Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Large heat supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

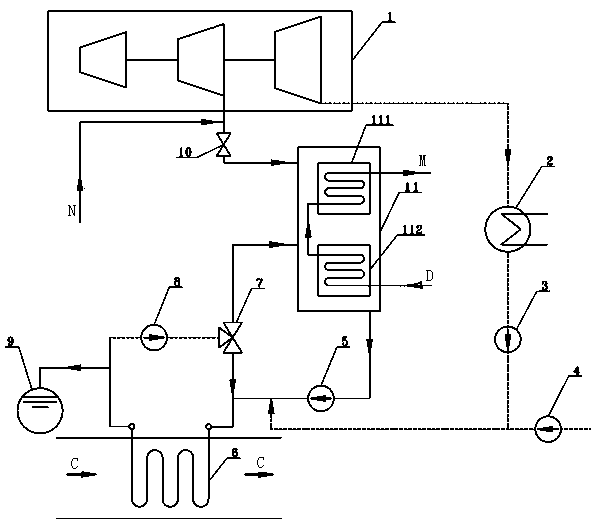

Method and system for reducing frosting degree of air-source heat pump hot water unit in winter

InactiveCN101566410AIncrease heating capacityLarge heat supplyHeat pumpsHeat storage plantsWater sourceEngineering

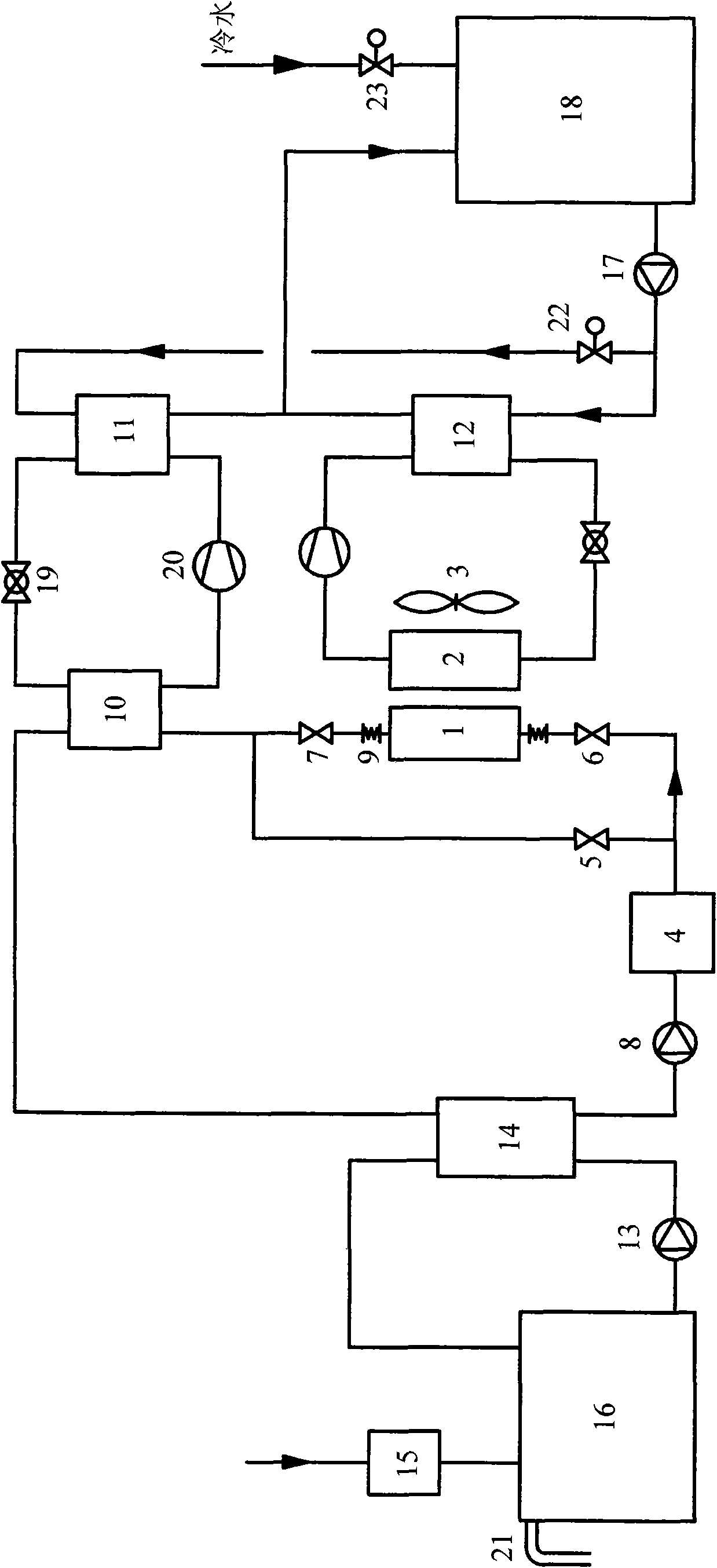

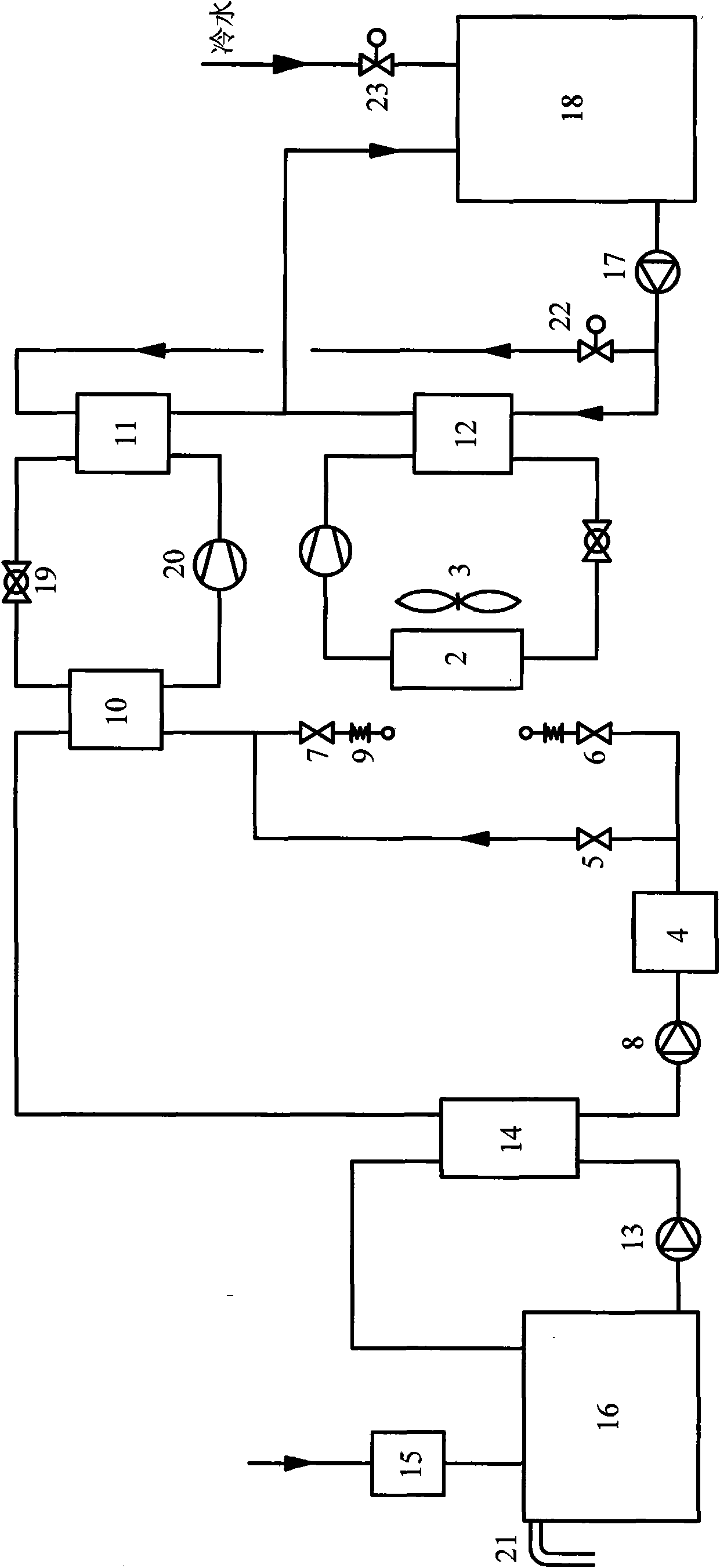

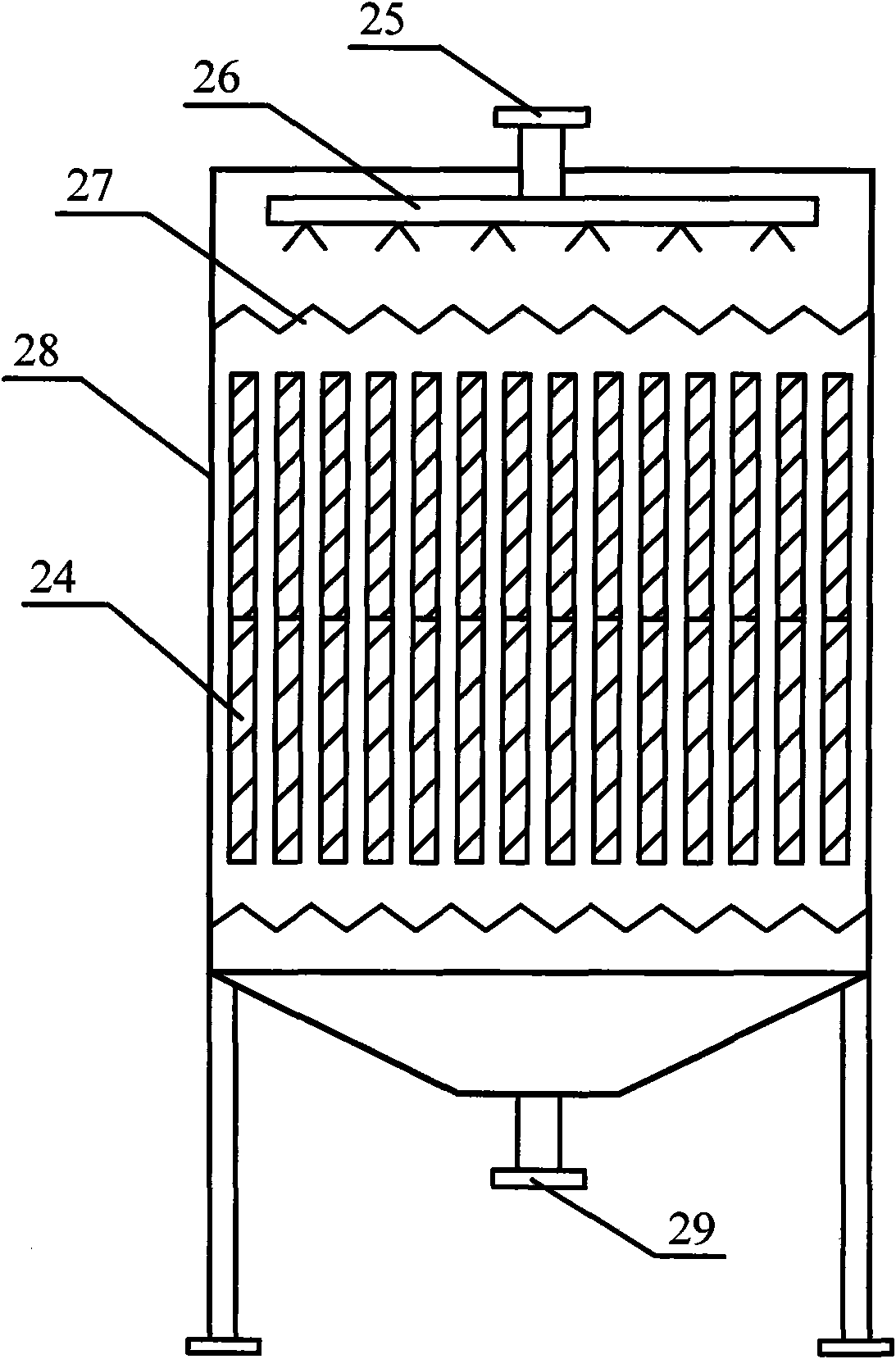

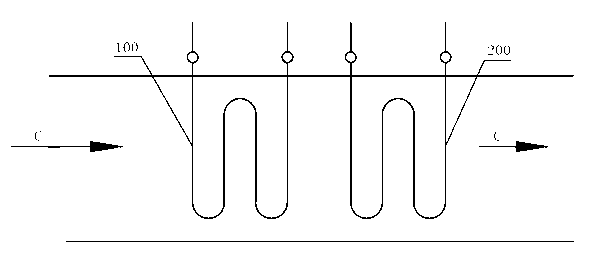

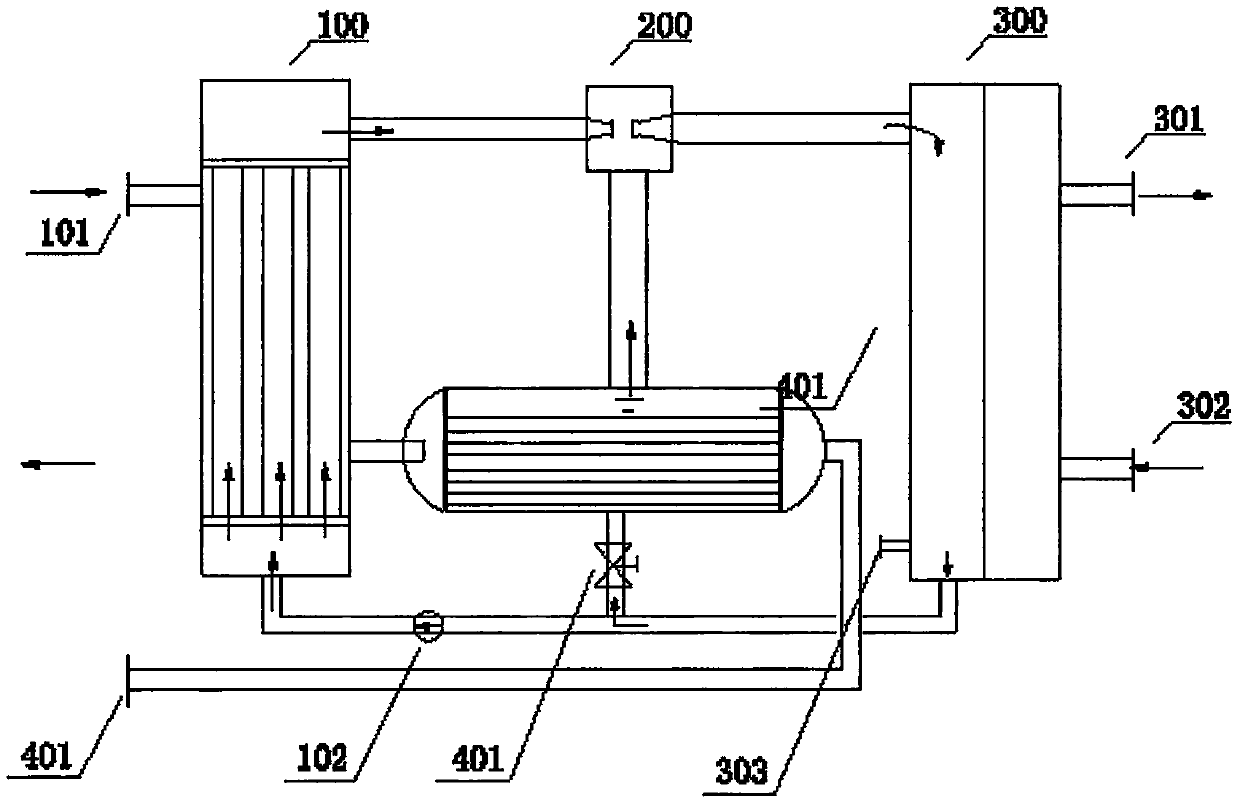

The invention relates to a waste heat utilizing method and a waste heat utilizing system for reducing the frosting degree of an evaporator of an air-source heat pump hot water unit in winter. In order to overcome the defects in energy dissipation and influence on the system stability, which are existed in the existing defrosting technology, the invention provides a technical proposal as follows: domestic hot water after use is pumped into a waste water heat exchanger and then undergoes heat exchange with medium water in the waste water heat exchanger; the medium water after the heat exchange is pumped into a phase-change heat storage device and then flows into an air heater arranged at the air inlet side of the evaporator of the air-source heat pump hot water unit; the medium water flowing out of the air heater then flows into an evaporator of a water source heat pump unit and then flows back into the waste water heat exchanger. By using the method of heating and warming up the air with the waste hot water, the method and the system improve the temperature of the air entering the evaporator, reduce the relative humidity of the air, greatly reduce the frosting possibility, not only save the energy consumed for defrosting, but also increase the heat supply of the unit and enhance the reliability and the stability of operation of the system.

Owner:GUANGDONG NEW ENERGY TECH DEV

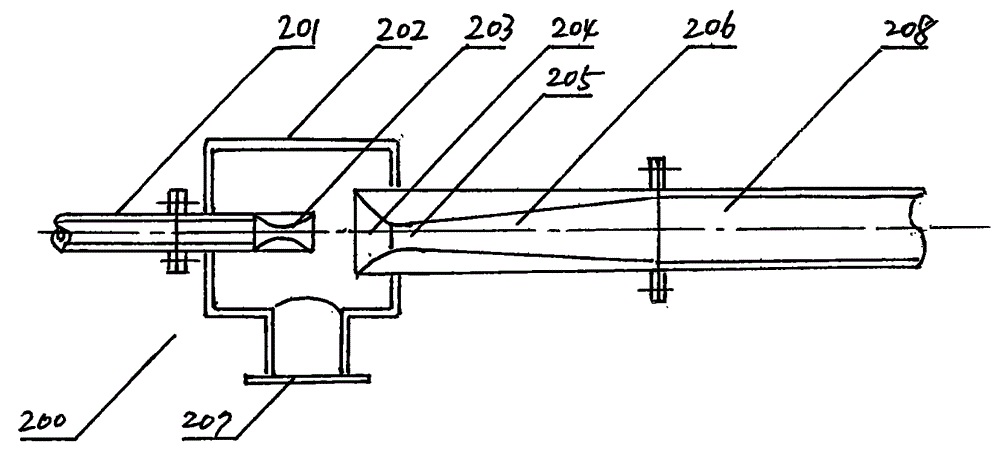

Low-pressure expanded economizer system

ActiveCN103256644ALess investmentSimple operation and maintenanceFeed water supplyHot-water central heatingEngineeringRecuperator

The invention discloses a low-pressure expanded economizer system comprising a turbine, a condenser, a condensate pump, a make-up pump, a drain pump, a low-pressure expanding economizer, a recycle pump, a low pressure steam pocket, a turn-off valve and a heat exchanger. The heat exchanger comprises a heat exchanger high-temperature section and a heat exchanger low-temperature section which are mutually communicated. Non-heating season condensate working condition is utilized as a basis and heating season heat supplying working condition is combined to combine the low-pressure expanded economizer with a smoke heating network heater (heat-supplying economizer) to form one heated surface (the low-pressure expanded economizer), and users can flexibly adjust according to heating demand and electric load condition. Compared with the prior art with the low-pressure expanding economizer and the smoke heater for heating network arranged respectively, the low-pressure expanded economizer system does not need to mount the smoke heating network heater independently, pipelines and valves needed to be arranged are reduced, the structure is simple, system reliability is high, and the problem of non-heating season burning is avoided.

