Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Low luminous efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

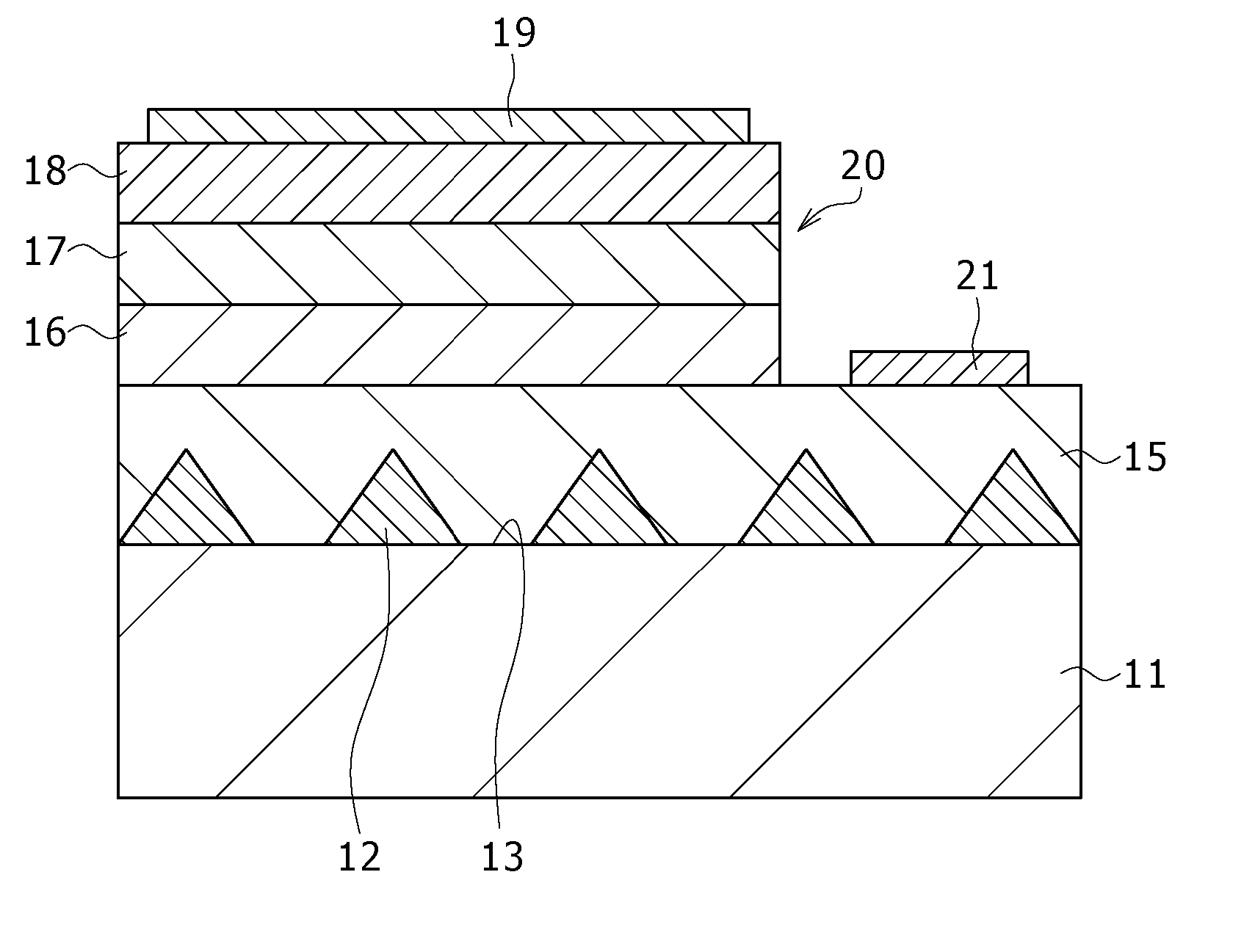

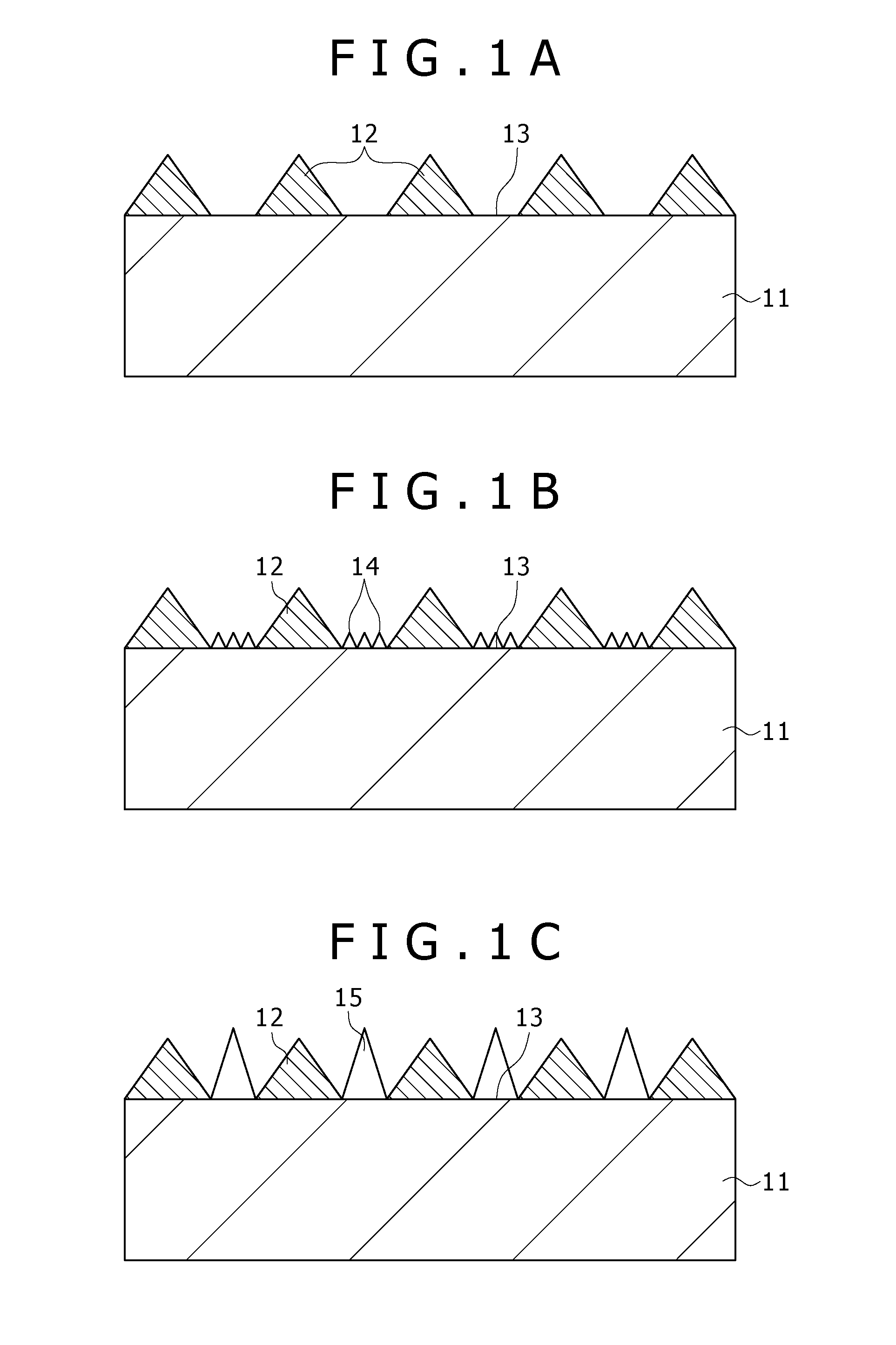

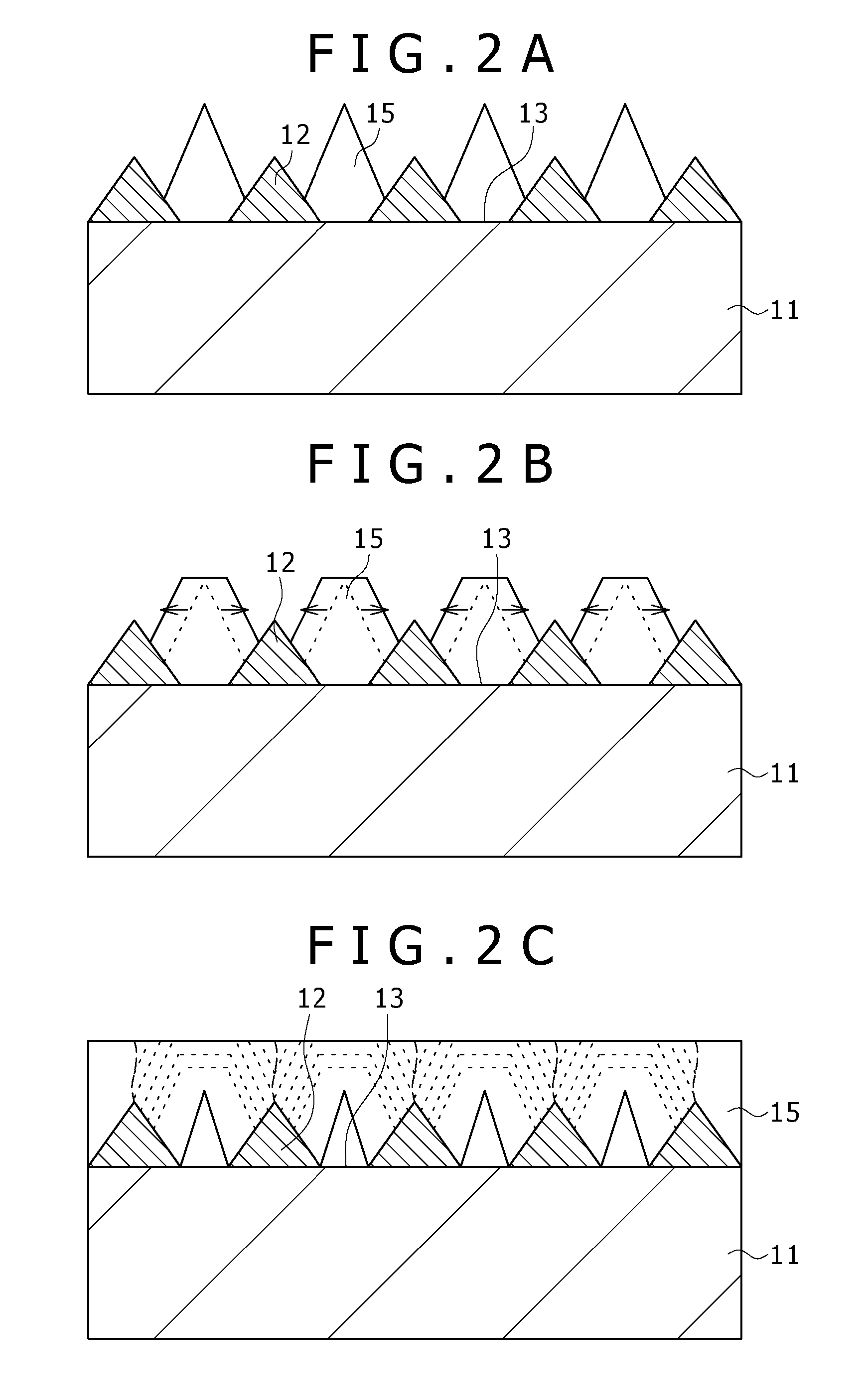

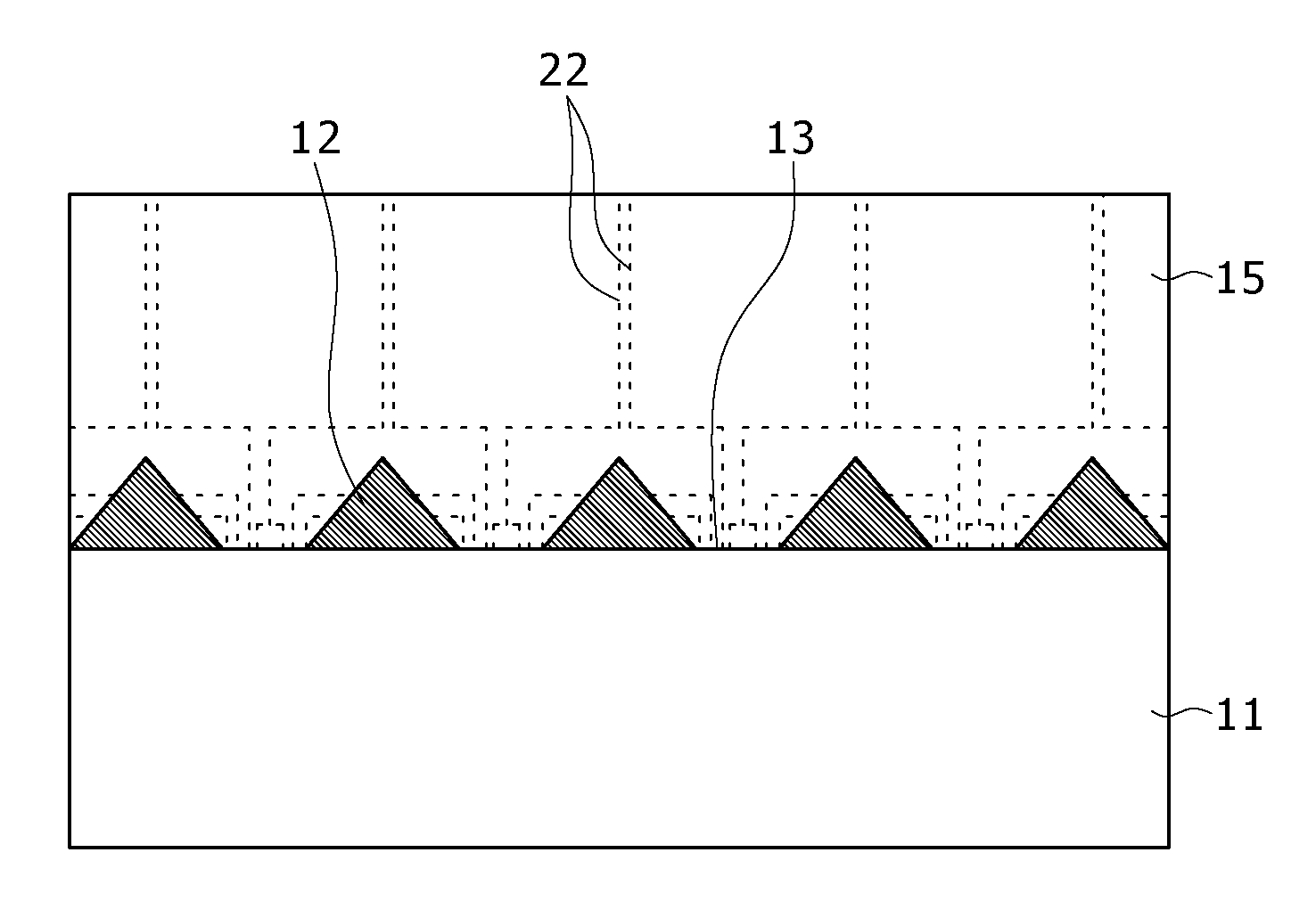

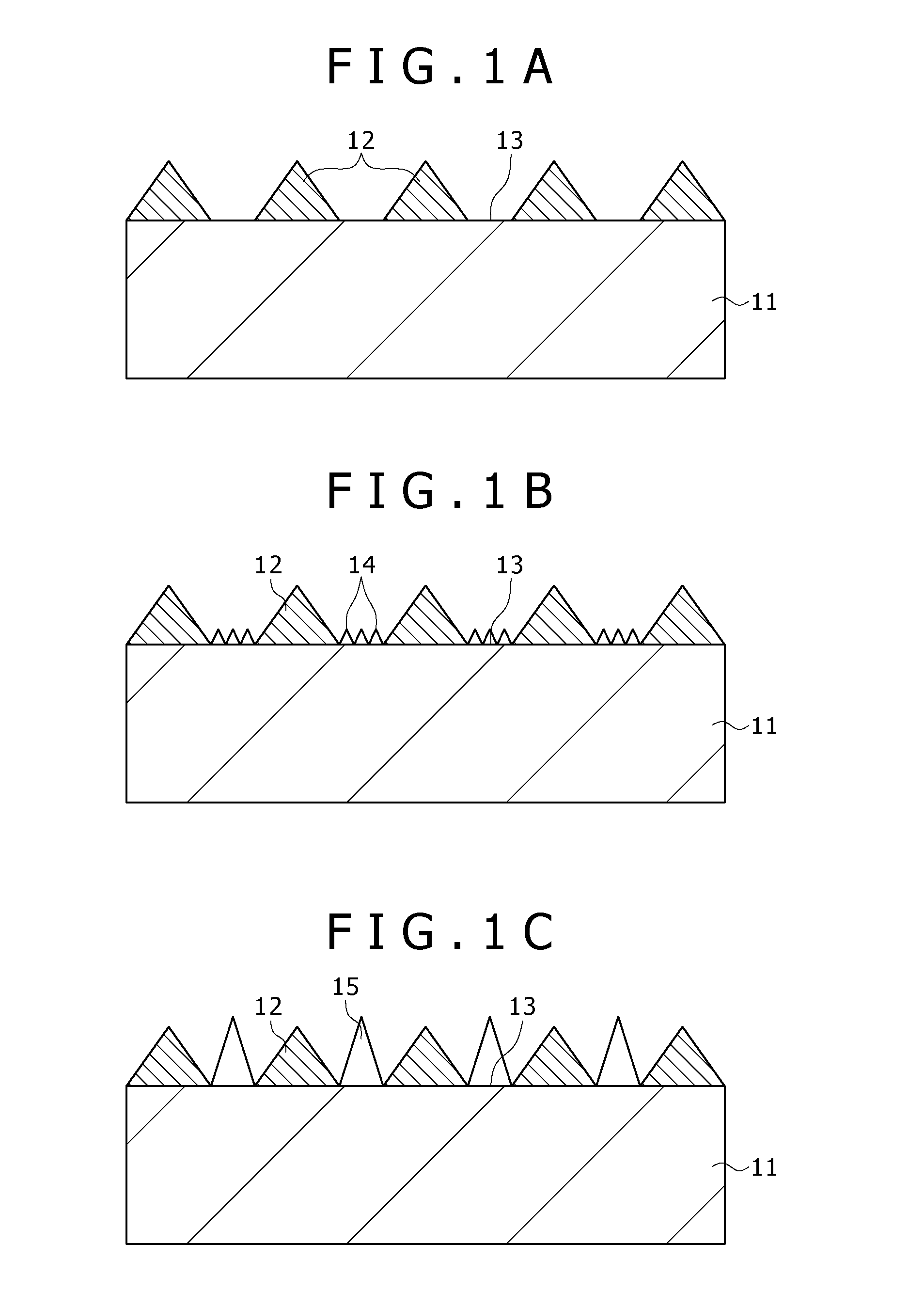

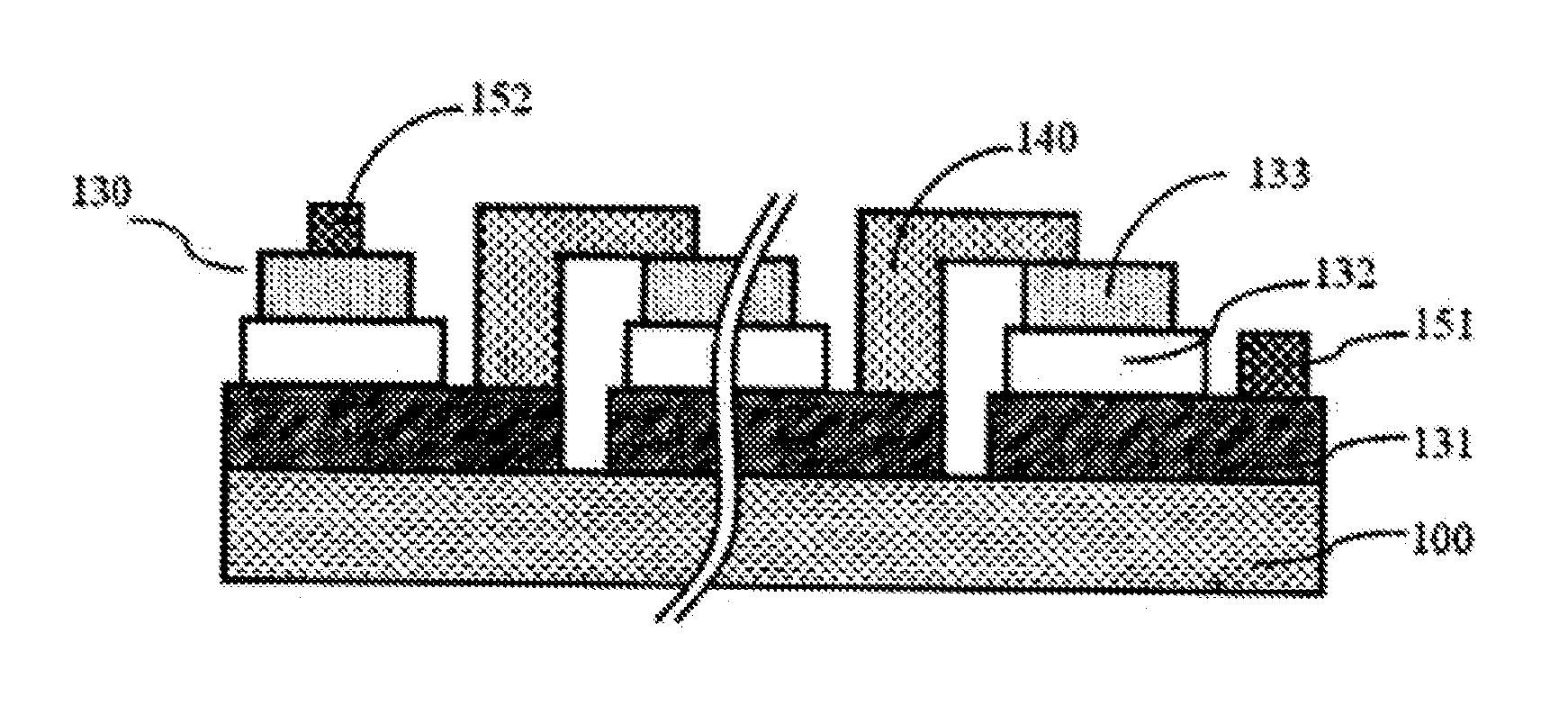

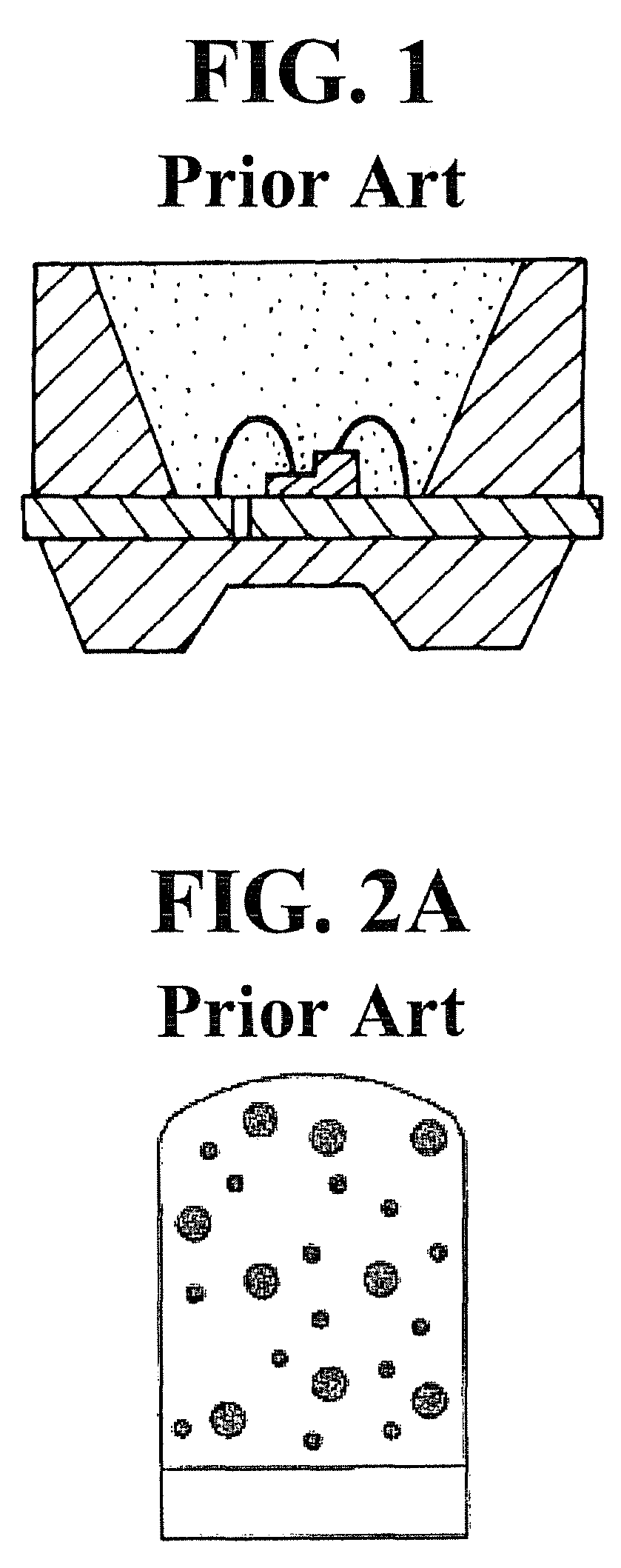

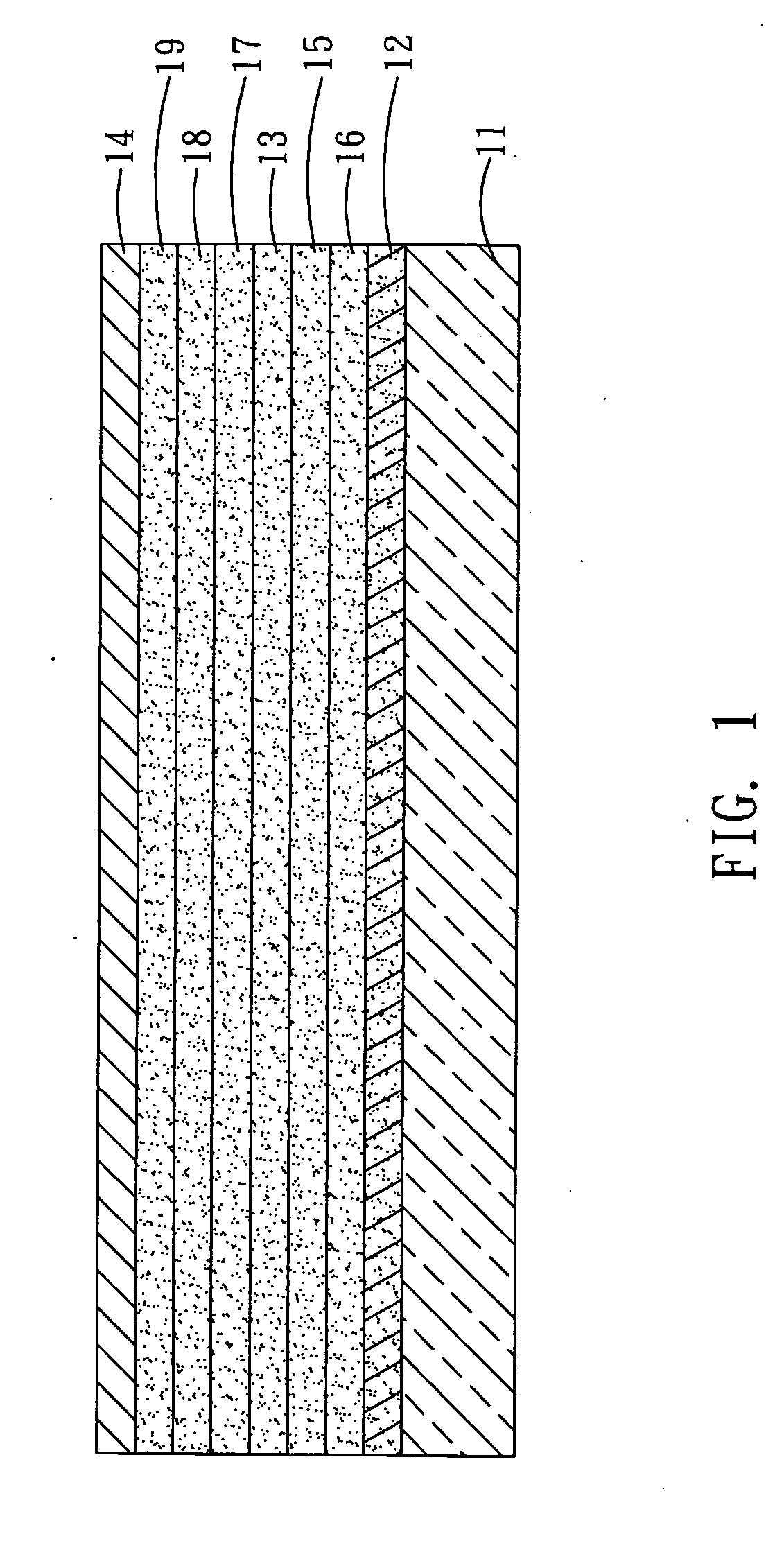

Light-emitting diode and method for manufacturing same, integrated light-emitting diode and method for manufacturing same, method for growing a nitride-based iii-v group compound semiconductor, substrate for growing a nitride-based iii-v group compound semiconductor, light source cell unit, light-emitting diode backlight, light-emitting diode illuminating device, light-emitting diode display and electronic instrument, electronic device and method for manufacturing same

InactiveUS20070085093A1Low luminous efficiencyLight extraction efficiencyPolycrystalline material growthSolid-state devicesDisplay deviceEngineering

A method for manufacturing a light-emitting diode, which includes the steps of: providing a substrate having a plurality of protruded portions on one main surface thereof wherein the protruded portion is made of a material different in type from that of the substrate and growing a first nitride-based III-V Group compound semiconductor layer on each recess portion of the substrate through a state of making a triangle in section wherein a bottom surface of the recess portion becomes a base of the triangle; laterally growing a second nitride-based III-V Group compound semiconductor layer on the substrate from the first nitride-based III-V Group compound semiconductor layer; and successively growing, on the second nitride-based III-V Group compound semiconductor layer, a third nitride-based III-V Group compound semiconductor layer of a first conduction type, an active layer, and a fourth nitride-based III-V compound semiconductor layer of a second conduction type.

