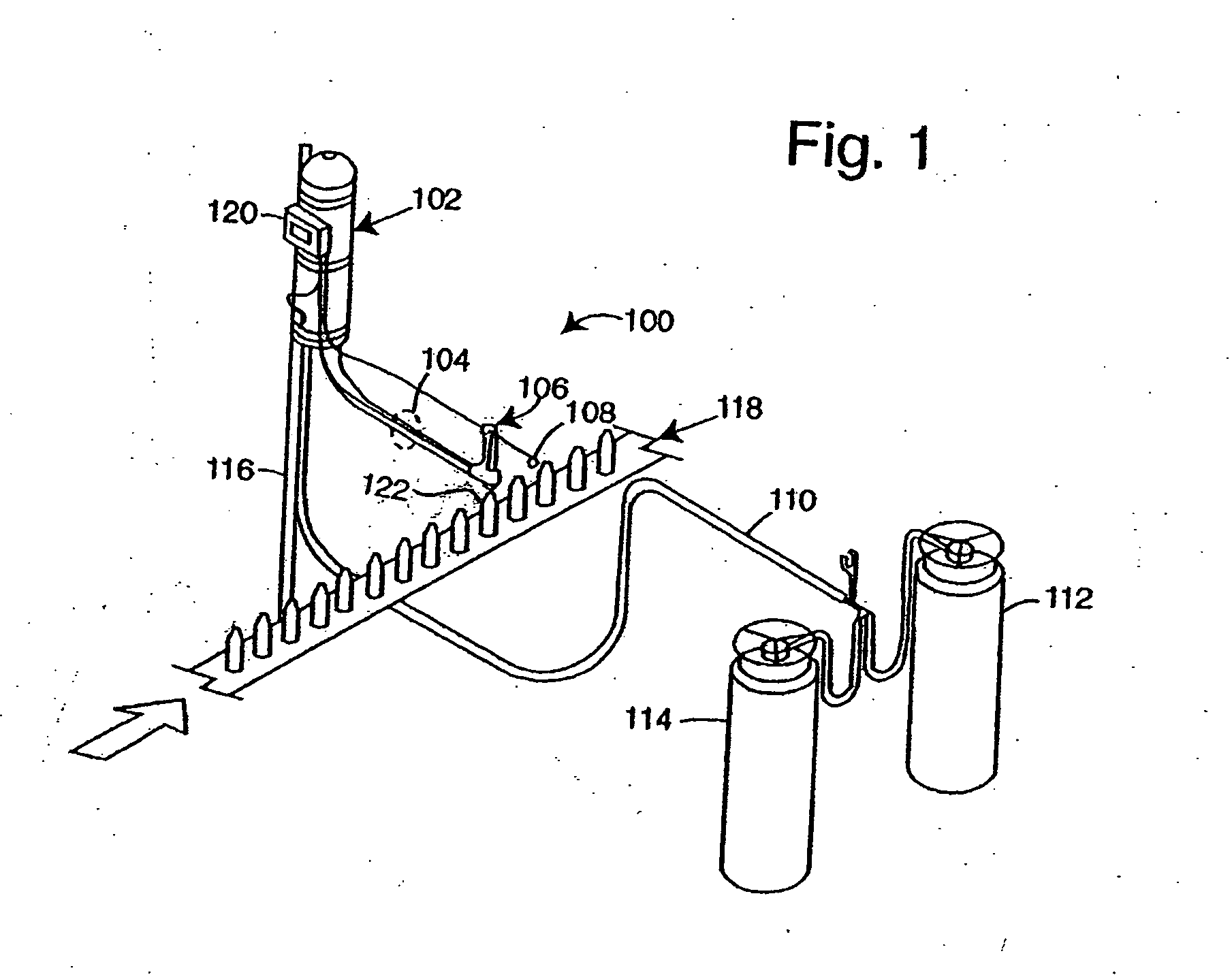

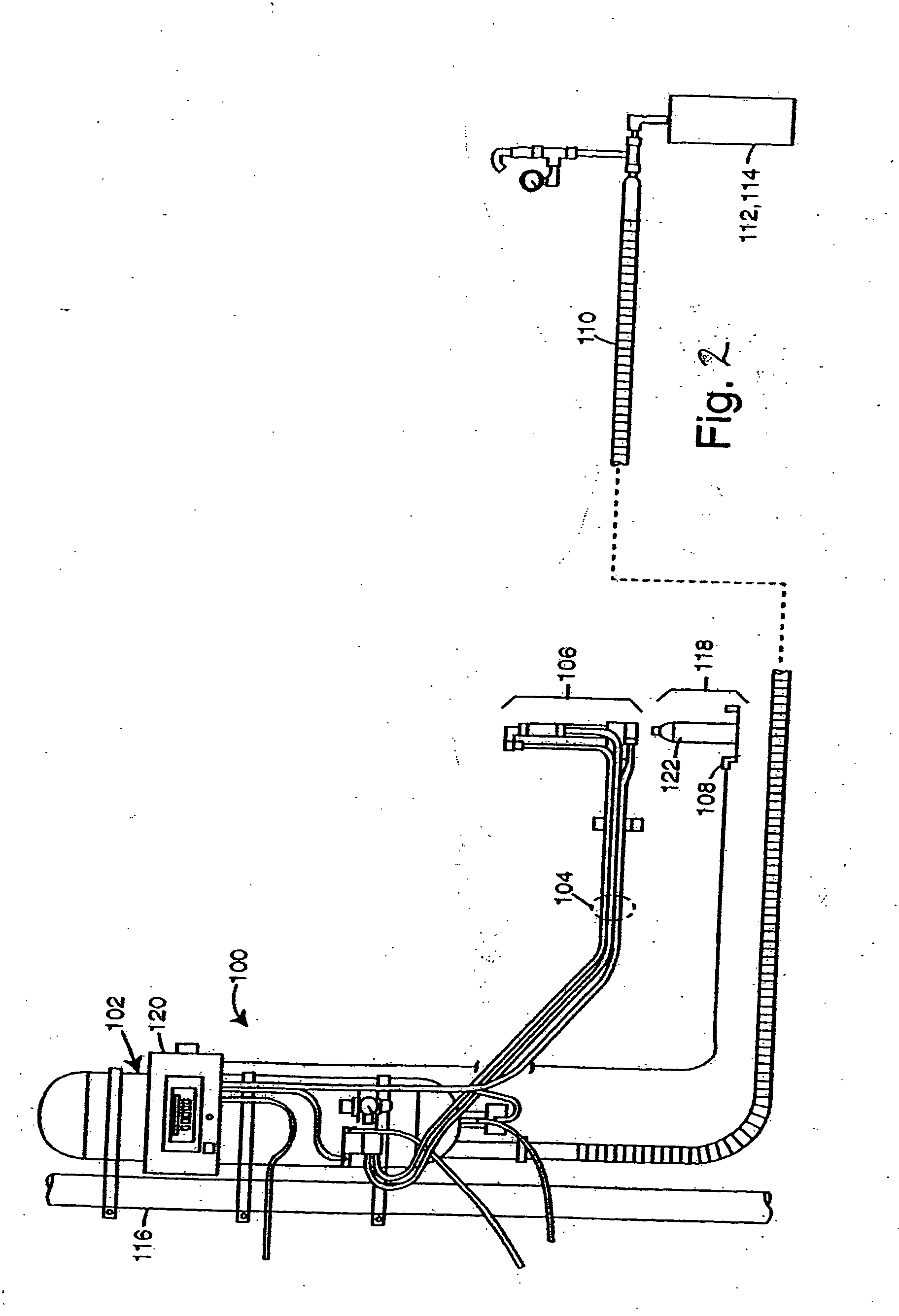

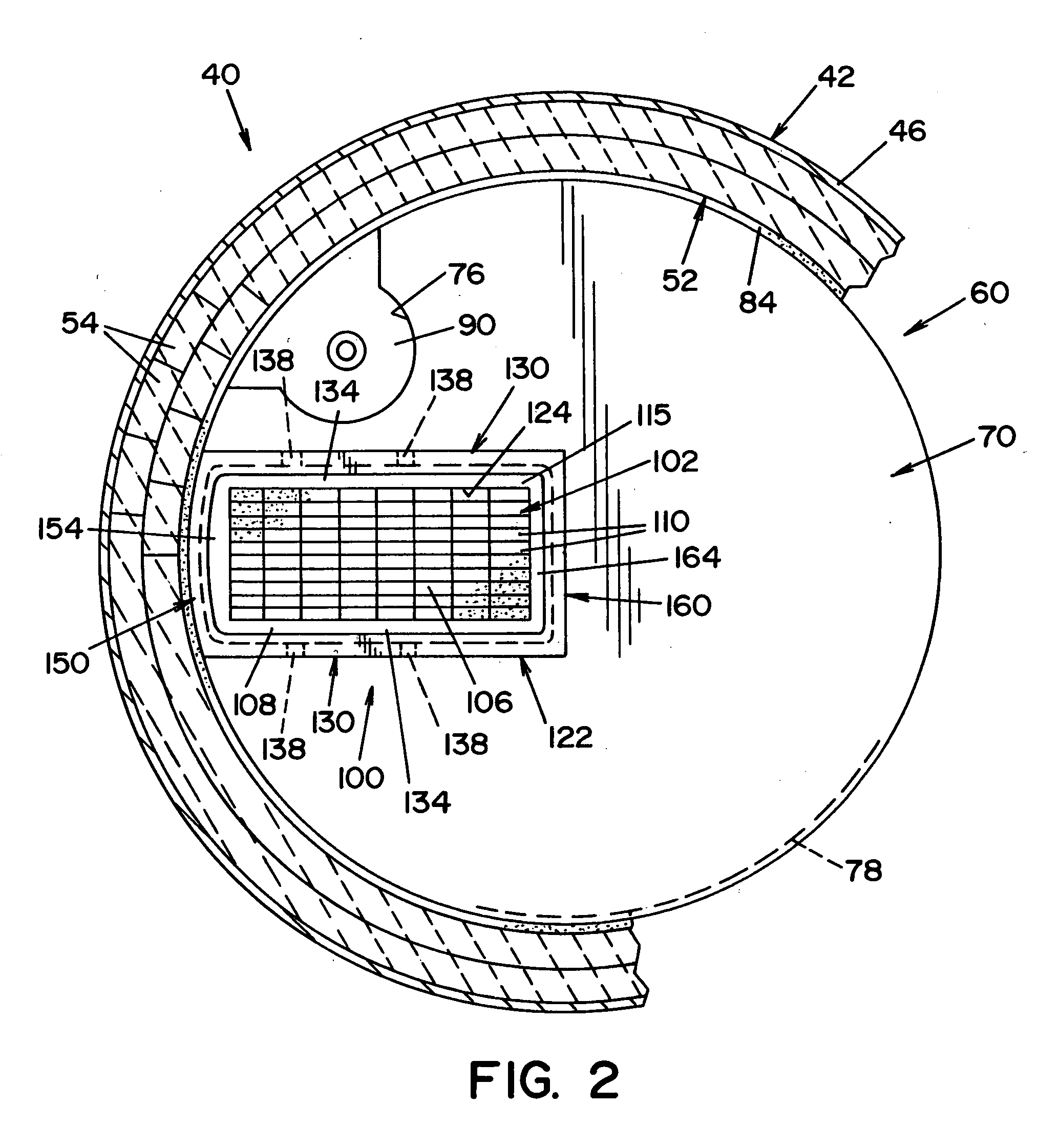

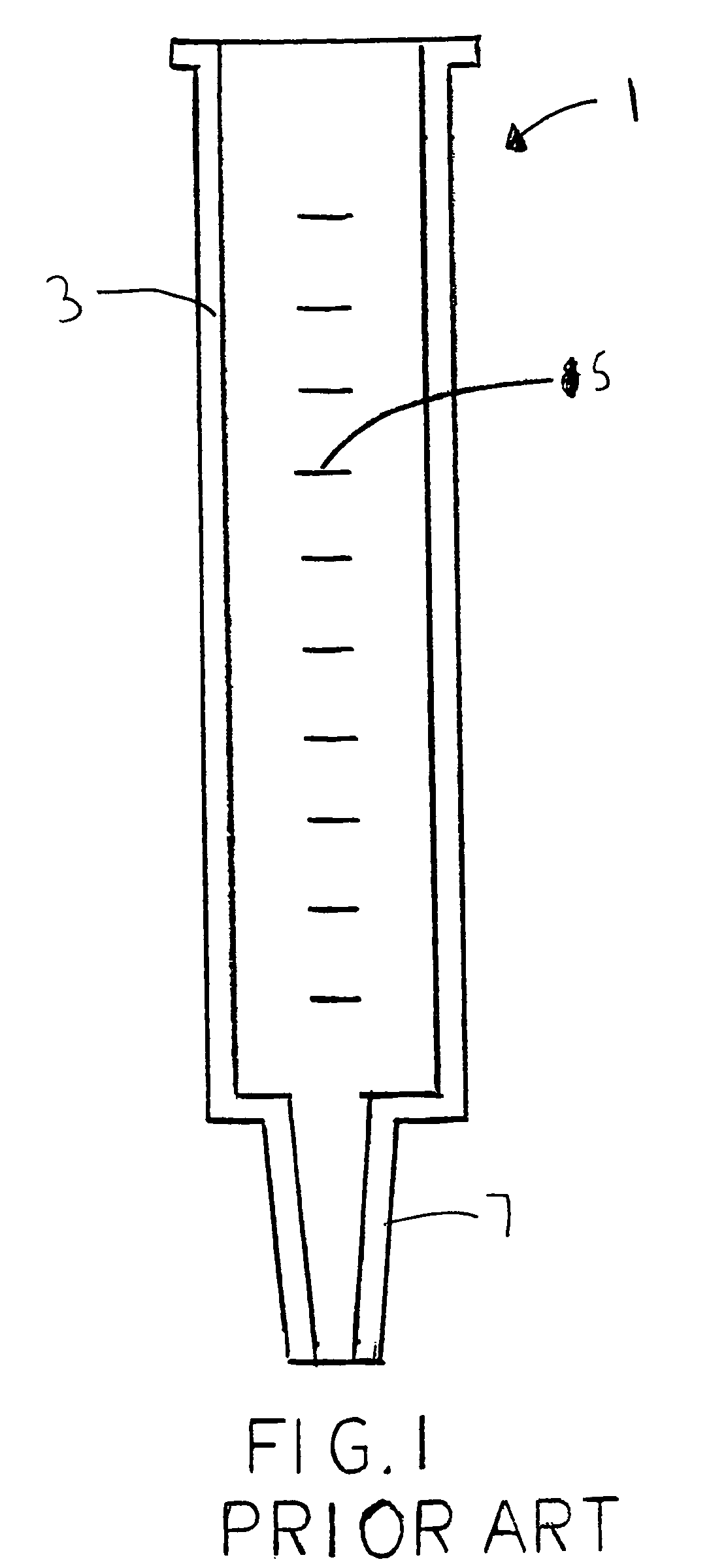

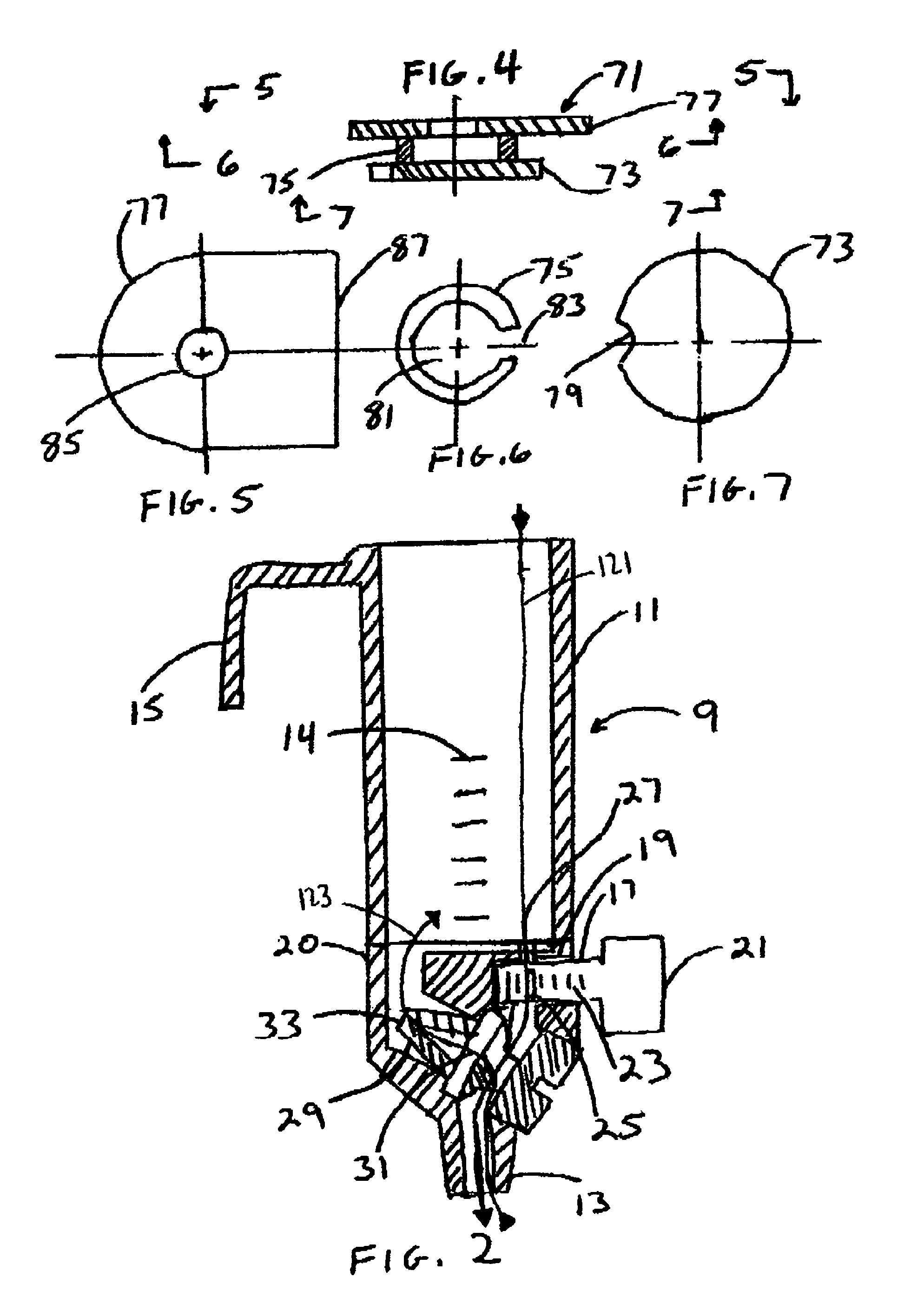

Combination gravimetric and volumetric dispenser for multiple fluids

A combination gravimetric and volumetric fluid dispenser is disclosed which includes a scale linked to a controller. The controller is linked to a plurality of two stage valves which control the dispensing of large quantities of base materials. The controller is also linked to a plurality of nutating pumps which together with the controller controls the dispensing of smaller quantities of additive materials. The dispensing system disclosed is particularly useful for paints or other liquid formulations where larger quantities of base materials are added and which can be added by weight and whereby precise measurements of the larger base materials is not particularly required. However, the incorporation of nutating pumps and the addition of smaller amounts of additives by volume using the nutating pumps enables precise dispensing of the additives, such as colorants for paint. The larger containers or reservoirs of base material may be disposed at a remote location from the dispensing apparatus. The dispensing apparatus is also preferably designed with a modular configuration as shown and described. For viscous materials, an improved dispensing method is disclosed whereby viscous base material is added to the container first followed by smaller amounts of additives followed by additional dispensing of viscous base materials. By sandwiching the smaller amounts of additives between layers of base materials, an improved mix ability results for viscous materials such as base materials of paints and colorants.

Owner:FLUID MANAGEMENT LLC

Combination gravimetric and volumetric dispenser for multiple fluids

ActiveUS20050092386A1Easy to optimizeMinimizes splashingLiquid fillingMixer accessoriesEngineeringVALVE PORT

A combination gravimetric and volumetric fluid dispenser is disclosed which includes a scale linked to a controller. The controller is linked to a plurality of two stage valves which control the dispensing of large quantities of base materials. The controller is also linked to a plurality of nutating pumps which together with the controller controls the dispensing of smaller quantities of additive materials. The dispensing system disclosed is particularly useful for paints or other liquid formulations where larger quantities of base materials are added and which can be added by weight and whereby precise measurements of the larger base materials is not particularly required. However, the incorporation of nutating pumps and the addition of smaller amounts of additives by volume using the nutating pumps enables precise dispensing of the additives, such as colorants for paint. The larger containers or reservoirs of base material may be disposed at a remote location from the dispensing apparatus. The dispensing apparatus is also preferably designed with a modular configuration as shown and described. For viscous materials, an improved dispensing method is disclosed whereby viscous base material is added to the container first followed by smaller amounts of additives followed by additional dispensing of viscous base materials. By sandwiching the smaller amounts of additives between layers of base materials, an improved mix ability results for viscous materials such as base materials of paints and colorants.

Owner:FLUID MANAGEMENT LLC

Controlled gastric bolus feeding device

A gravity bolus feeding device having a cylindrical body with and intake valve to control or prevent flow of fluid through the feeding device. The device also has a check valve to receive fluids expelled from the patient back into the feeding device. The check valve allows such fluids to rejoin the fluid path and be re-fed to the patient, while allowing air to vent. A burp baffle for use with this or another feeding device to prevent spillage or splashing, while taking in or venting air. The burp baffle has a bottom section which snugly fits into the device, with a notch or opening near its outer periphery, allowing fluid to pass. A center section connected to the bottom section allows fluid to flow around it and into an opening generally opposite the notch. A top section covers the feeding device, and has a hole that allows fluid to vent out the top of the feeding device.