Owner:HANGZHOU BOILER GRP CO LTD

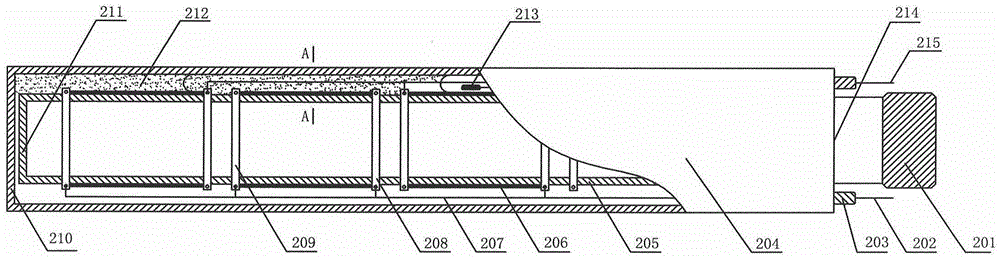

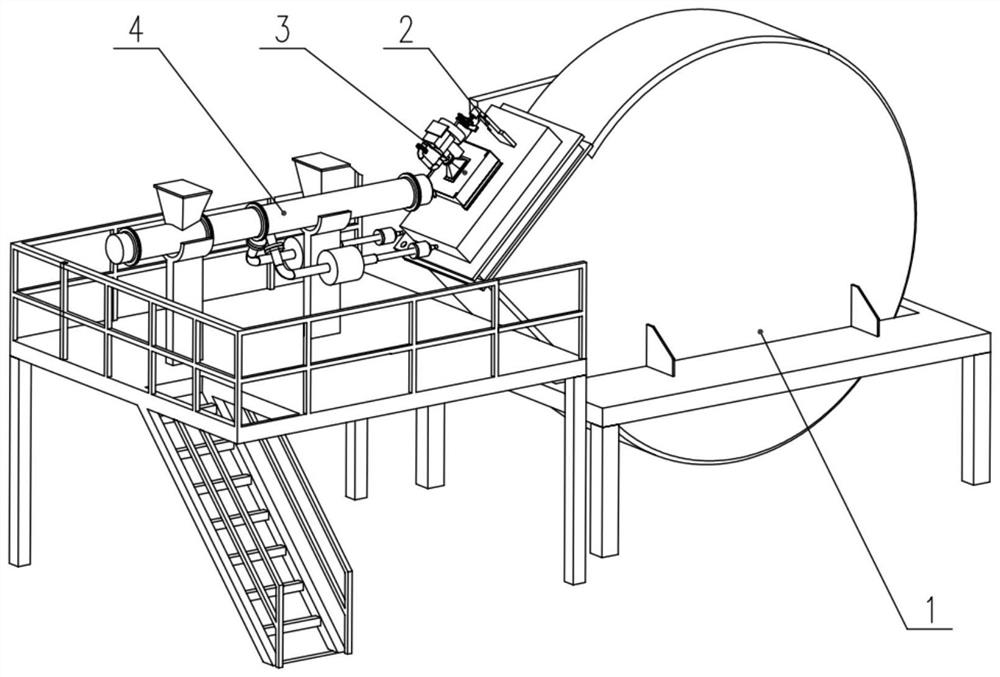

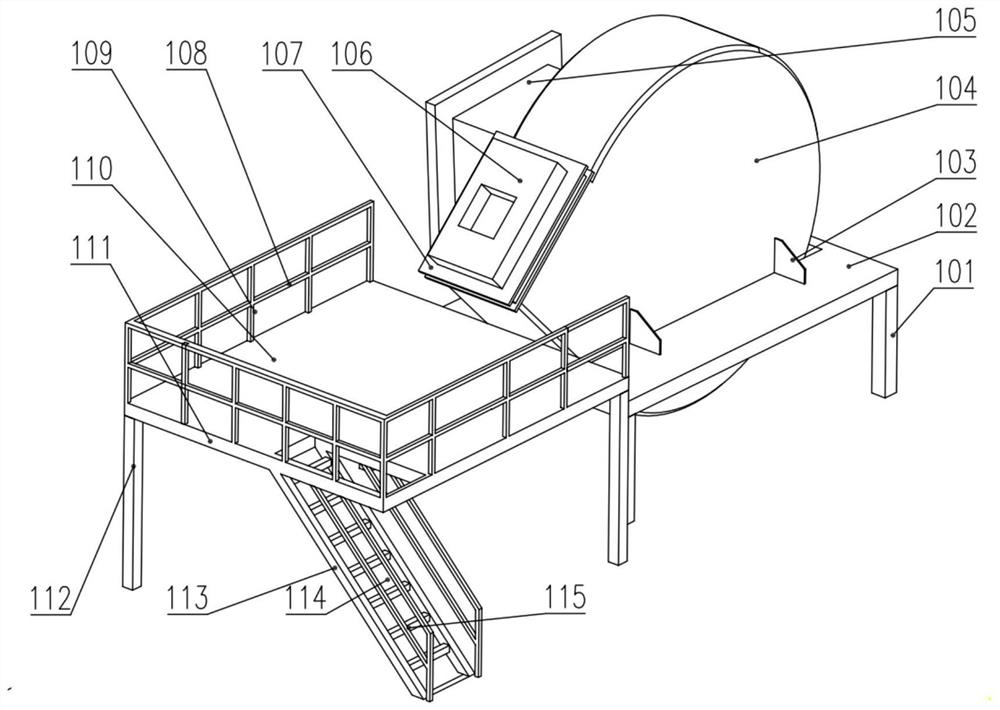

Drum-type material drying device and using method thereof

InactiveCN106273124AReduce energy consumptionImprove the heating effectDrying solid materials with heatDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention discloses a drum-type material drying device and a using method thereof and belongs to the technical field of material drying. The drum-type material drying device comprises a rotary drum (1); a feeding hole (11) is formed in one end of the rotary drum (1), and a discharging hole (12) is formed in the other end of the rotary drum (1); a drum supporting and driving device (2) is arranged below the rotary drum (1); the rotary drum (1) is a screen drum or a screen section (13) is at least arranged in the length direction of the rotary drum (1); and a hot water pipeline (3) passes through the length direction inside the rotary drum (1). Not only can the negative-pressure drying be realized, but also the convective drying can be realized, plastic granular materials can be baked or dried by directly utilizing heat of hot water in a granulator cooling water tank, and the drum-type material drying device is reasonable in process, reduced in production cost, wide in application range and particularly suitable for baking or drying materials such as grain crops such as cereals and beans internally containing more water.

Owner:HUBEI YANGTIAN PLASTIC PROD CO LTD

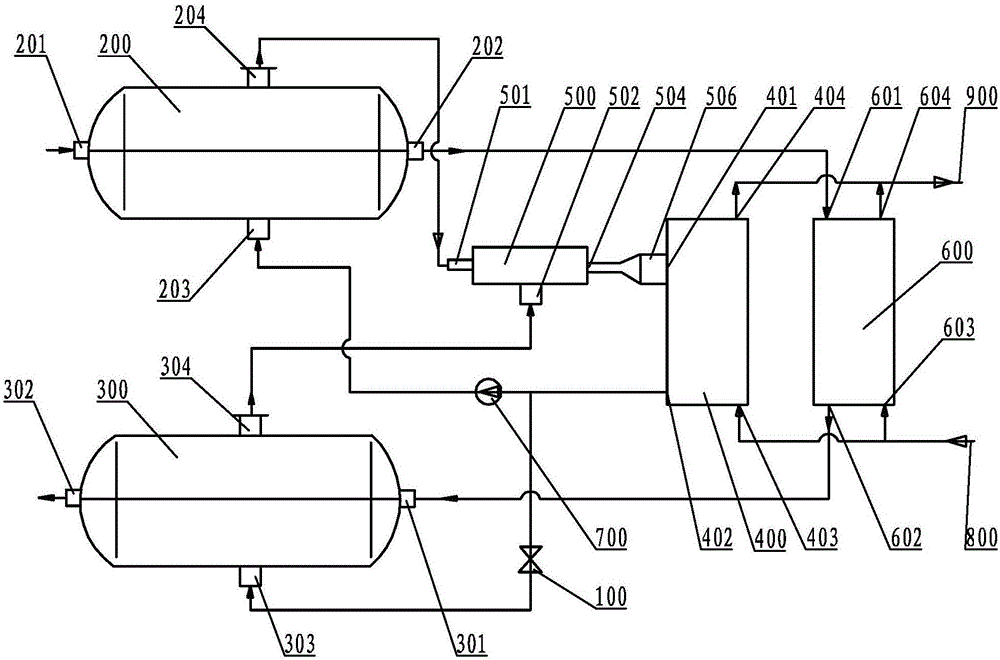

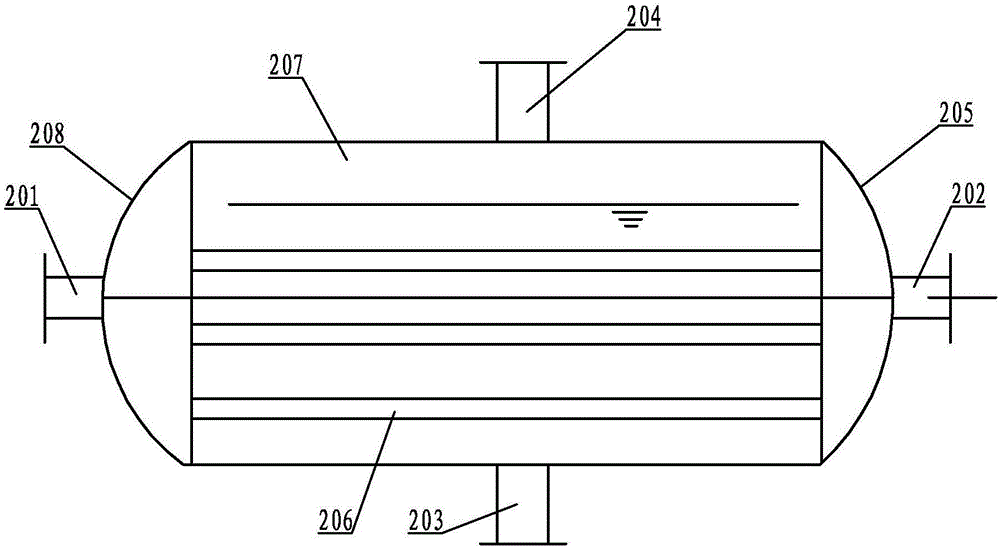

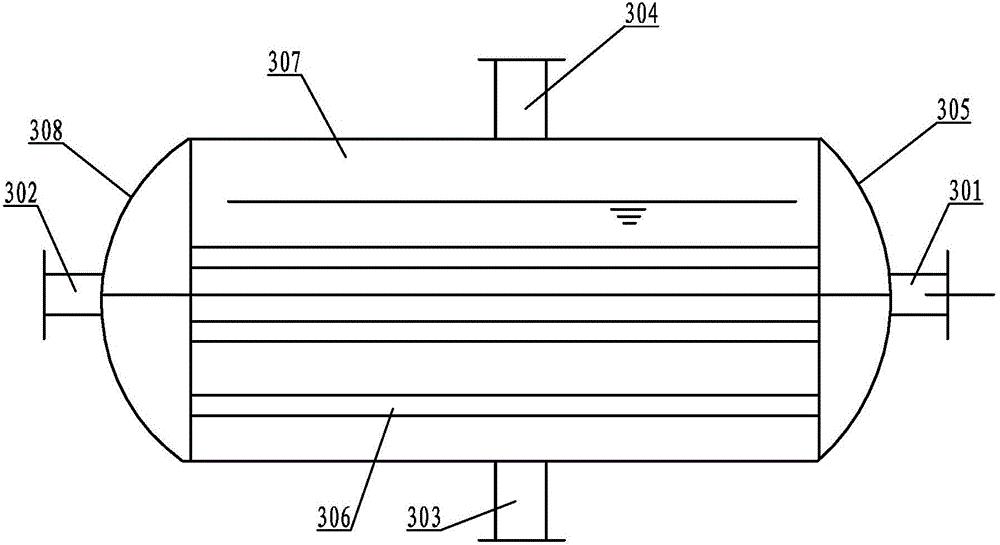

Large-temperature-difference heat exchange method and large-temperature-difference heat exchange device

InactiveCN107166475ASolve the shortage of heat supplyLarge heat supplyLighting and heating apparatusSpace heating and ventilation detailsInjectorSteam condensation

The present invention provides a large temperature difference heat exchange method and a large temperature difference heat exchange device capable of reducing the return water temperature of the heating network. Its working process is: (1) the high-temperature hot water for heating from the heating network enters the high-temperature evaporator The device releases heat, so that the high-temperature circulating water in it is heated and evaporated to produce high-temperature water vapor to flow out, and the high-temperature water vapor enters the steam injector as driving steam; (2) The incoming water from the heating network flows out from the high-temperature evaporator device and enters the heating heat exchanger to release heat , used for heating; (3) The incoming water from the heating network flows out from the heating heat exchanger, enters the low-temperature evaporator device to release heat, and the low-temperature circulating water is heated and evaporated to produce low-temperature steam to flow out; The return water pipe of the heating network; (4) The low-temperature water vapor generated by the heating and evaporation of the low-temperature circulating water in the low-temperature evaporator device is injected into the absorption chamber of the steam ejector, and the two are mixed into the diffuser tube of the ejector, and then enter To the condensing heat exchanger to release heat for heating.

Owner:HIT HARBIN INST OF TECH KINT TECH

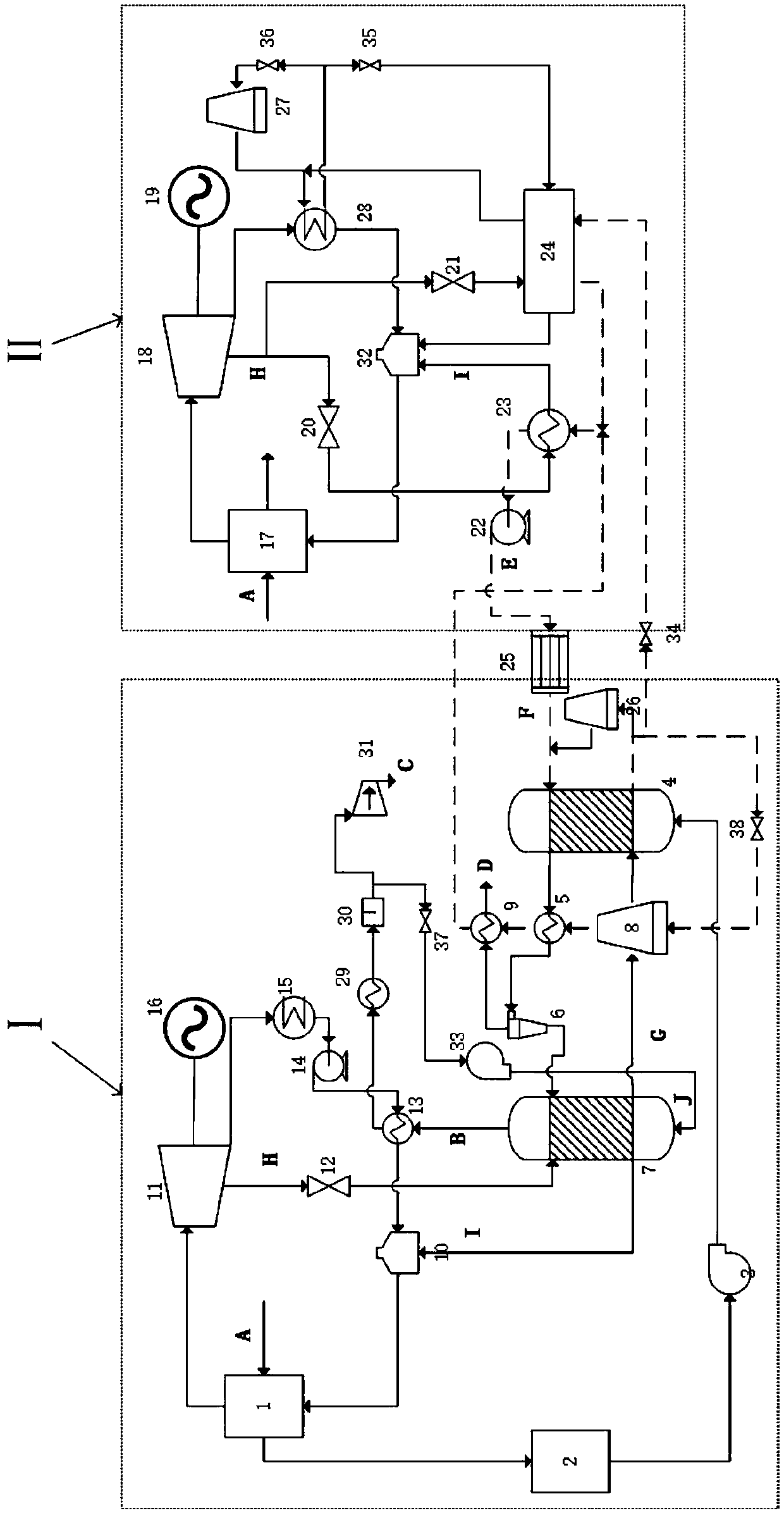

System for recovering waste heat during dry capture of CO2 for thermal power stations and using waste heat for heat supply

ActiveCN108679682AReduce overall energy consumptionReduce the impactLighting and heating apparatusEnergy efficient heating/coolingCarbonationLow graded

The invention discloses a system for recovering waste heat during dry capture of CO2 for thermal power stations and using the waste heat for heat supply. The system comprises a carbon capture unit andan extraction steam heating unit. The invention adopts the low-temperature heat network backwater as the cooling medium for cooling the carbonation reactor in the carbon capture unit, and realizes the recycling of a large amount of low-grade heat released during the adsorption process; the regeneration gas at the outlet of the regenerative reactor is used to replace the low-temperature regenerator in the carbon capture unit to heat the condensed water, recover the cooling heat of the regeneration gas, and reduce the low-pressure extraction of the carbon capture unit; part of exhaust heat of steam turbines in the heating unit is recovered by the absorption heat pumps. The invention combines the advantages of low temperature dry capture CO2 technology and absorption heat transfer technologyto recover waste heat during carbon capture. At the same time, power generation, CO2 capture and central heating are realized, which is in line with the principle of energy cascade utilization, and the whole system has good economy.

Owner:SOUTHEAST UNIV

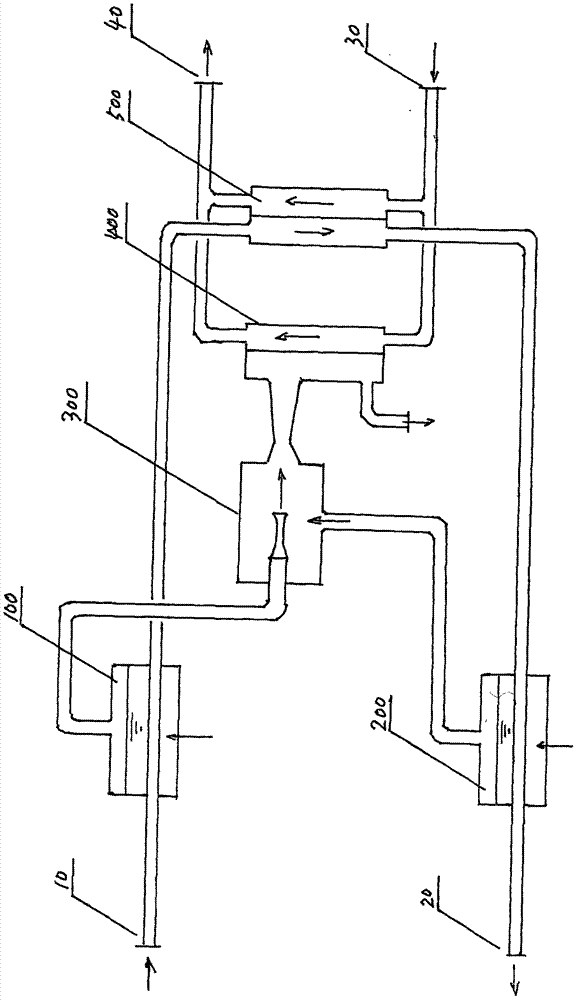

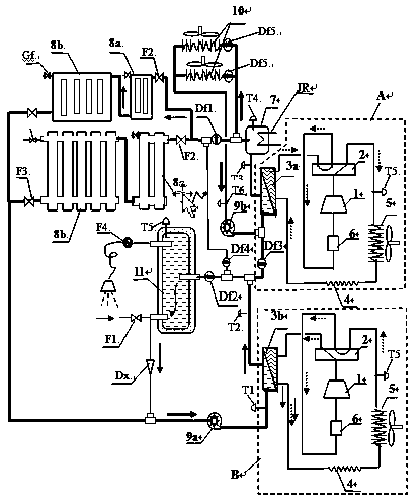

Jet type large temperature difference heat exchange method and device

InactiveCN106839049AGuaranteed to workSolve the shortage of heat supplyLighting and heating apparatusHot-water central heatingWater dischargeWater flow

The invention discloses a jet type large temperature difference heat exchange method and device. The device structurally comprises an evaporator, jetting devices, a condenser and connecting pipelines. The device is divided into the left portion, the middle portion and the right portion, the upright multi-stage evaporator is arranged on the left portion, the upright multi-stage condenser is arranged on the right portion, and each steam jetting device is arranged between the corresponding stage of the evaporator and the corresponding stage of the condenser for connection; the jetting devices jet low-pressure water steam in the evaporator by means of high-temperature water, with certain pressure, coming from a heat supply pipe network, and a steam-water mixture with the medium pressure is formed and enters the condenser; the steam-water mixture entering the condenser heats heat supply circulating water, the steam is condensed and dissolved in the rest of water to form medium-temperature water, and the medium-temperature water flows out of a water outlet of the condenser and flows into the evaporator; and through stage-by-stage evaporation of several evaporation chambers from top to bottom, the medium-temperature water is cooled to form low-temperature water, and the low-temperature water is discharged out of a water discharging outlet in the bottom of the evaporator and flows back to a water return pipeline of the heat supply pipe network.

