Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Insert labor-saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

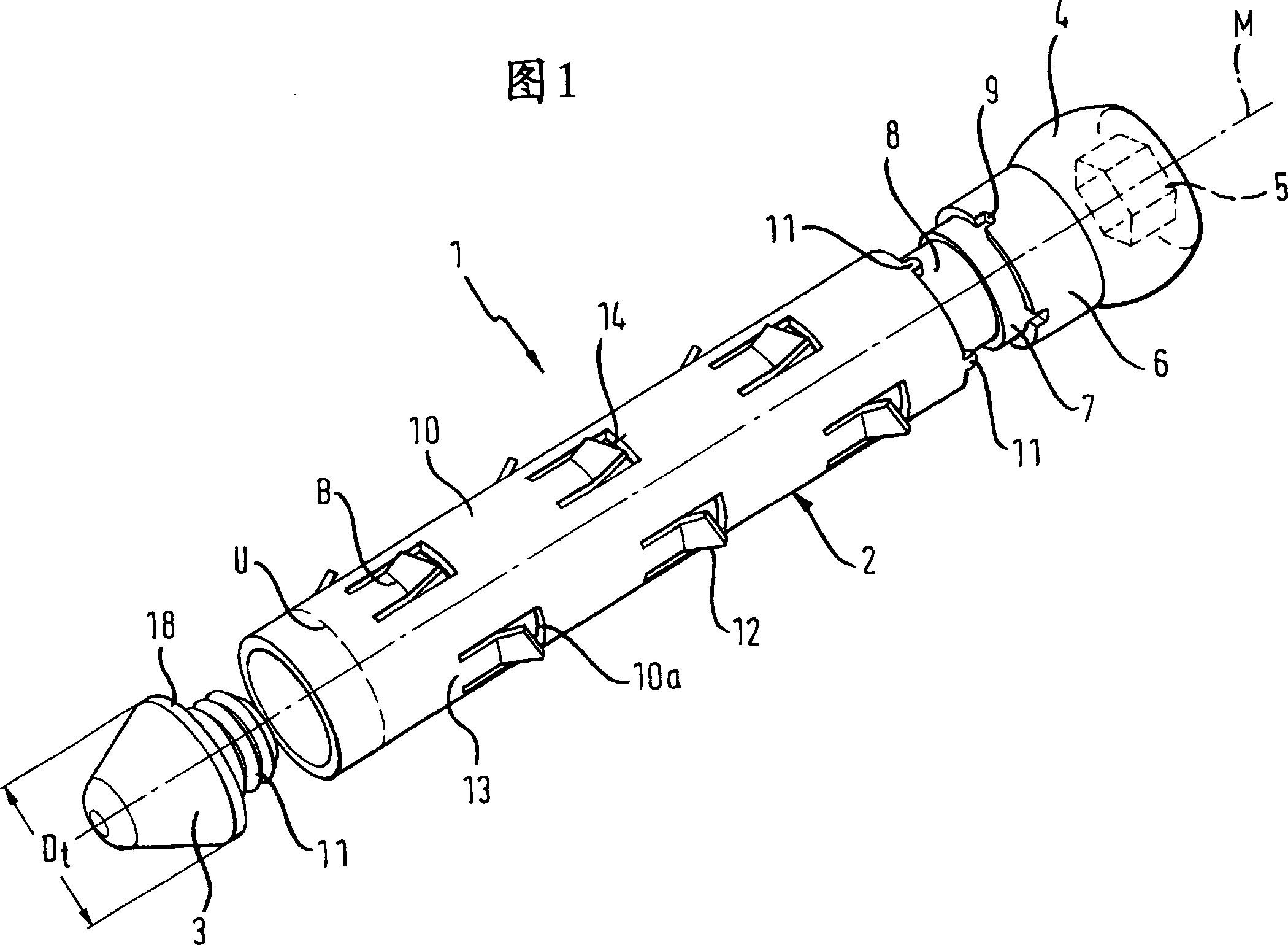

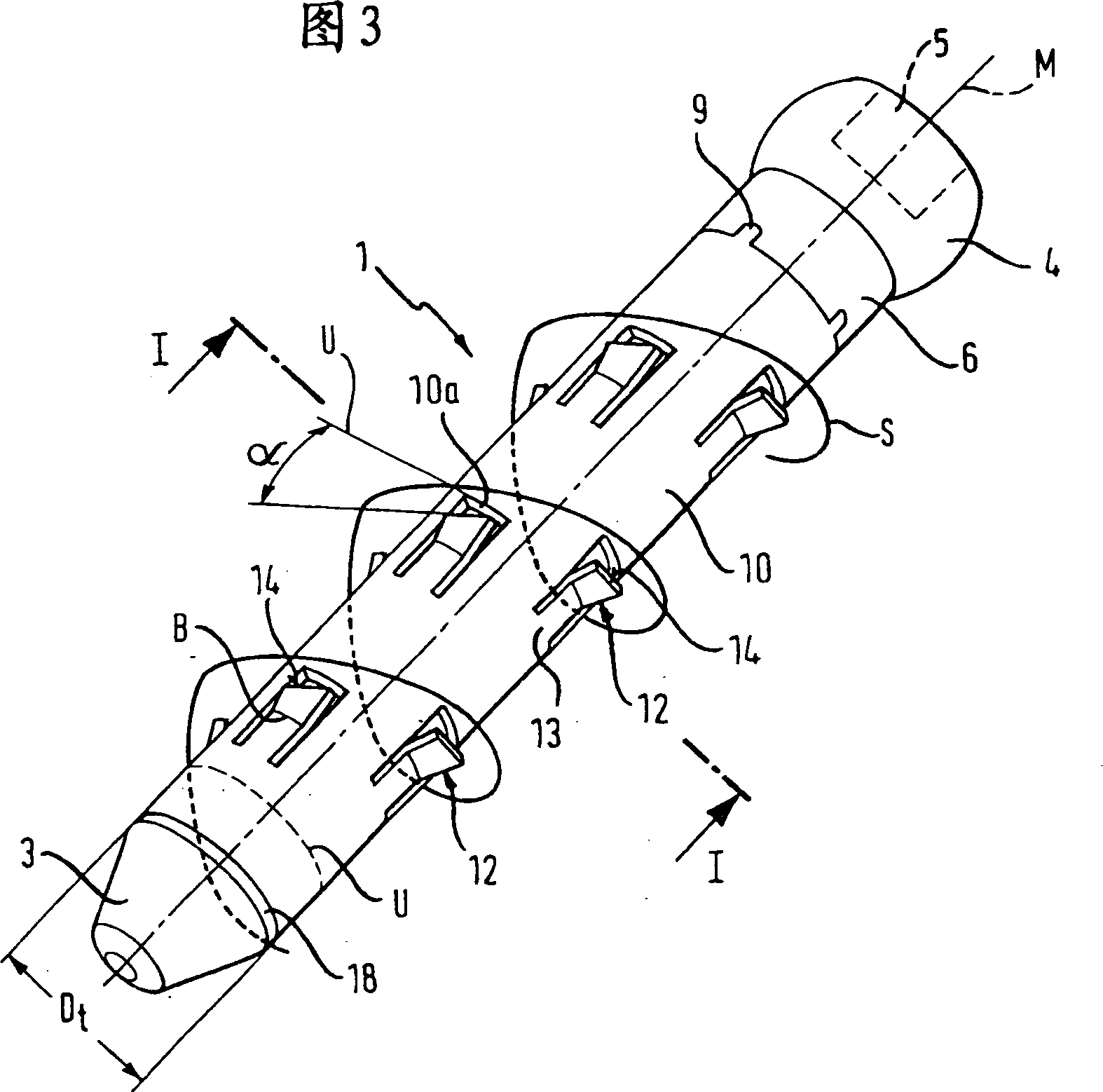

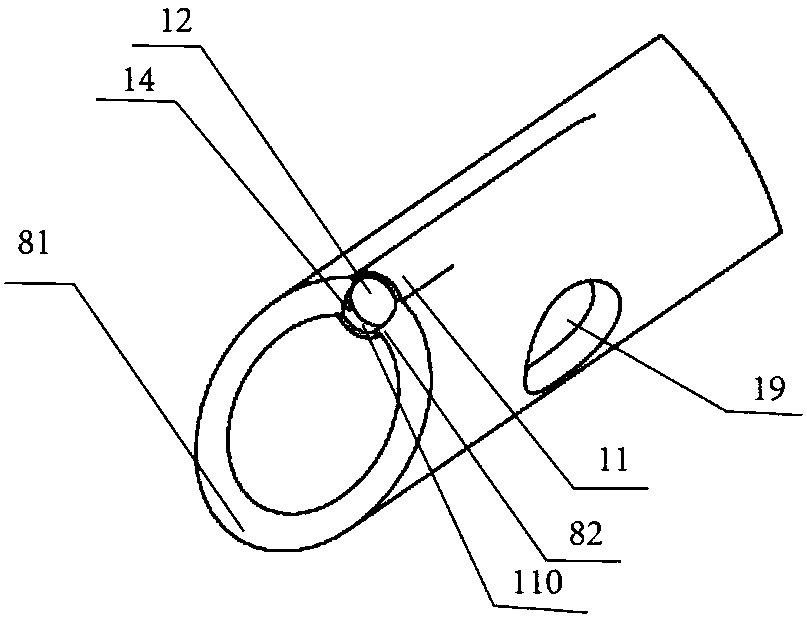

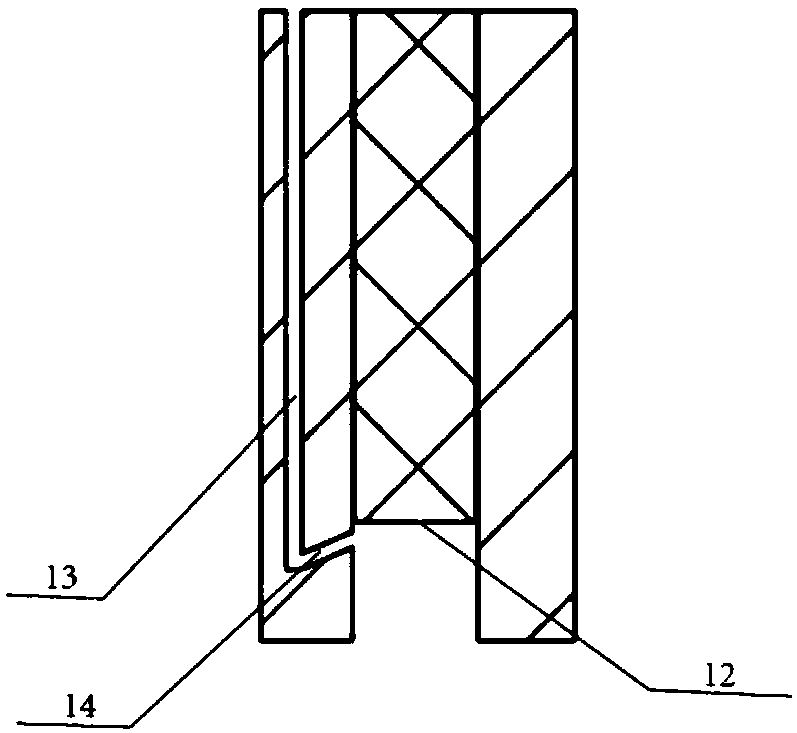

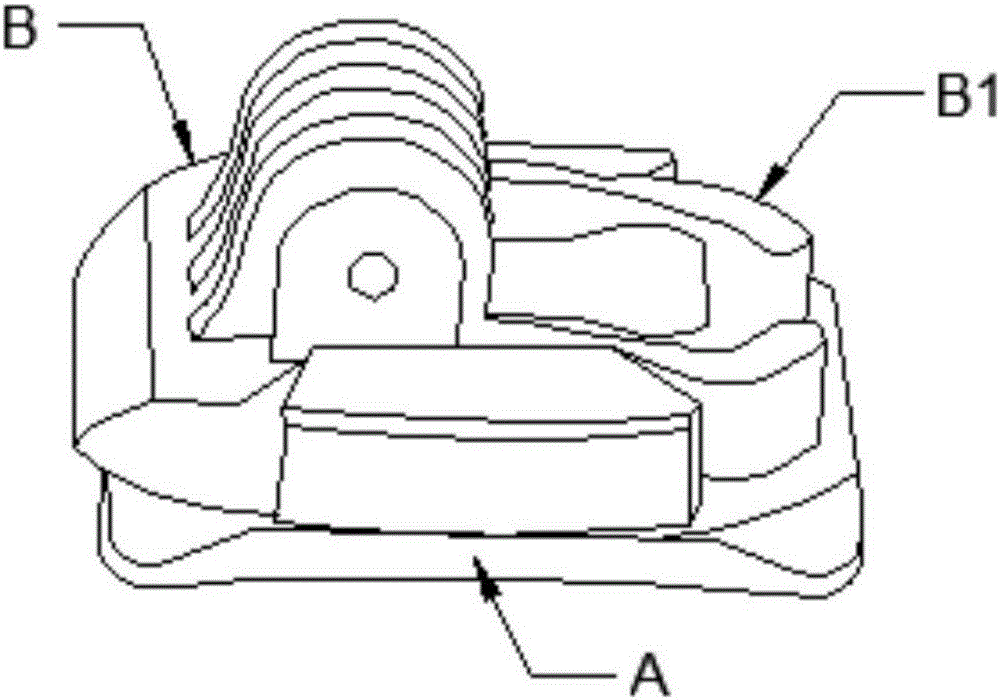

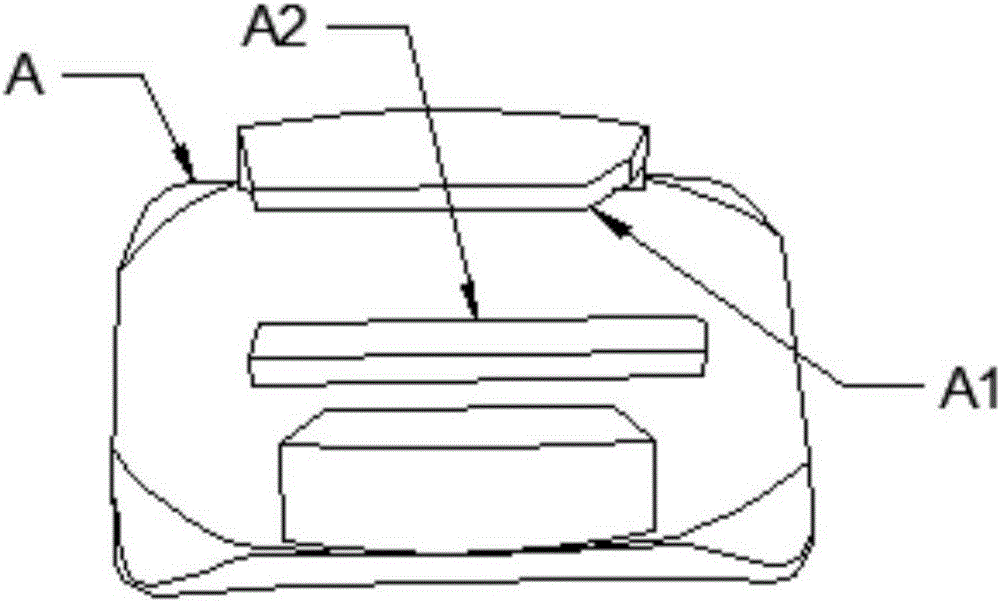

Bone anchoring element

ActiveCN1943522AFast and secure anchoringLower insertion forceInternal osteosythesisFastenersBiomedical engineeringEdge connector

Owner:BIEDERMANN TECH GMBH & CO KG

Improved visual trachea cannula

PendingCN108245755AReduce difficultyReduce operational complexityTracheal tubesBronchoscopesIntratracheal intubationCuff

The invention provides a visual trachea cannula. The cannula comprises a cannula body and a cuff. The cannula body comprises a flexible patient end, a machine end and a cannula cavity extended from the patient end to the machine end. The cuff is installed at the flexible patient end, and connected with an inflating device. The cannula body is provided with a bevel opening. The inner wall of the cannula body extended along the near end of the bevel opening is provided with an accommodating cavity and a washing channel. The opening end of the accommodating cavity is aligned to the near end of the bevel opening. The washing channel is adjacent to and separated from the accommodating cavity. A camera device is installed in the accommodating cavity. The camera device is inwards retracted relative to the near end of the bevel opening. The washing channel is provided with a washing hole which faces to the camera device and is communicated with the accommodating cavity. The flexible advantageof the flexible patient end is reserved, and the visual effect is achieved. In addition, the effect of cleaning a camera is remarkable.

Owner:ZHEJIANG UE MEDICAL

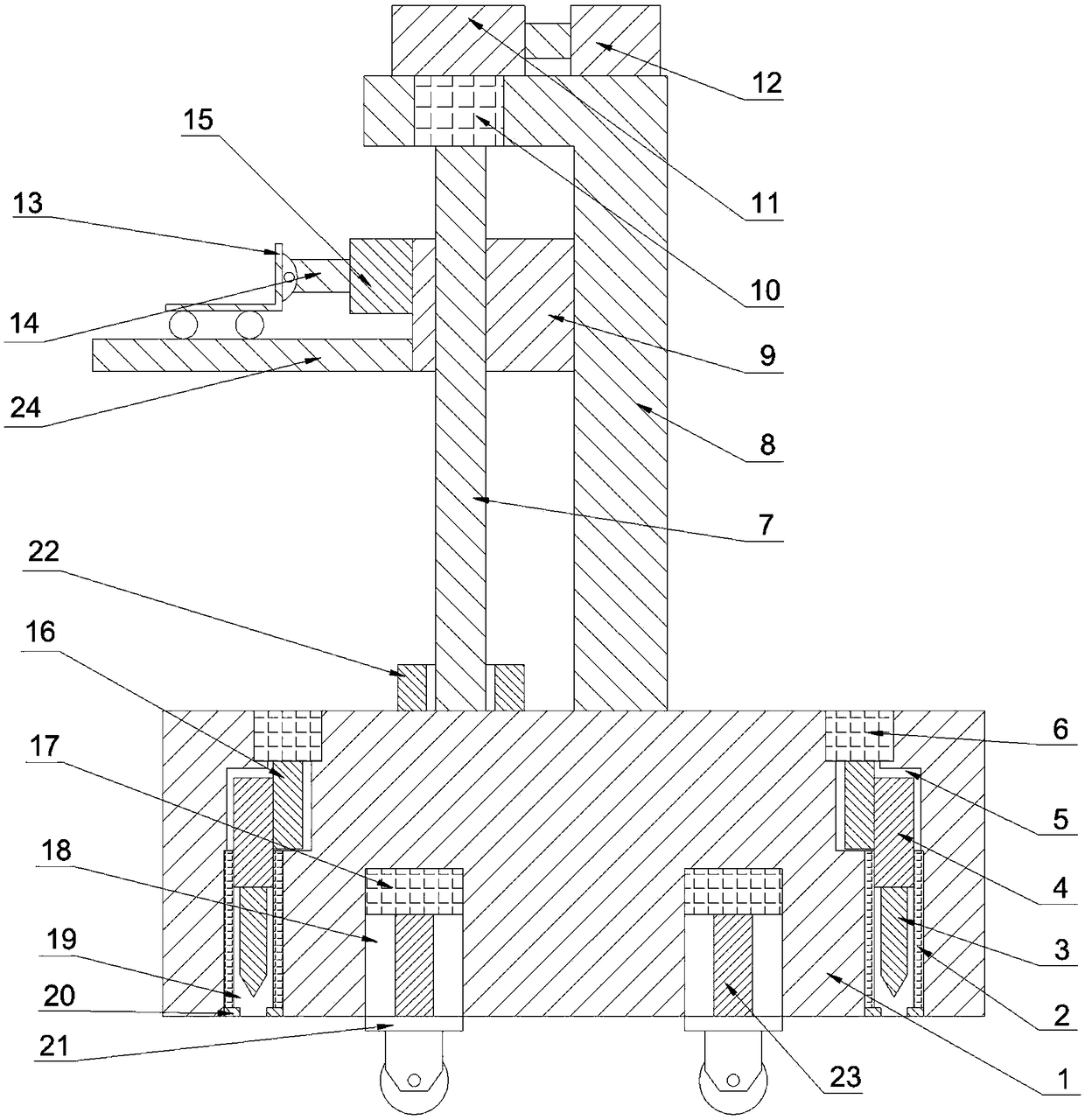

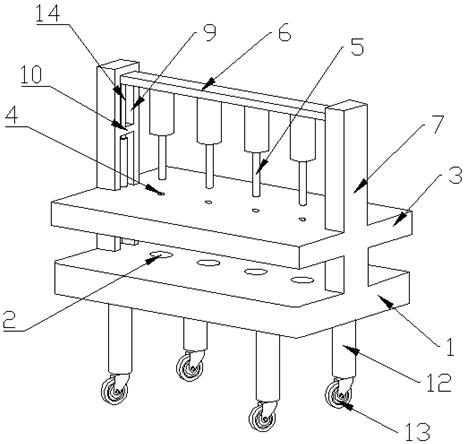

Building construction material transport apparatus for sludge ground

InactiveCN109131484AIncrease contact areaNot easy to slideCastorsBuilding material handlingSludgeEngineering

The invention relates to the technical field of building construction, and disclosed is a building construction material transport apparatus for a sludge ground, comprising a base, a plurality of universal wheels for supporting and sliding are arranged on the lower surface of the base, a telescoping mechanism for telescoping the universal wheels into the base is arranged in the base opposite to the universal wheels, two sides of the base are provided with fixing mechanisms for connecting the base and the soft mud floor, and an elevating mechanism for transporting materials is arranged on theupper surface of the base. The invention solves the problem that the wheels will sink into the soft mud ground due to the pressure of the materials in the use process of the existing material transportation equipment, which causes the material transportation process to be unstable, easy to roll over, and causes the injury of the construction personnel.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