Owner:OCTIC MEDICAL DEVICES

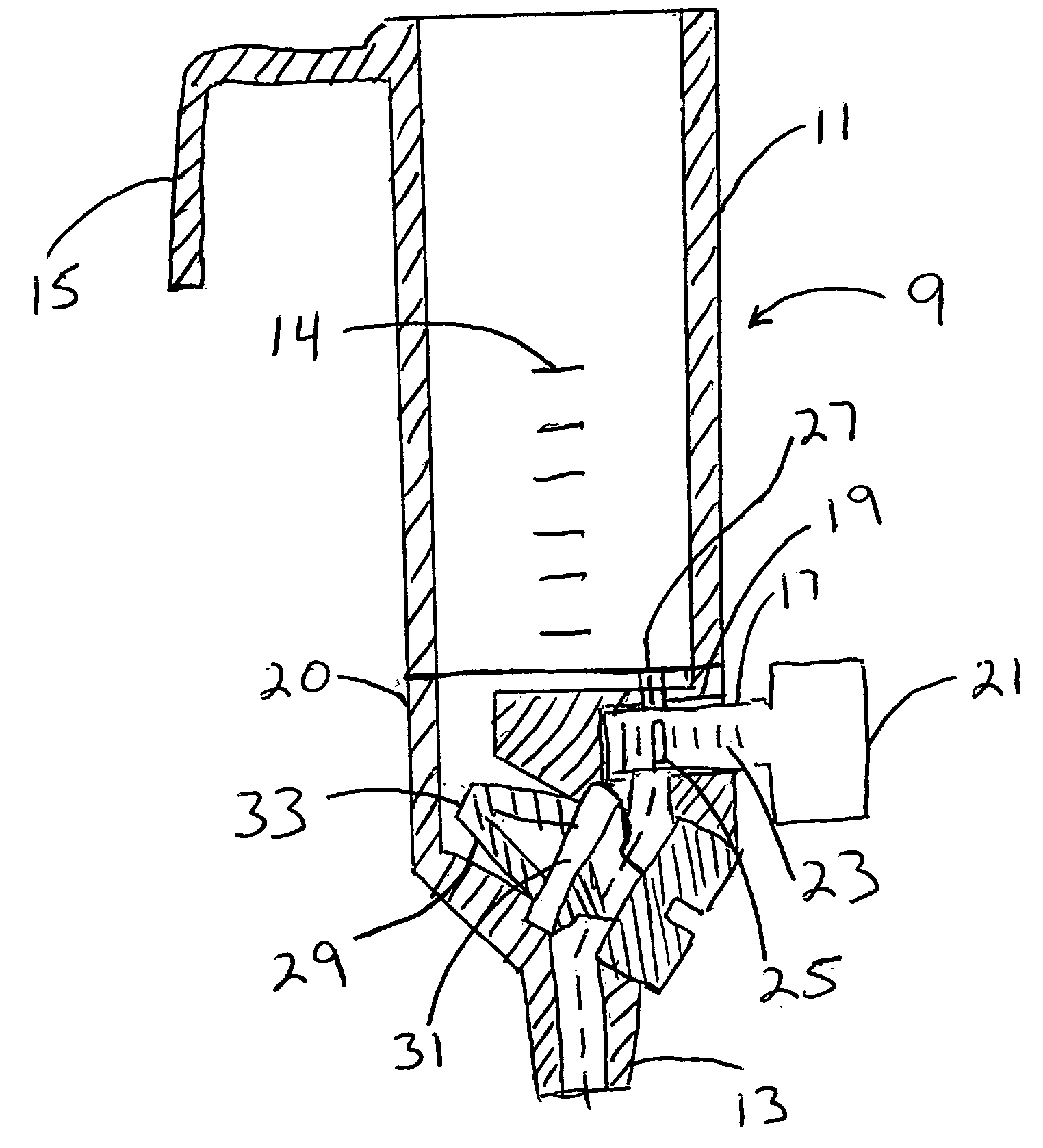

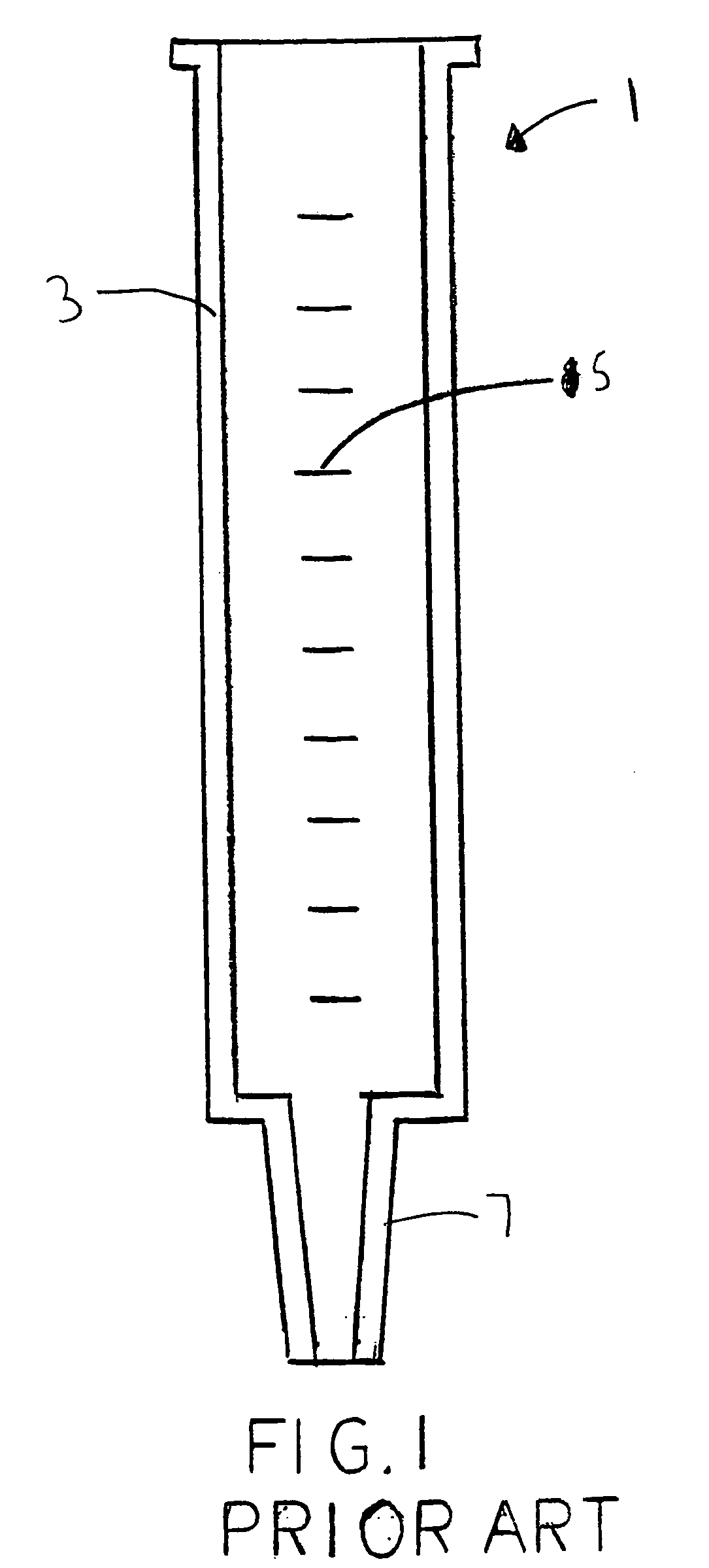

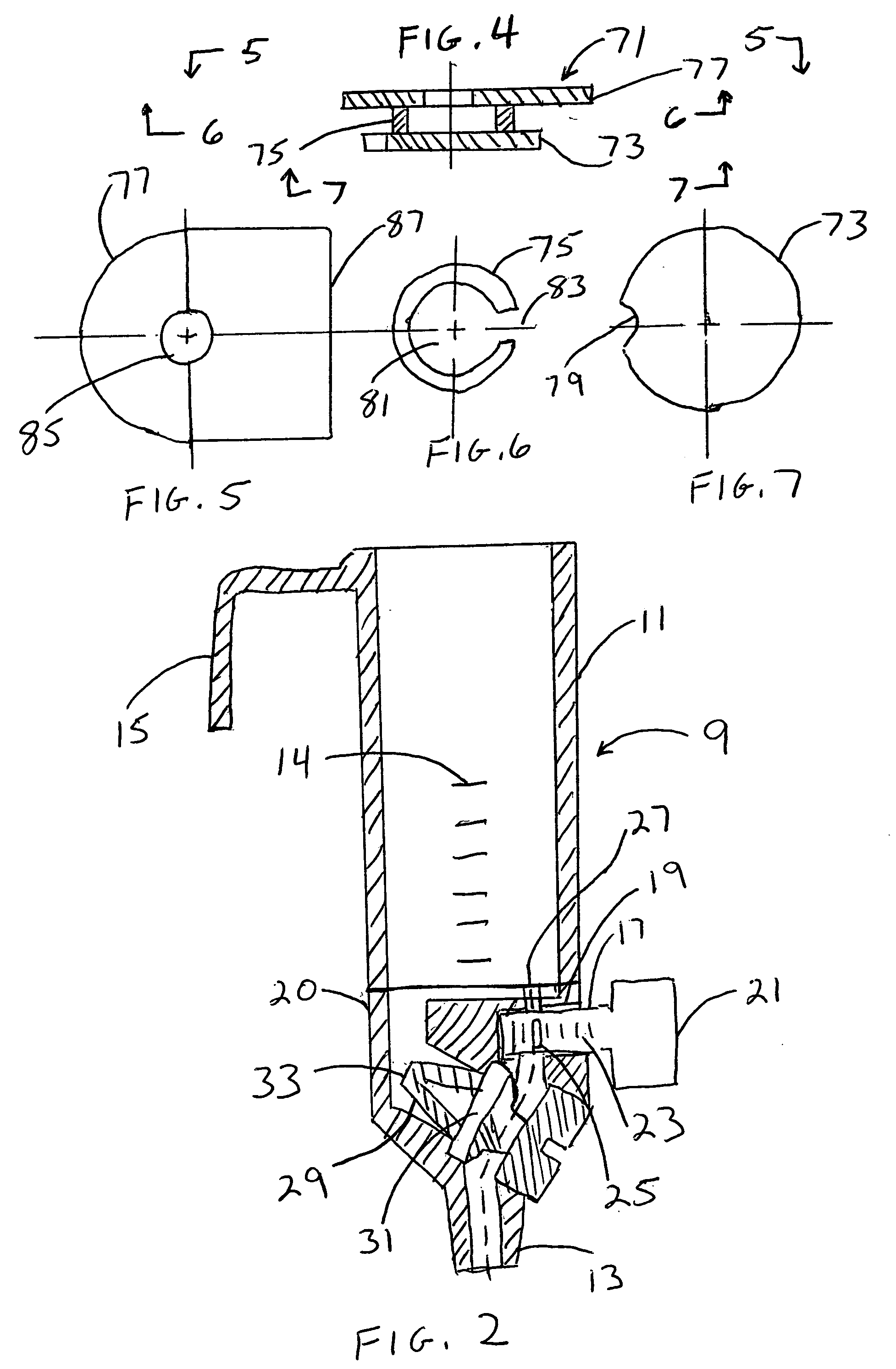

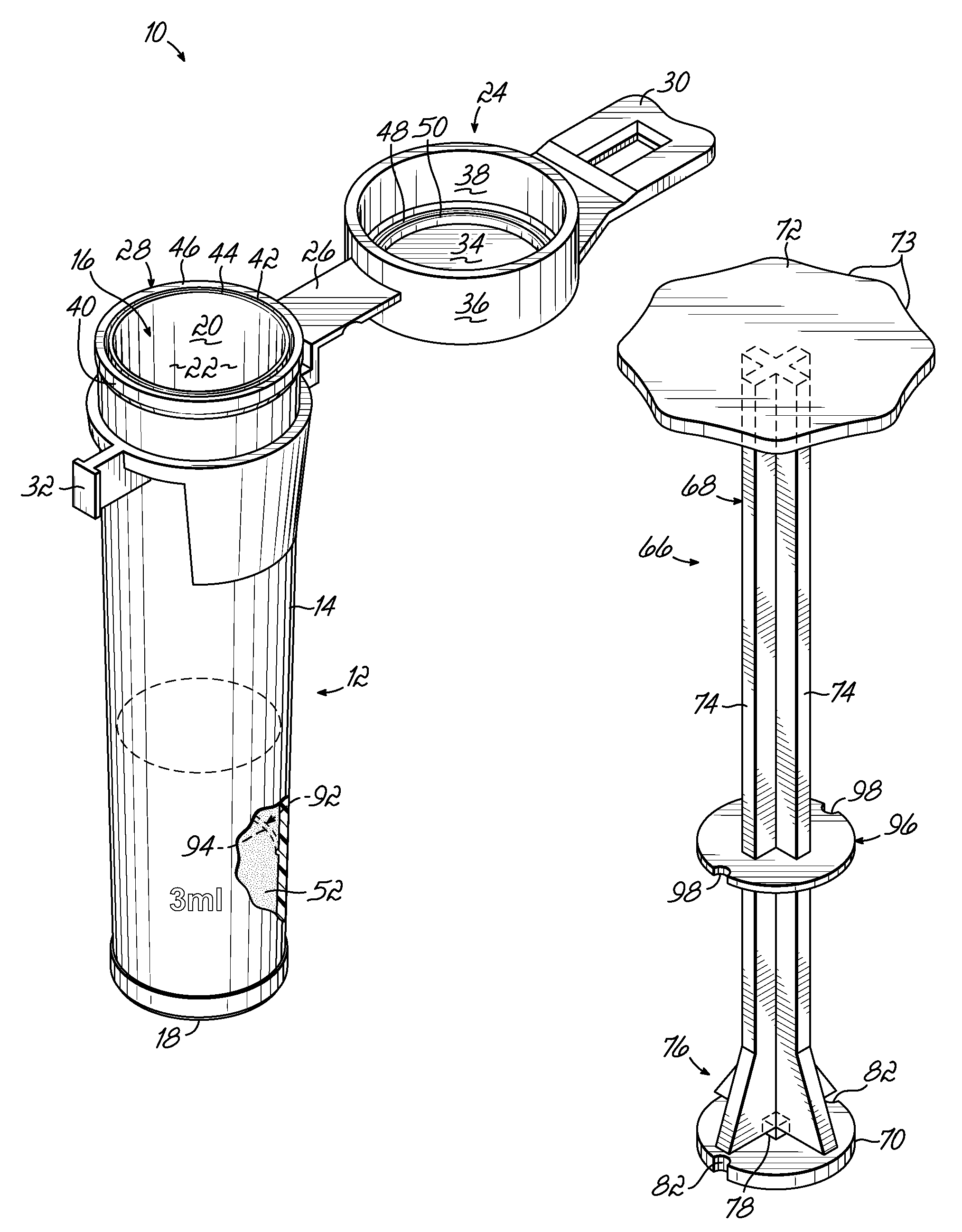

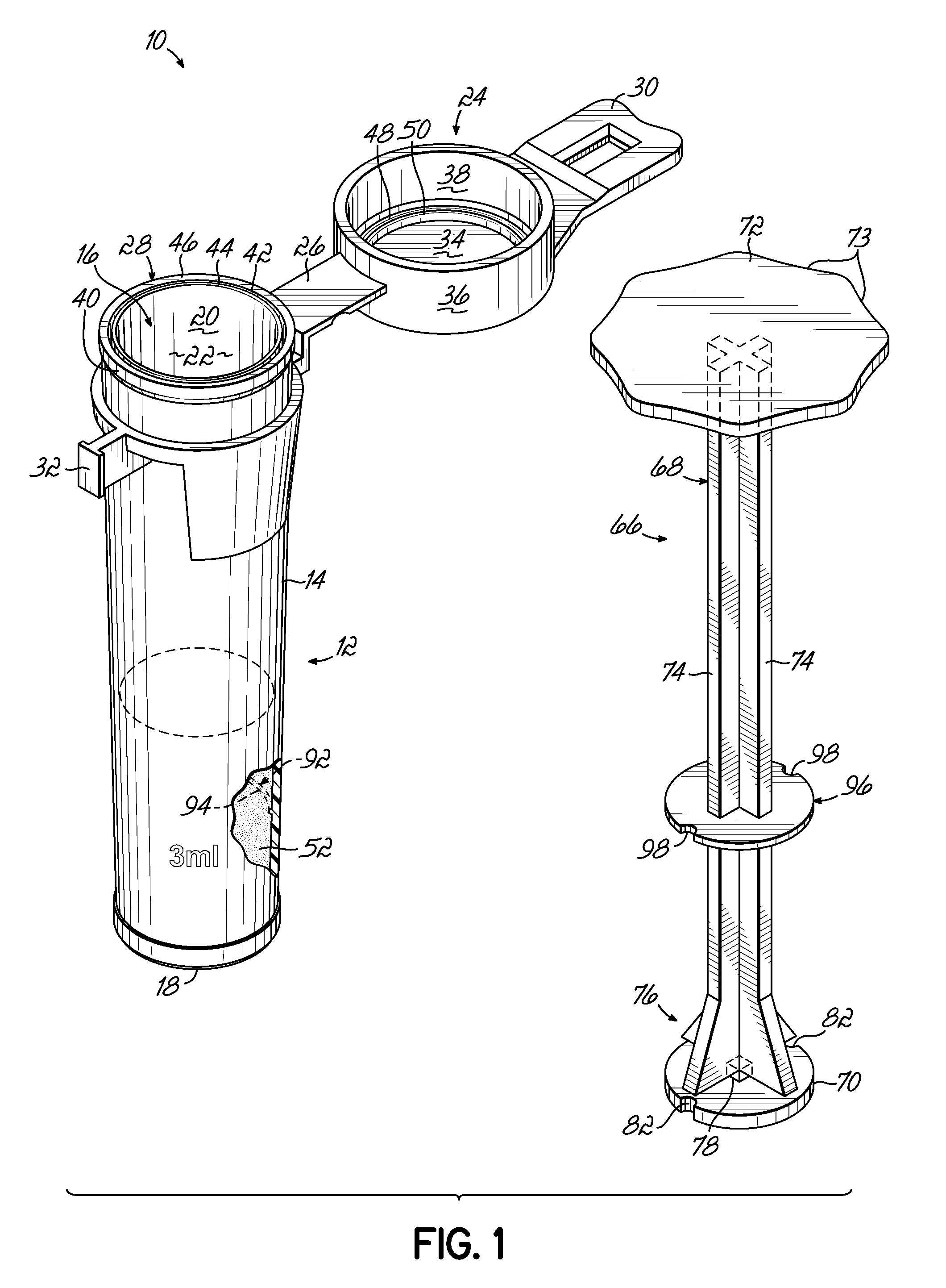

Fluid sample collection system and method

ActiveUS7854895B2Minimizes splashingReduces potential lossAnalysis using chemical indicatorsChemical analysis using titrationCollection systemBiomedical engineering

Owner:CAPITOL VIAL

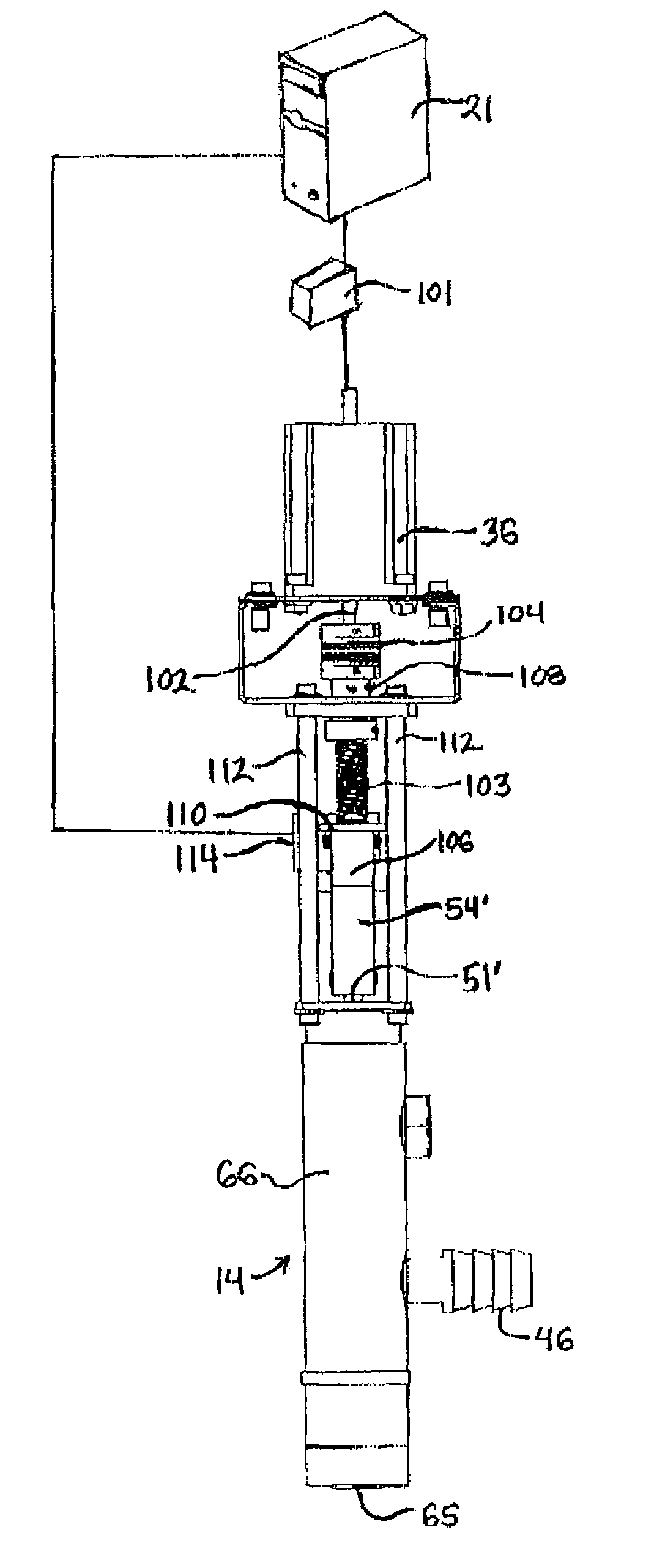

Combination Gravimetric and Volumetric Dispenser for Multiple Fluids

ActiveUS20070095421A1Easy to optimizeReduce flow rateOperating means/releasing devices for valvesMixer accessoriesDrive shaftEngineering

A combination gravimetric and volumetric fluid dispenser is disclosed which includes a scale linked to a controller. The controller is linked to a plurality of two stage valves which control the dispensing of large quantities of base materials. The controller is also linked to a plurality of nutating pumps which together with the controller controls the dispensing of smaller quantities of additive materials. The dispensing system disclosed is particularly useful for paints or other liquid formulations where large quantities of base materials are added and which can be added by weight and whereby precise measurements of the larger base materials is not particularly required. However, the incorporation of nutating pumps and the addition of smaller amounts of additives by volume using the nutating pumps enables precise dispensing of the additives, such as colorants for paint. The base material dispensing valves include stepper motor actuators having multiple steps per revolution. The stepper motor actuators are under the control of an analog signal from a controller. The base material dispensing valve is opened or closed via a rod that is slidably raised or lowered upon rotation of the drive shaft of the stepper motor actuator. The larger containers or reservoirs of base material may be disposed at a remote location from the dispensing apparatus. The dispensing apparatus is also preferably designed with a modular configuration as shown and described.

Owner:FLUID MANAGEMENT LLC

Fluid sample collection system

ActiveUS7850922B2Minimizes splashingReduces potential lossAnalysis using chemical indicatorsWithdrawing sample devicesCollection systemBiomedical engineering

Owner:CAPITOL VIAL INC

Continuous gas flow trocar assembly

InactiveUS20070088276A1Constant pressureMinimizes splashingCannulasDiagnosticsSurgical deviceAbdominal trocar

A trocar assembly for providing a pressurized insufflation fluid into a patient cavity and for providing sealable access to the patient cavity by a surgical instrument. The assembly comprises an inner tubular member having a proximal end and a distal end. An outer tubular member is disposed about the inner tubular member, the outer tubular member having a proximal end and a distal end. The distal end of the inner tubular member and the distal end of the outer tubular member define a trocar seal nozzle arranged therebetween.