Owner:HIT HARBIN INST OF TECH KINT TECH

Re-combustion hot gas generating furnace

InactiveCN102809148ALiquidEasy to implement automation controlLump/pulverulent fuel feeder/distributionCoal briquetteAutomatic control

The invention relates to generating furnace equipment, in particular to a re-combustion hot gas generating furnace, which can meet the requirements of heat supply energy sources under various coal conditions. The re-combustion hot gas generating furnace comprises a generating furnace body, a raw material proportioning bin, a hopper type elevator, a rotary disc feeder and a blower, wherein the bottom of the raw material proportioning bin is provided with a coal grinder which is communicated with the raw material proportioning bin; the coal grinder is communicated with a coal powder storage bin; the coal powder storage bin is communicated with the rotary disc feeder through the hopper type elevator and a chute; the rotary disc feeder is communicated with the generating furnace body; the bottom of the generating furnace body is provided with an air inlet; an air distribution plate is arranged at the air inlet, and is provided with an air cap; and the air inlet is communicated with the blower through an air box. Due to the adoption of a novel autonomously-developed automatic re-combustion efficient heat energy generating furnace, the defects of unstable heat, difficulty in realizing automatic control, incomplete burning, adversity to energy saving and environment friendliness and the like caused by large size of burning coal briquette in the conventional process are overcome.

Owner:ZHENGZHOU DINGLI DRYING EQUIP

Intelligent heating desk

InactiveCN107490989AWide heating areaLarge heat supplyServing tablesProgramme control in sequence/logic controllersTemperature senseEngineering

The invention discloses an intelligent heating desk which comprises a pressure sensor, infrared sensors, a processing center, a control unit, a desktop heating board, a desk bottom heater, a temperature sensing device and heat radiating holes. The pressure sensor and the infrared sensors transmit information to the processing center. The processing center transmits an instruction to the control unit. The control unit makes the desktop heating board and the desk bottom heating board perform operation. The temperature sensor performs real-time feedback of the temperature to the processing center and aims to increase the temperature on the condition of relatively low temperature and reduce the temperature on the condition of overhigh temperature. The intelligent heating desk is advantageous in that when the desk is used when the air temperature is relatively low, the desk can intelligently sense placement of dishes on the table and furthermore can perform heating for keeping warm and furthermore can sense approaching of a person to the desk for performing amusement, thereby performing heating for warming. The intelligent heating desk can automatically adjust the heating power according to different temperatures, thereby performing intelligent heating and creating a more comfortable living environment for the people.

Owner:合肥智贤智能化科技有限公司

Multi-fuel heating furnace

ActiveCN103615744AEmission reductionLarge heat supplyDomestic stoves or rangesCombustion processHeating efficiencyEngineering

A multi-fuel heating furnace comprises a furnace body provided with a hearth inside. An ash bucket is disposed below the hearth. The upper portion of the furnace body is provided with a chimney holder and a feed hole communicated with the hearth. The hearth is provided with an internal compartment communicated with the hearth. The compartment houses a thermoelectric blower which is provided with a switch and which is disposed on the inner wall of the compartment. Both the compartment and the furnace body are provided with a plurality of pores allowing the thermoelectric blower to suck in air. The multi-fuel heating furnace has the advantages that combustion can be subjected to blow pressurizing to achieve thorough combustion and higher heating amount; the switch for controlling the thermoelectric blower to start and stop is provided, the thermoelectric blower is stopped when not needed, fire sealing time is longer, and continuous combustion is achieved; operation of the thermoelectric blower allows the furnace to well combust in the area lower than 4500m in altitude, and the furnace is well adaptable to high altitudes and high in heat efficiency; the multi-fuel heating furnace is also applicable to flat areas and is low in production cost, low in application and maintenance costs and stable and reliable in performance.

Owner:中国人民解放军32181部队

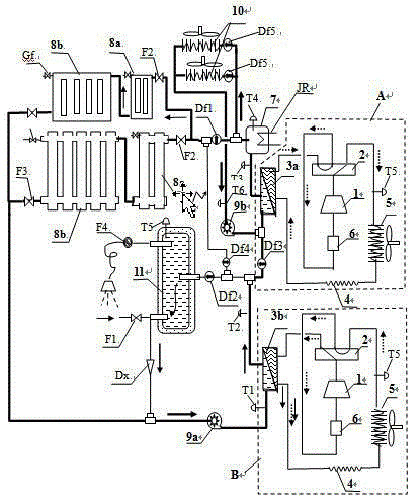

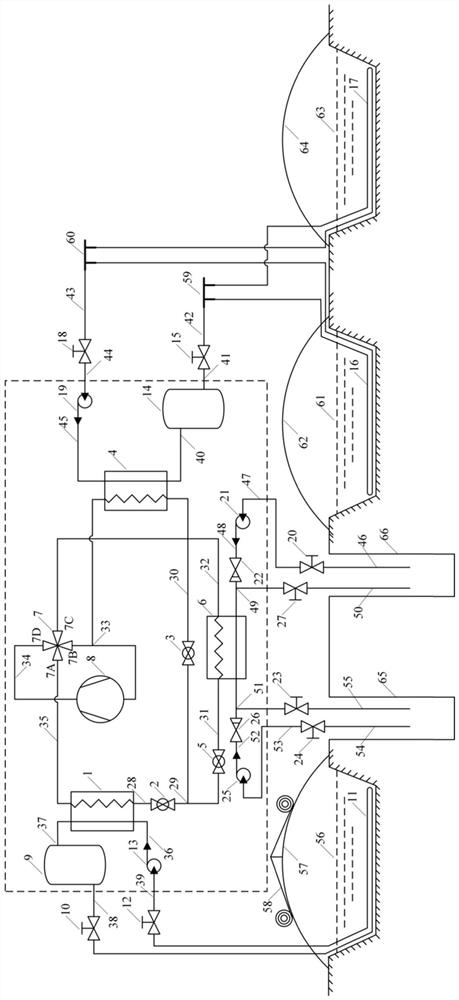

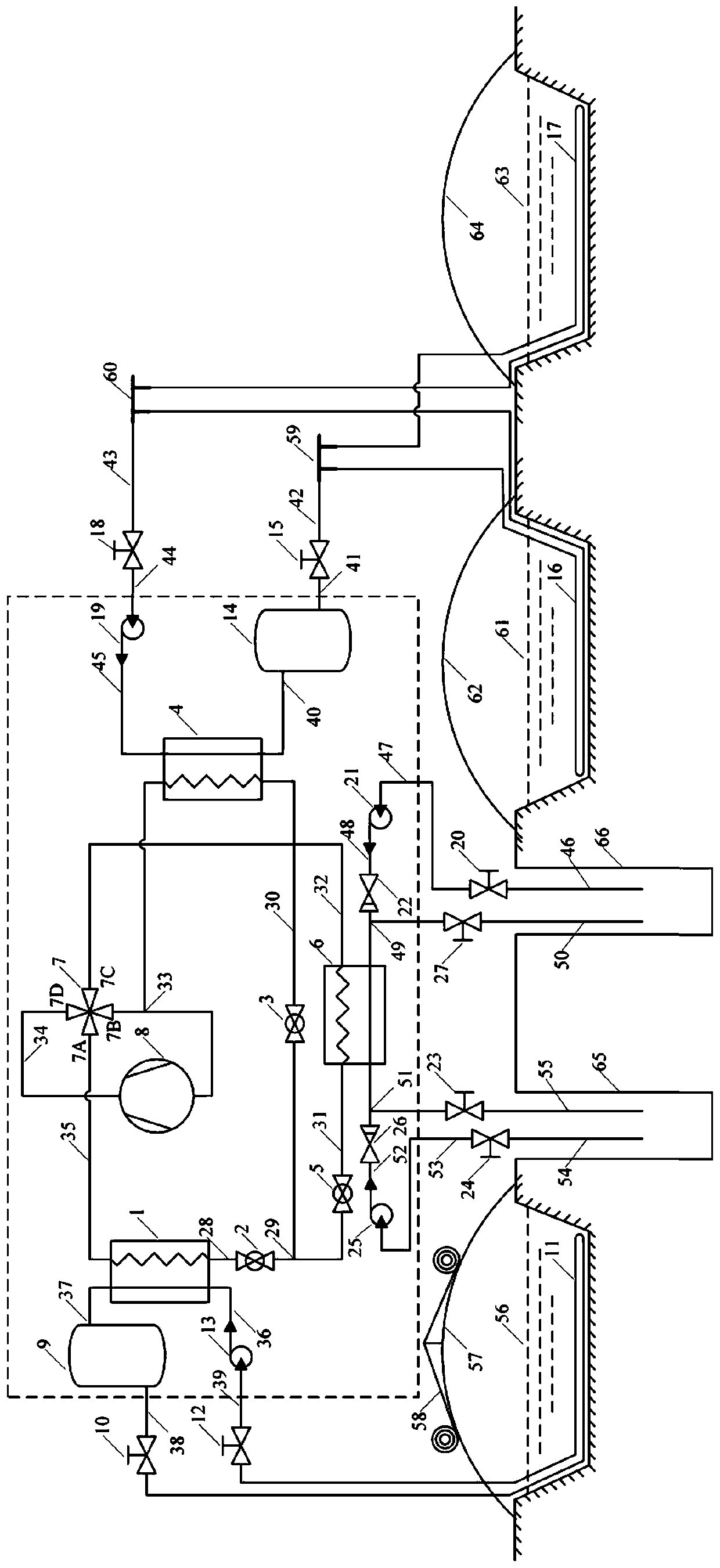

Household heat pump heating air-conditioner hot water dehumidifying combined system

ActiveCN106802025AStable indoor temperatureSave energyCompression machines with reversible cycleHeating and refrigeration combinationsWater circulationHeat pump and refrigeration cycle

The invention provides a household heat pump heating air-conditioner hot water dehumidifying combined system. The combined system comprises two heat pump refrigeration systems; the waterways of water- to-water heat exchangers of the two systems are connected in series; the water flow velocity is increased and thermal efficiency is raised; an auxiliary electric water heater is assembled for heating hot water so that allostatic load is added; hot water and hot air are adopted in parallel or in series connection for heating; front-back series connection mode is adopted in the combined water heating radiator so that normal operation of the heat pump can be guaranteed by the circulation return water temperature during heavy load heating in winter; two units are successively used for defrosting during defrosting stage and heating is not interrupted; one refrigerating air-conditioner is used in summer; the refrigeration dehumidifying and heat pump compensation heat circulation are designed; an independent heat pump generates domestic hot water circulation. The system of the invention can be adapted to the variation of loads; muting bedrooms and quick heating for living rooms are realized; the refrigeration air-conditioning amount is reasonable; living hot water is continuously provided; dehumidification and constant temperature are kept for rooms; the utilization rate of devices is high; the technology is reliable; the system has good market prospect.

Owner:盐城瑞阳科技有限公司

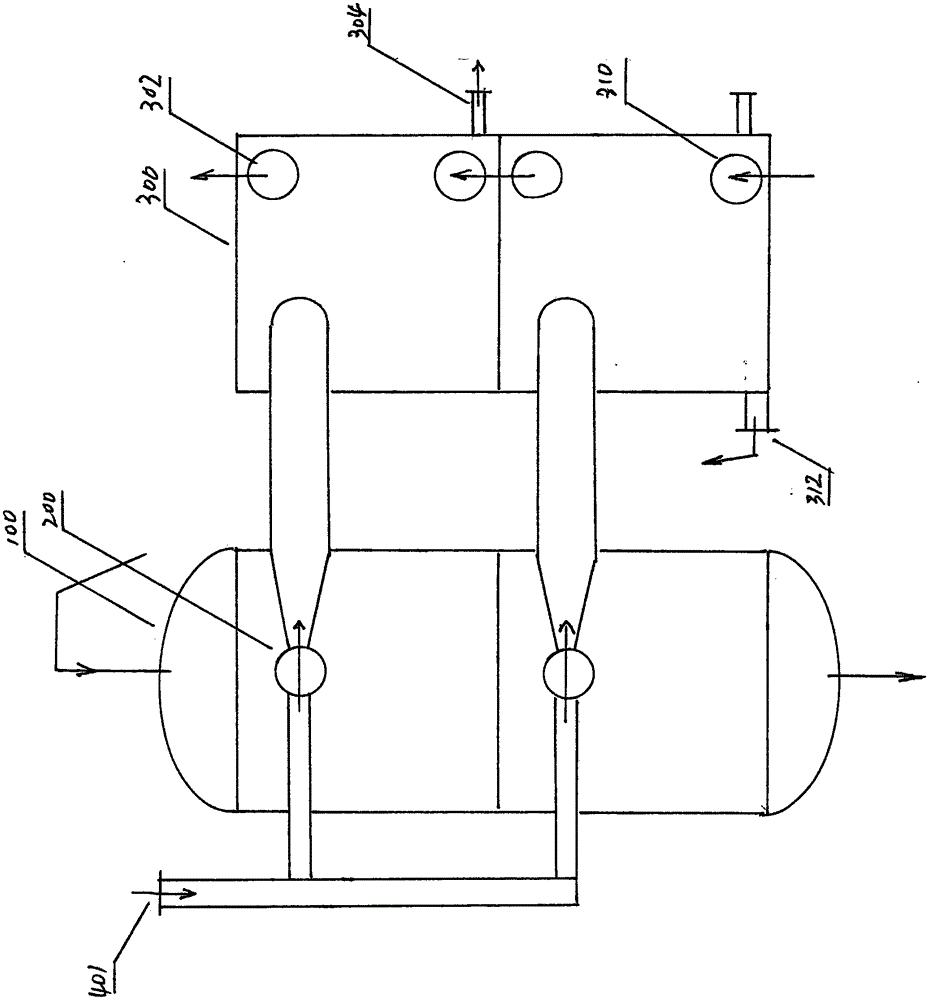

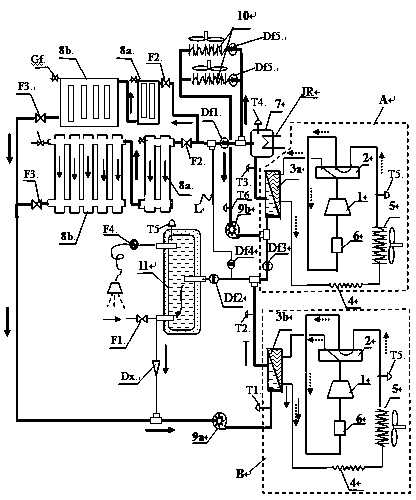

Large temperature difference heat exchange method and large temperature difference heat exchange device capable of reducing return water temperature of heat supply network

InactiveCN106152230ASolve the shortage of heat supplyLarge heat supplyLighting and heating apparatusSpace heating and ventilation detailsEvaporationEngineering

The invention provides a large temperature difference heat exchange method and a large temperature difference heat exchange device capable of reducing the return water temperature of a heat supply network to increase a heating load of the heat supply network. The large temperature difference heat exchange method and the large temperature difference heat exchange device are specially provided for a newly-built or rebuilt old heat supply network to solve the problem that the heating load of the old heat supply network is generally not sufficient. The large temperature difference heat exchange method comprises the following steps: incoming water of the heat supply network enters a high temperature heat exchanger and heats high pressure freon, produced high pressure freon vapor injects low pressure freon vapor in an evaporator through an ejector, freon vapor ejected by the ejector heats heating circulating water, the incoming water of the heat supply network flows out of the high temperature heat exchanger, then enters a middle temperature heat exchanger, heats the heating circulating water and then flows into a low temperature heat exchanger, the incoming water of the heat supply network releases heat to low temperature liquid freon, left after evaporation, from the evaporator, and the incoming water of the heat supply network releases heat for cooling for three times and then returns to a return water pipeline of the heat supply network. The large temperature difference heat exchange device comprises the high temperature heat exchanger, the middle temperature heat exchanger, the low temperature heat exchanger, the evaporator, a condenser, the ejector and three freon pumps.