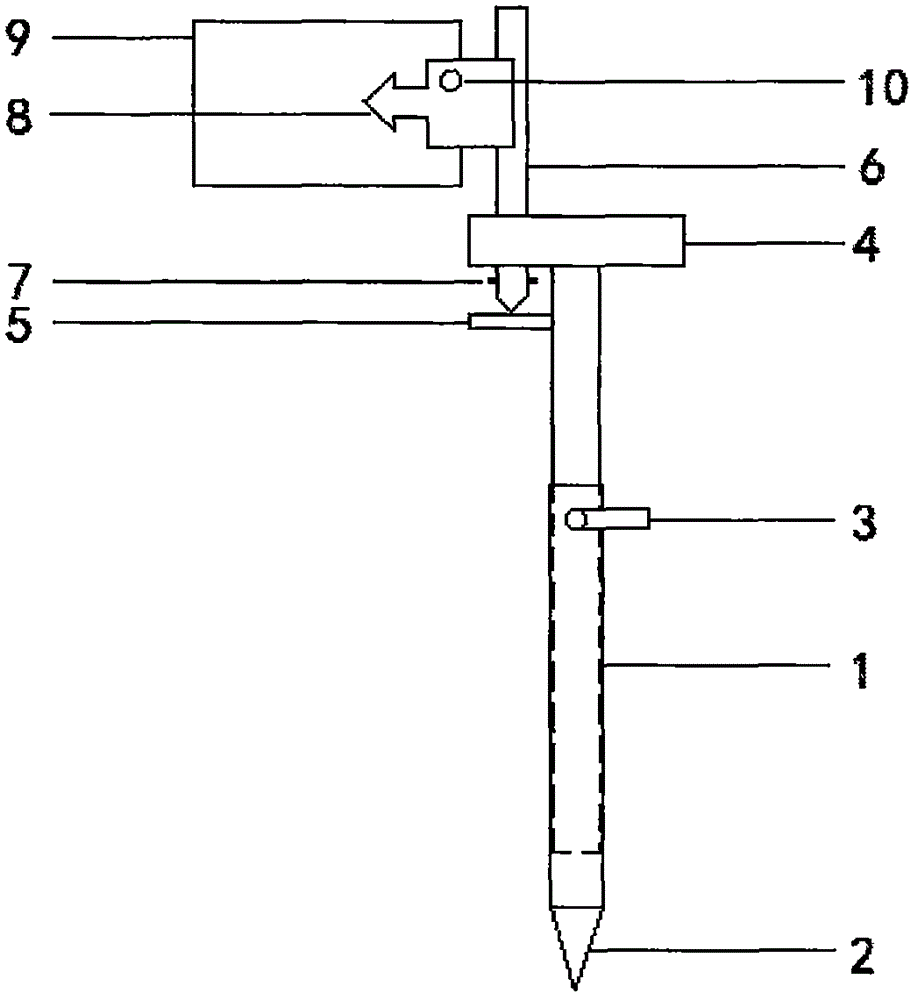

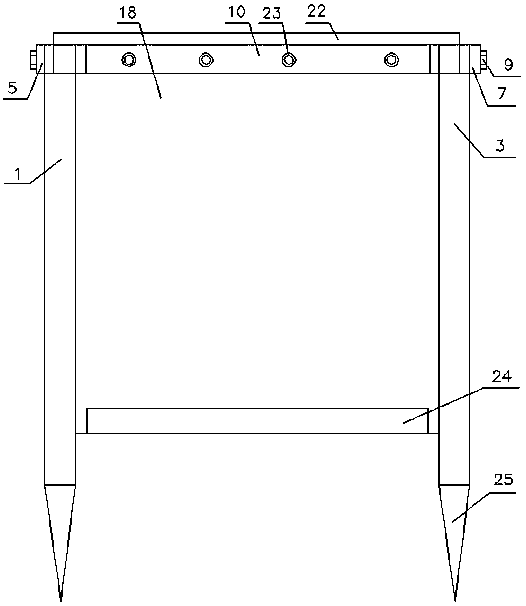

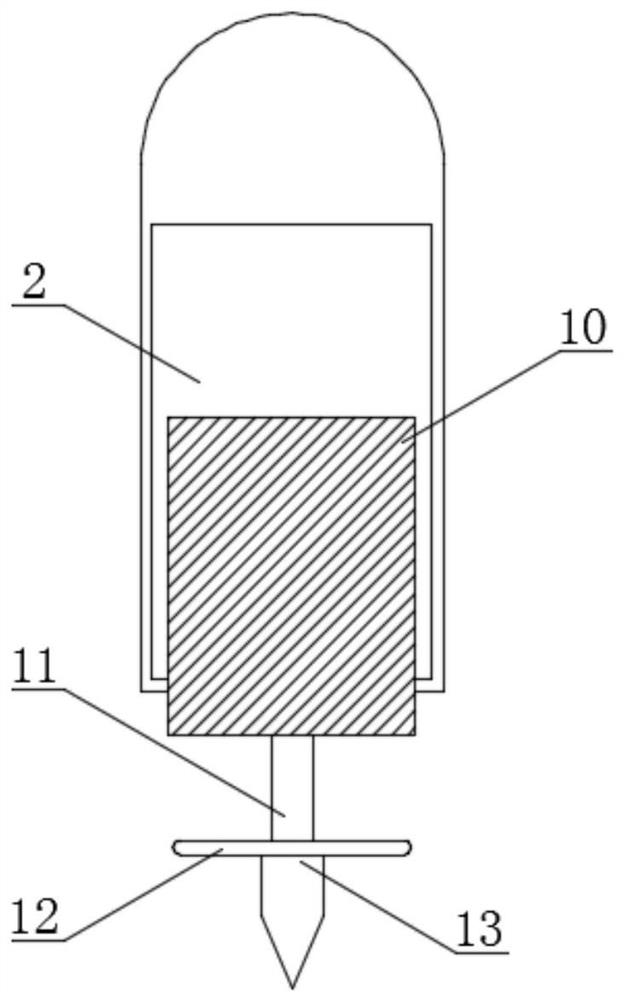

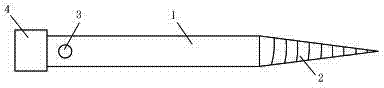

Insect sticking plate and sex pheromone trapping and forecasting tool

The invention discloses an insect sticking plate and sex pheromone trapping and forecasting tool which is particularly applicable to agricultural insect population study. The insect sticking plate and sex pheromone trapping and forecasting tool structurally comprises a circular upright rod, wherein the lower end of the upright rod is a conical tip; the middle of the upright rod is formed in a pull manner; a jack screw is arranged at the middle part of the upright rod; a long square handle is arranged at the upper end of the upright rod; a shaft hole is formed in the front end of the handle; a support plate is arranged below the handle; a sharp shaft is matched with the shaft hole and is propped against the support plate through the shaft hole; a hinge pin is arranged at the lower end of the sharp shaft; the upper end of the sharp shaft is fixedly connected with a clamp; and a suspension hole is formed in the clamp. The insect sticking plate and sex pheromone trapping and forecasting tool is simple in structure, low in cost, easy in insertion, good in stability, convenient to replace, convenient to lift, and easy to popularize.

Owner:李红光

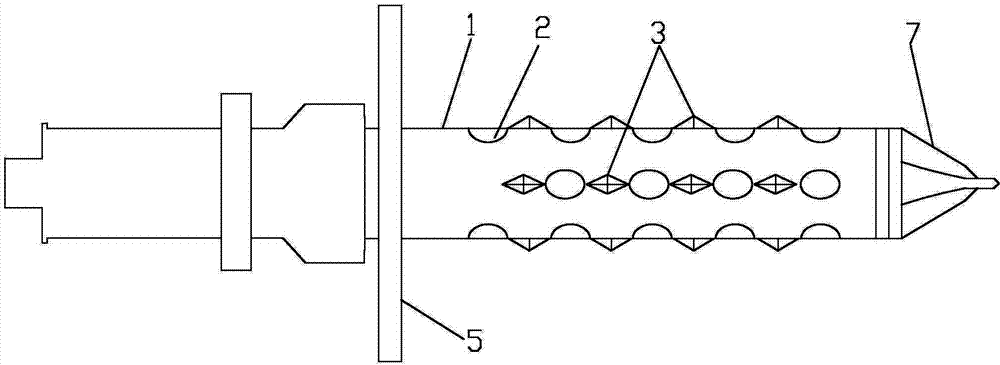

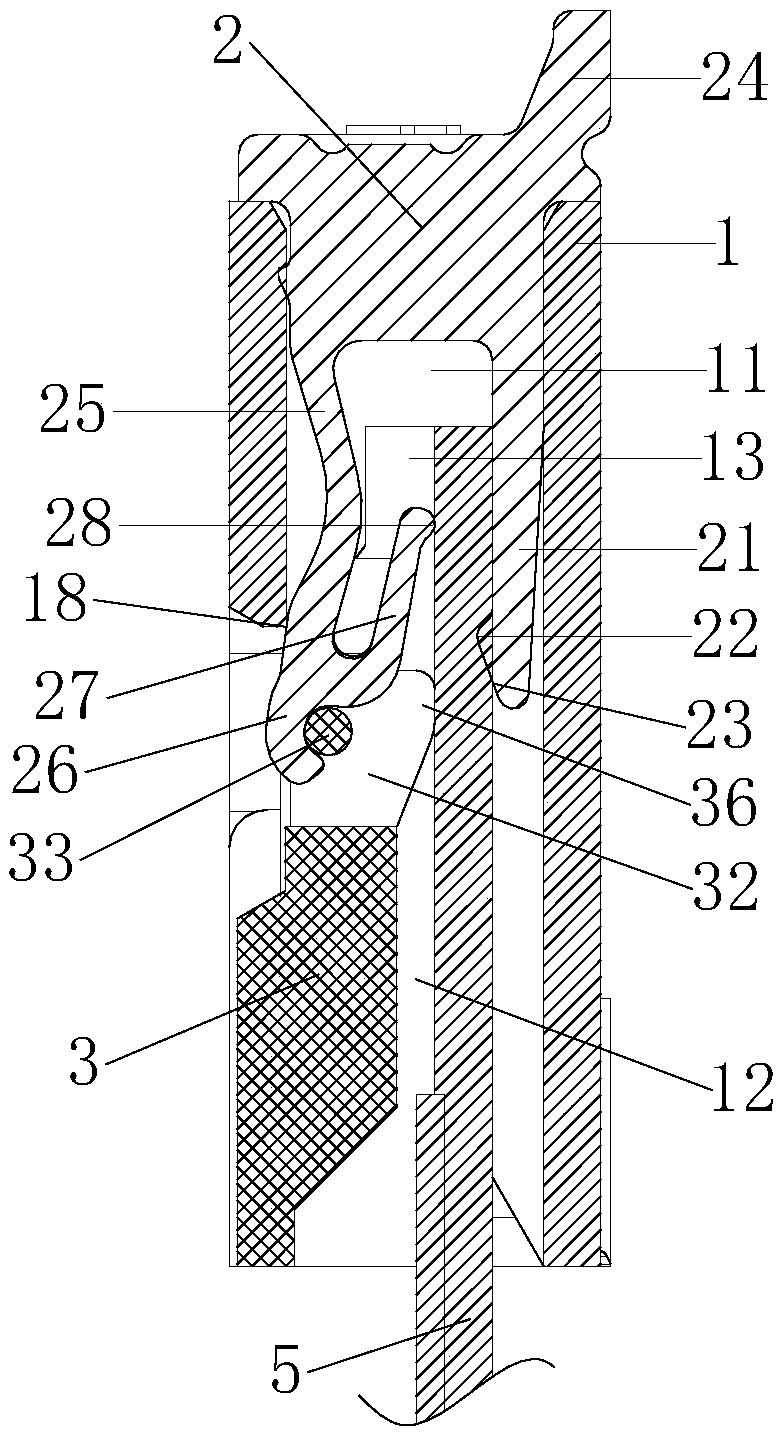

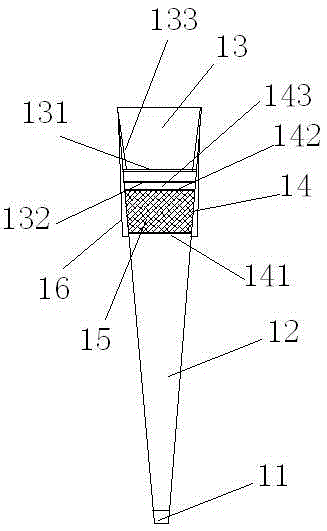

Disposable pipette tip

The invention belongs to the field of experimental apparatuses, and relates to a disposable pipette tip. The disposable pipette tip comprises a tip body, wherein the tip body comprises a suction nozzle area, a quantitative liquid storage area and a pipette active area from bottom to top, wherein a vacant area is arranged between the quantitative liquid storage area and the pipette active area, a filter element is arranged in the vacant area, a first seal ring and a second seal ring are vertically arranged on the inner surface of the lower part of the pipette active area, and the second seal ring is located on a junction surface of the pipette active area and the vacant area. The disposable pipette tip is good in sealing performance and accurate in liquid suction, a pipette can be inserted into the tip in a more labor-saving manner, and is convenient to dismount; and by means of the filter element, a liquid cannot be sucked into the pipette, and the filter element cannot influence results of smooth liquid suction and quantitative liquid suction.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

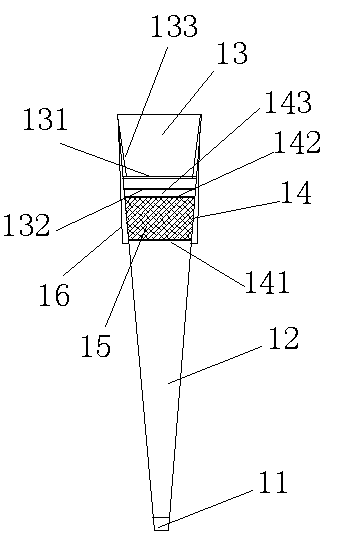

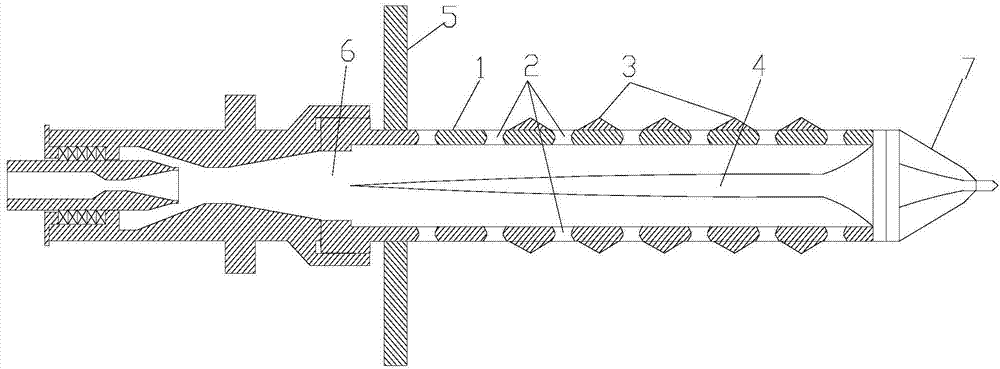

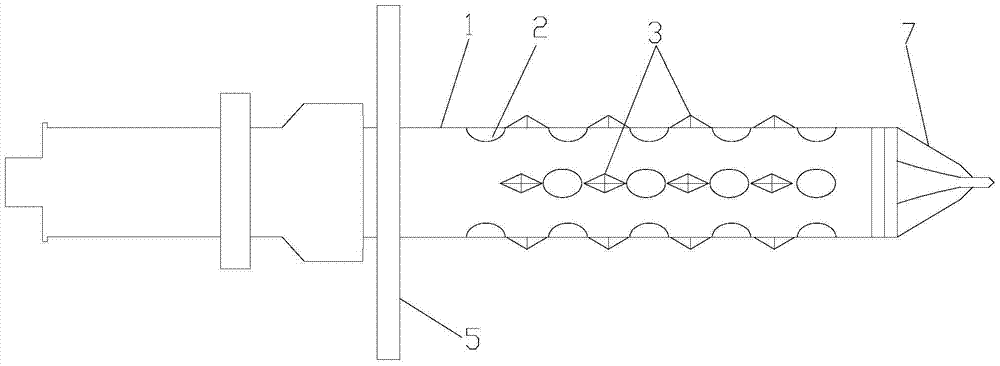

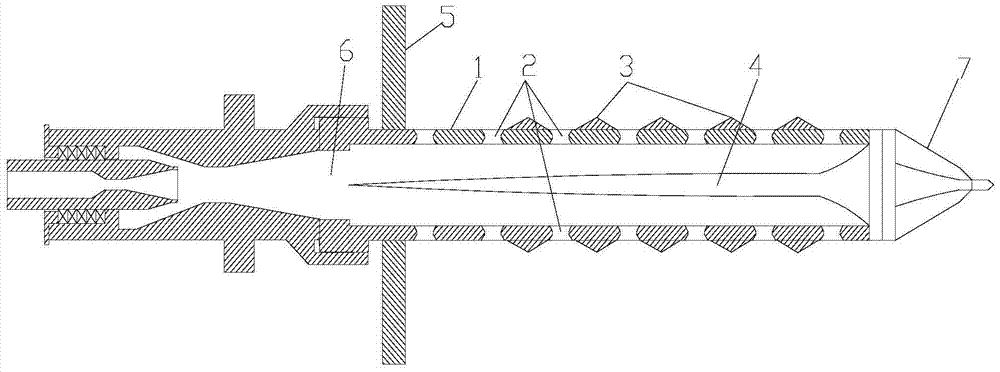

Easily-plugged-in soil loosening head

The invention aims at providing an easily-plugged-in soil loosening head. The easily-plugged-in soil loosening head comprises a soil loosening head body of a cylindrical structure. Jet holes used for jetting gas flow are formed in the side wall of the soil loosening head body. A drill bit is fixedly arranged at the front end of the soil loosening head. The soil loosening head can occupy a small area in soil where the soil loosening head is inserted, labor is saved when the soil loosening head is inserted, and therefore damage to root systems of crops is avoided; the spray explosion effect is achieved through the high-speed gas flow jetted out of the soil loosening head so that soil loosening can be achieved, deep turning is effectively prevented from being conducted on soil, damage to soil granular structures is avoided, damage to the root systems can be effectively avoided in the soil loosening process, and growth of the crops is facilitated.