Owner:SURGIQUEST

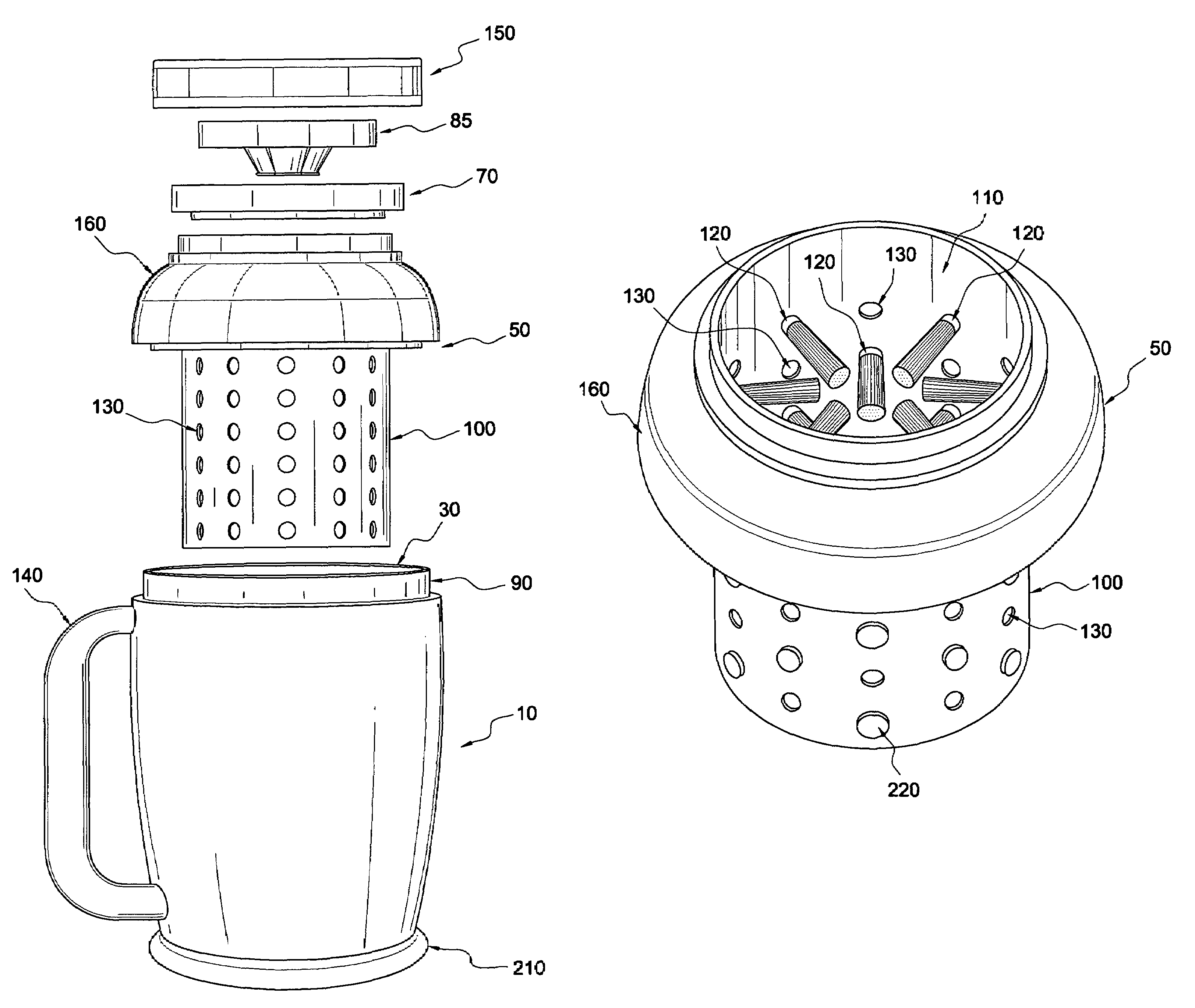

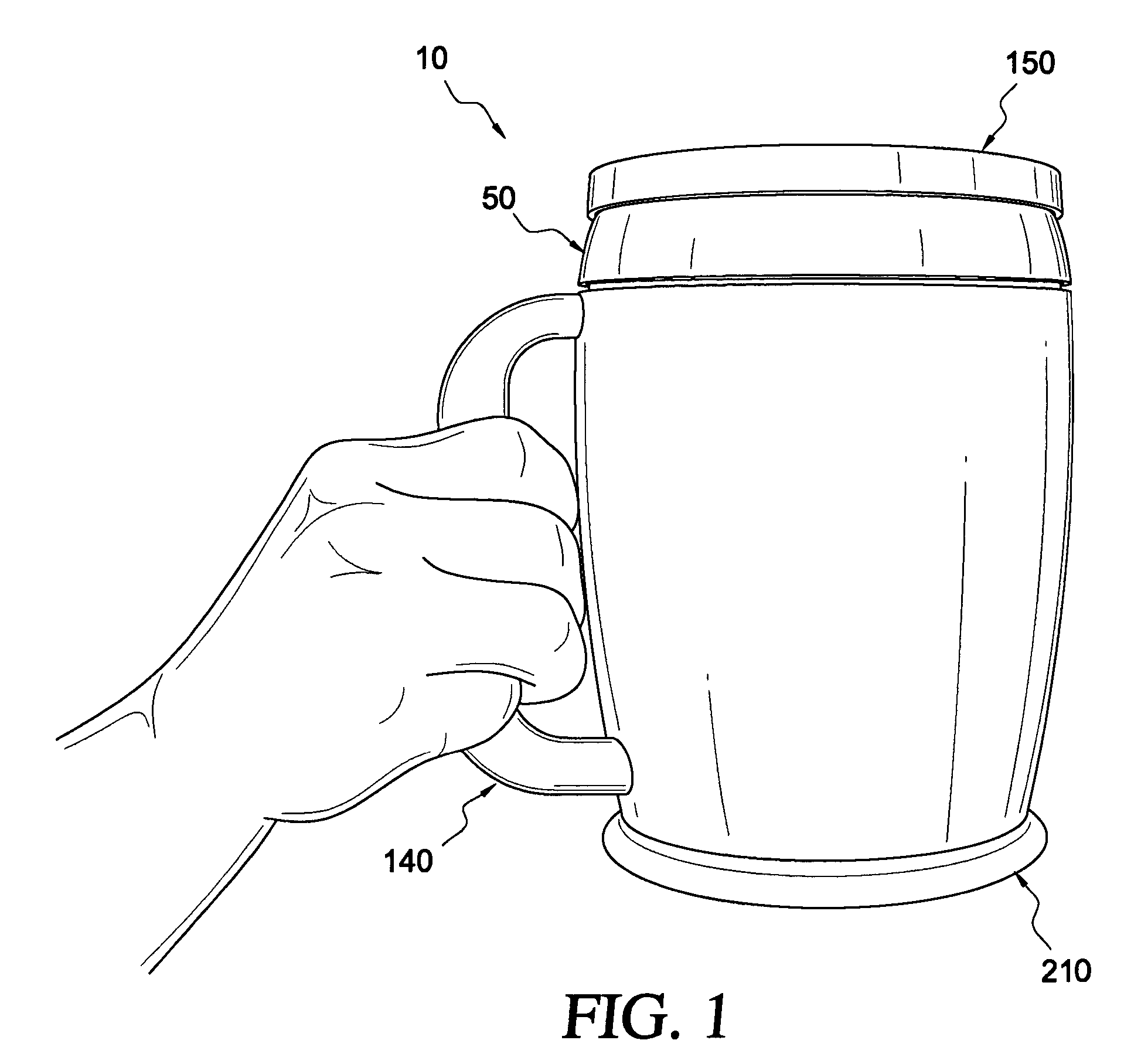

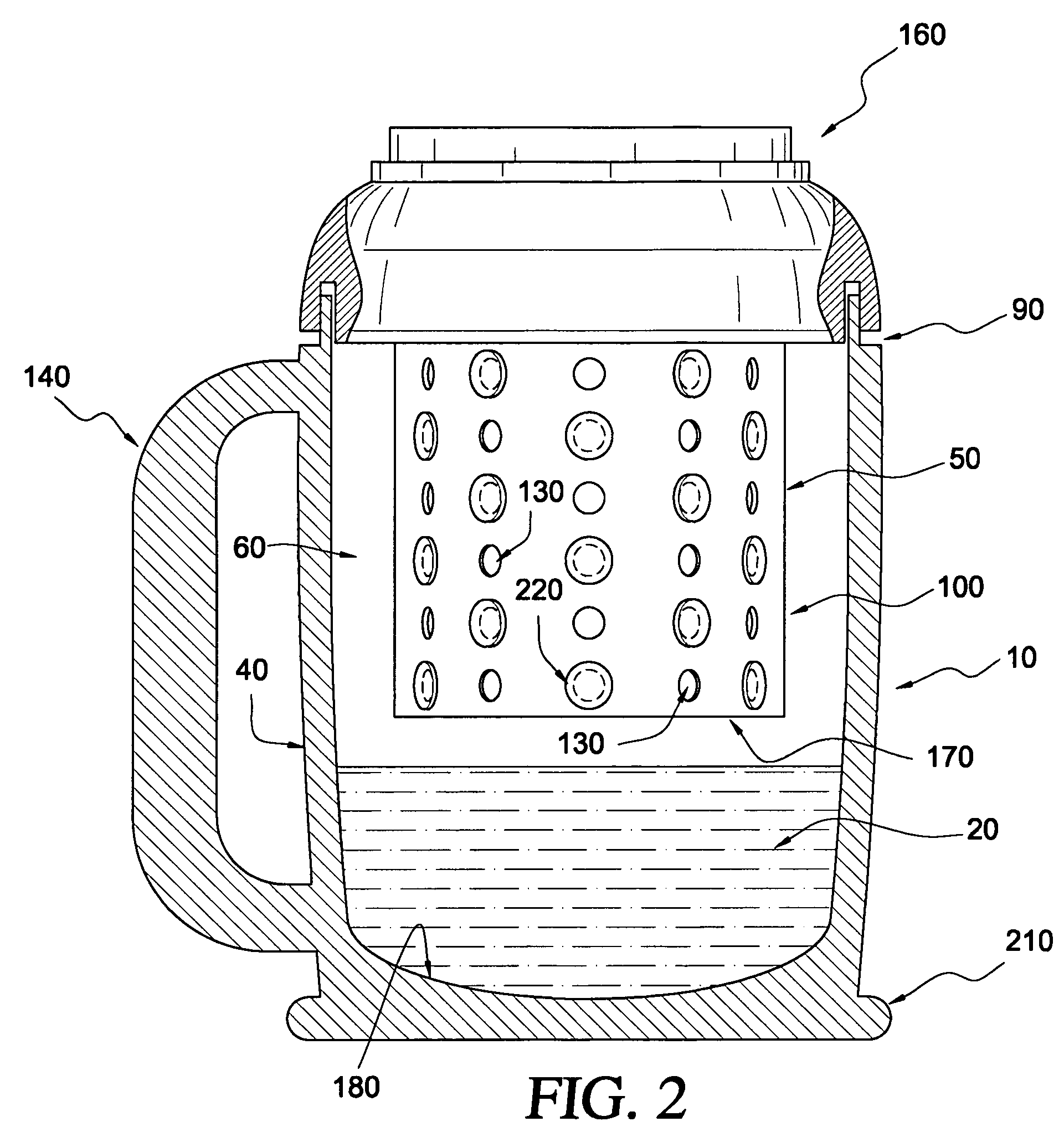

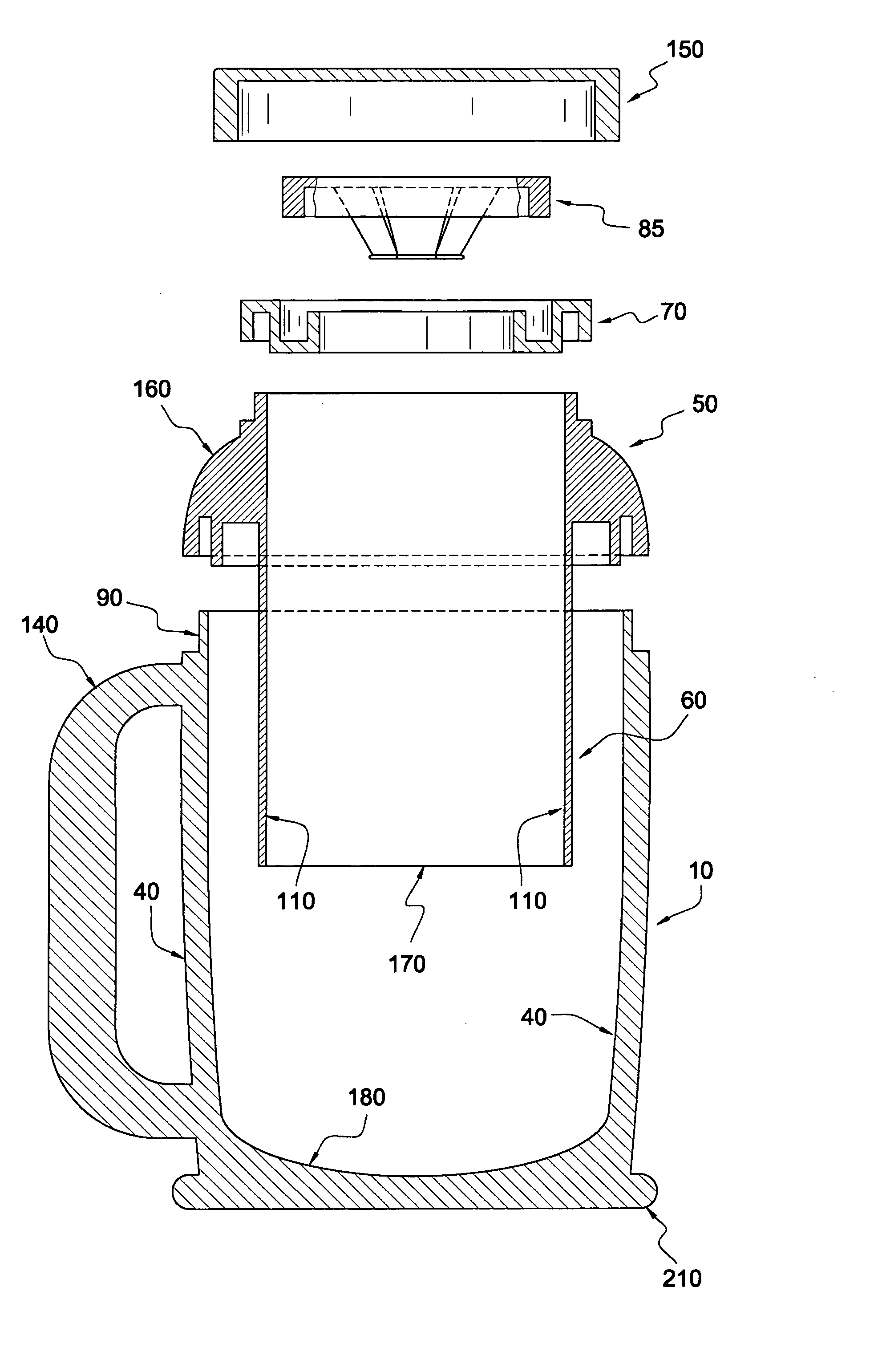

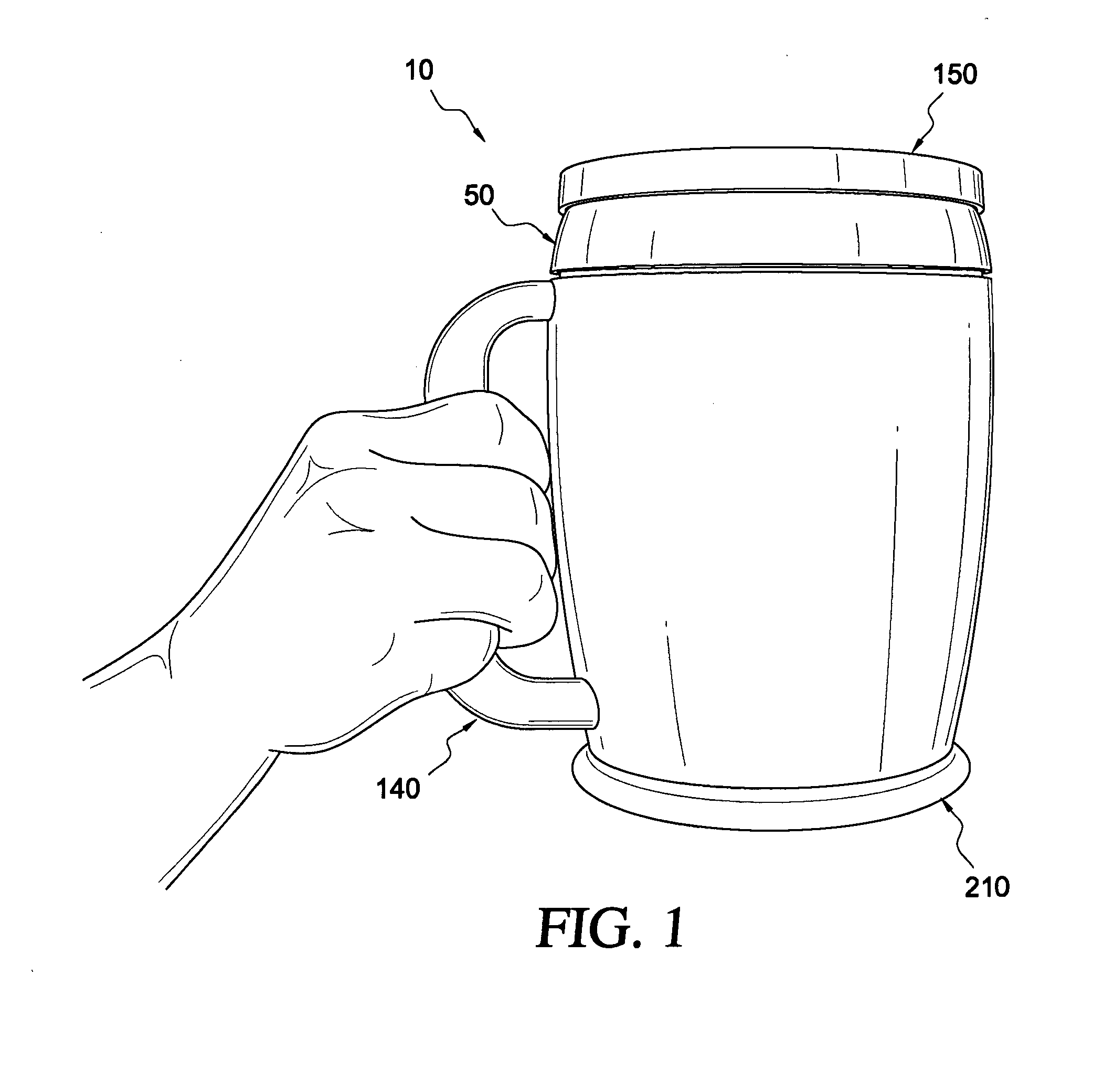

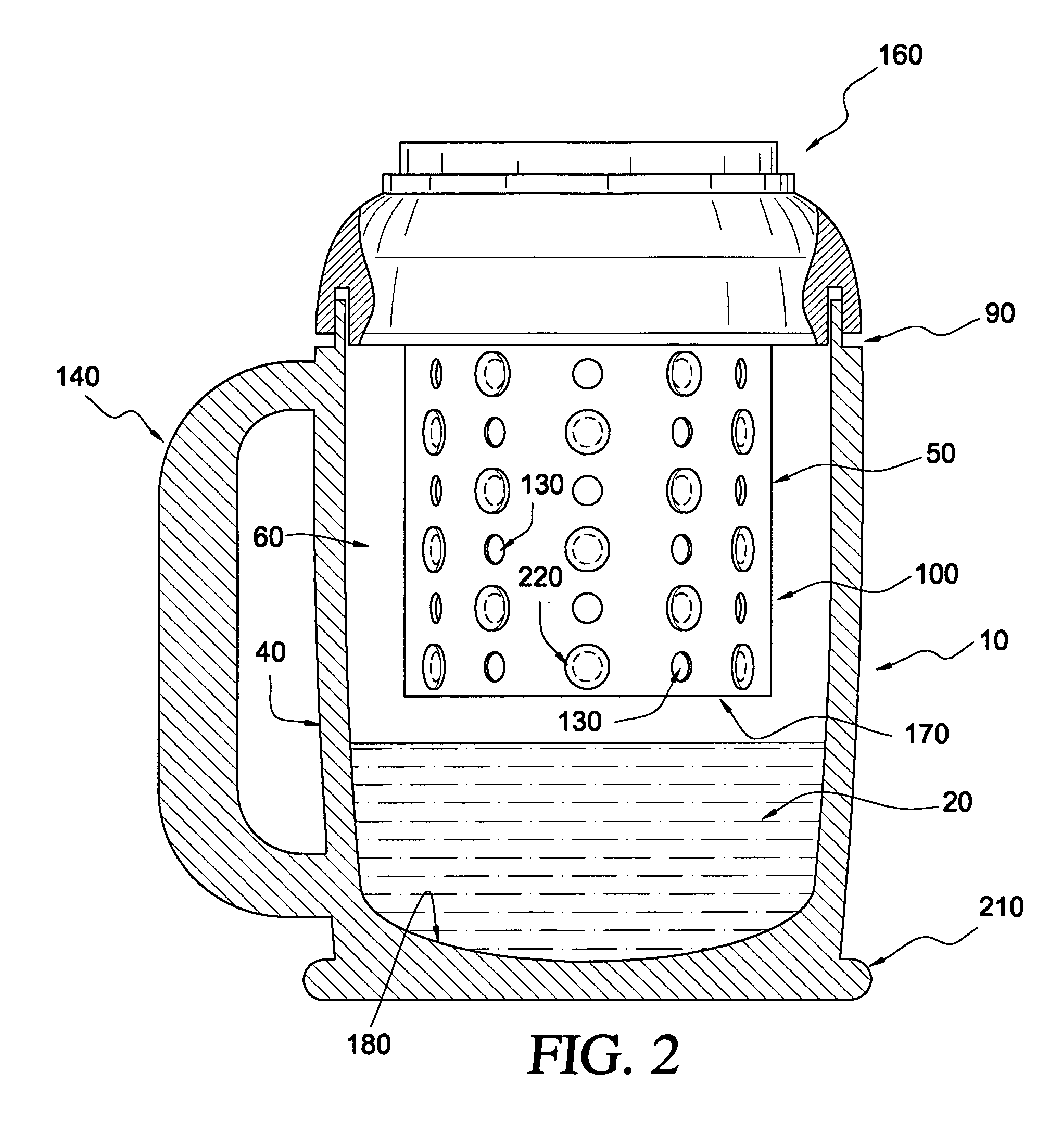

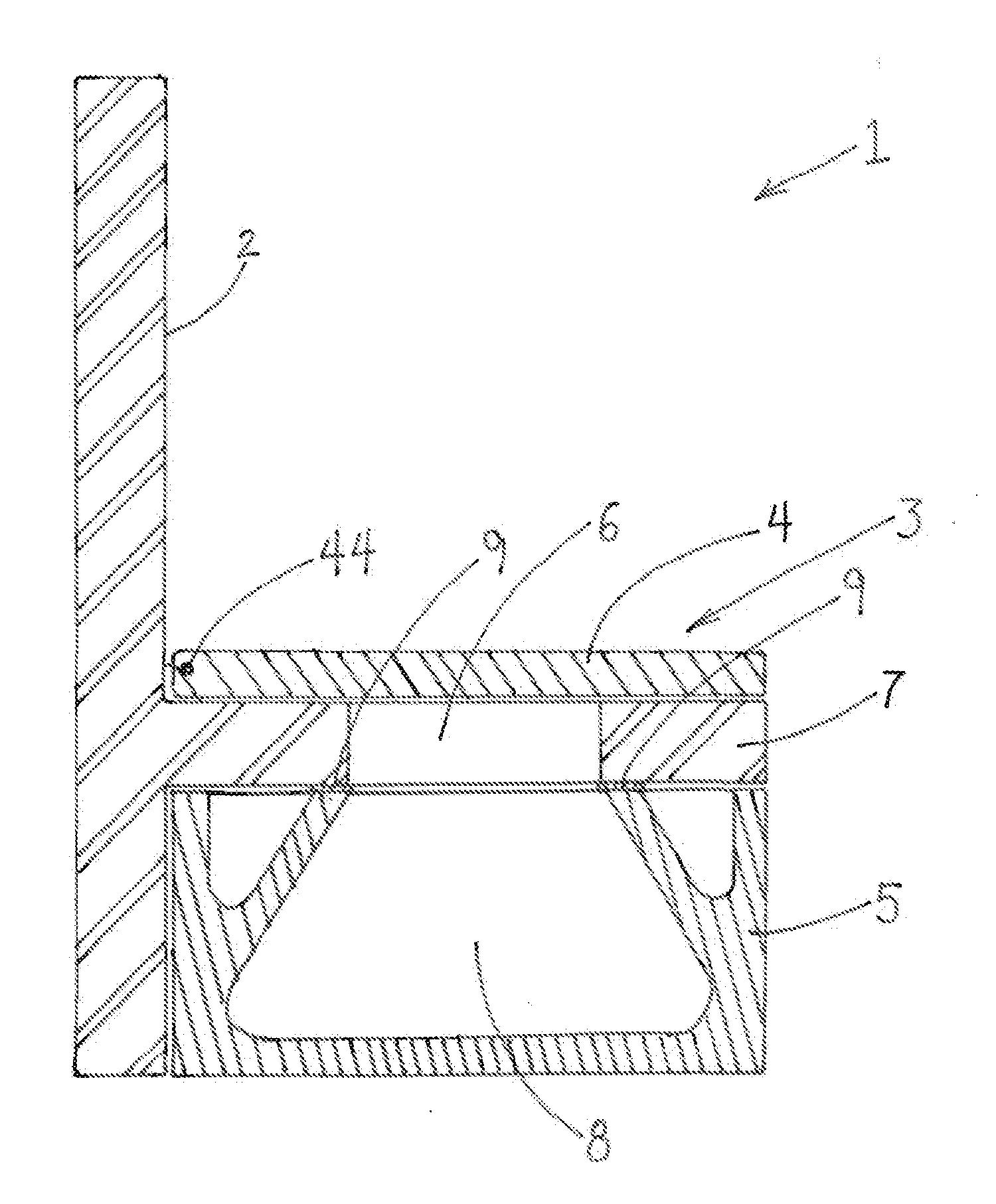

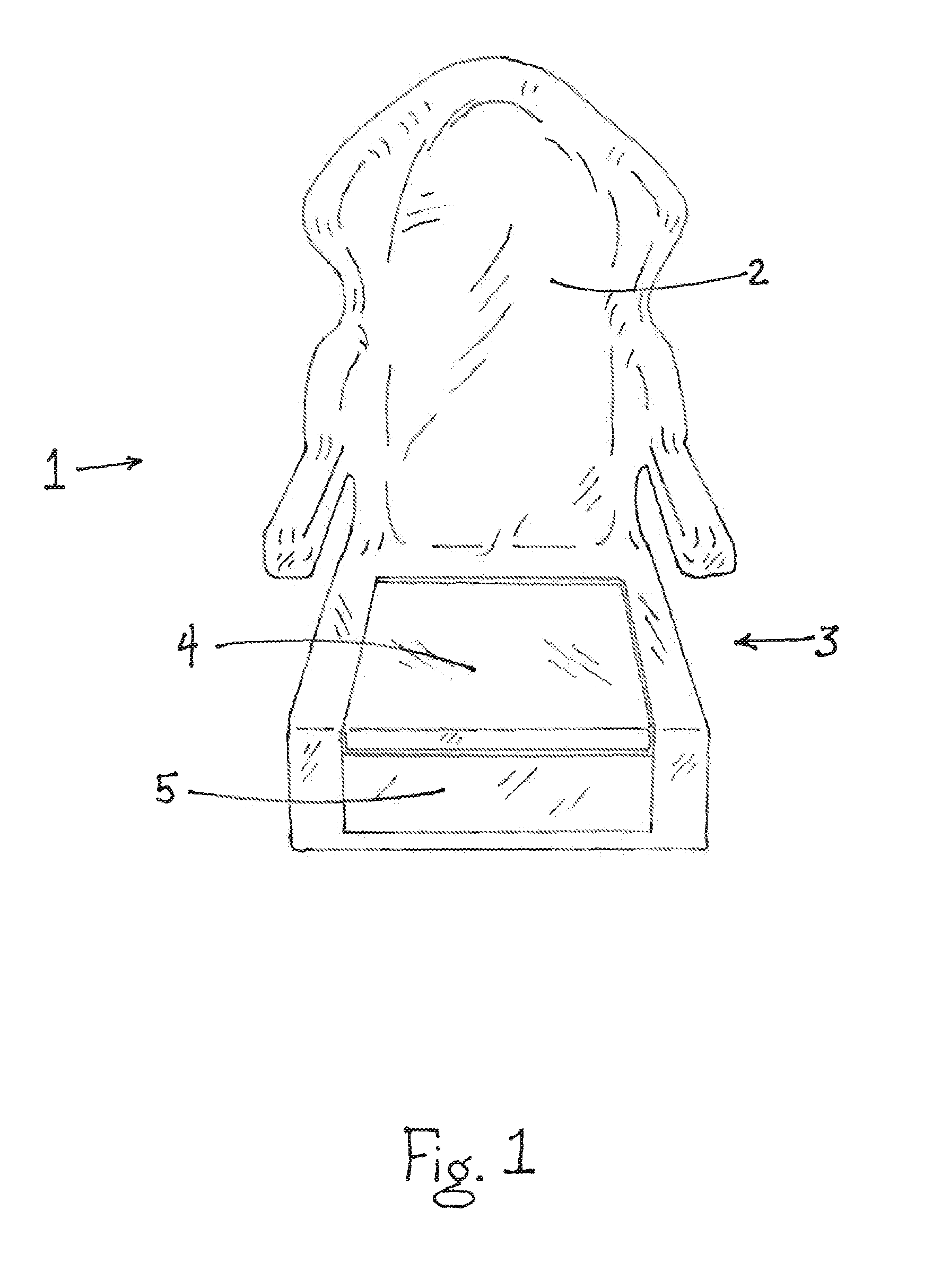

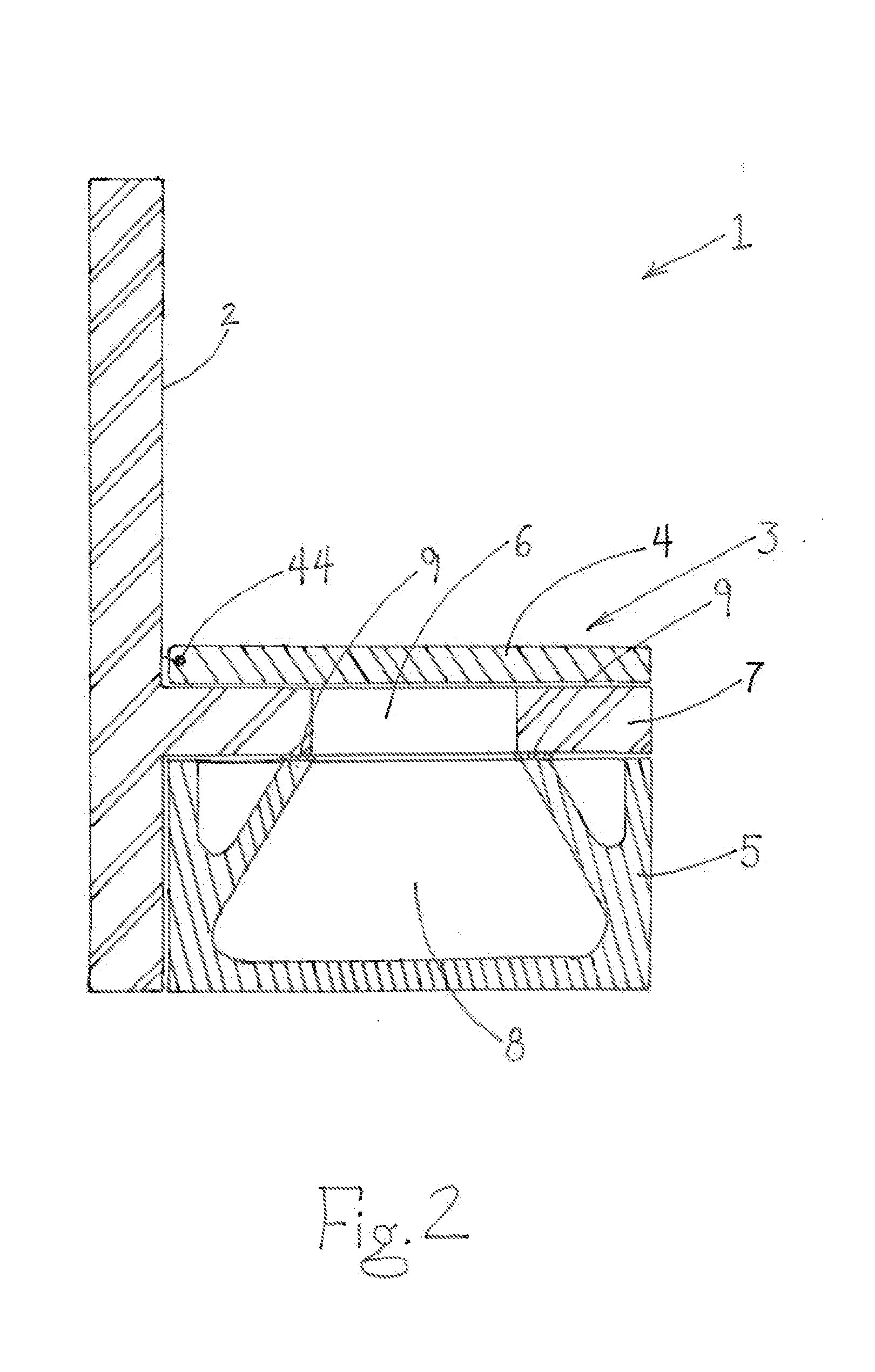

Portable device for cleaning an animal's paw

ActiveUS7302915B2Sufficient amountFully contactedCleaning using toolsOther apparatusCleansing AgentsMechanical engineering

An assembly device for cleaning an animal's paw and assembly methods thereof are disclosed including a container adapted to retain a cleaning agent, the container defining an opening and including a side wall, a cleaning platform disposed in said container and defining a space between said cleaning platform and said container side wall, and a squeegee member substantially covering said opening.