Owner:HIT HARBIN INST OF TECH KINT TECH

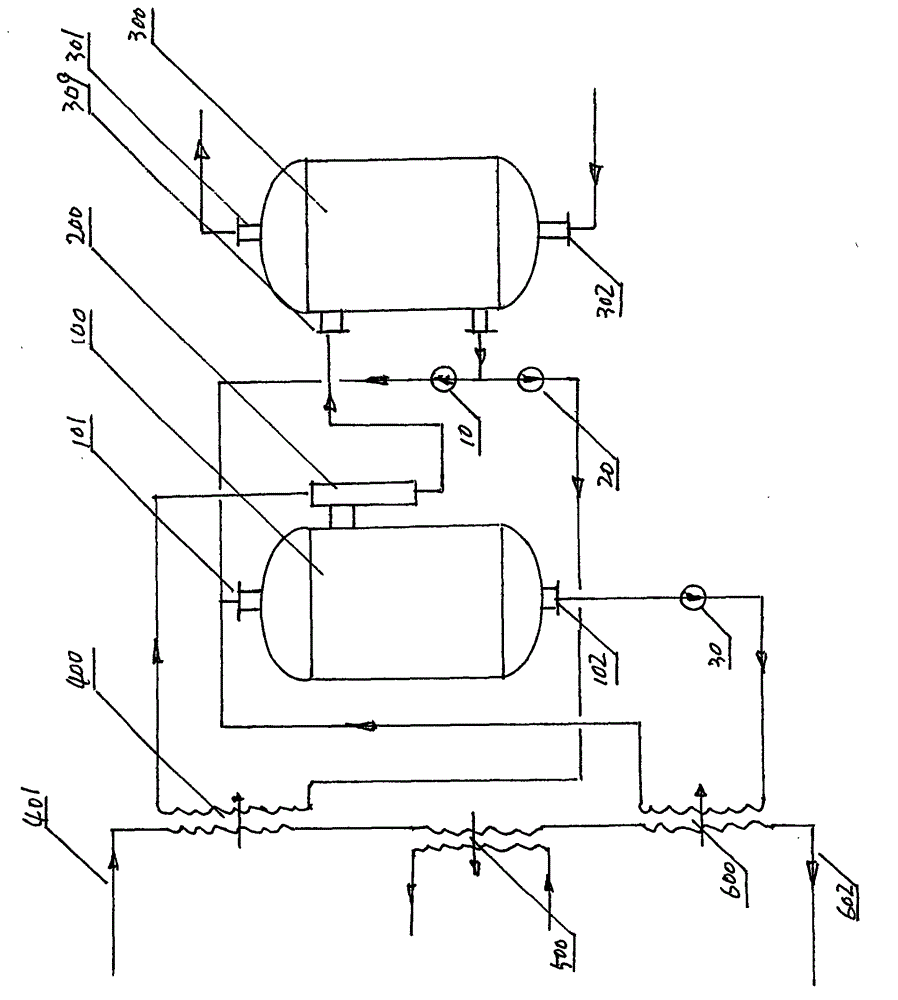

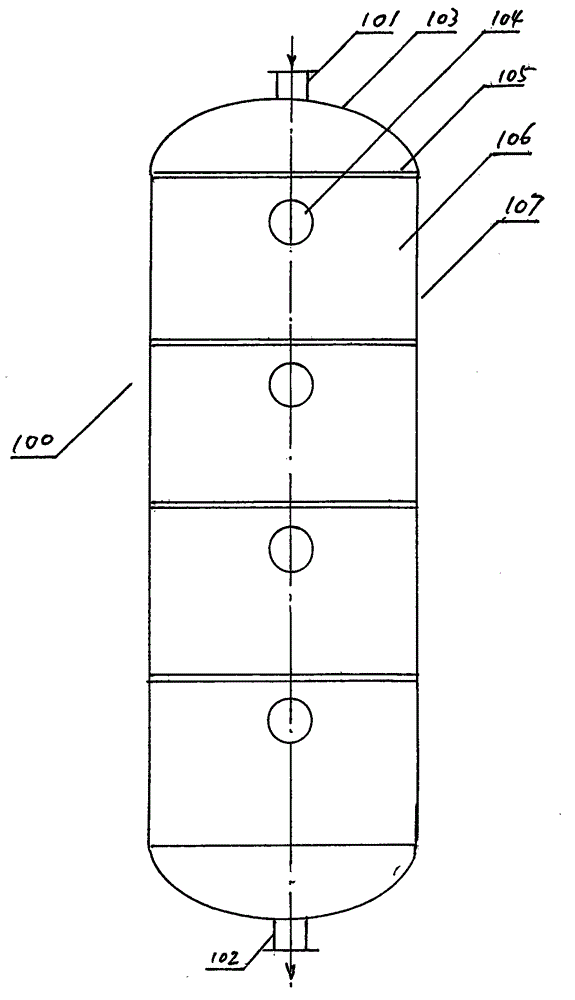

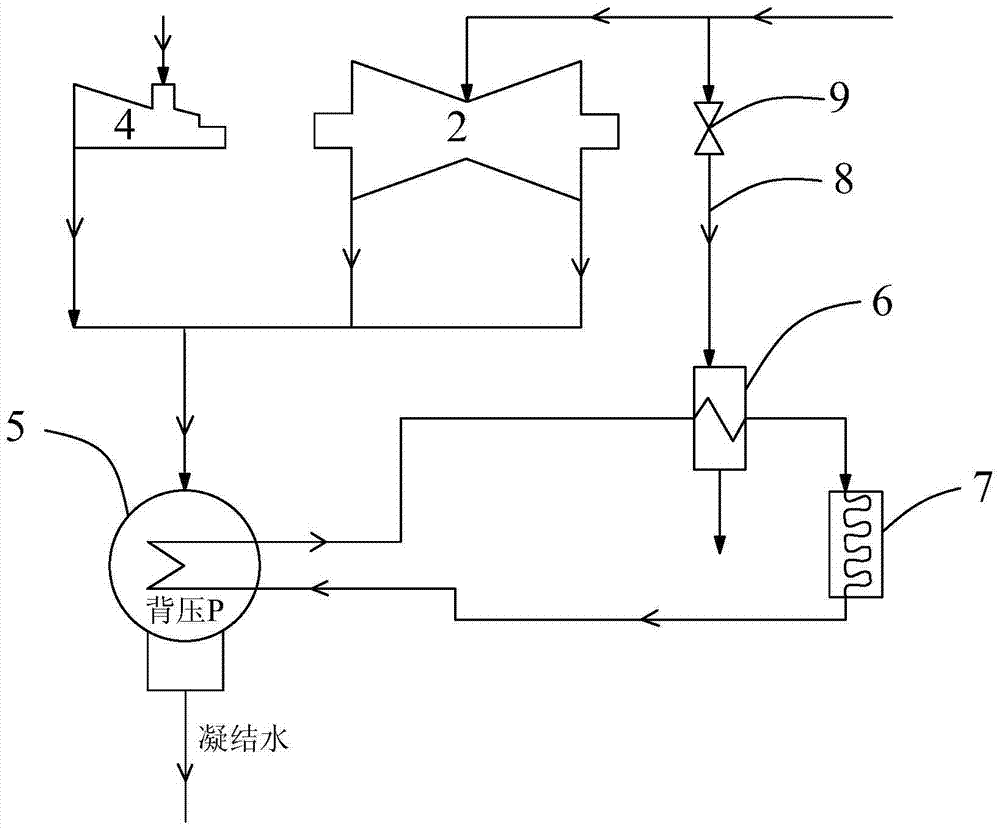

Recovery system and recovery method of residual pressure and residual heat in backpressure heat supply unit

PendingCN111520205AReduce water and heat lossEliminate white smokeHeat recovery systemsRecuperative heat exchangersProcess engineeringInjection pump

The invention provides a recovery system and a recovery method of residual pressure and residual heat in a backpressure heat supply unit. The system and the method can reduce loss if water, heat and pressure energy, increase heat supply of the backpressure heat supply unit and eliminate a phenomenon of 'generating white smoke'. The system comprises a backpressure steam turbine, a deaerator, a drain tank, a drain flash tank, periodic blowdown flash tank, valves from No.1 to No.7, a steam jet pump, a main pipeline and a bypass pipeline. In normal operation, the No.3 valve and the No.4 valve areclosed, and other valves are opened; discharged steam of the backpressure steam turbine is conveyed into the steam jet pump to be used as working steam, thus, after the steam jet pump extracts the discharged steam in the periodic blowdown flash tank, the drain flash tank and the drain tank, pressure is reduced and the steam becomes medium pressure steam usable for the deaerator, and the medium pressure steam enters into the deaerator; if the steam jet pump goes wrong, the No.3 valve and the No.4 valve of a bypass line are opened, and the No.1 valve and the No.2 valve are closed, the system cancontinue working, and thus continuous running of the system is guaranteed.

Owner:CHINA UNITED ENG

Solar heat storage type water and ground dual heat source heat pump system for temperature control of aquaculture soil pond

ActiveCN110470075BReduce loadGuaranteed heating stabilitySolar heating energyMechanical apparatusWater source heat pumpTemperature control