Owner:CHENGDU TOBEST DIYUAN TECH CO LTD

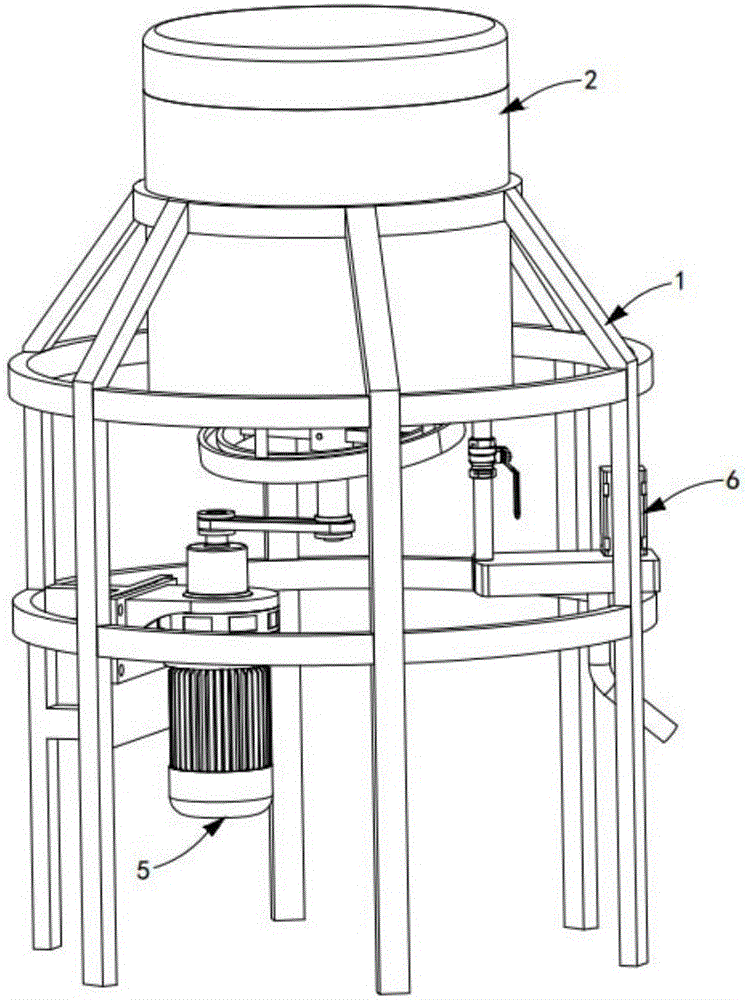

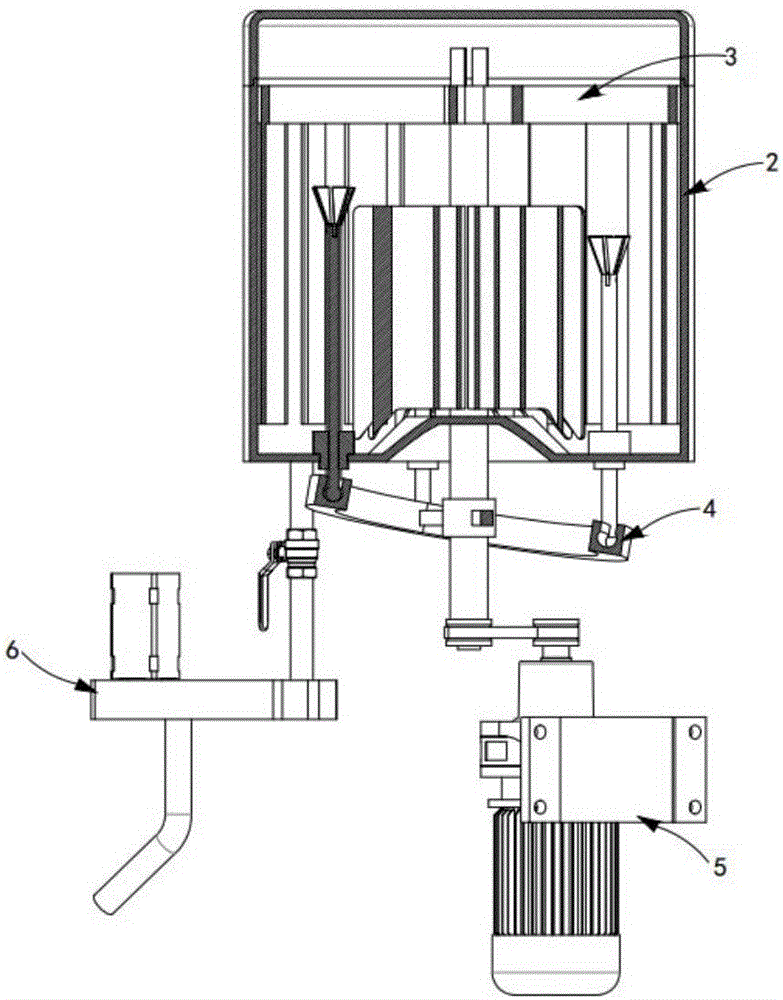

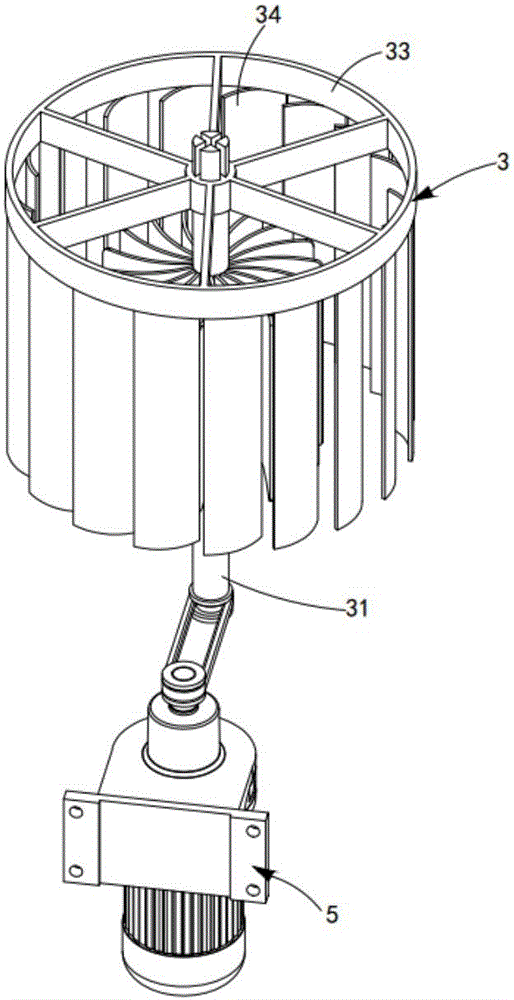

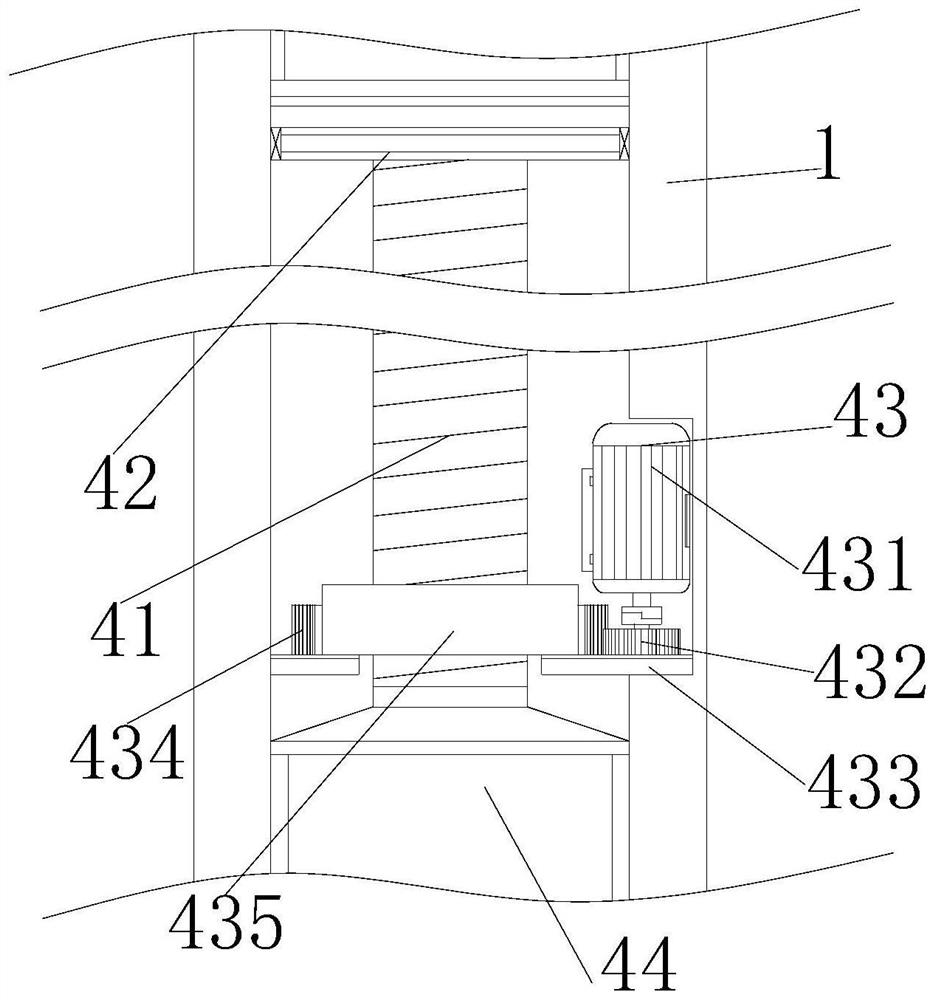

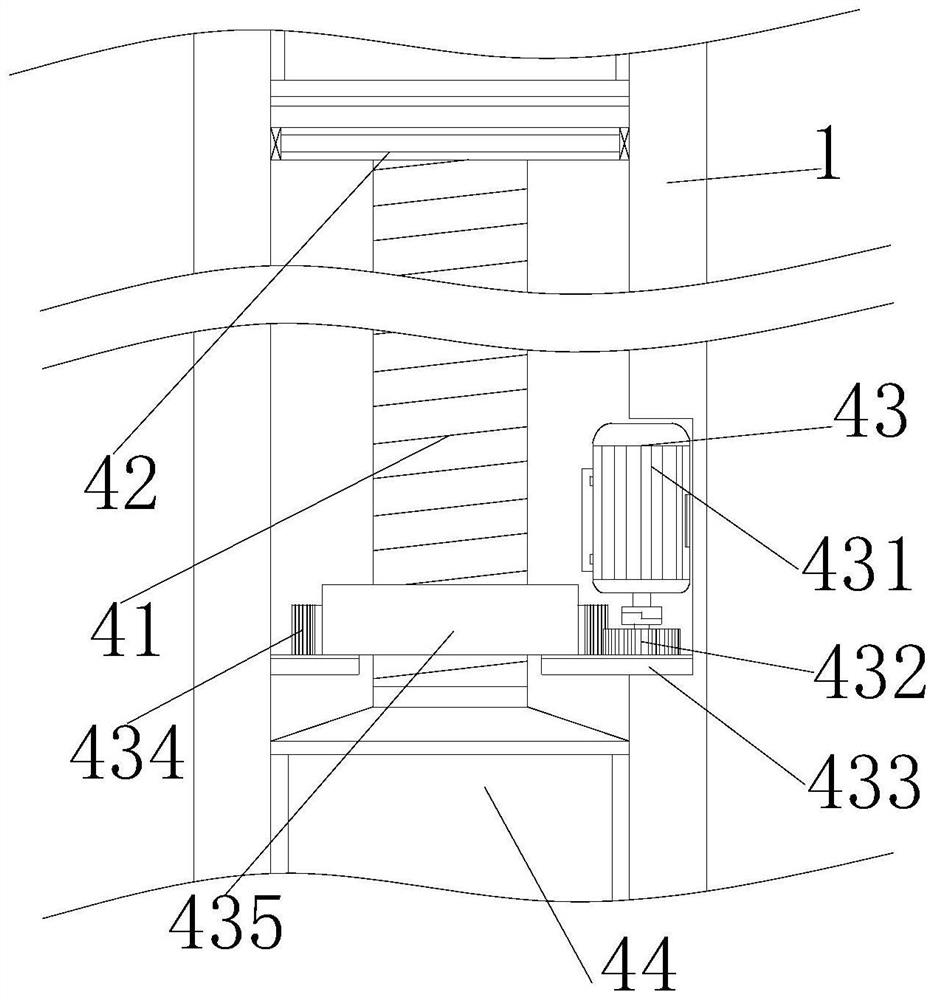

Double-stirring automatic chemical fertilizer stirring device

InactiveCN106823965AStir wellImprove the mixing effectTransportation and packagingMixersEngineeringFertilizer

The invention discloses a double-stirring automatic chemical fertilizer stirring device. A horizontal stirring mechanism and a longitudinal stirring mechanism are synchronously driven to act by the same drive mechanism, synchronous circulation of horizontal stirring and longitudinal stirring of the mixed chemical fertilizer is realized, the technical problems that traditional stirring device performs local stirring separately and effective stirring circulation cannot be realized are solved, local circular stirring of mixed chemical fertilizer is avoided, and the chemical fertilizer is fully stirred so that the mixed chemical fertilizer is truly stirred uniformly.

Owner:长兴宏诚机械科技有限公司

Microorganism-based inhibitory water treatment system

InactiveCN110407330APromote microbial degradation rateAlleviating the Urgency of Pollution ControlBiological water/sewage treatmentSewageWater treatment system

The invention discloses a microorganism-based inhibitory water treatment system, and belongs to the field of water treatment. The microorganism based inhibitory water treatment system includes a plurality of microorganism balanced degradation benchmarks, wherein the microorganism balanced degradation benchmarks are evenly distributed in sewage; the microorganism balanced degradation benchmarks include microorganism inhibition storage barrels, connecting pipes and auxiliary floating plates, the microorganism inhibition storage barrel are connected to the lower ends of the connecting pipes, andthe auxiliary floating plates are connected to the upper ends of the connecting pipes. The inhibitory circulating water treatment system of microorganisms in the sewage in the scheme is composed of the multiple microorganism balanced degradation benchmarks, the multiple microorganism balanced degradation benchmarks are evenly distributed in the sewage, the microorganism balanced degradation benchmarks are used for automatically balanced management of the microbial degradation in the sewage, so that the microbial degradation rate of the sewage is kept at a high value, an improved basis for further promoting the microbial degradation rate is provided, and the urgency of sewage pollution treatment is fundamentally alleviated.

Owner:福建钛鹭科技有限公司

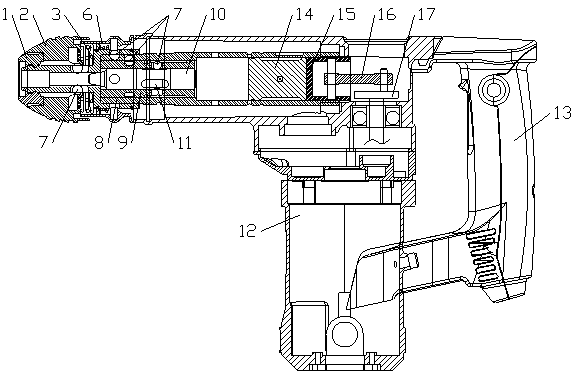

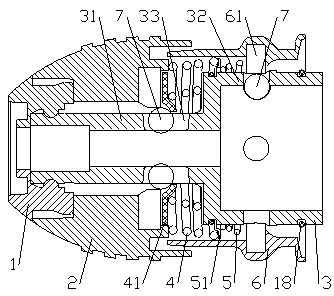

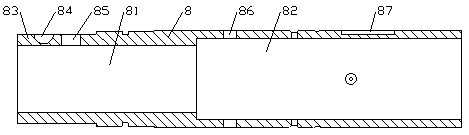

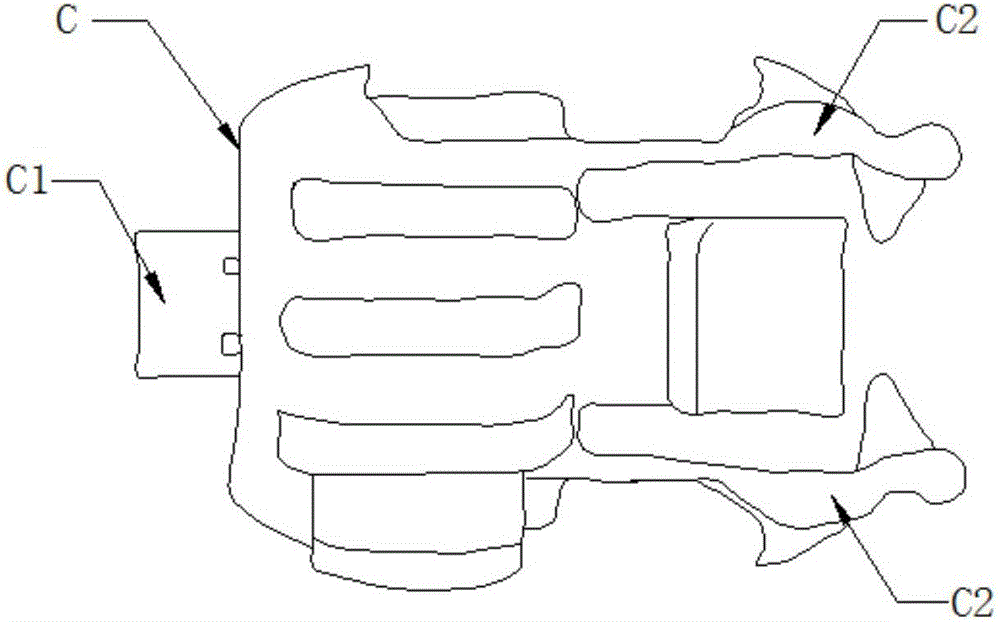

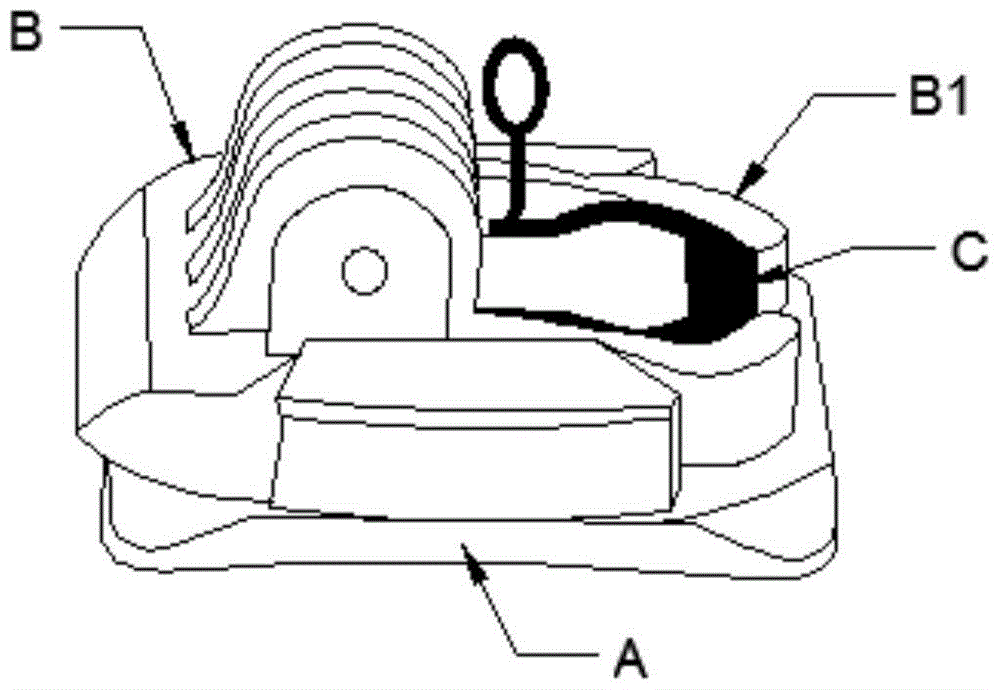

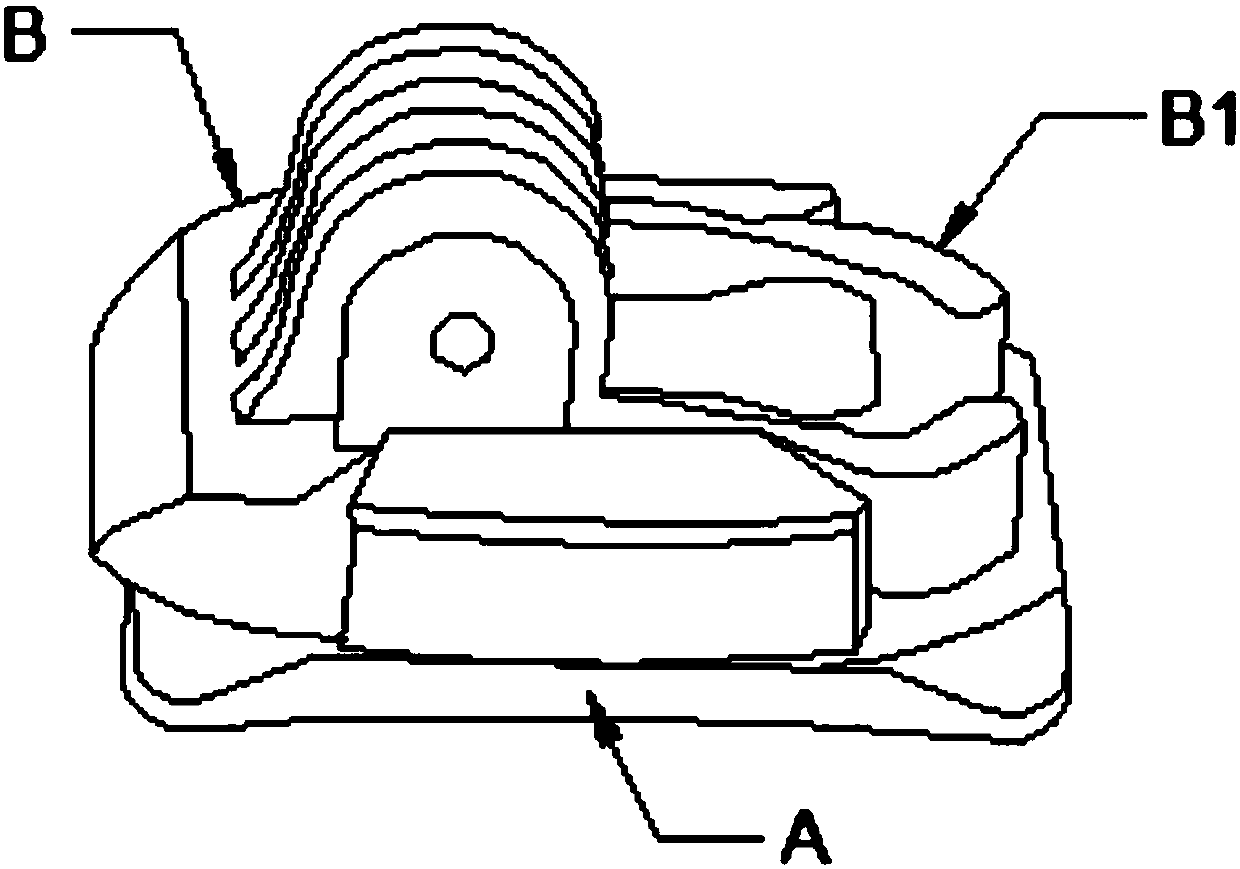

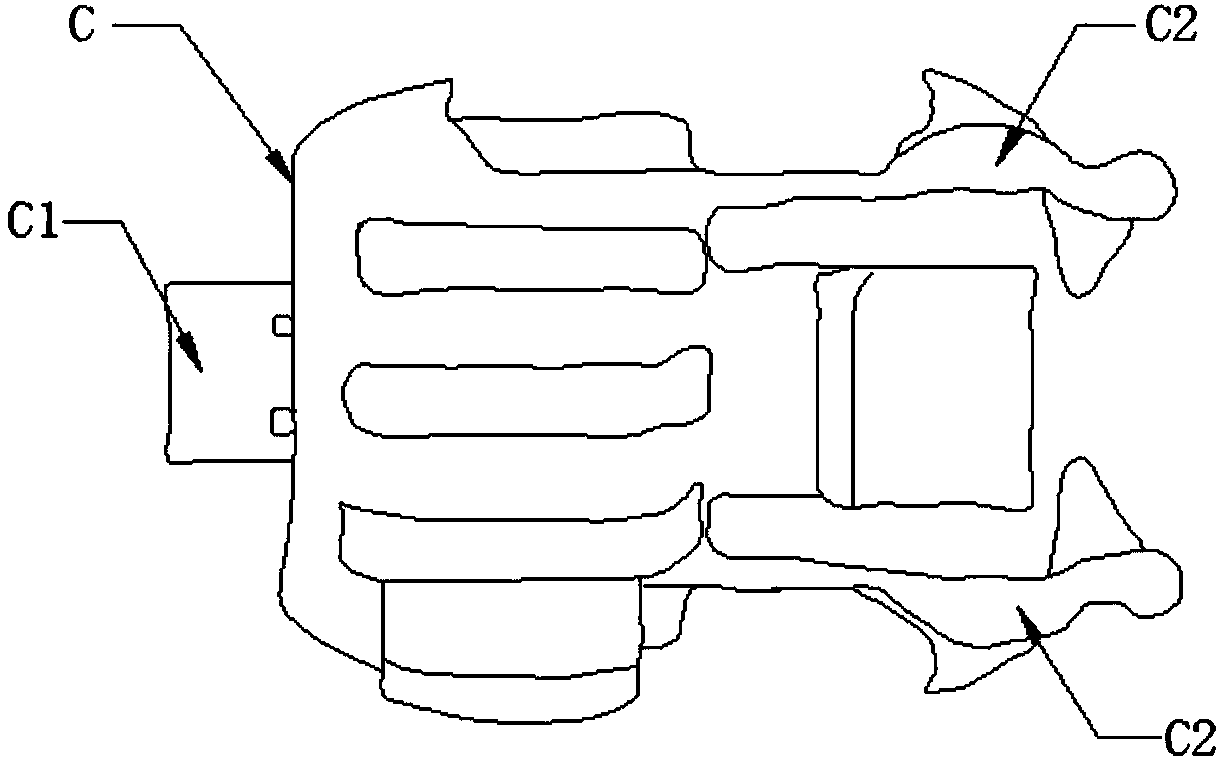

an electric hammer

The invention discloses an electric hammer which comprises a chuck, a shell, an air cylinder assembly and a transmission assembly, wherein the air cylinder assembly and the transmission assembly are arranged in the shell. The side face of the shell is provided with a handle. The chuck comprises a chuck body, a tetragonal sleeve and a clamp cover. The air cylinder assembly comprises a cylinder body. A drill brush hole and a piston hole are formed in the front part and the rear part of the cylinder body respectively. A first step at the front portion of the cylinder body extends into the tetragonal sleeve. According to the electric hammer, a drill bit is inserted and then directly collides with an impact oscillator, and impact drilling is easier; the chuck is convenient to assemble, the drill bit is inserted into and pulled out directly and quickly through cooperation of steel balls and springs; by adjusting a connection structure between the cylinder body and an impact sleeve and a connection structure between the cylinder body and the chuck, the length of the air cylinder assembly is shorter compared with a traditional air cylinder assembly; through clamping of the steel balls, quick-wear parts are more convenient to disassemble, assemble and maintain, and the service life of the electric hammer is prolonged greatly; and furthermore, the hammering strength on a drill bush assembly of a punch hammer is improved by enlarging the hole diameter of the large piston hole, and the working efficiency of the electric hammer is improved greatly.