Owner:PET PROD INNOVATIONS

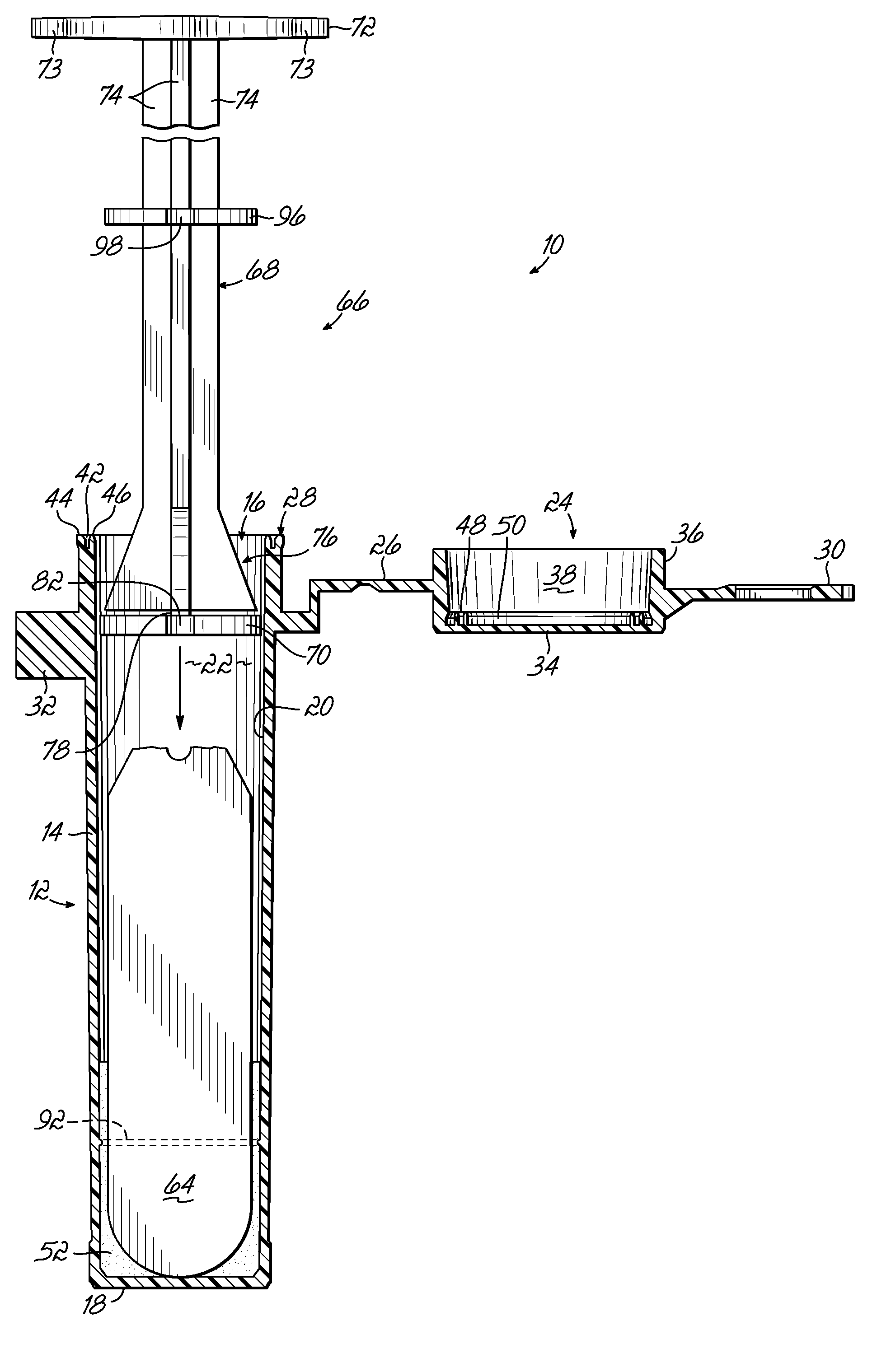

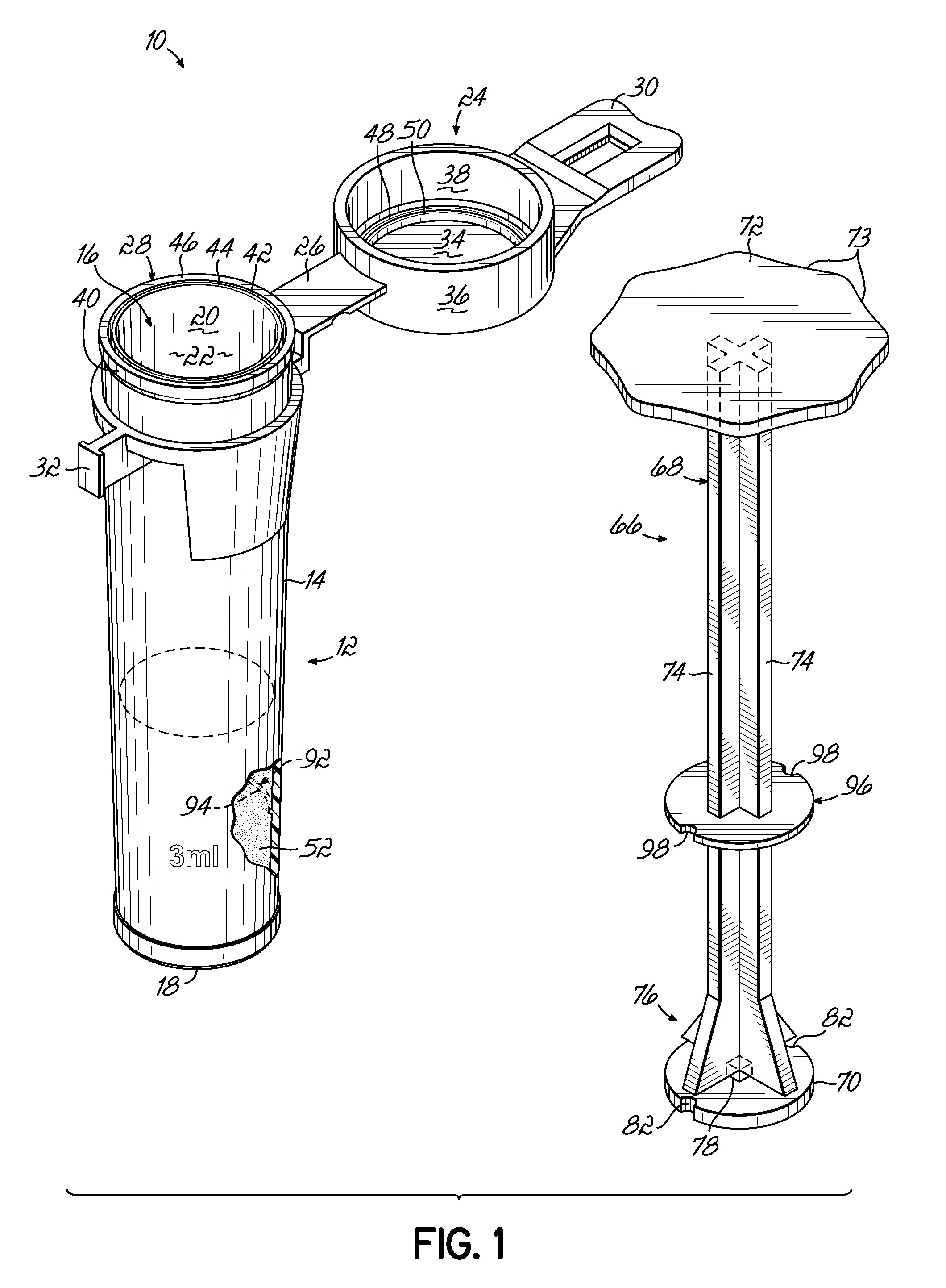

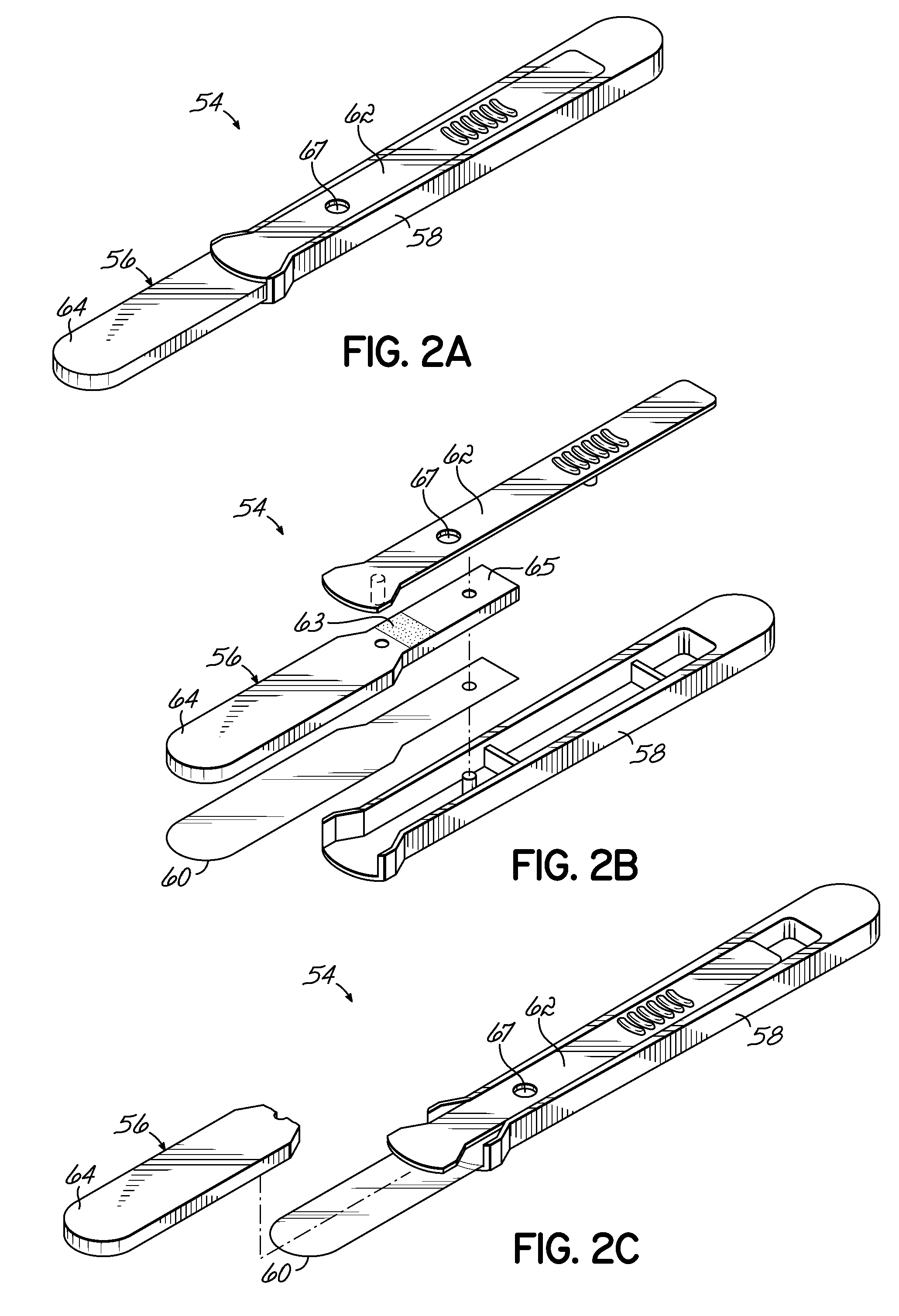

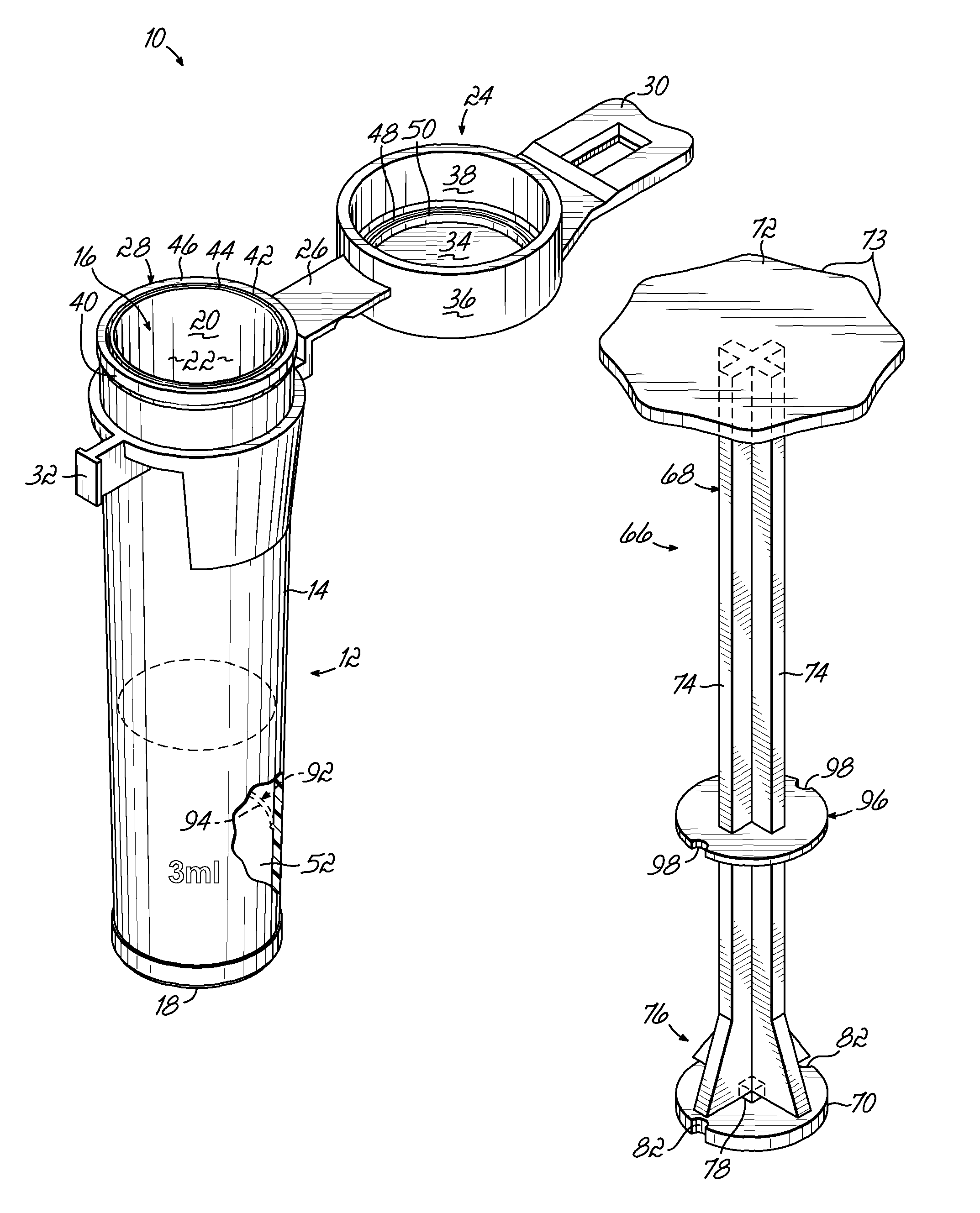

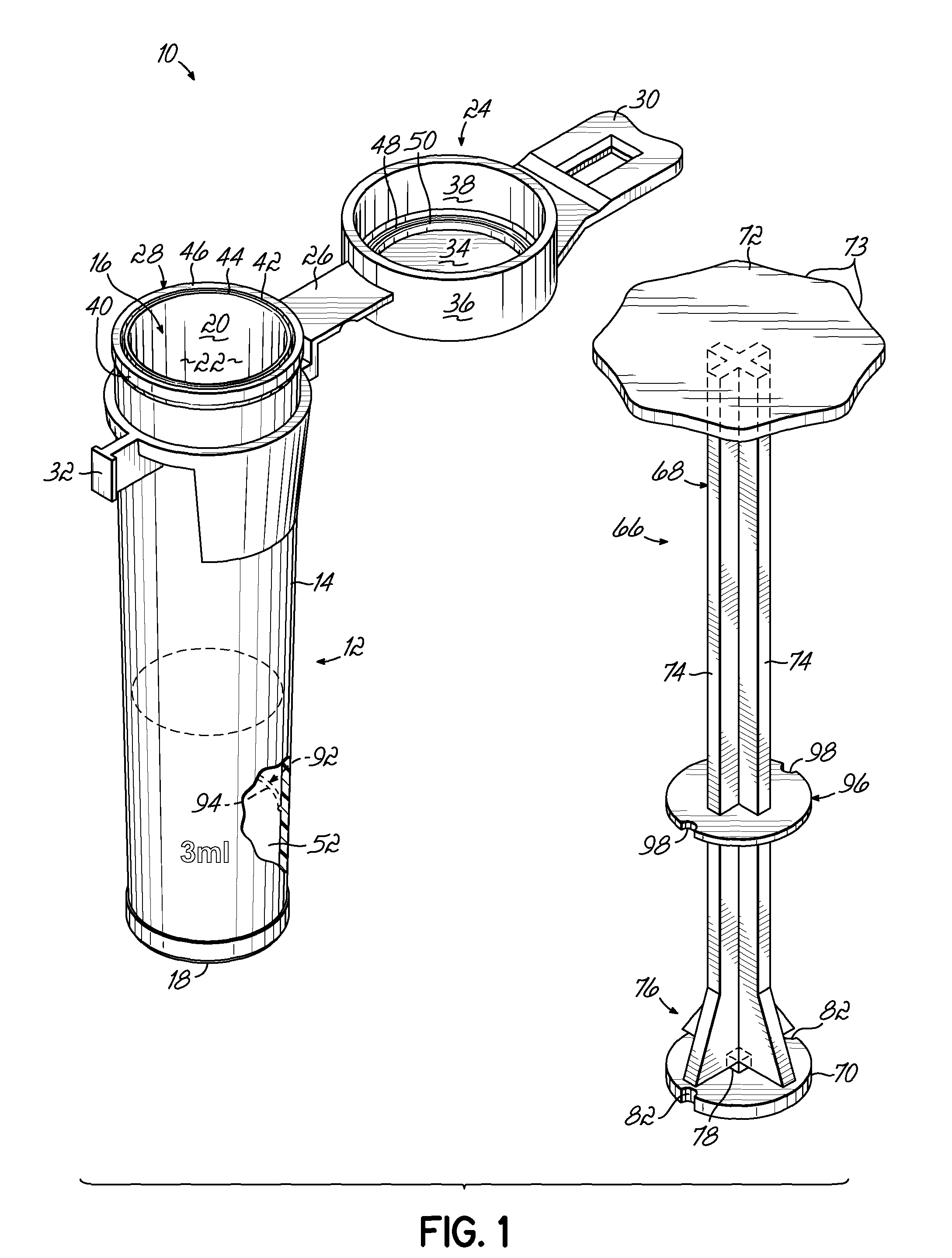

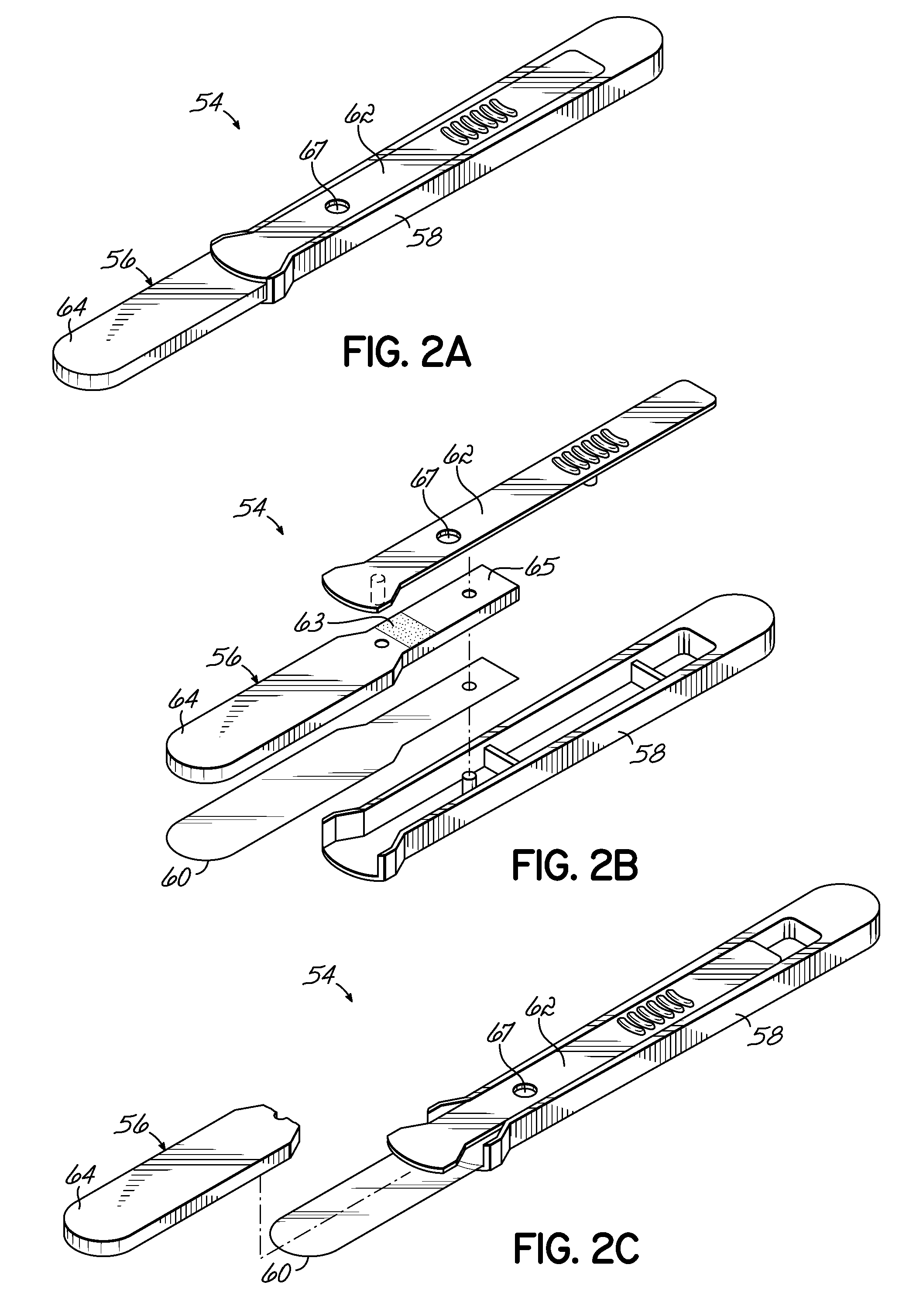

Fluid Sample Collection System and Method

ActiveUS20090209044A1Minimize fluid movementMinimizes splashingAnalysis using chemical indicatorsChemical analysis using titrationCollection systemBiomedical engineering

A fluid sample collection system includes a vial, a plunger and a fluid sample collection device having an absorbent for absorbing and retaining a fluid sample therein. The plunger includes an elongated handle portion and a plunger head portion detachably connected to the handle portion. The plunger also includes a splash guard supported on the handle portion. During the sample collection process, the saturated absorbent from the sample collection device is placed into the vial and the plunger is then advanced toward a closed end of the vial to express the fluid sample from the absorbent. The plunger head portion is retained within the vial with the absorbent in a generally compressed state and the handle portion is detached and removed from the vial.

Owner:CAPITOL VIAL

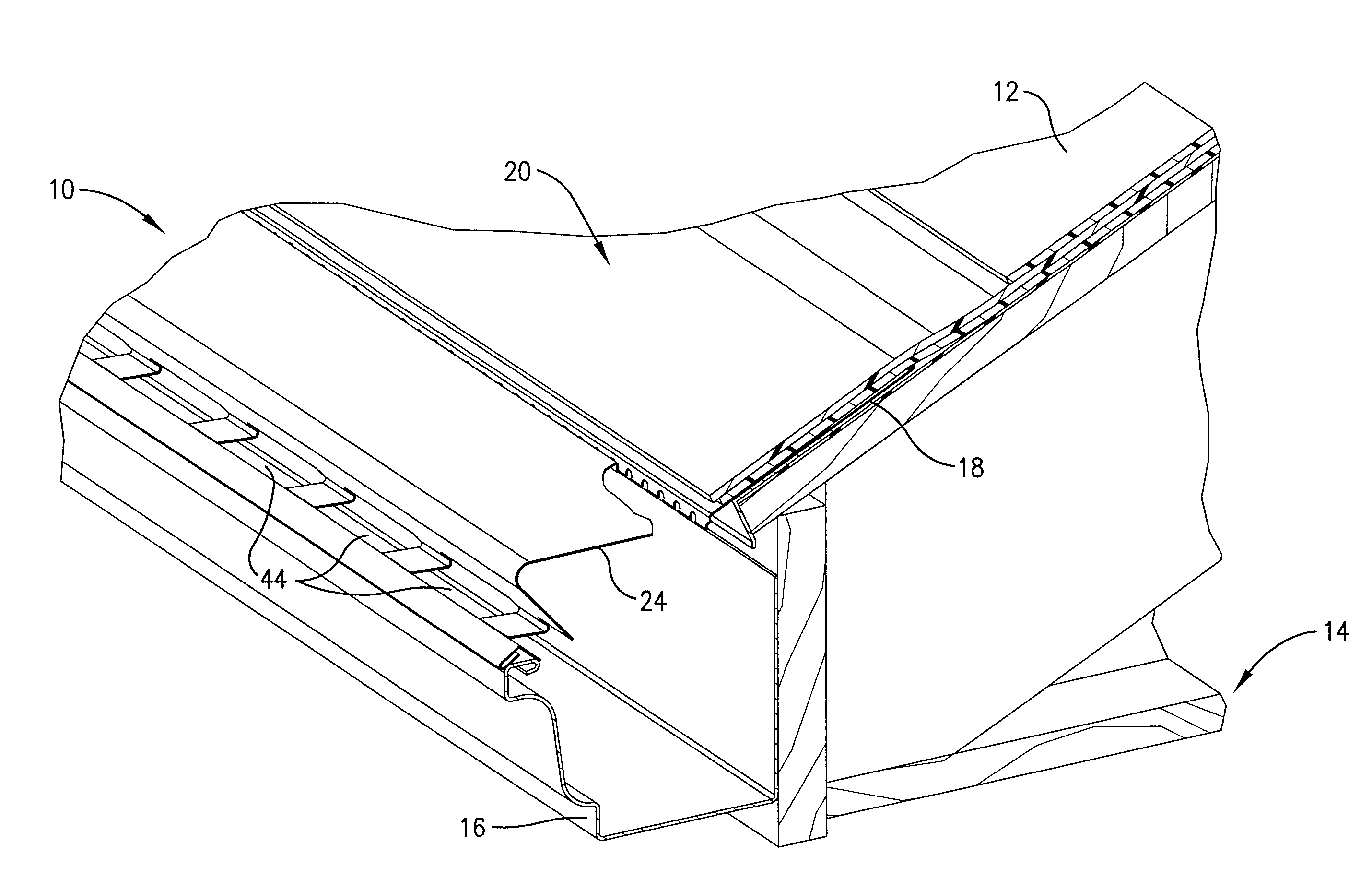

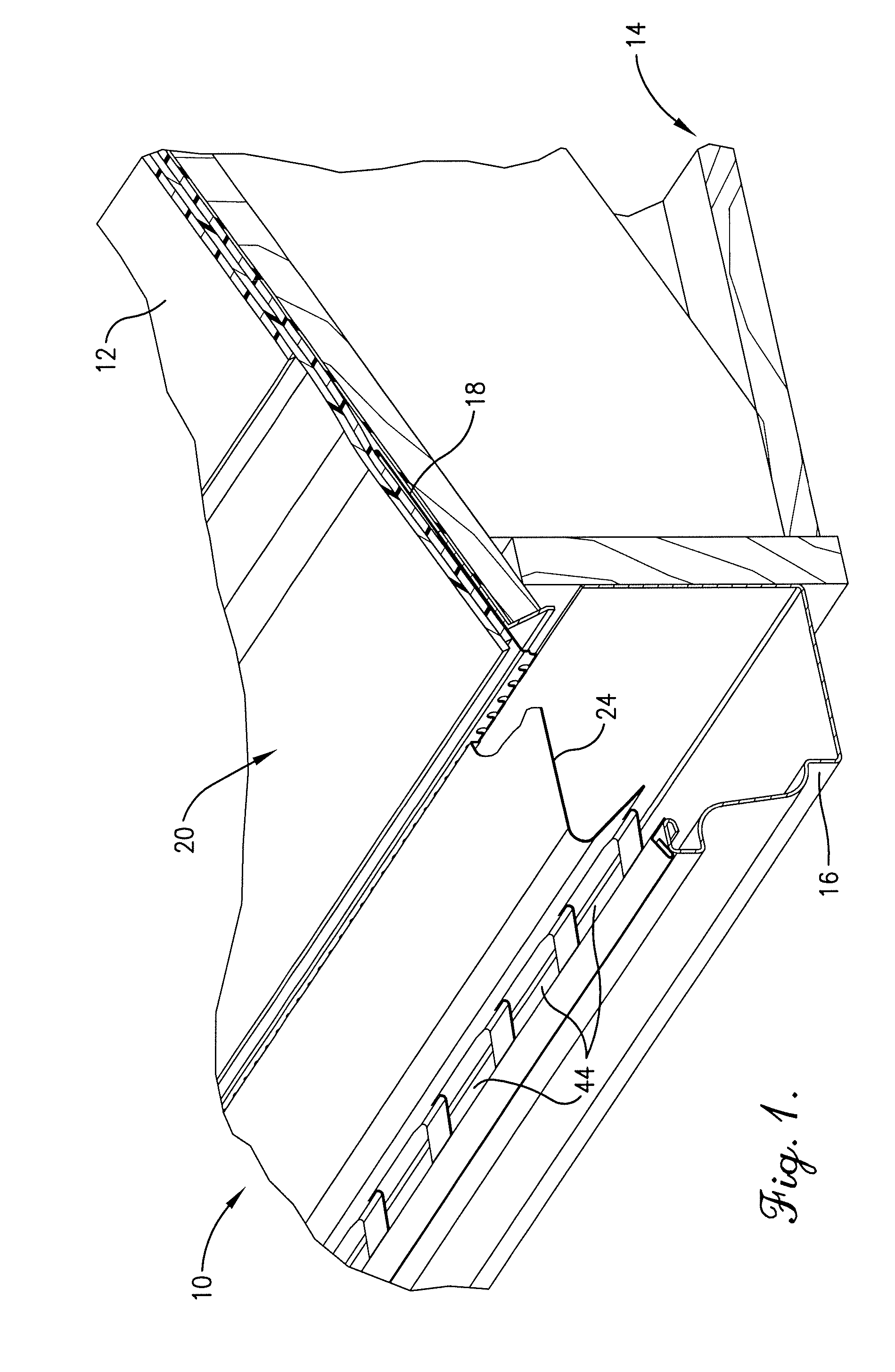

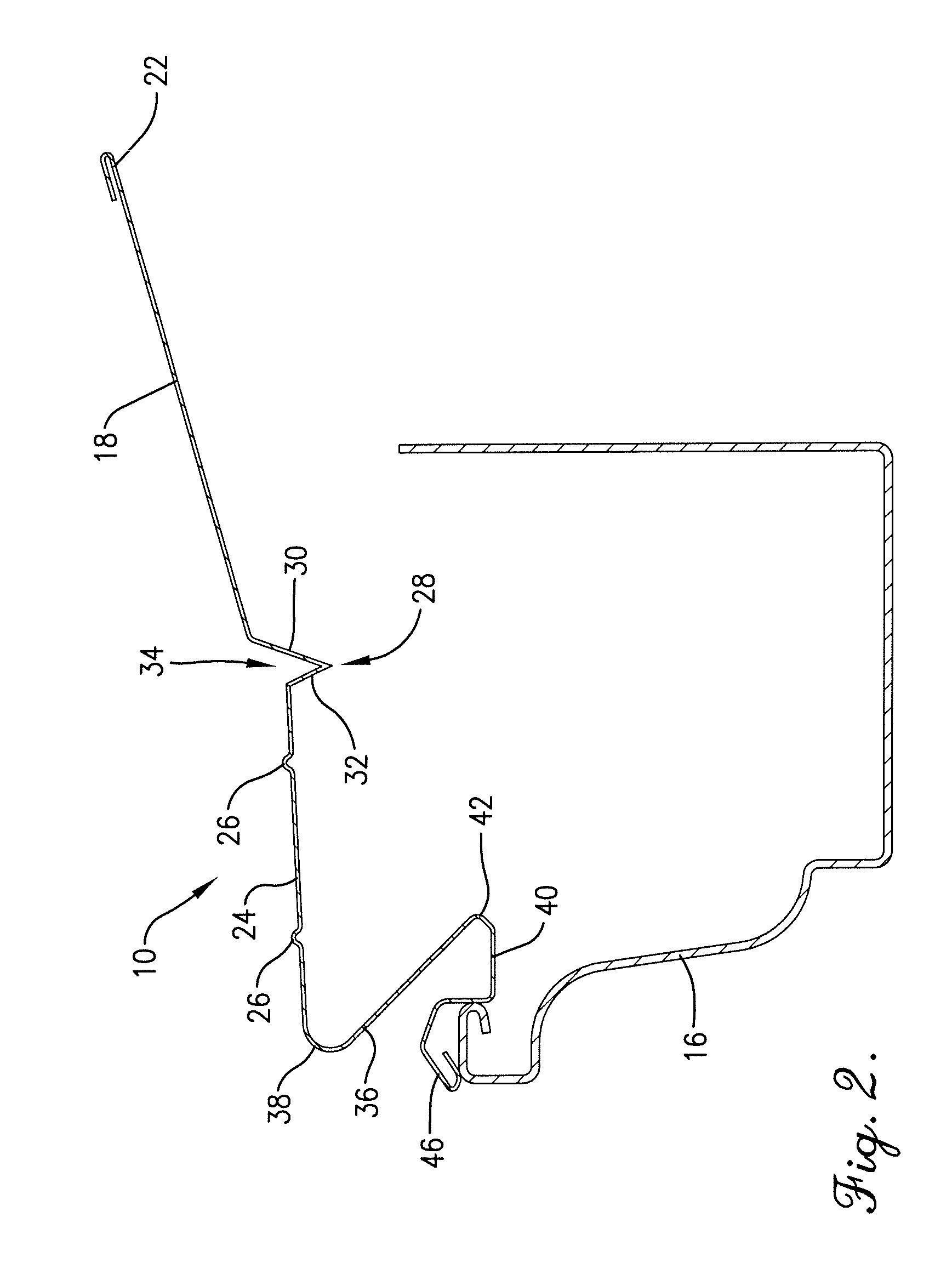

Gutter cover

A gutter cover which can be more easily installed over a gutter without the use of siding breaks or other clamping tools. The gutter cover comprises a generally planar first section adapted to be installed under or over a row of shingles on a roof; a generally planar second section adapted to overlie the open end of a gutter; and a bend between the first and second sections. The bend is shaped and configured to permit the angle of the first section to be easily adjusted relative to the second section without the use of tools and to slow the flow of water from the roof through capillary action. The bend is generally V-shaped in cross section and includes a first leg that depends from one edge of the first section and a second leg that depends from one edge of the second section. The two legs are joined at the bottom to form a crevice that slows the flow of water over the gutter cover.