Owner:SONY CORP

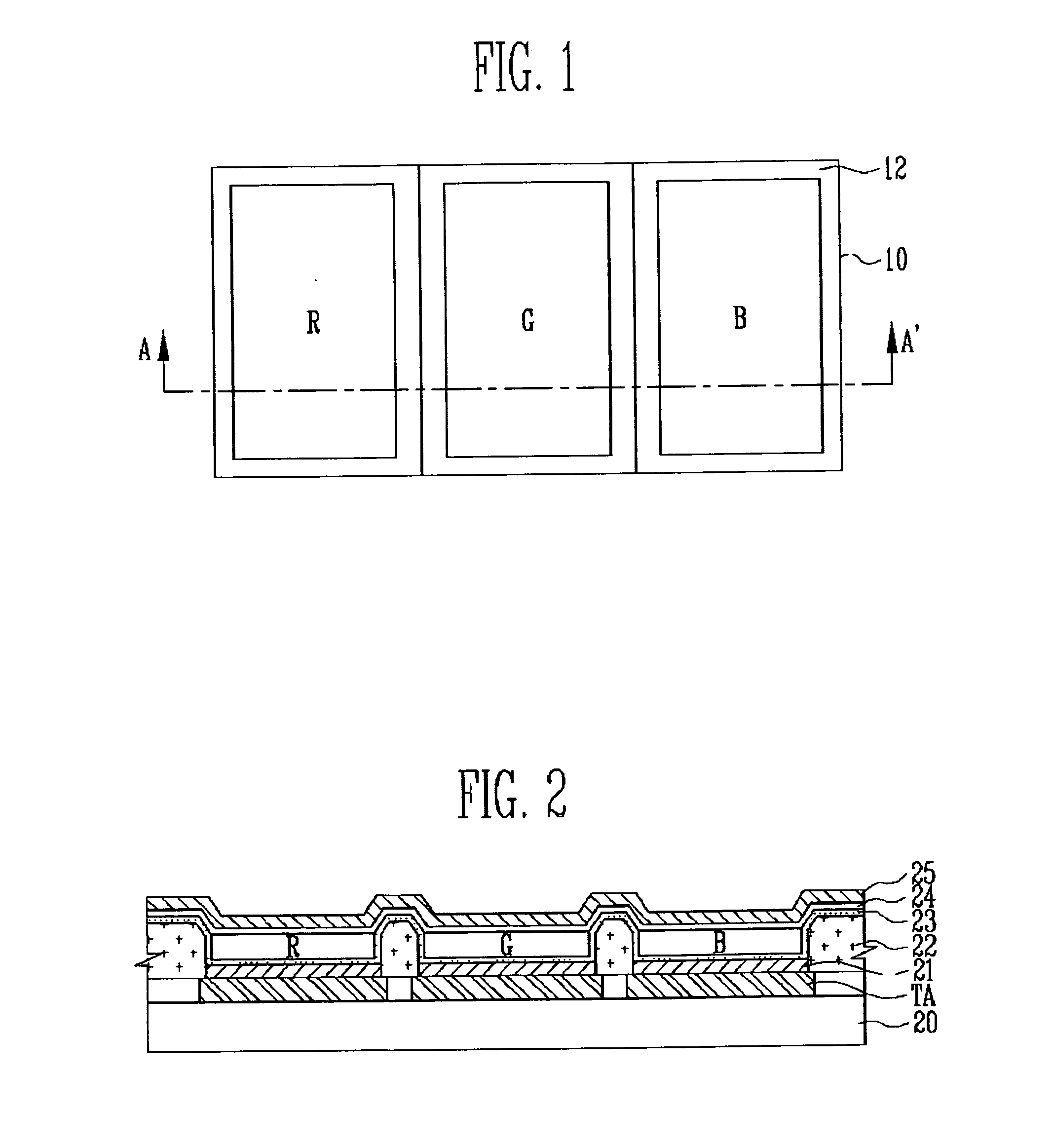

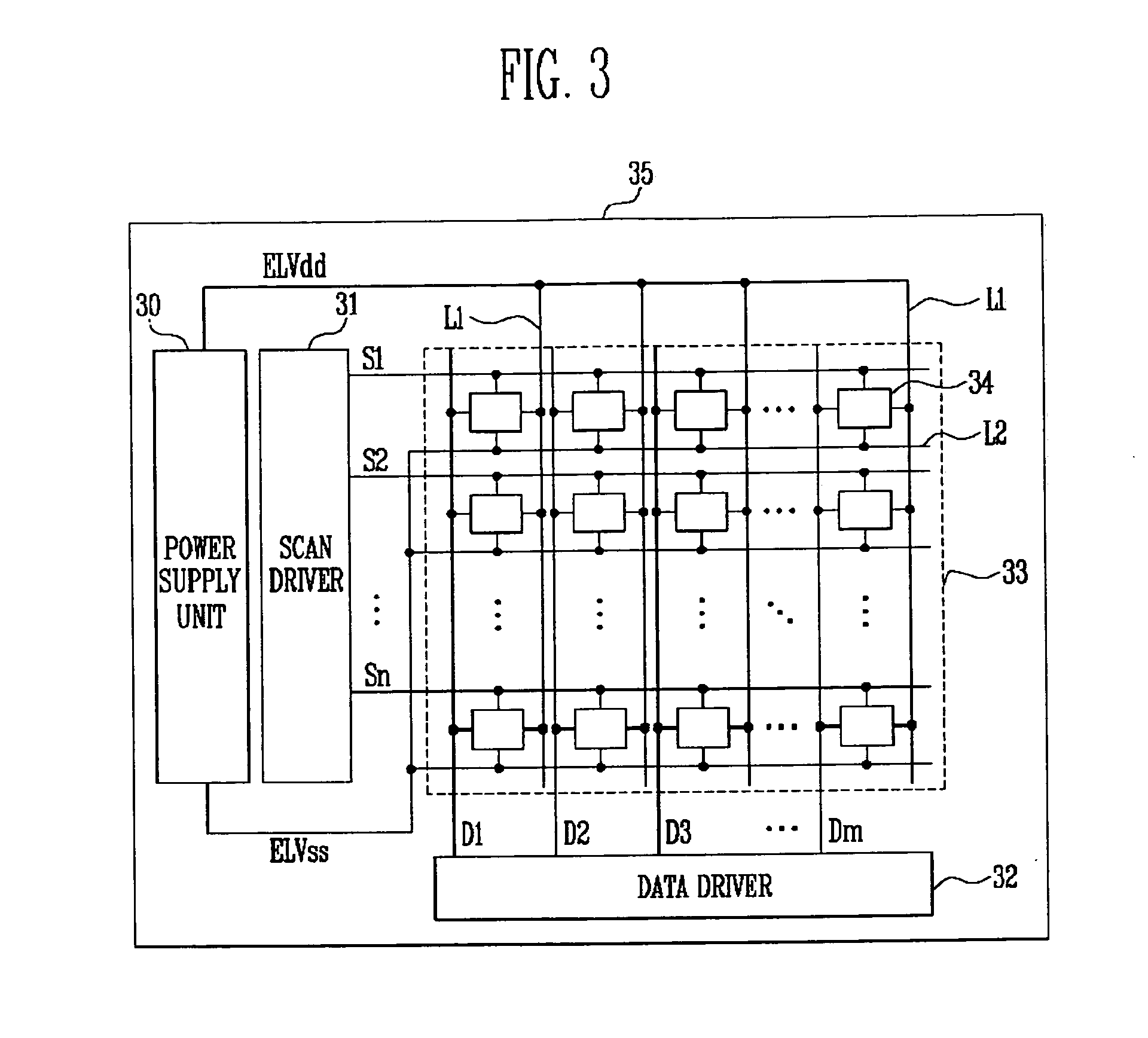

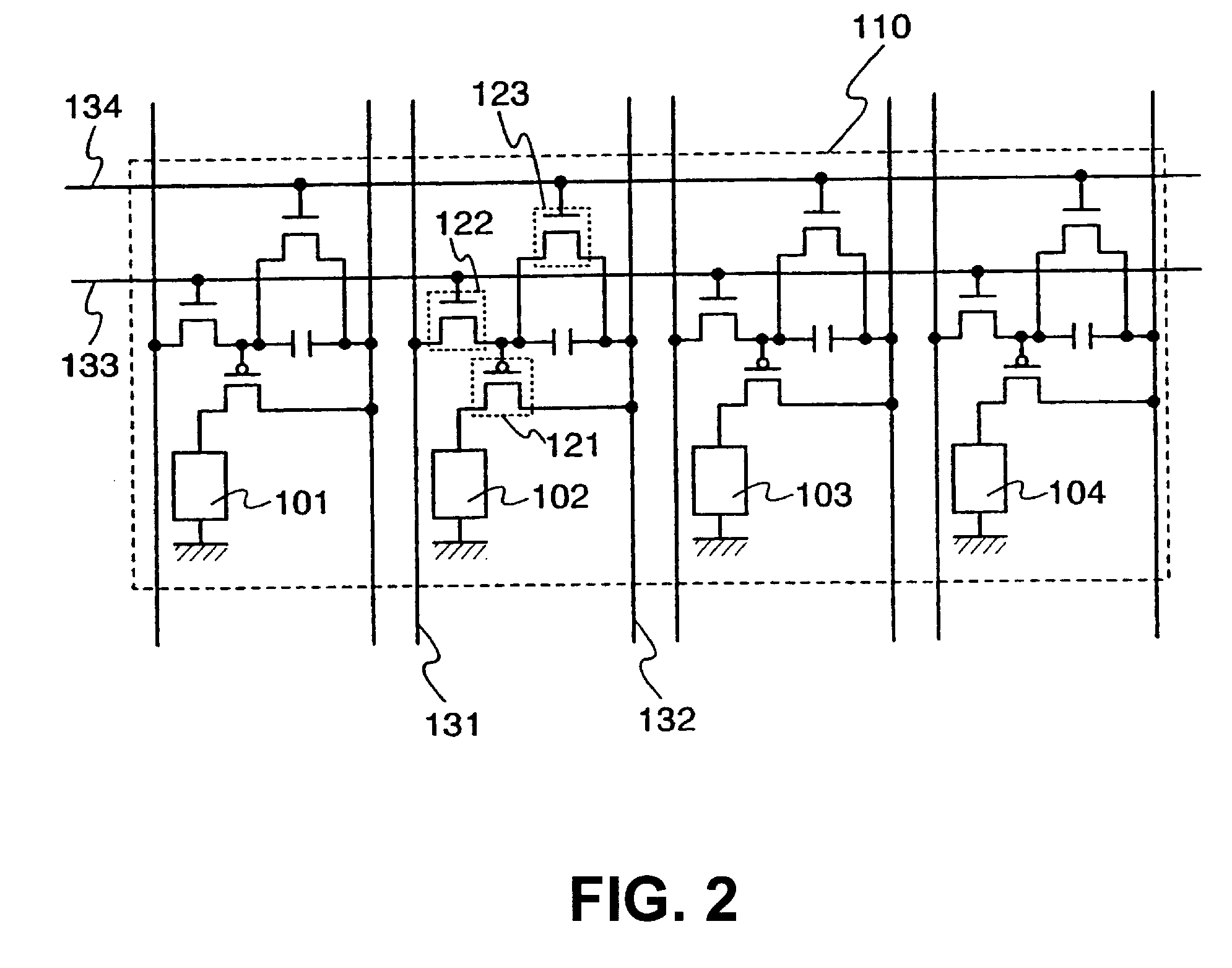

Organic light emitting display and method for fabricating the same

InactiveUS20070046185A1Extend your lifeLow luminous efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesImage resolutionDisplay device

In an organic light emitting display and a method for fabricating the same, a layout of respective pixels is changed in order to improve life span so that one pixel region having low luminous efficiency is increased. The organic light emitting display includes at least one pixel comprising sub pixels having a plurality of colors. A first sub pixel emission layer is formed over an entire surface of a pixel region. At least two second sub pixel emission layers are formed at the first sub pixel emission layer so as to have a closed curve. The layout of respective pixels is changed so as to increase an area of one sub pixel region having low luminous efficiency in order to improve the life span and aperture ratio of the organic light emitting display. In addition, during formation of an emission layer, the number of masks is reduced. Accordingly, the possibility of misalignment is reduced, thereby maximizing resolution, improving yield, and reducing manufacturing cost.

Owner:SAMSUNG DISPLAY CO LTD

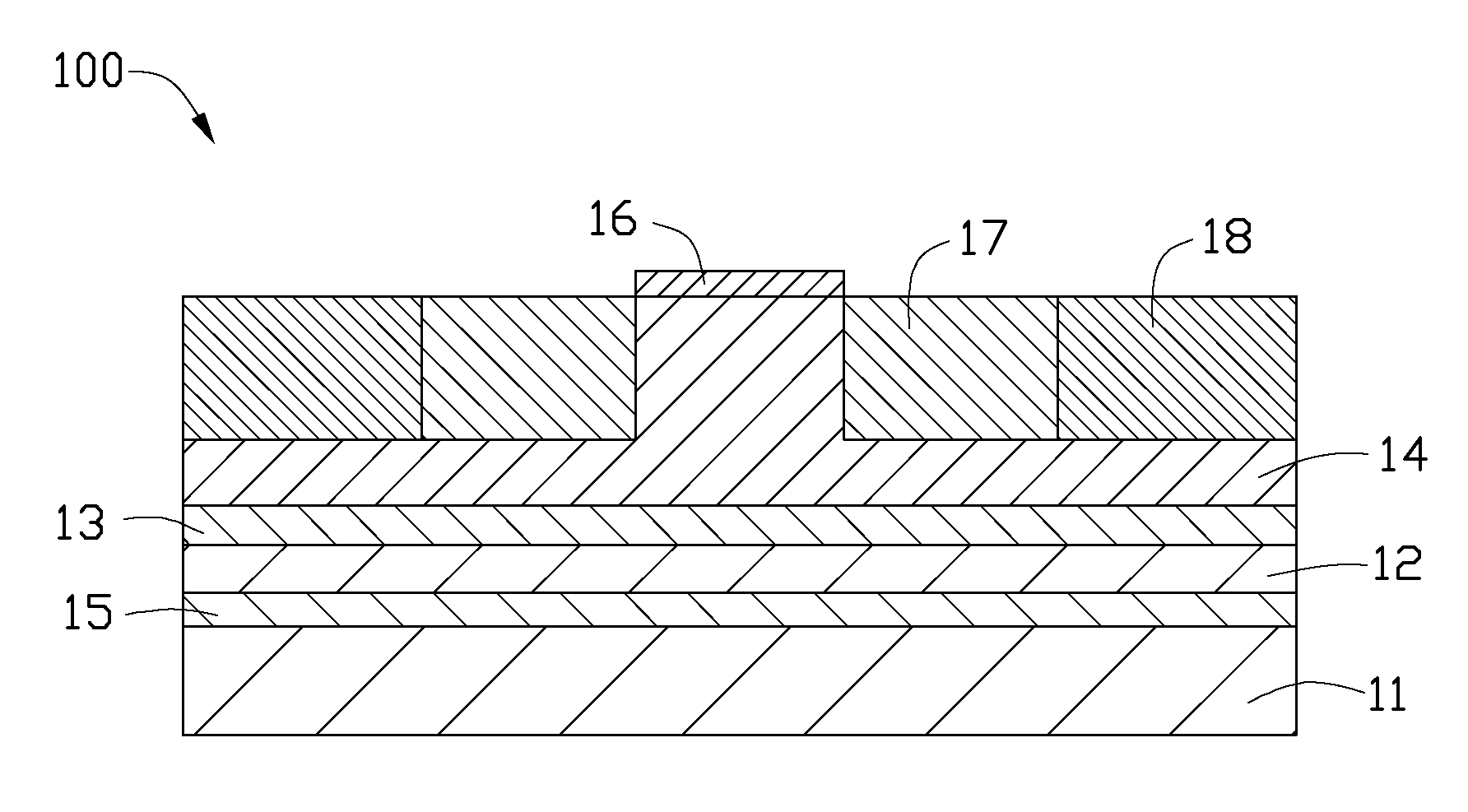

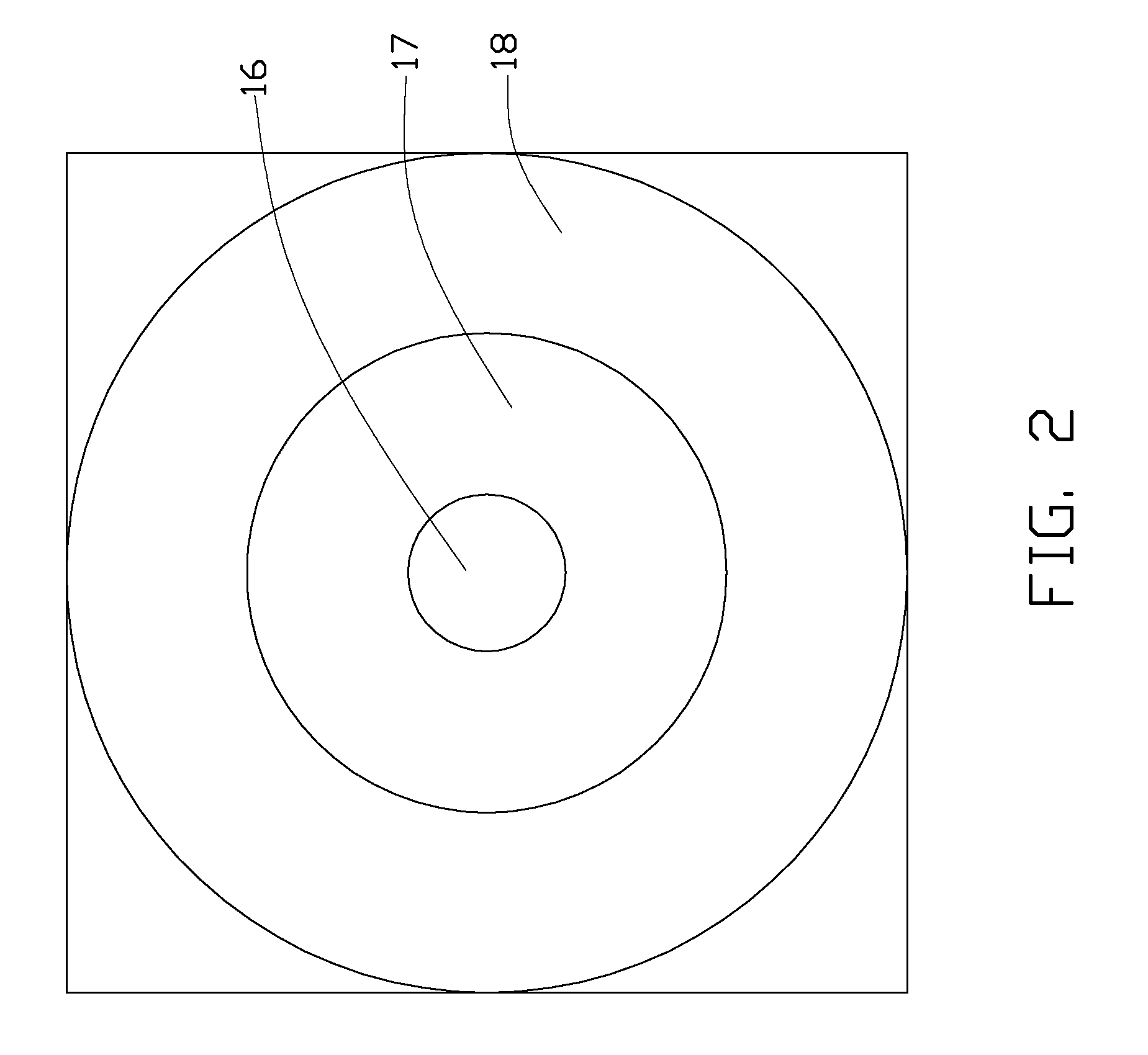

Light emitting diode and manufacturing method thereof

InactiveUS20110133204A1Improve luminous efficiencyLow luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeDiode

A light emitting diode includes a thermal conductive substrate, an p-type GaN layer, an active layer and an n-type GaN layer sequentially stacked above the substrate and an electrode pad deposited on the n-type GaN layer. A surface of n-type GaN layer away from the active layer has a first diffusing section and a second diffusing section. The first diffusing section is adjacent to the electrode pad and the second diffusing section is located at the other side of the first diffusing section opposite to the electrode pad, wherein the doping concentration of the first diffusing section is less than that of the second diffusing section. The n-type GaN layer has an electrical resistance larger than that of the first diffusing section which in turn is larger than that of the second diffusing section.