Owner:JIANGSU HENGFENG ELECTRIC TOOLS

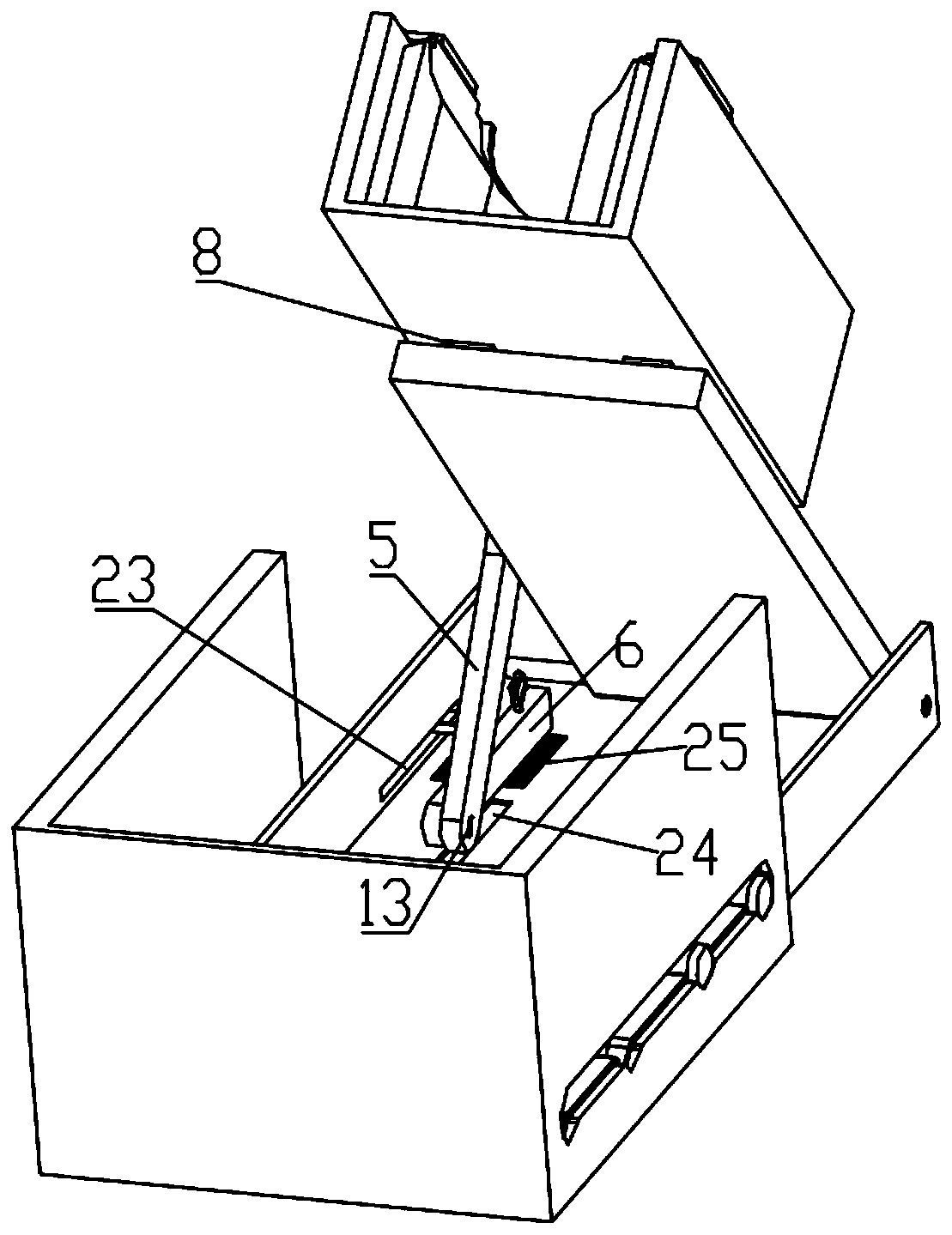

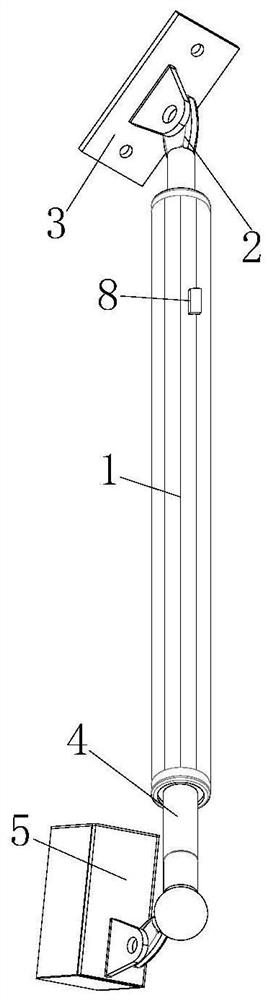

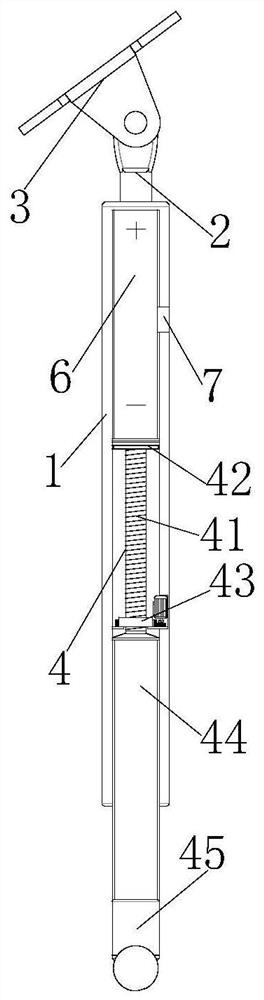

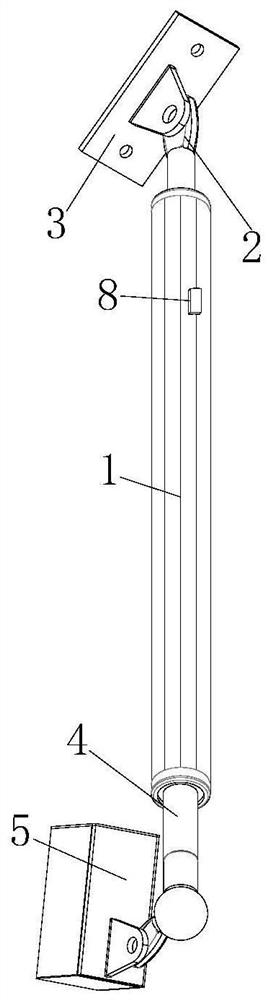

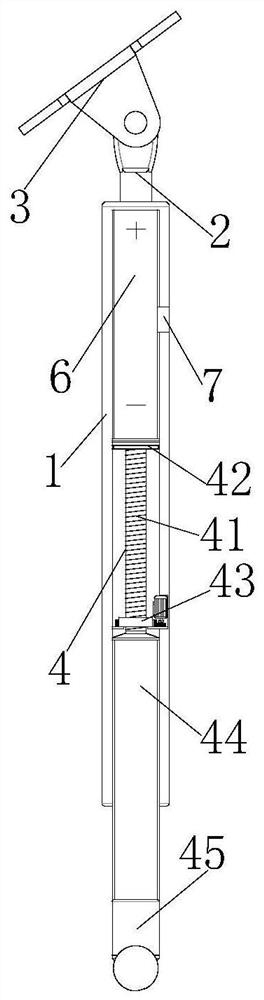

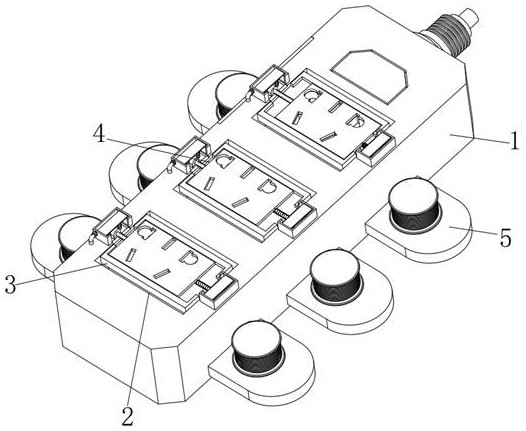

Portable shore power plug auxiliary plugging device

ActiveCN110829113AInsert labor-savingEasy to insertCoupling device detailsControl theoryElectric cables

The invention discloses a portable shore power plug auxiliary plugging device, which comprises a fixed base, a sliding base, a sliding rail seat, a plug supporting seat, a supporting rod, a supportingblock and a limiting rod. Horizontal pulley guide slots are formed in the fixed base. Pulleys are installed on the two sides of the sliding base and arranged in the pulley guide slots. A horizontal guide slot, a longitudinal limit slot and a horizontal open slot are formed in the sliding base. The front end of the sliding base is hinged to the sliding rail seat, and sliding rails are arranged ina groove in the sliding rail seat. The side wall of the sliding rail seat is hinged to the supporting rod, and the other end of the supporting rod is movably placed in a guide slot. The supporting block is hinged to the lower portion of the supporting rod. The problem that it is inconvenient to plug a plug into an existing high-voltage socket shore power socket box because the plug and a cable behind the plug are too heavy is solved, and the storage problem of the plug auxiliary quick plugging device when the shore power box is in a non-working state is also solved.

Owner:WUHAN UNIV OF SCI & TECH +1

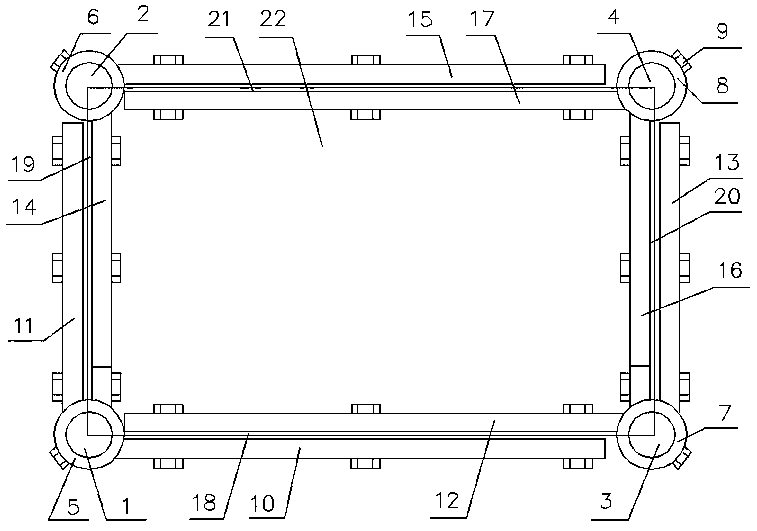

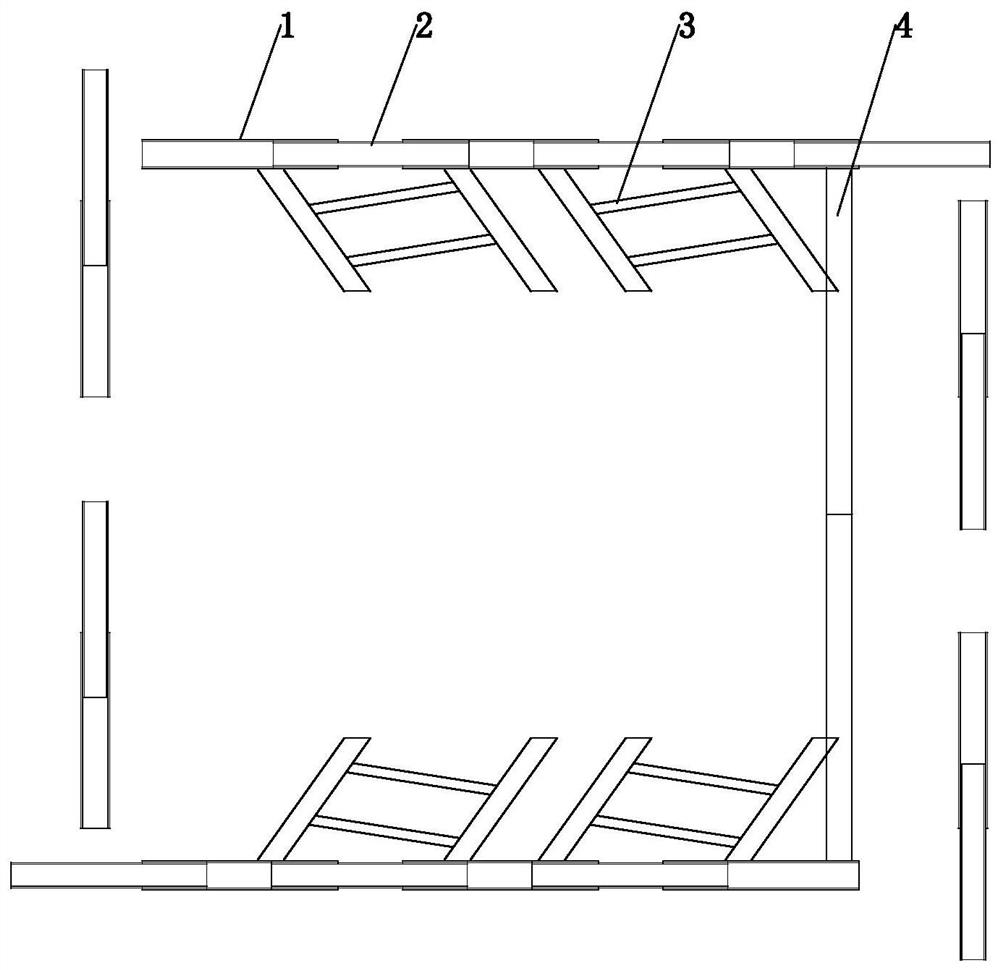

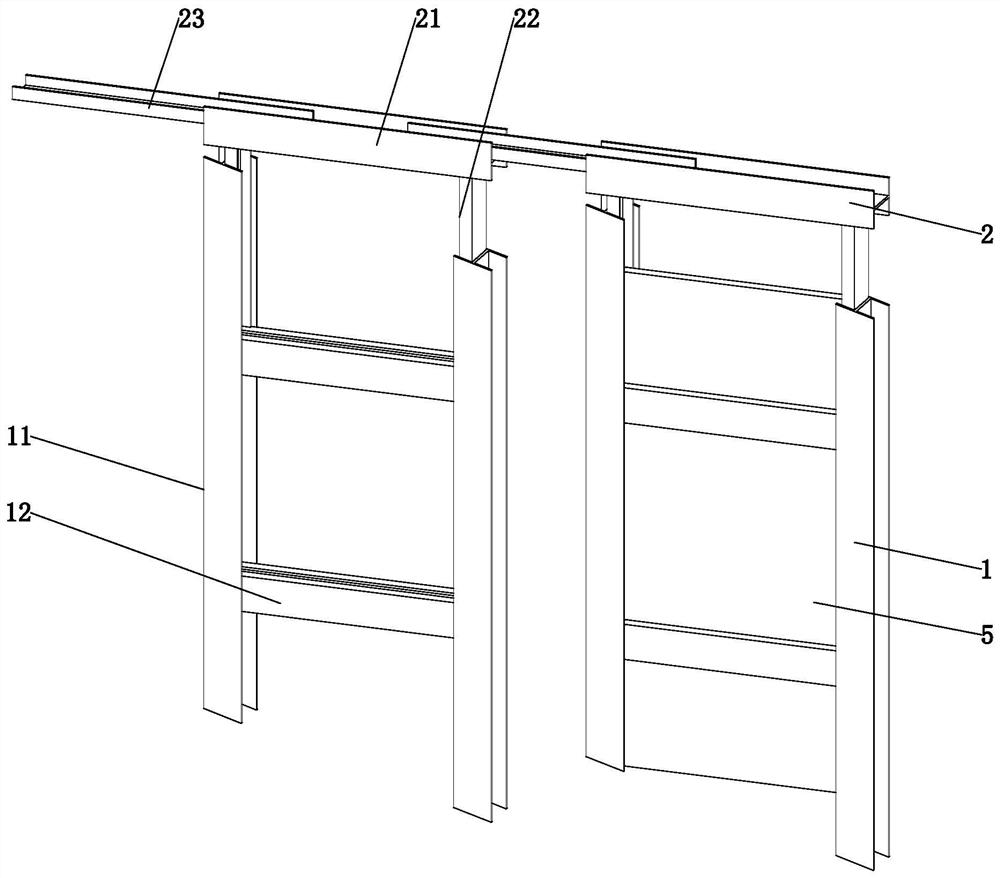

Agricultural straw recovery fermentation device for environmental protection and installation method

InactiveCN110041107AMeet recovery fermentationEasy to fixBio-organic fraction processingOrganic fertiliser apparatusAgricultural engineeringFermentation

The invention provides an agricultural straw recovery fermentation device for environmental protection and an installation method. The product of the invention consists of a vertical rod, wherein thevertical rod includes a left front vertical rod, a left rear vertical rod, a right front vertical rod and a right rear vertical rod; the left front vertical rod is connected to a left front fixing sleeve and fixed by a screw, the left rear vertical rod is connected to a left rear fixing sleeve and fixed by a screw, the right front vertical rod is connected to a right front fixing sleeve and fixedby a screw, and the right rear vertical rod is connected to a right rear fixing sleeve and fixed by a screw; the left front fixing sleeve is welded to a front outer clamping plate and a left outer clamping plate, the right front fixing sleeve is welded to a front inner clamping plate and a right outer clamping plate, the left rear fixing is welded to a left inner clamping plate and a rear outer clamping plate, and the right rear fixing sleeve is welded to the right inner clamping plate and rear inner clamping plate; the top of front plastic cloth is clamped between the front outer clamping plate and the front inner clamping plate, the top of left plastic cloth is clamped between the left outer clamping plate and the left inner clamping plate, the top of right plastic cloth is clamped between the right outer clamping plate and right inner clamping plate, and the top of rear plastic cloth is clamped between the rear outer clamping plate and the rear inner clamping plate. The device of the invention is used for straw recovery fermentation.

Owner:TIANJIN SHUFENG AGRI TECH

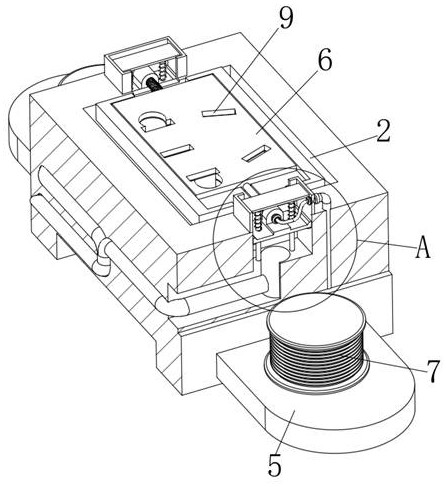

Stable socket based on Internet of Things

ActiveCN111697379AReduce damagePrevent entry of dustCouplings bases/casesFlexible/turnable line connectorsInternet of ThingsStructural engineering

The invention discloses a stable socket based on the Internet of Things. The socket comprises a socket shell, wherein a plurality of mounting grooves are formed in the socket shell, a plurality of bases for inserting plugs are mounted in the mounting groove, the two ends of the base are rotationally connected with the inner wall of the mounting groove through rotating shafts, and the positions, corresponding to the bases, of the socket shell are each provided with a pull-assisting protection assembly which facilitates plugging and unplugging of personnel and can protect the socket. According to the invention, ejection of the plug inserted into the base is realized by using the pull-assisting protection assembly, so that the plug is separated from the clamping sheet in the base; the base isrotationally connected with the mounting groove, so that the base can rotate by a certain angle, and a person can stand at different angles for plugging; compared with an existing bowing plugging mode, more labor is saved when the plug is plugged out, and damage to the socket plug is reduced; and through reset of the baffle, the base can be effectively protected, and dust is prevented from entering the base.