Owner:ERAN INDS

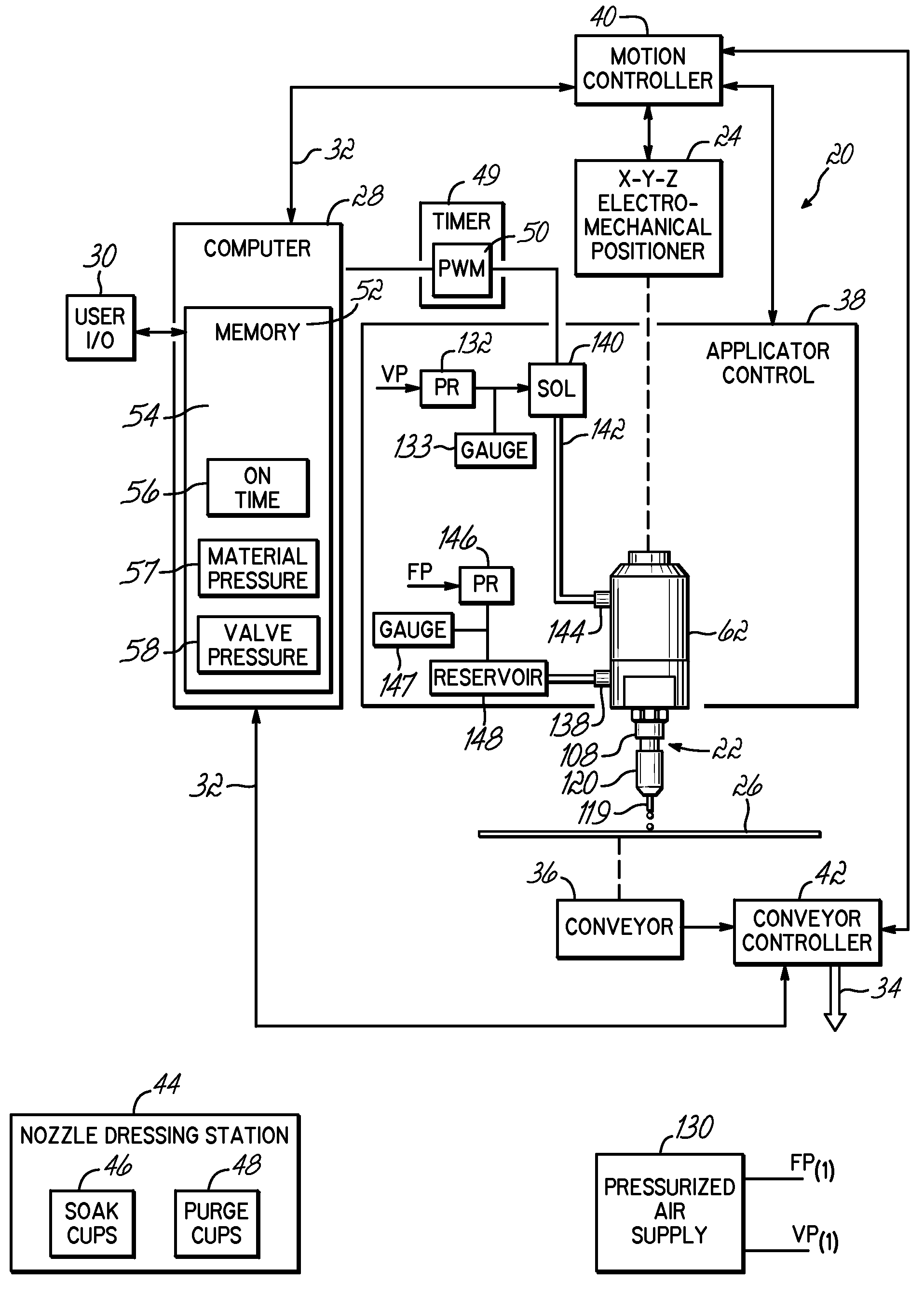

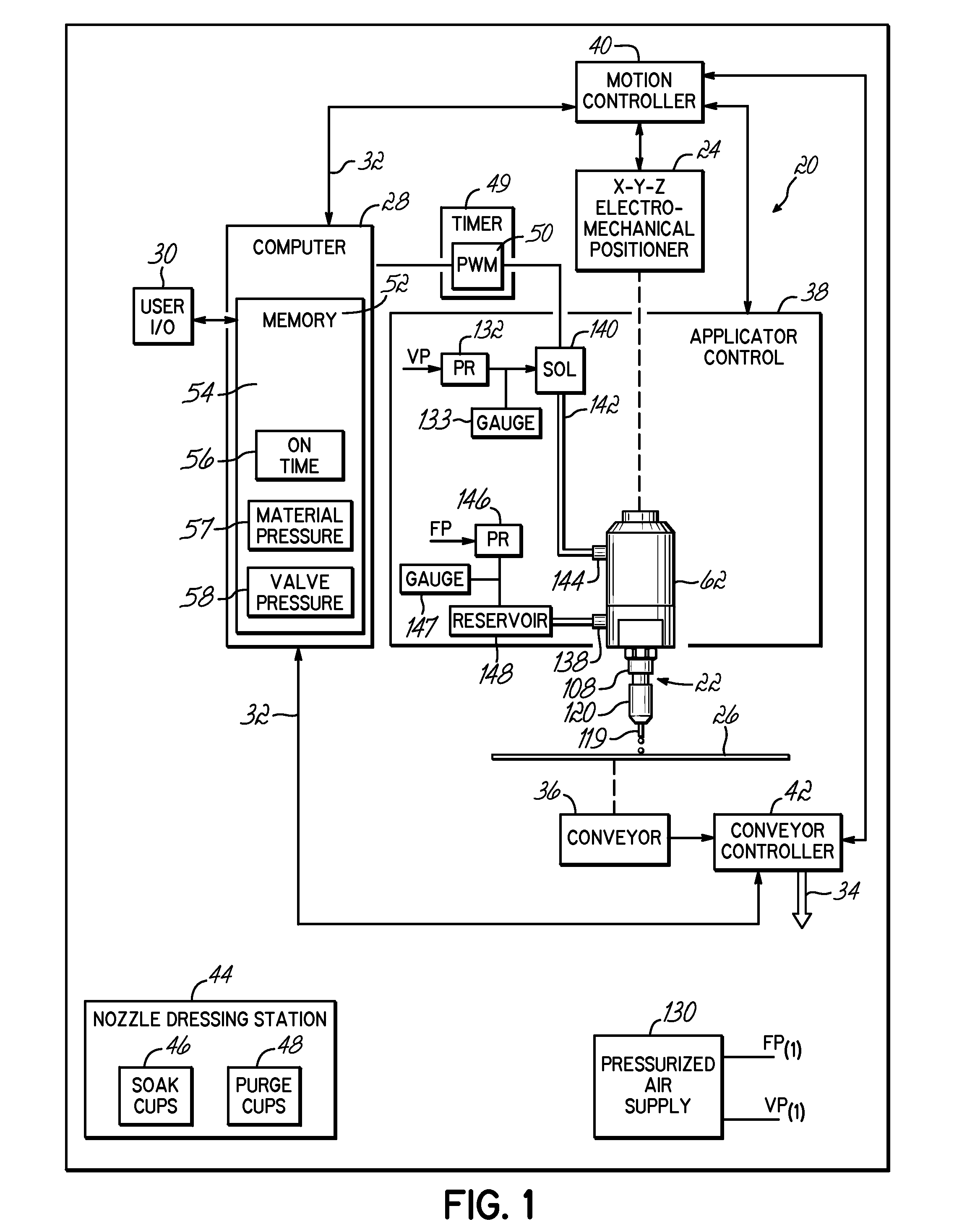

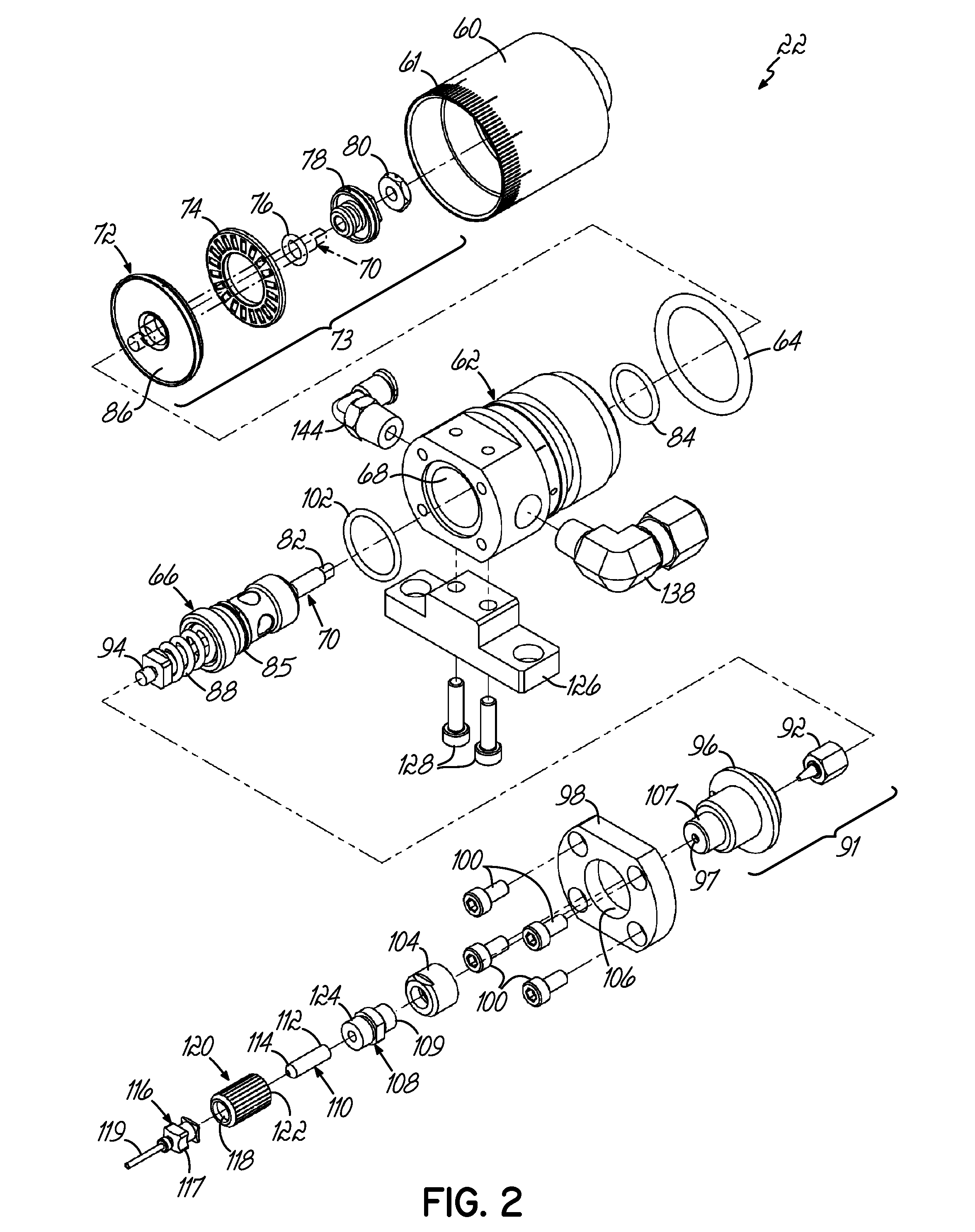

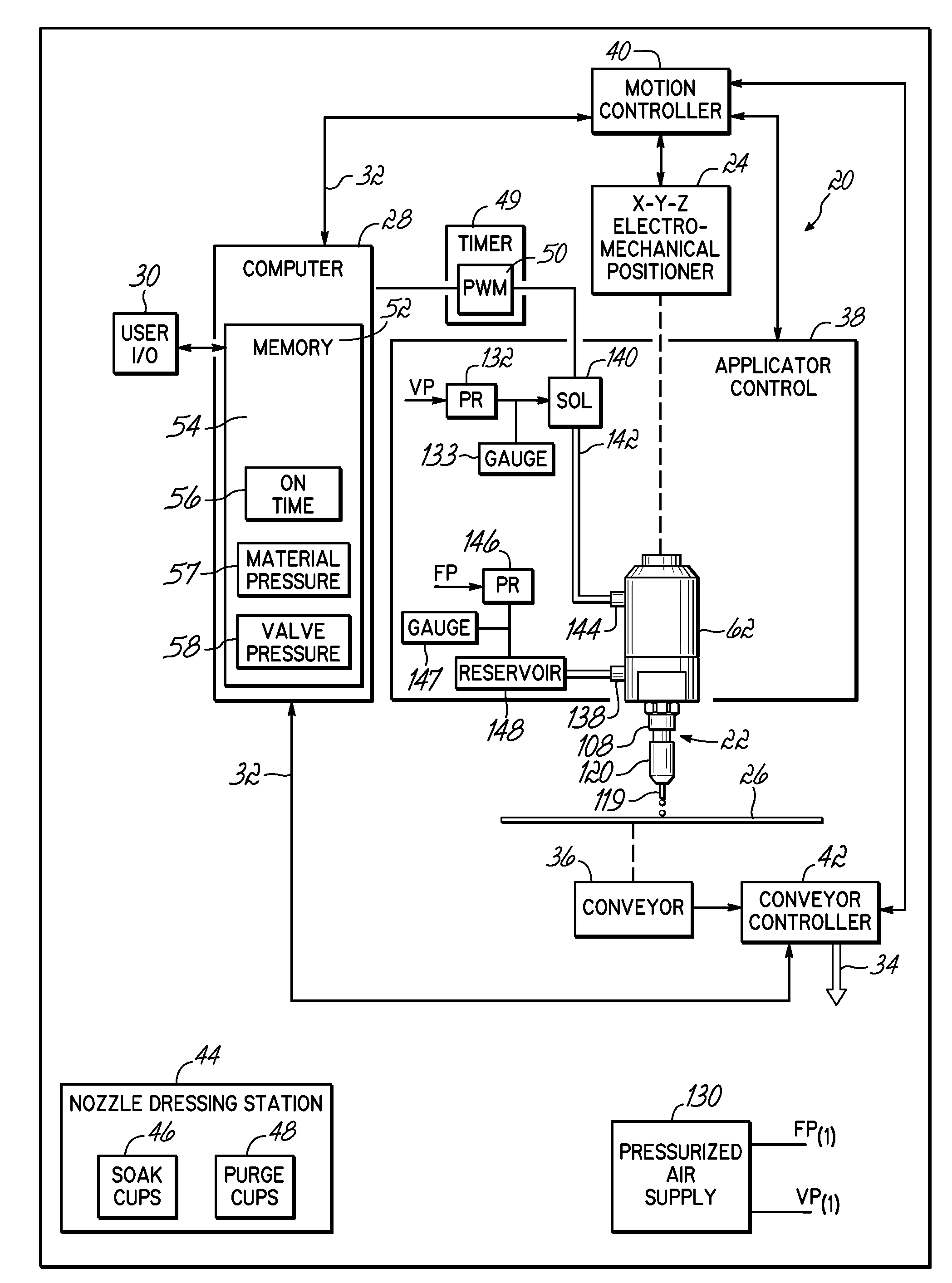

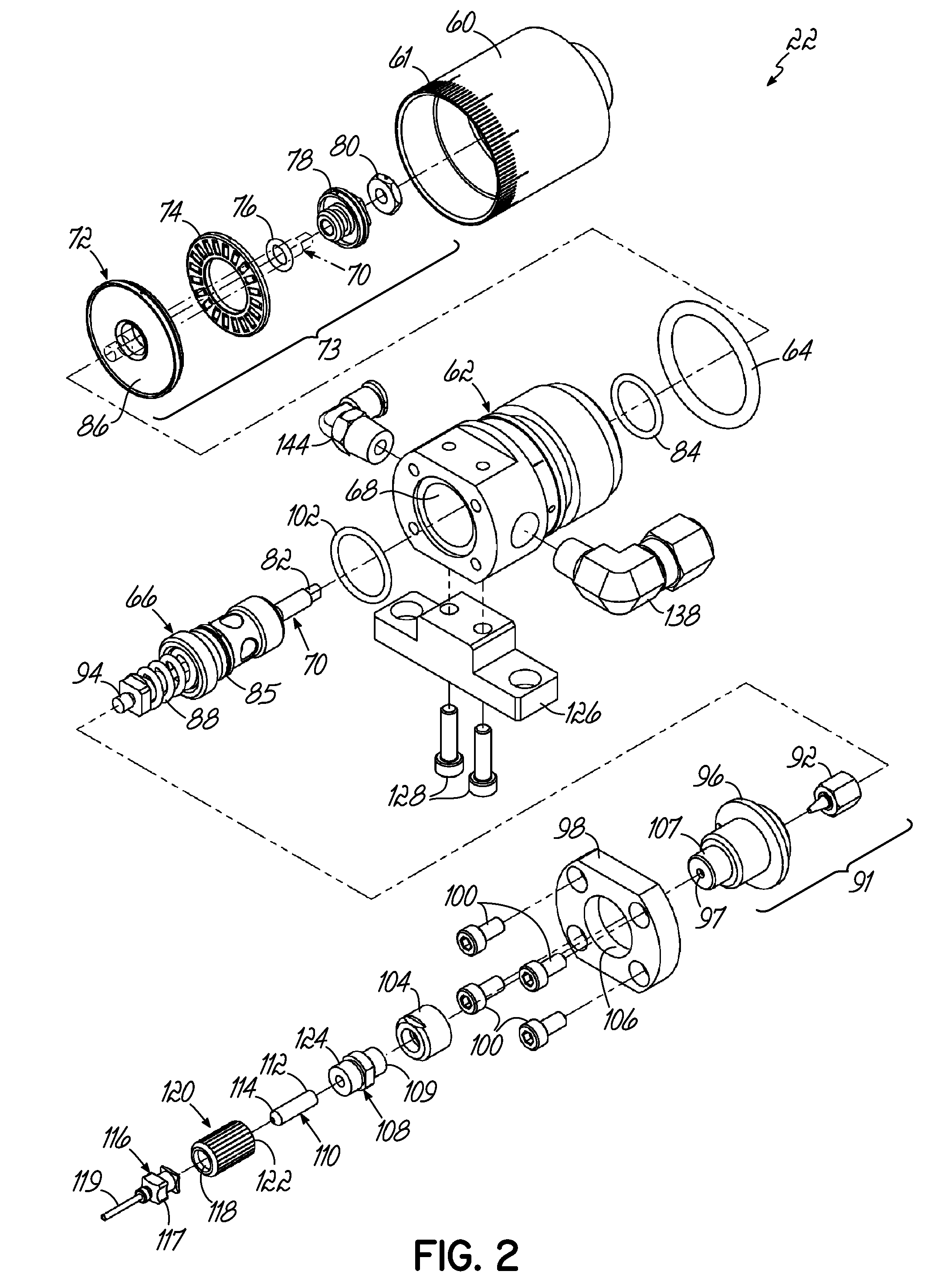

Thin line conformal coating apparatus and method

InactiveUS20080099515A1Low viscosityImprove abilitiesPrinted circuit aspectsMovable spraying apparatusCoating systemEngineering

A coating system with an applicator that has an air cylinder with a needle valve. A control has a timer that provides a string of electrical pulses to a solenoid. With each pulse, the solenoid applies pressurized air to a cylinder piston, thereby opening the needle valve and permitting coating material to flow past the needle valve. The needle valve is closed for durations of time between pulses, and the coating material is ejected from a dispensing needle in response to closings of the needle valve.

Owner:NORDSON CORP

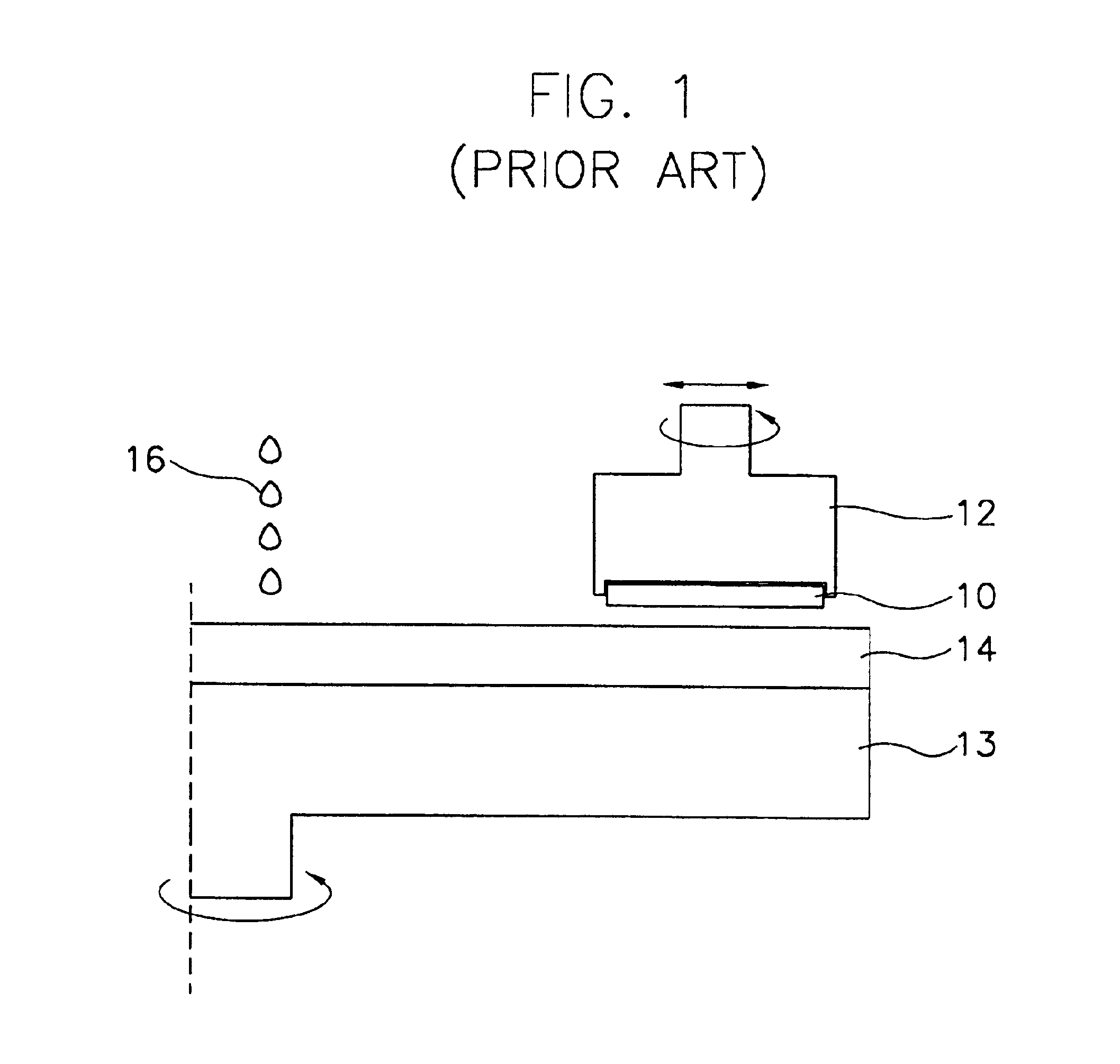

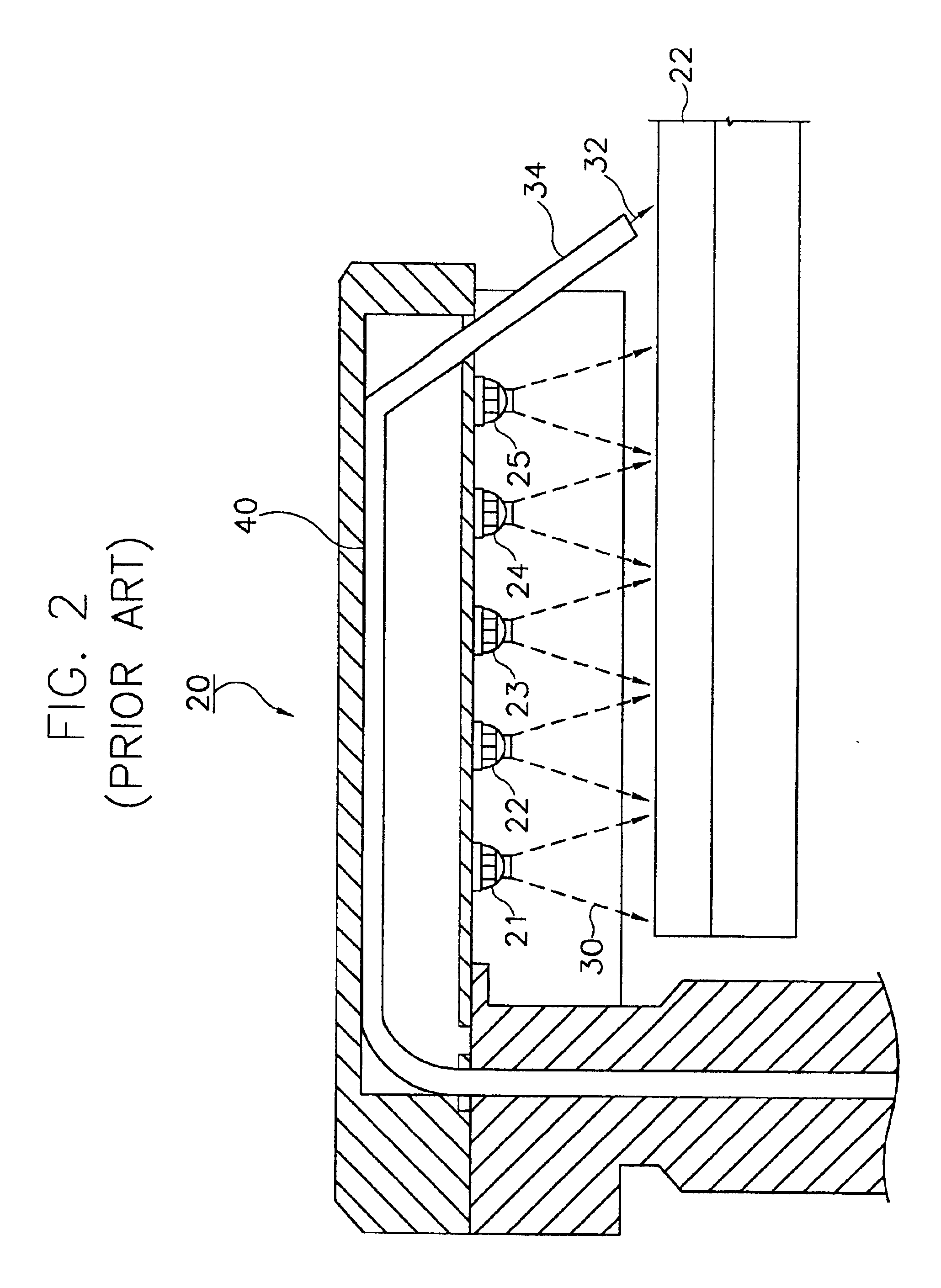

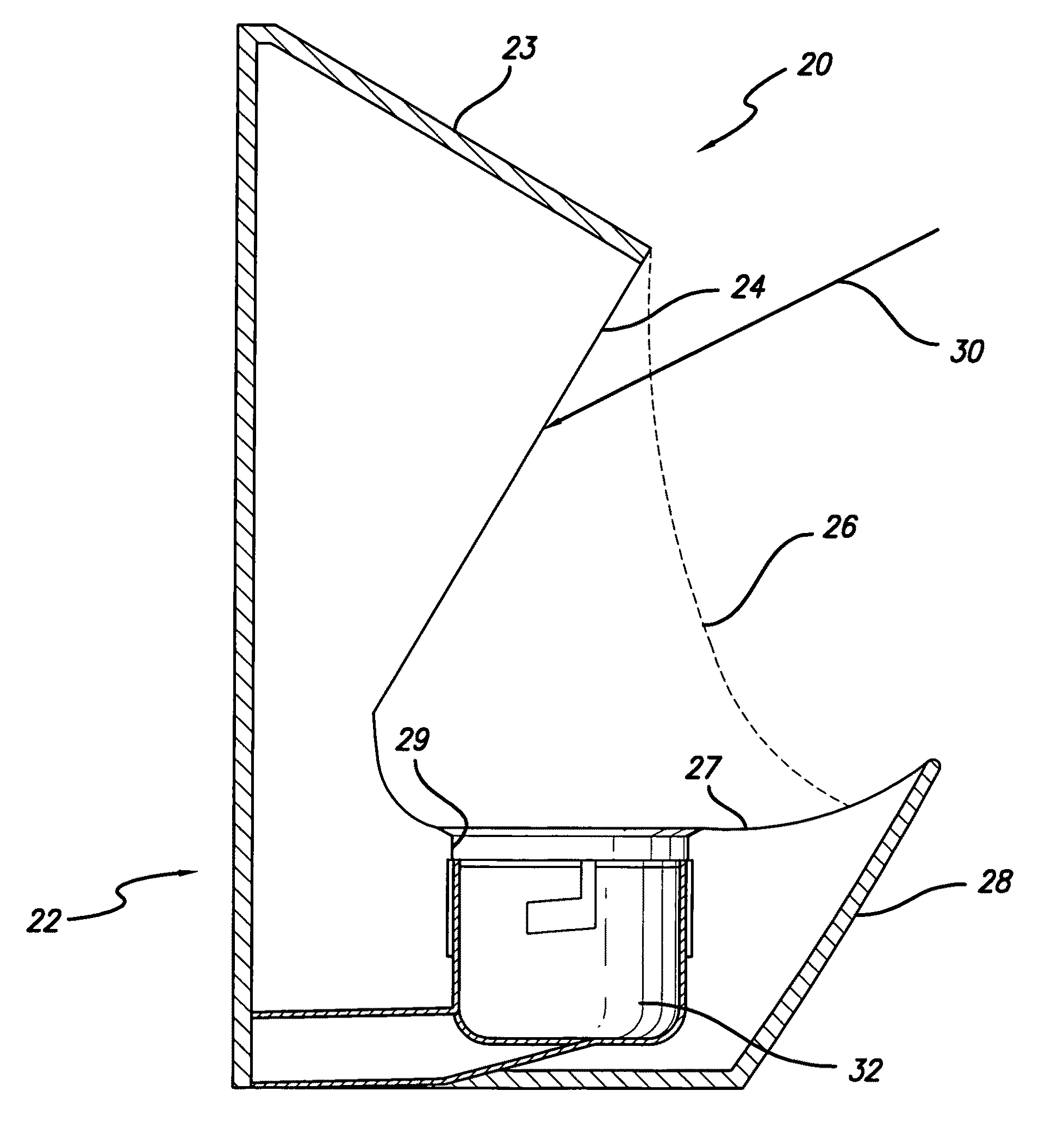

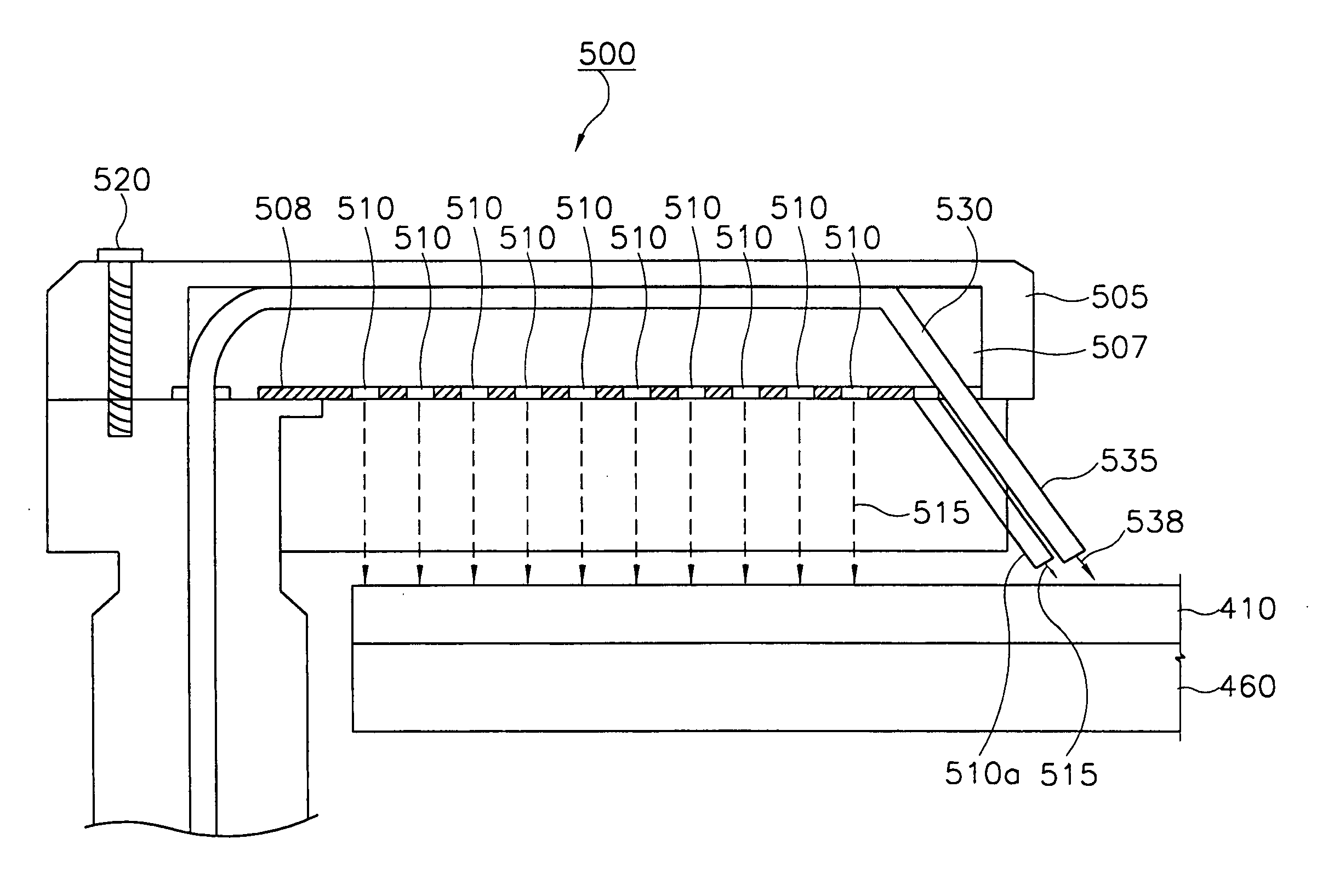

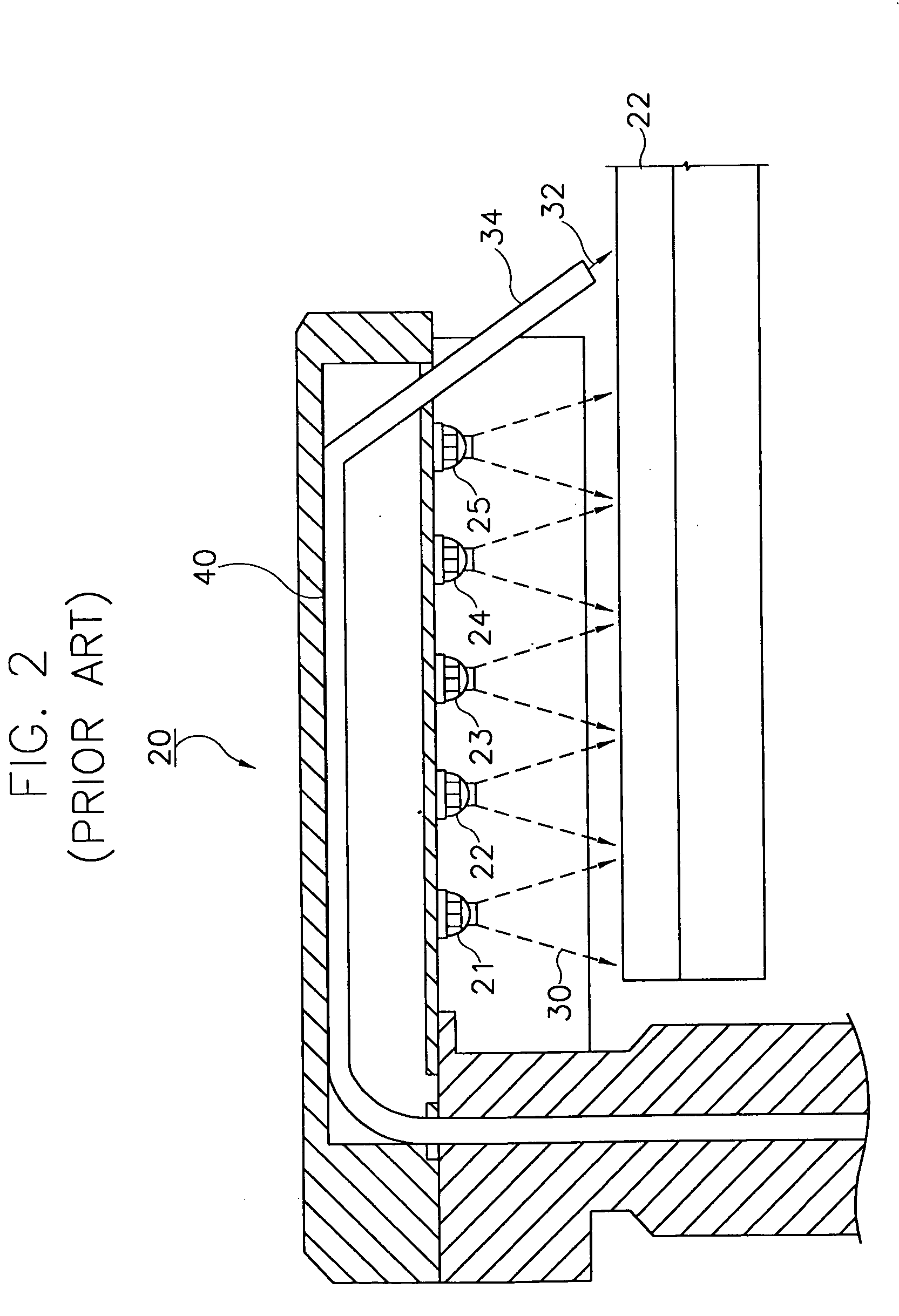

Method and apparatus for polishing a substrate while washing a polishing pad of the apparatus with at least one free-flowing vertical stream of liquid

InactiveUS6863770B2Prevent reboundDefect in polishing processSemiconductor/solid-state device manufacturingLapping machinesEngineeringSlurry

A method and apparatus for polishing a substrate with a polishing pad and slurry entails washing polishing-pollutants produced by the polishing operation off of the pad in such a way that the pollutants are not splashed onto components of the polishing apparatus. A washing solution for removing the pollutants is directed onto the polishing pad as at least one free-flowing vertical stream. Because the washing solution flows freely and vertically as it impinges the polishing pad, the washing solution does not rebound from the pad and flows from the surface of the polishing pad without causing the pollutants on the pad to be splashed up from the surface of the pad.

Owner:SAMSUNG ELECTRONICS CO LTD

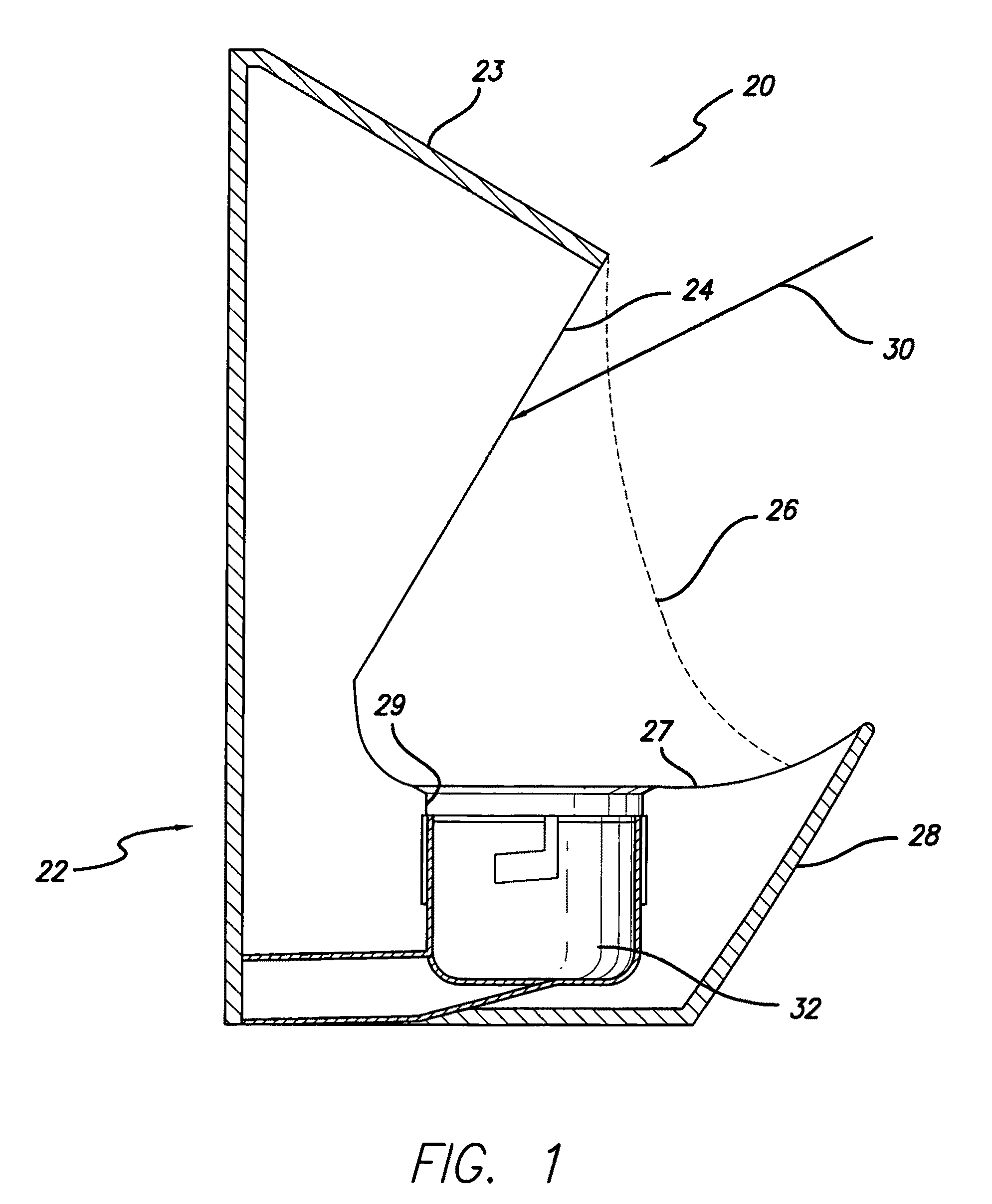

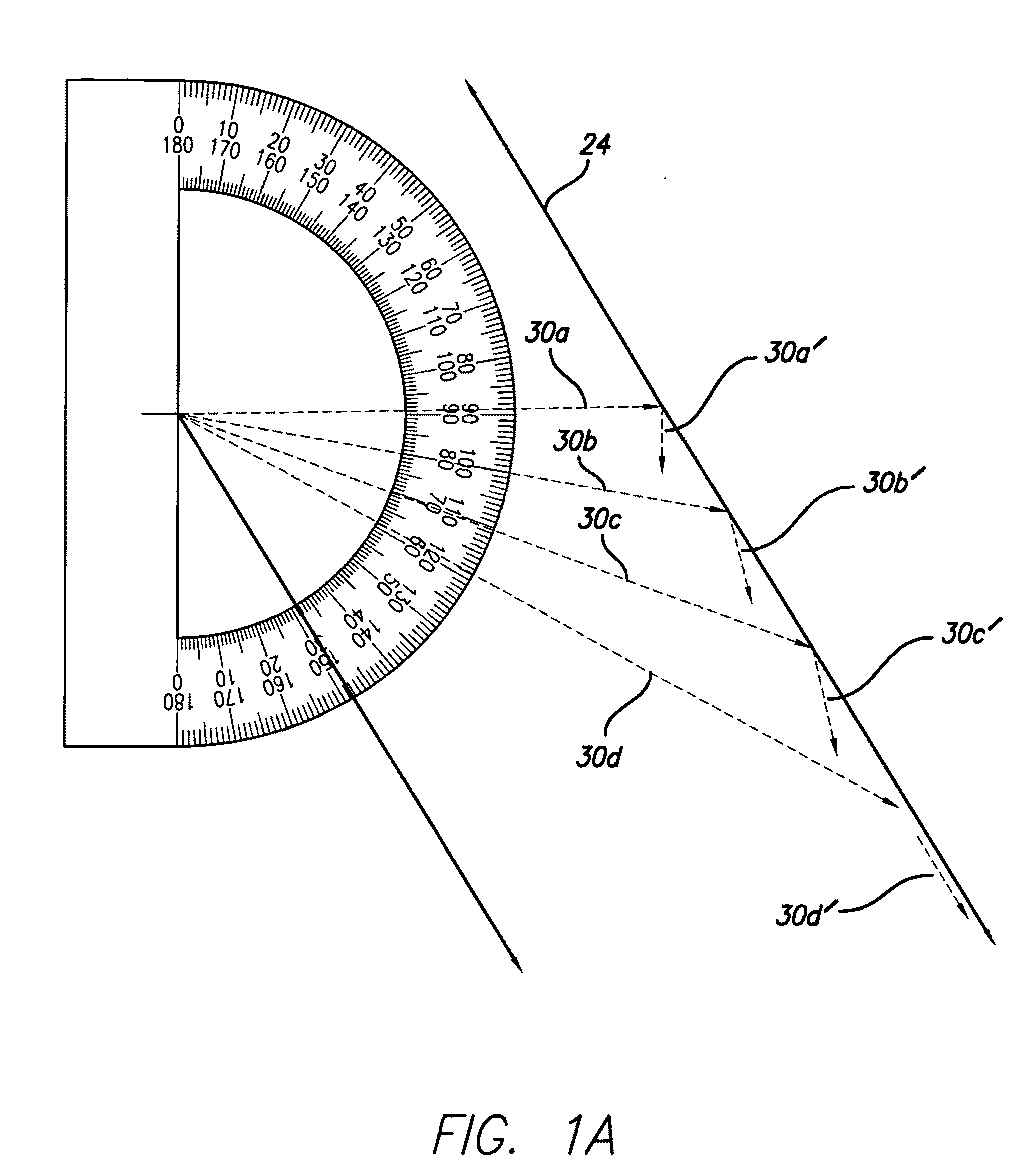

Anti-splash urinals

InactiveUS20100095445A1Splashing from the urinal is at least minimizedCleanliness exterior to the urinal is enhancedUrinalsHysteresisUrine stream

A urinal uses a sloped interior back wall to create a specific angle between an incoming urine stream and the back wall to effect an anti-splash phenomenon which involves the contact angle hysteresis and the coanda effect, thereby at least to minimize urine splashing. The contact angle hysteresis deals with the perpendicular angles at which the urine stream comes into contact with the back wall of the urinal bowl, that is the amount of angle degrees between the angle of surface of the bowl and the angle of the urine stream at the point of contact. This angle takes advantage of the Coanda effect so as to cause the fluid (urine) to run down the surface of the back wall to the bottom of the urinal, rather than splashing back. The Coanda effect is the tendency of a fluid jet to stay attached to an adjacent curved surface that is very well shaped. In one embodiment, the interior back wall is vertically sloped towards the user, at an angle greater than 20° from the vertical (e.g., 30° to accommodate a 60° urine stream), and the back wall may be further curved from side to side. In an other embodiment, the interior back wall has a undulated top-to-bottom or vertical contour.