Owner:TONGJI UNIV

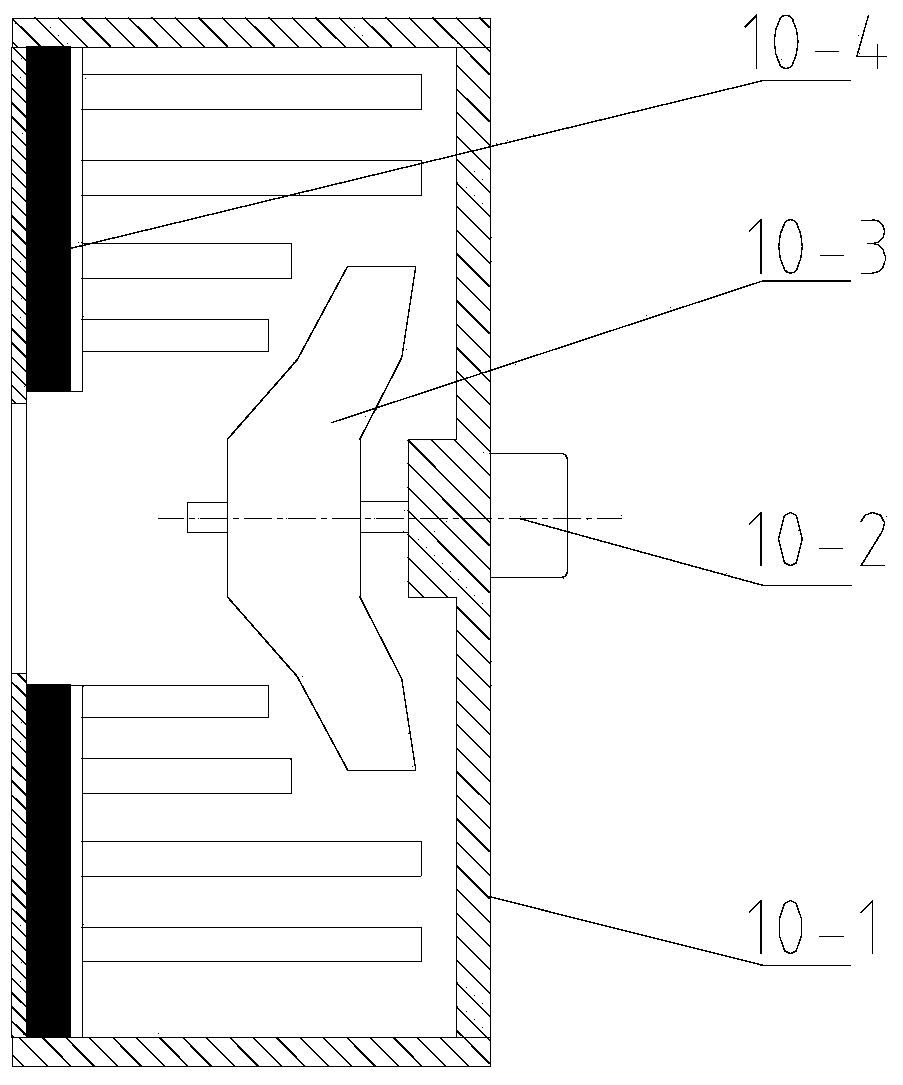

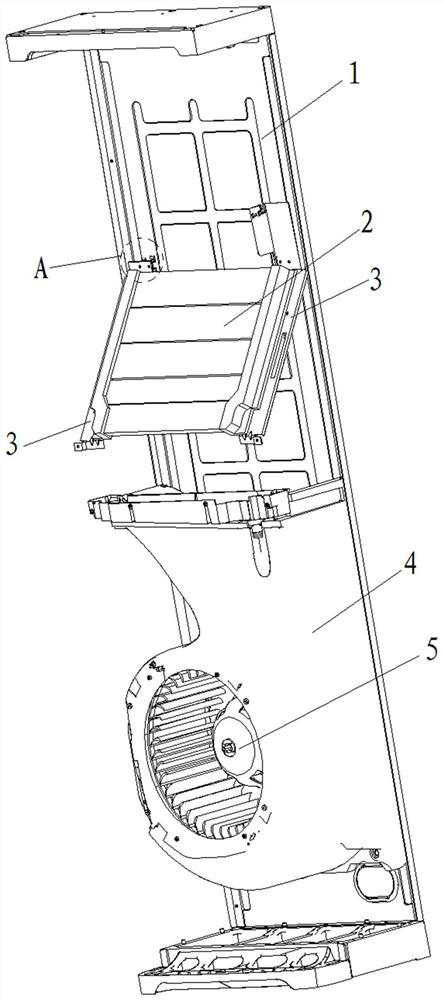

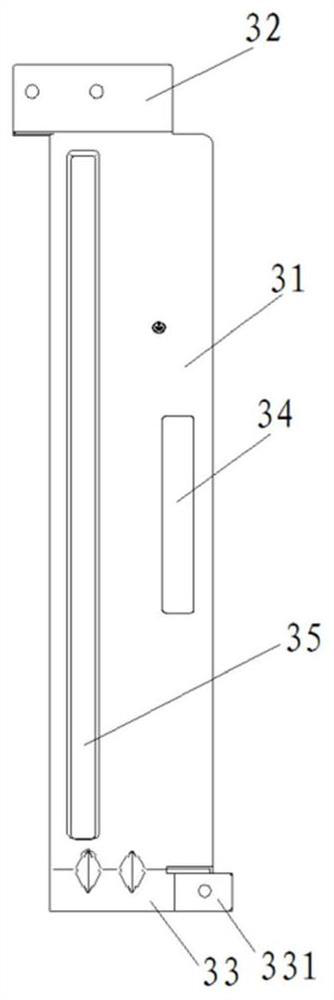

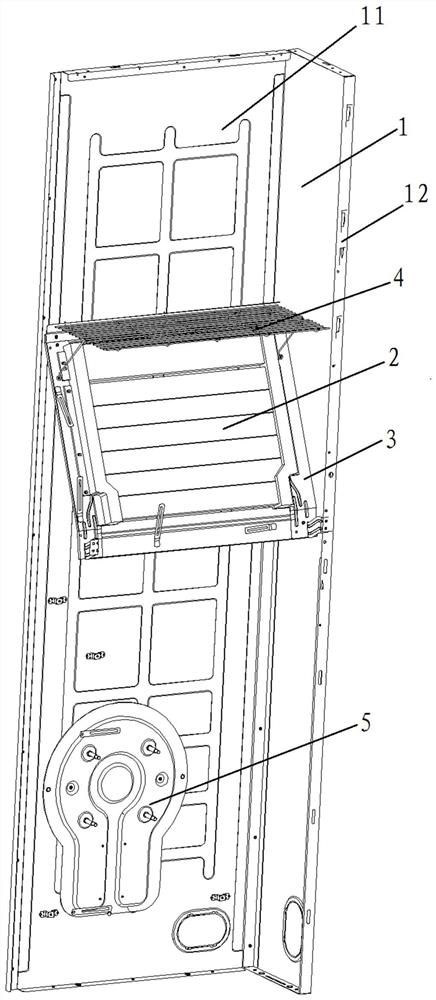

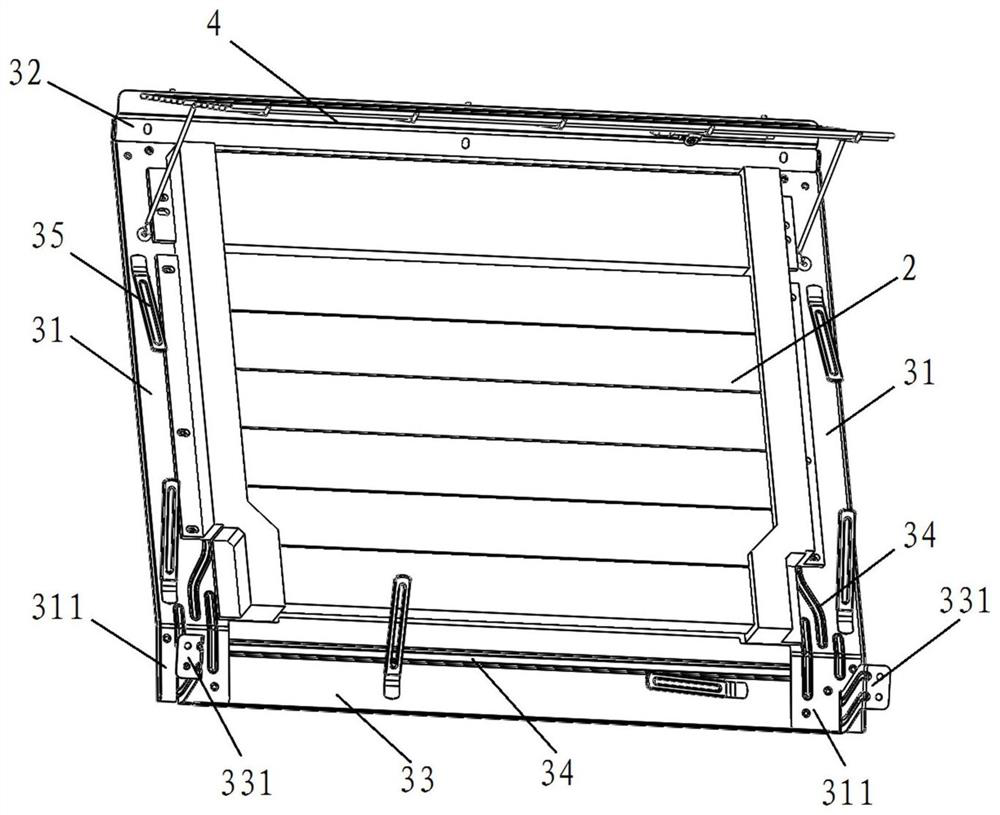

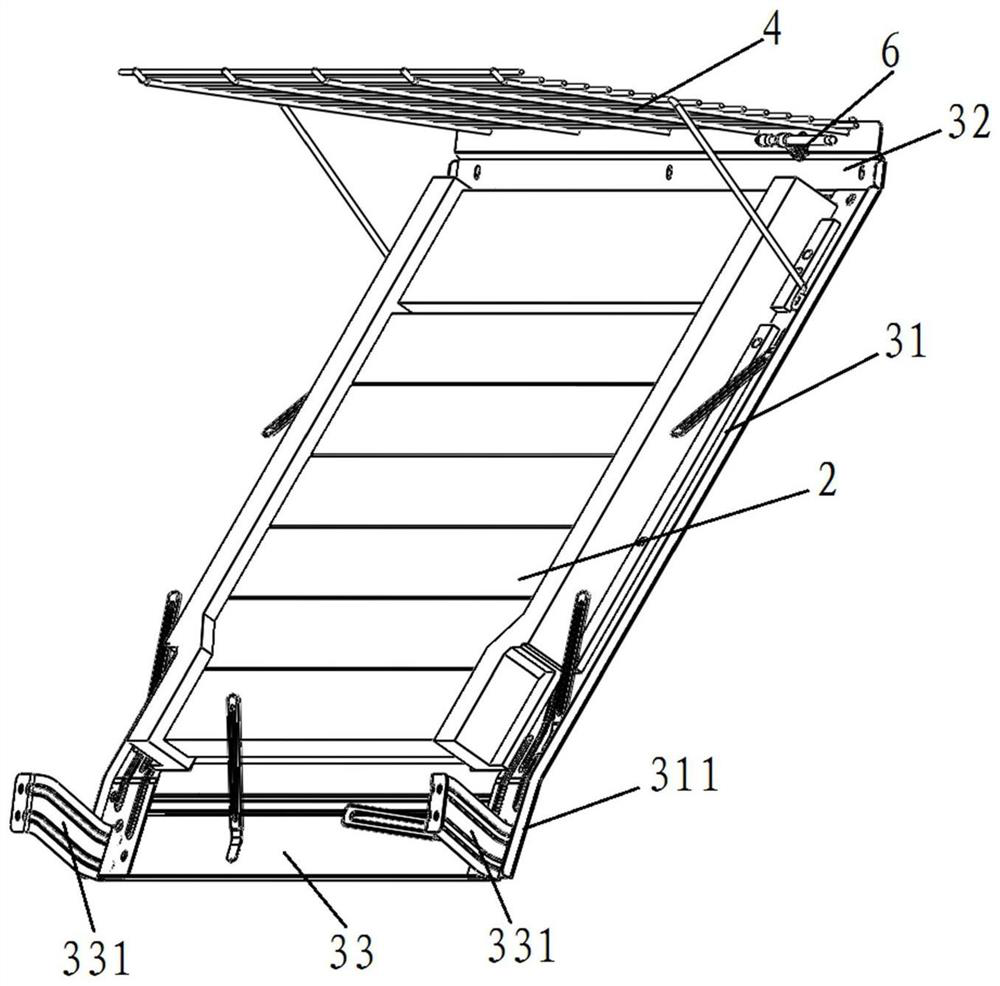

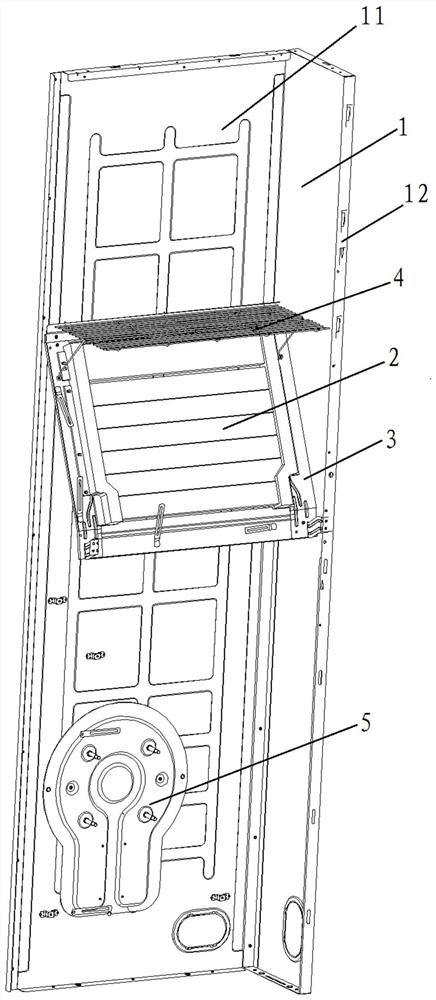

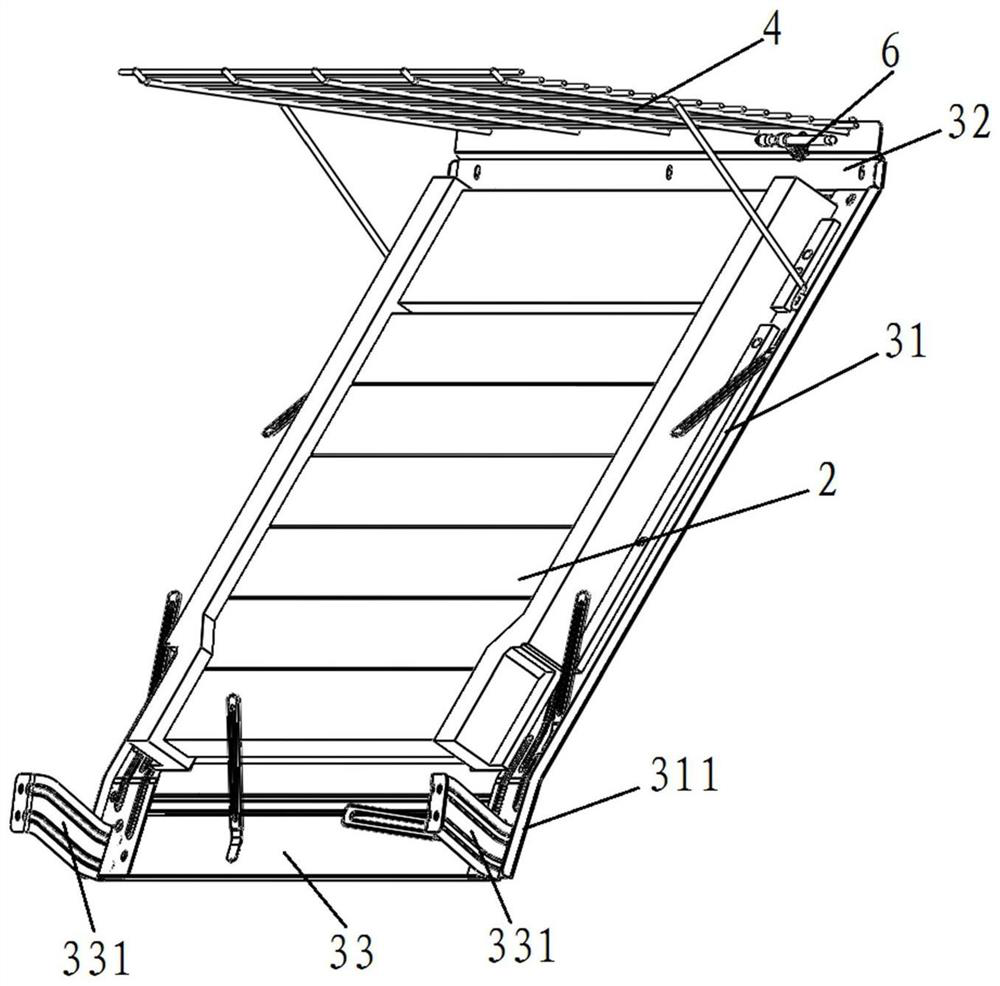

Heating element fixing structure of air treatment equipment and air treatment equipment

The invention relates to the technical field of air treatment equipment, and discloses a heating element fixing structure of air treatment equipment and the air treatment equipment. A heating element is fixed in a machine shell of the air treatment equipment; the heating element fixing structure comprises supporting plate assemblies respectively arranged at two sides of the heating element; each supporting plate assembly comprises a supporting plate body; the back end of the supporting plate body is connected to the back side of the machine shell; the front end of the supporting plate body is connected with the front side of the machine shell; the two sides of the heating element are correspondingly supported and placed on the supporting plate bodies at two sides; and the supporting plate bodies are obliquely arranged relative to the horizontal direction. The heating element fixing structure of the air treatment equipment and the air treatment equipment provided by the invention have the advantages that the supporting plate assemblies are correspondingly arranged at the two sides of the heating element to support and fix the heating element, the structure is simple, and the heating element can be conveniently installed; and in addition, the heating element is arranged to be in an inclined state through the supporting plate assemblies, the arrangement area of the heating element is increased, the heat supply amount is favorably increased, and the heat supply effect is guaranteed.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Large-temperature-difference heat exchange device for Freon

InactiveCN106369654ALowering height running dripReduce consumptionMechanical apparatusEnergy efficient heating/coolingEngineeringTemperature difference

The invention discloses a large-temperature-difference heat exchange device for Freon, and relates to a heat engineering technology, and the large-temperature-difference heat exchange device is used for solving the problem that heat supply of newly building a heat supply pipe network or modifying an old heat supply pipe network at present is insufficient. The large-temperature-difference heat exchange device for Freon comprises a high-temperature evaporator, a low-temperature evaporator, a condenser, a heat exchanger, a throttling valve and an Freon pump, wherein a high-temperature water outlet of the high-temperature evaporator is connected with a heat exchanger water inlet of the heat exchanger; a heat exchanger water outlet of the heat exchanger is connected with a low-temperature water inlet of the low-temperature evaporator; a high-temperature Freon steam outlet of the high-temperature evaporator is connected with a drive steam inlet of an ejector; a suction inlet of the ejector is connected with a low-temperature Freon steam outlet of the low-temperature evaporator; a diffuser pipe outlet of the ejector is connected with a condensed steam inlet of the condenser; and a Freon liquid outlet of the condenser is divided into two paths, wherein one path is connected with the low-temperature Freon liquid inlet of a low-temperature evaporator through the throttling valve, and the other path is connected with a high-temperature Freon liquid inlet of the high-temperature evaporator through the Freon pump. The large-temperature-difference heat exchange device is used for newly building the heat supply pipe network or modifying the old heat supply pipe network.

Owner:HIT HARBIN INST OF TECH KINT TECH

Energy storing device for heating tail flue gas of boiler and operating method of energy storing device

PendingCN111256193AImprove peak shaving abilityWide range of applicationsCentral heating with accumulated heatHeat storage plantsFlueProcess engineering

The invention discloses an energy storing device for heating tail flue gas of a boiler and an operating method. The energy storing device comprises a first heater, wherein the first heater is connected with a boiler tail flue, a first heat exchange medium is introduced into the first heater, the first heat exchange medium in the first heater and flue gas in the boiler tail flue are subjected to heat exchange heating, an outlet of the first heater is connected with an inlet of a medium hot tank, the medium hot tank is used for storing the first heat exchange medium for heat exchange heating, anoutlet of the medium hot tank is connected with a second heater, a first regulating valve is arranged on a pipeline, connected to the second heater, of the medium hot tank, the first heat exchange medium subjected to heat exchange heating in the second heater and a second heat exchange medium in a heat supply network are subjected to heat exchange, and the second heat exchange medium enters the heat supply network after absorbing heat. The energy storing device is suitable for meeting multiple heat supply demands of the heat supply network, improves peak load regulation capacity of the boiler, and has a wide application range, smaller improvement for the boiler body and low improvement cost, the whole device has a simple and flexible structure, and realization of industrialization is facilitated.

Owner:HUANENG CLEAN ENERGY RES INST

Heating element mounting structure of warm air blower and warm air blower

ActiveCN113091317AEasy to installMeet high temperature installation requirementsAir heatersHeat resistanceAir treatment

The invention relates to the technical field of air treatment equipment, and discloses a heating element mounting structure of a warm air blower and the warm air blower. The warm air blower comprises a machine shell, wherein a heating element is arranged in the machine shell. The mounting structure comprises a supporting plate frame, wherein the rear end of the supporting plate frame is connected to the rear side of the machine shell, and the front end of the supporting plate frame is connected to the front side of the machine shell; the supporting plate frame is obliquely arranged in the front-back direction; the supporting plate frame comprises two supporting plates which are parallel to each other and are arranged front and back, a first connecting plate connected between the higher ends of the two supporting plates and a second connecting plate connected between the lower ends of the two supporting plates; and the two supporting plates are used for being correspondingly connected with the two sides of the heating element. According to the heating element mounting structure of the warm air blower and the warm air blower, the supporting plate frame is arranged to support and fix the heating element, the high-temperature mounting requirement of the heating element can be met through heat resistance of the supporting plate frame, and the heating element can be conveniently mounted due to a simple connecting structure.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

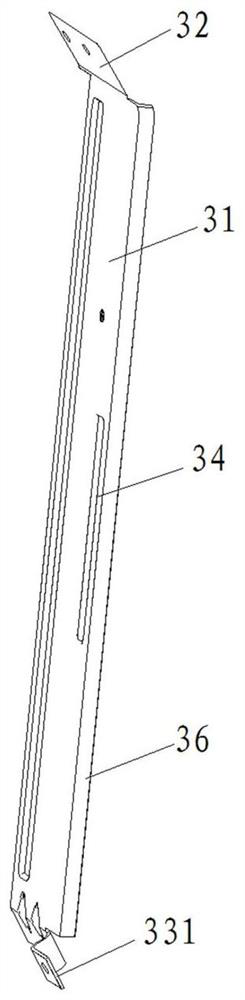

Multi-steam-source steam spraying heat pump

InactiveCN106812729AReduce lossesIncrease profitJet pumpsMachines/enginesEngineeringExpansion chamber

The invention discloses a multi-steam source injection heat pump. The steam injection heat pump is provided with a driving steam chamber, a suction chamber, a mixing chamber, an expansion chamber and an outlet pipe. The drive steam chamber is provided with an independent drive steam inlet connected to the drive steam pipe, and the elbow type suction chamber is provided with a suction steam inlet connected to the low-pressure steam pipe. The characteristic is that the drive steam chamber is composed of multiple independent small drive steam pipes. Each small driving steam chamber corresponds to a nozzle and a driving steam inlet. Each needle-shaped valve core is connected with a needle-shaped valve stem, and the needle-shaped valve stem passes through the sealing packing chamber and is connected with the valve stem connecting piece outside the driving steam chamber, and the other end of the valve stem connecting piece is connected with the main valve stem. The other ends of the two or more expansion chambers are all connected with the outlet pipe. The invention has simple structure and high thermal efficiency, and can be applied to different driving steam sources and different low-pressure steam so as to obtain stable outlet pressure and temperature.

Owner:HANGZHOU HENGXUN ENERGY TECH CO LTD

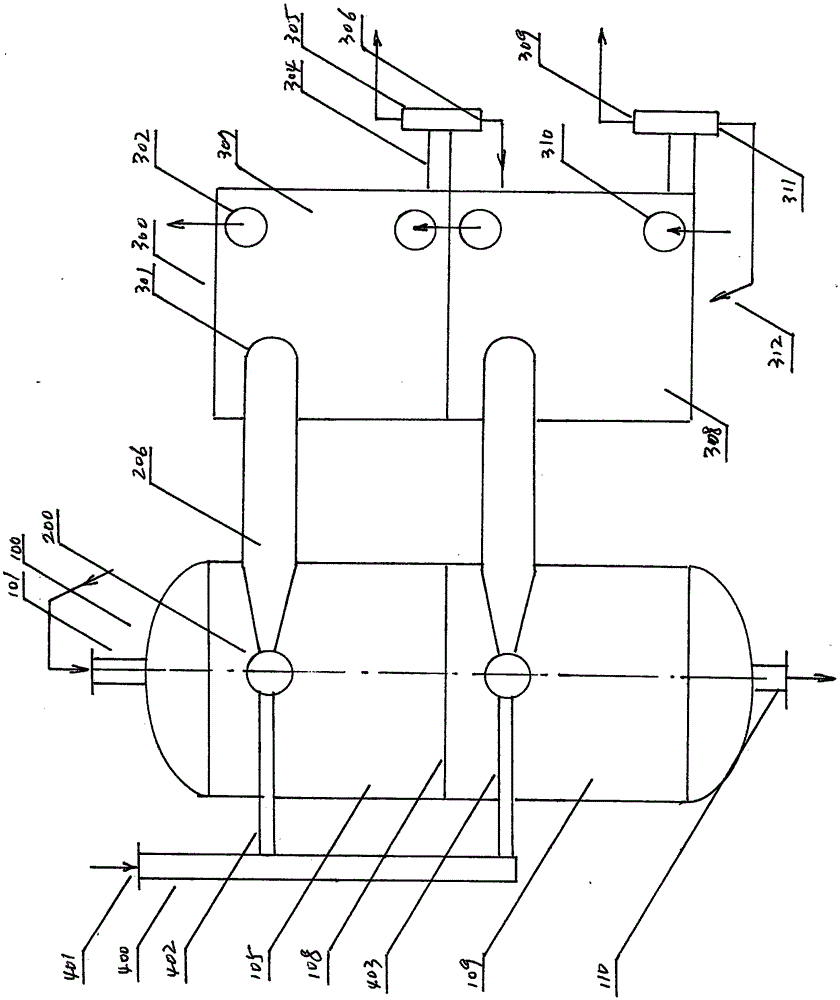

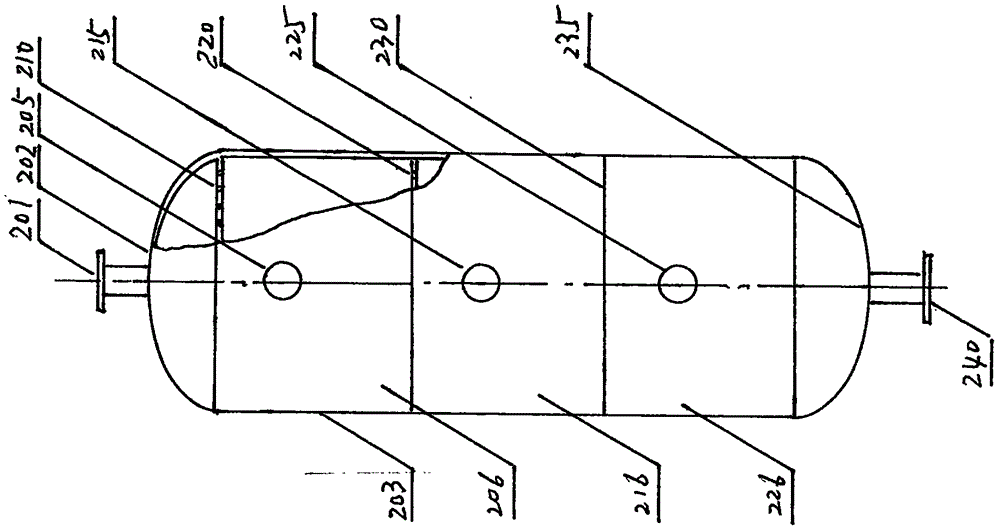

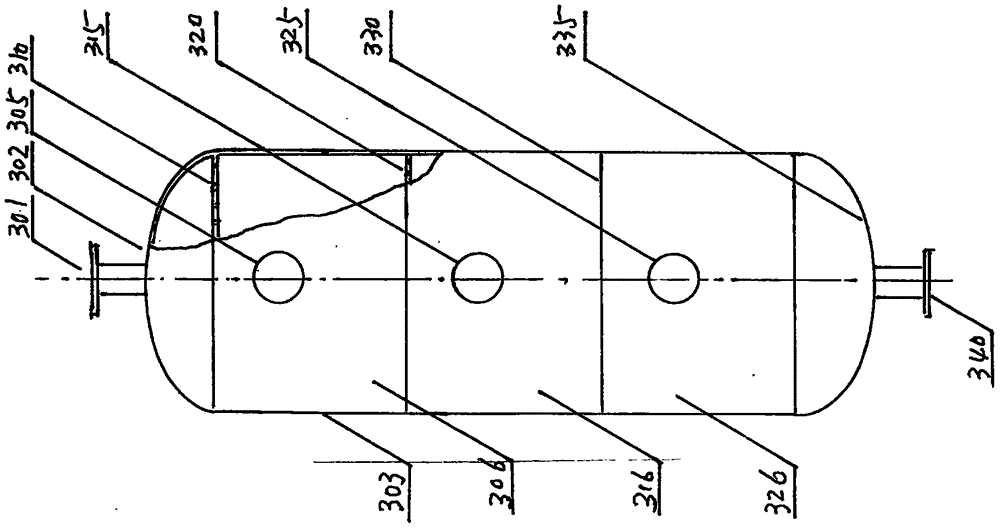

Large-temperature-difference heat exchange device

PendingCN109869788ASolve the shortage of heat supplyLarge heat supplyIndirect heat exchangersHot-water central heatingVacuum pumpingSteam condensation

The invention provides a large-temperature-difference heat exchange device. After hot-net high-temperature hot water enters a high-temperature evaporator and releases heat to become medium-temperaturehot water, the hot-net high-temperature hot water enters a low-temperature evaporator and continuously releases the heat to become low-temperature hot water, and the low-temperature hot water returnsto a hot-net water return pipeline; the high-temperature hot water in the high-temperature evaporator flows outside a heat exchange tube from top to bottom, and the heat medium water in the heat exchange tube is evaporated to generate steam; the low-temperature hot water in the low-temperature evaporator horizontally flows and releases heat in the heat exchange tube, the heat medium water outsidethe heat exchange tube is heated and evaporated to generate steam; and a steam ejector is arranged, steam is generated by the high-temperature evaporator to serve as driving steam, steam generated bythe low-temperature evaporator serves as suction steam, and steam sprayed out of the outlet of the steam ejector enters the condenser. The condensed water generated by the condenser enters the low-temperature evaporator through a throttling valve, and the other part of the condensed water enters the high-temperature evaporator through the water pump; the other side of the condenser is used for heating the heating circulating water; and a vacuum air extracting opening is formed in the lower part of the steam condensation side of the condenser;