Owner:NINGBO XINGHONG INTELLIGENT TECH CO LTD

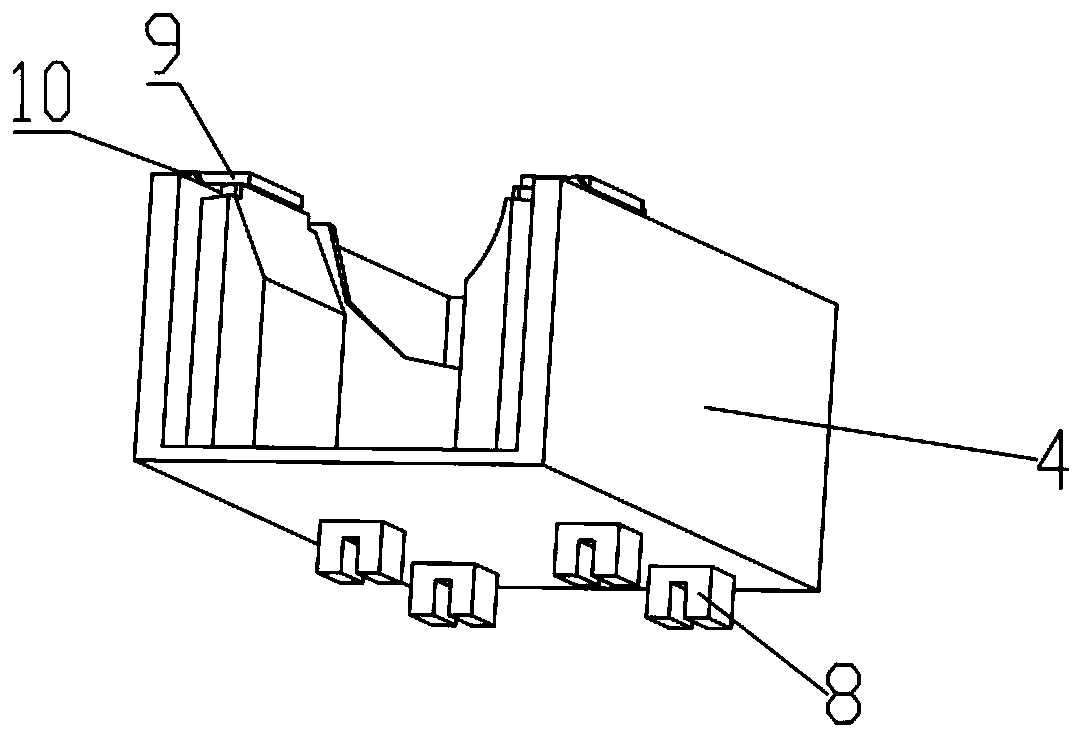

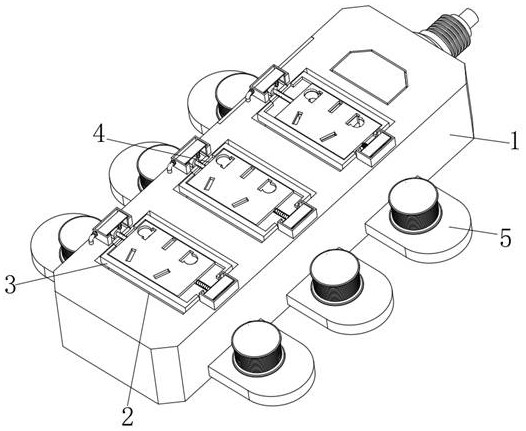

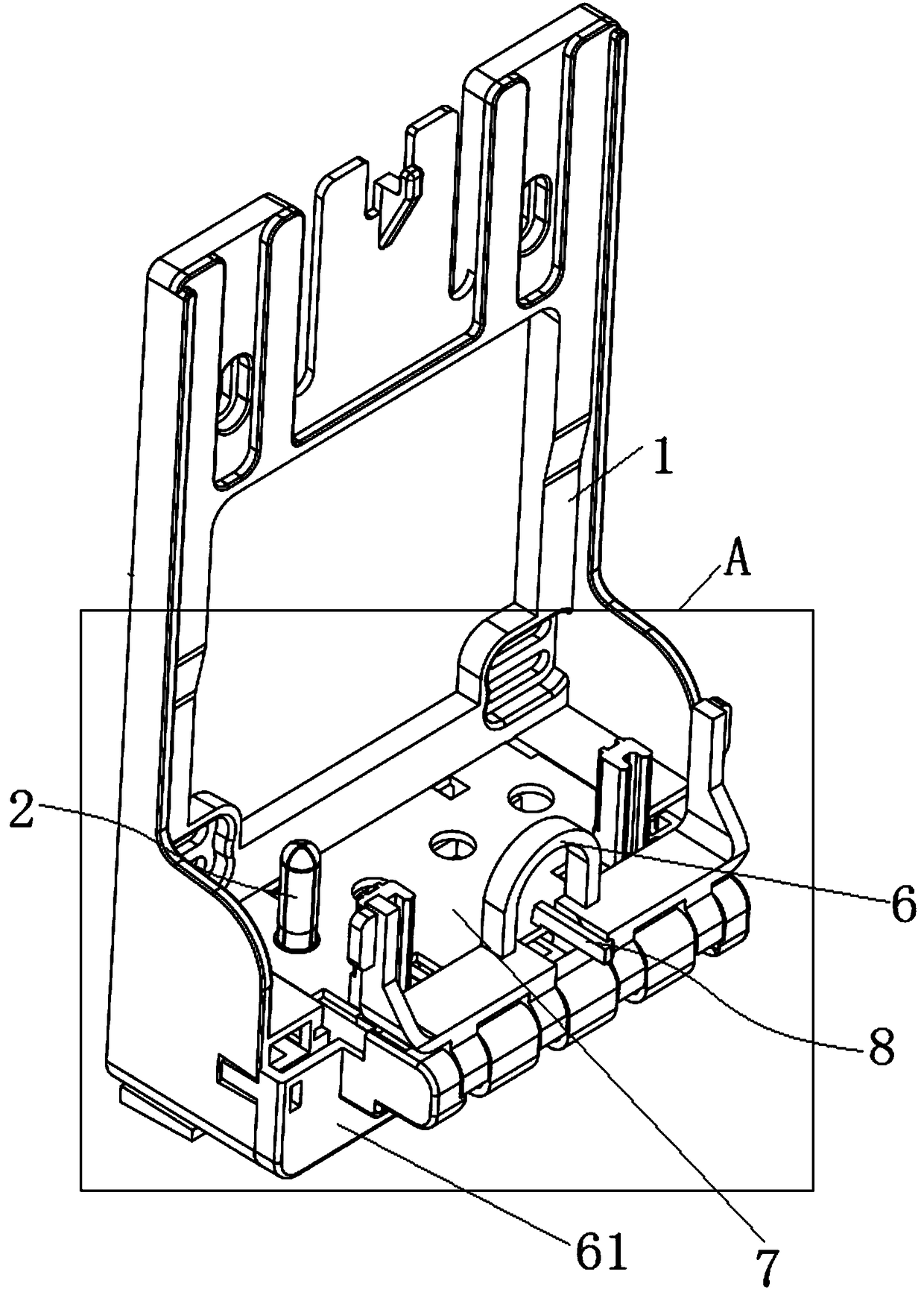

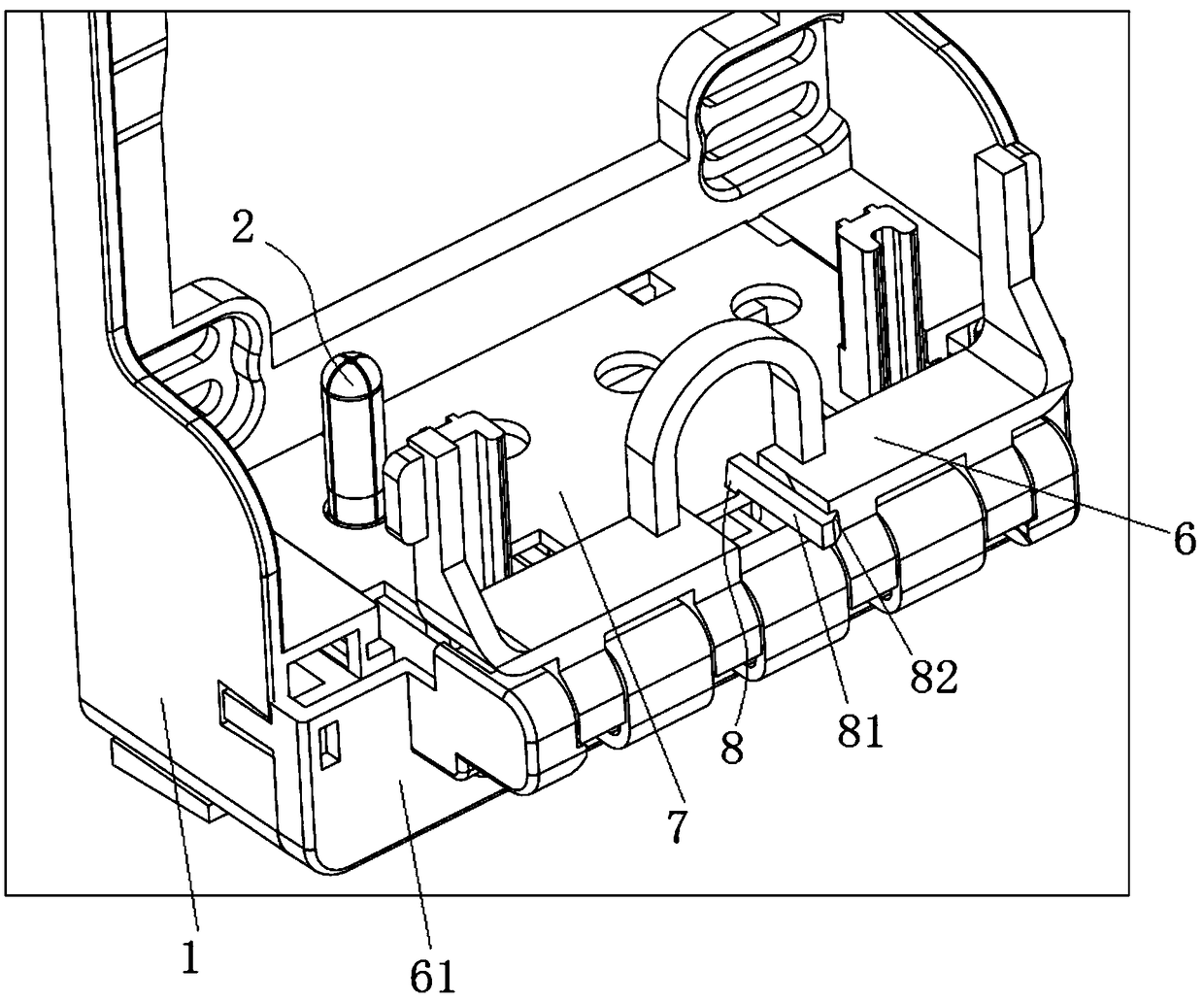

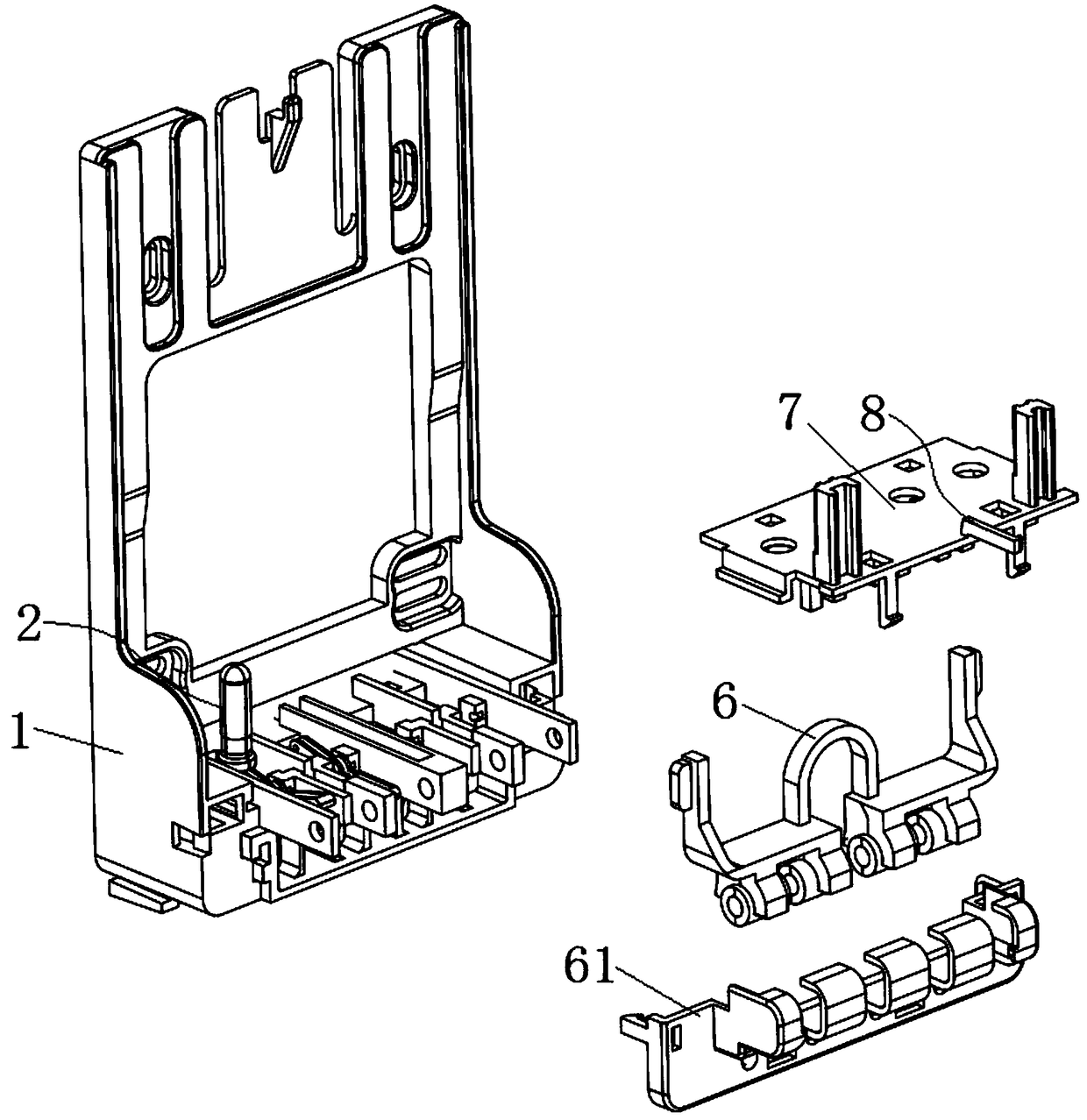

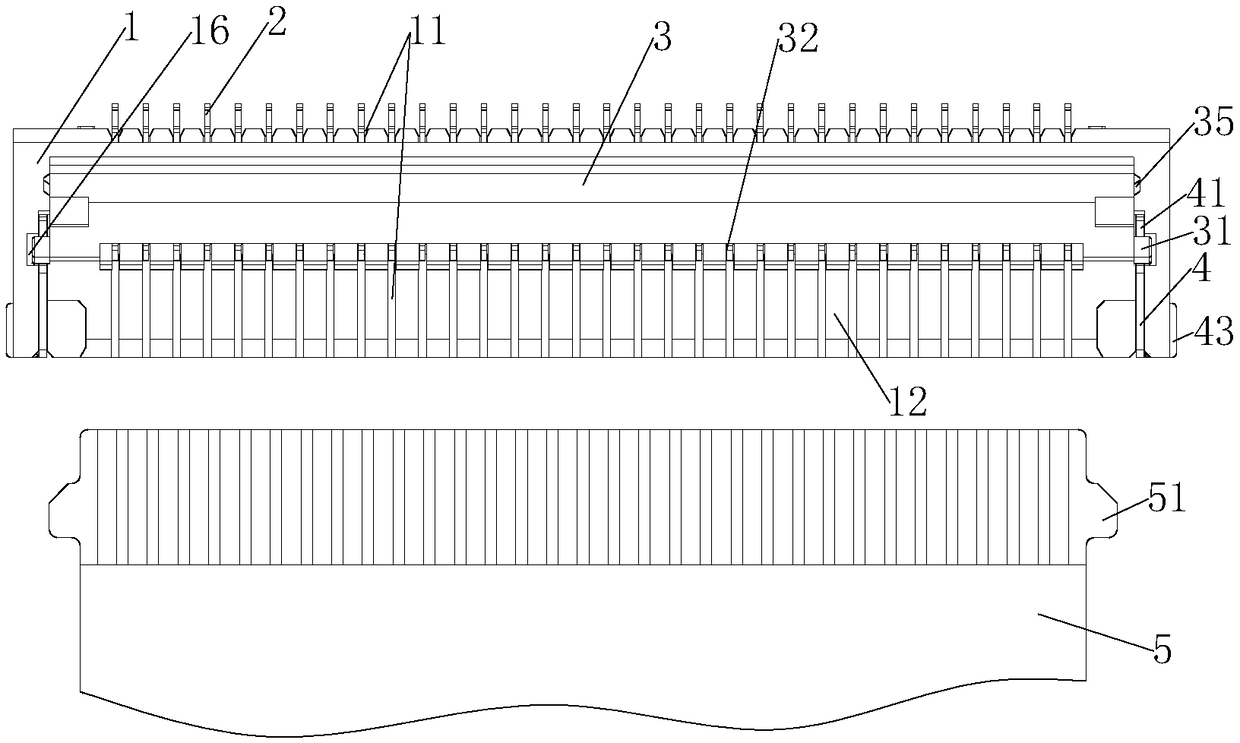

Electric energy meter plugging device with operation mechanism

PendingCN109444495AInsert labor-savingImprove installation efficiencyTime integral measurementInterference fitEngineering

The invention provides an electric energy meter plugging device with an operation mechanism. The electric meter plugging device is arranged in an electric energy meter metering box. The plugging device comprises a pedestal, socket connectors arranged on the pedestal and a driving mechanism; each socket connector includes an insertion end plugged into a jack of an electric meter, the insertion endis provided with plugging sheets, and each plugging sheet is in clearance fit with the jack in an initial position and in interference fit to the jack in a connection position; and the driving mechanism is connected with the plugging sheets to switch the plugging sheets between the initial position and the connection position. According to the electric meter plugging device with the operation mechanism, the plugging sheets are in clearance fit with the jacks when being inserted into the plugging holes, so that plugging is more labor-saving, the installation efficiency is improved, there is notfriction when the plugging sheets are plugged with binding posts of the electric meter, and the service life is prolonged.

Owner:ZHEJIANG TIANSHUN GLASS FIBER REINFORCED PLASTIC

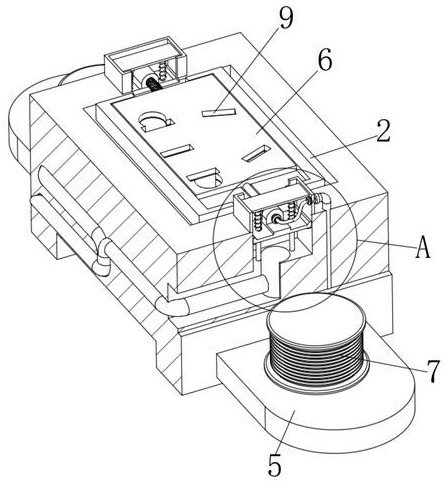

Action camera slide block connecting base with locking structure

ActiveCN106122695AQuick installationQuick disassemblyStands/trestlesCamera body detailsEngineeringMechanical engineering

The invention discloses an action camera slide block connecting base with a locking structure. The action camera slide block connecting base comprises a connecting part, a chute and two elastic insertion feet; extension feet are respectively arranged forwards at the front ends of the two elastic insertion feet; the two extension feet are opposite to each other; an overturning buckle is provided; the back end of the overturning buckle is rotationally connected to a slide block connecting base; and the front part of the overturning buckle can be clamped between the two extension feet. The overturning buckle can be conveniently locked or unlocked, and can realize convenient and fast installation or disassembly of the slide block connecting base and an action camera thereon; the extension feet are provided for enabling insertion or pulling of the slide block connecting base to become more labor-saving and easier; and the overturning buckle can be loosened when being collided, so that the slide block connecting base inserted on a fixed base and the action camera fixed by the slide block connecting base quickly slide out from the fixed base to prevent personal injury caused by the action camera.

Owner:KUNSHAN DESHANGDAJIN SOFTWARE TECH CO LTD

Building basement foundation pit slope support fixing device

The invention discloses a building basement foundation pit slope support fixing device. The building basement foundation pit slope support fixing device comprises an outer rod seat, a connecting rod frame, a mounting piece, a distance adjusting rod frame mechanism, a supporting mechanism, a storage battery, a charging interface and a control switch. According to the building basement foundation pit slope support fixing device, the distance adjusting rod frame mechanism and the supporting mechanism are optimally arranged, a driving motor is used as a power source, a threaded rod drives a lower rod frame to move up and down in the outer rod seat through the cooperation between a pinion and an outer gear ring, then the height position of the supporting mechanism is adjusted, and the supporting mechanism can be conveniently installed at different height positions of a slope support; and an electric push rod is used as a power source, a supporting frame drives a first inserting rod, a second inserting rod and a third inserting rod to be quickly inserted into the ground soil for supporting and fixing through the vertical movement of a sliding seat on a sliding piece, the operation is simple and convenient, and the working efficiency of construction is improved to a certain extent.