Owner:HON HAI PRECISION IND CO LTD

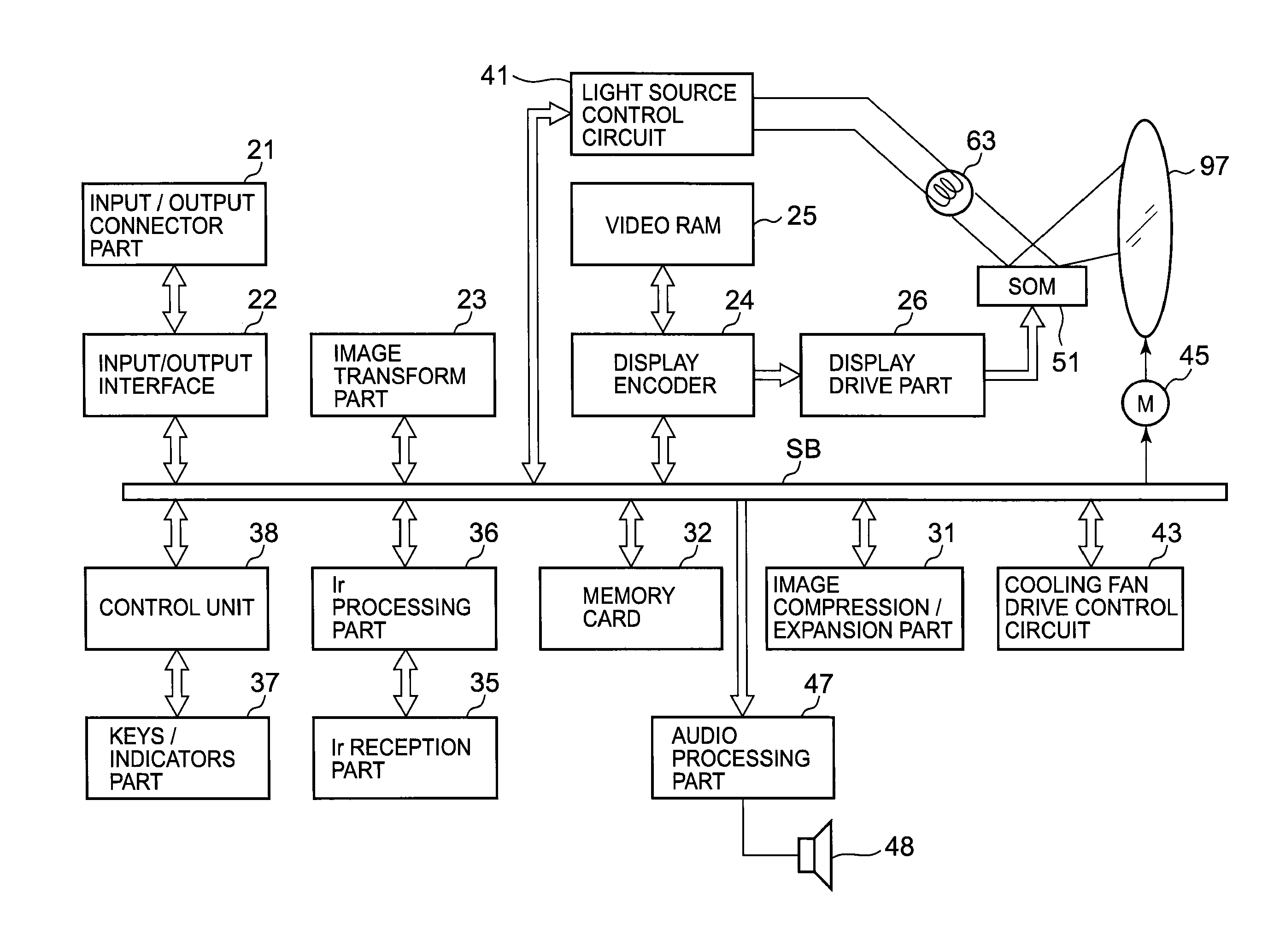

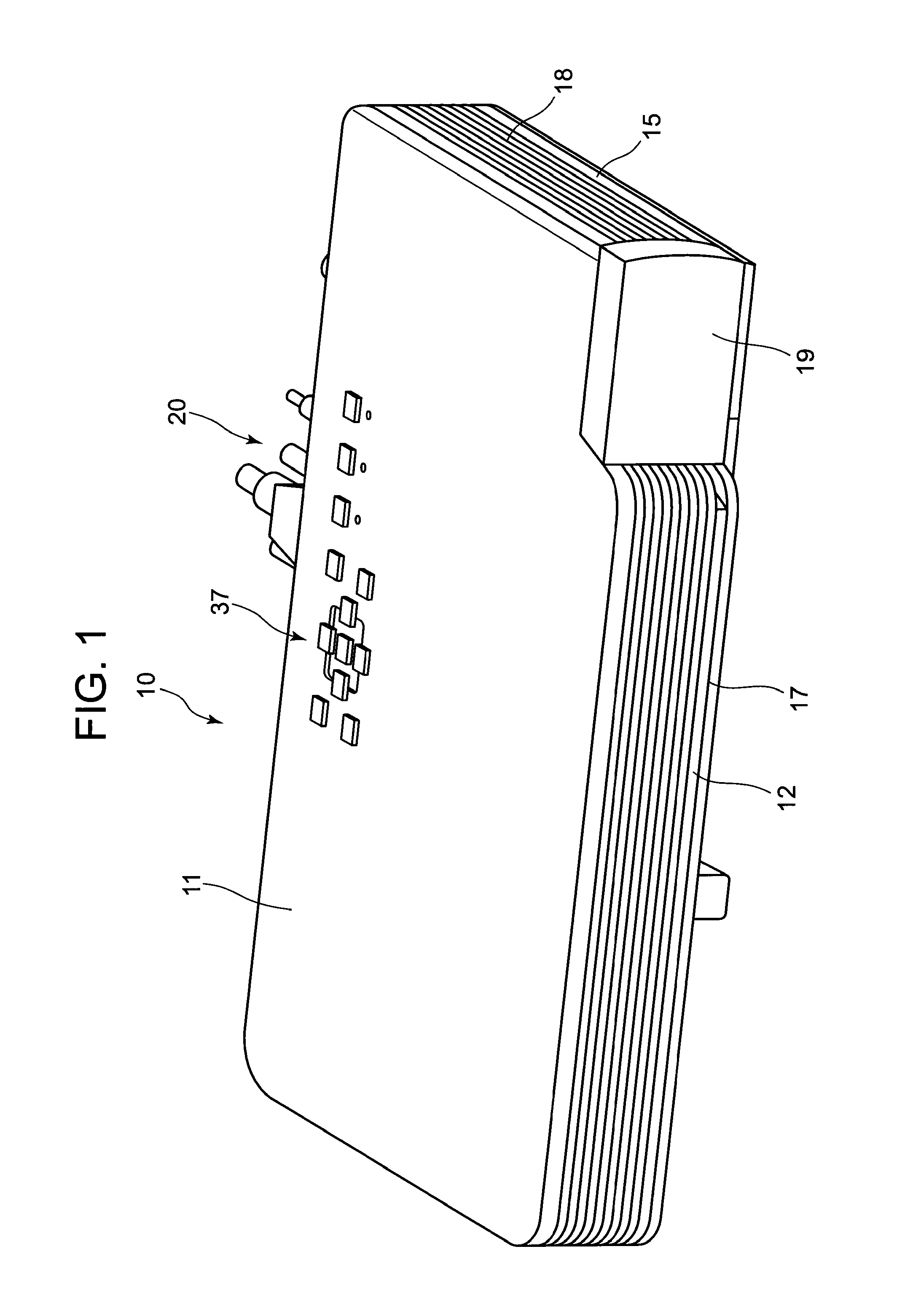

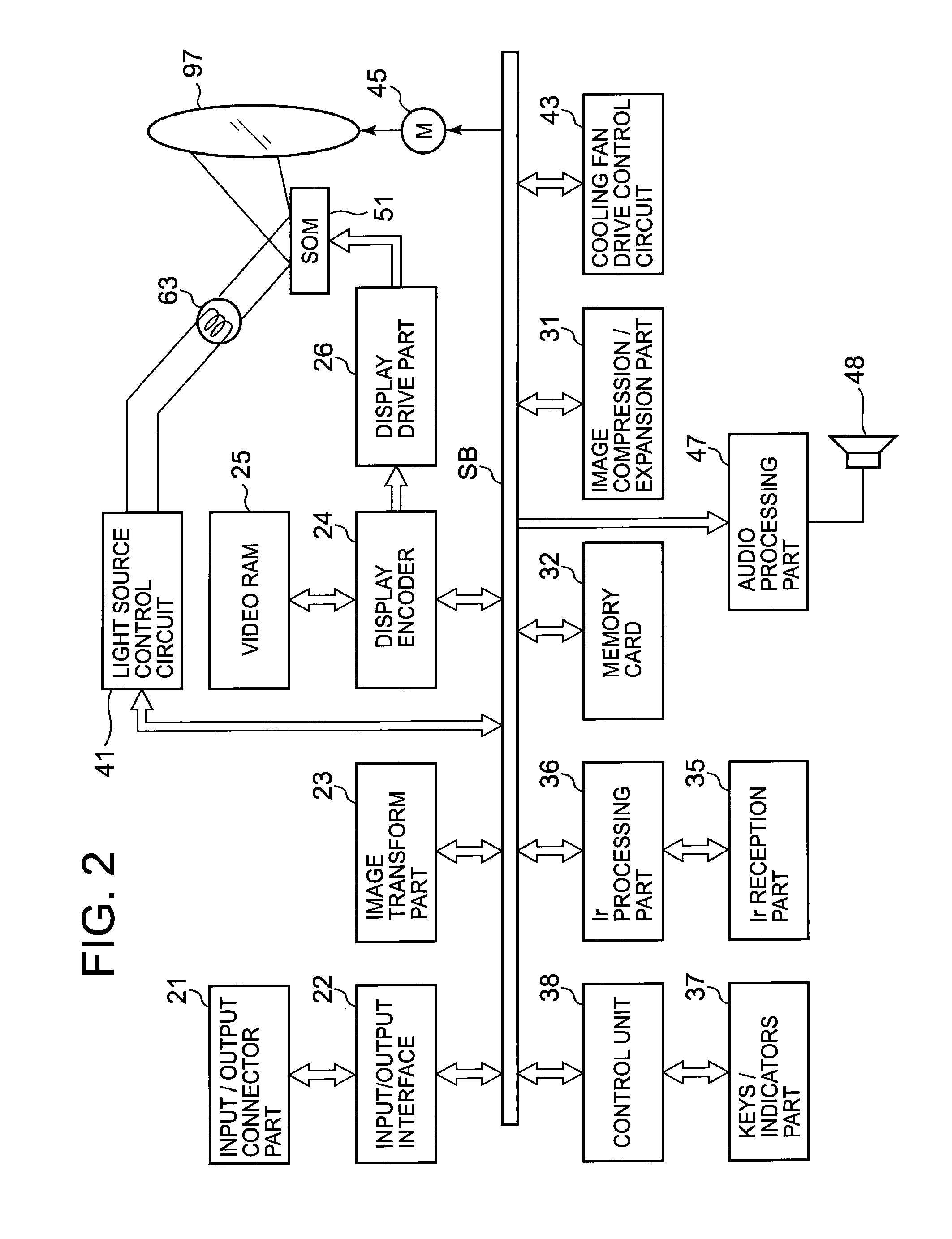

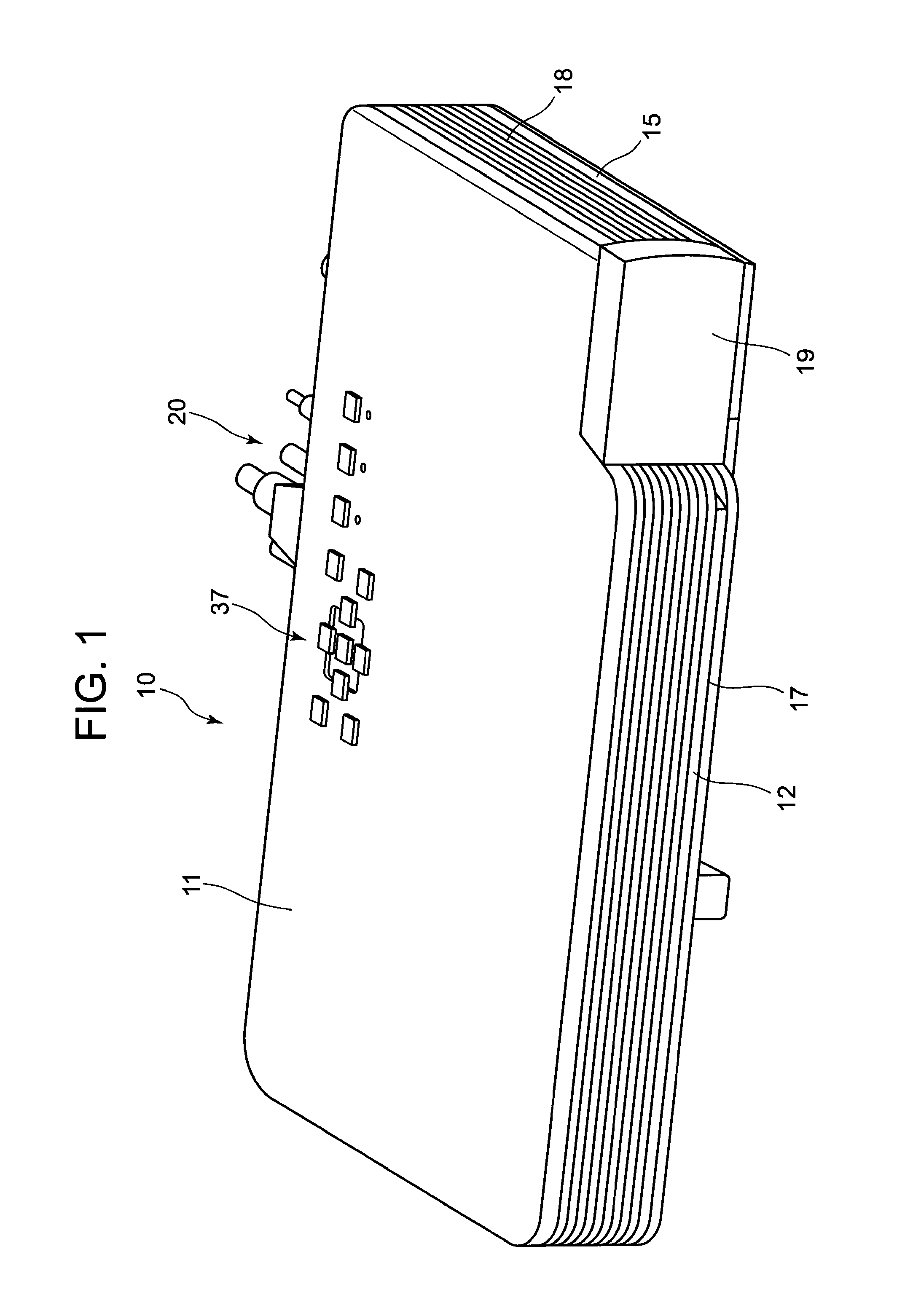

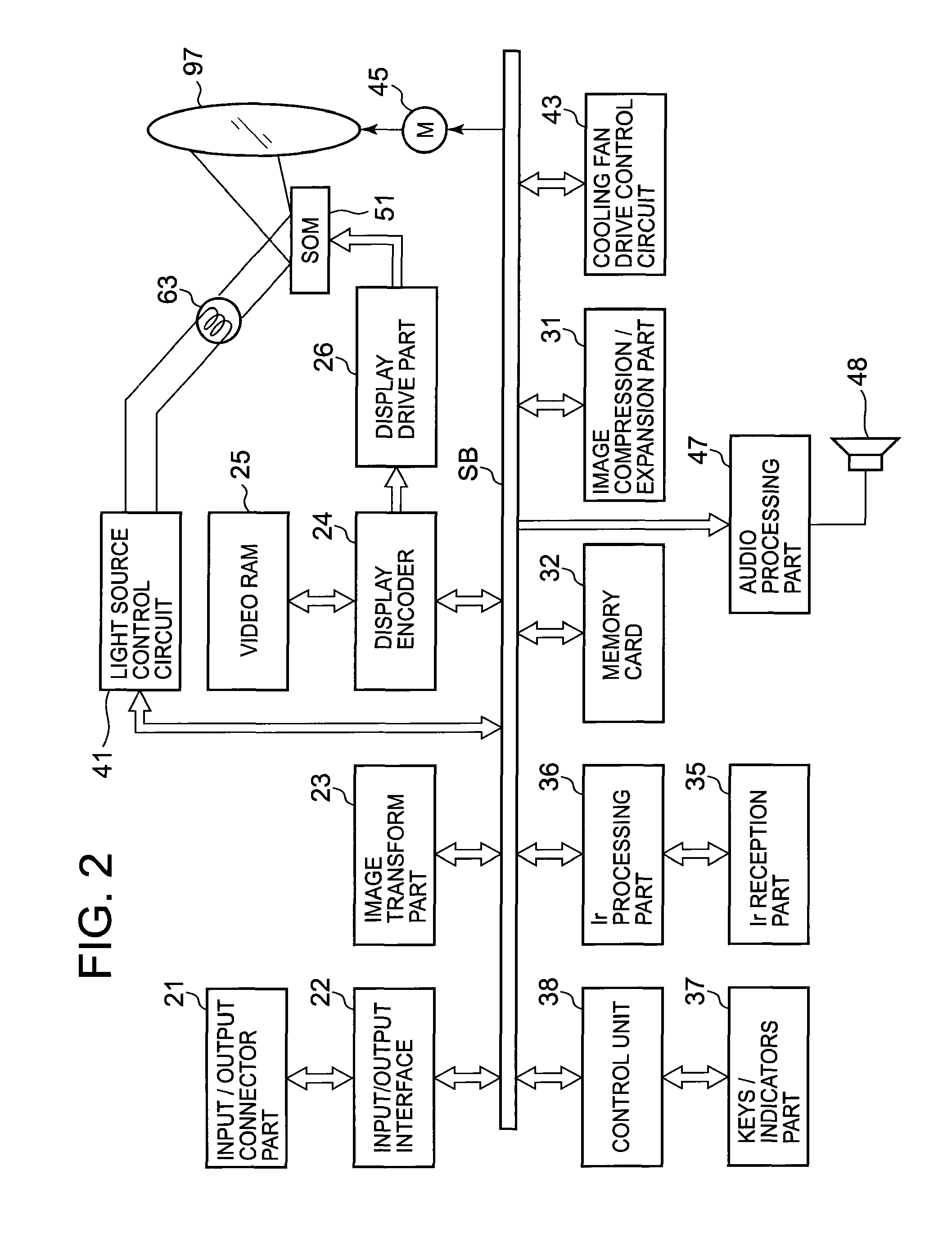

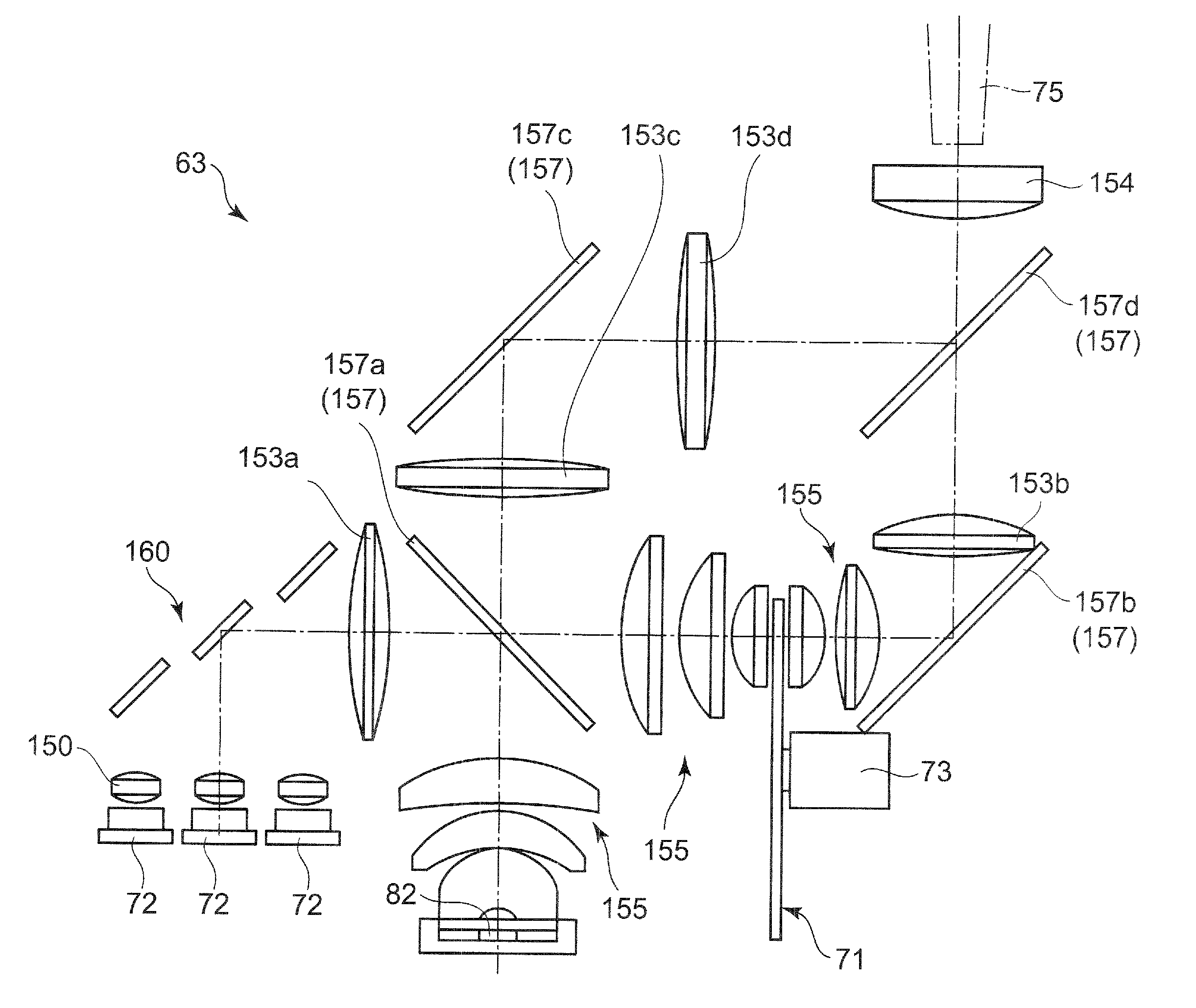

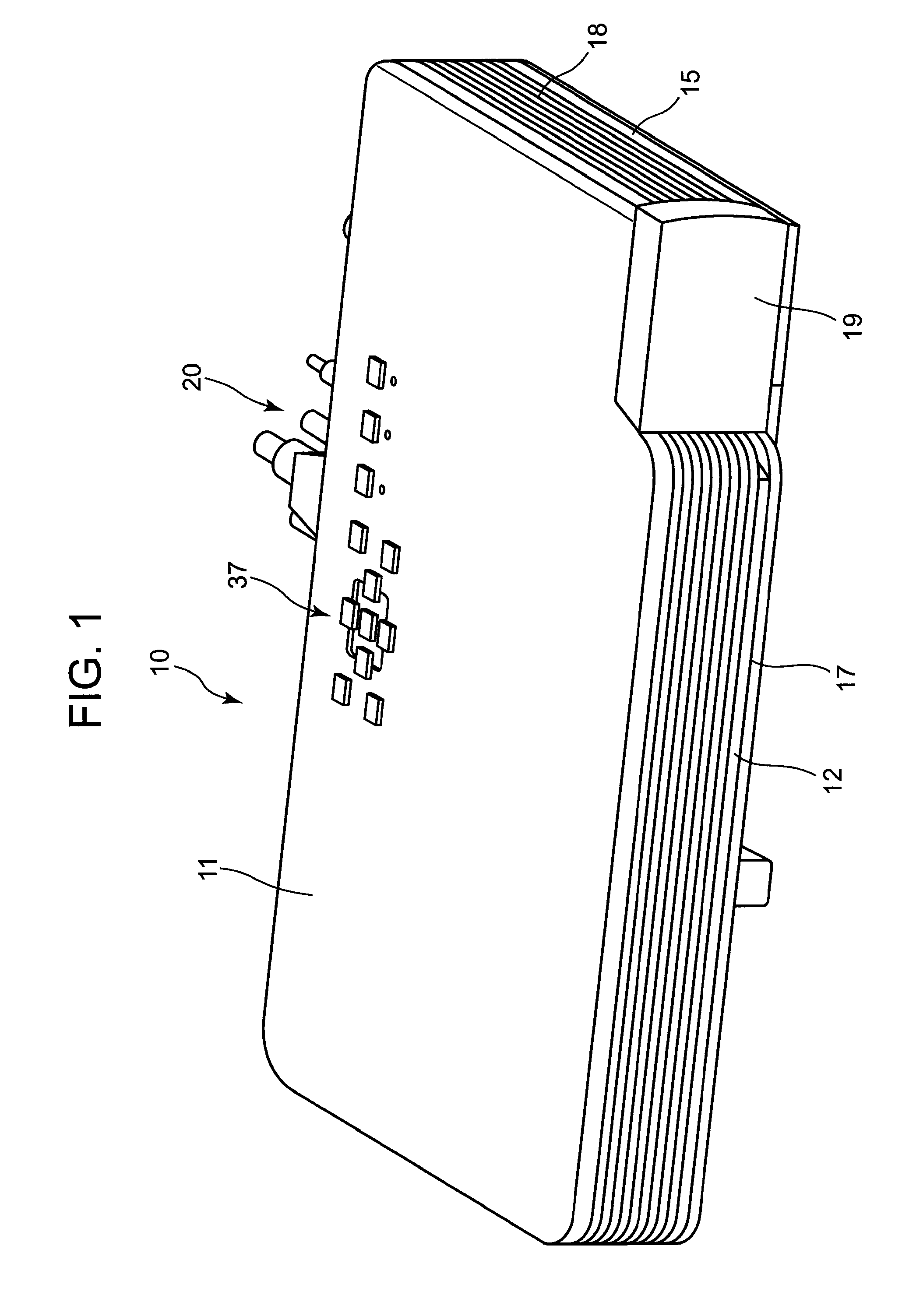

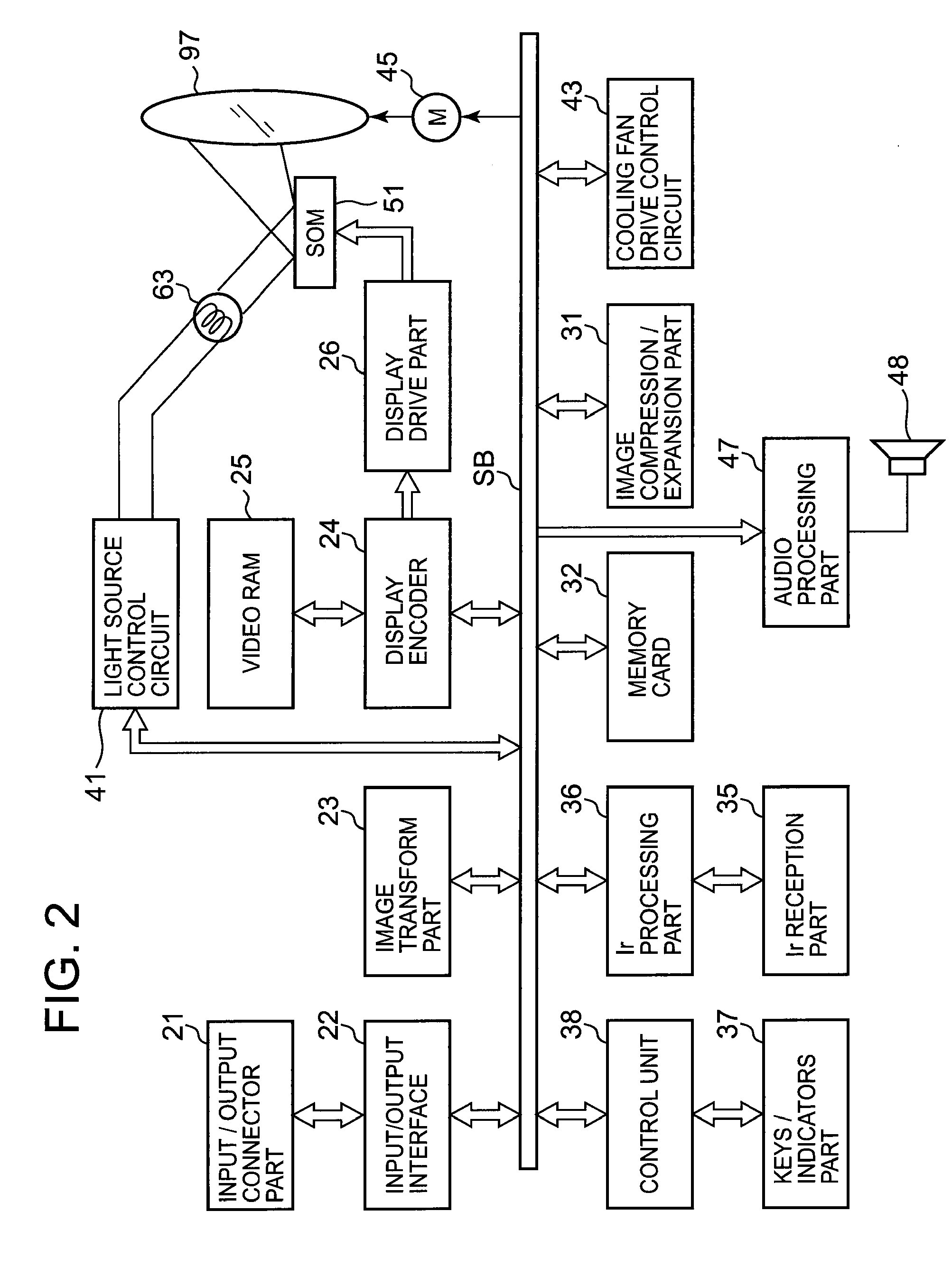

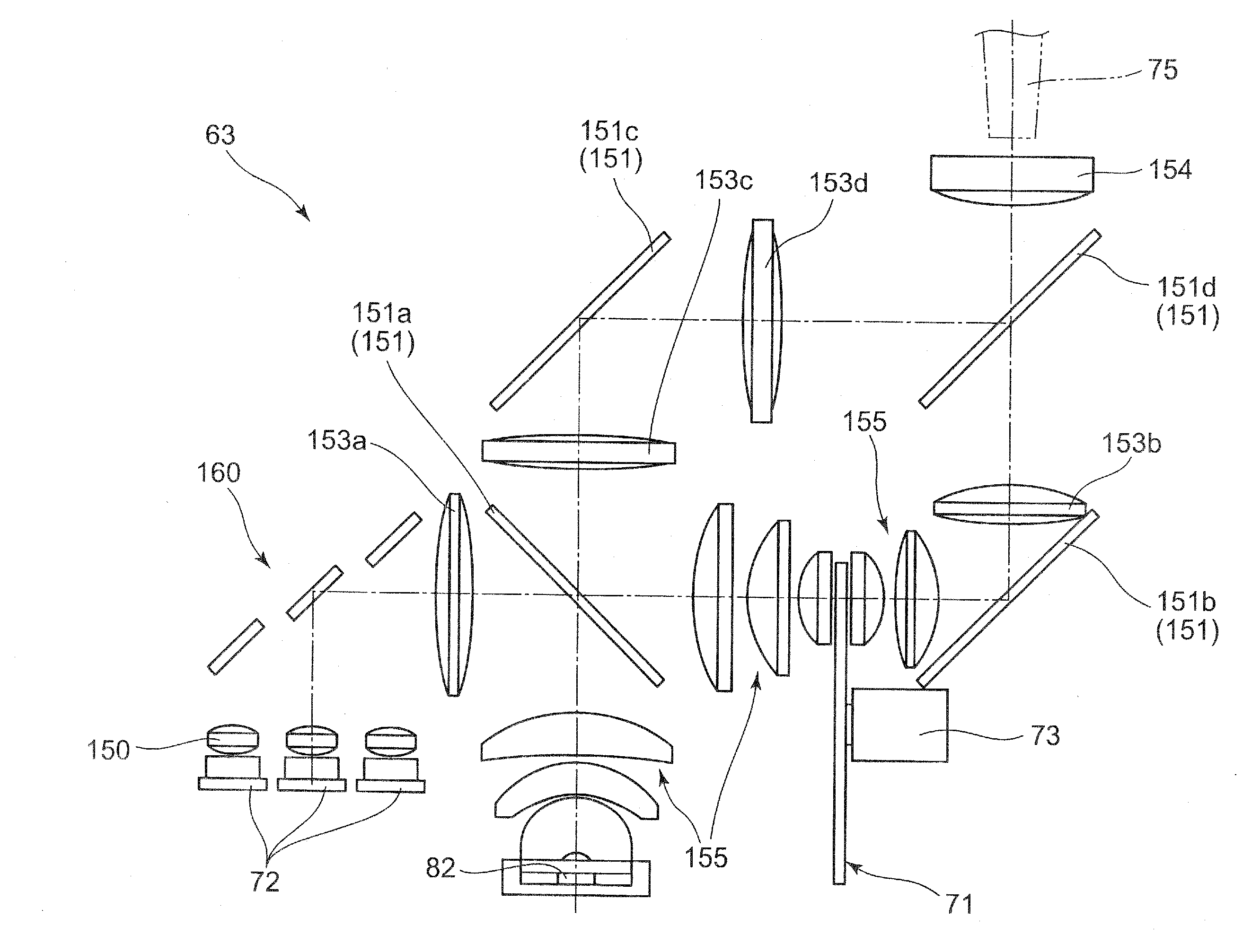

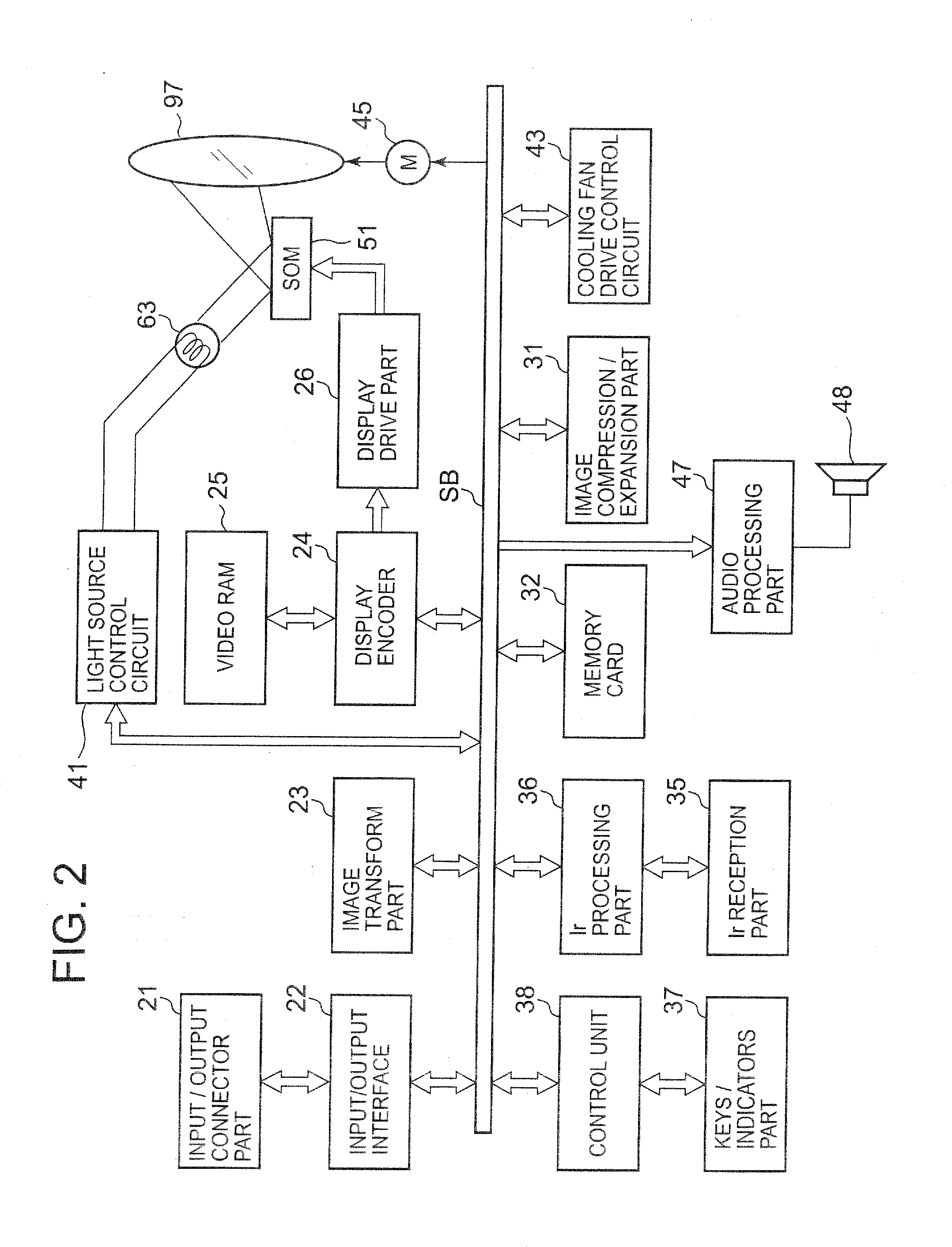

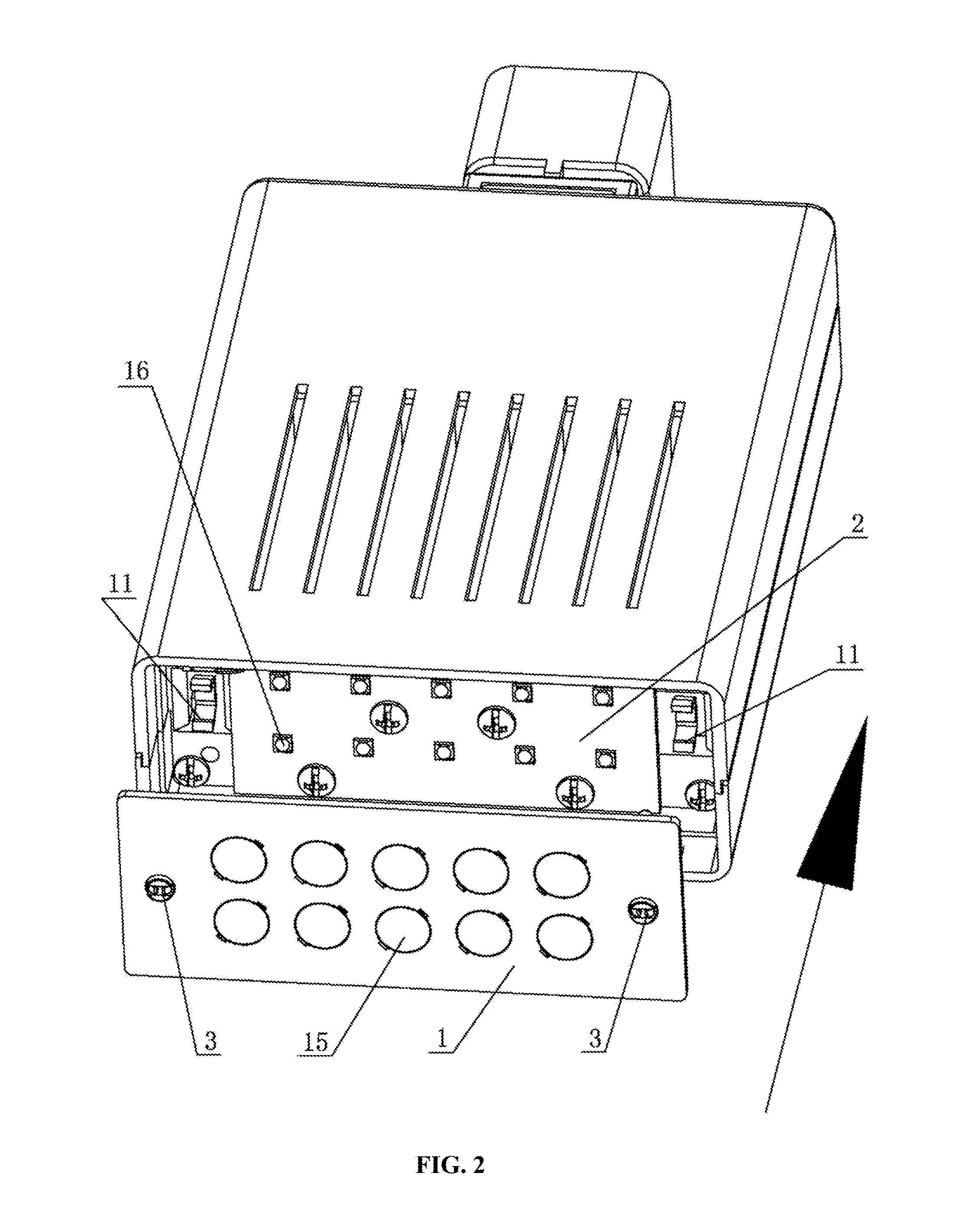

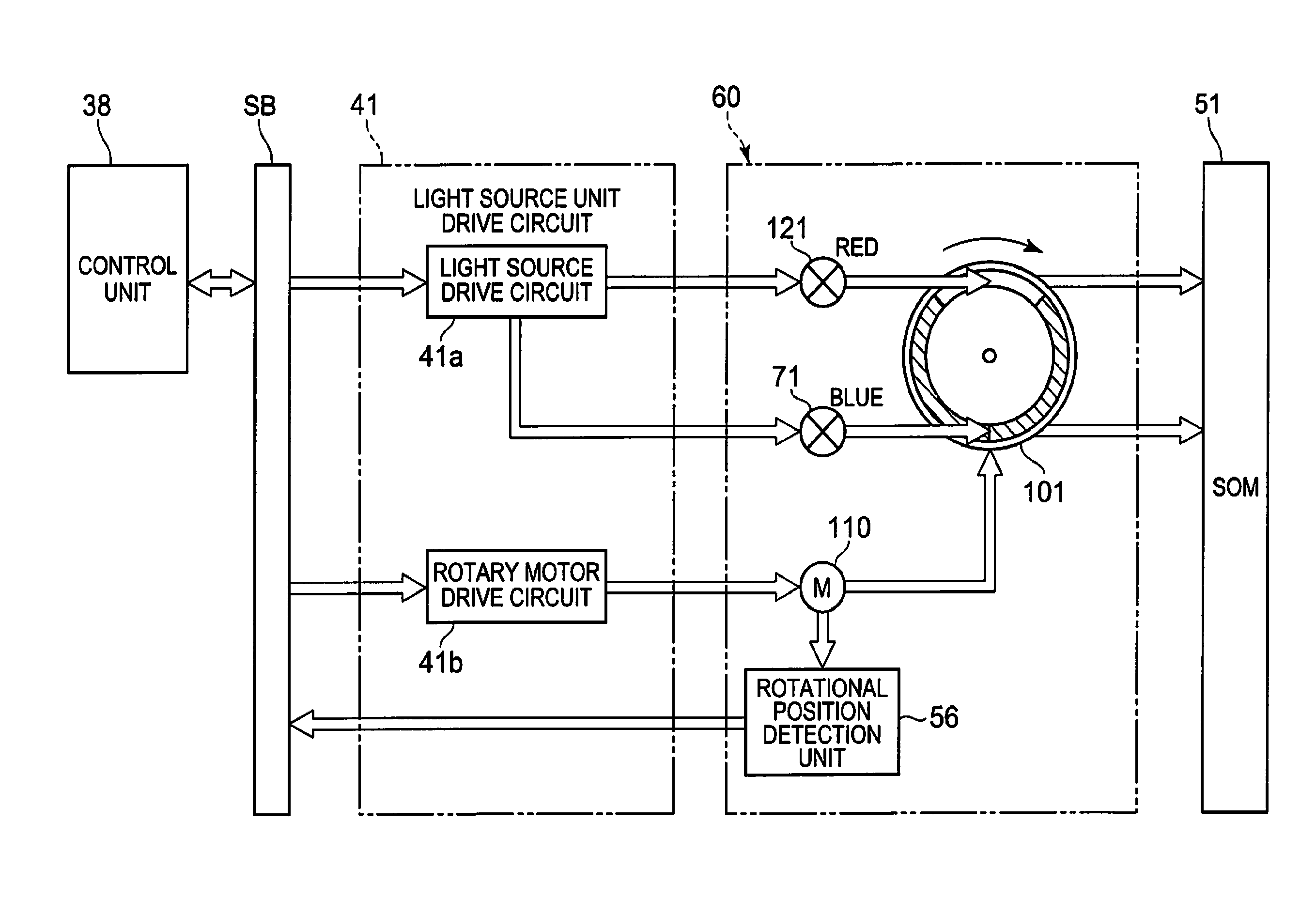

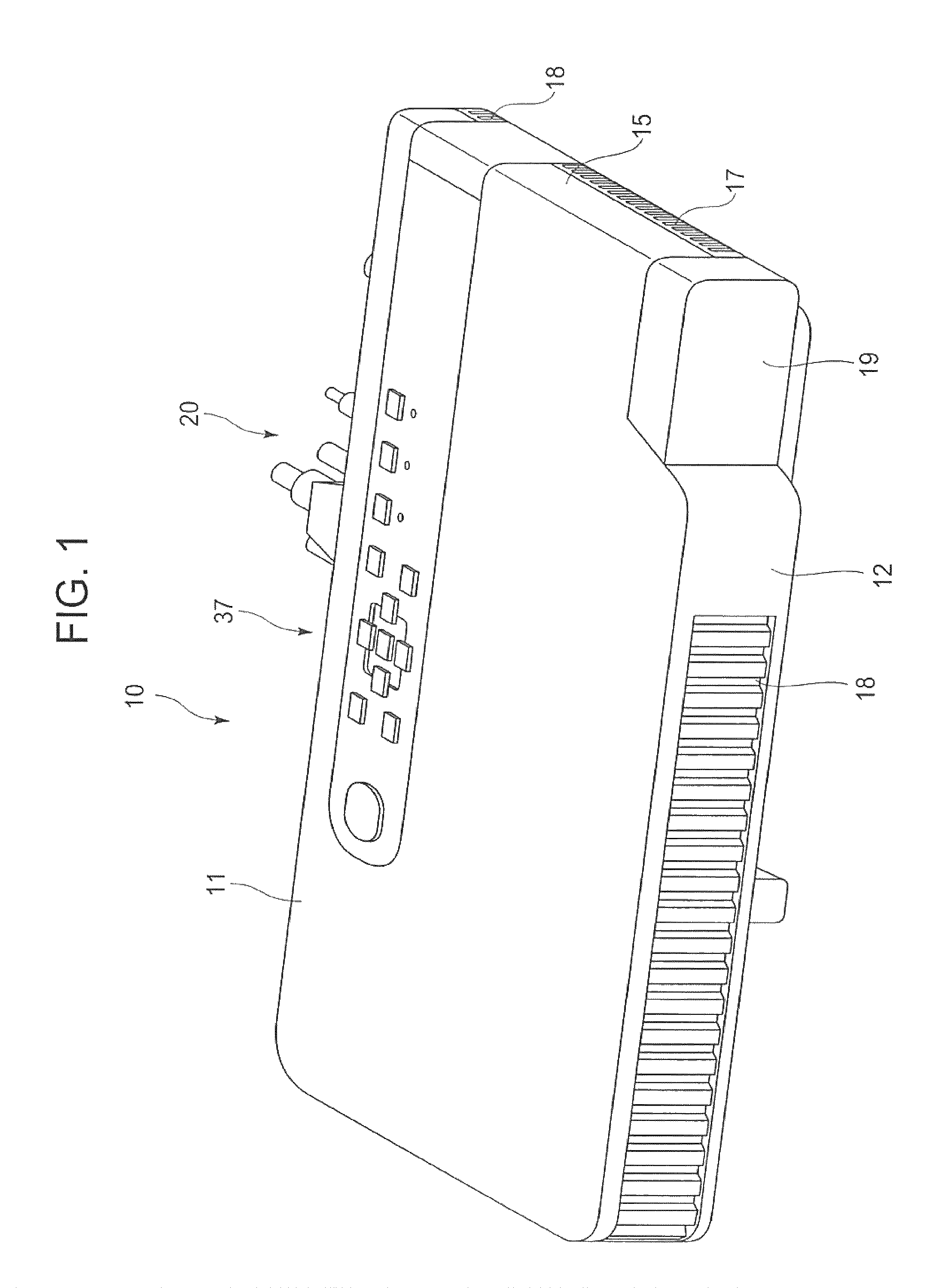

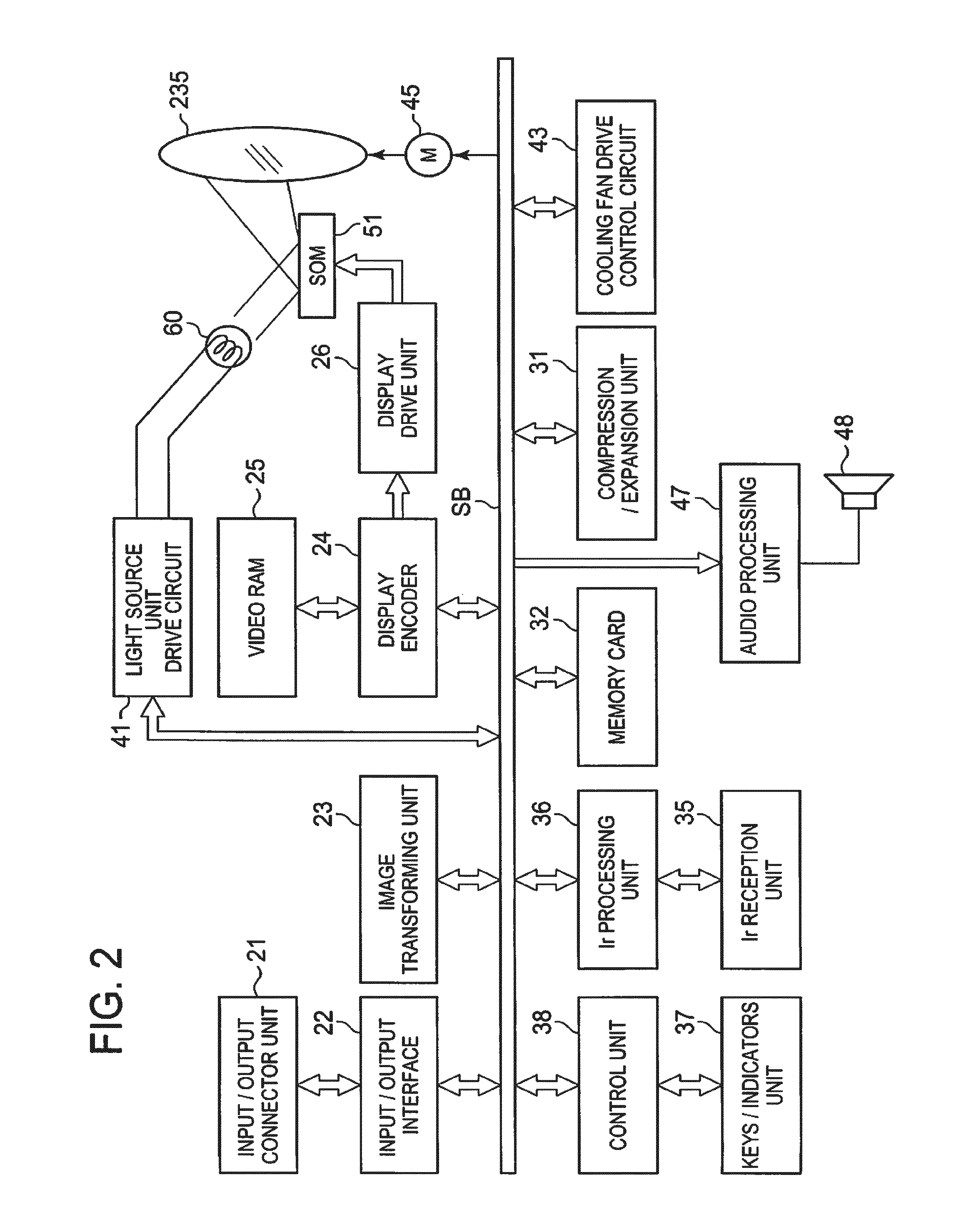

Light source unit and projector

ActiveUS20100328627A1Increase brightnessShine wellProjectorsColor photographyLuminescent materialTransmitted light

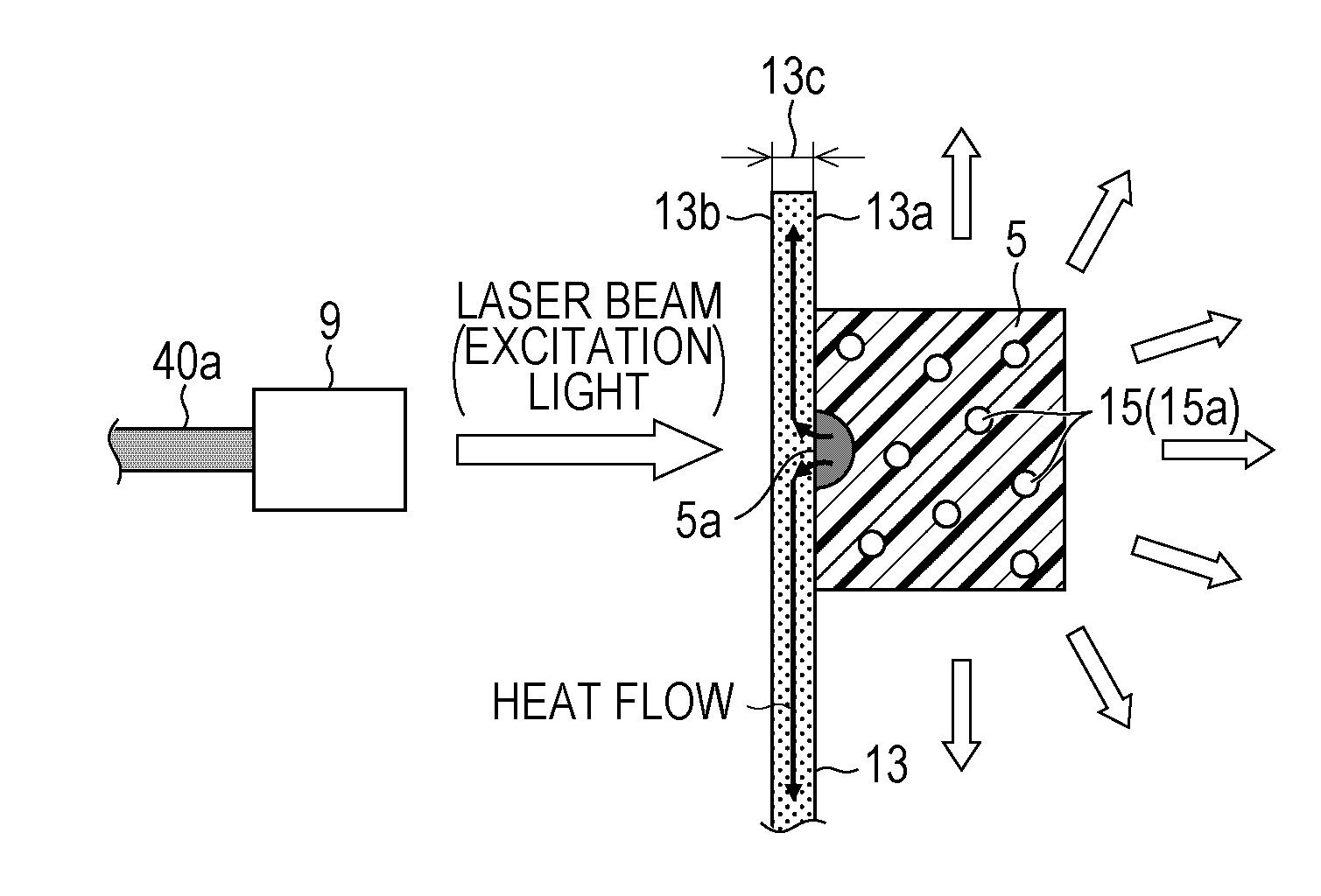

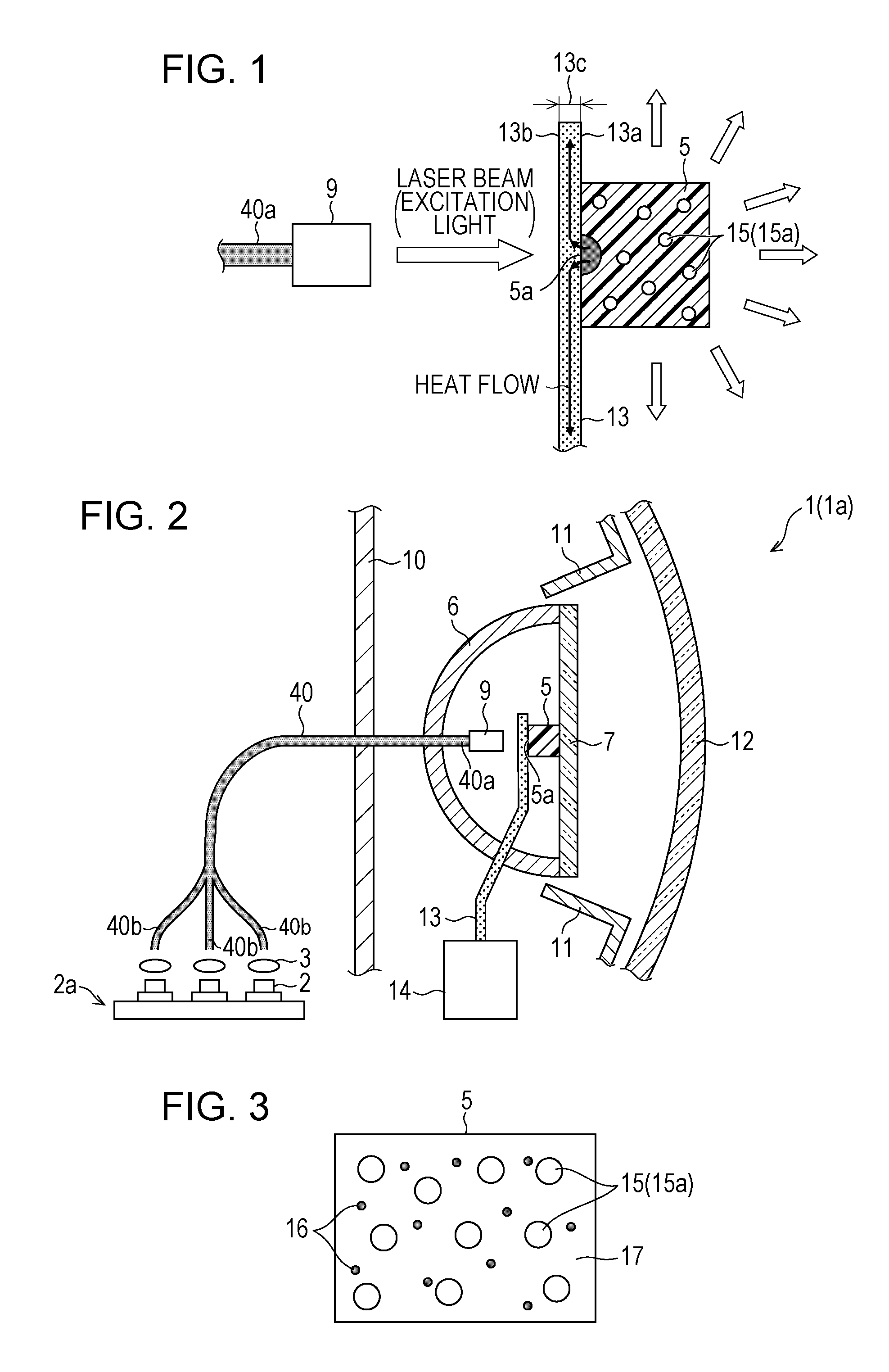

To provide a light source unit which can increase luminance and a projector including this light source unit. This light source unit includes a luminous wheel having a segment area on which a luminescent material layer is formed which emits light of a predetermined wavelength band by receiving light, and a segment area which is made into a