Owner:HIT HARBIN INST OF TECH KINT TECH

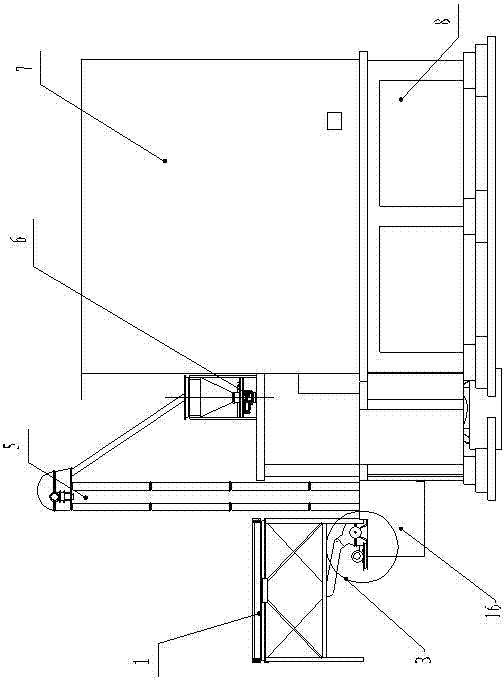

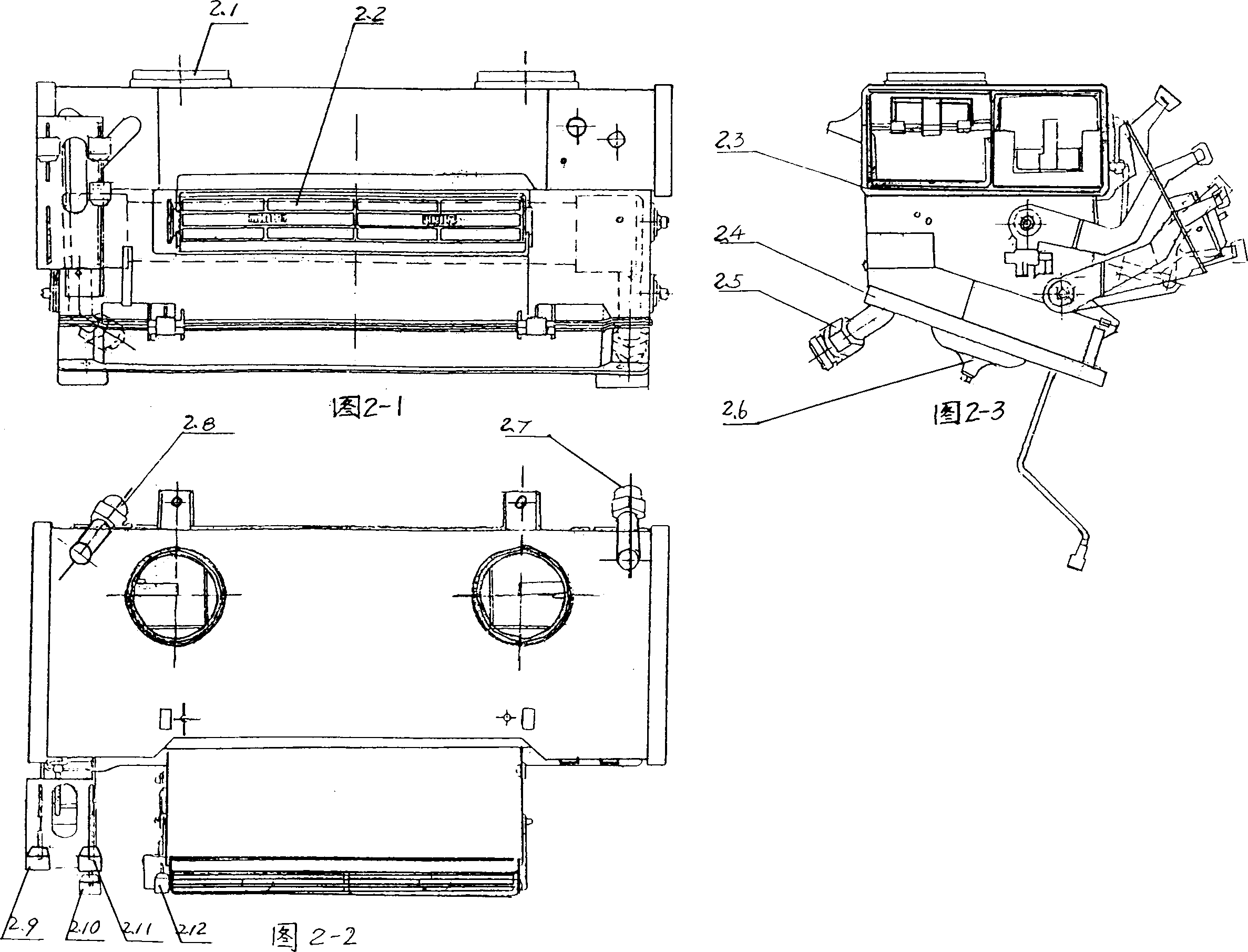

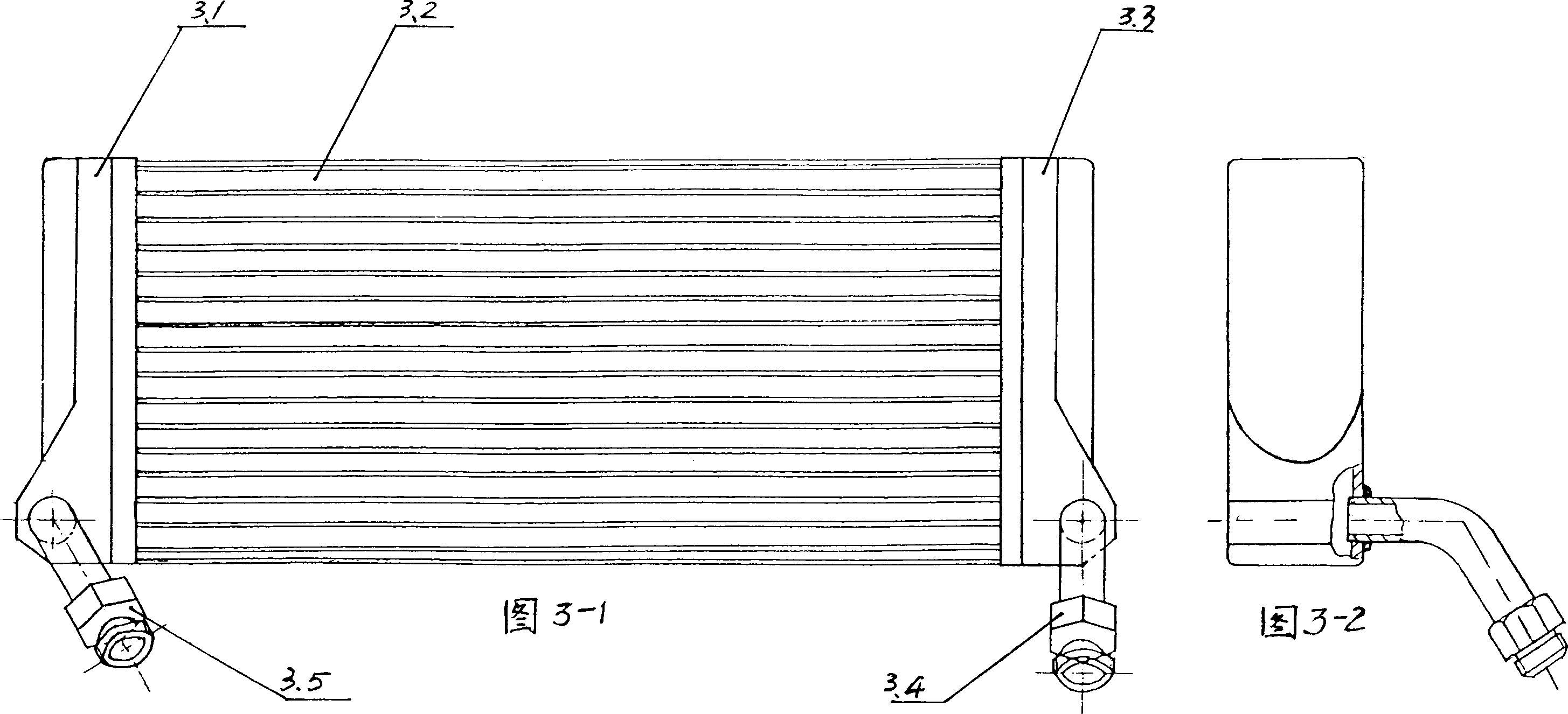

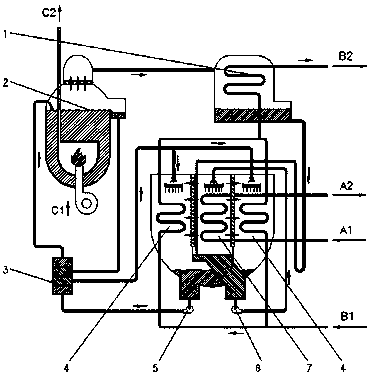

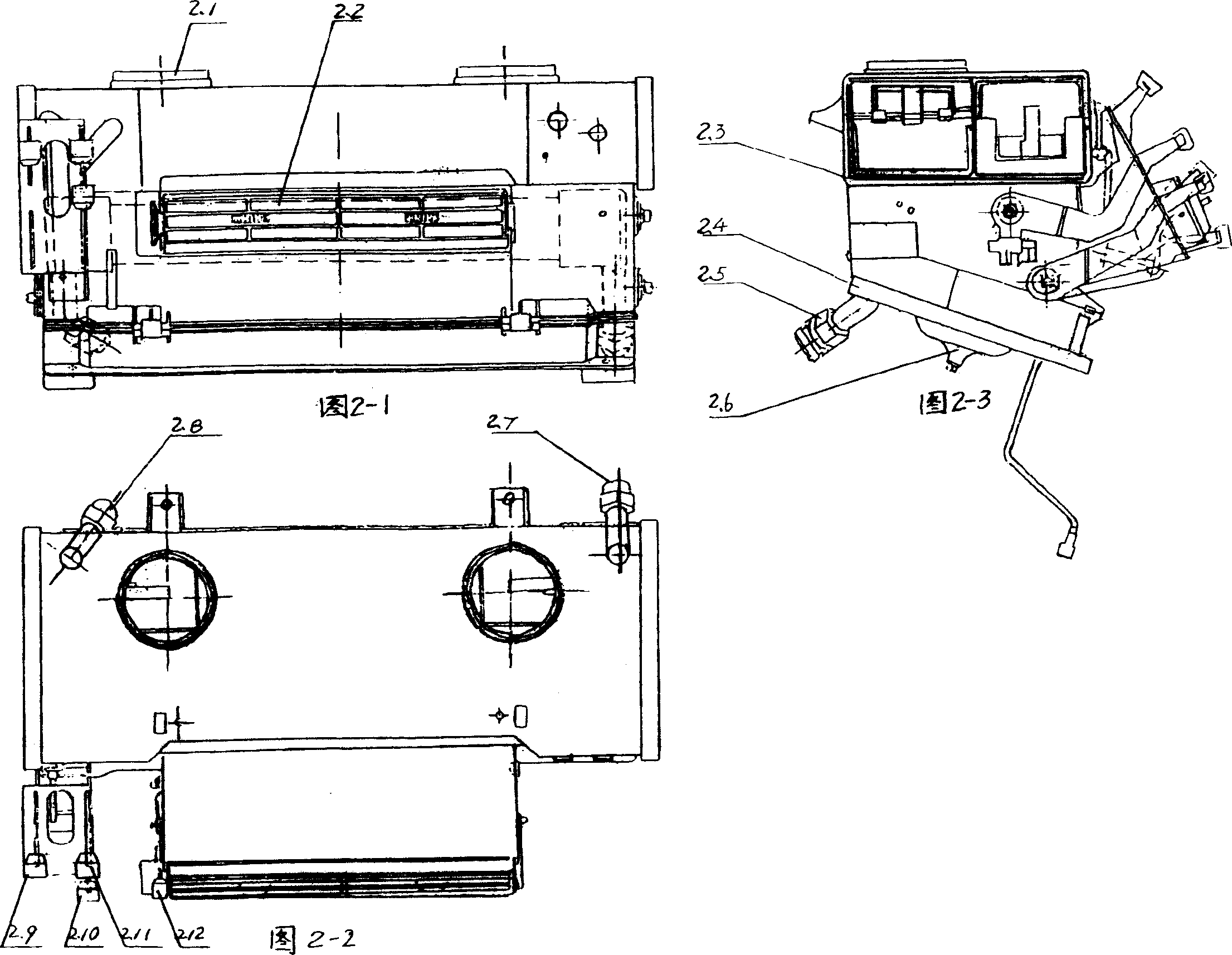

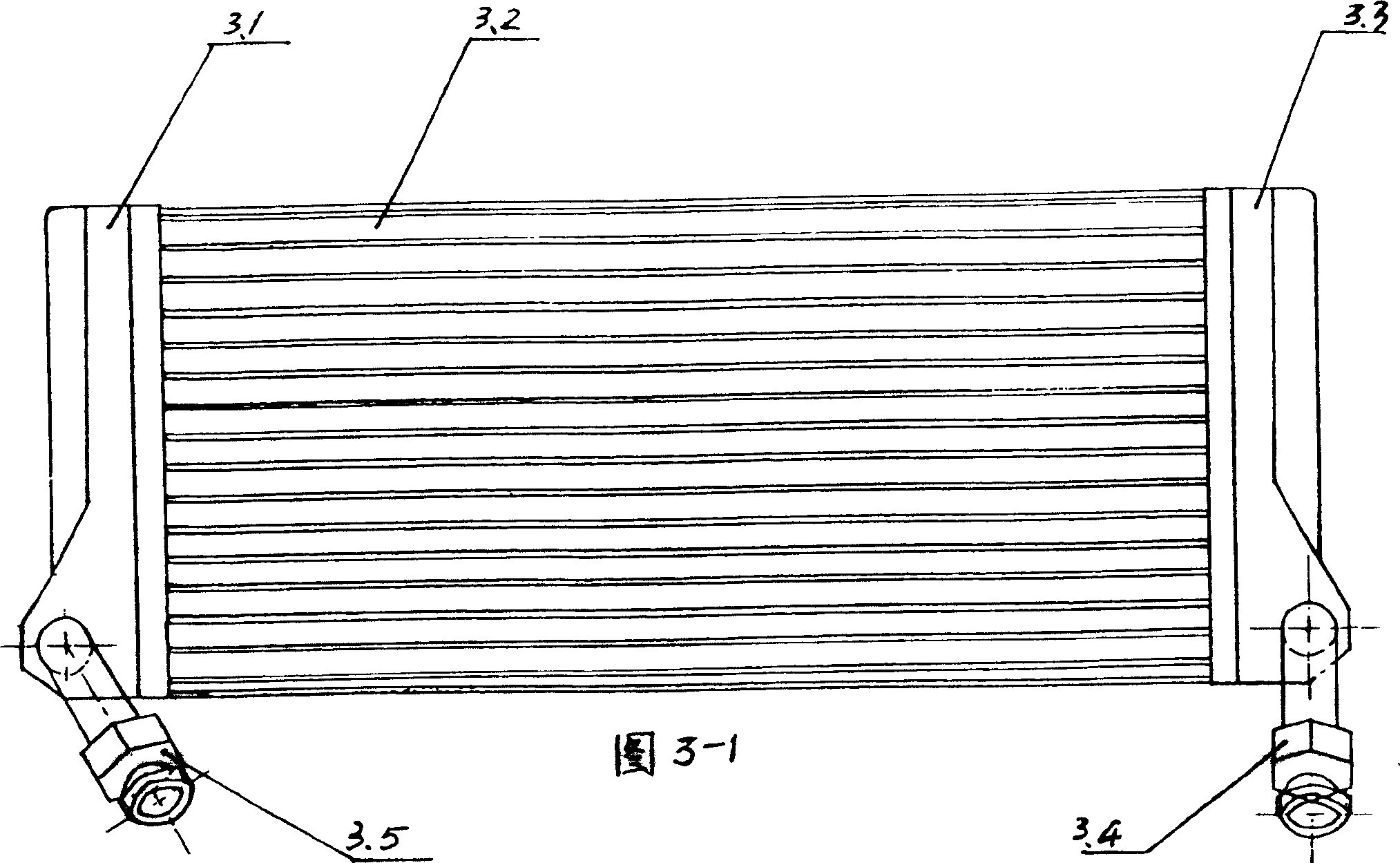

Flat-tube radiator as air heater with 3D ribs for truck

InactiveCN1378923AImprove cooling effectReduce volumeAir-treating devicesVehicle heating/cooling devicesEngineeringTruck

A 3D fin flat-tube radiator as the air heater for truck is composed of a fan, 3D-fin flat-tube radiator, case cap assemblage, case body assemblage, manipulating system and motor. The flat tubes with internal and external fins are welded between two support plates, which are in turn welded to closure heads and sealing plates sequentially. Its advantages are small size and high heating capacity.

Owner:徐光伦

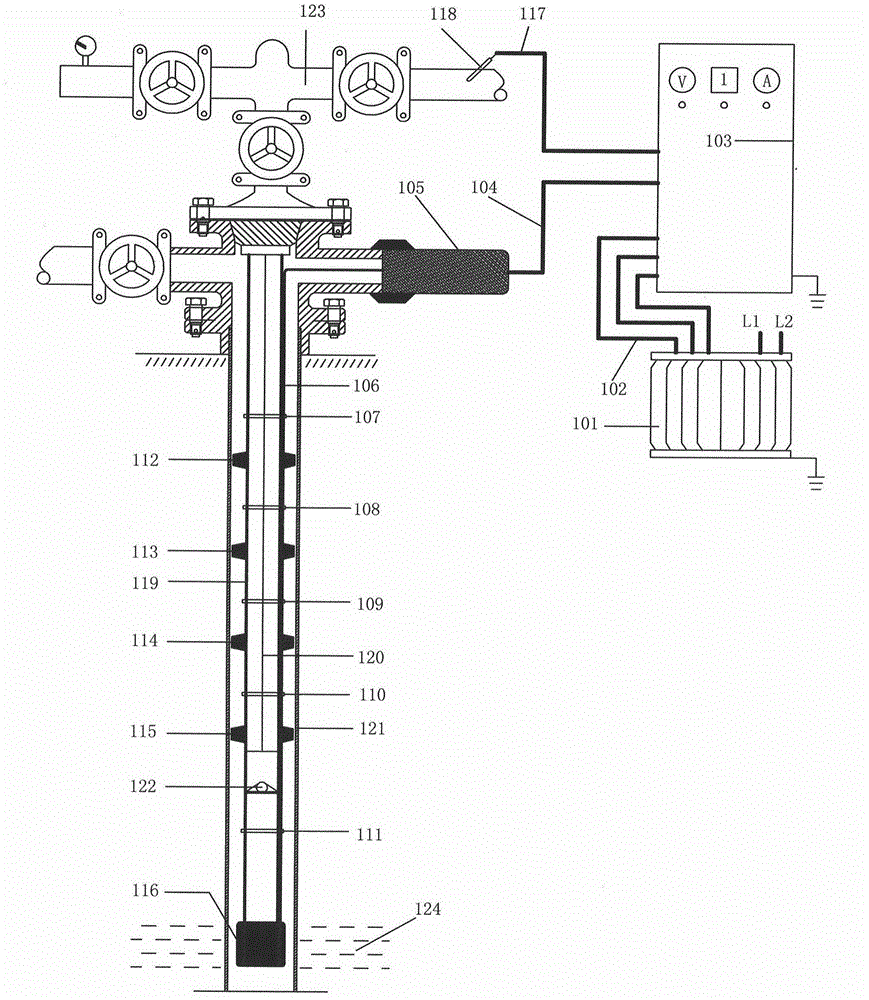

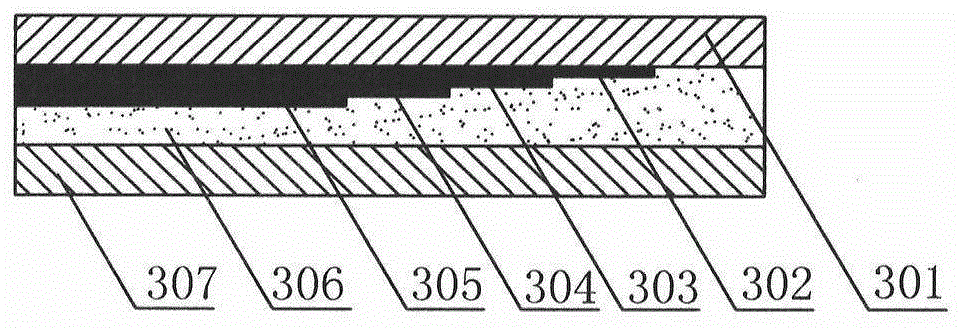

Condensate oil well reservoir RC electric heating film heating oil extraction system

The invention relates to a technology of relieving near-well zone condensate oil blockage and shaft liquid accumulation, in particular to a condensate oil well reservoir RC electric heating film heating oil extraction system. The condensate oil well reservoir RC electric heating film heating oil extraction system has the characteristic of underground local high-power heating, and has the advantages that a heater adopts a design realizing the flexible power regulation; the electric heating conversion efficiency is high; the service life is long; safety and reliability are realized; the operation is convenient; and the use range is wide. Contaminants blocked in a near-well zone oil flow passage can be relieved, and a shut-down oil well can recover the normal production.

