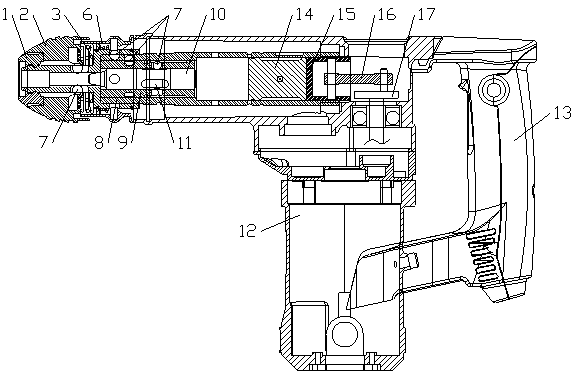

an electric hammer

An electric hammer and collet technology, applied in the direction of striking tools, light impact tools, manufacturing tools, etc., can solve the problems of long replacement time, increased disassembly and assembly force, and insufficient hammering force, and achieve disassembly and maintenance. The wearing parts are convenient, improve the hammering force, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

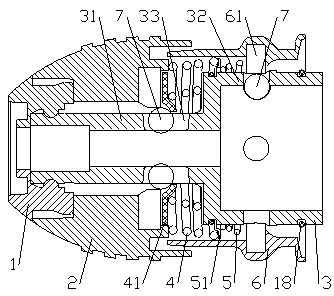

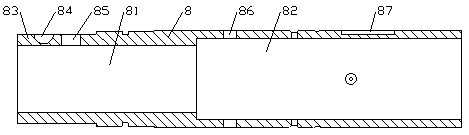

[0019] Such as Figure 1 to Figure 4 As shown, an electric hammer includes a chuck, a housing 12, a cylinder assembly and a transmission assembly arranged in the housing 12, a handle 13 is provided on the side of the housing 12, and the chuck includes a chuck body 2, a square The sleeve 3 and the jacket 6, the square sleeve 3 has a convex structure composed of a small diameter part 31 and a large diameter part 32, the side of the large diameter part 32 is clamped with the boss 61 inside the jacket 6 through the steel ball 7, the jacket 6 is located A lower spring 5 is sleeved between the part above the boss 61 and the large diameter portion 32, the top of the lower spring 5 is provided with a fixed pad 51, and the side of the small diameter portion 31 is provided with a limiting hole 33, and the length of the limiting hole 33 is longer than that of the steel plate. The diameter of the ball 7, the upper spring 4 is set between the small diameter part 31 and the jacket 6, the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com