transmission portion which transmits light, a primary light source which shines light of a visible wavelength band on to the luminous wheel, a secondary light source which emits light of a wavelength band which is different from light from the luminescent material layer and light from the primary light source, a collective optical system which collects light from the luminous wheel and the secondary light source to cause them to converge to the same optical path, and a light source control device which controls the emission of light from the light sources.

Owner:CASIO COMPUTER CO LTD

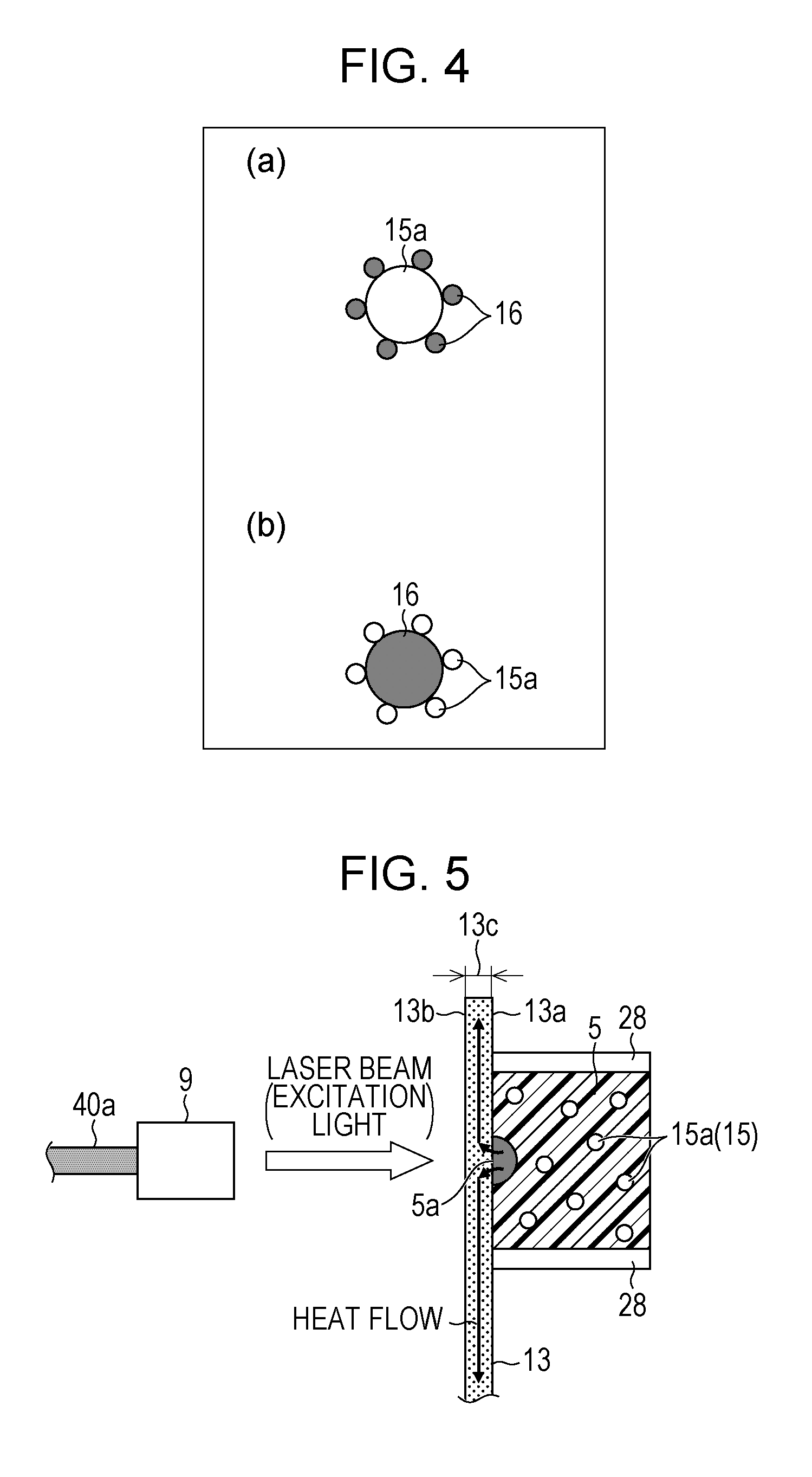

Wavelength conversion member and method for manufacturing the same, and light-emitting device, illuminating device, and headlight

InactiveUS20140003074A1Low luminous efficiencyImprove luminous efficiencyConductive materialSolid-state devicesFluorescenceLight emitting device

A headlamp (1) includes a laser diode (2) for emitting a laser beam and a light-emitting section (5), which contains a fluorescent substance for emitting fluorescence upon receiving the laser beam emitted from the laser diode (2) and diffusing particles (15) for diffusing the laser beam.