Owner:温州城建集团股份有限公司

Front-lifting type double-contact connector

PendingCN109119794ASimple structureEasy to open with flip coverSecuring/insulating coupling contact membersCoupling protective earth/shielding arrangementsSolderingElectrical and Electronics engineering

The invention relates to a front-lifting type double-contact connector. A conductive terminal array is disposed on an insulating seat, and a lifting cover is rotatably mounted in a cover slot of the insulating seat. Grounding terminals are fixed at both ends of the insulating seat, and one end of the conductive terminal is provided with a soldering leg, and the other end is provided with an upperelastic arm and a lower elastic arm, wherein the upper elastic arm and the lower elastic arm are respectively provided with an upper conductive contact and a lower conductive contact. A limiting hookof the end of the upper elastic arm is movably inserted in a terminal groove of the lifting cover and is pressed above a limiting shaft. The limiting hook is used for limiting the rotating shaft of the lifting cover in a rotating slot. A pressing boss on the rotating shaft is used for pressing a FFC cable to the lower conductive terminal. The intersection of the cover slot with a cable slot is taken as the fulcrum. The limiting shaft and the fulcrum are used to press the upper conductive contact on the upper elastic arm toward the FFC cable. The connector has a simple structure, and the lifting cable is easy to open. The FFC cable can be inserted easily and quickly, and the FFC cable can be pressed from the front and back sides of the FFC cable. The contact is good, and the FFC cable is not easy to fall off.

Owner:CVILUX TECH SUZHOU

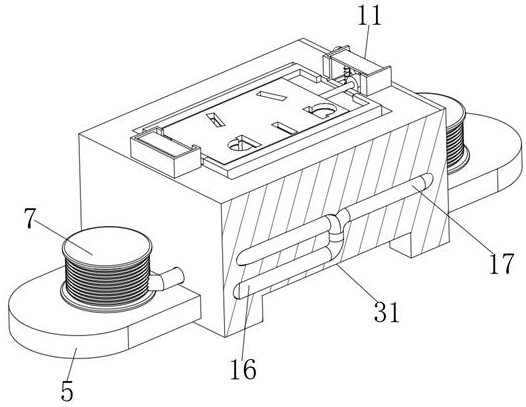

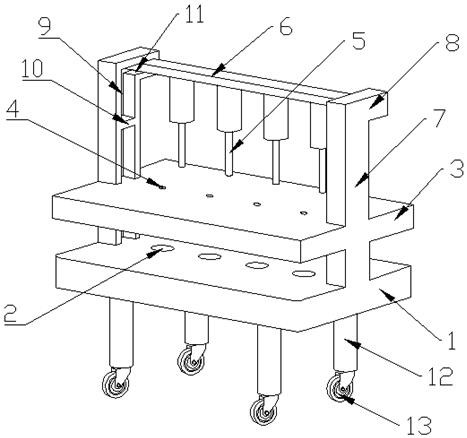

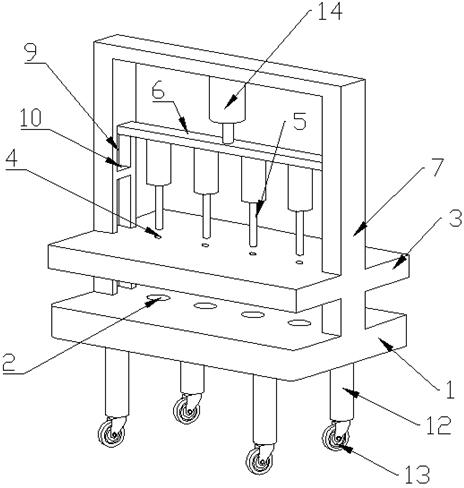

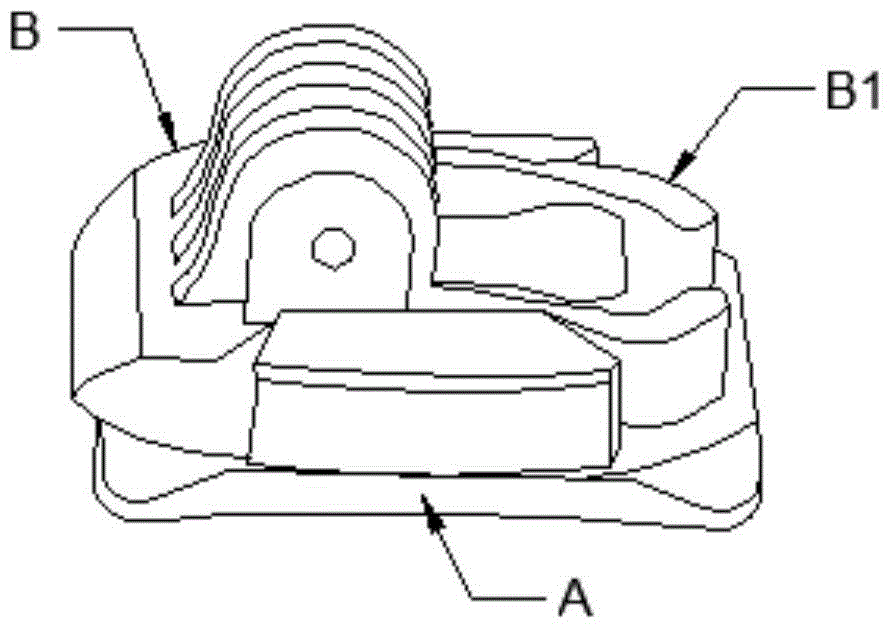

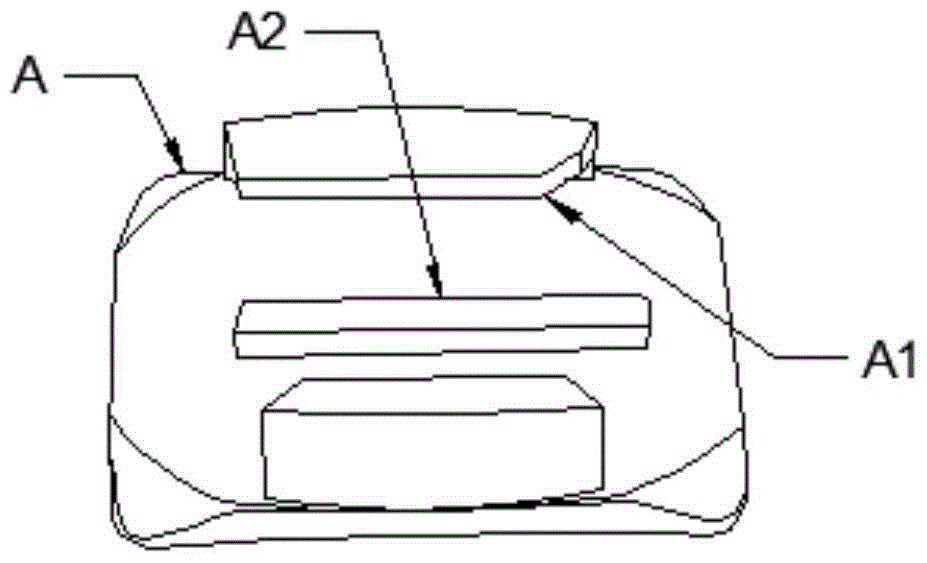

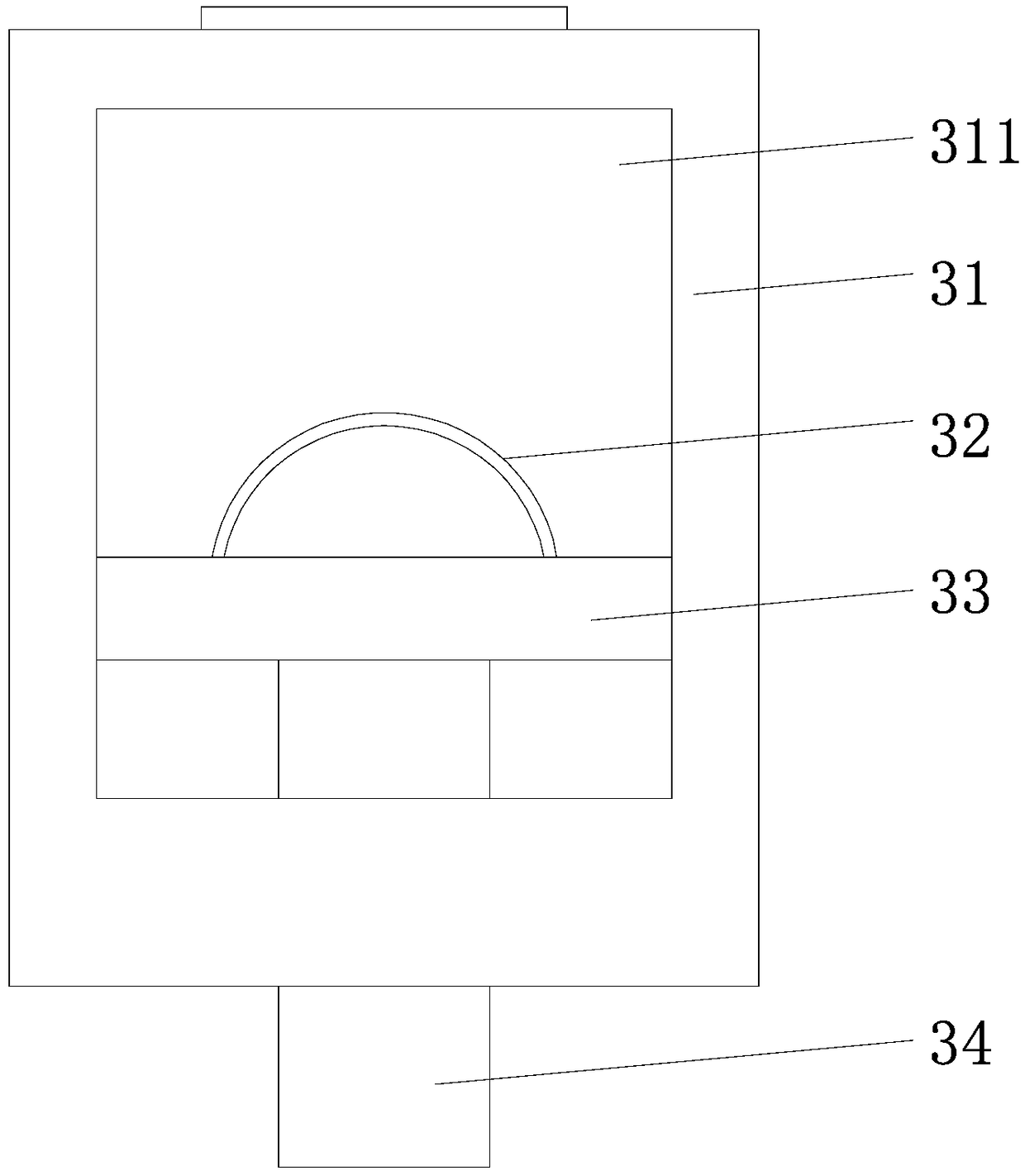

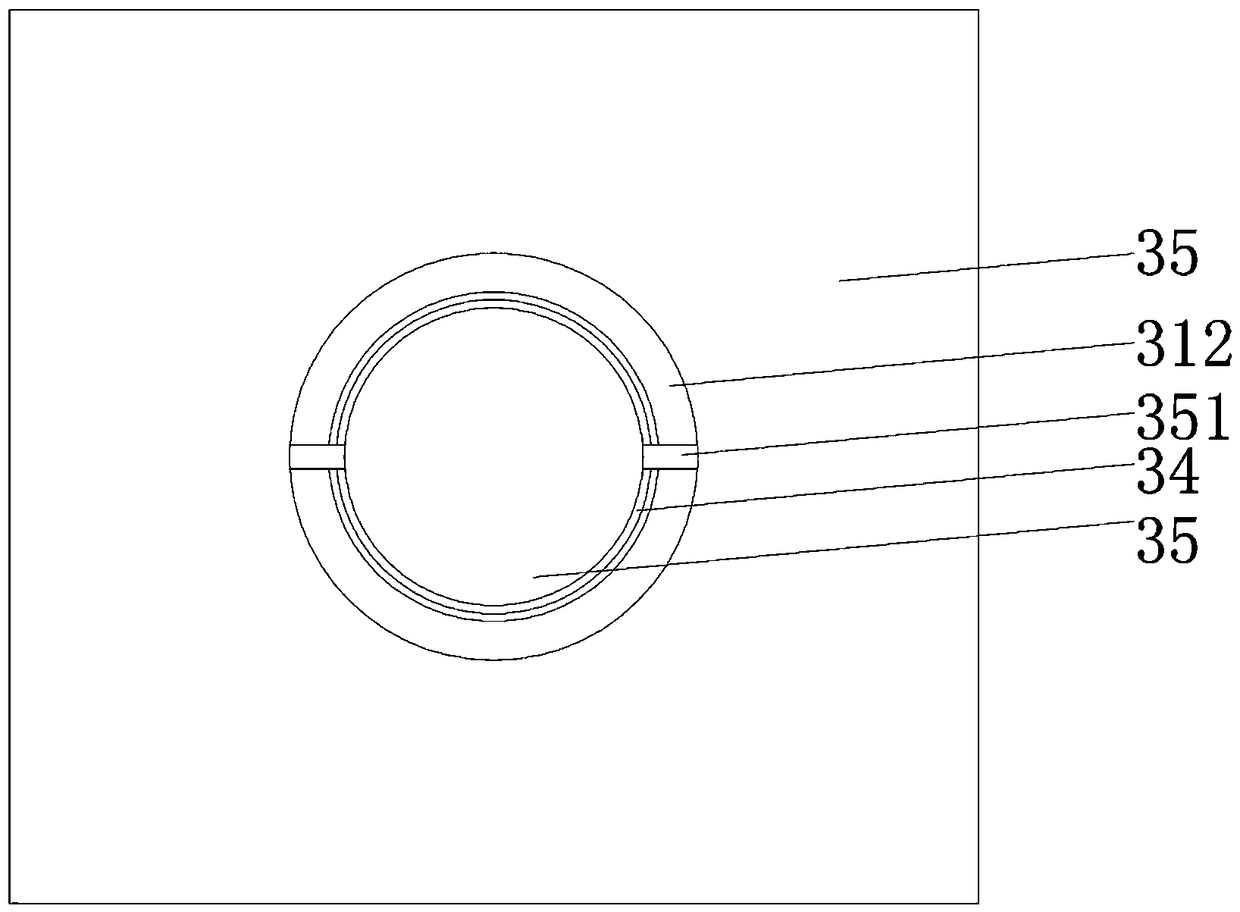

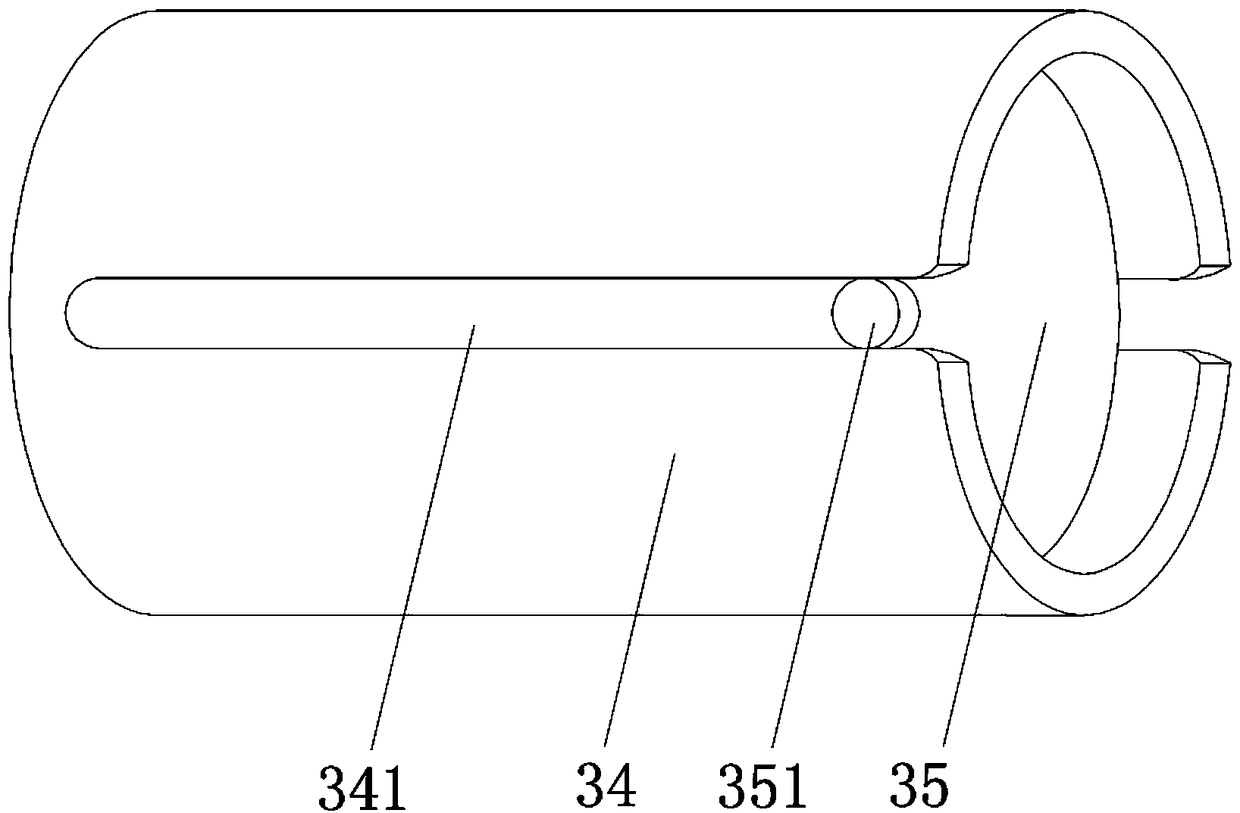

Dental implant embedding tool

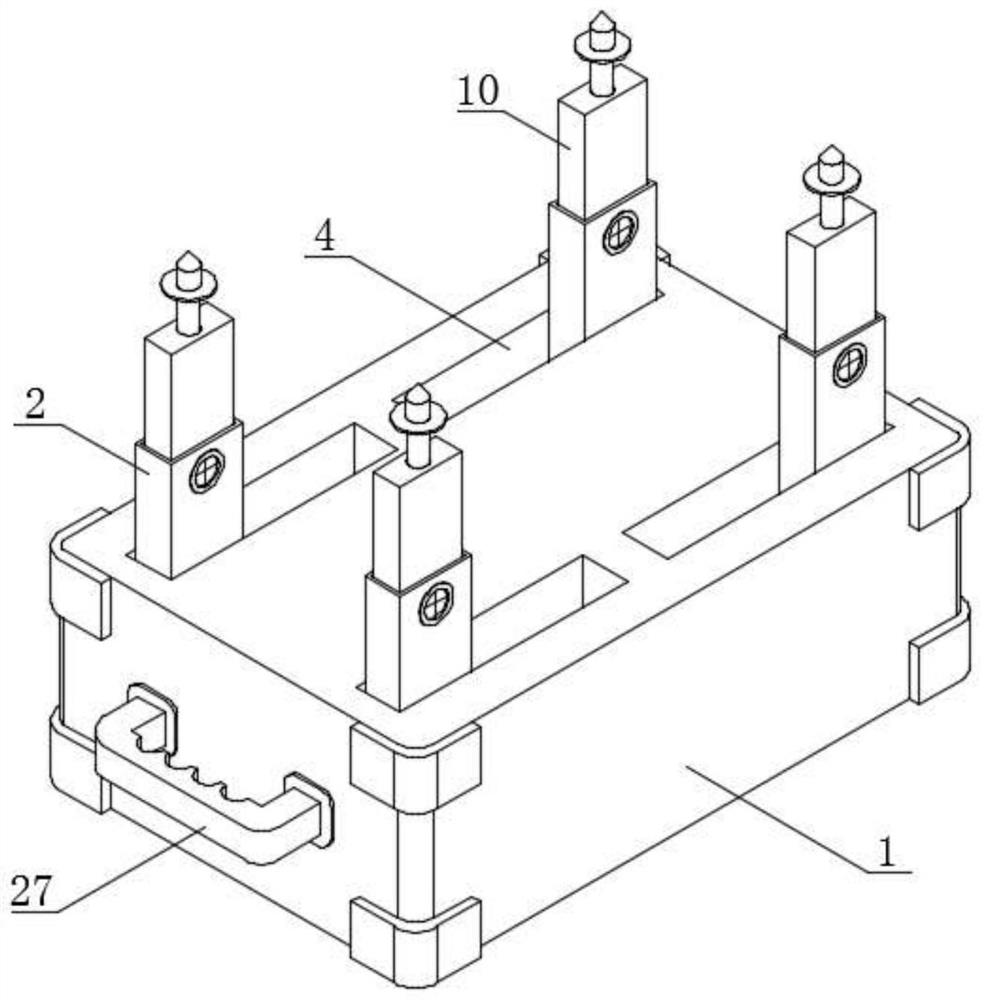

ActiveCN112730014AInsert labor-savingImprove efficiencyPreparing sample for investigationMaterial strength using repeated/pulsating forcesEngineeringApparatus instruments

The invention discloses a dental implant embedding tool, which belongs to the technical field of medical instrument inspection, and structurally comprises a bottom plate, a placing groove for accommodating a sleeve is formed in the bottom plate, a top plate is arranged above the bottom plate, the top plate is parallel to the bottom plate, and the top plate and the bottom plate are connected through a connecting frame. A guide hole through which the dental implant passes is formed in the top plate, the guide hole corresponds to the placement groove, and the axis of the guide hole is perpendicular to the bottom surface of the placement groove; a lower pressing rod is arranged above the top plate, corresponds to the guide hole and can penetrate through the guide hole, the lower pressing rod can move up and down, and a limiting device is arranged on a rail where the lower pressing rod moves up and down. The technical scheme provided by the embodiment of the invention is suitable for embedding the dental implant in a fatigue test, the embedding efficiency can be improved, the manpower can be saved, and the verticality and the height accuracy of extending out of the liquid level of the liquid alloy can be ensured.