Owner:PANJIN HONGCHANG IND CO LTD

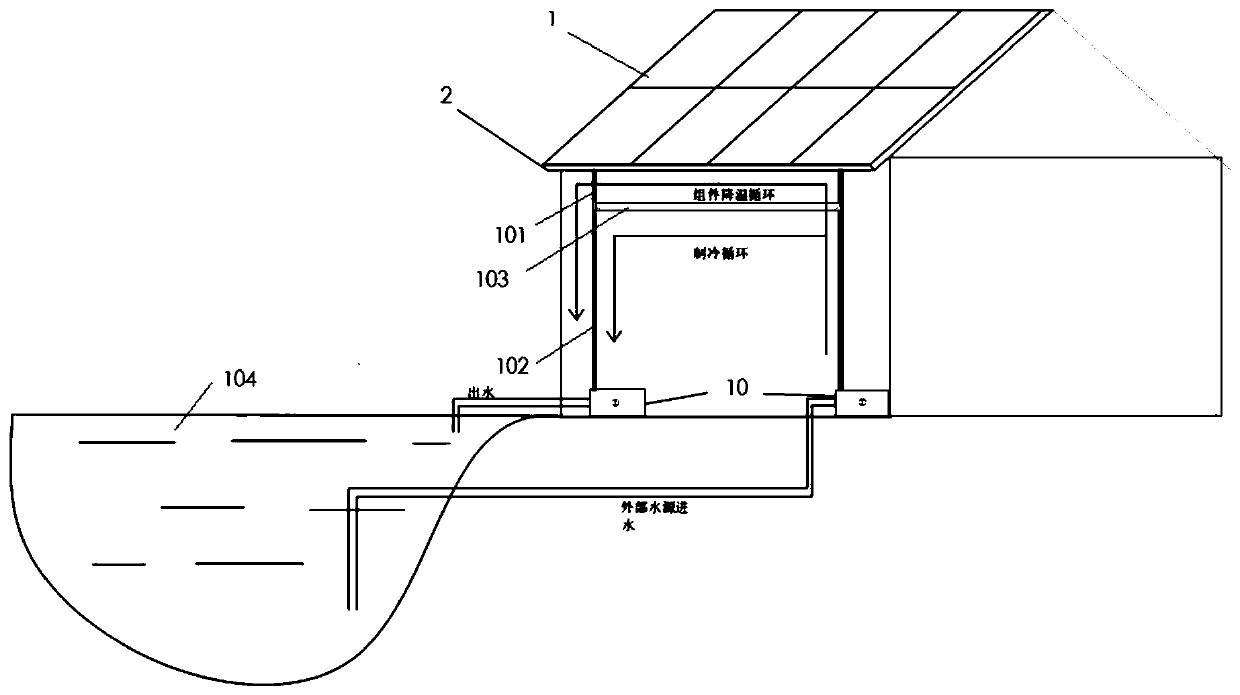

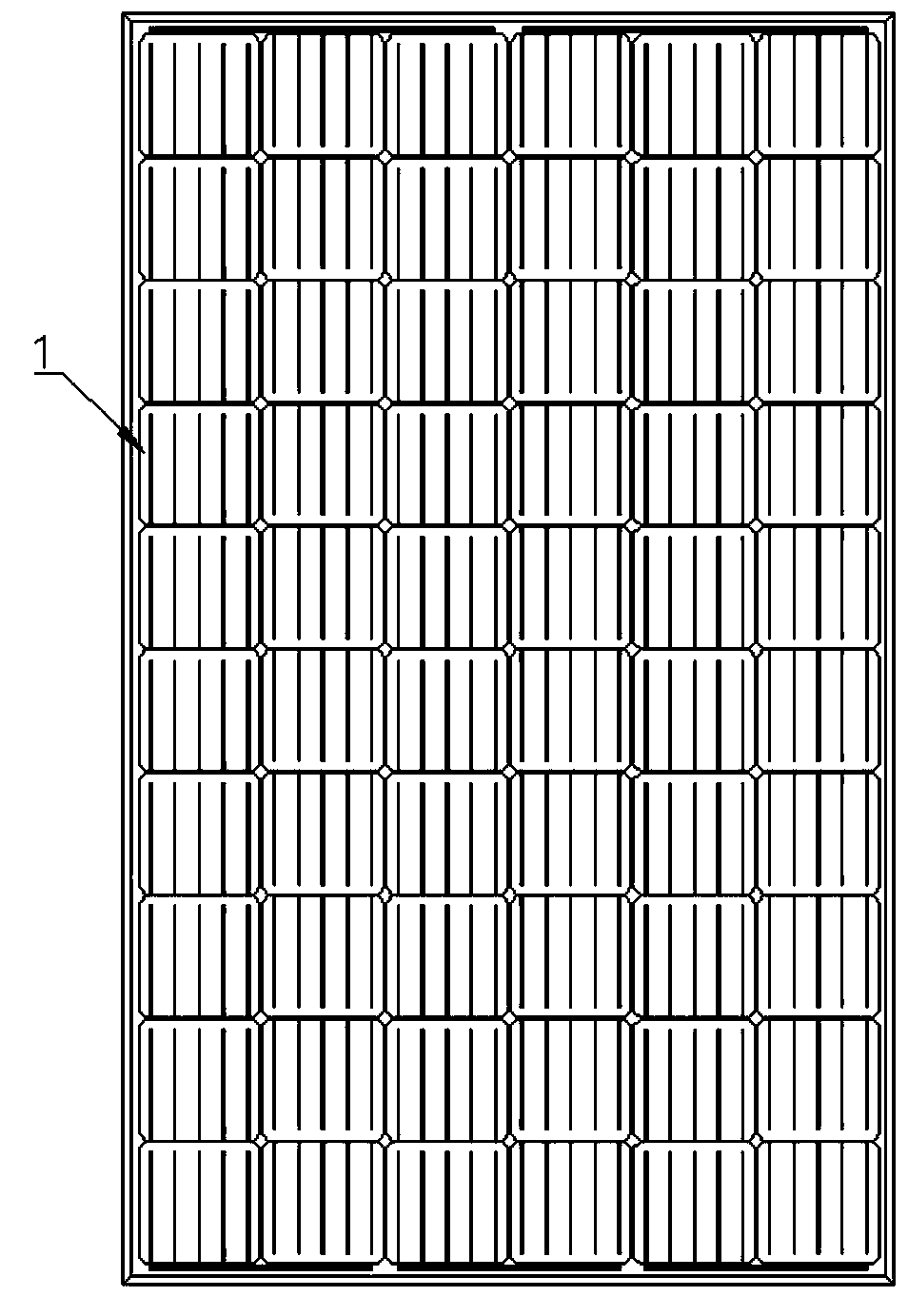

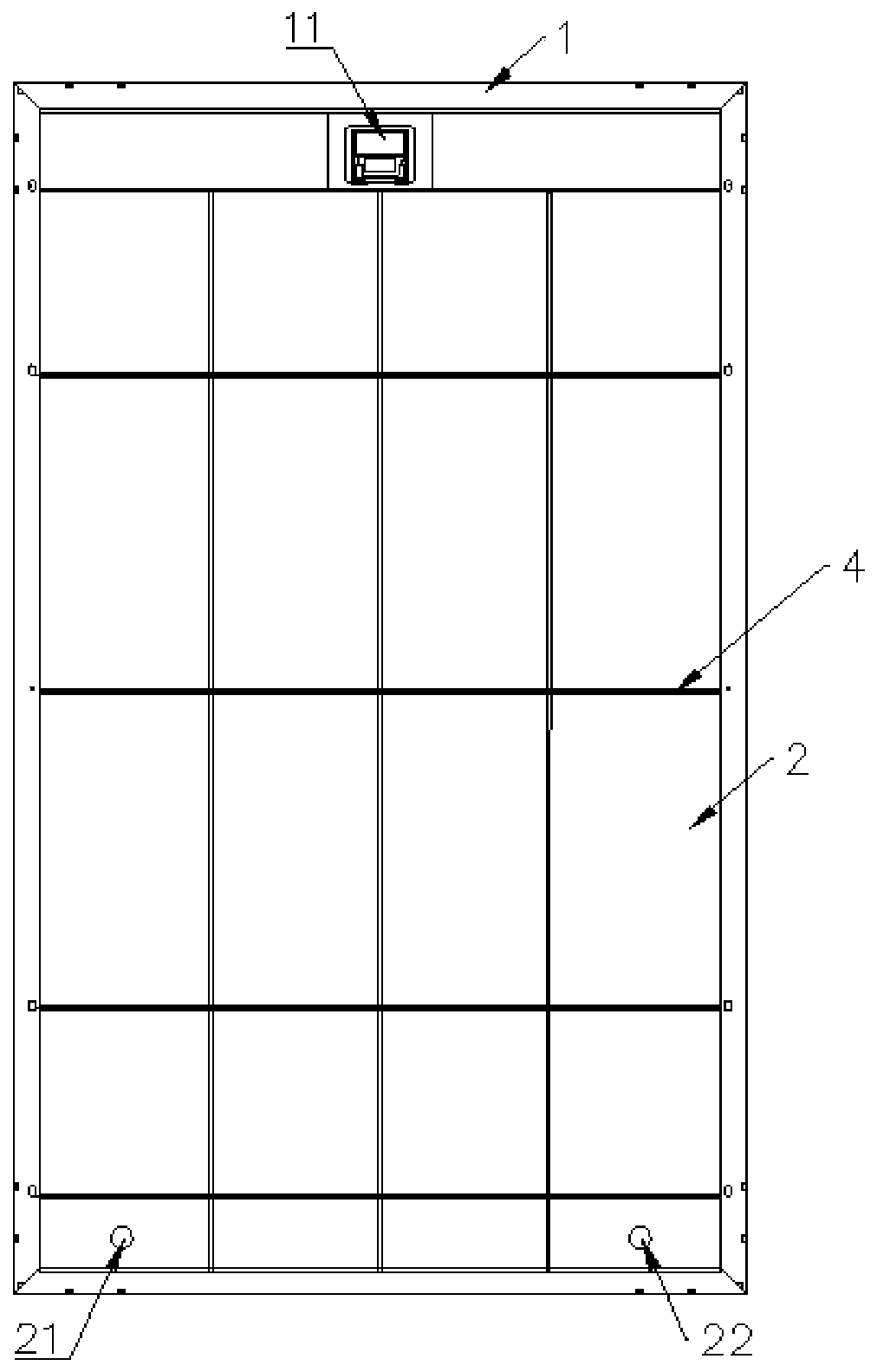

Solar heat pump system and work method thereof

PendingCN110425772ASimple structureImprove power generation efficiencyHeat pumpsPhotovoltaicsWater circulationExternal connection

The invention discloses a solar heat pump system and a work method thereof. A water storing bag type photovoltaic assembly, a pump machine assembly, a water bag circulating pipeline, an indoor circulating pipeline, a middle pipeline and a temperature gauge are included, wherein the water storing bag type photovoltaic assembly is arranged on the surface of a roof, and comprises a photovoltaic assembly for converting solar energy into electric energy, a water storing bag arranged on the back side of the photovoltaic assembly and a water bag support used for supporting the water storing bag; thepump machine assembly comprises one or more heat pumps; part of the electric energy converted by the photovoltaic assembly is used for providing electric power supporting for the heat pumps, and the heat pumps are used for achieving water circulation; the water bag circulating pipeline is used for communicating an underground water source or an external connection water source with the water storing bag; the indoor circulating pipeline is arranged indoors and used for circulating the underground water source or the external connection water source; the middle pipeline communicates with the water bag circulating pipeline and the indoor circulating pipeline, and is provided with a temperature control valve; and the temperature gauge is arranged on the indoor environment. Double-circulation design is adopted for the solar heat pump system, so that the summer cooling and winter heating effect can be effectively achieved.

Owner:PERLIGHT SOLAR

Household heat pump heating air conditioning hot water dehumidification combined system

ActiveCN106802025BImprove heat transfer performanceIncrease heating powerCompression machines with reversible cycleHeating and refrigeration combinationsLiving roomWater circulation

Owner:盐城瑞阳科技有限公司

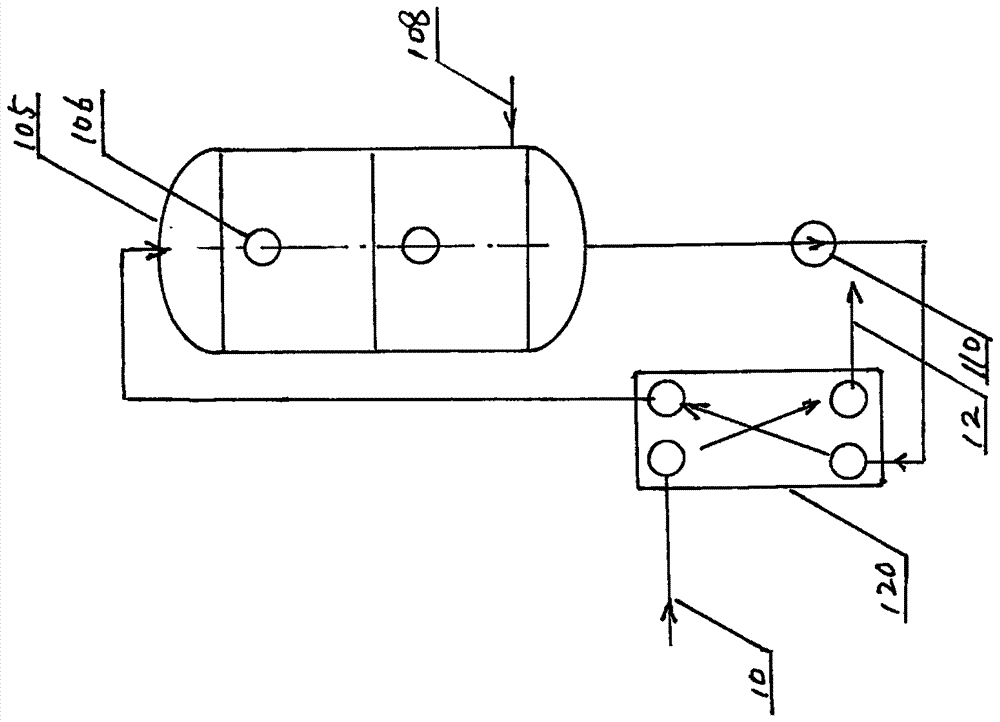

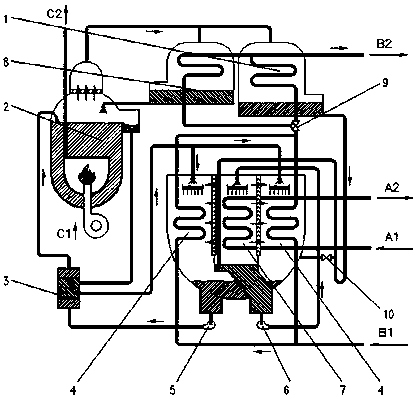

First-type lithium bromide heat pump unit provided with peak-load calorifier and capable of realizing direct heating

ActiveCN108534207ALarge heat supplyReduce areaHeat pumpsHot-water central heatingPeak load shavingLithium bromide

The invention relates to a first-type lithium bromide heat pump unit provided with a peak-load calorifier and capable of realizing direct heating, and belongs to the technical field of air conditioning equipment. The first-type lithium bromide heat pump comprises a condenser (1), a generator (2), a heat exchanger (3), an absorber (4), a solution pump (5), a coolant pump (6), an evaporator (7), thepeak-load calorifier (8), a hot water regulating valve (9) and a coolant regulating valve (10), wherein the hot water regulating valve regulates the amount of hot water entering the peak-load calorifier, and high-temperature coolant steam in the generator enters the condenser and the peak-load calorifier in parallel; after the coolant regulating valve is opened, direct heating can be realized when waste-heat water is absent. According to the unit, the heat pump and a peak load shaving boiler are integrated, the direct heating can be realized, the machine room area can be saved, besides, heatof waste-heat water can be recovered preferably as far as possible, and energy is saved.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Flat-tube radiator as air heater with 3D ribs for truck

InactiveCN1143787CImprove cooling effectReduce volumeAir-treating devicesVehicle heating/cooling devicesEngineeringTruck

A 3D fin flat-tube radiator as the air heater for truck is composed of a fan, 3D-fin flat-tube radiator, case cap assemblage, case body assemblage, manipulating system and motor. The flat tubes with internal and external fins are welded between two support plates, which are in turn welded to closure heads and sealing plates sequentially. Its advantages are small size and high heating capacity.

Owner:徐光伦

A heating element installation structure of a heater and the heater

ActiveCN113091317BEasy to installMeet high temperature installation requirementsAir heatersHeat resistanceAir treatment

The invention relates to the technical field of air treatment equipment, and discloses a heating element installation structure of a fan heater and the fan heater, wherein the fan heater includes a casing, a heating element is arranged inside the casing, and the installation structure includes: a supporting plate frame, a supporting plate frame The rear end is connected to the rear side of the casing, the front end of the supporting plate frame is connected to the front side of the casing, and the supporting plate frame is inclined along the front and rear directions; A first connecting plate between the upper ends of the two support plates and a second connecting plate between the lower ends of the two support plates for corresponding connection with both sides of the heating element . The invention provides a heating element installation structure for a fan heater and the fan heater. A support plate frame is provided to realize the support and fixation of the heating element. The support plate frame can meet the high temperature installation requirements of the heating element with heat resistance, and the connection structure is simple and convenient. Installation of heating elements.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Solar heat storage type water and ground double heat source heat pump system for aquaculture soil pond temperature control

ActiveCN110470075AReduce loadGuaranteed heating stabilitySolar heating energyMechanical apparatusWater sourceCarnot cycle

The invention relates to a solar heat storage type water and ground double heat source heat pump system for aquaculture soil pond temperature control. Heating / refrigeration is realized based on a reverse Carnot cycle principle. The solar heat storage type water and ground double heat source heat pump system for aquaculture soil pond temperature control comprises a heat pump unit, a culture soil pond, an auxiliary heat storage pond and an underground heat source well, and also comprises a refrigerant loop, a water source loop and an underground water flow path which are formed in the system. Compared with the prior art, the solar heat storage type water and ground double heat source heat pump system for aquaculture soil pond temperature control has the following advantages: an idle pond stores heat to serve as a heat source of a water source heat pump, so heat supply quantity is large, energy efficiency is high and operation cost is low; and the defrosting problem of an air source heatpump is avoided, the whole culture period is stable in load, the installed capacity is small and the initial invest is low. The underground water with constant temperature serves as a heat source of the a ground source heat pump, so the solar heat storage type water and ground double heat source heat pump system for aquaculture soil pond temperature control is high in energy efficiency, wide in application range and stable in heat supply.

Owner:TONGJI UNIV

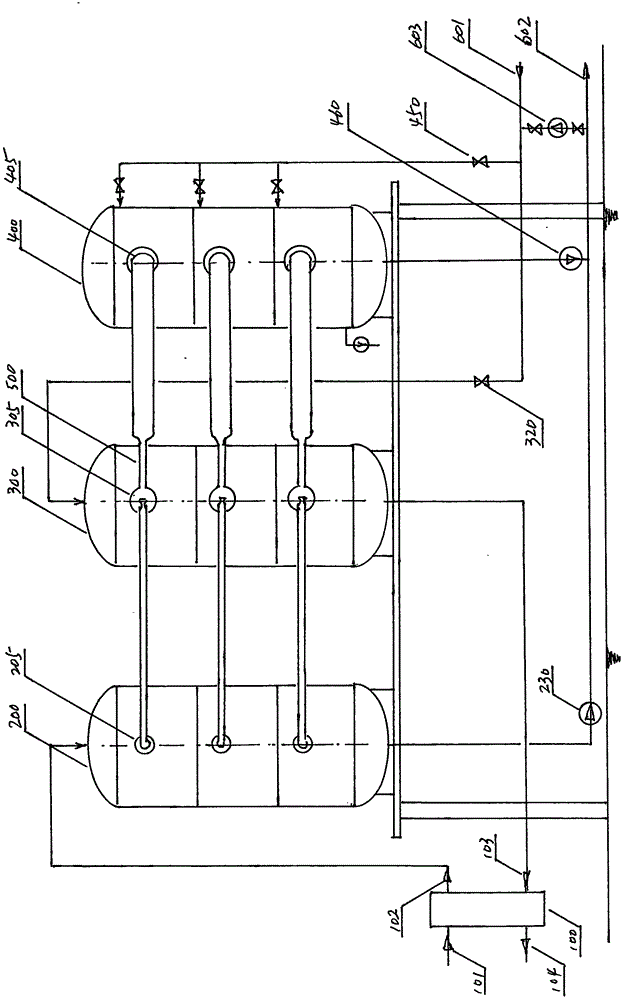

Intelligent afterheat recycling device for urban waste incineration

PendingCN112923381AReduce deliveryAvoid churnRecuperative heat exchangersIncinerator apparatusThermodynamicsGear wheel

The invention discloses an intelligent afterheat recycling device for urban waste incineration. The intelligent afterheat recycling device comprises recycling integration, a transmission system, a heat feeding device and a heat collecting system, wherein the recycling integration is used as a main support body, and the transmission system, the heat feeding device and the heat collecting system are fixedly mounted on the recycling integration. An inlet of the recycling integration is connected to a smoke flue joint of a waste incineration plant; and incinerating afterheat is introduced into a spiral box from the inlet and is filtered through the spiral box, so that clean smoke flue is introduced into the heat feeding device. The transmission mechanism which consists of an input gear, a middle gear, a transitional gear and an output gear is driven through a motor of the transmission system, so that an air blower in the heat feeding device is driven again to perform air suction; blown air on the heat feeding device pass through a ventilation pipeline and is fed into the heat collecting system; and the smoke flue is fed into a heat storage pipeline through the pipeline in the heat collecting system, and is exhausted from the used channel when the smoke flue needs to be heated.