Owner:FALCON WATERLESS TECH INC

Combination gravimetric and volumetric dispenser for multiple fluids

ActiveUS7918435B2Reduce flow rateImprove accuracyOperating means/releasing devices for valvesMixer accessoriesDrive shaftEngineering

A combination gravimetric and volumetric fluid dispenser which includes a scale linked to a controller. The controller is linked to a plurality of two stage valves which control the dispensing of large quantities of base materials. The controller is also linked to a plurality of nutating pumps which together with the controller controls the dispensing of smaller quantities of additive materials. The base material dispensing valves include stepper motor actuators having multiple steps per revolution and are under the control of an analog signal from a controller. The base material dispensing valve is opened or closed via a rod that is slidably raised or lowered upon rotation of the drive shaft of the stepper motor actuator.

Owner:FLUID MANAGEMENT LLC

Portable device for cleaning an animal's paw and assembly method thereof

ActiveUS20060185616A1Minimizes splashingEasy to disassembleCleaning using toolsOther apparatusEngineeringCleansing Agents

An assembly device for cleaning an animal's paw and assembly methods thereof are disclosed including a container adapted to retain a cleaning agent, the container defining an opening and including a side wall, a cleaning platform disposed in said container and defining a space between said cleaning platform and said container side wall, and a squeegee member substantially covering said opening.

Owner:PET PROD INNOVATIONS

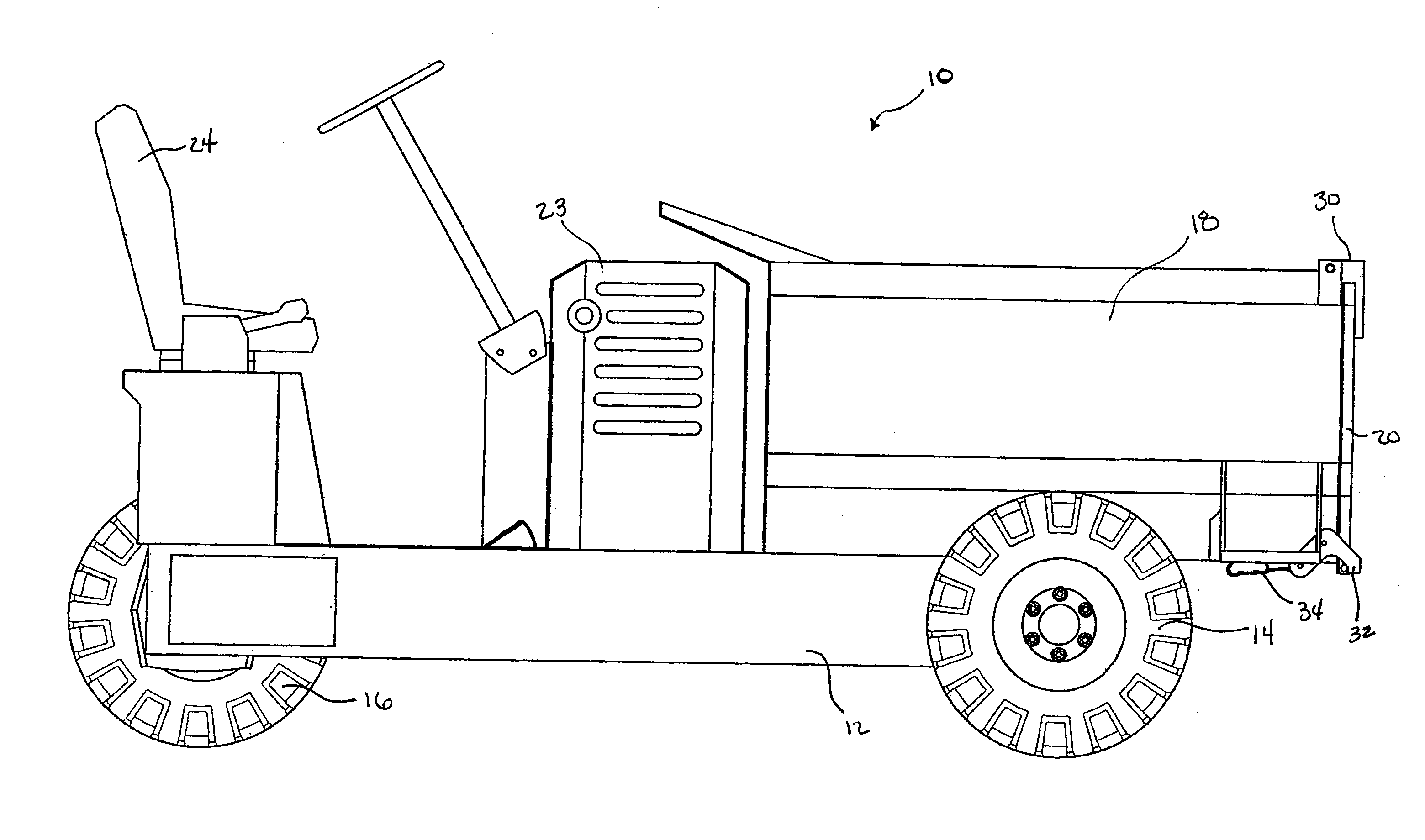

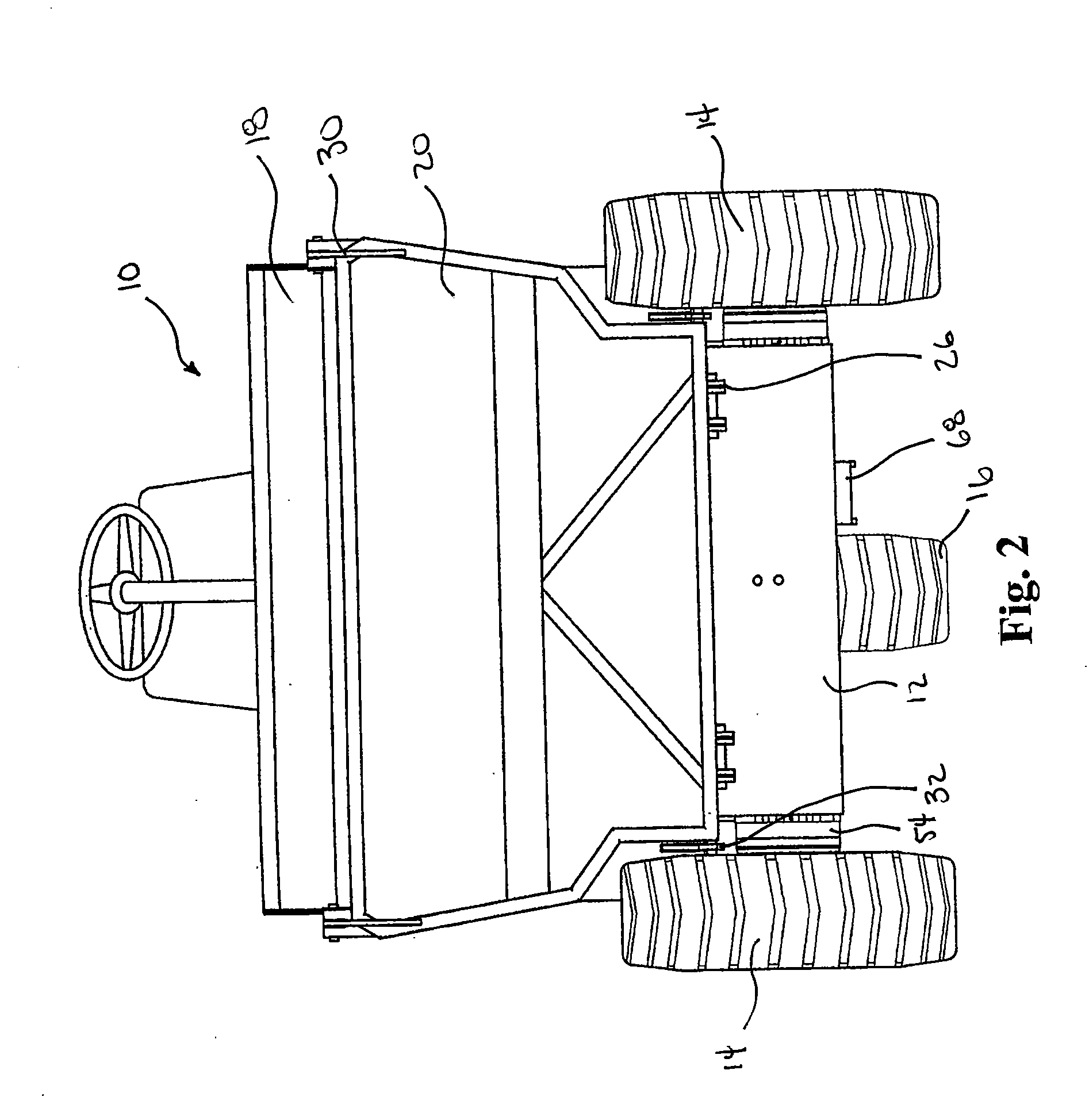

Tractor

ActiveUS20100194174A1Reduce the possibilityMinimizes splashingLoading/unloadingVehicle with tipping movementEngine powerTractor

A tractor for hauling concrete and similar materials at a construction site. The tractor includes an engine powering two pumps connected in series. The two pumps providing hydraulic pressure to: independently power each of a plurality of wheels; to rotate at least one of the wheels to provide steering to the tractor; to raise and lower a bucket; and to release and close a latch for a gate connected to the bucket.

Owner:DEETJEN DUSTY

Thin line conformal coating method

ActiveUS20090202709A1Low viscosityImprove abilitiesPrinted circuit aspectsLiquid/solution decomposition chemical coatingCoating systemConformal coating

A coating system with an applicator that has an air cylinder with a needle valve. A control has a timer that provides a string of electrical pulses to a solenoid. With each pulse, the solenoid applies pressurized air to a cylinder piston, thereby opening the needle valve and permitting coating material to flow past the needle valve. The needle valve is closed for durations of time between pulses, and the coating material is ejected from a dispensing needle in response to closings of the needle valve.

Owner:NORDSON CORP

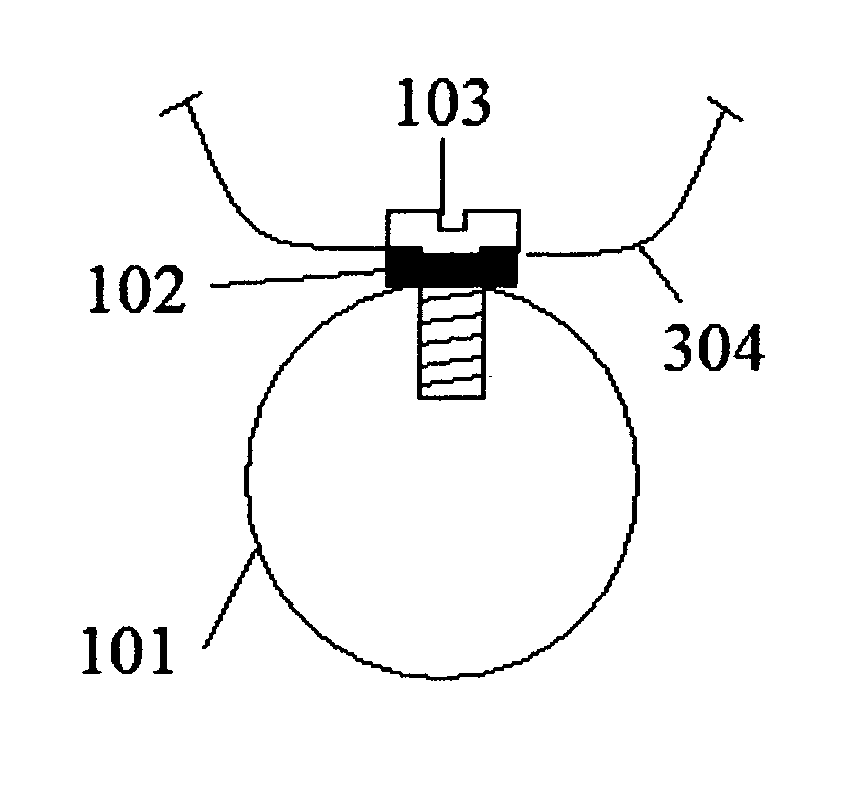

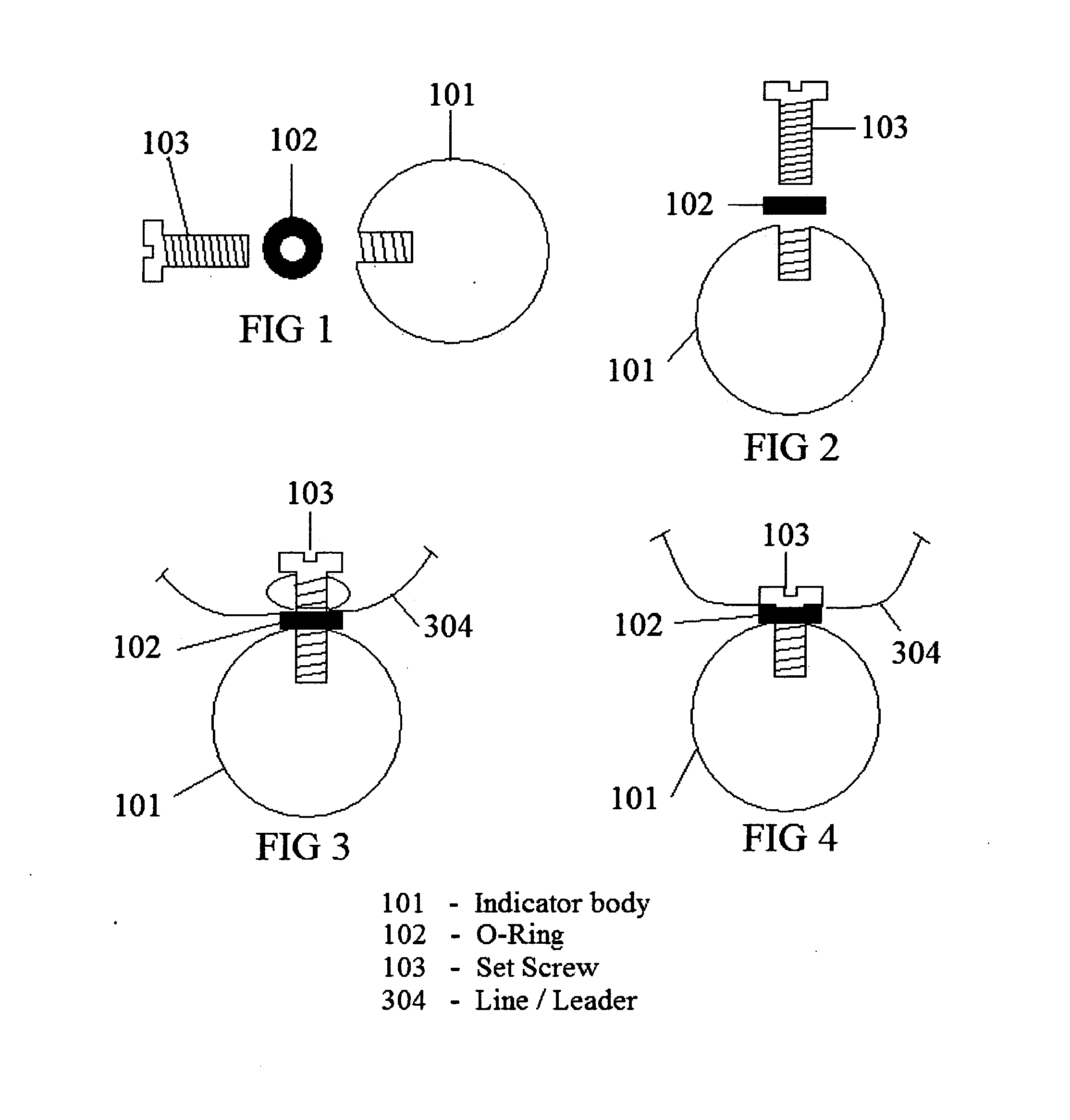

Screw-ball strike indicator

A fly fishing device for indicating a strike from a fish which suspends a fly or lure a fixed distance above the bottom of a lake or river is disclosed. The device may include a strike indicator made from foam or other buoyant materials that includes a threaded set screw and O-Ring to attach the line / leader to the indicator body. Most strike indicators are either difficult to attach, or difficult to adjust. This invention will allow easy attachment, and easy adjustment.

Owner:BARON MICHAEL J

Scented tablet for toilet and method for scenting restroom effluent

InactiveUS7563756B2Good foaming effectIncrease aromaLavatory sanitoryDetergent materialsFlavorSodium bicarbonate

Owner:BRADY BRANDI

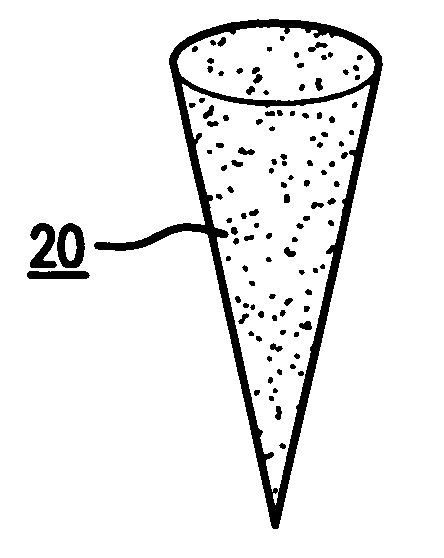

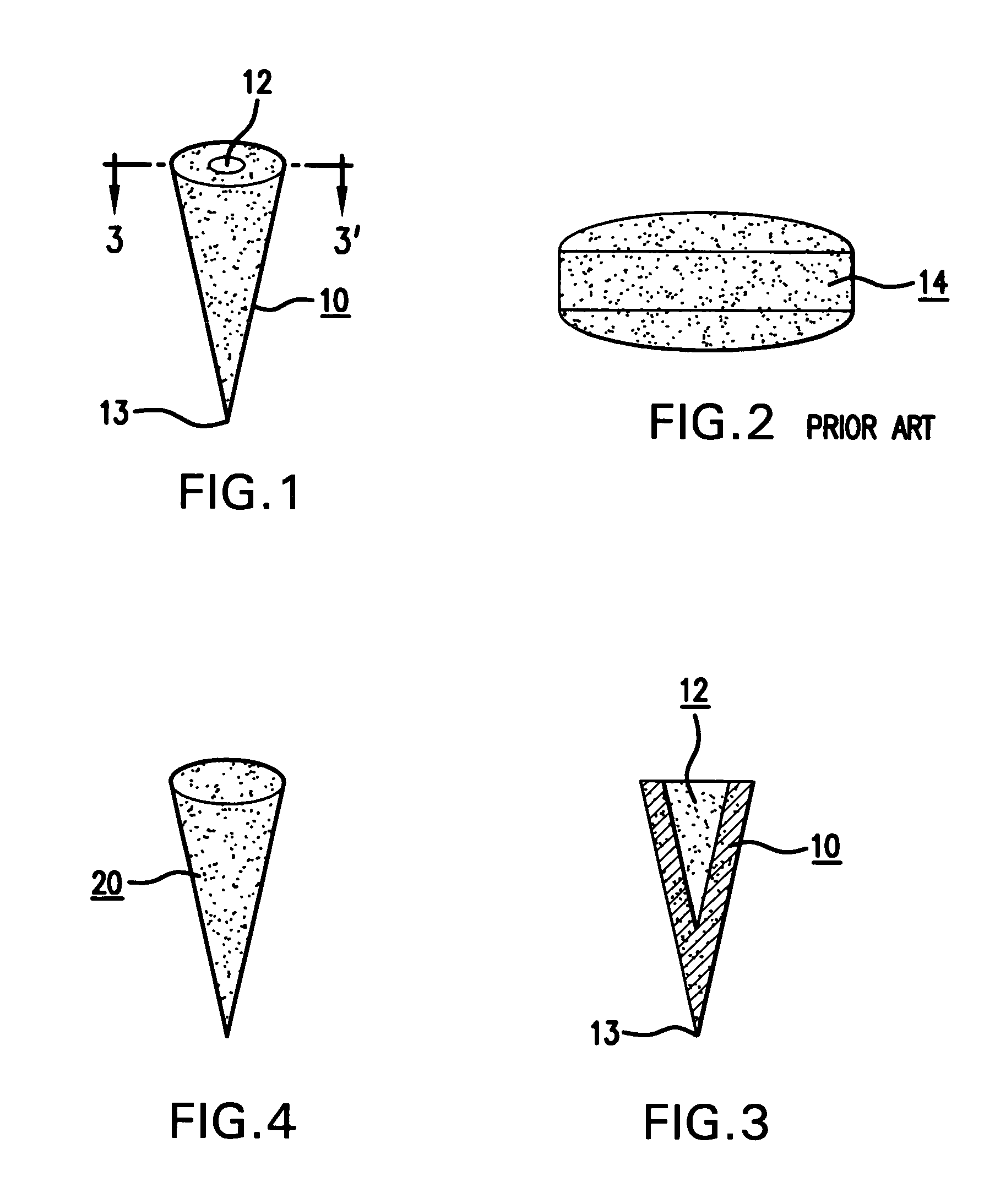

Liquid cryogen dosing system with nozzle for pressurizing and inerting containers

InactiveUS20060010886A1Less apt to misshape during capping, sealing, and or handlingMinimizes splashingLighting and heating apparatusPressure vesselsVena contracta diameterEngineering

A liquid cryogen dispensing system employing a splash-reducing nozzle for substantially reliable and uniform dispensing of liquid cryogen into a container for a beverage, food product, or other product, such as a still (non-carbonated) hot-filled container. The dispensing system has a nozzle which includes an orifice plate having an array of apertures to dispense a dose of liquid cryogen into an underlying container as a generally ring-shaped “shower” of discrete liquid cryogen streams, which can be gently impacted upon the surface of the contents of the container to minimize splashing, and help ensure satisfactory pressurization or inerting of the container.