Owner:山东省医疗器械产品质量检验中心

Sports camera professional slider connection base

ActiveCN104930326BIncrease the lengthAvoid harmMachine supportsCamera body detailsHuman bodyBlocked Connection

The invention discloses a professional sliding block connection base for an action camera. The professional sliding block connection base comprises a connection part and two elastic pins, wherein each of the front ends of the two elastic pins is provided with an extension part forward, and the two extension parts are opposite. One end of a safe lock is rotationally connected with the front end of one extension part, and the other end of the safe lock can be buckled at the front end of the other extension part through a buckle structure. The buckle structure means that a bump is arranged at the other end of the safe lock, a sink is formed in the front end of the other extension part, and the bump and the sink are buckled with each other. When the safe lock is made of rigid plastic, the bump is of an annular structure encircled by a circle of wall. When the safe lock is made of flexible plastic, the bump is a solid bump. When the professional sliding block connection base is impacted, the safe lock can automatically disengage, and a sliding block connection seat originally inserted into a fixed base and the action camera fixed by the fixed base can quickly slip off from the fixed base, so that the injury to the human body caused by the action camera is avoided, and the sliding block connection seat is more easily inserted and pulled out conventionally.

Owner:KUNSHAN DESHANGDAJIN SOFTWARE TECH CO LTD

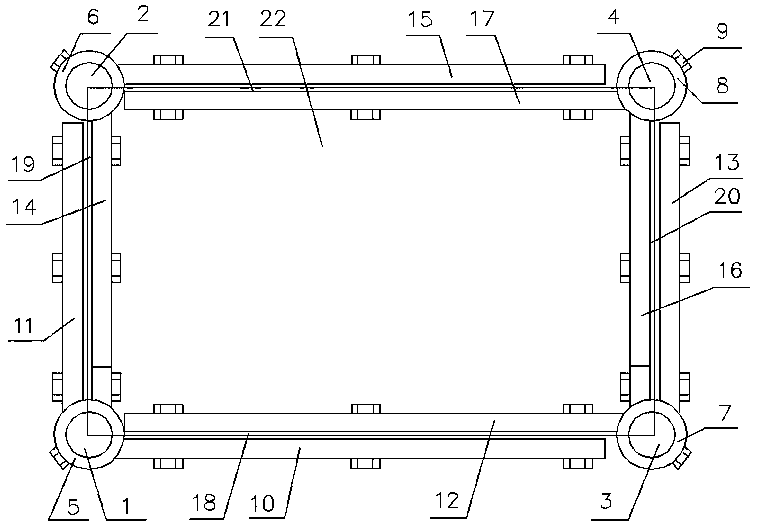

Agricultural environmentally friendly type plant greenhouse

InactiveCN109287339AImprove efficiencyEasy to useClimate change adaptationGreenhouse cultivationGreenhouseAgricultural engineering

The present invention provides an agricultural environmentally friendly type plant greenhouse. The agricultural environmentally friendly type plant greenhouse comprises support frames and a sunshade device, bottom ends of the support frames are provided with anchoring devices, the anchoring device comprises a base seat frame, a pedal sleeve, a sliding block, an anchoring pipe and a soil removing block, a passing hole is arranged in the bottom end of the base seat frame, an inner side of the passing hole is provided with the soil removing block, side edges of the soil removing block is providedwith a support rod, the pedal sleeve and sliding block are both located inside the base seat frame, an outer wall of the sliding block is movably connected with an inner wall of the base seat frame,and the anchoring pipe is fixedly connected with a center part of a bottom end of the sliding block. In the agricultural environmentally friendly type plant greenhouse, the anchoring devices are tightly inserted into land to ensure the stability of the whole greenhouse, the anchoring devices are convenient to use, when the anchoring devices are withdrawn, the soil removing blocks can discharge soil from the anchoring pipes to ensure cleanness of the whole device, bottom ends of the anchoring pipes are provided with knife edges, inserting of the anchoring pipes is more labor-saving, and the anchoring devices can be used for multiple times, thereby improving use efficiency of the greenhouse and indirectly achieving an effect of saving energy and protecting environment.

Owner:湖北文龙景观园艺有限公司

Laundry powder feeding box of washing machine

InactiveCN102677431BQuick and easy deliveryNovel structureOther washing machinesTextiles and paperCoil springEngineering

The invention relates to a component of a washing machine, in particular to a laundry powder feeding box of the washing machine. The laundry powder feeding box of the washing machine comprises a box body, wherein the box body is pushed rightwards into a washing machine body; the left end of the bottom plate of the box body is in rotational connection with the box body; an inserting port is propped upwards against the bottom plate of the box body in the insertion process of the box body; and when the box body is completely inserted into the washing machine body, the bottom plate just rotates and falls into a laundry powder channel. The bottom plate of the box body rotates to open or close the bottom surface of the box body along with insertion or drawing, so that laundry powder can be fed conveniently and fast without the need of water flushing, the structure is novel, and convenience and practicability are achieved; the bottom plate can be opened more stably due to the adoption of a coil spring; and the box body is inserted and drawn out with less effort due to a rolling shaft.

Owner:飞龙家电集团有限公司

Cleaning device with detachable scraper blade and using method of cleaning device

ActiveCN113951789AGood cleaning effectEasy to disassembleCarpet cleanersFloor cleanersStructural engineeringManufacturing engineering

The invention belongs to the technical field of cleaning equipment, and particularly relates to a cleaning device with a detachable scraper blade, which comprises a layered cleaning box body assembly, a scraper blade assembly, a pressing assembly, a treading pedal assembly and an air pressure water injection assembly, and the scraper assembly comprises a scraper mounting plate, a scraper blade and a bearing roller. The cleaning device is used for solving the problems that in the prior art, a scraper blade is inconvenient to take down for cleaning and damaged parts are inconvenient to replace; cleaning is laborious; a traditional pedal type cleaning barrel is prone to water leakage; the water conveying mode is very tedious, and due to the limitation of the water conveying mode, the water storage capacity is also limited. The cleaning device is convenient to operate, an operator can clean a mop through the cleaning device, the good cleaning effect is achieved, stains and impurities on the mop can be removed, meanwhile, the operator can provide cleaning power in a foot stepping mode, time and labor are saved, meanwhile, a scraper blade can be conveniently detached, the detached scraper blade is cleaned, and damaged parts of the scraper blade can be replaced.