Owner:覃军良

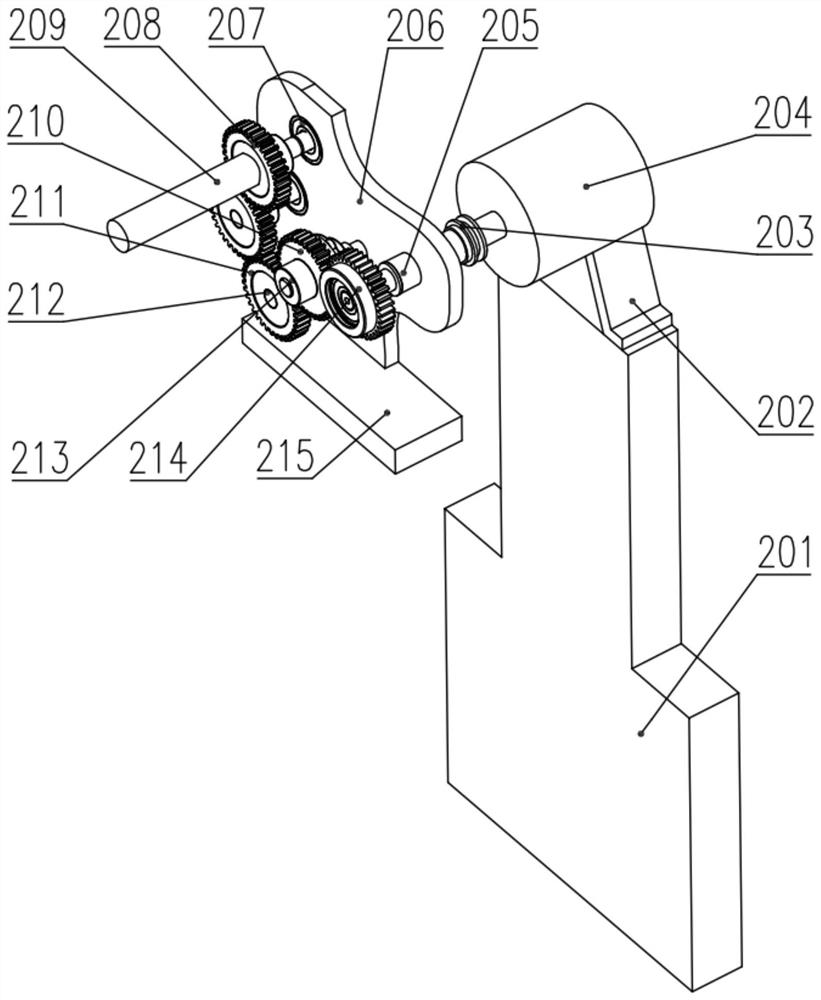

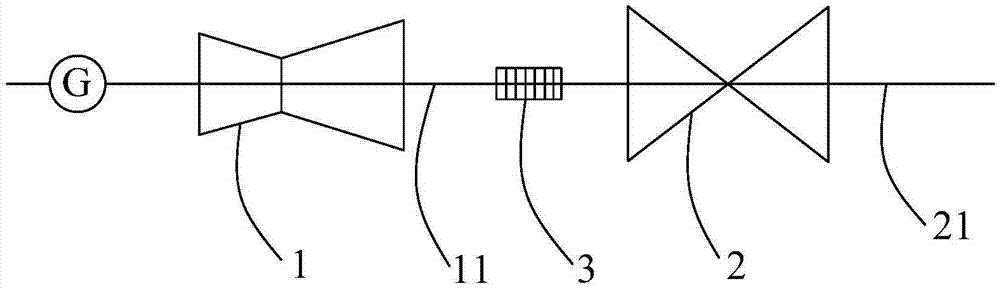

Variable-rotation-speed turbine and heat supply system thereof

ActiveCN106870021AGuaranteed safe operationImprove economyMachines/enginesEngine controlEngineeringTurbine

The invention provides a variable-rotation-speed turbine. The variable-rotation-speed turbine comprises a high-and-intermediate-pressure cylinder and a low-pressure cylinder, wherein the high-and-intermediate-pressure cylinder is provided with a first rotor shaft, and the low-pressure cylinder is provided with a second rotor shaft. The variable-rotation-speed turbine further comprises a speed change mechanism. The output end of the speed change mechanism is connected with the first rotor shaft. The input end of the speed change mechanism is connected with the second rotor shaft. When the operation backpressure of the turbine rises, the steam enthalpy drop delta h of the low-pressure cylinder is reduced, and the speed change mechanism is used for reducing the rotation speed n of the second rotor shaft of the low-pressure cylinder. When the operation backpressure of the turbine lowers, the steam enthalpy drop delta h of the low-pressure cylinder is increased, and the speed change mechanism is used for increasing the rotation speed n of the second rotor shaft of the low-pressure cylinder. According to the variable-rotation-speed turbine, the rotation speed of the low-pressure cylinder of the turbine is changed through the speed change mechanism, the variation of the rotation speed of the low-pressure cylinder corresponds to the enthalpy drop variation, generated when the operation backpressure of the turbine changes, of the low-pressure cylinder, and therefore the speed ratio of the low-pressure cylinder is always within a reasonable design range; and in this way, safe operation of the turbine set is guaranteed, and the economical efficiency of the turbine set is also improved.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

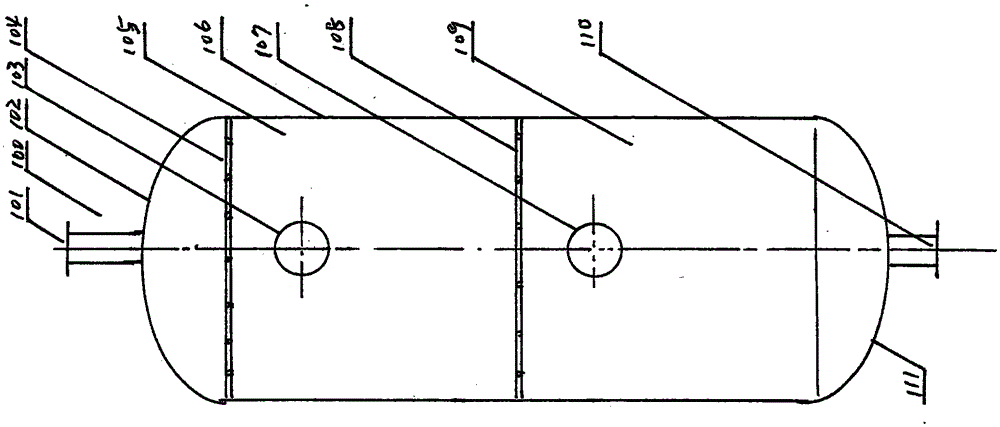

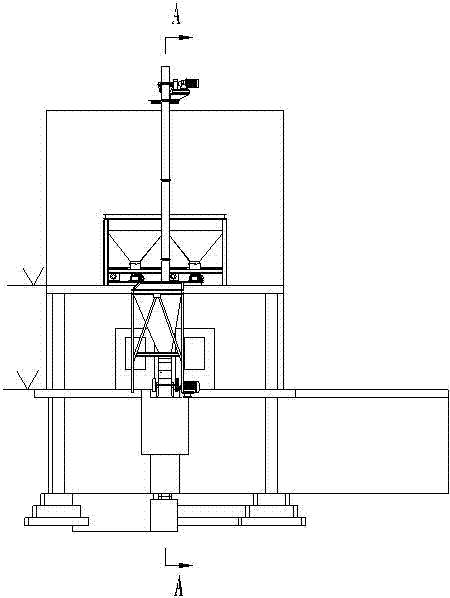

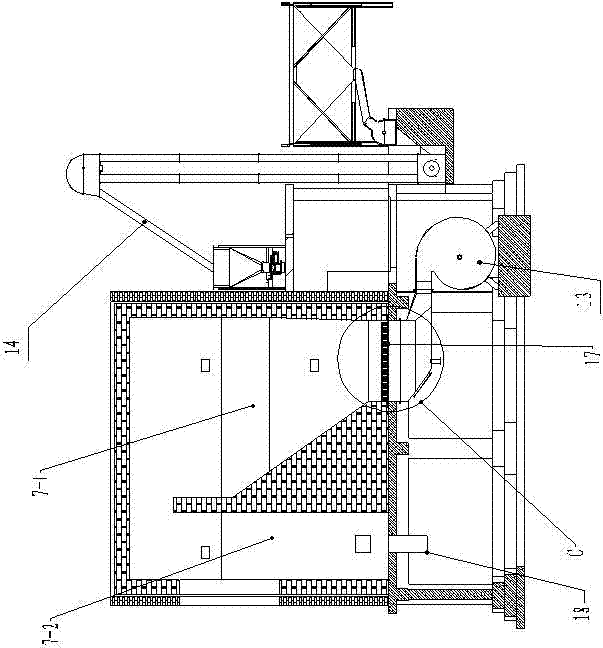

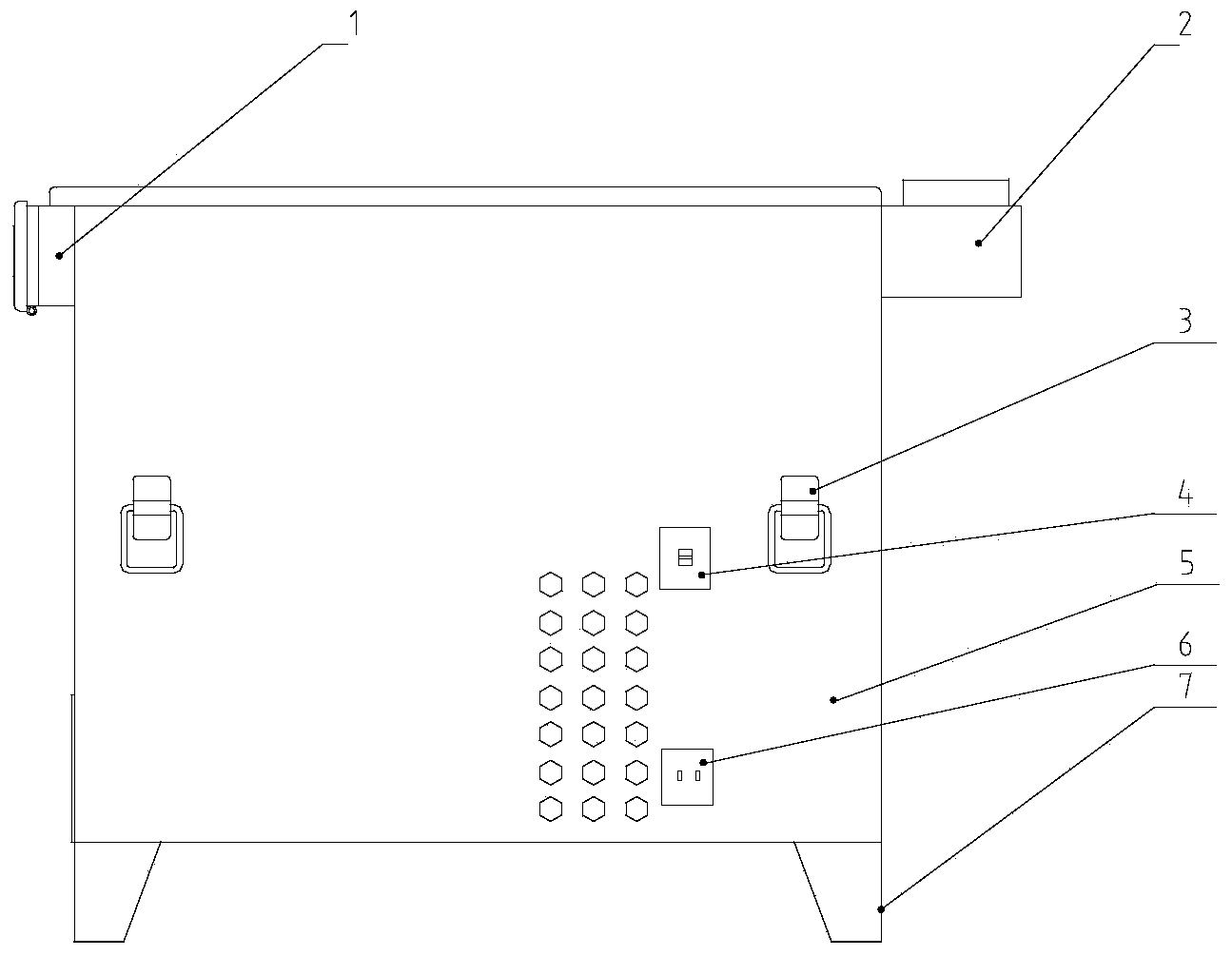

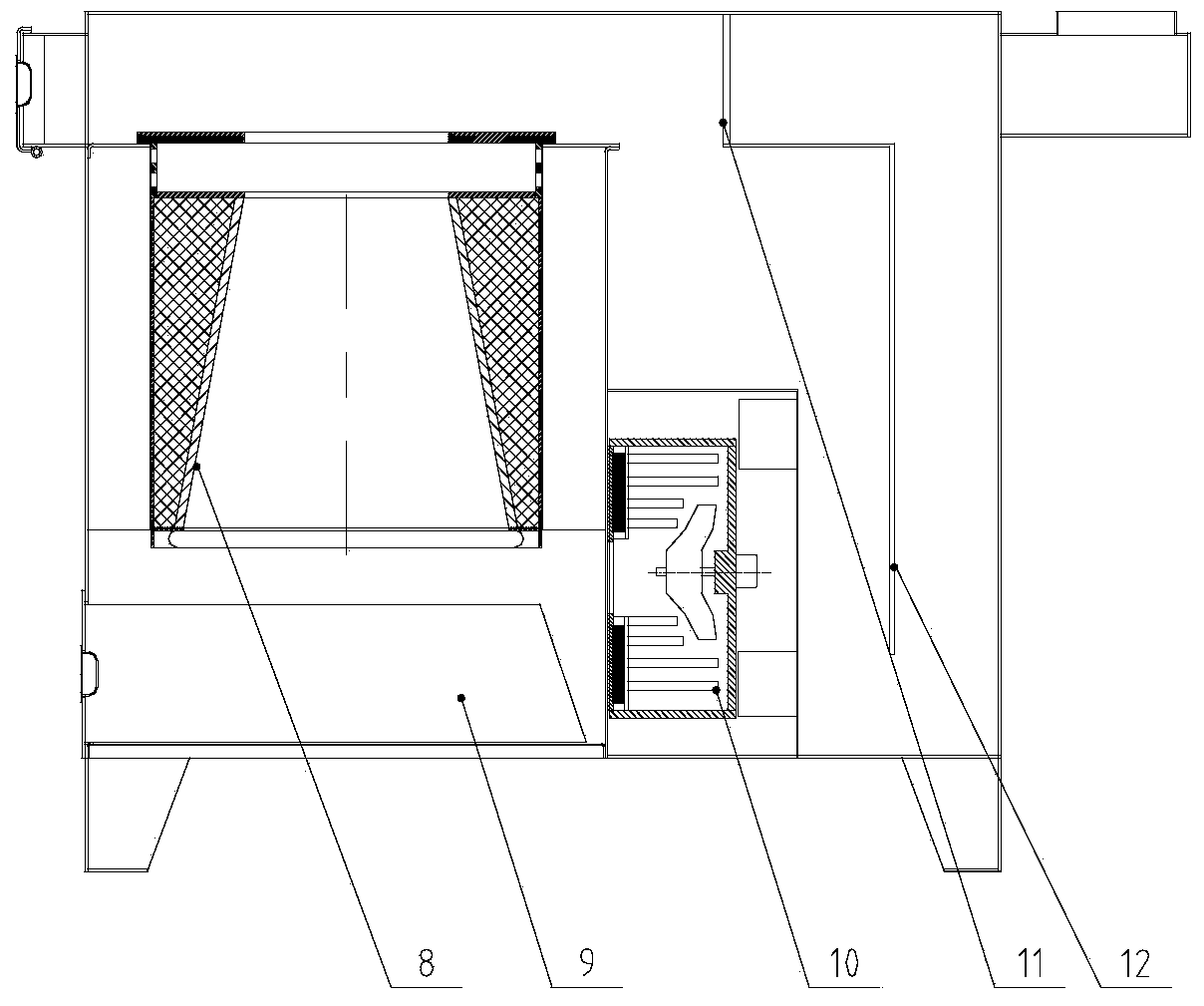

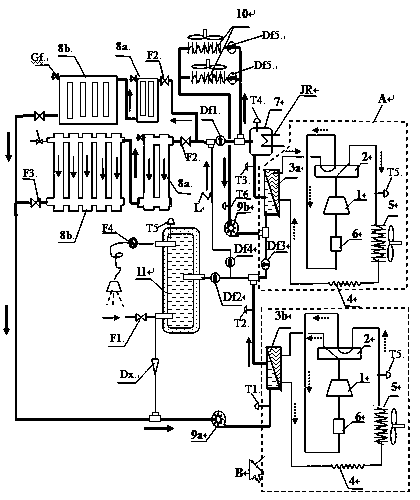

Direct connection type large-temperature-difference heat exchange device

ActiveCN107435973ASolve the shortage of heat supplyLarge heat supplyLighting and heating apparatusSpace heating and ventilation detailsAir pumpEngineering

The invention provides a direct connection type large-temperature-difference heat exchange device. The direct connection type large-temperature-difference heat exchange device structurally comprises a water return device, a high-temperature evaporator, a low-temperature evaporator, a condenser, an ejector, a plurality of valves, water pumps and some connecting pipelines. The working process comprises the following steps, high-temperature hot water with a certain pressure from a heat supply pipe network enters the high-temperature evaporator through a water return device, flash evaporations are performed stage by stage from top to bottom, and the residual hot water supplies heat to heat users; after supplying the heat, the hot water returns and enters he low-temperature evaporator, flash evaporations are performed stage by stage from top to bottom, and residual hot water flows back to the heat network through the water return device; and the ejector uses flash evaporation steam from the high-temperature evaporator as the driving steam to guide and inject the steam from the low-temperature evaporator, then the mixed steam enters the condenser and heat the sprayed heating returned water, and the heated water supplies heat the heat users. A vacuum air pump is arranged on the side wall of the last stage of the condenser, the non-condensable gas such as air is drawn out, and the vacuum degree of the whole device is maintained; and the water return device is a self-service power device for carrying out hot water circulation, and uses the water pressure from the water from the heat network to do work to push the heat network returned water with insufficient boosting pressure back to the heat network pipeline.

Owner:HIT HARBIN INST OF TECH KINT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com