Owner:SHARP KK

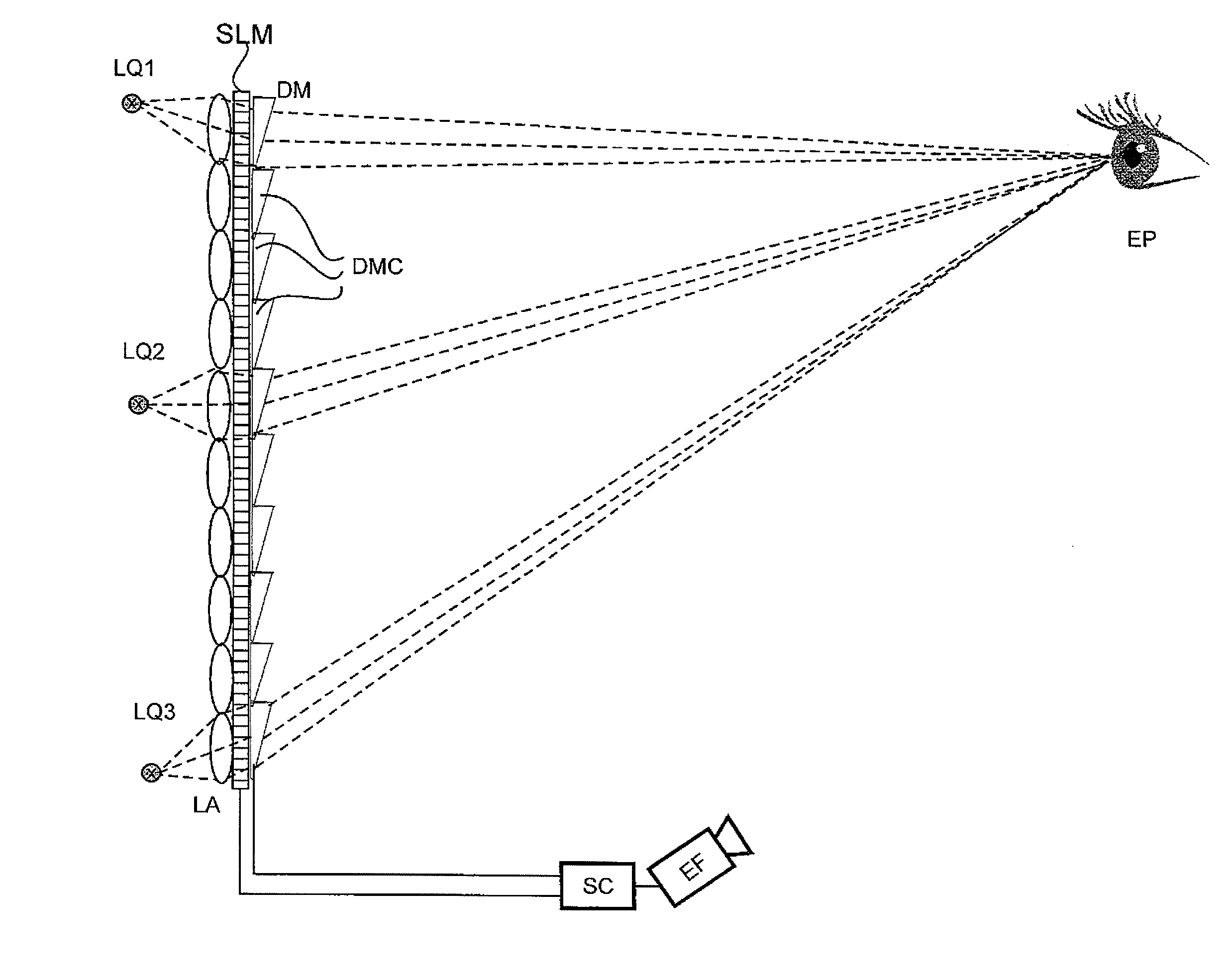

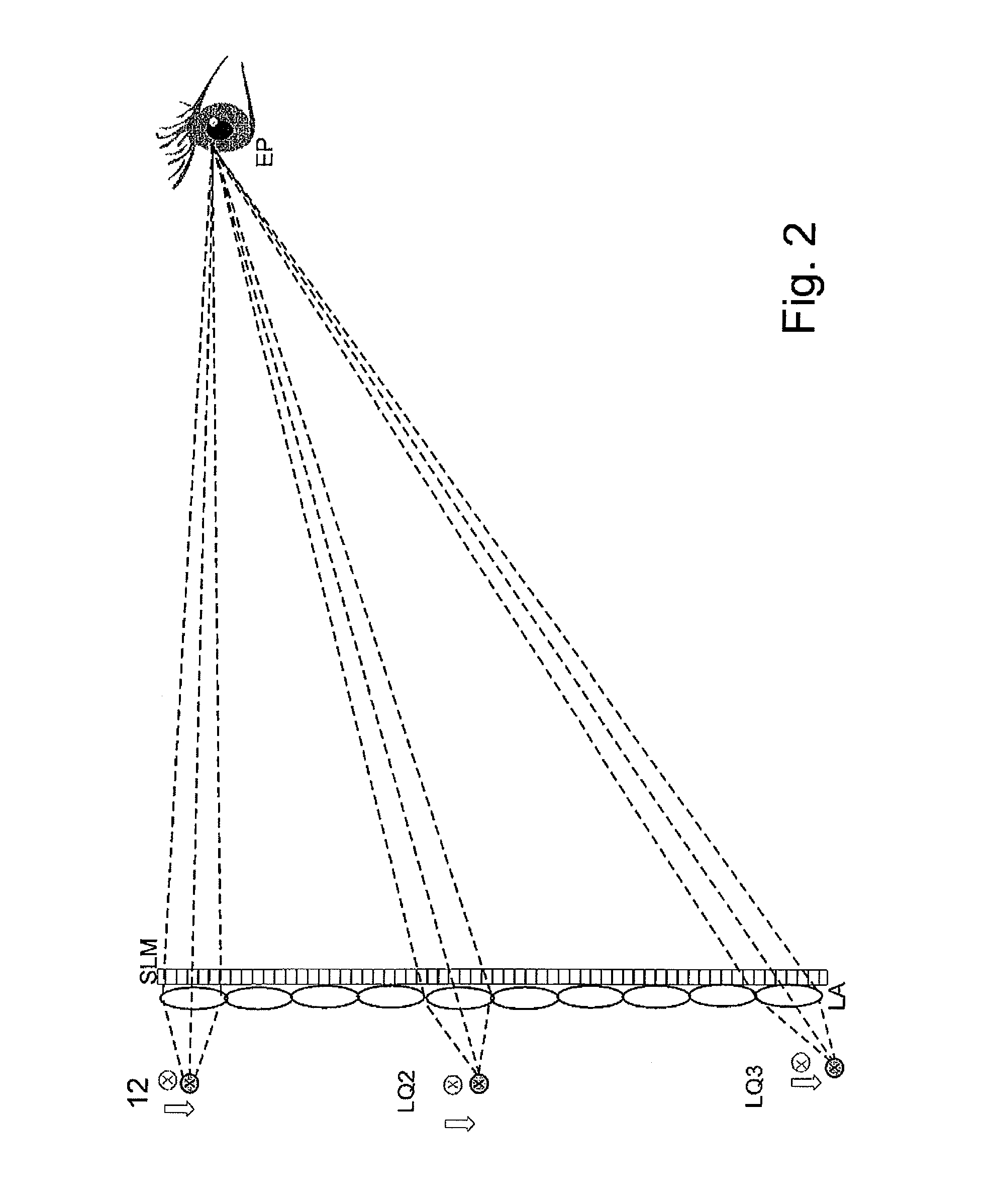

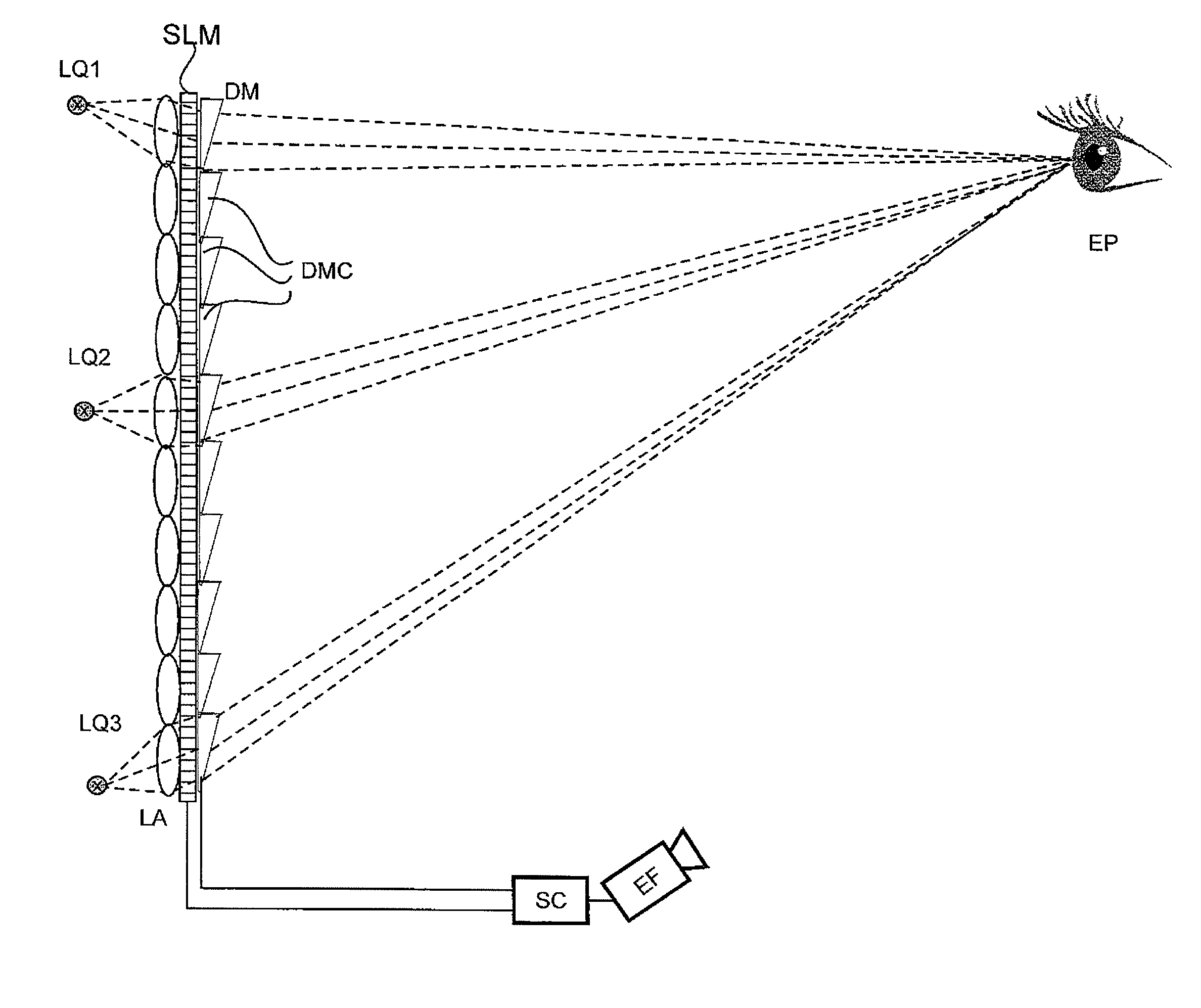

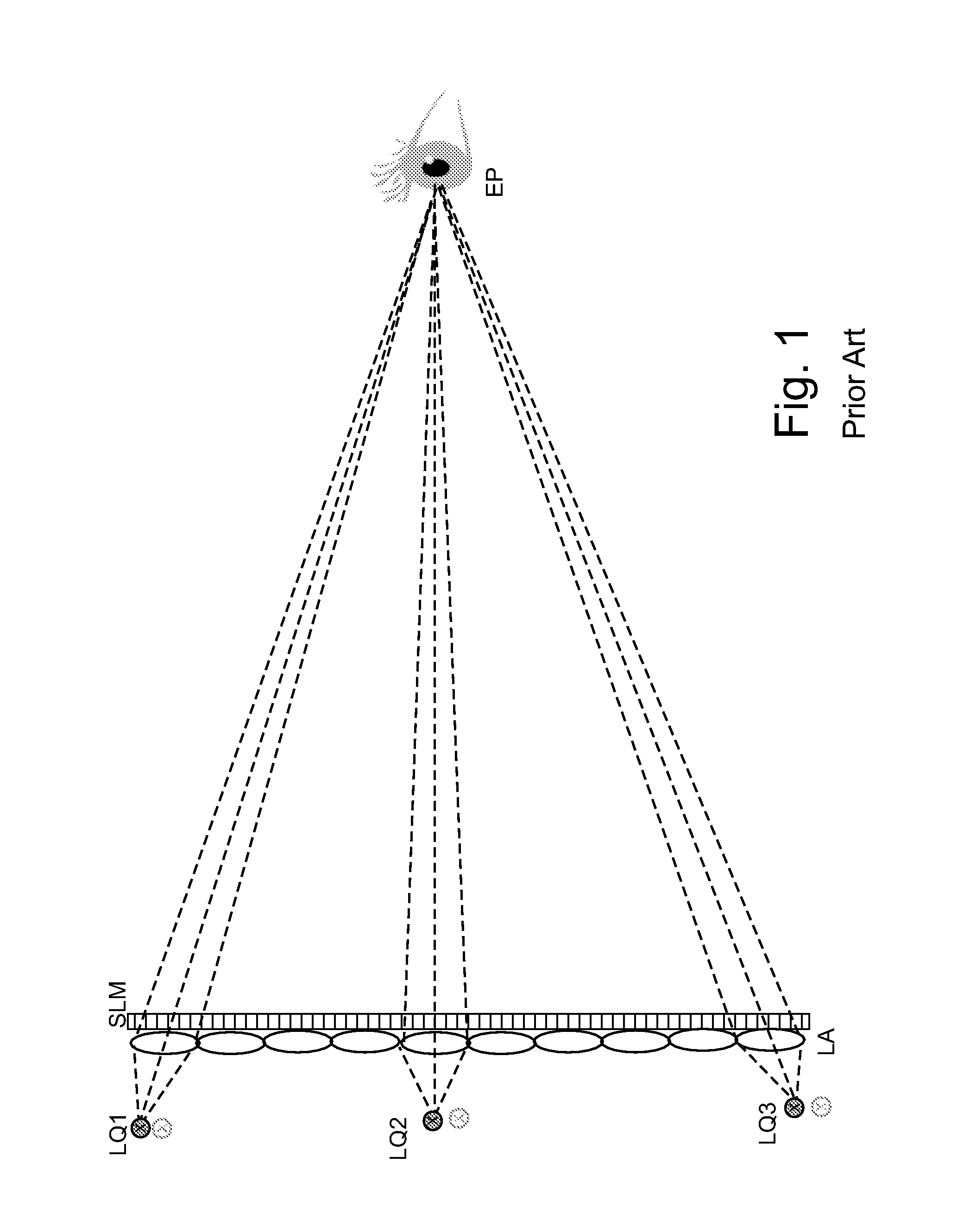

Holographic Reconstruction System with an Optical Wave Tracking Means

InactiveUS20100214634A1Low luminous efficiencyLittle errorPrismsHolographic optical componentsOptical pathLight wave

A holographic reconstruction system is disclosed with spatial light modulation means, modulating interferable light waves from light sources with at least one video hologram, comprising optical focusing means, focusing the modulated light waves with the reconstructed object light points for at least one eye position for the eyes of observers and controllable electro-optical deflector means, which direct the focused modulated light waves with the reconstructed light points to at least one eye position in order to reduce the aberrations. The reconstruction system has the optical focusing means in a field of focusing elements, wherein each focusing element is provided with at least one interferable light source. The electro-optical deflector means lie in the light path of the interferable light waves after the optical focusing mean and have at least one field of deflector elements, which has at least one separately controllable electro-optical deflector element for each focusing element.

Owner:SEEREAL TECHNOLOGIES

Light source unit that includes a luminescent material, a primary light source that emits light to excite the luminescent material, and a secondary light source, and projector

ActiveUS8348432B2Increase brightnessShine wellProjectorsColor photographyOptoelectronicsOptic system

To provide a light source unit which can increase luminance and a projector including this light source unit. This light source unit includes a luminous wheel having a segment area on which a luminescent material layer is formed which emits light of a predetermined wavelength band by receiving light, and a segment area which is made into a transmission portion which transmits light, a primary light source which shines light of a visible wavelength band on to the luminous wheel, a secondary light source which emits light of a wavelength band which is different from light from the luminescent material layer and light from the primary light source, a collective optical system which collects light from the luminous wheel and the secondary light source to cause them to converge to the same optical path, and a light source control device which controls the emission of light from the light sources.

Owner:CASIO COMPUTER CO LTD

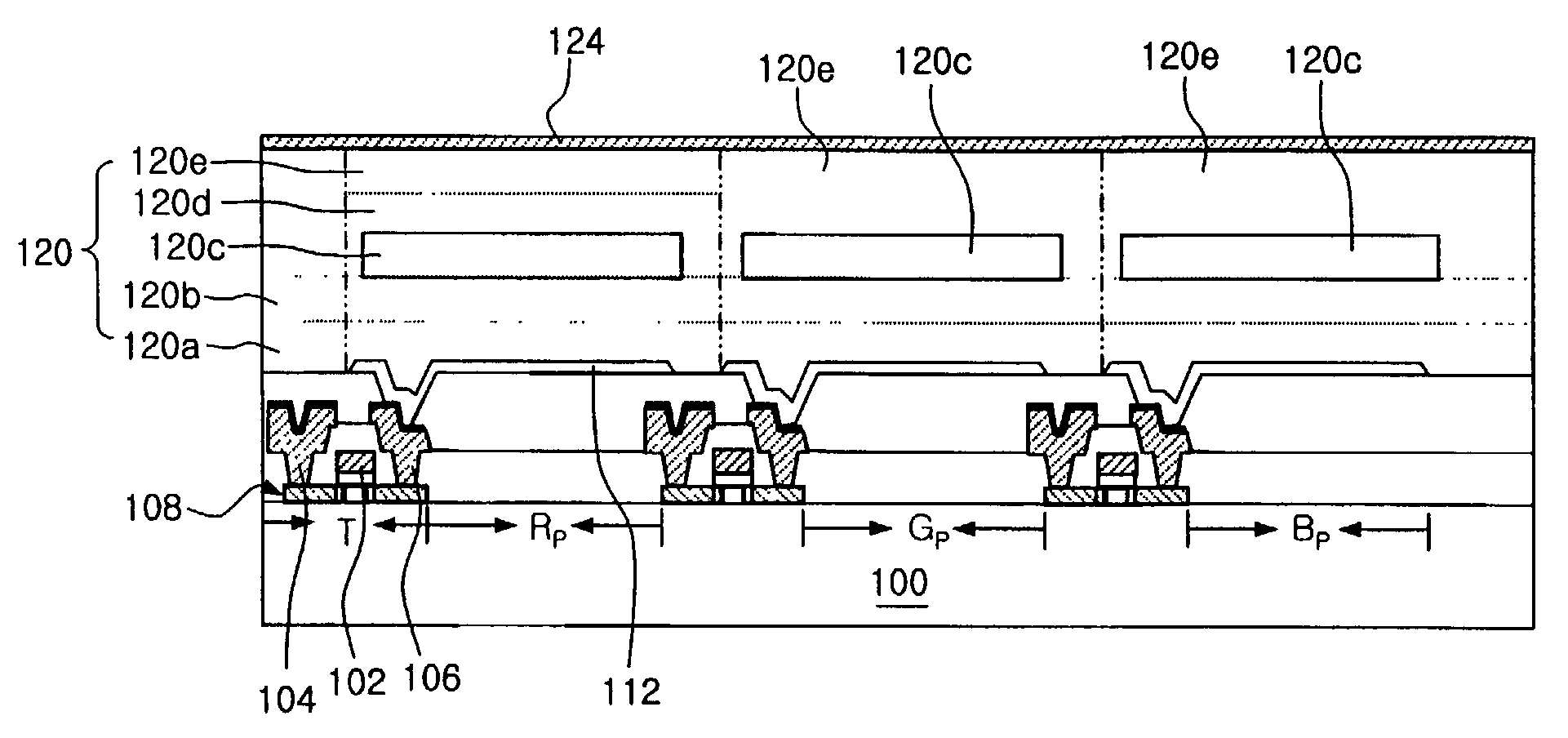

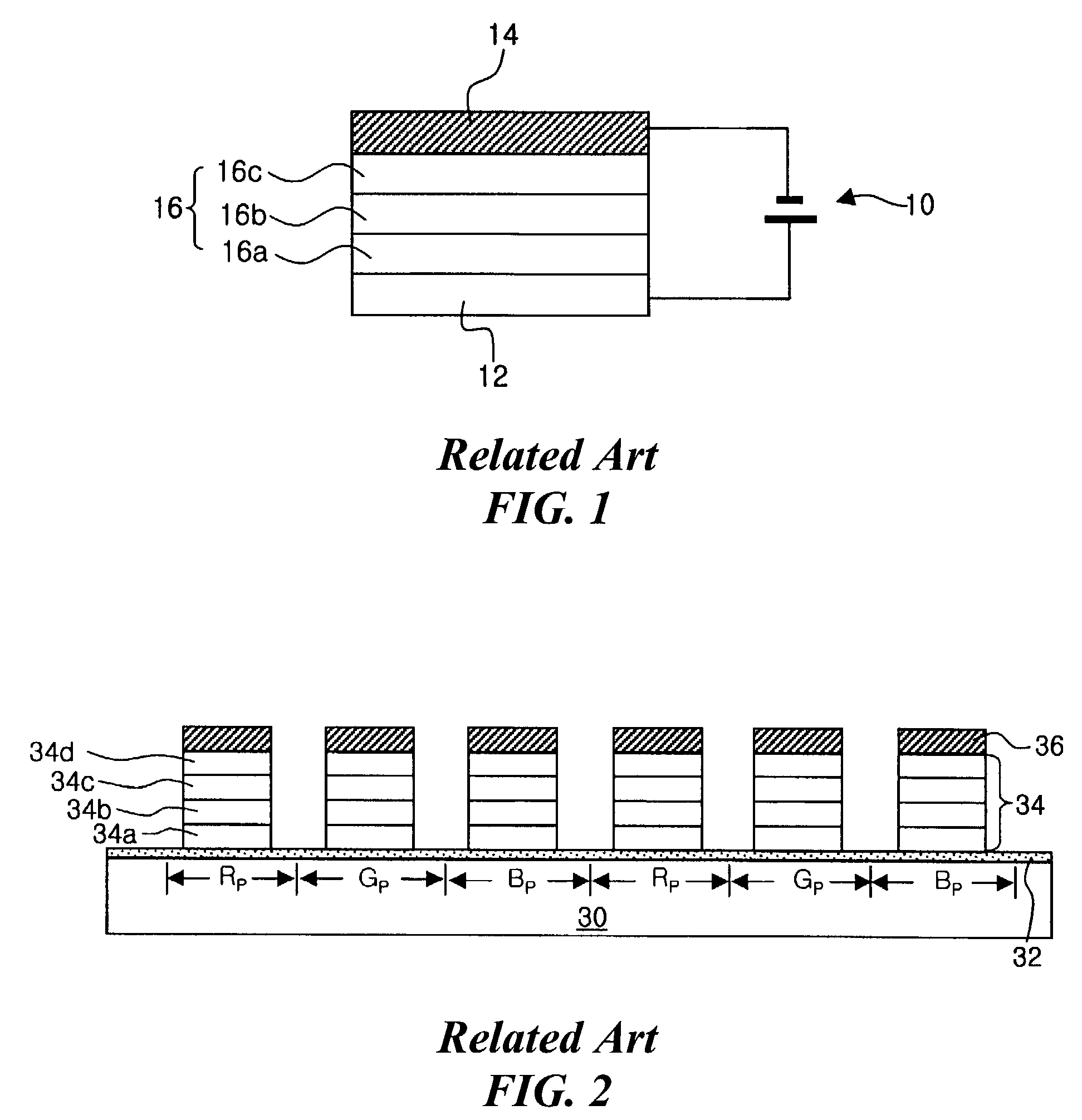

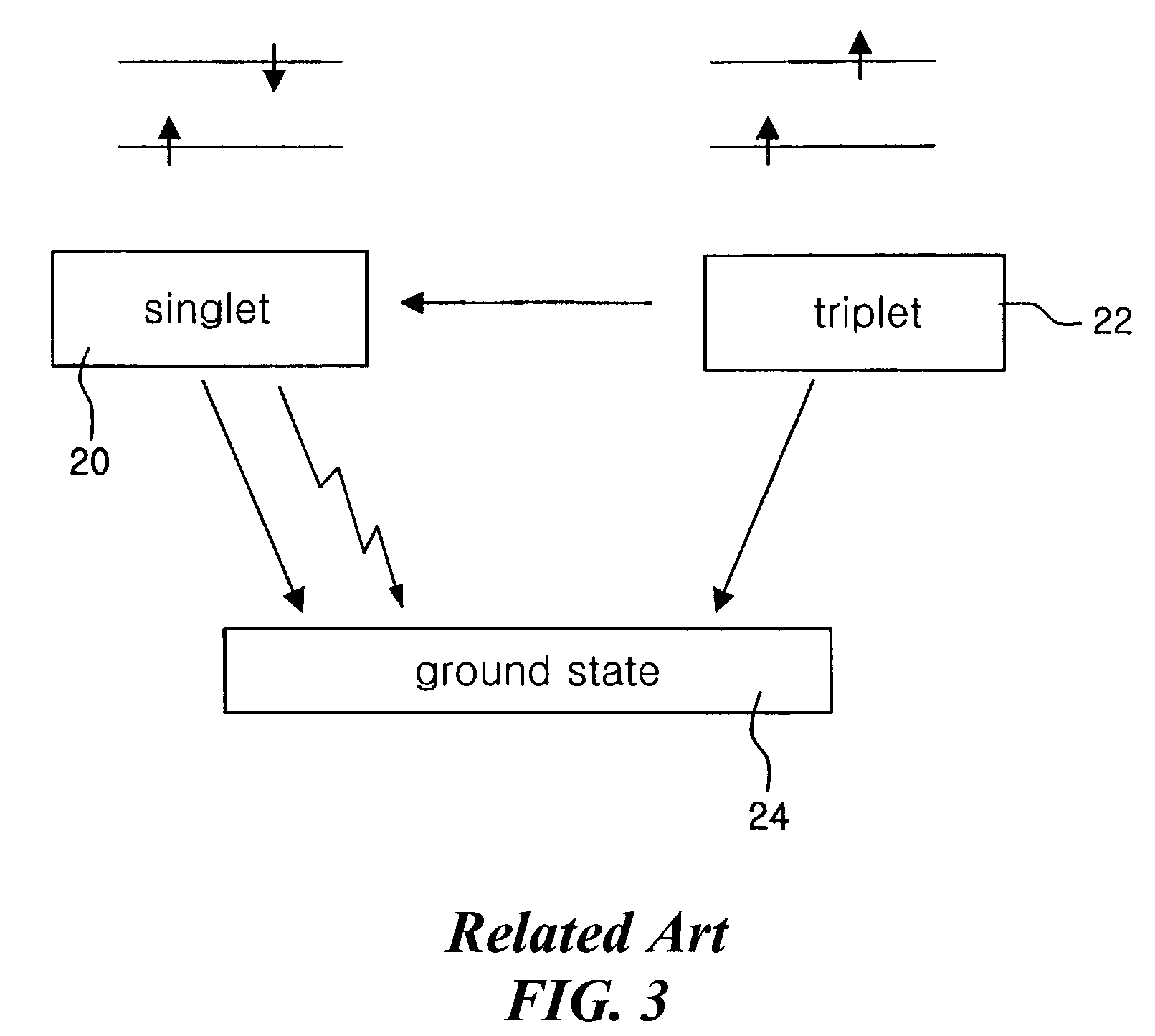

Organic electroluminescent device and method of fabricating the same

InactiveUS7129632B2Low luminous efficiencyReduce power consumptionDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsOrganic electroluminescence

An organic electroluminescent display device includes a substrate having a plurality of sub-pixel regions for red, green and blue, a driving device on the substrate, a first electrode connected to the driving device, a hole being injected from the first electrode, a second electrode over the first electrode, an electron being injected from the second electrode, and a light emitting material layer interposed between the first and second electrodes, the light emitting material layer of at least one of the plurality of sub-pixel regions includes a phosphorescent material.