Owner:KRAFT FOODS INC

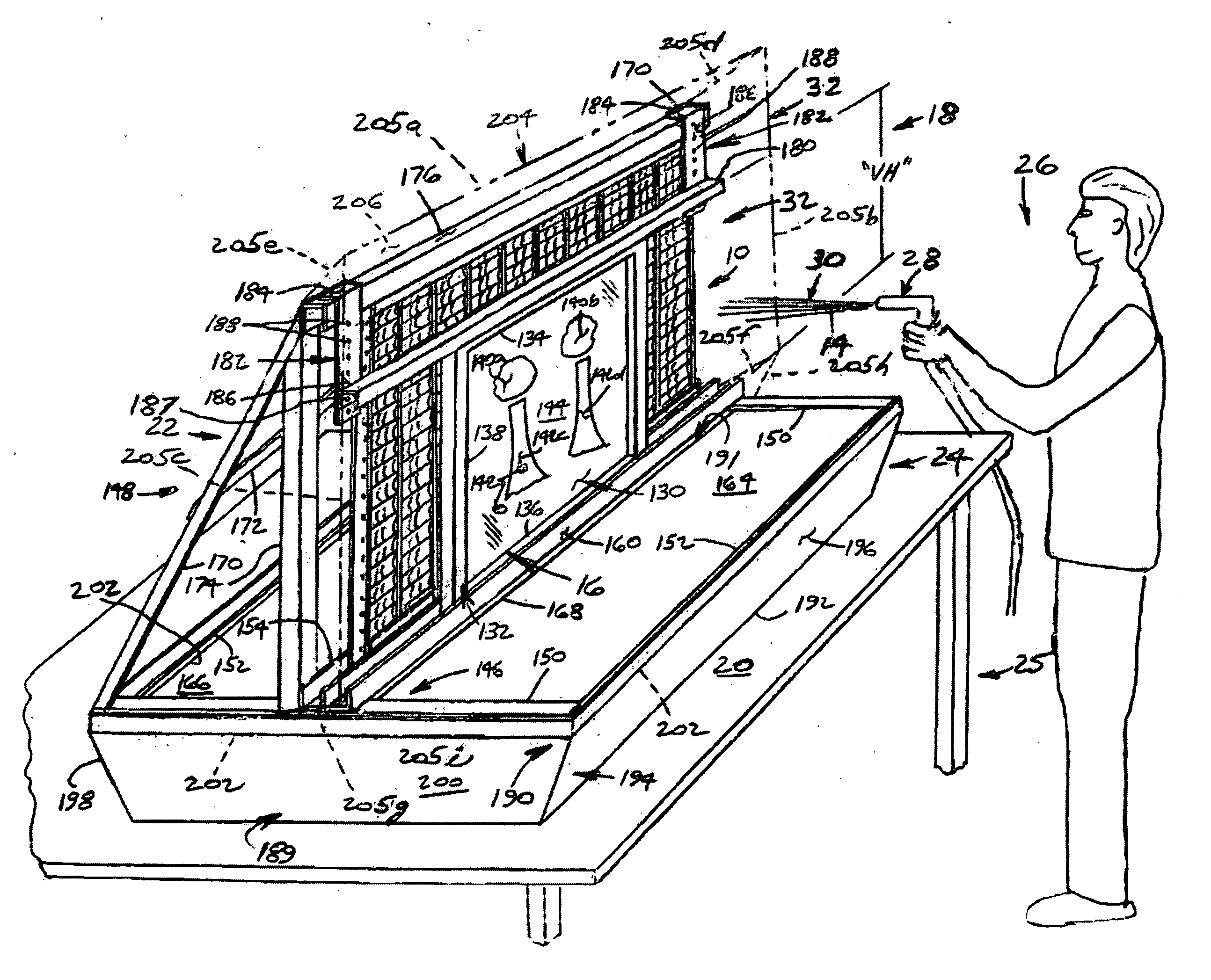

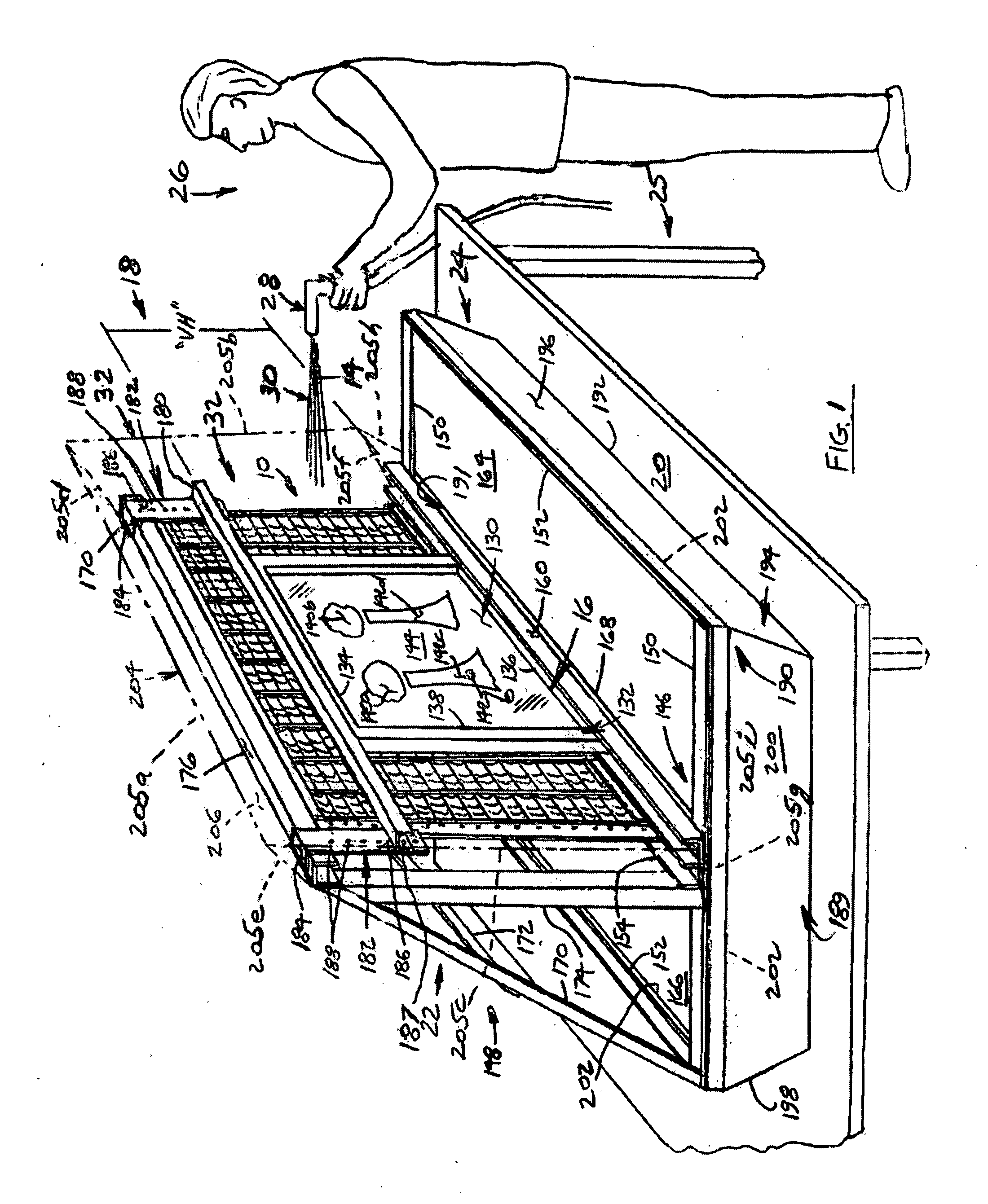

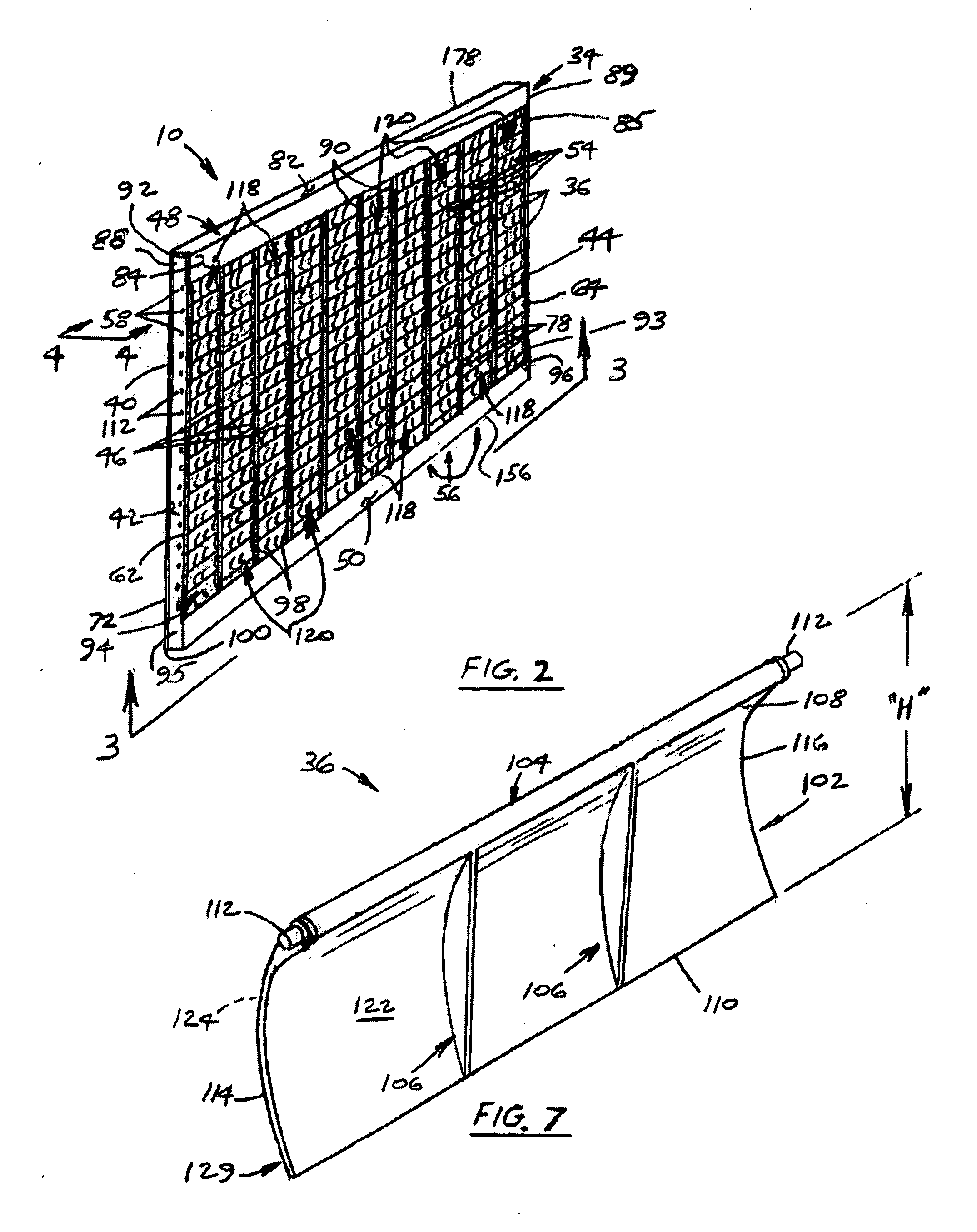

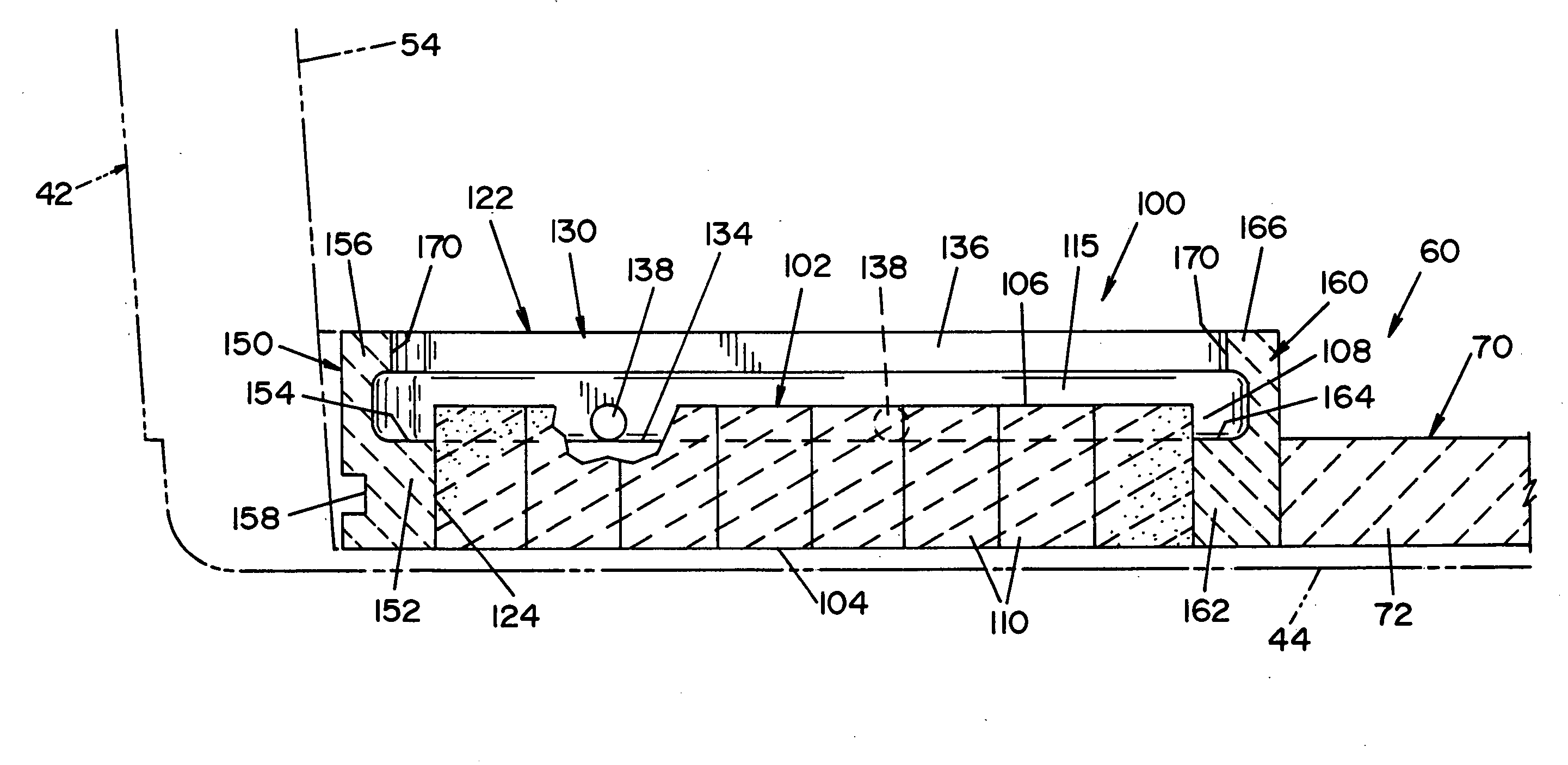

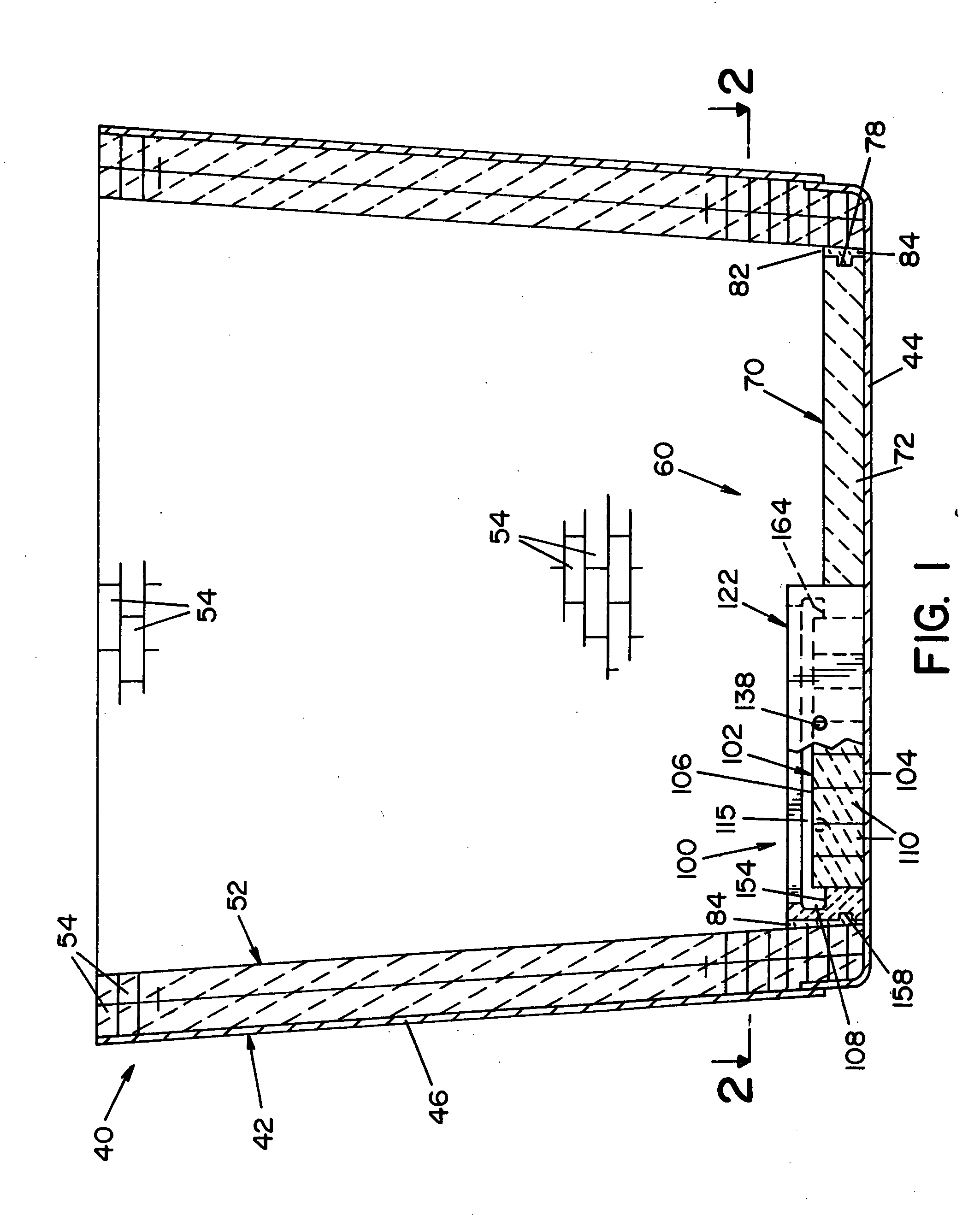

Louvered spray guard for trapping overspray during spray washing of silk screens

InactiveUS20050241674A1Minimizes splashingReduce momentumElectrostatic cleaningDirt cleaningBraced frameCollection system

A louvered spray guard for receiving and trapping overspray during spray washing of ink from silk screens. The spray guard includes an upright support frame with a rectangular backing sheet sized to stop overspray behind the silk screen. A plurality of narrow vertical strips are affixed edgewise to the backing sheet forming a plurality of vertical channels. A plurality of rectangular deflector blades are pivotally mounted between the vertical members spaced forward of the backing sheet hanging downwardly in slightly overlapping manner. The blades are biased to a closed position by gravity to cover the backing sheet. A transverse angle member seals off upper ends of the channels. A transverse strip across the lower front of the vertical strips leaves bottom ends of the channels open for discharge of trapped overspray. Momentum of the overspray contacting the blades causes individual rearward pivoting thereof to an open position during contact to pass the overspray downwardly through the channels without splashing off the backing sheet. A spray collection system utilizes the spray guard along with a main frame to support the spray guard and the silk screen in a vertical position. The overspray drains from the spray guard into a collection tank for subsequent disposal.

Owner:DEMCHUK JAMES W

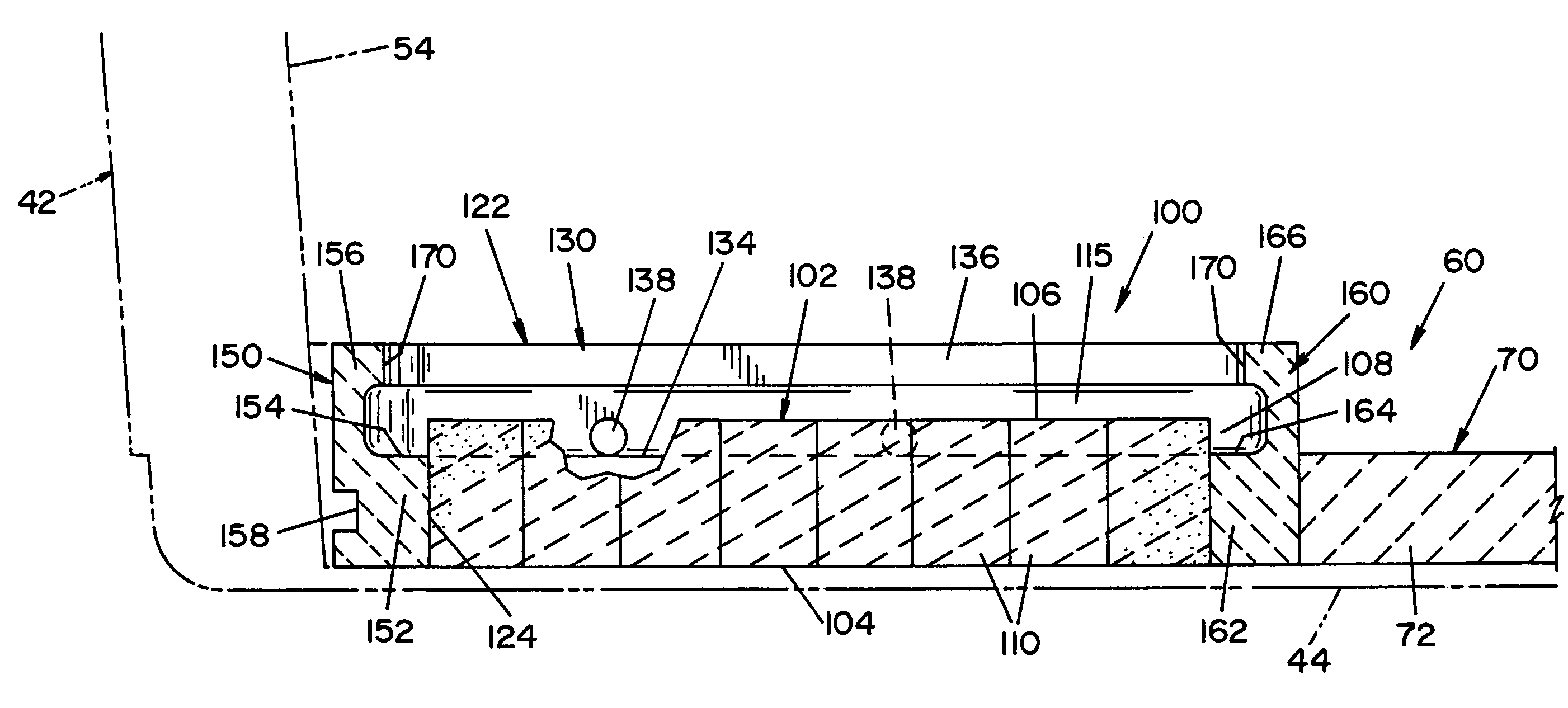

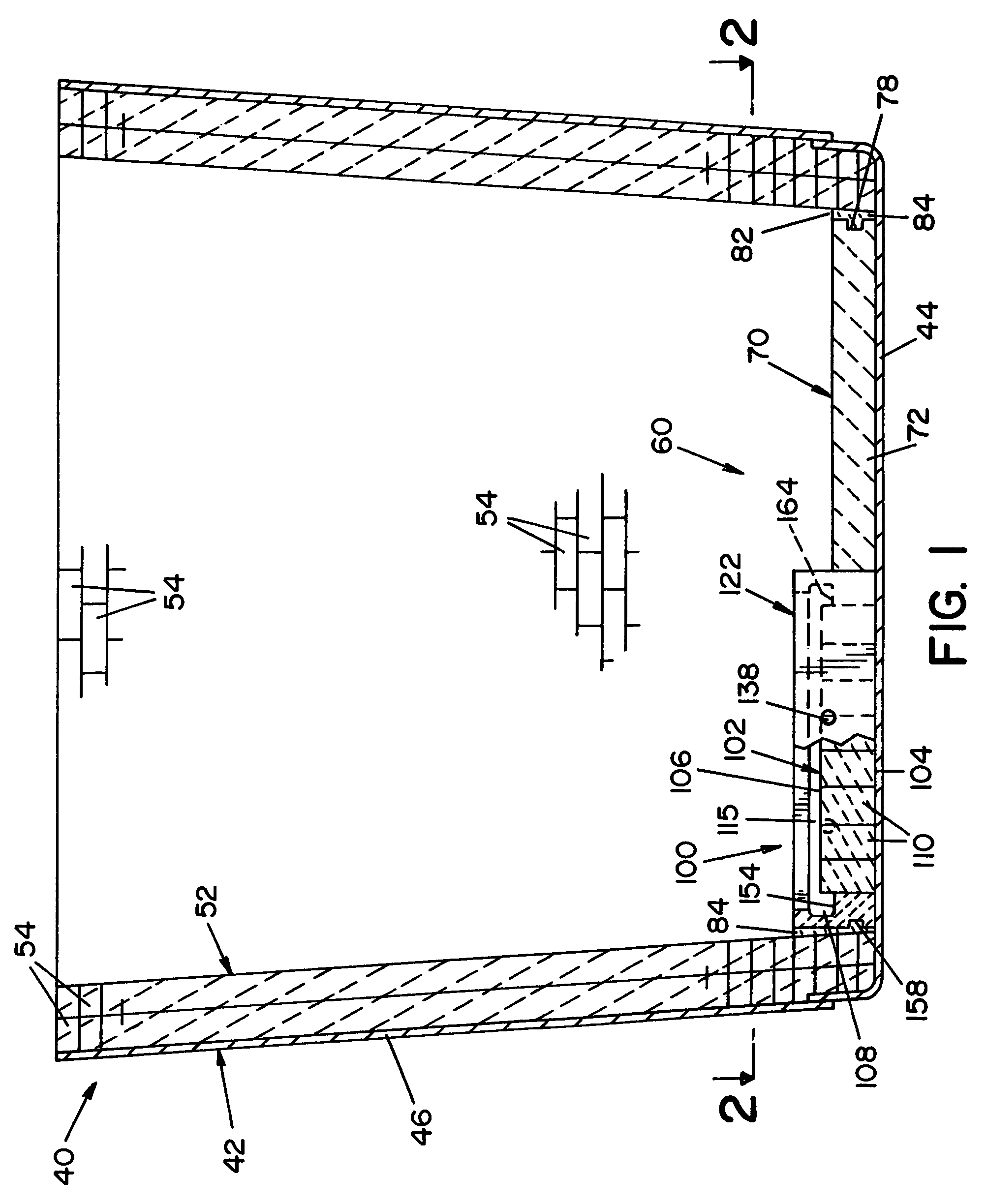

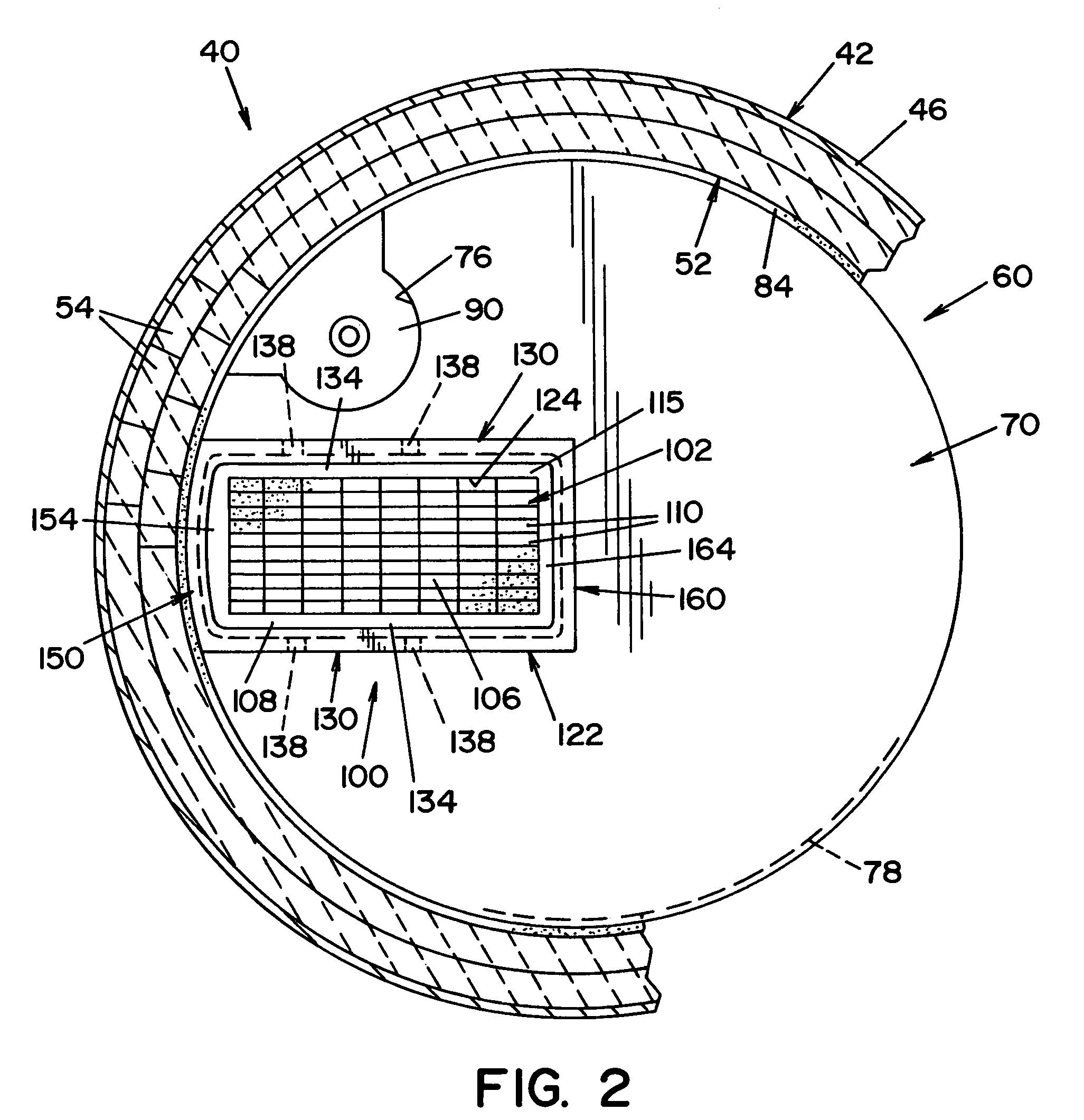

Impact pad for metallurgical vessels

InactiveUS20070132162A1Reduce wearMinimizes splashingMelt-holding vesselsBlast furnace componentsMolten metalMaterials science

An impact pad for a bottom lining of a metallurgical vessel, such as a ladle. The impact pad reduces wear to side walls of the metallurgical vessel by controlling the flow of an incoming stream of molten metal to minimize splashing and turbulence. The impact pad includes a frame portion and a bottom wall portion. The frame portion and bottom wall portion define an interior cavity for receiving the stream of molten metal.

Owner:NORTH AMERICAN REFRACTORIES

Combination Potty and Child Car Seat

InactiveUS20160037980A1Improve securityEasy to replaceBathroom accessoriesChild seatsEngineeringCushion

The present invention relates to an automobile child safety seat that includes a potty feature allowing the containment of a child's urine and excrement discharge in a container under the seating cushion and in which the potty feature, after being unfixed, can slide out forward for access to the collected discharge. Further, the present invention is directed to an automobile child safety seat that easily converts to a potty by the convenient removal of the seating cushion to gain access to an opening to discharge a child's urine and excrement into the container.

Owner:CARROLL EDWARD W +1

Controlled gastric bolus feeding device

A gravity bolus feeding device having a cylindrical body with and intake valve to control or prevent flow of fluid through the feeding device. The device also has a check valve to receive fluids expelled from the patient back into the feeding device. The check valve allows such fluids to rejoin the fluid path and be re-fed to the patient, while allowing air to vent. A burp baffle for use with this or another feeding device to prevent spillage or splashing, while taking in or venting air. The burp baffle has a bottom section which snugly fits into the device, with a notch or opening near its outer periphery, allowing fluid to pass. A center section connected to the bottom section allows fluid to flow around it and into an opening generally opposite the notch. A top section covers the feeding device, and has a hole that allows fluid to vent out the top of the feeding device.