Owner:郭鑫

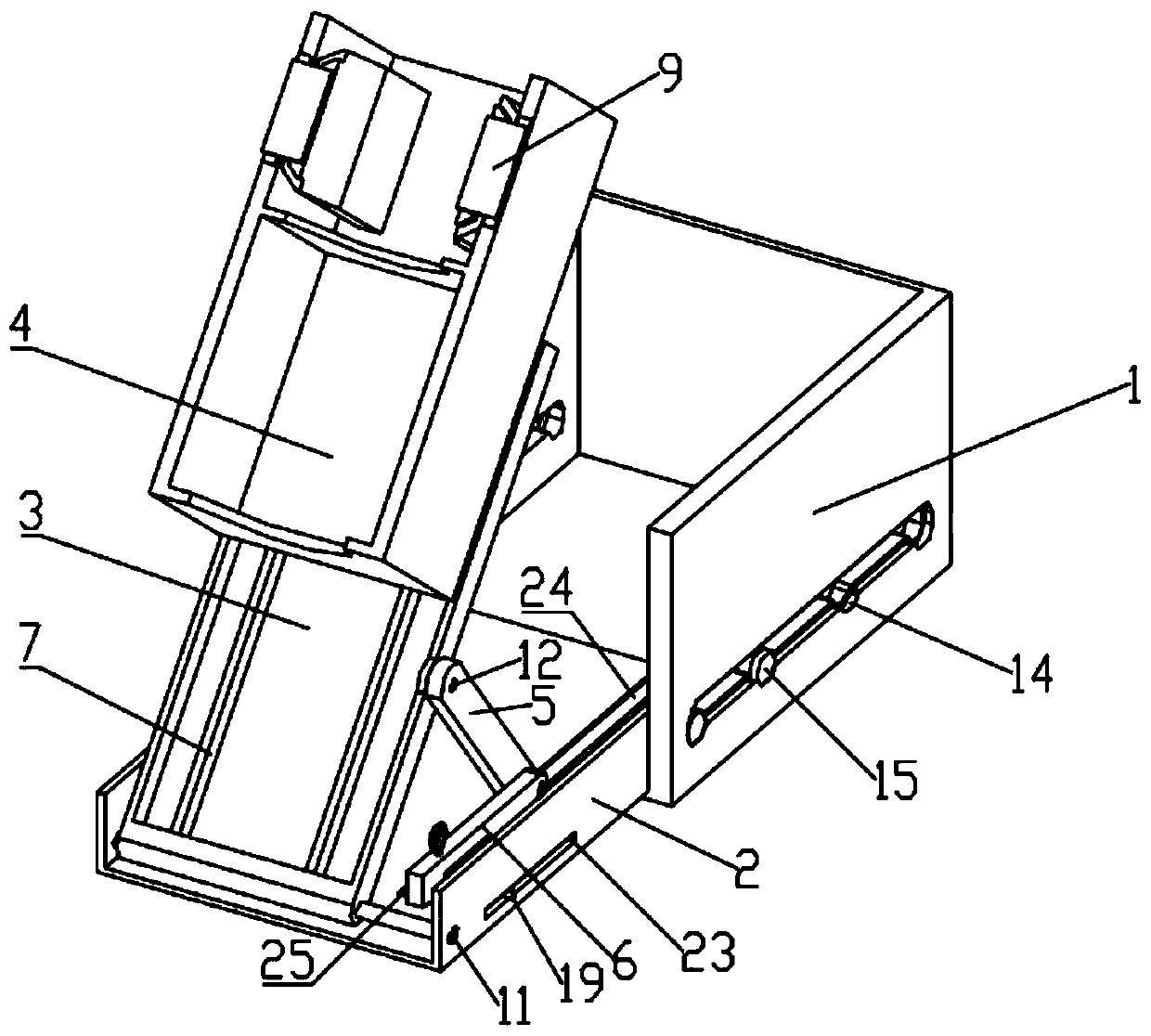

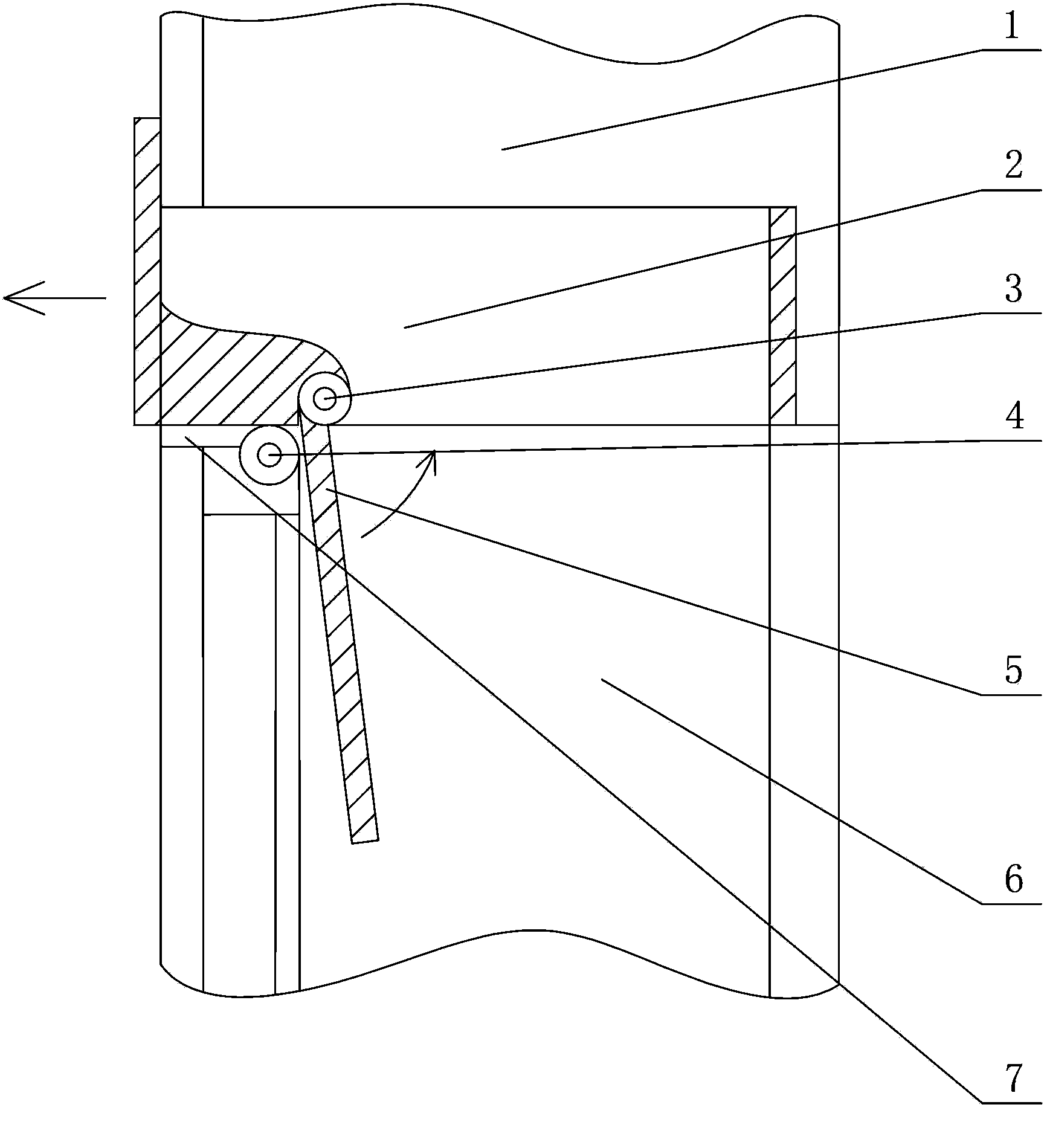

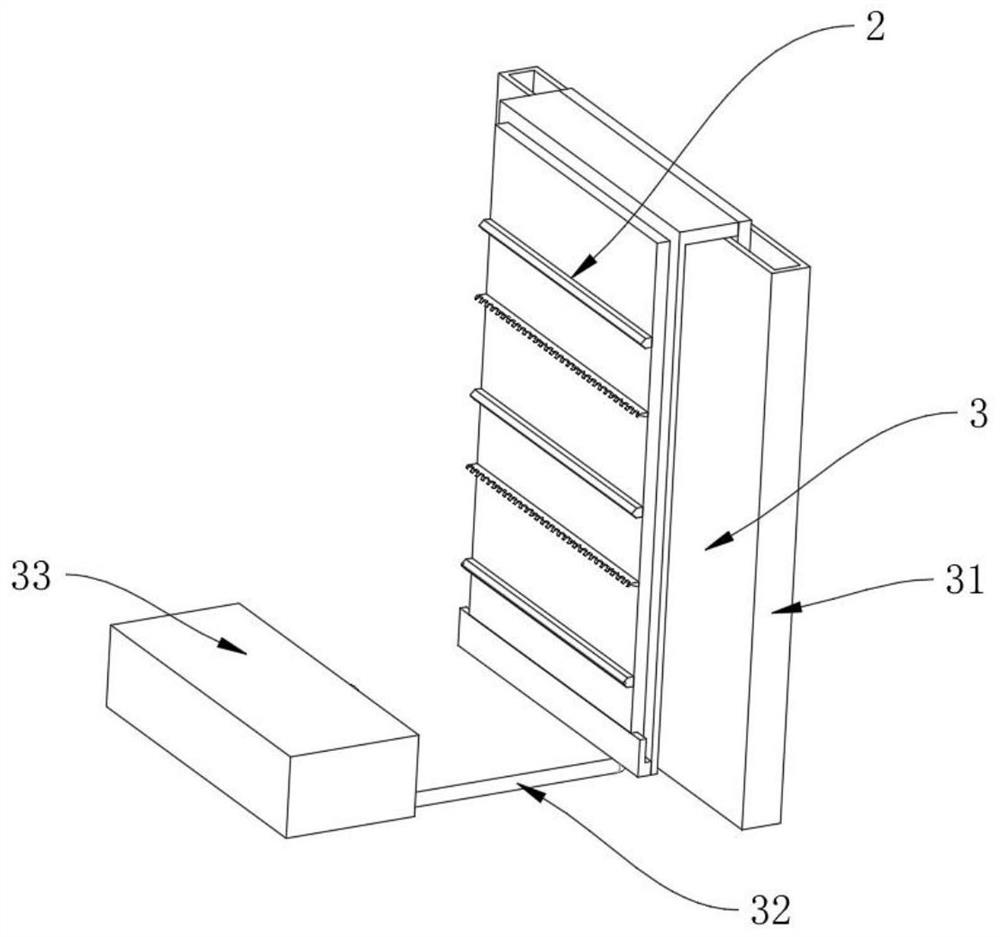

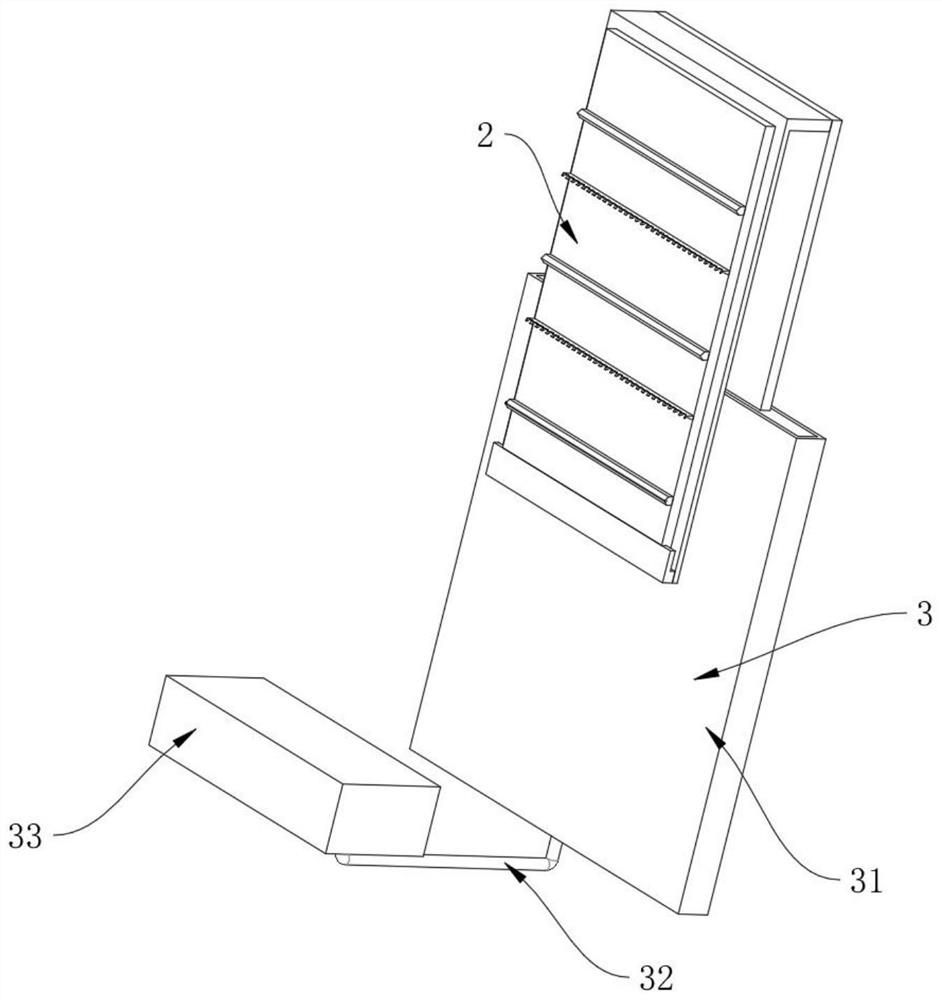

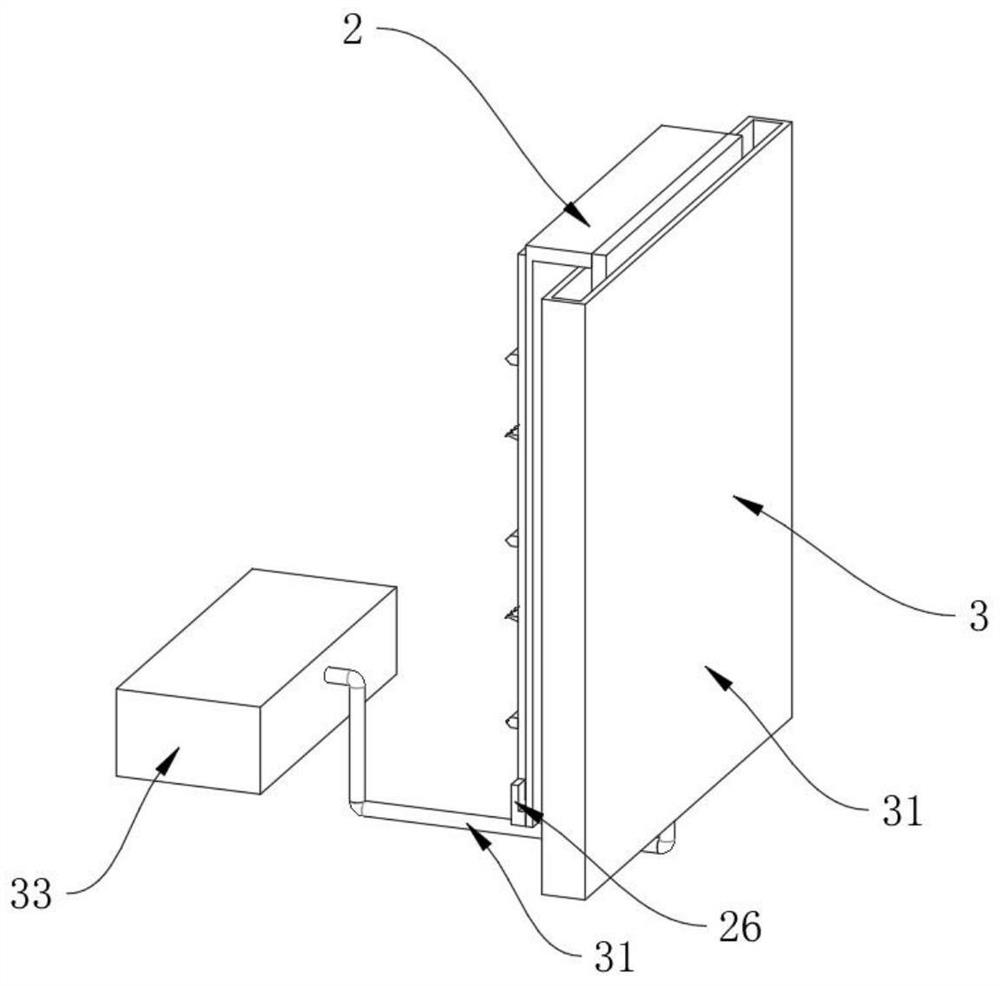

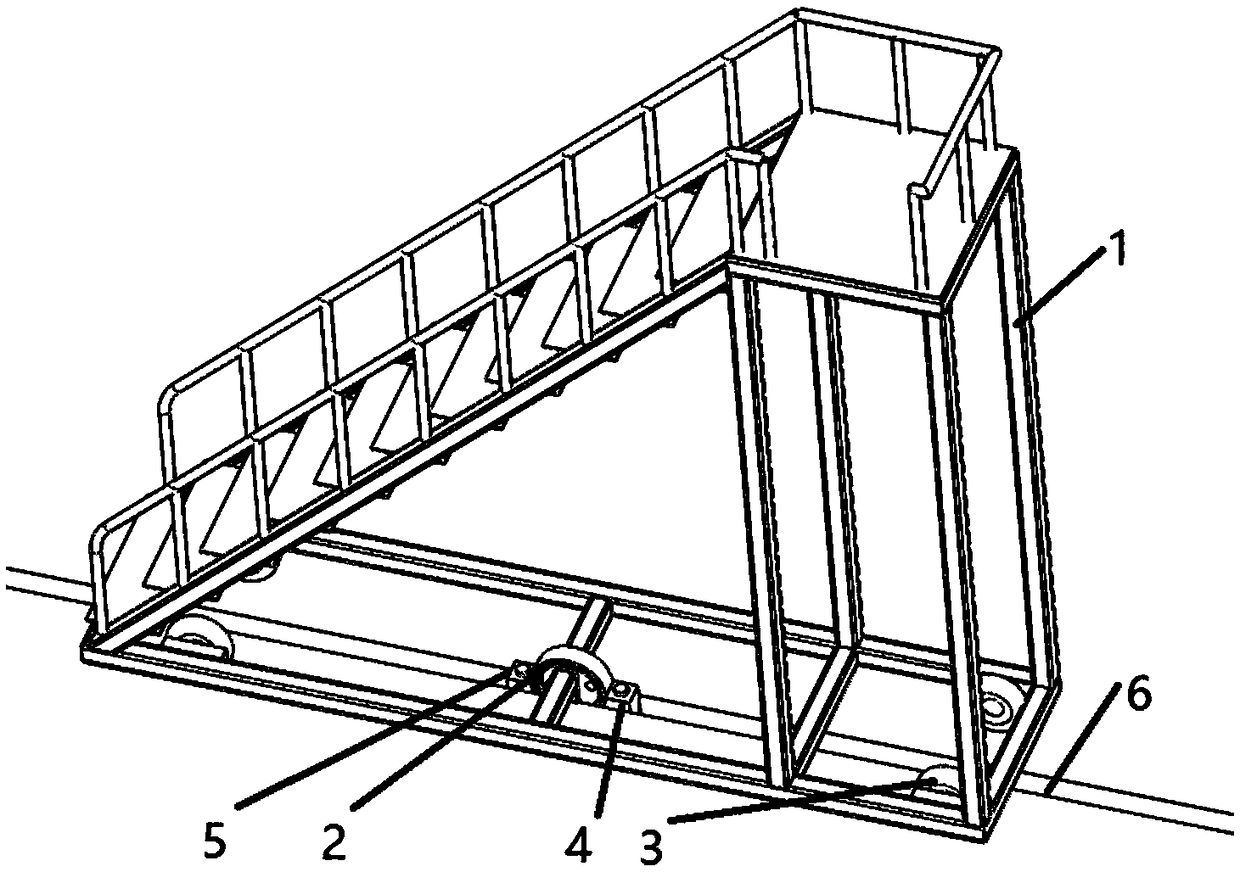

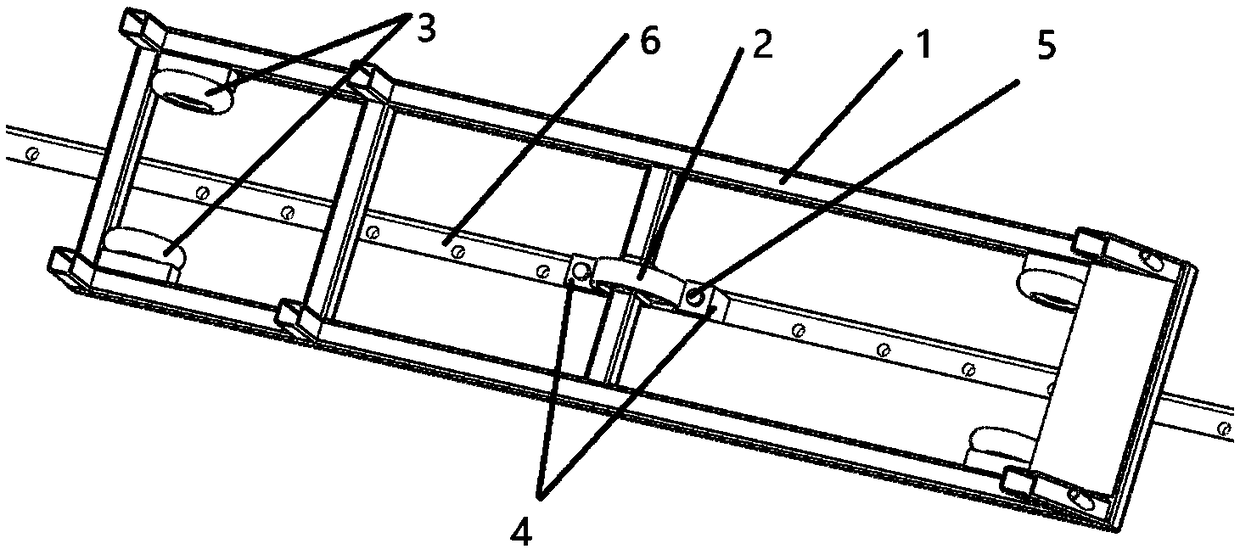

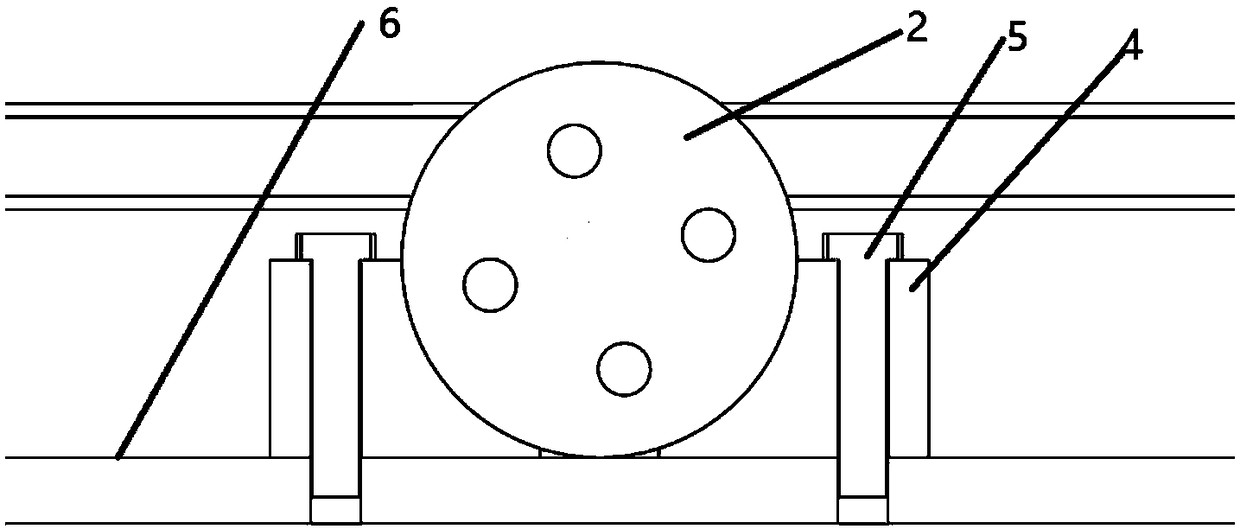

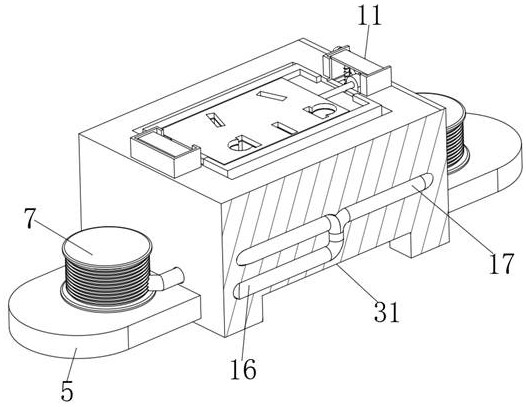

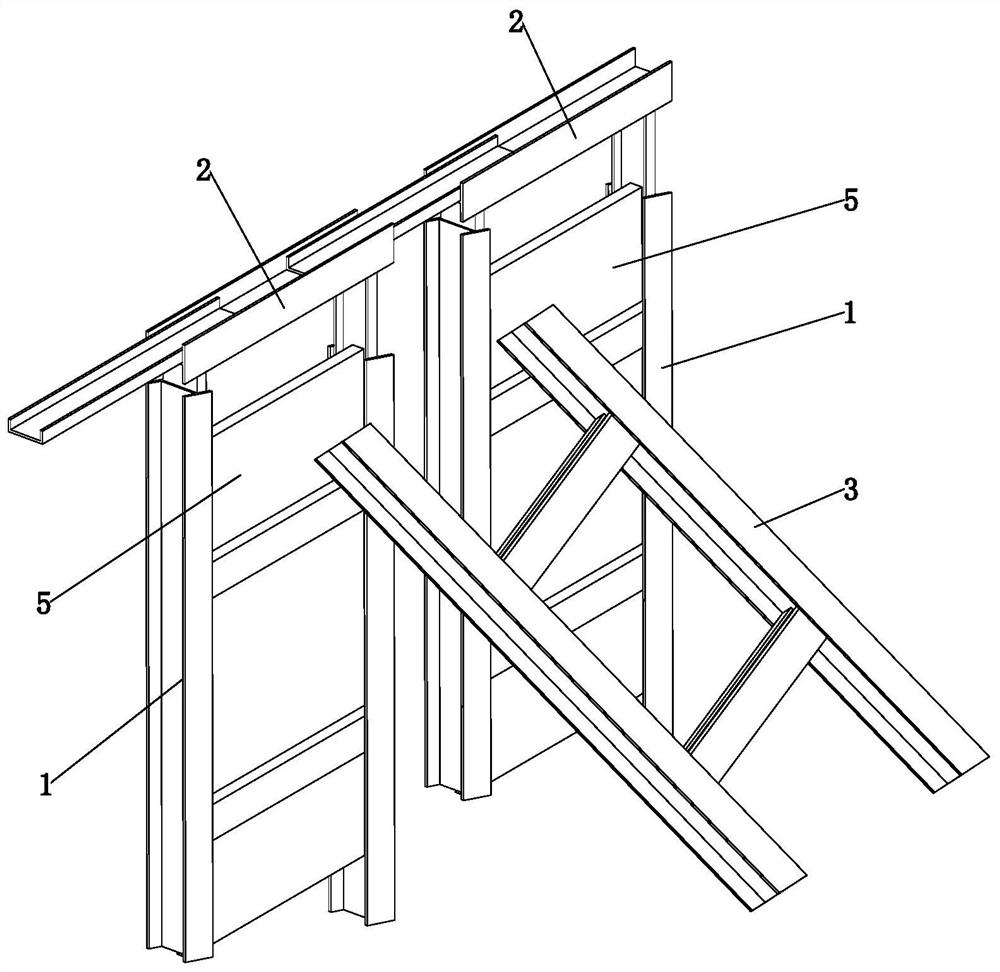

Movable type straddle single-track boarding ladder system

PendingCN108331522AMove preciselyMeet the needs of mixed running and boarding at the same timeLaddersMovable typeAgricultural engineering

The invention discloses a movable type straddle single-track boarding ladder system. The movable type straddle single-track boarding ladder system comprises a frame (1), a plurality of walking wheels(3) are symmetrically arranged on the inner side of the bottom of the frame (1), a fixed track (6) parallel to a straddle single-track track is arranged below the frame (1), and a row of fixing holesare arranged on the fixed track (6) at intervals. A guide wheel (2) is fixedly arranged at the bottom of the frame (1), the guide wheel (2) is arranged on the fixed track (6), wedge-shaped baffle blocks (4) are symmetrically arranged at two sides of the guide wheel (2), and through holes are formed in the wedge-shaped baffle blocks (4). The spacing of the through holes of the wedge-shaped baffle blocks (4) on the two sides is the same as the distance between adjacent fixing holes, and the though holes and the fixing holes are provided with fixed pins (5). According to the movable type straddlesingle-track boarding ladder system, the guide wheel and the walking wheels can drive a boarding ladder to move along the track, and the guide wheel locks independently to fix the boarding ladder oncar doors of vehicles of different trainlengths.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

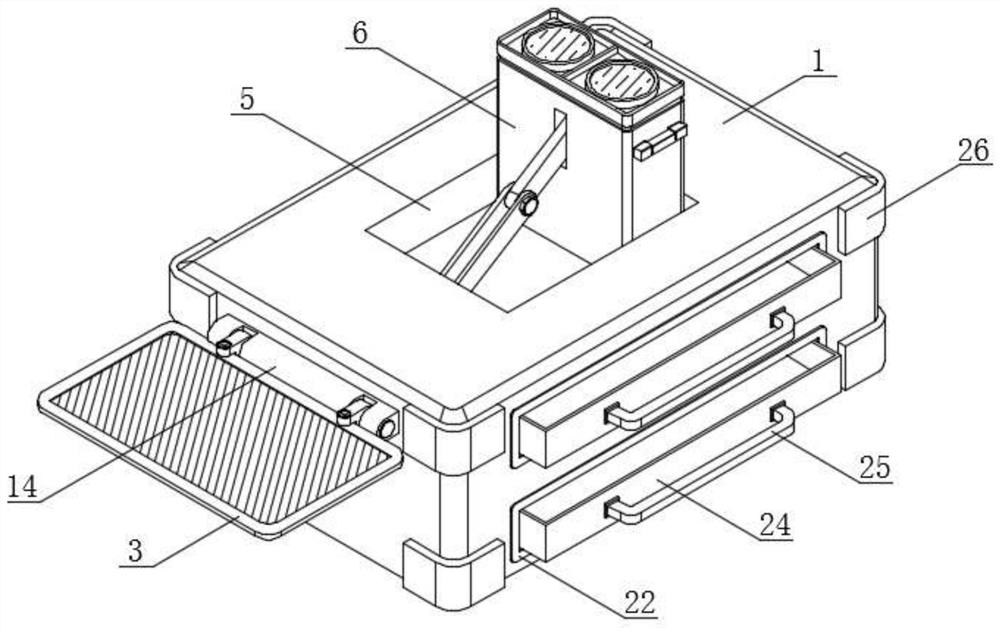

Surveying and mapping data acquisition device for constructional engineering based on unmanned aerial vehicle oblique photography technology

PendingCN113932778AEasy to fixImprove work efficiencyPhotogrammetry/videogrammetrySurveying instrumentsLaser rangingMarine engineering

The invention discloses a surveying and mapping data acquisition device for constructional engineering based on an unmanned aerial vehicle oblique photography technology. The surveying and mapping data acquisition device comprises a working box, fixed sleeves and a working plate, the fixed sleeves are arranged around the bottom of the working box, the working plate is arranged on one side of the working box, and a limiting groove is formed in the bottom of the working box. Through the arrangement of the fixed sleeves and a laser range finder body, the arrangement of a placing groove, the laser range finder body, a supporting rod and a fastening knob, and the matched use of the fixed sleeves and adjusting plates, the extension length of the structure can be quickly adjusted, and the four adjusting plates sequentially extend to different lengths according to different terrains. Therefore, the whole working box can be kept stable, the structure can be conveniently inserted into the ground in a more labor-saving manner by a worker through the arrangement of a ground pricking cone, whether the whole device is kept horizontal or not can be determined by the worker through observing whether a water source in a horizontal column is kept horizontal or not through the arrangement of the horizontal column, and therefore the measurement precision of the device is improved.

Owner:重庆建筑科技职业学院

A foundation pit slope support and fixing device for a building basement

The invention discloses a foundation pit slope support and fixing device in a building basement, which includes an outer pole seat, a connecting pole frame, a mounting piece, a distance adjusting pole frame mechanism, a supporting mechanism, a storage battery, a charging interface and a control switch. The distance-adjusting rod frame mechanism and the supporting mechanism are set up, and the driving motor is used as the power source. Through the cooperation between the pinion and the outer gear ring, the threaded rod drives the lower rod frame to move up and down inside the outer rod seat, and then adjusts the height position of the supporting mechanism. It is easy to be installed at different heights of the slope support, and the electric push rod is used as the power source, and the support frame drives the first insertion rod, the second insertion rod and the second insertion rod through the vertical movement of the sliding seat on the slide. The three inserting rods are quickly inserted into the ground soil for support and fixation, which is easy to operate and improves the working efficiency of construction to a certain extent.

Owner:温州城建集团股份有限公司

A Robust Socket Based on the Internet of Things

ActiveCN111697379BEffective protectionInsert labor-savingCouplings bases/casesFlexible/turnable line connectorsThe InternetComputer science

The invention discloses a stable socket based on the Internet of Things, which includes a socket housing, a plurality of installation slots are opened in the socket housing, and a plurality of bases for plug insertion are installed in the installation slots, and the base Both ends are rotatably connected to the inner wall of the installation groove through the rotating shaft, and the corresponding base position on the socket housing is equipped with a pull-out protection component that is convenient for personnel to pull out and can protect the socket. The invention utilizes the pull-out protection component to realize Push out the plug inserted into the base, so that the plug is separated from the clip in the base, and at the same time, the rotating connection between the base and the installation groove allows the base to rotate at a certain angle, so that personnel can stand at different angles. Unplugging, compared with the existing bending over plugging method, makes plugging out more labor-saving and reduces damage to the socket plug. At the same time, through the reset of the baffle, it can effectively protect the base and avoid dust. Enter.

Owner:NINGBO XINGHONG INTELLIGENT TECH CO LTD

Easy-to-insert loosening head

Owner:CHENGDU TOBEST DIYUAN TECH CO LTD

An assembled pipe jacking pit support structure and its construction technology

ActiveCN111576447BSave installation timeImprove work efficiencyArtificial islandsExcavationsArchitectural engineeringSupport plane

The invention relates to an assembled pipe jacking working pit support structure, comprising a pit wall support structure and a support reinforcement structure; the pit wall support structure includes a plurality of support frames arranged along the inner wall of the work pit and a The connecting frame on the top of the support frame, the lower end of the support frame is buried in the bottom of the work pit, the upper end is connected with the connecting frame, and the adjacent connecting frames are connected together; the support and strengthening structure includes a lower support frame and an upper part The support frame, the lower support frame has the same structure as the support frame, and is connected between the support frame and the bottom of the working pit, and the upper support frame has the same structure as the support frame and is connected between the two opposite support frames. between. The invention adopts a prefabricated support structure, which can quickly support in the working pit, has fast installation speed and high support strength.

Owner:北京诺和兴建设工程有限公司

Spiral type ground nail with locking function

InactiveCN104711982AInsert labor-savingEasy to insertTowersBulkheads/pilesPulp and paper industryEngineering

Owner:DEQING YICHENG IMPORT & EXPORT

Disposable Pipette Tips

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

Action camera slider connection seat with locking structure

ActiveCN106122695BQuick installationQuick disassemblyStands/trestlesCamera body detailsEngineeringMechanical engineering

A slider connection seat having a locking structure for use with an action camera, the slider connection seat has a connecting portion (1), a sliding slot (6) and two elastic insertion pins (2); front ends of the two elastic insertion pins (2) are respectively provided with an extending leg (3) in a forward manner, wherein the two extending legs (3) are provided opposite to each other, and are provided with a turnover buckle (4); a rear end of the turnover buckle (4) is rotatably connected to the slider connection seat, while a front part of the turnover buckle (4) can be clamped between the two extending legs (3). The configuration of the turnover buckle (4) enables conveniently locking and unlocking, thus allowing for convenient and quick mounting / disassembling of an action camera onto / from the slider connection seat; the configuration of the extending legs (3) enables the slider connection seat to be inserted or withdrawn more effortlessly and easily; the turnover buckle (4) may be loosened upon impact, so that the slider connection seat which is originally inserted into a fixed base and an action camera mounted on the slider connection seat can quickly slide out from the fixed base, thus preventing the action camera from causing bodily injuries to people.

Owner:KUNSHAN DESHANGDAJIN SOFTWARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com