Owner:LG DISPLAY CO LTD

Light-emitting diode and method for manufacturing same, integrated light-emitting diode and method for manufacturing same, method for growing a nitride-based iii-v group compound semiconductor, substrate for growing a nitride-based iii-v group compound semiconductor, light source cell unit, light-emitting diode backlight, light-emitting diode illuminating device, light-emitting diode display and electronic instrument, electronic device and method for manufacturing the same

InactiveUS20110212559A1Low luminous efficiencyLight extraction efficiencyPolycrystalline material growthSolid-state devicesDisplay deviceEngineering

A method for manufacturing a light-emitting diode, which includes the steps of: providing a substrate having a plurality of protruded portions on one main surface thereof wherein the protruded portion is made of a material different in type from that of the substrate and growing a first nitride-based III-V Group compound semiconductor layer on each recess portion of the substrate through a state of making a triangle in section wherein a bottom surface of the recess portion becomes a base of the triangle; laterally growing a second nitride-based III-V Group compound semiconductor layer on the substrate from the first nitride-based III-V Group compound semiconductor layer; and successively growing, on the second nitride-based III-V Group compound semiconductor layer, a third nitride-based III-V Group compound semiconductor layer of a first conduction type, an active layer, and a fourth nitride-based III-V compound semiconductor layer of a second conduction type.

Owner:SONY CORP

Light source unit and projector

ActiveUS8342697B2Improve luminous efficiencyLow luminous efficiencyProjectorsElectric light circuit arrangementLight guideLightness

To provide a light source unit which can enhance luminance and a projector, a projector of the invention includes a light source unit comprising a luminescent wheel with luminescent light emitting portions to emit blue and green rays, a primary light source shining an excitation light to the luminescent light emitting portions, a secondary light source emitting a red ray, a light guiding optical system guiding the rays from the luminescent wheel and the ray from the secondary light source to the same optical path and a light source control means controlling the emissions from the respective light sources, wherein the light source control means turns on the secondary light source when the ray from the primary light source is shone onto a boundary between the luminescent light emitting portions to synthesize the rays from the luminescent wheel and the ray from the secondary light source to generate white ray.

Owner:CASIO COMPUTER CO LTD

Light emitting device with specific four color arrangement

InactiveUS7439667B2Low luminous efficiencyIncrease powerDischarge tube luminescnet screensElectroluminescent light sourcesLight emitting deviceElectric power

It is an object of the invention to provide a light emitting device in which burden on a light emitting element having low luminous efficiency is relieved, and the deterioration of a light emitting element, the reduction in color reproduction due to the deteriorated light emitting element, and increase in electric power consumption can be suppressed. A light emitting device according to the invention has light emitting elements each of which emits one of colors corresponding to three primary colors. Further, one feature of the light emitting device according to the invention has a light emitting element which emits a neutral color. The light emitting device according to the invention has a structure in which a plurality of pixels having light emitting elements each of which emits one of colors corresponding to three primary colors, and a light emitting element which emits a neutral color as one group, are arranged.

Owner:SEMICON ENERGY LAB CO LTD

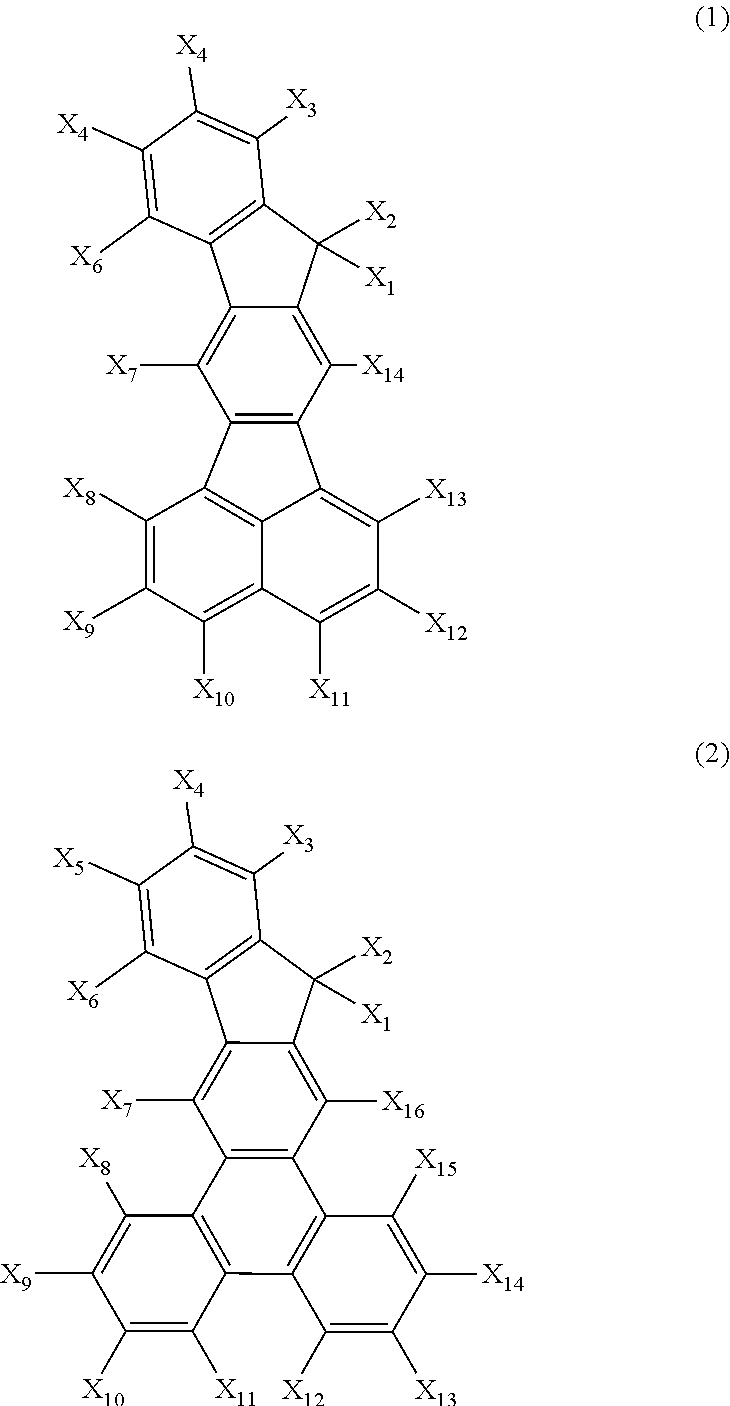

Organic Electroluminescence Device

ActiveUS20110073845A1Improve luminous efficiencyLow luminous efficiencyOrganic chemistrySolid-state devicesArylHydrogen atom

An organic electroluminescence device includes an organic layer disposed between at least one pair of electrodes, wherein the organic layer includes at least one fluorescent compound selected from compounds represented by the following general formulae (1) and (2):wherein X1 to X16 each independently represents a hydrogen atom, a linear, branched or cyclic alkyl group having 1 to 20 carbon atoms, a linear, branched or cyclic alkoxy group having 1 to 20 carbon atoms, a substituted or unsubstituted aryl group having 6 to 30 carbon atoms, a substituted or unsubstituted aryloxy group having 6 to 30 carbon groups, a substituted or unsubstituted arylamino group having 6 to 30 carbon atoms, a substituted or unsubstituted alkylamino group having 1 to 30 carbon atoms, a substituted or unsubstituted arylalkylamino group having 7 to 30 carbon atoms or a substituted or unsubstituted alkenyl group having 8 to 30 carbon atoms; a pair of adjacent groups represented by X1 to X2 and a pair of adjacent substituents to groups represented by X1 to X2 may form a cyclic structure in combination; a pair of adjacent groups represented by X3 to X16 and a pair of adjacent substituents to groups represented by X3 to X16 may form a cyclic structure in combination; when the pair of adjacent substituents are aryl groups, the pair of substituents may be a single group; and in the formulae at least one of the substituents of X3 to X14 or X16 includes amino group.

Owner:RITDISPLAY

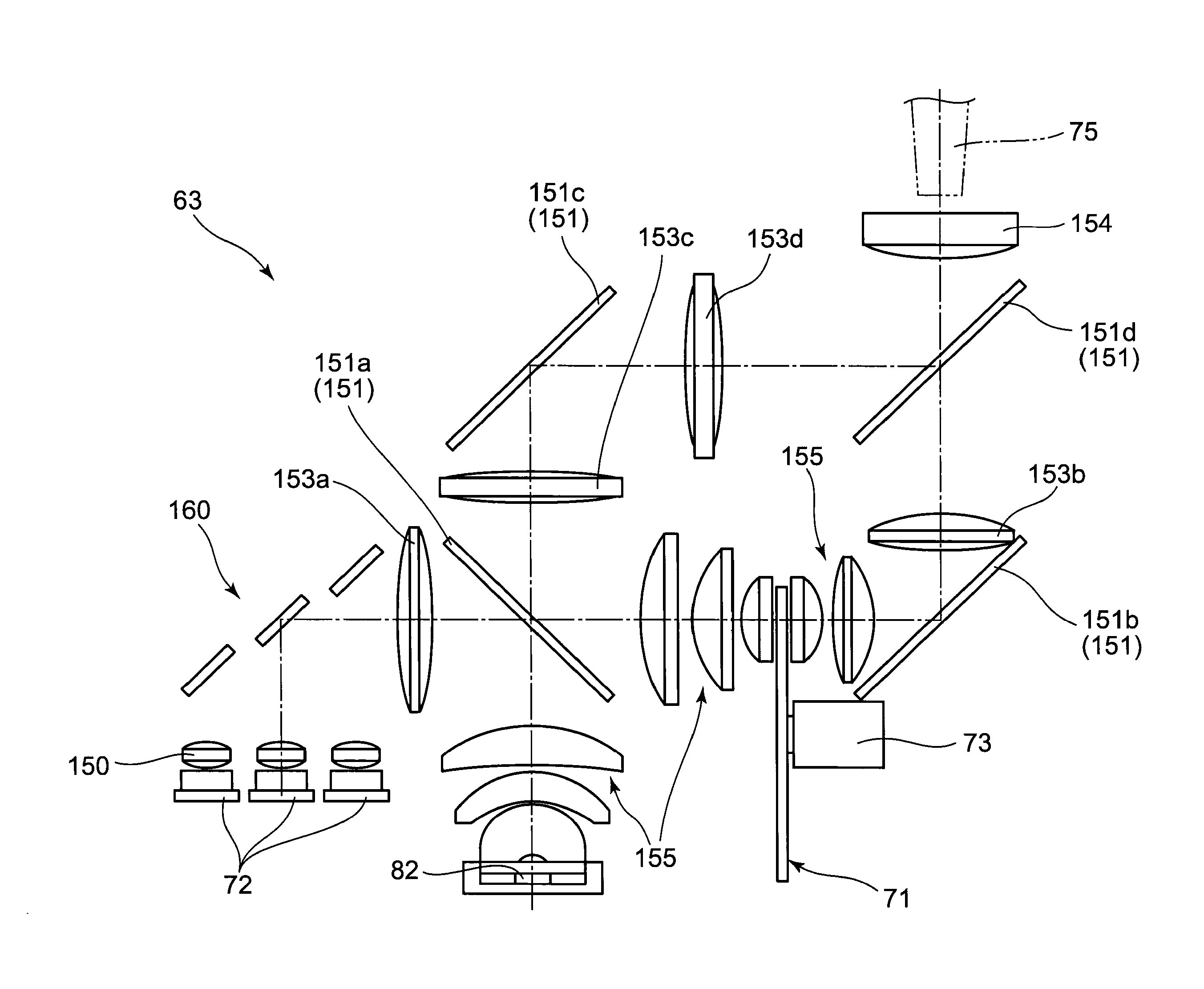

Light source unit that includes a luminescent material layer, a primary light source that emits light to excite the luminescent material layer, and an optical system including a plurality of mirrors, and projector

ActiveUS20130107225A1Increase brightnessShine wellProjectorsColor photographyLuminescent materialTransmitted light

A light source unit and a projector including the light source unit are provided. The light source unit includes a luminous wheel having a segment area on which a luminescent material layer is formed which emits light of a predetermined wavelength band by receiving light, and a segment area which is made into a transmission portion which transmits light, a primary light source which shines light of a visible wavelength band onto the luminous wheel, a secondary light source which emits light of a wavelength band which is different from light from the luminescent material layer and light from the primary light source, a collective optical system which collects light from the luminous wheel and the secondary light source to cause them to converge to a same optical path, and a light source control device which controls the emission of light from the light sources.

Owner:CASIO COMPUTER CO LTD

Vertical Light Emitting Device and Manufacturing Method Thereof

ActiveUS20150060895A1Low luminous efficiencyImprove heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingHigh pressureDie bonding

A vertical high-voltage light emitting device and a manufacturing method thereof. Polarities of two adjacent light emitting diodes (LEDs) are reversed by means of area laser stripping and die bonding, and the two diodes whose polarities are reversed are disposed on an insulating substrate comprising a bonding metal layer (320). A conductive wire (140) is distributed on a surface of the light emitting device, so that a single LED unit (330) has a vertical structure, and multiple LEDs are connected in series to form a high-voltage LED, thereby solving the problems of low light emitting efficiency and large thermal resistance of a horizontal structure.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

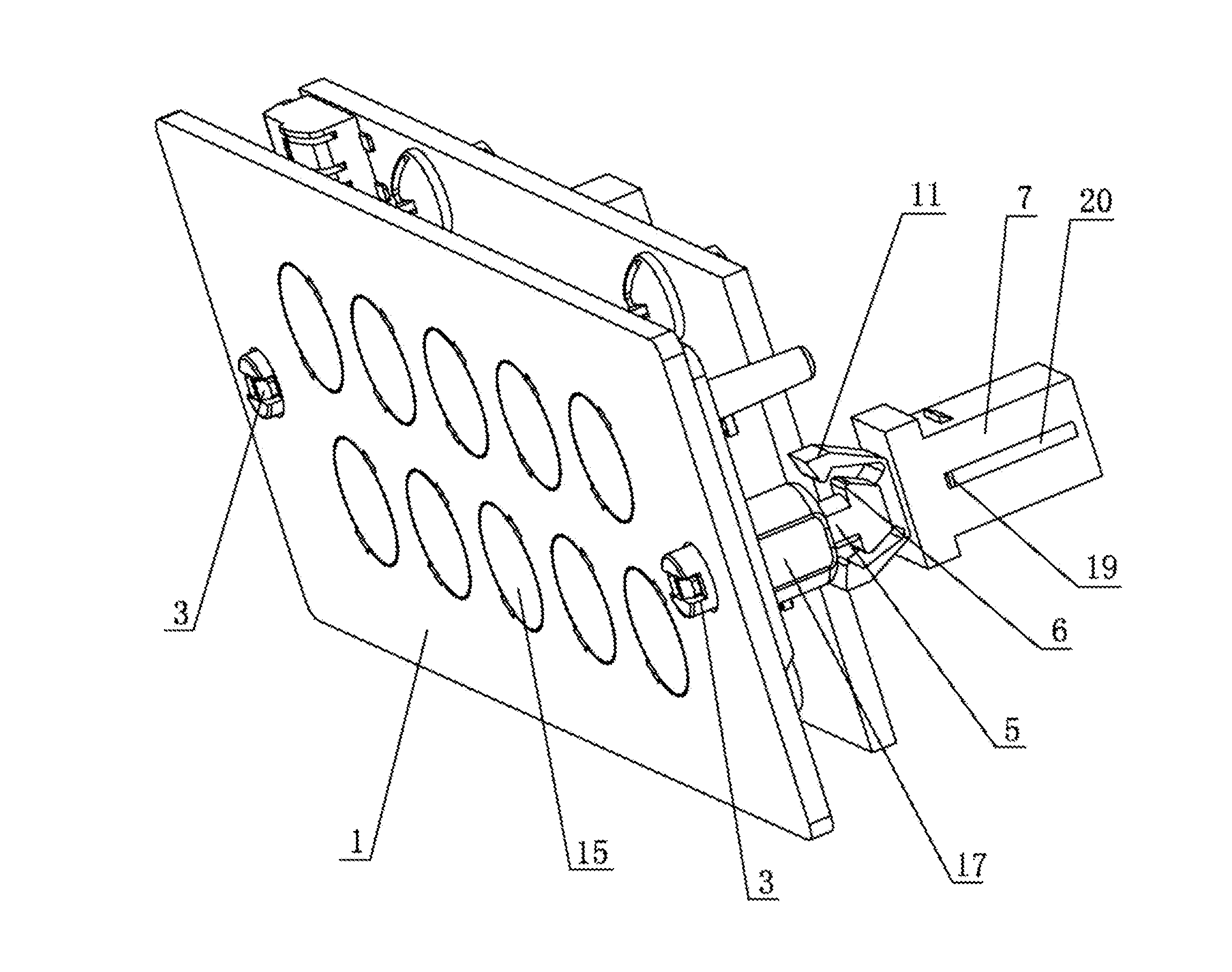

Connecting device for light fixtures

ActiveUS20160018088A1Convenient in mounting and dismountingLarge luminous efficiencyPlanar light sourcesLighting support devicesEngineeringLight fixture

A connecting device for light fixtures has a lens fixing plate, a light fixture assembly, a button, a first spring, a connecting rod and a buckle. The buckle is fixedly connected to the light fixture assembly. A mounting base is disposed on the lens fixing plate. One end of the connecting rod is located in an inner cavity of the mounting base and the other end thereof is extended out from the mounting base. The end of the connecting rod extending out from the mounting base is provided with a boss, and the connecting rod located in the inner cavity of the mounting base is sleeved with the first spring. The button is connected to the end of the connecting rod located in the inner cavity of the mounting base.

Owner:WAC LIGHTING DONGGUAN +1

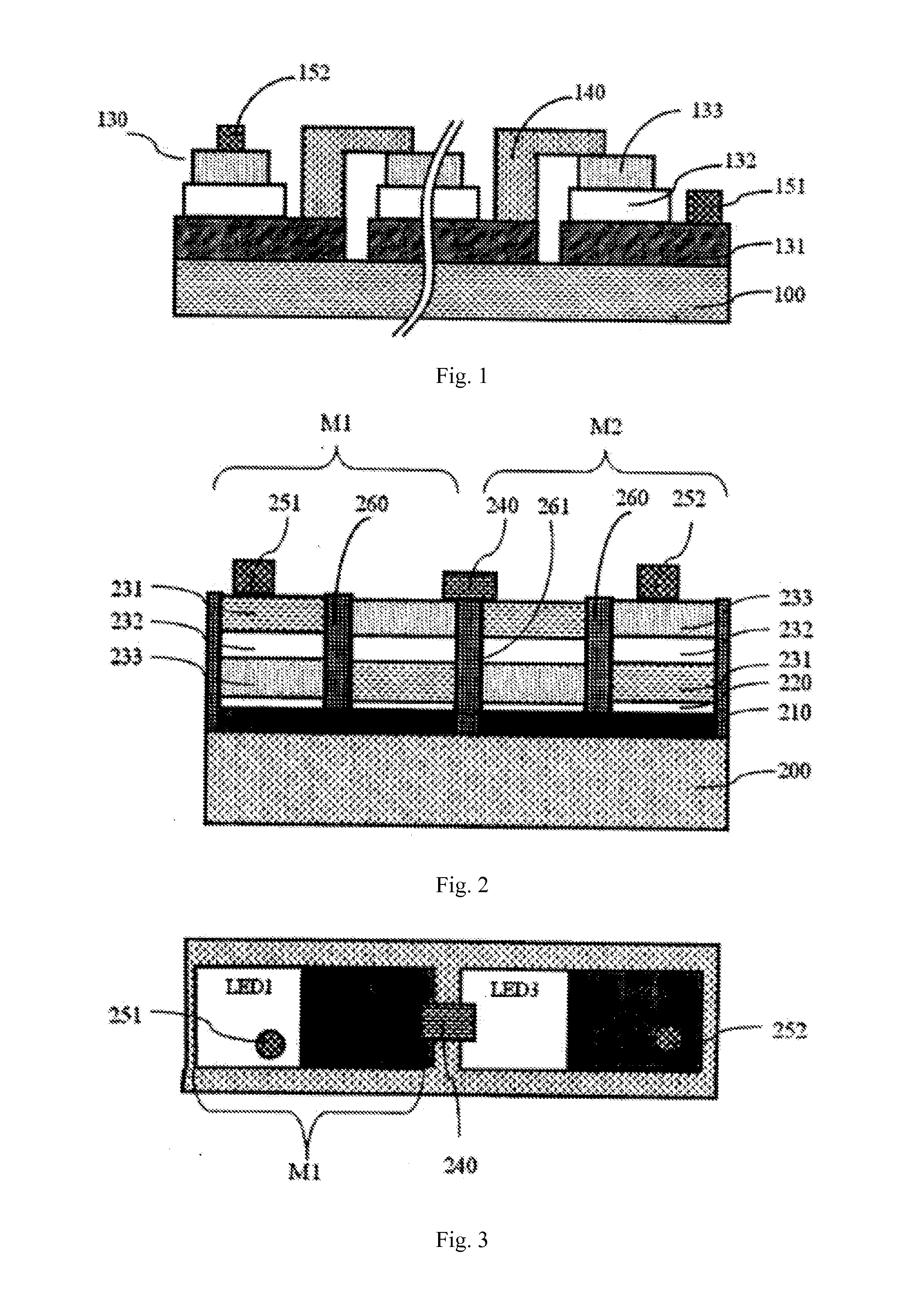

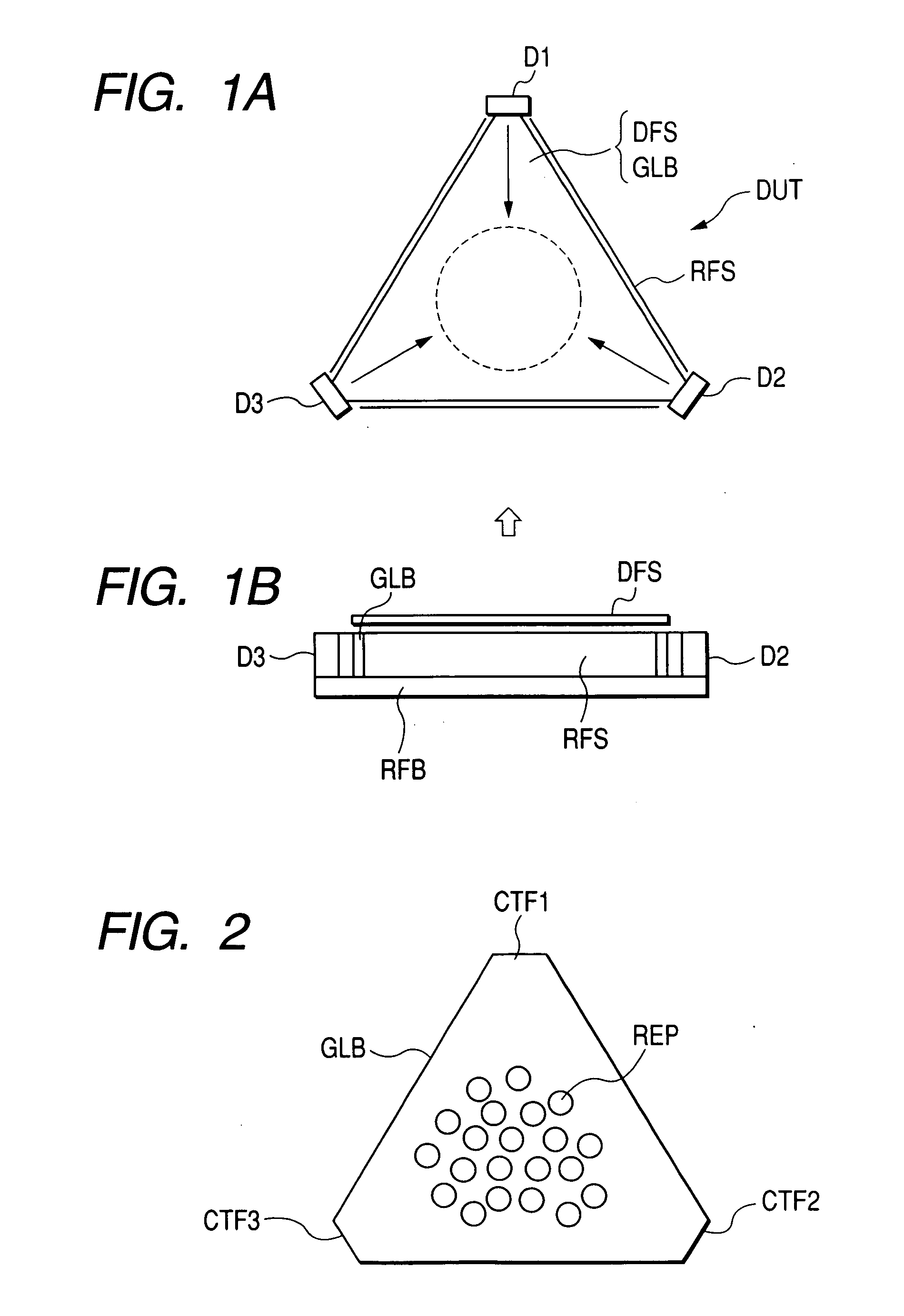

Planar illumination device and liquid crystal display device using the planar illumination device as a backlight

ActiveUS20070152135A1Small sizeReduce power consumptionMechanical apparatusPoint-like light sourceLiquid-crystal displayLight guide

A planar illumination device is provided that can achieve even distributions of mixed colors and luminance, downsizing and weight saving without lowering the luminous efficiency of LED chips. In addition, a liquid crystal display device using the planar illumination device as a backlight is provided. A polygonal flat plate-like light guide plate GLB is combined with a plurality of LED chips D1, D2, D3 emitting light with different colors from each other to constitute a color mixing unit DUT. A plurality of the color mixing units are arranged on printed circuit boards RFB having a reflection function to constitute a planar illumination device. The planer illumination device is installed on the back of a liquid crystal display panel, thus constituting a liquid crystal display device.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