Owner:OCTIC MEDICAL DEVICES

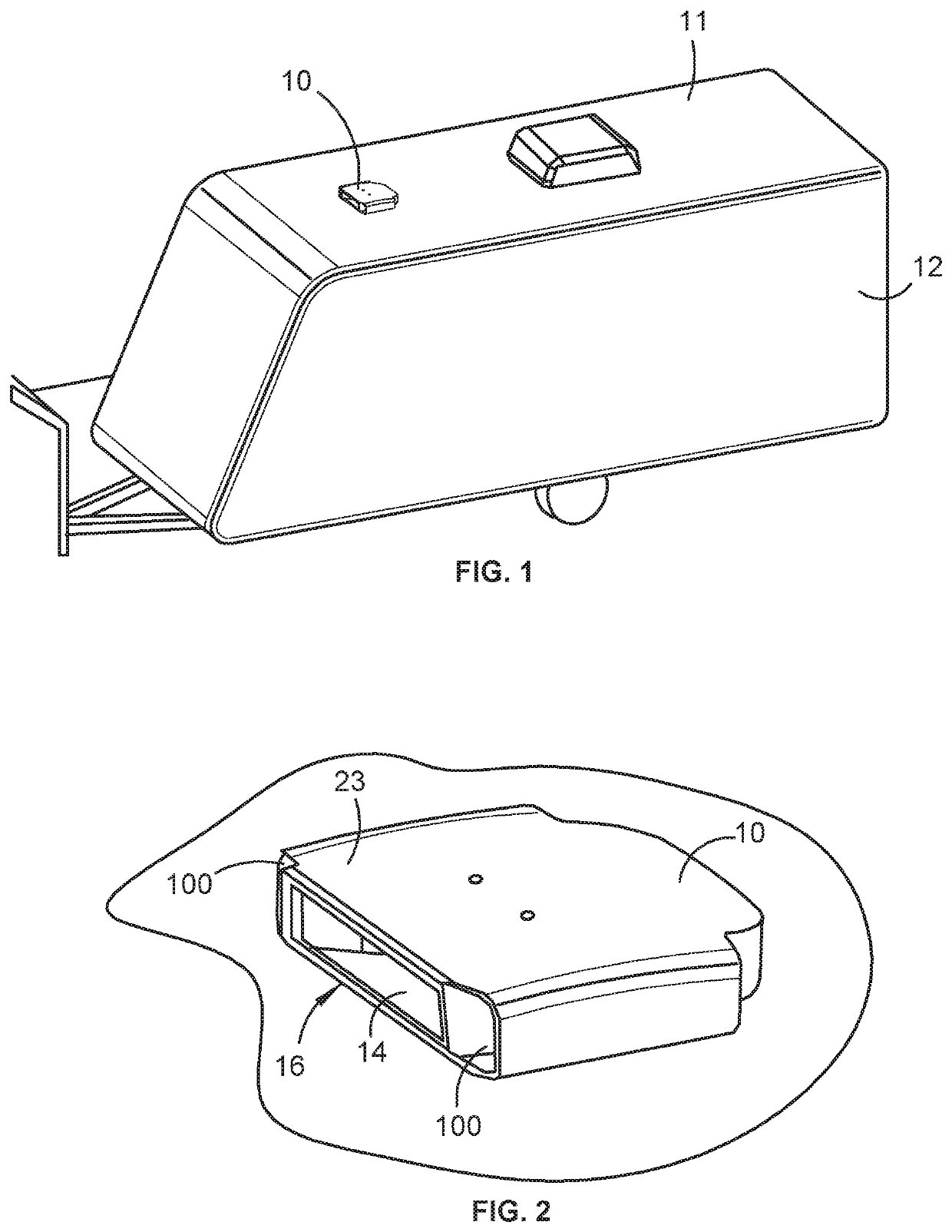

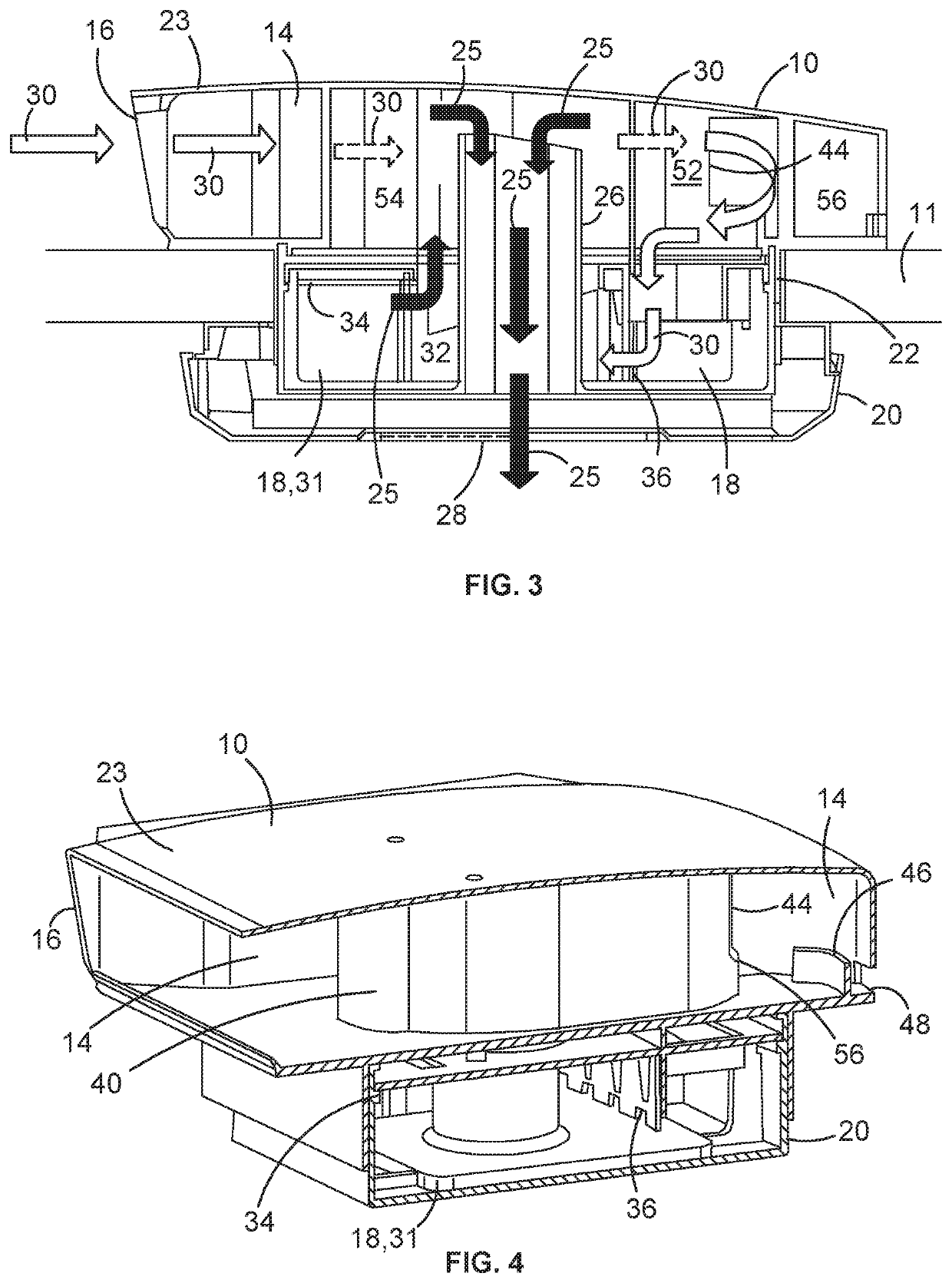

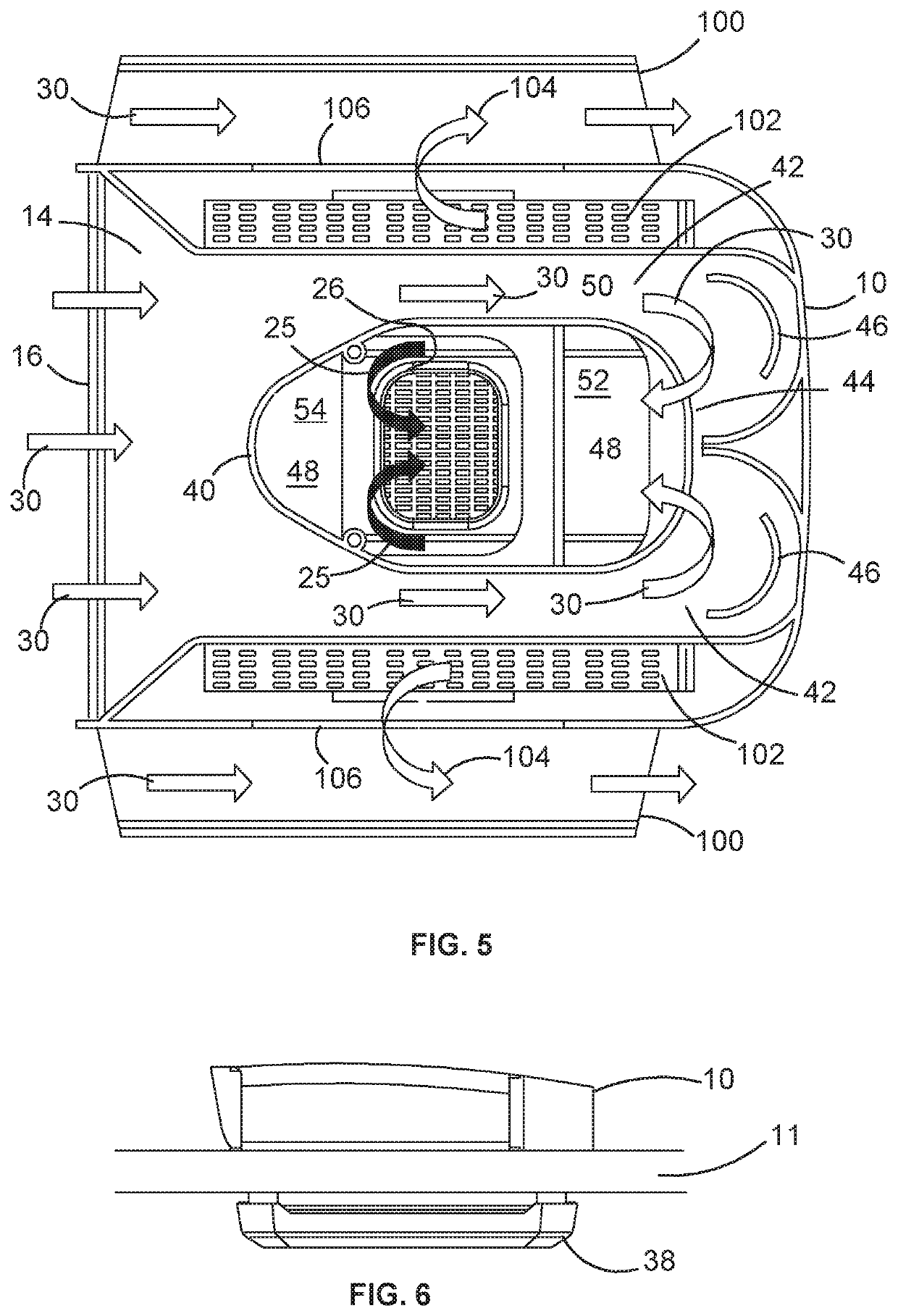

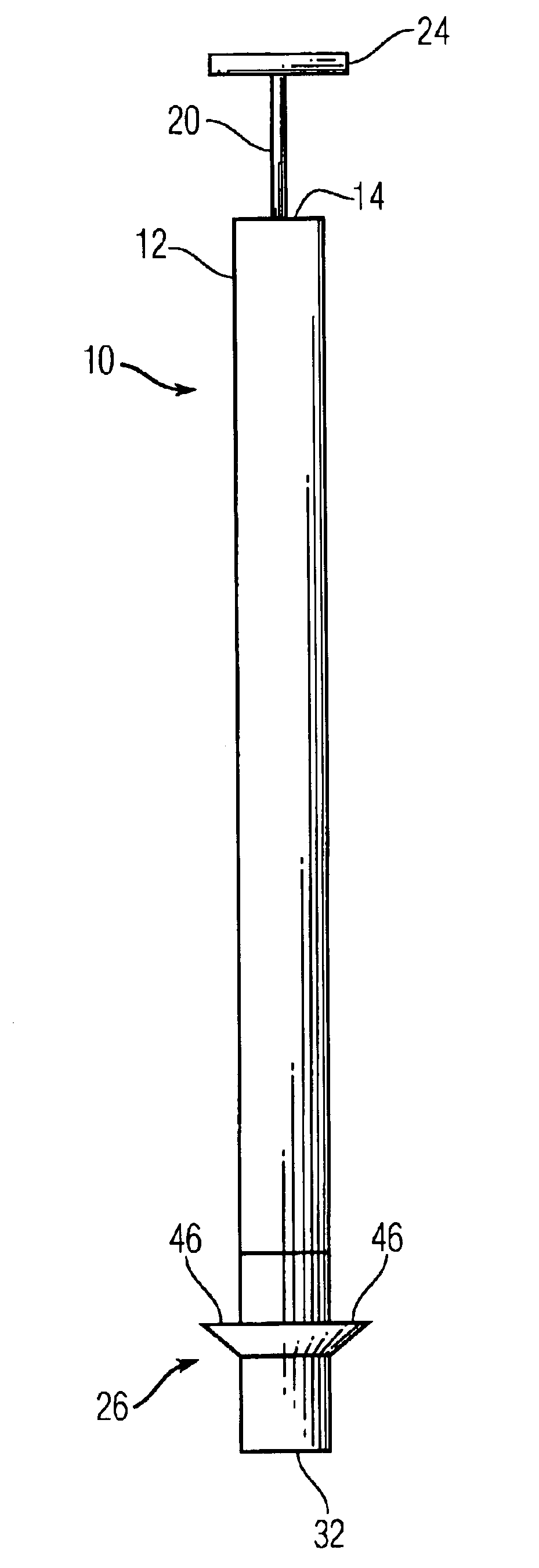

Positive Pressure Vent for a Vehicle

ActiveUS20200215879A1Minimizes splashingHigh speedAir-treating devicesVehicle heating/cooling devicesParticulatesMechanics

According to the invention, there is provided a positive pressure vent (10) for a vehicle (12). The vent (10) includes an inlet chamber (14) having an air intake port (16) facing into an air stream generated by motion of the vehicle (12) so as to collect air and form a positive pressure inside the inlet chamber (14). There is further provided a filter (18) adapted to filter air from the inlet chamber (14) of particulate matter. A filtered air path (25) is further provided for allowing filtered air from the filter (18) to travel to the interior of the vehicle (12) under the urging of the positive pressure from the inlet chamber (14).

Owner:DOMETIC APPLIANCES

Method and apparatus for polishing a substrate while washing a polishing pad of the apparatus with at least one free-flowing vertical stream of liquid

InactiveUS20050107012A1Reduce reboundEliminating polishing-pollutantsGrinding drivesBelt grinding machinesEngineeringSlurry

Owner:JAE MAN HO +1

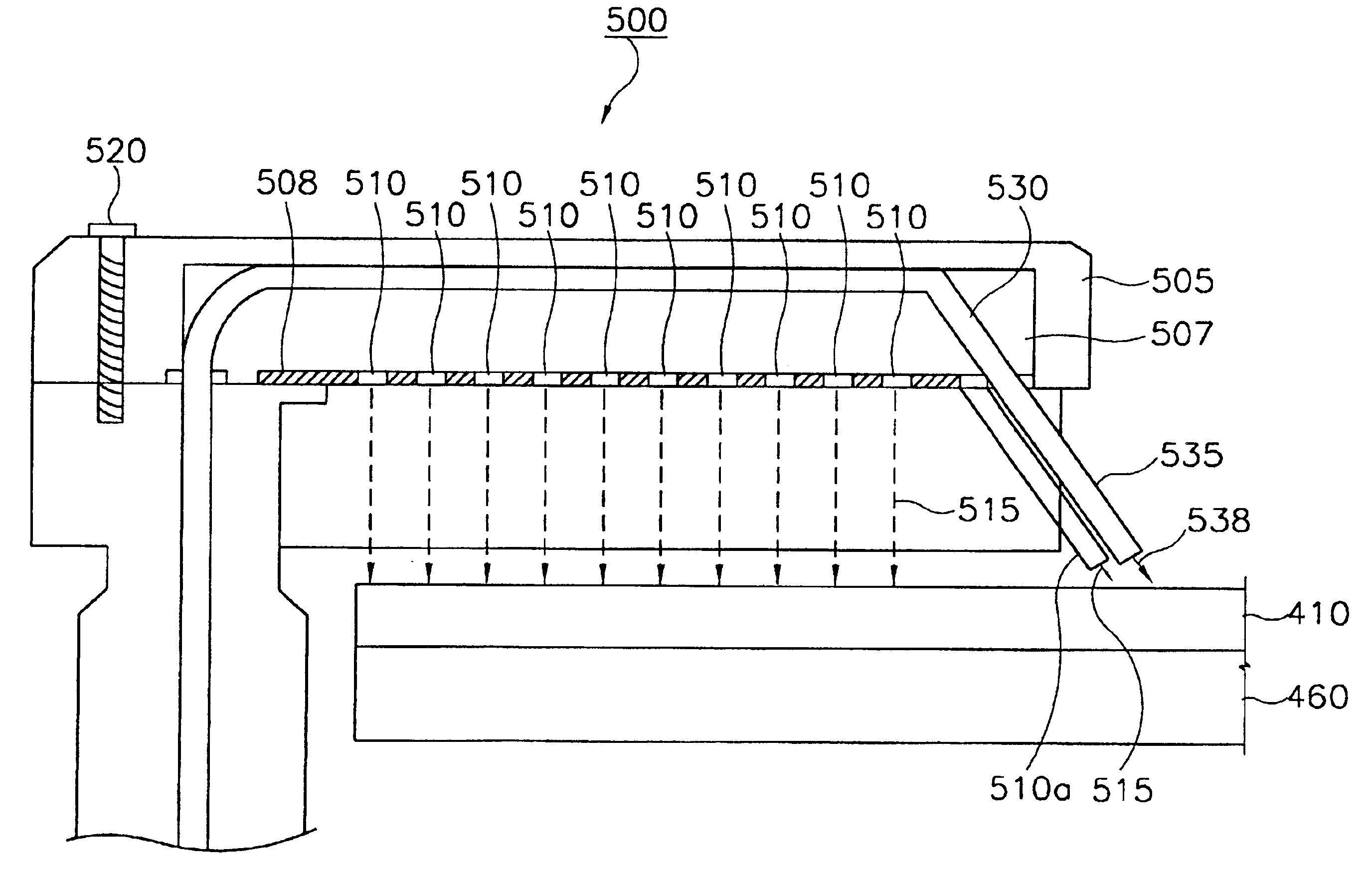

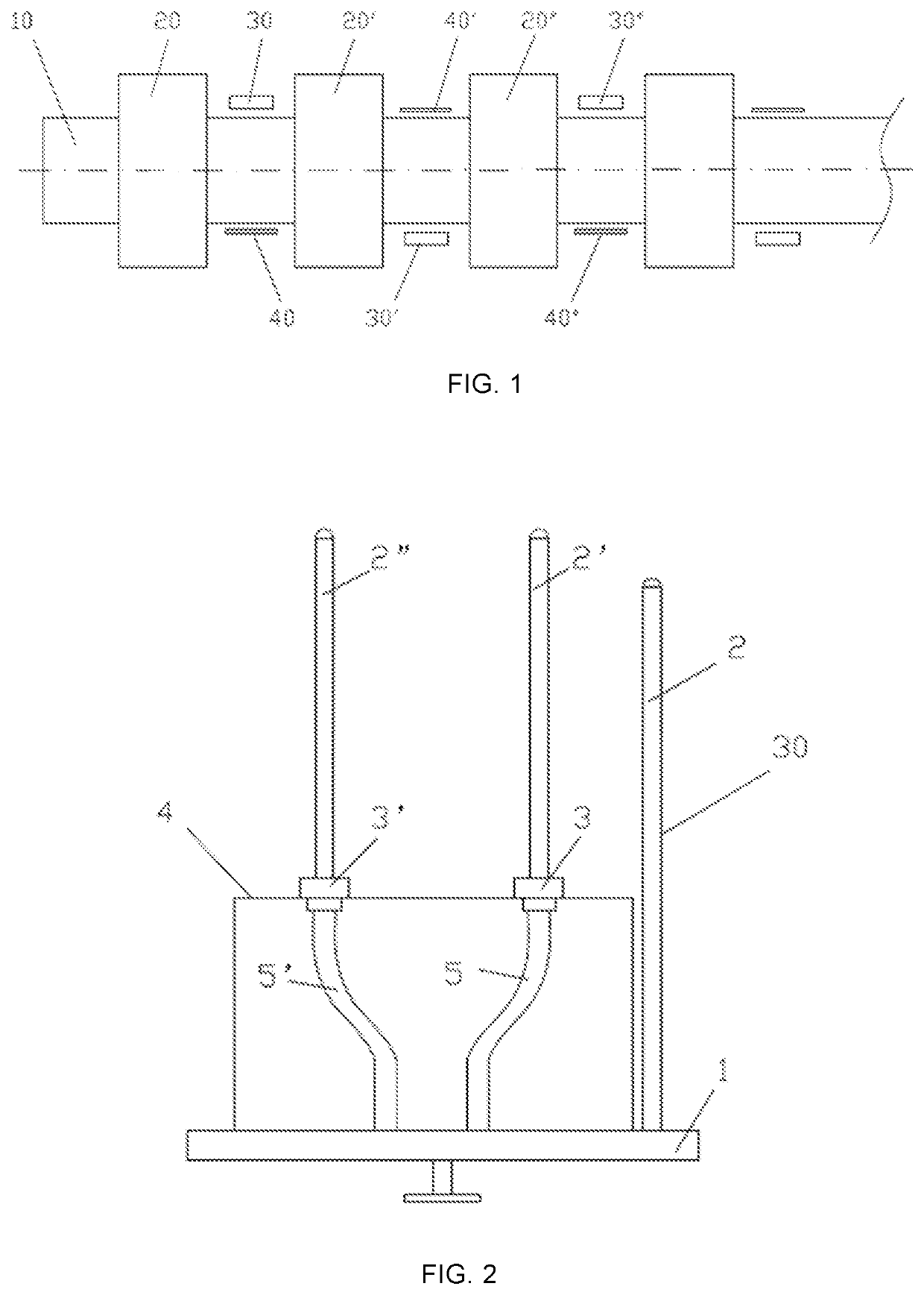

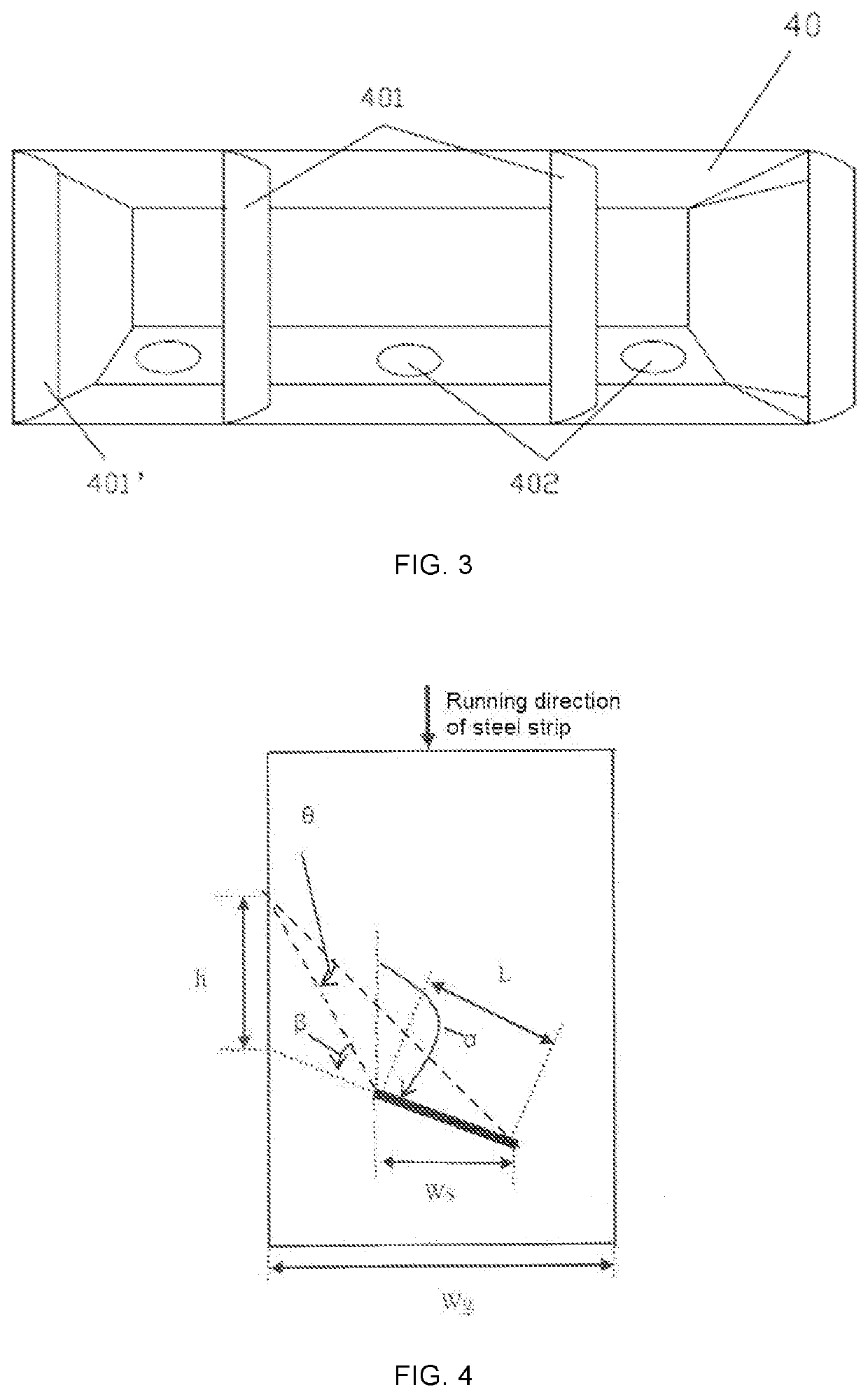

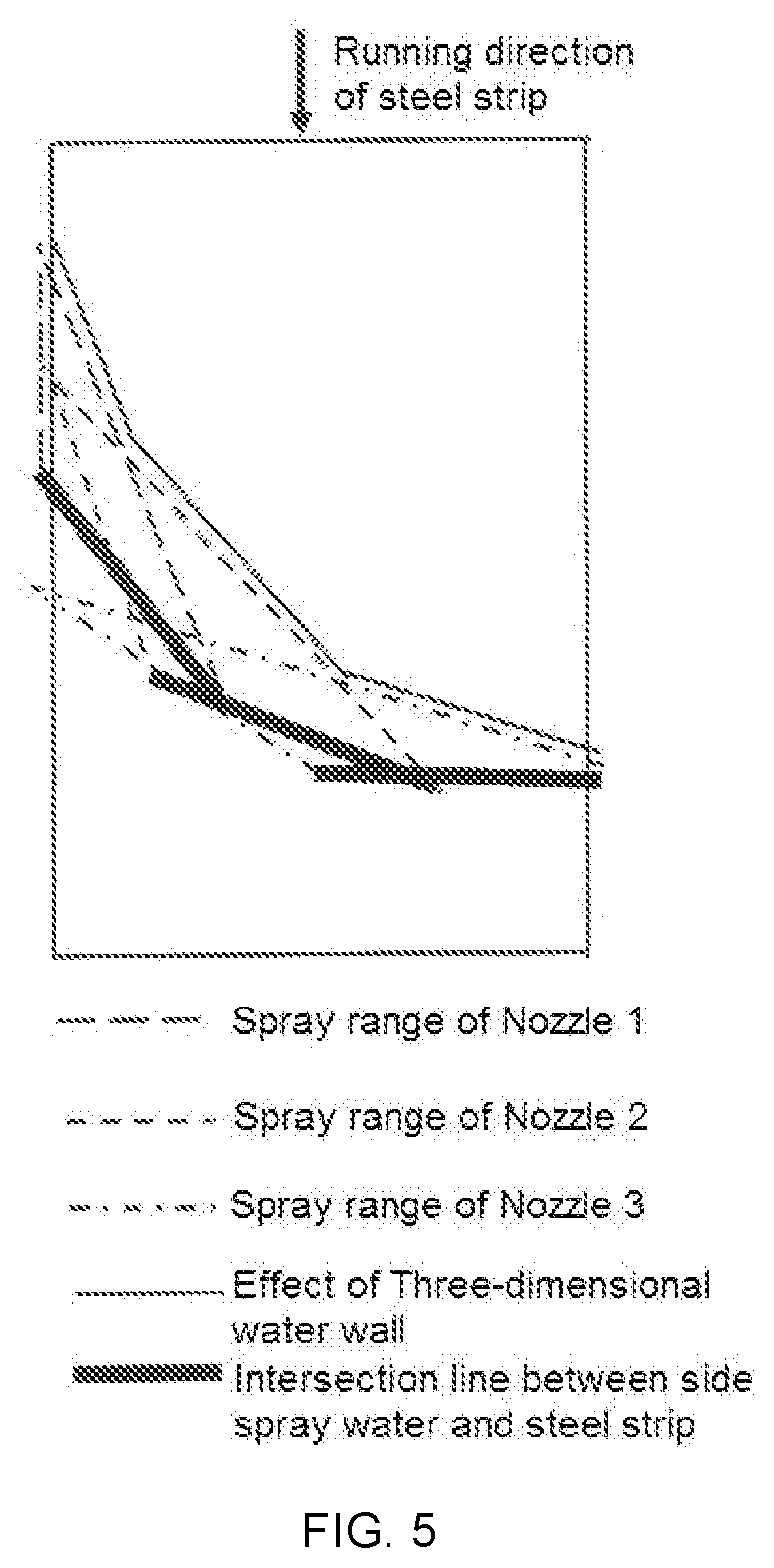

A side spray method for cooling the steel strip after hot rolling

ActiveUS20210078061A1Minimizes splashingImprove uniformityTemperature control deviceFurnace typesEngineeringStructural engineering

Aside spray method for cooling the steel strip after hot rolling, comprising the following steps: a) providing side spray devices (30, 30′, 30″) behind each of cooling sections after hot rolling (20, 20′, 20″), the side spray devices being staggered along the two sides of an run out roller table (10), each side spray device comprising at least two spray units, each spray unit comprising spray tubes (2, 2′, 2″) and nozzles on the tubes, the spray tubes being in parallel and vertically arranged along running direction of the steel strip, the covering ranges of adjacent nozzles are partially overlapped, and a total spray coverage of nozzles covers the width of the entire run out roller table; side spray water collecting devices (40, 40′, 40″) are provided on the other side of the run out roller table that is opposite to side spray devices, so that side spray water being collected by the water collecting devices; b) controlling the side spray devices in a mode of open-in-pairs, i.e., side spray devices on either side of the run out roller table must be started simultaneously. The side spray method can effectively purge the residual water on the surface of steel strip having different width specifications, improves the cooling uniformity, and reduces splashes as far as possible to avoid adverse effects on the environment and electrical equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

Impact pad for metallurgical vessels

InactiveUS7468157B2Reduce wearMinimizes splashingMelt-holding vesselsBlast furnace componentsMolten metalMaterials science

An impact pad for a bottom lining of a metallurgical vessel, such as a ladle. The impact pad reduces wear to side walls of the metallurgical vessel by controlling the flow of an incoming stream of molten metal to minimize splashing and turbulence. The impact pad includes a frame portion and a bottom wall portion. The frame portion and bottom wall portion define an interior cavity for receiving the stream of molten metal.

Owner:NORTH AMERICAN REFRACTORIES

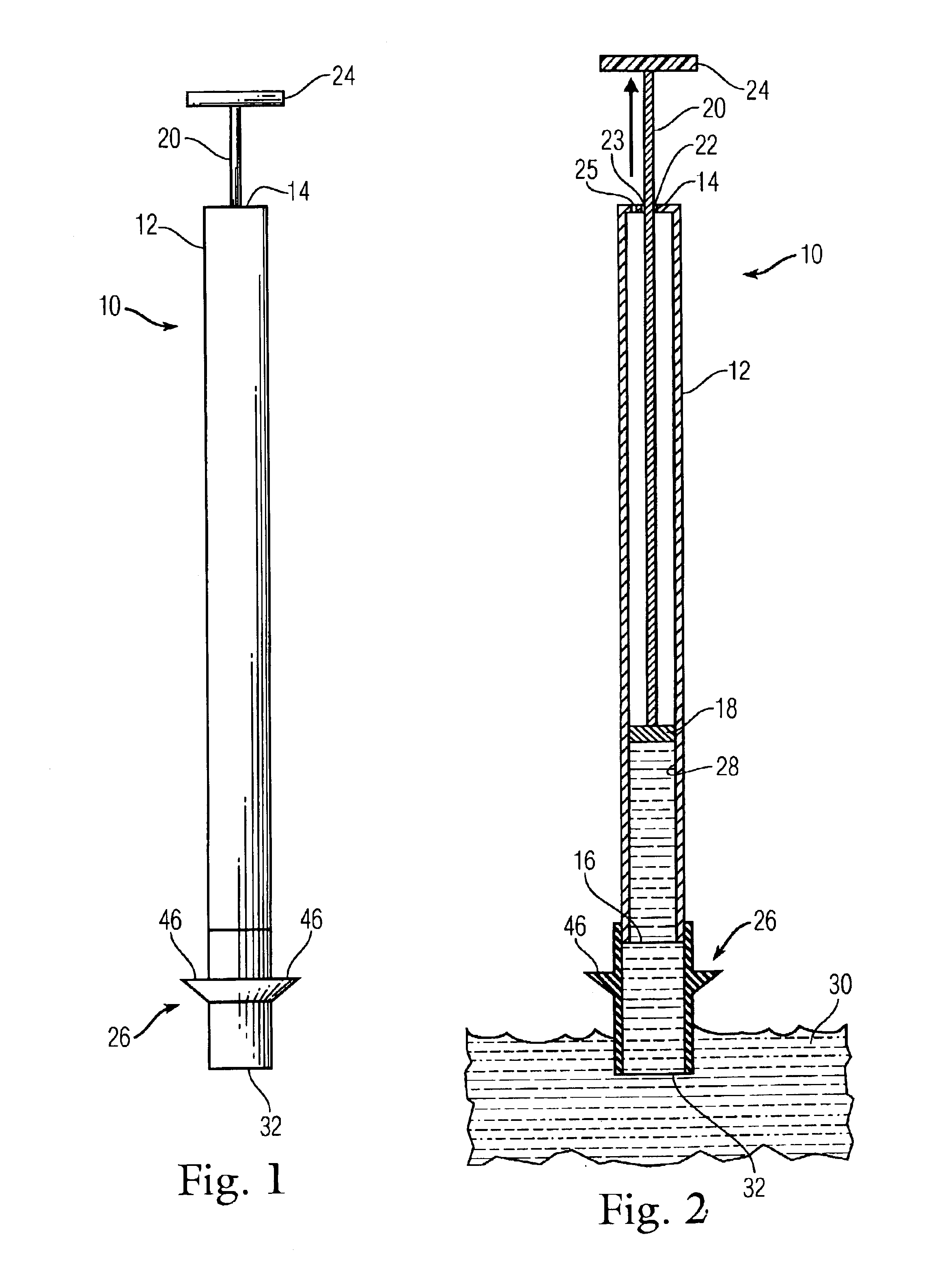

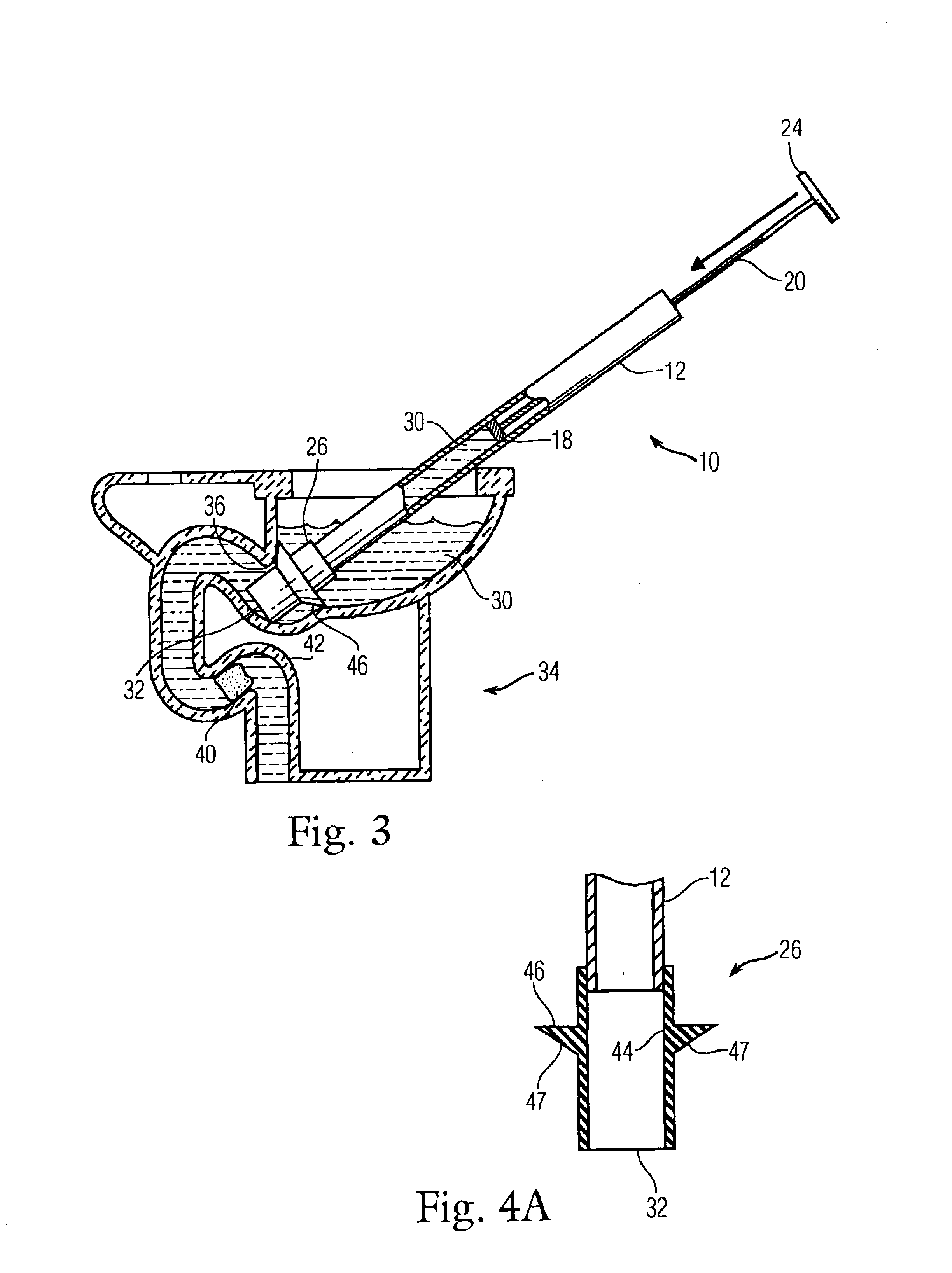

Piston type drain clearing apparatus

InactiveUS6895606B2Increase the applied forceMinimizes splashingDomestic plumbingLavatory sanitoryReciprocating motionEngineering

An apparatus for clearing a clog in a pipe having a diameter, the apparatus including a hollow, rigid cylindrical body, the body having a closed end, an open end and an inside diameter that is less than the diameter of the pipe at the clog thereby providing a mechanical advantage in removing the clog; a piston disposed in the body for reciprocation therein; a rod attached to the piston and extending through an opening in the closed end of the body; a handle located on an upper portion of the rod; and a seal attached to the open end of the body.

Owner:WALSH PATRICK JAMES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com