Double-stirring automatic chemical fertilizer stirring device

An automatic mixing and fertilizer technology, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inability to mix and circulate, local circulation and mixing, etc., to achieve excellent synchronization and coordination, uniform mixing, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

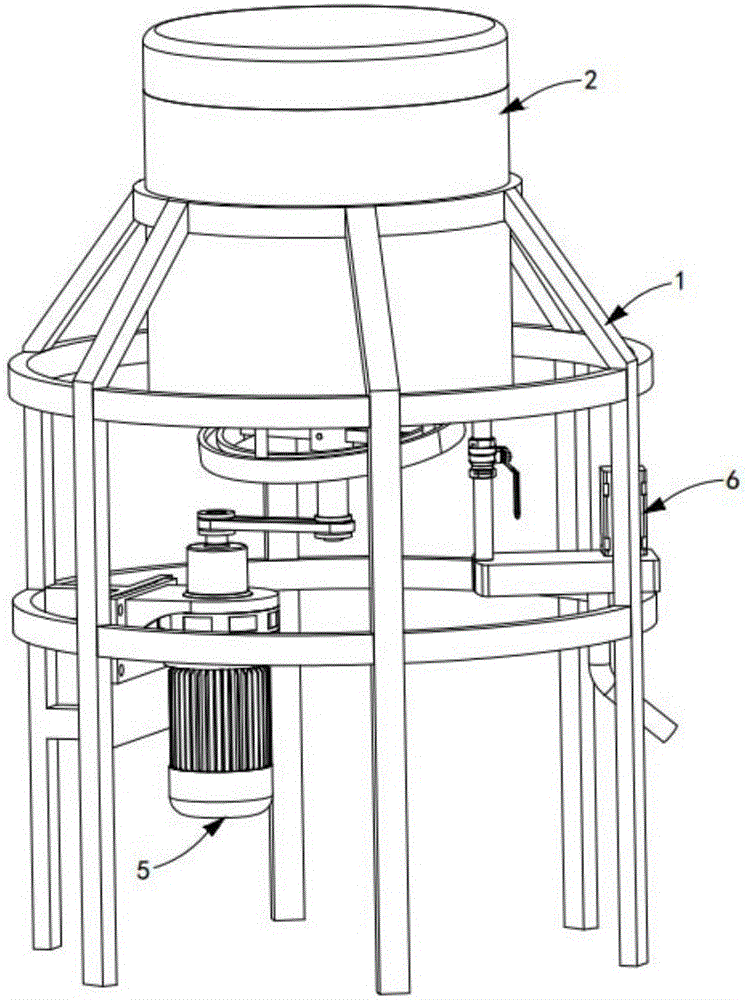

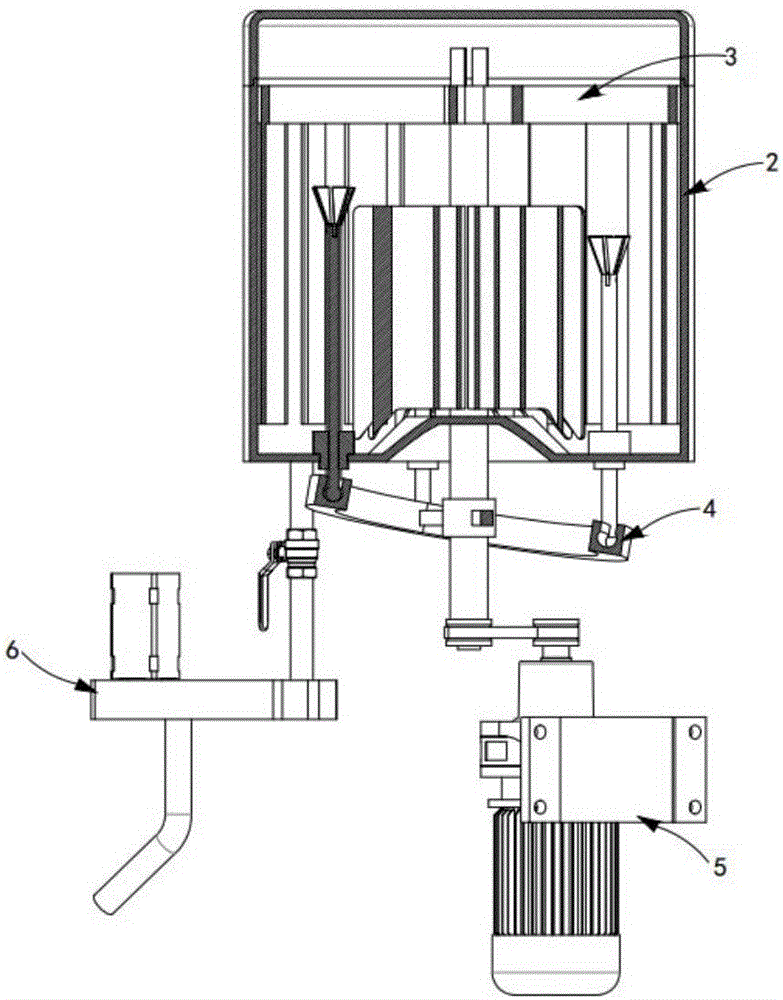

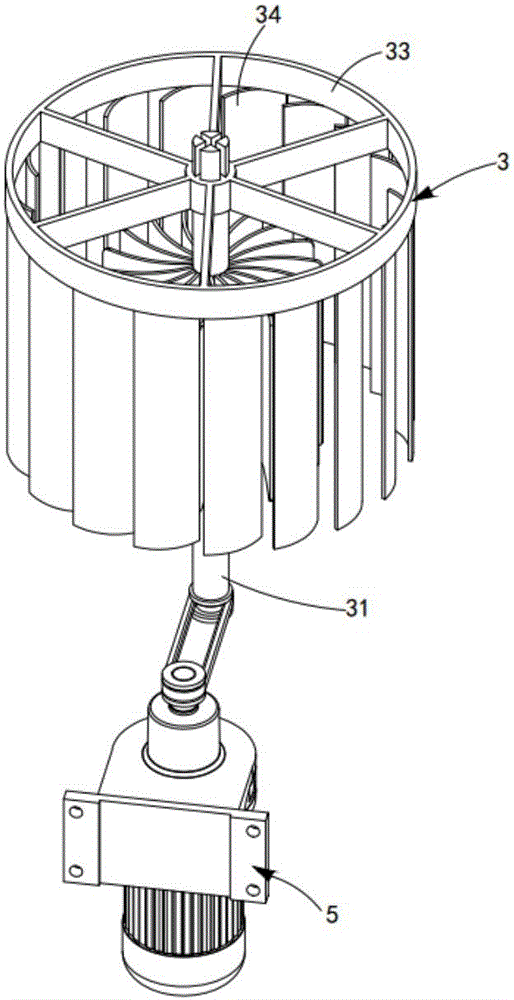

[0056] Such as figure 1 and figure 2 As shown, a dual-stirring fertilizer automatic stirring device includes a frame 1, a stirring bin 2, a horizontal stirring mechanism 3, a longitudinal stirring mechanism 4, and a power mechanism 5; the stirring bin 2 is fixedly arranged on the top of the frame 1, The stirring chamber 2 is provided with a horizontal stirring mechanism 3 and a vertical stirring mechanism 4 along its circumference, and the horizontal stirring mechanism 3 and the vertical stirring mechanism 4 are alternately arranged. The horizontal stirring mechanism 3 includes a rotating shaft 31, and the rotating shaft 31 The upper end of the upper end passes through the bottom of the stirring bin 2 and is vertically arranged in the stirring bin 2 along its axial direction. The longitudinal stirring mechanism 41 includes a curved ring 41, which is fixed on the lower end of the rotating shaft 31. It can rotate synchronously with the rotating shaft 31; the power mechanism 5 ...

Embodiment approach

[0076] Such as Figure 10 As shown, as a preferred embodiment, the mixing chamber 2 includes:

[0077] A mixing bucket 21 fixedly connected to the frame 1, the center of the bottom of the mixing bucket 21 is set in the shape of a truncated cone, and one side thereof is provided with a first discharge hole 211; and

[0078] Stirring barrel cover 22, described stirring barrel cover 22 is arranged on the upper end of described stirring barrel 21, and its stirring barrel 21 is sealed and connected;

[0079] The first discharge pipe 23 , the upper end of the first discharge pipe 23 is fixedly connected with the first discharge hole 211 , and a discharge ball valve 24 is arranged in the middle of the first discharge pipe 23 .

[0080] It should be noted that the sealed mixing chamber 2 effectively isolates the irritating odor that the mixed fertilizer may volatilize during the mixing process, avoids the impact of the irritating odor on the human respiratory tract, and ensures the h...

Embodiment 2

[0082] Figure 11 and Figure 12 It is a schematic structural view of Embodiment 2 of a dual-stirring fertilizer automatic stirring device of the present invention; as Figure 11 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment two and embodiment one is:

[0083] Such as Figure 11 and Figure 12 As shown, a dual-stirring fertilizer automatic stirring device also includes a crushing mechanism 6 fixedly connected to the lower end of the first discharge pipe 23 , and the crushing mechanism 6 is fixedly arranged on the frame 1 .

[0084] As an improved technical solution, the crushing mechanism 6 includes:

[0085] The crushing box 61 fixedly connected with the frame 1, the upper end of the crushing box 61 is fixedly connected with the lower end of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com