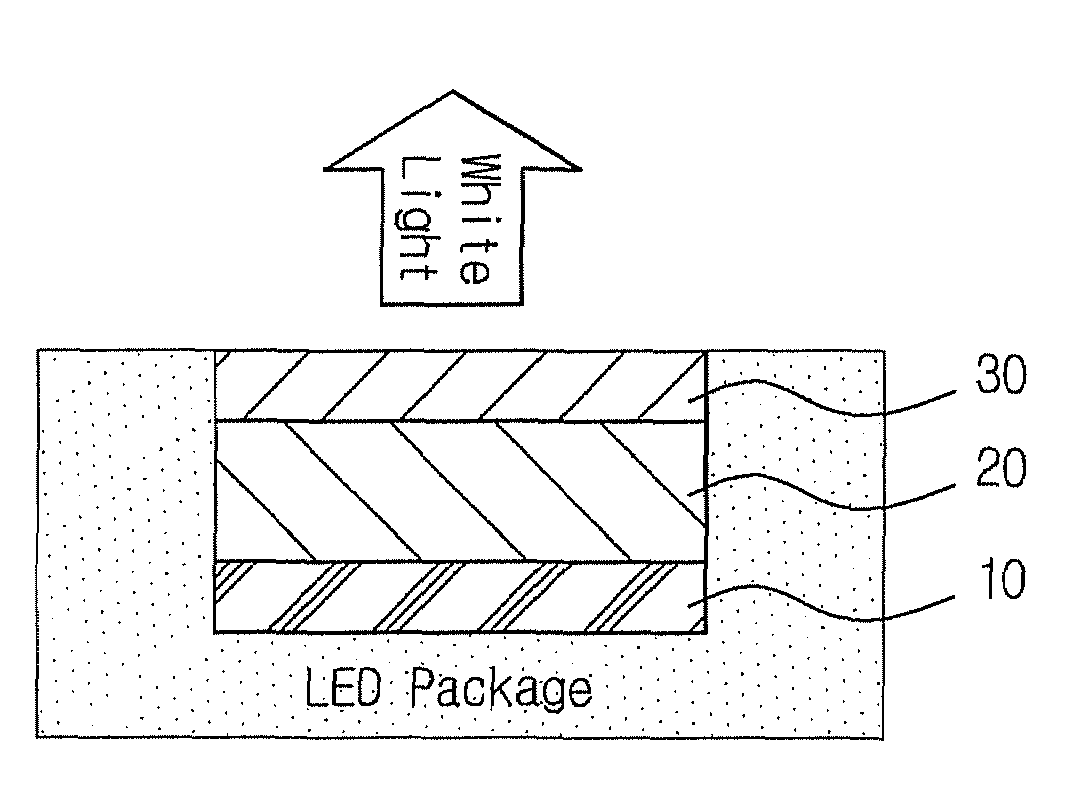

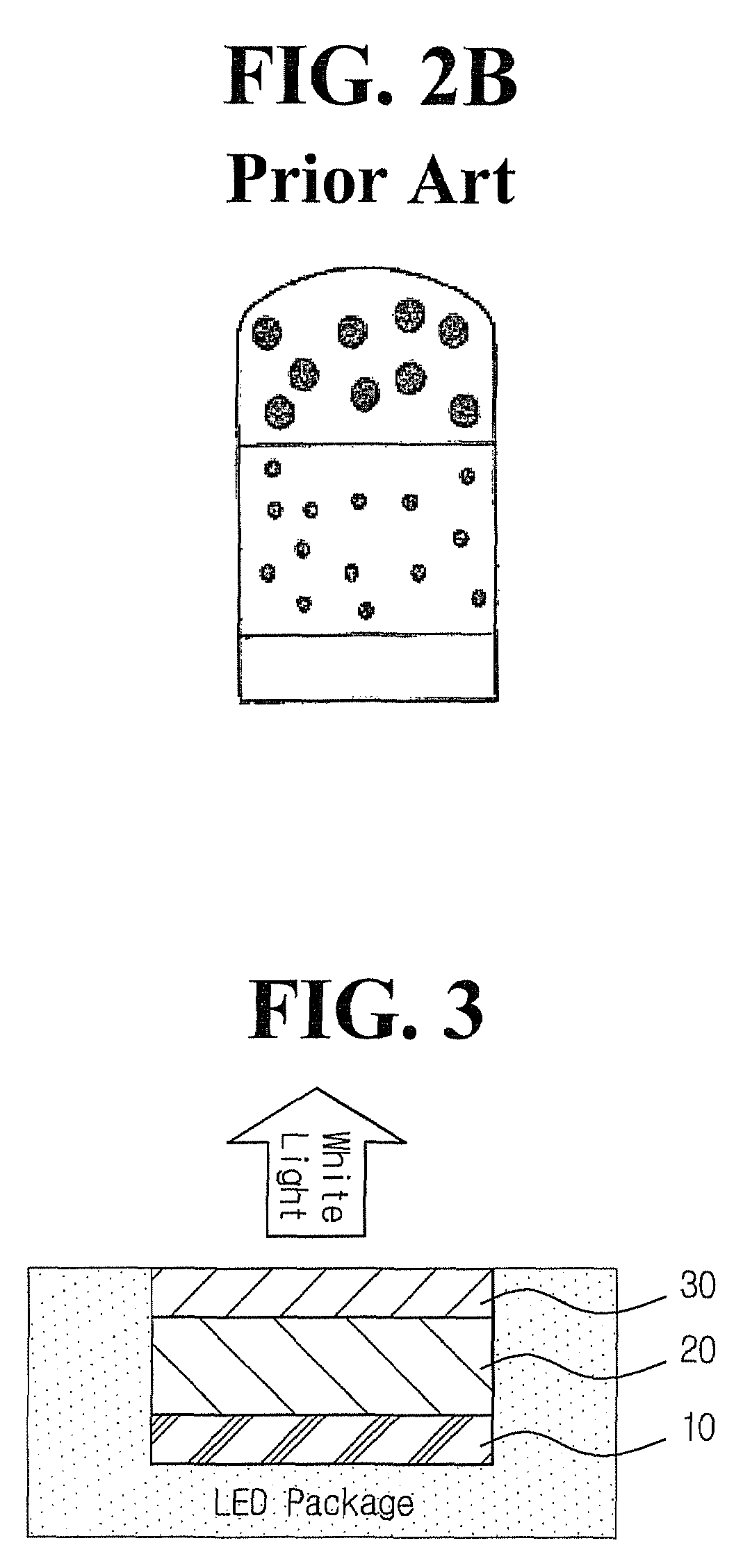

Multilayered white light emitting diode using quantum dots and method of fabricating the same

ActiveUS8017972B2Stably maintaining white lightImprove luminous efficiencySolid-state devicesGas discharge lamp usagePhosphorQuantum dot

A multilayered white light emitting diode and a method of fabricating the same include forming a phosphor mixture layer including a green phosphor and a blue phosphor on a UV light emitting diode and forming a red quantum dot layer on the phosphor mixture layer. In the white light emitting diode of the present invention, the quantum dots are excited by green and blue visible light, thus increasing luminescence efficiency and realizing stable white light. Moreover, the white light emitting diode can be widely used as a light source having high output and high efficiency, thus being capable of substituting for a backlight unit of an illumination device or display device.

Owner:SAMSUNG ELECTRONICS CO LTD

Planar illumination device and liquid crystal display device using the planar illumination device as a backlight

ActiveUS7837375B2Hindering downsizing and weight savingLow luminous efficiencyMechanical apparatusPoint-like light sourceLiquid-crystal displayLight guide

A planar illumination device is provided that can achieve even distributions of mixed colors and luminance, downsizing and weight saving without lowering the luminous efficiency of LED chips. In addition, a liquid crystal display device using the planar illumination device as a backlight is provided.A polygonal flat plate-like light guide plate GLB is combined with a plurality of LED chips D1, D2, D3 emitting light with different colors from each other to constitute a color mixing unit DUT. A plurality of the color mixing units are arranged on printed circuit boards RFB having a reflection function to constitute a planar illumination device. The planer illumination device is installed on the back of a liquid crystal display panel, thus constituting a liquid crystal display device.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

Holographic reconstruction system with an optical wave tracking means

InactiveUS8462408B2Low luminous efficiencyRelatively small errorPrismsHolographic optical componentsEye positionLight source

A holographic reconstruction system is disclosed with spatial light modulation means, modulating interferable light waves from light sources with at least one video hologram, comprising optical focusing means, focusing the modulated light waves with the reconstructed object light points for at least one eye position for the eyes of observers and controllable electro-optical deflector means, which direct the focused modulated light waves with the reconstructed light points to at least one eye position in order to reduce the aberrations. The reconstruction system has the optical focusing means in a field of focusing elements, wherein each focusing element is provided with at least one interferable light source. The electro-optical deflector means lie in the light path of the interferable light waves after the optical focusing mean and have at least one field of deflector elements, which has at least one separately controllable electro-optical deflector element for each focusing element.

Owner:SEEREAL TECHNOLOGIES

Light source unit and projector

ActiveUS8556432B2Increase brightnessImprove luminous efficiencyElectrical apparatusProjectorsLight guideLength wave

There is provided a light source unit comprising a luminescent plate having a luminescent light emission portion and a diffuse transmission portion, a first light source which emits light of a wavelength band which can excite the luminescent material, a second light source which emits light of a wavelength band which differs from the luminous light and the light emitted from the first light source, a light guiding optical system which guides light of respective wavelength bands in color emitted from the luminescent plate to a predetermined plane, and a light source control part for controlling individually the emission of light from the first light source and the second light source, wherein the luminescent plate is disposed on optical paths of the first light source and the second light source, wherein a light shining position of light from the first light source and a light shining position of light from the second light source are made to differ from each other on the luminescent plate, and wherein the light source control part controls so that the first light source and the second light source emit light simultaneously or separately to thereby emit synthesized light or monochromatic light.

Owner:CASIO COMPUTER CO LTD

Method for preparing two-dimensional material by stripping layered material with oxide semiconductor nano-powder

InactiveCN112158888ALow luminous efficiencyEfficient light emittingAmino compound purification/separationOxide/hydroxide preparationNanoparticlePhysical chemistry

The invention relates to a method for preparing a two-dimensional material by stripping a layered material with oxide semiconductor nano-powder. The method comprises the following steps: adsorbing p-type semiconductor nano-particles containing oxygen vacancies (oxygen holes) on the surface of the layered material while reactively adsorbing the semiconductor nano-particles on the surface of the layered material, and carrying out grinding in a grinder to realize inter-layer separation, carrying out stripping to prepare the two-dimensional material which is an intermediate film formed by compounding a single-layer or few-layer atom or molecular layer two-dimensional material and nanoparticles. and then separating the nanoparticles from the two-dimensional film to obtain the two-dimensional material. According to the technology, two types of practical products can be obtained, one type is an intermediate film formed by compounding a single-layer or few-layer atom or molecular layer two-dimensional material and nanoparticles; the other type is a two-dimensional material, and the two types of materials have wide and special applications.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

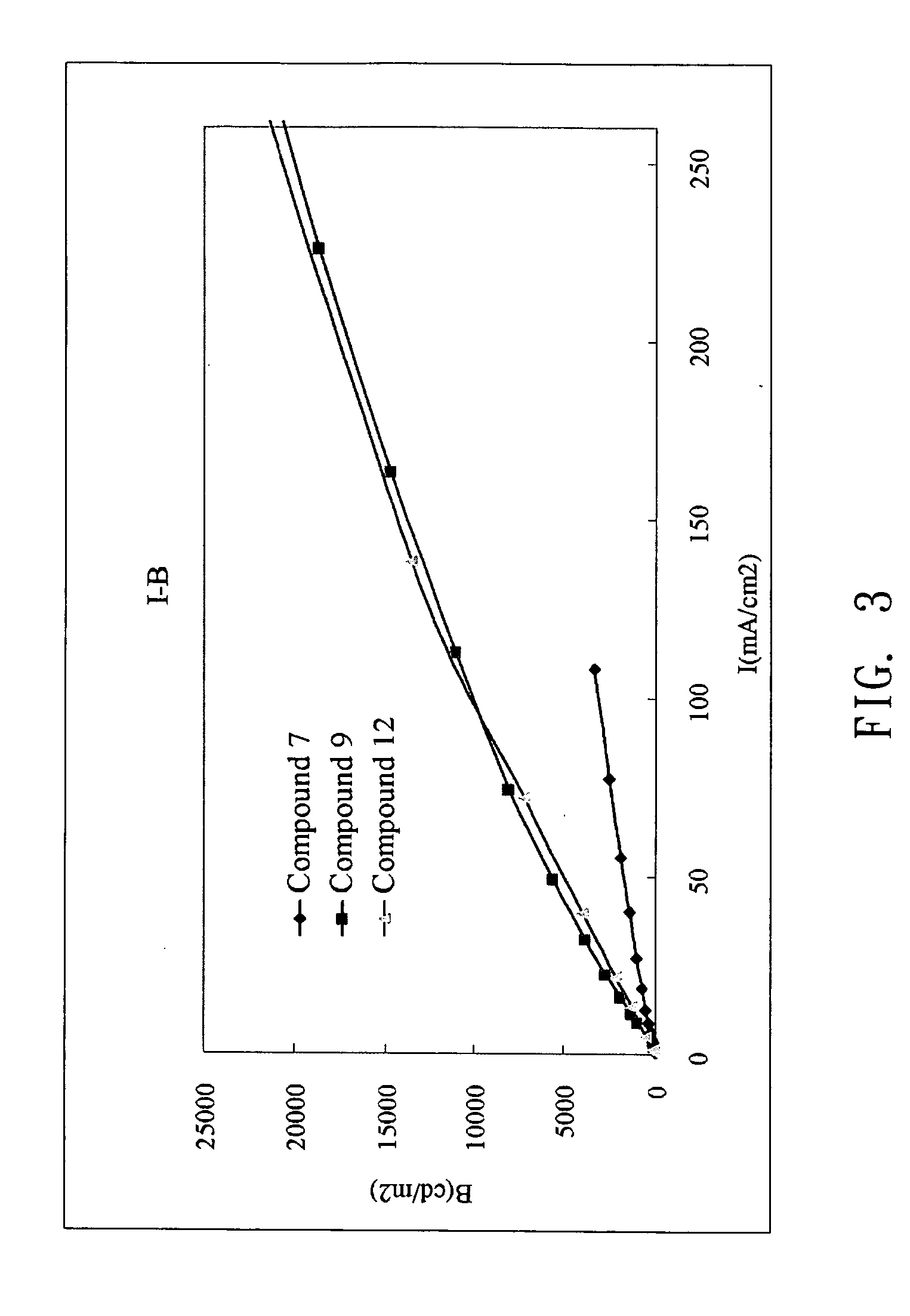

Organic electroluminescent material and organic electroluminescent device by using the same

InactiveUS20060063034A1Low luminous efficiencyImprove thermal stabilityOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceElectron

Owner:RITDISPLAY

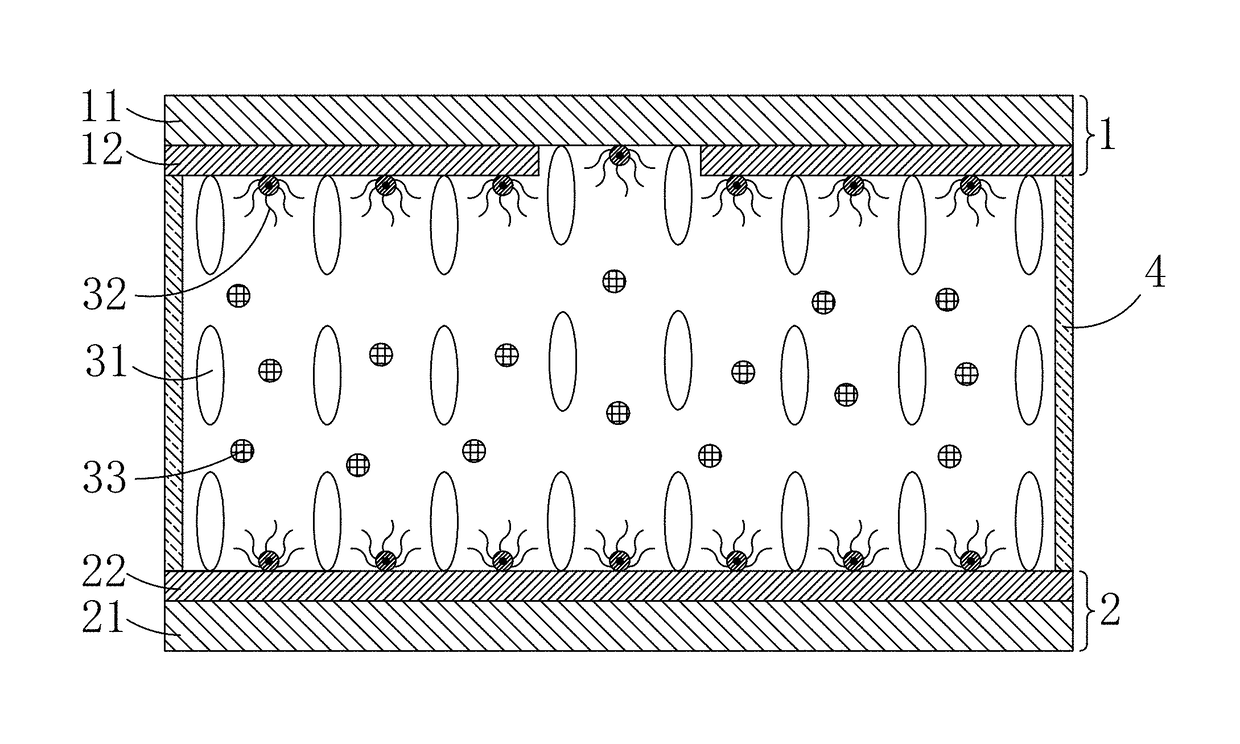

Ligand-modified quantum dot materials, methods of fabricating liquid crystal display panels and liquid crystal display panels

ActiveUS10100256B2Easy alignmentCost is economizedLiquid crystal compositionsThin material handlingLiquid-crystal displayQuantum dot

The present application provides a ligand-modified quantum dot material, a method of fabricating a liquid crystal display panel, and a liquid crystal display panel. The ligand-modified quantum dot material of the present application can occur a polymerization with the ligand-modified quantum dot material under ultraviolet irradiation to form a polymer, while the polymer deposits on a substrate to form a polymer film, which can replace the PI alignment film, so that an alignment process of liquid crystal is simplified, and a cost is economized; simultaneously, display quality of a liquid crystal display panel can be improved by the quantum dots anchored in the polymer film. The method of fabricating the liquid crystal display panel of the present application eliminates the fabricating process of the PI alignment film, the method has simple process and low cost, and a liquid crystal display panel obtained thereby has better display quality. The liquid crystal display panel of the present application utilizes the polymer film, which is obtained by polymerizing the ligand-modified quantum dot material and a polymerizable monomer, to replace the PI alignment film, so as to greatly enhance quality of the panel, and to have a low fabricating cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Light-emitting material comprising photoactive group-bonded polysilsesquioxane having a ladder structure, thin film using the same and organic electronic device comprising the same

InactiveUS20110260139A1Improve luminous efficiencyImproved cotabilitySynthetic resin layered productsSolid-state devicesHeat resistanceOrganic base

Disclosed is a light-emitting material including a polysilsesquioxane having a ladder structure with photoactive groups bonded to a siloxane backbone. In addition to superior heat resistance and mechanical property, the light-emitting material provides improved cotability and film property when prepared into a thin film. Further, it provides higher luminous efficiency than the existing organic-based light-emitting material.

Owner:KOREA INST OF SCI & TECH

Ligand-modified quantum dot materials, methods of fabricating liquid crystal display panels and liquid crystal display panels

ActiveUS20180079960A1Easy alignmentCost is economizedLiquid crystal compositionsLuminescent compositionsLiquid-crystal displayQuantum dot

The present application provides a ligand-modified quantum dot material, a method of fabricating a liquid crystal display panel, and a liquid crystal display panel. The ligand-modified quantum dot material of the present application can occur a polymerization with the ligand-modified quantum dot material under ultraviolet irradiation to form a polymer, while the polymer deposits on a substrate to form a polymer film, which can replace the PI alignment film, so that an alignment process of liquid crystal is simplified, and a cost is economized; simultaneously, display quality of a liquid crystal display panel can be improved by the quantum dots anchored in the polymer film. The method of fabricating the liquid crystal display panel of the present application eliminates the fabricating process of the PI alignment film, the method has simple process and low cost, and a liquid crystal display panel obtained thereby has better display quality. The liquid crystal display panel of the present application utilizes the polymer film, which is obtained by polymerizing the ligand-modified quantum dot material and a polymerizable monomer, to replace the PI alignment film, so as to greatly enhance quality of the panel, and to have a low fabricating cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

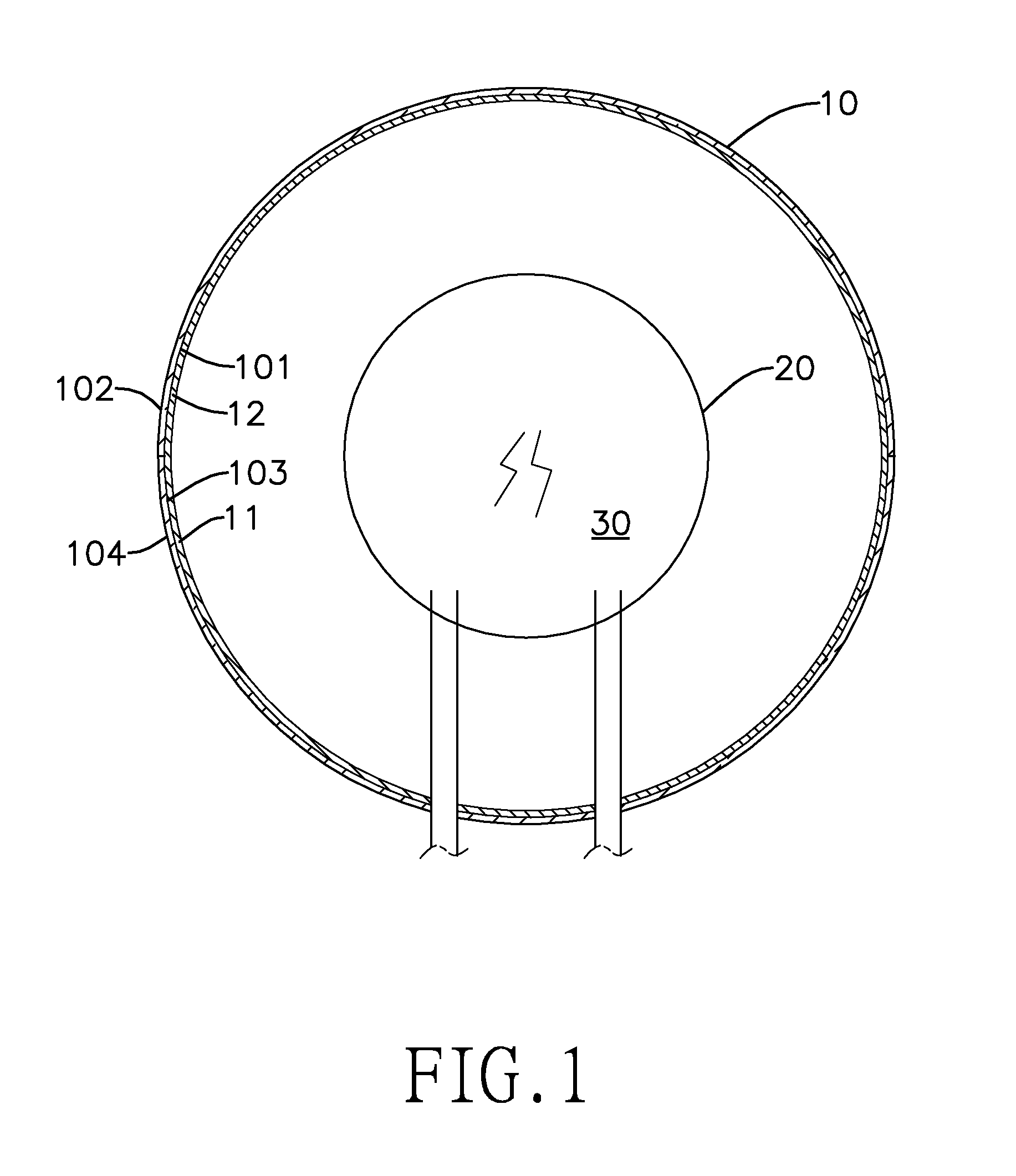

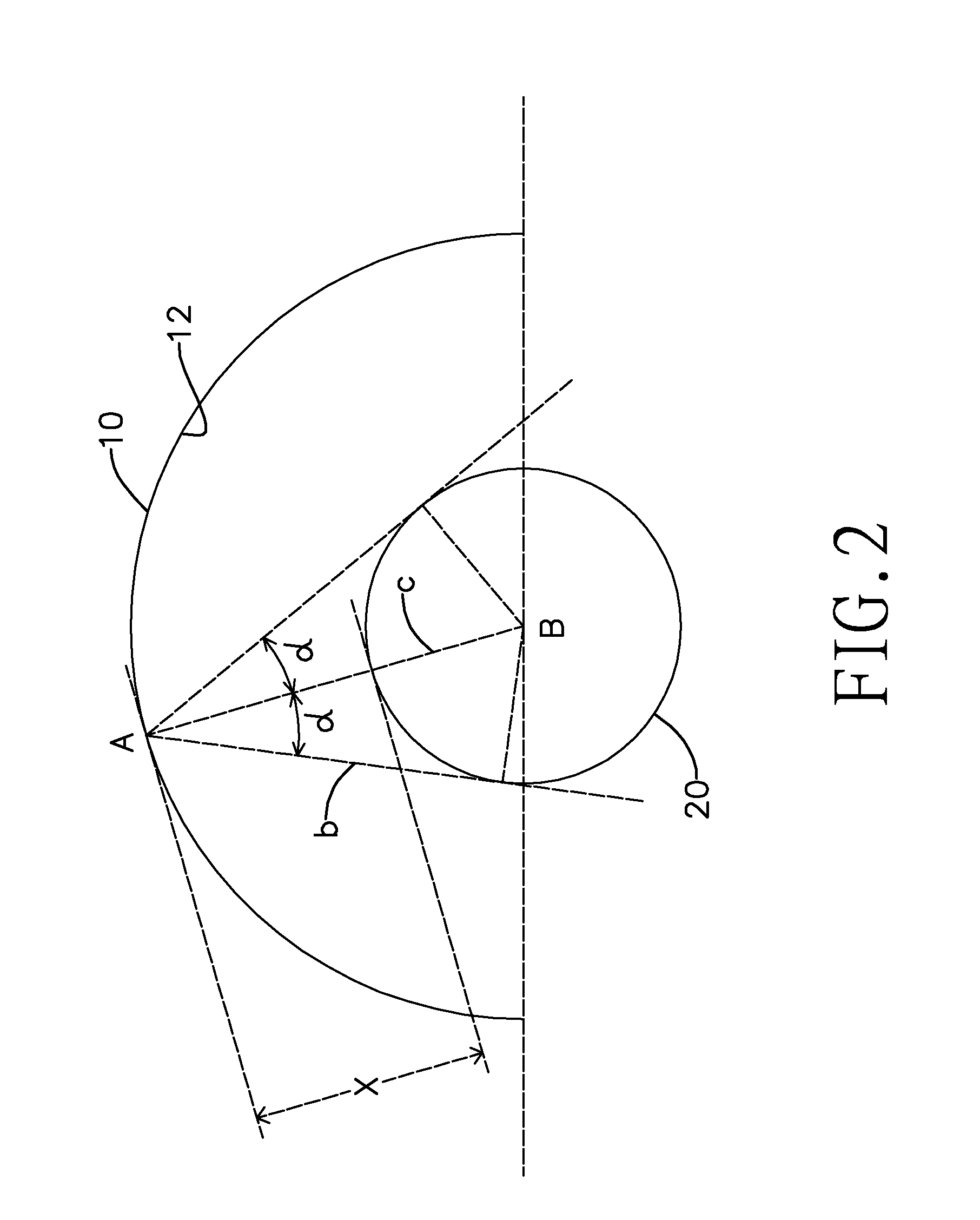

Brightness improving structure of light-emitting module with an optical film surface layer

ActiveUS20100308709A1Increase brightnessImprove efficiencyDischarge tube luminescnet screensPoint-like light sourceSurface layerOptical thin film

A brightness improving structure of a light-emitting module with an optical film surface layer 12, wherein a light-emitting part 20 is provided inside a transparent envelop 10 and may emit ultraviolet or blue light, the said transparent envelop 10 has first wall and second wall, first inside wall 101 and second inside wall 103 are oppositely formed inside thereof, first outside wall 102 and second outside wall 104 are oppositely formed outside thereof. The first wall is partly or entirely provided with the optical film coating 12, the optical film coating 12 may at least reflect the ultraviolet or blue light exciting fluorescent / phosphorescent light, and may pass light rays comprising visible light. A visible light layer or both the visible light layer and a reflective layer are provided on the second wall, and the said light-emitting part 20 is placed at a setting location from the envelop 10.

Owner:MII JENN WEI

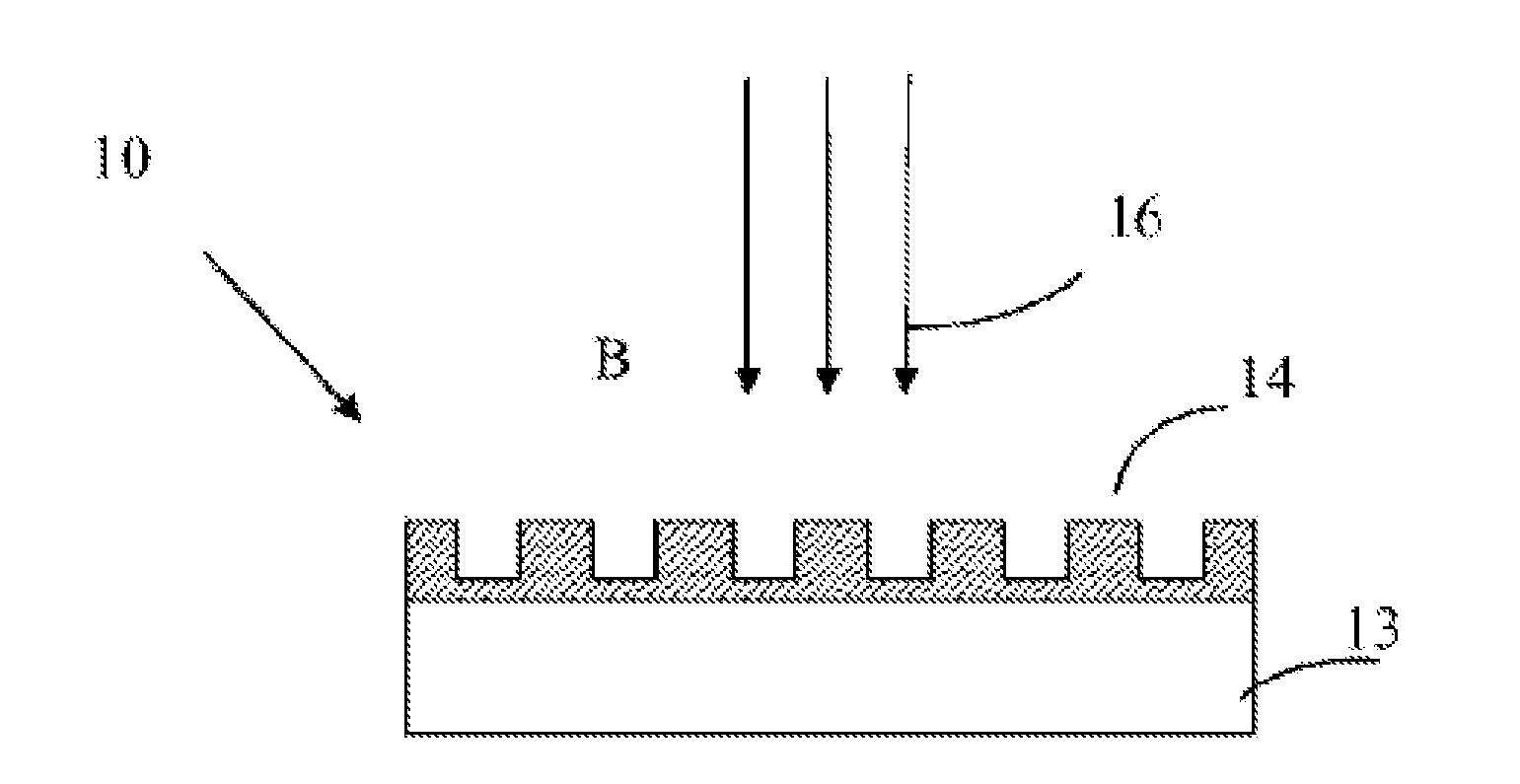

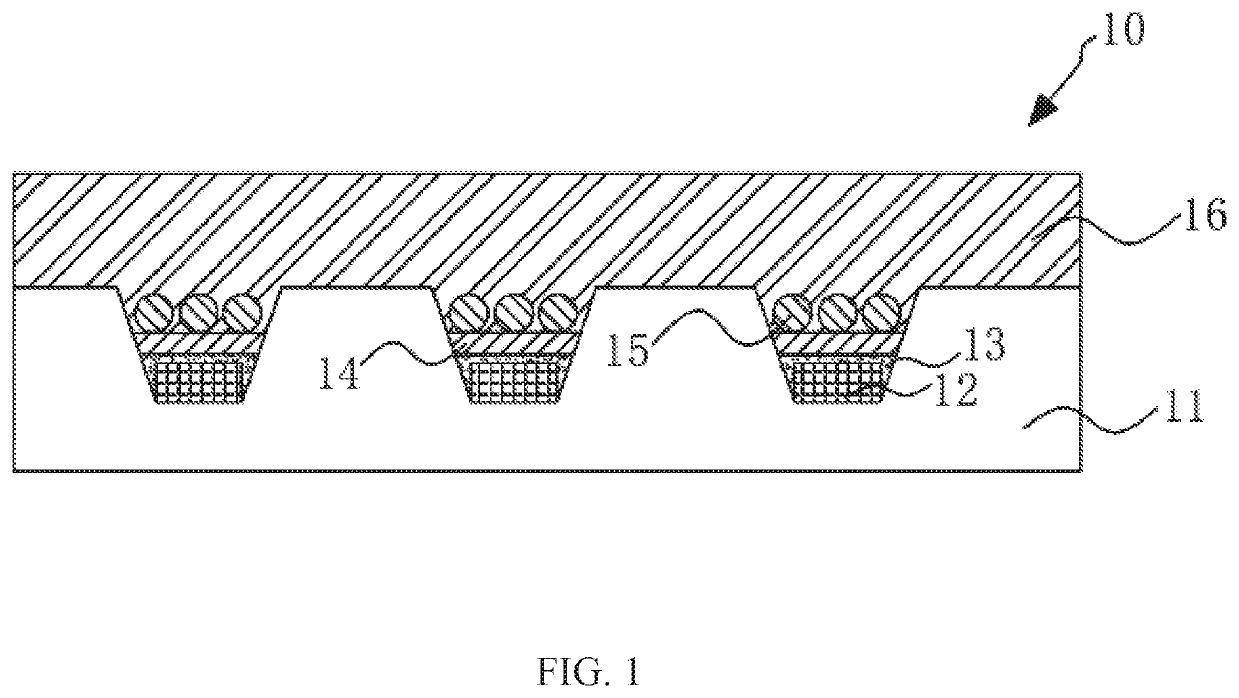

Glass substrate light emitting element and methods for manufacturing and luminescence thereof

InactiveUS20120326056A1Improve luminous efficiencyHigh luminescent homogeneity and stabilityOptical radiation measurementRadiation measurementChemical compositionRare earth ions

A light emitting element (10) is provided, which includes luminescent glass (13), a metal layer (14) formed on the surface of the luminescent glass (13), wherein periodic micro and nano structure is provided on the metal layer (14), and the chemical constituent of the luminescent glass (13) is rare-earth-ion doped silicate. Further provided are manufacturing and luminescence methods of the light emitting element. The luminescent glass (13) in the present invention includes a metal layer (14) with periodic micro and nano structure, which can enhance the luminous efficiency and luminous homogeneity and stability of the luminescent glass, and can be used on superluminescent and high-speed operating light emitting devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

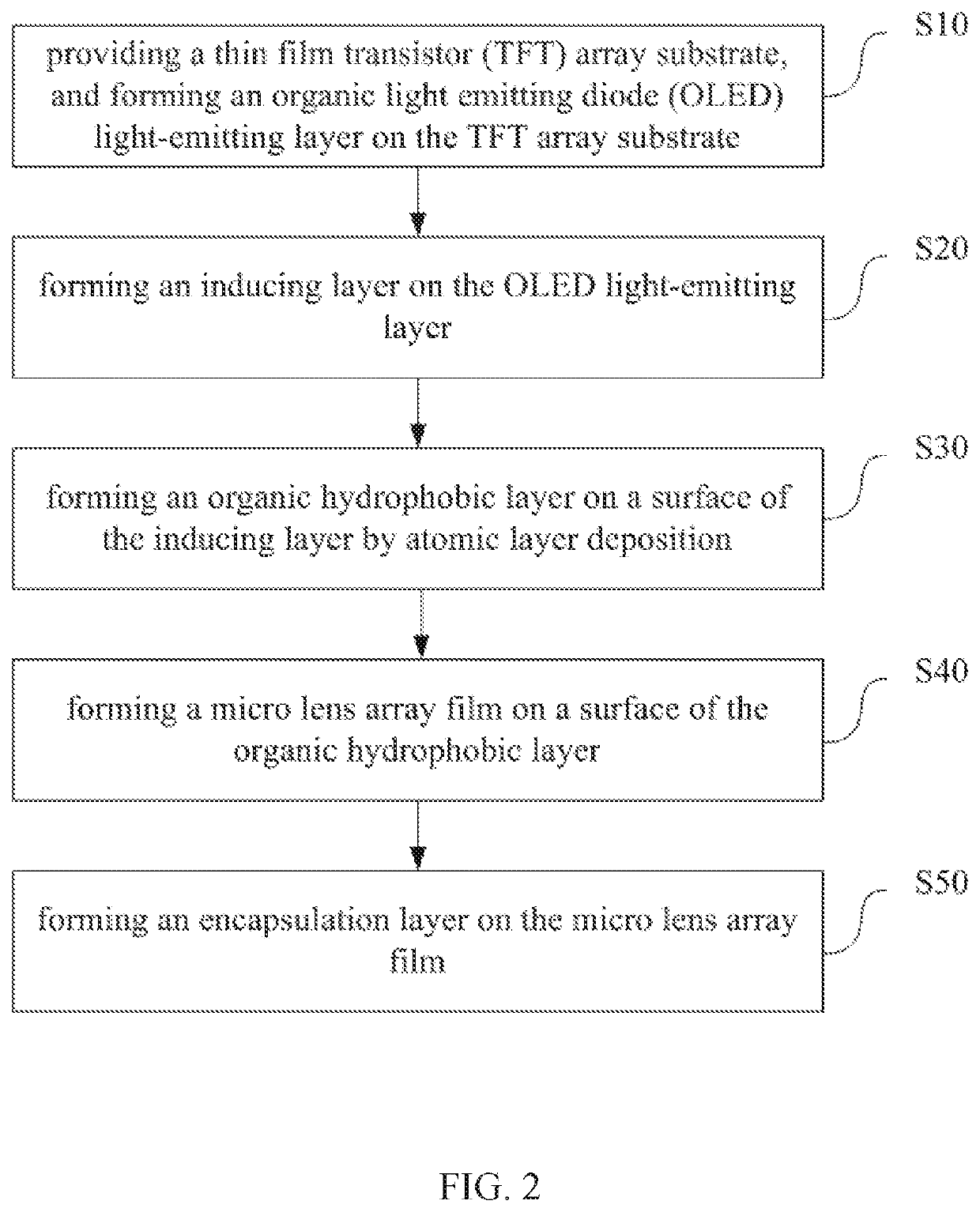

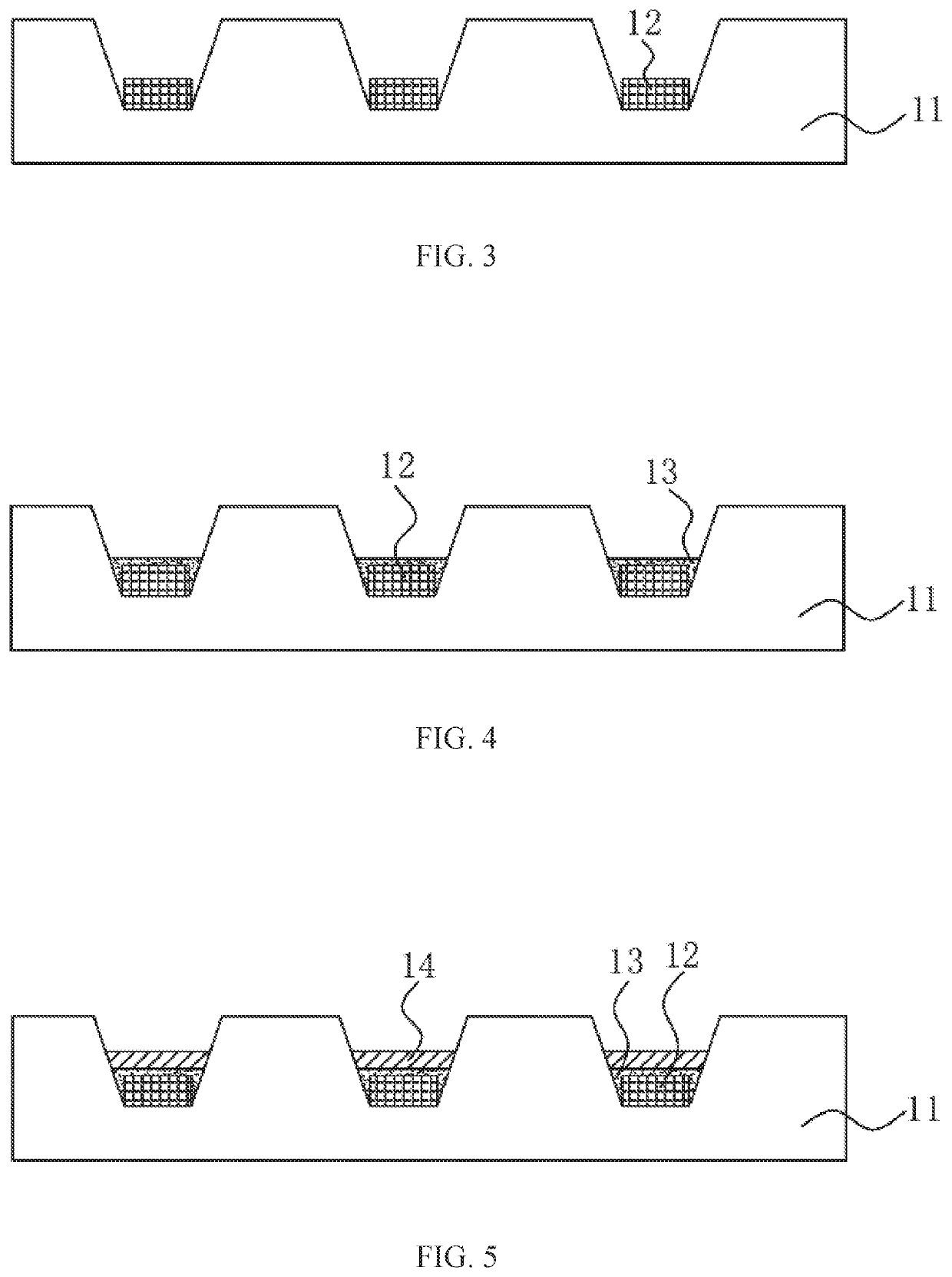

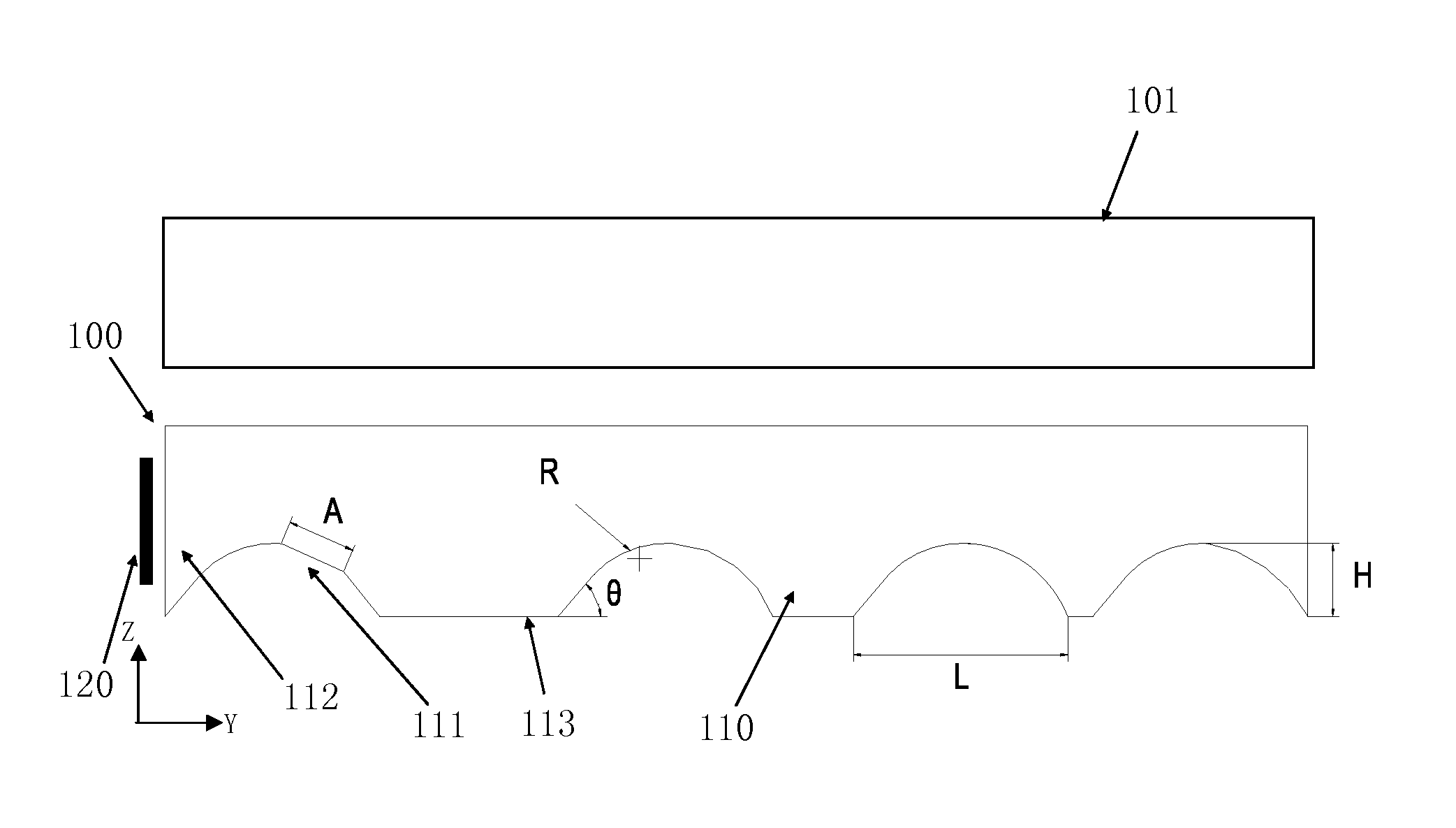

Organic light emitting diode display panel and manufacturing method thereof

ActiveUS20200091463A1Improve hydrophobicityImproving optical coupling ratioSolid-state devicesSemiconductor/solid-state device manufacturingMicro lens arrayOptical coupling

An organic light emitting diode (OLED) display panel includes a thin film transistor (TFT) array substrate; an OLED light-emitting layer; an encapsulation layer; an inducing layer disposed on a light-emitting side of the OLED light-emitting layer; a micro lens array film disposed over the inducing layer; and an organic hydrophobic layer disposed between the inducing layer and the micro lens array film. By providing the organic hydrophobic layer with strong hydrophobic performance, a surface with a large water contact angle is provided for a subsequent formation of the micro lens array film, thereby improving an optical coupling ratio of the micro lens, and improving luminous efficiency of the OLED light emitting layer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

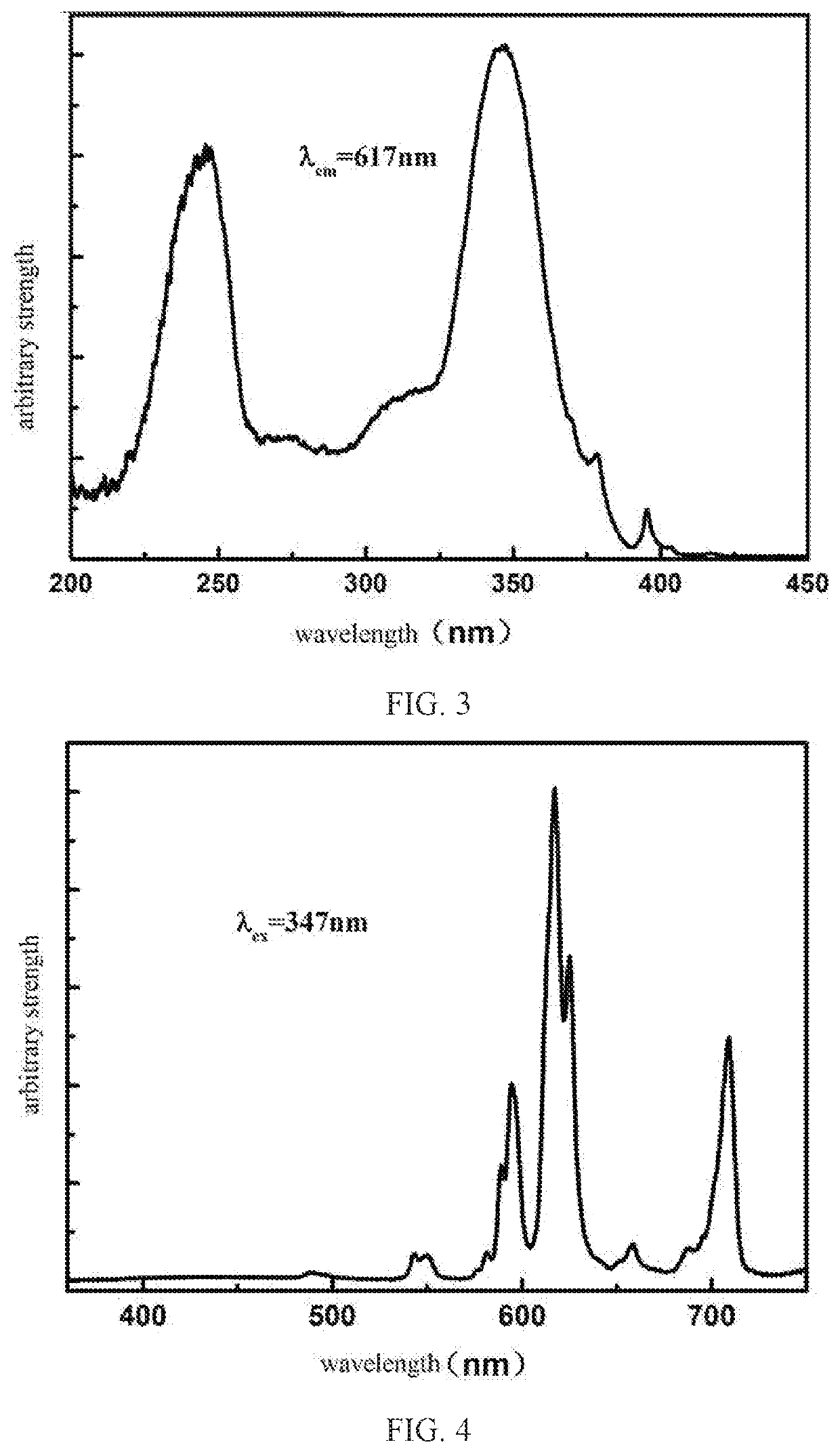

Borate fluorescent powder and preparing method thereof

ActiveUS20210301204A1Low luminous efficiencyCrystal phase stabilityEnergy efficient lightingLuminescent compositionsPhysical chemistryUltraviolet

A borate fluorescent powder and a preparing method thereof are provided. The formula of the borate fluorescent powder is Ba2-nSrnLu5-x-y-m-zLmCexTbyEuzB5O17. L is one or any combination of the elements Gd, La, and Sc. Ranges of x, y, z, m, and n are respectively 0<x≤0.6, 0<y≤3, 0<z≤0.4, 0≤m≤1, and 0≤n≤0.5. The borate fluorescent powder provided has a stable crystalline phase, high luminous efficiency, and decent thermal stability, and can be applied to ultraviolet LEDs or near-ultraviolet LEDs to construct white LEDs.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

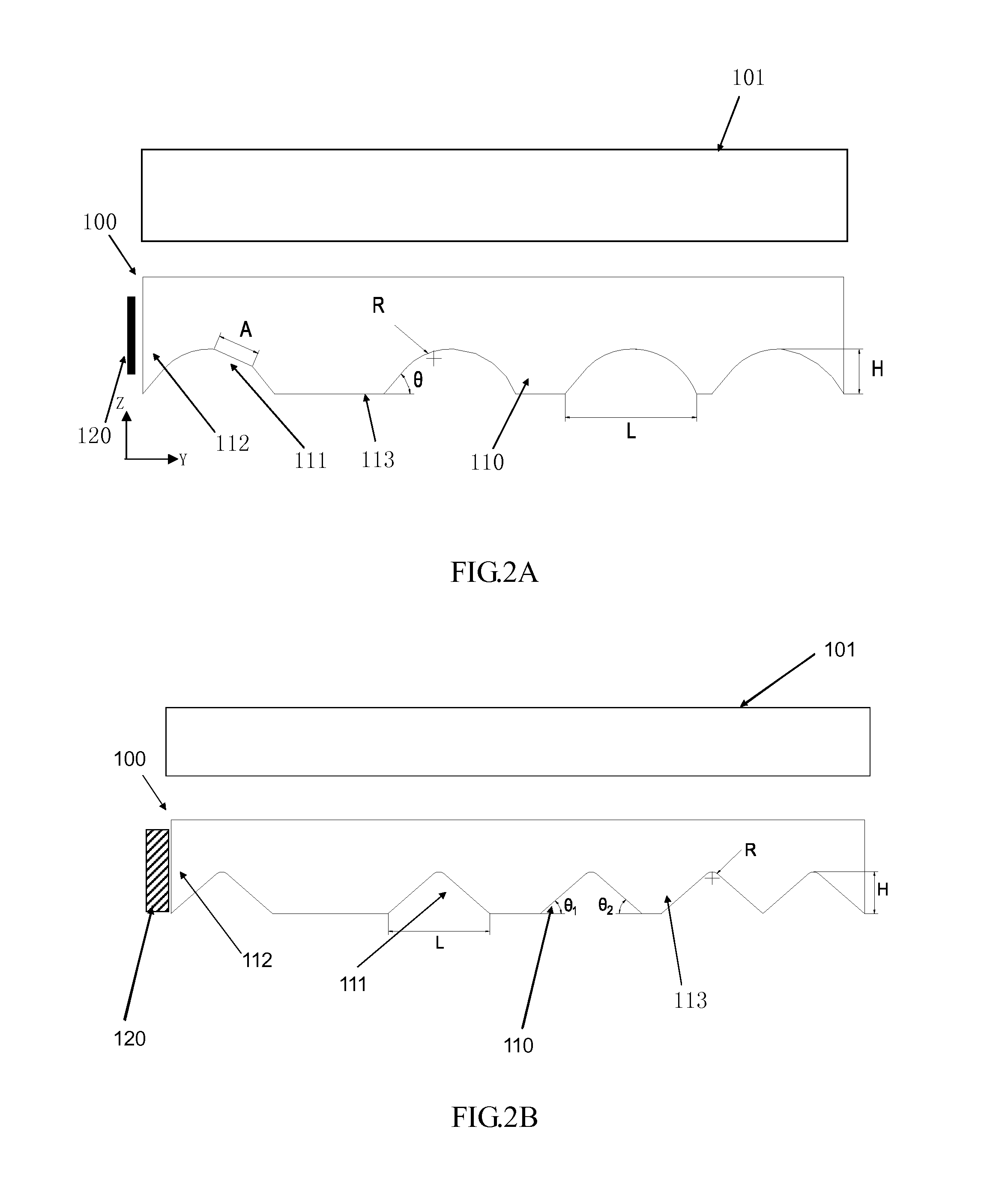

Light guide plate and backlight module

ActiveUS20130021824A1Increase brightnessLow luminous efficiencyMechanical apparatusLight guides for lighting systemsLight guideOptoelectronics

The present invention provides a light guide plate and a backlight module. The backlight module comprises the light guide plate. The light guide plate comprises a plurality of elongated microstructures disposed on the light guide plate and parallel to a light-incident surface thereof. At least one curve parameter of profiles of the elongated microstructures is altered according to a position variation in an extending direction of the elongated microstructures, so as to adjust a brightness distribution in the extending direction of the elongated microstructures. The invention can improve a luminous efficiency of the light guide plate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com